Leybold vacuum TURBO.DRIVE 400, 800073V0002, 800073V0003, 800073V0004, 800073V0008 Operating Instructions Manual

TURBO.DRIVE 400

Frequency Converter for

Turbomolecular Pumps

Operating Instructions 17200492_002_A5

Part Numbers

800073V0002

800073V0003

800073V0004

800073V0008

D

r

ive (

DC 2

X

3)

4

V(X4)

H

EAT

S

IN

K

H

EAT

S

IN

K

Contents

Page

Important Safety Information 4

1 Description 7

1.1 Design and function 7

1.2 Standard equipment 7

1.3 Technical data 8

1.4 Ordering data 10

1.5 Accessories 10

2 Installation 13

2.1 Conforming utilization 13

2.2 Operating environment 14

2.3 Mounting the frequency converter 15

2.4 Connecting the pump 16

2.5 Connecting the power supply 16

2.6 Relay status 21

3 Operation 22

3.1 Start-up 22

3.2 Interfaces 23

3.2.1 RS 232 C interface (SERVICE X5) 26

3.2.2 RS 485 interface 27

3.2.3 Profibus DP 29

3.2.4 USB interface (X106) 30

3.2.5 Parameter list 31

3.2.6 Specific parameter data for the pumps 36

3.2.7 Warning codes for parameter 227 38

3.3 Switching on 40

3.4 Shutting down 41

3.5 Emergency shut down 41

3.6 Setting pumping speed and rotational speed 42

3.7 Operation at reduced current 43

3.8 Changing the frequency dependent normal

operation level 44

3.9

3.10 Changing the start delay time 46

3.11 Selecting relay functions 47

3.12 Reading the error memory 47

Changing the maximum permissible run up time 45

2

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Contents / Safety Information

4 Maintenance 48

5 Troubleshooting 49

6 Waste Disposal 57

EC Conformance Declaration 59

Obligation to Provide Information

Before installing and commissioning the TURBO.DRIVE,

carefully read these Operating Instructions and follow

the information so as to ensure optimum and safe

working right from the start.

The Oerlikon Leybold Vacuum TURBO.DRIVE 400 has

been designed for safe and efficient operation when used

properly and in accordance with these Operating

Instructions. It is the responsibility of the user to carefully

read and strictly observe all safety precautions described in

this section and throughout the Operating Instructions. The

TURBO.DRIVE

tion and under the conditions described in the Operating

Instructions

personnel only. Consult local, state, and national agencies

regarding specific requirements and regulations. Address

any further safety, operation and/or maintenance questions

to our nearest office.

must only be operated in the proper condi-

. It must be operated and maintained by trained

NOTICE

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazar

if not avoided, could result in minor or moderate injury.

DANGER

WARNING

dous situation which,

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

CAUTION

acuum

3

Safety Information

NOTICE

WARNING

NOTICE is used to notify users of installation, operation,

programming or maintenance information that is important,

but not hazard related.

We reserve the right to alter the design or any data given in

these Operating Instructions.

The illustrations are not binding.

Retain the Operating Instructions for further use.

Important Safety Information

The frequency converter must only be connected to

power supplies which meet the requirements for functional extra low voltage with positive isolation in accordance with IEC 364 (VDE 0100, Part 410, or local regulations) (PELV).

During operation the frequency converter may attain

temperatures up to 75 °C. We recommend that the unit

be installed so that it can not be touched inadvertently.

NOTICE

Inside the unit there is the risk of suffering burns from

hot components.

The pump may be operated only with a suitable frequency converter and suitable connecting cables.

Ensure correct polarity.

Route all cables so as to protect them from damage.

Disconnect and connect the cable connections only

while the pump is turning no longer (green status LED

off) and with the mains power switched off (yellow

power LED off). Otherwise there is the risk of damaging

the TURBO.DRIVE 400.

4

17200492_002_A5 - 04/2011 - © Oerlikon Leybold Vacuum

Description

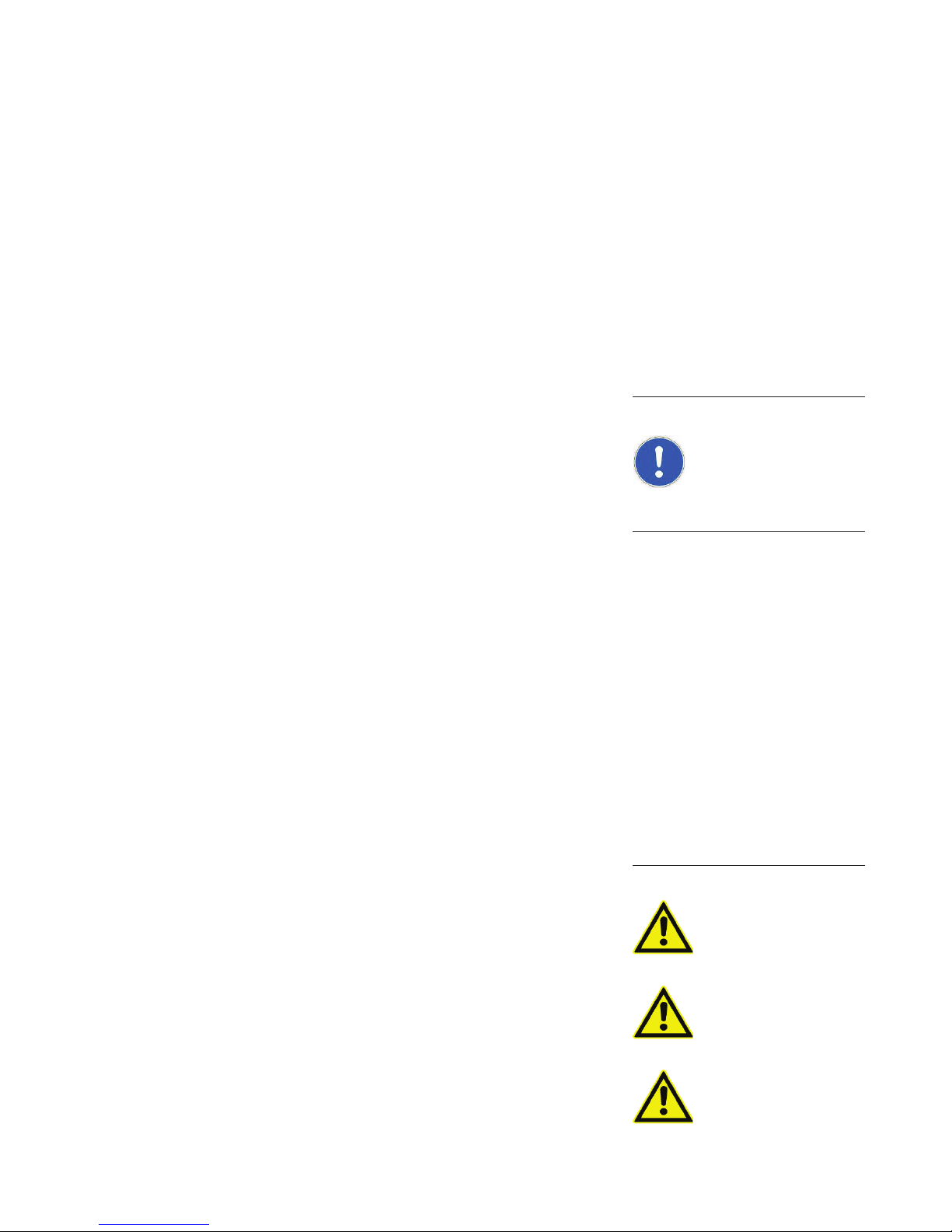

DRIVE (X3)

HEAT SINK HEAT SINK

Pump

connection

connection male 24 V

upply voltage

S

Green LED STS

Yellow LED PWR

24 VDC (X4)

g surfaces

Coolin

off: Pump at standstill (< 3 Hz)

flashes slowly 1/s: Start command is present (about 10 s after start)

flashes fast 3/s: Running up or running down

on: Normal operation

off: No supply voltage

flashes: Supply voltage too low or too high

on: Supply voltage is present

pin Sub-D connector

9

male for RS

fe

TU R B O .DRIVE

TD 400

232 interface

LEDs

REMOTE connector

9 pin Sub-D (female)

Red LED ERR

Fig. 1.1 TURBO.DRIVE 400, front and rear side

off: No error, no warning

flashes: Warning is present, pump can be operated

possibly with some restrictions

on: Fault is present, pump stopped or can not

be operated

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

5

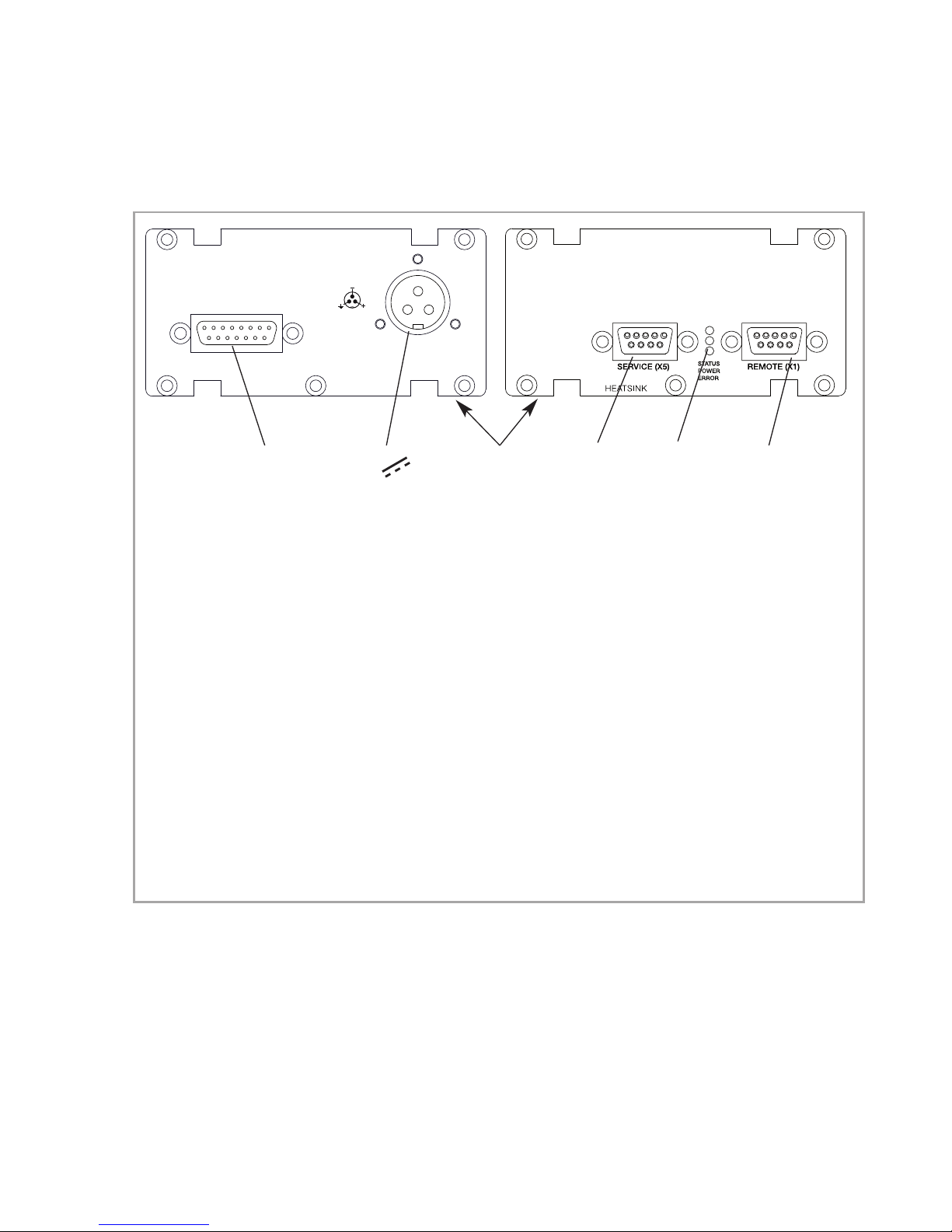

Description

connection

9-way Profibus

PRO FIBUS (X105) H IGH LOW

E

E

F

F

D

D

1

C

B

A

9

1

C

2

2

B

3

3

A

4

4

9

5

5

8

8

6

7

6

7

mal format

address in the h

setting the Profibus

Selector switches for

i-

exadec

DRIVE (X3)

HEAT SINK HEAT SINK

24 VDC (X4)

Fig. 1.2 Rear side of TURBO.DRIVE 400 with additional Profibus interface

Selector switch for setting the bus

RS 485 (X104)

TU R B O .DRIVE

TD 400

address for RS 485 communication

in the hexadecimal format

Fig. 1.3 Front side of TURBO.DRIVE 400 with additional RS 485 interface

TU R B O .DRIVE

TD 400

Abb. 1.4 FTURBO.DRIVE 400 front panel with additional USB interface

6

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

USB connection

(X106)

acuum

1 Description

1.1 Design and function

The TURBO.DRIVE 400 supplies power to the TW and SL

series turbomolecular pumps and is used to control their

operation.

The TURBO.DRIVE 400 is either integrated in the pump or

it is separate and linked to the pump by means of a

connecting cable.

The TURBO.DRIVE 400 requires a supply voltage of 24 V

DC. It is equipped with interfaces for programmable controls (REMOTE) and an optional interface for serial communication.

Description

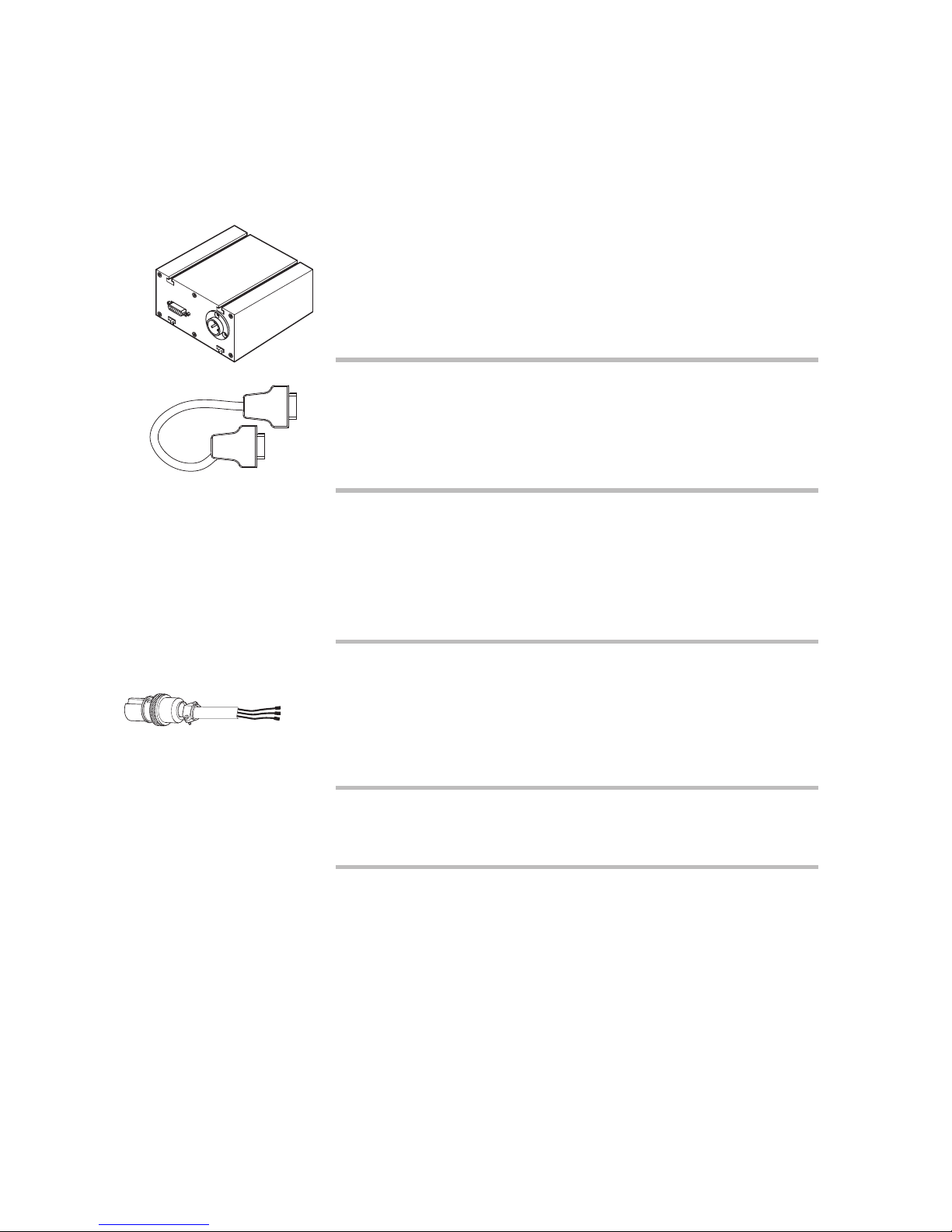

1.2 Standard equipment

Included with the delivery are the DC connector Hirose

HS16P-3, four moving nuts M4 for affixing the frequency

converter and the Operating Instructions.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

7

Description

1.3 Technical data

Supply voltage 24 V (± 10%)

Residual ripple

<3%

Output

Voltage 0 - 24 V 3~

Power 160 W

Frequency 0 - 1500 Hz

When operating a TW 300, TW 300 H, TW 220/150(/15) S,

SL 300

Nominal voltage 24 V

Max. power consumption

190 W

Max. peak current, input side 8 A DC

Required power output from the power supply ≥ 200 W

When operating a TW 70 H, TW 250 S. SL 80

Nominal voltage 24 V

Max. power consumption

140 W

Max. peak current, input side 6 A DC

Required power output from the power supply ≥ 150 W

Max. length of the DC cable (shielded)

at 3 x 1.5 mm

at 3 x 2.5 mm

Relay output rating 42 V, 0.5 A

Ambient temperature

during operation 5 - 45 °C

storage - 15 - + 70 °C

Relative air humidity 5 to 85 %

Overvoltage category II

Contamination grade 2

Temp. of the cooling surface 5 - 55 °C

For Part Nos. 800073V0004 5 - 50 °C

Power consumption ≤ 20 W

2

2

non condensing

5m

20 m

8

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Type of protection IP 20

Weight, approx. 0.7 kg

acuum

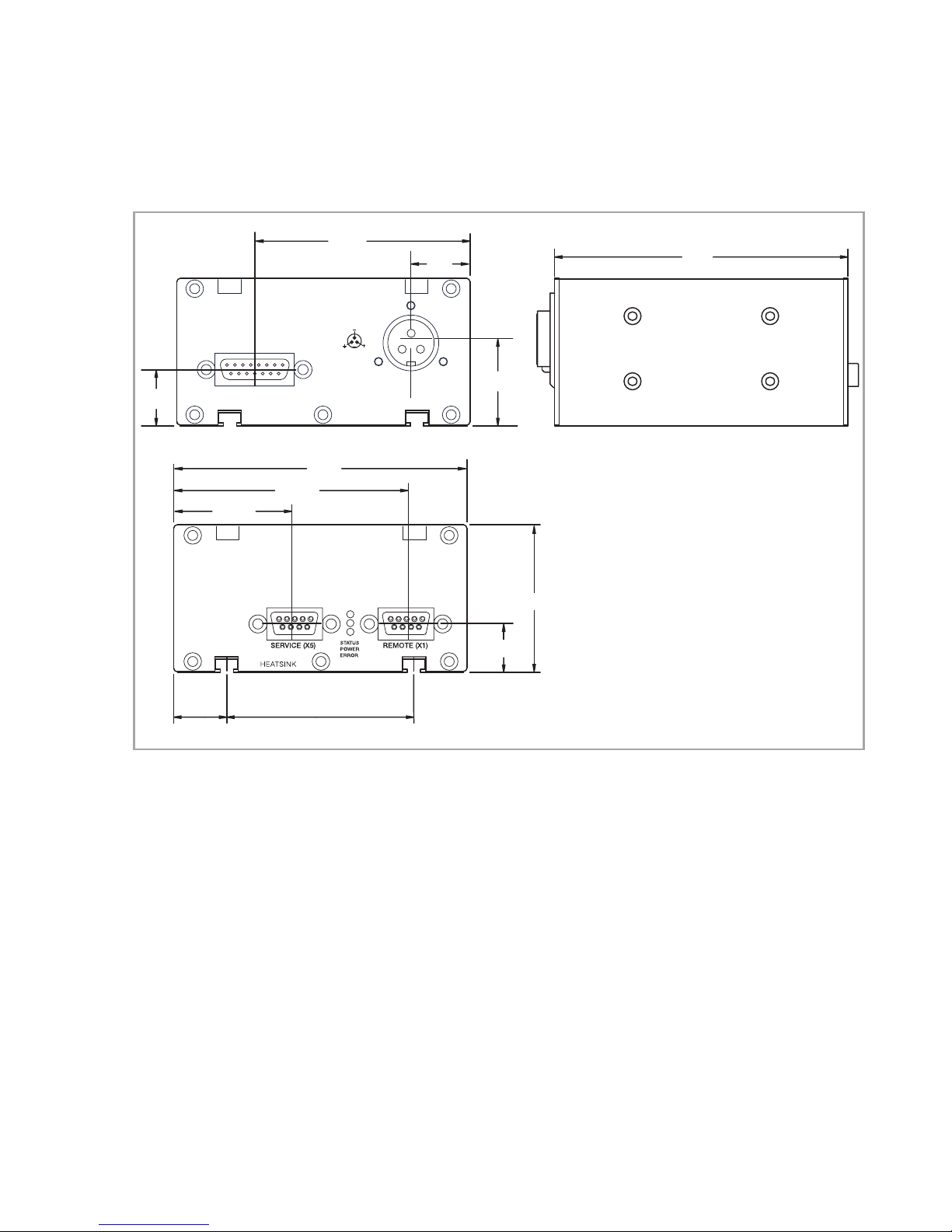

18,5

DRIVE (X3)

HEAT SINK HEAT SINK

79,0

41,0

100

73,3

24 VDC (X4)

32*

27,6

Description

100

* Profibus-Version 20

* Profibus version 20

TURBO.DRIVE

TD 400

50

15,9

18,2 63,8

Fig. 1.5 Dimensional drawing for the frequency converter; dimensions in mm

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

9

Description

D

r

i

ve

D

(

X

C24

3)

V

(

X

4)

H

E

A

T

S

I

NK

H

E

A

TS

I

NK

1.4 Ordering data

Frequency converter TURBO.DRIVE 400

with RS 232 C interface 800073V0002

with RS 485 C interface 800073V0003

with Profibus interface 800073V0004

wiht USB interface 800073V0008

Connecting cable pump - frequency converter

1.0 m long 152 47

2.5 m long 864 49

3.0 m long 864 40

5.0 m long 864 50

1.5 Accessories

OEM power supply (with screw terminals)

SITOP 24 V / 10 A (120/230 VAC / 50/60 Hz) 152 50

■ supplies the TURBO.DRIVE 400 with 24 V DC

■ other power supplies on request

24 V DC cable

(TURBO.DRIVE 400 – OEM power supply)

3 m 200 12 732

5 m 200 12 733

10 m 200 12 734

20 m 200 12 735

Mains cable for power supply, 2 m long

with EURO plug 800102V0001

with US plug 5-15P 800102V1001

10

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

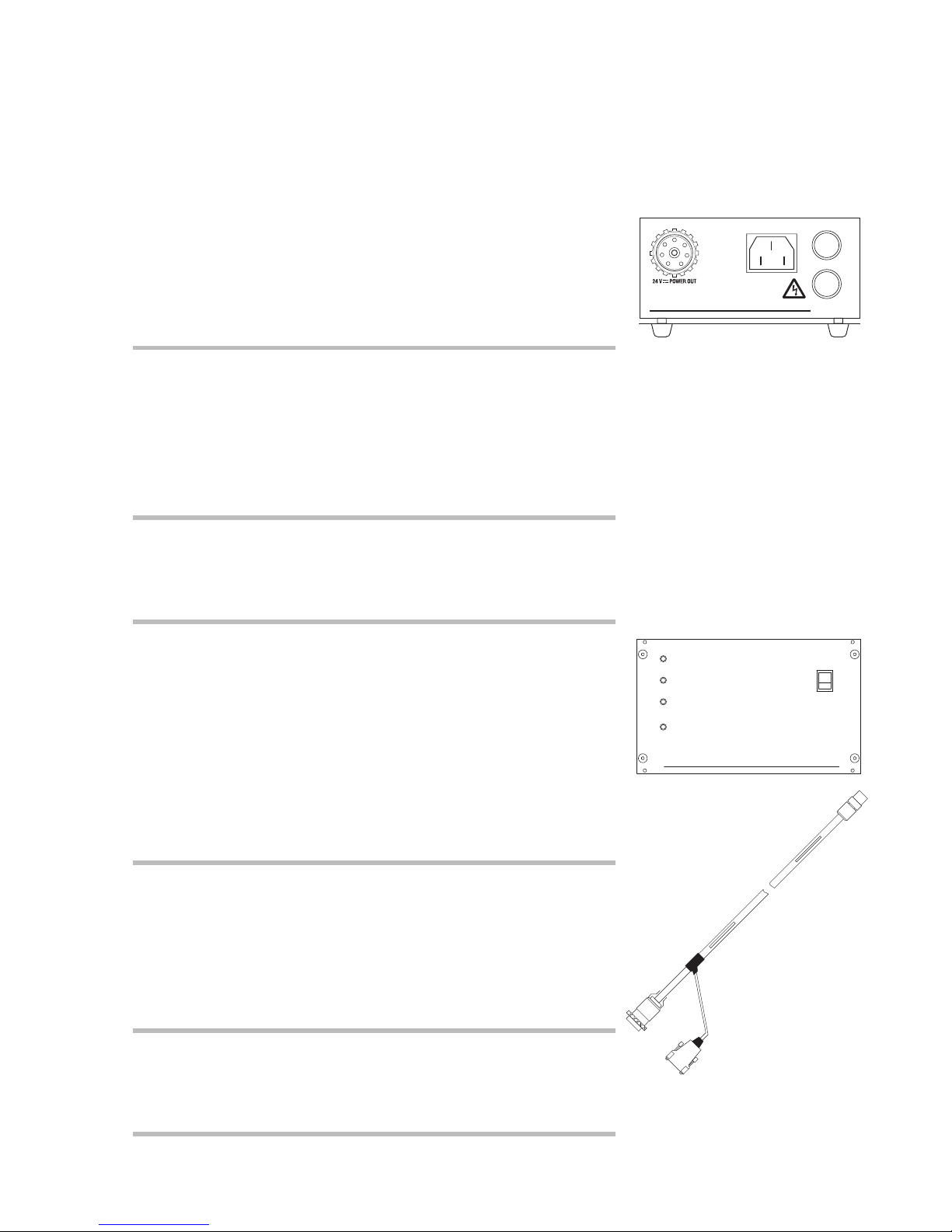

Power supply unit - plug and play

TURBO.POWER 300 800100V0002

■ supplies the TURBO.DRIVE 400 with 24 V DC

■ plug & play cables

■ desktop unit or rack mountable

24V DC Power cable TURBO.DRIVE 400 –

TURBO.POWER 300)

1 m 800094V0100

3 m 800094V0300

5 m 800094V0500

10 m 800094V1000

20 m 800094V2000

Description

100 - 240 V AC

TURBO.POWER 300

T5A~250 V

T5A~250 V

Mains cable for TURBO.POWER 300, 3 m long

with EURO plug 800102V0002

with US plug 6-15P 800102V1002

with UK plug 800102V0003

Power supply and control unit

TURBO.CONTROL 300 800100V0001

■ supplies the TURBO.DRIVE 400 with 24 V DC

■ plug & play cables

■ desktop unit or rack mountable

■ with power switch

■ with start/stop switch for the turbomolecular pump

■ remote control

■ status LEDs and status relays

24V DC Control cable

(TURBO.DRIVE 400 – TURBO.CONTROL 300)

1 m 800091V0100

3 m 800091V0300

5 m 800091V0500

10 m 800091V1000

20 m 800091V2000

START

NORMAL

POWER

ERROR

START

1

0

STOP

TURBO.CONTROL 300

Mains cable for TURBO.CONTROL 300, 3 m long

with EURO plug 800102V0002

with US plug 6-15P 800102V1002

with UK plug 800102V0003

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

11

Description

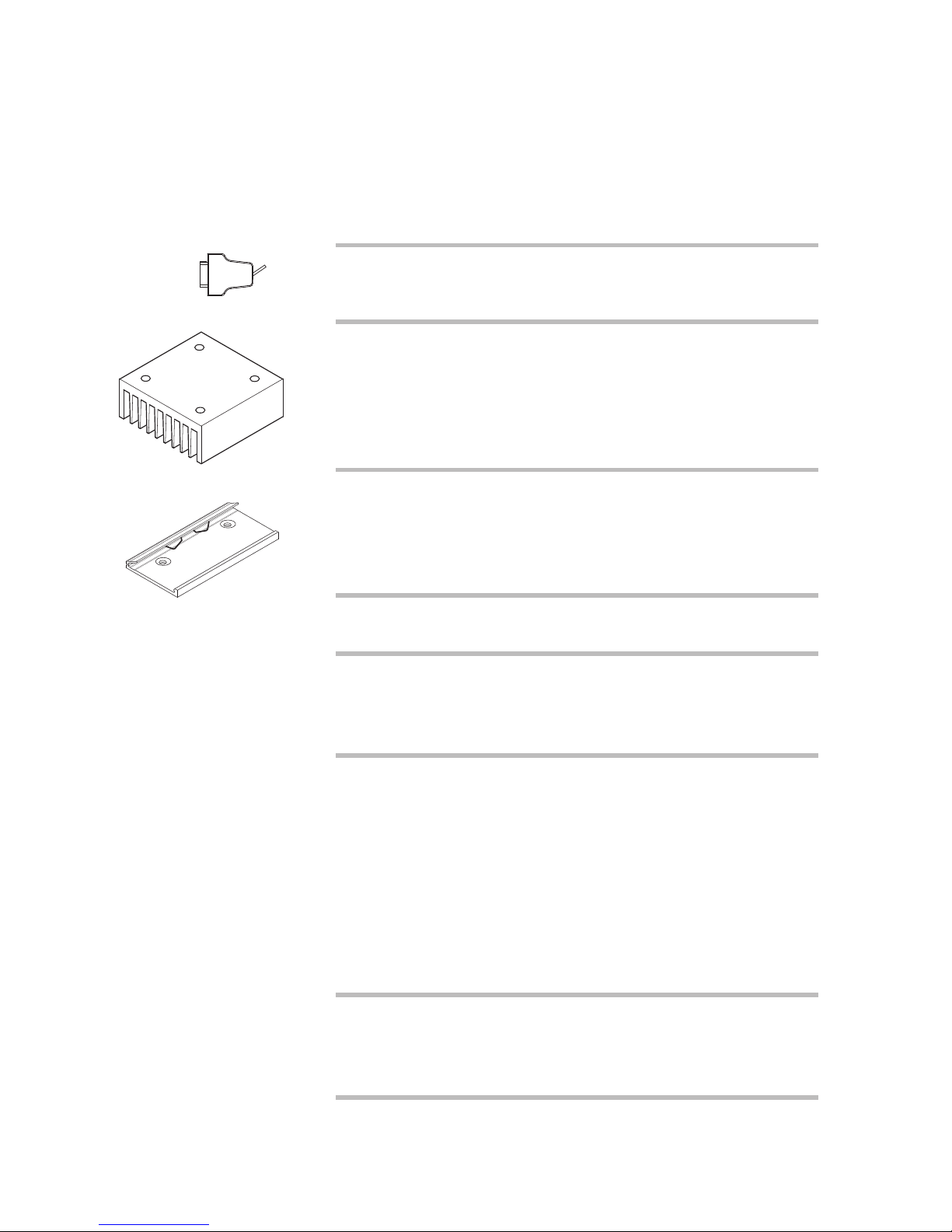

Mechanical accessories

on

off

Plug for connector REMOTE with integrated

ON/OFF switch for the pump

(Sub-D plug, 9 way) 152 48

Heat sink for frequency converter 800110V0001

Top hat rail adaptor (mounting aid for

TURBO.DRIVE 400 and TURBO.POWER 300)

800110V0003

Accessories for serial interfaces

USB driver: the Windows driver can be downloaded from

www.oerlikon.com after selecting menu item

www.oerlikon.com in the menu Oerlikon Leybold Vacuum

→ Documentation → Download Software

12

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

PC software "Turbo.Drive Server" for Windows 95

and higher, CD-ROM

■ Display, change, save and compare parameter lists

■ Integration of customer’s software

■ Record parameter data 800110V0102

(new parameter library for TURBO.DRIVE 400

is required, please ask us for a quotation)

The software can also be downloaded from

www.oerlikon.com in the menu Oerlikon Leybold Vacuum

→ Documentation → Download Software

GSD file for Profibus DP upon request

The software can also be downloaded from

www.oerlikon.com in the menu Oerlikon Leybold Vacuum

→ Documentation → Download Software

acuum

2 Installation

2.1 Conforming utilization

The TURBO.DRIVE 400 supplies power to the TW series

turbomolecular pumps and is used to control their operation.

The TURBO.DRIVE 400 is suited for operation of the following pumps:

■ TURBOVAC TW 70 H

■ TURBOVAC TW 220/150 S, TW 220/150/15 S,

TW 400/300/25 S

■ TURBOVAC TW 250 S

■ TURBOVAC TW 290 H

■ TURBOVAC TW 300, TW 300 H

Installation

■ TURBOVAC SL 80, SL 300

Other pumps may only be operated after approval from

Oerlikon Leybold Vacuum or if the operation of such pumps

is expressly permitted in the Operating Instructions for the

specific pump.

The TURBO.DRIVE may only be operated with power

supply units which meet PELV (Safety Extra Low Voltage)

requirements.

The TURBO.DRIVE must only be opened by certified

Oerlikon Leybold Vacuum Service Centres. Opening by

unauthorised personnel voids warranty.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

13

Installation

2.2 Operating environment

See also Chapter 1.3 Technical Data.

Places of installation up to 1000 m above sea level (3300 ft)

are possible without restrictions. At altitudes over 1000 m

heat dissipation by the ambient air is impaired. Please consult us.

If the TURBO.DRIVE 400 has been integrated in the pump,

it is cooled by the pump.

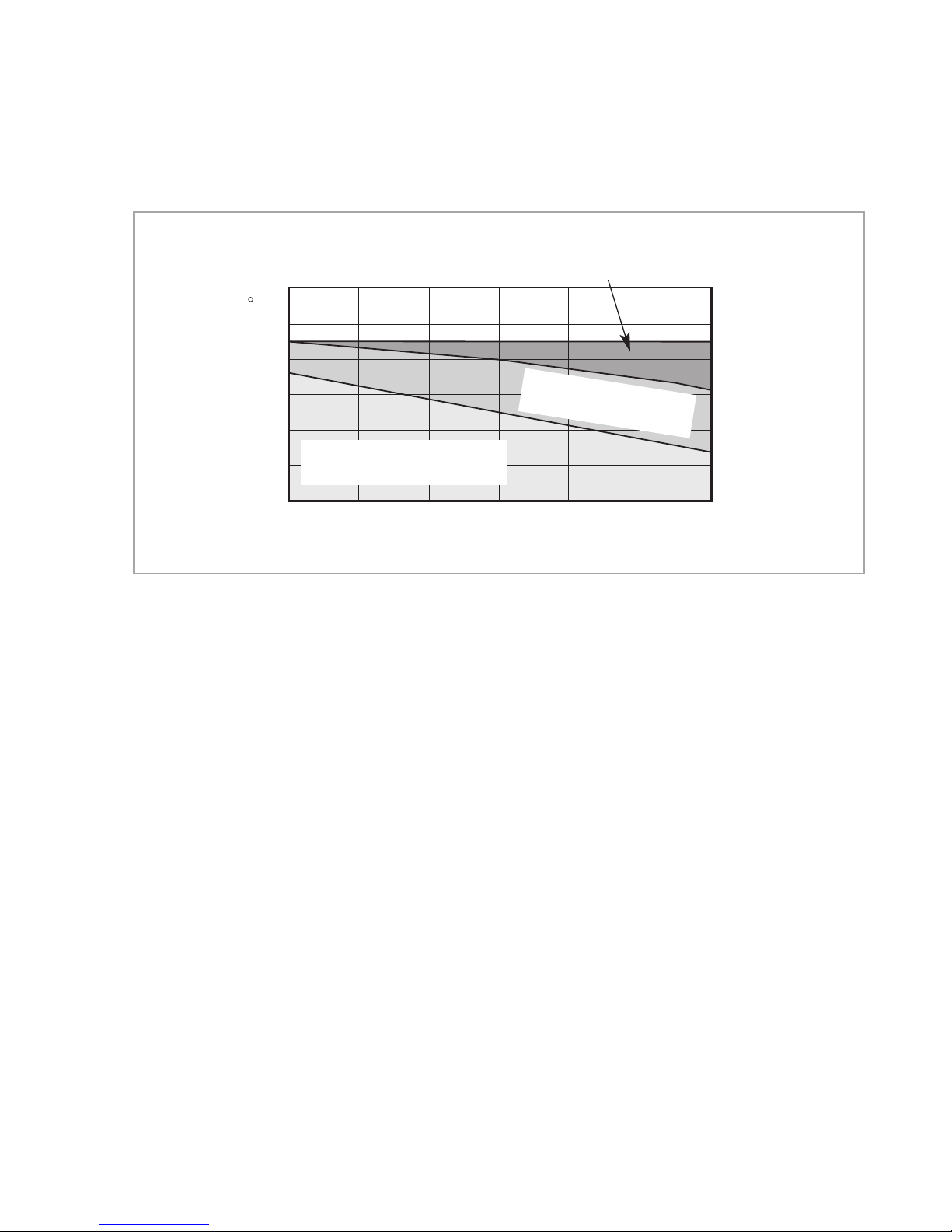

As to the cooling requirements for the separately fitted

TURBO. DRIVE see Fig. 2.1. The bottom side of the frequency converter must not be allowed to attain too high

temperatures; see technical data.

CAUTION

Max. magnetic induction levels are 15 mT, max. radioactive

radiation spec. is 10

The frequency converter must only be used in rooms within

buildings. It must not be operated in explosive gas atmospheres.

The frequency converter and the connecting lines must be

protected against exposure to sprayed and condensing

water.

During operation the frequency converter may attain

temperatures up to 75 °C. We recommend that the unit

be installed so that it can not be touched inadvertently.

Owing to the small quantity of combustible material and the

proven safety of the instrument by testing in accordance

with EN 61010, the risk through fire and burning can

almost completely be excluded.

5

rad (103Gy).

14

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Installation

Heat sink and forced

cooling required

60

C

50

40

H

30

20

10

Ambient temperature

0

Operation possible

without additional cooling

12345

Motor current (Parameter 5)

eat sink required

(convection cooling)

6

A

Fig. 2.1 Cooling requirements for the TURBO.DRIVE 400 when fitted separately

2.3 Mounting the frequency converter

The frequency converter may be affixed with the aid of the

enclosed M4 sliding nuts. The bottom side of the frequency

converter must be cooled sufficiently.

Ensure an adequate supply and discharge of cooling air.

For special requirements please contact us.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

15

Installation

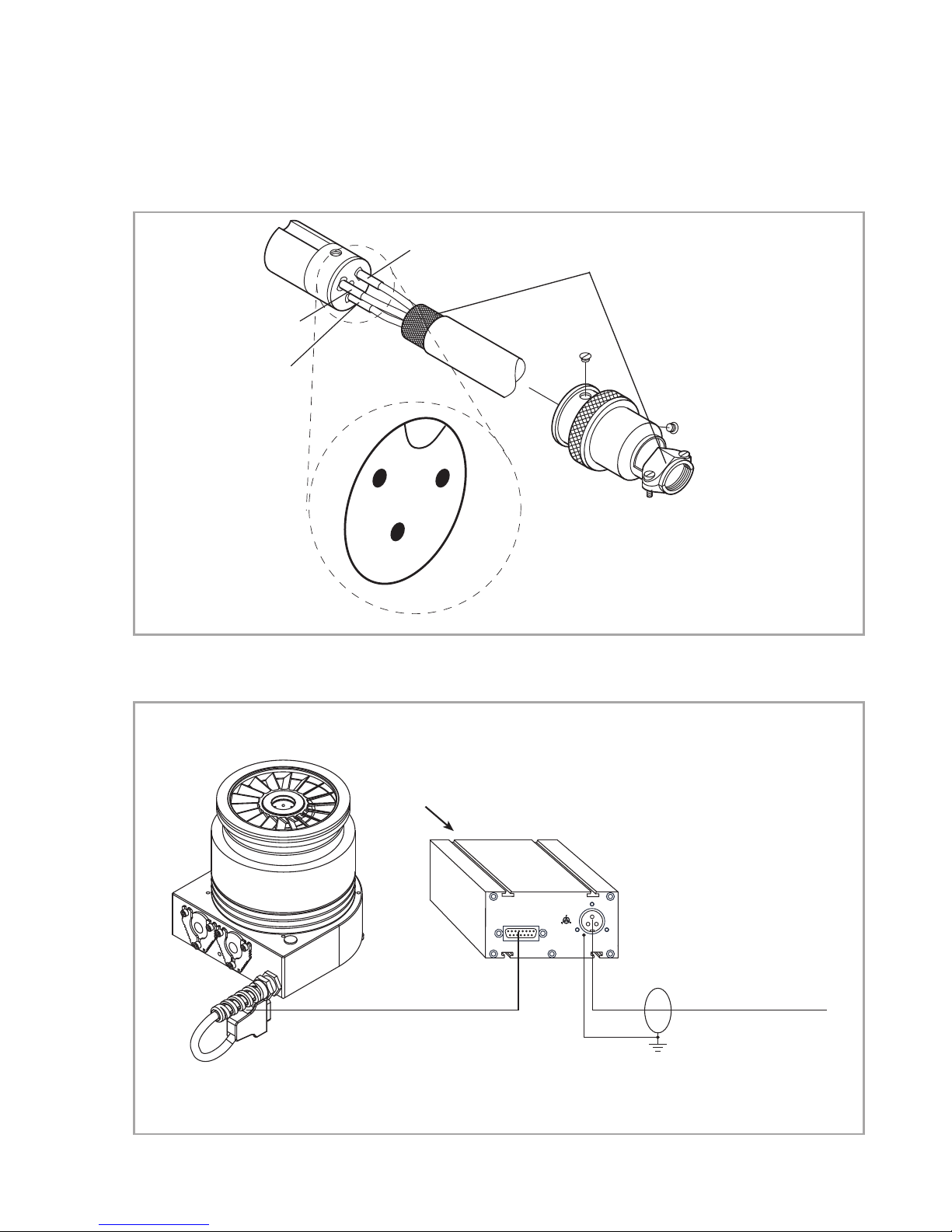

2.4 Connecting the pump

In the case of a separately fitted TURBO.DRIVE 400

connect the pump using the connecting cable.

NOTICE

WARNING

The pump may be operated only with a suitable frequency converter and suitable connecting cables.

Route all cables so as to protect them from damage.

Disconnect and connect the cable connections only

while the pump is turning no longer (green status

LED off) and with the mains power switched off (yellow power LED off). Otherwise there is the risk of

damaging the TURBO.DRIVE 400.

2.5 Connecting the power supply

The frequency converter must only be connected to

power supplies which meet the requirements for functional extra low voltage with positive isolation in accordance with IEC 364 (VDE 0100, Part 410, or local regulations) (PELV).

The power supply must meet the requirements given in

Section 1.3. Peak currents in the kHz range may be present on the DC side. The power supply should have a current limiter of the current regulated type.

NOTICE

16

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Connect the frequency converter to the 24 V DC power

supply or to the TURBO.CONTROL 300 or to the

TURBO.POWER 300 via the 24 V DC cable.

Ensure correct polarity.

Pin 1 + 24 VDC

Pin 2 0 V

Pin 3 GND

The frequency converter is equipped with an internal 8 AT

(slow blow) fuse. It can only be replaced by Oerlikon

Leybold Vacuum staff.

Connect the power supply to the mains.

acuum

Installation

REMOTE

93 - 132 /

187 - 264

V AC,

50/60 Hz

24 V DC

L

N

D

RIVE (X3)

HEAT SINK HEAT SINK

24 V DC (X4)

Pin 3 GND

Shielding

Pin 1 24 V

Pin 2 0 V

1

3

2

Fig. 2.2 Pin assignment of the DC connector (X4) Model Hirose HS16P-3

In the case of an integrated

connecting cable is omitted.

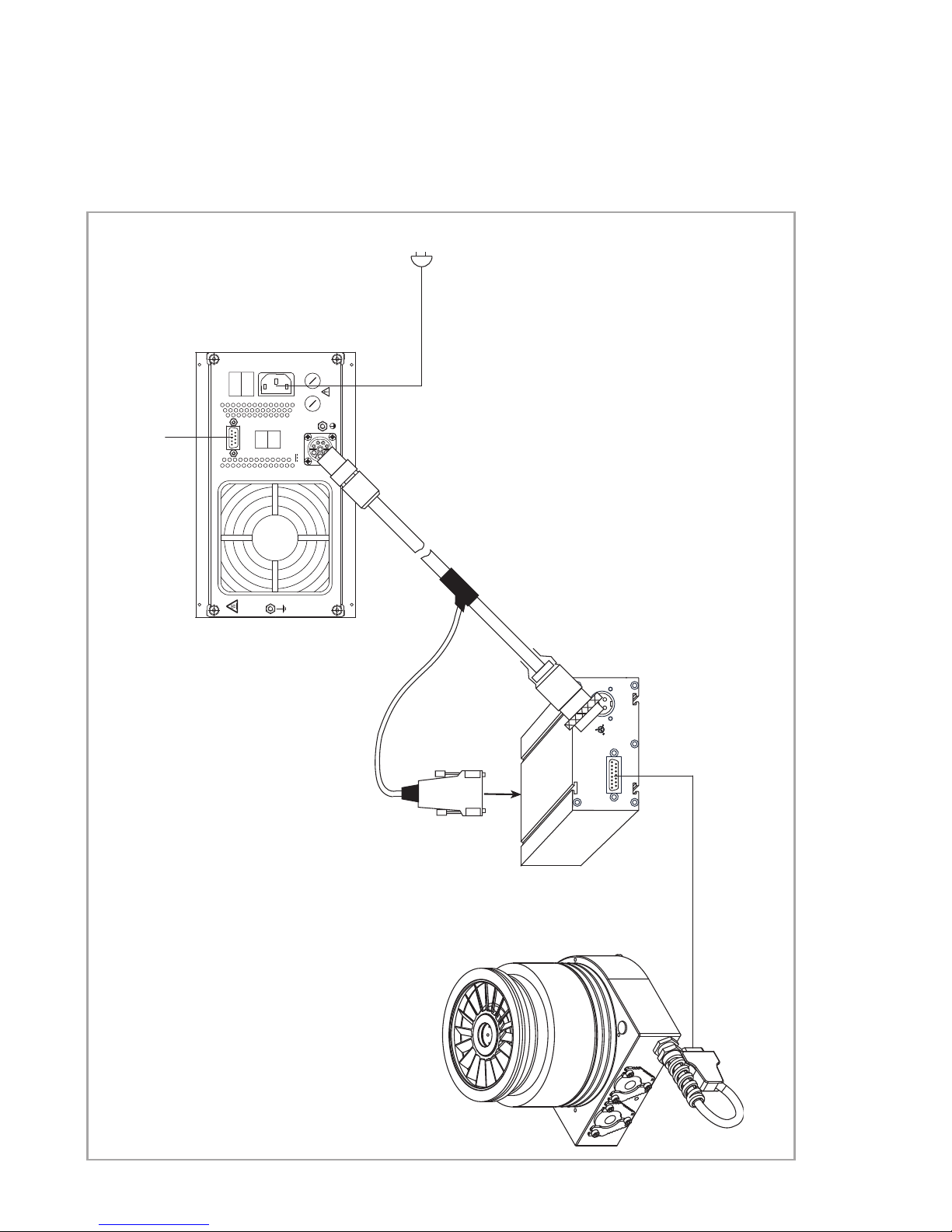

Fig. 2.3 Connecting the pump and the power supply

TURBO.DRIVE 400 the

DC cable,

with shielding,

max. 20 m

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

17

Installation

ON

OFF

1

0

MAINS

REMOTE IN

Programmable

logic control (PLC)

REMOTE

100 - 240 V ~

1

0

FRONT

T5 A

250 V ~

T5 A

250 V ~

REMOTE OUT

24 V POWER OUT

100 - 240 V ~

50 - 60 Hz

24 V DC Control cable

24 V DC (X4)

HEAT SINK HEAT SINK

DRIVE (X3)

REMOTE

TURBO.DRIVE 400 the

In the case of an integrated

connecting cable is omitted.

18

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Fig. 2.4 Connecting the pump and the TURBO.CONTROL 300

acuum

100 - 240 V AC

50/60 Hz

T 5 A ~ 250 V

T 5 A ~ 250 V

100 - 240 V AC

TURBO.POWER 300

Installation

24 V DC Power cable

24 V DC (X4)

HEAT SINK HEAT SINK

DRIVE (X3)

TURBO.DRIVE 400 the

In the case of an integrated

connecting cable is omitted.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Fig. 2.5 Connecting the pump and the TURBO.POWER 300

19

Installation

):

Relay - Normal operation

■ While deceleration, acceleration, Stop:

n. c.

Relay functions

nom.

4 connected to 5 (as shown; passive)

■ During normal operation (f > 0,9·f

534

n. o.

com.

4 connected to 3 (active)

Relay - Error

291

n. c.

■ No error: 1 connected to 2 (as shown; passive)

■ Error is present: 1 connected to 9 (active)

n. o.

com.

TURBO.DRIVE 400

TURBO.DRIVE S

TURBO.DRIVE 300

TURBO.DRIVE 400

7

Contact open = STOP

Contact closed = START

24 V

8

24 V

7

8

6

0 V = STOP

24 V = START

Relay output rating: 42 V, 0.5 A

Start/Stop operation

Example 1: Operation via a PLC

Example 2: Operation via contacts

TURBO.DRIVE 300

TURBO.DRIVE 400

6

876

9

54321

Pin assignment of the connector

20

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Pin assignment for the Start/Stop input

Switching threshold for

7,2 kΩ

the Start/Stop control

5 V

24 V

7

input:

Low-Level: < 7,5±0,5 V

6,2 V

2,6 kΩ

High-Level: > 10 ±0,5 V

8

acuum

3,6 kΩ

TURBO.DRIVE 400

Caution: No power feed is

allowed at pin 7

6

Fig. 2.6 Pin assignment of the REMOTE (X1) connector

operating mode before that

Installation

NORMAL ERROR STATUS ERROR

OPERATION (green) (red)

setpoint

frequency

Start/ Pump Normal Error is Motor Relay Relay LED LED

stop rotating frequency present drive

signal ≥ 90% of

Stop no no no off passive passive off off Pump not operating

Input data / status Output data Operating mode

2.6 Relay status

Stop yes no no off passive passive flashes off Pump is decelerating

Stop yes yes no off passive passive flashes off Just after stop; pump was in the normal

Start no no no on passive passive off off Just after start

Start yes no no on passive passive flashes off Pump is accelerating

Start yes yes no on active passive green off Pump is in the normal operating mode

Stop no no yes off passive active off red Error is present; pump is at standstill

Stop yes no yes off passive active flashes red Error is present; pump is decelerating

Stop yes yes yes off passive active flashes red Error has just occurred

Start no no yes off passive active off red Error is present; pump is at standstill

Start yes no yes off passive active flashes red Error is present; pump is decelerating

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Start yes yes yes off passive active flashes red Error has just occurred

acuum

Other modes are not possible; they indicate a failure affecting the TURBO.DRIVE 400.

21

Installation

3 Operation

3.1 Start-up

The TURBO.DRIVE 400 offers the possibility of gently running in pumps which were not operated for a period between 6 and 12 months.

For this set the parameter P119 “Bearing run-in function” to

1; thereafter start this function through the start command.

All three LEDs will flash rapidly, during acceleration the

green LED flash more slowly.

The run can be cancelled by revoking the start command.

Pausing is not possible.

After a completed run-in the pump stops. The LEDs continue to flash.

Parameter 119 remains set after the run and needs to be

set manually to 0.

In all, the entire bearing run-in process may take up to 4

hours.

Turbomolecular pumps which were not operated for a period of over 12 months should be returned to us. For more

information on this please contact your local sales partner.

22

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

3.2 Interfaces

The frequency converter has a RS 232 interface as standard (SERVICE X5) and is optionally equipped with serial

interfaces:

■ RS 485 C

■ Profibus DP

■ USB

The TURBO.DRIVE 400 is configured through the parameters according to the parameter list. Pxxx denotes parameter value xxx.

The PC software "TURBO.DRIVE Server" allows convenient

access by the user to the parameters of the frequency converter. It can be downloaded from www.oerlikon.com in the

menu Oerlikon Leybold Vacuum → Documentation →

Download Software.

Operation

Interfaces priority level

The optional interface has the highest priority level, followed

by the Service interface X5. The Remote input X1 has the

lowest priority level. See also parameter 179 in Section

3.2.4.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

23

Operation

Applications which can be implemented with the aid of the serial interface:

Application Benefits to the customer How to do it

Networking of several pumps Savings relating to the costs for With Field Bus systems like

and other equipment signalling cables Profibus

Automation Savings related to repetitive For example by a control

manual work computer

Avoidance of warnings and ■ Precise planning for Monitoring of:

warnings before overload maintenance ■ Motor current P5

operation and early detection ■ Improved reliability of sensitive ■ Ball bearing temperature

of a failing pump production processes in a P125 or P127

vacuum ■ Motor temperature P7

■ Frequency converter

temperature P11

Standby operation ■ Extending the service life Reducing the rotor’s frequency

for the ball bearings through P24

■ Cutting energy consumption

Troubleshooting Quick analysis of problems Reading of error memories

P171, P174 and P176:

error code, speed,

operating hours for error

Slow pressure control by Dispensing with a flow controller Changing the rotor frequency

changing the pumping speed through parameter 24

Reducing the maximum motor Cost savings through smaller With P139, motor current

current power supply units if peak loads reduction factor

can be reduced

Starting the pump with a delay if Cost savings through smaller With P36, delay

several consumers are power supply units

connected to the same PSU if peak loads can be reduced

Frequency converter as a simple Dispensing with pressure gauges Monitor motor current P5;

pressure gauge, since second function for “Normal

motor current is dependent Operation” relay: relay switches

on the vacuum conditions as soon as the motor

current threshold is tripped.

Adjust second function: P29

Set motor current thresh.: P27

Lowering the normal operation Normal operating mode is Reduce frequency threshold

threshold attained faster, processes through P25

24

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

can be started faster

acuum

Operation

TxD

RxD

1

6

2

7

3

8

4

1,4 and 6-9 are

internally

connected and

must not be

used.

9

GND

Fig. 3.1 Pin assignment for the socket at the frequency converter

(female) SERVICE X5

1,4 and 6-9 are

internally

connected and

must not be

used.

5

(2)

TxD

RxD

(3)

(5)

GND

TURBO.DRIVE

SERVICE X5

(2)

RxD

TxD

(3)

(5)

GND

Shield

9-pin IBM PC

RS 232

interface

Fig. 3.2 Providing a RS 232 connection

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

25

Operation

3.2.1 RS 232 C interface (SERVICE X5)

Standards DIN 66020

Protocol acc. to VDI/VDE 3689

Transmission rate 19200 baud

Response delay default setting 10 ms

(parameter 180)

Address range non-addressable

Max. cable length 5 m

Interface connector 9 way Sub-D type,

socket on the instrument (female)

thread UNC4-40

Note: If on the controlling side an RS 232 interface in

accordance with the PC standard with a 9-pin Sub-D male

connector is present, then a straight through cable as

shown in Fig. 3.2 may be used.

Refer also to Operating Instructions GA 05.281

Links for activation of the

bus terminator

0,5 A, 24 V DC

1

2

3

4

5

TxD/RxD +

TxD/RxD –

6

7

8

9

26

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Fig. 3.3 Pin assignment for the socket at the frequency converter for

RS 485 interface (male)

acuum

3.2.2 RS 485 interface

Standards ISO/IEC 8482, EIA 485

Protocol acc. to VDI/VDE 3689

Transmission rate 19200 baud fixed

Response delay default setting 10 ms

(parameter 180)

Address range 0 ... 15

Max. cable length 50 m (with bus termination)

Type of cable 2 wire twisted pair

(twisted pair cable)

Differential voltage levels logic "0":

(see also “Standards”) transmitter: 1.5 ... 5 V

receiver: > 0.3 V

Operation

logic "1":

transmitter: - 1,5 ... - 5 V

receiver: ≤ - 0,3 V

Interface connector 9 way Sub-D type,

socket on the instrument (male)

thread UNC4-40

Note: After having changed the bus address through the

rotary switch (see Fig. 1.3), the frequency converter must

be switched off (yellow power LED off) and then on again

so as to enable the new address setting.

Bus addresses over 15 can only be set via Parameter 37.

Refer also to Operating Instructions GA 05.281

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

27

Operation

Bus terminator

for longer cable runs

120 Ω

Master

...

For longer cable runs:

Links for activation of the

bus terminator

X 5

(9)

(8)

(6)

TxD/RxD –

(7)

X 5

TxD/RxD +

TURBO.

X5 (7) X5 (8)

TURBO.

X5 (7) X5 (8)

DRIVE

DRIVE

+ 5 V

+ 3.3 V

28

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

390 Ω

150

150 Ω

TURBO.DRIVE

390 Ω

Fig. 3.4 Connection of the RS 485 bus

acuum

3.2.3 Profibus DP

The Profibus DP used has been defined in the standards

EN 50170 and VDI/VDE 3689.

For more information on the Profibus system:

"The New Rapid Way to Profibus DP",

Manfred Popp, Profibus Nutzerorganisation e.V.,

Haid-und-Neu-Str. 7

76131 Karlsruhe, Germany

P/N: 4.072

www.profibus.com

Upon request we shall be pleased to provide detailed information on the hardware and the protocol used for the data.

Operation

Refer also to Operating Instructions GA 05.281

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

29

Operation

3.2.4 USB Interface (X106)

Transmission rate 19,200 Baud

Response delay time 10 ms (default)

(parameter 180)

Address range non-addressable

Maximum cable length 5 m

Interface connector USB B

Notice: the USB interface has been electrically separated

from the converter and is supplied from the side of the USB

host with a current of approximately 15 mA. Via the protection diode, separation with respect to 33 V is maintained.

30

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Operation

3.2.5 Parameter list

* specific values for each pump; see table of pumps, Chapter 3.2.6; r = readable, w = writable

No. Designation Min. Max. Default Unit r/w Format Description

1 Converter type 0 65535 0 r u16 136 = Turbo.Drive 400

2 Software version 0 65535 10000 r u32 xx.yy: version, zz: correction index

3 Actual frequency 0 65535 0 Hz r u16 Actual rotor frequency

4 Actual intermediate 0 1500 30 0,1 V r u16 Actual intermediate circuit voltage

circuit voltage of the converter

5 Actual current 0 150 0 0,1 A r u16 Actual motor current

6 Actual electrical

power 0 65535 0 0,1 W r u16 Actual drive input power

7 Actual motor -10 150 0 °C r i16 Actual value of the motor

temperature temperature.

8 Save data command 0 65535 0 /w i16 A write command with any value

saves temporary data into

nonvolatile memory.

11 Actual converter -10 150 0 °C r i16 Actual heat sink temperature

temperature of the converter.

16 Motor temperature 0 150

warning threshold warning threshold results in a

17 Nominal motor

current 5 60

18 Maximum frequency 750 1200

19 Minimum frequency 0 1200

20 Critical frequency 0 1200

23 Pump type 0 255

24 Setpoint frequency 0 1200

25 Normal operation 35 99 90 % r/w u16 Setpoint of the frequency dependent

*

*

*

*

*

*

*

°C r i16 Exceeding the motor temperature

warning.

0,1 A r u16 Maximum permissible motor current

Hz r u16 Highest permissible frequency

Hz r u16 Lowest permissible frequency

Hz r u16 Minimum frequency level. When the

pump is accelerating this frequency

must be reached within the

maximum passing time (P183).

r u16

Hz r/w u16 Setpoint of the rotor frequency

normal operation level

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

31

Operation

No. Designation Min. Max. Default Unit r/w Format Description

27 Current norm. oper. 5 60 20 0,1 A r/w u16 Motor current dependent normal

operation level; ; If P29[0] = 1:

Defines the normal operation level.

Normal operation if P5 <= P27

Parameter cannot be changed

during operation of the system

29 Relay function X1 0 8 0 r/w u16 If required, special functions can be

assigned to the normal operation

and the error relay. Field 0

specifies the function for normal operation:

0 = Frequency dependent

1 = Motor current dependent

2 = Fieldbus controlled

3 = Trigger current bearing temperature (P122)

4 = Venting function (P247/P248)

5 = Pump at standstill (f < 3)

6 = Start command is present

7 = Ready for switch on (=STW Bit1)

8 = No mains power failure or no generator operation (P303 Bit 4 =1 = generator operation)

Field 1 specifies the function for the error relay:

0 = Energised when an error is present

1 = Deenergised when an error is present

2 = Fieldbus controlled

3 = Venting function

32 Max. run-up time 30 2000 720 s r/w u16 Max. permissible time during which

36 Start delay time 0 255 0 0,1 min r/w u16 Delays the start of the pump to

38 Start counter 0 65535 0 r u16 Increments each time when passing

37 RS485 address 0 31 0 r/w u16 Parameterizable RS485 address;

through the address switch or a value entered here provided the address switch is set to 0.

A change of this parameter setting will only be effective after the power

supply has been switched off and on.

119 Bearing run-in 0 1 0 r/w u16 0=deactivated

function 1=new pump type starts with

Run in using the run-in sequence specified through the pump table without run-up time monitoring

(a min at b Hz ….c min at d Hz…in total 4 stages for mechanical pumps)

32

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

the pump must attain the normal

operation threshold (P24*P25) with

the start signal present.

allow leadtime for the fore vacuum

pump for example.

through the critical speed range.

The address is specified either

run-in sequence

acuum

Operation

No. Designation Min. Max. Default Unit r/w Format Description

122 Normal TMS 20 70 40 °C r/w u16 Switch-on temperature for fan when

P29[0]=3. For P125 > P122 the

normal operation relay is energised.

125 Bearing temperature -10 150 0 °C r i16 Actual value of the bearing

temperature

126 Bearing temperature -10 150

warning threshold warning threshold results in a

127 Bearing temperature -10 150 0 °C r i16 Actual value of the bearing

128 Motor temperature -10 150 2 °C r i16 Falling below the motor temperature

lower warning lower warning threshold

threshold results in a warning.

131 Motor temperature 10 150 -10 °C r i16 Falling below the motor temperature

lower error threshold - lower error threshold causes the

132 Bearing temperature -10 150

error threshold error threshold causes the pump to

133 Motor temperature -10 150

error threshold error threshold causes the pump to

134 Enable cooling fan 0 19 19 r/w 116 0 = Cooling fan off

on turbopump 19 = Cooling fan on

*

*

*

°C r i16 Exceeding the bearing temperature

warning

temperature

pump to be switched off.

°C r i16 Exceeding the bearing temperature

be switched off.

°C r i16 Exceeding the motor temperature

be switched off.

139 Current reduction 30 100 100 % r/w u16 Is used for the reduction of the

factor maximum consumption current,

e.g. for adaptation of low performance power supplies. Note: values < 100 reduce the pump

performance and increase the run-up time.

140 Intermediate circuit 0 150 0 0,1 A r i16 Actual average intermediate circuit

current current of the converter.

150 Standby frequency 0 1200

151 Enable standby 0 1 0 r/w u16 0 = normal speed (P24);

*

Hz r/w u16 Standby operation frequency

setpoint

1 = standby speed (P150)

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

33

Operation

No. Designation Min. Max. Default Unit r/w Format Description

171 Error code memory 0 65535 0 r u16 Indexed parameter for storing the

most recent 40 error codes.

The individual error memory entries are accessed via this parameter with additional index number.

The last error code is accessed with index 0 and the oldest with index 39. See Section 5

Troubleshooting for the error codes.

174 Error rotor frequency 0 65535 0 Hz r u16 Actual speed, when error occurred.

Access analogously as for

parameter 171.

176 Error operating hours 0 0 h r u32 Operating hours, when error

2147483647 occurred. Access analogously as for

parameter 171.

179 Fallback PZD1 0 65535 1024 r/w u16 Response when cancelling the

control rights or in the case of a

communication interruption of the bus adapter

Behaviour in case bit 10 in the control word of the bus adapter is cancelled or when interrupting the

communication between converter and bus adapter (see also P182). Here it is assumed that the

respective bus adapters perform a cyclic communication on the USS side, so that the respective

converter electronics is capable of detecting a communication interruption

The bits in parameter 179 represent an equivalent to the control word in the USS protocol.

The actions linked to these bits are run provided bit 10 in the control word (USS protocol for bus

adapter) is cancelled or if there are interruptions in the communication between converter and bus

adapter.

Here bit 10 is of special significance:

Bit 10 = 0 The control rights are returned to the next lower priority level. All other bits are not relevant.

Bit 10 = 1 The control rights remain unchanged. The actions linked to the other bits are run.

180 Resp. delay time 0 20 10 ms r/w u16 Response delay time; Pause time

between received and transmitted

USS protocol string of the frequency converter's serial interface RS232 and RS485.

We recommend not to change the default setting (10ms).

182 Watchdog timer USS 0 65535 10 0,1 s r/w u16 Delay when cancelling the

control rights of the bus adapter

and time-out in the case of a communication interruption

Defines the time characteristic when cancelling bit 10 in the control word of the USS protocol or when

an interruption in the communication between bus adapter and converter and electronics is detected.

Handling when cancelling bit 10 or when there is an interruption on the communication side of the

USS bus adapter, is the same.

Value 0.0: Indefinite time delay. In this way a change of the control right is inhibited.

Values 0.1 ..6553.5: A change in the control right corresponding to the setting of parameter 179 is

only effected after the time span defined through parameter 182 has elapsed.

34

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Operation

No. Designation Min. Max. Default Unit r/w Format Description

183 Max. passing time 0 1800 500 s r u16 Max. permissible time during which

the pump must - with the start signal

present - have passed through the

critical speed range between 60 Hz

and P20.

184 Converter operating 0 0 0,01 h r u32 Counts the operating hours of the

hours 2147483647 converter during active pump

operation.

227 Warning bits 1 0 65535 0 r u16 Active warnings described bit per bit.

See Section 3.2.6.

247 Vent on frequency 0 1200 300 Hz r/w u16 Frequency at which the venting valve

shall be switched on in the event of a

mains power failure. Power failure

venting can be enabled through

P240.

248 Vent off frequency 0 1200 5 Hz r/w u16 Frequency at which the venting valve

shall be switched off in the event of a

mains power failure. Power failure

venting can be enabled through

P240.

249 Generator operation 0 1 1 r/w u16 0 = inactive

1 = active

303 Actual operating 0 65535 0 r u16 Bit 0: Normal operation

status Bit 1: Ready for switch on

Bit 2: Speed is increasing

Bit 3: Speed is dropping

Bit 4: Generator operation

Bit 5: Standby

Bit 6: reserved

Bit 7: reserved

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

35

Operation

No. Designation Min. Max. Default Unit r/w Format Description

312 Catalog number 0 127 :CHAR r u16 Catalogue number of the converter.

of converter [8000xxV000x] One ASCII char per index.

313 Product name 0 127 [TD_400] :CHAR r u16 Product name of the converter.

(Index 0...10 usable) 0 127 :CHAR r u16 One ASCII char per index.

Only for DeviceNet purpose

315 Serial number of 0 127 :CHAR r u16 Serial number of the converter.

converter [xxxxxxxxxxx] One ASCII char per index.

(Index 0...10 usable)

918 Act. Profibus addr. 0 65535 0 r u16 Active Profibus address

947 Current error number 0 65535 0 r u16 Currently pending error. See

Chapter 5 Troubleshooting.

3.2.6 Specific parameter data for the pumps

Bearing Motor

Ty pe of P u m p No m i na l M i ni m u m M i ni mu m M a x. M a x. M a x . t e mp . t e mp .

pump designation and setpoint setpoint frequency motor bearing motor warning warning

frequency frequency level current temp. temp. threshold threshold

P23 P18 / P24 P19 P20 P17 P132 P133 P126 P16

0 TW 220/150

TW 220/150/15 750 650 375 6.0 80 100 70 95

1 TW 400/300/25S

TW 250/200/40 800 650 375 6,0 80 100 70 95

2 TW 250S 860 750 340 5.0 67 100 60 95

3 TW 70 H 1200 910 340 5.0 67 90 60 85

4 TW 290 H /

TW 300 /

TW 300 H 1000 890 375 5.0 80 63 70 58

5 SL 80 1200 910 340 5.0 – 55 – 53

6 SL 300 1000 890 375 5.0 – 56 – 54

36

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Operation

Type of

pump designation [Hz]

P23 P150

0 TW 220/150

1 TW 400/300/25S

2 TW 250S 800

3 TW 70 H 910

4 TW 290 H /

5 SL 80 910

6 SL 300 960

Run-in sequence, bearing run-in function

Type of Pump Run-in Run-in Run-in Run-in Run-in Run-in

pump designation speed 1 time 1 speed 2 time 2 speed 3 time 3

P23 [Hz] [s] [Hz] [s] [Hz] [s]

Pump Standby frequency

TW 220/150/15 700

TW 250/200/40 700

TW 300 /

TW 300 H 960

0 TW 220/150

TW 220/150/15 100 3600 300 5400 300 5400

1 TW 400/300/25S

TW 250/200/40 100 3600 300 5400 300 5400

2 TW 250S 100 3600 300 5400 500 5400

3 TW 70 H 180 3600 350 5400 600 5400

4 TW 290 H /

TW 300 /

TW 300 H 200 3600 430 5400 580 5400

5 SL 80 180 3600 430 5400 580 5400

6 SL 300 200 3600 430 5400 580 5400

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

37

Operation

3.2.7 Warning codes for parameter 227

P227,

Bit

0 Motor tempe-

1 Converter

2 Bearing over-

Designation Meaning Possible cause Remedy

rature warning

temperature

warning

temperature

warning

The motor

temperature

has passed the

warning threshold

Overtemperature at the

power output

stage or within

the frequency

converter

The permissible warning

threshold for

the bearing

temperature

was exceeded.

Forevacuum pressure too high.

Gas flow too high

Fan defective

Water cooling

switched off

Ambient temperature

too high

Poor cooling

Forevacuum pressure too high.

Gas flow too high

Fan defective

Check the ultimate pressure of the backing pump

and install a bigger

backing pump if req.

Seal leak, check process

Replace fan

Switch on water cooling

Ensure max. ambient

temperature of 45°C

Improve cooling

Check the ultimate pressure of the backing pump

and install a bigger

backing pump if req.

Seal leak, check process

Replace fan

3 Motor under-

temperature

warning

4, 5 not used

6 Overspeed

warning

38

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

The minimum

permissible

motor temperature (warning

threshold) is

not reached.

Water cooling

switched off

Ambient temperature

too low

Pump cooling too

high

acuum

Switch on water cooling

Ensure min. ambient temperature of 0°C

Reduce water cooling

Operation

P227,

Bit

7, 8,

9, 10

11 Overload

12,

13

14 Power supply

Designation Meaning Possible cause Remedy

not used

warning

not used

voltage

warning

The pump

speed has

dropped under

the normal

operation

threshold

Supply voltage

failure during

active operation of the

pump

P4 > Umax or

P4 < Umin

Forevacuum pressure too high.

Gas flow too high

Intermediate circuit

voltage too low or

maximum time for

generator operation

was exceeded.

DC power supply

voltage below 24V

Check the ultimate pressure of the backing pump

and install a bigger

backing pump if req.

Seal leak, check process

15 Fan voltage

has failed

Mains voltage failure

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

39

Operation

3.3 Switching on

Switch on the DC power supply. The yellow LED at the frequency converter lights up.

Switch on the turbomolecular pump at the frequency converter

■ via pins 7 and 8 of the socket REMOTE (X1) (For example via a remote control or with the aid of the plug with

integrated ON/OFF switch: see Section 1.5

Accessories).

■ by a start command via the interface.

The turbomolecular pump accelerates. The green LED

flashes. When the pump reaches normal operation the

green LED lights up permanently.

After a mains power failure the pump can run up automatically once more.

40

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

3.4 Shutting down

Switch off the pump at the frequency converter.

■ via contacts 7 and 8 of the socket REMOTE (X1).

■ apply a stop command via the interface.

■ for the power supply units offered or recommended by

Oerlikon Leybold Vacuum switch off the DC voltage.

After switching off, the green status LED will flash until the

rotor of the turbomolecular pump is at standstill. This may

take several minutes. With the DC power supply off, the

turbomolecular pump will act as a generator supplying the

frequency converter with energy as indicated by the yellow

power LED.

Operation

If a failure occurs the turbomolecular pump will be shut

down automatically. The red LED at the frequency converter lights up.

To shut down the frequency converter, switch the pump off

and wait until the rotor of the turbomolecular pump has

arrived at standstill (green status LED off).

Then switch the mains power off and wait until the yellow

power LED is off. Then only disconnect any cable connections.

3.5 Emergency shut down

The emergency shutdown facility of a system controller

must be capable of shutting the pump down as detailed in

Chapter 3.3. The rotor of the turbomolecular pump may be

stopped faster by venting the pump; for this refer to the

Operating Instructions for the pump.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

41

Operation

3.6 Setting pumping speed and rotational speed

For the purpose of reducing the pumping speed of the

pump because of application requirements or for other reasons it can make sense to reduce the rotational speed.

In order to permanently reduce the speed we recommend

the following procedure:

With the aid of a Windows PC and the PC software

“TURBO. DRIVE Server” change the setting for the parameter 24 “Setpoint frequency”. The possible values for parameter 24 will depend on the type of pump connected.

Parameter 18 “Nominal pump frequency“ defines the maximum value and parameter 19 “Minimum setpoint frequency

for the pump” defines the minimum value.

So as to retain the value saved for parameter 24 when

switching the pump off, the parameter value needs to be

saved permanently. For this enter any value (for example 1)

for parameter 8. Thereafter changed parameters will be

saved permanently.

Parameters which are typical for the specific type of pump

(see Chapter 3.2.5) are reset to the factory defaults after

having changed the type of pump and when switching on

the power supply voltage again.

The rotational speed of the pump may be changed during

operation also with the aid of a Windows PC and the PC

software “TURBO.DRIVE Server”.

However, we here recommend a PLC compliant solution

with the aid of the Profibus. The speed can be set over the

Profibus in two ways:

■ by changing parameter 24 within the limits defined by

parameters 19 and 18 or

■ by transfer as the main setpoint (for this also refer to

VDI/VDE 3689).

42

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

3.7 Operation at reduced current

Not all applications require that the TURBO.DRIVE 400 be

operated at its maximum current. Operation at reduced

current will allow operation off a smaller power supply unit

or to operate two or more turbomolecular pumps off a

power supply unit which in practice is just not strong

enough to supply the maximum current for several connected pumps. However, this will increase the run up time, and

the maximum gas throughput and backing pressure specifications are reduced.

For this proceed as follows:

With the aid of a Windows PC and the PC software

“TURBO. DRIVE Server” change the setting for the parameter 139 “Current reduction factor”. The possible values for

parameter 139 can be varied within the limits of 30 to 100

% of parameter 17 (current dependents on the type of

connected pump. The newly entered current reduction factor will only be active after switching off and on again.

Operation

So as to retain the value saved for parameter 139 when

switching the pump off, the parameter value needs to be

saved permanently. For this enter any value (for example 1)

for parameter 8. Thereafter changed parameters will be

saved permanently.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

43

Operation

3.8 Changing the frequency dependent normal

operation level

Depending on the quality of the vacuum which needs to be

provided by the turbomolecular pump it may make sense

to reduce the frequency dependent normal operation threshold, so that the ready status can be attained faster by the

vacuum system. The factory default of 90 % represents a

good compromise so that a change will hardly ever be

required.

For this proceed as follows:

With the aid of a Windows PC and the PC software

“TURBO. DRIVE Server” change the setting for the parameter 25 “Frequency dependent normal operation level”. The

possible values for parameter 25 can be varied within the

limits of 35 to 99 % of parameter 24 (nominal speed

depends on the type of connected pump).

So as to retain the value saved for parameter 25 when

switching the pump off, the parameter value needs to be

saved permanently. For this enter any value (for example 1)

for parameter 8. Thereafter changed parameters will be

saved permanently.

44

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

3.9 Changing the maximum permissible run up

time

In vacuum systems at a high backing pressure or with

increased quantities of gas during the run up phase, the

run up time for the turbomolecular pump may be longer.

This will then cause the frequency converter to output an

error message,

The maximum permissible run up time is changed as

follows:

With the aid of a Windows PC and the PC software

“TURBO. DRIVE Server” change the setting for the parameter 32 “Maximum run up time”. The possible values for

parameter 32 can be varied within the limits of P183 to

2000 seconds. The default setting is 720 seconds. As a

rule, no value below 720 seconds should be entered as this

would give rise to unnecessary error messages. If a significantly higher value than 720 seconds is required, this may

indicate that the turbomolecular pump is being overloaded.

For this reason in such a case the temperature data from

the frequency converter and the turbomolecular pump

(parameter 7 = motor temperature, 11 = frequency converter temperature, 125/127 bearing temperature) should be

specially monitored during application trials.

Operation

So as to retain the value saved for parameter 32 when

switching the pump off, the parameter value needs to be

saved permanently. For this enter any value (for example 1)

for parameter 8. Thereafter changed parameters will be

saved permanently.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

45

Operation

3.10 Changing the start delay time

Generally it will make sense to let the turbomolecular pump

run up immediately after applying the start command.

However when operating two or more turbomolecular

pumps off a single power supply unit, it may make sense to

start the pumps one after the other. One way of achieving

this is to enter a start delay time differing from 0.

To set up the start delay time proceed as follows:

With the aid of a Windows PC and the PC software

“TURBO. DRIVE Server” change the setting for the parameter 36 “Start delay time”. The possible values for parameter

36 can be varied within the limits of 0 to 25.5 minutes (0 to

255).

So as to retain the value saved for parameter 36 when

switching the pump off, the parameter value needs to be

saved permanently. For this enter any value (for example 1)

for parameter 8. Thereafter changed parameters will be

saved permanently.

46

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

3.11 Selecting relay functions

See parameter 29.

3.12 Reading the error memory

The TURBO.DRIVE 400 is capable of permanently saving

up to 40 error events. The error codes are saved under

parameter number 171. In addition to each error code the

following is also saved:

■ Rotor frequency at the point of time when the error

event in parameter 174 occurred.

■ The corresponding number of operating hours in parameter 176.

Operation

Access to each of the 40 groups of values is accomplished

with the aid of an index value which needs to be stated

besides the parameter number when accessing via the protocol in accordance with VDI / VDE 3689. The range of

index numbers ranges from 0 to 39.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

47

Maintenance

4 Maintenance

The frequency converter is maintenance free. Repairs must

only be done by Oerlikon Leybold Vacuum.

If required clean the frequency converter of dust with a dry

cloth.

When removing a defective frequency converter from an

installation, please note the information given in Chapter

3.4.

During all work on the pump which is being driven by the

frequency converter, the system must be protected against

being switched on. For this disconnect the DC power

supply.

48

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Troubleshooting

5 Troubleshooting

Before you start searching for the source of the problem,

you should carry out a few simple checks:

Are the connections in good working order?

■ Mains connection,

■ DC power supply to the frequency converter,

■ Connector cable between the frequency converter and

the pump

Is the forevacuum pressure sufficient?

After having removed the cause for the error reset the error

message at the TURBO.DRIVE:

■ In case of error code 8 by switching the mains power

off.

■ In case of the other errors by applying a STOP signal

via the socket REMOTE (X1) or a reset sequence via the

serial interface or by switching the mains power off.

The error codes can only be read if a serial interface is present.

The following table has been provided as a guide when

determining the causes of errors.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

49

Troubleshooting

Error

code

1 Overspeed

2 Pass through

Designation Meaning Possible Cause Remedy

warning

time error

The actual frequency

exceeds the

setpoint by

over 10 Hz.

The pump has

not reached

the minimum

speed after the

maximum runup time has

elapsed.

Frequency converter defective

Forevacuum

pressure too

high.

Gas flow too

high

Rotor blocked

Contact Oerlikon

Leybold Vacuum

Service.

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Check if the rotor

turns freely. Contact

Oerlikon Leybold

Vacuum Service if the

rotor is damaged or

blocked.

Shutdown

no

yes

3 Bearing

temperature

error

4 Short circuit

error

5 Converter

temperature

error

The maximum

permissible

bearing temperature was

exceeded.

Overtemperature at the

power output

stage or within

the frequency

converter

Forevacuum

pressure too

high.

Gas flow too

high

Fan defective

Water cooling

switched off

Ambient temperature too high

Poor cooling

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Replace fan

Switch on water

cooling

Ensure max. ambient

temperature of 45°C

Improve cooling

yes

yes

yes

50

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Troubleshooting

Error

code

6 Run-up time

7 Motor tem-

Designation Meaning Possible Cause Remedy

error

perature error

The pump has

not reached

the normal

operating frequency after

the maximum

run-up time.

The motor

temperature

has exceeded

the shutdown

threshold.

Forevacuum

pressure too

high.

Gas flow too

high

Forevacuum

pressure too

high.

Gas flow too

high

Fan defective

Water cooling

switched off

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Replace fan

Switch on water

cooling

Shutdown

yes

yes

8 Pump error Pump couldn’t

be identified or

no pump is

connected

61 Bearing tem-

perature warning, top

82 Fan voltage

has failed

83 Motor tempe-

rature low

warning

Pump not connected correctly

to frequency

converter

Hardware

defective

Check connection

between pump and

frequency converter

Contact Oerlikon

Leybold Vacuum

Service

yes

no

no

no

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

51

Troubleshooting

Error

code

84 Motor over-

101 overload

103 Supply

Designation Meaning Possible Cause Remedy

temperature

warning

warning

voltage

warning

The pump

speed has

dropped under

the normal

operation

threshold

Intermediate

circuit voltage

too low or

maximum time

for generator

operation was

exceeded.

Forevacuum

pressure too

high.

Gas flow too

high

DC supply voltage below 24V

Mains voltage

has failed

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Check the voltage at

the power supply

and if required set up

correctly

Remedy the cause

for the mains power

failure

Shutdown

no

no

no

106 overload error The pump

speed has

dropped under

the minimum

speed

111 Motor under-

temperature

error

The minimum

permissible

motor temperature is not

attained.

Forevacuum

pressure too

high.

Gas flow too

high

Ambient temperature too low

Pump cooling

too high

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Ensure min. ambient

temperature of 0°C

Reduce water cooing

yes

yes

52

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Troubleshooting

Error

code

116 Permanent

117 Motor current

126 Bearing tem-

Designation Meaning Possible Cause Remedy

overload error

error

perature sensor error top

The speed of

the pump has

dropped below

the normal

operation

threshold and

has stayed

there for a longer period of

time.

Motor current

less than

nominal current

Bearing temperature sensor defective

Forevacuum

pressure too

high.

Gas flow too

high

Cable fault

Faulty

connector

Sensor defective, short circuit

or broken cable

Check the ultimate

pressure of the

backing pump and

install a bigger

backing pump if req.

Seal leak, check process

Contact Oerlikon

Leybold Vacuum

Service

Contact Oerlikon

Leybold Vacuum

Service

Shutdown

yes

yes

yes

128 Motor tem-

perature sensor error

143 Overspeed

error

Motor temperature sensor defective

Sensor defective, short circuit

or broken cable

Contact Oerlikon

Leybold Vacuum

Service

yes

yes

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

53

Troubleshooting

Error

code

– Yellow power

div. Red LED

Error Possible Cause Remedy

LED is not on

flashes

No DC power

DC power miswired

Frequency converter

defective

Warning message.

See Section “3.2.6

Warning codes” for the

possible reasons of the

warning.

Check cables and power

supply

Ensure correct polarity of

the DC cable.

Replace frequency converter. The following may

damage the freq. converter:

■ Disconnection of the DC

cable while the pump was

still rotating

■ Non-compliance with

the note related to

connecting several pump

to a single power supply.

The pump can continue to

run, as long as operation

limits are only exceeded

for a short time. In case of

longer exceeding send

pump and frequency converter to the OLV service.

Shutdown

–

no

54

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Troubleshooting

Error

code

– Turbomolecu-

– Turbomolecu-

Error Possible Cause Remedy

lar pump does

not start,

ERROR LED

does not light.

lar pump

produces loud

running noises

and vibrations.

Interface protocol error

No communication via the

serial interface.

REMOTE connector (X1)

connected wrongly.

REMOTE and SERVICE

connectors mixed up.

Wrong Profibus address

set.

Rotor out of balance

Bearing defective

Use USS protocol.

Connect bus as shown in

Section 3.2.

Connect as shown in Fig.

2.6

Connect correctly.

Set address between 0

and 126.

Balance the rotor

Replace the bearing

Shutdown

–

no

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

55

Troubleshooting

Error

code

– Turbomolecu-

– Running

Error Possible Cause Remedy

lar pump does

not reach ultimate

pressure.

pump can not

be stopped

via X1

Measurement instrument

defective

Measurement sensors

soiled

Leaks at the equipment,

lines or the pump

Pump soiled

Forevacuum pump provides insufficient pumping

speed or ultimate pressure

which is too high.

Frequency parameters

programmed wrongly

Pump has been started via

the serial interface, the

interface controls the

pump

Inspect the measurement

sensor

Clean or replace the

sensors

Check for leaks

Clean the pump

Check the ultimate pressure of the forevacuum

pump and install a highercapacity vacuum pump if

necessary

Check parameters.

Disconnect the DC supply

or connect serial interface

and stop via bus

Shutdown

no

no

56

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Waste Disposal

6 Waste Disposal

The equipment may have been contaminated by the process or by environmental influences. In this case the equipment must be decontaminated in accordance with the relevant regulations. We offer this service at fixed prices.

Further details are available on request.

Contamination

Contaminated parts can be detrimental to health and

environment. Before beginning with any work, first find

out whether any parts are contaminated. Adhere to the

relevant regulations and take the necessary precautions

when handling contaminated parts.

Separate clean components according to their materials,

and dispose of these accordingly. We offer this service.

Further details are available on request.

This product complies with the European Community

Regulation 2002/95 (RoHS Restriction of Hazardous

Substances).

CAUTION

RoHS compliance

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

57

Notes

58

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

59

www.oerlikon.com

LV_11139_2011 04.11

Oerlikon

Leybold Vacuum GmbH

Bonner Strasse 498

D-50968 Cologne

Phone: +49-(0)221-347 0

Fax: +49-(0)221-347 1250

info.vacuum@oerlikon.com

Loading...

Loading...