LFE 2000 Series, 2000, 2002, 2003, 2001 Instructions Manual

...

#1

Instruments

Division

P}-',

A

Mark

lV Company

MODIFICATION

AND

REPAIR

PRICE

s

2s

.00

958-]I

REV B

i 6s9

PR"OC

THESE INSTRUCTIONS

ARE

HAZARDOUS POTENTIALS,

SERVICING

UNLESS YOU ARE

CESSOR.

r.-*

IiARNJNG

-**

FOR USE BY

QUALIFIED

PERSONNEL.

TO AVOID

DO NOT PERFORM

ANY MODIFICATION

OR

QUALIFIED.

SER,

I

ESS

M

CON

ES

2()00

ICR.C)PR.O

TR.OI-f-TIR.

raq4--q-i-!-q!Eu!

SERIES

2OOO

CONTROLLERS-_

I NTRODUCTION-----_

CONTROLLER

SERVICING__-_---

DISPI-AY

CHANGE

-

MODEL

20IO_---_

CONTACT

PLATTNG

AND

COMPENSATOR

CHANGE---

CONTROLLER

IDENTIFICATION-_

CONTROLLER

PART

NTIMBERS_-

M0DELS

2000,

2001

,2002,

2003,

2004,

2005,

2010,

2011-----

MODELS

2012

& 2013-----

MODELS 2014

& 2015----MODEL 2017----SERIES

2OOO

CONTROLLER

SPECIFICATIONS_-__

MODEL DESCRIPTION----__GENERAL

SPECIFiCATIONS-___

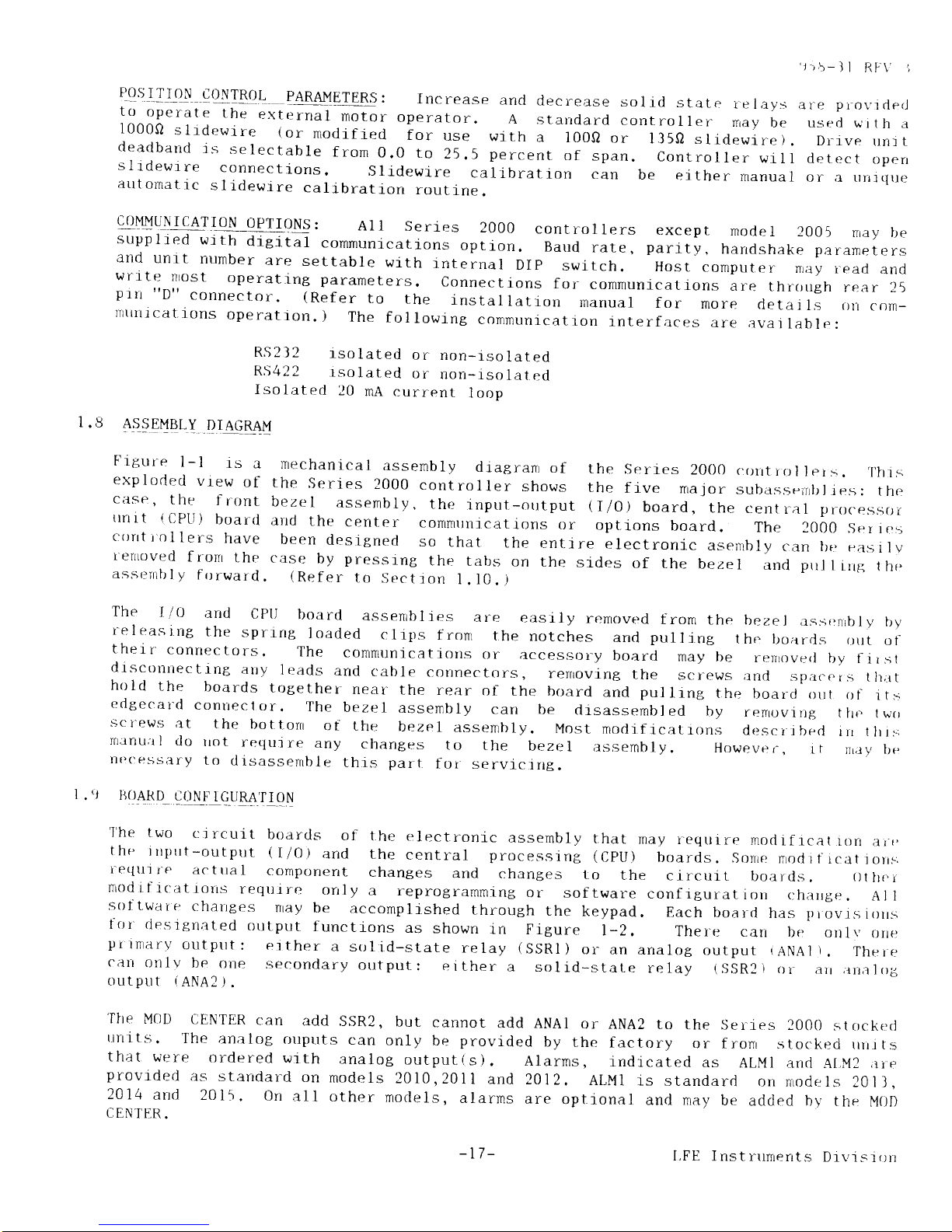

ASSEMBI,Y

DIAGRAM_-

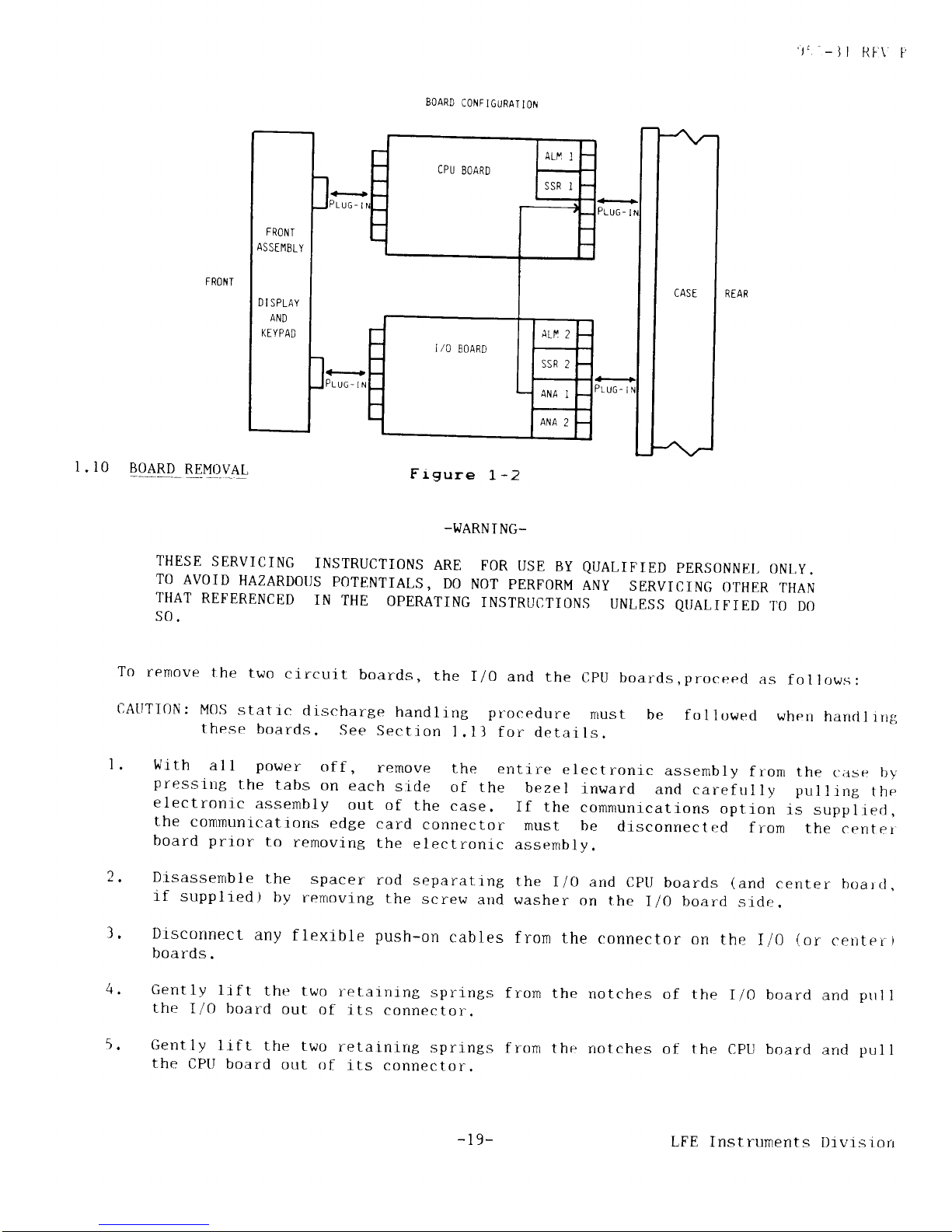

BOARD CONF

IGURATION--_--

CONTROLLER

ASSY

-

SERIES 2OOO-----

BOARD

CONFIGUMTION

DIAGR.AM-----BOARD REMOVAL_WIRING PRECAUTIONS-_-__-_

SOLDER

BRIDGING TECHNIQUE

MOS

STATIC DISOHARGE

HANDLING

PRECAUTIONS----_-

CALI BRATION/TROUBLESHOOTING

CONNECTORS-_---_-_-

SPECIFICATIONS

FOR RANGE

RESISTORS

INPUT MODI FICATION------

MODIEICATION

OF THERMOCOUPLE

INPUT

MODIFICATION

FROM THERMOCOUPLE

INPI]T

TO IOOO

PLATINUM

RTD INPUT

WITH

1 DEGREE

RESOLUTION-.

MODIFICA'IION

FROM

THERMOCOUPLE

INPUT

TO

IOOfI

PLATINUM RTD

INPUT

WITH

O.I DEGREE

RESOLUTION

MODIFICATION

FROM

THERMOCOUPLE

INPUT

TO

DC

VOLTAGE INPUT--

MODIFICATION

FROM

THERMOCOUPI,E

INPUT

TO

DC

CURRENT

INPUT--

958-31

REV.

B

F IGURE

SECTION

1

-

1.1

l?

l)

l.J

1.4

l\

I.rj

1.6.1

I A)

1

.6.3

1.6.4

t,7

1,7

,l

\,7

,2

IA

tq

1.10

r.11

I l,

t.l3

1.14

l.15

PAGE

1

t

I

I

1

n

a

.t

.i

(.

5

6

q

10

10

t2

t7

1''

l8

l9

l9

20

20

2l

22

23

l-1

1.)

t-L

S ECTI

ON

2.1

))

?1

2.4

,(

2 - MODIFICATION

I]NITS

AND

KITS-

-

25

MOD CONTROT,LERS---

25

INPUT

MODIFICATION KITS_

26

OUTPUT

MODIFICATION

KITS-

26

COMMUNICATION

KITS

26

OTHER KITS-_-__

26

SECTION ]

-

1.1

1'

1)

3.4

1.5

27

27

27

29

-1"-

30

LFE

Instrurnents

Division

.J5b-l

I

il[\/

J.6

l.i

la

lq

.1.10

t.t1

sFtcl'loN

4

-

i.

t

+.:

4.2.1

4,2.2

."

')

l

a.-.

J

4.2.4

4.2.5

4.)

t1t

-l

.

).1

4.1.2

4.1.3

4.1.4

4.1.5

4.l.rr

4.1,7

4.!+

4.5

4.5.1

/,

a )

a.)._

4.5.1

SF:(11'IoN

5

-

MODIFIT]ATIIJNS

TIJ

ADD

RTIM(]TE

IjETF,0INT

INF,TJT,---_

MODTF'ICATII)NSJ

FROM

THI]RMOCOIIPL,E

lNPUT

TI}

S ELI.

-POWERED

4

/

20

nLA

I NpUT____

M[)DIFICATION

FROM

THERMO(](]IJPI,E

INPUT

T'O

BRIDGF,

TRANSDTICER

INPITT'

(I,X(I

TTATION)-----_-_

M0DIFICATI(}N

FRT]M

TIIERMOCOIIPLF]

INPt]T

TO

ADD

INF'UT

ISOI,ATION

M0DIFICAT]0NS

FOR

II5fI

SI-IDEWIRE

(MODEIS

2011 ,'"

20t5

0NLY)________

MODIT'I(IAT][)NS

F'0R

IOOO

SI,IDEWIRE

(MODEI,S

l0li,'r,

2015

oNI

y)-*-------

I:0NTR(]I,I,ER

SF]I,r,](]'I'I(.}N

AND(.}II1'PI]T'

M0DTFICATION_-

CONTROI

I,F]R

SF,LF]I:T

ION_--_--

S{)I-II)-S'IATI]

RI,-,I,AY

ANI)

RELATED

O{II'PIITS---_--_--

PRIMARY

1

AMP

SSR

OI]TPIIT_--__--_

MoDIFI(lA'l-ION

I.'RrlM

I

AMF

SSR

T0

50

nrA SSR______

MODI

T]CATION

TO

ADD

A SF'UONDARY

SOI,ID-STATE

RI,].AY

(

SSR2

)---__-____

MTJDI

FI(;ATTON

OF

SSR

TO DC

TRIGGER

[JI]TPTJT_----_

MODIF]CATI0N

0F'

SSR

TO

(}PEN

COI,LECTOR

OLIT'P[rT--

ANAI

()(I

I)IJTt'UTS-_

i)RIMARY

i,i

20

nrA

ANALOG

0LrTpUT---

SF,C(INDARY

4r20

rnA

ANAL()(;

OtJTt,UT---

MtIDIFI(lA'lI(lN

(lF'

4,/20

nrA

ANALOG

OtrTptrT

TO 0/5

VDti

(lUTF,lll-----__-

MODI

F

I CA'l'J oN

OI.'

!+

I

2O

nrA

ANALo(i

(IU'I,F,LrT

TO

0 / l0

vDC OITTPIiT

--------

lvlol)l

F

Iflr\'f

loN'l'(l

PROVIDE

RH'TRANSMITTINt]

ANAL,()c

(JUTt'{J'f

---

M(]DI

F'I(]A't'I 0N

]'()

PROV]

DF]

ISOI,ATF]D

4 / 2O

N,A

ANAL0(; {)UTF

U'l'---

MODI

IT ] UA'I'I 0N

1'0

ADD

ZF]R0

AD.ITIS]MENT

PrJ]'

T(J

4

,1

20

rrrA

.\NAl,()i;

0tlTPli'f

---

ALARMi

TIMI-lR

Rlrtl

AY oPt'toNS--

OTHF,R

()F,TT

I)NS-.

MODI

I.'t

(lA't'loN

F'OR

220VArj

OR

240 vA(j

stippt

y_____

MOD]I-I(]ATION

T(J

ADD

REM(J'1'F,

START/STOP

OPTI(JN_-

MODIFI(;A,IIONS

T(]

MAKF,

A MODEI,

20] 4

INTt)

A

MriDFtt

20

t 5-----

MODII,'IT]A'fIONS

1'(I

ADD

{]OMMIiNICATI()NS

OPTION---_

PAGE

ll

3l

l3

l4

11

34

l5

l5

t-)

l5

l9

40

4l

41

/,'l

4')

4l

44

I.'I

(ILIRE

36

l6

l8

l8

llJ

)o

l8

LF'E

Inst

t.unents

D r rrt siorr

-11-

PAGE

46

958-31

REV.

B

F

I

GURI]

SECTION

5 - SOFTWARE PROGMMMING

IN THE CONFIGUMTION/

CALIBRATION

I,OOP--

6. I CHANGING THE

PART NUMBER---

47

6.2

PART

NUMBER

RULES-

47

5.3 CONFIGUMTION NIJI*{BER

-

MODELS

2OI2

AND 2013_-

49

6.4

SETTING

THE

LEGEND AND TIME BASE

(ALL

MODELS

EXCEPT MODELS 2OI2

AND

2013)

52

6.5 SETT]NG

THE

TIME BASE - MODELS 2OI2 &

2OI3

ONLY-----

52

6,6 SETTING THE DISPLAY LEGEND _ MODELS

2OI2 &

2013 ONLY

52

6.7

SETTING THE PV FILTER

(MODELS

2OT4 & 2OI5

ONLY) 52

5.8

SETTING THE

SI,IDEWIRE FILTER

(MODELS

2OI4

&

2015 0NLY)-------- 53

6.9 SETTING

THE

SPAN-

-

53

6.10 SETTING

THE DECIMAL POINT--

54

6.II

SETTING

THE DISPLAY

RANGE

(PROCESS

MNGES

ONLY)

54

6,12

INPUT

CALIBMTION

SUB-LOOP__----_

54

6.12,1

THERMOCOUPLE

INPUT

CALIBMTION_.___--

55

6.12.2

RTD

INPUT

CALIBMTION---___-

56

6.12.3

PROCESS

INPUT

CALIBMTION-------

57

6,12.4

REMOTE

SETPOINT

INPUT

CALIBRATION-------

57

6,12.5

OUTPUT

CALIBMTION

-

MODEL

2OI7 ONLY_--

58

6,12.6

CALIBRATION

COMPLETE-

58

SECTION

7

_

ADJUSTMENT

AND

TEST-

59

7

.1 I NPUT

TES'I-__--

5 9

7.1.

I

THERMOCOUPLE

INPUT

59

7.1.1

. I TEST

EQUTPMENT

59

7.1.1.2

INPUT

CALIBRATiON

CHECK-

59

7

,1.2

RTD

INPUT

60

7

.1,2. I TEST

EQUTPMENT

60

7,1.2.2

INPUT

CALIBRATION

CHECK-

60

7

.1.3

PROCESS

INPUTS---

_

60

7.

I

.3.

I TEST

EQUTPMENT

60

7.I.3.2

iNPUT

CALIBRATION

CHECK_

60

7

.1,4

SELF-POWERED

4/20

mA INPUT----

61

7

.1,4.1 TEST

EQUTPMENT

61

7,1.4.2

INPUT

CALIBRATION

CHECK-

6I

7

.1.5 BRIDGE

TRANSDUCER

INPUT-_

61

7

,1,6

REMOTE

SETPOINT

INPUT-_--

7,2

OUTPUT

ADJUSTMENT

AND TEST-----

62

7,2.I

4-20

mA

ANALOG

OUTPUT

1 AND ANALoc

OUTPUT 2

ADJUSTMENT--___---

62

7,2.1.I

CONTROLLERS

WITH

AUTO/UAruUEI

FEATURE--

62

7.2.1.2

MODELS

WITHOUT

AUTO/MANUAL

FEATURE---_---_--_

62

-111-

LFE Instruments

Drvision

95

8-3

I

RFtv.

B

7

.

).')

7.2.2.1

7

.2.2.2

7

.2.)

7.2.1.i

7

.2. ).2

7

.2,4

7.2.4.1

-,\

/.i..r.1.t

7

.'2

.4 .1

.2

7.2.4.2

1

1',')

I

|

.

!.-.

!.1

7

.2.4.2.2

7')\

7

.2.6

7

.

).7

71O

f')()

O/5

VDC

ANALOI;

OI]TPUTi

AND

ANA[,O(;

0(JTPtJl'

2

AD.IUST'MENT--_-_-

CONTROI,I,F]RS

WITH

AUTO/MANI]AI

FEAI,URE---_---

MODEI

S WIT'HOIJT

AIITIJ/MANUAL

FEATURE---__----

O

/

1O

VDC

ANAI,OT]

OLITFTI]T

I

AND

ANAL,OG

0{1T'PIJ'I

2

TF]ST___

CONTROLI,F]RS

WIT'H

ATITO/MANTJAI

FEATURE__--__-

MODET,S

WIT'HOUT

AIITO/MANIJAI,

FEATURE_--__--__

SOI,ID

,.JTATE

RET,AY

OUTPUT

1 AND

OIITPUT

2

TES'I

T)N/0I

F' AND

PROPORTIONING

OUTPTITS--__

TJN/OFII

SOI,I

D STATE

REL,AY

OIITPIITS'--

CONTROI,t,ER:J

WITH

AI]TO/MANT]AI,

FEATL]RE_-

CONTROI,I,ERS'

WITHOTIT

AU'TO/MANIJAI,

FEATURE__--

PROPOR'f

IONIN(;

S(]t,ID

STATE

REI,AY

OUTPUTS___-

CONTROT,I,ER,S

I'ITH

AI]T0/MANIIAI,

FEATT]RE-__----

tloNI'ROLt,ERS

I^rITHOtlT

AIITO/MANIJAL

T EATURE----

DC

TRIGGER

OIJTPTIT

'TES'I----_

I)PEN

I]OI

I,I](]TOR

OI]TPIIT

TEST-_*-_

RE'IRANSMIl'TING

OITTPUT

TEST---__

AI ARM/IIMI]R

RF]I,AY

OII]'PIIT

'TESTS_---

COMMIJN

I CAl'IONS

TEST]

NG---__--

PAGE

63

63

64

65

65

66

67

67

67

67

68

68

68

69

70

70

70

7l

72

a1

74

76

77

i8

7')

80

81

82

83

84

85

86

B7

BB

F I

GURE

3-1

8-2

8-l

8-4

8-5

8-6

8-7

8-8

8

-'J

8- 10

8-t

1

3-12

8-1 l

8-1 4

8-i 5

8-16

sri,cTToN

8

-

FLr)r^J

CHAIr'fS-_-

I)PERATOR

r,00p

-

MODI.tr,s

2000,

2001,

2002,

2001

ANI)

200

4-

0PHRAT0R

LOOp

-

Mr)Dhtt,2005_____

oF,uRATr)R

i,00p

-

MODF]

S

2010

AND

20il_____

r)PERATfIR

r.00p

-

M0DF],ti

2012

AND

20

| l_____

0PF]RAT0R

LOOp

-

Mot)Ftt,s

2014

ANll

2015_____

opERA'fr)R

Lo(Jp

-

MODL,t.

201 7-__

'fuNE

L00p

-

f't0Dlit,.s

2000,

2001

,

2002

AND

2005_________

ITINE

L00p

-

MoDEt,s

2001,

2004

AND

2005__-

tuNF.

LOOP

-

MUD|I

S 2010

AND

2011_____

,TIINE

I,OOP

-

M[)DEI,S

2012

AND

2O I ]__---

TllNFt

t.00p

-

M0DF]

s 2014

AND

2015_____

I IINF,

I,OOP

-

M(]DEI,

2O I i

_--

-*

(rAr,

t,rlof'

-

M()DELS

2000,

2001

,

200 I

,

2004.

2005

.

20

i0 AND

20 I 1

-----

cAt.

r.00p

-

MoDEt,S

20ll

AND

101.]-_-__

(

AI

I

r)OI,

-

MODF | .s

l0 I

r

qND

l(rl5

----

CAI

I-O(IP

_

MODEI

]017

LFE

Inst

i^rrnents

D ivlsl0rl

-iv-

SECTION

9

_

SERVICE

&

REPAIR-_--_--

9.1

CHANGING/ADDING

COMPONENTS-_---_--

g.2

EPROM

REPLACEMENT-------

9.3

MEMORY

CLEAR

PROCEDT]RE

g.4

MICROPROCESSOR

REPLACEMENT-------

9.5

BATTERY

REPLACEMENT---_---

g.6

KEYPAD

REPLACEMENT-------

g.7

VACUUM

DISPLAY

REPLACEMENT--_---_

g.ESYSTEMBI,OCKDIAGRAM_SERIES2OOOCONTROLLERS

SECTION

IO

-

TROUBI-ESHOOTING

GUIDE-

10.1

GENEMI,-_

10.2

TYPES

0F

FArLtlRE--------

10.3

ERROR

MESSAGES-

10.4

POWER

SUPPI,Y

VOLTAGES-

10.5

WAVEFORM

REFERENCE

10.5 .

I

RAM

FAIT,URE

DISPLAY_-

10.5.2

POWER

FAILURE

OR

RTC

FAILURE

DISPLAY__

10.5.3

DATA

I,OST

-

PLEASE

CAL

DISPLAY-_-----

10.5.4

DISPLAY

IS

ERRATIC_---_-_-

10.5.5

DISPT,AY

S'fABt,E,

BUT

I{RONG----

10.6

Ii

O BOARD

WAVEFORMS

IO.6.I

ANAT,OG

OTJTPUT

1/ANALOG

OUTPUT

2

WITH

4I2O

mA

OUTPUT

10.6.2

SOLID

STATE

REL,AY

OUTPUT

2

CIRCUIT

IO.7

MOTHER

BOARD

WAVEFORMS

IO.8

KEYPAD

CIRCUIT--

IO.9

COMMUNICATION

TROUBLESHOOTING--_-_--

IO.1O

NOISE

STIPPRESSION_-_---

SECTION

1I

-

CHECK

LIST_--

SECTION

12

_

SCHEMATICS,

LAYOUTS

AND

PARTS

LISTS_---

SCHEMATIC

_

CPU

BOARD-_-_

CPU

BOARD

OUTI,INE

-

EARI,Y

VERSION-_

CPU

BOARD

OUTLINE

-

LATER

VERSION--

CPI]

BOARD

COMPONE,NT

L,AYOUT

-

EARLY

VERSION--

CPU

BOARD

COMPONENT

LAYOUT

-

LATER

VERSION--

CPU

BOARD

_

COMPONENT

SIDE

SOLDER

BRIDGING

_

EARLY

VERSION_-

CPU

BOARD

-

T]OMPONENT

SIDE

SOI-DERBRIDGING

_

LATER

VERSION--

CPU

BOARD

-

SOLDER

SIDE

STJLDER

BRIDGING

-

EARLY

VERSION-_

CPU

BOARD

-

SOLDER

SIDE

SOLDER

BRIDGING

-

LATER

VERSION--

PAGE

89

89

89

90

90

9i

91

9l

92

93

93

94

95

96

96

96

97

97

97

98

100

101

i0l

102

102

to2

103

105

107

108

109

109

110

110

111

111

lr2

r72

t2-r

10 0

1 2-3

t2-4

l2-5

t2-6

12-7

I

2-8

12-9

958-31

REV.

B

F I

GURE

9-1

LFE

Instruments

Divisron

958-3

I

REV

BII,I,

0i.

MATERIAI,

.-

(]PIJ

B()ARD_---

VRl

VT]I

]AI;I,]

REGIII

ATOR

ASSEMBI,Y_

,SCHEMATIC

-

I/()

IJOARI)-

I /O

BOARD

OIiTI,INL]---_*.*

I/O

BOARI)

rtOMpoNI.tN't'

l_AyouT*-

I

/

0

RI)ARD

Cr)Mt)oNENT

:l

I DE

S0t,DER

BRI DGI

NG_______

I

/fi

BoARt)

,sr)LDER

Ij I t)ti

,SOLDER

BRIDGING______

F'ART'S

I,IS'T

_

Ii0

ROARD

-

WIO

ALARM

2-____.-_

PARTS

I,IST

-

I,/{)

I](IARD

*

Wi

AI-ARM

2--__----

THERM(IC0IIPI,T]

(]0I,I)

.]UC'I'I0N

RF,S

ISTOR

ASSY----_

SCHF]MA]

I

f]

_

Y111'NF:R

BOARD-

MU'tHI"lR

Rr)ARI)

t,(It

()tr,t't

I Nfi

---

-

MOTIIIlR

I}OARD

PAR'I'S

L,IST.-___-

ST]HEMAI']C

-

DISPI,AY

TJOARD_--_

DISPI,AY

BOARD

P(]IJ

(JUTI

INE--__--

DlSPI,AY

I}fJARIJ

PA}{I'S

t, tS'I_-*_*

SCHEMATIC

-

MODF]I.20I1i

&

2OI5

I/O

BOARD

Mol)Fll,

201lr

I

/{)

}}r)AItD

0tlt'LINE--

PCB

ASSEMBLY

-

MoDlrlt,

2014

ADDIiR---------

SI]HEMA'II(,

_

O.

I DI]GRT.]F]

ADDEIl--_--

PCB

ASSF]MT]I,Y

*

O.I

DF]GRTiT,]

ADDER---_

scHltMATi0

-

I/o

BOARI)

_

MODEL

20t7_____

I/0

BOARD OtrTt_INF,

-

MODEt,

2017--.---___

r/o

ROARD

COMPONr.tN',I

r,Ay0U1'

*

M0DEL

2017_____

I/0 BOAI{)

-

(lOMpf)NFtN'I'

SIDE

SOLDER

BRIDGING

-

MO|)EI

2017---

I/rJ BOARD

-

SOI.DER

StDri

SOI,DER

BRIDGING - MODEL

2017_-

F'AR',I'S

t,tSl' I/o

B()ARD

--

M()DF].

2017-----

S(]HF]MATI(]

-

COMMIJNICAIIONS

BOARD

(C0P1M

I)-._-----

I]CB

O{J'II,INF]

_

TIOMMUNICAT'IoNS

(C(]MM

I)--_----

P(IIJ

(]IJ'II,INf.]

.

I,]AI{I

Y RF]WOtlK

0t,' COMMUNICATIONS

I]OARD

PAI:;E

ll3

114

115

116

ll6

117

117

118

121

r23

124

125

t')q,

t26

127

127

128

r29

r29

130

ll0

131

132

132

133

133

134

Ll5

136

r

36

1i7

138

139

140

142

|

/+3

143

144

147

F IGURE

12-10

t2-1 1

t2-12

l2-ll

1,2-14

t2-t 5

1 2-16

12-]l7

12-18

1 2-t9

12-20

t2--21

12-22

12-2J

12-24

1 2-25

t2-26

r2-27

12-28

12-2j

t2-30

l2-3t

12-32

1n ))

t2-34

12-35

I 2-lb

12-37

i 2-38

12-)9

I 2-40

t2-41

1 2-42

| 2-43

1 2-44

12-45

12-46

| 2-47

PAR'IS

I ISl

t'(:B

ou

I't, I

Nu

sct{EMA

t't

c

-

ITARI'S

IISI'

SCHIIMAT

t

(r

-

FUB OlIl't,INIi

trctJ

{)trl't,tNI.l

t,AR'I'S I,IS'T'

(

(,Mf'ltIN

|

(tA]'t (JNS

(

COMM

I )

-- ----

-

(iOMMUNl(;A'ft()N.i

BLTARD

(rl0MM

II)__-_______

Cf )MMliN

|

(tA'l't ()NS

t]()ARI)

(

(;()MM

I I

)

------

-

(loMlltlNlriA'l'IONS

BOAITD

(CUMM

II )------

Ac(t F,ss0RY

IJOAT{t)----

-

A(l(llls.SORY

IJOARD-

-

.1

.WIRT.]

T'RANSJDIICER

P0WIIR

SUPPI,Y-

-

AC(i8SS()RY

tJ(.rARD-

SEiITI0N

ll

-

lN,5'IRtl(l'l

l()N

MANIJT\l,S--**--

ll.l

I I

')

i NS t'Rtit,

I I()N

&

()l,ERr|l I (JN

MANIJAL,S--------

147

5II}JPI,F,MFJN'IARY

J

NS'IIIIJI]1'I(JN

MANUALS-------

I47

LFE Irrstr-unents

Divis

roi'r

e)

5-

) l Rllv

ti

SEUT']0N I

-

SERIES2OOO

CONTROLLERS

l.l

rlfB.o_DulTr0ry

Thrs

manual

conta.iris detat Led irrfornrat.ion

crrr

the tnodrf

icatron,

ratrging,

calibratron

and servictng

tll

Ser

ies 200t1

rr icroprocessclr-based

control lers.

The Series

2000 fanri ly

oi

oorrt rollers

possess exterrsrve

capability

to

cttntrol

;r

multitude

of

dtffer-errt sinsle

ancl

two

loop

systerrs.

While

temperatul-e

control

is

the

fltost

popular

appljcatiorr,

t.hr: Ser-ies 2000

]nstrumetlts

can

colltrol

any

process

or

machrle

that

provides

a cur

rent ot voltage

rneastlrelTient.

rnput

srgnal

and

can

f unctrotr

fron a

reliry

or analog out.put

sjgnal l-n

a variety

of control

forms.

These

output

fun<rt,rons may

be

alarnr

,

orr-of f , or PID.

This

manual

is

structured

to

allow

a

nrgdi.flcilIton

center to change

rrne of

t.he

standard

stocked

cotrtrollers

to nr;rtch

a

wide

var-iety

of user requirernents

by fol lowing

the detailed

instructlons

glven

herertt.

Tirrs REPAIR

& MODIF'ICATION

MANtlAl,

(958-11

) is

directed

to

the Modrfrcatiorr

Center

pelsotllel

who have beel

tratned arrd

are

qualif.red

to work

on

this

type

of

inst.rtllrrent.

The INSTALLATIoN

ANI)

ItIIRING INS'IRU0l'ItJNS

normallv

supplred

with

the

controllers

should be

read first t.o fanriliarrze

oneself

wittr

the Series

2000

instrunrents

beftlre

proceedrng

with

thrs marrual.

This nranrra.l

contails 4

descripLir-rn

of

tlre corttrttller',

parts

lrsts,

schernatics,

PC

board layorrts

a1d flel.ailed

nroclif ir:atiorr

:rnd servicirrg

procrtdtlres. Where

practlcal,

charts and tables

are

providerd

ttt srrnplrfy

understatrdjng.

0nly specral

part-s

arrd

assernblies

are

specrf i.ed

as

"Purchase

f rom

[,F8".

Standard

ltems such as

resistors arrd

capacitors

may be

procured

locally.

The

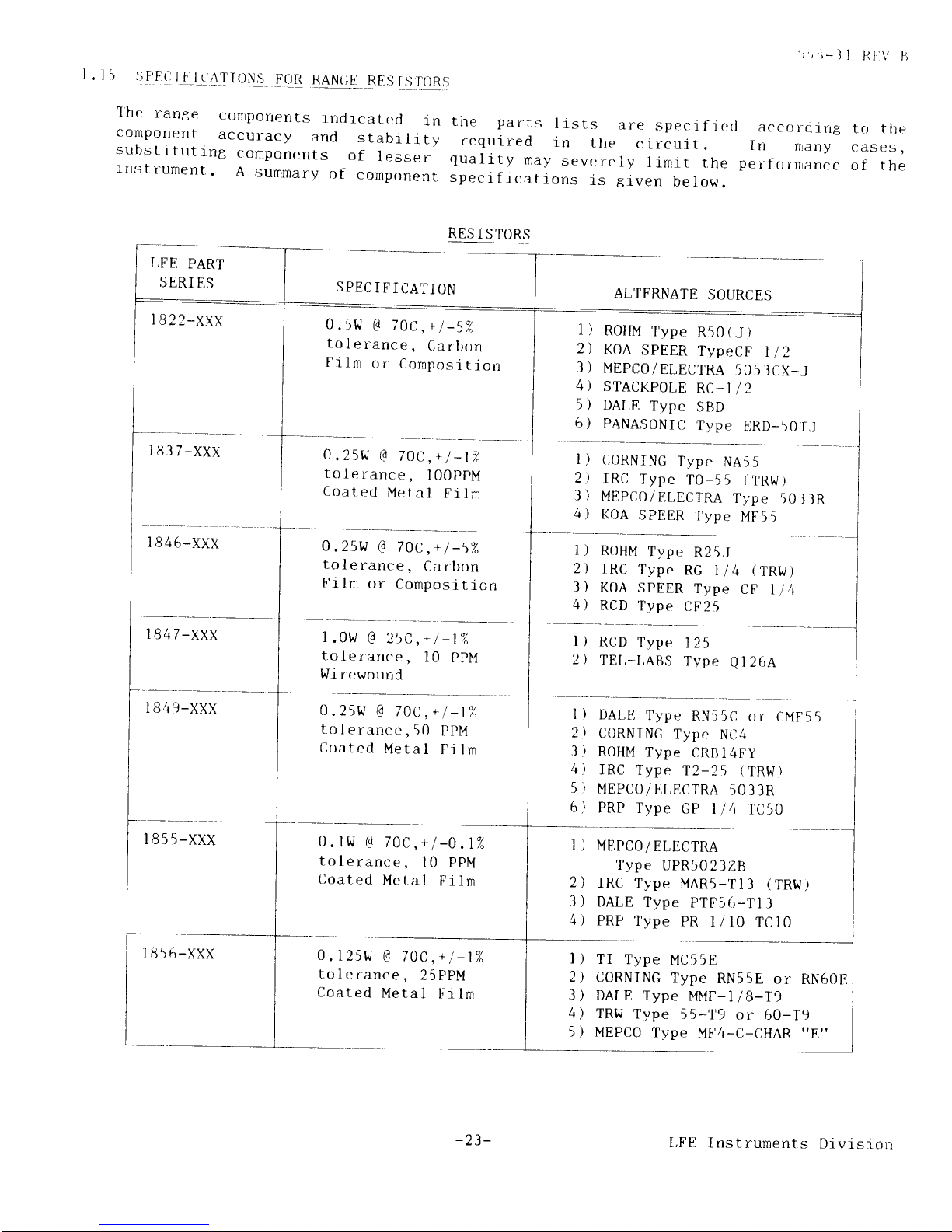

table

i.n

Set:tlcrn

1.15 contains

the specificatlons

for- range

resistors

required

for

the modifications

described rrr

this nrarrual.

Because

of thei r I rnrr ted arrd

spec ial rratrrr

e,

Models

2016,

2Ol9

and

2031

are not

coverecl by

this nranual.

Consult the

f actory f

ori nf orntat-rorr

on

these

products.

The

Model 2040

Lrmit Controller

is covered lu

MOD MANUAI,

958-33.

I

.2

cONrRor,L,E&

llBVIll

Nq

'Ihis

nrartrrai rrrr:lrrdes

detailerl trorrlileshoutirrg

arrd

repair

rnforrnatlotr

to allow

the MOD

CFINTER

to repair

a rnalfunctioning

controller.

If

the unit

cannot

be

r-epaired,

contact.

the fac:

tory t() oblarn authorjzat.ion

to returrt

the

unit

to

the factory

for

repal

rs,

-l-

LFE

Instruments

Divisiorr

'j55-ll

RL.\r

B

Fo

I lowrrrg

p

rope

r

brief

descriptrotr

1.3

authorization,

the

contr-oller

should

of

the

observed

problenr

and

shrpped

pr

LFE

Instruments

Dtvision

Repair

Departnent

11655

Chrillicothe

Roarl

Chesterland,

Ohlo

44026-1994

(216)

729-1681

t0

be

adequately packed

\rrttt

a

epaid

to:

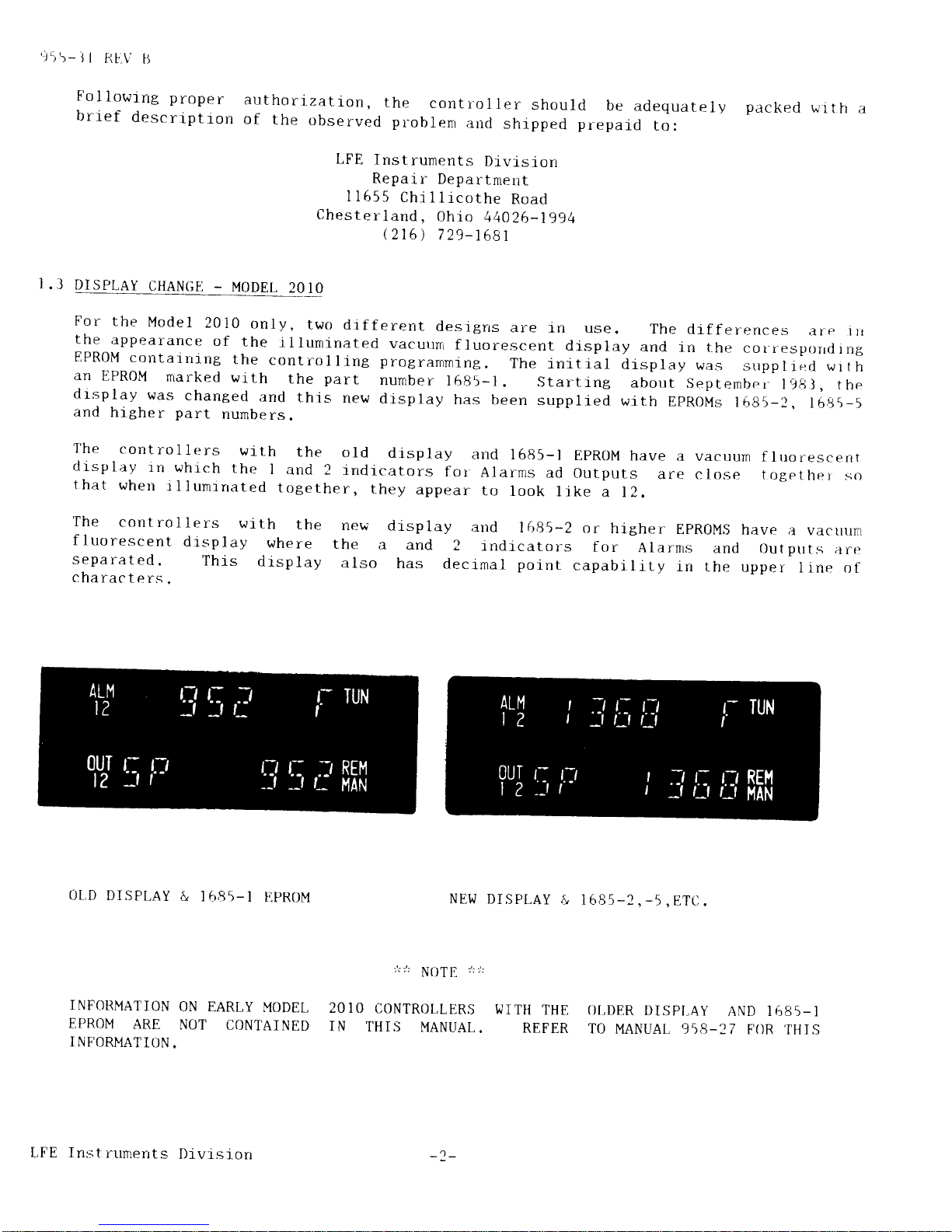

For

the

Model

2010

only,

two

dlfferent

desigrrs

are

in use.

The

drfferences

aie

'r

the

appearance

of

the

-il

luminated

vacurrnr

f

luorescent

display

and

rn the

col.resporrrl

rng

EPROM

cotrtaitrinB

the

controlline

programming.

The

j.nltial

display

\,ras

strpplred

wrth

an

EPROM

marked

wlth

the

part

number

l685-1.

,startrng

about

Septembei-l98l,

the

dlsplay

was

changed

and

this

new

drsplay

has

been

supplied

wlth

EpRoMs

l6g5-2,

l5g5-5

and

higher

part

numbers.

I'he

colltrollers

with

the

old

drsplay

and

1685-l

EpRoM

have

a

vacuum

fluorescent

di'splay

rn

which

the

I

and

2 indicators

for

Alarms

ad

outputs

are

close

togethei

so

that

when

illurnrrrated

together,

they

appear

to

look

like

a

12.

a$&al_qa!q!_

MODEL

20

The

cont

ro

1 lers

with

the

new

fluorescent

drsplay

where

the

separated.

Thls

display

also

characters.

display

arid

1685-2

or

hlgher

EPROM,S

have

;r

vacuum

a

and

2

tndrcators

for

Alarns

and

Outptrts

art:

has

decimal polnt

capability

in

the

upper

line

of

0L,D

DISPLAY

&

1{r85-l

}iPROM

INFORMATION

ON

EARLY

MODEL

EPROM

ARE

NOT

CONTAINED

I NF'ORMATION.

NEW DISPLAY

&

I 685-2

,

-5

,

ETC

;!;':

Na)T

F

/:

:':

20

IO CONTROLLERS

WITH

THE

OI,DER

DISPI,AY

AND 1685-

1

IN

THIS

MANUAL.

REFER

TO

MANUAL 958-27

FOR

'IHIS

LFE Instnunerrts

Divlsion

_')_

1.4

r::l-

CAUTI0N

TO

I)REVENT

CONTACT

DETERIORATION

DUE

TO

DISSIMILAR

METALS

'

DO

NOT

I

N'II]RM

I X

I

I

O

BOARD

AND

CPU

BOARD

GOI-D

AND

SOLDER

PLATED

TERMI

NALS

'

AL,S(I

MAKE

SURE

THAT

THE

EDGE

CARD

AND

CASE

TERMINAT'S

ALSO

HAVE

THE

SAME

TYPE,oFPI,AI,ING.FAILURE,TOFOLLOWTHISINSTRUCTI0NMAYCALISE

CON'TRO[,T,ER

MAI,FUNI]T

ION .

r

.5

qo_!!TBll!,LE&

IDENI

rFI!rATI-qN

F0tti

l;rtre

ls

;rre

ttsed

to .tclerrtif

y

a

Serres

2000

Control

ler'

l.rt.uh.nlr

orvrlon

Cr.rdd

tu..6-B

'iiB-11

Rflv

B

co!!t4!I

-LILA

r

I

ltq-

4N-D-qoI',tPEt{-'14roR

CHANGE

--4!!-!Lo!J!',s

Beginni'g

early

ln

198b,

the

cold

junction

compensating

resistor

was

moved

from

rTrount

jng

on

the

rear

of

the

case

to

place

it

on

^-t'-tppott

assembled

to

the

I

/o

board

so

that

the

c:o*persatirrg

resf

stor

i,

no"

un

,-ni"r.ut

pu.a

of

the

I

/0

board

'

At

the

sarne

timrr,

a

change

was

made

to

add

gold

platrng

to

the

edge

card

finters

and

also

to

the

case

ternrrnals.

Although

the

I/O

board

w'ith

gold fingers

and

board

mounted

conpensator

cannot

be

installed

in

an

older

cas(l

without

gold terminals

and

a

clearancr:

hole

for

the

compensator,

care

must

be

taken

to

prevent

gold

plated

CPU

boards

f

r-orn

betne

n,jxed

with

I

/o

board

with

solder

plated

f ingers

'

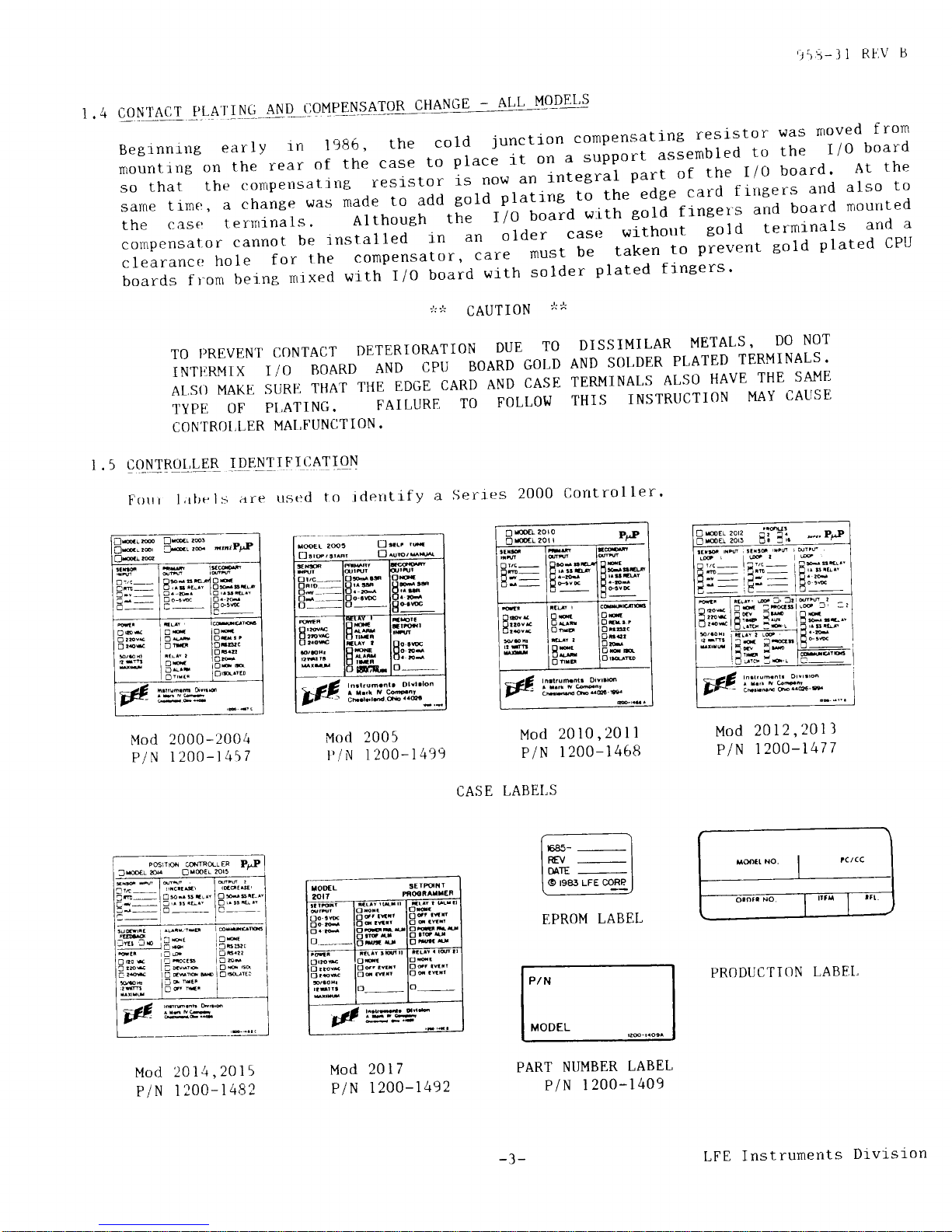

Mod

2000-2004

P/N

1 2OO-14\7

Mod

2014,2015

P/N

1200-1482

XOEL

SEIBiT

PNOOiATXER

oo-aw

o

---,,__

od.

efr

oq

l[it

ox's

0da

Od'

.vtir

t_

I

oMau

o-

,tF'W^--.

F,PROM

LABEL

P/N

MODEL

PART

NUMBER

LABEL

P/N

1

200-1409

Mod

2005

Mod

20 10,20

I

1

l,/N

1200-1499

P/N

1200-1468

CASE

LABEI,S

Mod

2012,2011

P/N

1 200-1477

Mm:t

No.

I

rcrcc

ornrr

No

tft

PRODUCTI(IN

LABET,

Mod

2017

P/N

1200-1.492

Ore&

o2Fv&

O

r.o*

o

1.__

3tv

_

ad_

od

D1€

Bri,#

H:::-

l^drumn[

Drvr16

cbdtu!6_@

EffiEi:sl3

rj:lr

_:_1.

r=

tEI=

iE,#""

ld

3ffi

l%

l:f

E..B:o

:g:*

Posrre csmftr

ER

Pu?

3m

ry

OreE!

rcr!

e@.d lffi l@6,

l,,ictE' lrddtst'

i

ni]-

I o

s-

s r'- j o

-.s'r--

e--1-r,.'r.LN lD'r$eN

l

-3-

LFE

Instruments

Di.vi-sion

:,r'i-Jl

RL,\'lJ

The

CASFI

L,ABEL

rs

located

on

the

outsrde

top of the

Serres

2000 case.

l'h r s labe I

h.rs

space

foi^

rdentlfying,

the

prrmary

and

secondary output,

alarm,

setlsor

and supply

volt'age

specif

icatrons.

Any

lnput

or output

hardware

rnocllf

lcation

to these

controllers

requires

that this

label

be remarked

or replaced

with

a new

label and thr:

appropriate

conf

rguration

nrarked.

The

coutroller

PART NUMBER

LABEL

is

located on the

mother

board at the

rear

of the'

front

beze-l

assembly.

Any

modificatron

to

a

Serles

2000 controller

requlrt's

that

this

label

be

changed

to

irrdicate

the

part

number

shipped.

The SpAN

rs

also lrsted

on thrs

label

and

must be

changed

when

the span linrits

ar-e changed.

Ihe

EPROM

LABEI,

is attached

to

the

EpR0M

at

EPR0M

part

number,

its

revisjon

letter

arrd

changed

ln any

way.

Reprogramming

the

replacetnent

EPROM

ts required,the

new EpR0M

'l'he

PRODUCTI0N

t,ABEL

is

located

next

to the

fr-ont

flange.

This

It

rdentifres

data

relevarrt

to

modrftcatfon

h;rs been

completed

the

tinre of

nanuf actuye arrd

specif

jes

t

he

date. This

label

rs

NOT

to be rerrroved crr'

EPR0M rs

a factory

procedure.

If a

will

have its

own label.

on

the

out.stde

top

of the

Serres 2000 c()rttl'oller case

rs

the

production

control

label used

by the factor)i.

the

manufacturing

cycle

and may be covered

up after a

since the data will

no

longer be needed.

LF E Inst ruments Divis

ron

i5B-ll

RF\I

IJ

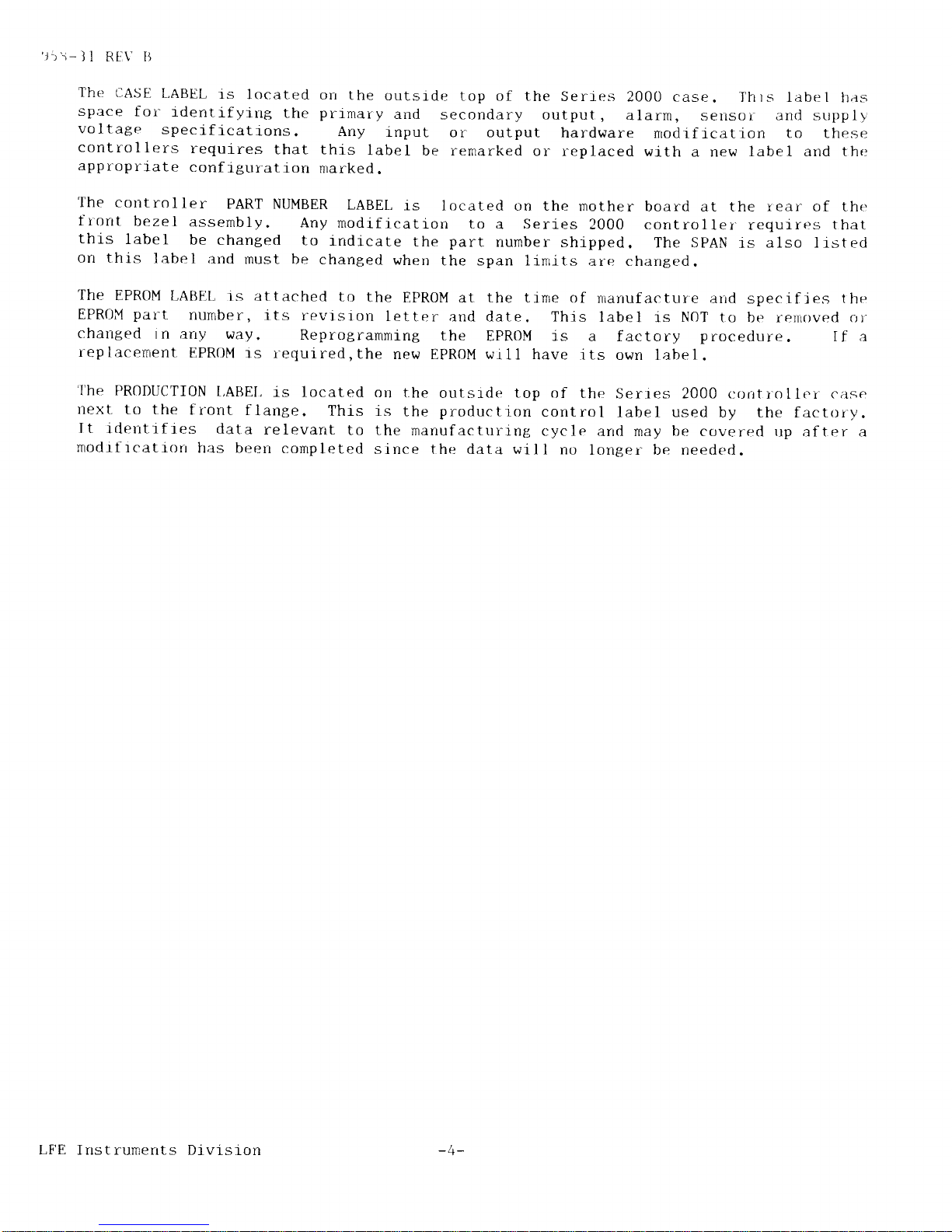

r.6

qqryM,L_LqB

g4Br

Nqf{9qR!

Each

Serres

2000

controller

is

assigned

a

ten

dicit

number

that

specifles

lts

harclware

and software

confl€luration.

The

MOD

CENTER

can

chanBe

this

part

number

to

sutt

the

applrcation

ancl

the

required

modificatjons

using

the

following

description'

l

. 6 .

r

YO!4!,!

2000

,

2o0

)

,2o_9?299)

,299!.2.0!5

-ZQ

1-0_120

!-!

1. & 2,

fl0DEl-

NUI'IBIR ANtt

t0l'11'1U|.l

ICAT l0NS

i

fl0Dtls

'

lnnl

r'tn1

lnn?

)nnI

?nnA' ?nn5 701il

'

zL'uu

zvul

1"u.' 4uv / aut'1.

,

t0,

10 EA,

lA1

',

D0

11

'

:r

FR

IB

,

'

DI

LI

LI LU

'

t;

1

il 1t

I

I'.ri,zl

,

it,'lDi

'i

,'

rq u

[[,

lt

', t

i

'

t5 l\',

rt

ff',

'i 'l

.

i6'

16,

tG

lG,

'.

'|

.

.

':

I

I

'

I

'

I I

'

.

F|lI

r:

3, _ PRII'1ARY

OU]PUT

[l

|.]O PR II'IARY

1

PRI,

|']TAI

35R O|IIOFI

?

PRi. COOI SSR ON/(]FF

]

PR],

HIAI

SSR

TPR

4

pRt

, c00t ssR

IPR

5 PRI.

i]EAT 4/20

ilA|)[

6

Ppt.

l00r

4/20 l'lAD[

7 PRI, ilEAI O/5

Vt)I

8 PR I , f 00r

0/5

l/0l'

I

2U1

i,,

DtStRIPlloN

';

'

l"StJndard

lodel

-No

Communicatlon:

'

Unit

rlith

Remote Set

Point

(ALl'12

not

available)

D2

flith

llon-isolated

RS232

Communications

t)3

, t{ith Isolated

RS232

Commttnication.c

D4

t4ith

|'ion-isolated

RS422 Communications

D5

I |littr Isolated

RS422

Communications

D6 r llith

lsolated

Current

Loop

Communications

-

,

l'lodel

2005 lrith

Start/Stop

'

i

l'lodel 2005

* ith Auto/l'lanual

^

I

l'lodel 2005

Self

.Iune

with

Start/Stop

,

,

flodel

2005 Self

Tune

with Auto/l,lanual

4.

.

SECONDARY

OUIPUI

O

NO SECO|IT)ARY

1 SEI,

HTA.t SSR

()N/OTT

2 Srf,

t00t ssR

0N/0FF

4 STC,

CO{]L SSR

IPR

6

StC, C00t

4/20

|,IADC

7 SFC,

COOI O/5

VDC

9 ANATOG

R[]RANSI'JIITIN6

4/20

I'IADC

TABI,E

1 - 1

r4ts!-t*!EB

-----]-;;

-

;;

x

x-=-I

I r,"

-l

Drgit

Nurnber

I

l.

2.

3.

4.5.6.

7'

8'

9'

10'

I

l---l

-5-

LFE

Instruments

Drvtslon

'J)5-l

I RFIV tJ

I

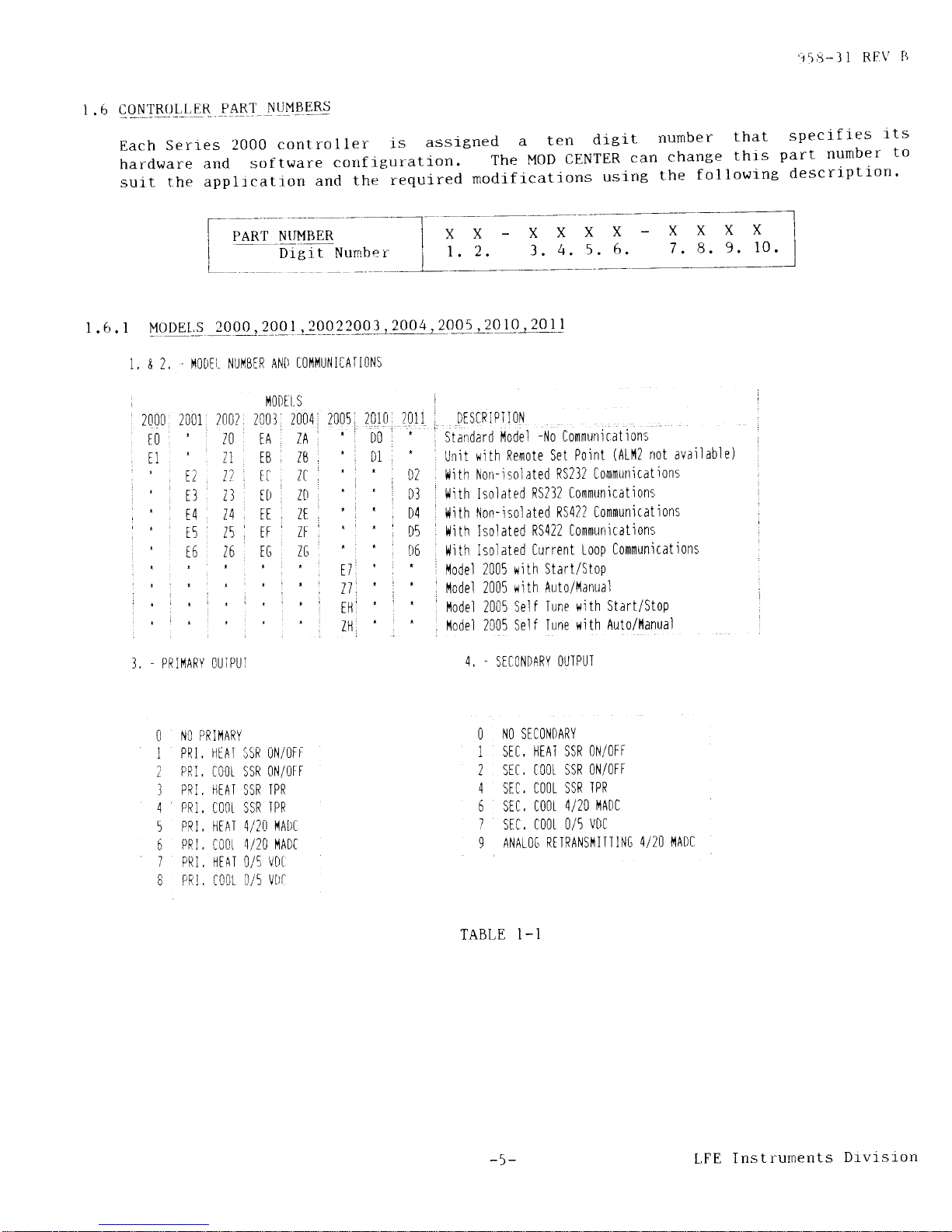

.6

.

1

UqllFL.>?q_0q_2q0!,?0q?,

2003

,

200trr290_5_,,2!

1q,?01 t_( contr_nued

)

5.

&

6,

.

I|!PUI

CO[)T

00

J

.IHIRI'10t0UPtt

O1 |( ]|lERI'IOCO(JPLE

O2 R IHTRI'IOCOUPLI

t]]

S THERI1OCOUPLE

04 T THIRI'IOCOI']PIT

05 N

T|.1ERI{OCOUPIE

06 t THtRI'10c0tJPti

O7 B

THERI'lOCOUPLE

OB

PI AT]NIL

I I

IHERI'lOCOUPLT

09 Ni/N11Bt'lo

I|1tRI'10C0UPLt

10 li5?Re/l{26?Re

Tl-]ERT'{0C0UPLE

], ' PRiI,IARY

OTIIPU'I

,

(t00P

ilL

lNtY)

|

0

N0

[ rTDl't_

L

r-tA'

;!F

,t,:,,]c

I

I i 00 .51

0\/0FF

I ltA-:5RltP

:

4

0':,qa'pR

5

-fATd,'20l]1A0[

,

5 I t00t 4/20

mA0t l

'

r'a'0/5

vDt

8 [0tL 0t5

u0t

'

a

il'[^/

qF_Ay

I

et'Rail:lilrov

,

t

Ri.|RA'lst'{lT

SP

7, OR 8, - ALAR]'1 CODI

O NO ATARII

1

HIGH

PROCTSS

2 t0l'l PR0CtSS

3

HI6H DTVIA.IION

'

l.lot avai I

abl e on

l'lodels 2002,

2004

or 2005

(27

or Z|]),

4 t0l1

DIVIATI0N

f

t'lodel

2005 only,

5 0N IItltR

'

6

OFF TII(ER'

7

I)TVIAIIO|l

BAND

9 REiIOIT PAUSE

#

Ll

fil?Pe/i,125?Re

THtRlilOC0UPtE

7,

&

10, - SPICIAt C0Dt

12

lllli2b?Re

I||ERI'10C0UPtt

20

lOOA

Pt

FID

i" RISOTUIION

?1

1OOA Pt RID

0,1"

RTSOLUIION

40

0/5

VDC

60

,1,,lf

mA0t

b1

4i

?0 mA|ll

:t

r

P014tRtt)

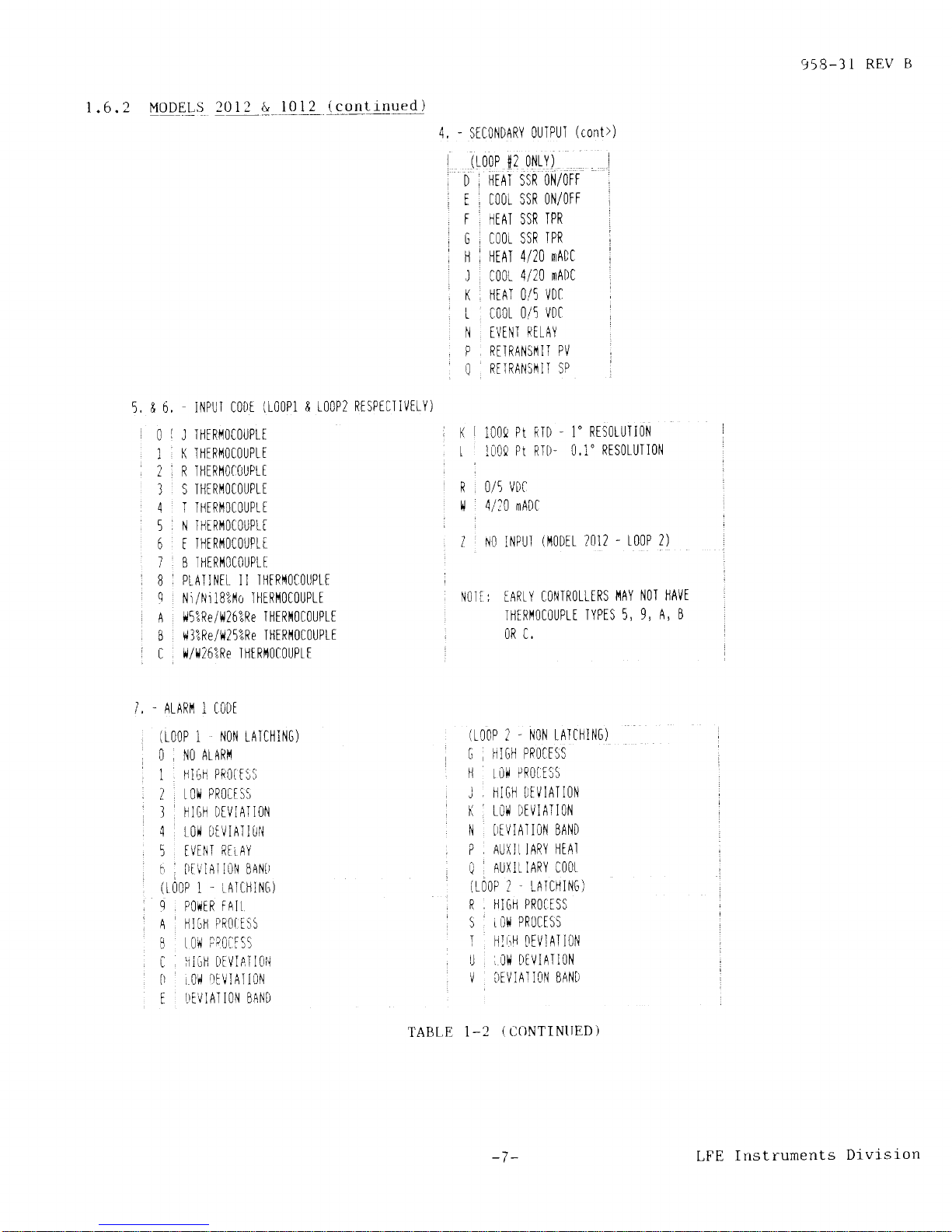

r.6.2

ryq!_E-t,s

2_q!?_&

zqll

1 , &

2,

-

r'100tt

&

PR0t

lLt

StLiC.t I0|'l

OO

.

STANDARD UNII

Att OI|lIRS

-

ASSIG|{ED BY FACTORY

N0it: tARtY

C0NIR0LLtRS l'1AY |,{0.I

|iAVt

I|"iIRI'lOCOUPLE ]YPtS

05, 09, 10,

11 0R 12,

TABLE

I-1

(CONTINUED)

4,

_

SFTONDARY OUTPUI

(r00P

fl1

0|'rrY)

O NO O|]IPUT

i]TAI

SSR

ON/OTF

COOL

SSR ON/OFF

'

.4 fnn

(eD

TDo

l'10D

t L S

?f12 ;

2013

TDESCRIPil0N

1/0 C0rl'1,

lrl-n

(0lrih,

l4/0

t0i!i,1, filTH

tOr'tl'l

81

85

,'C1

''fa"

2PROFILES

82

i

86

,

C2

I

C6

i

4PR0FIL[S

3T 87

t]

'

C7

I

BDBOFIIIS

84 88

,

t4 .

lB

.

16 PR0FI[[S

6 r C00l

4/20

mADC

B,

l00t

0/5 VDC

I A

] [VENI RITAY

. B RTTRA|'iSI1II

PV

l].RETRA|'{SI'1II

SP

TABLE I-2

-6-

LFE

Instrurnents

Divrsion

1

.6.2

Uqlqlsj

?q12 !

Ql2_

(

continued )

StC0l'lDARY

0UIPUI

(cont>)

1!-00P

{2

0l'lLY)

I

D

I

HrnI SSR

otl/OrF

t

i

C00t SSR

0N/0FF

F i IIAT SSR

TPR

G

i

C00t SSR

TPR

|.|

i

l.|[AT 4/20

mADC

I C00t

4/20

mADC

K , HIAT O/5

VDC

t . COOL

O/5

VDC

N IVINI

RITAY

P.

RI]RANSIII.| PV

0

RtiRANSI'IlT SP

|( I lOOA

Pt

RTD _ 1"

RTSOLUIION

I

lUOA

Pt R.|D.

0.1"

RESOTUTIO|l

R . 0/5

VDC

ll

,

4/10 mADC

I

N0 TNPUI

il'l0Dil

?012

-

t00P

2)

N0Tf: IARtY

C0|iIR0LLtRS

l'lAY

N0I |]AVt

THtRI'l0cOtjPtt

lYPts 5,9,

A, B

OR C.

958-31

REV

tJ

4,

I

:

I

5, & 6,

L

RTSPTCI IVTTY)

0l

1,

2t,

I

4'

5i

6

l',

Bi

qi

:

Al

B

C

iNPUI

C00r

(100P1

& t00P2

J

I|]ERI'lOCOUPLI

K THIRI'IOiOUPLi

R

T|lERIIOTtlUPtI

S THTRI'IOCOUPtE

I I|lERIIOCOUPtE

N

I|1iRI'IOCOUPtI

T

IHIRI'tOCOUPLT

B

IilIRI'lOC{)UPLT

PTATINTI

I I

IlTRilOTOIJPI"T

N r

/N

i

18?l'10

TlltRl'10C0UPtt

fl5ZRelll26?Re

I|lERIiI0C0UPLE

$ l?Re/i425?Re

I|1ERI'l0C0UPtE

ll I t26ZRe I Hi Rfl0C0UPt

E

ALARI'1 I itlDI

(tOOP

i

|.{ON

tATCHIN6)

O N(]

At ARI'1

1

|lI6i1 PR0tt5:j

2

[ 0ll

PR0C[55

]

HI6H DtVIAIiO|l

4,10i]

DtvlAllirt{

5 tVtf!T

RtiAY

h , OT!IAI]U|i

BAN|)

(tOOP

1'LAlCHI|'1G)

9

POiItR

FAII

A

fll6il PR0t_ts5

I | 0i4

pp0i-rss

C

fil,H

t)FVIAIl0ll

0 i 0l{

ltvIATi0l'1

I

I.)IVIA]IO|'1 BAND

(tOOP2-|1(]|.itATC|"]lNG)

G FrIGl.l PROCFSS

H

I OIi

PROI,ESS

J

i,]IGI] |)iVIATION

|( . tOiI

DIV]AIION

l'l I)iVIATIO|'1

BAt.lO

P

AUX]IIARY

HIAI

Q

.

AUXILIARY

COOI

(t0OP

2 TATCHING)

R

|"]IGH

PROT

ISS

S ,

Li]Ii

PR(]CISS

'f

ilI

.,H 0tvlAI

iliN

U

IOII DIViAIION

V OIVIATlC|{ BAND

TABI

E 1-2

(

CONTINIIED )

-7-

LFE Instruments

Divisron

J>r-Jl

REV

B

I

.6.2

MODELS

2012

&

201i

(

cont

irruerl )

B..ALARl'I2IO|)E

(LOOP

1.

NON

tATCHI|]G)

i

0i|l0ALARtl

I

1 r |-|IGHPROCTSS

'2.10*PROCISS

;3IHIGHDiVIA.IION

4

:

t0l{ DiVIAII0N

I

5:tvtNTRttAY

i

TiDiVIATI0|.lBAND

I

(t00P

P1.IA]CHI|.IC)

!

ERROR

ALARil

I

ln

iB

ic

t0

:I

HIG|| PR0CISS

I

t0i4

PR0ctss

.

HIG|I

DEVIATION

J

Lo|l

DEVIATI0N

I

DtVIAll0l'] SAND

r

9, &

10,

-

SPFIIAL

r-0LlF

L:'r

'

STANlrARl

Ullp

:

Art

0riltRs

-

ASstGNID

BY FA(]IoRY

i

TABLE

1-2

(CONTINUED)

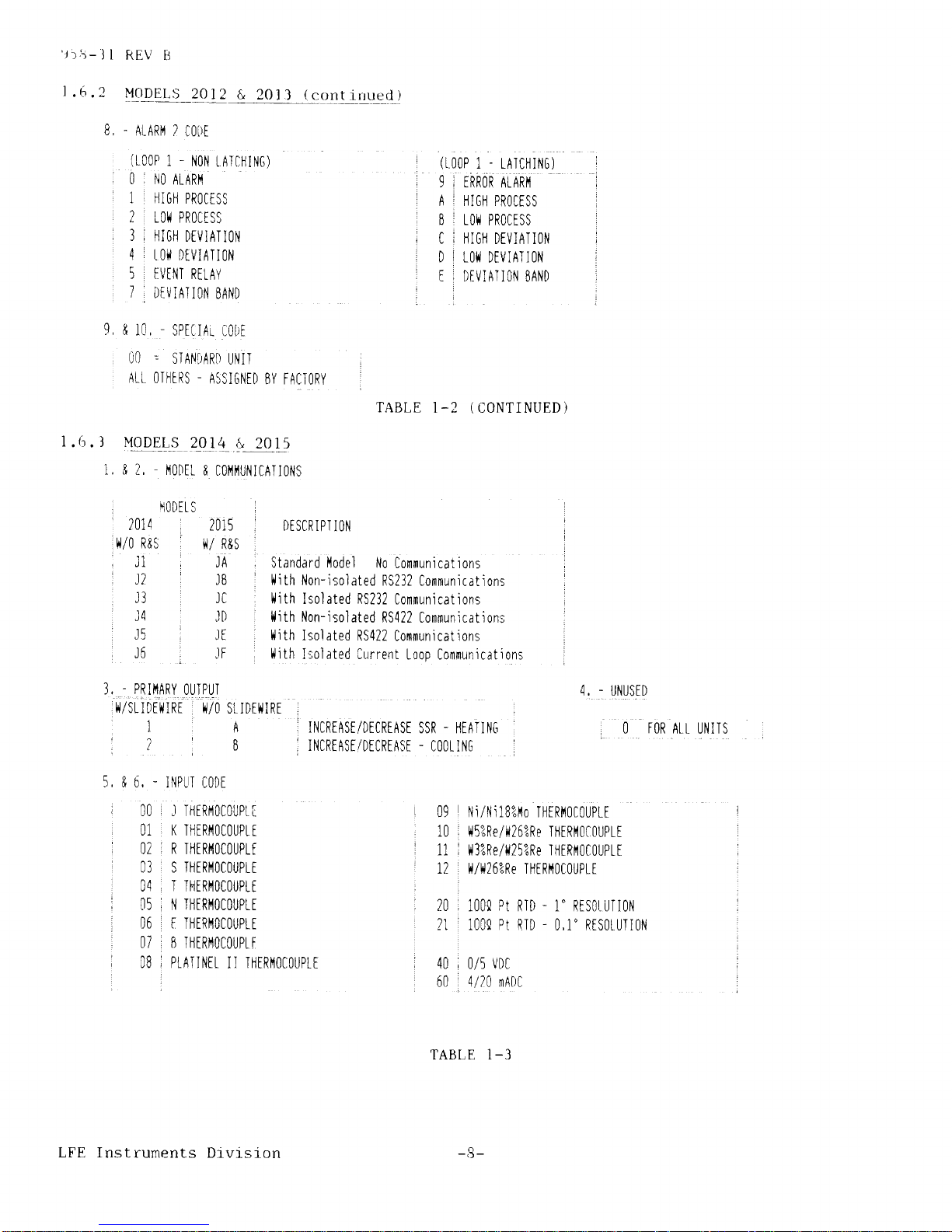

1.{r.

J

{qqE_L_.s

2_oJL

-&_

!0L5

1,

& 2, - t'l0t)tL

& C0t'll'lUNICATIO|\lS

,

h0DELS

i

,

',

2014

i

2015 I DESCRIPTION

i

tuO

R&s

ii/

R&5

,

,

11

JA

Standard

flodel |{o

Communicat ions

,

:

J?

.

JB : l,lith

Non-rsolated

RS232 Communications

.

Jl

Jt

'

ilith

Isolated

RS232

Communications

J4

JD ' l{ith Non-isolated

RS422 [ommunicationr

J5

,

lt ilith

Isolated

RS422

Communications

:

J6

,

lF

'

ilith

I;olated Current

Loop [ommunicat

ions

3,

'

PRII'IARY

0UTPUI

4, - UNUSED

itsL

rorwrBr

frlo

sr rDriltRr

]

A

INCRTASI/DICRTASE

sSR. |lIA'IN['

O

FOR

AtL UNITS

',

7

i

s

ir|1cRrRsilorcRtAsE-l]00li|'lG

:

5. & 6,

-

I|lPTT CODE

00 .t

-rlERf40f0uPr[

09

\i/Ni18""lrlo

THtRI'l0rOLJpL[

r

01 i K

.IHERf'l0C0UpLi

l0 li5""Re/lrl26?Re

.I|1[RI'10[0UPLE

i

02 i R IHtRil0C0UPtt

!

11

,

li3";Re/1i25?Re I||tRt'1gCgUPtt

03

iSIHFRI'10C0UPI[

i

12t l4l1,125?ReT|1[R||0C0UPIE

,

04, T TfttRt'l0C0UPLt

,

i

05 , |i

I|ltRt'l0C0UpL[

,

20

100a

pt

RTD - 1" R[S0LUTI0|.i

.

06 i F IHERtl0C0UPtt

?1 1000 Pt

RID - 0,1" R[S0LU.II0N

i

0i i B

Il"1tRt'10COUPt

F

i

08 i PLAI]NEL

II

T|IIRI'IOCOUPLT

!

40 i O/5 lDC

,

,

60

. 4/20

mADC

TABLE I-3

LFE Instrunents

Drvrslon

-8-

'15\-11

RIi.t/

l'l

l.b.I

M0DEI,S__201.{

& :015

(coltrrrued)

1 ,

AtARr'l/

til(iR

1

O NO

ALARI'1

1 HIG|l PROCTSS

2 r0it

PR0ctss

3 |lI6|i

DIVIA]

ION

4

tOIi

DTVIATION

5

0N T If'tER

6 0FF TII'ltR

1

DTV ] AT

i ON BANI)

B,

ALASr'1lrlili8

2

sAr'rt AS eLiniZrrr,trn

r

toB

colrnoiLrns

I{ITHOU'I

SLIDII]IRI FTIDBACK ONtY.

IHIS

DIGII iIUST

BE

"O'FOR

SLIDEIIIRT UNITS,

9, & 10, - SPECIAt C0DE

OO = S]

ANDARD

UN i I

Att OIHTRS.

ASSIGNID

BY FACTORY

TABI,E 1-3

(CONTINUED)

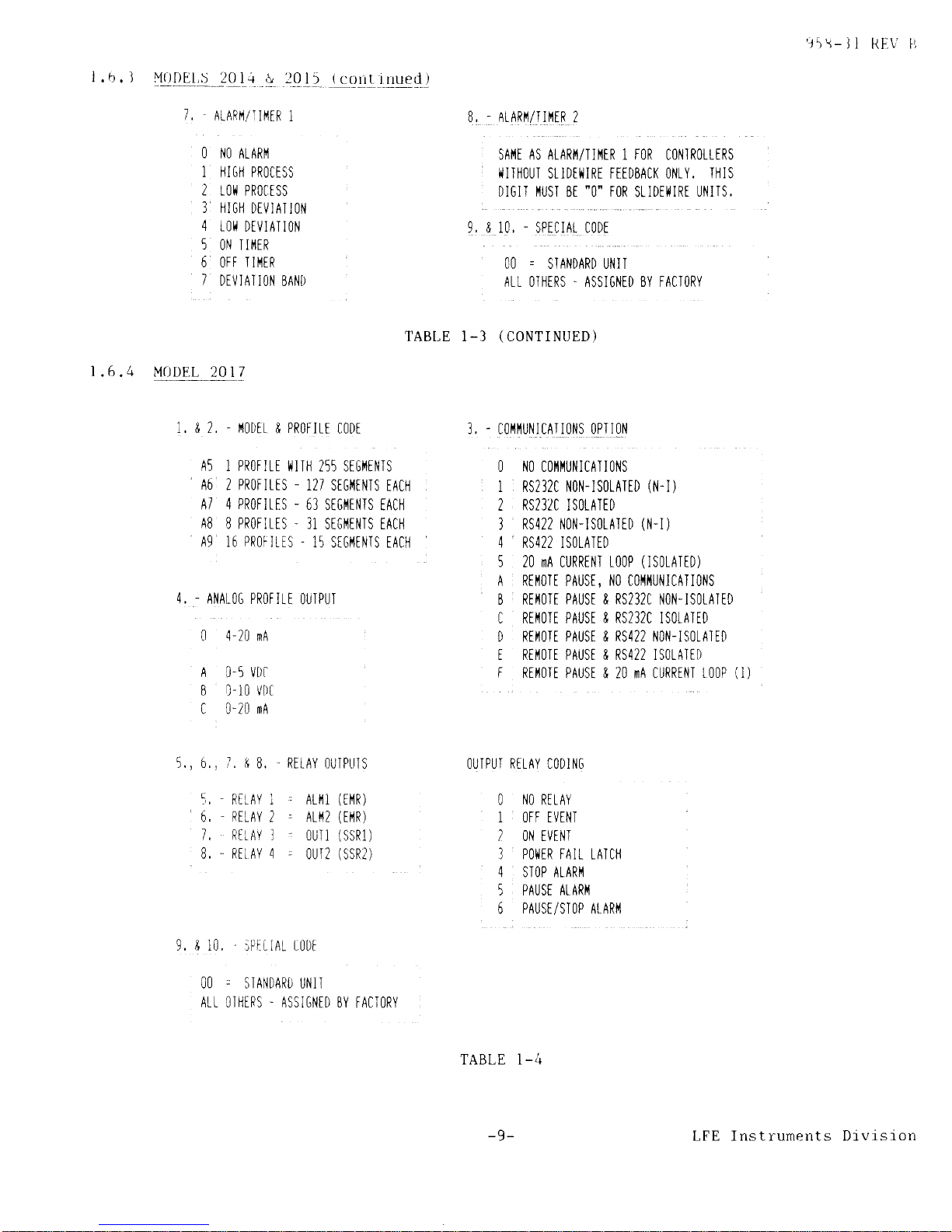

|

.6.4 MODEL

20 1

7

1, & 2,'r(0DtL & PR0r-trt

c0Dt

3, - cOl'lt'ltJt'llcAII0NS 0iTloll

A5 I PROFItT

iIIT|] 255 SIGI1TNIS

O |'lO COI'II'IUNICA.I]Ot'{S

A6 2 PROFILIS

-

127

SIGiIII'ITS

IAC|I

1 RS232C NO|'I-]SOIAIID

(|.l-I)

A7 4

PROFITIS

-

63

SIGI{I|'ITS TAC||

2

RS232C

ISOLATID

AB

8 PROFITIS . 31

SIGI'ITI,IIS TACI1

3

RS422 NON'ISOLATiD

(N-I)

A9

16

PROF]LIS

.

15 SI6I'1E|'iTS IACil 4

RS422 ISOTA]TD

5

20 mA CURREl.lI

t00P

(lS0LATtD)

A R[t'l0II PAUSE, NO COI'II|IUiIICATIONS

4,

-

ANATOG PROFITI

OUIPUI

8 REI'IOTE

PAUSE & RS232C

I'IOi.{-ISOLAITD

0 4-20 mA

I [il3[ lli:: I

[3i]l'-li!ii;il,''

I RII'1OIt PAUST & RS422 ISOTATID

A

0-5 VDi

F

Ril't0lt PAUSE & 20 mA CURRIN]

t00P

(l)

B l-10

t'Dt

C 0-20 mA

5., 6,, I. &

B. REI AY I)UIPI]TS

5,-RrLAYi. AUil(iflR)

6,

'RELAY

2 . ALf'12

(Et'1R)

7.

RitAY

]

.

OUII

(SSR1)

B,-RIIAY4

-

OUI2(SSR2)

OUIPUI RELAY CODII'I6

O

|'lO

RELAY

1 OFF EVTN]

2 O|l TVINI

] POIIER FAIt LA]C||

4 STOP ALARI'I

5 PAUSE AtARI'l

6 PAUSTISTOP AtARil

9, & 10, iP[L r At r0Dt

OO . STANDARD

UN]T

Att O]HIRS.

ASSI6|{iD BY FACTORY

TABLE 1-4

-9-

LFE Instruments Drvision

lr\-Jl

Rhl

tJ

I

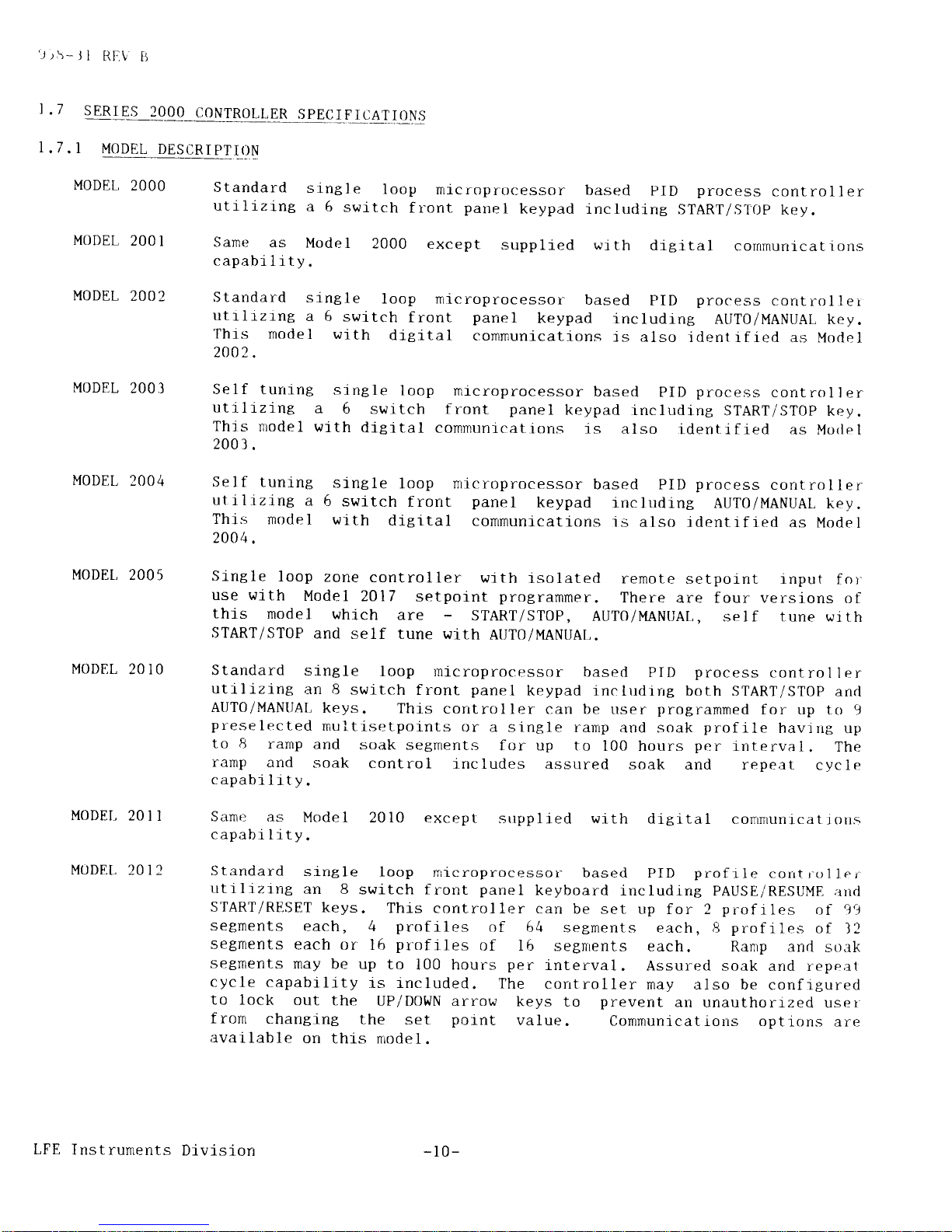

.7

sER!E!_?.0!QIqNTR0LLER

spECrFrcATroN.s

1.7.

I

MODEL

DESCRIPTI(]N

MODEL,

2OOO

MODEL

2OO1

MODEL

20O2

MODEL

2OO3

MODEL

2OO4

MODEL,

2OO5

MODEL

201O

MODEI-

201

1

MODEL

20 I 2

Standard

single

loop

microprocessor

based

PID

process

controller

ut1l1zing

a 6

switch

front

panel

keypad including

srART/srtjp

key.

Same

as

Model

2000

except

supplied wrth

digital

cornmunicattons

capability.

Standard

single

loop rnicroprocessor

based

PID

process

corrtrol

ler

utrlizing

a

6 switch

front

panel

keypad

includrng

AUTO/MANUAL

key.

Thls

rnodel

with

dieital

cornmunications

is also

ident ified

as Model

2002.

Self

turring

single

loop

microprocessor

based

PID

process

control

l er

utilizing

a

6

switch front

panel

keypad

including

srARTi srop

key.

Thjs

model

with

dieital

communicatiorrs

is

also

identified

as Morl

e1

2003.

Self

tuning

single

loop nicroprocessor

based PID

process

control

ler

utilizing

a

6

switch

frorrt

panel

keypad

including

AUTO/MANUAL

key.

This

model

with

digital

comrnunications

rs

also identifled

as Model

2004.

Srngle

loop

zone

controller

with

rsolated

remote

setpoint tnput

for

use wlt"h

Model

2017 setpolnt

protrammer.

There

are four versions

of

this

model

which

are

-

srART/srOP,

AUT0/MANUAL,

self tune with

START/STOP

and

self tune

with

AUT0/MANUAL.

Standard

single

loop microprocessor

based

PID

process

control

I er

utrlizing

an

8 switch

front

panel

keypad includirrg

both START/STOP

and

AUTO/MANIIAL

keys.

Thjs

controller

can be

user

programmed

for

up to 9

preselected

multisetpoints

or a single

ramp

and soal<

profile

havirrg

up

to 8

ramp

and

soak segments

for up to

100 hours

per

interval.

The

ranp

and

soak

control

includes

assured soak

and repeat

cycle

capabilr-ty.

Same

as

Mode

I 20 l0

capability.

except

srrpplied with

digital

conrmunicat

i ons

Standard

single

loop

rnicroprocessor^

based

PID

prof

rle corrt r-o11er-

utilizing

an 8

switch front

panel

keyboard

irrcluding

PAUSE/RESUME;rrid

SrART/RESET

keys.

Thi-s controller

can

be set

up for 2

profiles

of

j')

segments

each,

4

profiles

of

64

segments

each,8

proflles

of

l2

setments

each or

l6

profiles

of 16

setfirents

each.

Ranp and

so;rk

setnents

may

be up

to

100 hours

per

interval.

Assured

soak and repeal

cycle

capability

is rncluded.

The

corrtroller

may also be

confrgured

to lock

out

the

UP/DOWN

arro\t

keys

to

prevent

an

unauthorized

user

fronr

changing

the

set

point

value.

available

on

this nrodel.

LFE

Instruments

Divis

ion

-10-

Communications

options

are

t

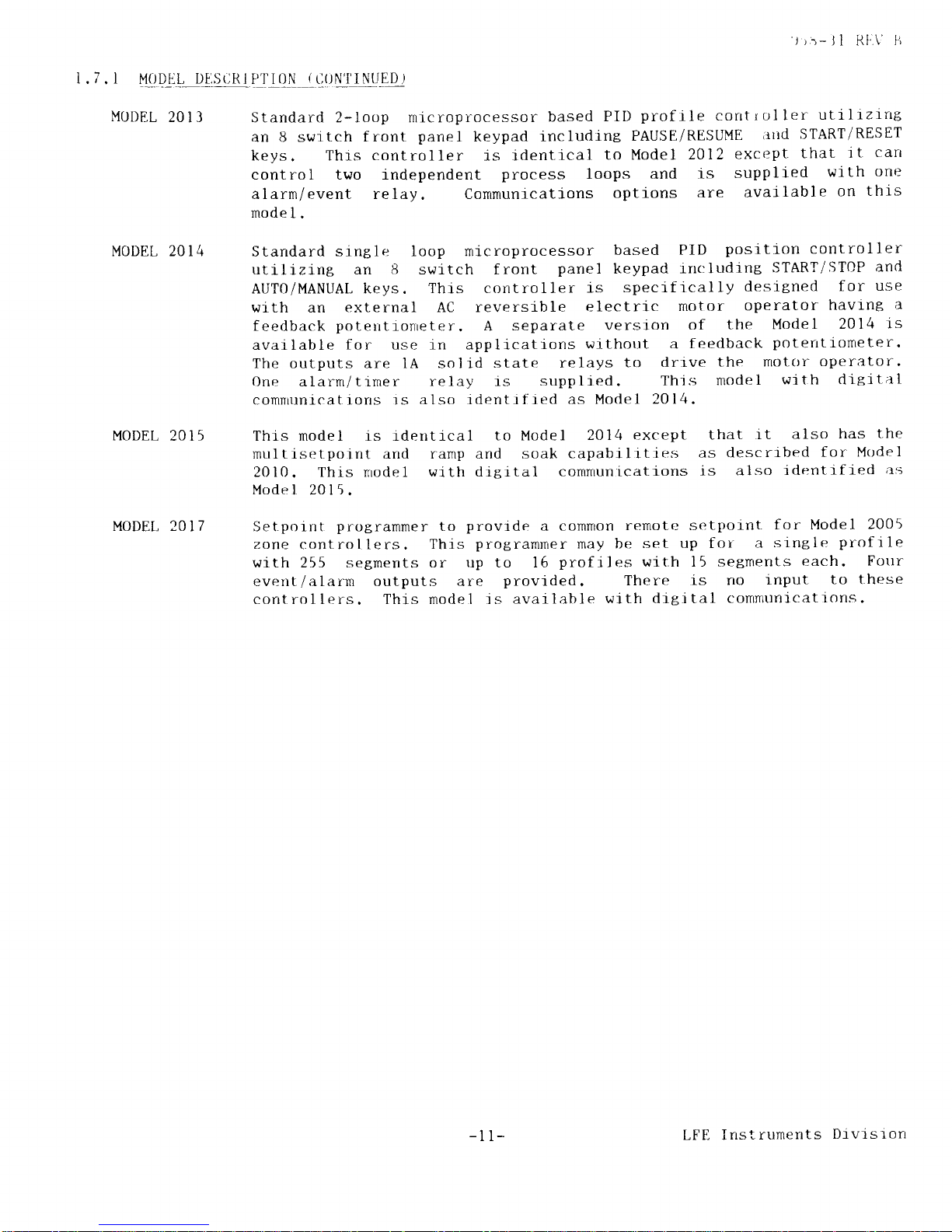

.7. I t-,lODLL

DFlStlRi

l1l

ltN

i!(rUIlIN!l_E_!!

MODEL

20 I 3

MODEL 20 I 4

MODEL

20I5

Jrr-J1

RI'.\'tr

to Model

2014

except that

rt

also

has

the

and soak

capabilrties

as descrrbed

for

Mrldel

dieital

communications

is

also

jdentrfled;rs

Standard 2-loop microprocessor

based

PID

profrle

corrt

r o1 ler

utiltztnt

an B switch

front

panel

keypad

lncluding

PAUSE/RESUME

;rnd

START/RESET

keys. This

controller

is identical

to Model

2012

except

that

tt

cart

control two independent

process

loops and

is

supplied

with

one

alarnl event relay.

mode

I

.

Communrcations

options

are

available

on

thrs

Standard

single loop rnicroprocessor

based PID

position control

1er

utilizing an B switch front

panel

keypad

irrcluding

START/STOP

and

AUTO/MANUAL keys.

Thrs controller

is

speclfically

designed

for

use

wlth an

external AC reversible

electric

motor

operator

havrng

a

feerltrack

potetrtionreter.

A

separate

version

of

the

Model

2014

is

avarlable

for use in applications

wlthout a

feedback

potentrometer.

The

outputs

are lA solid

state relays

to

drive

the

motor

operator.

One

alarmltimer

relay 1s

supplied.

Thjs

nodel

with diSit.al

cornnrunications is

also ident-tfred

as ModeI

2014.

Thrs model 1s identical

multisetpoint and ramp

2010 . This nrode I

wi

th

Model

2015.

MODET, 20 I 7

Set.point

proBramner

to

provtde

a

common

remote setpornt

for Model

2005

zone

cont.rollers.

This

progranner

may be

set up for

a

single

profrle

with 255 segments or llp to 16

profiIes

with I5

segments

each.

Fortr

event/alar-nt outputs aye

provided.

There

is no

lnput

to these

controllers. This model is

available

with drgjtal

commttnlcations.

-11-

LFE Ins*.ruments

Drvtslon

\-

i

I

i.:

t{i V

tl

!;lt\il81t

ill!.!!i

1

|AT

I ONS

IJQJ[

;,: /:

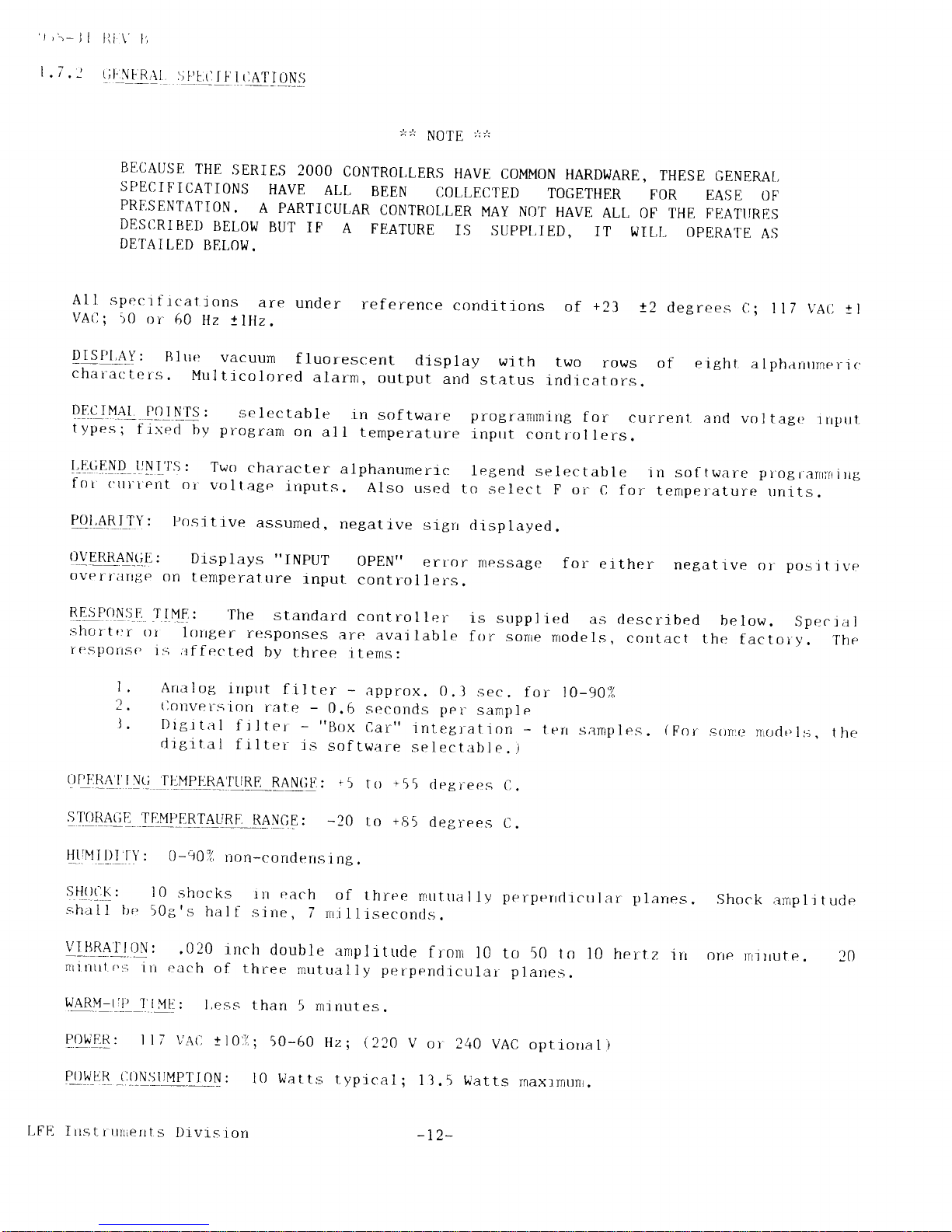

BECAUSE

THE

SERIES

2OOO

CONTROT,LERS

HAVE

COMMON

HARDWARE,

THESE

GENER]\I,

SPECIFICATIONS

HAVE

ALL

BEEN

COLLECTED

TOGETHER

FOR

EASII

OF

PRESENTATION.

A PARTICUT,AR

CONTROL,LER

MAY NOT

HAVE

ALL

OF' THE

FI1ATIIRES

DES(]RIBEI)

BEI OW

BUT

IF

A

FEATURE

IS

SUPPI,IED,

IT

WIL,I,

OPERATE

AS

DETAI

LED

BELOW.

AI

I sper:i

f rcat

jons

are

under

reference

corrditions

of

+23

t2

degrees

ll7 \'Arl

tl

!ISf'1.{!:

Bltlr:

vacuun

fluorescent

display

wrth

two

rows

of

eight

alpharrr'neri.

chalar:ters.

Multrcolored

alarm,

output

and

status

rnclrcators.

DE9JY4l

lllryls:

selectable

in

sof

tware

progranrnring

f or

currerr

t. and

vol

tagc

rrprt

types;

f ired

by

progr;rnr

on al

l temperature

inprrt

corrtr-ol

Iers.

I'-4!;EryQ

lJNIr':;:

Twrt

character

alphanumeric

legend

selectable

jn

sot

tware pi-ograrrfr

rrg,

fot

t'ttl'tent

oi-voltage

inputs.

Also

used

to

select

F or

c

for

temper-ature

rlnlts.

P(ll

4RITY:

I,ositive

assumecl

,

negatrve

slgrr

displayed.

qYU\

!'{!iE:

Displays

"INplJT

OPEN"

err-or

message

for

erther

netarlve

oi-posrrrvp

over^rilnije

on

Ienperature

]"npul,

control

lers.

B-q:jlqrysf,

l'!ME:

'Il're

standarcl

controller

is

supplied

as

ciescrrbed

below.

Specrzr1

sh0r'ter

ol

lorrg,er

responses

are

avaj

lable

for

sonre

nrodels,

contact

the

factoi-y.

Ttre

I

esportse

is

irf

f

r:cted

by

t.hree

itenrs:

I,

Arralog,

inprrt

filtt_.r

-

approx.

0.1sec.

for

2.

(loltvers'ion

rate

-

0.6

seconds per

sample

l.

Drgrt;rl

frlter

-

"Box

Car"

jntegrat.i

on

_

t

drg,ltal

f rlter

js

sof

tw;rre

selectable.

)

to-90i(

err

samp

i es

9rllt14lI."rtj

IL.-YIEE

ryEE

RANGII

:

r

5

,!!!84!E

T!{fl!8,!ALrRI.

RAN0E:

-20

trt

.55

rleEirets

C,

lo

'65

degrees

t..

(For

sorrtr.t

nroclr'ls,

lhe

Shock

amp

1i

t ucle

one

rrri

rlut e

. 20

L1!]MilllfY

:

0-907

r-ion-condensing.

SHll!,t!:

I0

shoclts

rn

r:ach

of

t hree

nrutrril

I

1y

perperrclicu

lar

p

larres

s;hall

ire

509's

hillf

sine,

7

rrr.i

lliseconris.

Ui84I!tliN:

.020

inch

double

amplrtude

fronr

l0

to 50

to

l0

hertz

rn

nrinrrt r'::

irr

r:ach

of

three

mrrtu;rlly

perpendrcular

planes.

ry48ryr-L-ltl

l]ll

P0ttER:

ll7

than

5 rninutes.

;

50-60

Hz;

(220

V

l0

l,riat

ts t

ypical;

I

240

VAC

optrorra

1)

5

Watts

rnaxrrnunr

.

:I

VA(,

ESS

r 102

oi

l.

Flq![g

_(i{),NSt

]MPT

rON

:

LFFI

Irrstrrurients

I)rvts

ion

-t2-

'153-i

l REV B

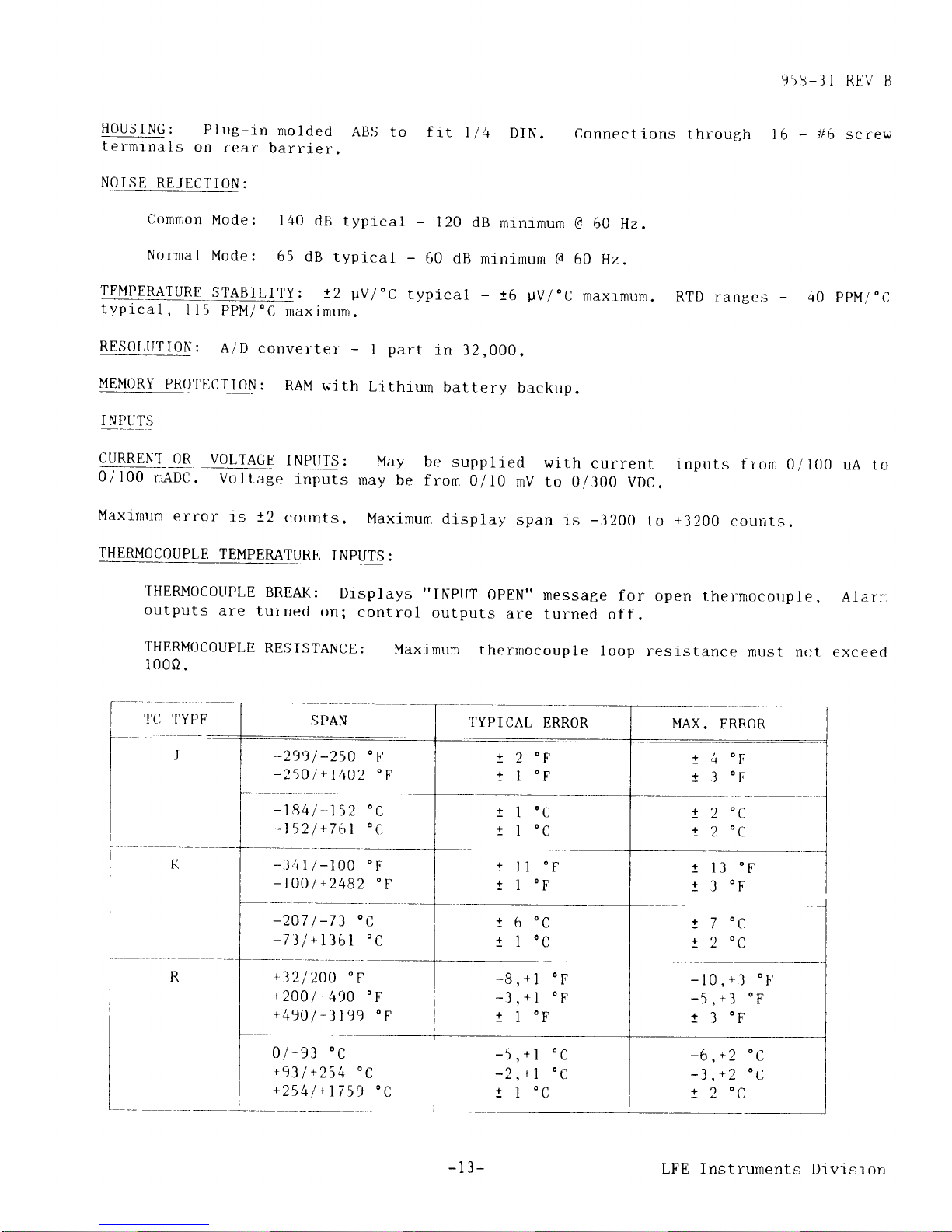

16

-

1t6

screw

FIOUSING:

Plug-rn

moldecl

ABS

to

termlnals

on

rear

barrler.

NoIS!_sErEQrflN:

f

1t ),l4

DrN

Connections

through

[]omnron

Mode:

140

dB typicar

-

120

dB

minirnum

G

60

Hz.

Normal

Mode:

65

dB

typical

-

60

dB mi-nimurn

G

6O

Hz.

TIUIIEATUB!_STABIL,ITY:

!2

uV/'C

typicat

-

!6

vv

loC

rnaximum.

I NPI]TS

CURRENL

0R

_LOLTAGE

INpltTS:

May

be

supplred

with

0/100

nrADC.

vottaee

lnilas

may

be from

0/10

mV to

0/

Maxrrnum

error

rs t2

counts.

Maximum

display

span

is

typrcal,

115

PPM/oC

rnaximunr

.

BE{,04rulQ!:

AID converter

-

MEMORY

PR0TECTION:

RAM with

I

part

in 32,000.

Lrthium

battery

backup.

RTD ranges

-

40

PPM/

"C

current,

rrrput.s

fiom 0/100

uA

to

3OO

VDC.

-3200

to

+3200

counts.

AIarnr

exceed

THERMOCOUPLE

TEMPERATURE

INPUTS

:

'IHERM0COIIPLE

BREAK:

Displays

"INPUT

0PEN"

message

f or open

t,hernrocorrple,

outputs

are turned

on;

control

outputs

are

turned

off.

THERMOCOUPLE

RESISTANCE:

Maxjmum

therrnocouple

loop

reslstance

rrust

not

1000.

SPAN

TYPICAL

ERROR

MAX.

ERROR

-2991-250'F

-25O

I

+1

4O2

o

F

t84

I

-152

l52l+761

+

-341l-100

oF

-100/

+2482

"F

-207

I

-73

oC

-7)l+1361

oC

+321200'F

+2001+49O

oF

+4901+3199

"F

0l*gl

oc

+93

1

+254

'C

+2541+

1759

'C

!4

t3

!2

tl

z

2

OC

OC

OC

OC

On

OF

O^

t,

OC

+

+

OF

OF

lr

I

OC

OC

1 l3

0F

t I

oF

r

OC

!()

11

7

'c,

2

0c

-.'

-l

1

-10

(

tl

+

+

'-)

r

f

) I

OF

(

a

+

-6

-1

!2

t

z t,

+1 o a

-13-

LFE Instruments

Divrsi.on

'j'>r-Jl

RI.l\;

tt

B

PLATIN!]1,

II

N1/Nll8%Mo

+321

+

185

oF

+185,+450

oF

+45O1+3181

oF'

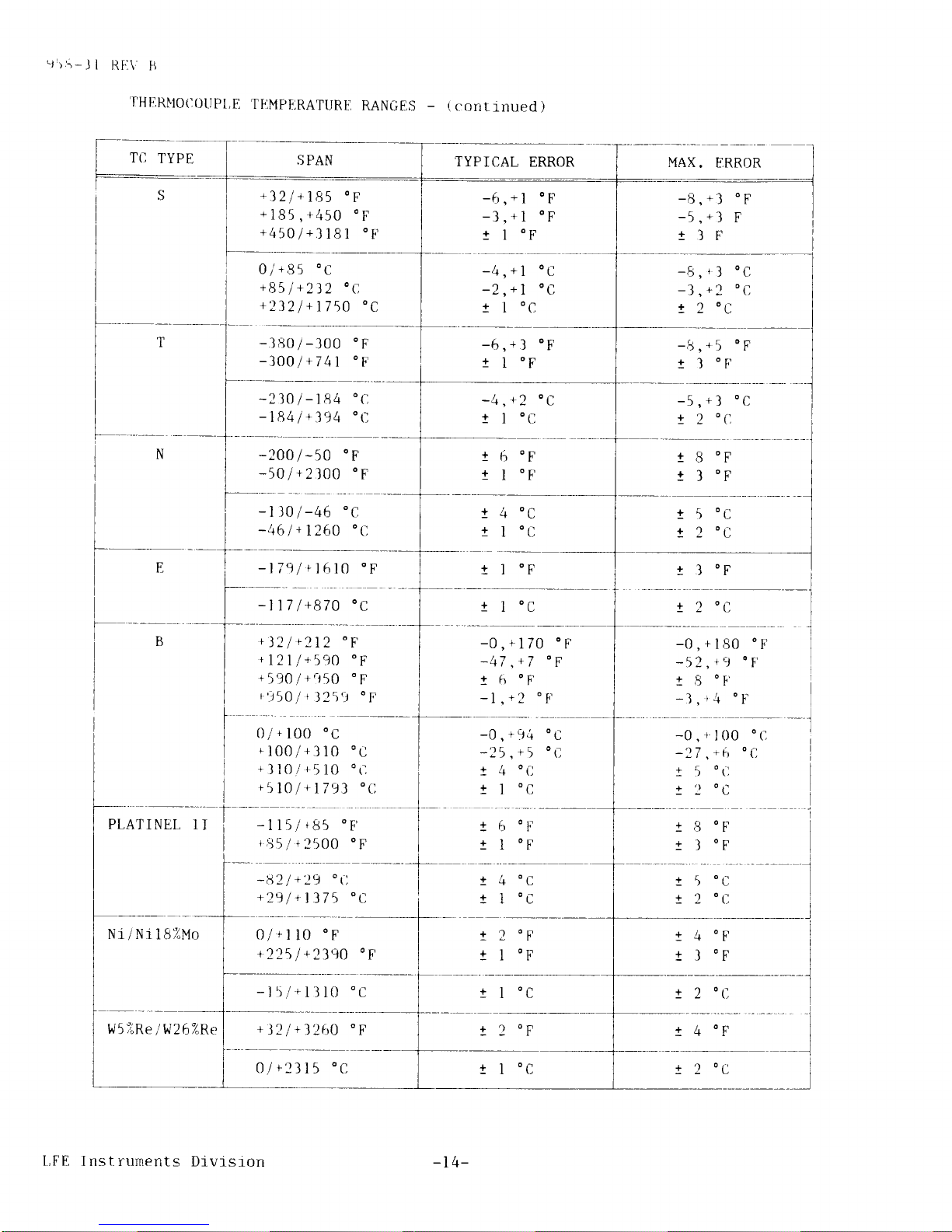

.fHII,RNIO(](JIIPI,E

TF]MPII,RATURE,

RANGES

-

(

contrnued

)

SPAN

TYPICAL

ERROR

oi*gl

oc

+B5

l

+2i2

'C,

+2321+1750

oC

-380/-300

oF

-3OOl+741

oF

-2]O

I

-184

-184

I

+394

-200/-50

oF

-501+2100

'F

-t

t0/-46

'c

-461+126O

o(l

-1791

fl

610

oF

-6,*1

oF

-l

+l

oF'

t I

oF

-4'*7

oC

-2,*7

oC

1

I

oC

r)

r

t:

t,

o^

(,

6

"F

I

"F

4'c

I

'c

t I

oF

6

"1.'

I

oF

.+ (,

1

0,-

rlF

-A

4n

+

I

oC

+)

oc

or-

I

l

L

!

-A'r5

oF

t I

oF,

o(l

,+l

oc

2

'(,

5

0c

2

0c

1

+

?

+

,)l

3

"F

t 3

0F

I

-117

l+870

oC

! 2

0c

+ l1/ 1111

otrr

').t

LrL

+121/+590

oF'

+\9Olr.J50

.F

t't\Ol1l25'l

"f

0/+100

'c

+100/+310

oC

+ll0/+510

oC

+510/

t1793

'[]

-0,+170

oF

-47

,+7

'F

t

fr

ot'

-l

1')

oFr

-0,+94

-lr5

+5

I

4

"C

!

I

oc

-0,+180

oF

-52,

t9

'F

t 8

0F'

-3,r4

o!'

-nr

,\a

t5

tl

100

+6

o

tl

OC

OC

'C

-115/

t$5

oF'

rB5/+2500

oF

t .9

ol'

t I

oF

I

+

I

OD

r

-82

l+

29

'fl

+291 +1375

oC

0/ f l

l0

'F

+22\l

*2390

oF

-15/tlll0'C

+)21+1260

oF

OC

t 4

"F

I

I

l

--l

t,FE

Inst-ruments

Divisrorr

-t

4-

! 2

0F

t 2

0c

'J)3-ll

til-\ lt

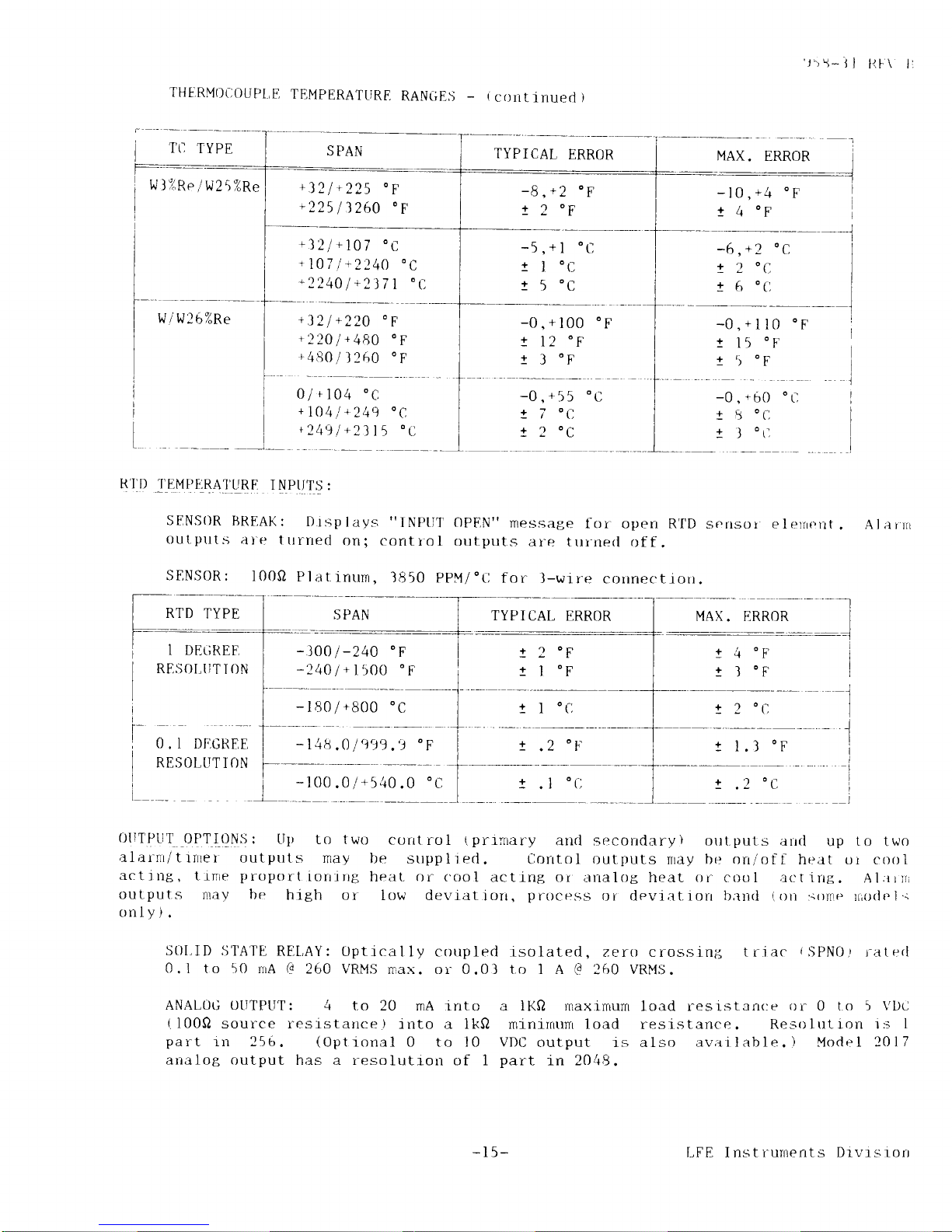

THF

RM(I(jOUPI

!-.

TFIMPERATLTRE

RANGES

_

(

cont

inued )

]'(I

TYPE

SPAN

TYPICAL

ERROR

l{l,"lRe

lvt2SiRe

MAX.

ERROR

+321+225

oF

+22513260

0F

+3'21

+107

o

C

+

107

I

+2

)40

*2240

I

+2)l

I

-R

+?

oF

!

2

0F

-5

t

t

l0

,

+d

o

F

4

0F

t,

OC

+l

OC

t,

-A

+1

oa

! 2

0c

t

6

0c

-j

I

l

W i W2

6%Re

+321+220

oF

+2201+480

oF

t4S0/l2rr0

oF

l

-0,+

!12

13

I nn o I.'

r

r

+110

0F

5

0F

r

0/

r

104

'c

+lO4l+249

"C

+2491+2115

"C

-0

t

t

+55

0C

t,

OC

,

+b0

I

o[]

)

(,

SENSoR

IJREAK:

Dtsplays

"INPtll'oPF,N"

message

for open R'I'D

sensor elr-'rnent

out

put

s

ai'e I rrrrred

on;

cont

ro l outputs

at"e

t rrr-ne<l

of f

.

SENS0R:

100s1

Plar.rnurn,

1850

ppM/"Ll

for

l-wire

connectiorr.

RTD

TYPE

MAX.

ERROR

Alainr

I DF]GREF,

REST-}I,tiT

T ON

O

.

I DF]GREE

RESOI-IIT I {]N

--l

_l

! 4

0F

t I

oF

RORER

I

(l

ol.

o

1

2

I

I

.t

.1

CPI

t

I

1

! 2

0c

t l.l

oF

!

.'2

oLl

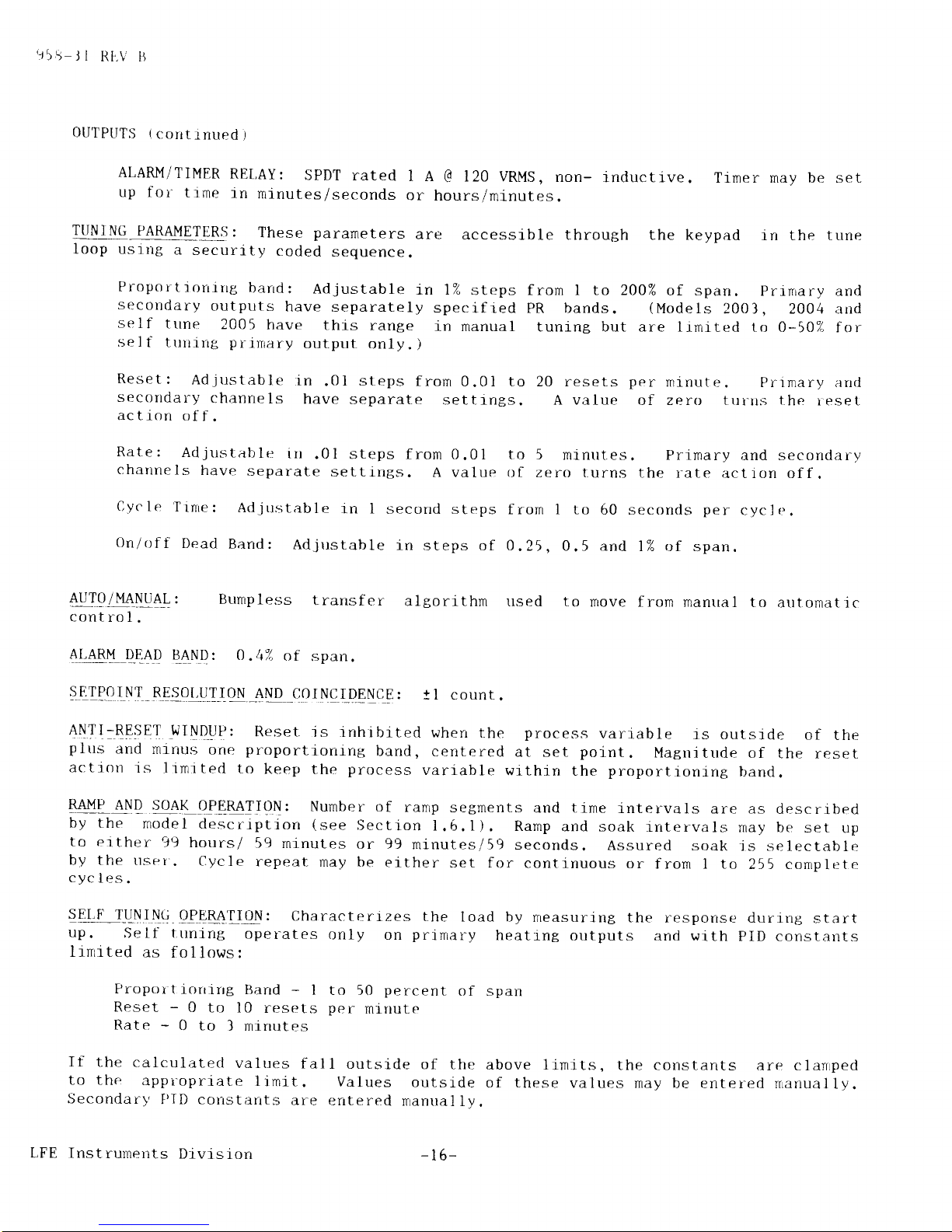

(illrPllr

OPTI(]Nsj:

LIp

to two

corrt

rcll

tprrriar-y

and secorrdary)

orrl.puts alrd

up

to

two

alarnr/trrrter

outputs

nay t-re

strpplted.

tlclrrtol outputs

rrray

be orr/off

heat ol crlol

actitrg,

tinre

proport

iorrrrrg

heat. or

('ool

actir-rg or

irnalog heat

()r

cool a<'t irrg.

A.l

;rriri

ouLputs

nlay be

high or

iow der.latiorr.

procpss

or devi;rt.iorr b;rlrl

(r)n

:;olnr.

rriurl

el.r

only).

St)l.ID

S1'ATE

RFlt,AY: Optrcal

ly coupled

0.1

to

50

rrA

@

260 VRMS

max. or-0.01

ANAL0rl

OIITPLIT: 4

to 20 mA rnto

(

100Q

source resistance )

into a 1k0

part

in 256.

(Opt

ronal 0 to l 0

analog

output has a resolution

of 1

rsolated,

?.ero crossint

triac

rSPNO.t

i^aterl

to 1 A

(q

?60

VRMti.

a

IKQ

naxrmum load res istan<:e

or 0 t o 5 \'De

mlnrrnunL load

resi

stance

.

Reso ltrt ron r.'s

I

VDC

output 1s also

av;ri I able. ) Model 2017

part

in 2048.

-15-

I-FE

Inst

rurnerrts Drvrsrorr

'J5\-JI

RL.\ ti

OUTPUTS

(

contrnued

)

AI,ARM/TIMER

REL,AY:

SPDT

rated

1 A

G

I20 VRMS,

non-

inductrve.

up fof

tfme

in

minutes/seconds

or

hours/ninutes.

TqNlllc

PAMME_TE&S:

These

pararneters

are

loop

usitrg

a

security

coded

sequence.

accessj.ble

through the keypad

rn the tune

Trmer may be set

Proportiorrrng

barrd:

Adjustable

in l%

steps

secondary

outputs

have

separately

specifred

self

ttrne

2005

have

this

range

in manual

self

turring

prirrrary

output

only.

)

Reset:

Adjustable

in

.01

sl.eps

from

0.01 to

secondary

channe

ls

have

separate

set t lnts

.

actron

off.

Rate:

Adjusl,able

in

.01 steps fron

0.01

channels

have

separate

set-tings.

A

valr_re

Cyc1e

Ttnre:

AdjustabIe

in I

second steps

On/of

f Dead

Barrd:

Adjrrstable

in

steps of

f rom I Lo 2OO%

of span.

Prinrary and

PR bands

.

(

Mode ls

200 3 , 2004 and

tuning but are lrmtted

to 0-50%

for

20 resets

per

A

value

of

mtnut e

.

zeYo I ll

I

Prirnary and

ns

the

ieset

to 5

rninutes. Primary

of zei^o turns

the rate;rc

from 1 to

60 seconds

per

O.25,0.5

and

17. of

span.

and secondary

tion off.

cyclr:.

{uf_o1lg!!!{_!:

cont

ro I

.

Bumpless

transfer

algorithm

used to

lTlove f rom manrral

to

automat ic

AIrAeU

QEAD

tsaND:

0.4i(,

of

span.

|fl(llNI_R_EIO!q_!I0N

AND

C0INitIDENCE:

rl count.

nllTI

BEfnT

IdITDUP:

Reset.

is rnhibited

when the

process

variable

rs outsrde

of

the

pltts

and

mlnus

one

proportlonrng

band,

centered

at set

point.

Magnitude

of

the reset

actloll

rs

lrmtted

to

keep

the

process

varrable

wrthin

the

proportfonrng

band.

E4{P

4liq

U4L9P-E84TIQI!:

Nurnber

of

ranrp

serments

and tirne

intervals

are

as

descrrbed

by

the

nrodel

descr_iption

(see

Section

1.6.1).

Ramp

and soak

irrtervals

may be

ser

up

to erther

99

hours/ 59

rninutes

or 99

mlnutes/59

seconds.

Assured

soak

js

selectable

by the

tlsPt.

Cycle

repeat

may be

either

set

for continuous

or

from I to

255 complete

cycles.

qUl-.LlNllllt

Ql-EqALI0I:

Characterizes

the

load by

measurjnB

the

response durrng

start

up.

Self trrning

operates

only

on

primary

heating

outputs and with

PID constants

lrnLrted

as

f ol1ows:

F'ropoi-t

iorrirrg

Il;rrrd

-

1

Reset

-

0

to 10

resets

Rate

-

0 to

I rnlnutes

If

t-he

calcul;rtecl

values

fal

to the

appr-opriate

1imit.

Secondary'

['TD cor.tstatlts

are

LFE Instruments

D-ivisrorr

to 50

percent.

of span

per

minute

I outside

of the

above lirnits,

the constants

are clanrped

Values

outside

of these

values may

be entered rranually.

errtered

manual

ly.

-r6-

qQsiITIII

.caITBq!

qABAyEIq$:

Increase

ancl

decrease

solrd

stare

retays

to

operate

the

external

motor

operator.

A

standard

controller

nray

be

1000Q

slrdewire

ior modified

io,

.,."

with

a

l00o

or

1350

slrdewire).

deadba.d

is

selectabre

from

0.0

to

25.5

percent

of

span.

controrler

will

slldewrre

connections.

slidewr-re

calibration

can

be

either

rnanual

autorrratic

slidewrre

calrbratlon

routrne.

'lr5-ll

RI-\'

',

are

pi-ovjded

used wtth

a

Drrve

rrni

t

detect

operr

or

a rrrritlue

qqryu.t'l-Il4.Tl_!l\Q!!!oNs:

A11

Series

2000

controtlers

excepr

mortel

2005

rriay