Page 1

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : AL-05PA

MODEL : 32LX2D-AA

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

PRODUCT SAFETY ..................................................................................3

SPECIFICATION........................................................................................6

ADJUSTMENT INSTRUCTION................................................................11

SVC REMOCON ......................................................................................14

TROUBLE SHOOTING............................................................................15

BLOCK DIAGRAM...................................................................................24

WIRING DIAGRAM..................................................................................26

EXPLODED VIEW .................................................................................. 27

REPLACEMENT PARTS LIST ............................................................... 29

SVC. SHEET ...........................................................................................47

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

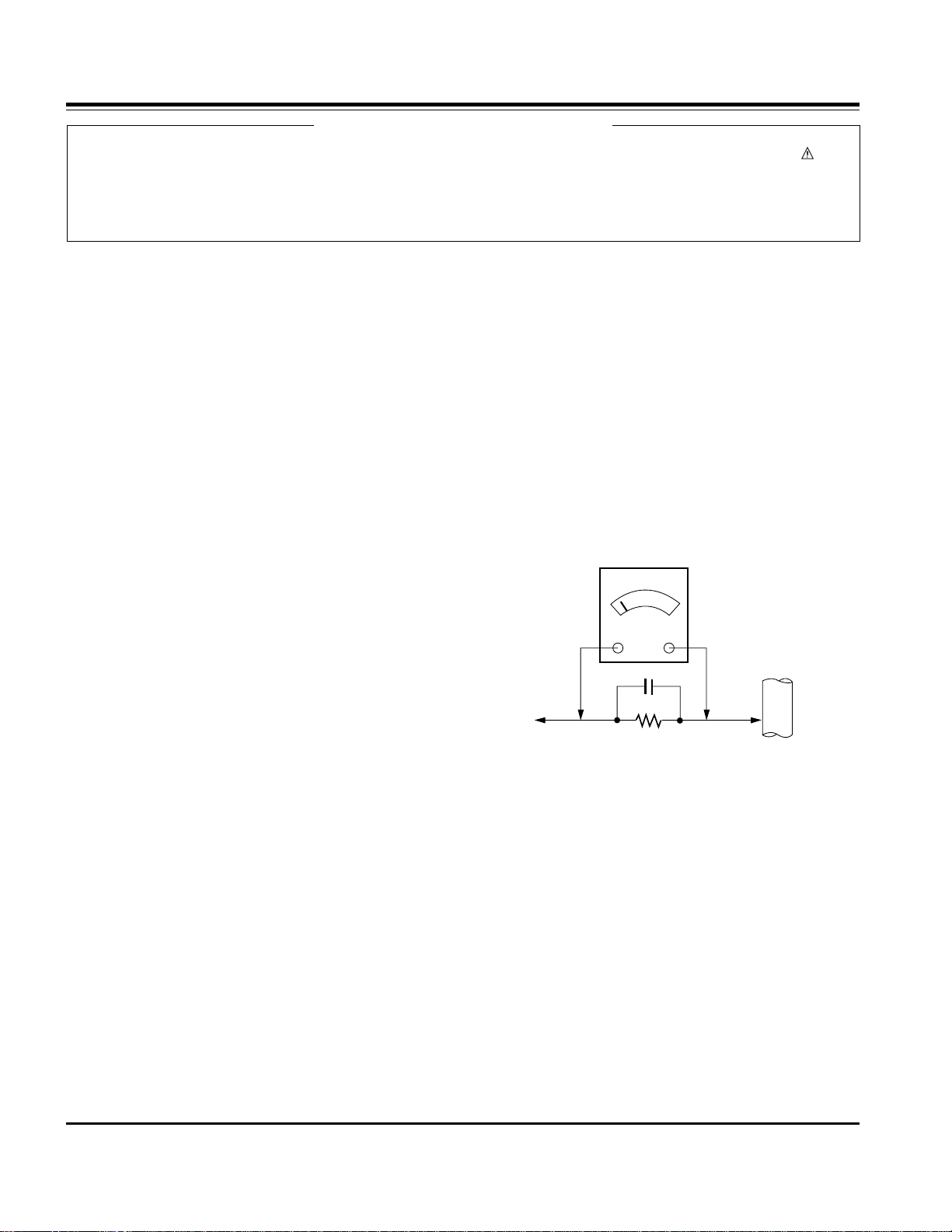

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

IMPORTANT SAFETY NOTICE

0.15uF

To Instrument's

exposed

METALLIC PARTS

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 4

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500

o

F to 600oF.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500

o

F to 600oF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500

o

F to 600oF)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

SERVICING PRECAUTIONS

Page 5

- 5 -

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Page 6

- 6 -

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

1.1 This spec sheet is applied all of the 32" LCD TV with

AL-05PA chassis.

1.2 Not included spec and each product spec in this spec

sheet apply correspondingly to the following each country

standard and requirement of Buye

2. Specification

Each part is tested as below without special appointment.

A. Temperature : 20 ± 5°C

B. Relative Humidity : 65 ± 10%

C. Power Voltage : Standard input voltage

(110~240V@ 50/60Hz)

* Standard Voltage of each product is marked by models

D. Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM.

E. The receiver must be operated for about 20 minutes prior

to the adjustment.

3. Test method

3.1 Performance : LGE TV test method followed.

3.2 Demanded other specification.

EMC : CISPR 13 specification

SAFETY : CB Specification

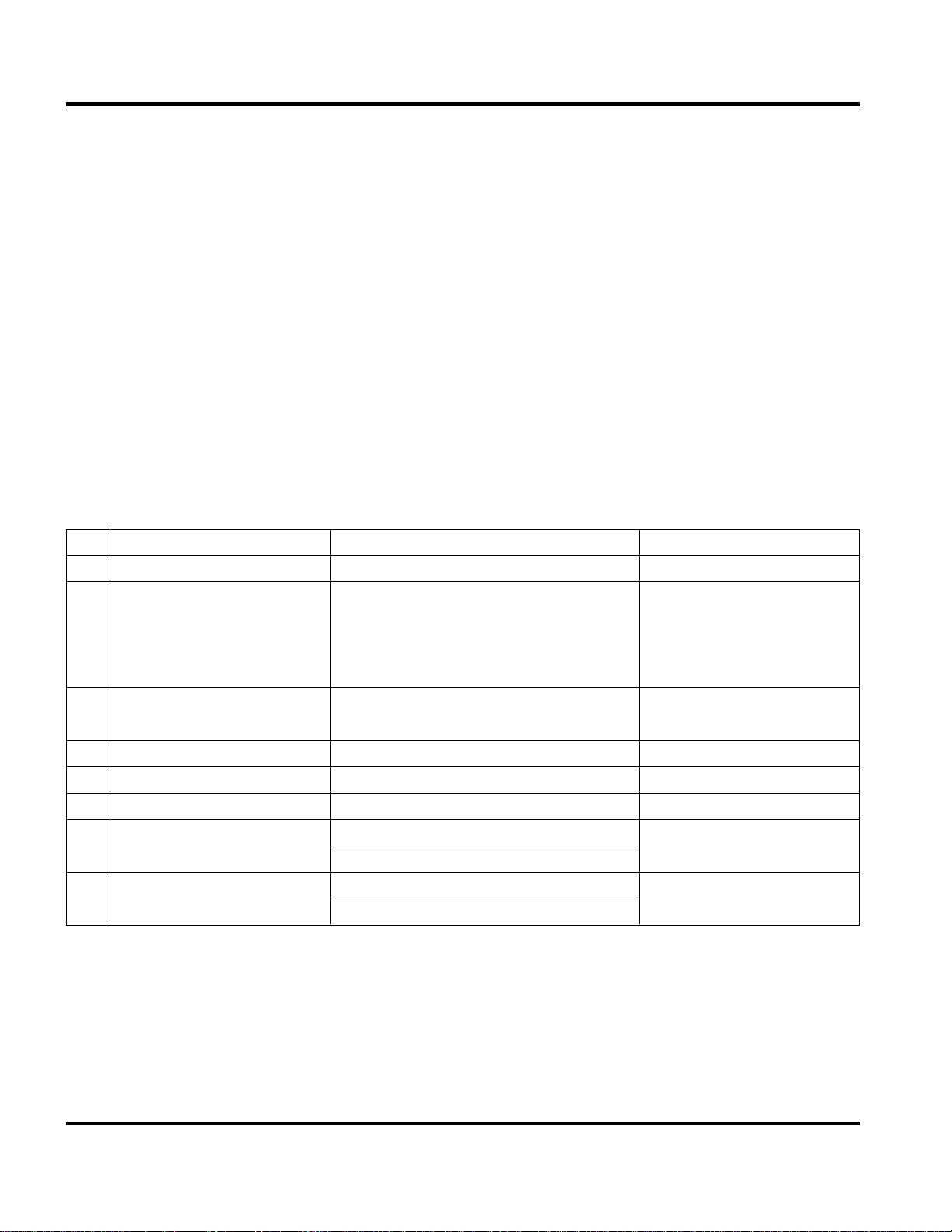

4. General Specification

No Item Specification Remark

1. Broadcasting System PAL-B/G, DTV : DVB-T

2. Available Channel 1) VHF : 02~13

2) UHF : 14~69

3) CATV : 01~125

4) DTV : 06~12, 27~69

3 Tuner IF 1) PAL : 38.90MHz

2) DVB-T : 36.167MHz

4. Input Voltage 1) AC 240V, 50Hz

5. Aspect Ratio 16:9(Wide)

6. LCD Module LC320W01-A6K6 (1366 x 768) LPL

7. Operating Environment 1) Temp : 0 ~ 40 deg

2) Humidity : 10 ~ 80 %

8. Storage Environment 1)Temp : -20 ~ 50 deg

2) Humidity : 10 ~ 90 %

Page 7

- 7 -

5. Chroma & Brightness

6. Power

No Item Min Typ Max Unit Remark

1. AC Power Operating Voltage 90 264 V

2. DC Voltage, LCD Panel Drive 11.4 12.0 12.6 V

3. DC Voltage, Inverter 22.8 24.0 25.2 V

4. DC Voltage, Sound AMP 17.4 18.0 18.6 V

5. DC Voltage, Stand By 5.6 6.0 6.4 V

6. DC Voltage, Scaler(HD2) 3.1 3.3 3.5 V

7. DC Voltage, Scaler(HD2) 1.6 1.8 1.9

8. DC Voltage, ADC 3.1 3.3 3.5 V AD9883

9. DC Voltage, VCD 5 V 4.7 5 5.3 V

10. DC Voltage, VCD 3.3V 3.1 3.3 3.5 V

11. DC Voltage, Micom 4.7 5 5.3 V

12. DC Voltage, Tuner 4.75 5.00 5.25 V

DC Voltage, Tuner 31.5 33.0 34.5 V

13. DC Voltage,Video decoder IO 3.00 3.30 3.60 V

14. DC Voltage,Video decoder Core 1.35 1.50 1.65 V

15. DC Voltage, CPLD 3.00 3.30 3.60 V XC95288

16. Audio Amp, PVDD 16.20 18.00 19.80 V TAS5122

17. Audio Amp, DVDD 3.00 3.30 3.60 V TAS5122

18 PWM Modulator IO 3.00 3.30 3.60 V NSP-6241B

19 PWM Modulator Core 2.30 2.50 2.70 V NSP-6241B

No Item Min Typ Max Unit Remark

1. Brightness 300 450 cd/m

2

2. Contrast Ratio 500:1 600:1

3. Luminance Variation 1.3 %

4. Viewing Angle(Left, Right, Up, Down) 85 88 Degree

5 Color coordinate RED X Typ 0.640 Typ

Y -0.03 0.343 +0.03

GREEN X 0.280

Y 0.605

BLUE X 0.145

Y 0.065

WHITE X 0.285

(Standard) Y 0.293

6 Color Temperature Medium 8,800 9,300 9,800 OK <Test Signal>

Cool 11,000 12,000 13,000 OK Video input, 85%

Warm 6,000 6,500 7,000 OK

Full white pattern, 5MOCD

Page 8

- 8 -

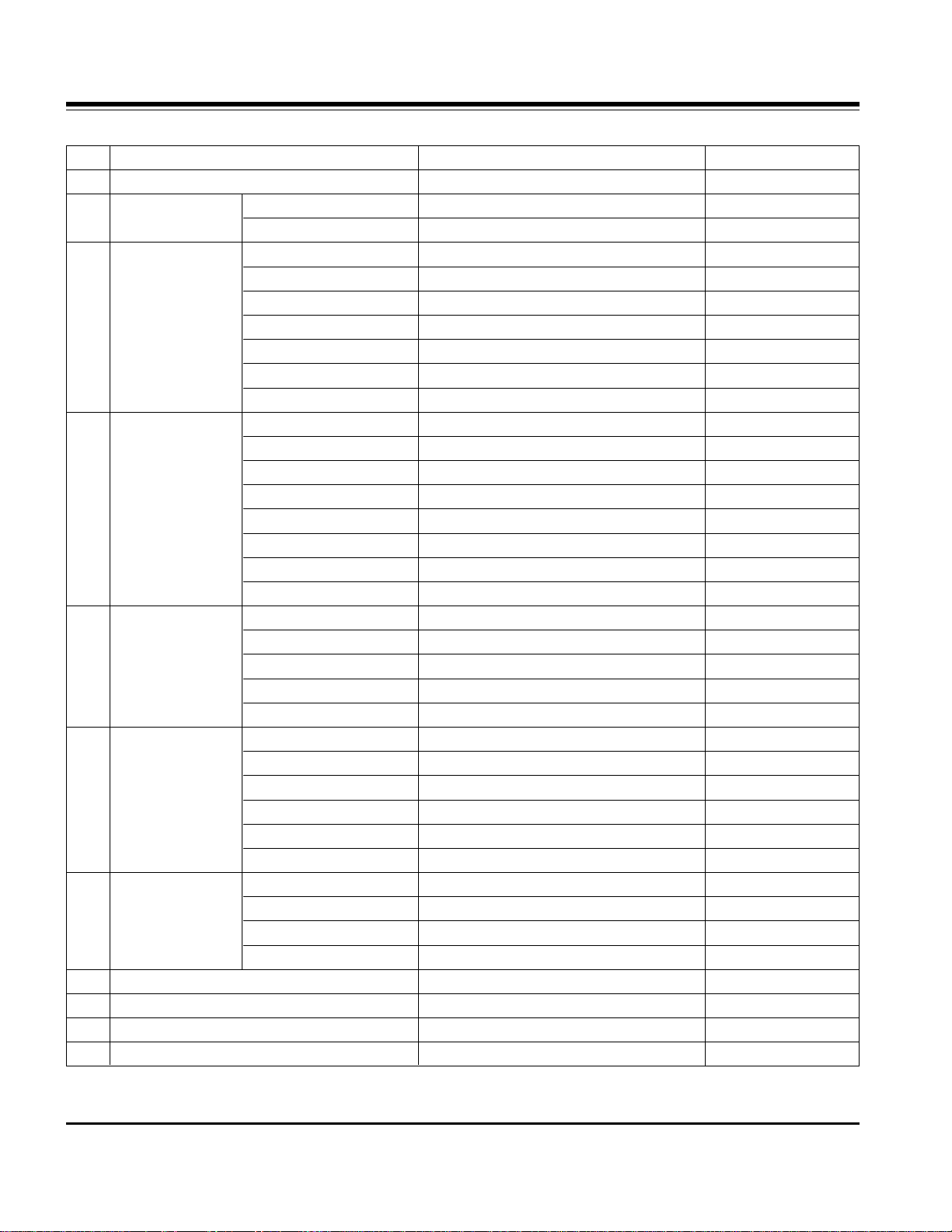

7. Component Video Input (Y, PB, PR)

8. RGB, HDMI/DVI input (DTV / PC)

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

1. 720x576 15.625 50

2. 720x576 31.25 50

3. 640x480 15.73 59.94/60

4. 704x480 31.47 59.94/60

5. 1280x720(50/60) 37.5/45.0 50/59.94/60

6. 1920x1080(50/60) 28.125/33.75 50/59.94/60.0

No Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

DTV

1. 720x576 31.25 50 EDTV576p

2. 704x480 31.47 59.94 EDTV 480p

3. 1280x720(50/60) 37.5/45.0 50/59.94/60 HDTV 720p

4. 1920x1080(50/60) 28.125/33.75 50/59.94/60.0 HDTV 1080i

PC

1. 640x350 31.468 70.09 25.17 EGA

2. 640x480 31.469 59.94 25.17 VESA(VGA)

3. 640*480 37.861 72.80 31.50 VESA(VGA)

4. 640x480 37.500 75.00 31.50 VESA(VGA)

5. 800x600 35.156 56.25 36.00 VESA(SVGA)

6. 800x600 37.879 60.31 40.00 VESA(SVGA)

7. 800x600 48.077 72.18 50.00 VESA(SVGA)

8. 800x*600 46.875 75.00 49.50 VESA(SVGA)

9. 1024x768 48.363 60.00 65.00 VESA(XGA)

10. 1024x768 56.476 70.06 75.00 VESA(XGA)

11. 1024x768 60.023 75.02 78.75 VESA(XGA)

Page 9

- 9 -

No Item Min Typ Max Unit Remark

1 Active Screen Size 800.4(diagonal) mm 31.51 inches

2 Outline Dimension 760(H) x 450(V) x 48(D) mm Typ.

3 Pixel Pitch 170.25 x 510.75 x RGB

4 Pixel Format 1366(H)x768(V) RGB stripe arrangement

5 Color Depth 8bit 16.7 Mbit

6 Luminance ,White 500 cd/m2 Center 1 point

7 Viewing Angle (CR>10) R/L 176(Typ),U/P 176(Typ) degree

8 Power Consumption 89.5 Watt Typ.

9 Weight 7.2 kg

10 Display Operating Mode Transmissive mode ,normally black

11 Surface Treatment Hard coating (3H), Anti-glare treatment

12 Altitude Operating 0 - 14,000 feet 4,267.2 m

Storage/Shipment 0 - 40,000 feet 12,192.0 m

13 Lamp Life Time 50,000 (min.) Hrs 25±2°C

9. General specifications(module)

9-1. Electro Optical Characteristic Specifications(module standard)

No Item Min Typ Max Unit Remark

1 Contrast Ratio 800 1,200 It measured at center point

2 Surface Luminance, White 400 600 Cd/m

2

Full white

3 Luminance Variation 1.3 (

white/5P)

4 Response Time Tr (Rising time) 12 msec

5 Color coordinate RED X 0.640 Full Pattern

Y 0.343

GREEN X Typ 0.280 Typ

Y -0.03 0.605 +0.03

BLUE X 0.145

Y 0.065

WHITE X 0.285

Y 0.293

6 Viewing Angle (CR>10) X axis right(

=0) 85 88

degree

X axis left(

=180) 85 88

Yaxis up (

=90) 85 88

Z axis down(

=270) 85 88

Page 10

- 10 -

10. Set factoring Condition

No Item Value Remark

1 Power Off

2 CH Memory Analog C0,C5,C6,S11,S27,C35,C52,C68

Digital C43

3 Picture PSM Dynamic

Contrast 100

Brightness 55

Color 60

Sharpness 60

Tint (Not available)

Color temperature Medium

4 Audio SSM Standard

AVL Off

Balance 0

Treble 50

Bass 50

Front surround Off

TV speaker On

BBE Off

5 Time Auto clock On Manual Clock Enable

Off timer Off

On timer Off

Sleep timer Off

Auto sleep Off

6 Special Main input Digital

Sub input Analogue

Sub title Off

Child lock Off

ARC 16:9

Cinema Off

7 LOCK Lock System Off

Block Program All programs unblocked

Parental Guide All Grade unblocked

Aux.Block All Source unblocked

8 RGB Initial DTV

9 PIP Position Right Lower

10 Volume 30

11 Favorite No Program set

Page 11

- 11 -

1. Application Object

This document is applied to 32" LCD TV which is

manufactured in Monitor Factory or is produced on the basis

of this data.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 220V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEATRUN mode)

Enter into HEAT-RUN MODE

- Press the POWER ON KEY on R/C for adjustment.

OSD display and screen display 100% full WHITE

PATTERN.

[ Set is activated HEAT-RUN without signal generator in

this mode.

If you turn on a still screen more than 20 minutes (Especially

Digital pattern, Cross Hatch Pattern), an afterimage may occur

in the black level part of the screen.

3. EDID

(The extended display Identification data)

/ DDC(Display Data Channel) Download

This is the function that enables “Plug and Play".

3-1. Required Test Equipment

1) PC, Jig for adjusting DDC (PC serial to D-sub.

Connection equipment)

2) DVI to HDMI Connector

3-2. Composition of Device

3-3. EDID DATA

- Download only EDID for HDMI.

- Download only EDID for RGB.

ADJUSTMENT INSTRUCTION

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the LCD Module.)

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 00 FF FF FF FF FF FF 00 1E 6D 00 00 01 01 01 01

10 00 0F 01 03 80 46 27 78 0A 36 E9 A3 56 49 9B 25

20 11 48 4B 4F EE 80 31 4F 45 4F 61 4F 01 01 01 01

30 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 36 00 BA 88 21 00 00 18 00 00 00 FD 00 38 4B 1E

50 3D 08 00 0A 20 20 20 20 20 20 00 00 00 FC 00 33

60 32 4C 58 32 44 2D 41 41 20 20 20 20 00 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 01 48

80 02 03 1A 72 23 15 07 50 47 85 01 04 14 13 12 00

90 83 0F 00 00 65 03 0C 00 10 00 01 1D 80 D0 72 1C

A0 16 20 10 2C 25 80 C4 8E 21 00 00 9E 01 1D 80 18

B0 71 1C 16 20 58 2C 25 00 C4 8E 21 00 00 9E 01 1D

C0 00 BC 52 D0 1E 20 B8 28 55 40 C4 8E 21 00 00 1E

D0 01 1D 00 72 51 D0 1E 20 6E 28 55 00 C4 8E 21 00

E0 00 1E 8C 0A D0 90 20 40 31 20 0C 40 55 00 C4 8E

F0 21 00 00 18 00 00 00 00 00 00 00 00 00 00 00

EB

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 00 FF FF FF FF FF FF 00 1E 6D 5D 46 01 01 01 01

10 07 0F 01 03 68 46 27 96 0A FB 2C A3 57 47 9A 25

20 10 48 4B AF CE 00 31 4F 45 4F 61 4F 01 01 01 01

30 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 36 00 BC 88 21 00 00 18 00 00 00 FD 00 38 4B 1F

50 3D 08 00 0A 20 20 20 20 20 20 00 00 00 FC 00 33

60 32 4C 58 32 44 2D 41 41 0A 20 20 20 00 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 48

Page 12

- 12 -

3-4. EDID S/W Execution and Setting

1) Connect the Set, EDID Download Jig, PC & Cable. And

Execute the S/W : EDID TESTER Ver,2.5

2) Set up S/W option

Repeat Number : 3

Device Address : A0

PageByte : 8

3-5. Sequence of Adjustment

1) Init the data

2) Load the EDID data.(Open File)

[Digital(HDMI) : Checksum(5750)]

3) Set the S/W as below.

4) Push the “Write Data & Verify”button. And input the data.

5) If the writing is finished, you will see the “OK” message.

4. AD9883A-Set Adjustment

4-1. Synopsis

AD9883A-Set adjustment to set the black level and the Gain

of optimum with an automatic movement from the analog =>

digital converter.

4-2. Test Equipment

Service R/C, MSPG925 Series Pattern Generator (720P 60Hz

Color Bar Pattern output will be possible and the output level

will accurately have to be revised with 0.7±0.1Vp-p)

4-3. Adjustment

(1) Input the color Bar Pattern of the 720P 60Hz Mode what is

supportable to Component2 or RGB-DTV INPUT and the

select the Input Mode as Component2.

(2) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and then

select the ‘1. AD9883A-Set’.

Pressing the Vol + Key to adjust with automatic movement.

(3) If Component adjustment is completed normality,

'Component Adjustment OK' is displayed and if RGB

adjustment is completed normality, 'RGB Adjustment OK' is

displayed. If the adjustment has errors, 'AD9883A-Failed!

Try Again' is displayed.

(4) Readjust after confirming the case Pattern or adjustment

condition where the adjustment errors.

(5) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

<Fig. 2> Adjustment Pattern : 720P 60Hz Color Bar Pattern

Page 13

- 13 -

5. Adjustment of White Balance

5-1. Required Equipment

(1) Color analyzer (CA-110 or similar product)

(2) Automatic adjustor (with automatic adjustment hour

necessity and the RS-232C communication being possible)

(3) AV Pattern Generator

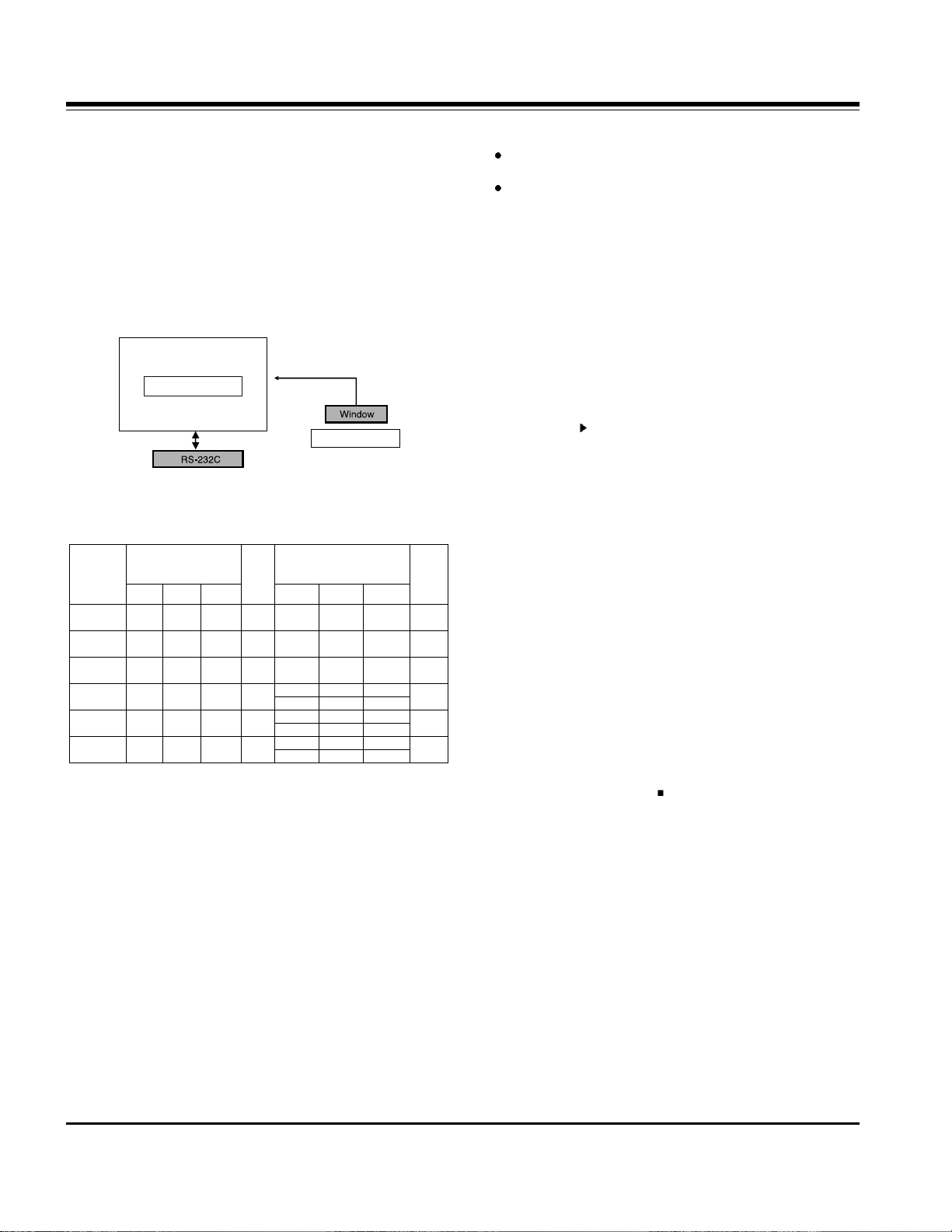

5-2. Connection Diagram of Equipment

for Measuring (Automatic Adjustment)

RS-232C Command (Automatic Adjustment)

5-3. Adjustment of White Balance(manual)

Operate the Zero-calibration of the CA-110, then attach

sensor to PDP module surface when you adjust.

Manual adjustment is also possible by the following

sequence.

(1) Enter ‘3.White-Pattern’ by pressing ADJ KEY on the

Service Remote Control.

(2) Select "Test Pattern White" using Vol +/- Key and Execute

HEAT RUN at least 15 minutes.

(3) Receive the HDMI/DVI 720p 60Hz, Full size, 216 Gray

window pattern signal from AV Pattern Generator.

Input mode : HDMI/DVI

Baud rate = 115200bps

(4) Select the condition of screen Adjustment as ‘Dynamic’.

(5) After attaching sensor to center of screen, select ‘2. White-

Balance’ in ‘Ez - Adjust’ by pressing the ADJ KEY on the

Service R/C. Then enter adjustment mode by pressing the

Right KEY ( ) .

a. In case color temperature is Cool.

B Gain = 192(lock)

R-Offset:64, G-Offset:64, B-Offset:64

Adjust the High Light by using R Gain/ G Gain.

b. In case color temperature is Medium

R Gain = 64(lock)

R-Offset:64, G-Offset:64, B-Offset:64

Adjust the High Light by using G Gain/ R Gain-37"

c. In case color temperature is Warm

R Gain = 192 (lock)

R-Offset:64, G-Offset:64, B-Offset:64

Adjust the High Light by using G Gain/ B Gain.

(6) Adjust using Volume +/- KEY.

luminosity value : High Level : 216gray

a. Cool : X=0.274±0.002, Y=0.274±0.002

Color temperature : 12000°K±1000°K, dUV=-3dUV

b. Medium : X=0.287±0.002, Y=0.289±0.002

Color temperature : 9300°K±1000°K, dUV=-3dUV

c. Warm : X=0.315±0.002, Y=0.316±0.002

Color temperature : 6500°K±1000°K, dUV=-3dUV

(7) After adjustment is complete, move to Ez - Adjust screen

by pressing the ENTER(

) KEY. Then exit the adjustment

mode by press ADJ KEY.

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

00

00

00

00

00

00

ff

ff

ff

7f

7f

7f

Jg

Jh

Ji

Ja

Jb

Jc

Jd

Je

Jf

C0

C0

C0

C0

C0

C0

C0

C0

C0

RS-232C Command

[CMD ID DATA]

Cool

Mid

Warm

Cool Mid

Warm

MIN

CENTER

(DEFAULT)(Hex)

MAX

<Fig. 3> Connection Diagram of Automatic Adjustment

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

216 FULL WHITE

COLOR

ANALYZER

TYPE; CA-110

HDMI signal input

PDP MONITOR

MSPG-925 Series

Page 14

- 14 -

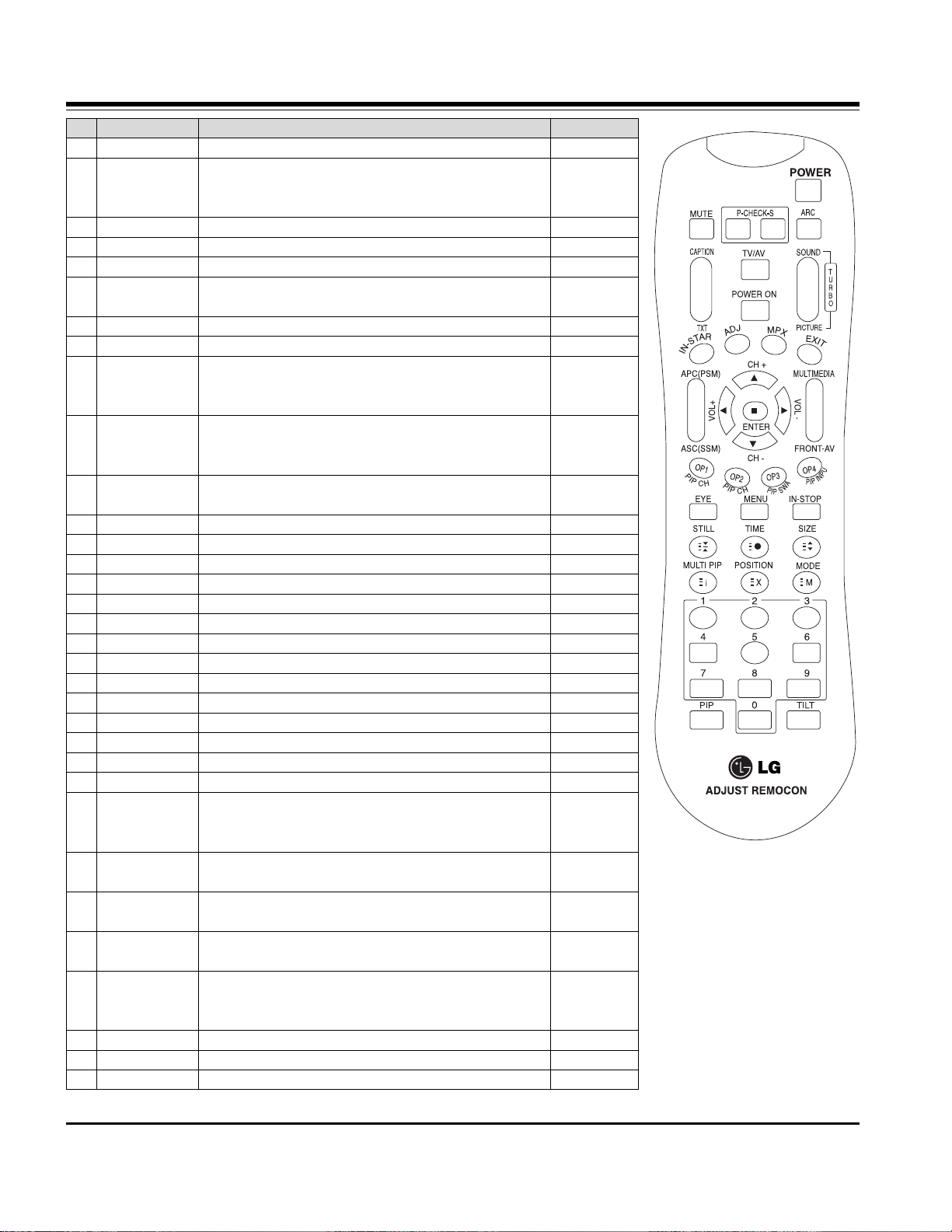

SVC REMOCON

NO. KEY FUNTION REMARK

1 POWER To turn the TV on or off

2 POWER ON

To turn the TV on automatically if the power is supplied to the TV.

(Use the POWER key to deactivate)

: It should be deactivated when delivered.

3 MUTE To activate the mute function.

4 P-CHECK To check TV screen image easily. Shortcut keys

5 S-CHECK To check TV screen sound easily Shortcut keys

6 ARC To select size of the main screen Shortcut keys

(Auto, 4:3, 16:9, 14:3, Zoom, Cinema Zoom)

7 TXT To toggle on/off the teletext mode

8 TV/AV To select an external input for the TV screen

9 IN-START To enter adjustment mode when manufacturing the TV sets.

Use the AV key to

enter the screen W/B

adjustment mode.

10 ADJ To enter into the adjustment mode.

To adjust horizontal To enter into the adjustment mode.

To adjust horizontal

11 MPX To select the multiple sound mode

(Mono, Stereo or MPEG, BOLBY, Digital)

12 EXIT To release the adjustment mode

13 APC(PSM)

To easily adjust the screen according to surrounding brightness

14 ASC(SSM) To easily adjust sound according to the program type

15 MULTIMIDIA To check component input(+RGB, HDMI/DVI) Shortcut keys

16 FRONT-AV To check the front HDMI Shortcut keys

17 CH±

To move channel up/down or to select a functiondisplayed on the screen.

18 VOL± To adjust the volume or accurately control a specific function.

19 ENTER To set a specific function or complete setting.

20 PIP CH-(OP1) To use as a red key in the teletext mode

21 PIP CH+(OP2) To use as a green key in the teletext mode

22 PIP SWAP(OP3) To use as a yellow key in the teletext mode

23 PIP INPUT(OP4) To use as a blue key in the teletext mode

24 MENU

To select the functions such as video, voice, function or channel.

25 IN-STOP

To set the delivery condition status after manufacturing the TV set.

26 STILL To halt the main screen in the normal mode,

or the sub screen at the PIP screen.

Used as a hold key in the teletext mode (Page updating is stopped.)

27 TIME Displays the teletext time in the normal mode

Enables to select the sub code in the teletext mode

28 SIZE Used as the size key in the PIP screen in the normal mode

Used as the size key in the teletext mode

29 MULTI PIP Used as the index key in the teletext mode

(Top index will be displayed if it is the top text.)

30 POSITION To select the position of the PIP screen in the normal mode

Used as the update key in the teletext mode

(Text will be displayed if the current page is updated.)

31 MODE Used as Mode in the teletext mode

32 PIP To select the simultaneous screen

33 0~9 To manually select the channel.

Page 15

- 15 -

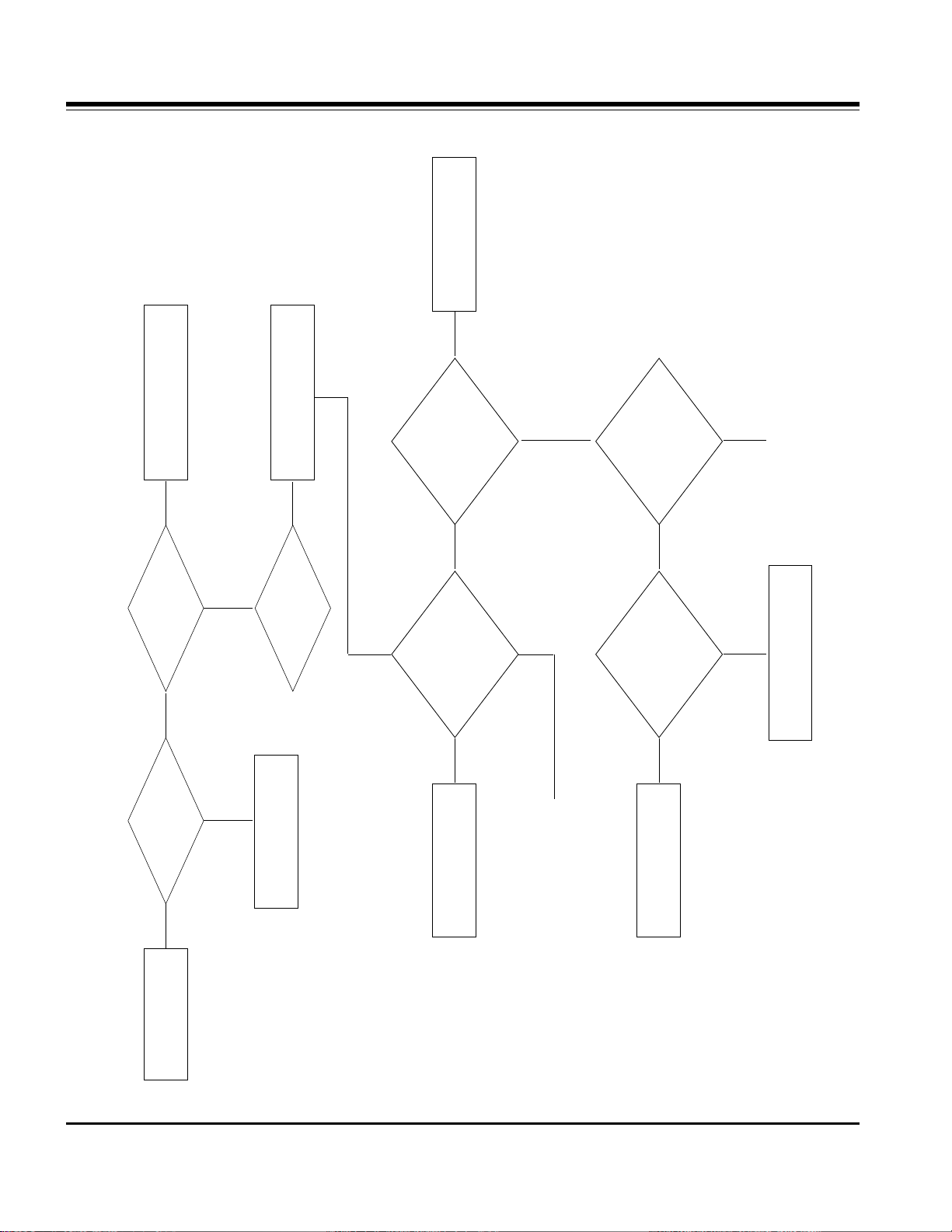

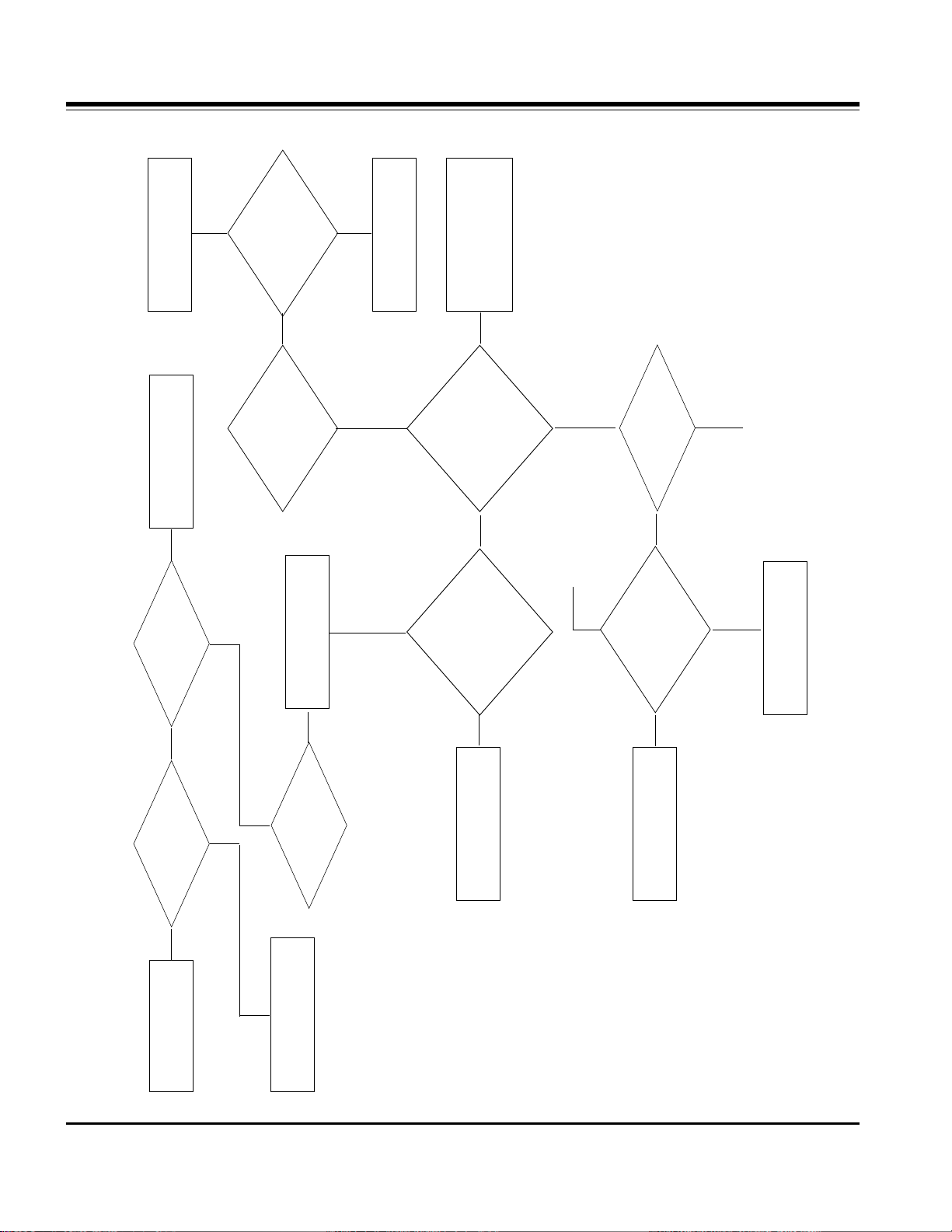

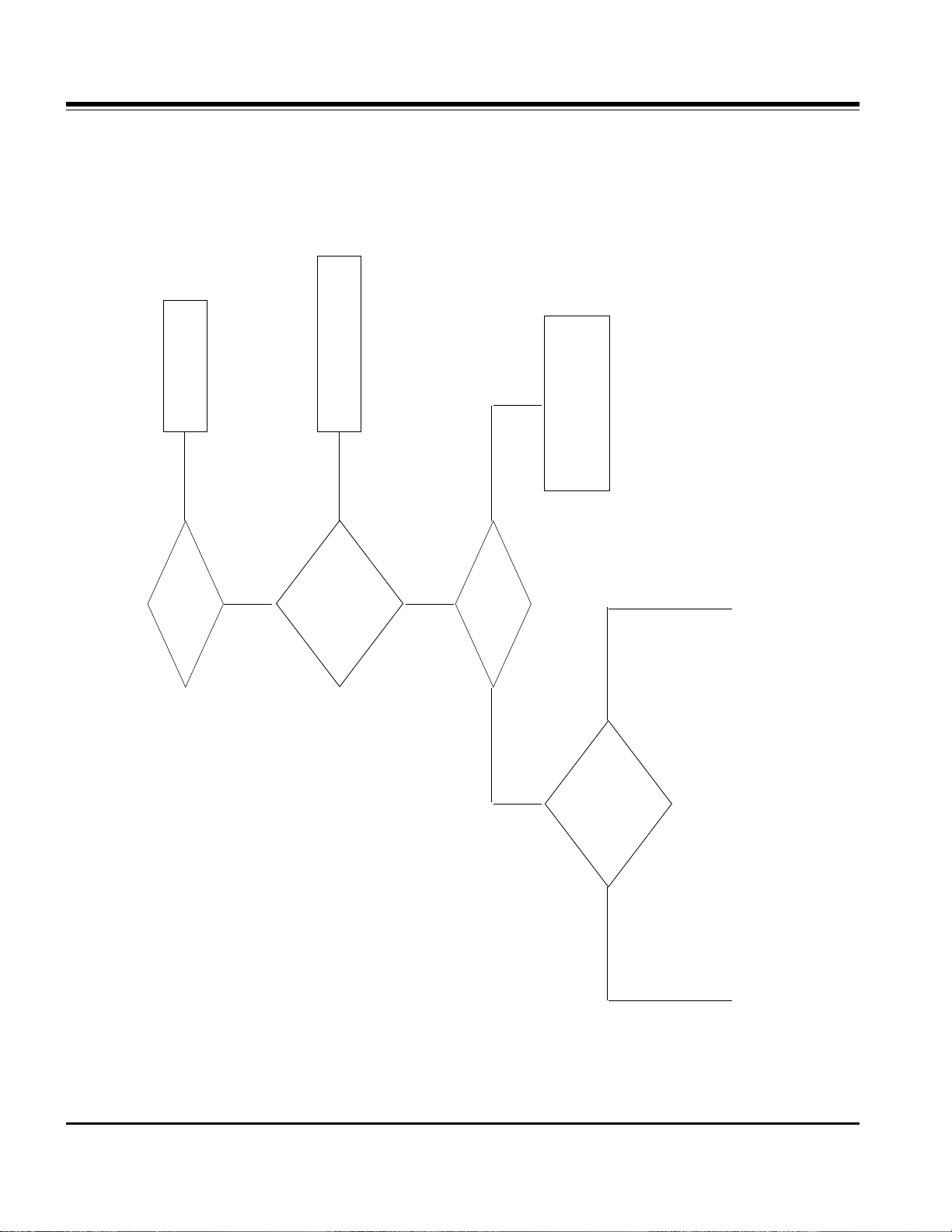

TROUBLESHOOTING

No image

Attach the input cable(s)

Push the POWER ON key

Is the Set ON?

Is the input cable

attached?

Component / S-Video

Replace SideAV boardCorrect them

What is

the input signal

mode?

Check the

Input Y, Cb, Cr

At the pin no.5,7,9 of

IC-AN15865 on

Jack board

Check the

Condition of all

Connectors, wafers, I2C

In component

Signal flow

Power Error

Replace IC1 AN15865

To sheet 20

To sheet 21

Yes

NO Yes

FAIL PASS

(component)

PASS

(S-Video)

FAIL

FAIL

PASS PASS

PASS

FAIL

NO

Check the

output YUV at

R 418, 415, 412

respectively

Check 9V

Across L401and

5V across L404

and L402

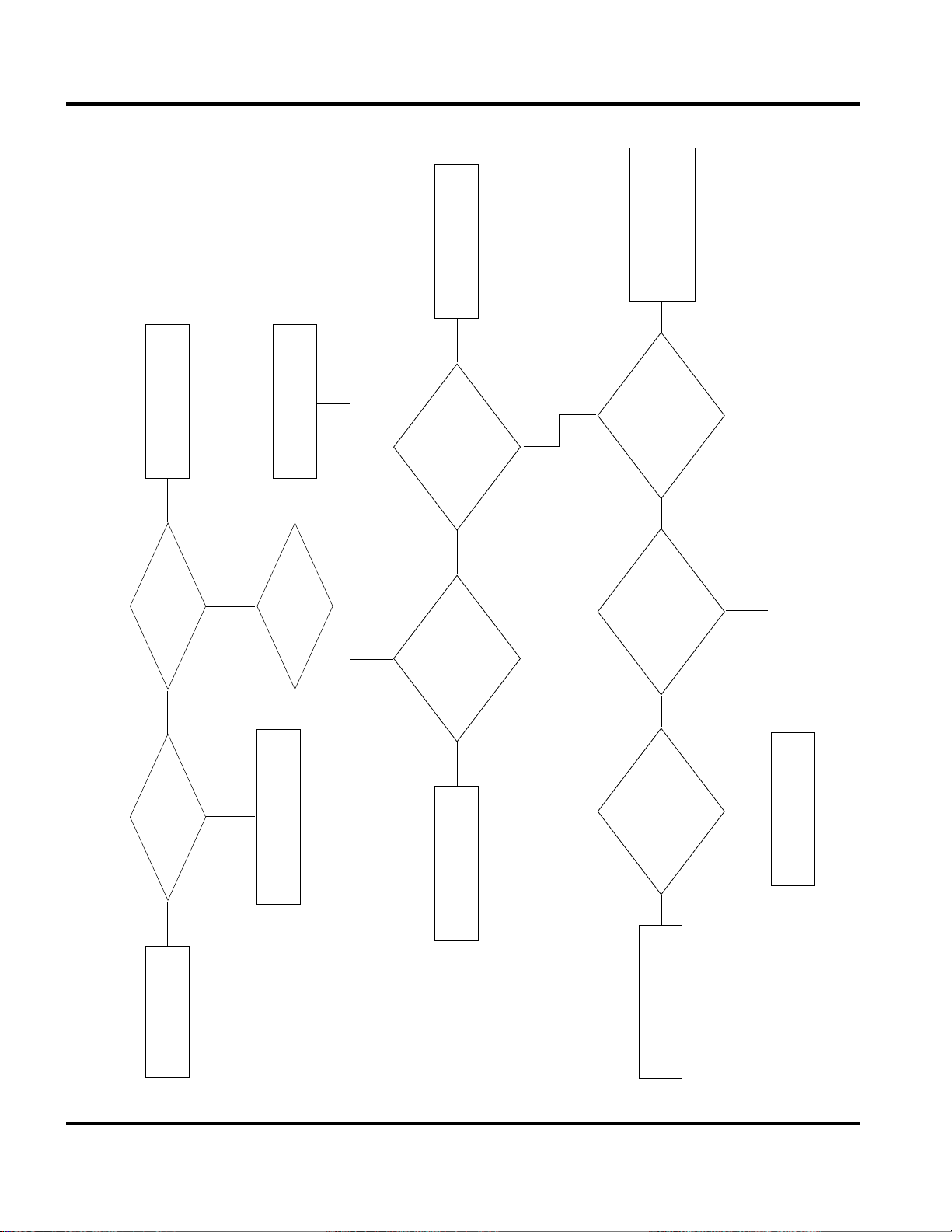

Page 16

- 16 -

No image

Power Error

Attach the input cable(s)

RF/AV/IDTV input

Push the POWER ON key

Correct them

Replace IC1 AN15865

Check Tuner, SCART1/2

Front AV or Digital board

Accordingly w.r.t the Mode.

Is the

Set ON?

Power Error

Replace IC1 AN15865

Is the input cable

attached?

What is

the input signal

mode?

Check main

CVBS at R303

Check

Secondary CVBS

at R434 (for PiP)

Check 9V

Across L401and

at pin 3 of IC100

5V across

L404 , L402

Check 9V

Across L401and

at pin 3 of IC100

5V across

L404,L402

Check the

input video signal

at pin 48, 50, 52, 54, 60

of AN15865 For RF,

AV1/2/3, IDTV

Resp.

Check the

Condition of all

Connectors, wafers, I2C

In corresponding

Signal flow

Yes

NO

Yes

FAIL

PASS

FAIL

FAIL

PASS

PASS

PASS

FAIL

FAIL

FAIL

PASS

PASS

NO

To sheet 21

From sheet 22

Page 17

- 17 -

No image

Attach the input cable(s)

Push the POWER ON key

Is theSet ON?

Is the input cable

attached?

HDMI / DVI DTV

Replace IC accordingly

Correct them

What is

the input signal

mode?

Check the

Corresponding EDID

Storage memory (I.e.,

IC202 for DVI and

IC203 for HDMI)

Check the

Condition of all

Connectors, wafers, I2C

In corresponding

Signal flow

Power

Error

Replace IC1 AN15865

To sheet 21

Yes

Yes Yes

FAIL

FAILFAIL

PASS

PASS

PASS

PASSPASS

FAIL

FAIL

Check the interfacing ckt

Of corresponding mode

On jack board

NO

Check the

input TMDS signal

at pins 39-52 for

DVI and 58-71 for

HDMI of IC601

SiI9021

Check 24

Bit RGB output

Across AR 601-606

Check 3.3V at

L601-605 and

1.8V at pin 2 of

IC602

Page 18

- 18 -

No image

Attach input cable or

memory card

Push the POWER ON key

Is the Set ON?

Is the input cable

attached?

DVI PC / X-Studio

Check the interfacing

circuit At the jack

board or replace X-studio

Board accordingly

Correct them

What is

the input signal

mode?

Check the

i/p RGB/HV signal

At the pin no.72-76 for

X-studio and 1-2,78-80

For PC, of

AN15865

Check the

Condition of all

Connectors,wafers,I2C

and slots In corres

Ponding Signal

flow

Power Error

Replace IC1 AN15865

To sheet 20

Yes

NO Yes

FAIL PASS

FAIL FAIL

PASS

PASS

PASS

FAIL

NO

Check the

output YUV at

R 418, 415, 412

respectively

Check 9V

Across L401and

5V across L404

and L402

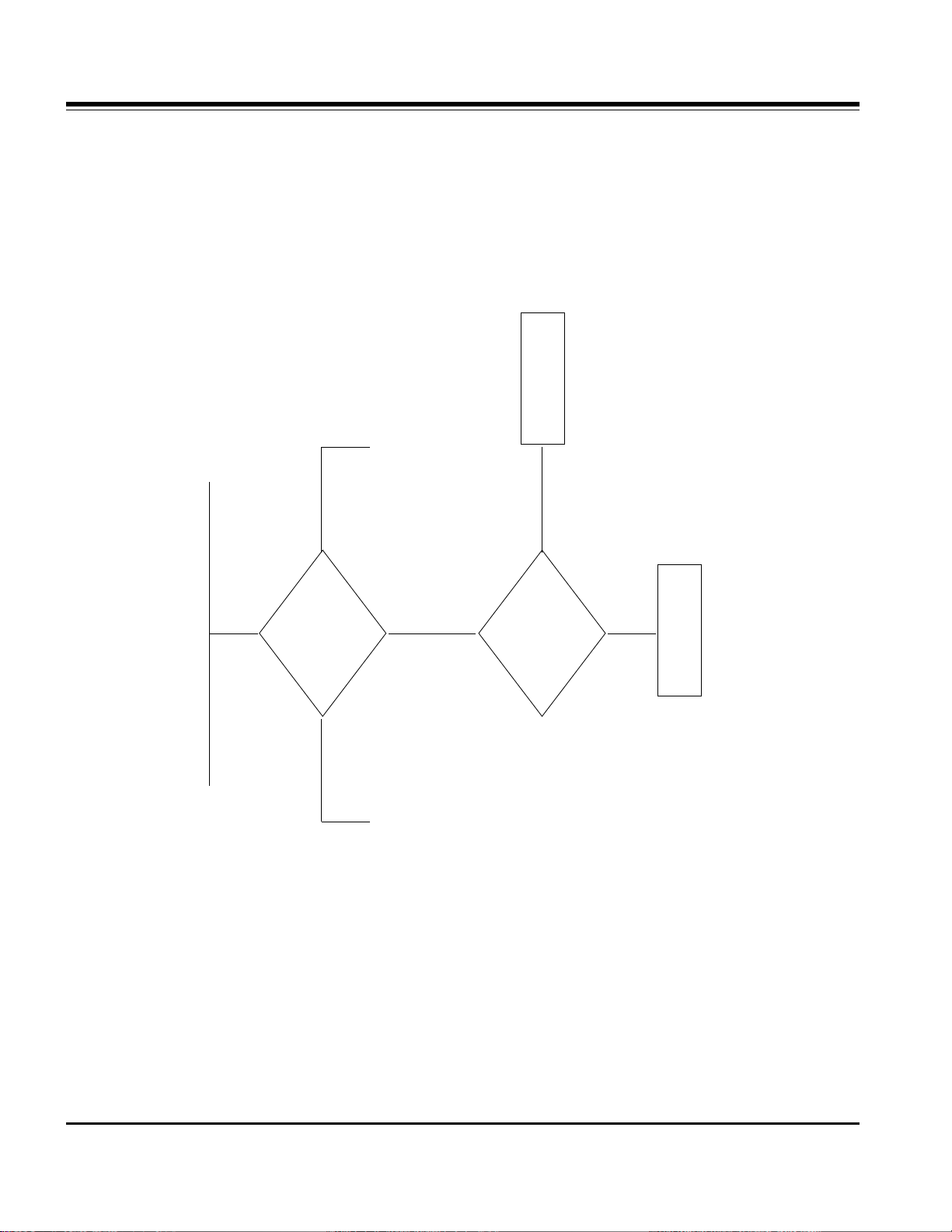

Page 19

- 19 -

Check the

24 bit RGB signal

output of ADC(X98014)

across RA500-501

Check the

3.3V supply volt

across L503, L504

And clock frequency

at pin 39,40

of ADC

From sheet 19

From sheet 16

To sheet 21

(DVI PC / X-Studio)

To sheet 21

(component)

Power Error

Replace ADC

PASS

PASS

PASS

FAIL

FAIL

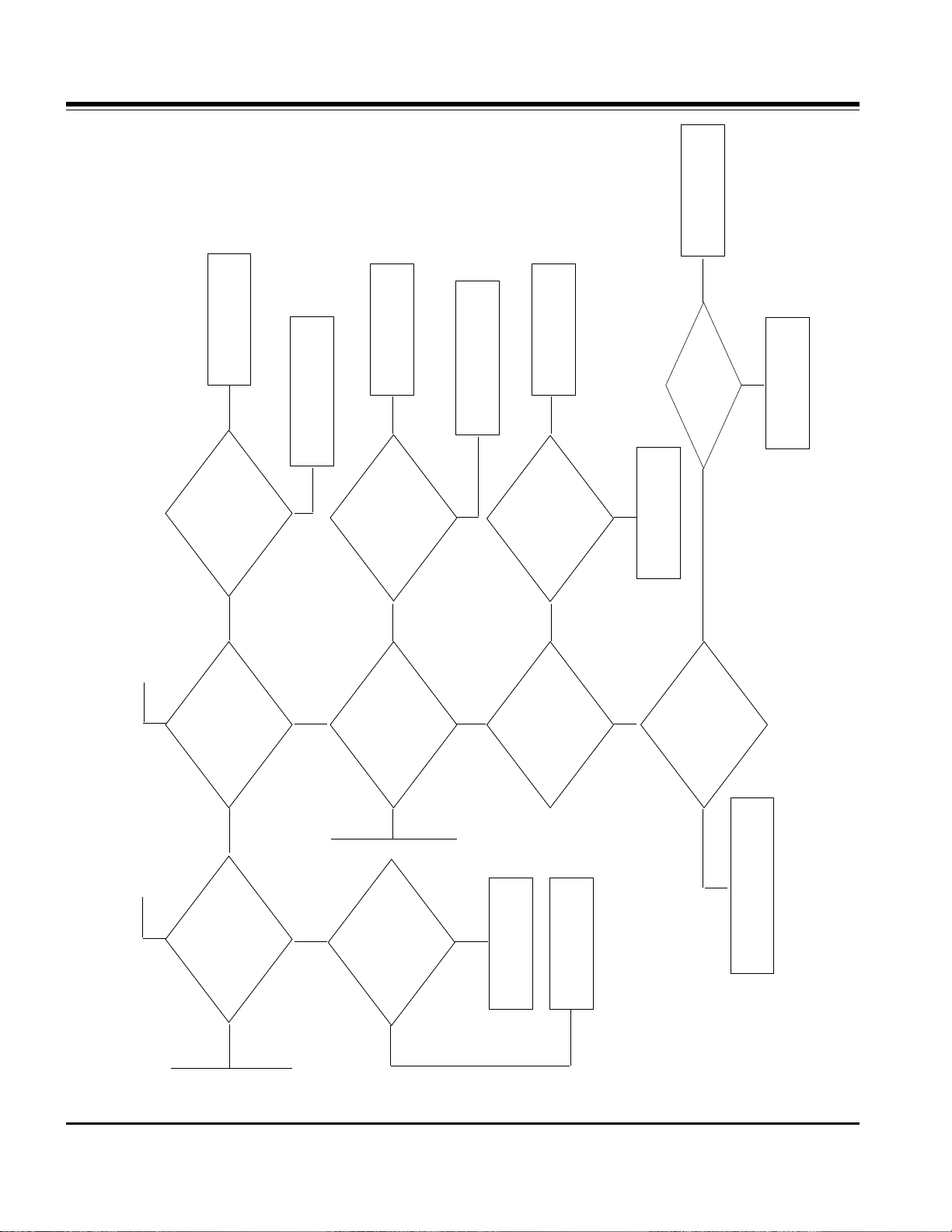

Page 20

- 20 -

check the

output of VSP at.

10,15,16,18,20,21,22

30,31,32 pin

Check the

supply Vcc 3.3V

across L6,7 and 1.8V at pin 2

of IC11,12 and crystal

Frequency at

Pin 69,70

Check the

output of Froudja.

at pin 148-155,130-137 for

Y/C signal and clk,

VS,Hs at RF21-23

check the

RGB output of

PW181 across RAS

10-15 and sync and clk

Signal across RS

45-48

check the

supply 3.3V at LS

4, 2.5V at LS3 and 1.5V

at LS6 and LS9 and

Crystal freq

Check the

IEP output across

RAIP 1-6 and RIP

1,3,4,6

Check LVDS

output for PiP at pin

37,41,45,47 & for main image

at pin 48,46,42,38 of

IC902(LVDS IC).

check 3.3Vdd

and 2.5Vdd across

respectively

LIP2 and LIP1

check the

3.3Vdd across

CF12 and 1.8Vdd

across CF27,CF33 and 13.5

MHz at pin 191-192

of Froudja

Replace

Froudja

Replace

PW181

Power Error

Power Error

Replace LVDS

Replace IEP

Crystal or Power

Error

Replace VSP9437B

Crystal or Power Error

Crystal or Power Error

Check Power Levels and do

Power Troubleshooting

From sheet 20

(component)

From sheet 16

(S-Video)

From sheet 22

From shee 17

From sheet 18

From sheet 20

(DVI PC / X-Studio)

Check

Vcc_PLL 3.3V

Across L901

PASS

FAIL PASS

FAIL

FAIL

PASS

PASS

PASS

FAIL

FAIL

PASS

PASS

FAIL

PASSFAIL

FAILPASS

PASS

FAIL FAIL

Page 21

- 21 -

Check in

owners manual

whether the input

given for PiP is

supported

or not

Check the

YUV ouput across

RA18,20,22 if PiP is

digital or CVBS at R434

if PiP is RF/AV at

AN15865

Is PiP mode ON?

What is the

PIP input

Push PiP key

Change the input for PiP

Follow the corresponding

Troubleshooting

Procedure for same mode

To sheet 21

To sheet 17

NO

Not Supported

PASSFAIL

Any otherDTV/RF/AV

Supported

Yes

Page 22

- 22 -

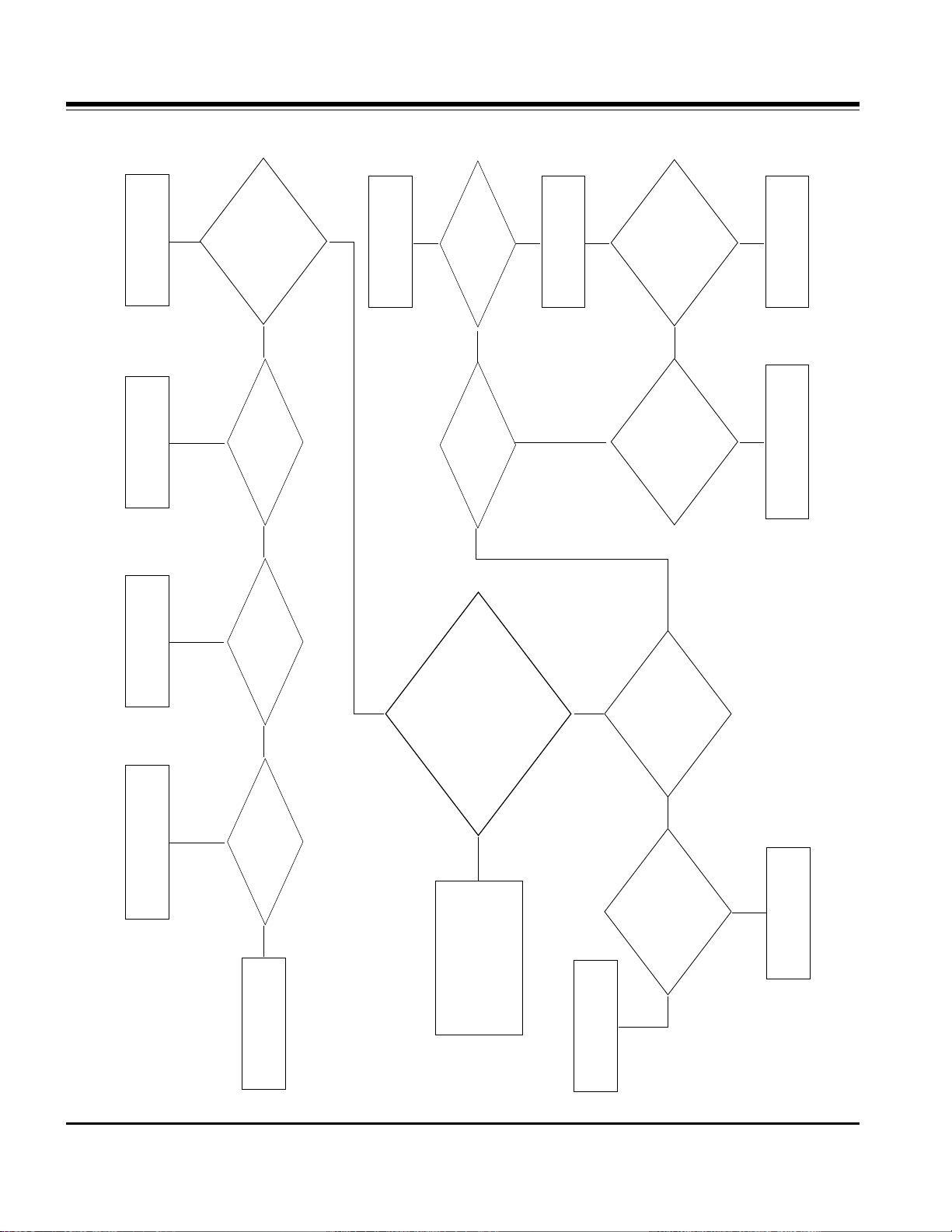

1. RF/AV/Component/ X-Studio/PC-Audio

Check the

Condition of all

Connectors, wafers, I2C

In corresponding

Signal flow?

Check 18V

supply at pin 55and

pin 30 of

AMP

Check audio

output at MSP

across R655,656,657

And 605.

Check the

supply voltage 8V

across L601-602

Check the PC

R/L signal across

R621,630; Analog_SIF at

R602; Side R/L at R619,620;

Front R/L at R617,618 and X-Studio

R/L at R658-659 according to

The corresponding

mode

Is

Volume level

Of the set

0?

Check

3.3V supply across

L305 and 2.5V at

L304

Check the

PWM output of NSP

across R325-328

Is

Mute ON?

Is the Set ON?

Correct them

Replace NSP

Power Error

Replace

TAS5122 (amp)

Power Error

Check the

Amplifier output level

At L300-303

There may be some

error in Audio source.

Increase the VolumeTurn OFF the Mute

Push the POWER ON key

Check the interfacing ciruit

of PC audio, Analog Tuner,

Front AV board, Side AV

board or X-Studio board

accordingly w.r.t the mode.

No Audio

Replace the MSP

NO Yes Yes

NO

NO

Yes

FAIL

PASS

PASS

FAIL

FAIL

PASSPASS

PASS

FAIL

FAIL

PASS

PASS

FAIL

PASS

FAIL

FAIL

Page 23

- 23 -

2. IDTV/HDMI-Audio

Check the

Condition of all

Connectors, wafers, I2C

In corresponding

Signal flow?

Check the

input HDMI_I2S at

pin 1,3,6 and DTV_I2S

at pin 2,5,11 of

IC603

Check the

input I2S signal across

R632-634 of

MSP

Check audio

output at MSP

across R655,656,657

And 605.

Check the

supply voltage 8V

across L601-602

Is

Volume level

Of the set 0?

Is Mute ON?

Check the

PWM output of NSP

across R325-328

Check the

Amplifier output level

At L300-303

Check

3.3V supply across

L305 and 2.5V at

L304

Check 18V

supply at pin 55and

pin 30 of

AMP

Is the

Set ON?

Correct them

Replace the MSP

Power Error

Increase the Volume

Turn OFF the Mute

Power Error

Power Error

Replace NSP

Push the POWER ON key

There may be some

error in PC input.

Replace TAS5122(amp)

Check the SiI9021 or

Digital board accordingly.

No Audio

FAIL PASS PASS

FAILFAILPASS

FAIL

Check

5V at pin 16 of

IC603

Replace IC907

PASS

FAIL

PASS

PASS

FAIL

PASS

FAIL

FAIL

PASS

PASS

FAIL

PASS

PASS

PASS

FAIL

FAIL

FAIL

PASS

FAIL

Page 24

- 24 -

BLOCK DIAGRAM(Video)

Page 25

- 25 -

BLOCK DIAGRAM(Audio)

DH_LINE_SCK

DH_LINE_LRCK

DH_LINE_LRCH

*AV : LR

*Component1

CS5330A

∆LR, SPDIF (Priority)

*Component2 : LR

*RGB (PC/DTV) : LR

mode

Slave

HA_MCLK

(ADC)

Master mode

(Buffer)

MC33078

∆LR, SPDIF (Priority)

*DVI (PC/DTV)

*HDMI

HD2.3

*Dolby Digital

HB_DAC_SCK

HB_DAC_LRCK

(Buffer)

74LCX224

AH_IEC958IN (I2S)

AH_SPDIFCLK (MCLK)

mode

Master

(CPLD)

XC95288XL

SPDIF_MUX_OUT

SPDIF IN

OPTIC (DVD)

SPDIF_DVD

SPDIF_HDMI

(HDMI)

SiI9011

RXC/0/1/2C

(from CPU)

SEL_SPDIF_DVD/nDVI

SPDIF OUT

74LCX157

(Tx Buffer)

HA_IEC958OUT (SPDIF)

SPDIF IN

OPTIC (DVI)

SPDIF_DVI

(from CPU)

SEL_SPDIF_HD2_nSPDIF

I2S

CS8415A

(SPDIF Rx)

(to CPU)

(to CPU)

AC_ERROR_SPDIF

nAC_EMPH_SPDIF

(to CPU)

8415_IRQ_ERR

Slave mode

SPDIF =>

SPDIF_DVI

SPDIF_DVD

SPDIF_HDMI

(from CPU)

nCA_RST_SPDIF

DIGITAL TUNER_TP_DATA

Analog_LR

AV_LR

CXA2069

AV1

MSP4410

(AV Switch)

EPF

AV2

BA_DAC_SCK

BA_DAC_LRCK

HA_DAC_LRCH

*SIF Demod.

*Treble/bass

*Balance

*Volume

*SRS True

Comp1_LR

Comp2_LR

*BBE

Master mode

RGB_LR

PAL TUNER_SIF

MNT_LROUT

MNT

OUT

(PWM)

NSP6241B

Slave mode

I2S_MCLK

I2S_SCK

I2S_LRCK

AN_LINE_LRCH

PWM_LR

TAS5122

LC

SPK

Out

(D.Amp)

LPF

Page 26

- 26 -

WIRING DIAGRAM

1

2

1 - 6631T11023F : 31P

2 - 6631T20037D : 12P

3 - 6631T20037E : 12P

4 - 6631T25024G : 3P

5 - 6631T25024H : 4P

6 - 6631T25023H : 15P

7 - 6631T25024Z : 3P

8 - 6631T11022A : 31P

9 - 6631T25019W : 5P

10 - 6631T25023R : 13P

11 - 6631T20037H : 12P

12 - 6631T20037N : 7P

13 - 6631T20037Q : 3P

14 - 6631T11022A : 31P

15 - 6631T25020L : 13P

16 - 6631T20037H : 12P

17 - 6631T20037L : 10P

3

4

5

6

7

8

8 8

9

10

11

12

13

14

15

16

17

Page 27

- 27 -

EXPLODED VIEW

030

050

180

110

070

060

170

160

100

150

090

080

140

040

020

010

130

120

Page 28

- 28 -

EXPLODED VIEW PARTS LIST

No.

PART NO.

DESCRIPTION

3091TKE037H CABINET ASSEMBLY, 32LX2D-AA BRAND CABINET ASSY

6304FLP288A

LCD(LIQUID CRYSTAL DISPLAY), LC320W01-SL01 LG PHILPS TFT COLOR WXGA AIODC SPEC UP LEAD FREE

3809TKE030V BACK COVER ASSEMBLY, 32LX2D-AA DTV 3808TKE025 SET

3043TKK252A TILT SWIVEL ASSEMBLY, 32LX2D-UA STAND ASSY

3550TKK881C COVER, 32LX2D NO SPRAY REAR AV COVER

4951TKS222G METAL ASSEMBLY, FRAME METAL ASSY 32LX1D-NA

6400GESF01A

SPEAKER,FULLRANGE, C112A02K1450 ESTEC FULL-RANGE(GENERAL) 8OHM 10/15W .DB 110 32LG10

6871TPT303B

PWB(PCB) ASSEMBLY,POWER, DU/DN/DI-32LP10 POWER TOTAL BRAND DU(DCR) COMM - SH(D112)

33139D3012A MAIN TOTAL ASSEMBLY, 32LX2D BRAND AL-05PB

68719ST791A PWB(PCB) ASSEMBLY,SUB, SUB T.T AB 32LX2D-AA ALAULVX TUNER

4951TKK238J METAL ASSEMBLY, FRAME, REAR 32LX2D-AA

68719ST790A PWB(PCB) ASSEMBLY,SUB, SUB T.T AB 32LX2D-AA ALAULVX CONTROL KEY

68719ST789A PWB(PCB) ASSEMBLY,SUB, SUB T.T AB 32LX2D-AA ALAULVX LIGHT&IR ETC

4950TKA210A METAL, SIDE BRACKET 32LX1D LPL MODULE

33139D3011A MAIN TOTAL ASSEMBLY, 32LX2D-AA BRAND AL-05PB

68719ST788A PWB(PCB) ASSEMBLY,SUB, SUB T.T AB 32LX2D-AA ALAULVX SIDE COMP SUB TOTAL

4815TKK046J SHIELD ASSEMBLY, REAR SHIELD ASSY 32LX2D-AA

3551TKK589U COVER ASSEMBLY, DTV 32LX2D-AA REAR AV BRACKET ASSY

010

020

030

040

050

060

070

080

090

100

110

120

130

140

150

160

170

180

Page 29

- 29 -

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C110 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C112 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C113 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C114 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C206 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C208 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C219 0CH5102K416 1000PF 50V 5% NP0 2012 R/TP

C220 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C221 0CH5102K416 1000PF 50V 5% NP0 2012 R/TP

C222 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C224 0CH5181K416 180PF 50V 5% NP0 2012 R/TP

C304 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C310 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C311 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C318 0CK225DFK4A "2.2UF 2012 16V 20%,-20% F(Y"

C319 0CK225DFK4A "2.2UF 2012 16V 20%,-20% F(Y"

C325 0CK225DFK4A "2.2UF 2012 16V 20%,-20% F(Y"

C327 0CK225DFK4A "2.2UF 2012 16V 20%,-20% F(Y"

C410 0CH5680K416 68PF 50V 5% NP0 2012 R/TP

C411 0CH5330K416 33PF 50V 5% NP0 2012 R/TP

C412 0CH5330K416 33PF 50V 5% NP0 2012 R/TP

C420 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C421 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C422 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C423 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C424 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C427 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C434 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C439 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C440 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C441 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C442 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C444 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C501 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C503 0CH2822K516 8200PF 50V 10% B(Y5P) 2012

C506 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C508 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C512 0CH5020K116 2PF 2012 50V 0.5 PF NP0 R/T

C513 0CH5020K116 2PF 2012 50V 0.5 PF NP0 R/T

C515 0CH5560K416 56PF 50V 5% NP0 2012 R/TP

C516 0CH5560K416 56PF 50V 5% NP0 2012 R/TP

C522 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C524 0CH5102K416 1000PF 50V 5% NP0 2012 R/TP

C527 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C530 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C537 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C541 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C559 0CK225DFK4A "2.2UF 2012 16V 20%,-20% F(Y"

C570 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C571 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C572 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C573 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C574 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C575 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C578 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C586 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C587 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C588 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C589 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C590 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C591 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C592 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C593 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C601 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C603 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C605 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C606 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C608 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C609 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C610 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C611 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C614 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C615 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C618 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C619 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C622 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C623 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C625 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C627 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C628 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C631 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C637 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C638 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C642 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C643 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C645 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C653 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C656 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C662 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C664 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C667 0CH2103K666 0.01UF 50V 20% X7R 2012 R/T

C668 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C680 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C702 0CH5471K416 470PF 50V 5% NP0 2012 R/TP

C703 0CH5471K416 470PF 50V 5% NP0 2012 R/TP

C301 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C305 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C306 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C312 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C313 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C314 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C316 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C320 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C321 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C322 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C324 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C428 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C430 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C435 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C437 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

REPLACEMENT PARTS LIST

MAIN BOARD(Analog)

CAPACITOR

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit in the

P/No. means as follows;

CC, CX, CK, CN, CH : Ceramic

CQ : Polyestor

CE : Electrolytic

CF : Fixed Film

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RH : CHIP, Metal Glazed(Chip)

RR : Drawing

Page 30

- 30 -

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C514 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C517 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C518 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C519 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C521 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C525 0CK102CK56A 1000PF 1608 50V 0.1 R/TP X7

C528 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C529 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C532 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C534 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C535 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C536 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C539 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C540 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C542 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C546 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C547 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C548 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C549 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C550 0CK222CK51A 2200PF 1608 50V 10% R/TP B(

C553 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C556 0CK105DK94A "1UF 2012 50V 80%,-20% R/TP"

C557 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C560 0CK105DK94A "1UF 2012 50V 80%,-20% R/TP"

C561 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C564 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C569 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C579 0CK333CK56A 33000PF 1608 50V 10% R/TP X

C580 0CK333CK56A 33000PF 1608 50V 10% R/TP X

C581 0CK333CK56A 33000PF 1608 50V 10% R/TP X

C582 0CK333CK56A 33000PF 1608 50V 10% R/TP X

C594 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C595 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C596 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C626 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C632 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C651 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C654 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C658 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C661 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C674 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C675 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C701 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C101 0CH6101K416 100PF 50V 5% NP0 2012 R/TP

C104 0CH6101K416 100PF 50V 5% NP0 2012 R/TP

C115 0CH6101K416 100PF 50V 5% NP0 2012 R/TP

C116 0CH6101K416 100PF 50V 5% NP0 2012 R/TP

C223 0CH6101K416 100PF 50V 5% NP0 2012 R/TP

C323 0CH2474F566 0.47UF 16V 10% X7R 2012 R/T

C326 0CH2474F566 0.47UF 16V 10% X7R 2012 R/T

C413 0CH2474F566 0.47UF 16V 10% X7R 2012 R/T

C502 0CH2152K516 1500PF 50V 10% B(Y5P) 2012

C505 0CH2152K516 1500PF 50V 10% B(Y5P) 2012

C538 0CH2474F566 0.47UF 16V 10% X7R 2012 R/T

C543 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C554 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C583 0CE108EJK18 "1000UF KMG,RD 35V 20%,-20%"

C597 0CE108EJK18 "1000UF KMG,RD 35V 20%,-20%"

C111 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C226 0CE227SF6DC 220UF MVG 16V 20% R/TP(SMD)

C227 0CE227SF6DC 220UF MVG 16V 20% R/TP(SMD)

C307 0CE226SF6DC 22UF MVG 16V 20% SMD R/TP

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C308 0CE227SF6DC 220UF MVG 16V 20% R/TP(SMD)

C309 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C414 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C415 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C416 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C417 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C418 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C426 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C429 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C431 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C432 0CE105SK6DC 1UF MVG 50V 20% SMD R/TP

C433 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C436 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C438 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C443 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C507 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C511 0CE226SF6DC 22UF MVG 16V 20% SMD R/TP

C520 0CE335SK6DC 3.3UF MVG 50V 20% SMD R/TP

C531 0CE226SF6DC 22UF MVG 16V 20% SMD R/TP

C533 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C544 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C555 0CE335SK6DC 3.3UF MVG 50V 20% SMD R/TP

C563 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C566 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C567 0CE106SF6DC 10UF MVG 16V 20% R/TP(SMD)

C576 0CE475VK6DC 4.7UF MV 50V 20% R/TP(SMD)

C577 0CE475VK6DC 4.7UF MV 50V 20% R/TP(SMD)

C602 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C604 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C607 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C612 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C613 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C616 0CE477SF6DC 470UF MVG 16V 20% R/TP(SMD)

C617 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C620 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C621 0CE227SF6DC 220UF MVG 16V 20% R/TP(SMD)

C629 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C633 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C635 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C636 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C639 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C640 0CE476VK6DC 47UF MV 50V 20% R/TP(SMD) S

C641 0CE476VK6DC 47UF MV 50V 20% R/TP(SMD) S

C644 0CE107VH6DC 100UF MV 25V 20% R/TP(SMD)

C646 0CE107VH6DC 100UF MV 25V 20% R/TP(SMD)

C652 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C655 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C657 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C659 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C660 0CE107SF6DC 100UF MVG 16V 20% SMD R/TP

C663 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C665 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C666 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C672 0CE476SF6DC 47UF MVG 16V 20% SMD R/TP

C681 0CE476WF6DC 47UF MVK 16V 20% R/TP(SMD)

C584 0CF4741L438 0.47UF D 63V 5% TP 5 M/PE N

C585 0CF4741L438 0.47UF D 63V 5% TP 5 M/PE N

ZD101 0DR050008AA SD05.TC R/TP SEMTECH SOD323

ZD102 0DR050008AA SD05.TC R/TP SEMTECH SOD323

DIODEs

Page 31

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

ZD301 0DR050008AA SD05.TC R/TP SEMTECH SOD323

ZD302 0DR050008AA SD05.TC R/TP SEMTECH SOD323

D101 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D102 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D103 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D403 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D404 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D601 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D602 0DS226009AA KDS226 TP KEC - 80V - - 4NS

D603 0DS226009AA KDS226 TP KEC - 80V - - 4NS

ZD108 0DZ510009EE UDZ S 5.1B TP ROHM-K SOD323

ZD109 0DZ510009EE UDZ S 5.1B TP ROHM-K SOD323

ZD303 0DZ510009EE UDZ S 5.1B TP ROHM-K SOD323

ZD304 0DZ510009EE UDZ S 5.1B TP ROHM-K SOD323

ZD501 0DZ820009AH MTZJ8.2B TP ROHM-K DO34 - 8

IC403 0IMMRMR006E "MX29LV160BTTC-70G,LF MACRON"

IC101 0IMMR00018A 24LC02BT-I/SNG(PB FREE) MIC

IC402 0IMMRHY001L "HY57V641620ETP-H,LF HYNIX 5"

IC404 0IMCRAL006A "AT24C16AN-10SU-2.7,LF ATMEL"

IC301 0ISO206900A CXA2069Q QFP64 BK I2C BUS A

IC401 0IMCRMN023A SDA6001 QH B12 MICRONAS 128

IC501 0IMCRMN028B MSP4410K MICRONAS 80P/PQFP

IC502 0IMCRNL001C "NSP-6241B,PB FREE NEOFIDELI"

IC503 0IMCRTI028C "TAS5122DCARG4,LF TEXAS INS"

IC405 0IKE702700D "KIA7027AF 3, SOT-89 TP RESE"

IC601 0IMCRFA010A "KA7809R, FAIRCHILD 2P D-PAK"

IC602 0IPRPML001A MIC39100 MICREL 3P SOT223 R

IC603 0IPMGKE030A KIA78R05F KEC 5PIN DPAK R/T

L506 6140VB0022A CPS-0810 GET 22UH 21.5TURNS

L507 6140VB0022A CPS-0810 GET 22UH 21.5TURNS

L508 6140VB0022A CPS-0810 GET 22UH 21.5TURNS

L509 6140VB0022A CPS-0810 GET 22UH 21.5TURNS

R707 6210TCE001P HB-1S2012-121JT CERATECH 20

R708 6210TCE001P HB-1S2012-121JT CERATECH 20

L600 6210TCE001P HB-1S2012-121JT CERATECH 20

L601 6210TCE001P HB-1S2012-121JT CERATECH 20

L602 6210TCE001P HB-1S2012-121JT CERATECH 20

L603 6210TCE001P HB-1S2012-121JT CERATECH 20

L206 6210VC0005A BK2125 HS 750 TAIYOYUDEN 2X

L208 6210VC0005A BK2125 HS 750 TAIYOYUDEN 2X

L209 6210VC0005A BK2125 HS 750 TAIYOYUDEN 2X

L211 6200JB8010L MLB-201209-1000L-N2 MAG LAY

L216 6200JB8010L MLB-201209-1000L-N2 MAG LAY

L217 6200JB8010L MLB-201209-1000L-N2 MAG LAY

L218 6200JB8010L MLB-201209-1000L-N2 MAG LAY

L303 6210TCE001A HB-1S2012-080JT CERATEC 201

L305 6210TCE001A HB-1S2012-080JT CERATEC 201

L307 6210TCE001A HB-1S2012-080JT CERATEC 201

L309 6210TCE001A HB-1S2012-080JT CERATEC 201

L311 6210TCE001A HB-1S2012-080JT CERATEC 201

L408 6210TCE001G HH-1M3216-501 CERATEC 3216M

L510 6200JB8010L MLB-201209-1000L-N2 MAG LAY

L511 6200JB8010L MLB-201209-1000L-N2 MAG LAY

L613 6210TCE001G HH-1M3216-501 CERATEC 3216M

L614 6210TCE001G HH-1M3216-501 CERATEC 3216M

L616 6210TCE001G HH-1M3216-501 CERATEC 3216M

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

L618 6210TCE001G HH-1M3216-501 CERATEC 3216M

L619 6210TCE001G HH-1M3216-501 CERATEC 3216M

L620 6210TCE001G HH-1M3216-501 CERATEC 3216M

L621 6210TCE001G HH-1M3216-501 CERATEC 3216M

L622 6210TCE001G HH-1M3216-501 CERATEC 3216M

L108 6210TCE001G HH-1M3216-501 CERATEC 3216M

L302 6210TCE001G HH-1M3216-501 CERATEC 3216M

L405 6210TCE001G HH-1M3216-501 CERATEC 3216M

L407 6210TCE001G HH-1M3216-501 CERATEC 3216M

L608 6210TCE001G HH-1M3216-501 CERATEC 3216M

L609 6210TCE001G HH-1M3216-501 CERATEC 3216M

L624 6210TCE001G HH-1M3216-501 CERATEC 3216M

L625 6210TCE001G HH-1M3216-501 CERATEC 3216M

L626 6210TCE001G HH-1M3216-501 CERATEC 3216M

L627 6210TCE001G HH-1M3216-501 CERATEC 3216M

L629 6210TCE001G HH-1M3216-501 CERATEC 3216M

L630 6210TCE001G HH-1M3216-501 CERATEC 3216M

L700 6210TCE001G HH-1M3216-501 CERATEC 3216M

L109 0LC2000005H "FI-B2012-472,4.7UH CERATECH"

L110 0LC2000005H "FI-B2012-472,4.7UH CERATECH"

L202 0LC0233002A 3.3UH CERATECH R/TP

L204 0LC0233002A 3.3UH CERATECH R/TP

L212 0LC0233002A 3.3UH CERATECH R/TP

L213 0LC0233002A 3.3UH CERATECH R/TP

L214 0LC0233002A 3.3UH CERATECH R/TP

L215 0LC0233002A 3.3UH CERATECH R/TP

L501 0LC2232101A 22UH 10% 3216 R/TC FI-D3216

L502 0LC2232101A 22UH 10% 3216 R/TC FI-D3216

L504 0LC2232101A 22UH 10% 3216 R/TC FI-D3216

L512 0LC1020101A 1UH 10% 2012 R/TC FI-B2012L513 0LC1020101A 1UH 10% 2012 R/TC FI-B2012L503 0LC2232101A 22UH 10% 3216 R/TC FI-D3216

L640 0LC6832101A 6.8UH 10% 3216 R/TC FI-C321

Q101 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q102 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q103 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q204 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q205 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q206 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q307 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q501 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q502 0TR150400BA CHIP 2SA1504S(ASY) BK KEC Q503 0TR150400BA CHIP 2SA1504S(ASY) BK KEC Q504 0TR150400BA CHIP 2SA1504S(ASY) BK KEC Q505 0TR150400BA CHIP 2SA1504S(ASY) BK KEC Q506 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q507 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q508 0TR102008AA KRA102S R/TP KEC SOT23 CHIP

Q301 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q302 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q303 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q304 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q305 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q306 0TR387500AA CHIP 2SC3875S(ALY) BK KEC Q308 0TR387500AA CHIP 2SC3875S(ALY) BK KEC -

L304 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

- 31 -

TRANSISTOR

RESISTORs

IC

COIL & CORE & & FILTER & INDUCTOR

Page 32

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

L306 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

L308 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

L310 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

L312 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

L313 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

L314 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R101 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R102 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R103 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R104 0RH4701D622 4.7K OHM 1 / 10 W 2012 5.00

R105 0RH4701D622 4.7K OHM 1 / 10 W 2012 5.00

R107 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R108 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R109 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R110 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R111 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R112 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R113 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R114 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R117 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R128 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R129 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R132 0RH4701D622 4.7K OHM 1 / 10 W 2012 5.00

R133 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R135 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R136 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R137 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R138 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R139 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R140 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R141 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R201 0RH0822D622 82 OHM 1 / 10 W 2012 5.00%

R203 0RH0822D622 82 OHM 1 / 10 W 2012 5.00%

R205 0RH0822D622 82 OHM 1 / 10 W 2012 5.00%

R208 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R210 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R212 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R214 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R220 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R222 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R237 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R238 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R239 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R240 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R241 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R244 0RH0822D622 82 OHM 1 / 10 W 2012 5.00%

R245 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R246 0RH0822D622 82 OHM 1 / 10 W 2012 5.00%

R247 0RH0822D622 82 OHM 1 / 10 W 2012 5.00%

R248 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R251 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R252 0RH2203D622 220K OHM 1 / 10 W 2012 5.00

R253 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R254 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R315 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R316 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R332 0RH4702D622 47K OHM 1 / 10 W 2012 5.00%

R336 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R338 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R340 0RH1201D622 1.2K OHM 1 / 10 W 2012 5.00

R341 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R342 0RH1201D622 1.2K OHM 1 / 10 W 2012 5.00

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R343 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R348 0RH4702D622 47K OHM 1 / 10 W 2012 5.00%

R349 0RH2001D622 2K OHM 1 / 10 W 2012 5.00%

R350 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R351 0RH4702D622 47K OHM 1 / 10 W 2012 5.00%

R356 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R358 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R405 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R407 0RH0222D622 22 OHM 1 / 10 W 2012 5.00%

R412 0RH8200D622 820 OHM 1 / 10 W 2012 5.00%

R413 0RH1801D622 1.8K OHM 1 / 10 W 2012 5.00

R418 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R437 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R438 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R439 0RH0752D622 75 OHM 1 / 10 W 2012 5.00%

R442 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R443 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R5 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R501 0RH3300D622 330 OHM 1 / 10 W 2012 5.00%

R502 0RH1202D622 12K OHM 1 / 10 W 2012 5.00%

R503 0RH3901D622 3.9K OHM 1 / 10 W 2012 5.00

R508 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R510 0RH4700D622 470 OHM 1 / 10 W 2012 5.00%

R511 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R513 0RH0432D622 43 OHM 1 / 10 W 2012 5.00%

R514 0RH0432D622 43 OHM 1 / 10 W 2012 5.00%

R516 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R525 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R526 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R541 0RH1000D622 100 OHM 1 / 10 W 2012 5.00%

R559 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R560 0RH2200D622 220 OHM 1 / 10 W 2012 5.00%

R561 0RH2200D622 220 OHM 1 / 10 W 2012 5.00%

R562 0RH2200D622 220 OHM 1 / 10 W 2012 5.00%

R563 0RH2200D622 220 OHM 1 / 10 W 2012 5.00%

R564 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R565 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R566 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R567 0RH1001D622 1K OHM 1 / 10 W 2012 5.00%

R568 0RH0221D622 2.2 OHM 1 / 10 W 2012 5.00%

R569 0RH0221D622 2.2 OHM 1 / 10 W 2012 5.00%

R570 0RH2201D622 2.2K OHM 1 / 10 W 2012 5.00

R572 0RH0221D622 2.2 OHM 1 / 10 W 2012 5.00%

R573 0RH2201D622 2.2K OHM 1 / 10 W 2012 5.00

R574 0RH0221D622 2.2 OHM 1 / 10 W 2012 5.00%

R575 0RH0331D622 3.3 OHM 1 / 10 W 2012 5.00%

R579 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R581 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R582 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R583 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R584 0RH2001D622 2K OHM 1 / 10 W 2012 5.00%

R585 0RH2001D622 2K OHM 1 / 10 W 2012 5.00%

R586 0RH4703D622 470K OHM 1 / 10 W 2012 5.00

R587 0RH4703D622 470K OHM 1 / 10 W 2012 5.00

R590 0RH0331D622 3.3 OHM 1 / 10 W 2012 5.00%

R591 0RH1002D622 10K OHM 1 / 10 W 2012 5.00%

R595 0RH0101D622 1.0 1/10W 5 TA

R599 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R6 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R7 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R701 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R703 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

- 32 -

Page 33

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R704 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R705 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R706 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R711 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R713 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R724 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R725 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R8 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R1 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R115 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R116 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R130 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R131 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R134 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R2 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R3 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R301 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R302 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R304 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R305 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R306 0RJ2200D677 220 OHM 1/10 W 5% 1608 R/TP

R307 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R309 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R310 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R311 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R312 0RJ3300D677 330 OHM 1/10 W 5% 1608 R/TP

R313 0RJ2200D677 220 OHM 1/10 W 5% 1608 R/TP

R314 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R319 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R320 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R321 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R322 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R323 0RJ8200D677 820 OHM 1/10 W 5% 1608 R/TP

R324 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R325 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R326 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R327 0RJ1201D677 1200 OHM 1/10 W 5% 1608 R/T

R328 0RJ1201D677 1200 OHM 1/10 W 5% 1608 R/T

R329 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R333 0RJ4702D677 47000 OHM 1/10 W 5% 1608 R/

R334 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R335 0RJ1201D677 1200 OHM 1/10 W 5% 1608 R/T

R337 0RJ1201D677 1200 OHM 1/10 W 5% 1608 R/T

R339 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R346 0RJ4702D677 47000 OHM 1/10 W 5% 1608 R/

R347 0RJ2001D677 2K OHM 1/10 W 5% 1608 R/TP

R352 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R353 0RJ4702D677 47000 OHM 1/10 W 5% 1608 R/

R354 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R4 0RH0000D622 0 OHM 1 / 10 W 2012 5.00% D

R401 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R402 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R419 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R420 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R421 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R422 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R429 0RJ3301D677 3.3K OHM 1/10 W 5% 1608 R/T

R430 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R431 0RJ3301D677 3.3K OHM 1/10 W 5% 1608 R/T

R432 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R433 0RJ8201D677 8.2K OHM 1/10 W 5% 1608 R/T

R436 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

DATE: 2005. 09. 12.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R504 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R505 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R506 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R507 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R517 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R518 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R519 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R521 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R524 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R527 0RJ2200D677 220 OHM 1/10 W 5% 1608 R/TP

R530 0RJ2200D677 220 OHM 1/10 W 5% 1608 R/TP

R532 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R533 0RJ2200D677 220 OHM 1/10 W 5% 1608 R/TP

R536 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R537 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP