LEXMARK X5100 Service Manual

Lexmark™ X5100 Series

• Table of Contents

•Start Diagnostics

• Safety and Notices

All-In-One

4407-XXX

• Trademarks

•Index

Lexmark and Lexmark with diamond

design are trade ma rks of Lexmark

International, Inc., registered in the

United States and/or ot her countries.

4407-XXX

Edition: March 24, 2006

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTERN ATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING , BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not all o w di sc la im er o f e x pres s o r i mpl i ed wa rr an tie s i n c ertai n t ra ns act ion s; t he refore, t hi s

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the info rmation herein; these changes will be inco rporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

Comments may be addressed to Lexmark International, Inc., Department D2 2A/032-2,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or e-mail at

ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of the

information you supply in any way it believes appropriate without incurring an y obligatio n

to yo u.

Lexmark is a trademark of Lexmark International, Inc., registered in the United States

and/or other countries.

Other trademarks are the propert y of their respec tive owners.

© 2003 Lexmark Inte rna t io nal , Inc.

All rights reserved.

UNITED STATES GOVERNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are

commercial computer sof tware and documentation developed exclusively at pri vate

expense.

U.S.A. P/N: 12G9219

Japanese P/N: 12G9220

4407-XXX

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scanner Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power-On Self Test (POST) Sequence . . . . . . . . . . . . . . . . . . . . 2-1

POST Symptom Tabl e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Symptom Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Carrier Transport Service Check . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

CCD Module Assembly Service Check . . . . . . . . . . . . . . . . . . . . 2-8

Maintenance Station Service Check . . . . . . . . . . . . . . . . . . . . . . 2-9

Paper Feed Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -10

Paper Path Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -12

Power Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -13

Print Quality Service Che ck . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Scan/Copy Quality Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-16

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Repair Informatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-S ensi tive Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Releasing Plastic Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Scanner Lid Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Scanner Module Assemb ly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Scanner Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Mid-Frame Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Rear Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Carrier Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

iii

4407-XXX

Maintenance Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

ASF Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Assembly 2: Print Engine and Carrier Transport . . . . . . . . . . . . . . . .7-4

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

iv Service Manual

4407-XXX

Safety Information

• The safety of this product is based on testing and approvals of

the original design and specific components. The manufacturer

is not responsible for safety in the event of use of unauthorized

replacement par ts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precaut ions.

Consignes de Sécurité

• La sécurité de ce produit repose sur des tests et des

agréations por tant sur sa conception d'origine et sur des

composants particuliers. Le fabricant n'assume aucune

responsabilité concernant la sécurité en cas d'utilisation de

pièces de rechange non agréées.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriqu es, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Safety Information v

4407-XXX

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione

del progetto originale e dei componenti specifici. Il produttore

non è responsabile per la sicurezza in caso di sostituzione non

autorizzata delle parti.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

• Die Sicherheit dieses Produkts basiert auf Tests und

Zulassungen des ursprünglichen Modells und bestimmter

Bauteile. Bei Verwendung nicht genehmigter Ersatzteile wird

vom Hersteller keine Verantwortung oder Haftung für die

Sicherheit übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinanderne hme ns und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständig e

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

vi Service Manual

4407-XXX

Pautas de Seguridad

• La seguridad de este producto se basa en pruebas y

aprobaciones del diseño original y component es esp ecíficos.

El fabricante no es responsable de la seguridad en caso de uso

de piezas de repuesto no autorizadas.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

• A segur a n ça deste produto baseia-se em testes e aprovações

do modelo original e de componentes específicos. O fabricante

não é responsável pela segunrança, no caso de uso de peças

de substituição não autorizadas.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Safety Information vii

4407-XXX

Informació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i

aprovació del disseny original i els components específics.

El fabricant no es fa responsable de les qüestions de

seguretat si s'utilitzen peces de recanvi no autoritzades.

• La in formaci ó pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre

les mesures convenie n ts.

viii Service Manual

4407-XXX

Safe ty In formation ix

4407-XXX

Preface

This manual contains maintenance procedures for service

personnel. It is divided into the following chapters:

1. General Informati on contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

2. D iagnostic Information contains an error indicator table,

symptom tables, and service checks used to isolate failing field

replaceable units (FRUs).

3. D iagnostic Aids contains tests and checks used to locate or

repeat symptoms of printer problems.

4. Repair Information provides instructions for making printer

adjustments and removing and installing FRUs.

5. Connector Locations uses illustrations to identify the

connector locations and test points on the printer.

6. Preventive Maintenance contains the lubrication specifications

and recommendations to prevent problems.

7. Parts Catalog contains illustrations and part numbers for

individual FRUs.

x Service Manual

4407-XXX

1. Gen e r a l Informat io n

The Lexmark™ X5150 (4407-XXX) machine features an electromechanical scanner, printer, and copier that creates characters and

graphics by composing programmed patterns of ink dots using a

printhead and liquid ink. The printhead uses small heater plates and

nozzles to control ink flow and the formation of characters on the

print media. The printhea d assembly and ink supply are combined

into a single-unit, print cartridge available as a customer replaceable

supply item. Dual printheads provide color and true black printing

without changing printheads. The number and size of inkjets or

nozzles, in the printhead, determines the overall quality and

capability of the printer. The black cartridg e has a total of 640

nozzles and installs on the right. The color cartridge has a total of

480 nozzles and installs on the left. The printer is capable of printing

in two directions from either cartridge.

Power Cons umption

• 0.6 Watts - Power “Off”

• 9 Watts - Idle Mode (power on - not printing)

• 23 Watts - Printing (average)

• 21 Watts - Continuous Copying (average)

• 18 Watts - Continuous Scanning (average)

General Information 1-1

4407-XXX

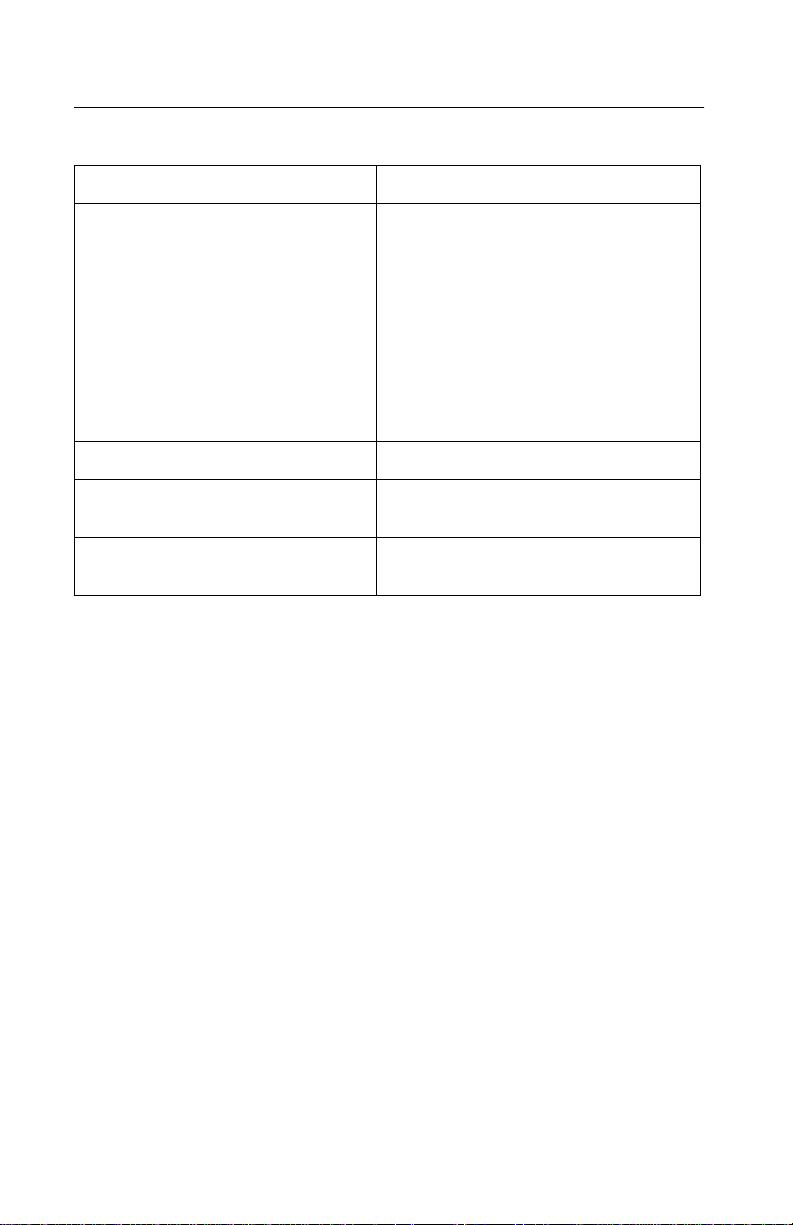

Scanner Specif ications

Scanner Type Flatbed, CCD

Scan Modes T rue Color:

48 Bit Internal (68.7 Billion Color s)

24 Bit External (16.7 Million Col ors)

Gray Mode:

12 Bits Internal (4,096 Shades of

Gray)

8 Bits External (256 Shades of G ray)

Te xt/Line Art:

1 Bit Per Pixel

Scan Method One Pass Scanni ng

Scan Area 8.5 X 11.7 inches

216 X 292 mm

Scan Resolution Optical: 600 dpi (H) X 2400 dpi (V)

Interpolated: 19,200 X 19,200

1-2 Service Manual

4407-XXX

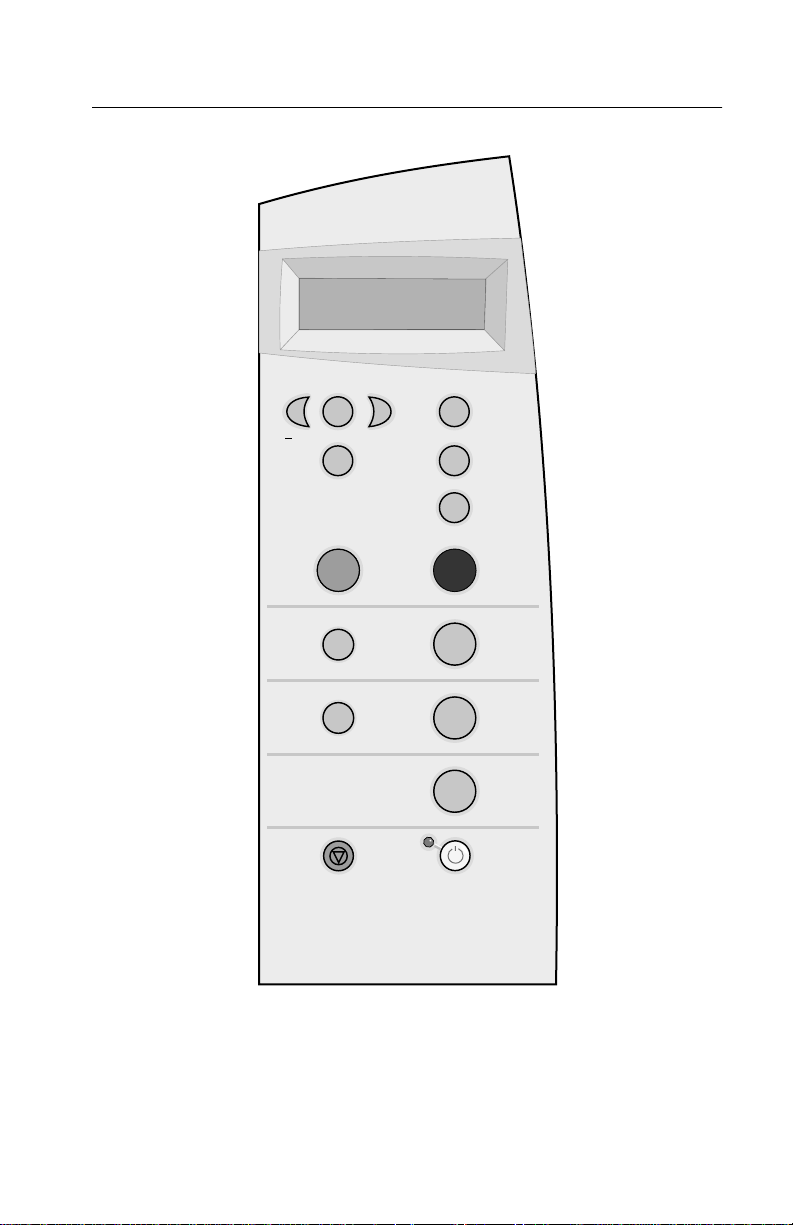

Operator Panel

Options

Select

Number

of Copies

+

Reduce/

Enlarge

Copy

Quantity

Start

Copy:

Photos:

Scan

To:

Fax:

Color

Copy

Photo

Options

-E-mail

-File

-Software

Stop/

Clear

Black

Copy

Photo

Copy

Start

Scan

Start

Fax

Power

General Information 1-3

4407-XXX

Press this

button:

Number of

Copies

Lighter/Darker Make the document lighter or darker than the original.

Reduce/Enlarge Make the document smaller or larger than the original .

Paper Type Select glossy, photo, transparency, or plain paper type.

- or + Scroll through menu sub-categories.

Menu Change settings using the menus.

Select Choose the displa yed selection.

Quality Choose photo , qui ck, or normal cop y setting.

Colo r Copy Make a color copy.

Black Copy Make a black and white copy.

Scan To Select a scan destina ti on, such as To copy, To an e-

Scan Press the scan button after selecting a Scan To

When you want to:

Select the number of cop ies.

mail, To an application, To a file, or To fax.

destination.

Cancel Cancel a scan, print, or copy job, or return to a menu

Power Turn the printer on or off.

category from a menu sub-category.

1-4 Service Manual

4407-XXX

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the symptom index, service

checks, and diagnostic aids to determine the symptom and repair

the failure.

After you complete the repair, perform tests as needed to verify the

repair.

General Information 1-5

4407-XXX

Abbreviations

B/M Bill of Material

CCD Charge-Coupled Device

EOF End of Form

ESD Electrostatic Discharge

FPC Flat Printhead Cable

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LCD Liquid Crystal Display

LVPS Low Voltage Power Supply

OEM Original Equipment Manufacturer

V ac Volts alternating current

V dc Volts direct current

ZIF Zero Insertion Force

1-6 Service Manual

4407-XXX

2. Diagnostic Information

Start

Use the symptom tables, service checks, and diagnostic aids in

chapter three, to determine the printer failure.

Power-On Self Test (POST) Sequence

Press the power button to turn machine on.

• The Power indicator light turns on.

• The Charge-Coupled Device (CCD) lamp turns on and the

scanner moves to the left, then returns to the right.

• The paper feed motor runs then stops.

• The carrier moves to the right then returns to the left stopping at

the maintenance station.

• Power light stays on.

• The message below is displayed on the LCD.

1

PY

Normal Quality

If your printer completes POST with no errors, go to the “Symptom

Tables” on page 2- 3, locate the symptom and take the indicated

action.

If your printer does not complete POST, locate the symptom in the

following table and take the indicated action.

1

Diagnostic Information 2-1

4407-XXX

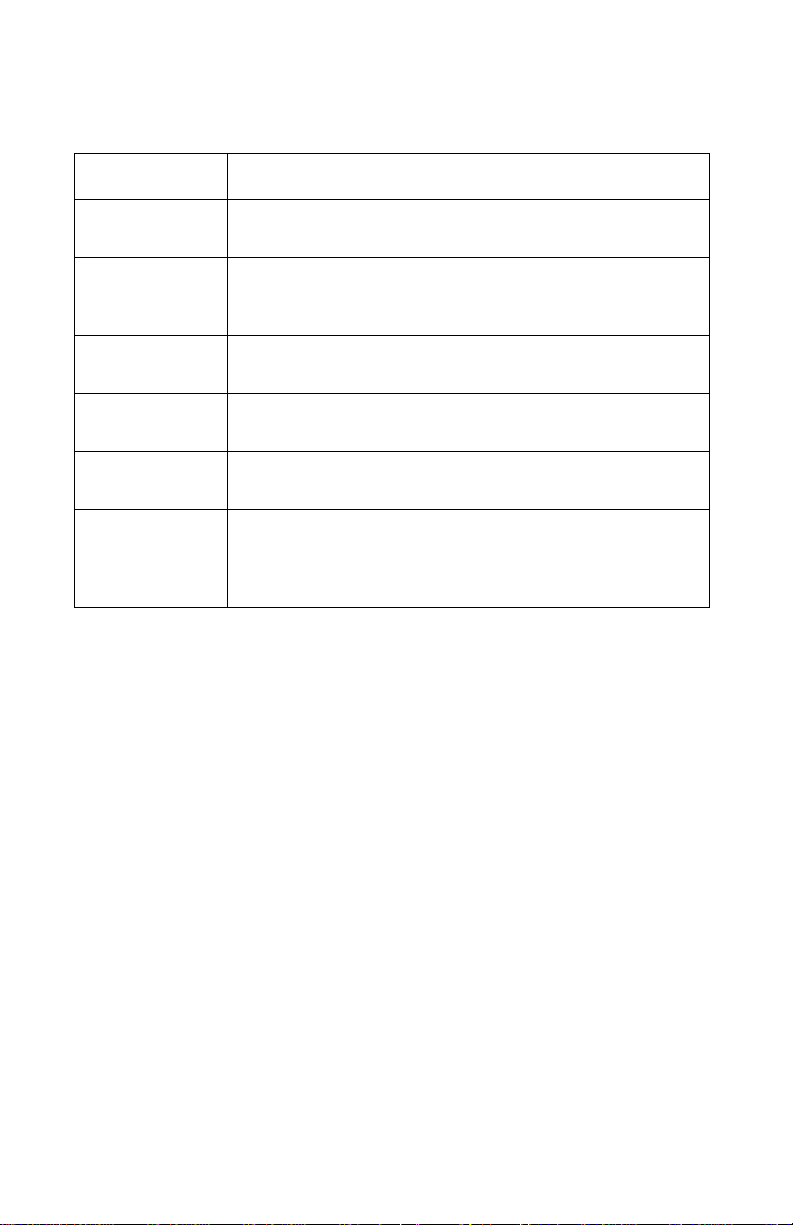

POST Symp tom Table

Symptom Action

No power light

No motors run

Paper feed

gears do not

turn

Carrier does not

move

Carrier slam s

side frame

CCD lamp does

not tu rn on

LCD displays

“Unlock Scanner

Clear Paper

Jam”

Go to the “Power Service Check” on page 2-12. If ok ay,

go to the “Operator Panel Problems” on page 2-3.

Go to the “Paper Feed Service Check ” on page 2-10.

Go to the “Carrier Transport Service Chec k” on

page 2-6.

Go to the “Carrier Transport Service Chec k” on

page 2-6.

Go to the “CCD Module Assembly Service Check” on

page 2-8.

Go to the “CCD Module Assembly Service Check” on

page 2-8.

2-2 Service Manual

4407-XXX

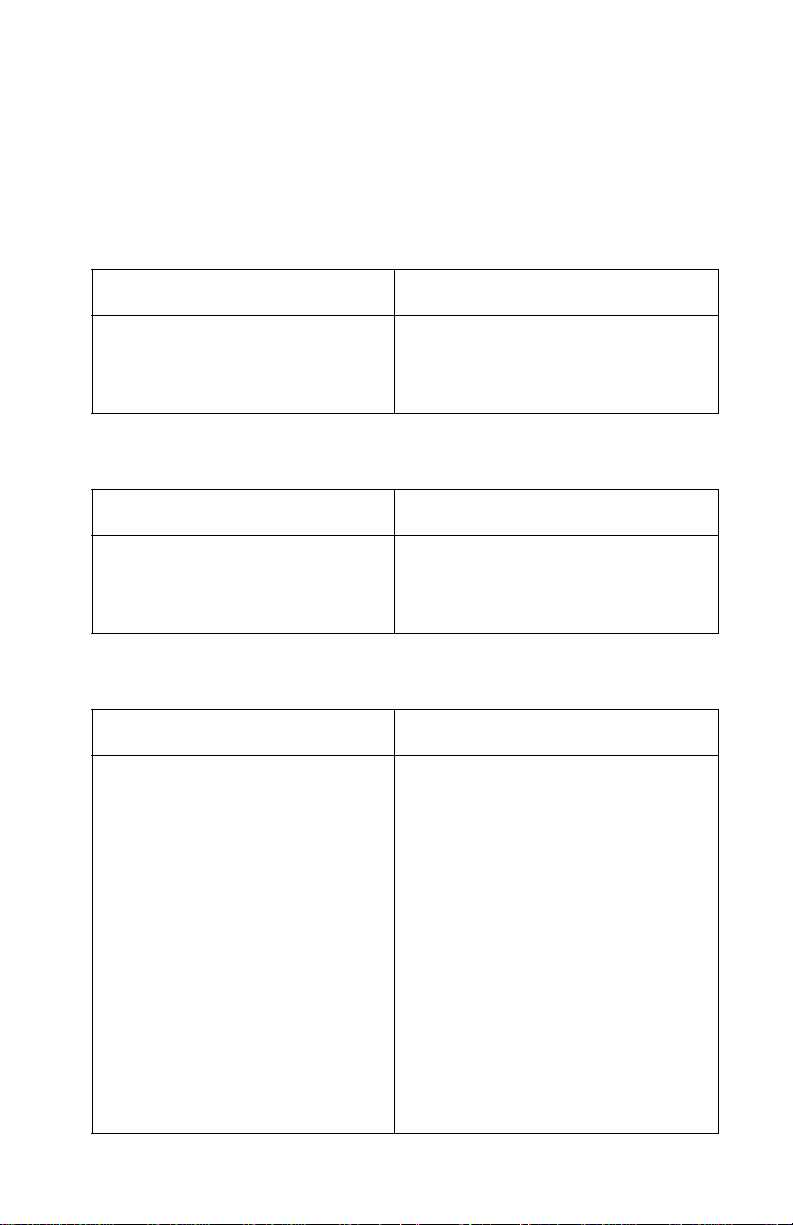

Symptom Tables

Locate the symptom in the following tables and take the appropriate

action.

Carrier Transport Problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slams side frame

Go to the “Carrier T ransport

Service Check” on page 2-6.

Maintenance Station Problems

Symptom Action

Maintenance station:

• Fails to cap the printheads

• Fails to clean the printheads

Go to the “Maintenance Station

Service Check” on page 2-9.

Operator Panel Problems

Symptom Action

• Buttons do not work

• LCD does not display

Check operator panel cable

connection at JP6 on the system

board. Then run th e “Power- On Self

Test (POST) Sequence” on

page 2-1.

If the LED buttons or any lights fail,

check c onnection JP6 . If the prob lem

remains, replace the scanner

module assembly. Go to the

“Scanner Module Assembly” on

page 4-3.

If the pr oblem still exists, replace the

system board. Go to the “System

Board” on page 4-15.

Diagnostic Information 2-3

Loading...

Loading...