Leybold vacuum TRIVAC S 4 B, TRIVAC B Series, TRIVAC D 4 B, TRIVAC D 8 B, TRIVAC S 8 B Operating Instructions Manual

TRIVAC®B

Rotary Vane Vacuum Pump

S/D 4 / 8 B

Cat. No.

102 45/46/55/56

103 01/02/03/04/05/06/07

103 11/12/13/14/15/16/17

112 45/46/55/56

113 01/02/03/04/05/06/07/08

113 11/12/13/14/15/16/17/18

Operating Instructions

Vacuum Pumps Instrumentation Fittings and Valves LEYBOLD VACUUM

GA 01.201/8.02

Contents

2

Contents

Page

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Supplied equipment . . . . . . . . . . . . . . . . . . . . . 5

1.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Connection to the system . . . . . . . . . . . . . . . . 9

2.3 Electrical connection . . . . . . . . . . . . . . . . . . . 10

2.3.1 Pump with single-phase AC motor . . . . . . . . . 10

2.3.2 Pump with three-phase AC motor . . . . . . . . . 10

2.4 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.1 Areas of application . . . . . . . . . . . . . . . . . . . . 11

2.5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.1 Pumping of non-condensable gases . . . . . . . 12

2.5.2 Pumping of condensable gases and vapours . 12

2.6 Switching off/shutdown . . . . . . . . . . . . . . . . . 12

2.6.1 Shutdown through monitoring components . . . 13

2.6.2 Failure of the control system or the

mains power . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Checking the oil level . . . . . . . . . . . . . . . . . . . 14

3.1.1 Checking the condition of N 62 or HE-200 Oil 14

3.2 Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Cleaning the dirt trap . . . . . . . . . . . . . . . . . . . 15

3.4 Removing and fitting the internal demister . . . 15

3.5 Disassembly and reassembly of the

electric motor . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 Replacing the outer shaft seal . . . . . . . . . . . . 17

3.7 Removing and remounting the pump module . 18

3.7.1 Removing the pump module . . . . . . . . . . . . . 18

3.7.2 Remounting the pump module . . . . . . . . . . . . 19

3.8 Leybold service . . . . . . . . . . . . . . . . . . . . . . . 20

3.8.1 Waste disposal of used pump materials . . . . . 20

3.9 Storing the pump . . . . . . . . . . . . . . . . . . . . . . 20

3.10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 21

3.11 Maintenance plan . . . . . . . . . . . . . . . . . . . . . 22

EEC Declaration of Conformity . . . . . . . . . . 24

Figures

The references to figures, e.g. (1/2) consist of the Fig.

No.and the Item No. in that order.

Indicates procedures that must be strictly

observed to prevent hazards to persons.

Indicates procedures that must strictly be

observed to prevent damage to, or

destruction of the equipment.

Leybold Service

If a pump is returned to Leybold, indicate whether the

pump is free of substances damaging to health or

whether it is contaminated.

If it is contaminated also indicate the nature of the

hazard. Leybold must return any pumps without a

“Declaration of Contamination” to the sender’s address.

Disposal of waste oil

Under the amended law relating to waste disposal dated

November 1, 1986 (valid in the Federal Republic of

Germany) the disposal of used oil is subject to new

provisions. According to legislation relating to waste

disposal the so-called principle of causality is applied.

Hence, anyone in possession of used oil is responsible

for its proper disposal.

Used oils coming from vacuum pumps must not be

mixed with other substances.

Used oils from vacuum pumps (LH-oils on the basis of

mineral oils) having been affected by normal

contamination due to oxygen from the ambient air,

increases in temperature and mechanical wear, must be

disposed of as used oil in accordance with the

regulations. Used oils from vacuum pumps that have

been contaminated by other substances must be

labelled, stored and disposed of as special waste with

reference to the kind of contamination.

When disposing of used oil please observe the safety

regulations that are valid in your country.

In many countries proof of were the oil has finally been

left is required by Law and often shipping of such

contaminated waste requires permission by the

authorities. Waste disposal information is available

through:

Bundesamt für Gewerbliche Wir tschaft (BAW)

Frankfurter Str.29-31

D-65760 Eschborn/Taunus

Phone: +49 (0)6196 4041 – Telex: 415603/04

Warning

Caution

123

Description

3

1 Description

TRIVAC-B pumps are oil-sealed rotary vane pumps.The

TRIVAC S 4 B and S 8 B are single-stage pumps, and

the TRIVAC D 4 B and D 8 B are dual-stage pumps.The

number in the type designation (4 or 8) indicates the

pumping speed in m3x h-1.

TRIVAC-B pumps can pump gases and vapours and

evacuate vessels or vacuum systems in the fine vacuum

range. Those of standard design are not suitable for

pumping greater than atmospheric concentrations of

oxygen, hazardous gases, or extremely aggressive or

corrosive media.

The drive motor of the TRIVAC-B is directly flanged to

the pump at the coupling housing. The pump and motor

shafts are directly connected by a flexible coupling.The

bearing points of the pump module are force lubricated

sliding bearings. All controls as well as the oil-level glass

and the nameplate are arranged on the front. All

connections are to be found at the sides of the pump.

The oil-level glass is provided with prisms for better

observation of the oil level.

The pump module consists of assembly parts which are

pin-fitted so as to allow easy disassembly and

reassembly. The pump module can be easily removed

without special tools.

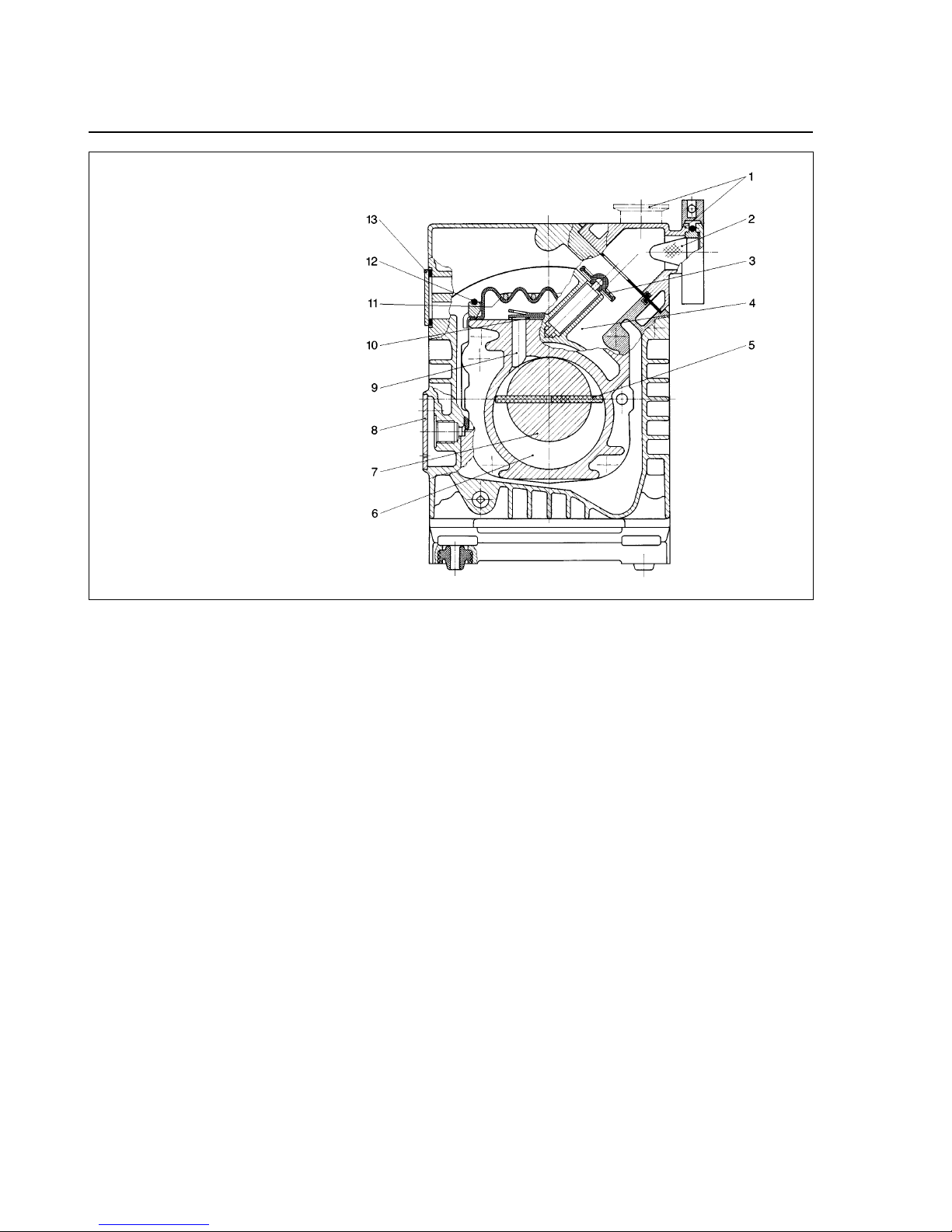

1.1 Function

The rotor (2/7), mounted eccentrically in the pump

housing (2/6) (pump chamber), has two radially sliding

vanes (2/5) which divide the pump chamber into several

compartments. The volume of each compartment

changes periodically with the rotation of the rotor.

As a result, gas is sucked in at the intake port (2/1).The

gas passes through the dirt trap sieve (2/2), flows past

the open anti-suckback valve (2/3) and then enters the

pump chamber.In the pump chamber, the gas is passed

on and compressed, after the inlet aperture is closed by

the vane.

The oil injected into the pump chamber is used for

sealing and lubricating. The slap noise of the oil in the

pump which usually occurs when attaining the ultimate

pressure is prevented by admitting a very small amount

of air into the pump chamber.

The compressed gas in the pump chamber is ejected

through the exhaust valve (2/10). The oil entrained in the

gas is coarsely trapped in the internal demister (2/11);

there the oil is also freed of mechanical impurities. The

gas leaves the TRIVAC-B through the exhaust por t.

During compression, a controlled amount of air – the socalled gas ballast – can be allowed to enter the pump

chamber by opening the gas ballast valve.

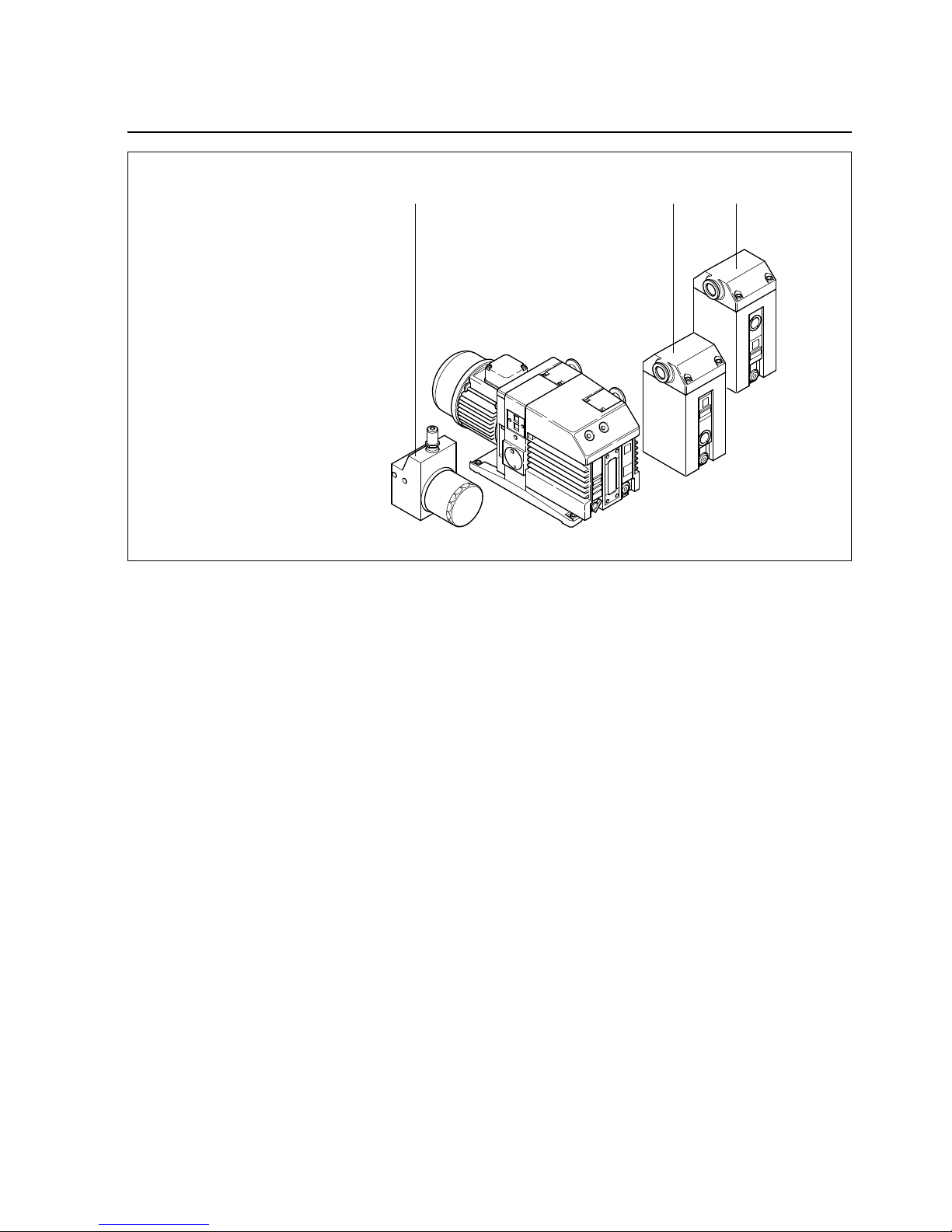

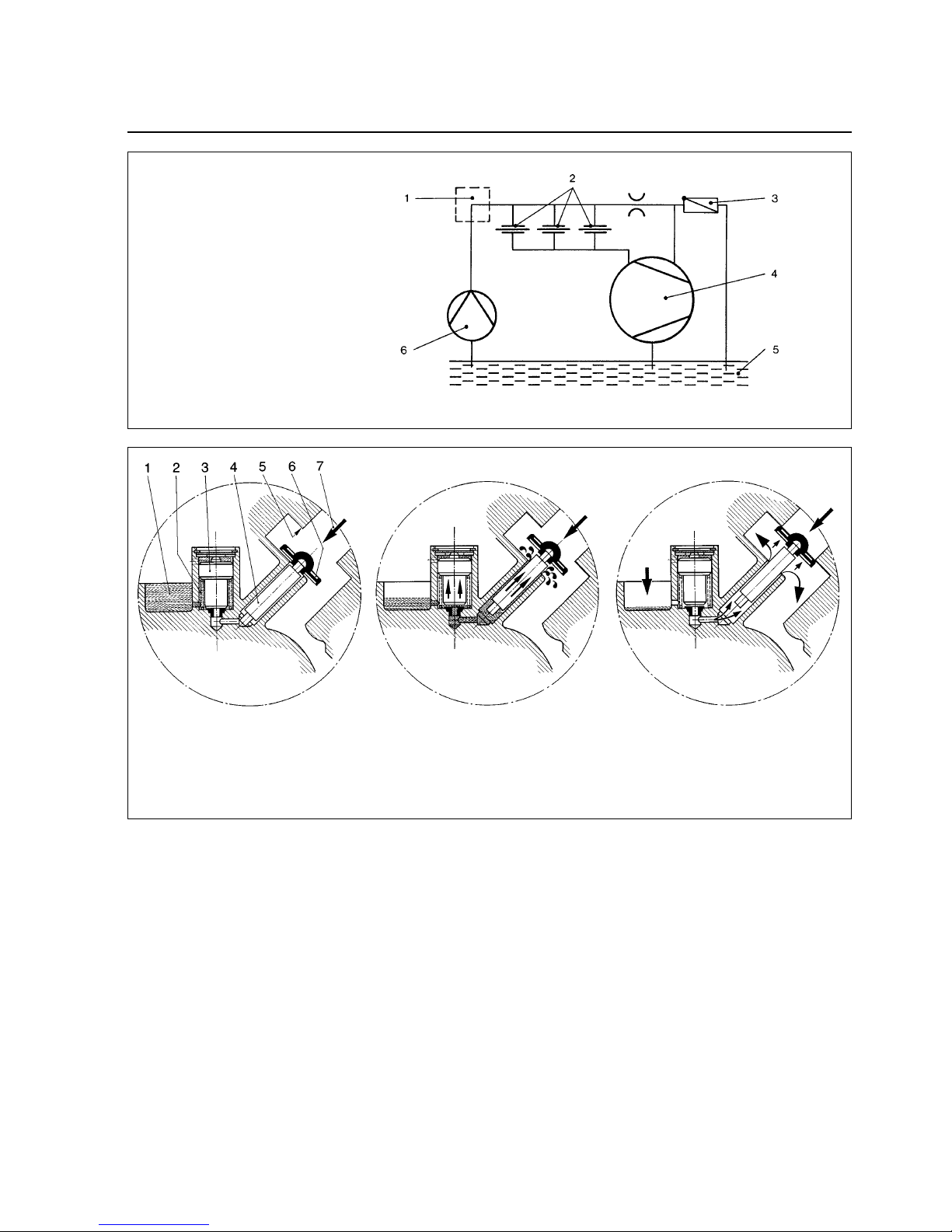

Key to Fig. 1

1 Oil filter OF 4-25

2 Exhaust filter AF 4-8

3 Condensate trap AK 4-8

Fig. 1 TRIVAC-B with accessories

The gas ballast stops condensation of vapours in the

pump chamber up to the limit of vapour tolerance as

specified in the technical data for the pump (the data

refer to water vapour).

The gas ballast valve is opened and closed by turning

the gas ballast knob (7/5) on the front.

To enable the TRIVAC-B to be used at intake pressures

as high as 1,000 mbar, a special lubricating system was

developed featuring force-lubrication of the sliding

bearings.

An oil pump (3/6) pumps the oil from the oil reservoir

(3/5) into a pressure-lubrication system which supplies

oil to all bearing points (3/2).From there the oil enters the

pump chamber area (3/4) of the vacuum pump.

The oil pump is fitted in the front end plate on the

coupling side of the pump module.The oil suction line is

placed low, resulting in a large usable oil reser voir.

The oil is separated from the gas in the TRIVAC-B in two

steps as described above. First, small droplets are

coalesced into large drops in the internal demister (2/11)

fitted above the exhaust valve (2/10). Then, the large

drops fall into the oil reservoir as the exhaust gas is

diverted by the inner walls of the oil case.Thus a low loss

of oil is obtained. This and the large usable oil reservoir

ensure long intervals between oil changes even at high

intake pressures.

Description

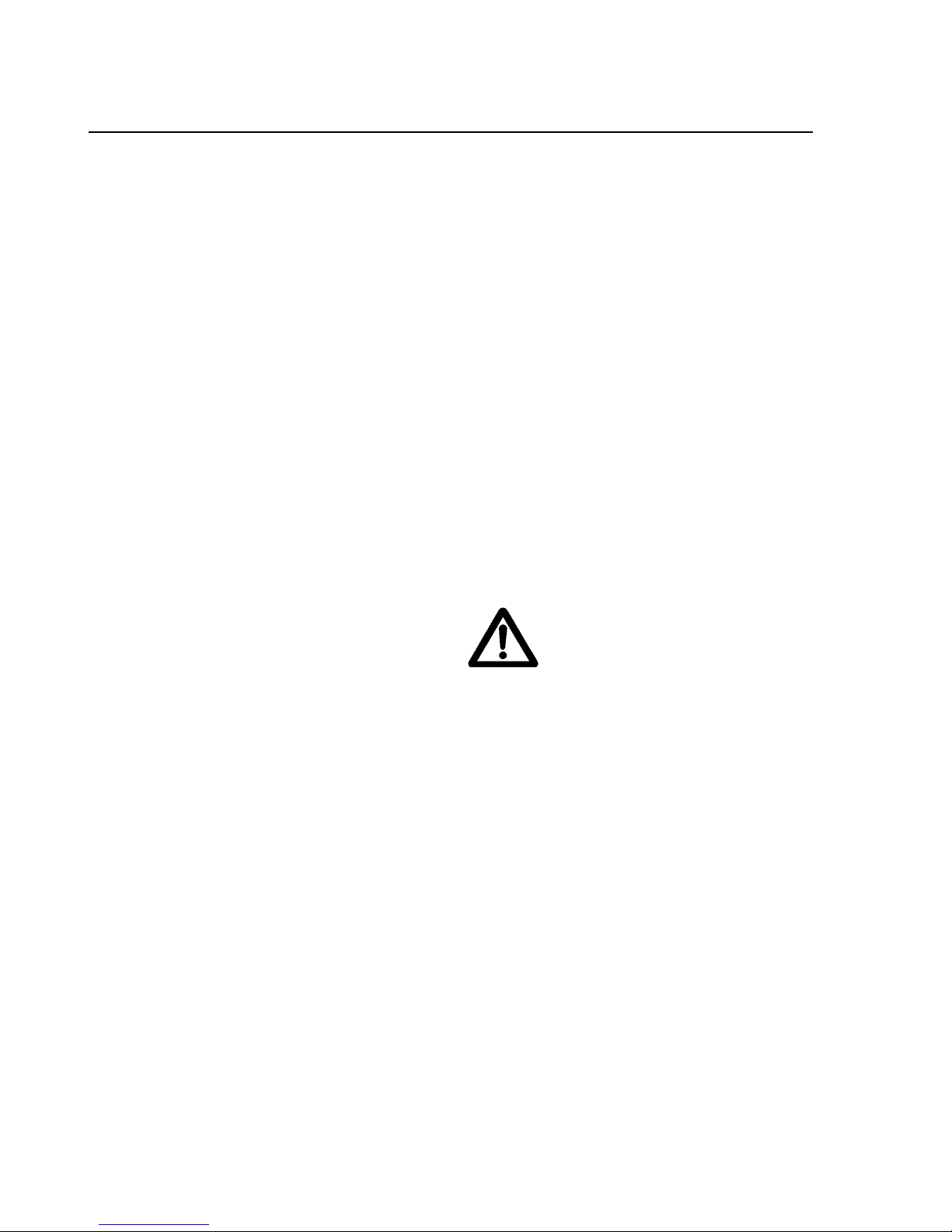

The vacuum is maintained by the TRIVAC-B through an

integrated hydropneumatic anti-suckback valve (2/3)

which is controlled via the oil pressure.

During operation of the TRIVAC-B the control piston (4/3)

remains sealed against a spring (4/2) by the oil pressure.

The valve disc (4/6) of the anti-suckback valve is held at

the lower position by its own weight (valve open). When

the pump stops (because it has been switched off or

because of a failure), the oil pressure drops and the

spring (4/2) presses the control piston (4/3) up. Thus a

connection is provided between the oil case or the oil

reservoir (4/1) and the piston (4/4) of the anti-suckback

valve. Due to the pressure difference between the oil

case and the intake port the oil presses the piston (4/4)

up and the valve plate (4/6) against the valve seat (4/5).

The quantity of oil in the oil reservoir (4/1) prevents the

entry of air into the intake port (2/1) at the beginning of

this process.

After the oil has flowed out from the reservoir and when

the valve plate rests on the valve seat, air follows in,

which vents the pump chamber and forces the v alve disc

(4/6) against its seat. This effectively prevents

backstreaming of oil. The anti-suckback valve (2/3)

operates independently of the operating mode of the

pump, i.e.also with gas ballast.

4

Fig. 2 Sectional drawing of the TRIVAC-B

Key to Fig. 2

1 Intake port

2 Dirt trap

3 Anti-suckback valve

4 Intake channel

5 Vanes

6 Pump chamber

7 Rotor

8 Cover plate, connection for inert gas ballast

9 Exhaust channel

10 Exhaust valve

11 Internal demister

12 Spring buckles

13 Cover plate, connection for oil filter

Description

1.2 Supplied Equipment

The equipment supplied with the TRIVAC-B pump

includes:

Pump with motor, including initial filling of N 62, HE-200

oil or Arctic oil SHC 244

Ref. No.200 28 229 (for Cat. No. 113 08 and 113 18)

1 centering ring,

1 centering ring with dirt trap,

2 clamping rings DN 16 KF.

5

As protection during shipment, the connection ports are

each blanked off by rubber diaphragms and supporting

rings.

TRIVAC-B pumps with single-phase AC motor are

supplied ready to operate with switch, built-in thermal

motor protection switch, mains cable (2 m) and mains

plug.

For TRIVAC-B pumps with three-phase AC motor, the

switch, motor protection switch, mains cable etc. are not

included but can be delivered upon request with motor

protection switch, mains plug and mains cable.

Fig. 3 Schematic of the lubr icating system

Fig. 4 Hydropneumatic anti-suckback valve

Key to Fig. 3

1 Accessories

2 Bearings

3 Non-return valve

4 Pump chamber of the TRIVAC

5 Oil reservoir

6 Oil pump

Key to Fig. 4

1 Oil reservoir 5 Valve seat

2 Spring 6 Valve disk

3 Control piston 7 Gas inlet

4 Anti-suckback piston

Description

1.3 Accessories

Cat. No. / Ref. No.

Condensate trap AK 4-8, DN 16 KF . . . . . . . . . .188 06

Exhaust filter AF 4-8, DN 16 KF . . . . . . . . . . . . .189 06

Drain tap for condensate trap, exhaust filter,

oil drain of the pump,

vacuum-tight . . . . . . . . . . . . . . . . . . . . . . . . . . .188 91

oil tight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188 90

Exhaust filter with lubricant return

AR 4-8, DN 16 KF . . . . . . . . . . . . . . . . . . . . . . .189 20

Dust filter FS 2-4 . . . . . . . . . . . . . . . . . . . . . . . .186 05

Fine vacuum adsorption trap FA 2-4

(with zeolite) . . . . . . . . . . . . . . . . . . . . . . . . . . .187 05

Adsorption trap

(with aluminium oxide) . . . . . . . . . . . . . . . . . . . .854 14

(with cryo insert) . . . . . . . . . . . . . . . . . . . . . . . .854 17

Cold trap TK 4-8 . . . . . . . . . . . . . . . . . . . . . . . .188 20

Oil filter OF 4-25 . . . . . . . . . . . . . . . . . . . . . . . .101 91

Chemical filter CF 4-25 . . . . . . . . . . . . . . . . . . .101 96

Adapter for gas ballast port

M 16 x 1.5 – DN 16 KF . . . . . . . . . . . . . . . . . . .168 40

M 16 x 1.5 – 3/8 inch NPT . . . . . . . . . . . . .99 175 011

Oil N 62 1l 177 01

5l 177 02

20 l 177 03

Arctic oil SHC 244 1l 200 28 229

(Order from LH Cologne, Germany)

Oil HE-200 1 qt 98 198 006

12 qt case 98 198 049

1 gal 98 198 007

5 gal 98 198 008

(Order from LHVP, Export Pa., USA)

The oil grades N 62 and HE-200 are interchangeable.

Special oils upon request.

Only use the kind of oil specified by

Leybold. Alternative types of oil are

specified upon request.

1.4 Spare Parts

Set of gaskets 197 20

Pump module, complete S 4 B 200 10 988

D 4 B 200 10 989

S 8 B 200 10 990

S 8 B 200 10 990

D 8 B 200 10 991

Module-gasket 200 10 730*)

Oil case gasket 200 10 733*)

Internal demister S/D 4 B 390 26 010*)

S/D 8 B 390 26 011*)

*) included in gasket set

1.5 Transportation

• Pumps which are filled with operating

agents must only be moved while

standing upright. Otherwise oil may

escape. Avoid any other orientations

during transport.

• Check the pump for the presence of any

oil leaks, since there exists the danger

that someone may slip on spilt oil.

• When lifting the pump you must make

use of the crane eyes provided on the

pump for this purpose; also use the

recommended type of lifting device.

6

Caution

Caution

Warning

Description

7

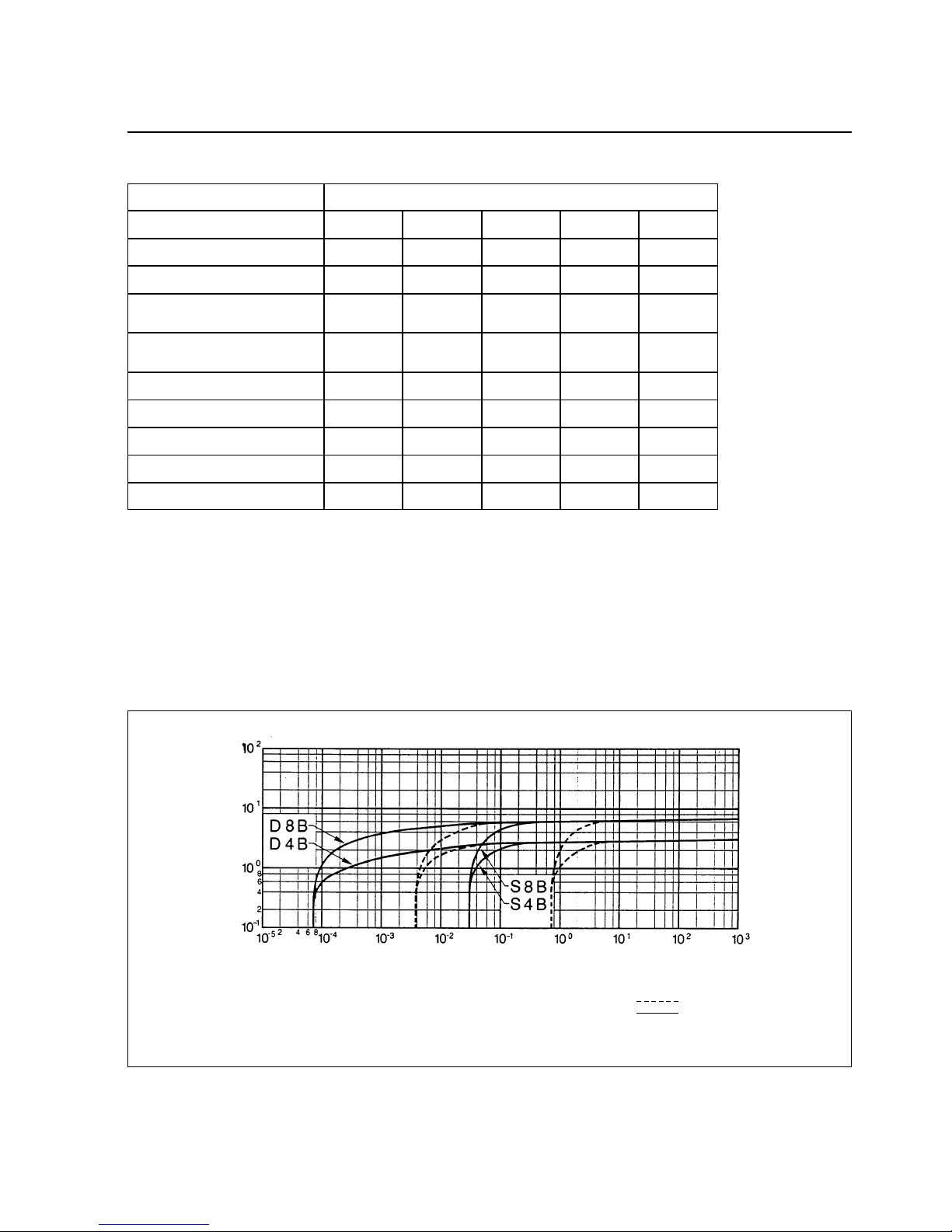

Fig. 5 Pumping speed characteristics of the TRIVAC S 4 B to TRIVAC D 8 B, 50 Hz operation, SI units

m3· h

-1

m3· h

-1

mbar

mbar

mbar

DN

cm

3

IP

S 4 B

4.8

4.2

< 4 · 10

-2

< 1

30

16 KF

300/1000

54

D 4 B

4.8

4.2

< 1 · 10

-4

< 5 · 10

-3

40

16 KF

300/800

54

S 8 B

9.7

8.5

< 4 · 10

-

2

< 1

40

16 KF

300/800

54

50Hz operation, SI units

D 8 B

9.7

8.5

< 1 · 10

-4

< 5 · 10

-3

25

16 KF

300/900

54

Nominal pumping speed*

Pumping speed*

Ultimate partial pressure

without gas ballast*

Ultimate total pressure

with gas ballast*

Water vapour tolerance*

Connection ports

Oil filling min./max.

Type of protection

* as per DIN 28 400 and following numbers

1) Weight for the version with single-phase motor 230 V, 50 Hz

1.6 Technical Data

with gas ballast

without gas ballast

kg 15.7 18.7 18.7 21.2Weight

1)

We can only guarantee that the pump will

meet its specifications when using the type

of lubricant which has been specified by us.

Caution

Pressure

Pumping speed

Description

8

Motor related data

n

m

l

ca

b

1

o

h

1

h

h

2

h

3

b

2

b

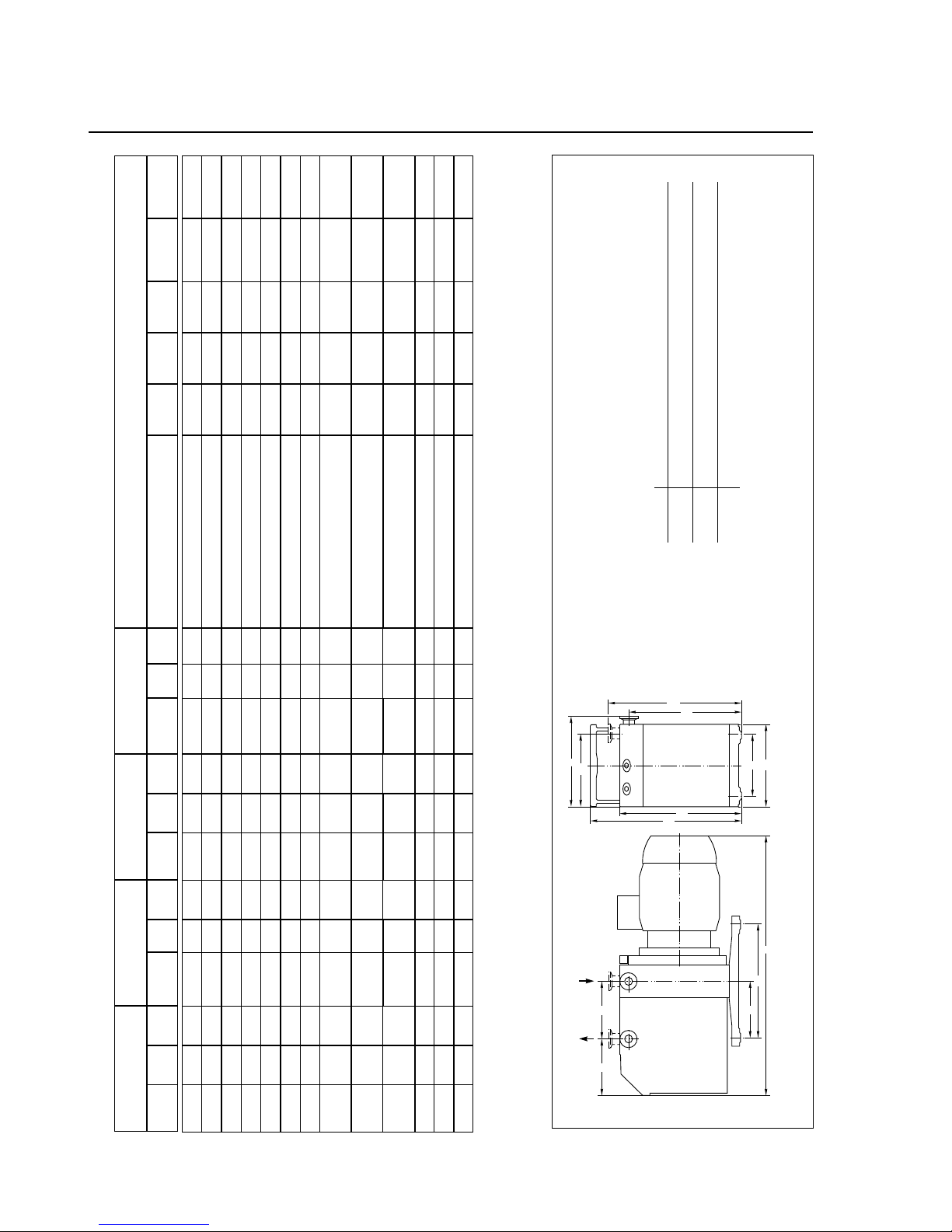

Fig. 6 Dimensional drawing for the TRIVAC rotary vane pumps (Dimensions a, l, b to b

2

and h

1

are approximate)

abb

1

b

2

chh

1

h

2

h

3

mno

S/D 4 B 75 162 147 132 100 265 215 200 230 198 99 108

S 8 B 75 162 147 132 100 265 215 200 230 198 99 108

D 8 B 100 162 147 132 100 265 215 200 230 198 99 108

dimensions in mm

1)

Motor with UL cable NEMA 5-158 and 2.5 m long cable

S 4 B

D 4 B

S 8 B

D 8 B

Cat. No. l (mm)

W (kg)

Cat. No. l (mm)

W (kg) Cat. No. l (mm)

W (kg)

Cat. No.

l (mm)

W (kg)

Motor connection voltage, frequency

Motor

power

Rated

current

Speed

Motor noise

level

Order No.for

the motor

102 45

–

–

103 01

103 02

103 03

103 04

102 46

–

–

103 05

103 06

103 07

430

430

430

430

470

430

430

430

223

15.7

15.7

15.7

15.7

19.7

13.4

13.4

15.0

7.8

–

112 45

–

113 01

113 02

113 03

103 04/08

1)

–

112 46–113 05

113 06

113 07

430

430

430

430

470

430

430

430

223

18.7

18.7

18.7

18.7

19.7

16.4

16.4

18

10.6

–

102 55

–

103 11

103 12

103 13

103 14

–

102 56–103 15

103 16

103 17

430

430

430

430

470

430

430

430

223

18.7

18.7

18.7

18.7

19.7

16.1

16.1

17.7

10.3

–

–

112 55

113 11

113 12

113 13

113 14/18

1)

–

–

112 56

113 15

113 16

113 17

455

455

455

455

495

455

455

455

248

21.2

21.2

21.2

21.2

25.2

18.6

18.6

18.6

12.8

430

1 ~ , 230 V, 50 Hz

1 ~ , 230 V, 50 Hz

1 ~ , 230 V, 50 Hz

1 ~ , 220 V, 50 Hz / 60 Hz

1 ~ , 240 V, 50 Hz / 60 Hz

1 ~ , 115 V, 60 Hz

1 ~ , 100 V, 50 Hz; 110 V, 60 Hz

3 ~ , 230/400 V, 50 Hz

250/440 V, 60 Hz

3 ~ , 230/400 V, 50 Hz

250/440 V, 60 Hz

3 ~ , 230/400 V, 50 Hz

250/440 V, 60 Hz

3 ~ , 400 V, 50 Hz

3 ~ , 230/400 V, 50 Hz

without motor

180 W

250 W

370 W

370 W

370 W

370 W

370 W

180 W

250 W

370 W

370 W

370 W

–

2.5 A

2.8 A

2.9 A

3 A

2.7 A

5.6 A

8.7/6.1 A

2.1/1.2 A

1.75/1 A

2.25/1.3 A

1.9/1.1 A

1.95/1.12A

1.73/1.0 A

1.12 A

1.92/1.11A

–

1400

1400

1400

1400/1660

1380/1680

1700

1400/1700

1400

1700

1400

1700

1970

1680

1370

1395

–

47 dB (A)

47 dB (A)

47 dB (A)

49/51 dB (A)

49/51 dB (A)

51 dB (A)

53/56 dB (A)

47 dB (A)

51 dB (A)

47 dB (A)

51 dB (A)

46 dB (A)

50 dB (A)

46 dB (A)

45 dB (A)

48 dB (A)

380 66 010

380 66 007

380 66 008

200 10 401

200 10 402

200 10 403

200 10 404

380 66 009

380 66 005

380 66 006

200 10 405

200 10 406

–

Loading...

Loading...