LG 21SA1RL Schematic

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : CW81B

MODEL : 21SA1RL/RG/RLX

MODEL :

21SA1RL/RG/RLX-L4

North/ Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Aug., 2009

Printed in ChinaP/NO : MFL42466416

Internal Use Only

- 2 -

Copyright©2009 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

CONTENTS

SAFETY PRECAUTIONS ...........................................................................................................................................................................3

ADJUSTMENT INSTRUCTIONS ................................................................................................................................................................4

TROUBLE SHOOTING..............................................................................................................................................................................12

EXPLODED VIEW.....................................................................................................................................................................................16

SCHEMATIC DIAGRAM ...............................................................................................................................................................................

PRINTED CIRCUIT BOARD..........................................................................................................................................................................

BLOCK DIAGRAM.........................................................................................................................................................................................

SPECIFICATIONS

POWER INPUT ....................................................................................................................................................... AC100-240V~50/60Hz

POWER CONSUMPTION ....................................................................................................................................................................85W

ANTENNA INPUT IMPEDANCE .....................................................................................................................VHF/UHF 75 ohm Balanced

CHANNEL RANGE

VHF .................................................................................................................................................................................................. 2-13

UHF ................................................................................................................................................................................................. 14-69

CATV(125) .................................................................................................................................................................01, 02

¡› 13, 14¡› 125

INTERMEDIATE FREQUENCIES

Picture I-F carrier frequency........................................................................................................................................................45.75MHz

Sound I-F carrier frequency ......................................................................................................................................................41.25 MHz

Color Sub-carrier frequency ..................................................................................................................................................... 42.17 MHz

Center frequency ............................................................................................................................................................................44 MHz

CHASSIS CONSTRUCTION ..................................................................................................................................... IC-Solid state chassis

PICTURE TUBE ....................................................................................................................................... Type No. : A51QGV991X001(D)

SOUND OUTPUT .................................................................................................................................................................... 7W or 10W

CABINET ........................................................................................................................................................................................... Plastic

ABBREVIATIONS: Used in this book

ADJ ...............................................................Adjustment or Adjust

AFC .................................................Automatic Frequency Control

AGC.......................................................... Automatic Gain Control

AMP .................................................................................Amplifier

CRT .................................................................Cathode Ray Tube

DEF ............................................................................... Deflection

DET.................................................................................. Detector

FBT............................................................... Flyback Transformer

H.V............................................................................ High Voltage

OSC................................................................................ Oscillator

SEP................................................................................ Separator

SYNC................................................................... Synchronization

S.I.F.............................................. Sound Intermediate Frequency

V.I.F ...............................................Video Intermediate Frequency

H ....................................................................................Horizontal

V ........................................................................................Vertical

IC ......................................................................Intergrated Circuit

OSD .................................................................On-Screen Display

SAP ......................................................... Second Audio Program

BPF .....................................................................Band Pass Filter

ST ...................................................................................... Stereo

LPF .......................................................................Low Pass Filter

DP .................................................................... Differential Phase

DG .....................................................................Differential Group

PLL ................................................................ Phase Locked Loop

APC ......................................................Automatic Picture Control

BM ....................................................................................B+ Main

BT .................................................................................B+ Tuning

- 3 -

Copyright©2009 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

SAFETY PRECAUTIONS

1. Before returning an instrument to the customer, always make a safety

check of the entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are defective and/or have

been defeated during servicing. (1) Protective shields are provided on

this chassis to protect both the technician and the customer. Correctly

replace all missing protective shields, including any removed for

servicing convenience. (2) When reinstalling the chassis and/or other

assemblies in the cabinet, be sure to put back in place all protective

devices, including, but not limited to, nonmetallic control knobs,

insulating fishpapers, adjustment and compartment covers/shields, and

isolation resistor/capacitor networks.

Do not operate this instrument

or permit it to be operated without all protective devices correctly

installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or

child might be able to insert their fingers and contact a hazardous

voltage. Such openings include, but are not limited to, (1) spacing

between the picture tube and the cabinet back, (2) excessively wide

cabinet ventilation slots, and (3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check-With the instrument AC plug removed from any

AC source, connect an electrical jumper across the two AC plug prongs.

Place the instrument AC switch in the on position. Connect one lead of

an ohmmeter to the AC plug prongs tied together and touch the other

ohmmeter lead in turn to each tuner antenna input exposed terminal

screw and, if applicable, to the coaxial connector. If the measured

resistance is less than 1.0 megohm or greater than 5.2 megohm, an

abnormality exists that must be corrected before the instrument is

returned to the customer. Repeat this test with the instrument AC

switch in the off position.

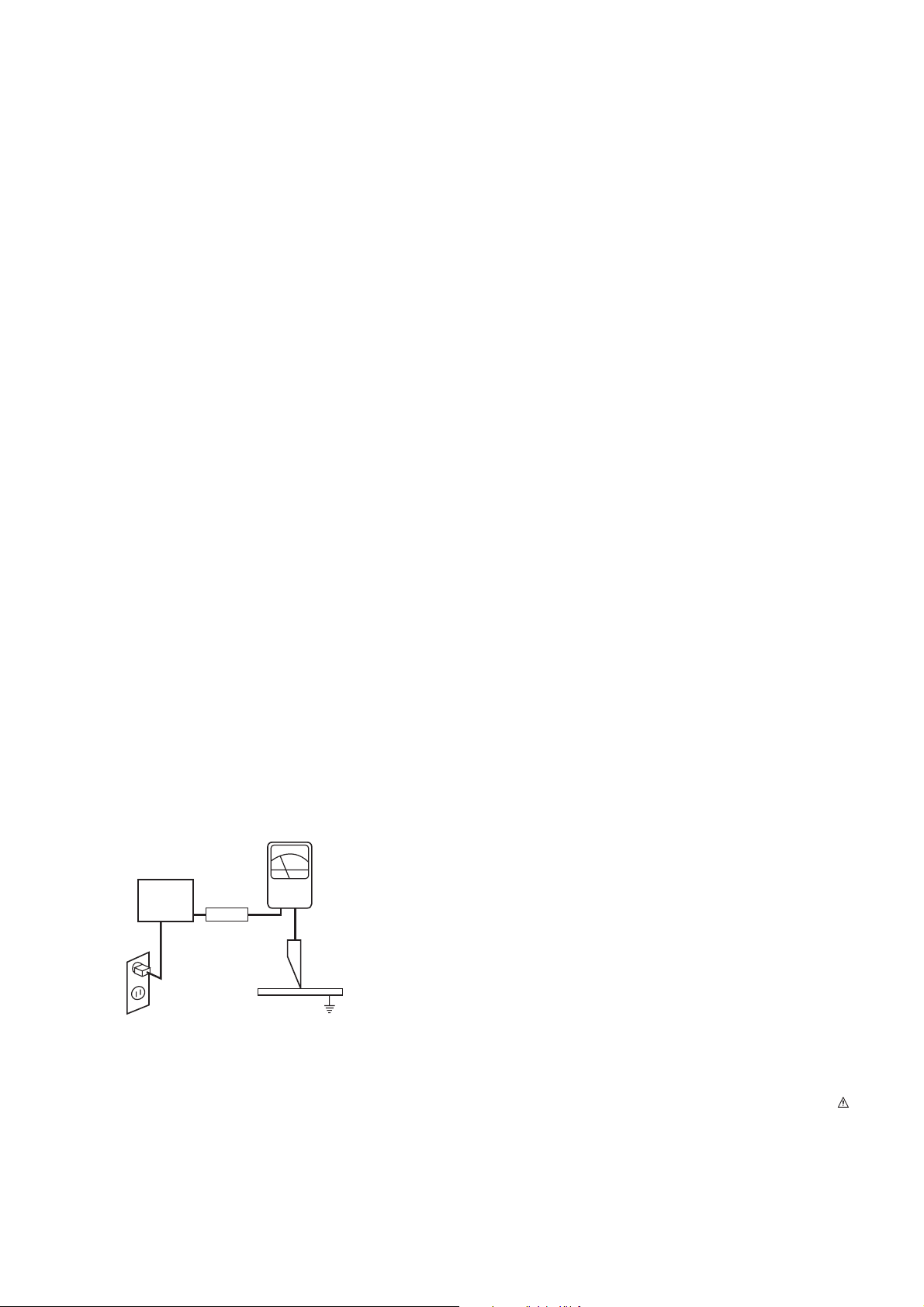

d. Leakage Current Hot Check-With the instrument completely

reassembled, plug the AC line cord directly into a 120 V AC outlet.

(Do not use an isolation transformer during this test.) Use a leakage

current tester or a metering system that complies with American

National Standards Institute (ANSI)

C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL) 1410, (50.7). With the

instrument AC switch first in the on position and then in the off position,

measure from a known earth ground (metal waterpipe, conduit, etc.) to

all exposed metal parts of the instrument (antennas, handle bracket,

metal cabinet, screwheads, metallic overlays, control shafts, etc.),

especially any exposed metal parts that offer an electrical return path to

the chassis. Any current measured must not exceed 0.5 milliamp.

Reverse the instrument power cord plug in the outlet and repeat the

test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER.

e. X-Radiation and High Voltage Limits-Because the picture tube is the

primary potential source of X-radiation in solid-state TV receivers, it is

specially constructed to prohibit X-radiation emissions. For continued Xradiation protection, the replacement picture tube must be the same

type as the original. Also, because the picture tube shields and mounting

hardware perform an X-radiation protection function, they must be

correctly in place.

High voltage must be measured each time servicing is done that

involves B+, horizontal deflection, or high voltage. Correct operation of

the X-radiation protection circuits also must be reconfirmed each time

they are serviced. (X-radiation protection circuits also may be called

"horizontal disable" or "hold-down.") Read and apply the high voltage

limits and, if the chassis is so equipped, the X-radiation protection circuit

specifications given on instrument labels and in the Product Safety & Xradia

tion Warning note on the service data chassis schematic.

High voltage is maintained within specified limits by close-tolerance

safety-related components/adjustments in the high-voltage circuit.

If high voltage exceeds specified limits, check each component

specified on the chassis schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside

the receiver cabinet, on the receiver chassis, or on the picture tube.

3. Design Alteration Warning- Do not alter or add to the mechanical or

electrical design of this TV receiver. Design alterations and additions,

including, but not limited to, circuit modifications and the addition of

items such as auxiliary audio and/or video output connections, might

alter the safety characteristics of this receiver and create a hazard to

the user. Any design alterations or additions will void the manufacturer's

warranty and will make you, the servicer responsible for personal injury

or property damage resulting therefrom.

4. Picture Tube Implosion Protection Warning-The picture tube in this

receiver employs integral implosion protection. For continued implosion

protection, replace the picture tube only with one of the same type and

number. Do not remove, install, or otherwise handle the picture tube in

any manner without first putting on shatterproof goggles equipped with

side shields. People not so equipped must be kept safely away while

picture tubes are handled. Keep the picture tube away from your body.

Do not handle the picture tube by its neck. Some "in-line" picture tubes

are equipped with a permanently attached deflection yoke; because of

potential hazard, do not try to remove such "permanently attached"

yokes from the picture tube.

5. Hot Chassis Warning-a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC power cord and may be

safely serviced without an isolation transformer only if the AC power

plug is inserted so that the chassis is connected to the ground side of

the AC power source. To confirm that the AC power plug is inserted

correctly, with an AC voltmeter measure between the chassis and a

known earth ground. If a voltage reading in excess of 1.0 V is obtained,

remove and reinsert the AC power plug in the opposite polarity and

again measure the voltage potential between the chassis and a known

earth ground. b. Some TV receiver chassis normally have 85 V AC (RMS)

between chassis and earth ground regardless of the AC plug polarity.

These chassis can be safely serviced only with an isolation transformer

inserted in the power line between the receiver and the AC power

source, for both personnel and test equipment protection. c. Some TV

receiver chassis have a secondary ground system in addition to the main

chassis ground. This secondary ground system is isolated from the AC

power line. The two ground systems are electrically separated by

insulating material that must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead

dress in the following areas: a. near sharp edges, b. near thermally hot

parts- be sure that leads and components do not touch, c. the AC

supply, d. high voltage, and e.antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring. Do not change spacing

between components, and between components and the printed circuit

board. Check the AC power cord for damage.

7. Components, parts, and/or wiring that appear to have overheated or are

otherwise damaged should be replaced with components, parts, or

wiring that meet original specifications. Additionally, determine the

cause of overheating and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

8. PRODUCT SAFETY NOTICE

Some electrical and mechanical parts have special safety related

characteristics which are often not evident from visual inspection, nor can

the protection they give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts that have

special safety characteristics are identified by shading, by a ¡,or by

on schematics and parts lists. Use of a substitute replacement that does

not have the same safety characteristics as the recommended

replacement parts might create shock, fire, and/or other hazards. Product

safety is under review continuously and new instructions are issued

whenever appropriate.

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

LEAKAGE

CURRENT

TESTER

(READING SHOULD

NOT BE ABOVE

0.5mA)

+-

AC Leakage Test

1. Scope of Application

These instructions are applied to CW81B Chassis.

2. Notes

1) Because this is a cold chassis, it is not necessary to use an

isolation transformer. However, operating it using a

transformer between the power supply line and chassis input

to prevent electric shock and to protect the test instrument.

2) All adjustment must be done in the correct sequence.

However, for better productivity, it can be change in a prepermitted range.

3) Environment conditions : If not specified, it must be done in

following conditions.

Temperature : 25 ± 5°C

Humidity: 60% ± 10%

4) Power supply of SET for NTSC

Korea market: 220V±10%, 60Hz

Taiwan market: 110V±10%, 60Hz

Japan market: 100V±10%, 50/60Hz

5) If not specified, the receiver must be operated for more than

20 minutes prior to the adjustment.

6) Signal : Received the standard color signal (65dB±1dBuV).

NTSC: LG standard signal means the digital pattern 13CH

(480NC)

7) If not specified, APC ON is APC CLEAR (DYNAMIC)

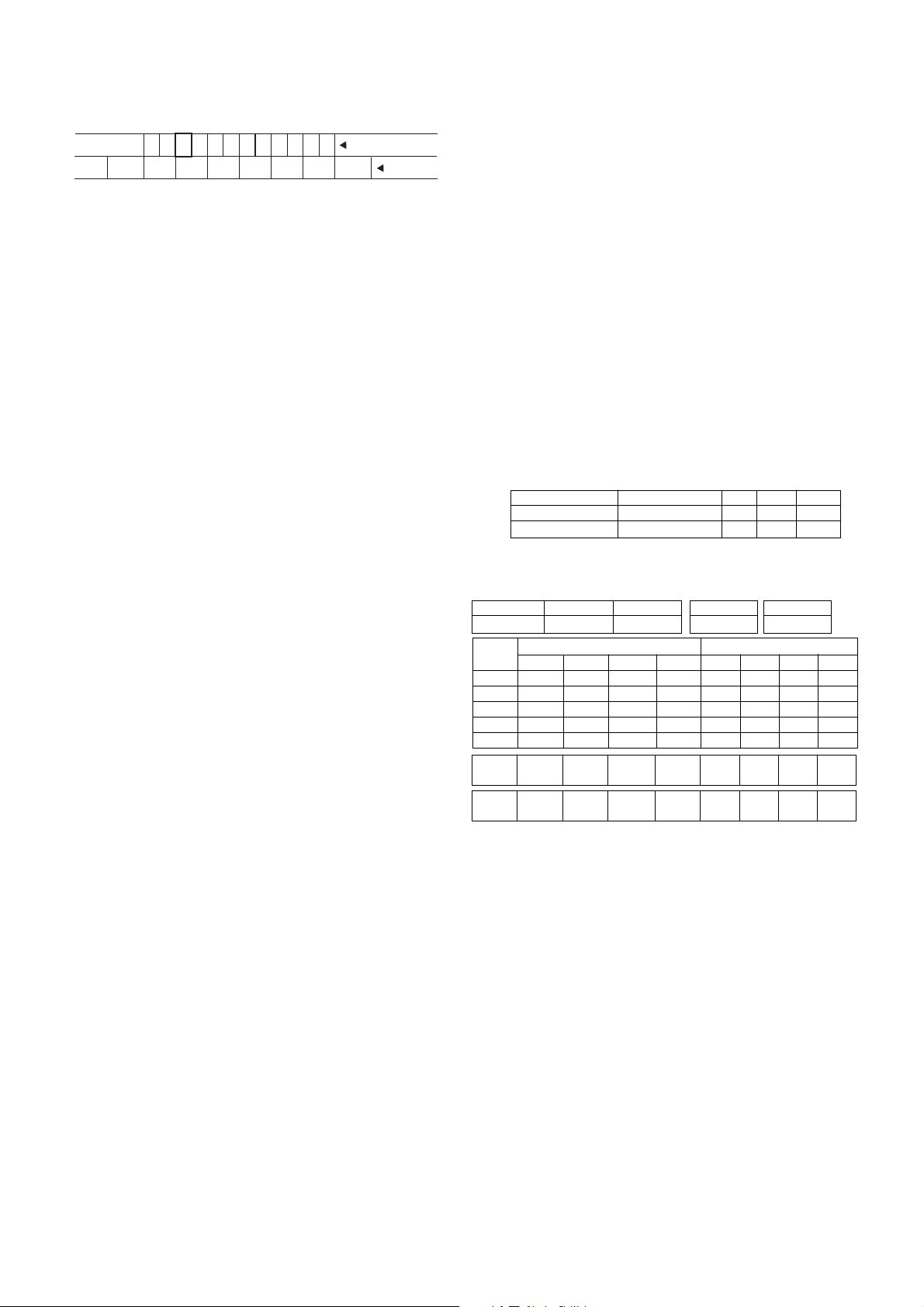

3. AGC Voltage Adjustment

3-1. Necessary Instrument

- Digital Multi-meter: 1 set

- Max Input Current : Over 1A/ Max Input Voltage : 500Vdc

- Measurement Range : 10mV-100mVdc/ Accuracy : 0.03%

3-2. Adjustment Preparation

1) Input in the 75Ω cable 65dB(±1dB) LG standard signal.

2) Connect the multi-meter to J105 (AGC Check, Marking).

3-3. Adjustment

1) Press the “INSTART” key of factory remote control and

select “VP0 (RF AGC)” adjustment mode.

2) Press the VOL+/- (

F/ G) key until the multi-meter shows

reading as shown below.

3) CAUTION: Since the signal strength can be easily

changed by the condition of signal cable, you need to

check the signal strength frequently in order to prevent

error.

4. Screen Voltage Adjustment

4-1. Adjustment (Using Factory Remote Control)

1) Input in the 75Ω cable LG standard signal (Digital Pattern,

480NC).

2) Press the “ADJ’ key of factory remote control once to make

the TV set display horizontal line.

3) Turn the screen volume on the FBT clockwise until the

horizontal line is visible and turn it counterclockwise until

horizontal line faintly visible.

(Exit screen voltage adjustment by press “Enter(

A)” key of

factory remote control.)

5. Purity and Convergence Adjustment

5-1. Purity adjustment

(1) Adjustment Preparation

1) Receive Red Raster Pattern for purity adjustment (51CH).

2) Demagnetize the CPT and Cabinet with a degaussing coil.

(2) Adjustment

1) Pre-adjust the static convergence (STC) with the 4 and

6pole magnet.

2) If the horizontal Line is inline with CPT Mark, 2-Pole

magnet should direct 3-9 o’clock direction.

3) If not, direct 2-pole magnet handle toward 6-12 o’clock

direction and adjust the Horizontal Line to fall onto the

mark opening the magnet at an angle.

4) Push the DY(deflection yoke) all the way to the CPT

funnel.

5) Turn the purity magnet(2-pole magnet) so that the “green”

color portion of left side and the “blue” color portion on the

right side have equal amount of color.

6) Pull the DY slowly backward and fix it when the whole

screen becomes red.

(The specified torque for fixing DY screw should be

10Kg/cm.)

5-2. Convergency Adjustment

(1) Necessary Instrument

1) Degaussing Coil

2) Convergency fixing instrument (Speical tools)

(2) Adjustment Preparation

1) Operate the unit at least 15 minutes before adjustment.

2) Using degaussing coil, remove the stains on CPT &

Cabinet.

3) Received the Cross Hatch Pattern of Convergence. (09ch)

4) Let the Contrast in normal luminance level

.

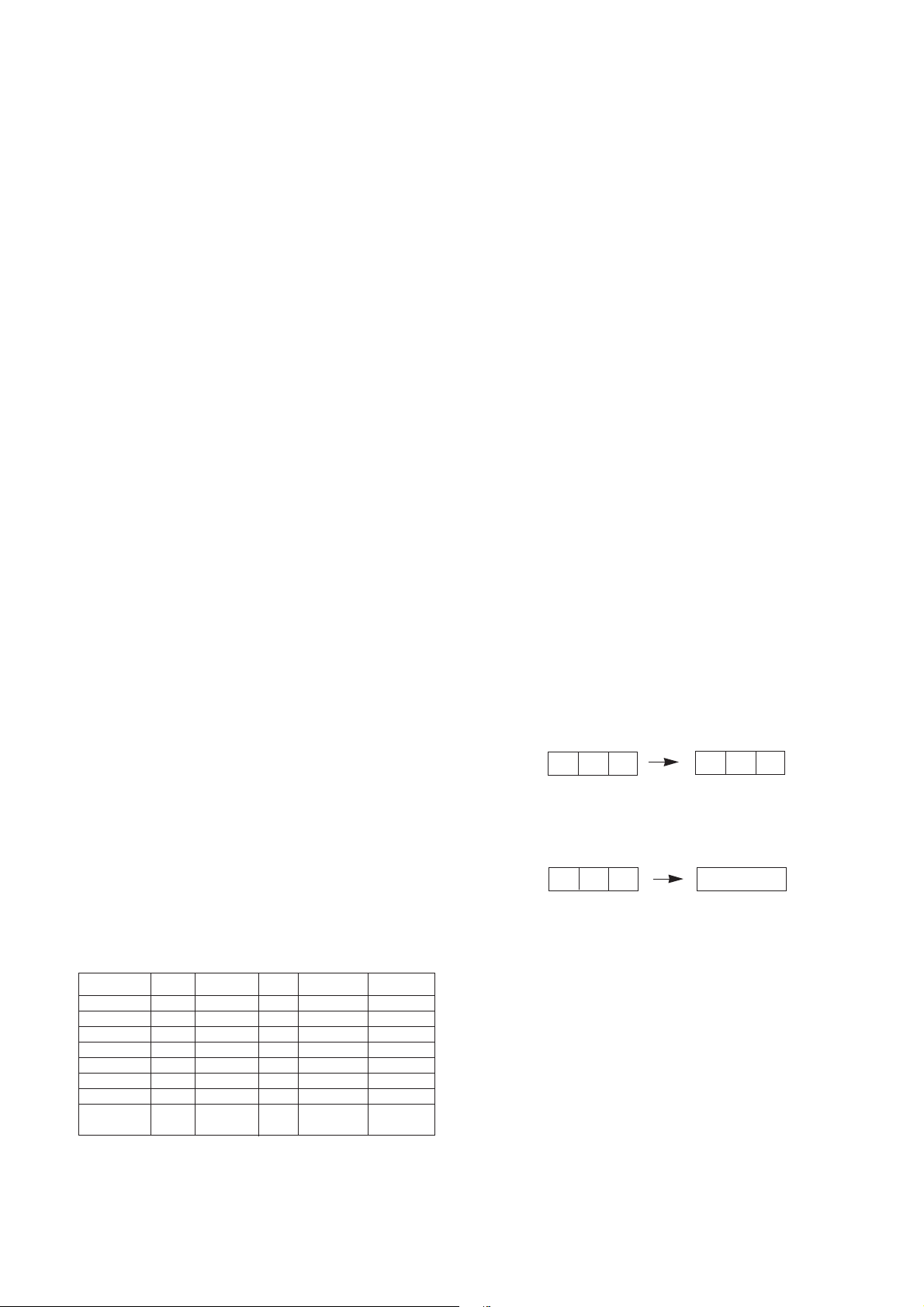

(3) Static Convergence (STC) Adjustment

1) Receive the Cross Hatch Pattern Convergence (09ch).

G R B

- 4 -

ADJUSTMENT INSTRUCTIONS

G R B

R

G R B

Copyright©2009 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

6700NFNS11E

6700VS0002F

6700PF0006B

6870NB0026A

6700MF0014A

6700MF0018A

6700MF0018B

6700MF0018D

6700MF0018E

LGIT

LGIT

SANYO

LGIT

LGIT

LGIT

LGIT

LGIT

LGIT

2.15 ± 0.05V

3.0 ± 0.05V

2.3 ± 0.05V

2.15 ± 0.05V

2.3 ± 0.05V

2.5 ± 0.05V

2.4 ± 0.05V

2.4 ± 0.05V

2.5 ± 0.05V

65dBu

65dBu

65dBu

65dBu

65dBu

65dBu

65dBu

65dBu

65dBu

TAEA-H111F

TAEW-G002D

115-B-A86EL

TAEA-J001F

TAEW-G013D

TAEA-G011D

TAEA-G001D

TAEA-G011D

TAEA-G111D

Korea

PAL

PAL

HITACHI

PAL

SECAM(CIS)

PAL

PAL

SECAM(CIS)

Tuner P/N Maker AGC Vol Signal Tuner Spec. Remark

- 5 -

2) Before adjusting Static Convergence (STC), adjust the

focus first seeing to it that the WHITE color picture quality

is sharp enough.

3) Converge the RED vertical and BLUE vertical line in unity

(same line) by changing the angle between the 2 tabs of

4-pole magnet.

4) Converge the RED horizontal and BLUE horizontal line in

unity(same line) by turning the 2 tabs of the 4-pole

magnet. At this time, do not change the angle between

the 2 tabs.

5) Converge the R, G, B vertical line in unity (same line) by

changing the angle between the 2 tabs of the 6-pole

magnet.

6) Converge the R, G, B horizontal line in unity(same line) by

turning the 2 tabs of the 6-pole magnet. At this time, do

not change the angle between the 2 tabs.

(4) Dynamic Convergence (DYC) Adjustment

1) Y-axis Adjustment:

Adjust convergence of Y-axis (vertical) by moving the

deflection yoke (DY) left and right.

2) X-axis Adjustment:

Adjust convergence of X-axis (horizontal) by moving the

deflection yoke (DY) up and down.

6. White Balance Adjustment

6-1. Necessary Instrument

1) Automatic White Balance Meter (Low/High light Pattern

generator)

2) CRTColor Analyzer, CA -100: 1 set

3) Factory Remote Control

6-2. Adjustment Preparation

Prior to this adjustment, the Screen Voltage adjustment

should be finished.

6-3. Automatic adjustment

1) Adjust using Auto White Balance Meter.

2) Enter CPU OFF Mode by pressing “IN-START” & “MUTE”

key of factor remote control in turn before adjustment.

Exit CPU OFF mode by press the “MUTE” key of factory

remote control after adjustment finished.

* In case there is excess RED color at screen voltage

adjustment, adjust it using “volume - (

F) key of factory remote

control until the RED color disappear.

6-4. Manual adjustment

1) Adjust using white Balance meter and factory remote

control.

2) Enter white balance adjustment mode by pressing

“INSTART” key of factory remote control.

3) Use the CH

D, CHE Key to choose adjustment item.

4) Use the VOL

F, VOLG Key to change item data.

5) Adjustment Procedure

a. Make the picture luminance 45Ft-L by changing the

“CONTRAST” and “BRIGHTNESS”.

b. Adjust X data of High light with R-DRIVE and Y data of

high light with B-DRIVE to have the color temperature

as shown below.

c. Make the picture luminance 4.5Ft-L by changing the

“CONTRAST” and “BRIGHTNESS”.

d. Adjust X data of low light with R-BIAS and Y data of low

light with B-BIAS to have the color temperature as

shown below.

e. Repeat steps a~d until both low and high light have the

same readings as shown below.

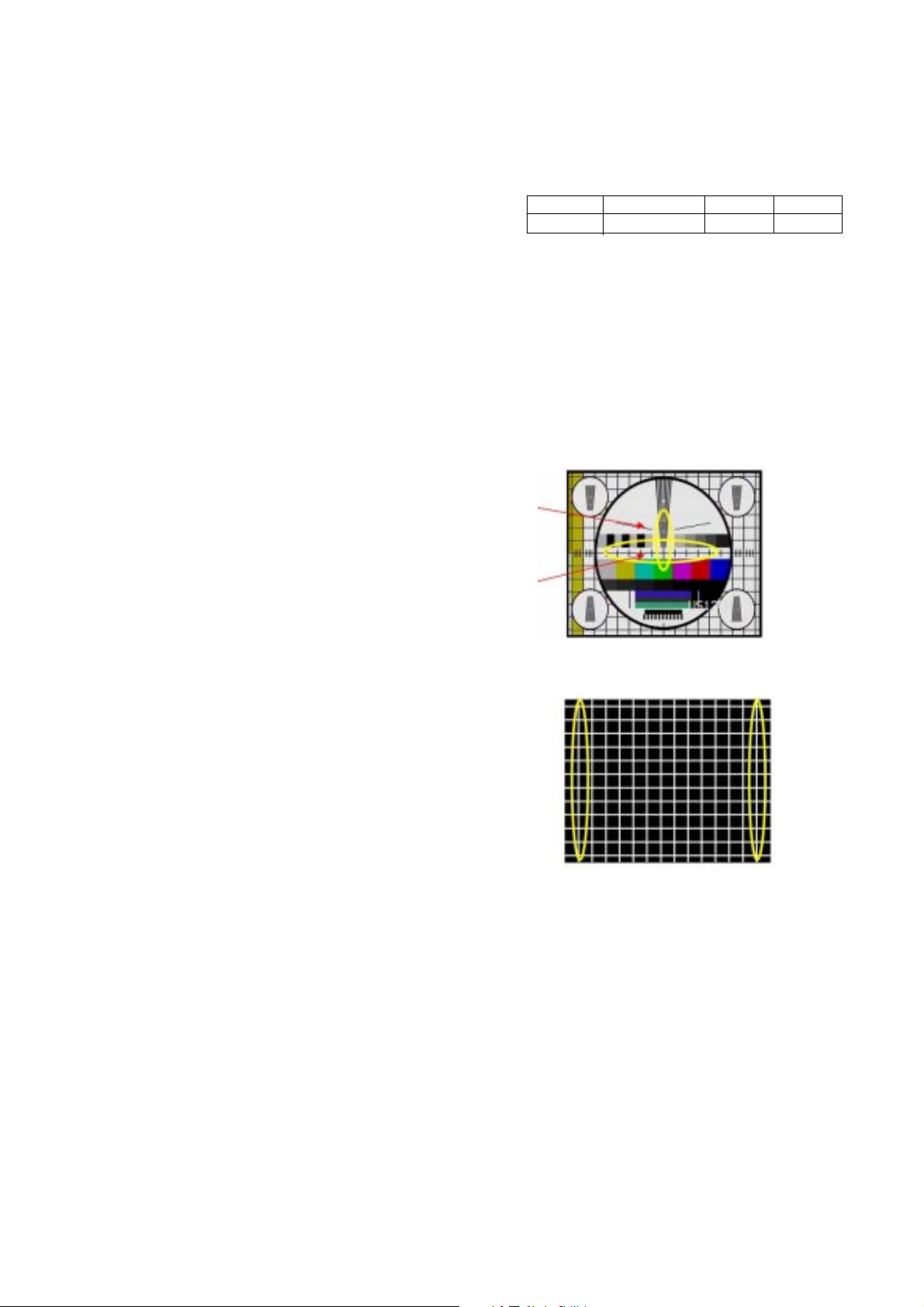

7. Focus Voltage Adjustment

This adjustment must be done after operating the TV set

receiver sufficiently.

7-1. Adjustment Preparation

Receive LG standard pattern (NTSC: Crosshatch pattern, Ch.09)

and set the picture condition on “APC ON”(CLEAR) mode.

7-2. Adjustment

Turn the focus volume on the FBT upper direction to have

the best focus vertical line (Fig. 1(a)) and horizontal line (Fig.

1(b)) as shown below

In ultra NTSC model, do in the signal of Ch.09 (Crosshatch

pattern) refer to <Fig. 2>

8. SUB-BRIGHTNESS Adjustment

This adjustment must be done after White balance adjustment.

8-1. Adjustment Preparation

1) Receive LG standard Mono scope pattern. (14CH)

2)Set the picture condition on " APC ON" (CLEAR) mode.

8-2. Adjustment

1) Press the “ADJ” key of the factory remote control twice to

enter to “SUB-BRIGHTNESS” adjustment mode.

2) Change the Sub-Brightness data by pressing the VOL

F,

VOL

G key so that the number 1 in gray scale of mono

scope pattern almost disappear . In the ultraslim , do until

the number "1" completely disappear.

See <Fig. 3>

Market Color Temperature X-AXIS Y-AXIS

ALL 13,000 268±5 273±5

<Fig. 1>

<Fig. 2>

Copyright©2009 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

(a)

(b)

- 6 -

8-3. Sub-Tint adjustment

This adjustment has to be done only if the picture has bad tint

otherwise, it can be omitted if the picture has good tint.

1) Receive LG standard pattern signal (SMPTE, 2CH)

2) Set the picture condition on “APC ON” (CLEAR) mode.

3) Press the “ADJ” key of the factory remote control three

times to enter to “SUB-TINT” adjustment mode.

4) Change the Sub-Tint data by pressing the VOL

F, VOLG

key until the upper and lower CYAN color becomes same

color.

9. Deflection setting data adjustment

These adjustment will be done by automatic adjustment

Equipment.

For manual adjustment, it is also possible by the following

procedure.

9-1. Adjustment Preparation

1) Deflection setting data adjustment can be done only with

remote control.

2) Press “IN-START” key on factory remote control continuously

to enter to Deflection Adjustment mode.

3) Press the CH

D, E key to select adjustment item.

4) Press the VOL

F, G key to change the data.

9-2. Adjustment

1) Horizontal Position Adjustment

Select SVC02(H-POS) and adjust so that the left and right

vertical line are symmetrical as possible.

2) Vertical Position Adjustment

Select SVC02(V-POS) and adjust so that the horizontal

center line coincide with geometric horizontal center of the

CPT.

3) Vertical Size Adjustment

Select SVC02(VA) and adjust so that the middle circle of the

Digital Pattern(480NC, 13CH) coincide with the effective

screen of CPT.

9-3. Adjustment (21'' Superslim, Ultra S/S

Model)

1) Vertical Position Adjustment

Select SVC02(V-POS) and adjust so that the horizontal

center line coincide with geometric horizontal center of the

CPT.

2) Vertical linearity Adjustment

Select SVC02(V-LIN) and adjust so that the size of the upper

circle is alike with the one of the lower circle at LG standard

pattern (PAL: EU05CH, NTSC: 13CH)

3) Vertical Size Adjustment

Select SVC02(VA) and adjust so that the middle circle of the

Digital Pattern(480NC, 13CH) coincide with the effective

screen of CPT.

4) Horizontal Position Adjustment

Select SVC02(H-POS) and adjust so that the left and right

vertival line are symmetrical as possible.

5) Horizontal Size Adjustment

Select SVC02(EW WIDTH) and adjust so that the outer line of

the left and right and the remotest grid will correspond to the

effective boundary surface. (The remotest grid PAL: within

0~25%; NTSC: within 2.5~3.0 column)

6) Parabora Adjustment

Select SVC02(EW PARAB) and adjust so that the vertical line

of the remotest grid at the left or right side of the screen will

be parallel to the vertical line of the center of screen. (or the

remotest grid of CPT)

7) Trapezoidal Adjustment

Select SVC02(EW TRAPE) and adjust so that the width of

the upper part of screen is alike with the one of the lower part

of the screen.

8) EW UPCOR / LOCOR Adjustment

Select SVC02(EW UPCOR, EW LOCOR) and adjust so that

the vertical line in the four corners become straight line.

9) BOW Adjustment

Select SVC02(HP BOW) and adjust so that the vertical line in

the four corners become straight line.

10. IIC BUS SUB Adjustment Data

Table

11. Auto Adjustment Preparation

Setting Table

Copyright©2009 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

0 1 2 3 4 5 6 7 8 9

Gray Scale

Color Bar

<Fig. 3> MONO SCOPE Patter Signal

OSD

SUB-BRIGHTNESS

SUB-TINT

Range

0 ~ 100

-20 (R) ~ +20 (G)

PAL

40

R5

Secam

40

R5

PAL

40

R5

NTSC

40

R1

Speed

1

SLave ADD

VIDEO ICBAEEPROM

A0

Delay

5

EEPROM

Sub Add

8D 8A 8F 8C

SpeedPlus

Step/Data

3 3 3 3

Sub Add

Start Bit

Stop Bit

Masking

Direction

VCD

TV PC

R DRIVE

D

6

0

0

1

R BIAS

A

7

0

0

1

B DRIVE

F

6

0

0

1

B BIAS

C

7

0

0

1

B AMP B CUT G AMP G CUT

Loading...

Loading...