Leybold vacuum Sogevac SV65 BI FC, Sogevac SV40 B FC Operating Instructions Manual

Sogevac®

SV40-65 BI FC

Single-stage, oil-sealed rotary vane pump

Operating instructions GA02341_002_A6

and spare parts list

Part-Nr:

960363V3001

960461V3001

960462V3001

960463V3001

960465V3001

960465V3002

and other variants

Document 300338321/002/A6

Original Operating Instructions

Contents

Page

Important Safety Information 3

1 Description 6

1.1 Principle of operation 6

1.2 Technical characteristics 7

1.3 Accessories 10

1.4 Lubricants 10

2 Transport and Storing 11

2.1 Transport and packaging 11

2.2 Mounting orientation 11

2.3 Storing 11

3 Installation 12

3.1 Setting up 12

3.2 Electrical connections 13

3.3 Oil filling 15

3.4 Start-up 15

4 Operation 15

4.1 Operation 15

4.2 Working in cycles in / out 16

4.3 Switching off / Shutdown 17

4.4 Conditions of use 17

4.5 Taking out of use 17

5 Maintenance 18

5.1 Safety Information 18

5.2 Maintenance Intervals 18

5.3 Oerlikon Leybold Vacuum Service 19

5.4 Maintenance Work 19

6 Troubleshooting 21

7 Spare parts 23

EC Conformance Declaration 26

Declaration of Contamination of Compressors,

Vacuum Pumps and Components 27

2

GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

Important Safety Information

Indicates procedures that must be strictly observed to prevent hazards to

persons.

Indicates procedures that must be strictly observed to prevent damage to, or

destruction of the product.

Emphasizes additional application information and other useful information

provided within these Operating Instructions.

The Oerlikon Leybold Vacuum Sogevac® has been designed for safe and

efficient operation when used properly and in accordance with these

Operating Instructions. It is the responsibility of the user to carefully

read and strictly observe all safety precautions described in this section

and throughout the Operating Instructions. The Sogevac® must only be

operated indoor. In proper condition and under the conditions described

in the Operating Instructions. If not, the protection provided by the

equipment may be impaired. It must be operated and maintained by trained

personnel only. Consult local, state, and national agencies regarding specific

requirements and regulations. Address any further safety, operation and/or

maintenance questions to our nearest office.

Failure to observe the following precautions could result in serious

personal injury!

Sogevac® pumps are not designed:

■ for pumping of dusty, aggressive, corrosive, flammable or explosive gases or

gases mixtures,

■ for pumping of oxygen or other highly reactive gases with a greater

concentration than atmospheric concentration (>20%),

■ for working in flammable, explosive or dusty environment.

For all these cases, special materials must be used. In case of doubt, please

contact Oerlikon Leybold Vacuum.

See also the limits of use indicated in the CE declaration of conformity.

Never expose part of the body to the vacuum. There is a danger of injury.

Never operate the pump with an open and thus accessible inlet. Vacuum

connections as well as oil filling and oil draining openings must not be

opened during operation of the pump.

Depending on the process involved, dangerous substances and oil may escape

from the pump. Take the necessary safety precautions !

Disconnect the unit from the power supply before starting any work.

Pump must not be operated above 2000 m sea level.

Safety Information

Warning

Caution

Note

Warning

3

GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

The Sogevac® vacuum pumps have been manufactured according to the latest

technical standards and safety regulations. If not installed properly or not used

as directed, dangerous situations or damages could occur.

It is mandatory that these operating instructions be read and understood

prior to vacuum pump installation and start-up.

The pump complies to the standard EN 61010-1-2001.

High electric voltages! When touching parts at high electric voltages, there is

the risk of suffering severe injuries by an electric shock! Covers marked with this

symbol must only be opened by trained electricians after having reliably deenergised (lockout/tagout) the equipment and waited minimum 10 minutes.

Always operate the pump with a properly connected protective earth conductor

and make sure that the motor & FC connection box are closed.

Observe the manufacturer’s information and operating instructions for the

respective frequency converter (enclosed).

Use only the OLV frequency converter for the pumps equipped with one.

After having made changes to the wiring, check the motor’s direction of rotation.

Lay the connecting lines so that these cannot be damaged. Protect the lines

against humidity and contact with fluids. Avoid thermally stressing the lines by

unfavourable laying. Provide strain relief for the connecting lines so that the

plugs and the line connectors are not subjected to excessively high mechanical

stresses.

Lay electric feed lines so that there is no risk of tripping over these.

Take appropriate precautions to insure that the pump cannot start.

If the pump has pumped hazardous gases it will be absolutely necessary to

determine the nature of the hazard involved and take the appropriate safety

precautions.

Observe all safety regulations!

Take adequate safety precautions prior to opening the intake or exhaust port.

Failure to observe the following precautions could result in damage to

the equipment!

Liquid and solid particles must not enter the pump. Install the adequate

filters, separators and/or condensers. In case of doubt consult Oerlikon

Leybold Vacuum.

The intake line of the pump must never be connected to a device with over

atmospheric pressure. Design the exhaust line so that no pressure higher

than 1,15 bar abs. (0,15 bar rel.) can occur.

Operating of the pump without oil or operating with incorrect direction of

rotation can destroy the pump.

Caution

Safety Information

Warning

Warning

4

GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

5GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

Never use discarded seals. Always assemble using new seals.

Respect the instructions concerning environment protection when discarding

used oil or exhaust filters!

The pump must be packaged in such a way that it will not be damaged

during shipping, and so that no harmful substances can escape from the

package.

We reserve the right to alter the design or any data given in these Operating

Instructions. The illustrations are not binding.

Caution : hot surface ! In normal operation, the pump surface temperature can

reach 85°C. There is a risk of burning. Switch off the pump and let it cool down

before any intervention or take appropriate precautions. It is recommended to

use an oil casing or pump touching protection at high ambient temperatures.

As a touching protection, you can use the “Noise enclosure for SV40 BI + 65 BI

FC” P/N 960331NENC. The noise enclosure is an accessory not included in the

pump delivery.

All work on a pump which is “still warm from operation” should be done only

whilst wearing protective gloves.

Handle the pump only while vented and after having let it cool down.

Never remove the oil-fill or oil-drain plugs while the pump is running. There

exists the risk of suffering burns. Always wear protective gloves and protective

goggles also for protection against the oil.

Some pumps use perfluoropolyether (PFPE) as lubricant.

When handling PFPE you should observe the following:

During thermal decomposition at temperatures over 290 °C toxic and corrosive

gases are released. This is not likely to happen in a Sogevac® pump. When

handling PFPE keep it way from open fires. Do not smoke with PFPE on your

fingers.

Touch the inner sections of the pumps only while wearing clean gloves, and use

clean tools; do the necessary work in clean and dry rooms.

Do not allow the ingestion of any objects (screws, welding beads, nuts, washers,

pieces of wire, fittings etc.) through the intake port of the pump.

Objects falling into the pump can cause severe damage.

Note

Caution

Safety Information

Caution

Warning

6 GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

1 Description

Sogevac® pumps are designed for pumping of inert gases in the range of rough

vacuum, between atmospheric pressure and ultimate pressure of the pump.

When removing condensable vapours, periodic opening of the gas ballast valve

is required.

1.1 Principle of operation

The Sogevac® pumps are single-stage oil-sealed rotary vane vacuum pumps.

The rotor, having three slots in which the vanes are sliding, is eccentrically

installed in a pump cylinder (stator).

The vanes separate the interior space into 3 chambers. The volume of these

chambers varies with the rotation of the rotor.

The gas sucked into the inlet chamber is compressed and then pushed out at

the exhaust valve.

The oil injected in the inlet chamber guarantees the air-tightness, the

lubrication and cooling of the pump. It is dragged off by the compressed

gases and roughly separated by gravity when entering in the oil sump. A fine

separation is then operated in the exhaust filter. An internal transfer pushes the

collected oil back into the vacuum generator, the transfer is operated by a float

valve to avoid atmospheric air coming from the oil casing to the inlet of the

pump when no oil is present in the recovery system.

The oil circulation functions by differential pressures.

The pumps are equipped with a gas ballast valve for pumping condensable

vapours.

The anti suckback valve at the inlet flange avoids oil coming back into the

inlet line when the pump is stopped. This is valid for working pressures below

100 mbar and under the condition that the valve is kept clean and in good

condition. The anti suck-back valve is not a safety valve. If oil back flowing is to

be avoided by all means, it is necessary to mount a separate safety valve on the

pump inlet.

Some variants are equipped with a frequency converter giving a constant

pumping speed independently of the mains frequency and regulating

the pump power consumption. At high inlet pressures, the pump speed is

decreased.

Description

7GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

Description

The pump speed can be reduced to 900 rpm (idle mode) to reduce the power

consumption w/o loss of end pressure on some pump variants. In this idle

mode, the pump inlet pressure must remain below 10 mbar.

Information to user

The user's manual or instruction manual for an intentional or unintentional

radiator shall caution the user that changes or modifications not expressly

approved by the party responsible for compliance could void the user's

authority to operate the equipment.

Note : This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference

to radio communications Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

This product has been tested to the requirements of CAN/CSA-C22.2 No. 610101, second edition, including Amendment 1, or a later version of the same

standard incorporating the same level of testing requirements

1.2 Technical characteristics

SV40 B FC

Technical data 50 Hz & 60 Hz

Nominal pumping speed m3/h ≥ 53

Pumping speed (according to PNEUROP) m

3

/h à 2 mbar ≥ 36

Ultimate partial pressure without gas ballast mbar ≤ 0,2

Ultimate total pressure with small gas ballast mbar ≤ 1,0

Water vap our tolera nce:

■ with small gas ballast approx. mbar 10

Water vap our tolera ble loa d:

■ with small gas ballast approx. kg.h

-1

0,34

Noise level (according to DIN 46 635) dB (A) ≤ 59

Motor power - Rated rotational speed kW - min

-1

1,6-1800

Mains voltage (+/- 10 %) AC ~ V 200

... 240

Protection - Insulation

1)

IP 20 - F

Leak rate mbar.I.s

-1

<1 x 10-3

Ambient temperature °C 18 ... 40

See pump nameplate for further data.

1)

Given by power & interface connections.

16AT 500 A @ 250 VAC

8 GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

SV65 BI FC

Technical data 50 Hz & 60 Hz

Nominal pumping speed m3/h 71

Pumping speed (Norme PNEUROP) m

3

/h à 2 mbar ≥ 50

Ultimate partial pressure without gas ballast mbar ≤ 0,2

Ultimate total pressure with small gas ballast mbar ≤ 1,0

Water vap our tolera nce:

■ with small gas ballast approx. mbar 10

Water vap our tolera ble loa d:

■ with small gas ballast approx. kg.h

-1

0,41

Noise level (Norme DIN 46 635) dB (A) ≤ 60

Motor power - Rated rotational speed kW - min

-1

1,5-1800

Mains voltage (+/- 10 %) AC ~ V 200

... 240

Protection - Insulation

1)

IP 20 - F

Leak rate mbar.I.s

-1

<1 x 10-3

Ambient temperature °C 18 ... 40

See pump nameplate for further data.

1)

Given by power & interface connections.

Description

9GA02341_002_A6 - 12/2013 - © Oerlikon Leybold Vacuum

Description

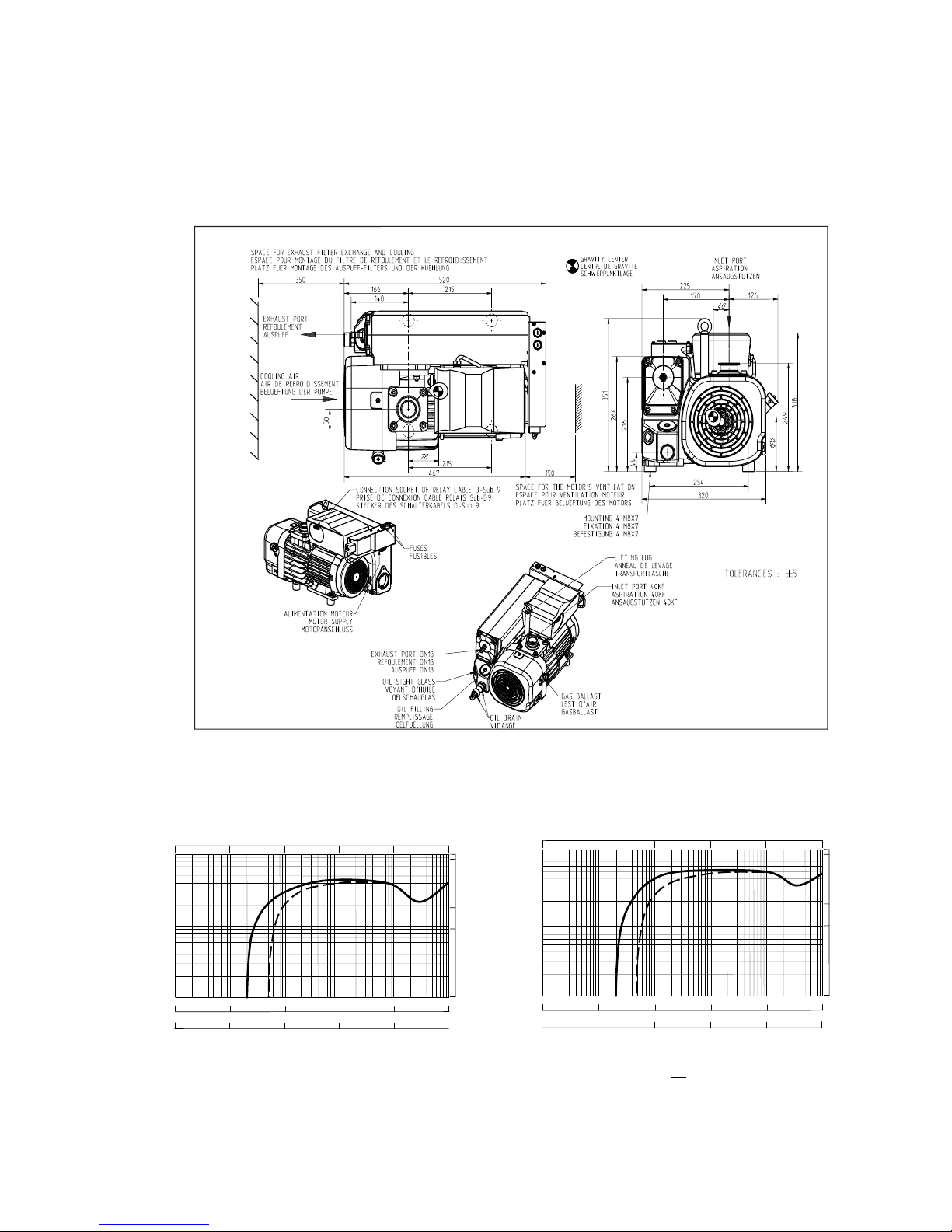

SV40 BI FC & SV65 BI FC

10

-

1

1 10

1102103

10

1

10

3104105

10

2

mbar

Pa

29.918 29.530 25.980 0 29.9

Inches.Hg

Druck / pressure / pression

Saugvermögen / pumping speed / débit

bei / at / à 50 & 60 Hz

10

50

5

CFM

Saugvermögenskurven ohne Gasballast mit Gasballast

Pumping speed (volume flow rate) without gas ballast with gas ballast

Courbes de débit sans lest d'air avec lest d'air

m3.h

-

1

100

10

1

29.921

10

-

2

10

0

Torr

7,5.10

-

3

7,5.10

-

2

7,5.10

-

1

7,5.10

0

7,5.10

1

7,5.10

2

10

-

1

1 10

1102103

10

1

10

3104105

10

2

mbar

Pa

29.918 29.530 25.980 0 29.9

Inches.Hg

Druck / pressure / pression

Saugvermögen / pumping speed / débit

bei / at / à 50 & 60 Hz

10

50

5

CFM

Saugvermögenskurven ohne Gasballast mit Gasballast

Pumping speed (volume flow rate) without gas ballast with gas ballast

Courbes de débit sans lest d'air avec lest d'air

m3.h

-

1

100

10

1

29.921

10

-

2

10

0

Torr

7,5.10

-

3

7,5.10

-

2

7,5.10

-

1

7,5.1007,5.10

1

7,5.10

2

1 Pa = 10

-2

mbar

1 Torr = 1,33 mbar

SV40 BI FC SV65 BI FC

Loading...

Loading...