Lexus Electronic Weighing AXIS ATA Series, ATZ2200, AXIS ATZ Series, ATZ220, ATZ520 User Manual

ATZ2200

ATZ220÷ATZ520

USER MANUAL

AXIS ATA and AXIS ATZ Series

Ver. 1 2014-08

2

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Contents:

1. General description............................................................................................... ....................................................... 3

2. Completeness ............................................................................................................................................................. 3

3. Safety rules......................................................................................................................................................................................................................................................................................................................... 4

4. Technical data ............................................................................................................................................................. 5

5. General scale view ...................................................................................................................................................... 6

6. Keys and indicators.............................................................................................................................................................................................................. 8

7. Preparing working environment ............................................................................................................................... ..... 9

8. Preparing scale to work ............................................................................................................................................. 10

9. General operation principles ...................................................................................................................................... 11

10. Start-up .................................................................................................................................................................... . 12

11. Internal calibration............................................................................................... ...................................................... 13

12. Checking the balance ................................................................................................................................................ 14

13. Connection with computer or a printer ........................................................................................................................ 15

14. Basic scale functions ............................................................................................... .................................................. 19

14.1. Simple weighing ........................................................................................................................................................ 19

14.2. Weighing with tare ............................................................................................... ...................................................... 19

15. Special functions ............................................................................................................................. .......................... 20

15.1. Customization of special functions menu (ACtIV and dEFAULt) .................................................................................. 21

15.2. Autozeroing function (AutotAr) ............................................................................................................................... .... 22

15.3. Pieces counting function (PCS) .................................................................................................................................. 23

15.4. Function for changing mass unit (UnIt) ............................................................................................... ........................ 24

15.5. Percent calculation functions (PErCEnt) ..................................................................................................................... 25

15.6. Function for summing recipe ingredients (rECIPE) ...................................................................................................... 26

15.7. Calibration with external weight / calibration options (CALIbr)...................................................................................... 27

15.8. Label choosing function (LAbEL)............................................................................................................................. ... 31

15.9. Function for setting serial interface parameter (SErIAL) ............................................................................................. . 32

15.10. Printout configuration (PrInt)........................................................................................................................... .... 33

15.11. Animal weighting function (LOC) ........................................................................................................................ 35

15.12. Memorizing tare function (tArE) .......................................................................................................................... 36

15.13. Maximum value indication function (UP) ............................................................................................................ . 37

15.14. Force measuring function (nEWton) ................................................................................................................... 38

15.15. Anty-disturbance filter option (FILtEr).................................................................................................................. 38

15.16. Setting backlight function (b_LIGHt) ................................................................................................................... 39

15.17. Function for choosing reading unit (rESOLUt) ..................................................................................................... 39

15.18. Statistical calculations function (StAt) ................................................................................................................. 40

15.19. Basis weight of paper counting function (PAPEr) ................................................................................................ 43

15.20 Density determination (dEnSity) ......................................................................................................................... 44

15.20.1 Solids density determination........................................................................................................................... 44

15.20.2 Liquid density determination............................................................................................... ............................ 46

15.21. Total weight function (totAL)............................................................................................................................. .. 47

15.22. Date and time setting (dAtE) ............................................................................................................................. . 49

15.23. Function of comparing with preset threshold values (thr) ..................................................................................... 50

15.24 Firmware (FIrMW).............................................................................................................................................. 53

16. Troubleshooting and maintenance ............................................................................................... .............................. 53

Declaration of Conformity............................................................................................... ..................................................... 54

ATA firmware diagram ............................................................................................................................. ........................... 55

3

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1. General description

ATA i ATZ series electronic scales are destined for laboratory works which require

high accuracy and for wide range of technical purposes as well. ATZ series are not

equipped with internal calibration system.

All scales are metrologically tested by manufacturer.

All balances can be prepared to comply with verification requirements but legally

verification is not possible yet.

According to an order balances can be calibrated.

NACE classification: 33.20.31.

2. Completeness

Standard set consists of:

1. Scale

2. Feeder

3. Draft shield with cover,

4. User manual

5. Guarantee card

4

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Safety rules

It is necessary to follow safety rules of work with the scale

shown below. Obeying those rules is the condition to

avoid electrical shock or damage of the scale or

connected peripheral devices.

All repairs and necessary regulations can be made by authorised personnel

only.

To avoid fire risk use a feeder of an appropriate type (if feeder is supplied

with the scale) and supply voltage has to be compatible with specified

technical data.

Do not use the scale when its cover is opened.

Do not use the scale in explosive conditions.

Do not use the scale in high humidity environment.

If the scale seems not to operate properly, switch it off and do not use until

checked by authorised service.

According to current acts of low about protection of

natural environment, wasted scales should not be put into

waste containers together with ordinary waste.

Wasted scale after operation period can be delivered to units authorized for

gathering wasted electronic devices or to the place where it was bought.

5

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

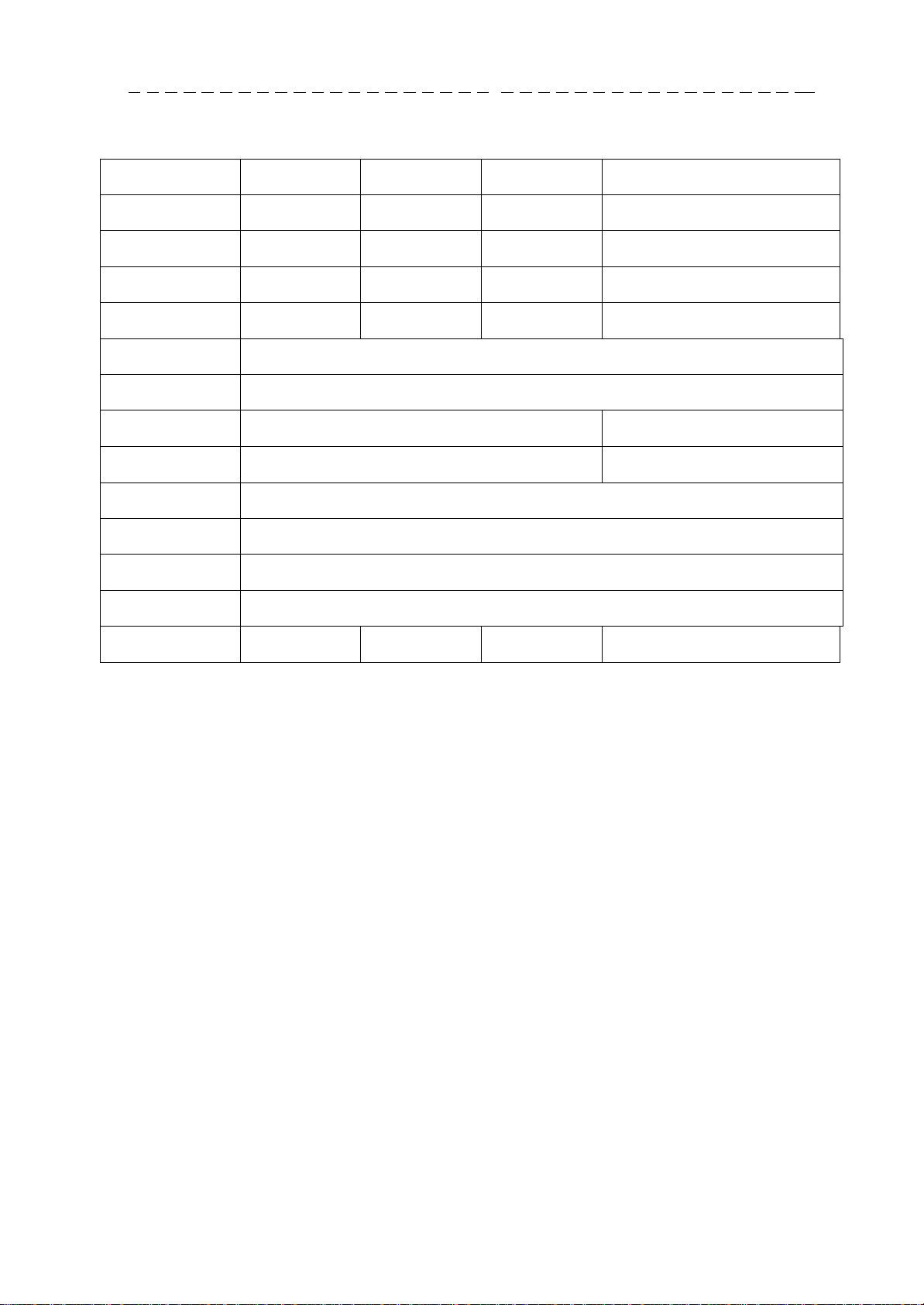

Type

ATZ320

ATZ520

ATZ1200

ATZ2200

Load (Max)

320g

520g

1200g 2200g

Readout unit (d)

0,001g

0,001g

0,01g 0,01g

Verification plot

(e)

0,01g

0,01g

0,1g 0,1g

Tare range

-320g

-520g

-1200g

-2200g

Accuracy class

II

Working

temperature

+18 ÷ +33°C

Weighing time

< 3s

< 2s

Pan dimension

Ø115mm

Ø150mm

Dimensions

185x290x90mm

Interfaces

In standard: RS232C and USB

Supply

~230V 50Hz 6VA / =12V 1,2A

Scale weight

ATA : 2,6kg ATZ: 2,1kg

Recommended

standard of mass

F2 200g

F1 500g

F2 1000g

F2 2000g

4. Technical data

Note:

F2 and F1 are names of international calibration weight classes according to O.I.M.L.

Requirements about calibration weight accuracy are connected with these classes.

6

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

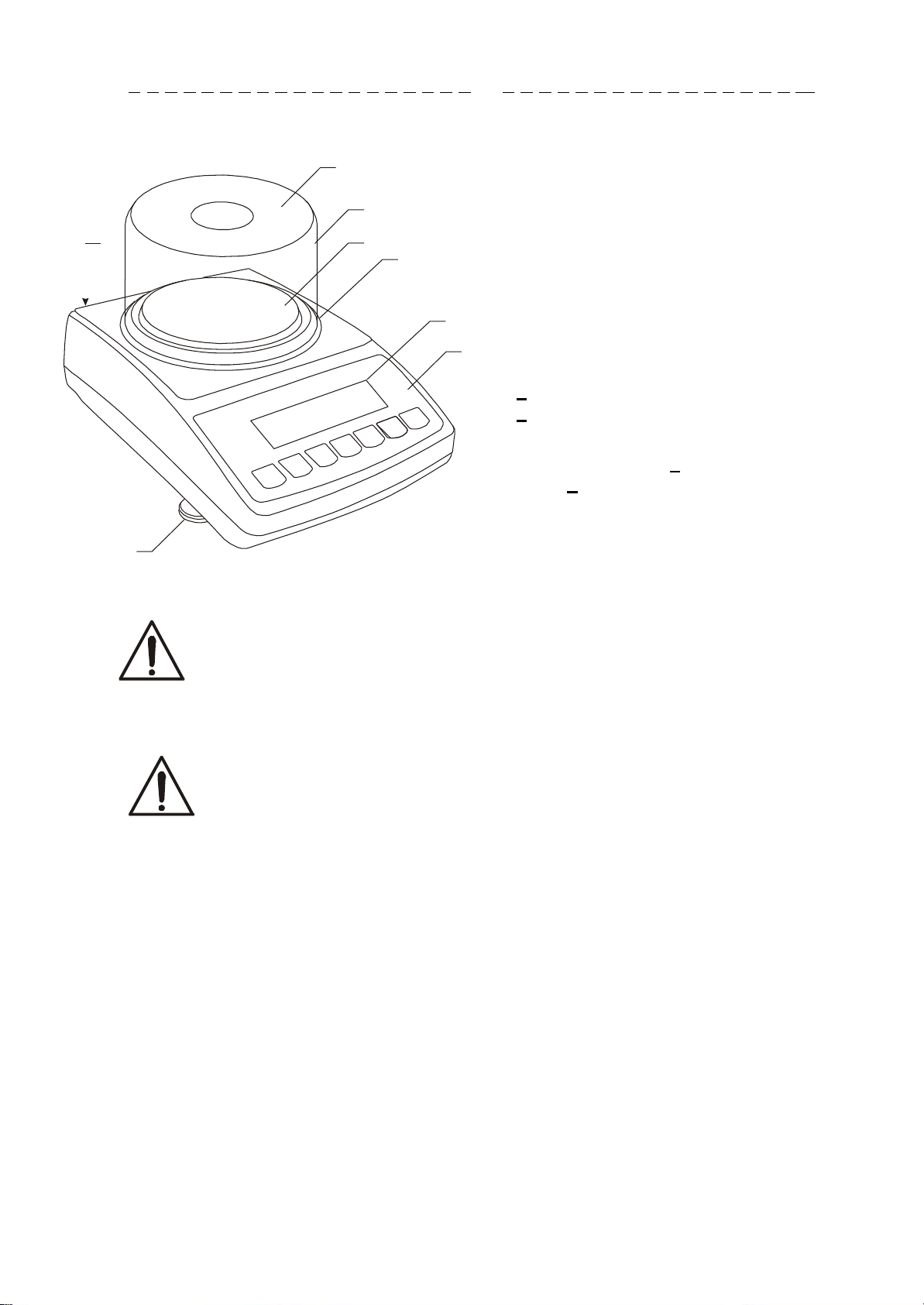

5. General scale view

ATA120÷ATA520 and ATZ120÷ATZ520 scale:

9

8

7

1

2

3

6

ATA1200÷ATA2200 and ATZ1200÷ATZ2200 scale:

1

7

2

6

1 – pan

2 – pan support

(under pan)

3 – pan ring

(against blows)

4 – display LCD

5 – keys

6 – rotating legs

4

5

7 – water level

8 – draft shield

(option)

9 – draft shield cover

(option)

1 – pan

2 – pan support

4

5

3 – information window

4 – display LCD

5 – keys

6 – rotating legs

7 – level

7

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

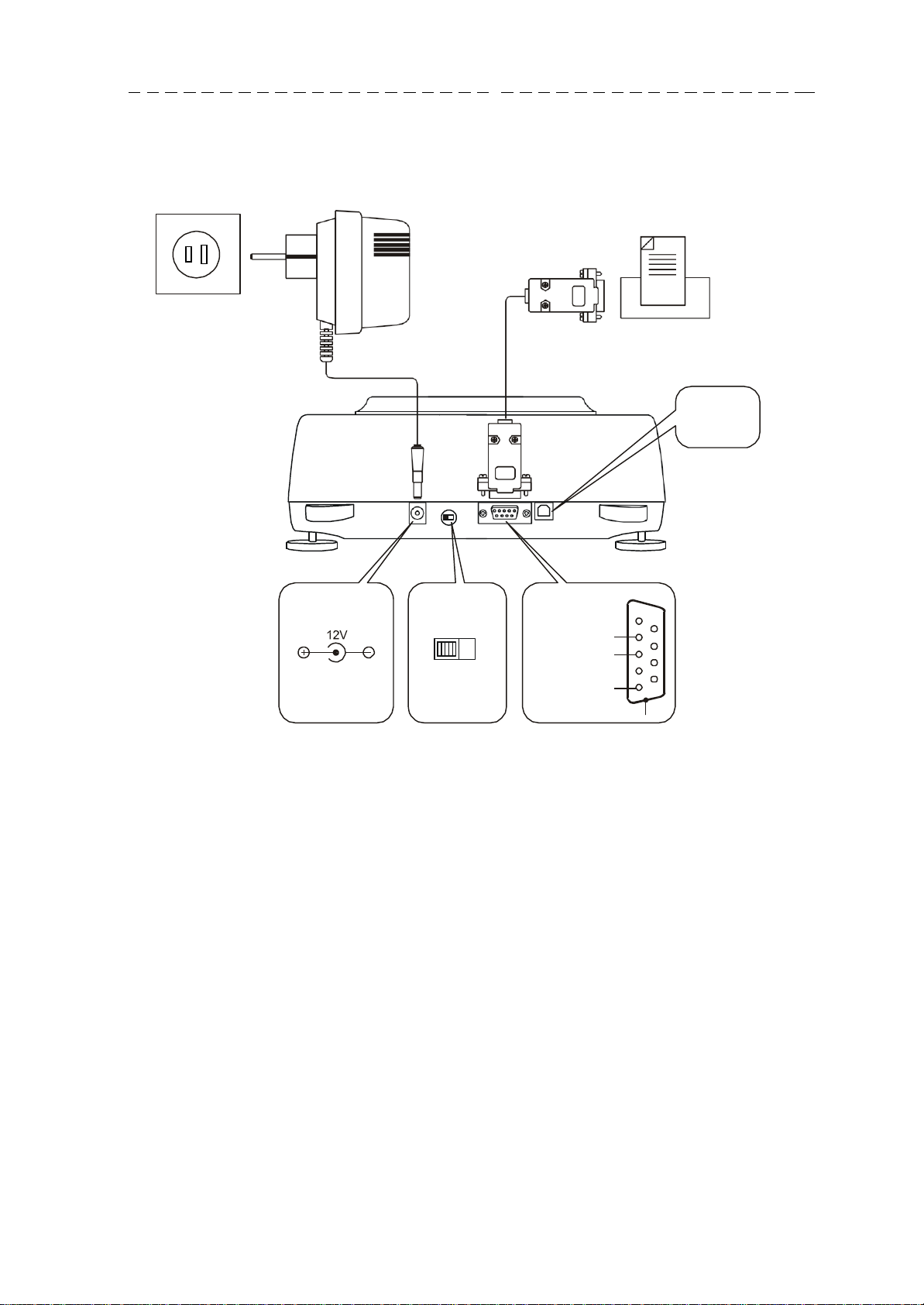

1

2

3

4

5

Connectors view:

~100V

Feeder Printer or computer

USB

Feeder

Adjustment

switching

ON OFF

RS232C

RxD (receiver)

TxD (transmitter)

ground

case

6

7

8

9

8

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

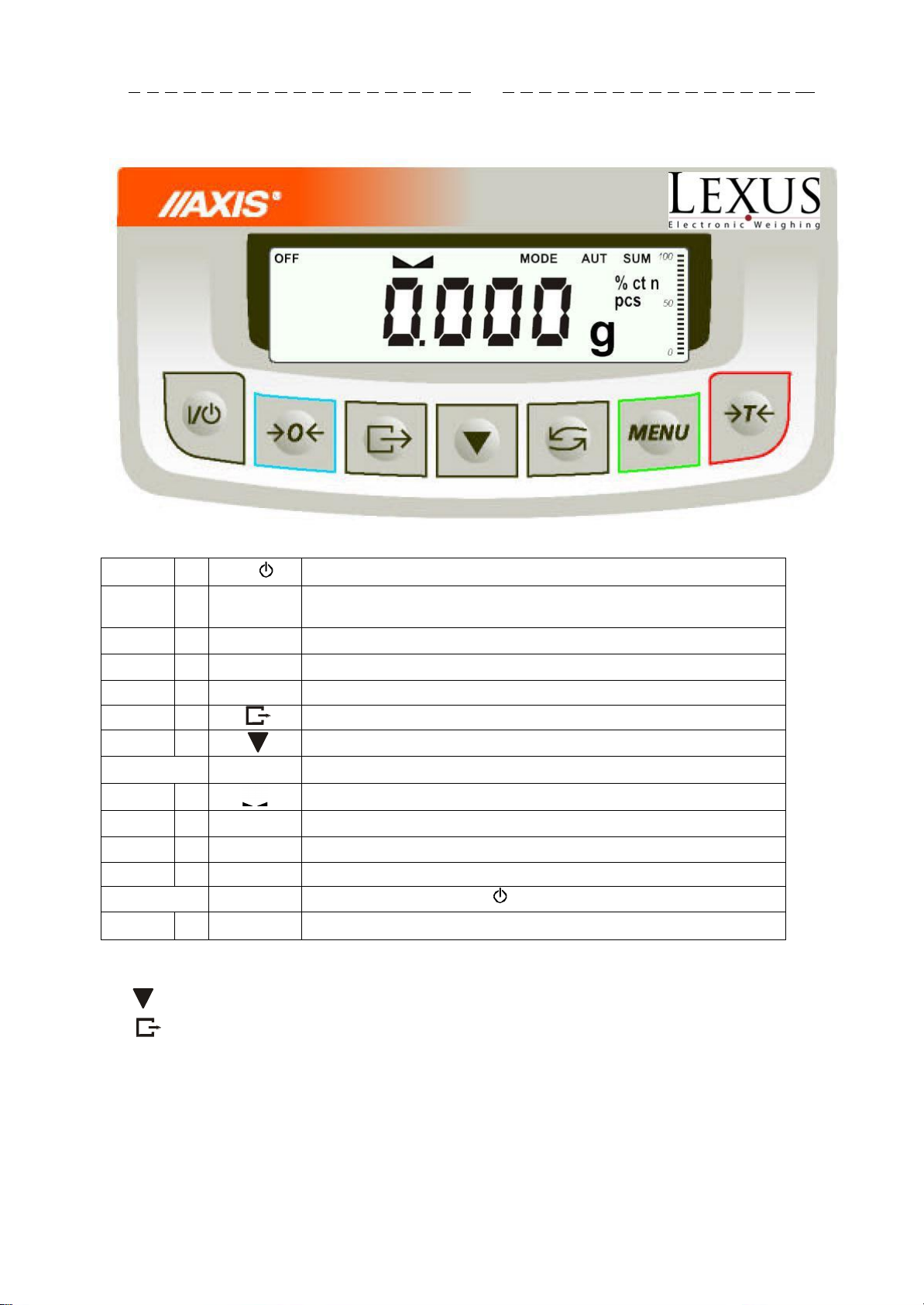

key

I/

- switch on / switch off (standby),

"

T

- taring (storing package mass subtracted from weighed

mass)

"

- change mode of balance work,

"

0

- zeroing the scale when pan is empty (option) ,

"

MENU

-special function menu,

"

- result printout,

"

- internal calibration / quick option view,

indicator

0

- zero indicator (when scale pan is empty),

"

- indicator of weighing result stabilisation,

"

NET

- net mass (after use of →T← key),

"

MODE

- indicator of switching special function on,

bar

indicator

- indicator of scale load (0-100%).

indicator

OFF

- switching scale with key (standby),

"

pcs

- indication in pieces

6. Keys and indicators

The use of keys during entering numeric values (special functions):

- Increment current digit,

- insert comma,

T - move to next position,

MENU - finish entering

Note:

0 keys and 0 indicators only work in balances with d=e.

9

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

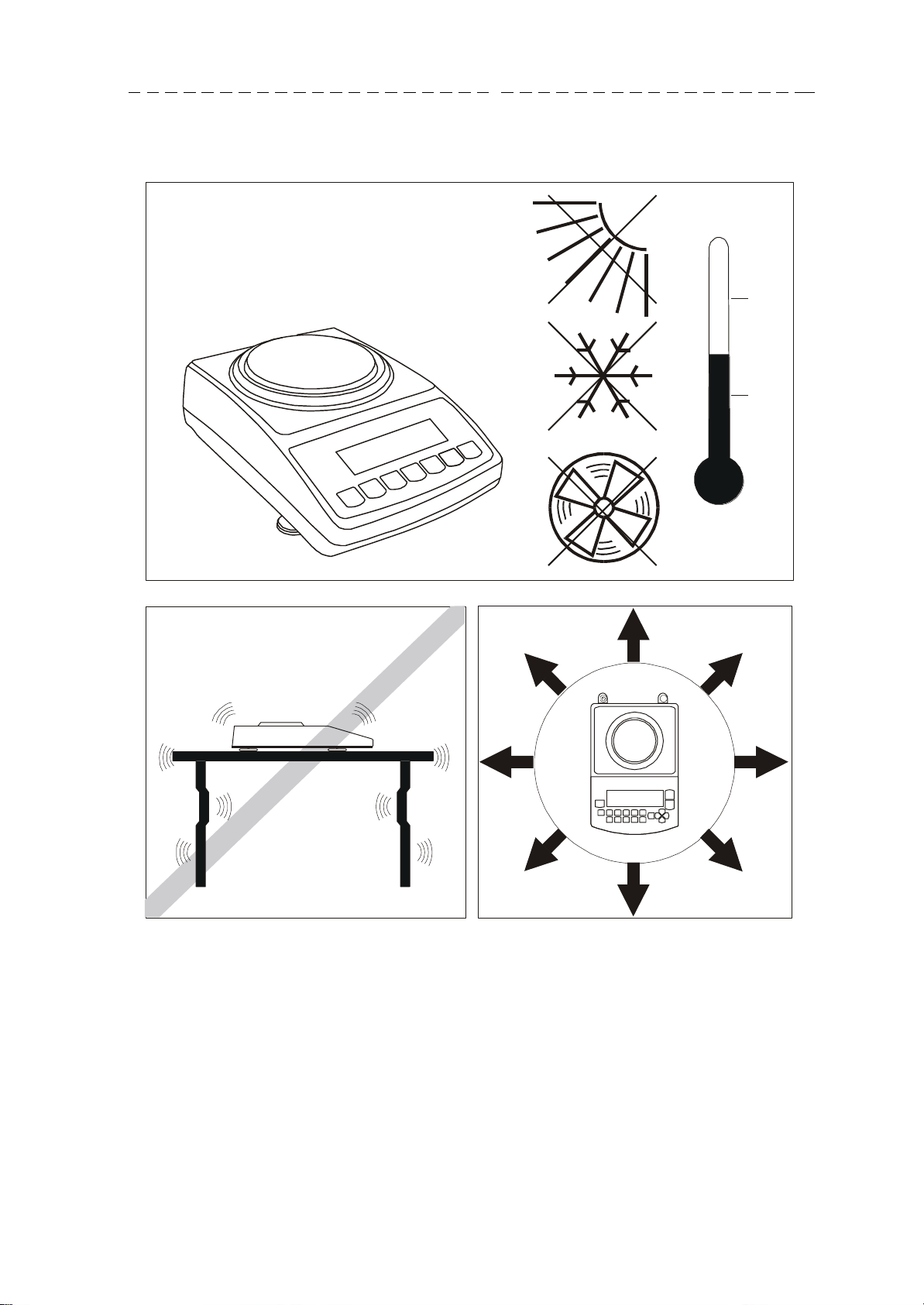

7. Preparing working environment

+33°C

+18°C

Location for the scale should be chosen with care in order to limit influence of the

factors that can interrupt working scale. This location has to maintain proper

temperature for working scale and necessary space for its operating. The scale should

stay on stable table made of material that does not influence magnetically on the

scale.

Rapid air blasts, vibrations, dust, rapid temperature changes or air humidity over 90%

are not allowed in scale surrounding. The scale should be far from heat sources and

devices emitting strong electromagnetic or magnetic fields.

10

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

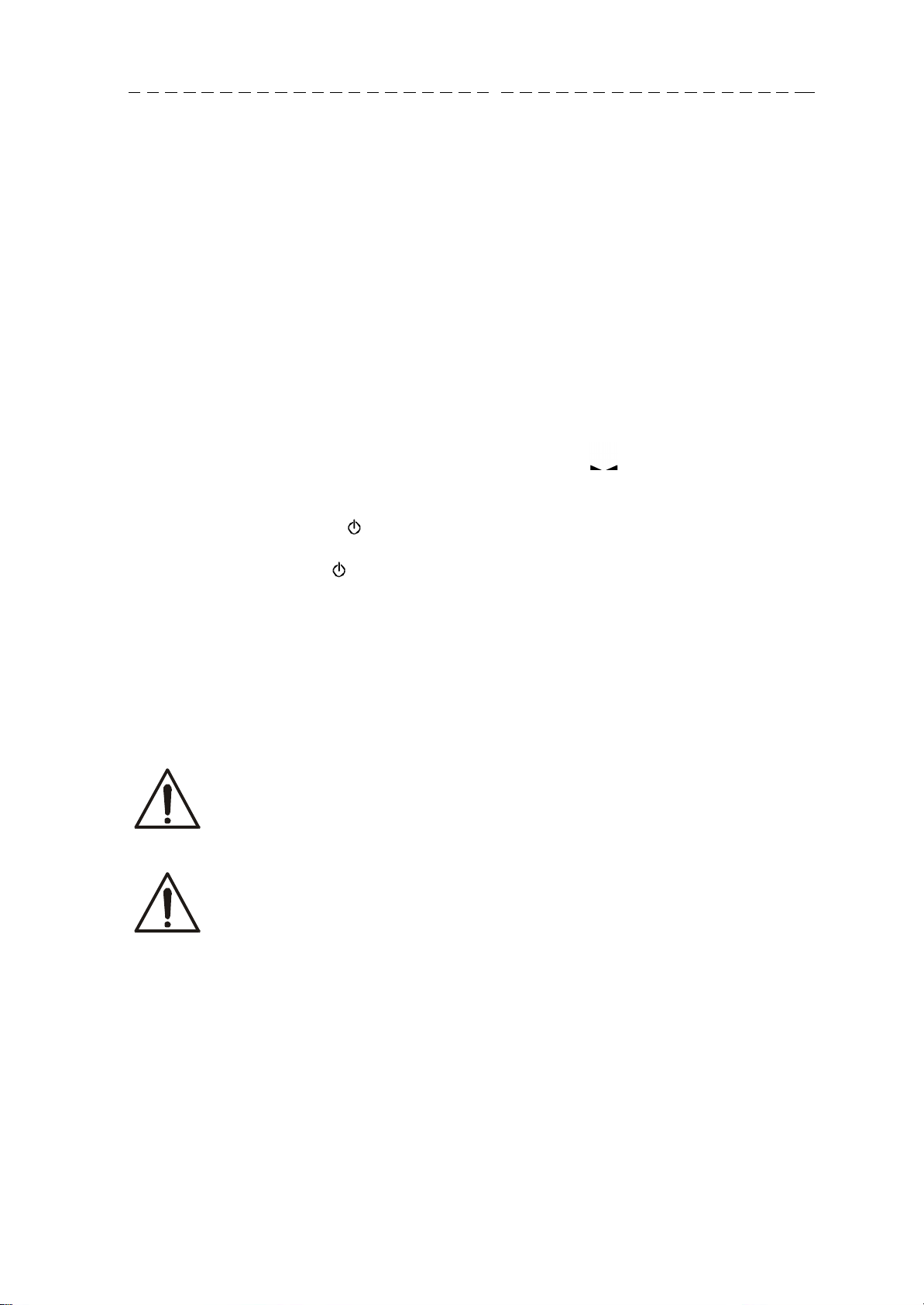

8. Preparing scale to work

7

6

Scale should be transported in the way, that there is no risk of

accidental pressing or overweighing a pan.

If the scale was taken from a lower temperature surrounding to a room with

9

8

1

2

3

1. Take the scale and feeder out of

the package. It is recommended to

keep the original scale package in

order to transport the balance safely

in future.

4

5

2. Place the scale on a stable ground

not affected by mechanical vibrations

and airflows.

3. Level the scale using rotating legs

6 so that the air bubble in water level

7 at the back of the scale is in the

middle.

4. Put draft shield 8 on the scale and

cover 9 on it.

higher temperature, e.g. in winter, moisture can liquefy on the scale casing.

Do not connect power supply to the scale, because this can cause damage

or improper work of the scale. In this case leave the scale for at least 4

hours unplugged for acclimatization.

11

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9. General operation principles

1. In order to confirm correctness of the scale during its operation, before starting and

after finishing every valid measurement series it is recommended to check weighing

accuracy putting calibration weight or other object of exactly kno wn mass on the

scale. In the case when allowable measurement error of the scale is exceeded, it is

recommended to perform calibration with external weight or contact authorised

service centre.

2. Weighed mass should be placed in the middle of the pan.

3. The scale allows taring in the whole measuring range. To tare the scale press

->T<- key. Taring does not extend measuring range, but only subtracts tare value

from mass value of a sample placed on the pan. To make the control of a load on

the pan easier and to avoid exceeding measurement range, the scales have load

indicator calibrated 0÷100%.

4. Weighing result should be read when the indicator lights, which signalises

result stabilisation.

5. When the scale is not used but it is necessary for it to be ready to work, it can be

switched off by pressing I/ key. The scale reading system is then switched off and

scale goes to standby mode signalled with OFF indicator. Switching the scale on is

preformed by pressing I/ key.

6. In sales having →0← key (zeroing) active it should be checked if zero indicator

→0← is displayed before sample is placed on the pan. If not, press →0← key and

wait until the scale is zeroed and zero indicator appears. After that load can be

placed on scale pan.

7. Scale mechanism is a precise device sensitive to overweight, mechanical shocks

and strokes.

8. After every change of balance position, level the balance and perform internal

calibration.

Do not overload the scale more than 20% of maximum capacity.

Do not press the pan with a hand.

For transportation time, pan support and pan ring should be packed

separately.

12

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

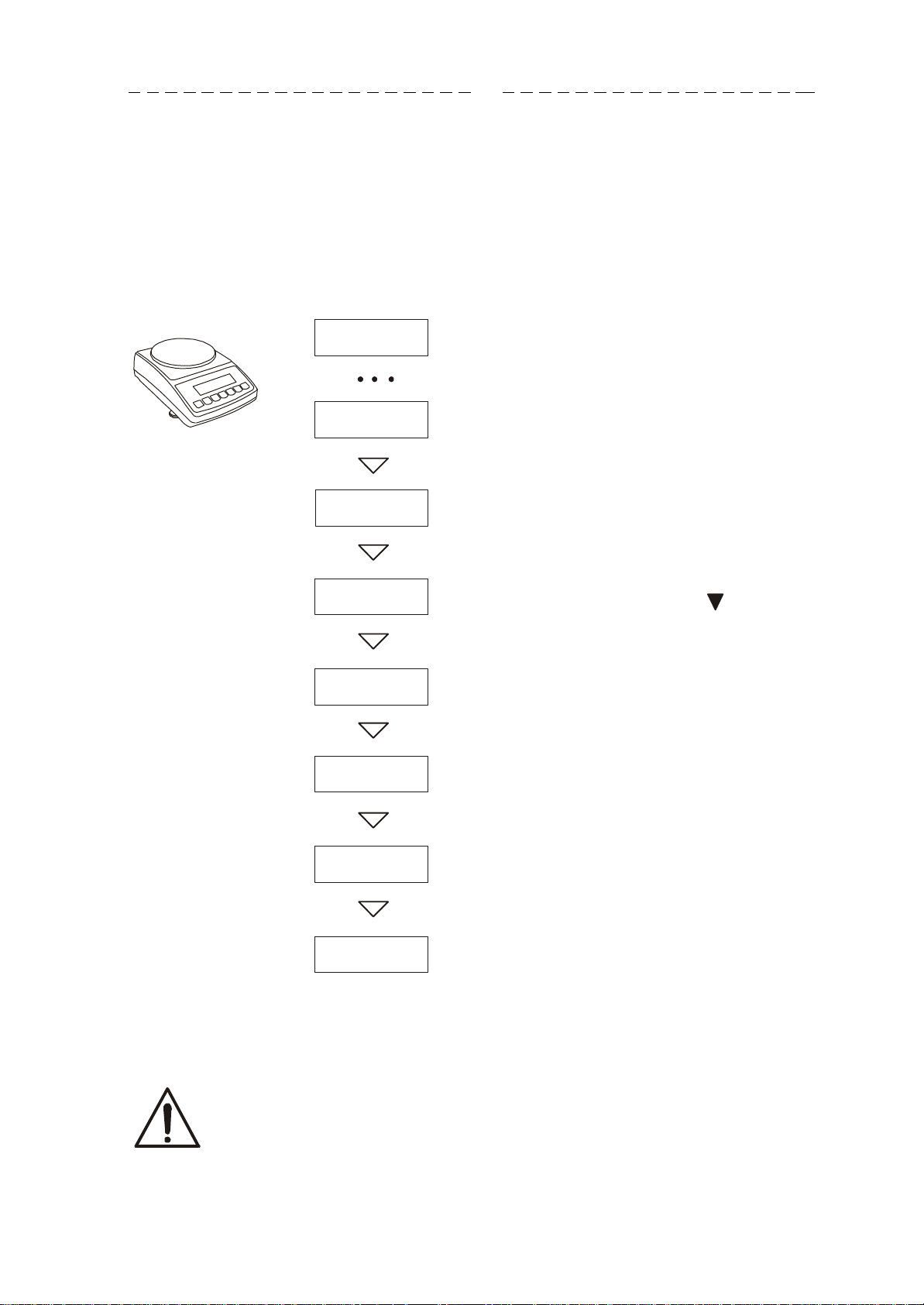

10. Start-up

Plug feeder into ~230V power supply socket. When the pan is empty plug feeder

output connector into 12V socket at back of the scale. Autotests and internal

calibration will be performed.

C-1

C-6

Tests of electronic scale components.

(displayed only when any test result is

negative)

Showing scale program version.

Internal calibration (press key if You

want to terminate calibration)

Steps after start-up of the scale:

AtA...

-d0Wn-

-UP-

CCCC

-------

0.00g

It is recommended that before you start measuring the internal

temperature has stabilized weight. For this to happen, the weight

should remain enabled for at least 2 hours. To maintain the accuracy

of the weight is not recommended to turn off the power.

Zeroing the scale.

Ready to work.

13

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

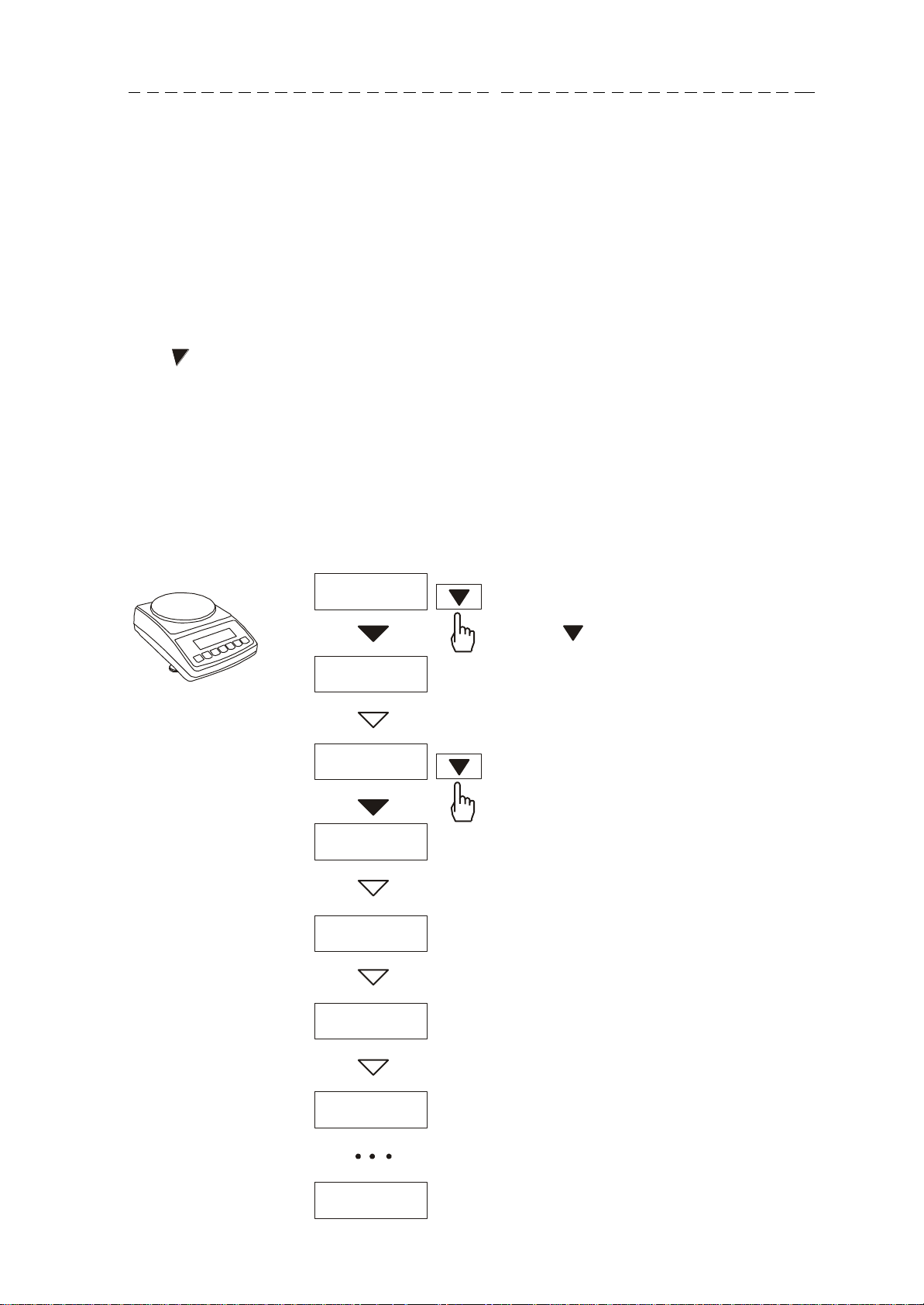

11. Internal calibration

The balance is equipped with internal calibration system, which general task is to

maintain required measurement accuracy on the balance.

Internal calibration is the process of putting internal weight on automatically by

balance mechanism and correcting accuracy in balance firmware. The correction is

necessary because of differences between values of gravitational acceleration in

the place where the balance was manufactured and in the place where it is

operated, as well as due to changes of balance level and temperature.

Internal calibration is performed in the following situations:

- when key is pressed twice,

- after defined time interval (for balances comply with verification requirements - 2

hours),

- after temperature change (for balances comply with verification requirements –

more than 2oC).

For balances comply with verification requirements time interval is set to 2 hours and

defined temperature change is 1oC. In other balances those values can be set as

calibration options. The reason of starting internal calibration is shown as an icon near

weight picture.

In order to perform internal calibration

0.00

PrESS

g

proceed with the following:

Empty the pan.

Press key twice (double pressing

the key helps to avoid accidental

starting calibration procedure).

During calibration internal weight is

put three times on and obtained

A

GAIn

-d0Wn-

-UP

-

CCCC

results are compared.

Discrepancy of results is signalled

with a message and causes the

balance being blocked.

Until calibration process is finished do

not perform any operation on the

balance. Any vibrations and shocks

interfere calibration process and may

delay it or deteriorate accuracy of its

result.

When internal calibration is performed

successfully the balance indicates

zero on the display at empty pan.

-------

0.00g

14

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Note:

In order to terminate internal calibration process in balances not comply with

verification requirements press key and wait until balance mechanism is not

settled in initial position.

12. Checking the balance

In order to confirm correctness of the balance during its operation, before starting and

after finishing every measurement series it is advised to check weighing accuracy. It

can be done by weighing external calibration weight or other object with exactly known

mass.

If exceeding of allowable measurement error is affirmed, the following things should

be checked:

- if the balance stands stable and it is levelled,

- if the balance is exposed on rapid air blasts, vibrations, rapid temperature

changes or air humidity,

- if the balance is not affected directly by heat source, electromagnetic radiation

or magnetic field.

The cause of inaccuracy can be too low temperature of the balance as well, when it

was unplugged from power supply. In this situation leave the bal ance switched on for

several minutes in order to adjust its internal temperature.

If none of above causes of inaccuracy occurs, calibration with external weight should

be performed to the balance. Recommended external calibration weight (to buy for

additional charge) is given in technical data table. In order to calibrate the balance with

external weight in legally verified balances verification seals should be removed and

another legal verification should be performed. In this case it is recommended to

contact authorized service centre.

Calibration with external weight is described in details in chapter 15.7.

15

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7

13. Connection with computer or a printer

The scale may send data to a computer or a printer via RS232C interface.

RxD

(receiver)

TxD (transmitter)

GND

1

2

3

4

5

6

8

9

Case

When cooperating with a computer, the scale

sends weighing result after initialising signal

from a computer or after pressing key on

the scale.

For cooperation with the scale a computer

should be equipped with software allowing

receiving data from the scale and using it

further.

- Communication – free program for sending simple commands to the scale and

receiving weighing results,

- ProCell – program for cooperation with Microsoft EXCEL and other Microsoft

Windows applications (demo version).

Three modes of work serial connections are possible:

- standard mode (stb - with stabilization of indicator or without)

- automatic mode (auto)

- continuous mode (Cont.)

Special function (SErIAL) is serve to choice a type of work serial connector (see

below).

Standard type.

Scale sends result of weighting on an initialize signal from computer, or after pressed

key.

Automatic mode (this mode can be use to cooperation with a printer)

Data are send automatically after result stabilization, but next transmission is possible

after removing previously weighted sample. Data contains next number of sample and

result of weighting.

Continuous mode.

Scale sends result of weighting on each 0,1 seconds.

16

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_____

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Byte

1 - sign „-” or space

Byte

2 - space

Byte

34

-

digit or space

Byte

5÷9

-

digit, decimal point or space

Byte

10 - digit

Byte

11 - space

Byte

12 - k, l, c, p or space

Byte

13 - g, b, t, c or %

Byte

14 - space

Byte

15 - CR

Byte

16 - LF

Detailed protocol description in standard mode

LonG protocol

Transmission proceeds in the following way:

1. Communication parameters: 8 bits, 1 stop bit, no parity, baud rate 4800bps,

2. Available orders send from computer and balance answers:

Readout of scale indication ( corresponds to pressing key

ComputerScale: S I CR LF (53h 49h 0Dh 0Ah),

ScaleComputer: scale response according to description below (16 bytes):

Attention:

Network number different than zero (SErIAL / nr function) changes scale working

mode: communication with a computer is possible after logging the scale in with 02h

scale number command. To log the scale out use 03h command.

For example: Using a program to test RS232 interface for scale number 1 please

write: $0201 to log in, then SI, and write: $03 to close communication.

Asking for scale presence in system (testing scale connection with computer):

ComputerScale: S J CR LF (53h 4Ah 0Dh 0Ah),

ScaleComputer: M J CR LF (4Dh 4Ah 0Dh 0Ah),

Displaying a sign on scale display (text message from computer):

ComputerScale: S N n n X X X X X X CR LF (53h 4Eh 0Dh 0Ah), nndisplaying time in seconds; XXXXXX- signs to display

ScaleComputer: M N CR LF (4Dh 4Eh 0Dh 0Ah),

Scale tarring (calling T key press) :

ComputerScale: S T CR LF (53h 54h 0Dh 0Ah),

ScaleComputer: without response,

Scale zeroing (calling 0 key press):

Computer Scale: S Z CR LF (53h 5Ah 0Dh 0Ah),

Scale Computer: without response,

Scale turning on / off (calling I/ key press):

Computer Scale: S S CR LF (53h 53h 0Dh 0Ah),

17

USER MANUAL

___

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

__

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

SW-1

SW-2

SW-3

SW-4

SW-5

SW-6

SW-7

SW-8

on

off

on

off

off

on

off

off

Scale Computer: without response,

Entering to special function menu (calling MENU key press):

Computer Scale: S F CR LF (53h 46h 0Dh 0Ah),

Scale Computer: without response,

Setting low threshold value (option):

Computer Scale: S L D1...DN CR LF (53h 4Ch D1...DN 0Dh 0Ah)

D1...DN – threshold value, maximum 8 characters („-” – negative value, digits, dot

– decimal separator), number of digits after dot should be the same as on scale

display,

Scale Computer: without response,

Example:

in order to set low threshold 1000g in scale B1.5 (d=0.5g) the following order

should be sent:

S L 1 0 0 0 . 0 CR LF (53h 4Ch 31h 30h 30h 30h 2Eh 30h 0Dh 0Ah),

in order to set low threshold 100kg in scale B150 (d=50g) the following order

should be sent:

S L 1 0 0 . 0 0 CR LF (53h 4Ch 31h 30h 30h 2Eh 30h 30h 0Dh 0Ah),),

Setting high threshold value (option):

Computer Scale: S H D1...DN CR LF (53h 48h D1...DN 0Dh 0Ah),

D1...DN – threshold value (see )

Scale Computer: without response.

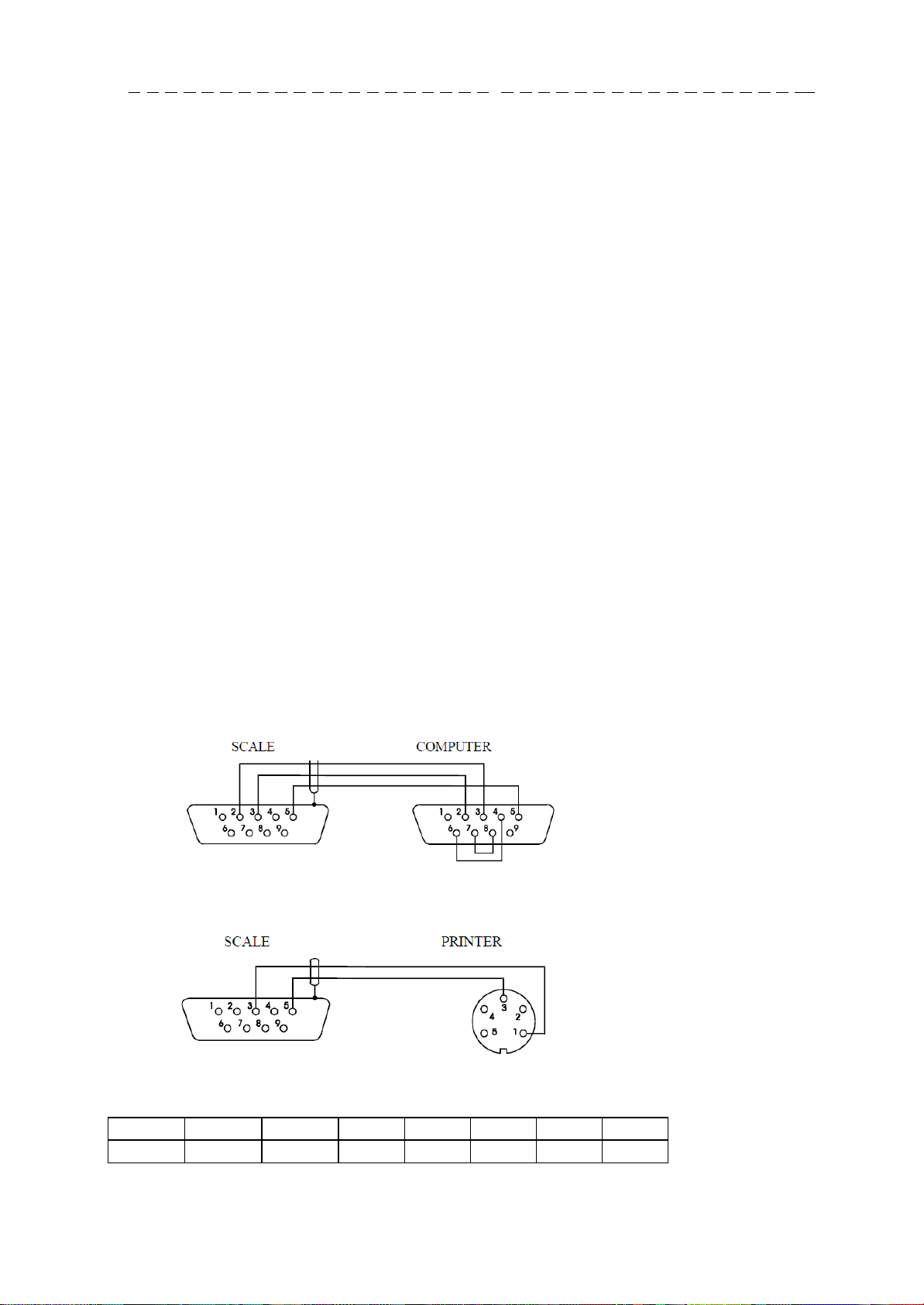

Connecting cable WK-1 (scale – computer / 9-pin interface):

Connecting cable WD-1 (connects printer with scale):

AXIS C-001 printer internal switches setting:

Loading...

Loading...