Leyman TLS3510RL Hide-A-Way Installation Manual

Installation Manual

TLS3510RL Hide-A-Way®

Trailer Side Gate

LEYMAN MANUFACTURING CORPORATION

10335 Wayne Avenue

Cincinnati, OH 45242

1-866-LEYMAN-1 • 1-866-539-6261 • 513-891-6210

Fax 513-891-4901

www.leymanlift.com

sales@leymanlift.com

LML00084-04/20/17

2

TABLE OF CONTENTS

General Terminology

3

Gen. Spec. – Min. Mounting Space Req.

4

Before you install the Lift Gate

5

Pre-Installation of the Lift Gate

6

Side Door Mounting Information

7

Out Stop Mounting and Floor Thickness

8

Installation of the Lift Gate

9 - 10

Toggle Switch or Walk Around Installation

11 – 12

Charge Line

13

Grounding Recommendations

14

Wiring Diagrams – Circuit Breaker and

Additional Options

15 – 16

Installation Adjustments

17

Installation of Safety Decals

18

Final Installation Inspection

19

Recommended Oils and Lubrication

20

Operating Instructions

21

Operating the Optional Emergency Hand Pump

22

Maintenance Minder 2

23 - 25

Electric / Hydraulic diagram - Reference 26

Troubleshooting Guide

27

Notes

28

3

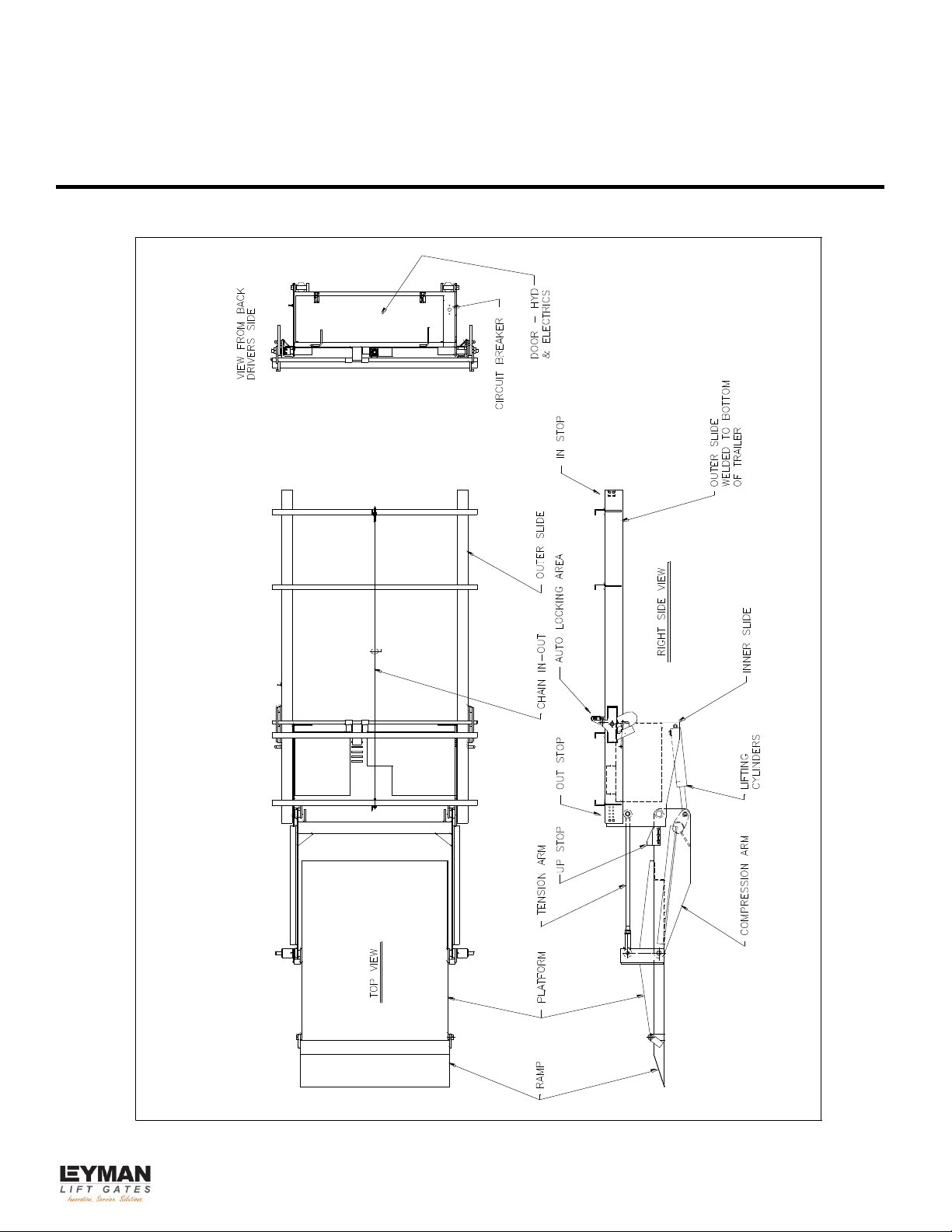

GENERAL TERMINOLOGY

4

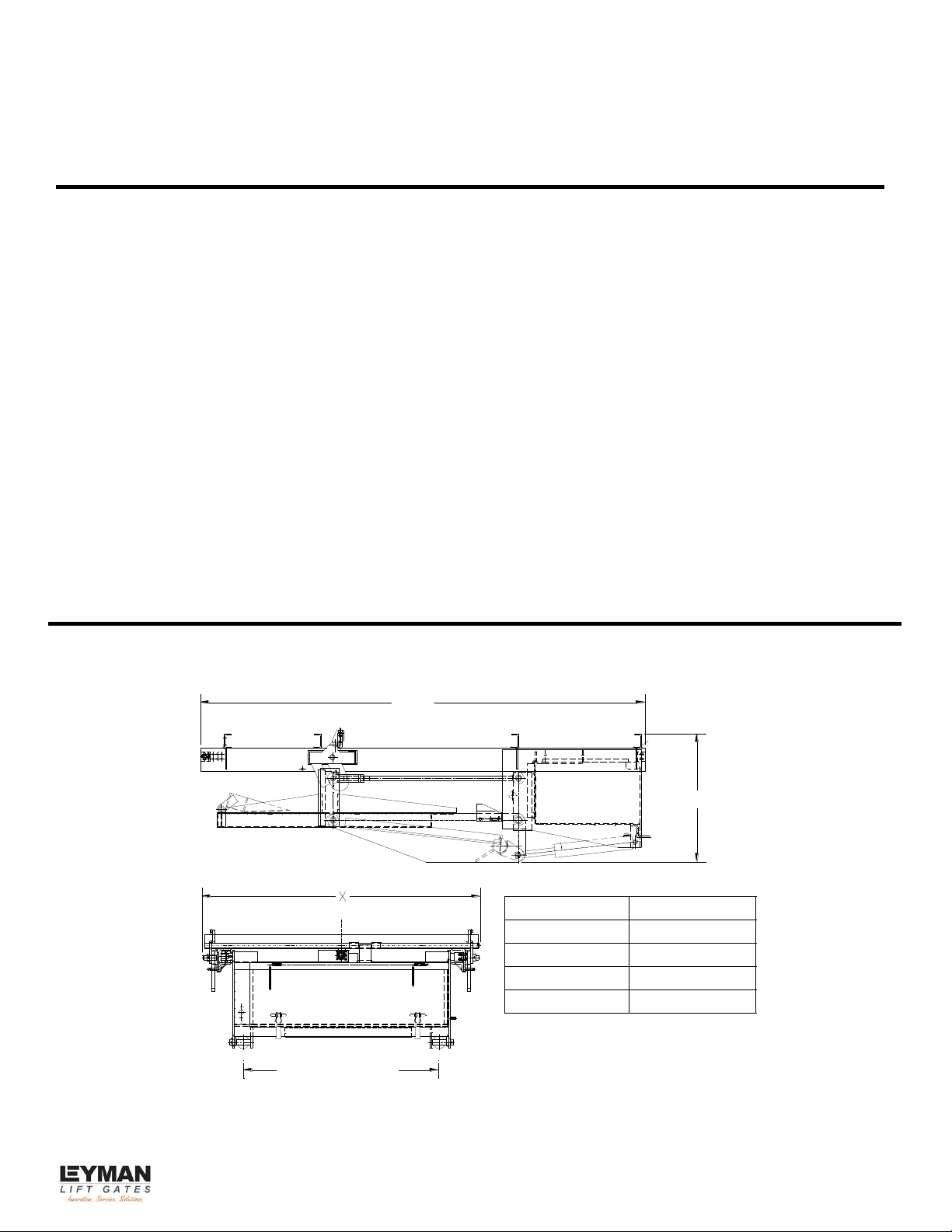

GENERAL SPECIFICATIONS

CUSTOMER:

_____________________________________________________

MODEL:

TLS3510RL

CAPACITY:

3500 lbs.

TYPE:

Trailer Side Door Lift Gate

HYDRAULIC

PRESSURE:

2500PSI – Up Function

800PSI – In/Out Function

OPERATION:

Power up/Gravity down

Power in/out

SERIAL #:

_____________________________________________________

MINIMUM MOUNTING SPACE REQUIREMENTS

MINIMUM SPACE REQUIREMENTS NEEDED TO INSTALL THE TLS3510 SERIES GATE.

PLATFORM WIDTH

DIM. X = 90

DIM. X = 78

DIM. X = 66

DIM. X = 60

DIM. X WIDTH REQ.

27 1/2

95 3/4

PLATFORM WIDTH

72

48

60

42

5

BEFORE YOU INSTALL THE LIFT GATE

1. Check the lift gate for shipping damage.

2. Remove the shipping bands, etc. if the gate was shipped vertically, set the gate on the ground.

CAUTION – DO NOT INSERT FORKLIFT FORKS AT BOTTOM OF GATE NEAR DOOR.

Remove the shipping bands, etc. To set lift gate horizontal, chain or lash top cross tube

near chain anchor

3. Remove the box, open and read the installation manual. Check that all major parts have

arrived, such as the electrical box, optional mud flap (if ordered), etc.

4. Inspect the area under the trailer where the lift gate is to be mounted. Be sure the area is clear

of obstructions where the lift gate will be installed. Check the cross member material. If the

cross members are made of aluminum, the aluminum conversion kit (Option #133TLS) must

be ordered and used to mount the lift gate.

5. The use of a battery charger as the sole power source to operate the lift gate is unauthorized

and will prevent the lift gate from working properly. The lift gate must always be operated in

conjunction with at least one (1) 12 volt heavy duty lift gate battery. A minimum of 9.5 volts

must be maintained in order for the DOWN valve and 10.5 volts for the IN/OUT valves to

operate.

6. Read the following pages prior to beginning the installation.

A. Minimum mounting space requirements

B. Pre-installation of the lift gate.

C. Side door mounting information.

D. Installation of the lift gate.

E. Installation adjustments.

6

PRE-INSTALLATION OF THE LIFT GATE

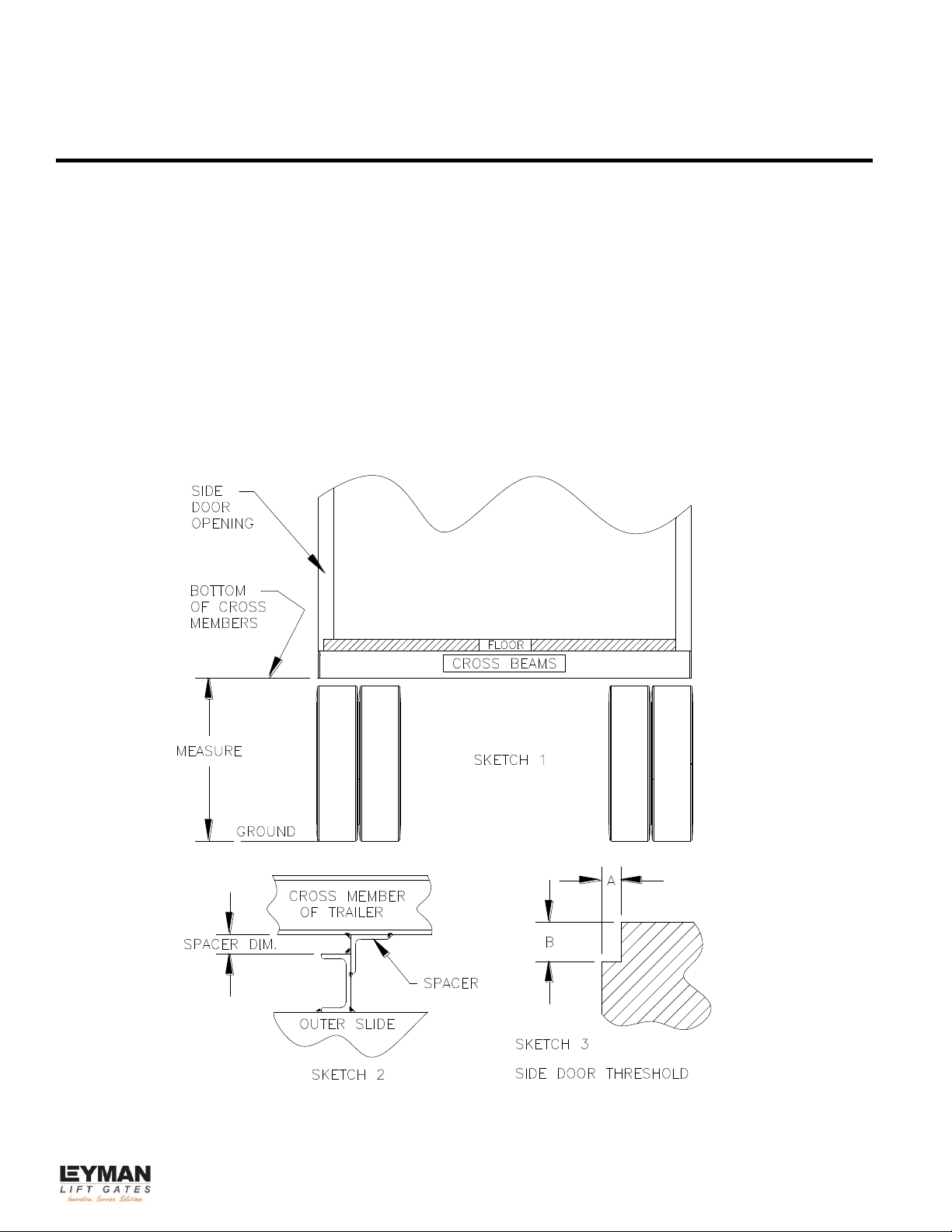

1. Measure from the bottom of the cross members to the ground. If this measurement is less than

47 inches, spacers will not be required. This measurement must be 41.5 inches minimum in

order to yield 14 inches ground clearance for the gate. If the measurement is more than 47

inches, the amount in excess of 47 inches is the height of the spacer that must be added to the

four channels at the top of the Outer Slide. See Sketches 1 and 2.

2. Check the side door threshold. See Sketch 3. For the platform to properly enter the opening,

dimension “B” must be at least 1.5 times dimension “A”.

7

SIDE DOOR MOUNTING INFORMATION

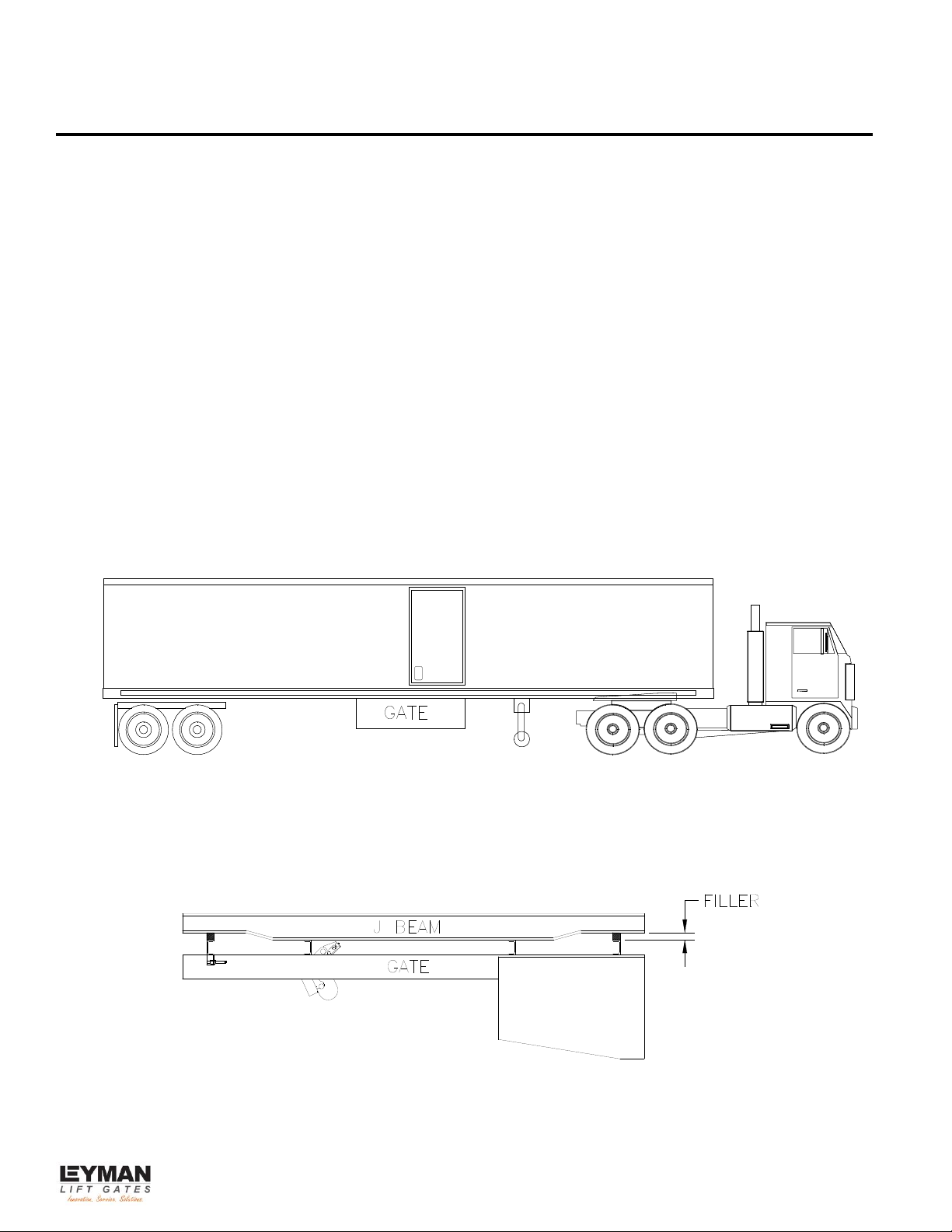

Installation of Leyman side gates that are 42” wide are usually centered on the door opening

providing that the door opening is at least 42” wide.

For installation of Leyman side gates that are wider than the door opening, we recommend the gate

be offset to the rear of the trailer so when the door is open, it will not interfere with movement of the

platform.

Depending on the side door threshold, the platform may not fill the gap between the floor and the

platform. There are three options to correct this:

1. Notch the tip of the platform.

2. Add material to the tip of the platform (use a minimum thickness of 3/16” for proper

strength.)

3. Fabricate a flip plate to span the gap.

NOTE: End user option, material is not provided by Leyman.

MOUNTING ON “J” CHANNELS

NOTE: FILLER MATERIAL NOT SUPPLIED BY LEYMAN

NOTE: Mounting to aluminum cross members will require the use of kit #133TLS.

8

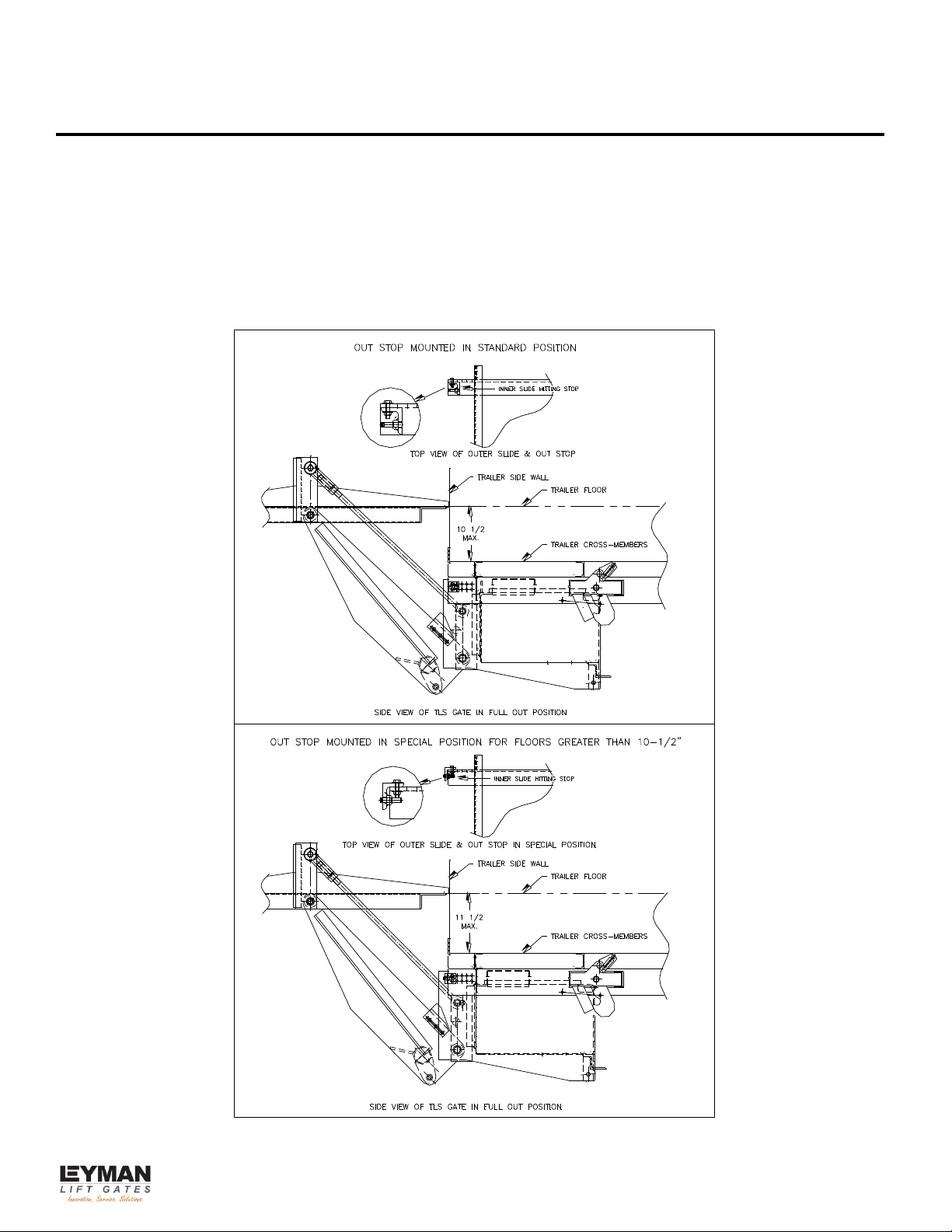

OUT STOP MOUNTING AND FLOOR THICKNESS

Determine the total floor thickness (vertical distance between the bottom of the cross-members

and the top of the floor inside the trailer). If that dimension is 10-1/2” or less, leave the Out Stops

mounted in the standard position. Mount Outer Slide rail face (fixed rail) flush with the rub rail.

If the total floor thickness dimension is larger than 10-1/2”, the Out Stops must be flipped around

as shown in the bottom half of the sketch below. In this case, the set screws in the Out Stops are

reversed as well. CAUTION! Out Stops must be adjusted so that Front Chain Anchor does not

strike Chain Cover Box.

9

INSTALLATION OF THE LIFT GATE

1. Mark the door opening on the vertical rub rail.

• For the 42” wide gate, mark the centerline of the door opening. For all others, mark the

leading edge of the door opening.

• NOTE: The centerline of the 42” wide gate is the center of the chain. Mark the centerline

on the channel. For all others mark the leading edge of the platform on the channel.

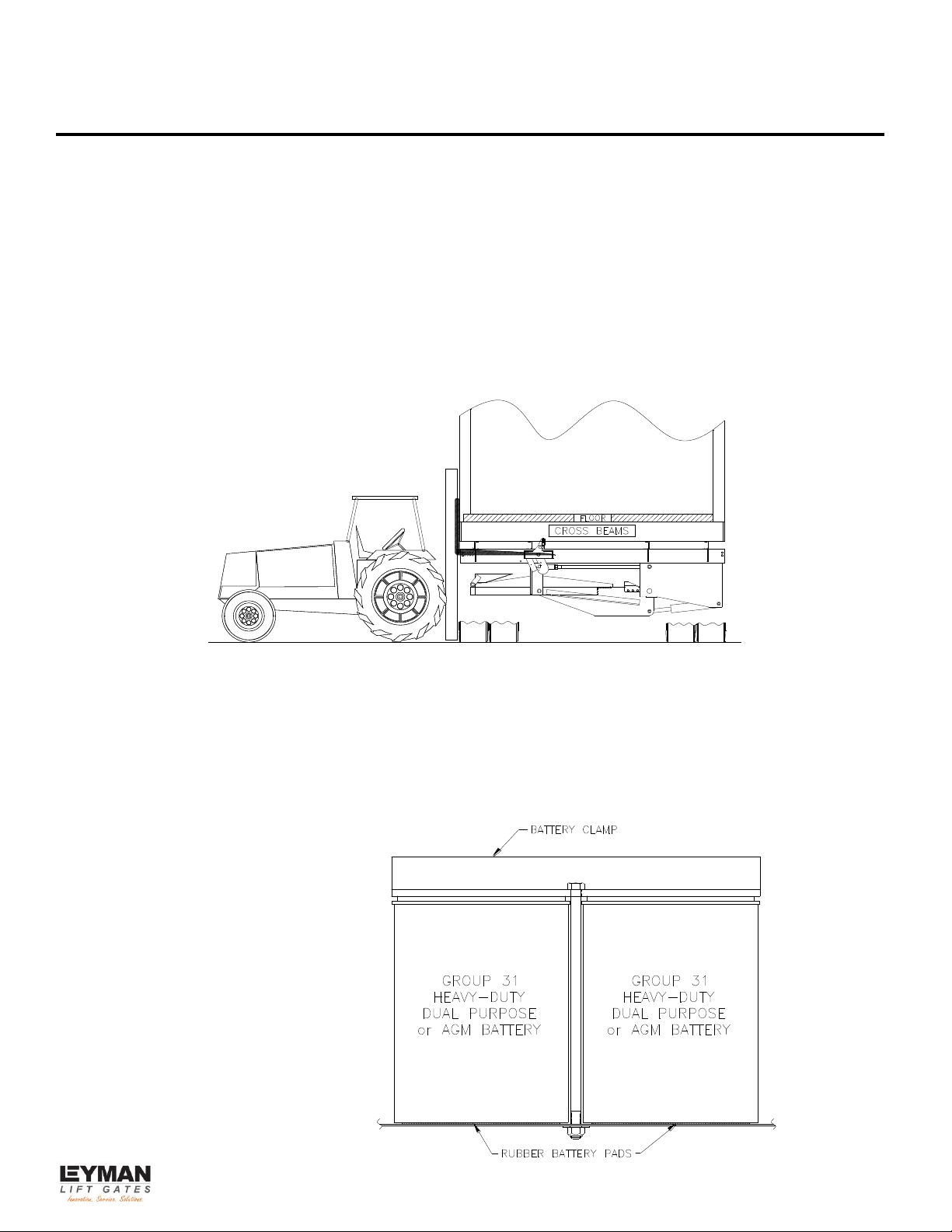

2. Raise the lift gate, use a lift truck. See the sketch below. Position the forks under the

spreaders (the four (4) three inch channels). Spread the forks as wide as possible.

CAUTION: Do not hit anything with the forks. Clamp the unit to the forks using two (2) “C”

clamps.

3. Pick the unit up, position it under the trailer. Line up the marks, which you put on the gate and

the rub rail. The front edge of the gate’s Outer Slide should be flush to the outside of the rub

rail. Weld the four (4) corners to the cross members.

4. Mount the electrical box. See the wiring drawings for location information. Drawings are

labeled “Toggle Switch Electrics or Walk-Around Electrics”. Finish wiring.

5. Install at least two (2) heavy-duty Dual Purpose or AGM batteries. Place rubber battery pads

under batteries. See sketch.

Loading...

Loading...