Page 1

LG

Room

Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

Page 2

—2—

1. PREFACE

1.1 SPECIFICATIONS ..........................................3

1.2 FEATURES AND BENEFITS..........................4

1.3 CONTROL LOCATIONS.................................6

1.4 ADDITIONAL CONTROLS..............................7

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS....................................9

2.1.1 FRONT GRILLE.....................................9

2.1.2 CONTROL BOX (Half-Disassembly)....10

2.1.3 CONTROL BOX (Full-Disassembly)....10

2.2 AIR HANDLING PARTS................................11

2.2.1 HEATER ASSEMBLY AND CROSS

FLOW FAN...........................................11

2.2.2 FAN......................................................11

2.2.3 SHROUD..............................................12

2.3 ELECTRICAL PARTS...................................12

2.3.1 OUTDOOR MOTOR ............................12

2.3.2 INDOOR MOTOR ................................12

2.3.3 COMPRESSOR...................................12

2.3.4 CAPACITOR........................................12

2.3.5 POWER CORD....................................13

2.3.6 P.C.B....................................................13

2.4 REFRIGERATION CYCLE............................14

2.4.1 CONDENSER......................................14

2.4.2 EVAPORATOR....................................14

2.4.3 CAPILLARY TUBE...............................14

3.

INSTALLATION

3.1 HOW TO INSTALL THE UNIT ......................17

3.2 SUGGESTED TOOL REQUIREMENTS.......18

3.2.1 PREPARATION OF SLEEVE ..............18

3.2.2 PREPARATION OF THE FRONT

GRILLE ................................................18

3.2.3 UNIT INSTALLATION..........................19

3.3 ELECTRICAL REQUIREMENTS..................20

3.3.1

ELECTRICAL DATA (FOR 230V/208 MODEL)........

20

3.3.2 ELECTRICAL SAFETY

............................

20

4.

FERFORMANCE DATA

.................................

21

5.

TROUBLESHOOTING GUIDE

5.1 OUTSIDE DIMENSIONS...............................26

5.2 PIPING SYSTEM ..........................................26

5.3 TROUBLESHOOTING GUIDE......................27

6. SCHEMATIC DIAGRAM.....................32

7. EXPLODED VIEW..................................33

8. REPLACEMENT PARTS LIST.......34

1. PREFACE

This

SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the ROTARY SWITCH

or POWER SWITCH to OFF(O) and unplug the

power cord.

2. Observe the original lead dress.

If a short circuit is found, replace all parts which

have been overheated or damaged by the short

circuit.

3. After servicing the unit, make an insulation

resistance test to protect the customer from being

exposed to shock hazards.

1.2

INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper

between 2 pins (black and white).

2. The grounding conductor (green or green & yellow)

is to be open.

3. Measure the resistance value with an ohm meter

between the jumpered lead and each exposed

metallic part on the equipment at all the positions

(except OFF or O) of the ROTARY SWITCH.

4. The value should be over 2MΩ.

CONTENTS

Page 3

—3—

1.1 SPECIFICATIONS

LP120CEM 11800/11500 1055/1025 11.2/11.2 - - 20

Model Name Cooling(Btu/h) Cooling Watts(W) EER

Electric Heat

(Btu/h)

Electric Heat

Amps(A)

Min Circuit

Protection (Amps)

Cooling / Electric Heater

LP090HEM 9300/9000 800/775 11.6/11.6 8200/8000 3.4/3.4 11900/9900 3.2/3.5 20

LP120HEM 12100/11800 1090/1065 11.1/11.1 10900/10700 3.3/3.3 11900/9900 4.4/4.8 20

Model Name Cooling(Btu/h)

Cooling

Watts(W)

EER

Electric Cycle

Heat (Btu/h)

COP

Electric Heat

(Btu/h)

Electric Heat

Amps(A)

Min Circuit

Protection (Amps)

Cooling / Heat Pump / Electric

LP 12 0 C M 2

12 34 5 6 7 8

Digits 1,2 - LG Packaged Terminal Air Conditioner Digit 6 - Product Type

Digits 3,4 - Unit Cooling Capacity C = Air Conditoner

07 = 7,000 Btu/h H = Heat Pump

09 = 9,000 Btu/h Digit 7- Control Type

12 = 12,000 Btu/h M = Mechanical Control

15 = 15,000 Btu/h Digit 8 - Electric Heating Capacity

Digit 5 - Serial No. 2 = 2.0 kW

3 = 3.5 kW

5 = 5.0 kW

Page 4

1.2 features

Unit Features

The PTAC has many features, some of which are different than those found on conventional PTAC units. The servicer must be

familiar with these features in order to

properly service the unit.

• Highly featured Micom controls using IIR (infinite impulse response)

IIR function can make Micom controls maximize and keep the comfort conditions to sense the small changes in temperature

per second.

• Compressor Restart delay

This feature extends the overall life of compressor by preventing the short-cycling of the air-conditioner. When the

compressor restarts, LG PTAC is designed to give a minimum of three minutes to have a time of equalizing the refrigerant

pressures for optimizing cycling.

• Fan-Only Setting - High/Low

The unit provides the function of selecting the either High or Low speed for Fan-Only operation.

• Indoor Fan Speed Selections - High/Low

The unit is operated in High-Heat or Low-Heat or High Cool or Low Cool.

• Two Fan motors

The unit has two fan motors to provide the occupants with the quiet environment to enjoy the peaceful life and maximum

operating efficiency.

• LED Diagnostics

All units have this feature indicating the problem when the unit is not operating properly with easy -to-read diagnostics. For

example, 1 blink every 2 seconds indicates the compressor failure.

• Indoor Filters

The unit uses the two indoor filters easily slide in and out. The filters may be cleaned by washing and brushing without

removing the front grille.

• Rotary Compressor

The unit uses the rotary compressor for the quiet, reliable operation and prolong life.

• 2 Position Discharge Grille

The discharge grille can provide air flows upward at an angle of 40 off vertical or 80 15 degree off vertical. An angle is

changed by removing the front grille and 4screws that fasten the discharge grille to the front grille to rotate an alternate

position of the louvers.

• Indoor Room Freeze Protection

When the unit senses the room temperature falls to 40˚F below, the unit activates the fan motor and either the electric

resistance heater or the hydronic heater to prevent pipes or fixtures from freezing. This also overrides front desk control of the

unit mounted or wall mounted controls.

• Door Switch/Occupancy Sensor

The unit is capable of accommodating a field installed door switch and occupancy sensor to operate the energy management

feature. For additional information, refer to the Unit Operation section.

• Compressor Overload Protection

This feature prevents the damage of the compressor by sensing the indoor tube temperature in heating. If the indoor

temperature is over 130˚F, the outdoor fan will be switched off and on below 120˚F.

—4—

Page 5

• Outdoor Air Temperature Switchover

The unit is designed to control the electric heater interfacing with the outdoor temperature. When the outdoor temperature falls

to 20˚F below, it makes the compressor be off and the electric heater be turned on until the outdoor temperature is above

25˚F. This will effectively change the Unit from heat pump mode to total electric resistance heat.

• Temperature limits

The unit is programmed to provide both heating and cooling temperature limits by dip switches on control panel from 50˚F to

90˚F. Temperature limits help to prevent overheating and overcooling for reducing the energy costs.

• Condensate Drain Valve

The unit has the condensate drain valve that prevents water from freezing in basepan.

• Quick Heater Recovery

The unit is designed to operate the electric heater to warm the room to the temperature set point as soon as heat pump cycle

is on in heating. This feature has an advantage of reducing the time to reach the set point and improving the temperature

increase for better comfort.

• Reverse Cycle Defrosting - (PTHDs only)

The unit will activate the reverse cycle defrost When the outdoor coil temperature has remained at a cold temperature to form

the ice on the coil.This ice will reduce airflow though the coil and will also reduce the efficiency of unit. The LG PTHP will

employ an active reverse cycle defrost function to melt the ice off the outdoor coil for insuring room comfort conditions and

savings from extended operation.

• High Temperature Heat Pump Operation Protection

The compressor will be switched off to prevent damage when the heat pump is operated in high outdoor temperatures.

• Remote Thermostat Control

Each unit is built to be operated from any standard 4 or 5 wire remote-mounted thermostat, if desired. The unit has a built-in

low voltage power source which can accommodate a large variety of thermostat choices-manual, auto changeover or

programmable. A remote thermostat can also be added to any installed unit.

• Zone Sensor

Occupants enjoy ultimate comfort with consistent climate control. Attach an optional, inexpensive remote Zone Sensor, to

exactly match the functions of the PTAC without disabling any features.

—5—

Page 6

—6—

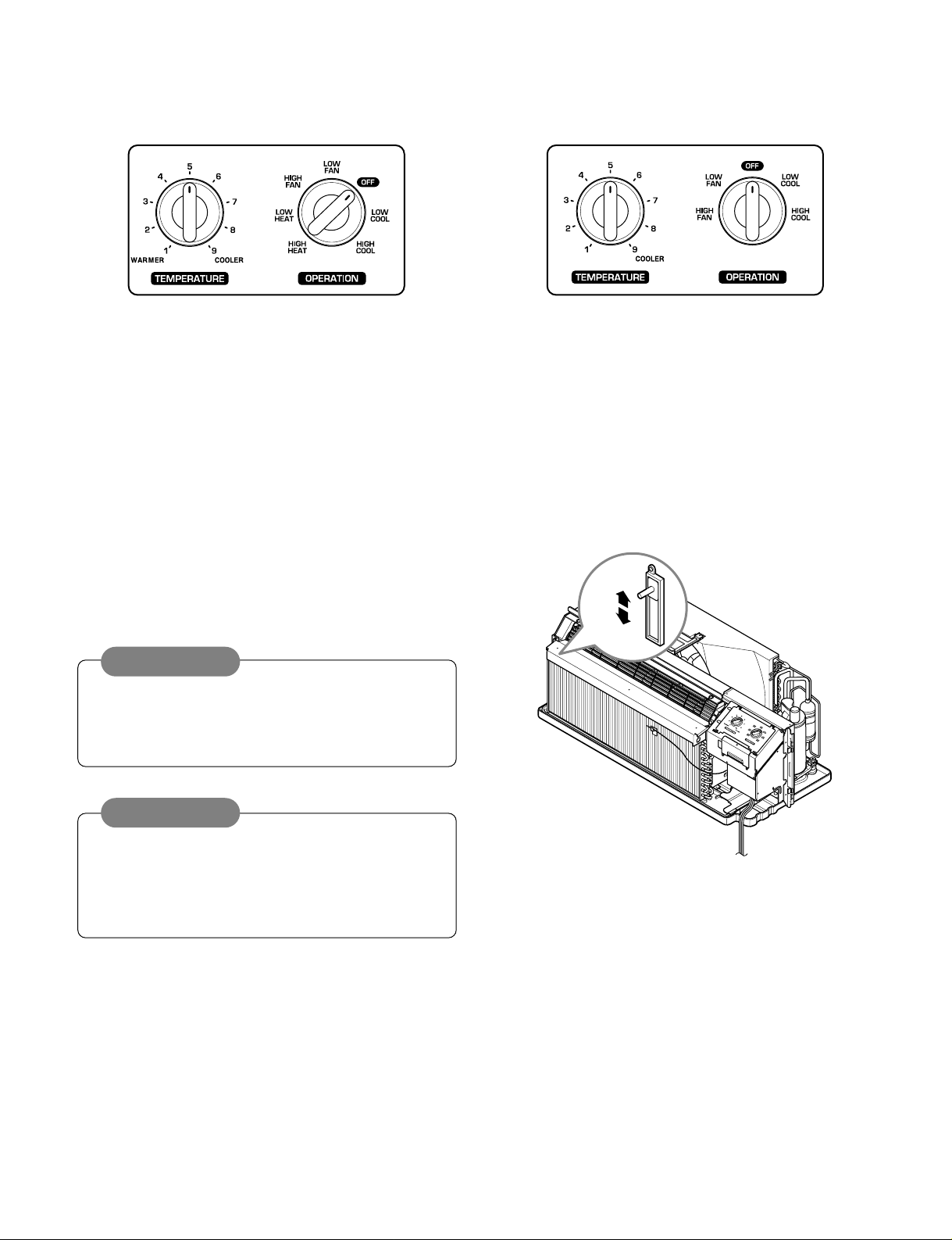

1.3 CONTROL LOCATIONS

• OPERATION

ELECTRIC HEATING MODEL COOLING ONLY MODEL

VENT

CLOSE

VENT

OPEN

TEMPERATURE CONTROL

Set the Thermostat control to the desired temperature

mark 5 (the mid-point is a good starting position). If the

room temperature is not satisfactory after a reasonable

time, adjust the control to a cooler or warmer setting, as

appropriate.

OPERATION MODE SELECTOR

OFF: Turns air conditioner off.

LOW FAN: Low speed fan operation without cooling.

HIGH FAN: High speed fan operation without cooling.

LOW COOL: Cooling with the low speed fan operation.

HIGH COOL: Cooling with the high speed fan operation.

LOW HEAT: Heating with the low speed fan operation.

HIGH HEAT: Heating with the high speed fan operation.

• VENTILATION

The ventilation lever is located to the lower left side of the unit.

The ventilation lever must be in the CLOSE position in order

to maintain the best cooling conditions.

When fresh air is necessary in the room, set the ventilation

lever to the OPEN position.

The damper is opened and outdoor air is drawn into the room.

This will reduce the cooling or heating efficiency.

When the air conditioner has performed a cooling or

heating operation and is turned off or set to the fan

position, wait at least 3 minutes before resetting to the

cooling operation.

A slight heat odor may come from the unit when first

switching to HEAT after the cooling season is over.

This odor, caused by fine dust particles on the heater, will

disappear quickly.

This is harmless.

CAUTION

NOTE

Page 7

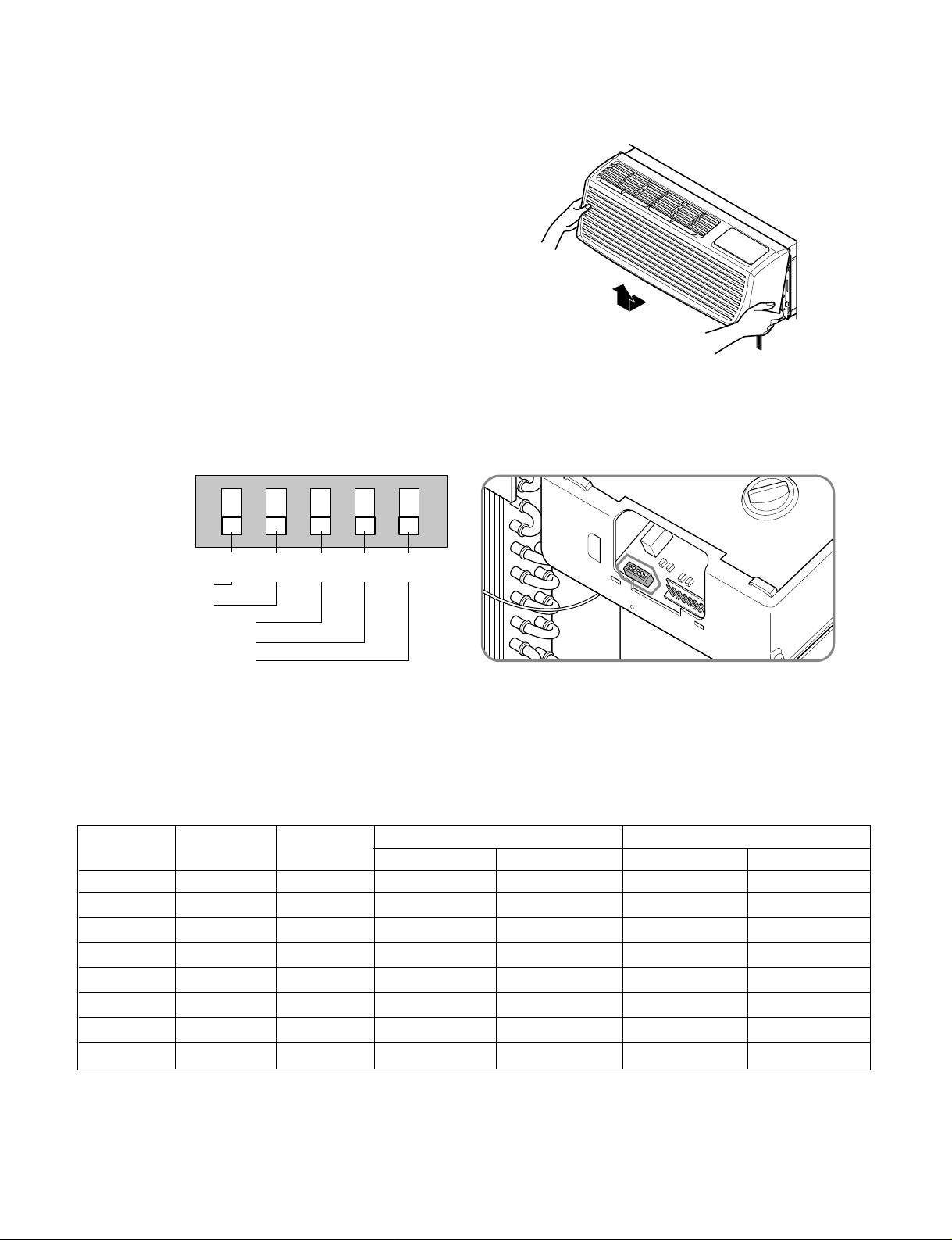

1.4 ADDITIONAL CONTROLS

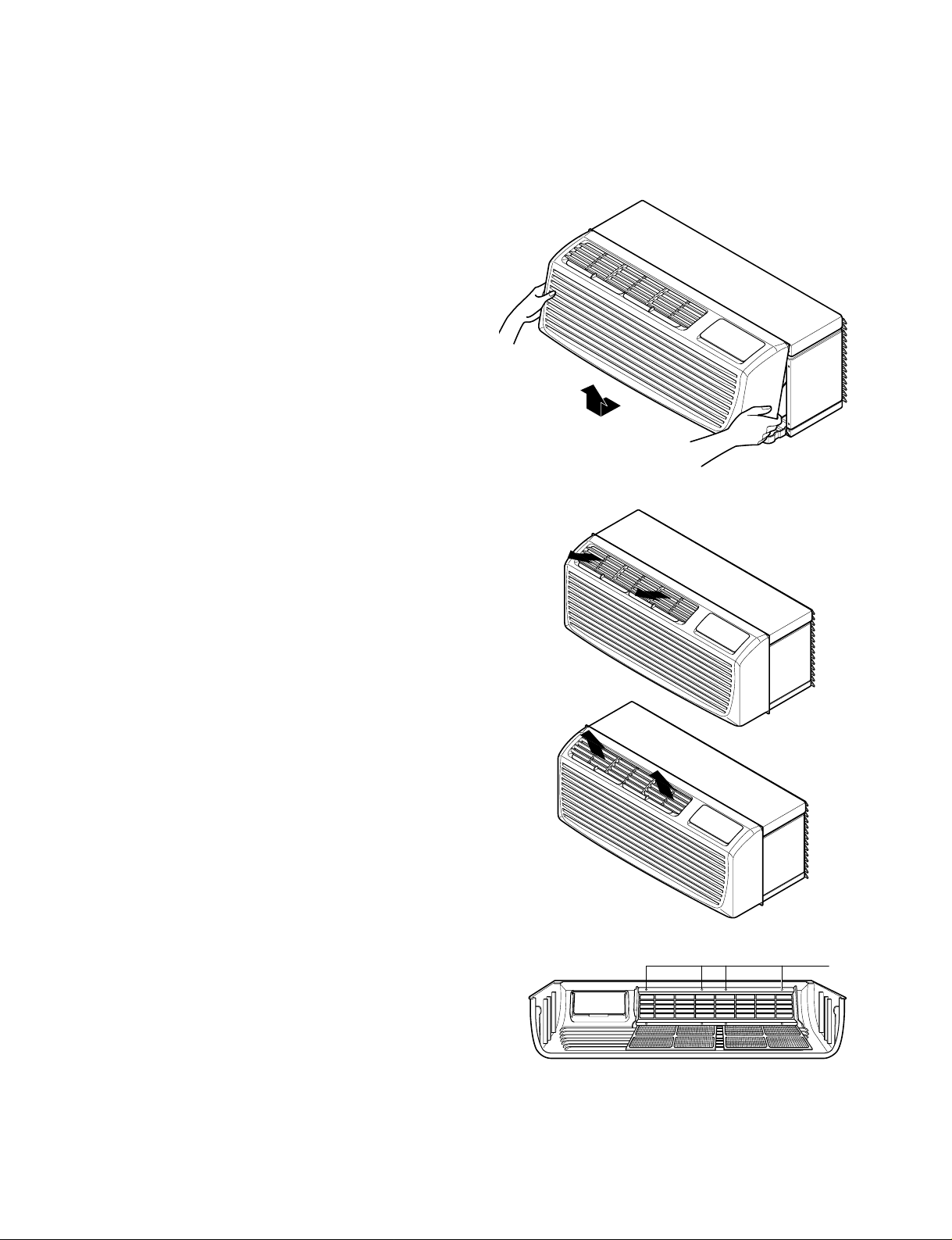

• REMOVING THE FRONT GRILLE

Additional controls are available after removing the front

grille and option cover of control box.

To remove the front grille, pull out the bottom of front

grille and then lift up.

To replace the front grille, place the tabs over the top of

the unit and push the bottom of front grille until the clips

snap into place.

• ADDITIONAL CONTROLS

The additional controls are located behind the option cover of control box. The standard settings will be in the OFF position.

The authorized service man has to check switches and ensure the switches are in the desired position.

• TEMPERATURE LIMITING

Temperature Limiting can save money by limiting the lowest temperature for cooling and the highest temperature for heating.

The temperature limiting is controlled by dip switch #1 - #3.

This temperature limiting is not available with the Remote Wall Thermostat.

—7—

ON

ONREMOTE

OFF

ON ON ON

Remote/Local

Energy Saver

Temperature Limit 1

Temperature Limit 2

Temperature Limit 3

LOCALLOCAL

1

OFF

OFF

2

OFF

OFF

3

OFF

OFF

4

OFF

OFF

5

LOCAL

1

OFF2OFF3OFF4OFF

5

LOCALLOCAL

1

OFF

OFF

2

OFF

OFF

3

OFF

OFF

4

OFF

OFF

5

LOCAL

1

OFF2OFF3OFF4OFF

5

Temperature Temperature Temperature

Limit #1 Limit #2 Limit #3

OFF OFF OFF 54°F (12.2°C) 86°F (30.0°C)

ON OFF OFF 56°F (13.3°C)

OFF ON OFF 58°F (14.4°C)

ON ON OFF 60°F (15.5°C)

OFF

ON OFF ON 64°F (17.7°C)

OFF ON ON 66°F (18.9°C) 74°F (23.3°C)

ON ON ON 68°F (20.0°C) 72°F (22.2°C)

OFF ON 62°F (16.6°C)

Cooling Operation

Heating Operation

Lowest Temp. Highest Temp. Lowest Temp. Highest Temp.

86°F (30.0°C)

86°F (30.0°C)

86°F (30.0°C)

86°F (30.0°C)

86°F (30.0°C)

86°F (30.0°C)

86°F (30.0°C)

54°F (12.2°C)

54°F (12.2°C)

54°F (12.2°C)

54°F (12.2°C)

54°F (12.2°C)

54°F (12.2°C)

54°F (12.2°C)

54°F (12.2°C)

86°F (30.0°C)

84°F (28.9°C)

82°F (27.8°C)

80°F (26.7°C)

78°F (25.5°C)

76°F (24.4°C)

Page 8

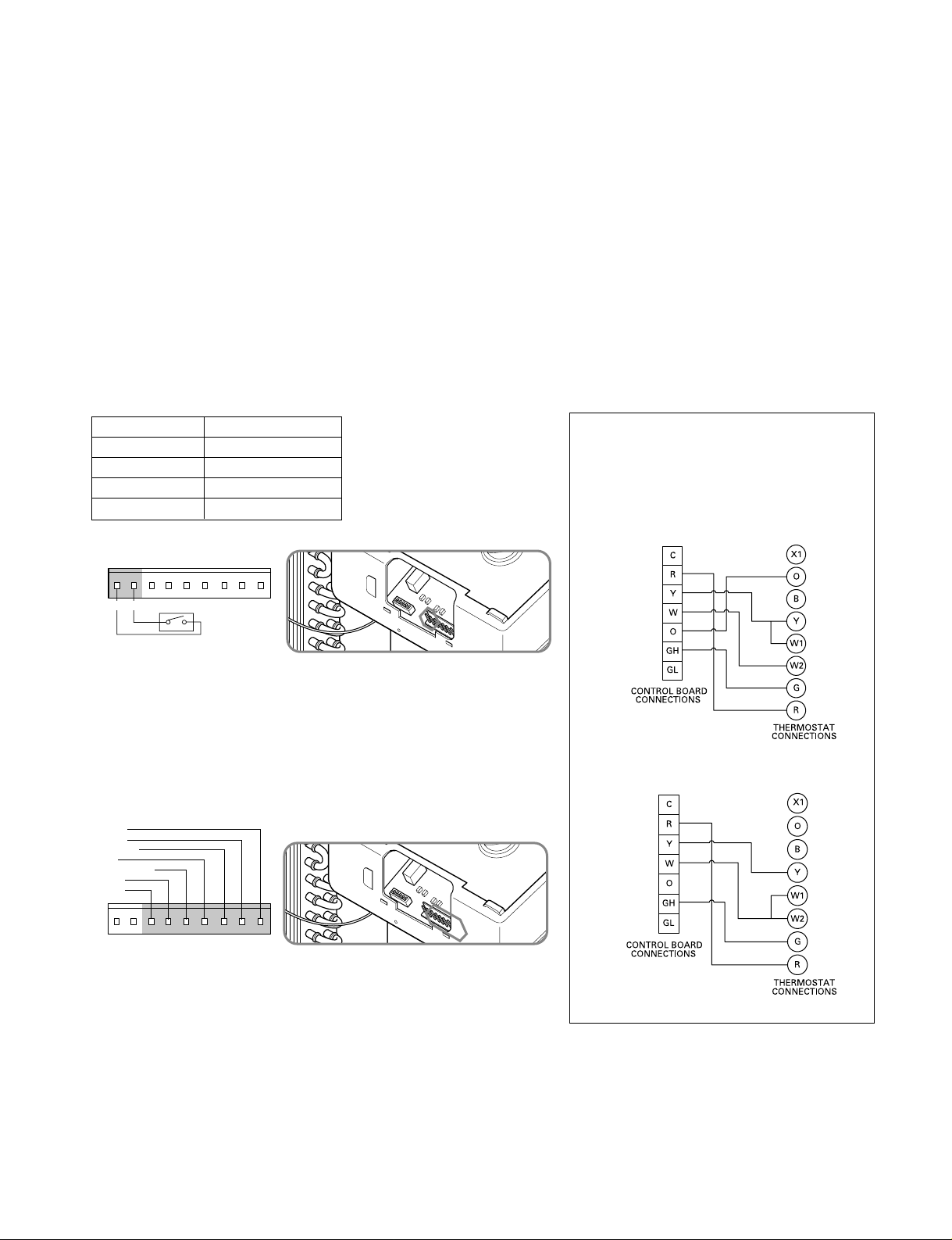

• REMOTE/LOCAL CONTROL

When remote/local switch #1 is on, it allow the unit to operate by the control of Remote Wall Thermostat.

The unit control by knobs are not available.

• ENERGY SAVER

The energy saver switch #2 is on. This switch is set at continuous fan to provide continuous fan operation in cool or heat

modes. When the switch is off the continuous fan allows continuous circulation of room air and make the more balanced

temperature of the room. When the switch is on the fan is on or off with the compressor or with the heater.

• FRONT DESK CONTROL

When the pair wire is connected to the connector LOand LI, the unit can be turned ON or OFF with a switch located at the

Front Desk Control panel. When the front desk switch is ON, the fan operate according to the condition of setting without

working compressor and heater. When the front desk switch is OFF, the unit can operate according to the setting of controls.

• REMOTE WALL THERMOSTAT

When the wires are connected, the unit will be controlled by a remote wall

thermostat.

The thermostat connections supply the 24 Volt AC. When you install the

digital / electronic thermostat, you must set it to the 24 Volt AC. See the

installation Instruction in this manual for the Remote Wall Thermostat.

—8—

GL GH O W Y R CLO LI

Front Desk Switch

LO LI GL GH O W Y R C

Low Fan

High Fan

Reversing V alve

Heater

Compressor

24 Volt-L

24 Volt-N

Wiring Schematic for

Remote Heat Pump

Wiring Schematic for

Straight Cool Unit.

Note: The following figures show wiring

schematics for heat pump and straight cool

units with electric heat, respectively.

Wire # AWG Maximum Length

#22

600ft(180m)

#20 900ft(270m)

#18 1500ft(450m)

#16 2000ft(610m)

Page 9

—9—

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Remove the front grille. (See Fig. 1)

2. To remove the front grille, pull out the bottom of

the front grille and then lift up.

Re-install the component by referring to the

removal procedure.

3. To replace the front grille, place the tabs over the

top of the unit and push the bottom of front grille

until the clips snap into place.

• This Room Air Conditioner (PTAC) discharges air

from the top of the unit through reversible, 2-position

discharge grille louvers. The unit is shipped from the

factory with the discharge grille louvers at an angle

of 40˚ off vertical. In an alternate position the louvers

will be at an angle of 15˚ off vertical.

To adjust air direction, remove the front grille.

Remove the 4 screws that fasten the discharge grille

to the front grille.

Flip the discharge grille 180°, then reattach the

discharge grille to the front grille with 4 screws.

2. DISASSEMBLY INSTRUCTIONS

— Before the following disassembly, POWER SWITCH is set to OFF and disconnected the power cord.

Figure 1

40˚

15˚

Screws

Page 10

—10—

2.1.2 CONTROL BOX (Half-Disassembly)

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the three screw which fasten the control

box. (See Fig. 2)

3. Pull the control box from the barrier. (See Fig.2)

4. Discharge the capacitor by placing a 20,000 ohm

resistor across the capacitor terminals.

5. Disconnect three wire housings in the control box.

6. Pull the control box forward completely.

7. Re-install the components by referring to the

removal procedure. (See Fig. 2)

(Refer to the circuit diagram found on page 25 in

this manual and on the control box.)

2.1.3 CONTROL BOX (Full-Disassembly)

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the 4 screws which fasten the control box

cover. (See Fig.3)

3. Disconnect three wire housings in the control box.

4. Remove three screws which fasten the control box

assembly.

5. Pull the control box assembly out from the unit.

Figure 2

Figure 3

Page 11

Figure 7

—11—

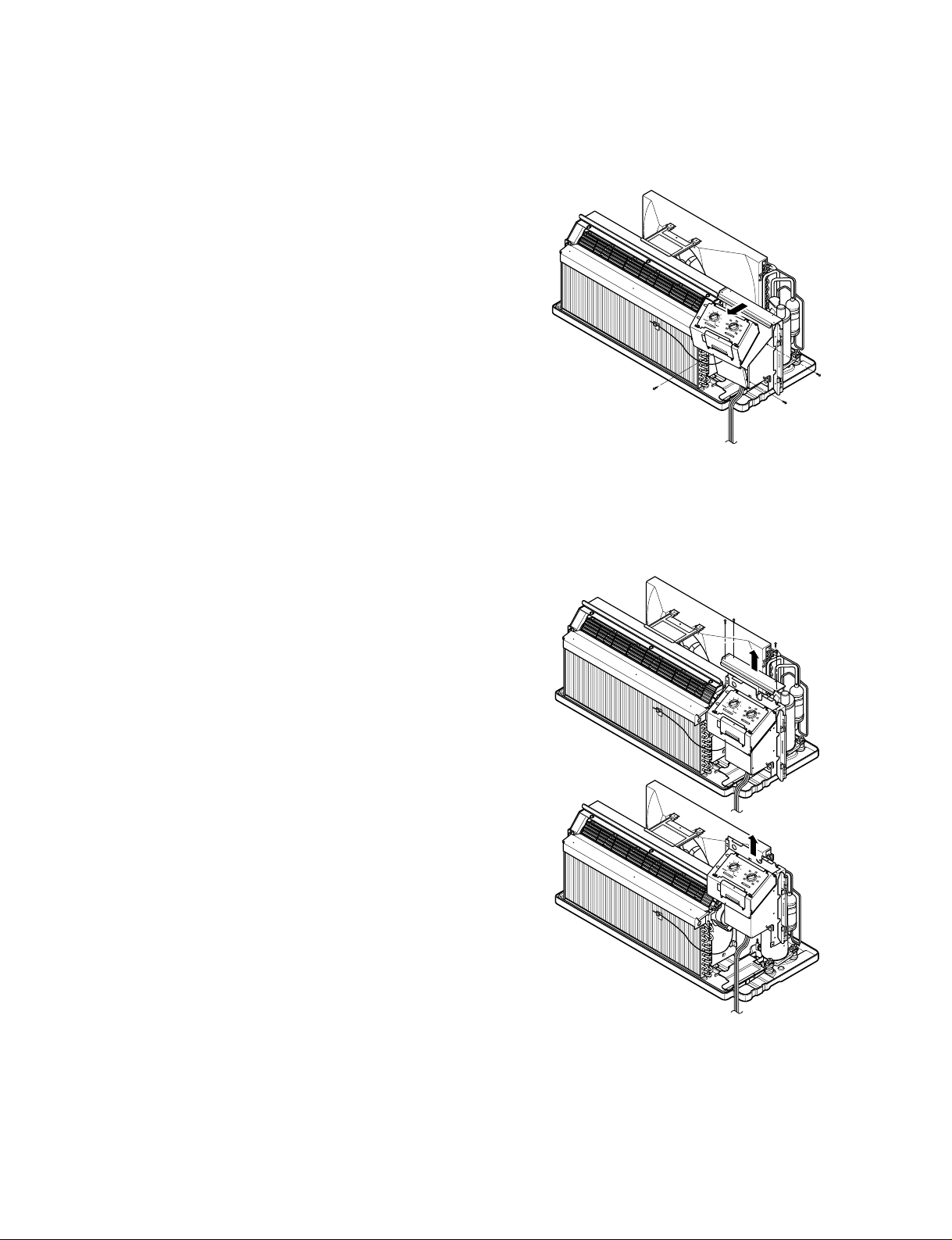

2.2 AIR HANDLING PARTS

2.2.1 HEATER ASSEMBLY AND CROSS

FLOW FAN

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the control box assembly.

(Refer to section 2.1.3)

3. Remove the 3 screws which fasten the net steel.

(See Fig. 4)

4. Remove the 3 screws which fasten the electric

heater assembly. (Electric heater model only)

(See Fig.4).

5. Loosen the hexagon screw with the Hex-wrench

(See Fig.5)

6. Remove the 4 screws which fasten the indoor

motor and the earth wire. (See Fig. 5. 6)

7. Re-install the components by referring to the

removal procedure, above.

2.2.2 FAN

1. Remove the brace.

2. Remove the 4 screws which fasten the condenser

with the shroud and the basepan.

3. Move the condenser sideways carefully.

4. Remove the clamp which secures the fan with

pliers.

5. Remove the fan. (See Fig. 7)

6. Re-install the components by referring to the

removal procedure, above.

Figure 4

Figure 5

Figure 6

Page 12

—12—

2.2.3 SHROUD

1. Remove the fan. (Refer to section 2.2.2)

2. Remove the screw which fastens the shroud.

3. Remove the shroud. (See Fig. 8)

4. Re-install the component by referring to the

removal procedure, above.

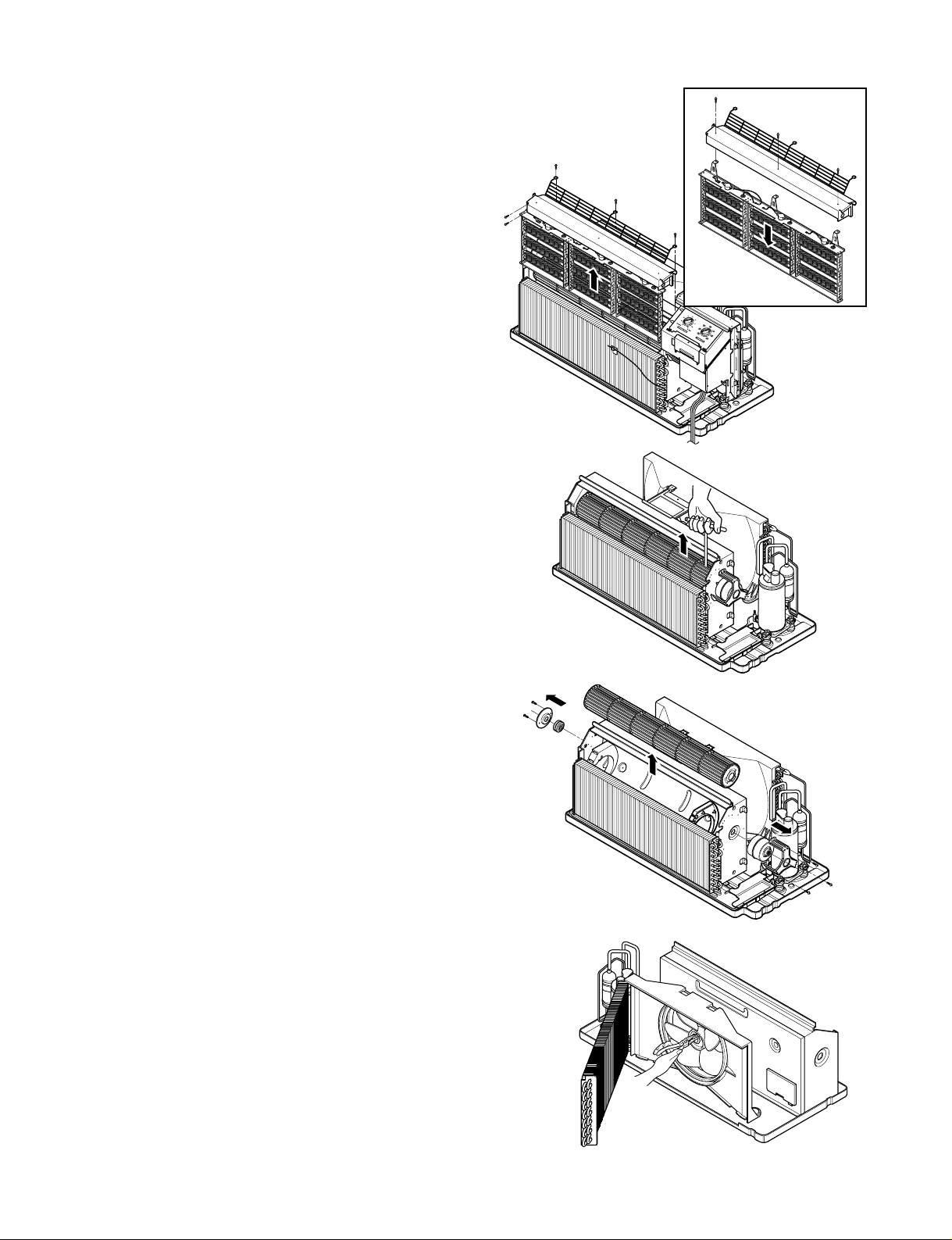

2.3 ELECTRICAL PARTS

2.3.1 OUTDOOR MOTOR

1. Remove the clamp cord and disconnect a wire

housing in control box. (Refer to section 2.1.2)

2. Remove the fan. (Refer to section 2.2.2)

3. Remove the 2 screws which fasten the motor.

(See Fig. 9)

4. Remove the motor.

5. Re-install the components by referring to the

removal procedure, above.

2.3.2 INDOOR MOTOR (Refer to section 2.2.1)

2.3.3 COMPRESSOR

1. Discharge the refrigerant system using Freon

TM

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the Freon

TM

. Leave the valve in place after

servicing the system.

2. Disconnect the 3 leads from the compressor.

3. After purging the unit completely, unbraze the

suction and discharge tubes at the compressor

connections.

4. Remove the 3 nuts and the 3 washers which

fasten the compressor. (See Fig. 10)

5. Remove the compressor.

6. Re-instill the components by referring to the

removal procedure, above.

2.3.4 CAPACITOR

1. Remove the control box. (Refer to section 2.1.2)

2. Remove 1 screw and disconnect the leads which

connected to the box type capacitor.

(See Fig. 11)

3. Remove 1 screw and the clamp which fastens the

can-type capacitor. (See Fig. 11)

4. Disconnect all the leads of capacitor terminals.

5. Re-install the components by referring to the

removal procedure, above.

Figure 8

Figure 9

Figure 10

Figure 11

Page 13

—13—

2.3.5 POWER CORD

1. Remove the control box. (Refer to section 2.1.2)

2. Disconnect the grounding screw from the control

box.

3. Disconnect 2 receptacles.

4. Remove a screw which fastens the clip cord.

5. Separate the power cord from the control box.

(See Fig. 12)

6. Re-install the component by referring to the

removal procedure, above.

(Use only one ground-marked hole for ground

connection.)

7. If the supply cord of this appliance is damaged, it

must be replaced by the special cord.

(The special cord means the cord which has the

same specification marked on the supply cord

fitted to the unit.)

2.3.6 P.C.B.

1. Remove the escutcheon.

2. Remove the two knobs.

3. Remove the 2 screws which fasten P.C.B. cover.

4. Disconnect all the leads which connected to the

P.C.B.

5. Remove the two screws which fasten the P.C.B.

board.

6. Re-install the components by referring to the

removal procedure, above.

Figure 12

Figure 13

Page 14

—14—

2.4 REFRIGERATION CYCLE

2.4.1 CONDENSER

1. Remove the brace and the shroud.

(Refer to section 2.2.2)

2. Remove the 4 screws which fasten the shroud.

(Refer to section 2.2.2)

3. Push forward the shroud and remove the 2 screws

which fasten the condenser with the basepan.

4. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

5. Remove the condenser.

6. Re-install the components by referring to notes.

(See Fig. 14)

2.4.2 EVAPORATOR

1. Remove the front grille. (Refer to section 2.1.1)

2. Discharge the refrigerant completely.

3. Remove the control box assembly.

(Refer to section 2.1.2)

4. Remove the 4 screws which fasten the evaporator

at the left side and the right side.

5. Move the evaporator sideward carefully and then

unbraze the interconnecting tube at the evaporator

connectors.

6. Remove the evaporator.

7. Re-install the components by referring to notes.

(See Fig. 15)

2.4.3 CAPILLARY TUBE

1. After discharging the refrigerant completely,

unbraze the interconnecting tube at the capillary

tube.

2. Remove the capillary tube.

3. Re-install the components by referring to notes.

Figure 14

Figure 15

Discharge the refrigerant system using Freon

TM

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before

venting the Freon

TM

. Leave the valve in place

after servicing the system.

CAUTION

Figure 15

Page 15

—15—

— Replacement of the refrigeration cycle.

1. When replacing the refrigeration cycle, be sure to

discharge the refrigerant system using a Freon

TM

recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the FreonTM. Leave the valve in place after

servicing the system.

2. After discharging the unit completely, remove the

desired component, and unbraze the pinch-off

tubes.

3. Solder service valves into the pinch-off tube ports,

leaving the valves open.

4. Solder the pinch-off tubes with Service valves.

5. Evacuate as follows.

1) Connect the vacuum pump, as illustrated Fig.

16A.

2) Start the vacuum pump, slowly open manifold

valves A and B with two full turns

counterclockwise and leave the valves closed.

The vacuum pump is now pulling through valves

A and B up to valve C by means of the manifold

and entire system.

3) Operate the vacuum pump for 20 to 30 minutes,

until 600 microns of vacuum is obtained. Close

valves A and B, and observe vacuum gauge for

a few minutes. A rise in pressure would

indicate a possible leak or moisture remaining in

the system. With valves A and B closed, stop

the vacuum pump.

4) Remove the hose from the vacuum pump and

place it on the charging cylinder. See Fig. 16B.

Open valve C.

Discharge the line at the manifold connection.

5) The system is now ready for final charging.

6. Recharge as follows :

1) Refrigeration cycle systems are charged from the

High-side. If the total charge cannot be put

in the High-side, the balance will be put in the

suction line through the access valve which you

installed as the system was opened.

2)

Connect the charging cylinder as shown in Fig. 16B.

With valve C open, discharge the hose at the

manifold connection.

3) Open valve A and allow the proper charge to

enter the system. Valve B is still closed.

4) If more charge is required, the high-side will not

take it. Close valve A.

5) With the unit running, open valve B and add the

balance of the charge.

a. Do not add the liquid refrigerant to the Low-

side.

b. Watch the Low-side gauge; allow pressure to

rise to 30 lbs.

c. Turn off valve B and allow pressure to drop.

d. Repeat steps B and C until the balance of the

charge is in the system.

6) When satisfied the unit is operating correctly,

use the pinch-off tool with the unit still running

and clamp on to the pinch-off tube. Using a tube

cutter, cut the pinch-off tube about 2 inches from

the pinch-off tool. Use sil-fos solder and solder

pinch-off tube closed. Turn off the unit, allow it to

set for a while, and then test the leakage of the

pinch-off connection.

NOTES

If high vacuum equipment is used, just crack

valves A and B for a few minutes, then open

slowly with the two full turns counterclockwise.

This will keep oil from foaming and being

drawn into the vacuum pump.

CAUTION

Page 16

—16—

Equipment needed: Vacuum pump, Charging cylinder, Manifold gauge, Brazing equipment. Pinch-off tool

capable of making a vapor-proof seal, Leak detector, Tubing cutter, Hand Tools to remove components, Service

valve.

A

COMPOUND GAUGE

EVAPORATOR

(LOW PRESSURE SIDE)

COMPRESSOR

CAPILLARY TUBE

CONDENSER

(HIGH PRESSURE SIDE)

SEE INSETS

BELOW

MANIFOLD

GAUGE

B

Figure 16A-Pulling Vacuum

Figure 16B-Charging

A

B

EXTERNAL

VACUUM PUMP

LOW

B

HI

A

CHARGING

CYLINDER

C

Page 17

—17—

3. INSTALLATION

3.1 HOW TO INSTALL THE UNIT

For existing sleeve, you should measure the wall sleeve

dimensions.

You can install the new air conditioner according to these

installation instructions to achieve the best performence. All

wall sleeves used to mount the new air conditioner must be in

good structural condition and have the rear grille that securely

attaches to the sleeve or the flange of the sleeve to secure the

new air conditioner.

• To avoid vibration and noise, make sure the unit is installed

securely and firmly.

A. BEFORE ATTACHING THE FRONT

GRILLE TO THE SLEEVE, IF YOU WANT

TO PULL OUT THE FILTER UPWARD;

1. There should be no obstacle, like a fence, within 20" which

might restrict heat radiation from the condenser.

B. IF YOU WANT TO PULL OUT THE FILTER

DOWNWARD;

The grille is already designed for that way.

1. Install the unit a little obliquely outward not to leak the

condensed water into the room (about 1/2" or 1/4" bubble

with level).

2. Install the unit with its bottom portion 30~60" above the floor

level.

3. The power cord must be connected to an independent

circuit. The green wire must be grounded.

406mm

(16")

406mm

(16")

1,066mm(42")

1066mm

(42")

318mm

(12 1/2")

318mm

(12 1/2")

505mm

(20")

Over 20"

HEAT

RADIATION

WALL

WALL

INSULATION SLEEVE

INTAKE

AIR

COOLED

AIR

Level

1/4" Bubble

1/4" Bubble

of the level

• There are sharp edges that can cause serious cuts.

• When lifting the air conditioner, it is HEAVY.

Use 2 peoples to lift.

CAUTION

Dimension of air conditioner

Dimension of sleeve assembly (optional)

Page 18

—18—

3.2.1 PREPARATION OF SLEEVE

ASSEMBLE THE WALL SLEEVE

• Raise the sleeve side panels to upright position as shown on

the right.

• Place sleeve upper on top of side panels.

• Fasten the four screws as shown on the right.

• Assemble drain kit.

• Fasten this assembly to the each side of the wall sleeve as

shown on the right.

• Assemble the outdoor grille and fasten the 4 screws as

shown on the right.

3.2.2 PREPARATION OF THE FRONT GRILLE

Carefully remove shipping tape, if there is any, from the front

grille.

SCREWDRIVER(+, -), RULER, KNIFE, HAMMER, PENCIL, LEVEL

INDOOR

3.2 SUGGESTED TOOL REQUIREMENTS

SLEEVE HARDWARE

NUMBER NAME OF PARTS Q’TY

SLEEVE LOWER 1

SLEEVE UPPER 1

SCREW 4

OUTDOOR GRILLE 1

DRAIN KIT 1

12

14

R

O

O

D

N

11

I

R

O

O

D

N

I

R

O

O

D

IN

I

N

D

O

O

R

R

O

O

D

N

I

Shipping tape

Page 19

—19—

3.2.3 UNIT INSTALLATION

1. Remove the shipping screw from the ventilation door.

(See Fig. 17)

2. Remove the front gille by pulling it out at the bottom to

release it, then lift it up along the unit top front.

(See Fig. 18)

3. Slide the unit into the wall sleeve and secure with 6 screws

through the unit flange holes. (See Fig. 19)

4. Reinstall the front grille by hooking the top over the unit top,

then pushing it in at the bottom. (See Fig. 20)

Figure 17

Figure 18

Figure 19

Figure 20

Page 20

—20—

Perpendicular

20 A

Tandem

15 A

Large T andem

30 A

230/208 volt receptacle configuration

CAUTION

1. Do not use an extension cord with this unit.

2. When the unit is in the OFF position, the power supply to the

electrical controls.

3. Disconnect the power to the unit before servicing

the unit.

4. Remove the power cord from the wall receptacle.

5. Remove or turn off the protective device (fuses or circuit breaker).

Wirings including installation of the receptacle must comply with the

NEC and local codes, local regulations.

FUSE- Use a time-delay fuse or circuit breaker. Refer to the nameplate

for proper power supply requirements.

3.3.1 ELECTRICAL DATA (FOR 230/208V MODEL)

3.3.2 ELECTRICAL SAFETY

IMPORTANT GROUNDING INSTRUCTIONS

Air conditioner has a three-prong grounding plug on its power supply cord, which must be plugged into properly grounded

three-prong wall receptacle for your protection against possible shock hazard.

FUSE – Use a time-delay fuse or circuit breaker. Refer to the nameplate for proper power supply requirements.

208, 230, and 208/230 VOLT UNITS

These units are equipped with a three-prong grounding plug on the power supply cord, which must be plugged into a matching

properly grounded three-prong wall receptacle for your protection against possible shock hazard. If such an outlet is not

present, one must be installed by a qualified electrician in accordance with the National Electrical Code and local codes and

ordinances.

NOTE: DO NOT USE AN EXTENSION CORD on 208, 230, and 208/230 Volt units.

3.3 ELECTRICAL REQUIREMENTS

Page 21

4. PERFORMANCE DATA

—21—

Voltage (V)

Cooling Data

Cooling Capacity

(Btu/h)

Cooling Amps (A)

Cooling Power (W)

EER (Btuh/Watt)

Moisture Removal

(Pts/h)

Airflow

Indoor CFM (Wet)

@0.3ESP (Hi)

Indoor CFM (W

et)

@0.3ESP (Lo)

Indoor CFM (Dry)

@0.3ESP (Hi)

Indoor CFM (Dry)

@0.3ESP (Lo)

208 230

11,500

4.8

1025

11.0

LP120CEM

208 230

11,800

5.2

1055

11.0

Voltage (V)

Cooling Data

Cooling Capacity (Btu/h)

Cooling Amps (A)

Cooling Power (W)

EER (Btuh/Watt)

Moisture Removal (Pts/h)

Heat Pump Heating Data

Heating Capacity (Btu/h)

Heating Amps (A)

Heating Power (W)

COP (W/W)

Airflow

Indoor CFM (W

et)

@0.3ESP (Hi)

Indoor CFM (W

et)

@0.3ESP (Lo)

Indoor CFM (Dry)

@0.3ESP (Hi)

Indoor CFM (Dry)

@0.3ESP (Lo)

LP090HEM

208 230

9,000 9,300

3.9 3.7

775 800

11.6 11.6

3.4 3.4

8,000 8,200

3.5 3.2

690 705

LP120HEM

208 230

4.8

950

208 230

3.3

970

Air Conditioner Performance Data

Heat Pump Performance Data

11,800

5.4

12,100

5.0

1,065

11.1

1,090

11.1

3.3

10,700 10,900

4.4

3.3

240

190

260

220

3.3

270

230

290

250

3.3

330

290

350

310

3.3

300

290

320

280

3.4

310

270

330

290

3.4

340

300

360

330

Page 22

—22—

Model LP120CEM

T emperature

Outdoor

Air Return Air Total Wattage

Dry Bulb Wet Bulb

Input

Min Max

Rating Wattage 1045 1090

85 1050 1180

80 1055 1180

75 1060 1180

100 70 1055 1180

65 1050 1180

60 1045 1175

55 1030 1160

85 1000 1125

80 1005 1130

75 1005 1135

95 70 1005 1130

65 1000 1125

60 990 1120

55 980 1105

85 950 1070

80 950 1075

75 955 1080

90 70 950 1075

65 950 1070

60 940 1060

55 930 1055

85 895 1020

80 900 1020

75 905 1030

85 70 900 1020

65 895 1020

60 890 1010

55 880 1000

85 850 970

80 850 970

75 850 975

80 70 850 970

65 850 970

60 940 960

55 830

950

Cooling Wattage - Air Conditioners

Page 23

—23—

Model LP090HM* LP120HEM

T emperature

Outdoor

Air Return Air T otal W attage Total Wattage

Dry Bulb Wet Bulb Input

Input

Min Max Min Max

Rating Wattage 810 850 1120

1145

85 830 935 1120 1230

80 835 940 1125 1235

75 835 940 1130 1240

100 70 835 940 1125 1240

65 830 935 1120 1230

60 820 925 1115 1230

55 810 915 1100 1210

85 785 890 1070 1180

80 790 890 1075 1190

75 795 890 1075 1190

95 70 790 890 1075 1190

65 785 890 1070 1180

60 780 880 1060 1170

55 770 865 1050 1160

85 745 845 1020 1130

80 750 850 1025 1135

75 750 850 1025 1135

90 70 750 850 1025 1125

65 745 845 1020 1130

60 735 835 1010 1120

55 720 825 1000 1110

85 700 800 970 1080

80 705 800 975 1085

75 705 810 975 1085

85 70 705 800 975 1085

65 700 800 970 1080

60 690 790 960 1070

55 680 775 950 1060

85 655 755 920 1030

80 660 760 925 1030

75 660 760 925 1035

80 70 660 760 920 1030

65 655 755 920 1030

60 650 745 910 1020

55 635 735 900

1010

Cooling Wattage - Heat Pumps

Page 24

—24—

Cooling change of temperature - Air Conditioners

Room Air Room Air LP120CEM

Dry Wet T

emperature Across

Bulb Bulb

Indoor Coil (∆ T)

Min Max

Rating Btu/h 11700

12000

Rating CFM 300 330

85 1 5

80 9 13

90 75 18 22

70 26 30

80 5 10

75 13 18

85 70 21 25

65 29 33

75 9 13

70 15 20

80 65 23 26

60 29 33

70 10 15

65 15 20

75 60 21 25

55 26 30

65 9 13

70 60 13

17

55 18

21

Model

Room Air Room Air LP090HEM LP120HEM

Dr y Wet Temperature Across T

emperature Across

Bulb Bulb Indoor Coil (∆ T) Indoor Coil (∆

T)

Min Max Min Max

Rating Btu/h 9300 9600 12300

12600

Rating CFM 240 270 310 340

85 2 6 1 5

80 11 15 10 13

90 75 19 22 18 22

70 29 30 26 30

80 7 11 5 10

75 15 18 14 18

85 70 23 25 21 25

65 31 33 30 33

75 11 15 10 13

70 18 20 16 20

80 65 24 27 23 26

60 32 33 30 33

70 13 16 11 15

65 18 21 16 20

75 60 23 26 21 25

55 29 31 26 30

65 12 15 10 13

70 60 16 18 14

17

55 20 22 18

21

Cooling Change of Temperature - Heat Pumps

Page 25

—25—

Cooling Ampere Chart - Air Conditioners

Cond Inlet Air

Te

mperature

Rating Ampere

100

95

90

85

80

LP120CEM

Model

Amperage

Min Max

4.8 5.2

5.6 5.6

5.4 5.3

5.2 5.1

4.9 4.8

4.7 4.6

Model

Room Air Room Air LP090HEM LP120HEM

Dry Wet T emperature Across Temperature Across

Bulb Bulb Indoor Coil (∆ T)

Indoor Coil (∆ T)

Min Max Min Max

Rating Btu/h 8200 8400 10900 11200

Rating CFM 260 290 330 360

85 24 27 27 30

80 25 28 28 31

50 75 26 29 29 32

70 28 30 31 34

65 28 30 31 34

85 22 24 24 29

80 23 25 25 29

45 75 24 26 26 30

70 24 27 27 31

65 25 28 28 32

85 20 22 23 27

80 21 23 23 28

40 75 22 24 24 29

70 23 24 25 29

65 24 25 26 30

85 17 20 21 24

80 18 21 22 25

35 75 19 22 23 26

70 20 23 23 27

65 21 24 24

28

Heating Change of Temperature - Heat Pumps

Cond Inlet Air

Te

mperature

Rating Ampere

10

0

95

90

85

80

LP090HM* LP120HEM

Model

Amperage

Min Max

3.6 3.9

3.4 4.0

3.2 3.8

3.1 3.6

3.1 3.4

2.9 3.3

Model

Amperage

Min Max

4.8 5.2

5.6 5.5

5.3 5.2

5.0 5.0

4.8 4.7

4.6 4.5

Cooling Ampere Chart - Heat Pumps

Page 26

—26—

5. TROUBLESHOOTING GUIDE

5.1 OUTSIDE DIMENSIONS

1,066mm(42")

505mm(20")

406mm(16")

406mm(16")

5.2 PIPING SYSTEM

Following is a brief description of the important components and their functions in the refrigeration system.

Refer to Fig. 21 to follow the refrigeration cycle and the flow of the refrigerant in the cooling cycle.

MOTOR

COMPRESSOR

OIL

(LIQUID REFRIGERANT)

CAPILLARY TUBE

OUTSIDE COOLING

AIR FOR REFRIGERANT

PASS THROUGH

SUCTION LIME

COOL LOW PRESSURE VAPOR

COOLED

AIR

COMPLETE LIQUID

BOIL OFF POINT

LIQUID

PRESSURE

DROP

ROOM AIR HEAT LOAD

VAPOR INLET

HOT

DISCHARGED

AIR

LIQUID OUTLET

HIGH PRESSURE VAPOR

LIQUID PEFRIGERANT

LOW PRESSURE VAPOR

ROOM AIR CONDITIONER

EVAPORATOR COILS CONDENSER COILS

CYCLE OF REFRIGERATION

Figure 21

Page 27

—27—

5.3 TROUBLESHOOTING GUIDE

In general, possible trouble is classified in two causes.

The one is called Starting Failure which is caused from an electrical defect, and the other is Ineffective Air

Conditioning caused by a defect in the refrigeration circuit and improper application.

Unit is running but cooling is ineffective

Ineffective Cooling

Check of outdoor coil

(heat exchanger) & the fan

operation.

Check gas leakage.

Repair gas leak.

Replacement of unit if the

unit is beyond repair.

Satisfactory operation with

temperature difference of

inlet & outlet air ; 44.6~50˚F

Check heat load increase.

Unexpected residue

Overloaded Circuit

Check of inside gas

pressure.

Adjusting of refrigerant

charge

Malfunction of compressor

Replacement of

compressor

Check of cold air circulation

for smooth flow.

Dirty indoor coil

(Heat exchanger)

Malfunction of fan

Clogged of air filter

Obstruction at air outlet

Correct above trouble

Check clogging in

refrigeration circuit.

Repair clogging in

refrigeration circuit.

Page 28

—28—

Fails to Start

Check of circuit breaker

and fuse.

Gas leakage of feeler bulb

of thermostat

Check of control switch.

Only fan fails to start.

Improper wiring.

Defect of fan motor

capacitor.

Irregular motor resistance

( ).

Irregular motor insulation

( ).

Replacement of fan motor

Regular but fails to start

Replacement of compressor

(locking of rotor, metal)

Improper thermostat setting

Loose terminal connection.

Improper wiring

Irregular motor resistance ( )

Irregular motor insulation ( )

Replacement of compressor

(Motor damaged)

Drop of power voltage.

Check capacitor.

Replacement.

Only compressor fails to

start.

Defect of compressor

capacitor.

Check of power source.

Check of control switch

setting.

Page 29

—29——29—

COMPLAINT CAUSE REMEDY

Check voltage at outlet. Correct if none.

Check voltage to rotary switch. If none, check

power supply cord. Replace cord if circuit is open.

Check switch continuity. Refer to wiring diagram

for terminal identification. Replace switch if

defective.

Connect wire. Refer to wiring diagram for terminal

identification. Repair or replace loose terminal.

Test capacitor.

Replace if not within ±10% of manufacturer's

rating. Replace if shorted, open, or damaged.

Fan blade hitting shroud or cross flow fan hitting

scroll. Realign assembly.

Units using slinger ring condenser fans must

have 1/4to 5/16inch clearance to the base. If it is

hitting the base, shim up the bottom of the fan

motor with mounting screw(s).

Check fan motor bearings; if motor shaft will not

rotate, replace the motor.

Check voltage. See limits on this page. If not within

limits, call an electrician.

Test capacitor.

Check bearings. Does the fan blade rotate freely?

If not, replace fan motor.

Pay attention to any change from high speed to

low speed. If the speed does not change, replace

the motor.

Check grommets; if worn or missing, replace them.

If cracked, out of balance, or partially missing,

replace it.

If cracked, out of balance, or partially missing,

replace it.

Tighten it.

If knocking sounds continue when running or

loose, replace the motor. If the motor hums or

noise appears to be internal while running,

replace motor.

No power

Power supply cord

Rotary switch

Wire disconnected or

connection loose

Capacitor (Discharge

capacitor before testing.)

Will not rotate

Revolves on overload.

Grommets

Fan

Turbo fan

Loose set screw

Worn bearings

Fan motor will not run.

Fan motor runs

intermittently

Fan motor noise.

Page 30

—30—

NAME PLATE RATING MINIMUM MAXIMUM

208/230V 187V 253V

COMPLAINT CAUSE REMEDY

Check voltage. See the limits on the preceding.

page. If not within limits, call an electrician.

Check the wire connections, if loose, repair or

replace the terminal. If wires are off, refer to wiring

diagram for identification, and replace. Check wire

locations. If not per wiring diagram, correct.

Check for continuity, refer to the wiring diagram

for terminal identification. Replace the switch if

circuit is open.

Check the position of knob If not at the coldest

setting, advance the knob to this setting and

restart unit.

Check continuity of the thermostat. Replace

thermostat if circuit is open.

Check the capacitor.

Replace if not within ±10% of manufacturers

rating. Replace if shorted, open, or damaged.

Check the compressor for open circuit or

ground. If open or grounded, replace the

compressor.

Check the compressor overload, if externally

mounted. Replace if open. (If the compressor

temperature is high, remove the overload, cool it,

and retest.)

Voltage

Wiring

Rotary

Thermostat

Capacitor (Discharge

capacitor before

servicing.)

Compressor

Overload

Compressor will not run,

but fan motor runs.

ROOM AIR CONDITIONER VOLTAGE LIMITS

Page 31

—31—

COMPLAINT CAUSE

REMEDY

Check the voltage. See the limits on the preceding page. If not within limits, call an electrician.

Check overload, if externally mounted.

Replace if open. (If the compressor temperature

is high, remove the overload, cool, and retest.)

If not running, determine the cause. Replace if

required.

Remove the cabinet. inspect the interior surface

of the condenser; if restricted, clean carefully

with a vacuum cleaner (do not damage fins) or

brush. Clean the interior base before

reassembling.

If condenser fins are closed over a large area

on the coil surface, head pressures will increase,

causing the compressor to cycle. Straighten the

fins or replace the coil.

Test capacitor.

Check the terminals. If loose, repair or replace.

Check the system for a restriction.

If restricted, clean of replace.

Close if open.

Determine if the unit is properly sized for the area to

be cooled.

Check the set screw or clamp. If loose or missing,

correct. If the blower or fan is hitting air guide,

rearrange the air handling parts.

Carefully rearrange tubing not to contact,

compressor, shroud, and barrier.

Voltage

Overload

Fan motor

Condenser air flow

restriction

Condenser fins

(damaged)

Capacitor

Wiring

Refrigerating system

Air filter

Exhaust damper door

Unit undersized

Cross flow fan

Copper tubing

Compressor cycles

on overload.

Insufficient cooling or

heating

Excessive noise.

Page 32

—32—

6. SCHEMATIC DIAGRAM

HEATER ASSY

HEATER

FOR E/HEATER MODEL

INDOOR PIPE

THERMISTOR

INDOOR AIR

THERMISTOR

FDC

REMOTE

THERMOSTAT

EXTERNAL

TRANS

CF

CAPACITOR

CAPACITOR

P/NO:3854A20196A

BK RD

TB-1

TB-2

TB-3 TB-4

POWER INPUT

WH WH

RD

RD

BK BK

WH

WH(BL)

(Ribbed)

BK(BR)

(Plain)

GN(GN/YL)

BL

VR1

WARM

COOL

BL

LOW

FAN

CN-ODFH

CN-ODF

CN-ICR

CN-IDF

CN-L

CN-N

CN-COMP

RY-COMP

CN-EXT(L)

CN-EXT(N)

CN-EXT2

CN-TRANS

CN-4WAY

CN-IDFH CN-IDFLCN-ODFL CN-ICR CN-4WAY

HIGH

FAN

LOW

HEAT

LOW

COOL

HIGH

COOL

HIGH

HEAT

IN

COILINAIR

OFF

SW1

BL

RD

RD RD

OR

BR

YL YL

BR

OR

RD

BL

BL BL BR C

C

H

F

YL YL

S

R

O.L.P

COMP

BK

BK BK

BK

RD

OR(BR) OR(BR)

RD

INDOOR

FAN

MOTOR

OUTDOOR

FAN

MOTOR

GN(GN/YL)

RD

BK

BK

BK

3

RY-HEAT1

RY-HEAT2

4

3

4

FUSE

LINK

5KW

BI-METAL

THERMOSTAT

LOCATION

NO.

1

2

3

4

5

6

POWER CORD

CAPACITOR

MOTOR

THERMOSTAT

COMPRESSOR

OVERLOAD PROTECTOR

DESCRIPTION

INDOOR

OUTDOOR

BOX TYPE

CAN TYPE

Q'TY

PER SET

1

1

1

1

1

1

1

1

REMARKS

Page 33

—33—

7. EXPLODED VIEW

C

D

F

E

A B

552111

35211A

346810

152302

359011

753000

W50400

152302

135312

149410

237200

237204

238310

W0CZZ-1

W0CZZ-2

264110

263230-1

W50400

W6640

249951

268714 237200

354210

349600-1

546811

559011

W48602

149980

130411

554160

554030

135515

349600

552114

552102

552113

135500

567502

135510

147900

550140

148000

552206

263230-2

Page 34

—34—

8. REPLACEMENT PARTS LIST

PART NO.

DESCRIPTION

REMARK

LOCATION

NO

.

LP090HEM LP120CEM LP120HEM

A 249951 CONTROL BOX,ASM(INDOOR) 4995A20466U 4995A20463W 4995A20463U

264110 POWER CORD ASM 6411A20048M

268714 PCB ASM(MAIN) 6871A10082J 6871A10082C

149410 KNOB ASM 4941A30015B

237200 PANEL ASM,CONTROL 3720A20169A

237204 PANEL,SIDE 3720A20186A

238310 ESCUTCHEON 3831A30008A

263230 THERMISTOR ASM 6323A20003K

263230 THERMISTOR ASM 6323A20006A

WOCZZ CAPACITOR,DRAWING(INDOOR) 3H00660C

WOCZZ CAPACITOR,DRAWING(OUTDOOR) 6120AR2194A 6120AR2194D 6120AR2194B

W6640 TERMINAL BLOCK 3H00390A

261704 TRANSFORMER,POWER 6170A20012A

249940 CONTROL BOS ASM,SINGLE 4994A20052A

147900 BARRIER,SINGLE 4790A20033A

135510 COVER ASM(CONTROL) 3551A20062G

B 554160 COMPRESSOR SET 2520UKYK2BA 2520UKLK2BA 2520UKHK2AA

550140 ISOLATOR,COMP 4H00982E

567502 O.L.P 6750U-L014A 6750U-L061A 6750U-L039A

C 35211A TUBE ASM,SUCTION - 5211A21365A -

552114 TUBE ASM,DISCHARGE - 5211A20531A 552111 TUBE ASM,CAPILLARY - 5211A20623D 552113 TUBE ASM, CONDENSER OUT - 5211A30434A 552102 TUBE CAPILLARY,BEND - 5210A22614D -

D 147911 BARRIER ASM,INDOOR 4791A10005D 4791A10005A

346810 MOTOR ASM(INDOOR) 4681A20064E 4681A20064A

349600 MOUNT,MOTOR 4960A20026A 4960A20032A

359011 FAN ASM,CROSS FLOW 5901A10027A

349011 DAMPER ASM 4901A30002A

152302 FILTER(MECH),A/C 5230A20016A

E 135312 GRILLE ASM,FRONT 3531A10149D

152302 FILTER(MECH),A/C 5230A20021A

F 135515 COVER ASM,TOP 3551A20197P

753000 HEATER,ELECTRIC 5300A20006A

W50400 RUBBER 5040A30032A

546811 MOTOR ASM(OUTDOOR) 4681A20063E 4681A20063A

130411 BASE ASM,WELD 3041A20028B

135500 DRAIN COVER 3550A20102A

552206 DRAIN,VALVE 5220A30006A

349600 MOUNT,MOTOR 4960A20005A

149980 SHROUD 4998A20001B

559010 FAN ASM,AXIAL 5900AR1173A

W48602 CLAMP,SPRING 3H02932B

148000 BRACE 4800A20002A

354210 EVAPORATOR ASM 5421A20118A 5421A20118C 5421A20118A

554030 CONDENSER ASM 5403A20091D 5403A20076B 5403A20091D

Page 35

P/No.: 3828A20308H

May, 2006

Printed in Korea

Loading...

Loading...