Page 1

Internal Use Only

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

LED TV

SERVICE MANUAL

CHASSIS : 15ODMCAT

MODEL : 32LF520D

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Page 2

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SERVICING PRECAUTIONS ................................................................... 4

SPECIFICATION ...................................................................................... 6

ADJUSTMENT INSTRUCTION ............................................................... 8

BLOCK DIAGRAM ................................................................................. 11

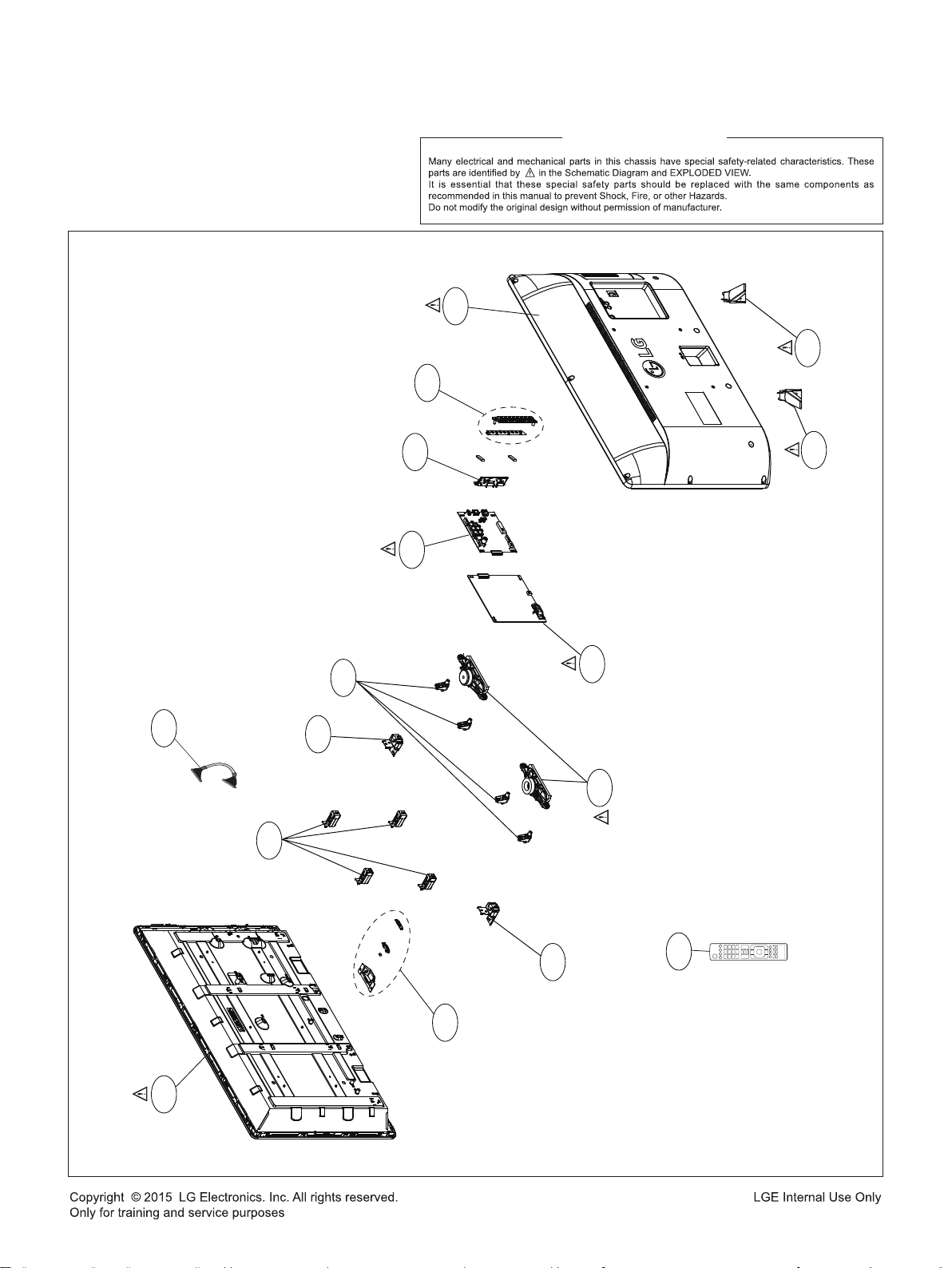

EXPLODED VIEW .................................................................................. 13

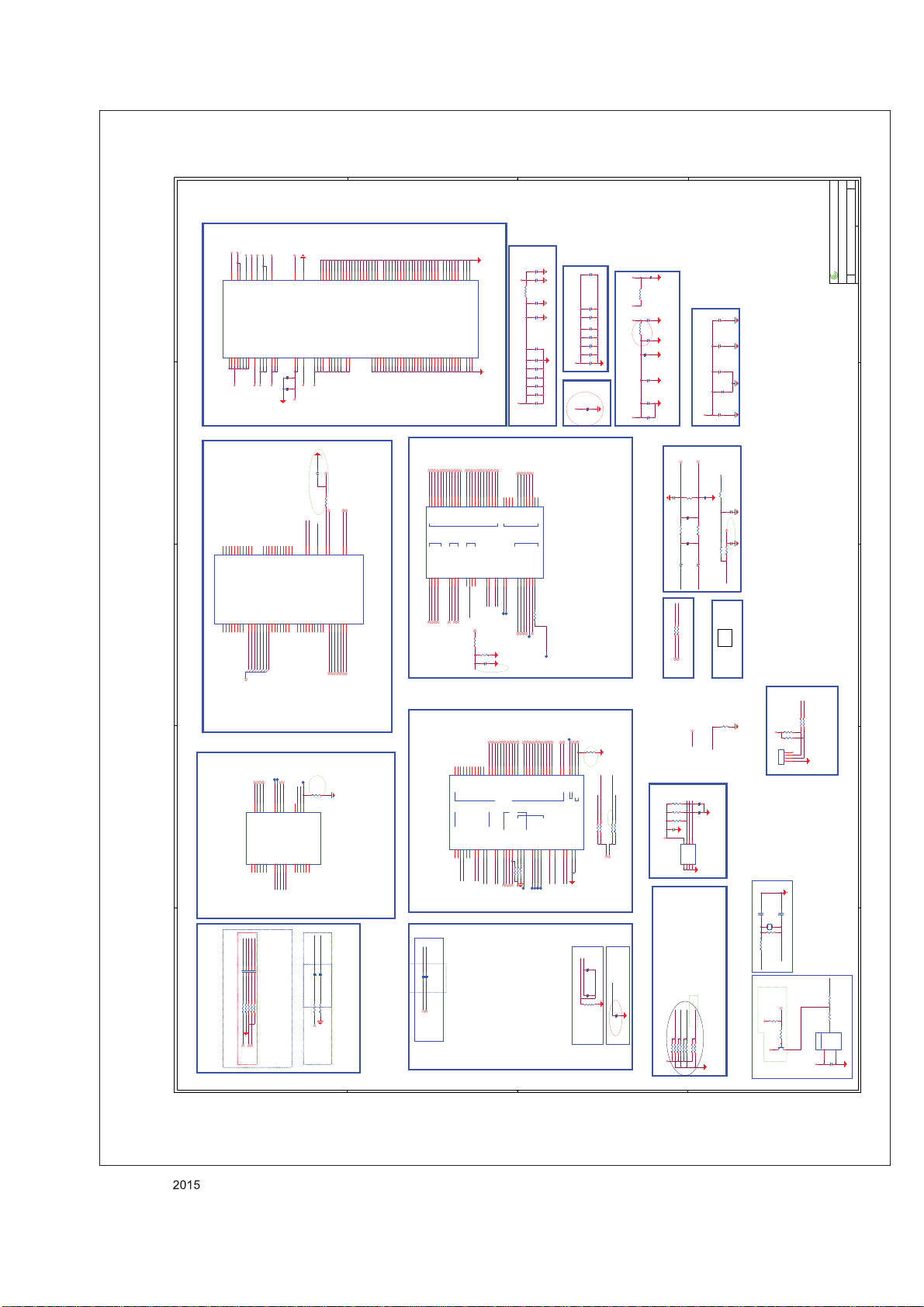

SCHEMATIC CIRCUIT DIAGRAM ........................................... APPENDIX

SCHEMATIC KEY BOARD ...................................................... APPENDIX

SCHEMATIC IR/LED BOARD ................................................. APPENDIX

SCHEMATIC MAIN BOARD .................................................... APPENDIX

POWER DRIVER CIRCUIT ...................................................... APPENDIX

TROUBLE SHOOTING GUIDE ................................................ APPENDIX

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 3

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

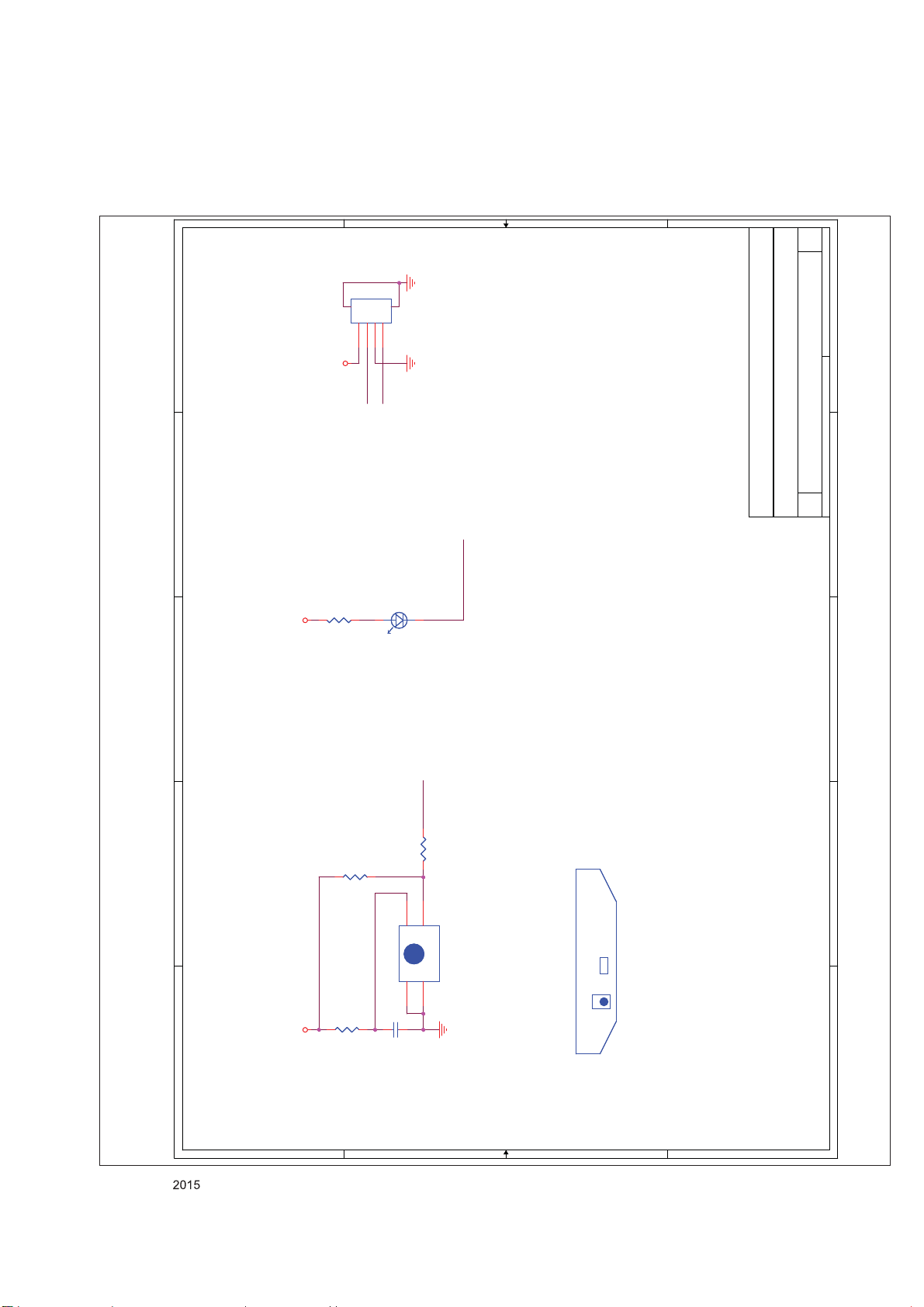

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create confl ict between the

following servicing precautions and any of the safety precautions

on page 3 of this publication, always follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug

or other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specifi ed otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10 % (by volume) Acetone and 90 %

(by volume) isopropyl alcohol (90 % - 99 % strength)

CAUTION: This is a fl ammable mixture.

Unless specifi ed otherwise in this service manual, lubrication

of contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fi xtures specifi ed in this

service manual.

CAUTION: Do not connect the test fi xture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some fi eld-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be removed to prevent

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some solder removal devices not classifi ed as “anti-static” can generate

electrical charges suffi cient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges suffi cient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to the chassis or circuit assembly into which the device will

be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.

Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your

foot from a carpeted fl oor can generate static electricity suf-

fi cient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate tip size and shape that will maintain tip temperature within

the range or 500 °F to 600 °F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25 cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500 °F to 600 °F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500 °F to 600 °F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder fl ows onto and around both the compo-

nent lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 5

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent fl at against the cir-

cuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing

the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close

as possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and

if necessary, apply additional solder.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the

good copper pattern. Solder the overlapped area and clip off

any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the

lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

Only for training and service purposes

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 6

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This specification is applied to the LED TV used 15ODMCAT

chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

1) Temperature: 25 °C ± 5 °C(77 °F ± 9 °F), CST: 40 °C ± 5 °C

2) Relative Humidity: 65 % ± 10 %

3) Power Voltage

: Standard input voltage (AC 100-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM.

5) The receiver must be operated for about 5 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety : CB, IEC specification

- EMC : CE, IEC/CISPR

4. Model General Specification

No. Item Specifi cation Remarks

Receiving System PAL-B/G/D/K, PAL-I, NTSC-M, DVB-T/T2

1

2 Promramme coverage V/UHF :1-69 and Cable: 1-47

3 Input Voltage AC 100 ~ 240V @ 50/60Hz

4 Screen Size

5 Aspect Ratio 16:9

6 Module

Component & Com-

7

posite Input

8 HDMI Input

9 USB

10 Head phone

32 inch Wide (1366 × 768)

LCM Model No. Panel Model No. Panel Maker Resolution Frame Rate

U320DH01-WY101 HV320WHB-N00 BOE HD 60 Hz

Component + AV

HDMI2 Side

HDMI1

USB

Head phone

Bottom : CVBS(Y), Pb,

Pr

Bottom : Audio L/R

Bottom

Side (USB 2.0)

Side

Only for training and service purposes

- 6 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 7

5. Component Video Input (Y, CB/PB, CR/PR)

No. Resolution H-freq(kHz) V-freq.(kHz)

1 720*480i 15.625 60.00

2 720*480p 31.50 60.00

3 720(1440)*576i 15.63 50.00

4 720*576p 31.25 50.00

5 1280*720p 37.50 50.00

6 1280*720p

7 1920*1080i

8 1920*1080i

45.00

28.13

33.75

60.00

50.00

60.00

9 1920*1080p 56.25 50.00

10 1920*1080p 67.50 60.00

6. HDMI Input :

No. Resolution H-freq(kHz) V-freq.(kHz)

PC

1 720*400 31.469 70

2 640*480 31.469 59.940

3 800*600 37.879 60.310

4 1024*768 48.363 60.000

5 1360*768 47.712 60.015

DTV

1 640*480p 31.47 59.94

2 640*480p 31.5 60.00

3 720*480p 31.47 59.94

4 720*480p

5 1280*720p 44.96 59.94

6 1280*720p 45.00 60.00

7 720(1440)*480i 15.73 59.94

8 720(1440)*480i 15.75 60.00

9 720*576p 31.25 50.00

10 1280*720p 37.5 50.00

11 720(1440)*576i 15.63 50.00

12 1920*1080i 28.125 50.00

13 1920*1080i 33.72 59.94

14 1920*1080i 33.75 60.00

15

16

17 1920*1080i 33.716 29.97

18

19 1920*1080p 56.25 50.00

20

21 1920*1080p 67.50 60.00

1920*1080i

1920*1080i

1920*1080p

1920*1080p 67.432 59.94

31.50

26.97 23.976

27.00 24.00

33.75 30.00

60.00

Only for training and service purposes

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 8

7. Component port connecting information:

Component ports on the TV

Video output ports on DVD player

Signal

480i / 576i

480p / 576p

720p / 1080i

1080p

Component

O

O

O

O

(Only 50 Hz / 60 Hz )

Y P

YPBP

Y B-Y R-Y

YCbCr

YPbPr

P

B

R

R

Only for training and service purposes

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 9

ADJUSTMENT INSTRUCTION

1. Application Range

This specification sheet is applied to all of the LED TV with

15ODMCAT chassis.

2. Designation

(1) The adjustment is according to the order which is

designated and which must be followed, according to the

plan which can be changed only on agreeing.

(2) Power adjustment : Free Voltage.

(3) Magnetic Field Condition: Nil.

(4) Input signal Unit: Product Specification Standard.

(5) Reserve after operation: Above 5 Minutes (Heat Run)

Temperature : at 25 °C ± 5 °C

Relative humidity : 65 ± 10 %

Input voltage : 100-220 V~, 50/60 Hz

(6) Adjustment equipments

: Color Analyzer(CA-210 or CA-110), Service remote control.

3. USB DOWNLOAD(*.prg file download)

(1) Make sure USB disk format is FAT32.

(2) Copy "MBOOT_AS_*.prg"(for Mboot updated if need)

and "UPDATE_A71_INIT_PAD_*.prg" two files to root

of USB disk.

(3) Insert USB disk to USB solt.

(if no need to update Mboot, jump to step 7 directly)

(4) AC OFF

(5) TV set will display like as this photo. It will take arround

10 sec. please wait for 100%.

→ ON

(10) AC Off.

(11) unplug USB disk.

(12) AC On.

(13) Check firmware version : 2.00(for example)

When you finish initialization setting, you can check

firmware version on Factory Menu Switch to AV input

source, press "Left" key → 7 → 9 > "OK" key to enter

Factory Mode.

(6) Keep USB disk in USB solt.

(7) AC OFF

(8) TV set will display like as this photo.

(9) Wait for display "100%" as below.

Only for training and service purposes

→ ON

(14) Select a country : GHANA (for example)

Go to "Ship To" and use "Left", "Right" to select country and

press "OK", TV should be turn Off.

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 10

(15) After turn on again, Check selected country : GHANA

(for example)

Press "Right"→ "EXIT"→ "OK" to go to Engineering

Information menu

4. ADC Process

4.1. ADC

Enter Factory mode.

The screen will show as below, select Source Calibration and

pushing enter key.

After pushing the right key, this function will be implement and

show OK on screen button side as below.

Only Component is requested calibration.

The timing: 1080i/60Hz,

Pattern: 100% color bar.

Color Bar 100/100-h

1 2345 6 7 8

YmV 700 147 47 0

Pb mV 0 -81 350 0

Pr mV 0 350 -34 0

Y 16 to 235 235 62 31 16

Cb 16 to 240 128 102 240 128

Cr 16 to 240 128 240 117 128

remark

Adjust Luma

Gain

Adjust

Cr Gain

Adjust

Cb Gain

Adjust

YCbCr

Offset

Only for training and service purposes

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 11

5. Total Assembly line process

5.1. Adjustment Preparation

W/B Equipment condition

CA210: CH14, Test signal: Inner pattern (80IRE)-LED

Module

▪ Above 15 minutes H/run in the inner pattern.

The spec of color temperature and coordinate

* Connecting picture of the measuring instrument

(On Automatic control)

Inside Pattern is used when W/B is controlled.

Send IR COMMAND [40 EE 01 FE] and set TV to M mode.

Send IR COMMAND [51 AE 73 8C] and set TV to 80 IRE

pattern.

80 IRE pattern will come out

* Auto-control interface and directions

(1) Adjust in the place where the influx of light like

floodlight around is blocked. (Illumination is less than

10 lux).

(2) Adhere closely the Color analyzer (CA210) to the

module less than 10 cm distance; keep it with the

surface of the Module and Color analyzer's prove

vertically. (88° ~ 92°).

(3) Aging time

- After aging start, keep the power on (no suspension

of power supply) and heat-run over 15 minutes.

- Using ‘snow pattern’ or ‘full white pattern’ or the

others, check the back light on.

▪ Auto adjustment Map (IR COMMAND) IR COMMAND

[CMD ID DATA]

Item CMD1 CMD2 CMD3 CMD4

R Gain 0x51 0xA1 00 ~ FF FF ~ 00

G Gain 0x51 0xA2 00 ~ FF FF ~ 00

B Gain 0x51 0xA3 00 ~ FF FF ~ 00

R Offset 0x51 0xA4 00 ~ FF FF ~ 00

G Offset 0x51 0xA5 00 ~ FF FF ~ 00

B Offset 0x51 0xA6 00 ~ FF FF ~ 00

Send IR COMMAND [51 AE 16 E9] to save data.

<Caution>

Color Temperature: COOL, Medium, Warm.

G Gain should be kept on 0x84,

Only for training and service purposes

- 11 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 12

* Manual W/B process using adjust Remote control.

■ Color analyzer( CA210) should be used in the calibrated

ch by CS-2000.

■ Operate the zero-calibration of the CA-210, then stick

sensor to the module when adjusting.

■ After enter M Mode by pushing up or down key to select

“Cool”, ,

■ Press “enter” key to enter the item.

■ For manual adjustment, it is also possible by the following

sequence.

(1) Set TV in M mode using learning remote controller and

then operate heat run longer than 15 minutes. (If not

executed this step, the condition for W/B may be

different.)

(2) Zero Calibrate the probe of Color Analyzer, then place it

on the center of LCD module within 10 cm of the surface

(3) Select each items (Red/Green/Blue Gain) using ▲/▼

(CH +/-) key on Remote control.

(4) Adjust R/ G/ B Gain using ◄/►(VOL +/-) key on R/C.

(5) Adjust three modes all (Cool / Medium / Warm)

- For G-FIX model

Cool Mode

1) Fix the G gain to 132 (default data) and decrease the

others.

2) Adjust B Gain to set y in spec.

3) Adjust R Gain to set x in spec.

Medium / Warm Mode - Fix G gain to 132 (default

data) and adjust the others as above

(6) When adjustment is completed, exit adjustment mode

using EXIT key on Remote control.

* CASE Cool

First adjust the coordinate far away from the target

value(x, y).

1) x, y > target

i) Decrease the R, B.

2) x, y < target

i) First decrease the B gain,

ii) Decrease the one of the others.

3) x > target, y < target

i) First decrease B, so make y a little more than the

target.

ii) Adjust x value by decreasing the R.

4) x < target, y > target

i) First decrease B, so make x a little more than the

target.

ii) Adjust x value by decreasing the R.

* After you finish all adjustments unplug the AC cable.

Ex.

Only for training and service purposes

- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 13

1. MAIN

BLOCK DIAGRAM

Only for training and service purposes

- 13 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 14

2. Main board Power tree

1

DVB-T1/ ISDB

MSD8832RM2

2

+3.3V_Normal/295mA

+3.3V_Standby/5.26mA

IC124 (LDO)

DMG2301U-7

Q1653 (SW)

3

+5V_Normal

DVB-T2

MSD8832RKM2

MSD8832xxx

+1.5V_DDR/242mA

+1.15V_VDDC/1750mA

G5719CTB1U

G9661-25ADJ

U13 (DC-DC)

243mA

457mA

+5V_USB/500mA

(DVB-T2 only)

+1.2V_MCP/278mA

U24 (SW)

G912T63U

U3 (LDO)

BD82028FVJ-GE2

279mA

500mA

+3.3_TU/200mA

ZTP1117S33-223

U12 (LDO)

206mA

917

H9

917

16151413121110

1A

1A

1A

of

of

of

215Wednesday, June 10, 2015

215Wednesday, June 10, 2015

215Wednesday, June 10, 2015

1

401C7Z

401C7Z

401C7Z

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

2

2345678

2345678

917

1

H4.4X5.4-NPH9H4.4X5.4-NP

H6

16151413121110

2345678

1

3

H85D4-CH6H85D4-C

300.3mA

5V_MHL/900mA

LVDS_PWR/333mA

Vcc_AUDIO/950mA

TPS2553DBV

U2 (SW)

G5728BTO1U

U11 (DC-DC)

4

900mA

216mA

+5V_Standby/1116mA

APL3546AKAI

U15 (SW)

333mA

FB7

950mA

Bead

POWER IN

5

D D

PWR_ON_OFF

+5V_Normal/702mA

BD9D321EFJ

U6 (DC-DC)

857mA

+12V_Normal/2140mA

C C

917

H1

16151413121110

H8

16151413121110

917

H7

16151413121110

2345678

917

1

H4.4-NPH1H4.4-NP

H2

16151413121110

B B

1

H4.4X5.4-NPH8H4.4X5.4-NP

H5

16151413121110

2345678

2345678

917

1

H4.4X5.4-NPH7H4.4X5.4-NP

H4

16151413121110

917

1

H3

H4.4X5.4-NPH2H4.4X5.4-NP

16151413121110

A A

1

H85D4-CH5H85D4-C

2345678

4

1

H85D4-CH4H85D4-C

2345678

1

H85D4-CH3H85D4-C

5

2345678

917

Only for training and service purposes

- 14 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 15

EXPLODED VIEW

IMPORTANT SAFETY NOTICE

400

510

900

840

830

130

521

540

901

530

120

831

500

200 LV1

A2

- 15 -

Page 16

APPENDIX-Schematic-Key board

^^+

1

PCB3

PCB3

0F

0F

0F

of

of

404xxx

404xxx

404xxx

of

22Tuesday, March 10, 2015

22Tuesday, March 10, 2015

22Tuesday, March 10, 2015

1

_

OK

SETTING

INPUT

POWER

KEY PCB

KEY PCB

VTV-K23106 REV:0F

VTV-K23106 REV:0F

CN701

2

45

CN701

AMA-1257-3AW-S

CN701

AMA-1257-3AW-S

KEY1

3

4

KEY1

0.997V 0V2.000V2.993V

R702

R702

1.74K/1%

1.74K/1%

2 4

2 4

S708

123

KEY0

1 3

POWERSETTING

1 3

INPUT

S707

S701

SW PUSH/4P/1.5MM

S701

SW PUSH/4P/1.5MM

S702

SW PUSH/4P/1.5MM

S702

SW PUSH/4P/1.5MM

S706

KEY0

0.997V 0V2.000V2.993V

R706

R706

S705

1.74K/1%

1.74K/1%

2 4

2 4

S704

S703

_

1 3

S705

S705

+

1 3

S706

S706

S702

SW PUSH/4P/1.5MM

SW PUSH/4P/1.5MM

SW PUSH/4P/1.5MM

SW PUSH/4P/1.5MM

S701

KEY1

KEY0

OK

3V

^

^

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,KEY/B VTV-K32106

SCHEMATIC,KEY/B VTV-K32106

SCHEMATIC,KEY/B VTV-K32106

2

Size Document Number Rev

Date: Sheet

Size Document Number Rev

Date: Sheet

Size Document Number Rev

Date: Sheet

POWER

3

_

0V

4

SETTING

2V

INPUT

+

1V

Title

Title

Title

R703

6.19K/1%

R703

6.19K/1%

R704

39.2K/1%

R704

5

39.2K/1%

D D

Only for training and service purposes

2 4

2 4

- 16 -

^

1 3

S707

SW PUSH/4P/1.5MM

S707

SW PUSH/4P/1.5MM

^

1 3

S708

SW PUSH/4P/1.5MM

S708

SW PUSH/4P/1.5MM

B B

A A

5

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

R707

6.19K/1%

R707

2 4

2 4

OK

1 3

1 3

S703

SW PUSH/4P/1.5MM

S703

SW PUSH/4P/1.5MM

S704

SW PUSH/4P/1.5MM

S704

SW PUSH/4P/1.5MM

6.19K/1%

R708

39.2K/1%

R708

39.2K/1%

C C

Page 17

APPENDIX-Schematic-IR/LED board

1

CN1

AMA-1257-4AV-S

CN1

AMA-1257-4AV-S

123

5 6

4

0E

0E

0E

of

of

of

22Tuesday, March 10, 2015

22Tuesday, March 10, 2015

22Tuesday, March 10, 2015

1

+3.3V_Standby

IR_Data

LED_R

XXXXXX

XXXXXX

XXXXXX

)52173$1(/&211(&725

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,IR/B VTV-IR32106

SCHEMATIC,IR/B VTV-IR32106

SCHEMATIC,IR/B VTV-IR32106

2

LED_R

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

2

Date: Sheet

Date: Sheet

Date: Sheet

RED LED

LED

+3.3V_Standby

3

12

1K

R81KR8

LED2

LED2

LTST-C171KRKT

LTST-C171KRKT

IR_Data

3

4

REMOTE

5

D D

Only for training and service purposes

R147R1

47

4

R11

10K

R11

10K

IR/LED PCB

4

VCC3OUT

GND

GND

U1

IRM-H638M/TR2

U1

IRM-H638M/TR2

2

1

R5

220R5220

+3.3V_Standby

C4

2.2uF/6.3VC42.2uF/6.3V

C C

- 17 -

IR/LED PCB

PCB2

PCB2

B B

LED

LED

IR

IR

VTV-IR23106 REV:0E

VTV-IR23106 REV:0E

5

A A

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 18

APPENDIX-Schematic-Main board

22uF/10V/0805

22uF/10V/0805

C23

C23

1 2

100uF/6D3/16V/NC

100uF/6D3/16V/NC

C227

+5V_Normal

PN:SE042104K0J

C13 0.1uF/50V/NCC13 0.1uF/50V/NC

1

BS

IN

AN_SY8113/NC

AN_SY8113/NC

5

FB27

FB27

CLS UPB201212T-121Y-N 5A/NC

CLS UPB201212T-121Y-N 5A/NC

+12V_Normal

5.08V

FB14

CLS/0603/60/3A/NC

FB14

CLS/0603/60/3A/NC

L14

L14

ATPI04033R3MTB 4.7uH/2.5A/NC

ATPI04033R3MTB 4.7uH/2.5A/NC

C213 47pF/50V/NCC213 47pF/50V/NC

6

SW

R260

100K/1%/NC

R260

100K/1%/NC

C16

C16

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C15

C15

10uF/25V/1206/NC

10uF/25V/1206/NC

100uF/6D3/16V/NC

100uF/6D3/16V/NC

C226

C226

+

+

+1.5V_DDR power from +5V_Normal

R1201

2.7

R1201

2.7

+5V_Normal

C227

C22

C22

100uF/6D3/16V/NC

100uF/6D3/16V/NC

C218

C218

RA

R18 13.6K/1%/0402/NCR18 13.6K/1%/0402/NC

3

FB

GND

EN

4

for DDR3 STR

12/29 Add R1201

+

+

22uF/10V/0805

22uF/10V/0805

1 2

+

+

RB

R13 1.82K/1%/0402/NCR13 1.82K/1%/0402/NC

PN:SA08113000I

FP:TSOT23-6

2

RB=(0.6V/ (Vout-0.6V))xRA

Vout=5.08V

C200

C200

0.1uF/25V/NC

0.1uF/25V/NC

R191 0/0402/NCR191 0/0402/NCC1289

PWR_ON_OFF

PWR_ON_OFF

14,3,4

Reserve for +16V only

+1.5V_DDR

VPP

VPP

4

1uF/16V

C1289

1uF/16V

(2.4/0603) for reduce

ripple voltage when

USB shorting.

C C

1

+3.3V_Standby

FB6

PBY160808T-500Y 3A

FB6

PBY160808T-500Y 3A

C36

0.1uF/10V/0402/NC

C36

C37

C37

RA

C100

10nF/16V/0402

C100

10nF/16V/0402

R378 8.2K/1%R378 8.2K/1%

3

5

LX

VFB

GND

VIN4EN

1

C35

C35

C20

C20

FB5

PBY160808T-500Y 3A

FB5

PBY160808T-500Y 3A

C9

Vout= 1.17V MAX 2A

C8

C7

R122 200K/1%R122 200K/1%

RA

ATPI04033R3MTB 3.3uH/2.5AL1ATPI04033R3MTB 3.3uH/2.5A

R383 12.4K/1%R383 12.4K/1%

C6 68pF/50V/0402C6 68pF/50V/0402

3

5

6

LX

NC

VFB

GND

VIN4EN

G5719CTB1U

G5719CTB1U

1

C3

C2

FB10FB1

0

D D

0.1uF/10V/0402/NC

10uF/6.3V

10uF/6.3V

RB

R379

1.8K/1%

R379

1.8K/1%

Vout=0.6 x (1+(RA/RB))

2

0.1uF/10V/0402

0.1uF/10V/0402

10uF/25V

10uF/25V

9/10 Cost and Package

down C20 grade from

solid E-Cap.

22uF/6.3V/0805C922uF/6.3V/0805

VDDCVDI0

1 2

22uF/6.3V/0805C822uF/6.3V/0805

1 2

22uF/6.3V/0805C722uF/6.3V/0805

1 2

D

D

Q7

Q7

G

G

2N7002

2N7002

R119

R119

R121 200K/1%R121 200K/1%

+3.3V_Standby

R120

R120

R384

12.7K/1%

R384

12.7K/1%

4.7K/0402

4.7K/0402

VID0

RB

4

2

0.1uF/10V/0402C30.1uF/10V/0402

10uF/25VC210uF/25V

U14

U14

+5V_NORMAL

1.24V

H

L 1.17V

S

S

VGS > 2V

4.7K/0402

4.7K/0402

Vout=0.6 x (1+(RA/RB)

3.3Vstb

2

L4

ATPI04033R3MTB 3.3uH/2.5AL4ATPI04033R3MTB 3.3uH/2.5A

+3.3V_Standby power from +5V_Standby

U11

G5728BTO1U

U11

G5728BTO1U

+5V_Standby

R3

33K/1%R333K/1%

3

+5V_Standby

+1.15V_VDDC

4

L1

+1.15V_VDDC power from +5V_Normal

U13

U13

R1

+5V_Normal

33K/1%R133K/1%

5

+5V_Normal

(5V)

+5V_Normal

L9

ATPI04033R3MTB 3.3uH/2.5AL9ATPI04033R3MTB 3.3uH/2.5A

C158

0.1uF/10V/0402

C158

0.1uF/10V/0402

7

6

+5V_Normal power from +12V

SW

BOOT

VIN8EN

VREG

U6

BD9D321EFJU6BD9D321EFJ

1

3

R192 0/0402R192 0/0402

Vout=(RAx0.6)/RB+0.6

R1261

39K/0.5%/0402

R1261

39K/0.5%/0402

1

POK

POK

IC124

IC124

+5V_Normal

+12V_Normal

+12V_Normal

C1281

C1281

RA

1 2

R1259

R1259

679

VO

VO

ADJ

ADJ

UREG

UREG

VEN

VEN

238

0

1 2

R12410R1241

PWR_ON_OFF

14,3,4

C17

0.1uF/25V

C17

0.1uF/25V

C24

C24

C91

C91

C92

C92

C1282

C1282

1 2

1 2

1 2

2.2K/0.5%/0402

2.2K/0.5%/0402

Thermo Pad

Thermo Pad

GND

GND

VIN

VIN

G9661-25ADJF11U

G9661-25ADJF11U

1 2

C1280

C1280

10uF/10V

10uF/10V

RA

R177

3.3K/1%/0402

R177

3.3K/1%/0402

R172

R172

2

FB

TP-GND

9

GND

SS

5

4

C26

C26

3.3nF/50V/0402

3.3nF/50V/0402

C51

C51

1uF/6.3V

1uF/6.3V

C18

0.1uF/16V/0402

C18

0.1uF/16V/0402

C14

C14

10uF/16V/0805

10uF/16V/0805

C19

C19

10uF/16V/0805

10uF/16V/0805

10uF/25V

10uF/25V

10uF/25V

10uF/25V

10uF/25V

10uF/25V

22uF/6.3V/0805

22uF/6.3V/0805

22uF/6.3V/0805/NC

22uF/6.3V/0805/NC

RB

1 2

R1260

47K/0.5%/0402

R1260

47K/0.5%/0402

Vout=(0.8*(RA+RB))/RB

C27

22uF/10V/0805

C27

22uF/10V/0805

C50

22uF/10V/0805

C50

22uF/10V/0805

RB

R176

22K/1%/0402

R176

22K/1%/0402

120K/1%/0402

120K/1%/0402

Vout=0.765 x ( (1+RA)/RB)

R1657

R1657

+3.3V_Normal

+3.3V_Normal from +3.3V_Standby

Ctrl by +5V_Normal

12

12

C1654

C1654

DS

G

Q1653

DMG2301U-7

Q1653

DMG2301U-7

1 2

C1655

33nF/25V/0402

C1655

33nF/25V/0402

12

R1660

R1660

10K/0402

10K/0402

MPZ1608S221AT

MPZ1608S221AT

1 2

FL169

FL169

+3.3V_Standby

B B

1A

1A

1A

of

of

of

315Wednesday, June 10, 2015

315Wednesday, June 10, 2015

315Wednesday, June 10, 2015

1

401C7Z

401C7Z

401C7Z

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

12/29 Delete DCD which drawing by Stony

2

C195

0.1uF/10V/0402/NC

C195

0.1uF/10V/0402/NC

2

1

+1.2V_MCP

C194

10uF/6.3V

C194

10uF/6.3V

4

VOUT2VOUT

1

GND

VIN

U3

G912T63UU3G912T63U

3

C196

0.1uF/10V/0402

C196

0.1uF/10V/0402

2

1

C193

C193

10uF/25V

10uF/25V

FB32

PBY160808T-500Y 3A

FB32

PBY160808T-500Y 3A

+5V_Normal

+1.2V_MCP from +5V_Normal

for ASIA demodulation

330/1%

330/1%

0.1uF/10V0402

0.1uF/10V0402

1SS355VMTE-17

1SS355VMTE-17

220K/1%/0402

220K/1%/0402

D1652

D1652

1 2

A C

R1661

R1661

C

E

Q1654

2SC4081UB TLQ

Q1654

2SC4081UB TLQ

R1658

R1658

B

10K/0402

10K/0402

12

C1659

0.1uF/10V/0402

C1659

0.1uF/10V/0402

3.3K/1%/0402

3.3K/1%/0402

1 2

1 2

C1660

C1660

4.7uF/25V/0805

4.7uF/25V/0805

C1656

1uF/16V

C1656

1uF/16V

1 2

R1659

R1659

+5V_Normal

A A

3

4

5

Only for training and service purposes

- 18 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 19

靠近

晶體頻偏需要小於

AVDD_AU

+3.3V_Standby

+3.3V_Standby

1

2

3

4

5

AVDD_DVI

AVDD_NODIE

L7

R6

J7

AVDD_AU33

AVDD_NODIE

AVDD_DVI_USB_MPLLK7AVDD_DVI_USB_MPLL

VDDC

VDDC

VDDC

VDDC

VDDC

VDDC

VDDC

U201F

U201F

L11

P12

P13

N12

N13

N14

N15

M11

+1.15V_VDDC

POWER&GND

W14

W13

W11

Y15

Y13

Y12

Y14

W12

AA12

AA13

TS0_D0

TS0_D1

TS0_D2

TS0_D3

TS0_D4

TS0_D5

TS0_D6

TS0_D7

TS0_CLK

U201B

U201B

PCM_D0

PCM_D1

PCM_D2

PCM_D3

PCM_D4

PCM_D5

PCM_D6

PCM_D7

T16

T14

V15

Y20

Y21

Y18

U20

W18

AA18

PCM_A0

PCM_A[7:0]

NAND & CI & TS & Front End

12

U201E

U201E

GIN1N

RIN1

C209 47nF/16V/0402C209 47nF/16V/0402

C207 47nF/16V/0402C207 47nF/16V/0402

Close to MST IC

with wide trace

8

R205 68/0402R205 68/0402

R212 33/0402R212 33/0402

YPBPR

YPbPr-PR

RGB Interface

video

GIN1

C210 47nF/16V/0402C210 47nF/16V/0402

R206 33/0402R206 33/0402

AVDD_DMPLL

+3.3V_Normal

+3.3V_Normal

+3.3V_Normal

VDDP

AVDD_MOD

R5

R16

R17

R15

R18

VDDP

AVDD_MOD

AVDD_MOD

AVDD3P3_DMPLL

VDDC

AVDDL_MOD

DVDD_RX_1

P14

M12

M14

M13

+1.15V_VDDC

+1.15V_VDDC

+1.15V_VDDC_RX

T13

U13

T12

U10

Y11

TS1_D0

TS1_D1

TS1_D2

TS0_VLD

TS0_SYNC

PCM_A0

PCM_A1

PCM_A2

PCM_A3

PCM_A4

PCM_A5

PCM_A6

PCM_A7

Y17

Y16

Y19

W17

W16

W15

AA16

AA15

PCM_A6

PCM_A1

PCM_A7

PCM_A2

PCM_A3

PCM_A4

PCM_A5

13

MDI_RP13MDI_RN13MDI_TN13MDI_TP

MDI_RP

MDI_TP

MDI_RN

MDI_TN

C1

B2

C2

B1

TP

TN

RP

RN

GIN0PL3GIN0ML2HSYNC0M5VSYNC0M4GIN1PN3SOGIN1

RIN0PM3BIN0PK2RIN1PN2GIN1MN1BIN1P

SOG1

BIN1

C204 1nF/25V/0402C204 1nF/25V/0402

C211 47nF/16V/0402C211 47nF/16V/0402

1/22 Add R209 , change

C204 from 47nF to 1nF as

M-Star recommend.

4,8

8

R208 33/0402R208 33/0402

R209 0/0402R209 0/0402

YPbPr-Y

YPbPr-PB

D D

AVDD_PLL

AVDD_PLL

DVDD_RX_1A7DVDD_RX_2

T11

TS1_D3

PCM_A8

AA19

1

USB0_DM

C4

RIN1

DVDD_RX_2B7DVDD_DDR

DVDD_DDR

C7

U11

T10

TS1_D4

TS1_D5

PCM_A9

PCM_A10

W21

AA20

TP8TP 8

TP7TP 7

1

USB1_DM

USB0_DP

B4

Y10

DP_P0

DM_P0

RGB

RGB

GIN1N

GIN1

C281

C281

C283

C283

V12

V13

U12

TS1_D6

TS1_D7

TS1_CLK

PCM_A11

PCM_A12

PCM_A13

V20

V17

W20

9

USB1_DM9USB1_DP

USB1_DP

W10

DP_P1

DM_P1

USB

USB

M1

M2

SOG1

BIN1

AVDD5V_MHL_C

V6

H7

GND_EFUSE

AVDD5V_MHL

DVDD_NODIEF8AVDD_DDR0_DC5AVDD_DDR0_D

MCP_VDDC

MCP_VDDC

P11

N11

0.1uF/10V/0402

0.1uF/10V/0402

1uF/6.3V

1uF/6.3V

DVDD_NODIE

+1.2V_MCP

04/17 EMI solution

add R213 0/0402 and

C231 NC

VIFP

VIFM

V10

W1

W2

VIFP

TS1_VLD

TS1_SYNC

PCM_IOWR_N

PCM_RESET

PCM_IRQA_N

PCM_OE_N

PCM_A14

T15

V16

U17

U16

W19

TP211TP211

1

CVBS0

VCOM0

T2

R1

T1

VCOM0

CVBS0PT3CVBS1P

CVBS_OUT

CVBS PHY

CVBS PHY

RIN2PR2GIN2MR3GIN2PP2BIN2PP3HSYNC2K4VSYNC2

M6

Close to MST IC

with wide trace

AV Interface

K10

L10

J10

J11

J12

J13

J14

K8

GND

GND

GND

GND

GND

GNDK9GNDL8GND

AVDD_DRAMB5AVDD_DRAM

B6

11

T_SDA

Y1

T_I2C_SDA

MSD8832RKM2 BGA-402 ball

MSD8832RKM2 BGA-402 ball

U7

NAND_RBZ

video level check

L9

GND

GND

GNDM7GNDM8GNDM9GND

GND

GND

GND

GND

GND

GNDA6GNDC9GND

A13

A15

A18

B12

B14

B16

M10

GND

GND

B17

B19

H17

H18

H11

H12

H13

H14

H15

H16

GND

GND

GNDJ8GNDJ9GND

GND

GND

GND

GND

GND

GND

AVDD_DDR0_D

AVDD_DDR0_CMD

AVDD_DDR1_DC6AVDD_DDR1_D

AVDD_DDR1_D

AVDD_DDR1_CMD

AVDD_DDR1_CLK

L12

L14

L13

K12

K11

K14

K13

+1.5V_DDR

6

EEPROM_WP

C231

C231

10pF/50V/0402/NC

10pF/50V/0402/NC

11

T_SCL11T_SDA

RF_SW_CTL

R213 0/0402R213 0/0402

IFAGC

T_SCL

RF_SW_CTL

Y2

AA4

Y4

Y3

VIFM

IFAGC

TGPIO0

TGPIO1

T_I2C_CLK

PCM_WAIT_N

PCM_IORD_N

PCM_CE_N

PCM_WE_N

PCM_CD_N

PCM_REG_N

NAND_ALET8NAND_WPZT9NAND_CEZV7NAND_CLEU9NAND_REZV9NAND_WEZU8NAND_RBZ

V21

V19

V18

U15

U14

NAND_ALE

NAND_CLE

NAND_WPZ

NAND_CEZ

NAND_REZ

NAND_WEZ

NAND_ALE12NAND_CLE

NAND_WPZ12NAND_CEZ12NAND_REZ12NAND_RBZ12NAND_WEZ

12

12

R7

75/1%/0402R775/1%/0402

03/19 Add R7

(75-ohm) for A71 do

MSD8832RKM2 BGA-402 ball

MSD8832RKM2 BGA-402 ball

CVBS0

VCOM0

C217 47nF/16V/0402C217 47nF/16V/0402

C216 47nF/16V/0402C216 47nF/16V/0402

R216 33/0402R216 33/0402

R217 68/0402R217 68/0402

YPbPr-Y

4,8

N10

P10

P15

P16

P17

P18

R11

R12

R13

R14

GNDN4GNDN5GNDN6GNDN7GNDN8GNDN9GND

GNDP4GNDP5GNDP6GNDP7GND

GND

GND

GND

GNDD9GND

GND

GND

GND

F11

F13

F15

F17

B20

E20

C10

C21

GPIO & LVDS

LINE_IN_1L

C222 2.2uF/6.3V/0402C222 2.2uF/6.3V/0402

HD-LIN

Audio Line IN

U6

GND

GND

GND

GND

GNDR7GND

GND

GND

GND

GNDR4GNDT6GNDT7GND

GND

GND

GND

GNDG9GND

GND

GND

GND

GND

GND

GND

GND

GND

GNDH8GNDH9GND

GND

G8

F19

F21

G10

G11

G12

G13

G14

G15

G16

G17

G18

LVA0N6LVA0P6LVA1N6LVA1P6LVA2N6LVA2P6LVACLKP6LVACLKN6LVA3N6LVA3P6LVA4N6LVA4P6LVB0N6LVB0P6LVB1P6LVB1N6LVB2N6LVBCLKN6LVBCLKP6LVB2P6LVB3P6LVB3N6LVB4P6LVB4N

LVA0P

LVA2P

LVA4P

LVA3P

LVA1P

LVACLKP

LVA2N

LVA3N

LVA4N

LVACLKN

LVA1N

LVA0N

LVB0P

LVB0N

N21

P19

R19

T21

U19

J19

N19

N20

P20

T19

T20

H20

R20

R21

LVA0P

LVA1P

LVA2P

LVA3P

LVA4P

LVB0P

LVA0N

LVA1N

LVA2N

LVA3N

LVA4N

LVB0N

LVACKP

LVACKN

PWM SAR SPI

PWM SAR SPI

U201D

U201D

KEY0F4LED_RD4ARC_DETG73D_EN/PCM_PWR_EN

AMP_MUTE

BRI_ADJ

PM_SPI_CKD6PM_SPI_DIE7PM_SPI_DOD7UART0_RXL5UART0_TXL4M_I2C_SLC

PWM_PM

SAR3G5PM_SPI_CZ1N

K5

T18

T17

U18

ARC_DET

ACDET_M

BRI_ADJ

AMP_MUTE

SPI_SDI

ARC_DET7

BRI_ADJ

PWM_LED1

PWM_LED2

AMP_MUTE

SAR0_KEY_114SAR3_KEY_2

14

14

14

10

14

H2

J2

K3

J3

J1

K1

U201C

U201C

A_RX0P

A_RX1P

A_RX2P

A_RX0N

A_RX1N

A_RX2N

LINE_IN_3LV4LINE_IN_3R

U4

LINE_IN_1L

LINE_IN_1R

LINE_IN_1R

mstar IC

C223 2.2uF/6.3V/0402C223 2.2uF/6.3V/0402

HD-RIN

HD-LIN

HD-RIN

8

8

H10

LVB2P

LVB1P

LVB2N

LVB1N

J21

K21

J20

K19

LVB1P

LVB1N

LVB2N

LVDS

LVDS

F7

14

C_ACDET

R148

100/0402

R148

100/0402

R149 100/0402/NCR149 100/0402/NC

C234 33pF/50V/0402C234 33pF/50V/0402

ACDET_M

H3

H5

G2

A_RXCP

A_RXCN

DDCDA_CKH6DDCDA_DA

LINE_OUT_0LV2LINE_OUT_0RV1LINE_IN_1LU5LINE_IN_1RV5LINE_IN_2LT5LINE_IN_2RT4VAGV3VRM

LINE_OUT_L

LINE_OUT_R

MSD8832RKM2 BGA-402 ball

MSD8832RKM2 BGA-402 ball

LVBCLKP

LVBCLKN

K20

L19

LVB2P

LVBCKN

UART_RX

G4

HOTPLUGA

W4

EARPHONE_L

EARPHONE_R

HDMI & Audio

C C

C242

C242

+1.15V_VDDC_RX

C246

C246

FB205

FB205

BLM15AG601SN1D

BLM15AG601SN1D

C245

C245

AVDDL_MOD

C244

C244

C243

C243

C236

C236

C241

C241

CORE POWER

C240

C240

C239

C239

C238

C238

+1.15V_VDDC

C237

C237

10

8

7

6

AMP_RESET

HDMI-2_SENSE7COMPONENT_INS

CVBS_INS8HDMI-3_SENSE

LVDS_SEL 6

LVB3P

LVB4P

LVB3N

LVB4N

M19

M21

G20

H19

G19

L20

M20

G21

J16

J17

J15

K17

J18

K18

K16

L18

LDE

LCK

LVB3P

LVB4P

LVB3N

LVB4N

TCON0

TCON1

TCON2

TCON3

TCON4

TCON5

TCON6

LVBCKP

UART_TX

TCON7

LVSYNC

LHSYNC

TCON

TCON

GPIO_PM

GPIO_PM

M_I2C_SDA

UART_RX2

UART_TX2

VID0W3PANNEL_ON/OFFE8PWR_ON/OFFD1VBL_CTRLD8PMCONFIG0U33D_LR_IND5PMCONFIG1

G6

L15

L16

L17

K15

UART2_TX

UART2_RX

M_I2C_SCL

M_I2C_SDA

PM_CONFIG1

/PM_CONFIG0

1

1

TP205TP205

TP203TP203

R279 0/0402/NCR279 0/0402/NC

M_WLAN_POWER

EARPHONE_DEC_M

1

VID03

TP1TP 1

VBL_CTRL14

PWR_ON_OFF14,3

PANEL_ON_OFF6

EARPHONE_DEC_M 8

01/12 Modify C234 to 0402 to common part.

HDMI2_RX0N 7

HDMI2_RX0P 7

HDMI2_RX1N 7

HDMI2_RX1P 7

HDMI2_RX2N 7

HDMI2_RX2P 7

HDMI2_CLKP 7

HDMI2_CLKN 7

HDMI3_RX0N 7

HDMI3_RX0P 7

HDMI3_RX1N 7

HDMI3_RX1P 7

HDMI3_RX2N 7

HDMI3_RX2P 7

HDMI2_SDA 7

HDMI2_SCL 7

HDMI2_HPDIN 7

HDMI2_CLKN

HDMI2_RX1N

HDMI2_CLKP

HDMI2_RX1P

HDMI2_RX2N

HDMI2_RX0P

HDMI2_RX2P

HDMI2_RX0N

HDMI3_RX0P

HDMI3_RX1N

HDMI3_RX1P

HDMI3_RX2N

HDMI3_RX0N

HDMI3_RX2P

HDMI3_CLKN

HDMI2_SCL

HDMI2_SDA

HDMI2_HPDIN

Y6

AA7

D2

AA6

Y8

Y9

W9

F3

F1

G1

Y7

W7

W8

AA9

E2

F2

G3

C_RX0P

C_RX1P

C_RX2P

D_RX0P

D_RX1P

C_RX1N

C_RX2N

HDMI

HDMI

Analog audioI2S

Analog audioI2S

I2S_OUT_BCKA3I2S_OUT_SD

U2

AUVAG

AUVRM

I2S-OUT_BCK

I2S-OUT_MCK

I2S-OUT_MCK10I2S-OUT_WS10I2S-OUT_BCK10I2S-OUT_SD

D_RX2P

D_RX0N

D_RX1N

D_RX2N

C_RXCP

C_RXCN

HOTPLUGC

DDCDC_CKW6DDCDC_DA

I2S_OUT_MCKB3I2S_OUT_WS

I2S_IN_WS/T2_RESETE4I2S_IN_BCK/T2_I2CS_SCLF5I2S_IN_SD/T2_I2CS_SDA

SPI1_DIP9SPI1_CKR8SPI2_DIR9SPI2_CK

A2

E5

C3

R10

10

I2S-OUT_WS

SPI2_DI

SPI1_CK

SPI1_DI

SPI2_CK

I2S-OUT_SD

R145 4.7K/0402R145 4.7K/0402

R147 4.7K/0402R147 4.7K/0402

R146 4.7K/0402R146 4.7K/0402

1

1

1

1

TP208TP208

TP207TP207

TP212TP212

TP209TP2091TP210TP210

+3.3V_Standby

C_RX0N

EARPHONEOUTRY5EARPHONEOUTL

HDMI3_CLKN 7

HDMI3_CLKP 7

HDMI3_CLKP

E3

D_RXCN

demod

demod

1A

1A

1A

of

of

of

415Wednesday, June 10, 2015

415Wednesday, June 10, 2015

415Wednesday, June 10, 2015

401C7Z

401C7Z

401C7Z

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

10uF(M)/6.3V/0603/NC

10uF(M)/6.3V/0603/NC

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

2.2uF/6.3V/0402

2.2uF/6.3V/0402

MSD8832RKM2 BGA-402 ball

MSD8832RKM2 BGA-402 ball

1

M_WWOL_WAKEUP

TP2TP 2

HDMI3_SDA 7

HDMI3_SCL 7

HDMI3_HPDIN 7

HDMI3_SCL

HDMI3_SDA

HDMI3_HPDIN

HDMI_ARC

K6

L6

J5

D_RXCP

HOTPLUGD

DDCDD_CKJ4DDCDD_DA

IRINF6RESETD3XTALIN

IRIN

System_RST

DDR3 POWER

nodie

TP213TP213

SPDIF_OUT 8

HDMI_ARC 7

HDMI_CEC 7

1

SPDIF_OUT

HDMI_CEC

E6

A4

J6

CEC

SPDIF_IN

PAD_ARC0

SPDIF_OUT

SPDIF

SPDIF

XTALOUT

TESTPIN

F9

AA2

AA3

XTALI

XTALO

+1.5V_DDR

DVDD_NODIE

MHL_CABLE-DET

AA10

P8

AVDD_DRAM

MHL_VBUS-EN 7

MHL_CABLE-DET 7

MHL_VBUS-EN

W5

MHL_VBUS_EN

MHL_CABLE_DET

MHL

MHL

MCP_TEST

AUVRM

C255

C255

C254

C254

C259

C259

C253

C253

C252

C252

C251

C251

C250

C250

C249

C249

C267

1uF/6.3V

C267

1uF/6.3V

R12

R12

10K/0402

10K/0402

MSD8832RKM2 BGA-402 ball

MSD8832RKM2 BGA-402 ball

C233

4.7uF/6.3V/0402

C233

4.7uF/6.3V/0402

AUVAG

C232

0.1uF/10V/0402

C232

0.1uF/10V/0402

FB201

FB201

BLM15AG102SN1D

BLM15AG102SN1D

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

2.2uF/6.3V/0402

2.2uF/6.3V/0402

10uF/25V

10uF/25V

Close to MST IC

9/9 add R12 for drag low

MHL_VBUS-EN when Scaler

during reset.

EARPHONE_L

EARPHONE_R

LINE_OUT_L

LINE_OUT_R

R129 0/0402/NCR129 0/0402/NC

R127 1K/1%/0402R127 1K/1%/0402

R126 1K/1%/0402R126 1K/1%/0402

R128 0/0402/NCR128 0/0402/NC

EARPHONE_DRV_L15

EARPHONE_DRV_R15

Close to MSTAR IC

with width trace

SPDIF_OUT

C235

C235

B B

C288

C288

AVDD_AU

FB204

FB204

0.1uF/10V/0402

0.1uF/10V/0402

BLM15AG601SN1D

BLM15AG601SN1D

+3.3V_Standby

C280

C280

0.1uF/10V/0402

0.1uF/10V/0402

AVDD_DMPLL

FB202

FB202

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C279

C279

BLM15AG601SN1D

BLM15AG601SN1D

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C278

C278

AVDD_NODIEAVDD_DVI

C277

C277

C275

0.1uF/10V/0402

C275

0.1uF/10V/0402

Standby Power 3.3V

+3.3V_Standby

10uF/25V

10uF/25V

C274

C274

+3.3V_Normal

EEPROM ConnectorMode Selection

01/29 R126, R127 from 0 to 1K as M-Star request

for 4Mhz white noise from SOC

Close to MSTAR IC

33pF/50V/0402/NC

33pF/50V/0402/NC

+3.3V_Standby

VDDPAVDD_MOD AVDD_PLL

0.1uF/10V/0402

0.1uF/10V/0402

Normal Power 3.3V

+3.3V_Normal

11

DIFP11DIFM

FB30

PBY160808T-121Y-N 2.5/NC

FB30

PBY160808T-121Y-N 2.5/NC

C228

100pF/25V/0402/NC

C228

100pF/25V/0402/NC

C224

100pF/25V/0402/NC

C224

100pF/25V/0402/NC

C229

C229

100pF/25V/0402/NC

100pF/25V/0402/NC

R137 0/0402R137 0/0402

R136 0/0402R136 0/0402

C230

C230

100pF/25V/0402/NC

100pF/25V/0402/NC

C247 0.1uF/10V/0402C247 0.1uF/10V/0402

C248 0.1uF/10V/0402C248 0.1uF/10V/0402

VIFM

VIFP

RF

M_I2C_SCL

M_I2C_SDAM-SDA

R275 100/0402R275 100/0402

R274 100/0402R274 100/0402R229 4.7K/0402/NCR229 4.7K/0402/NC

M-SCLM_WLAN_POWER

M-SCL

M-SDA

Other

10,14,6

10,14,6

14

IRIN

IRIN

MHL_CABLE-DET

IR&KEYB

R232

4.7K/0402

R232

4.7K/0402

C264

33pF/50V/0402

C264

33pF/50V/0402

4.7K/0402

4.7K/0402

R231

R231

4.7K/0402

4.7K/0402

R244

R244

C263

C263

33pF/50V/0402

33pF/50V/0402

M-SCL

M-SDA

C261

C261

EEPROM_WP

5

6

7

8

WP

0.1uF/10V/0402

0.1uF/10V/0402

SCL

SDA

VCC

A01A12A23GND

U203

FM24C32A-SO-T-G

U203

FM24C32A-SO-T-G

4

PWM_PM Boot_Strap should

link to Scaler K5 (PWM_R)

which assign for LED R.

26Aug2014

// CHIP Config {PM_CONFIG0, SPI_DI, PM_CONFIG1, PWM_PM}

SB51_EXT spi 4'b1000 Boot from 51 EXT SPI flash

/PWM_PM

PM_CONFIG1

PWM_LED1

SPI_SDI

R236 4.7K/0402R236 4.7K/0402

R227 4.7K/0402R227 4.7K/0402

R235 4.7K/0402/NCR235 4.7K/0402/NC

R237 4.7K/0402R237 4.7K/0402

R241 4.7K/0402/NCR241 4.7K/0402/NC

R238 4.7K/0402/NCR238 4.7K/0402/NC

R240 4.7K/0402R240 4.7K/0402

1uF(K)/6.3V/NC

1uF(K)/6.3V/NC

C260

C260

0.1uF/10V/0402

0.1uF/10V/0402

C268

C268

0.1uF/10V/0402

0.1uF/10V/0402

C258

C258

0.1uF/10V/0402

0.1uF/10V/0402

C256

C256

10uF/25V

10uF/25V

C257

C257

+3.3V_TU

FB33

PBY160808T-121Y-N 2.5

FB33

PBY160808T-121Y-N 2.5

C272

0.1uF/10V/0402

C272

0.1uF/10V/0402

IF-AGC-T 11

C262

0.022uF/25V/0402

C262

0.022uF/25V/0402

R228 0/0402R228 0/0402

R226 10K/0402R226 10K/0402

04/08 Modify C262 from 0.1uF to 0.022uF as M-Star ask for.

IFAGC

HeatSink35x35

heat sink

UART_TX

UART_RX

100/0402

100/0402

ISP AND VGA EDID

MUST pull high to 5VSTB

R267

4.7K/0402

R267

4.7K/0402

R270 100/0402R270 100/0402

R271

R271

R245

R245

4.7K/0402/NC

4.7K/0402/NC

HEMCU_EXT spi 4'b1001 Boot from MIPS EXT SPI flash

HEMCU_ROM NAND 4'b1011 Boot from ROM outer storage is nand

+5V_Standby

R268

R268

4.7K/0402

4.7K/0402

1

2

3

4

CN206

CN206

HDR_1X4_H2031_P2

HDR_1X4_H2031_P2

DEBUG

30PPM

11/26 Modify

Y1

24MHz/20pF/S/2P_HARMONYY124MHz/20pF/S/2P_HARMONY

C79 27pF/50V/0402C79 27pF/50V/0402

C77 27pF/50V/0402C77 27pF/50V/0402

NOTE:

R124

R124

1M/1%/0402

1M/1%/0402

R130

R130

XTALI

Crystal

470/1%/0402

470/1%/0402

XTALO

9

USB_Fault

R167

10K/0402/NC

R167

10K/0402/NC

+3.3V_Standby

R202

1K/1%/0402/NC

R202

1K/1%/0402/NC

B

12/08 Add R171 1K/0402

C E

Q15

Q15

+3.3V_Standby

LRC3906/SOT23/NC

LRC3906/SOT23/NC

RESET CIRCUIT

A A

Q15 for USB_Fault

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

1

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

2

3

4

System_RST

5

R144

100/0402

R144

100/0402

R171

1K/1%/0402

R171

1K/1%/0402

2

RESET

POR

POR

VCC3GND

U7

G690H293

U7

G690H293

(High reset)

1

C269

C269

+3.3V_Standby

0.1uF/10V/0402

0.1uF/10V/0402

Only for training and service purposes

- 19 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 20

1A

1A

1A

of

of

of

515Wednesday, June 10, 2015

515Wednesday, June 10, 2015

515Wednesday, June 10, 2015

1

2

R62

56/1%/0402/NC

R62

56/1%/0402/NC

B-DDR3-DQU1

B-DDR3-DQL6B_DDR3_DQL6

B-DDR3-DQL4B_DDR3_DQL4

B-DDR3-DQU5B_DDR3_DQU5

B-DDR3-DQU7

7531

7531

7531

7531

7531

7531

8642

8642

8642

8642

8642

RN4 22/0804/MS/NC

RN4 22/0804/MS/NC

22/0804/MS/NC

22/0804/MS/NC

7531

7531

8642

8642

RN3

RN3

8642

R53 22/1%/0402/NCR53 22/1%/0402/NC

RN6 22/0804/MS/NC

RN6 22/0804/MS/NC

B_DDR3_DQU1

B_DDR3_DQU7

B-DDR3-A4

7531

7531

7531

7531

8642

8642

8642

8642

RN7 22/0804/MS/NC

RN7 22/0804/MS/NC

RN5 22/0804/MS/NC

RN5 22/0804/MS/NC

B_DDR3_A4

B_DDR3_A6 B-DDR3-A6

B_DDR3_A10 B-DDR3-A10

B_DDR3_CKE B-DDR3-CKE

RN2 22/0804/MS/NC

RN2 22/0804/MS/NC

B_DDR3_DQL0 B-DDR3-DQL0

B_DDR3_DQL2 B-DDR3-DQL2

3

B-DDR3-BA1

7531

7531

8642

8642

RN1 22/0804/MS/NC

RN1 22/0804/MS/NC

B_DDR3_BA1

B_DDR3_A12 B-DDR3-A12

B-DDR3-DQSLB_DDR3_DQSL

B-DDR3-DQSLBB_DDR3_DQSLB

B-DDR3-DQU3B_DDR3_DQU3

7531

7531

7531

7531

8642

8642

8642

8642

RN8 22/0804/MS/NC

RN8 22/0804/MS/NC

RN10 22/0804/MS/NC

RN10 22/0804/MS/NC

B_DDR3_DMU B-DDR3-DMU

B-DDR3-ODTB_DDR3_ODT

B-DDR3-RASZB_DDR3_RASZ

7531

7531

7531

7531

8642

8642

8642

8642

RN11 22/0804/MS/NC

RN11 22/0804/MS/NC

RN9 22/0804/MS/NC

RN9 22/0804/MS/NC

B_DDR3_A8 B-DDR3-A8

B_DDR3_A11 B-DDR3-A11

B-DDR3-A1B_DDR3_A1

B-DDR3-DQSUB

7531

7531

8642

8642

RN12 22/0804/MS/NC

RN12 22/0804/MS/NC

B_DDR3_DQSUB

B_DDR3_A14 B-DDR3-A14

B-DDR3-DQU4B_DDR3_DQU4

B-DDR3-DQSU

7531

7531

8642

8642

RN14 22/0804/MS/NC

RN14 22/0804/MS/NC

B_DDR3_DQU0 B-DDR3-DQU0

B_DDR3_DQSU

B-DDR3-A13B_DDR3_A13

B-DDR3-A9B_DDR3_A9

7531

7531

7531

7531

8642

8642

8642

8642

RN15 22/0804/MS/NC

RN15 22/0804/MS/NC

RN13 22/0804/MS/NC

RN13 22/0804/MS/NC

B-DDR3-WEZ

B_DDR3_WEZ

7531

7531

8642

8642

RN16 22/0804/MS/NC

RN16 22/0804/MS/NC

B-DDR3-CS0B_DDR3_CS0

B-DDR3-DQL7

B-DDR3-DQL1B_DDR3_DQL1

B-DDR3-DQL3B_DDR3_DQL3

B-DDR3-MCLKZ

B-DDR3-CASZB_DDR3_CASZ

7531

7531

8642

8642

RN21 22/0804/MS/NC

RN21 22/0804/MS/NC

B-DDR3-MCLK

7531

7531

8642

8642

R55 22/1%/0402/NCR55 22/1%/0402/NC

RN22 22/0804/MS/NC

RN22 22/0804/MS/NC

R56 22/1%/0402/NCR56 22/1%/0402/NC

B_DDR3_RESET B-DDR3-RESET

B_DDR3_DML B-DDR3-DML

B_DDR3_MCLK

B_DDR3_MCLKZ

B-DDR3-BA2B_DDR3_BA2

B-DDR3-BA0B_DDR3_BA0

7531

7531

8642

8642

RN23 22/0804/MS/NC

RN23 22/0804/MS/NC

B_DDR3_A3 B-DDR3-A3

B-DDR3-DMU

B-DDR3-DQU0

B-DDR3-DQSU

B-DDR3-DQSUB

C7

D3

B7

U8

K4B2G1646Q-BCMA/NCU8K4B2G1646Q-BCMA/NC

DMU

VDDQ

DQU0D7DQU1C3DQU2C8DQU3C2DQU4A7DQU5A2DQU6B8DQU7

DQSU

A8

/DQSU

VDDQ

A1

VDDQ

C1

VDDQ

C9

VDDQ

D2

VDDQ

E9

VDDQ

F1

VDDQ

H2

VDDQ

H9

VDD

B2

VDD

+1.5V_DDR

D9

VDD

G7

VDD

K2

VDD

K8

VDD

N1

VDD

N9

VDD

R1

VDD

R9

A0N3A1P7A2P3A3N2A4P8A5P2A6R8A7R2A8T8A9R3A10L7A11R7A12

B-DDR3-A1

B-DDR3-A2

B-DDR3-A3

B-DDR3-A4

B-DDR3-A0

B-DDR3-DQSL

B-DDR3-DQSLB

B-DDR3-DML

B-DDR3-DQL3

B-DDR3-DQL5

B-DDR3-DQL4

B-DDR3-DQL1

B-DDR3-DQL0

B-DDR3-DQU6

B-DDR3-A10

B-DDR3-DQU7

A3

N7

B-DDR3-A11

B-DDR3-A12

E7

G3

F3

DML

DQSL

/DQSL

BA0M2BA1N8BA2M3/CSL2/RASJ3/CASK3/WE

B-DDR3-BA2

B-DDR3-BA0

B-DDR3-BA1

B-DDR3-CS0

B-DDR3-DQL2

DQL0E3DQL1F7DQL2F2DQL3F8DQL4H3DQL5H8DQL6G2DQL7

ODT

L3

K1

B-DDR3-RASZ

B-DDR3-CASZ

B-DDR3-WEZ

B-DDR3-ODT

B-DDR3-DQU1

B-DDR3-DQU3

B-DDR3-DQU2

B-DDR3-DQU4

B-DDR3-DQU5

B-DDR3-A5

B-DDR3-A6

B-DDR3-A7

B-DDR3-A8

B-DDR3-A9

B-DDR3-DQL7

B-DDR3-DQL6

H7

VREFCA

NC1J1NC2J9NC3L1NC4L9NC5M7A13T3NC7

M8

B-MVREFCA

R61

R61

56/1%/0402/NC

56/1%/0402/NC

B-DDR3-RESET

B-DDR3-CKE

B-DDR3-MCLK

B-DDR3-MCLKZ

B-MVREFDQ

K7

H1

T2

J7

K9

VSSQ

VSSQ

CK

/CK

CKE

VSSQ

VSSQ

/RESET

VREFDQ

VSSQ

VSSQ

VSSQ

VSSQ

VSSQ

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

ZQ

T7

B-DDR3-A13

B-DDR3-A14

B-DDR3-DQU6B_DDR3_DQU6

B-DDR3-DQL5

7531

7531

7531

7531

8642

8642

8642

8642

RN20 22/0804/MS/NC

RN20 22/0804/MS/NC

RN18 22/0804/MS/NC

RN18 22/0804/MS/NC

B_DDR3_DQL5

B_DDR3_DQL7

B_DDR3_DQU2 B-DDR3-DQU2

B-DDR3-A5B_DDR3_A5

B-DDR3-A7B_DDR3_A7

B-DDR3-A0B_DDR3_A0

B-DDR3-A2B_DDR3_A2

7531

7531

7531

7531

8642

8642

8642

8642

RN17 22/0804/MS/NC

RN17 22/0804/MS/NC

RN19 22/0804/MS/NC

RN19 22/0804/MS/NC

1

401C7Z

401C7Z

401C7Z

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

SCHEMATIC,M/B VTV-L32107

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet

2

C99

10nF/16V/0402/NC

C99

10nF/16V/0402/NC

B1

B9

D1

D8

E2

E8

F9

G1

G9

B3

A9

E1

G8

J2

J8

M1

M9

P1

3

P9

T1

T9

L8

R63 240/1%/0402/NCR63 240/1%/0402/NC

4

B_DDR3_A14

B_DDR3_A5

B_DDR3_A9

B_DDR3_A12

B_DDR3_A11

B_DDR3_A3

B_DDR3_A1

B_DDR3_A10

B_DDR3_A2

B_DDR3_A0

B_DDR3_A6

B_DDR3_A7

B_DDR3_A13

B_DDR3_A8

B_DDR3_A4

E11

F12

D10

B10

E15

B11

F14

C11

B_A[0]

B_A[1]

B_A[2]

B_A[3]

B_A[4]

B_A[5]

B_A[6]

5

U201A

U201A

B_DDR3_DQL3

B_DDR3_DQL4

B_DDR3_DQL1

B_DDR3_DQL0

B_DDR3_DQL2

D14

A12

A20

A16

C19

C15

C20

F16

D13

D15

C12

E13

B_A[7]

B_A[8]

B_A[9]

B_A[10]

B_A[11]

B_A[12]

B_A[13]

B_A[14]

B_DQL[0]

B_DQL[1]

B_DQL[2]

B_DQL[3]

MIU0

MIU0

D D

Only for training and service purposes

4

B_DDR3_WEZ

B_DDR3_CKE

B_DDR3_BA2

B_DDR3_RESET

B_DDR3_BA1

B_DDR3_BA0

B_DDR3_ODT

B_DDR3_DQSL

B_DDR3_DQSU

B_DDR3_DQSLB

B_DDR3_DQSUB

B_DDR3_MCLK

B_DDR3_MCLKZ

B_DDR3_DMU

B_DDR3_DML

B_DDR3_DQU1

B_DDR3_DQU3

B_DDR3_DQU2

B_DDR3_DQU4

B_DDR3_DQL7

B_DDR3_DQU0

B_DDR3_DQL6

B_DDR3_DQL5

B_DDR3_DQU5

B_DDR3_DQU6

B_DDR3_DQU7

B_DDR3_RASZ

B_DDR3_CASZ

C16

D17

B_DQU[1]

B_DQU[2]

MSD8832RKM2 BGA-402 ball

MSD8832RKM2 BGA-402 ball

R54

R54

E21

E19

B_DQU[3]

MIU1

MIU1

D21

D11

D20

D18

F20

C8

B8

B_ODT

B_WEZ

B_BA[0]A9B_BA[1]

B_CASZB9B_RASZ

B_DQML

B_DQMU

B_DQU[4]

B_DQU[5]

B_DQU[6]

B_DQU[7]

240/1%/0402

240/1%/0402

C14

B21

B15

F18

D19

B_DQL[4]

B_DQL[5]

B_DQL[6]

B_DQL[7]

B_DQU[0]

ZQ

E9

B_DDR3_CS0

B13

A19

D16

A10

E17

B18

C18

D12

C17

F10

C13

B_CS0

B_RST

B_CKE

B_BA[2]

B_DQSL

B_MCLK

B_DQSU

B_MCLKZ

B_DQSLB

B_DQSUB

AVDD_DDR0

+1.5V_DDR

C C

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C89

C89

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C88

C88

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

2011-11-30

Place C312/C313/C314 on

bottom side for debug

C94

0.1uF/10V/0402/NC

C94

C87

C87

C86

C86

C85

C85

C84

C84

C83

C83

C82

C82

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

2.2uF/6.3V/0402/NC

2.2uF/6.3V/0402/NC

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C93

C93

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C102

C102

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

C101

C101

2.2uF/6.3V/0402/NC

2.2uF/6.3V/0402/NC

C90

C90

- 20 -

C95

C95

1nF/25V/0402/NC

1nF/25V/0402/NC

B-MVREFDQB-MVREFCA

C98

0.1uF/10V/0402/NC

C98

0.1uF/10V/0402/NC

R57

R57

1K/1%/0402/NC

1K/1%/0402/NC

R59 1K/1%/0402/NCR59 1K/1%/0402/NC

C97

C97

1nF/25V/0402/NC

1nF/25V/0402/NC

C96

C96

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

R60

R60

1K/1%/0402/NC

1K/1%/0402/NC

R58 1K/1%/0402/NCR58 1K/1%/0402/NC

+1.5V_DDR +1.5V_DDR

B B

A A

5

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 21

1A

1A

1A

1

2

3

4

5

C220

10uF/25V

C220

10uF/25V

LVDS_PWR

C219

C219

0.1uF/50V/NC

0.1uF/50V/NC

1 2

C221

C221

1nF/50V

1nF/50V

C201

C201

C192

C192

C187

C187

C186

C186

LVB3P LVB3N LVBCLKP LVBCLKN

B chanel for LVDS_ODD