Page 1

LED LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : LT01D

MODEL : 32LE4300 32LE4300-DA

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Printed in KoreaP/NO : MFL63141218 (1010-REV00)

Page 2

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

PRODUCT SAFETY ..................................................................................3

SPECIFICATION........................................................................................6

ADJUSTMENT INSTRUCTION .................................................................9

EXPLODED VIEW .................................................................................. 15

SVC. SHEET ...............................................................................................

Page 3

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

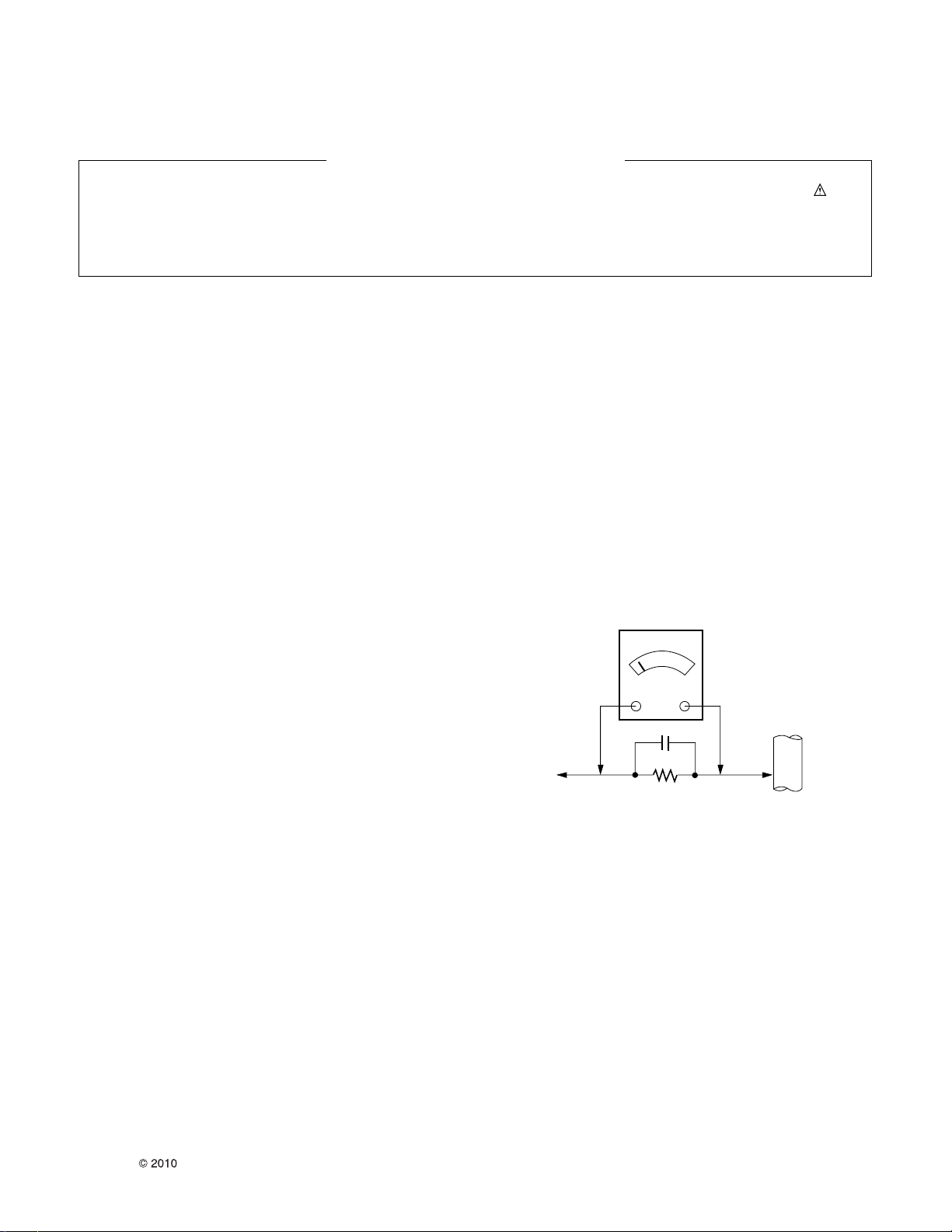

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

When 25A is impressed between Earth and 2nd Ground

for 1 second, Resistance must be less than 0.1

*Base on Adjustment standard

IMPORTANT SAFETY NOTICE

0.15uF

Ω

Page 4

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500

°F to 600°F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500

°F to 600°F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500

°F to 600°F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

SERVICING PRECAUTIONS

Page 5

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 5 -

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Page 6

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 6 -

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This specification is applied to LCD TV used LT01D chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

1) Temperature : 25 ºC ± 5 ºC

(77

± 9 ºF), CST : 40 ± 5 ºC

2) Relative Humidity : 65 ± 10 %

3) Power Voltage : Standard input voltage (100-240V~60Hz)

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM.

5) The receiver must be operated for about 20 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety: CE / ICE specification

EMI: CE / ICE

4. Electrical Spec.

No. Item Specification Remark

1 Display Screen Device 32 inch wide color display module

2 Aspect Ratio 16:9

3 LCD Module 32” TFT WUXGA EDGE LED

4 Storage Environment Temp. : -20 ~ 60 deg

Humidity : 0 ~ 85 %

5 Operating Environment Temp. : 0 ~ 40 deg

Humidity : 0 ~ 85 %

6 Input Voltage AC 100-240 V~ 50 / 60 Hz

7 Power Consumption 73.2W LC320EUH-SCA1

8 LCD Module(LGD) 741.4(H) X 435.8 (V) X 10.8 (D)

5. Chroma & Brightness

No. Item Specification Min. Typ. Max. Remark

1. Viewing Angle<CR>10> Right/Left/Up/Down 89/89/89/89 CR > 10

2. Luminance Luminance (cd/m

2

) 360 450

Variation 1.3

3. Contrast Ratio CR 900 1300

4. CIE Color Coordinates White Wx 0.279

Wy 0.292

RED Xr 0.651

Yr Typ. 0.332 Typ.

Green Xg -0.03 0.308 +0.03

Yg 0.597

Blue Xb 0.149

Yb 0.059

Page 7

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 7 -

6. Component Video Input (Y, CB/PB, CR/PR)

No

Specification

Remark

Resolution H-freq(kHz) V-freq(Hz)

1. 720x480 15.73 60.00 SDTV,DVD 480i

2. 720x480 15.63 59.94 SDTV,DVD 480i

3. 720x480 31.47 59.94 480p

4. 720x480 31.50 60.00 480p

5. 720x576 15.625 50.00 SDTV,DVD 625 Line

6. 720x576 31.25 50.00 HDTV 576p

7. 1280x720 37.50 50.00 HDTV 720p

8. 1280x720 44.96 59.94 HDTV 720p

9. 1280x720 45.00 60.00 HDTV 720p

10. 1920x1080 28.125 50.00 HDTV 1080i

11. 1920x1080 33.75 60.00 HDTV 1080i

12. 1920x1080 33.72 59.94 HDTV 1080i

13. 1920x1080 56.250 50 HDTV 1080p

14. 1920x1080 67.43/67.5 59.94/60 HDTV 1080p

No

Specification

Proposed Remark

Resolution H-freq(kHz) V-freq(Hz) Pixel Clock(MHz)

1. 720*400 31.468 70.08 28.321 For only DOS mode

2. 640*480 31.469 59.94 25.17 VESA

Input 848*480

60Hz, 852*480 60Hz

-> 640*480 60Hz Display

3. 800*600 37.879 60.31 40.00 VESA

4. 1024*768 48.363 60.00 65.00 VESA(XGA)

5. 1280*768 47.78 59.87 79.5 WXGA

6. 1360*768 47.72 59.8 84.75 WXGA

7. 1280*1024 63.595 60.0 108.875 SXGA FHD model

8. 1920*1080 66.587 59.93 138.625 WUXGA FHD model

7. RGB (PC)

Page 8

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 8 -

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed Remark

1. 720*400 31.468 70.08 28.321 HDCP

2. 640*480 31.469 59.94 25.17 VESA HDCP

3. 800*600 37.879 60.31 40.00 VESA HDCP

4. 1024*768 48.363 60.00 65.00 VESA(XGA) HDCP

5. 1280*768 47.78 59.87 79.5 WXGA HDCP

6. 1360*768 47.72 59.8 84.75 WXGA HDCP

7. 1280*1024 63.595 60.0 108.875 SXGA HDCP

8. 1920*1080 67.5 60 148.5 WUXGA HDCP

9.2. PC Mode

9. HDMI Input (PC/DTV)

9.1. DTV Mode

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed Remark

1. 720*480 31.469 /31.5 59.94 / 60 27.00/27.03 SDTV 480P

2. 720*576 31.25 50 54 SDTV 576P

3. 1280*720 37.500 50 74.25 HDTV 720P

4. 1280*720 44.96 / 45 59.94 / 60 74.17/ 74.25 HDTV 720P

5. 1920*1080 33.72 / 33.75 59.94 / 60 74.17/ 74.25 HDTV 1080I

6. 1920*1080 28.125 50.00 74.25 HDTV 1080I

7. 1920*1080 26.97 / 27 23.97 / 24 74.17/ 74.25 HDTV 1080P

8. 1920*1080 33.716 / 33.75 29.976 / 30.00 74.25 HDTV 1080P

9. 1920*1080 56.250 50 148.5 HDTV 1080P

10. 1920*1080 67.43 / 67.5 59.94 / 60 148.35/148.50 HDTV 1080P

Page 9

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 9 -

ADJUSTMENT INSTRUCTION

1. Application Range

This specification sheet is applied to all of the LCD TV with

LT01D chassis.

2. Designation

1) The adjustment is according to the order which is

designated and which must be followed, according to the

plan which can be changed only on agreeing.

2) Power Adjustment: Free Voltage

3) Magnetic Field Condition: Nil.

4) Input signal Unit: Product Specification Standard

5) Reserve after operation: Above 5 Minutes (Heat Run)

Temperature : at 25±5ºC

Relative humidity : 65±10%

Input voltage : 220V, 60Hz

6) Adjustment equipments: Color Analyzer (CA-210 or CA-

110), Pattern Generator(MSPG-925L or Equivalent), DDC

Adjustment Jig equipment, SVC remote controller

7) Push The “IN STOP KEY” - For memory initialization.

3. Main PCB check process

* APC - After Manual-Insert, executing APC

* Boot file Download

(1) Execute ISP program “Mstar ISP Utility” and then click

“Config” tab.

(2) Set as below, and then click “Auto Detect” and check “OK”

message.

If “Error” is displayed, Check connection between

computer, jig, and set..

(3) Click “Read” tab, and then load download file (XXXX.bin)

by clicking “Read”.

(4) Click “Connect” tab. If “Can’t” is displayed, check

connection between computer, jig, and set.

(5) Click “Auto” tab and set as below

(6) Click “Run”.

(7) After downloading, check “OK” message.

filexxx.bin

(7)

(5)

(8) ……….OK

(6)

(1) (3)

Please Check the Speed :

To use speed between

from 200KHz to 400KHz

(4)

filexxx.bin

Case1 : Software version up

1. After downloading S/W by USB, TV set will reboot

automatically

2. Push “In-stop” key

3. Push “Power on” key

4. Function inspection

5. After function inspection, Push “I n-stop” key.

Case2 : Function check at the assembly line

1. When TV set is entering on the assembly line, Push

“In-stop” key at first.

2. Push “Power on” key for turning it on.

-> If you push “Power on” key, TV set will recover

channel information by itself.

3. After function inspection, Push “In-stop” key.

Page 10

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 10 -

* USB DOWNLOAD(*.epk file download)

(1) Put the USB Stick to the USB socket.

(2) Automatically detecting update file in USB Stick.

- If your downloaded program version in USB Stick is Low,

it didn’t work. But your downloaded version is High, USB

data is automatically detecting

(3) Show the message “Copying files from memory”

(4) Updating is staring.

(5) After updating is complete, The TV will restart automatically.

(6) If TV turns on, check your updated version and Tool

option. (refer to the next page about tool option)

* If downloading version is higher than your TV have, TV

can lost all channel data. In this case, you have to

channel recover. If all channel data is cleared, you didn’t

have a DTV/ATV test on production line.

* After downloading, have to adjust Tool Option again.

1. Push "IN-START" key in service remote controller.

2. Select "Tool Option 1" and Push “OK” button.

3. Punch in the number. (Each model has their number.)

4. Completed selecting Tool option.

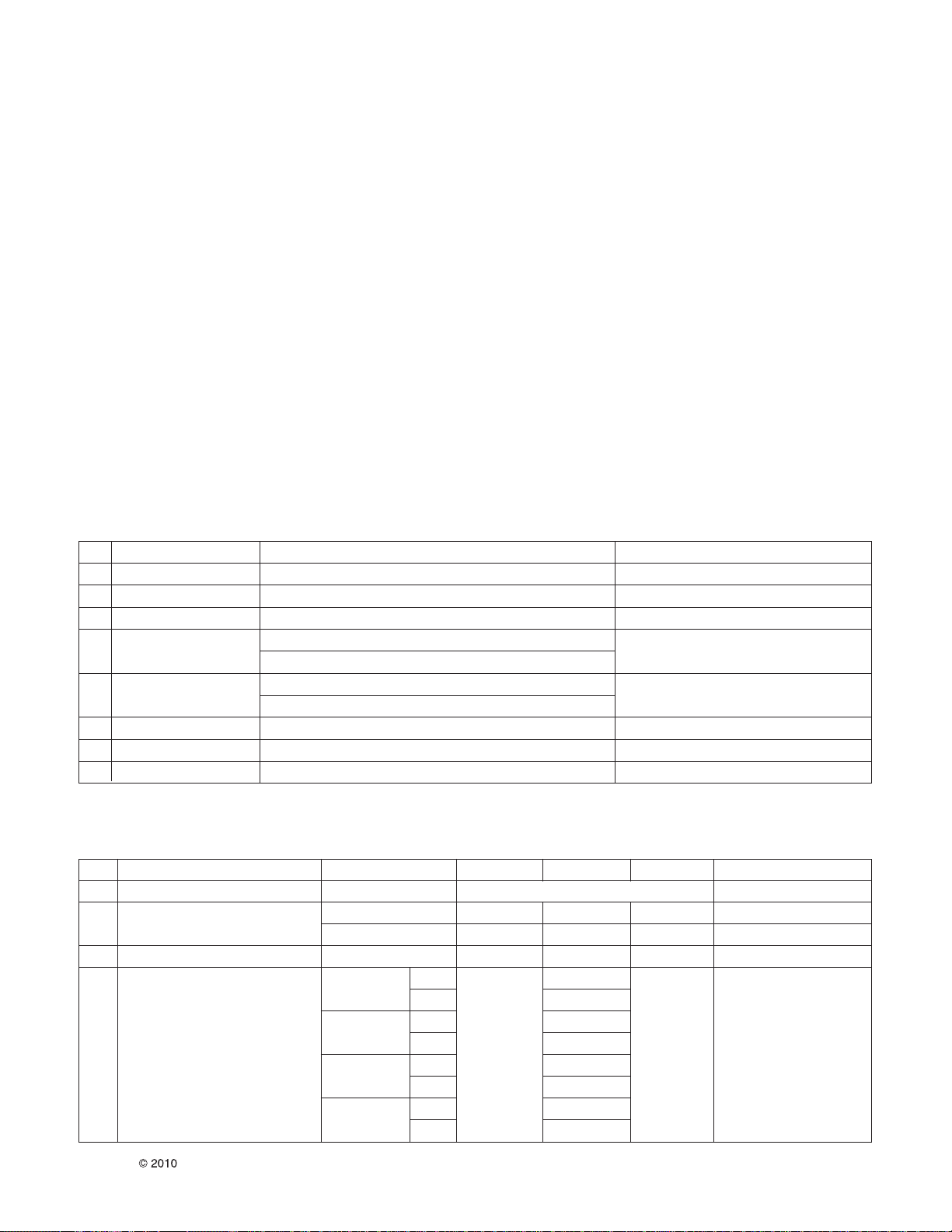

3.1. ADC Process

(1) ADC

• Enter Service Mode by pushing “ ADJ” key

• Enter Internal ADC mode by pushing “G” key at “6. ADC

Calibration”

*

Caution: Using ‘power on’ button of the Adj. R/C, power on TV.

* ADC Calibration Protocol (RS232)

- Adjust Sequence

• aa 00 00 [Enter Adjust Mode]

• xb 00 40 [Component1 Input (480i)]

• ad 00 10 [Adjust 480i Comp1]

• xb 00 60 [RGB Input (1024x768)]

• ad 00 10 [Adjust 1024x768 RGB]

• aa 00 90 [End Adjust Mode]

* Required equipment : Adjustment R/C

3.2. Function Check

(1) Check display and sound

- Check Input and Signal items. (cf. work instructions)

1) TV

2) AV (CVBS)

3) COMPONENT (480i)

4) RGB (PC : 1024 x 768 @ 60hz)

5) HDMI

6) PC Audio In

* Display and sound check is executed by remote control.

Model

Tool option1 Tool option2 Tool option3 Tool option4 Tool option5

32LE4300-DA 17888 19734 56364 26892 40

42LE4300-DA 26080 19734 56364 26892 40

47LE4500-DA 32960 19734 56364 26892 40

55LE4500-DA 45248 19734 56364 26892 40

32LE4600-DA 17216 19734 56868 26892 40

42LE4600-DA 25408 19734 56868 26892 40

47LE4600-DA 33600 19734 56868 26892 40

55LE4600-DA 45888 19734 56868 26892 40

i TV Software Upgrade

Upgrading...

Do not plug off!

63%

i TV Software Upgrade

Upgrading COMPLETED

The TV will restart after seconds.

100%

i TV Software Upgrade

Copying files from memory

Do not remove the memory card from the pc

Do not plug off!

No. Item CMD1 CMD2 Data0

1 Enter Adjust Mode A A 0 0

2 ADC Adjust A D 0 0

Page 11

- 11 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

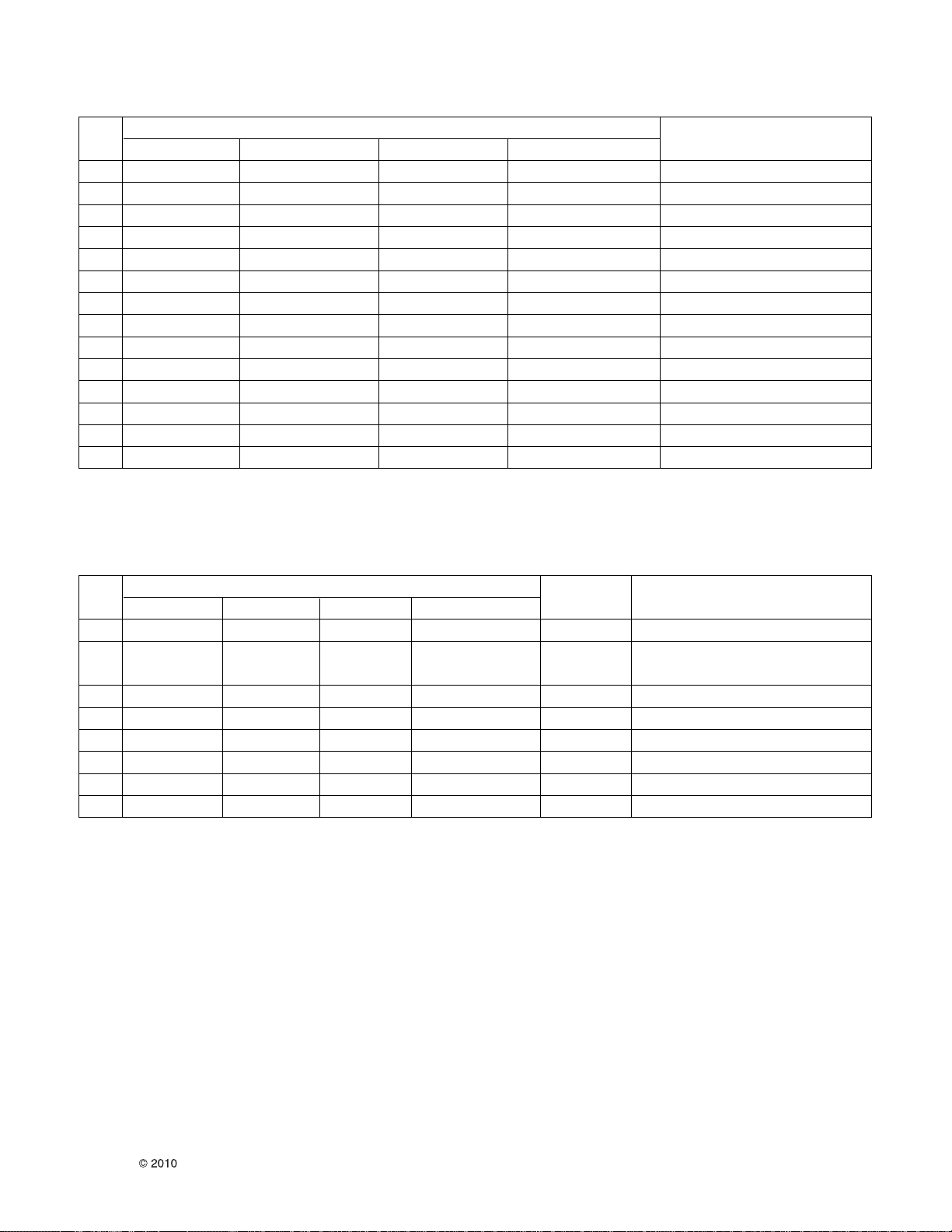

4. Total Assembly line process

4.1. Adjustment Preparation

· W/B Equipment condition

CA210 : CH 9, Test signal : Inner pattern (85IRE)

· Above 5 minutes H/run in the inner pattern. (“power on” key

of adjust remote control)

· In casw of Edge LED module, the color coordinates is

changing by aing, so you have to use the below table.

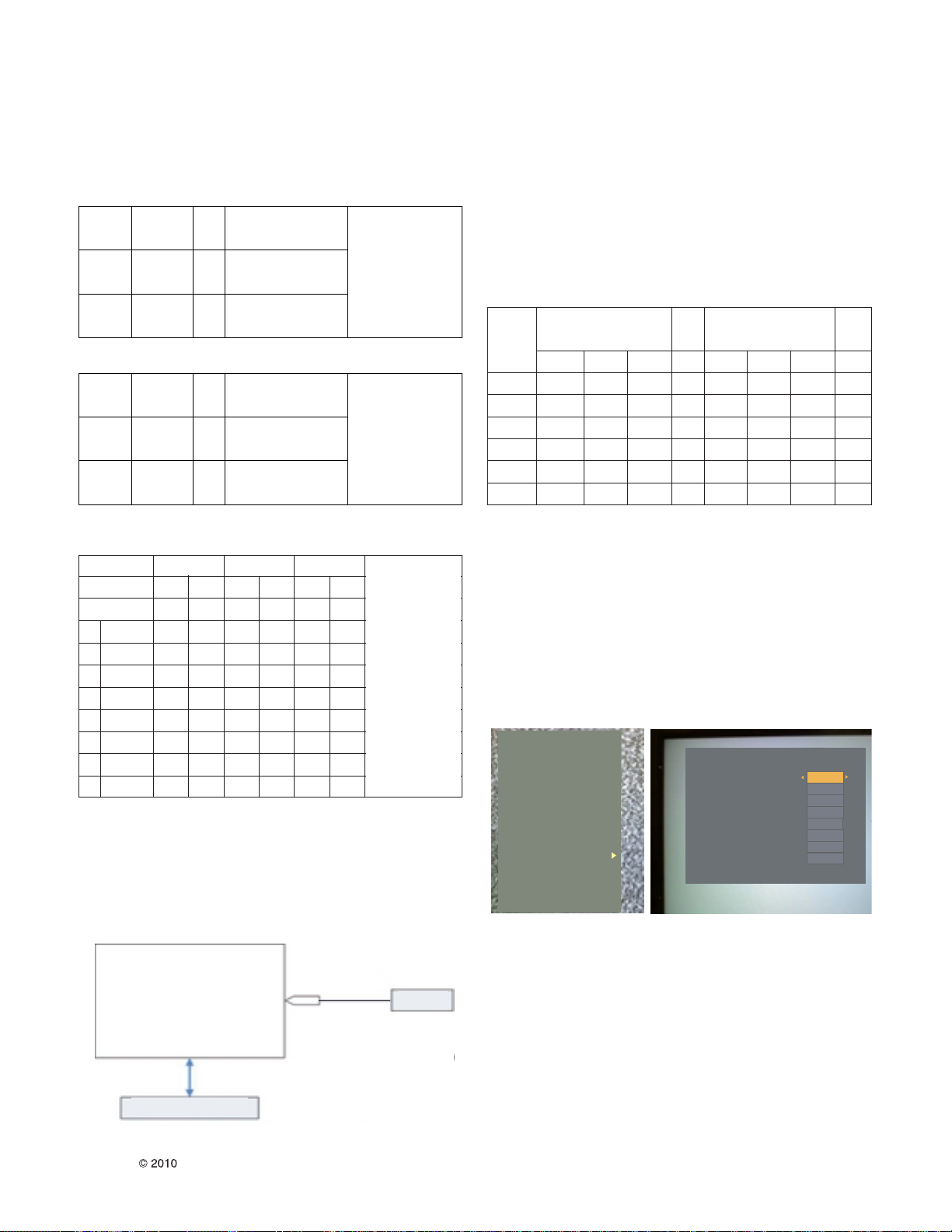

4.1.1. Connecting picture of the measuring instrument

(On Automatic control)

Inside PATTERN is used when W/B is controlled. Connect to

auto controller or push Adjustment R/C POWER ON -> Enter

the mode of White-Balance, the pattern will come out

4.1.2. Auto-control interface and directions

1) Adjust in the place where the influx of light like floodlight

around is blocked. (illumination is less than 10ux).

2) Adhere closely the Color Analyzer (CA210) to the module

less than 10cm distance, keep it with the surface of the

Module and Color Analyzer’s Prove vertically.(80~100°).

3) Aging time

- After aging start, keep the power on (no suspension of

power supply) and heat-run over 15minutes.

- Using ‘no signal’ or ‘full white pattern’ or the others, check

the back light on.

4.1.3. Auto adjustment Map (RS-232C)

**Caution **

Color Temperature : COOL, Medium, Warm.

One of R Gain/G Gain/ B Gain should be kept on 0xC0, and

adjust other two lower than C0.

(when R/G/B Gain are all C0, it is the FULL Dynamic Range of

Module)

4.2. Manual W/B process using adj. R/C

• After enter Service Mode by pushing “ADJ” key,

• Enter White Balance by pushing “G”

* After done all adjustments, Press “In-start” button and compare

Tool option and Area option

value with its BOM, if it is correctly same then unplug the AC

cable.

If it is not same, then correct it same with BOM and unplug AC

cable.

For correct it to the model’s module from factory JIG model.

* Push The “IN STOP KEY” after completing the function

inspection.

Cool 13,000k ºK X=0.269(±0.002) All

Y=0.273(±0.002) <Test Signal>

Medium 9,300k ºK X=0.285(±0.002) Inner pattern

Y=0.293(±0.002) (216gray,85IRE)

Warm 6,500k ºK X=0.313(±0.002)

Y=0.329(±0.002)

Cool 9,300k ºK X=0.285(±0.002) Only 22LD350

Y=0.293(±0.002) <Test Signal>

Medium 8,000k ºK X=0.295(±0.002) Inner pattern

Y=0.305(±0.002) (216gray,85IRE)

Warm 6,500k ºK X=0.313(±0.002)

Y=0.329(±0.002)

Full White Pattern

COLOR

ANALYZER

TYPE: CA-210

RS-232C Communication

CA-210

RS-232C COMMAND MIN CENTER MAX

[CMD ID DATA] (DEFAULT)

Cool Mid Warm Cool Mid Warm

R Gain jg Ja jd 00 172 192 192 255

G Gain jh Jb je 00 172 192 192 255

B Gain ji Jc jf 00 192 192 172 255

R Cut 64 64 64 128

G Cut 64 64 64 128

B Cut 64 64 64 128

EZ ADJUST

0. Tool Option1

1. Tool Option2

2. Tool Option3

3. Tool Option4

4. Country Group

5. ADC Calibration

6. White Balance

7. Test Pattern

8. EDID D/L

9. Sub B/C

White Balance

Color Temp.

R-Gain

G-Gain

B-Gain

R-Cut

G-Cut

B-Cut

Test-Pattern.

Reset

Cool

172

172

192

64

64

64

ON

To set

H/R Time(Min)

Cool Medium Warm

xyxxyx

269 273 285 293 313 329

1 0-2min 280 291 296 311 319 340

2 3-5min 278 288 294 308 317 338 xxLE4500

3 6-9min 276 285 292 305 315 335 xxLE4600

4

10-19min

274 282 290 302 313 332 xxLE5300

5

20-35min

273 279 289 299 312 329 xxLE4300

6

36-49min

270 276 287 296 310 326

7

50-79min

269 273 286 293 308 323

8

over 80min

269 273 285 293 308 323

Page 12

- 12 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

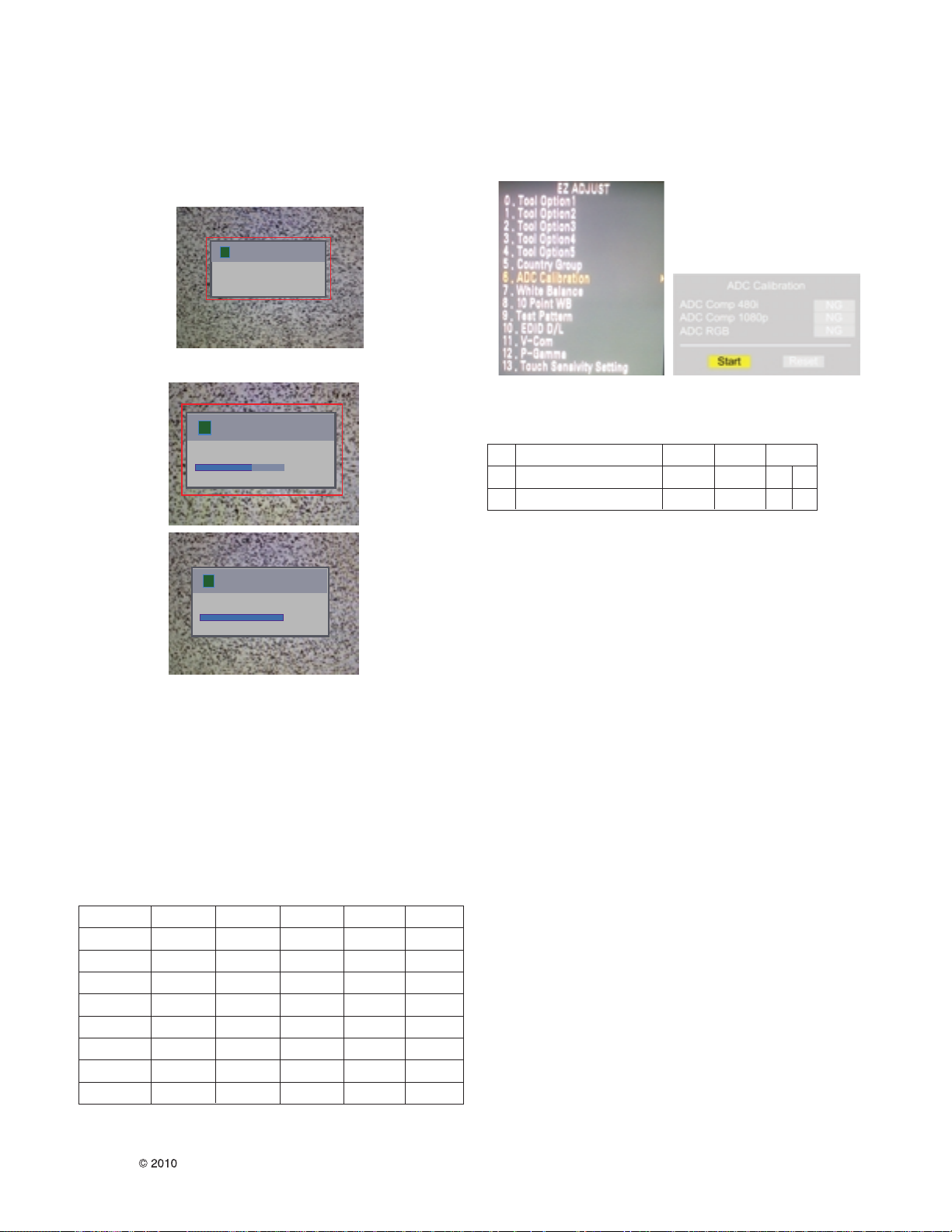

4.3. DDC EDID Write (RGB 128Byte )

· Connect D-sub Signal Cable to D-Sub Jack.

· Write EDID DATA to EEPROM (24C02) by using DDC2B

protocol.

· Check whether written EDID data is correct or not.

* For SVC main Ass’y, EDID have to be downloaded to Insert

Process in advance.

4.4 DDC EDID Write (HDMI 256Byte)

· Connect HDMI Signal Cable to HDMI Jack.

· Write EDID DATA to EEPROM(24C02) by using DDC2B

protocol.

· Check whether written EDID data is correct or not.

* For SVC main Ass’y, EDID have to be downloaded to Insert

Process in advance.

4.5 EDID DATA

1) All Data : HEXA Value

2) Changeable Data :

*: Serial No : Controlled / Data:01

**: Month : Controlled / Data:00

***:Year : Controlled

****:Check sum

- Auto Download

- Manual Download

* Caution

1) Use the proper signal cable for EDID Download

- Analog EDID : Pin3 exists

- Digital EDID : Pin3 exists

2) Nerver connect HDMI & D-sub Cable at the same time.

3) Use the proper cables below for EDID Writing.

4) Download HDMI1, HDMI2 separately because each data is

different.

EZ ADJUT

0. Tool Option1

1. Tool Option2

2. Tool Option3

3. Tool Option4

4. Country Group

5. ADC Calibration

6. White Balance

7. Test Pattern

8. EDID D/L

9. Sub B/C

EDID D/L

HDMI1

HDMI2

HDMI3

RGB

NG

NG

NG

NG

Reset

Start

EDID D/L

HDMI1

HDMI2

HDMI3

RGB

OK

OK

OK

OK

Reset

Start

D-sub to D-sub

DVI-D to HDMI or HDMI to HDMI

For HDMI EDIDFor Analog EDID

Item

Manufacturer ID

Version

Revision

Condition

GSM

Digital : 1

Digital : 3

Data(Hex)

1E6D

01

03

Page 13

- 13 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

(1) FHD RGB EDID Data (CS : 1D)

(2) FHD HDMI EDID Data (CS : D739)

(3) FHD HDM2 EDID Data (CS : D739)

(4) HD RGB EDID Data (CS : 93)

(5) HD HDMI1 EDID Data (CS : 7AD5)

(6) HD HDMI2 EDID Data (CS : 7AD5)

(7) HD HDMI3 EDID Data (CS : 7AB5)

(8) ASCII Code

Page 14

- 14 -

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

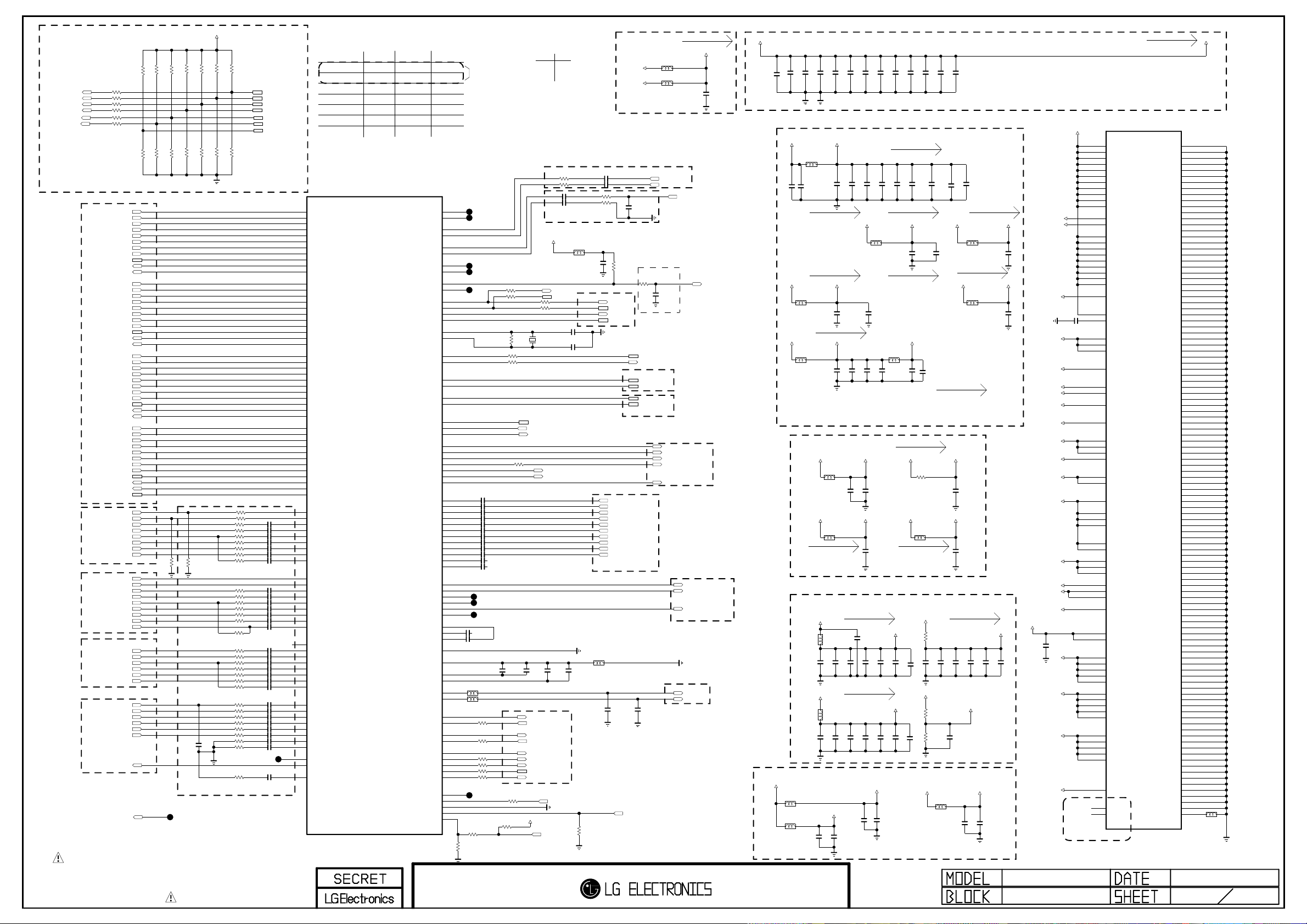

4.6. V-COM Adjust(Only LGD(M+S) Module)

- Why need Vcom adjustment?

A The Vcom (Common Voltage) is a Reference Voltage of

Liquid Crystal Driving.

-> Liquid Crystal need for Polarity Change with every frame.

- Adjust sequence

· Press the PIP key of th ADJ remote control.(This PIP key is

hot key to enter the VCOM adjusting mode)

(Or After enter Service Mode by pushing “ADJ” key, then

Enter V-Com Adjust mode by pushing “

G” key at “10. V-

Com”

· As pushing the right or the left key on the remote control,

and find the V-COM value which is no or minimized the

Flicker. (If there is no flicker at default value, Press the exit

key and finish the VCOM adjustment.)

· Push the “OK” key to store value. Then the message

“Saving OK” is pop.

· Press the exit key to finish VCOM adjustment.

(Visual Adjust and control the Voltage level)

· V-COM default value is different from module.

1) 32LD450 : 417

2) 37LD450 : 432

3) 42LD450 : 433

4.7. Outgoing condition Configuration

- When pressing IN-STOP key by SVC remocon, Red LED

are blinked alternatively. And then Automatically turn off.

(Must not AC power OFF during blinking)

4.8. Internal pressure

Confirm whether is normal or not when between power

board’s ac block and GND is impacted on 1.5 kV(dc) or 2.2

kV(dc) for one second.

Row Li ne

Column Line

CLC

CST

Panel

S

Y

S

T

E

M

Gat e Driv e IC

Source D r ive I C

Circuit Block

Tim i ng

Cont r o lle r

Pow er

Blo ck

V

COM

Gamma

Ref erence V oltage

Gamm a Reference

Volta ge

Data (R,G ,B) & C ont rol s ignal

Control si gnal

Data (R,G,B ) &

Control si gnal

In terf ace

TFT

Pow er I n put

Power Input

Da ta I n put

Da ta I n put

V

COM

Liquid

Crystal

V

COM

Page 15

LGE Internal Use OnlyCopyright LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 15 -

300

400

301

501501

560

302

500

310

510

120

A2

LV1

A21

A10

A5

A9

810

800

200

530

540

521

820

880

710

LV2

900

910

920

EXPLODED VIEW

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 16

/PF_WP

NC_1

1

NC_2

2

NC_3

3

NC_4

4

NC_5

5

NC_6

6

R/B

7

RE

8

CE

9

NC_7

10

NC_8

11

VCC_1

12

VSS_1

13

NC_9

14

NC_10

15

CLE

16

ALE

17

WE

18

WP

19

NC_11

20

NC_12

21

NC_13

22

NC_14

23

NC_15

24

S7M_NON_DIVX & MS10

IC101-*2

LGE107 (S7M Non Divx/RM)

AE1

FRC_DDR3_A0/DDR2_NC

AF16

FRC_DDR3_A1/DDR2_A6

AF1

FRC_DDR3_A2/DDR2_A7

AE3

FRC_DDR3_A3/DDR2_A1

AD14

FRC_DDR3_A4/DDR2_CASZ

AD3

FRC_DDR3_A5/DDR2_A10

AF15

FRC_DDR3_A6/DDR2_A0

AF2

FRC_DDR3_A7/DDR2_A5

AE15

FRC_DDR3_A8/DDR2_A2

AD2

FRC_DDR3_A9/DDR2_A9

AD16

FRC_DDR3_A10/DDR2_A11

AD15

FRC_DDR3_A11/DDR2_A4

AE16

FRC_DDR3_A12/DDR2_A8

AF3

FRC_DDR3_BA0/DDR2_BA2

AF14

FRC_DDR3_BA1/DDR2_ODT

AD1

FRC_DDR3_BA2/DDR2_A12

AD13

FRC_DDR3_MCLK/DDR2_MCLK

AE14

FRC_DDR3_CKE/DDR2_RASZ

AE13

FRC_DDR3_MCLKZ/DDR2_MCLKZ

AE4

FRC_DDR3_ODT/DDR2_BA1

AD5

FRC_DDR3_RASZ/DDR2_WEZ

AF4

FRC_DDR3_CASZ/DDR2_CKE

AD4

FRC_DDR3_WEZ/DDR2_BA0

AE2

FRC_DDR3_RESETB/DDR2_A3

AF8

FRC_DDR3_DQSL/DDR2_DQS0

AD9

FRC_DDR3_DQSLB/DDR2_DQSB0

AE9

FRC_DDR3_DQSU/DDR2_DQS1

AF9

FRC_DDR3_DQSUB/DDR2_DQSB1

AE11

FRC_DDR3_DML/DDR2_DQ7

AF6

FRC_DDR3_DMU/DDR2_DQ11

AE6

FRC_DDR3_DQL0/DDR2_DQ6

AF11

FRC_DDR3_DQL1/DDR2_DQ0

AD6

FRC_DDR3_DQL2/DDR2_DQ1

AD12

FRC_DDR3_DQL3/DDR2_DQ2

AE5

FRC_DDR3_DQL4/DDR2_DQ4

AF12

FRC_DDR3_DQL5/DDR2_NC

AF5

FRC_DDR3_DQL6/DDR2_DQ3

AE12

FRC_DDR3_DQL7/DDR2_DQ5

AE10

FRC_DDR3_DQU0/DDR2_DQ8

AF7

FRC_DDR3_DQU1/DDR2_DQ14

AD11

FRC_DDR3_DQU2/DDR2_DQ13

AD7

FRC_DDR3_DQU3/DDR2_DQ12

AD10

FRC_DDR3_DQU4/DDR2_DQ15

AE7

FRC_DDR3_DQU5/DDR2_DQ9

AF10

FRC_DDR3_DQU6/DDR2_DQ10

AD8

FRC_DDR3_DQU7/DDR2_DQM1

AE8

FRC_DDR3_NC/DDR2_DQM0

Y11

FRC_REXT

Y19

FRC_TESTPIN

NAND FLASH MEMORY

/PF_CE0

H : Serial Flash

L : NAND Flash

/PF_CE1

H : 16 bit

L : 8 bit

/F_RB

/PF_OE

/PF_CE0

+3.3V_Normal

OPT

+3.5V_ST

R101

IC102-*1

HY27US08121B-TPCB

512MBIT

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

GPIO0/TCON15/HSYNC/VDD_ODD

GPIO1/TCON14/VSYNC/VDD_EVEN

GPIO2/TCON7/LDE/GCLK4

GPIO3/TCON6/LCK/GCLK2

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

R104

R103

0

OPT

3.3K

B

3.3K

R102

W26

W25

U26

U25

U24

V26

V25

V24

W24

Y26

Y25

Y24

AC26

AC25

AA26

AA25

AA24

AB26

AB25

AB24

AC24

AD26

AD25

AD24

AD23

CCKP/LLV3P

AE23

CCKM/LLV3N

AE26

AE25

AF26

AF25

AE24

AF24

AF23

C3P/LLV4P

AD22

C3M/LLV4N

AE22

C4P/LLV5P

AF22

C4M/LLV5N

AD19

DCKP/TCON5

AE19

DCKM/TCON4

AD21

D0P/LLV6P

AE21

D0M/LLV6N

AF21

D1P/LLV7P

AD20

D1M/LLV7N

AE20

D2P/LLV8P

AF20

D2M/LLV8N

AF19

D3P/TCON3

AD18

D3M/TCON2

AE18

D4P/TCON1

AF18

D4M/TCON0

AB22

AB23

AC23

AC22

AB16

AA14

FRC_GPIO1

AC15

FRC_GPIO3

Y16

FRC_GPIO8

AC16

AC14

FRC_GPIO10

AA16

FRC_I2CM_DA

AA15

FRC_I2CM_CK

Y10

FRC_I2CS_DA

AA11

FRC_I2CS_CK

AB15

FRC_PWM0

AB14

FRC_PWM1

/PF_CE1

10K

PF_ALE

/PF_WE

C

Q101

KRC103S

OPT

E

NC_28

48

NC_27

47

NC_26

46

NC_25

45

I/O7

44

I/O6

43

I/O5

42

I/O4

41

NC_24

40

NC_23

39

PRE

38

VCC_2

37

VSS_2

36

NC_22

35

NC_21

34

NC_20

33

I/O3

32

I/O2

31

I/O1

30

I/O0

29

NC_19

28

NC_18

27

NC_17

26

NC_16

25

S7M_NON_DIVX & DD

LGE107B-LF-1 (S7M Non Divx/RM/MS10)

AE1

FRC_DDR3_A0/DDR2_NC

AF16

FRC_DDR3_A1/DDR2_A6

AF1

FRC_DDR3_A2/DDR2_A7

AE3

FRC_DDR3_A3/DDR2_A1

AD14

FRC_DDR3_A4/DDR2_CASZ

AD3

FRC_DDR3_A5/DDR2_A10

AF15

FRC_DDR3_A6/DDR2_A0

AF2

FRC_DDR3_A7/DDR2_A5

AE15

FRC_DDR3_A8/DDR2_A2

AD2

FRC_DDR3_A9/DDR2_A9

AD16

FRC_DDR3_A10/DDR2_A11

AD15

FRC_DDR3_A11/DDR2_A4

AE16

FRC_DDR3_A12/DDR2_A8

AF3

FRC_DDR3_BA0/DDR2_BA2

AF14

FRC_DDR3_BA1/DDR2_ODT

AD1

FRC_DDR3_BA2/DDR2_A12

AD13

FRC_DDR3_MCLK/DDR2_MCLK

AE14

FRC_DDR3_CKE/DDR2_RASZ

AE13

FRC_DDR3_MCLKZ/DDR2_MCLKZ

AE4

FRC_DDR3_ODT/DDR2_BA1

AD5

FRC_DDR3_RASZ/DDR2_WEZ

AF4

FRC_DDR3_CASZ/DDR2_CKE

AD4

FRC_DDR3_WEZ/DDR2_BA0

AE2

FRC_DDR3_RESETB/DDR2_A3

AF8

FRC_DDR3_DQSL/DDR2_DQS0

AD9

FRC_DDR3_DQSLB/DDR2_DQSB0

AE9

FRC_DDR3_DQSU/DDR2_DQS1

AF9

FRC_DDR3_DQSUB/DDR2_DQSB1

AE11

FRC_DDR3_DML/DDR2_DQ7

AF6

FRC_DDR3_DMU/DDR2_DQ11

AE6

FRC_DDR3_DQL0/DDR2_DQ6

AF11

FRC_DDR3_DQL1/DDR2_DQ0

AD6

FRC_DDR3_DQL2/DDR2_DQ1

AD12

FRC_DDR3_DQL3/DDR2_DQ2

AE5

FRC_DDR3_DQL4/DDR2_DQ4

AF12

FRC_DDR3_DQL5/DDR2_NC

AF5

FRC_DDR3_DQL6/DDR2_DQ3

AE12

FRC_DDR3_DQL7/DDR2_DQ5

AE10

FRC_DDR3_DQU0/DDR2_DQ8

AF7

FRC_DDR3_DQU1/DDR2_DQ14

AD11

FRC_DDR3_DQU2/DDR2_DQ13

AD7

FRC_DDR3_DQU3/DDR2_DQ12

AD10

FRC_DDR3_DQU4/DDR2_DQ15

AE7

FRC_DDR3_DQU5/DDR2_DQ9

AF10

FRC_DDR3_DQU6/DDR2_DQ10

AD8

FRC_DDR3_DQU7/DDR2_DQM1

AE8

FRC_DDR3_NC/DDR2_DQM0

Y11

FRC_REXT

Y19

FRC_TESTPIN

R105

1K

OPT

IC101-*3

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

GPIO0/TCON15/HSYNC/VDD_ODD

GPIO1/TCON14/VSYNC/VDD_EVEN

GPIO2/TCON7/LDE/GCLK4

GPIO3/TCON6/LCK/GCLK2

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

R106

CCKP/LLV3P

CCKM/LLV3N

C3P/LLV4P

C3M/LLV4N

C4P/LLV5P

C4M/LLV5N

DCKP/TCON5

DCKM/TCON4

D0P/LLV6P

D0M/LLV6N

D1P/LLV7P

D1M/LLV7N

D2P/LLV8P

D2M/LLV8N

D3P/TCON3

D3M/TCON2

D4P/TCON1

D4M/TCON0

FRC_GPIO1

FRC_GPIO3

FRC_GPIO8

FRC_GPIO10

FRC_I2CM_DA

FRC_I2CM_CK

FRC_I2CS_DA

FRC_I2CS_CK

IC102

NC_1

NC_2

NC_3

NC_4

NC_5

NC_6

NC_7

NC_8

VCC_1

VSS_1

NC_9

NC_10

NC_11

NC_12

NC_13

NC_14

NC_15

R/B

RE

CE

CLE

ALE

WE

WP

IC101-*4

HY27UF082G2B-TPCB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

NC_29

48

NC_28

47

NC_27

46

NC_26

45

I/O7

44

I/O6

43

I/O5

42

I/O4

41

NC_25

40

NC_24

39

NC_23

38

VDD_2

37

VSS_2

36

NC_22

35

NC_21

34

NC_20

33

I/O3

32

I/O2

31

I/O1

30

I/O0

29

NC_19

28

NC_18

27

NC_17

26

NC_16

25

W26

RLV3P

W25

RLV3N

U26

RLV0P

U25

RLV0N

U24

RLV1P

V26

RLV1N

V25

RLV2P

V24

RLV2N

W24

RLVCKP

Y26

RLVCKN

Y25

RLV4P

Y24

RLV4N

AC26

WPWM

AC25

OPTP/FLK2

AA26

RLV5P

AA25

RLV5N

AA24

RLV6P

AB26

RLV6N

AB25

RLV7P

AB24

RLV7N

AC24

OPTN/FLK3

AD26

FLK

AD25

GCLK6

AD24

GCLK5

AD23

LLV3P

AE23

LLV3N

AE26

LLV0P

AE25

LLV0N

AF26

LLV1P

AF25

LLV1N

AE24

LLV2P

AF24

LLV2N

AF23

LLVCKP

AD22

LLVCKN

AE22

LLV4P

AF22

LLV4N

AD19

GOE/GCLK1

AE19

GSC/GCLK3

AD21

LLV5P

AE21

LLV5N

AF21

LLV6P

AD20

LLV6N

AE20

LLV7P

AF20

LLV7N

AF19

GSPR

AD18

GSP/VST

AE18

SOE

AF18

POL

AB22

VDD_ODD

AB23

VDD_EVEN

AC23

GCLK4

AC22

GCLK2

AB16

NC_23

AA14

DPM

AC15

HCON

Y16

NC_15

AC16

NC_26

AC14

LEDON

AA16

NC_20

AA15

NC_19

Y10

NC_11

AA11

NC_17

AB15

SCAN_BLK

AB14

SCAN_BLK1

2GBIT

S7T_DIVX & DD

LGE105DB-LF-1 (S7-Tcon Divx_ Non_RM/MS10)

AE1

NC_43

AF16

NC_73

AF1

NC_59

AE3

NC_45

AD14

NC_40

AD3

NC_29

AF15

NC_72

AF2

NC_60

AE15

NC_57

AD2

NC_28

AD16

NC_42

AD15

NC_41

AE16

NC_58

AF3

NC_61

AF14

NC_71

AD1

NC_27

AD13

NC_39

AE14

NC_56

AE13

NC_55

AE4

NC_46

AD5

NC_31

AF4

NC_62

AD4

NC_30

AE2

NC_44

AF8

NC_66

AD9

NC_35

AE9

NC_51

AF9

NC_67

AE11

NC_53

AF6

NC_64

AE6

NC_48

AF11

NC_69

AD6

NC_32

AD12

NC_38

AE5

NC_47

AF12

NC_70

AF5

NC_63

AE12

NC_54

AE10

NC_52

AF7

NC_65

AD11

NC_37

AD7

NC_33

AD10

NC_36

AE7

NC_49

AF10

NC_68

AD8

NC_34

AE8

NC_50

Y11

NC_12

Y19

GND_105

+3.3V_Normal

NC_29

48

NC_28

47

NC_27

46

NC_26

45

I/O7

44

I/O6

43

I/O5

42

I/O4

41

NC_25

40

NC_24

39

NC_23

38

VCC_2

37

VSS_2

36

NC_22

35

NC_21

34

NC_20

33

I/O3

32

I/O2

31

I/O1

30

I/O0

29

NC_19

28

NC_18

27

NC_17

26

NC_16

25

AR101

22

C102

10uF

C103

0.1uF

AR102

22

S7M_NON_DIVX & MS10_SPIL

IC101-*12

LGE107B-LF (SPIL)(S7M Non Divx/RM)

AE1

FRC_DDR3_A0/DDR2_NC

AF16

FRC_DDR3_A1/DDR2_A6

AF1

FRC_DDR3_A2/DDR2_A7

AE3

FRC_DDR3_A3/DDR2_A1

AD14

FRC_DDR3_A4/DDR2_CASZ

AD3

FRC_DDR3_A5/DDR2_A10

AF15

FRC_DDR3_A6/DDR2_A0

AF2

FRC_DDR3_A7/DDR2_A5

AE15

FRC_DDR3_A8/DDR2_A2

AD2

FRC_DDR3_A9/DDR2_A9

AD16

FRC_DDR3_A10/DDR2_A11

AD15

FRC_DDR3_A11/DDR2_A4

AE16

FRC_DDR3_A12/DDR2_A8

AF3

FRC_DDR3_BA0/DDR2_BA2

AF14

FRC_DDR3_BA1/DDR2_ODT

AD1

FRC_DDR3_BA2/DDR2_A12

AD13

FRC_DDR3_MCLK/DDR2_MCLK

AE14

FRC_DDR3_CKE/DDR2_RASZ

AE13

FRC_DDR3_MCLKZ/DDR2_MCLKZ

AE4

FRC_DDR3_ODT/DDR2_BA1

AD5

FRC_DDR3_RASZ/DDR2_WEZ

AF4

FRC_DDR3_CASZ/DDR2_CKE

AD4

FRC_DDR3_WEZ/DDR2_BA0

AE2

FRC_DDR3_RESETB/DDR2_A3

AF8

FRC_DDR3_DQSL/DDR2_DQS0

AD9

FRC_DDR3_DQSLB/DDR2_DQSB0

AE9

FRC_DDR3_DQSU/DDR2_DQS1

AF9

FRC_DDR3_DQSUB/DDR2_DQSB1

AE11

FRC_DDR3_DML/DDR2_DQ7

AF6

FRC_DDR3_DMU/DDR2_DQ11

AE6

FRC_DDR3_DQL0/DDR2_DQ6

AF11

FRC_DDR3_DQL1/DDR2_DQ0

AD6

FRC_DDR3_DQL2/DDR2_DQ1

AD12

FRC_DDR3_DQL3/DDR2_DQ2

AE5

FRC_DDR3_DQL4/DDR2_DQ4

AF12

FRC_DDR3_DQL5/DDR2_NC

AF5

FRC_DDR3_DQL6/DDR2_DQ3

AE12

FRC_DDR3_DQL7/DDR2_DQ5

AE10

FRC_DDR3_DQU0/DDR2_DQ8

AF7

FRC_DDR3_DQU1/DDR2_DQ14

AD11

FRC_DDR3_DQU2/DDR2_DQ13

AD7

FRC_DDR3_DQU3/DDR2_DQ12

AD10

GPIO0/TCON15/HSYNC/VDD_ODD

FRC_DDR3_DQU4/DDR2_DQ15

AE7

GPIO1/TCON14/VSYNC/VDD_EVEN

FRC_DDR3_DQU5/DDR2_DQ9

AF10

GPIO2/TCON7/LDE/GCLK4

FRC_DDR3_DQU6/DDR2_DQ10

AD8

GPIO3/TCON6/LCK/GCLK2

FRC_DDR3_DQU7/DDR2_DQM1

AE8

FRC_DDR3_NC/DDR2_DQM0

Y11

FRC_REXT

Y19

FRC_TESTPIN

& MS10 :Region that support MS10(ex:DTV Country)

& DD :Region that support only Dolby Digital(ex:AISA Analog/KOREA)

IC101-*5

W26

RLV3P

W25

RLV3N

U26

RLV0P

U25

RLV0N

U24

RLV1P

V26

RLV1N

V25

RLV2P

V24

RLV2N

W24

RLVCKP

Y26

RLVCKN

Y25

RLV4P

Y24

RLV4N

AC26

WPWM

AC25

OPTP/FLK2

AA26

RLV5P

AA25

RLV5N

AA24

RLV6P

AB26

RLV6N

AB25

RLV7P

AB24

RLV7N

AC24

OPTN/FLK3

AD26

FLK

AD25

GCLK6

AD24

GCLK5

AD23

LLV3P

AE23

LLV3N

AE26

LLV0P

AE25

LLV0N

AF26

LLV1P

AF25

LLV1N

AE24

LLV2P

AF24

LLV2N

AF23

LLVCKP

AD22

LLVCKN

AE22

LLV4P

AF22

LLV4N

AD19

GOE/GCLK1

AE19

GSC/GCLK3

AD21

LLV5P

AE21

LLV5N

AF21

LLV6P

AD20

LLV6N

AE20

LLV7P

AF20

LLV7N

AF19

GSPR

AD18

GSP/VST

AE18

SOE

AF18

POL

AB22

VDD_ODD

AB23

VDD_EVEN

AC23

GCLK4

AC22

GCLK2

AB16

NC_23

AA14

DPM

AC15

HCON

Y16

NC_15

AC16

NC_26

AC14

LEDON

AA16

NC_20

AA15

NC_19

Y10

NC_11

AA11

NC_17

AB15

SCAN_BLK

AB14

SCAN_BLK1

S7T_NON_DIVX & MS10

PCM_A[0-7]

PCM_A[7]

PCM_A[6]

PCM_A[5]

PCM_A[4]

PCM_A[3]

PCM_A[2]

PCM_A[1]

PCM_A[0]

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

W26

W25

U26

U25

U24

V26

V25

V24

W24

Y26

Y25

Y24

AC26

AC25

AA26

AA25

AA24

AB26

AB25

AB24

AC24

AD26

AD25

AD24

AD23

CCKP/LLV3P

AE23

CCKM/LLV3N

AE26

AE25

AF26

AF25

AE24

AF24

AF23

C3P/LLV4P

AD22

C3M/LLV4N

AE22

C4P/LLV5P

AF22

C4M/LLV5N

AD19

DCKP/TCON5

AE19

DCKM/TCON4

AD21

D0P/LLV6P

AE21

D0M/LLV6N

AF21

D1P/LLV7P

AD20

D1M/LLV7N

AE20

D2P/LLV8P

AF20

D2M/LLV8N

AF19

D3P/TCON3

AD18

D3M/TCON2

AE18

D4P/TCON1

AF18

D4M/TCON0

AB22

AB23

AC23

AC22

AB16

AA14

FRC_GPIO1

AC15

FRC_GPIO3

Y16

FRC_GPIO8

AC16

AC14

FRC_GPIO10

AA16

FRC_I2CM_DA

AA15

FRC_I2CM_CK

Y10

FRC_I2CS_DA

AA11

FRC_I2CS_CK

AB15

FRC_PWM0

AB14

FRC_PWM1

S7M_NON_DIVX & DD_SPIL

IC101-*13

LGE107BS-LF-1(SPIL)(S7M Non Divx/RM/MS10)

AE1

FRC_DDR3_A0/DDR2_NC

AF16

FRC_DDR3_A1/DDR2_A6

AF1

FRC_DDR3_A2/DDR2_A7

AE3

FRC_DDR3_A3/DDR2_A1

AD14

FRC_DDR3_A4/DDR2_CASZ

AD3

FRC_DDR3_A5/DDR2_A10

AF15

FRC_DDR3_A6/DDR2_A0

AF2

FRC_DDR3_A7/DDR2_A5

AE15

FRC_DDR3_A8/DDR2_A2

AD2

FRC_DDR3_A9/DDR2_A9

AD16

FRC_DDR3_A10/DDR2_A11

AD15

FRC_DDR3_A11/DDR2_A4

AE16

FRC_DDR3_A12/DDR2_A8

AF3

FRC_DDR3_BA0/DDR2_BA2

AF14

FRC_DDR3_BA1/DDR2_ODT

AD1

FRC_DDR3_BA2/DDR2_A12

AD13

FRC_DDR3_MCLK/DDR2_MCLK

AE14

FRC_DDR3_CKE/DDR2_RASZ

AE13

FRC_DDR3_MCLKZ/DDR2_MCLKZ

AE4

FRC_DDR3_ODT/DDR2_BA1

AD5

FRC_DDR3_RASZ/DDR2_WEZ

AF4

FRC_DDR3_CASZ/DDR2_CKE

AD4

FRC_DDR3_WEZ/DDR2_BA0

AE2

FRC_DDR3_RESETB/DDR2_A3

AF8

FRC_DDR3_DQSL/DDR2_DQS0

AD9

FRC_DDR3_DQSLB/DDR2_DQSB0

AE9

FRC_DDR3_DQSU/DDR2_DQS1

AF9

FRC_DDR3_DQSUB/DDR2_DQSB1

AE11

FRC_DDR3_DML/DDR2_DQ7

AF6

FRC_DDR3_DMU/DDR2_DQ11

AE6

FRC_DDR3_DQL0/DDR2_DQ6

AF11

FRC_DDR3_DQL1/DDR2_DQ0

AD6

FRC_DDR3_DQL2/DDR2_DQ1

AD12

FRC_DDR3_DQL3/DDR2_DQ2

AE5

FRC_DDR3_DQL4/DDR2_DQ4

AF12

FRC_DDR3_DQL5/DDR2_NC

AF5

FRC_DDR3_DQL6/DDR2_DQ3

AE12

FRC_DDR3_DQL7/DDR2_DQ5

AE10

FRC_DDR3_DQU0/DDR2_DQ8

AF7

FRC_DDR3_DQU1/DDR2_DQ14

AD11

FRC_DDR3_DQU2/DDR2_DQ13

AD7

FRC_DDR3_DQU3/DDR2_DQ12

AD10

FRC_DDR3_DQU4/DDR2_DQ15

AE7

FRC_DDR3_DQU5/DDR2_DQ9

AF10

FRC_DDR3_DQU6/DDR2_DQ10

AD8

FRC_DDR3_DQU7/DDR2_DQM1

AE8

FRC_DDR3_NC/DDR2_DQM0

Y11

FRC_REXT

Y19

FRC_TESTPIN

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

GPIO0/TCON15/HSYNC/VDD_ODD

GPIO1/TCON14/VSYNC/VDD_EVEN

GPIO2/TCON7/LDE/GCLK4

GPIO3/TCON6/LCK/GCLK2

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

W26

W25

U26

U25

U24

V26

V25

V24

W24

Y26

Y25

Y24

AC26

AC25

AA26

AA25

AA24

AB26

AB25

AB24

AC24

AD26

AD25

AD24

AD23

CCKP/LLV3P

AE23

CCKM/LLV3N

AE26

AE25

AF26

AF25

AE24

AF24

AF23

C3P/LLV4P

AD22

C3M/LLV4N

AE22

C4P/LLV5P

AF22

C4M/LLV5N

AD19

DCKP/TCON5

AE19

DCKM/TCON4

AD21

D0P/LLV6P

AE21

D0M/LLV6N

AF21

D1P/LLV7P

AD20

D1M/LLV7N

AE20

D2P/LLV8P

AF20

D2M/LLV8N

AF19

D3P/TCON3

AD18

D3M/TCON2

AE18

D4P/TCON1

AF18

D4M/TCON0

AB22

AB23

AC23

AC22

AB16

AA14

FRC_GPIO1

AC15

FRC_GPIO3

Y16

FRC_GPIO8

AC16

AC14

FRC_GPIO10

AA16

FRC_I2CM_DA

AA15

FRC_I2CM_CK

Y10

FRC_I2CS_DA

AA11

FRC_I2CS_CK

AB15

FRC_PWM0

AB14

FRC_PWM1

S7M_DIVX & MS10_SPIL

AE1

AF16

AF1

AE3

AD14

AD3

AF15

AF2

AE15

AD2

AD16

AD15

AE16

AF3

AF14

AD1

AD13

AE14

AE13

AE4

AD5

AF4

AD4

AE2

AF8

AD9

AE9

AF9

AE11

AF6

AE6

AF11

AD6

AD12

AE5

AF12

AF5

AE12

AE10

AF7

AD11

AD7

AD10

AE7

AF10

AD8

AE8

Y11

Y19

For EMI Improvement in LED MODELS

RLV3P

RLV3N

RLV0P

RLV0N

RLV1P

RLV1N

RLV2P

RLV2N

RLVCKP

RLVCKN

RLV4P

RLV4N

WPWM

OPTP/FLK2

RLV5P

RLV5N

RLV6P

RLV6N

RLV7P

RLV7N

OPTN/FLK3

FLK

GCLK6

GCLK5

LLV3P

LLV3N

LLV0P

LLV0N

LLV1P

LLV1N

LLV2P

LLV2N

LLVCKP

LLVCKN

LLV4P

LLV4N

GOE/GCLK1

GSC/GCLK3

LLV5P

LLV5N

LLV6P

LLV6N

LLV7P

LLV7N

GSPR

GSP/VST

SOE

POL

VDD_ODD

VDD_EVEN

GCLK4

GCLK2

NC_23

DPM

HCON

NC_15

NC_26

LEDON

NC_20

NC_19

NC_11

NC_17

SCAN_BLK

SCAN_BLK1

W26

W25

U26

U25

U24

V26

V25

V24

W24

Y26

Y25

Y24

AC26

AC25

AA26

AA25

AA24

AB26

AB25

AB24

AC24

AD26

AD25

AD24

AD23

AE23

AE26

AE25

AF26

AF25

AE24

AF24

AF23

AD22

AE22

AF22

AD19

AE19

AD21

AE21

AF21

AD20

AE20

AF20

AF19

AD18

AE18

AF18

AB22

AB23

AC23

AC22

AB16

AA14

AC15

Y16

AC16

AC14

AA16

AA15

Y10

AA11

AB15

AB14

S7T_NON_DIVX & DD

IC101-*7

LGE105B-LF-1 (S7-Tcon Non_Divx/RM/MS10)

AE1

NC_43

AF16

NC_73

AF1

NC_59

AE3

NC_45

AD14

NC_40

AD3

NC_29

AF15

NC_72

AF2

NC_60

AE15

NC_57

AD2

NC_28

AD16

NC_42

AD15

NC_41

AE16

NC_58

AF3

NC_61

AF14

NC_71

AD1

NC_27

AD13

NC_39

AE14

NC_56

AE13

NC_55

AE4

NC_46

AD5

NC_31

AF4

NC_62

AD4

NC_30

AE2

NC_44

AF8

NC_66

AD9

NC_35

AE9

NC_51

AF9

NC_67

AE11

NC_53

AF6

NC_64

AE6

NC_48

AF11

NC_69

AD6

NC_32

AD12

NC_38

AE5

NC_47

AF12

NC_70

AF5

NC_63

AE12

NC_54

AE10

NC_52

AF7

NC_65

AD11

NC_37

AD7

NC_33

AD10

NC_36

AE7

NC_49

AF10

NC_68

AD8

NC_34

AE8

NC_50

Y11

NC_12

Y19

GND_105

LGE105 (S7-Tcon Non_Divx/RM)

AE1

NC_43

AF16

NC_73

AF1

NC_59

AE3

NC_45

AD14

NC_40

AD3

NC_29

AF15

NC_72

AF2

NC_60

AE15

NC_57

AD2

NC_28

AD16

NC_42

AD15

NC_41

AE16

NC_58

AF3

NC_61

AF14

NC_71

AD1

NC_27

AD13

NC_39

AE14

NC_56

AE13

NC_55

AE4

NC_46

AD5

NC_31

AF4

NC_62

AD4

NC_30

AE2

NC_44

AF8

NC_66

AD9

NC_35

AE9

NC_51

AF9

NC_67

AE11

NC_53

AF6

NC_64

AE6

NC_48

AF11

NC_69

AD6

NC_32

AD12

NC_38

AE5

NC_47

AF12

NC_70

AF5

NC_63

AE12

NC_54

AE10

NC_52

AF7

NC_65

AD11

NC_37

AD7

NC_33

AD10

NC_36

AE7

NC_49

AF10

NC_68

AD8

NC_34

AE8

NC_50

Y11

NC_12

Y19

GND_105

IC101-*6

<T3 CHIP Config(AUD_LRCH)>

Boot from SPI flash : 1’b0

Boot from NOR flash : 1’b1

<T3 CHIP Config>

(AUD_SCK, AUD_MASTER_CLK, PWM1, PWM0)

MIPS_no_EJ_NOR8 : 4’h3 (MIPS as host. No EJ PAD. Byte mode NAND flash.)

MIPS_EJ1_NOR8 : 4’h4 (MIPS as host. EJ use PAD1. Byte mode NAND flash.)

MIPS_EJ2_NOR8 : 4’h5 (MIPS as host. EJ use PAD2. Byte mode NAND flash.)

B51_Secure_no scramble : 4’hb (8051 as host. Internal SPI flash secure boot, no scramble)

B51_Sesure_scramble : 4’hc (8051 as host. Internal SPI flash secure boot with scarmble)

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

GPIO0/TCON15/HSYNC/VDD_ODD

GPIO1/TCON14/VSYNC/VDD_EVEN

GPIO2/TCON7/LDE/GCLK4

GPIO3/TCON6/LCK/GCLK2

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

CCKP/LLV3P

CCKM/LLV3N

C3P/LLV4P

C3M/LLV4N

C4P/LLV5P

C4M/LLV5N

DCKP/TCON5

DCKM/TCON4

D0P/LLV6P

D0M/LLV6N

D1P/LLV7P

D1M/LLV7N

D2P/LLV8P

D2M/LLV8N

D3P/TCON3

D3M/TCON2

D4P/TCON1

D4M/TCON0

FRC_GPIO1

FRC_GPIO3

FRC_GPIO8

FRC_GPIO10

FRC_I2CM_DA

FRC_I2CM_CK

FRC_I2CS_DA

FRC_I2CS_CK

FRC_PWM0

FRC_PWM1

S7M_DIVX & DD_SPIL

LGE107DBS-LF-1 (S7M Divx_Non RM/MS10)

W26

AE1

W25

AF16

U26

AF1

U25

AE3

U24

AD14

V26

AD3

V25

AF15

V24

AF2

W24

AE15

Y26

AD2

Y25

AD16

Y24

AD15

AE16

AC26

AC25

AA26

AA25

AF3

AA24

AF14

AB26

AD1

AB25

AB24

AD13

AC24

AE14

AD26

AE13

AD25

AD24

AE4

AD5

AD23

AF4

AE23

AD4

AE26

AE25

AE2

AF26

AF25

AE24

AF8

AF24

AD9

AF23

AD22

AE9

AE22

AF9

AF22

AE11

AF6

AD19

AE19

AE6

AD21

AF11

AE21

AD6

AF21

AD12

AD20

AE5

AE20

AF12

AF20

AF5

AF19

AE12

AD18

AE18

AE10

AF18

AF7

AD11

AD7

AB22

AD10

AB23

AE7

AC23

AF10

AC22

AD8

AB16

AA14

AC15

Y16

AC16

AC14

AE8

AA16

Y11

AA15

Y19

Y10

AA11

AB15

AB14

FRC_DDR3_A0/DDR2_NC

FRC_DDR3_A1/DDR2_A6

FRC_DDR3_A2/DDR2_A7

FRC_DDR3_A3/DDR2_A1

FRC_DDR3_A4/DDR2_CASZ

FRC_DDR3_A5/DDR2_A10

FRC_DDR3_A6/DDR2_A0

FRC_DDR3_A7/DDR2_A5

FRC_DDR3_A8/DDR2_A2

FRC_DDR3_A9/DDR2_A9

FRC_DDR3_A10/DDR2_A11

FRC_DDR3_A11/DDR2_A4

FRC_DDR3_A12/DDR2_A8

FRC_DDR3_BA0/DDR2_BA2

FRC_DDR3_BA1/DDR2_ODT

FRC_DDR3_BA2/DDR2_A12

FRC_DDR3_MCLK/DDR2_MCLK

FRC_DDR3_CKE/DDR2_RASZ

FRC_DDR3_MCLKZ/DDR2_MCLKZ

FRC_DDR3_ODT/DDR2_BA1

FRC_DDR3_RASZ/DDR2_WEZ

FRC_DDR3_CASZ/DDR2_CKE

FRC_DDR3_WEZ/DDR2_BA0

FRC_DDR3_RESETB/DDR2_A3

FRC_DDR3_DQSL/DDR2_DQS0

FRC_DDR3_DQSLB/DDR2_DQSB0

FRC_DDR3_DQSU/DDR2_DQS1

FRC_DDR3_DQSUB/DDR2_DQSB1

FRC_DDR3_DML/DDR2_DQ7

FRC_DDR3_DMU/DDR2_DQ11

FRC_DDR3_DQL0/DDR2_DQ6

FRC_DDR3_DQL1/DDR2_DQ0

FRC_DDR3_DQL2/DDR2_DQ1

FRC_DDR3_DQL3/DDR2_DQ2

FRC_DDR3_DQL4/DDR2_DQ4

FRC_DDR3_DQL5/DDR2_NC

FRC_DDR3_DQL6/DDR2_DQ3

FRC_DDR3_DQL7/DDR2_DQ5

FRC_DDR3_DQU0/DDR2_DQ8

FRC_DDR3_DQU1/DDR2_DQ14

FRC_DDR3_DQU2/DDR2_DQ13

FRC_DDR3_DQU3/DDR2_DQ12

FRC_DDR3_DQU4/DDR2_DQ15

FRC_DDR3_DQU5/DDR2_DQ9

FRC_DDR3_DQU6/DDR2_DQ10

FRC_DDR3_DQU7/DDR2_DQM1

FRC_DDR3_NC/DDR2_DQM0

FRC_REXT

FRC_TESTPIN

IC101-*15

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

GPIO0/TCON15/HSYNC/VDD_ODD

GPIO1/TCON14/VSYNC/VDD_EVEN

GPIO2/TCON7/LDE/GCLK4

GPIO3/TCON6/LCK/GCLK2

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

IC101-*14

LGE107DBS-LF(S7M Divx_Non RM)

FRC_DDR3_A0/DDR2_NC

FRC_DDR3_A1/DDR2_A6

FRC_DDR3_A2/DDR2_A7

FRC_DDR3_A3/DDR2_A1

FRC_DDR3_A4/DDR2_CASZ

FRC_DDR3_A5/DDR2_A10

FRC_DDR3_A6/DDR2_A0

FRC_DDR3_A7/DDR2_A5

FRC_DDR3_A8/DDR2_A2

FRC_DDR3_A9/DDR2_A9

FRC_DDR3_A10/DDR2_A11

FRC_DDR3_A11/DDR2_A4

FRC_DDR3_A12/DDR2_A8

FRC_DDR3_BA0/DDR2_BA2

FRC_DDR3_BA1/DDR2_ODT

FRC_DDR3_BA2/DDR2_A12

FRC_DDR3_MCLK/DDR2_MCLK

FRC_DDR3_CKE/DDR2_RASZ

FRC_DDR3_MCLKZ/DDR2_MCLKZ

FRC_DDR3_ODT/DDR2_BA1

FRC_DDR3_RASZ/DDR2_WEZ

FRC_DDR3_CASZ/DDR2_CKE

FRC_DDR3_WEZ/DDR2_BA0

FRC_DDR3_RESETB/DDR2_A3

FRC_DDR3_DQSL/DDR2_DQS0

FRC_DDR3_DQSLB/DDR2_DQSB0

FRC_DDR3_DQSU/DDR2_DQS1

FRC_DDR3_DQSUB/DDR2_DQSB1

FRC_DDR3_DML/DDR2_DQ7

FRC_DDR3_DMU/DDR2_DQ11

FRC_DDR3_DQL0/DDR2_DQ6

FRC_DDR3_DQL1/DDR2_DQ0

FRC_DDR3_DQL2/DDR2_DQ1

FRC_DDR3_DQL3/DDR2_DQ2

FRC_DDR3_DQL4/DDR2_DQ4

FRC_DDR3_DQL5/DDR2_NC

FRC_DDR3_DQL6/DDR2_DQ3

FRC_DDR3_DQL7/DDR2_DQ5

FRC_DDR3_DQU0/DDR2_DQ8

FRC_DDR3_DQU1/DDR2_DQ14

FRC_DDR3_DQU2/DDR2_DQ13

FRC_DDR3_DQU3/DDR2_DQ12

FRC_DDR3_DQU4/DDR2_DQ15

FRC_DDR3_DQU5/DDR2_DQ9

FRC_DDR3_DQU6/DDR2_DQ10

FRC_DDR3_DQU7/DDR2_DQM1

FRC_DDR3_NC/DDR2_DQM0

FRC_REXT

FRC_TESTPIN

+3.3V_Normal

R125

1K

R123

1K

R120

R117

1K

1K

R115

1K

OPT

R116

1K

W26

W25

U26

U25

U24

V26

V25

V24

W24

Y26

Y25

Y24

AC26

AC25

AA26

AA25

AA24

AB26

AB25

AB24

AC24

AD26

AD25

AD24

AD23

CCKP/LLV3P

AE23

CCKM/LLV3N

AE26

AE25

AF26

AF25

AE24

AF24

AF23

C3P/LLV4P

AD22

C3M/LLV4N

AE22

C4P/LLV5P

AF22

C4M/LLV5N

AD19

DCKP/TCON5

AE19

DCKM/TCON4

AD21

D0P/LLV6P

AE21

D0M/LLV6N

AF21

D1P/LLV7P

AD20

D1M/LLV7N

AE20

D2P/LLV8P

AF20

D2M/LLV8N

AF19

D3P/TCON3

AD18

D3M/TCON2

AE18

D4P/TCON1

AF18

D4M/TCON0

AB22

AB23

AC23

AC22

AB16

AA14

FRC_GPIO1

AC15

FRC_GPIO3

Y16

FRC_GPIO8

AC16

AC14

FRC_GPIO10

AA16

FRC_I2CM_DA

AA15

FRC_I2CM_CK

Y10

FRC_I2CS_DA

AA11

FRC_I2CS_CK

AB15

FRC_PWM0

AB14

FRC_PWM1

OPT

OPT

R118

R121

1K

1K

S7M_DIVX & DD

LGE107DB-LF-1 (S7M Divx_Non RM/MS10)

AE1

FRC_DDR3_A0/DDR2_NC

AF16

FRC_DDR3_A1/DDR2_A6

AF1

FRC_DDR3_A2/DDR2_A7

AE3

FRC_DDR3_A3/DDR2_A1

AD14

FRC_DDR3_A4/DDR2_CASZ

AD3

FRC_DDR3_A5/DDR2_A10

AF15

FRC_DDR3_A6/DDR2_A0

AF2

FRC_DDR3_A7/DDR2_A5

AE15

FRC_DDR3_A8/DDR2_A2

AD2

FRC_DDR3_A9/DDR2_A9

AD16

FRC_DDR3_A10/DDR2_A11

AD15

FRC_DDR3_A11/DDR2_A4

AE16

FRC_DDR3_A12/DDR2_A8

AF3

FRC_DDR3_BA0/DDR2_BA2

AF14

FRC_DDR3_BA1/DDR2_ODT

AD1

FRC_DDR3_BA2/DDR2_A12

AD13

FRC_DDR3_MCLK/DDR2_MCLK

AE14

FRC_DDR3_CKE/DDR2_RASZ

AE13

FRC_DDR3_MCLKZ/DDR2_MCLKZ

AE4

FRC_DDR3_ODT/DDR2_BA1

AD5

FRC_DDR3_RASZ/DDR2_WEZ

AF4

FRC_DDR3_CASZ/DDR2_CKE

AD4

FRC_DDR3_WEZ/DDR2_BA0

AE2

FRC_DDR3_RESETB/DDR2_A3

AF8

FRC_DDR3_DQSL/DDR2_DQS0

AD9

FRC_DDR3_DQSLB/DDR2_DQSB0

AE9

FRC_DDR3_DQSU/DDR2_DQS1

AF9

FRC_DDR3_DQSUB/DDR2_DQSB1

AE11

FRC_DDR3_DML/DDR2_DQ7

AF6

FRC_DDR3_DMU/DDR2_DQ11

AE6

FRC_DDR3_DQL0/DDR2_DQ6

AF11

FRC_DDR3_DQL1/DDR2_DQ0

AD6

FRC_DDR3_DQL2/DDR2_DQ1

AD12

FRC_DDR3_DQL3/DDR2_DQ2

AE5

FRC_DDR3_DQL4/DDR2_DQ4

AF12

FRC_DDR3_DQL5/DDR2_NC

AF5

FRC_DDR3_DQL6/DDR2_DQ3

AE12

FRC_DDR3_DQL7/DDR2_DQ5

AE10

FRC_DDR3_DQU0/DDR2_DQ8

AF7

FRC_DDR3_DQU1/DDR2_DQ14

AD11

FRC_DDR3_DQU2/DDR2_DQ13

AD7

FRC_DDR3_DQU3/DDR2_DQ12

AD10

FRC_DDR3_DQU4/DDR2_DQ15

AE7

FRC_DDR3_DQU5/DDR2_DQ9

AF10

FRC_DDR3_DQU6/DDR2_DQ10

AD8

FRC_DDR3_DQU7/DDR2_DQM1

AE8

FRC_DDR3_NC/DDR2_DQM0

Y11

FRC_REXT

Y19

FRC_TESTPIN

R124

1K

OPT

R126

IC101-*1

OPT

1K

ACKP/RLV3P/RED[3]

ACKM/RLV3N/RED[2]

A0P/RLV0P/RED[9]

A0M/RLV0N/RED[8]

A1P/RLV1P/RED[7]

A1M/RLV1N/RED[6]

A2P/RLV2P/RED[5]

A2M/RLV2N/RED[4]

A3P/RLV4P/RED[1]

A3M/RLV4N/RED[0]

A4P/RLV5P/GREEN[9]

A4M/RLV5N/GREEN[8]

BCKP/TCON13/GREEN[1]

BCKM/TCON12/GREEN[0]

B0P/RLV6P/GREEN[7]

B0M/RLV6N/GREEN[6]

B1P/RLV7P/GREEN[5]

B1M/RLV7N/GREEN[4]

B2P/RLV8P/GREEN[3]

B2M/RLV8N/GREEN[2]

B3P/TCON11/BLUE[9]

B3M/TCON10/BLUE[8]

B4P/TCON9/BLUE[7]

B4M/TCON8/BLUE[6]

C0P/LLV0P/BLUE[5]

C0M/LLV0N/BLUE[4]

C1P/LLV1P/BLUE[3]

C1M/LLV1N/BLUE[2]

C2P/LLV2P/BLUE[1]

C2M/LLV2N/BLUE[0]

GPIO0/TCON15/HSYNC/VDD_ODD

GPIO1/TCON14/VSYNC/VDD_EVEN

GPIO2/TCON7/LDE/GCLK4

GPIO3/TCON6/LCK/GCLK2

FRC_GPIO0/UART_RX

FRC_GPIO9/UART_TX

AUD_LRCH

AUD_SCK

AUD_MASTER_CLK

PWM1

PWM0

W26

W25

U26

U25

U24

V26

V25

V24

W24

Y26

Y25

Y24

AC26

AC25

AA26

AA25

AA24

AB26

AB25

AB24

AC24

AD26

AD25

AD24

AD23

CCKP/LLV3P

AE23

CCKM/LLV3N

AE26

AE25

AF26

AF25

AE24

AF24

AF23

C3P/LLV4P

AD22

C3M/LLV4N

AE22

C4P/LLV5P

AF22

C4M/LLV5N

AD19

DCKP/TCON5

AE19

DCKM/TCON4

AD21

D0P/LLV6P

AE21

D0M/LLV6N

AF21

D1P/LLV7P

AD20

D1M/LLV7N

AE20

D2P/LLV8P

AF20

D2M/LLV8N

AF19

D3P/TCON3

AD18

D3M/TCON2

AE18

D4P/TCON1

AF18

D4M/TCON0

AB22

AB23

AC23

AC22

AB16

AA14

FRC_GPIO1

AC15

FRC_GPIO3

Y16

FRC_GPIO8

AC16

AC14

FRC_GPIO10

AA16

FRC_I2CM_DA

AA15

FRC_I2CM_CK

Y10

FRC_I2CS_DA

AA11

FRC_I2CS_CK

AB15

FRC_PWM0

AB14

FRC_PWM1

for SYSTEM/HDCP

EEPROM&URSA3

S7M REVISION LIST

(Package ASEK)

S7M_R_NON_DIVX & MS10

IC101-*16

LGE107C-LF-SA (ASEK)(S7M Non Divx/RM)

W26

RLV3P

W25

RLV3N

U26

RLV0P

U25

RLV0N

U24

RLV1P

V26

RLV1N

V25

RLV2P

V24

RLV2N

W24

RLVCKP

Y26