Leybold vacuum TURBO.DRIVE 400, 800073V0002, 800073V0003, 800073V0004, 800073V0008 Operating Instructions Manual

TURBO.DRIVE 400

Frequency Converter for

Turbomolecular Pumps

Operating Instructions 17200492_002_A5

Part Numbers

800073V0002

800073V0003

800073V0004

800073V0008

D

r

ive (

DC 2

X

3)

4

V(X4)

H

EAT

S

IN

K

H

EAT

S

IN

K

Contents

Page

Important Safety Information 4

1 Description 7

1.1 Design and function 7

1.2 Standard equipment 7

1.3 Technical data 8

1.4 Ordering data 10

1.5 Accessories 10

2 Installation 13

2.1 Conforming utilization 13

2.2 Operating environment 14

2.3 Mounting the frequency converter 15

2.4 Connecting the pump 16

2.5 Connecting the power supply 16

2.6 Relay status 21

3 Operation 22

3.1 Start-up 22

3.2 Interfaces 23

3.2.1 RS 232 C interface (SERVICE X5) 26

3.2.2 RS 485 interface 27

3.2.3 Profibus DP 29

3.2.4 USB interface (X106) 30

3.2.5 Parameter list 31

3.2.6 Specific parameter data for the pumps 36

3.2.7 Warning codes for parameter 227 38

3.3 Switching on 40

3.4 Shutting down 41

3.5 Emergency shut down 41

3.6 Setting pumping speed and rotational speed 42

3.7 Operation at reduced current 43

3.8 Changing the frequency dependent normal

operation level 44

3.9

3.10 Changing the start delay time 46

3.11 Selecting relay functions 47

3.12 Reading the error memory 47

Changing the maximum permissible run up time 45

2

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Contents / Safety Information

4 Maintenance 48

5 Troubleshooting 49

6 Waste Disposal 57

EC Conformance Declaration 59

Obligation to Provide Information

Before installing and commissioning the TURBO.DRIVE,

carefully read these Operating Instructions and follow

the information so as to ensure optimum and safe

working right from the start.

The Oerlikon Leybold Vacuum TURBO.DRIVE 400 has

been designed for safe and efficient operation when used

properly and in accordance with these Operating

Instructions. It is the responsibility of the user to carefully

read and strictly observe all safety precautions described in

this section and throughout the Operating Instructions. The

TURBO.DRIVE

tion and under the conditions described in the Operating

Instructions

personnel only. Consult local, state, and national agencies

regarding specific requirements and regulations. Address

any further safety, operation and/or maintenance questions

to our nearest office.

must only be operated in the proper condi-

. It must be operated and maintained by trained

NOTICE

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazar

if not avoided, could result in minor or moderate injury.

DANGER

WARNING

dous situation which,

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

CAUTION

acuum

3

Safety Information

NOTICE

WARNING

NOTICE is used to notify users of installation, operation,

programming or maintenance information that is important,

but not hazard related.

We reserve the right to alter the design or any data given in

these Operating Instructions.

The illustrations are not binding.

Retain the Operating Instructions for further use.

Important Safety Information

The frequency converter must only be connected to

power supplies which meet the requirements for functional extra low voltage with positive isolation in accordance with IEC 364 (VDE 0100, Part 410, or local regulations) (PELV).

During operation the frequency converter may attain

temperatures up to 75 °C. We recommend that the unit

be installed so that it can not be touched inadvertently.

NOTICE

Inside the unit there is the risk of suffering burns from

hot components.

The pump may be operated only with a suitable frequency converter and suitable connecting cables.

Ensure correct polarity.

Route all cables so as to protect them from damage.

Disconnect and connect the cable connections only

while the pump is turning no longer (green status LED

off) and with the mains power switched off (yellow

power LED off). Otherwise there is the risk of damaging

the TURBO.DRIVE 400.

4

17200492_002_A5 - 04/2011 - © Oerlikon Leybold Vacuum

Description

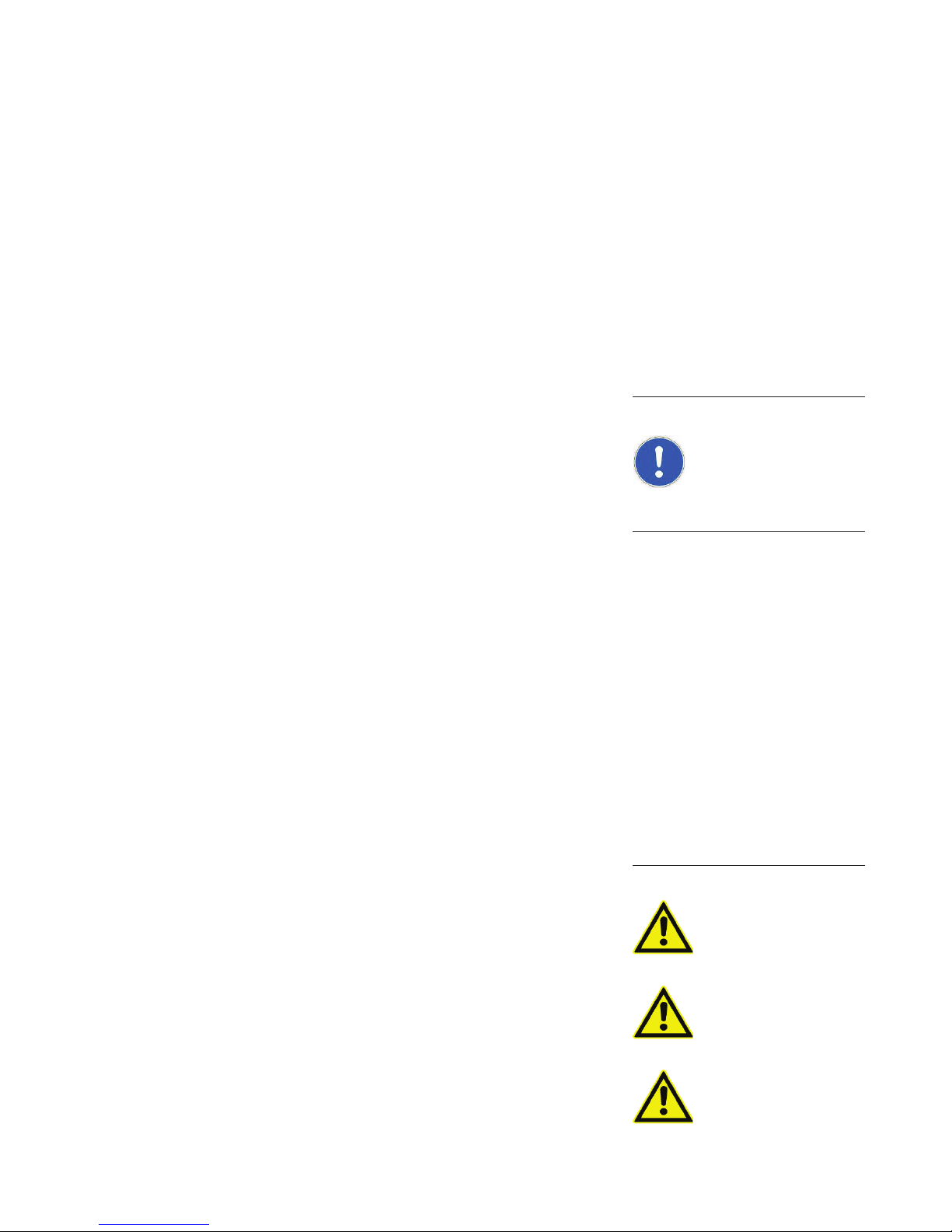

DRIVE (X3)

HEAT SINK HEAT SINK

Pump

connection

connection male 24 V

upply voltage

S

Green LED STS

Yellow LED PWR

24 VDC (X4)

g surfaces

Coolin

off: Pump at standstill (< 3 Hz)

flashes slowly 1/s: Start command is present (about 10 s after start)

flashes fast 3/s: Running up or running down

on: Normal operation

off: No supply voltage

flashes: Supply voltage too low or too high

on: Supply voltage is present

pin Sub-D connector

9

male for RS

fe

TU R B O .DRIVE

TD 400

232 interface

LEDs

REMOTE connector

9 pin Sub-D (female)

Red LED ERR

Fig. 1.1 TURBO.DRIVE 400, front and rear side

off: No error, no warning

flashes: Warning is present, pump can be operated

possibly with some restrictions

on: Fault is present, pump stopped or can not

be operated

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

5

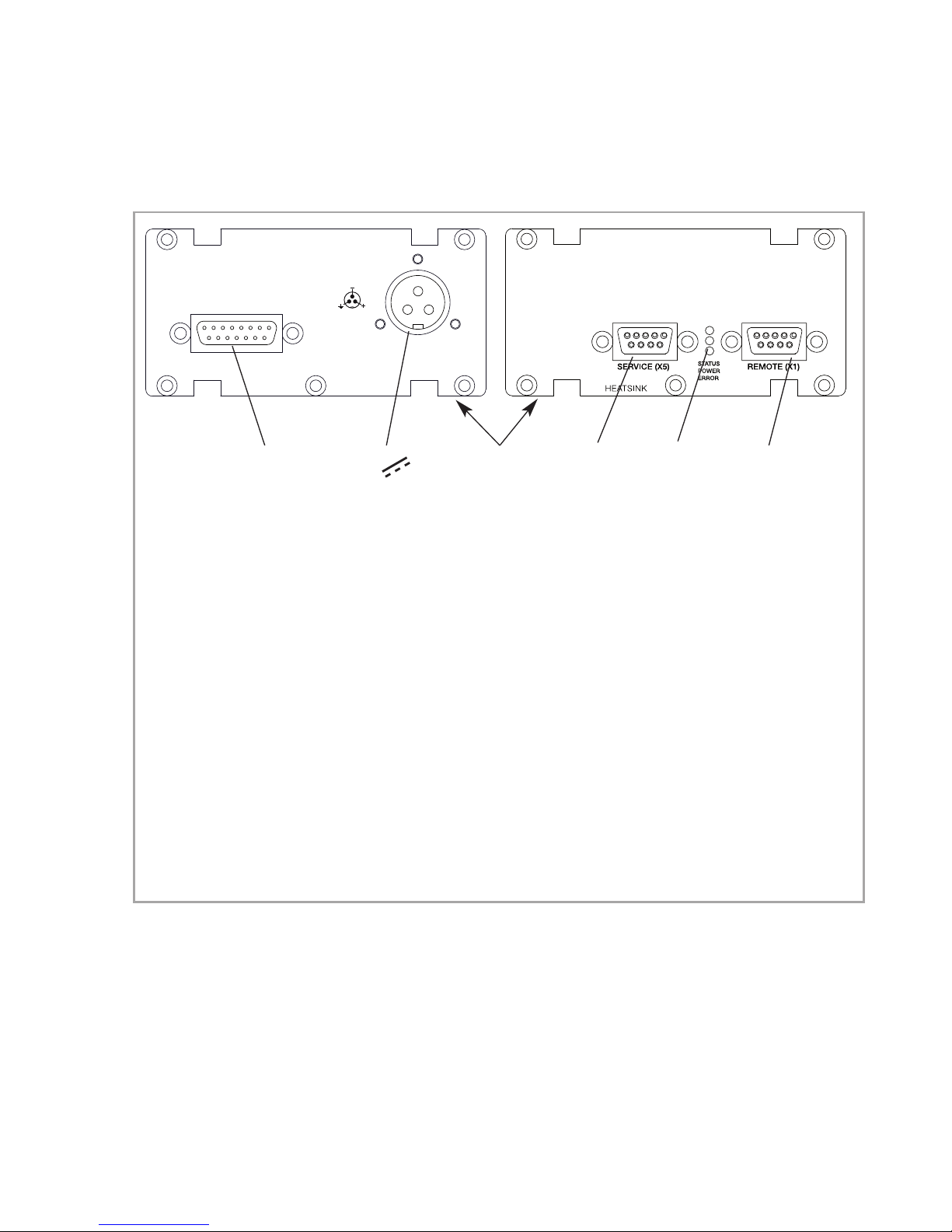

Description

connection

9-way Profibus

PRO FIBUS (X105) H IGH LOW

E

E

F

F

D

D

1

C

B

A

9

1

C

2

2

B

3

3

A

4

4

9

5

5

8

8

6

7

6

7

mal format

address in the h

setting the Profibus

Selector switches for

i-

exadec

DRIVE (X3)

HEAT SINK HEAT SINK

24 VDC (X4)

Fig. 1.2 Rear side of TURBO.DRIVE 400 with additional Profibus interface

Selector switch for setting the bus

RS 485 (X104)

TU R B O .DRIVE

TD 400

address for RS 485 communication

in the hexadecimal format

Fig. 1.3 Front side of TURBO.DRIVE 400 with additional RS 485 interface

TU R B O .DRIVE

TD 400

Abb. 1.4 FTURBO.DRIVE 400 front panel with additional USB interface

6

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

USB connection

(X106)

acuum

1 Description

1.1 Design and function

The TURBO.DRIVE 400 supplies power to the TW and SL

series turbomolecular pumps and is used to control their

operation.

The TURBO.DRIVE 400 is either integrated in the pump or

it is separate and linked to the pump by means of a

connecting cable.

The TURBO.DRIVE 400 requires a supply voltage of 24 V

DC. It is equipped with interfaces for programmable controls (REMOTE) and an optional interface for serial communication.

Description

1.2 Standard equipment

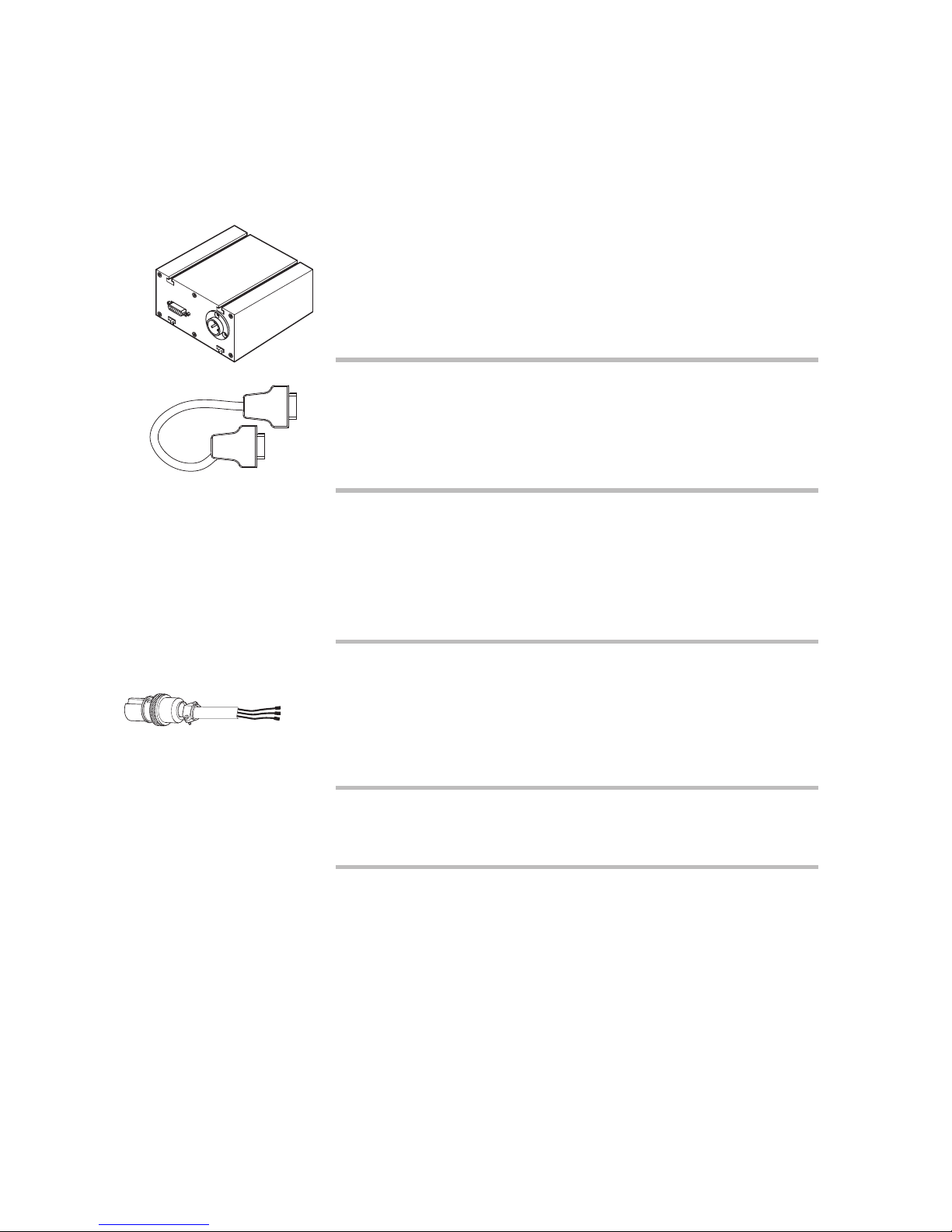

Included with the delivery are the DC connector Hirose

HS16P-3, four moving nuts M4 for affixing the frequency

converter and the Operating Instructions.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

7

Description

1.3 Technical data

Supply voltage 24 V (± 10%)

Residual ripple

<3%

Output

Voltage 0 - 24 V 3~

Power 160 W

Frequency 0 - 1500 Hz

When operating a TW 300, TW 300 H, TW 220/150(/15) S,

SL 300

Nominal voltage 24 V

Max. power consumption

190 W

Max. peak current, input side 8 A DC

Required power output from the power supply ≥ 200 W

When operating a TW 70 H, TW 250 S. SL 80

Nominal voltage 24 V

Max. power consumption

140 W

Max. peak current, input side 6 A DC

Required power output from the power supply ≥ 150 W

Max. length of the DC cable (shielded)

at 3 x 1.5 mm

at 3 x 2.5 mm

Relay output rating 42 V, 0.5 A

Ambient temperature

during operation 5 - 45 °C

storage - 15 - + 70 °C

Relative air humidity 5 to 85 %

Overvoltage category II

Contamination grade 2

Temp. of the cooling surface 5 - 55 °C

For Part Nos. 800073V0004 5 - 50 °C

Power consumption ≤ 20 W

2

2

non condensing

5m

20 m

8

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Type of protection IP 20

Weight, approx. 0.7 kg

acuum

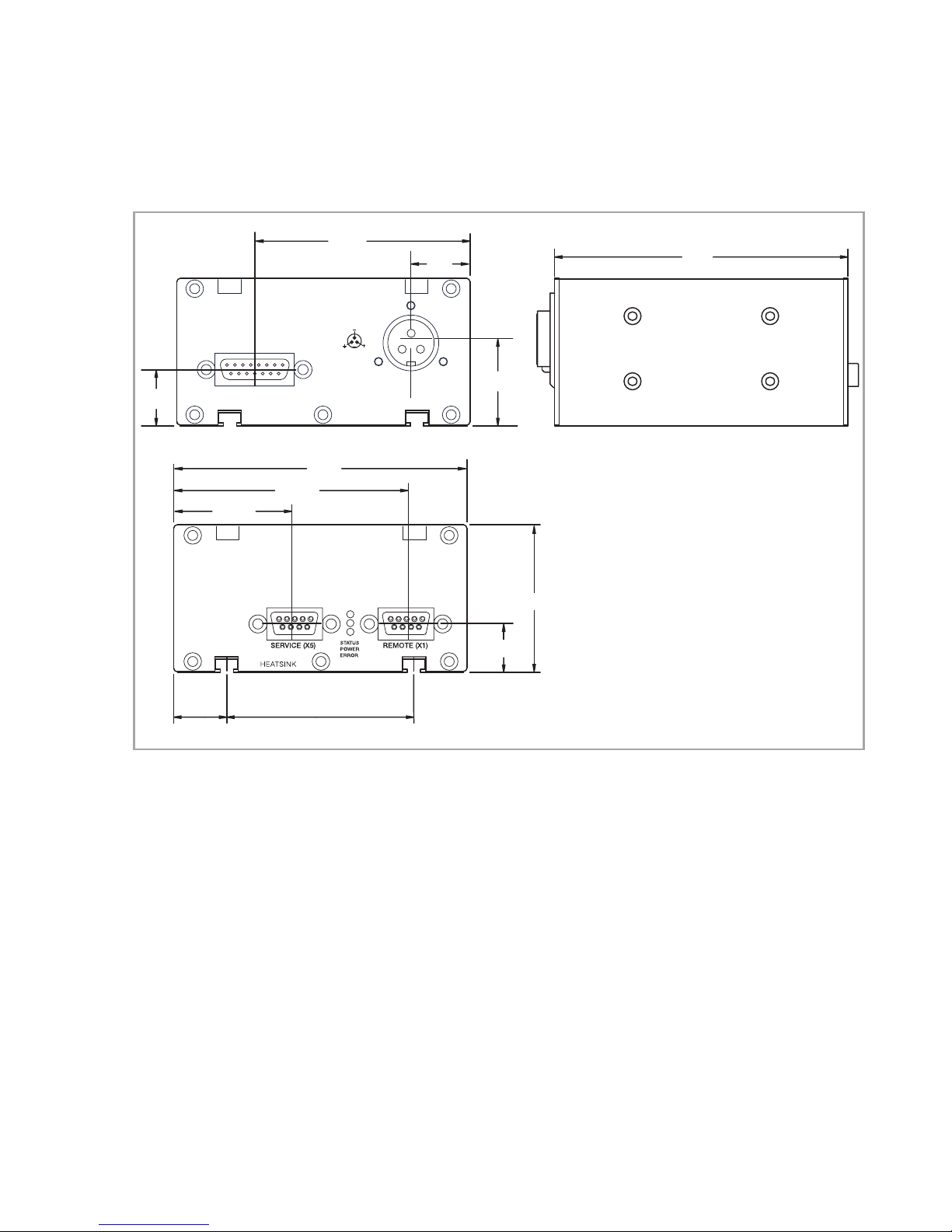

18,5

DRIVE (X3)

HEAT SINK HEAT SINK

79,0

41,0

100

73,3

24 VDC (X4)

32*

27,6

Description

100

* Profibus-Version 20

* Profibus version 20

TURBO.DRIVE

TD 400

50

15,9

18,2 63,8

Fig. 1.5 Dimensional drawing for the frequency converter; dimensions in mm

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

9

Description

D

r

i

ve

D

(

X

C24

3)

V

(

X

4)

H

E

A

T

S

I

NK

H

E

A

TS

I

NK

1.4 Ordering data

Frequency converter TURBO.DRIVE 400

with RS 232 C interface 800073V0002

with RS 485 C interface 800073V0003

with Profibus interface 800073V0004

wiht USB interface 800073V0008

Connecting cable pump - frequency converter

1.0 m long 152 47

2.5 m long 864 49

3.0 m long 864 40

5.0 m long 864 50

1.5 Accessories

OEM power supply (with screw terminals)

SITOP 24 V / 10 A (120/230 VAC / 50/60 Hz) 152 50

■ supplies the TURBO.DRIVE 400 with 24 V DC

■ other power supplies on request

24 V DC cable

(TURBO.DRIVE 400 – OEM power supply)

3 m 200 12 732

5 m 200 12 733

10 m 200 12 734

20 m 200 12 735

Mains cable for power supply, 2 m long

with EURO plug 800102V0001

with US plug 5-15P 800102V1001

10

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

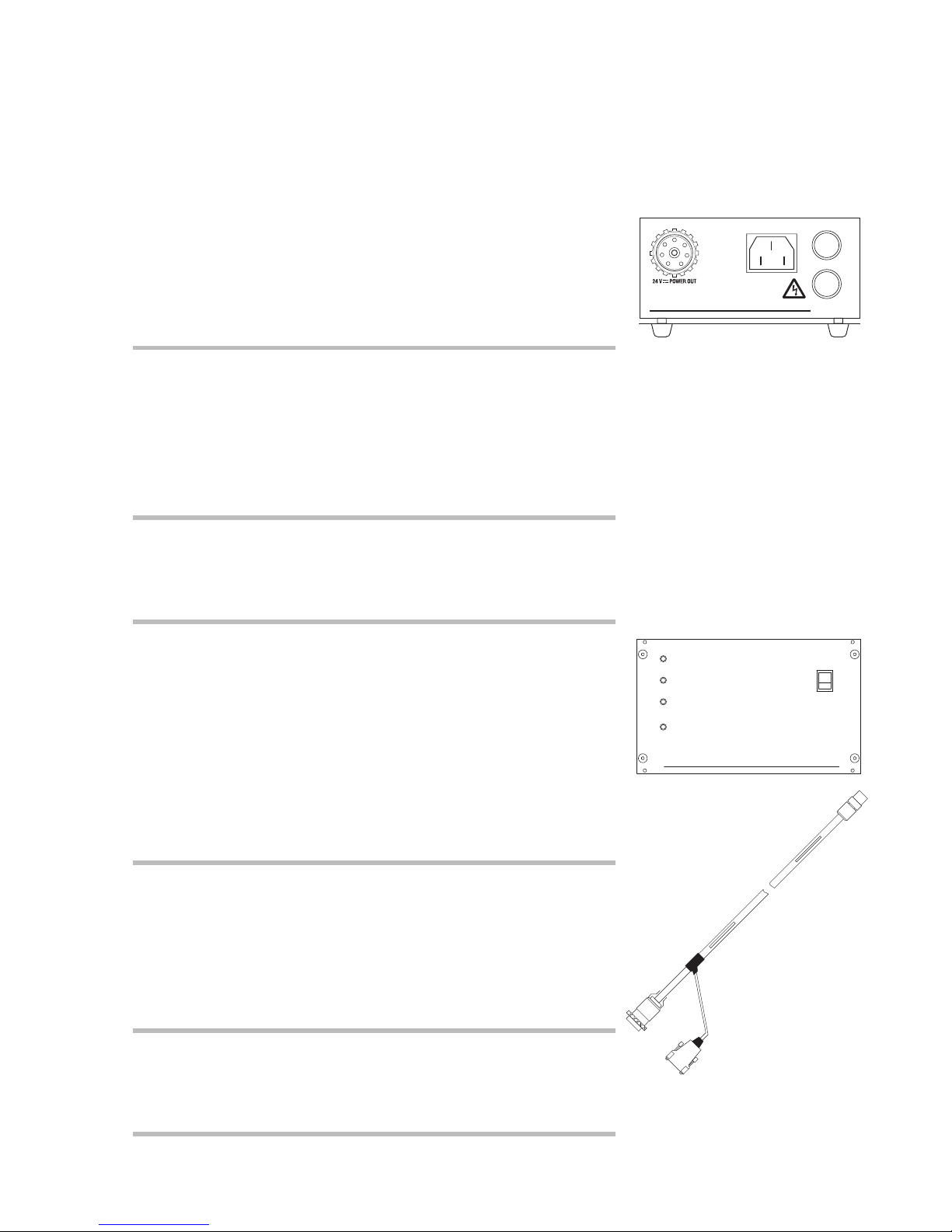

Power supply unit - plug and play

TURBO.POWER 300 800100V0002

■ supplies the TURBO.DRIVE 400 with 24 V DC

■ plug & play cables

■ desktop unit or rack mountable

24V DC Power cable TURBO.DRIVE 400 –

TURBO.POWER 300)

1 m 800094V0100

3 m 800094V0300

5 m 800094V0500

10 m 800094V1000

20 m 800094V2000

Description

100 - 240 V AC

TURBO.POWER 300

T5A~250 V

T5A~250 V

Mains cable for TURBO.POWER 300, 3 m long

with EURO plug 800102V0002

with US plug 6-15P 800102V1002

with UK plug 800102V0003

Power supply and control unit

TURBO.CONTROL 300 800100V0001

■ supplies the TURBO.DRIVE 400 with 24 V DC

■ plug & play cables

■ desktop unit or rack mountable

■ with power switch

■ with start/stop switch for the turbomolecular pump

■ remote control

■ status LEDs and status relays

24V DC Control cable

(TURBO.DRIVE 400 – TURBO.CONTROL 300)

1 m 800091V0100

3 m 800091V0300

5 m 800091V0500

10 m 800091V1000

20 m 800091V2000

START

NORMAL

POWER

ERROR

START

1

0

STOP

TURBO.CONTROL 300

Mains cable for TURBO.CONTROL 300, 3 m long

with EURO plug 800102V0002

with US plug 6-15P 800102V1002

with UK plug 800102V0003

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

11

Description

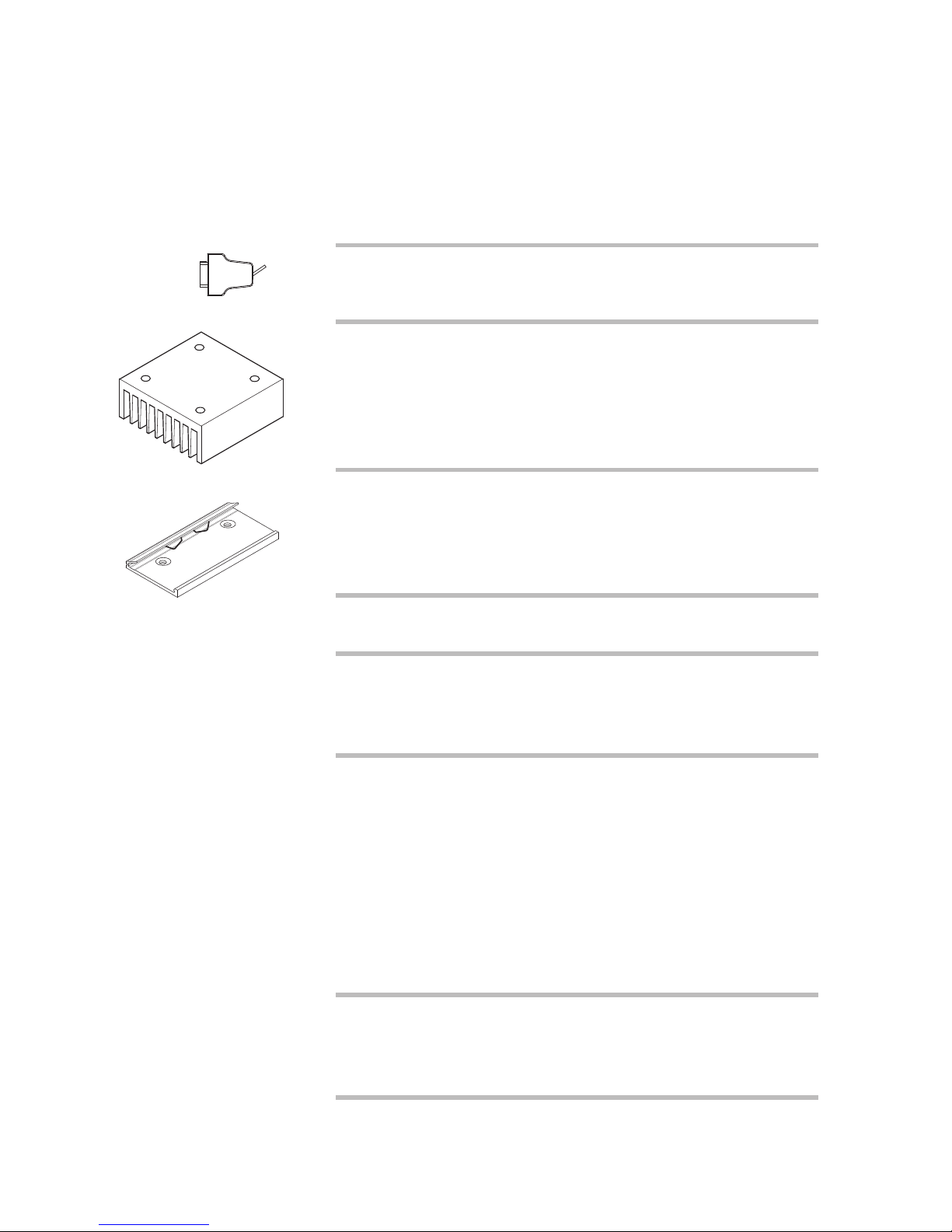

Mechanical accessories

on

off

Plug for connector REMOTE with integrated

ON/OFF switch for the pump

(Sub-D plug, 9 way) 152 48

Heat sink for frequency converter 800110V0001

Top hat rail adaptor (mounting aid for

TURBO.DRIVE 400 and TURBO.POWER 300)

800110V0003

Accessories for serial interfaces

USB driver: the Windows driver can be downloaded from

www.oerlikon.com after selecting menu item

www.oerlikon.com in the menu Oerlikon Leybold Vacuum

→ Documentation → Download Software

12

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

PC software "Turbo.Drive Server" for Windows 95

and higher, CD-ROM

■ Display, change, save and compare parameter lists

■ Integration of customer’s software

■ Record parameter data 800110V0102

(new parameter library for TURBO.DRIVE 400

is required, please ask us for a quotation)

The software can also be downloaded from

www.oerlikon.com in the menu Oerlikon Leybold Vacuum

→ Documentation → Download Software

GSD file for Profibus DP upon request

The software can also be downloaded from

www.oerlikon.com in the menu Oerlikon Leybold Vacuum

→ Documentation → Download Software

acuum

2 Installation

2.1 Conforming utilization

The TURBO.DRIVE 400 supplies power to the TW series

turbomolecular pumps and is used to control their operation.

The TURBO.DRIVE 400 is suited for operation of the following pumps:

■ TURBOVAC TW 70 H

■ TURBOVAC TW 220/150 S, TW 220/150/15 S,

TW 400/300/25 S

■ TURBOVAC TW 250 S

■ TURBOVAC TW 290 H

■ TURBOVAC TW 300, TW 300 H

Installation

■ TURBOVAC SL 80, SL 300

Other pumps may only be operated after approval from

Oerlikon Leybold Vacuum or if the operation of such pumps

is expressly permitted in the Operating Instructions for the

specific pump.

The TURBO.DRIVE may only be operated with power

supply units which meet PELV (Safety Extra Low Voltage)

requirements.

The TURBO.DRIVE must only be opened by certified

Oerlikon Leybold Vacuum Service Centres. Opening by

unauthorised personnel voids warranty.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

13

Installation

2.2 Operating environment

See also Chapter 1.3 Technical Data.

Places of installation up to 1000 m above sea level (3300 ft)

are possible without restrictions. At altitudes over 1000 m

heat dissipation by the ambient air is impaired. Please consult us.

If the TURBO.DRIVE 400 has been integrated in the pump,

it is cooled by the pump.

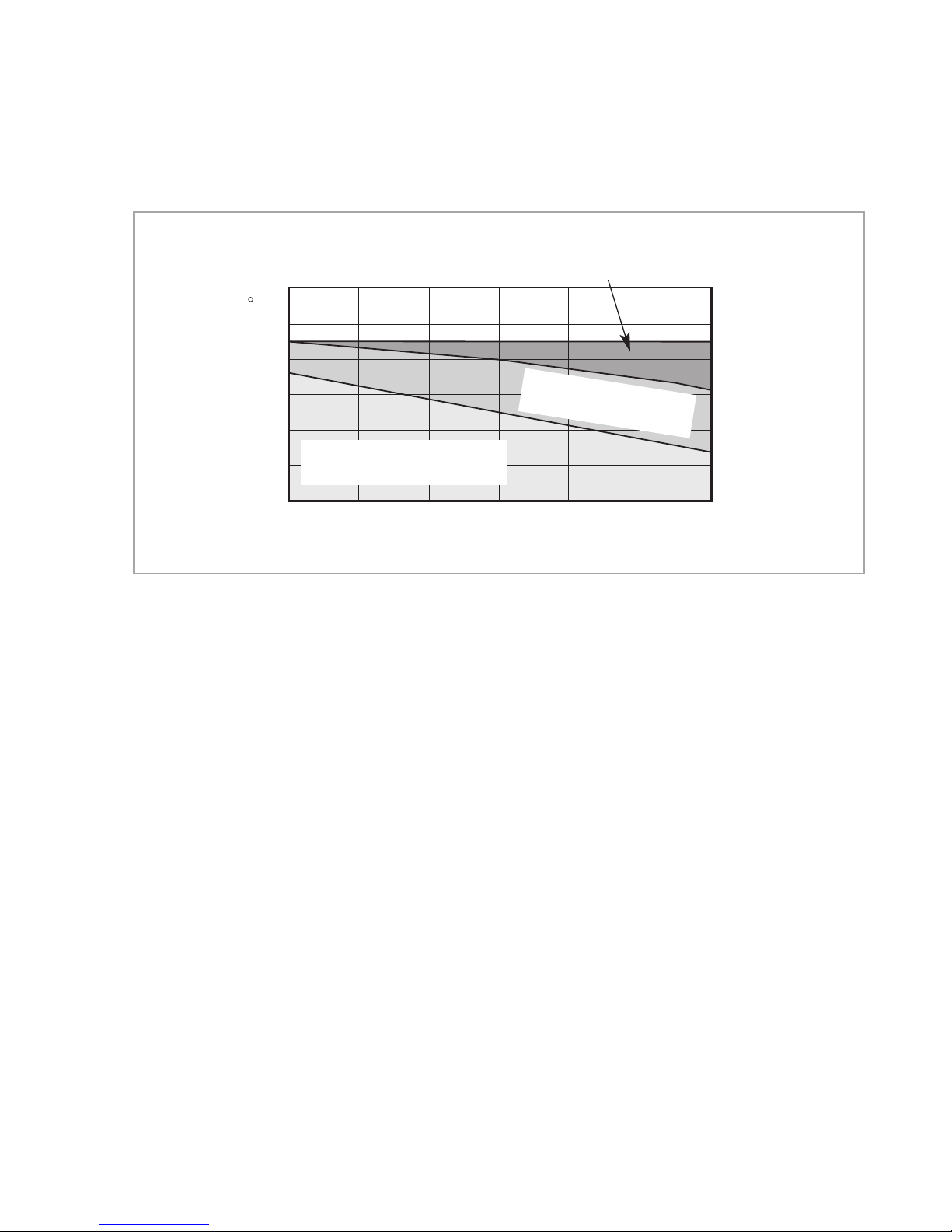

As to the cooling requirements for the separately fitted

TURBO. DRIVE see Fig. 2.1. The bottom side of the frequency converter must not be allowed to attain too high

temperatures; see technical data.

CAUTION

Max. magnetic induction levels are 15 mT, max. radioactive

radiation spec. is 10

The frequency converter must only be used in rooms within

buildings. It must not be operated in explosive gas atmospheres.

The frequency converter and the connecting lines must be

protected against exposure to sprayed and condensing

water.

During operation the frequency converter may attain

temperatures up to 75 °C. We recommend that the unit

be installed so that it can not be touched inadvertently.

Owing to the small quantity of combustible material and the

proven safety of the instrument by testing in accordance

with EN 61010, the risk through fire and burning can

almost completely be excluded.

5

rad (103Gy).

14

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

Installation

Heat sink and forced

cooling required

60

C

50

40

H

30

20

10

Ambient temperature

0

Operation possible

without additional cooling

12345

Motor current (Parameter 5)

eat sink required

(convection cooling)

6

A

Fig. 2.1 Cooling requirements for the TURBO.DRIVE 400 when fitted separately

2.3 Mounting the frequency converter

The frequency converter may be affixed with the aid of the

enclosed M4 sliding nuts. The bottom side of the frequency

converter must be cooled sufficiently.

Ensure an adequate supply and discharge of cooling air.

For special requirements please contact us.

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

15

Installation

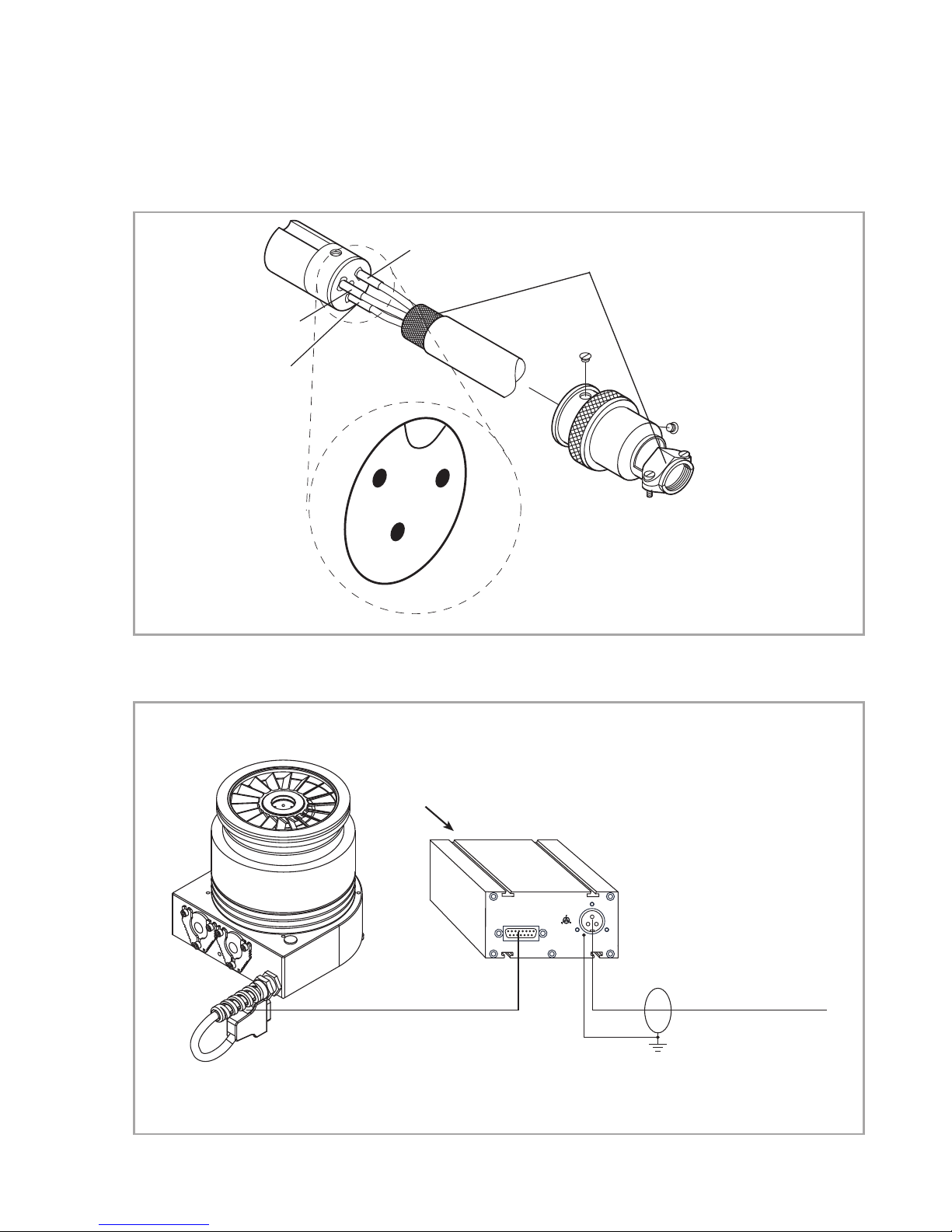

2.4 Connecting the pump

In the case of a separately fitted TURBO.DRIVE 400

connect the pump using the connecting cable.

NOTICE

WARNING

The pump may be operated only with a suitable frequency converter and suitable connecting cables.

Route all cables so as to protect them from damage.

Disconnect and connect the cable connections only

while the pump is turning no longer (green status

LED off) and with the mains power switched off (yellow power LED off). Otherwise there is the risk of

damaging the TURBO.DRIVE 400.

2.5 Connecting the power supply

The frequency converter must only be connected to

power supplies which meet the requirements for functional extra low voltage with positive isolation in accordance with IEC 364 (VDE 0100, Part 410, or local regulations) (PELV).

The power supply must meet the requirements given in

Section 1.3. Peak currents in the kHz range may be present on the DC side. The power supply should have a current limiter of the current regulated type.

NOTICE

16

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Connect the frequency converter to the 24 V DC power

supply or to the TURBO.CONTROL 300 or to the

TURBO.POWER 300 via the 24 V DC cable.

Ensure correct polarity.

Pin 1 + 24 VDC

Pin 2 0 V

Pin 3 GND

The frequency converter is equipped with an internal 8 AT

(slow blow) fuse. It can only be replaced by Oerlikon

Leybold Vacuum staff.

Connect the power supply to the mains.

acuum

Installation

REMOTE

93 - 132 /

187 - 264

V AC,

50/60 Hz

24 V DC

L

N

D

RIVE (X3)

HEAT SINK HEAT SINK

24 V DC (X4)

Pin 3 GND

Shielding

Pin 1 24 V

Pin 2 0 V

1

3

2

Fig. 2.2 Pin assignment of the DC connector (X4) Model Hirose HS16P-3

In the case of an integrated

connecting cable is omitted.

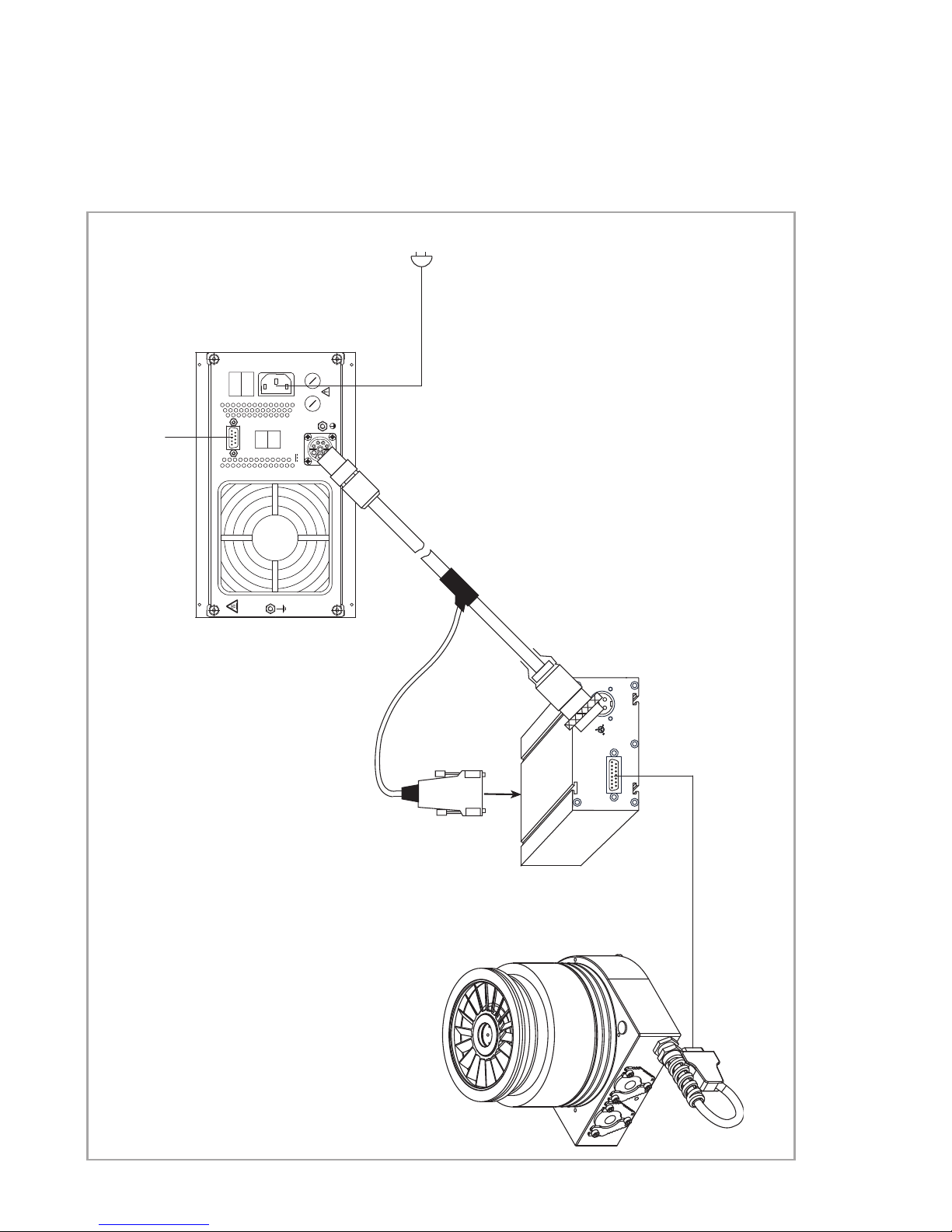

Fig. 2.3 Connecting the pump and the power supply

TURBO.DRIVE 400 the

DC cable,

with shielding,

max. 20 m

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

acuum

17

Installation

ON

OFF

1

0

MAINS

REMOTE IN

Programmable

logic control (PLC)

REMOTE

100 - 240 V ~

1

0

FRONT

T5 A

250 V ~

T5 A

250 V ~

REMOTE OUT

24 V POWER OUT

100 - 240 V ~

50 - 60 Hz

24 V DC Control cable

24 V DC (X4)

HEAT SINK HEAT SINK

DRIVE (X3)

REMOTE

TURBO.DRIVE 400 the

In the case of an integrated

connecting cable is omitted.

18

17200492_002_A5 - 04/2011 - © Oerlikon Leybold V

Fig. 2.4 Connecting the pump and the TURBO.CONTROL 300

acuum

Loading...

Loading...