LG 22LD330 Service Manual

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : LP91H

MODEL : 22LD330

22LD330-MB

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Printed in KoreaP/NO : MFL63285202 (1003-REV00)

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

SPECIFICATION....................................................................................... 3

ADJUSTMENT INSTRUCTION ................................................................ 7

TROUBLE SHOOTING........................................................................... 14

BLOCK DIAGRAM.................................................................................. 17

EXPLODED VIEW .................................................................................. 18

SVC. SHEET ...............................................................................................

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

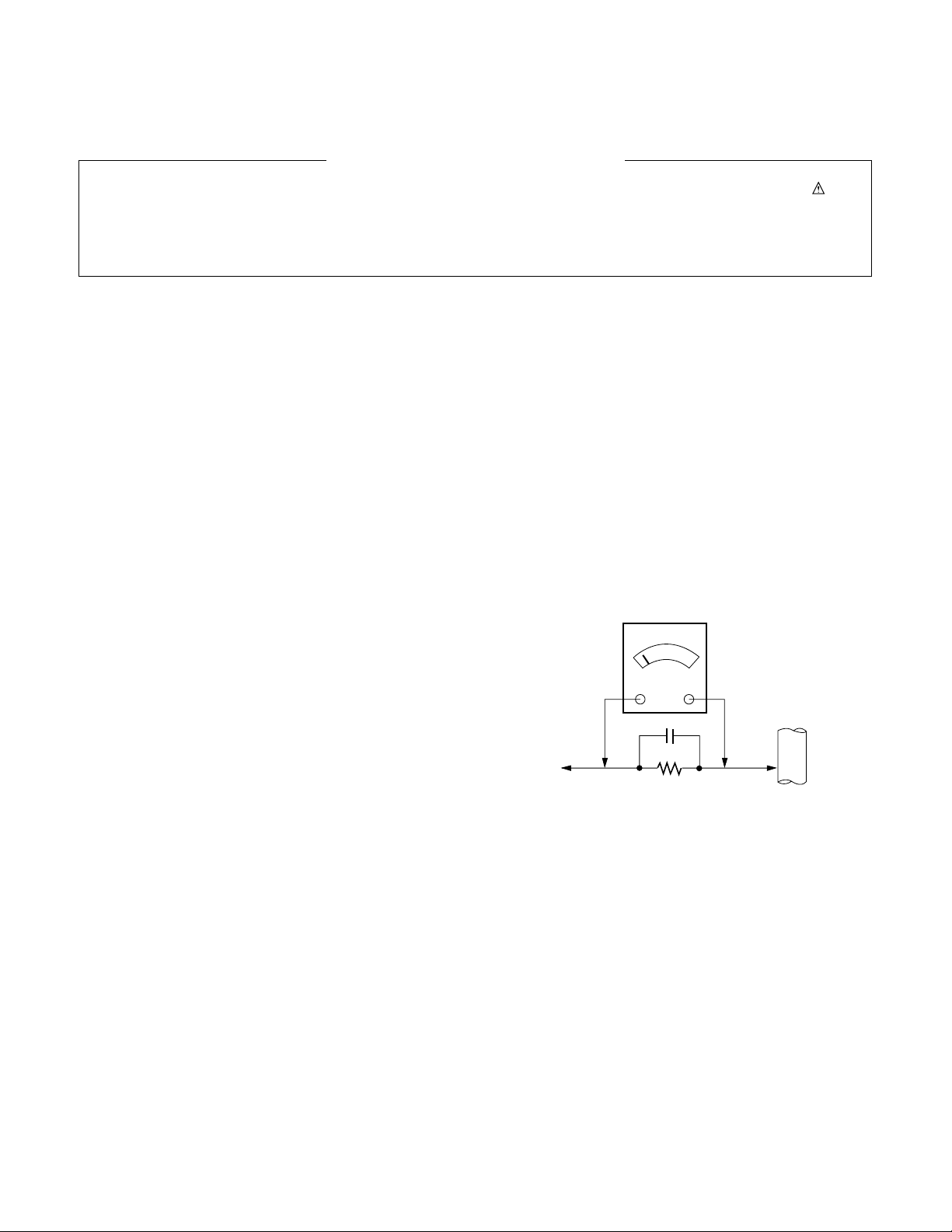

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

When 25A is impressed between Earth and 2nd Ground

for 1 second, Resistance must be less than 0.1

*Base on Adjustment standard

IMPORTANT SAFETY NOTICE

0.15 uF

Ω

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 4 -

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

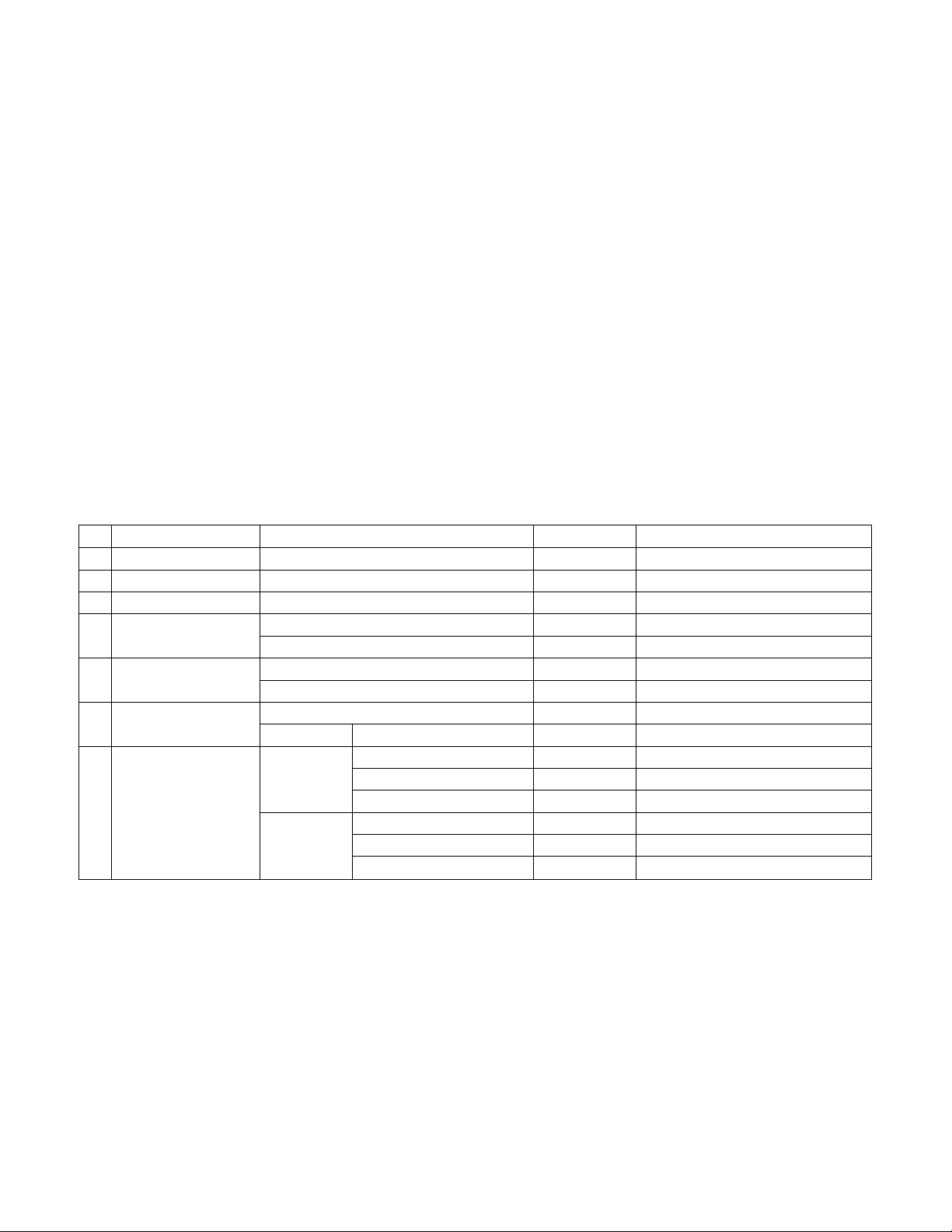

4. Electrical specification

1. Application range

This spec sheet is applied to LCD TV used LP91H chassis.

2. Specification

Each part is tested as below without special appointment.

1) Temperature : 25 ºC ± 5 ºC(77 ºF ± 9 ºF), CST : (40 ±5) ºC

2) Relative Humidity : 65 % ± 10 %

3) Power Voltage

: Standard input voltage(AC 100-240 V~ 50 / 60 Hz)

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM.

5) The receiver must be operated for about 5 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety: CE, IEC specification

- EMC : CE, IEC

No. Item Specification Measurement Remark

1 Screen Size 55 cm(22 inch) wide Color Display Module Resolution : 1366*768

2 Aspect Ratio 16:9

3 LCD Module 55 cm(22 inch) TFT WXGA LCD

4 Operating Environment Temp. : 0 deg ~ 40 deg

Humidity : 0 % ~ 85 %

5 Storage Environment Temp. : -20 ~ 60 deg

Humidity : 0 % ~ 85 %

6 Input Voltage AC 100-240 V~ 50 / 60 Hz

26.05 W HD

7 LCD Module LGD 501 x 297 x 17.3 Outline Dimension

116.5 x 349.5 Pixel Pitch

4 CCFLs Backlight assembly

CMO 481.5 x 272.5 Outline Dimension

0.1165 x 0.3495 Pixel Pitch

4 CCFL Backlight assembly

- 5 -

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

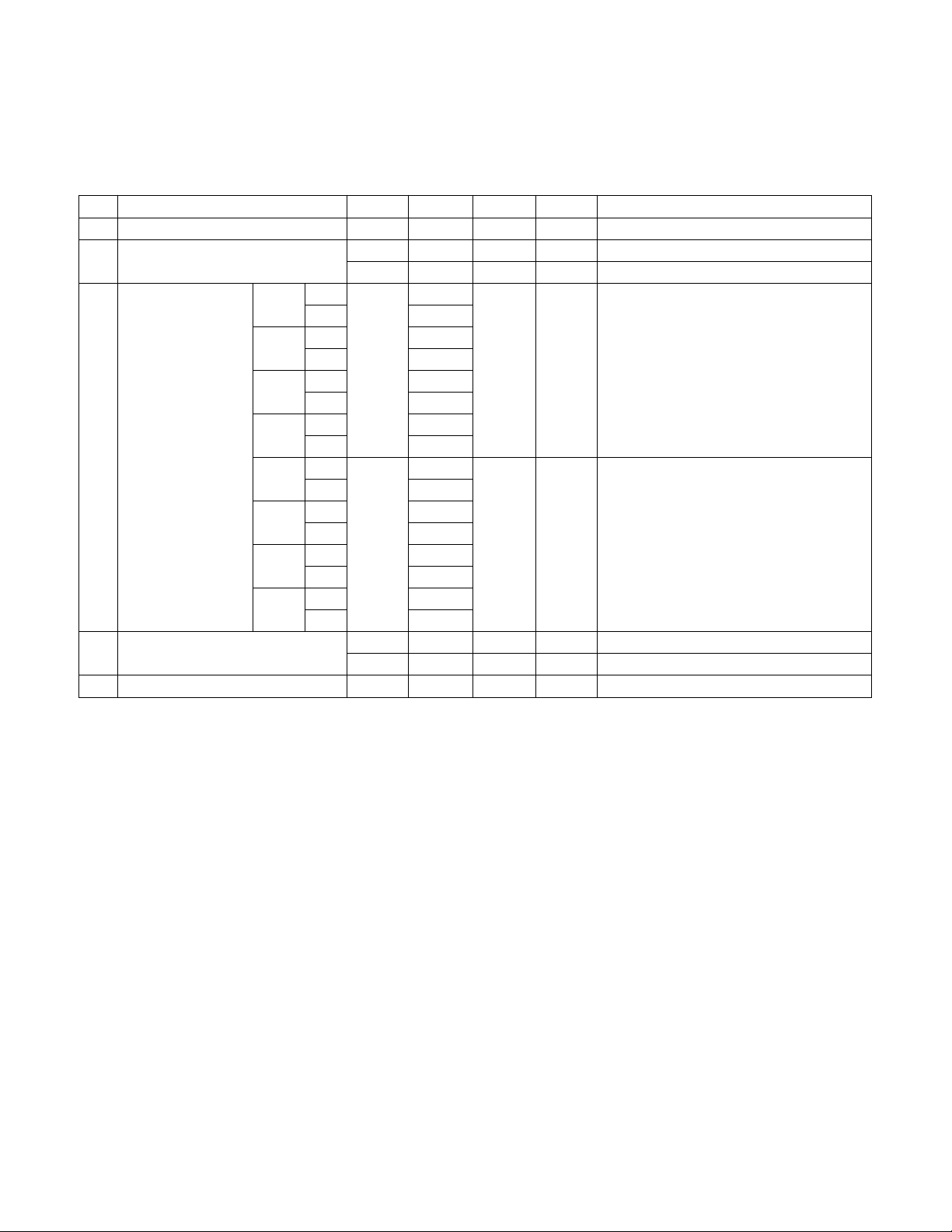

No. Item Min. Typ. Max. Unit Remark

1. Luminance (W/O PC mode) 185 250 cd/m

2

2. VIew angle (R/L, U/D) 170 / 158 degree LGD

170 / 160 CMO

3. Color Coordinates White X Typ 0.285 Typ LGD (HD)

Y -0.03 0.293 +0.03

RED X 0.642

Y 0.333

Green X 0.295

Y 0.608

Blue X 0.147

Y 0.063

White X Typ 0.285 Typ CMO (HD)

Y -0.03 0.293 +0.03

RED X 0.644

Y 0.331

Green X 0.273

Y 0.588

Blue X 0.151

Y 0.061

4. Module Contrast ratio 700 1,000 LGD

750 1,000 CMO

5. Luminance Variation 1.3

5. Chroma& Brightness (Optical)

(1) LCD Module

The Color Coordinates check condition

- 50 cm from the surface, Full White Pattern

- Picture mode Vivid

- 6 -

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

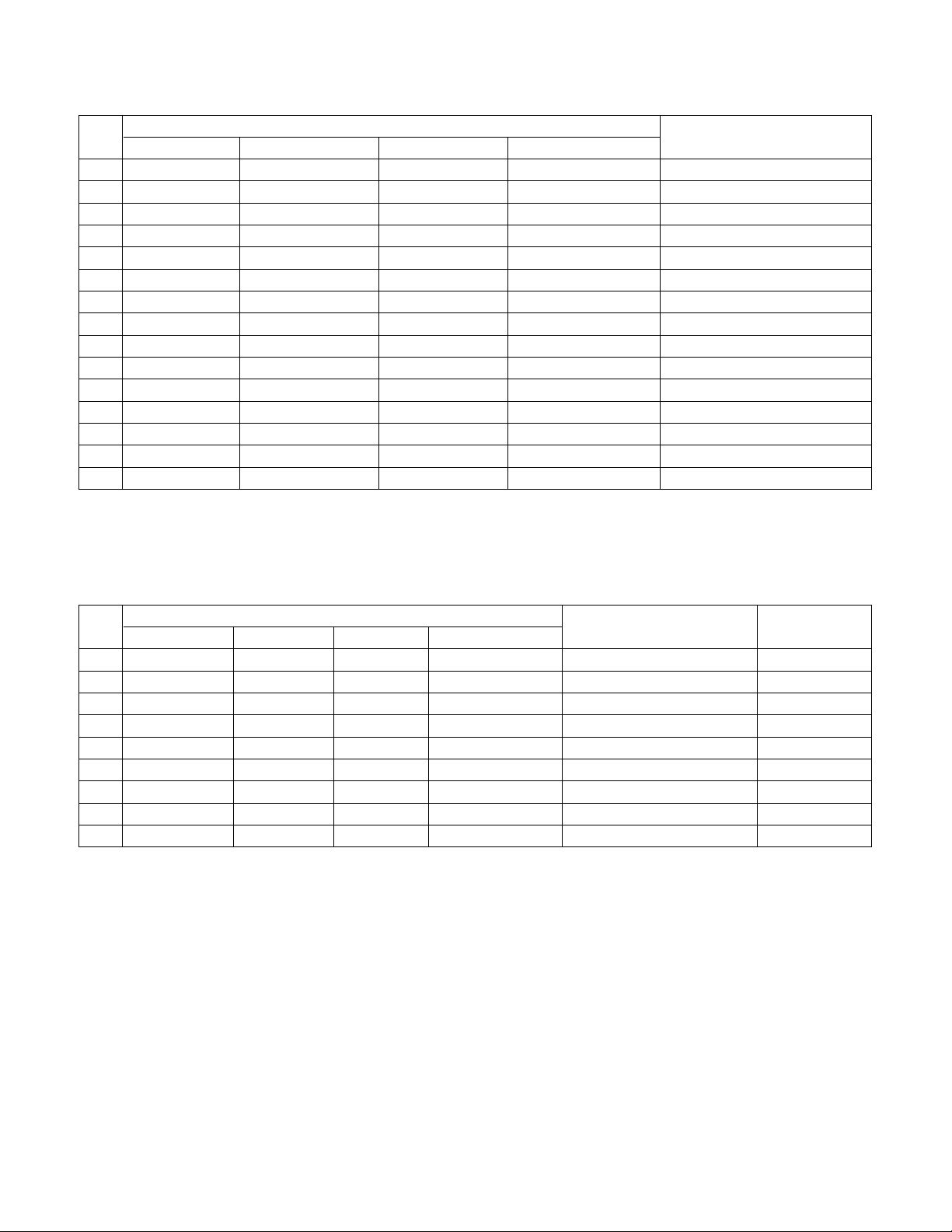

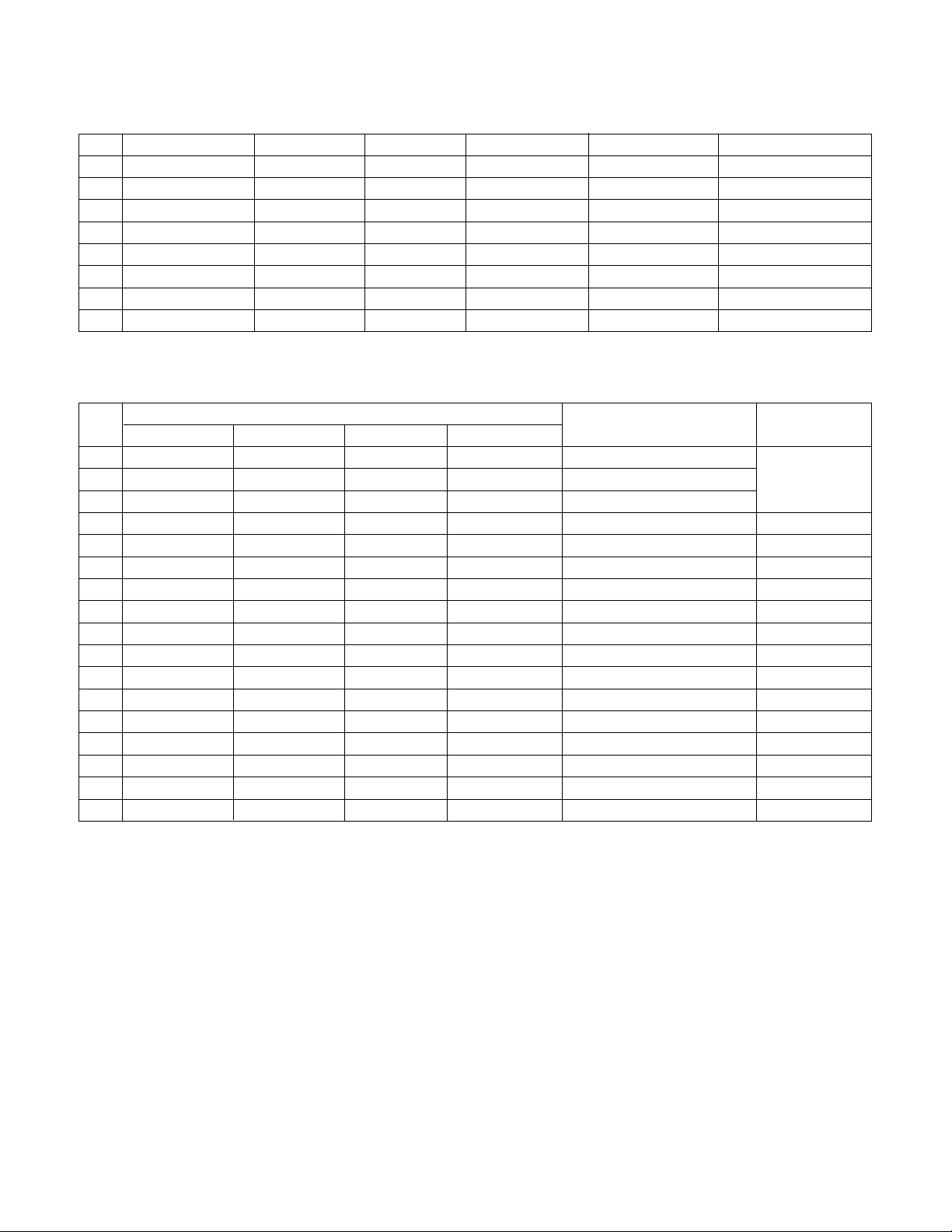

No.

Specification

Proposed Remarks

Resolution H-freq(kHz) V-freq(Hz) Pixel Clock(MHz)

1 640* 350 31.468 70.09 25.17 EGA

2 720* 400 31.469 70.09 28.32 DOS

3 640* 480 31.469 59.94 25.17 VESA( VGA)

4 800* 600 37.879 60.317 40 VESA( SVGA)

5 1024* 768 48.363 60.004 65 VESA( XGA)

6 1280* 768 47.776 59.87 79.5 VESA( WXGA)

7 1360* 768 47.72 59.799 84.75 VESA( WXGA)

8 1280* 1024 63.668 59.895 109.00 XGA Only FHD Model

9 1920* 1080 66.587 59.934 138.50 WUXGA(Reduced Blanking) Only FHD Model

7. RGB

(Analog PC, RGB-DTV - NOT SUPPORT)

6. Component Video Input (Y, PB, PR)

No.

Specification

Remarks

Resolution H-freq(kHz) V-freq(Hz) Pixel Clock(MHz)

1 720* 480 15.73 59.94 13.500 SDTV, DVD 480I( 525I)

2 720* 480 15.75 60.00 13.514 SDTV, DVD 480I( 525I)

3 720* 576 15.625 50.00 13.500 SDTV, DVD 576I( 625I) 50 Hz

4 720* 480 31.47 59.94 27.000 SDTV 480P

5 720* 480 31.50 60.00 27.027 SDTV 480P

6 720* 576 31.25 50.00 27.000 SDTV 576P 50 Hz

7 1280* 720 44.96 59.94 74.176 HDTV 720P

8 1280* 720 45.00 60.00 74.250 HDTV 720P

9 1280* 720 37.50 50.00 74.25 HDTV 720P 50 Hz

10 1920* 1080 28.125 50.00 74.250 HDTV 1080I 50 Hz,

11 1920* 1080 33.72 59.94 74.176 HDTV 1080I

12 1920* 1080 33.75 60.00 74.25 HDTV 1080I

13 1920* 1080 56.25 50 148.5 HDTV 1080P

14 1920* 1080 67.432 59.94 148.350 HDTV 1080P

15 1920* 1080 67.5 60.00 148.5 HDTV 1080P

- 7 -

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

8. HDMI Input(PC)

(PC-Spec. out but it can be shown the picture at only HDMI/ DVI IN 1 via DVI to HDMI Cable)

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed Remarks

1 640 x 480 31.469 59.94 25.17 VESA(VGA)

2 800 x 600 37.879 60.317 40.00 VESA(SVGA)

3 1024 x 768 48.363 60.004 65.00 VESA(XGA)

4 1280 x 768 47.776 59.87 79.5 VESA(WXGA)

5 1360 x 768 47.72 59.799 84.62 VESA(WXGA)

6 1366 x 768 47.7 60.00 84.62 WXGA

7 1280 x 1024 63.595 60.00 108.875 SXGA

8 1920 x 1080 66.647 59.988 138.625 WUXGA

9. HDMI Input(DTV)

No.

Specification

Proposed Remarks

Resolution H-freq(kHz) V-freq(Hz) Pixel Clock(MHz)

1 720 x 480 15.73 59.94 13.500 SDTV, DVD 480I(525I) Spec. out

2 720 x 480 15.75 60.00 13.514 SDTV, DVD 480I(525I) but display.

3 720 x 576 15.625 50.00 13.500 SDTV, DVD 576I(625I) 50 Hz

4 720 x 480 31.47 59.94 27 SDTV 480P

5 720 x 480 31.5 60.00 27.027 SDTV 480P

6 720 x 576 31.25 50.00 27 SDTV 576P

7 1280 x 720 44.96 59.94 74.176 HDTV 720P

8 1280 x 720 45 60.00 74.25 HDTV 720P

9 1280 x 720 37.5 50.00 74.25 HDTV 720P

10 1920 x 1080 28.125 50.00 74.25 HDTV 1080I

11 1920 x 1080 33.72 59.94 74.176 HDTV 1080I

12 1920 x 1080 33.75 60.00 74.25 HDTV 1080I

13 1920 x 1080 56.25 50.00 148.5 HDTV 1080P

14 1920 x 1080 67.432 59.94 148.350 HDTV 1080P

15 1920 x 1080 67.5 60.00 148.5 HDTV 1080P

16 1920 x 1080 27 24.00 74.25 HDTV 1080P

17 1920 x 1080 33.75 30.00 74.25 HDTV 1080P

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 8 -

ADJUSTMENT INSTRUCTION

1. Application Range

This specification sheet is applied to all of the LCD TV, LP91H

chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65 % ± 10 % of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep AC 100-220

V~ 50 / 60 Hz.

(5) Before adjustment, execute Heat-Run for 5 minutes at RF

no signal.

3. Adjustment items

3.1. PCB assembly adjustment items

(1) Download the MSTAR main software

(IC800, Mstar ISP Utility)

1) Using D/L Jig

2) Using USB Memory Stick.

(2) Input Tool-Option.

(3) Download the EDID

- EDID datas are automatically downloaded when adjusting

the Tool Option2

(4) ADC Calibration - RGB / Component

(4) Check SW Version.

3.2. SET assembly adjustment items

(1) Input Area option

(2) Adjustment of White Balance : Auto & Manual

(3) Input Tool-Option/Area option

(4) Intelligent Sensor Inspection Guide

(5) Preset CH information

(6) Factoring Option Data input

4. PCB assembly adjustment method

4.1. Mstar Main S/W program download

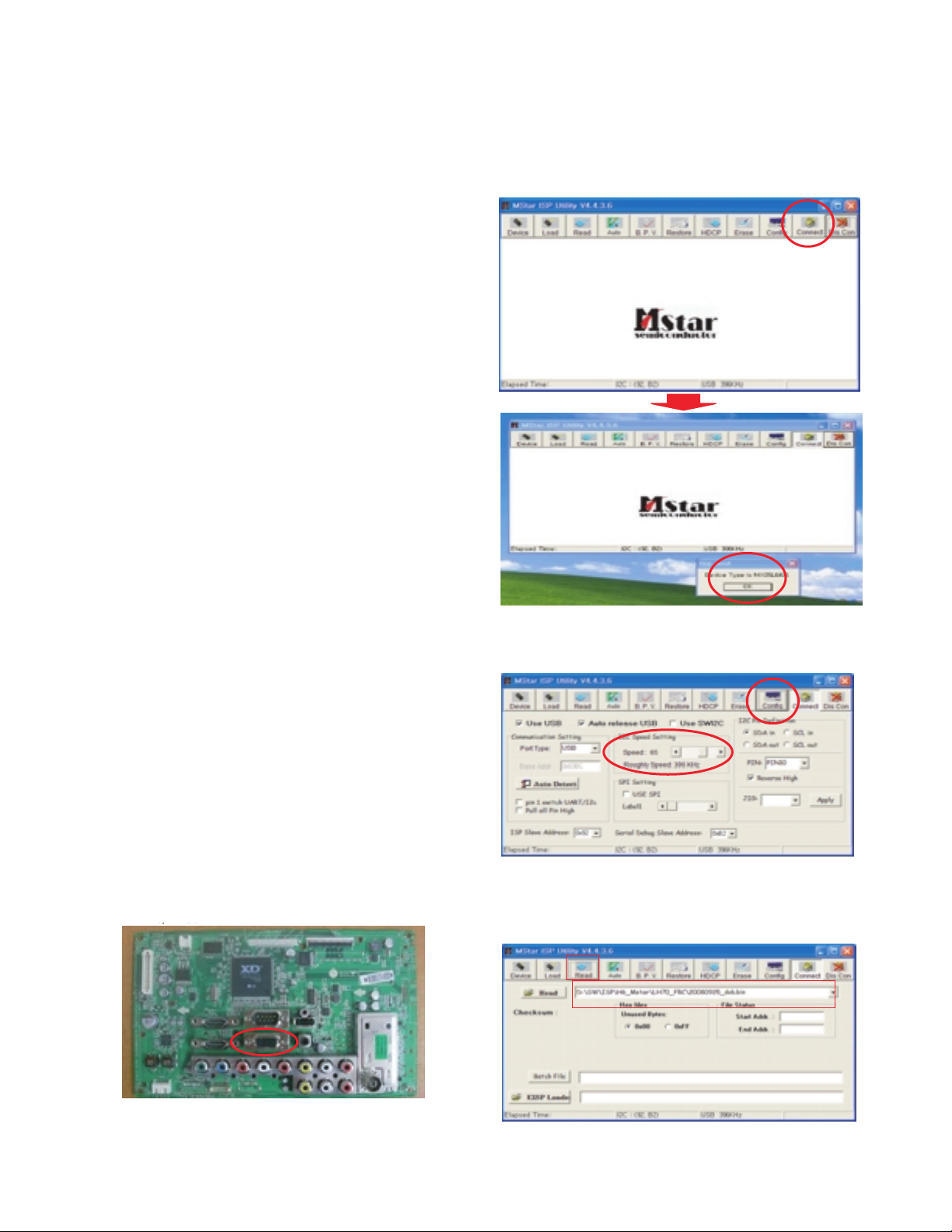

4.1.1. Using D/L Jig

(1) Preliminary steps

1) Connect the download jig to D-sub(RGB) jack.

(2) Download steps

1) Execute ‘ISP Tool’ program, the main window(Mstar ISP

utility Vx.x.x) will be opened.

2) Click the “Connect” button and confirm “Dialog Box”

3) Click the “Config.” button and Change speed I2C Speed

setting : 350 Khz ~ 400 Khz

4) Read and write bin file.

Click “(1)Read” tab, and then load download file

(XXXX.bin) by clicking “Read”.

- LH20/ LH30

1

Filexxx.bin

5) Click “(2) Auto” tab and set as below.

6) Click “(3) Run”.

7) After downloading, you can see the “(4) Pass” message.

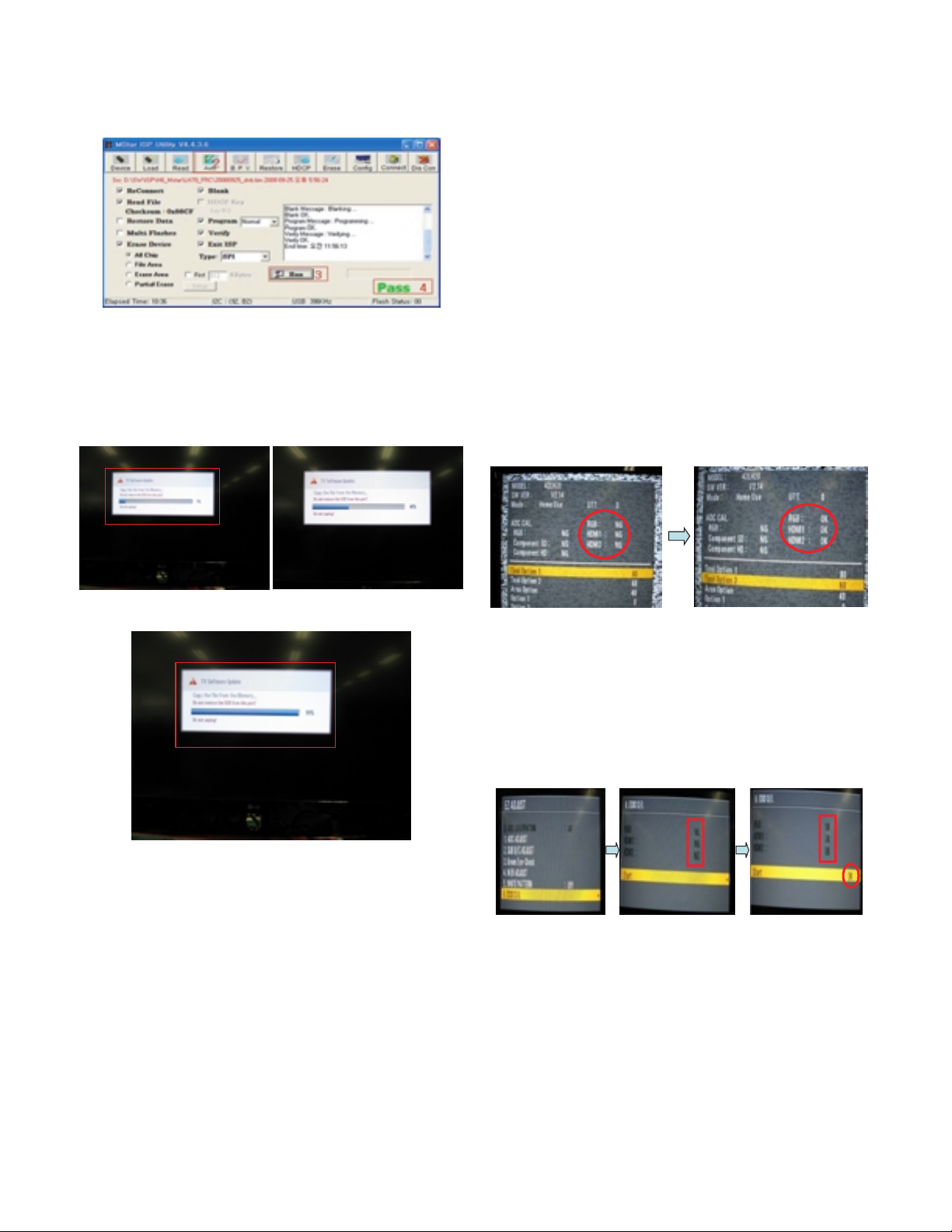

4.1.2. Using the Memory Stick

* USB download : Service Mode

1) Insert the USB memory stick to the ISB port.

2) Automatically detect the SW Version.

-> S/W download process is executed automatically.

3) Show the message “Copy the file from the Memory”.

4) After Finished the Download, Automatically DC Off -> On

5) Check The update SW Version.

4.2. Input tool option.

Adjust tool option refer to the BOM.

- Tool Option Input : PCBA Check Process

- Area Option Input : Set Assembly Process

After Input Tool Option and AC off

Before PCBA check, you have to change the Tool option and

have to AC off/on (Plug out and in)

(If missing this process, set can operate abnormally)

(1) Profile : Must be changed the option value because being

different with some setting value depend on

module maker, inch and market

(2) Equipment : adjustment remote control.

(3). Adjustment method

- The input methods are same as other chassis.(Use IN-

START Key on the Adjust Remocon.)

(If not changed the option, the input menu can differ the

model spec.)

Refer to Job Expression of each main chassis assembly

(EBTxxxxxxxx) for Option value

Caution : Don’t Press “IN-STOP” key after completing the

function inspection.

4.3. EDID D/L method

Recommend that don’t connect HDMI and RGB(D-SUB) cable

when downloading the EDID.

If not possible, recommend that connect the MSPG equipment.

There are two methods of downloading the edid data

4.3.1. 1st Method

EDID datas are automatically downloaded when adjusting the

Tool Option2.

Automatically downloaded when pushing the enter key after

adjusting the tool option2.

It takes about 2seconds.

4.3.2. 2nd Method

* Caution :

Must be checked that the tool option is right or not.

If tool option is wrong, hdmi edid data could not be

downloaded well.

1) Press the ADJ key

2) Move to the EDID D/L and Press the right direction key(

G).

3) Press the right direction key(

G) at Start.

4) After about a few seconds, appear “OK”, then compete.

4.3.3. RS-232C command Method

(1) Command : AE 00 10

* Caution

Don’t connect HDMI and RGB(D-SUB) cable when

downloading the EDID.

If the cables are connected, Downloading of edid could be

failed.

- 9 -

LGE Internal Use OnlyCopyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1

Filexxx.bin

Loading...

Loading...