Page 1

Revised: 10/23/06

Lexmark™ T430

• Table of contents

• Start diagnostics

4048-1xx

• Safety and notices

• Trademarks

•Index

Lexmark and Lexmark with diamond

design are trade ma rks of Lexmark

International, Inc., registered in the

United States and/or ot her countries.

Page 2

4048-1xx

Editi on: October 23, 2006

The following paragraph does not apply to any country where such provisions are

inconsiste nt with loc al law : LEXMARK INTERNATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow discl aimer of expr ess or implied wa rranties in certain transactions; therefore,

this statement may not apply to you.

This publica tion could include technical inaccuracies or typographical errors. Changes

are periodically made to the information herein; these changes will be incorporated in

later edition s . Improvements or changes in the products or the programs described may

be made at any time.

Comments may be a ddressed to Lex mark International, Inc., Dep artment D22A/032- 2,

740 WestNew Circle Road, Lexington, Kentucky 4055 0, U. S.A or e-mail at

ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of the

information you supply in any way it believes appropriate without incurring any obligation

to you.

References in this publication to products, programs, or services do not imply that the

manufacturer intends to make these available in all countries in which it operates. Any

reference to a product, progra m, or servi c e is not intended to state or imply that only that

product, program, or service may be used. Any f unctionally equivalent pr oduct, pr ogram,

or service that does not infringe any existing intellectual property right may be used

instead. Evaluation and verifica tion of operat ion in conjunction with other pr oducts ,

programs, or services, except those expressly designated by the manufacturer, are the

user’s responsibility.

Lexma rk, Lexmark with diamond design, MarkNet, and MarkVision are trademarks of

Lexmark International, Inc., registered in the United States and/or other countries.

ImageQuick, Optra Forms, and PrictureGrade are trademarks of Le mark Intern ational,

Inc.

®

PCL

is a registered trademark of the Hewlett-Packard Company.

®

PostScript

Other trademarks are the property of their respective owners.

© 2006, 2004 Lexmark International, Inc.

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RE STRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexi ngton, KY 40550.

is a registered trademark of Adobe Systems Incorporated.

U.S.A. P/N 12G9436

Page 3

4048-1xx

Table of Conte nt s

Laser notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer features and specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Resolution and print quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Memory and user flash memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Printer data streams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Print area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Media and paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Standard and optional paper sources . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Input media sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Output media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power–On Reset (POR) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

POST symptom table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Printer symptom tab le . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Messages and error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Service error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

User attendance messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Paper jam messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Sub error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Disconnects on the controller card. . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

iii

Page 4

4048-1xx

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Cooling fan service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Cover interlock switch service check. . . . . . . . . . . . . . . . . . . . . . . . .2-37

Controller card service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Dead machine service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Low voltage power supply (LVPS) service check . . . . . . . . . . . . . . .2-39

High voltage power supply (HVPS) service check. . . . . . . . . . . . . . .2-40

Fuser service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Main motor service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

Operator panel ser vice check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

Transfer rol l ser vice check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

Paper feed servic e checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

Parallel port ser vice check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

Print quality service checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

Solving print qual ity problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Additional service menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Entering Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

PRINT TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

HARDWARE TESTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

DUPLEX TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

INPUT TRAY TESTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

BASE SENSOR TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

DEVICE TESTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

PRINTER SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

EP SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

ERROR LOG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Entering CONFIG MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Maint Cn t V al ue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Reset Ma int Cnt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Prt Quality Pgs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

PPDS Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Download Emuls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Energy Conserve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

ERROR LOG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Paper Prompts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Env Prompts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Reduced Curl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Exit Conf ig M enu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

iv Service Manual

Page 5

4048-1xx

Repair information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-sensitive parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Printhead assembly adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjusting paper feed al ignment (skew) . . . . . . . . . . . . . . . . . . . . . . . 4-5

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

MPF door cover remov al . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Front cover removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Top cover assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Right side cover rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Left side cover remov a l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Rear cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Rear exit door removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Output tray full flag removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Operator panel cable removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Operator panel assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Duplex tray assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Bottom pan removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Fuser assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Fuser paper exit guide assem bly removal. . . . . . . . . . . . . . . . . . . . 4-29

Fuser exit sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Cartridge contact assembly removal . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Tray damper and spring remov al. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Door latch removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Paper guide roller removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Char ge ro ll remova l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Right guide removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Left guide removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Cartridge signature button sensor removal . . . . . . . . . . . . . . . . . . . 4-42

Transfer roll assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Bracket, paper detect (input sensor) re mo val . . . . . . . . . . . . . . . . . 4-44

D–ro ll fe e d rem o v a l, tr a y 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

D–roll shaft assembly removal, tray 1 . . . . . . . . . . . . . . . . . . . . . . . 4-45

3–pin and 2–pin connect ors removal. . . . . . . . . . . . . . . . . . . . . . . . 4-46

Printhead removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Controller card cage (with card in place) removal . . . . . . . . . . . . . . 4-48

Controller card assembly remo val . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

MPF gear removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Main drive motor assembly removal . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Main drive assembl y removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Exit drive motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Exit drive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Ratchet drive removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Reference feed assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

v

Page 6

4048-1xx

Cartridge coup li ng assembly removal . . . . . . . . . . . . . . . . . . . . . . . .4-65

Upper MPF housing asse mbly (with paper flag) removal . . . . . . . . .4-66

MPF paper sensor removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-67

Lower MPF housing asse mb ly removal. . . . . . . . . . . . . . . . . . . . . . .4-70

Backup feed roller assembly removal . . . . . . . . . . . . . . . . . . . . . . . .4-72

MPF pick roller assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . .4-73

HVPS card removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-75

LVPS fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-76

LVPS card removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-77

Inner link and outer link assembly rem oval . . . . . . . . . . . . . . . . . . . .4-78

Cooling fan removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

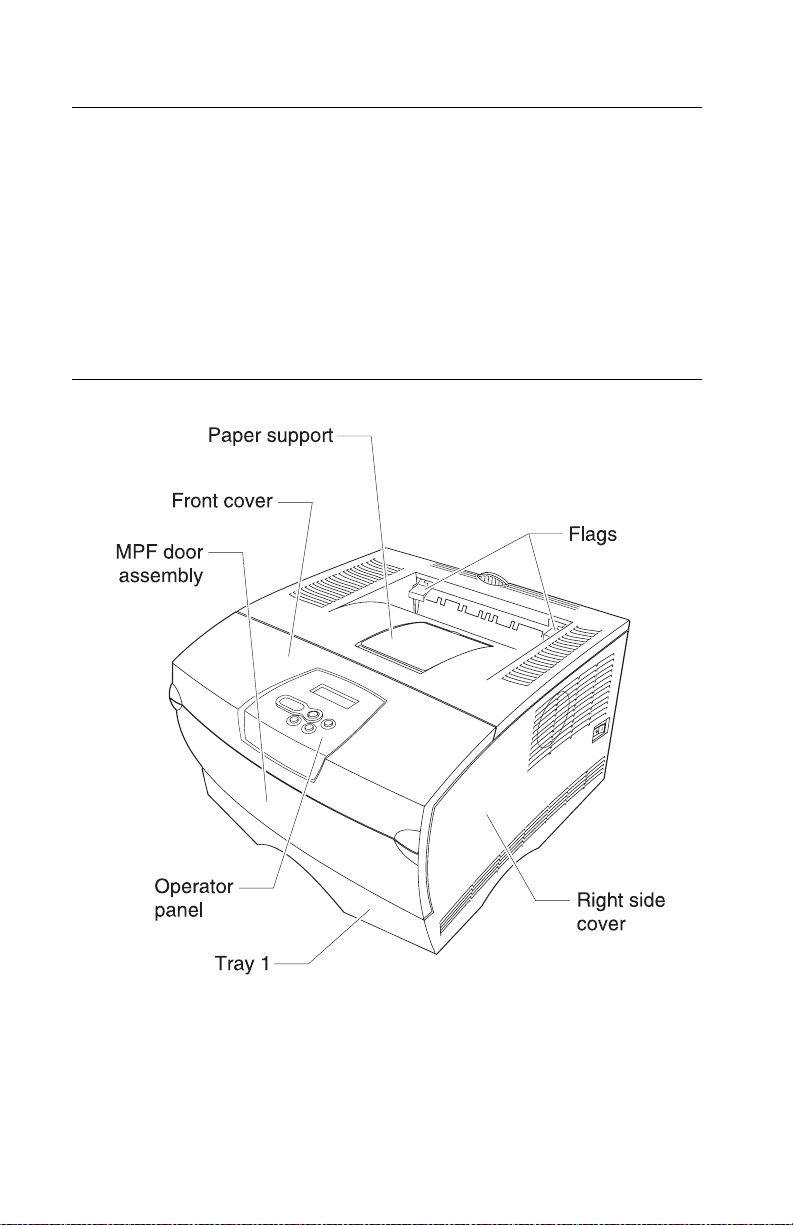

Locations and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Exterior locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Controller card assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Low voltage power supply (LVPS) . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

High voltage power supply (HVPS) . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Safety inspection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Scheduled maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Maintenance kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Maintenance kit parts group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Assembly 2: Paper feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Asse m b l y 3: Fram e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Assembly 4: Multipurpose feeder (MPF). . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Assembly 5: Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Assembly 6: Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Assembly 7: Electronics and cables 1 . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Assembly 8: Electronics and cables 2 . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Asse m b l y 9: Sens ors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Asse m b l y 10 : Opti on s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Part number index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-7

vi Service Manual

Page 7

4048-1xx

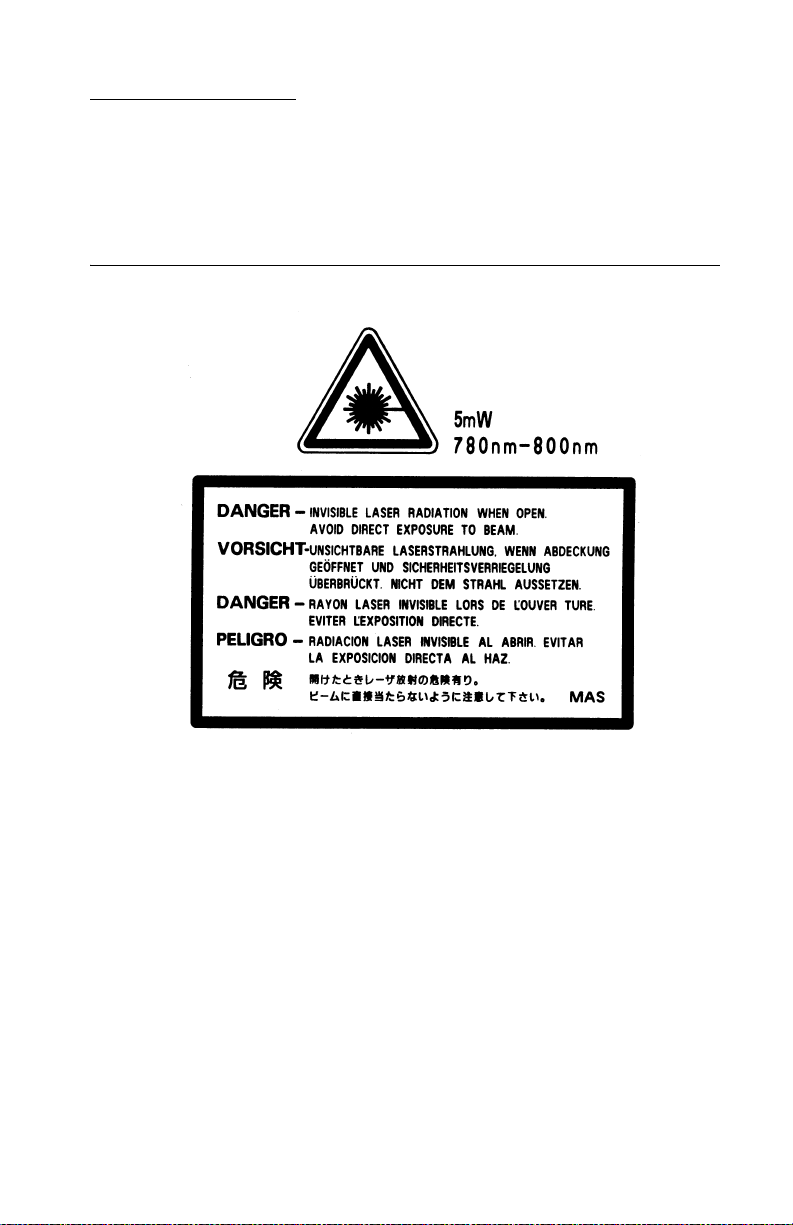

Laser notices

The following laser notice labels may be affixed to this printer as

shown:

Laser advis o ry label

Laser notices vii

Page 8

4048-1xx

Laser no tice

The printer is certified in the U.S. to conform to the requirements of

DHHS 21 CFR Subchapter J for Class I (1) laser products, and

elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 60825-1.

Class I laser products are not considered to be hazardous. The

printer contains internally a Class IIIb (3b) laser that is nominally a 5

milliwatt gallium arsenide laser operating in the wavelength region of

770-795 nanometers. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed

service condition.

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die

Anforderungen der Bestimmung DHHS (Department of Health and

Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1).

In anderen Ländern gilt der Drucker als Laserprodukt der Klasse I,

der die Anforderungen der IEC (International Electrotechnical

Commission) 60825-1 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des

Druckers befindet sich ein Laser der Klasse IIIb (3b), bei dem es

sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen

der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbetrieb, bei der Wartung

durch den Benutzer oder bei ordnungsgemäßer Wartung durch den

Kundendienst Laserbestrahlung, die die Klasse I übersteigen würde,

Menschen keinesfalls erreicht.

viii Service Manual

Page 9

4048-1xx

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette impr imant e est certifiée conforme aux

provisions DHHS 21 CFR alinéa J concernant les produits laser de

Classe I (1). Pour les autres pays : cette imprimante répond aux

normes IEC 60825-1 relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comme des produits

non dangereux. Cette imprimante est équipée d’un laser de Classe

IIIb (3b) (arséniure de gallium d’une puissance nominale de 5

milliwatts) émettant sur des longueurs d’onde comprises entre 770

et 795 nanomètres. L’imprimante et son système laser sont conçus

pour impossible, dans des conditions normales d’utilisation,

d’entretien par l’utilisateur ou de révision, l’exposition à des

rayonnements laser supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme

ai requisiti del DHHS 21 CFR Sottocapitolo J per i prodotti laser di

classe 1 ed è certificata negli altri Paesi come prodotto laser di

classe 1 conforme ai requisiti della norma CEI 60825-1.

I prodotti laser di classe non sono considerati pericolosi. La

stampante contiene al suo interno un laser di classe IIIb (3b)

all’arseniuro di gallio della potenza di 5mW che opera sulla

lunghezza d’onda compresa tra 770 e 795 nanometr i. Il sistema

laser e la stampante sono stati progettati in modo tale che le

persone a contatto con la stampante, durante il normale

funzionamento, le operazioni di servizio o quelle di assistenza

tecnica, non ricevano radiazioni laser superiori al livello della

classe 1.

Laser notices ix

Page 10

4048-1xx

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los

requisitos para los productos láser de Clase I (1) establecidos en el

subcapítulo J de la norma CFR 21 del DHHS (Departamento de

Sanidad y Servicios) y, en los demás países, reúne todas las

condiciones expuestas en la norma IEC 60825-1 para productos

láser de Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La

impresora contiene en su interior un láser de Clase IIIb (3b) de

arseniuro de galio de funcionamiento nominal a 5 milivatios en una

longitud de onda de 770 a 795 nanómetros. El sistema láser y la

impresora están diseñados de forma que ninguna persona pueda

verse afectada por ningún tipo de radiación láser superior al nivel de

la Clase I durante su uso normal, el mantenimiento realizado por el

usuario o cualquier otra situación de servicio técnico.

Declaração sobre Laser

A impressora está certificada nos E.U.A. em conformidade com os

requisitos da regulamentação DHHS 21 CFR Subcapítulo J para a

Classe I (1) de produtos laser. Em outros locais, está certificada

como um produto laser da Classe I, em conformidade com os

requisitos da norma IEC 60825-1.

Os produtos laser da Classe I não são considerados perigosos.

Internamente, a impressora contém um produto laser da Classe IIIb

(3b), designado laser de arseneto de potássio, de 5 milliwatts

,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de

forma a nunca existir qualquer possiblidade de acesso humano a

radiação laser superior a um nível de Classe I durante a operação

normal, a manutenção feita pelo utilizador ou condições de

assistência pres critas.

x Service Manual

Page 11

4048-1xx

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een

laserprodukt van klasse I. Voor de Verenigde Staten zijn deze eisen

vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in

IEC 60825-1.

Laserprodukt en van klasse I worden niet als ongevaarlijk

aangemerkt. De printer is voorzien van een laser van klasse IIIb

(3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt m e t

een golflengte van 770-795 nanometer. Het lasergedeelte en de

printer zijn zo ontworpen dat bij normaal gebrui k, bij onderhoud of

reparatie conform de voorschriften , nooit blootste lling mogelijk is

aan laserstraling boven een niveau zoals voorgeschrev en is voor

klasse 1.

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i

overenstemmelse med kravene i IEC 60825-1.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren

indeholder internt en Klasse IIIB (3b)-laser , der nominelt er en 5

milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet

770-795 nanometer. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over

Klasse I-niveau ved normal drift, brugervedligeholdelse eller

obligatoriske servicebetingelse r.

Laser notices xi

Page 12

4048-1xx

Huomautu s las er laitteesta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) laserlaitteiden DHHS

21 CFR Subchapter J -määrityksen mukainen ja muualla luokan I

laserlaitteiden IEC 60825-1 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle.

Kirjoittimessa on sisäinen luokan IIIb (3b) 5 milliwatin

galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä.

Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei

altistu luokan I määrityksiä voimakkaammalle säteilylle kirjoittimen

normaalin toiminnan, käyttäjän tekemien huoltotoimien tai muiden

huoltotoimien yhteydessä.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina

näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21

CFR, underparagraf J för laserprodukter av Klass I (1). I andra

länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt

kraven i IEC 60825-1.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en

inbyggd laser av Klass IIIb (3b) som består av en laserenhet av

gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770795 nanometer. Lasersyst emet och skrivaren är utfo rmade så att det

aldrig finns risk för att någon person utsätts för laserstrålning över

Klass I-nivå vid normal användning, underhåll som utförs av

användaren eller annan föreskriven serviceåtgärd.

xii Service Manual

Page 13

4048-1xx

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR,

underkapittel J, for klasse I (1) laserprodukter, og er i andre land

godkjent som et Klasse I-laserproduk t i samsvar med kravene i IEC

60825-1.

Klasse I-laserprodukter er ikke å betrakte som farlige. Skriveren

inneholder internt en klasse IIIb (3b)-laser, som består av en

gallium-arsenlaserenhet som avgir stråling i bølgelengdeområdet

770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk, vedlikehold som utføres av brukeren, eller foreskrevne

serviceopera sjoner.

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora

compleix els requisits de DHHS 21 CFR, apartat J, pels productes

làser de classe I (1), i segons ha estat certificat en altres llocs, és un

producte làser de classe I que compleix els requisits d’IEC 60825-1.

Els productes làser de classe I no es consideren perillosos. Aquesta

impressora conté un làser de classe IIIb (3b) d’arseniür de gal.li,

nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona

de 770-795 nanòmetres. El sistema làser i la impressora han sigut

concebuts de manera que mai hi hagi exposició a la radiació làser

per sobre d’un nivell de classe I durant una operació normal, durant

les tasques de manteniment d’usuar i ni durant els serveis que

satisfacin les condicions prescrites.

Laser notices xiii

Page 14

4048-1xx

Japanese Laser Notice

Chinese Laser Notice

xiv Service Manual

Page 15

4048-1xx

Korean Laser Notice

Laser notices xv

Page 16

4048-1xx

xvi Service Manual

Page 17

4048-1xx

Safety information

• The safety of this product is based on testing and approvals of

the original design and specific components. The manufacturer

is not responsible for safety in the event of use of unauthorized

replacement par ts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precaut ions.

• CAUTION: When you see this symbol, there is a

danger from hazardous voltage in the area of the

product where you are working. Unplug the product

before you begin, or use caution if the product must

receive power in order to perform the task.

Consig n es de sécu ri té

• La sécurité de ce produit repose sur des tests et des

agréations portant sur sa conception d'orig ine et sur des

composants particuliers. Le fabricant n'assume aucune

responsabilité concernant la sécurité en cas d'utilisation de

pièces de rechange non agréées.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains r isques électr iqu es, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

• ATTENTION : Ce symbole indique la présence

d'une tension dang ereus e dans la par t ie du produit

sur laquelle vous travaillez. Débranchez le produit

avant de commencer ou faites preuve de vigilance si

l'exécution de la tâche exige que le produit reste sous

tension.

Safety information xvii

Page 18

4048-10x

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione

del progetto originale e dei componenti specifici. Il produttore

non è responsabile per la sicurezza in caso di sostituzione non

autorizzata delle parti.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato deve, quindi,

adottare le precauzioni necessarie.

• ATTENZIONE: Questo simbolo indica la presenza

di tensione pericolosa nell'area del prodotto.

Scollegare il prodotto prima di iniziare o usare

cautela se il prodotto deve essere alimentato per

eseguire l'intervento.

Sicherheitshinweise

• Die Sicherheit dieses Produkts basiert auf T ests und

Zulassungen des ursprünglichen Modell s und bestimmter

Bauteile. Bei Verwendung nicht genehmigter Ersatzteile wird

vom Hersteller keine Verantwortung oder Haftung für die

Sicherheit übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehme ns und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

• ACHTUNG: Dieses Symbol weist auf eine

gefährliche elektrische Spannung hin, die in diesem

Bereich des Produkts auftreten kann. Ziehen Sie vor

den Arbeiten am Gerät den Netzstecker des Geräts,

bzw. arbeiten Sie mit großer Vorsicht, wenn das

Produkt für die Ausführung der Arbeiten an den

Strom angeschlossen sein muß.

xviii Service Manual

Page 19

4048-1xx

Pautas de Seguridad

• La seguridad de este producto se basa en pruebas y

aprobaciones del diseño original y componentes espec íficos.

El fabricante no es responsable de la seguridad en caso de uso

de piezas de repuesto no autorizadas.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

• PRECAUCIÓN: este símbolo indica que el voltaje

de la parte del equipo con la que está trabajando es

peligroso. Antes de empezar, desenchufe el equipo

o tenga cuidado si, para trabajar con él, debe

conectarlo.

Informações de Segurança

• A segurança deste produto baseia-se em testes e aprovações

do modelo original e de componentes específicos. O fabricante

não é responsável pela segunrança, no caso de uso de peças

de substituição não autorizadas.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

• CUIDADO: Quando vir este símbolo, existe a

possível presença de uma potencial tensão perigosa

na zona do produto em que está a trabalhar. Antes

de começar, desligue o produto da tomada eléctrica

ou seja cuidadoso caso o produto tenha de estar

ligado à corrente eléctrica para realizar a tarefa

necessária.

Safety information xix

Page 20

4048-10x

Inf ormació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i

aprovació del disseny original i els components específics.

El fabricant no es fa responsable de les qüestions de

seguretat si s'utilitzen peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre

les mesures convenie n ts.

• PRECAUCIÓ: aquest símbol indica que el voltatge

de la part de l'equip amb la qual esteu treballant és

perillós. Abans de començar, desendolleu l'equip

o extremeu les precaucions si, per treballar amb

l'equip, l'heu de connectar.

xx Service Manual

Page 21

4048-1xx

Safety information xxi

Page 22

4048-10x

Preface

This manual contains maintenance procedures for service

personnel. It is divided into the following chapters:

1. General informati on contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed, as well as general

environmental and safety instructions.

2. D iagnostic information contains an error indicator table,

symptom tables, and service checks used to isolate failing field

replaceable units (FRUs).

3. D iagnostic aids contains tests and checks used to locate or

repeat symptoms of printer problems.

4. Repair information provides instructions for making printer

adjustments and removing and installing FRUs.

5. Locations and connections uses illustrations to identify the

connector locations and test points on the printer.

6. Preventive maintenance contains the lubrication specifications

and recommendations to prevent problems.

7. Parts catalog contains illustrations and part numbers for

individual FRUs.

Definitions

Note: A note provides additional information.

Warning: A warning identifies something that might damage the

product hardware or software.

CAUTION: A caution identifies something that might cause a

service r harm.

CAUTION: When you see this symbol, there is a

danger from hazardous voltage in the area of the

product where you are working. Unplug the product

before you begin, or use caution if the product must

receive power in order to perform the task.

xxii Service Manual

Page 23

4048-1xx

1. Gen e r a l informa tion

The Lexmark™ T430 (4048-1xx) laser printer is a monochrome

laser printer designed for individual users or small workgroups.

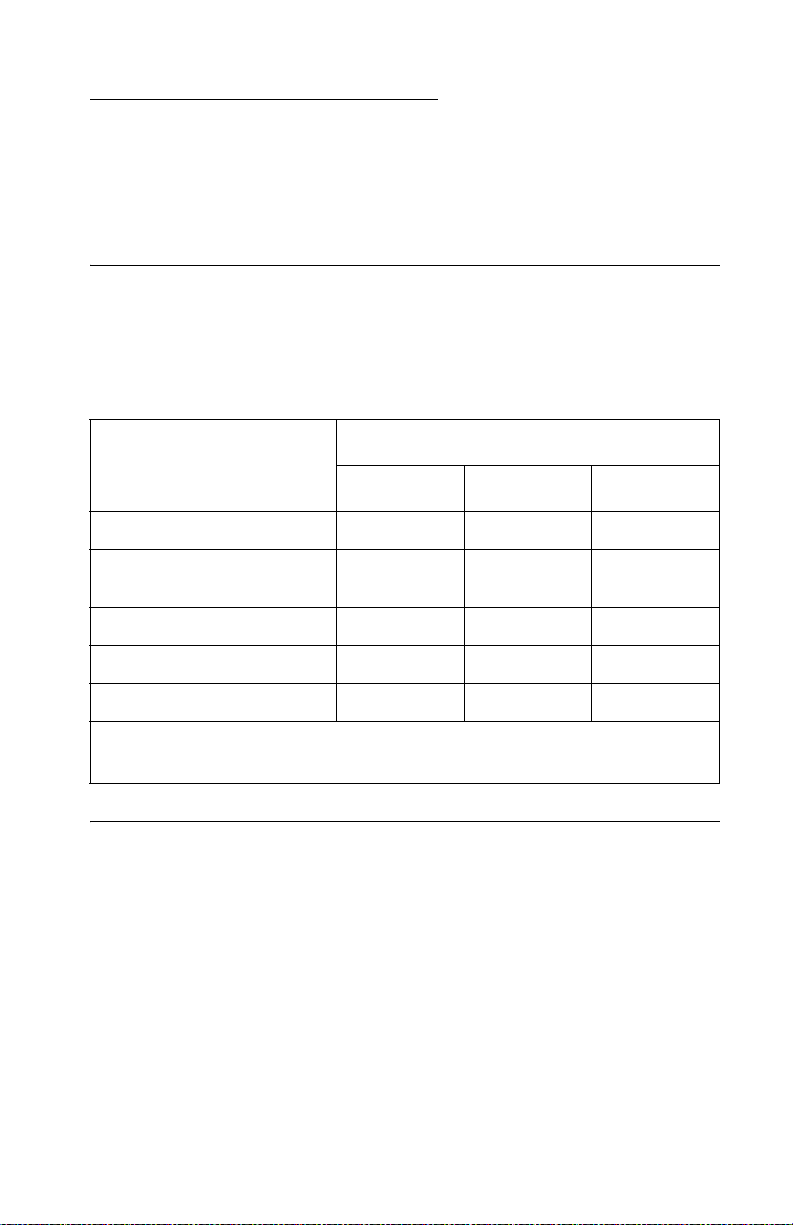

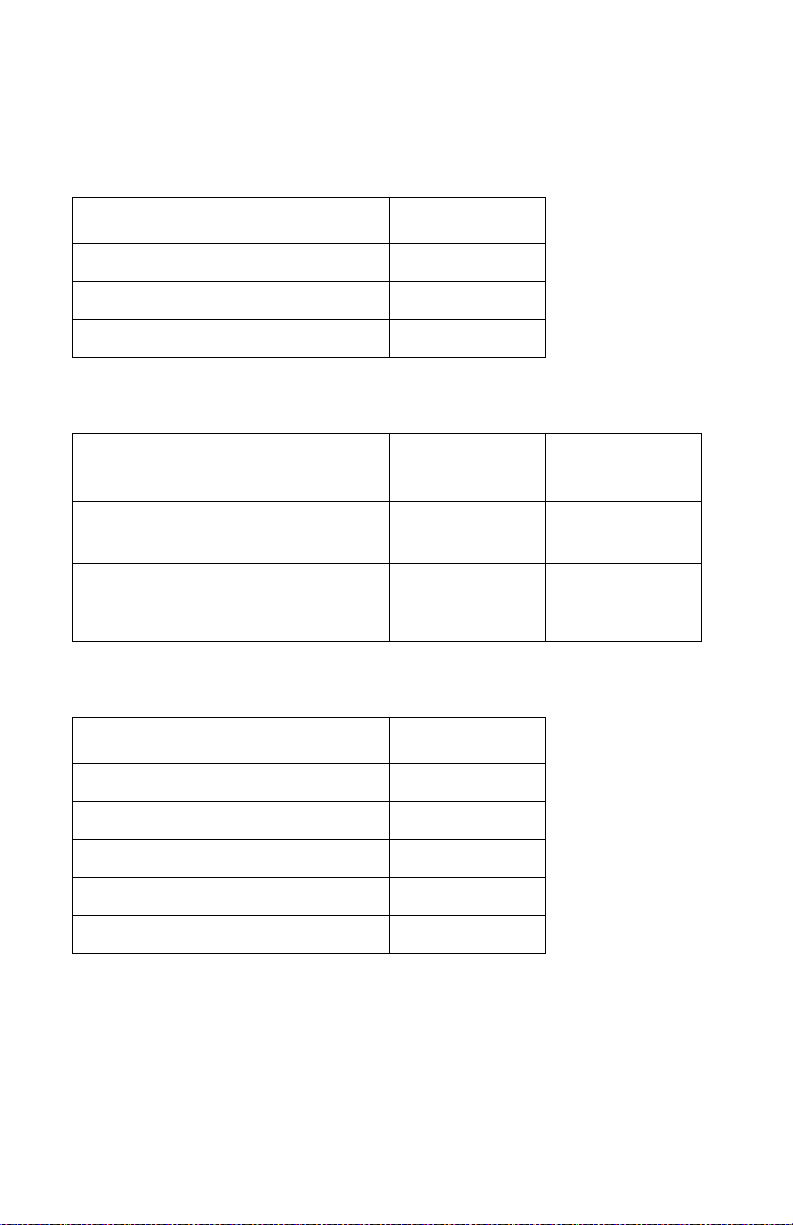

Models

There are three models, differing on standard features, including

standard memor y. For information on standard and optional

memory, see “Memory and user flash memory” on page 1-5.

Models

Standard features

Duplex ✓✓✗

Parallel interface connector

(1284–B connector.)

Parallel mod e 2 ✓✓✓

USB port ✓✓✓

Ethernet adapter, integrated ✗✓✗

✓ Indicates attachment is part of the factory ship ped configuration.

✗ Indicates att a chment is not part of the factory shi pped configuration.

101 102 111

✓✓✓

Maint en an ce ap proa ch

The diagnostic information leads you to the correct field replaceable

unit (FRU) or part. Use the error code charts, symptom index, and

service checks to determine the symptom and repair the failure. See

“Diagn ost ic in formation” on page 2-1, for the location of each

section. See the “Re pair i nformation” on page 4-1 to help identify

parts. After completing the repair, perform tests as needed to verify

the repair.

General information 1-1

Page 24

4048-1xx

Special tools

Long Phillips screwdr iver (appr oximately 6–inc h shank )

Slotted screwdriver

Small Phillips screwdriver

Spring hook

When taking voltage readings, always use the printer frame as

ground unless another ground is specified.

Printer identification

Serial number

Look for the serial number label on the inside front cover of the

printer.

1-2 Service Manual

Page 25

4048-1xx

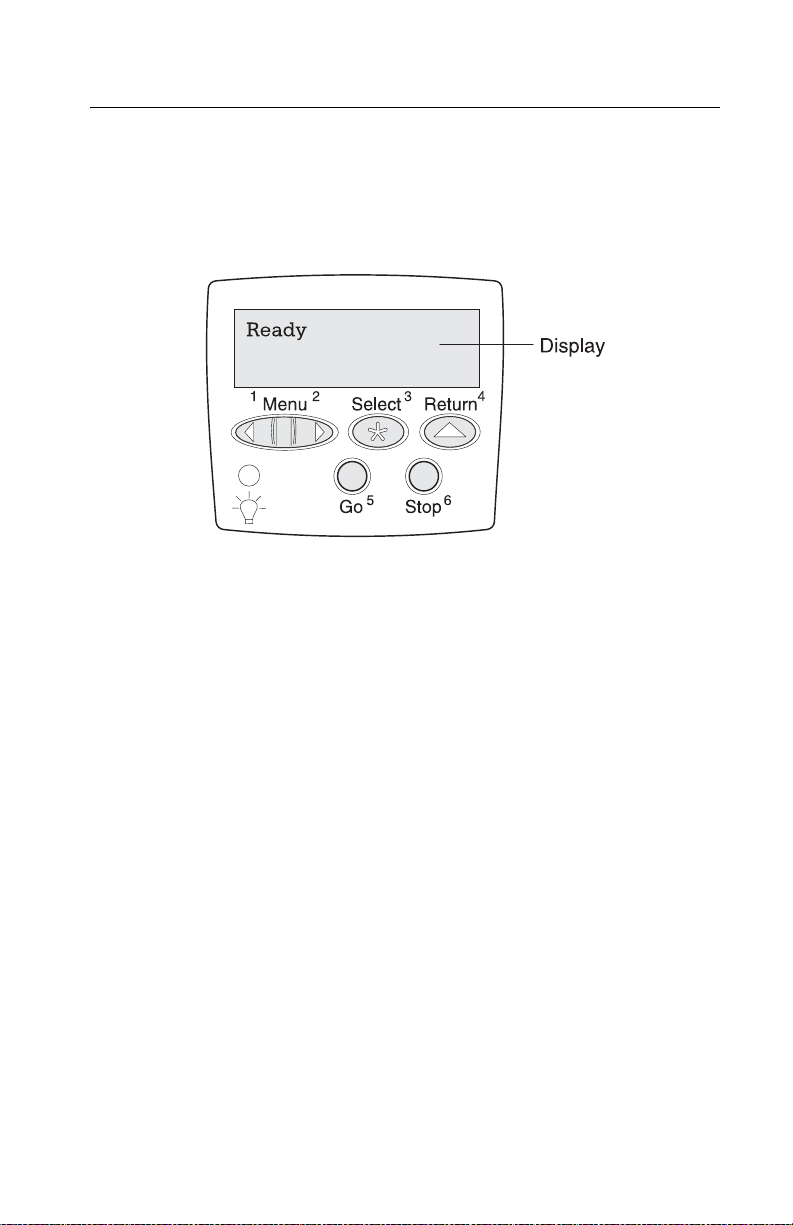

Printer features and specifications

Operator panel

The operator panel consists of a two-line display and six buttons

(Menu is two buttons).

General information 1-3

Page 26

4048-1xx

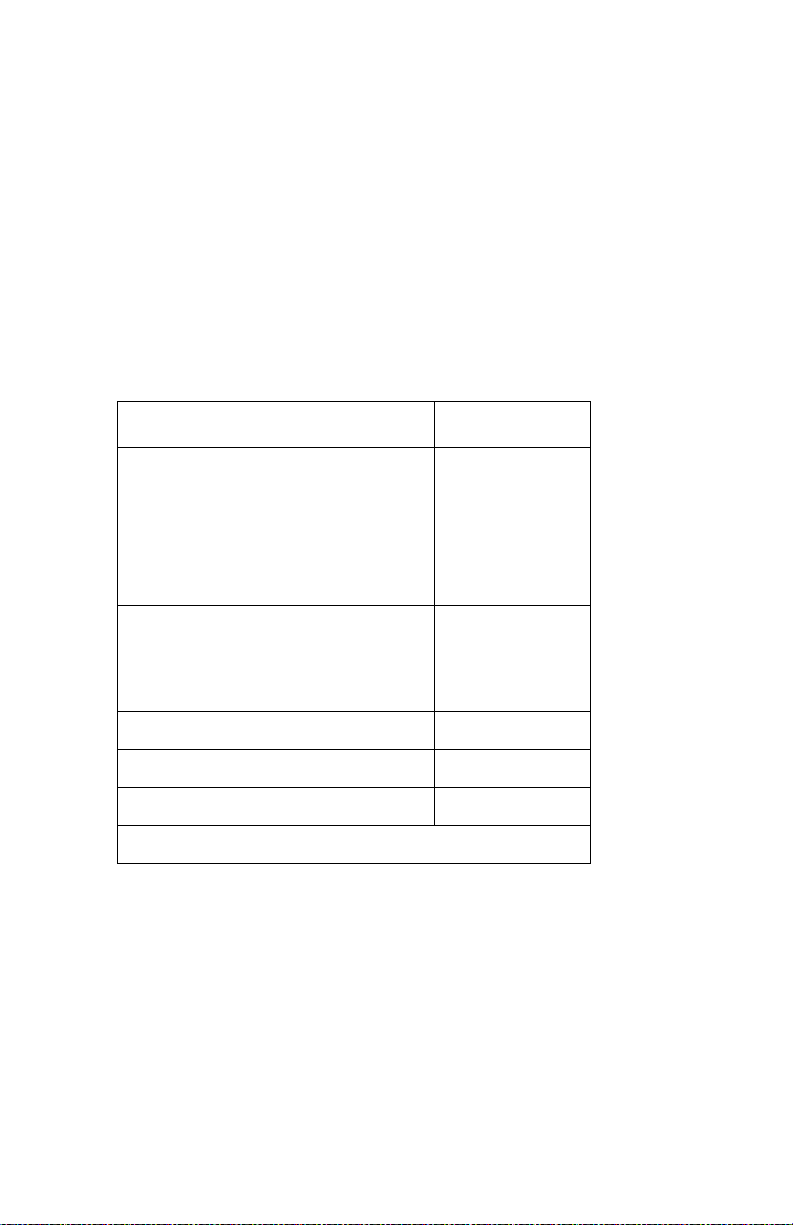

Resolution and print quality

• IET, PictureGrade™, print resolution, print darkness, and toner

saver can all be set independently of each other through the

data stream.

• Control panel menus let a user independently set PictureGrade

and print resolution.

• The IET setting is selected when a print resolution is selected

using the Quality Menu.

• Toner saver and print darkness settings are set when a toner

darkness is selected using the Quality Menu.

Print Quality setti ng All models

Print resoluti o n :

• 300 dpi

• 600 dpi

• 1200 Image Quality

• 2400 Image Quality

• 1200 dpi

Image Enhancement Technology

(IET):

• 2 bits/pel

• 4 bits/pel

✓

✓

✓

✓

✓

✓

✓

Toner sa ver ✓

Print darkness ✓

PictureGrade ✓

Indicates print quality setting is supported.

✓

1-4 Service Manual

Page 27

4048-1xx

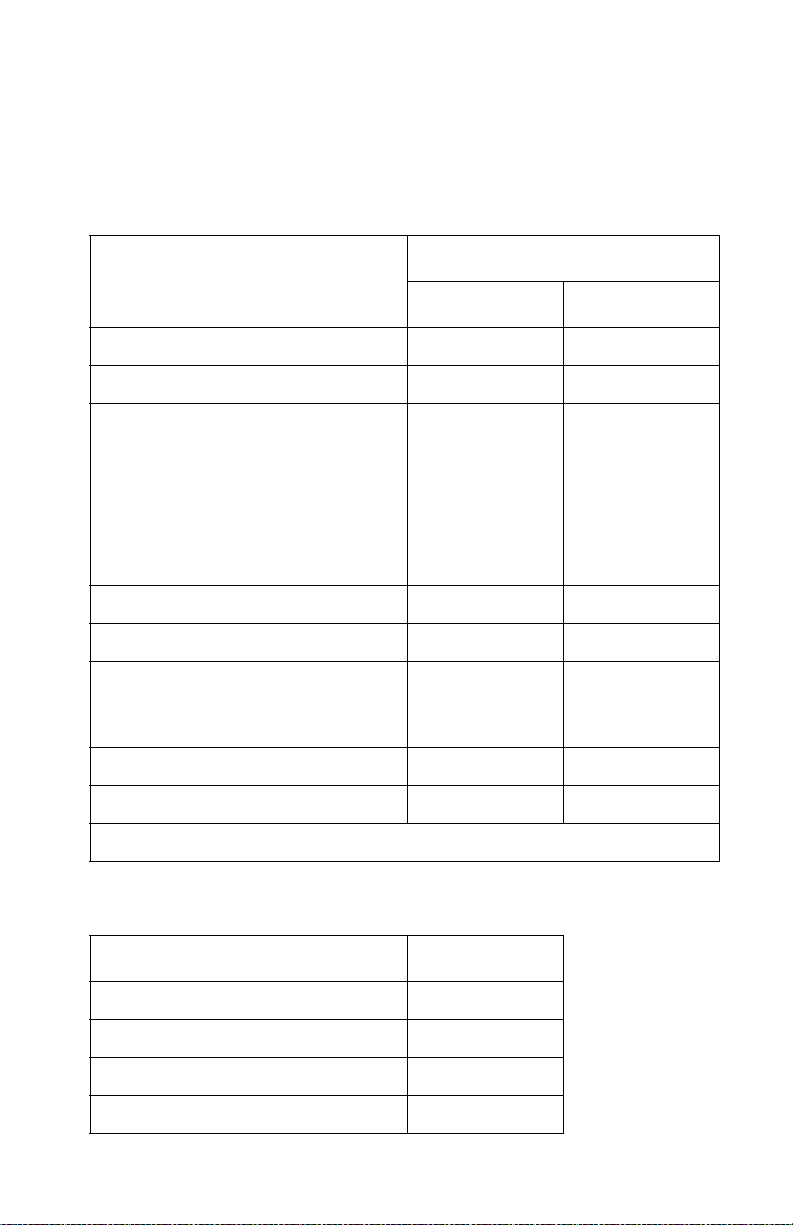

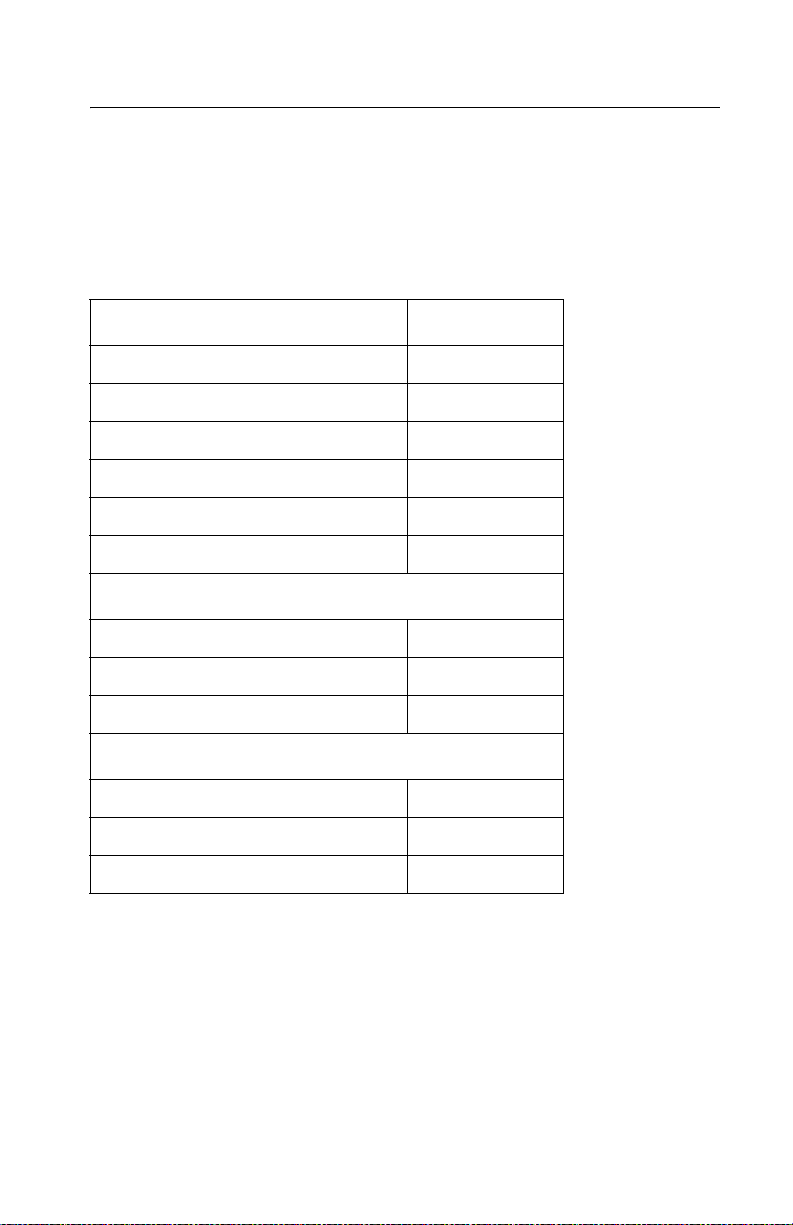

Memory and user flash memory

Each model has a standard amount of memory (RAM) soldered on the

controller card, and a certain number of 100-pin DIMM slots available for

installing addi tional memory or user flash memory options.

Models

Memory

Standard memory 32MB 64MB

Standard flash memory None None

Memory options

8MB DIMM

16MB DIMM

32MB DIMM

64MB DIMM

128MB DIMM

256MB DIMM

Maximum # of memory DIMM 1 1

Maximum possible memory 288MB 320MB

Flash memory options

16MB

32MB

Maximum # of flash memory options 1 1

Maximum possible flash memory 32MB 32MB

✓ Indicates opt ion is supported.

101 and 111 102

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

Printer data streams

Data streams All mode ls

PCL 6 emulation ✓

Post Scri pt 3 emulation ✓

PPDS ✓

PDF (version 1.3) ✓

General information 1-5

Page 28

4048-1xx

Print area

The following print area settings are available.

Print a re a o p tion All mode ls

Normal ✓

Fit to page ✗

Edge to edge ✓

Supplies

Print cartridge Average yield

Lexmark Return Progr am

print cartridges

Regular cartridges (without Lexmark

Return Program terms and

conditions)

6,000

12,000

6,000

12,000

Approximate

coverage

Fonts

Fonts/options All models

PCL bitmapped 2

PCL scalable 89

PostScript scalable 91

PPDS bitmapped 5

PPDS scalable 39

Note: Additional fonts can be downloaded to the printer RAM, or

optional user flash.

5%

5%

5%

5%

1-6 Service Manual

Page 29

4048-1xx

Media and pape r ha nd l in g

Media

The following table shows the supported media, media weights and

media textures which together provide optimal print quality across a

variety of media.

Media supported All models

Paper ✓

Card stock ✓

Transparency ✓

Labels ✓

Envelope ✓

Bond ✓

Media weights

Heavy ✓

Normal ✓

Light ✓

Media text ures

Rough ✓

Normal ✓

Smooth ✓

Note:

✓ Indicates media is suppor ted.

General information 1-7

Page 30

4048-1xx

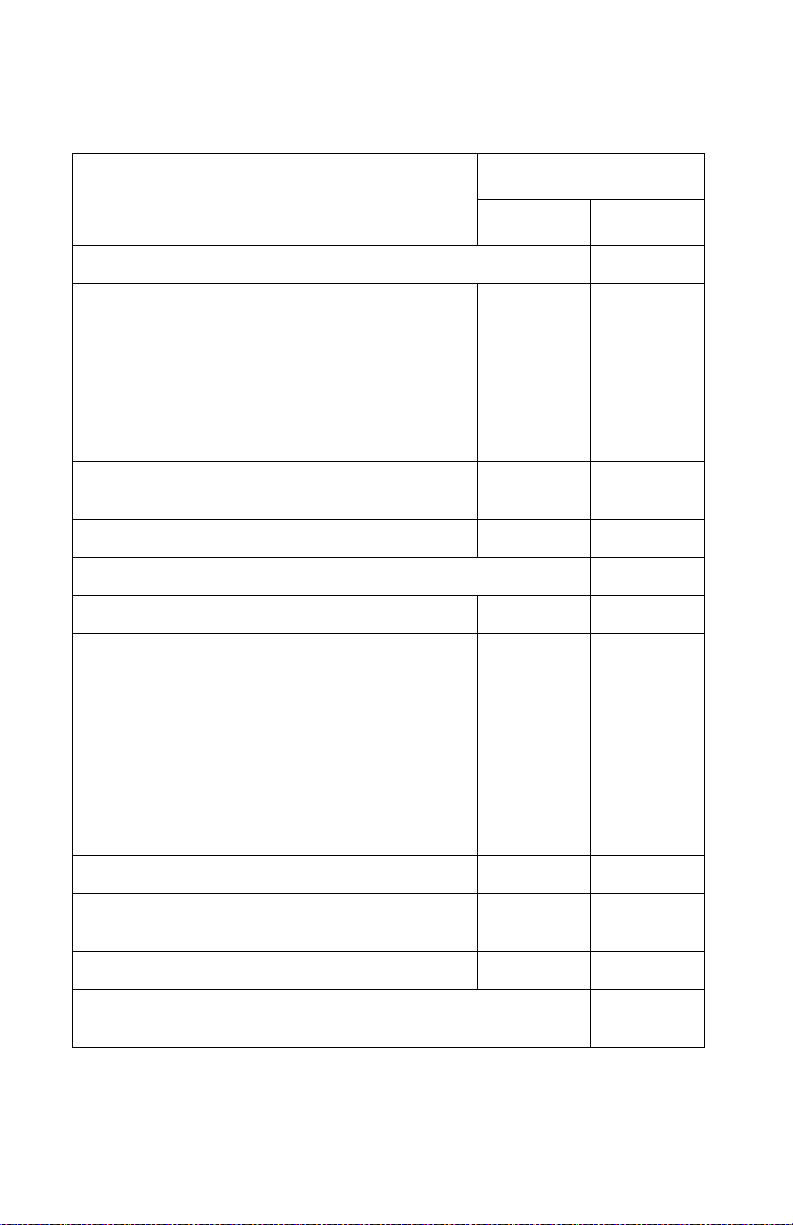

Standard and optional paper sources

Models

Media sources

Standard

Standard input sources: 2 2

• Integrated 250–sheet tray

The 250-sheet drawer supports the fo ll owing

sizes: A4, A5, JIS B5, folio, letter, legal,

ex ecutive, and statement.

• Multipurpose feeder 1 1

Standard output destination (150-s heet sensing

bin)

Duplex (standard in models 101 and 102, only) ✓✗

Options

Maximum # of optional drawers 2 2

Optional drawers:

Note: When two optional dra w ers are installed ,

the first must be a 250-sheet draw er.

• 250–sheet drawer ✓✓

• 500–sheet drawer

The 500 sheet drawer supports the following

sizes: A4, JIS B5, folio, letter , legal, and

executive.

101, 102 111

11

11

✓✓

Maximum number of media input sources 4 4

Maximum input sheet capacity (excluding

envelopes)

Maximum sheet capacity (excluding envelopes) 150 150

✓ Indicates associated capability is supported.

Assumes 20 lb xerographic pap er.

1000 1000

1-8 Service Manual

Page 31

4048-1xx

Input media sources

Supported input sizes

Letter ✓✓✓✓✓

11 x 17

Legal ✓✓✓✓✓

A4 ✓✓✓✓✓

A3

A5 ✓✓✓

Folio ✓✓✓✓✓

Statement ✓✓✓

JIS-B4

JIS-B5 ✓✓✓✓✓

Executive ✓✓✓✓✓

Universal ✓✓✓✓✓

*

Integrated

feeder

Multipurpose

250-sheet tray

Optional

Optional

250- sheet drawer

Duplex

500- sheet drawer

(models 101, 102 only)

7 3/4 envelope ✓

9 envelope ✓

10 envelope ✓

DL envelope ✓

C5 envelope ✓

B5 envelope ✓

Other envelope ✓

✓ Size supported without size sensing.

General information 1-9

Page 32

4048-1xx

Output media

Supported output sizes

Letter ✓✓

A4 ✓✓

Legal ✓ *

11 x 17

A3

Folio ✓✓

Statement ✓✓

A5 ✓✓

JIS-B4

JIS-B5 ✓✓

Executive ✓✓

Universal ✓ *

7 3/4 envelope ✓✓

9 enve lope ✓✓

150-sheet

standard bin

20-sheet

rear exit

10 envelope ✓✓

DL envelope ✓✓

C5 envelope ✓✓

B5 enve lope ✓✓

Other envelope ✓✓

* Size supported, but results may be unacceptable.

1-10 Service Manual

Page 33

4048-1xx

Acronyms

ASIC Application-Specific Integrated Circuit

C Charge Roll

CRC Cyclic Redundancy Check

DC Direct Current

DEV Developer Rol l

DIMM Dual In-line Memory Module

DRAM Dynamic Random Access Memory

ECC Error Checking and Correction

EPROM Erasabl e Programabl e Read-Only Memory

FRU Field Replaceable Unit

GND Ground

HVPS High Voltage Power Supply

IET Image Enhancement Technology

KB Kilobyte

LCD Liquid Crystal Display

LSU Laser Scanning Unit

LVPS Low Voltage Power Supply

MPF Multipurpose Feeder

NAND Not And (Gate)

NVRAM Nonvolatile Rando m Acce ss M em ory

PIN Personal Identification Number

PJL Printer Job Language

POR Power–On Reset

POST Power–On Self Test

PPDS Personal Printer Data Stream

RAM Random Access Memory

RIP Raster Image Processo r

SDRAM Synchronous Dynamic Random Access Memory

SRAM Sta ti c Random Access Memory

T Transfer (Roll )

TAR Toner Adde r Rol l

USB Universal Serial Bus

Vac Volts Alternating Current

General information 1-11

Page 34

4048-1xx

1-12 Service Manual

Page 35

4048-1xx

2. Diagnostic information

Start

CAUTION: Unplug power from the printer before

connecting or disconnecting any cable, assembly, or

electronic card. This is a precaution for personal safety

and to prevent damage to the printer.

This chapter contains the codes and diagnostic tools to aid in

providing corrective action for a malfunctioning printer. To determine

the corrective action to repair a printer, look for the following

information:

• Does the POR stop? Check the:

– “Power–On Reset (POR) sequence” on page 2-2

– “POST s ym ptom table” on page 2 -3.

• Do you have a symptom, rather than an error message? Check

the “Symptom tables” on page 2-3.

• If you have an error message or user message, check the

following:

– “Serv ice error codes ” on page 2-6

– “User attendance messages” on page 2-11.

• Additional information:

– “Service checks” on page 2-36

– “Solving print quality problems” on page 2-56.

Diagnostic information 2-1

Page 36

4048-1xx

Power–On Reset (POR) sequence

The following is an example of the events that occur during the POR

sequence when the printer is turned on.

1. Diamonds are displayed on the operator panel.

2. While code is being loaded into DRAM, dots scroll across the

operator panel.

3. A screen is displayed with the memory and processor speed. A

typical example of this message is:

*

32 Mb 366 Mhz

4. Performing Self Test is displayed.

5. Busy is displayed.

6. Close Door will be posted if the cover is open.

7. Any cartridge errors, such as Defective Cartridge are

posted.

8. Applicable maintenance messages are posted. For example, 80

Scheduled Maintenance.

9. Applicable toner low messages are posted.

10. T he pri nter displays Ready.

2-2 Service Manual

Page 37

4048-1xx

Symptom tables

POST symptom table

These symptoms may appear during the POST (Power-on Self

Test). See “Po wer–On Reset (POR) sequence” on page 2-2 for

the sequence when a printer is turned on.

Symptom Action

The main motor, cooling fan and

fuser do not come on.

POST complete s except displa y is

inco mplete or erratic.

POST complete e xcept display

does not function.

Main motor does not come on. See “M ai n moto r se rvice check”

Fan does not come on. See “Cooling fan service check”

Fuser heater does not com e on. See “ Cold fuser service ch eck” on

Fuser heater never turns off. See “Hot fuser service chec k” on

The paper feed picks and tries to

feed paper.

See “Cover inter lock switch

service check” on page 2-37.

See “Operator pane l service

check” on page 2-43.

See “Operator pane l service

check” on page 2-43.

on page 2-42.

on page 2-36.

page 2-41.

page 2-41.

See “Paper feed service checks”

on page 2-45.

Diagnostic information 2-3

Page 38

4048-1xx

Printer symptom table

Symptom Action

Dead machine (no power) See “Dead machine service

check” on page 2-39.

Fan noisy or not working See “Cooling fan service check”

Fuser parts melted See “Hot fuser service check” on

Fuser heater does not acti vate See “Cold fuser servic e check” on

Toner not fused to the paper See “Poor fusing of image” on

Blank page See “Blank page” on page 2-50.

Black page See “Black page” on page 2-51.

Heavy background See “Heavy background” on

Light print See “Light print” on page2-54.

White or blac k li nes or bands See “White or black lines or

Toner on back of page See “Toner on bac k of page” on

Paper jams See “Paper feed service checks”

Main motor noisy or does not

move

on page 2-36.

page 2-41.

page 2-41.

page 2-53.

page 2-52.

bands” on page 2-54.

page 2-55.

on page 2-45.

See “Main motor servi ce check”

on page 2-42.

Paper never picks See “Paper never picks” on

Paper feeds contin uously See “Paper picks during POST

Skewed paper See Note regarding align me nt on

page 2-48.

and/or continuous ly” on

page 2-46.

page 4-64 or “Pa per feed service

checks” on page 2-45.

2-4 Service Manual

Page 39

4048-1xx

Symptom Action

Printer not communicating with

host

Paper wrink led or bent See “Paper “trees,” wrinkles,

Top cover will not close See “Cover interlock switch

Operator panel button does not

respond

Operator pan el li ght does not light

or is very dim

See “Parallel port service chec k”

on page 2-49.

stacks poorly or curls” on

page 2-49.

service check” on page 2-37.

See “Operator pane l service

check” on page 2-43 or

“Controller card service check”

on page 2-38.

See “Controller card service

check” on page 2-38.

Diagnostic information 2-5

Page 40

4048-1xx

Messag es an d er ror code s

Service error codes

Service error codes are generally non-recoverabl e except in an

intermittent condition when you can POR the printer to temporarily

recover from the error condition.

Service error codes (9xx)

Error Description Action

900 RIP software Server firmware problem. Contact the

902 General engine

software failure

910 DC exit motor stall The load on the exit motor is too high or

911 DC exit motor

912 DC exit motor below

speed

913 DC exi t m otor over

speed

914 DC pick motor–no

encoder feedback

917 Transfer roll The most likely cause is a faulty HVPS. It

920 Fuser error Indicates that the fuser is below

next level of support.

An unrecoverable system software error.

Reset the printer (POR) . If the pr oblem

continues, replace the controller card.

there is a c abli ng prob l em. Fir st, c heck for

jams and then move the exit rol lers,

located between the rear door and fuser,

while observing the DC motor. If the

torque is too high, isolate the problem to

the redriv e and repair or replace as

necessary. If the torque seems normal,

check the cabling f or continuity and

replace the moto r with cabling.

Verify motor is plugged into controller

card correct ly. Also check load condition

(see service error 910, above).

may als o indi cate a problem in the

transfer roll area. Go to “Transfer roll

service check” on page 2-44.

temperature when printing. Go to “Fuser

service check” on page 2-40.

922 Fuser error Fuser fai led to reach standby

temperature. Verify line voltage to the

fuser. Go to “Fuser service check” on

page 2-40.

2-6 Service Manual

Page 41

4048-1xx

Service error codes (9xx) (continued)

Error Description Action

923 Fuser error Fuser is too hot during printing or when

924 Fuser error An open circuit has been detected in the

929 Toner sensor The toner sensor is not operating

931 Printhead—no first

hysnc

932 Printhead—lost hsyncs Replace the printhead.

934 Mirror motor lost lock Replace the printhead.

935 Mirror motor unable to

reach operati ng speed.

936 Transport motor initial

lock failure

937 Transport motor lost

lock

printer is idle. Go to “Fuser service

check” on page 2-40.

fuser thermistor circuit. Check cabling

and connectors. Go to “Fuser service

check” on page 2-40.

properly, the developer driv e assem bly is

not operating properly, or the print

cartridge is defective. Go to “Sensor

Tes t” on page 3-12.

Check for unplugged printhead, faulty

cabling, or faulty printhe ad.

Faulty printhead, cabl ing or connector.

Indicates a problem with the main drive

motor or a jam occurr ed during the motor

ramp-up to speed.

Faulty motor or a jam occurred after

motor ramp-up to speed. Possible

problem with the main drive.

939 RIP—engine

communications

The RIP processor cannot communicate

with the engine processor. Replace the

controller card. Go to “Controller card

assembly r em oval” on page 4-50. If the

problem persists, contact the next level of

support.

Diagnostic information 2-7

Page 42

4048-1xx

Service error codes (9xx) (continued)

Error Description Action

940 LV Po wer Supply The low voltage pow er supply zero

941 Controller card This error indicates an op en fuse in line to

950 Controller card There is a mismatch between the

crossover test failed.

Check the LVPS for correct installation.

Make sure the connector on the LVPS

assembl y is firmly seated with the

connector on the interconnect card

connector.

This error may also be caused by a noisy

AC input power source.

• Be sure the correct LVPS has been

installed.

• If all the above are correct, replace the

LVPS assembly.

tray 2. POR the pr i n te r to re se t the fuse.

Check for +24 V dc on J21, pin 6. If

correct, the fuse is okay. If incorrect,

remov e the drawer and check resistance

between pin 6 and 5 of the tray. If the

resistance is less than 50 ohms, re place

the drawer.

variables in the EPROM on the operator

panel card and those in the secure

NVRAM on the controller car d. This can

only occur aft er a replacement of one of

the two parts and the replaced part is

faulty. Replace the controller card or the

operator panel.

Warning: Always replace only one at a

time with a POR between.

951 Controller card The secure NVRAM was not detected on

952 NV failure:n Recoverable error. Reset (POR) the

953 NVRAM chip failure Indicates the NVRAM chip has failed.

954 NVRAM CRC failure Indicates the NVRAM experienced a CRC

the controller card. Replace the c ontroller

card.

printer.

Replace the controller card.

failure. Replace the controller card.

2-8 Service Manual

Page 43

4048-1xx

Service error codes (9xx) (continued)

Error Description Action

955 Code CRC <loc> Replace the controller card. Where

956 Controller card Error codes 956, 957, and 959 are

957 ASIC fai lure Error codes 956, 957, and 959 are

958 NAND fail ure Before proceeding, perform a power on

959 SRAM failure Error codes 956 , 957, and 959 are

960 RAM soldered on the

card is bad

<loc> = CRC Failure or ECC Failure on

the controller card.

controller card failures.

Perform a power on reset (POR). If th is

does not fix the problem, replace the

controller card.

controller card failures.

Perform a power on reset (POR). If th is

does not fix the problem, replace the

controller card.

reset (POR) to see if the ECC error

correction code can reflash NAND .

If this does not fix the problem, replace

the controller card.

controller card failures.

Perform a power on reset (POR). If th is

does not fix the problem, replace the

controller card.

Indicates a DRAM Memory Error on the

controller card. Replace the contro ll er

card.

961 RAM in slot 1 is bad If another SDRAM memory DIMM is

available, turn the power off and switch

the DIMM. If the memory card now works

correctly, replace the failing DIMM . I f thi s

does not fix the problem, replace the

controller card. If another DIMM is not

available, replace the memory option first

and then the controller card if necessary.

Diagnostic information 2-9

Page 44

4048-1xx

Service error codes (9xx) (continued)

Error Description Action

964 Download emulation

CRC failure. Chec ksum

failure detected in the

emulation header or

emulation file.

975 Unrecognizable

network port

976 Software error in

network port

978 Bad checksum while

programming network

port.

979 Flash parts failed while

programming network

port.

980 <dev ice> Co mm

The engine is

experienci ng unreliab le

communications to the

specified device.

Pe rform the following:

1. Disable the downloaded emulations.

See “Download Emuls” on

page 3-24.

2. Reprogram the downloaded

emulations.

If the prob lem persists, repl ace the

emulation card.

A failure with the network port.

If the printer is a network model, replace

the control ler card. See “Cont roller card

assembl y rem oval” on page 4-50.

Service errors 980 t hrough 9 84, <device>

can be one of the fo ll owing: Engine ,

Duplex, or Tray x (x=1, 2, or 3).

2-10 Service Manual

Page 45

4048-1xx

User attendance messages

User attendance messages

Message Explanation

Change Cartridge

Invalid Refill

Change <input source>

<custom type name>

Change <input source>

<custom string>

Change <input source>

<size>

Remove the print cartridge and install a new

cartridge.

This message displays when the user should

change the media installed in one of the input

options.

•<input source>=Tray 1 , Tray 2, Tray 3, or M P

feeder.

•<Custom Type name>=Custom 1 through

Custom 6 using the MarkVision™ utility.

When the printer is prompti ng for one of the

custom types which has been named by the

user , then only the custom type name i s

displayed on line 2. The name ma y be

truncat e d to fit the display.

This message displays when the user should

change the media installed in one of the input

options.

•<input source>=Tray 1, Tray 2,Tray 3 , o r M P

feeder.

•<custo m string>= a user definable name.

This message displays when the user should

change the media installed in one of the input

options:

•<input source>=Tray 1 , Tray 2, Tray 3, or M P

feeder.

•<size>=letter, l egal, B5, A4, Execut ive,

Universal , A5, Foli o, or Statement. F or

envelope s, <size>=7¾ En velope, 9 Envelope,

10 Envelope, DL Envelope, C5 Envelope,

B5 Envelope, or other Envelope.

Diagnostic information 2-11

Page 46

4048-1xx

User attendance messages (continued)

Message Explanation

Change <input source>

<type><size>

Check Tray x

Connection

This message displays when the user should

change the media insta ll ed in one of the input

options.

•<input source>=Tray 1, T ray2, Tray 3, or MP

feeder.

•<type>=Bond, Card st ock, Color ed, En velope ,

Labels, Lt rhead, Plain, Preprint, or

Transparency.

•<size>=letter, legal, B5, A4, Executive,

Universal, A5, Folio, or Statement. For

env elopes, <size>=7¾ Envelope , 9 Env elope ,

10 Envelope, DL Env e lope , C 5 Env e lope,

B5 Enve lope, or other Env elope.

Tray x=Tray 2 or Tray 3.

This messages dis plays for the following

conditions:

• The specified d e vice m a y ha v e been remo v ed

from the printer, possibly to cle ar a paper jam

or to uninstall the option.

• The option may be attached to t he printer, but

a communicat ions problem may prevent the

printer from detecting the option. For

exampl e, t here ma y be a po or connec tion o r a

hardware fa ilure.

The following actions may be taken:

• If the option was te mp orarily removed or not

connected properl y, reattach or reconnect it.

•Press Go to execute a conf iguration change

which notifies the printer the option has bee n

hot unplugged (rem oved with the power on).

Note: This acti on is no t av ail ab le i f the print er

is in Dia gnostics Mode or running diagnost ics.

• If the device is experiencing a hardware

problem, turn the printer off and on.

Close Door

2-12 Service Manual

Close the upper front door.

Page 47

4048-1xx

User attendance messages (continued)

Message Explanation

Delete All Jobs

Go/Stop?

Insert <tray>

When the user has selected the Print and

Hold Delete All Jobs selection, this

message is displ ay ed. The f ollo wing actions may

be taken:

• Press Go to confi rm the sele ction . All jobs ar e

deleted.

• Press Return or Stop to cancel the delete

operation.

Tray=Tray 1 or Tray 2.

The printer does not detect the presence or

absence of a tra y, but that paper was not pick ed .

Replace the tray and press Go.

Note: This situation usually occurs when the

tray i s refilled during a job. To refill a tray during

a printing session, press Stop and wa it for

pages to reach the output bin before refilling the

tray.

The foll owing actions ma y be taken:

• Insert the requested tray.

• Press Menu until Busy/Waiting displays.

The following selections are available:

–Cancel Job

–Reset Pri nter

If the message cannot be cleared, verify

whether the paper is being pi cked. I f so, and the

paper advanc es t o activate the input se nsor, this

message would indicate a sensor problem.

Otherwise, check the pick tires and pick

mechanism.

Diagnostic information 2-13

Page 48

4048-1xx

User attendance messages (continued)

Message Explanation

Install Tray x

or Cancel Job

Load <input source>

<custom type name>

Tray x=Tray 2 or Tray 3.

This message is displayed when a paper

handling option has been hot unplugged. The

printer requires the reinstallation of the option to

print a page which has been formatted by the

interpreter before the option was removed.

The following actions may be taken:

• Install the option.

•Press Menu until Busy/Waiting displays.

Select one of the following:

–Cancel Job

–Reset Printer

If the message cannot be cl eared, check

connections and then POR the printer with the

option attache d . If the message persists, check

the cables, starting at the controller card.

Input source=Tray 1, Tray 2, Tray 3, or MP

Feeder. Custo m type name is a user defined

media type.

The following actions may be taken:

• Load media in the indica ted source.

•Press Menu until Busy/Waiting displays.

Select one of the following:

–Cancel Job

–Reset Printer

If the message cannot be cl eared, go to “Input

tray(s) service check” on page 2-64.

Load <input source>

<size>

2-14 Service Manual

Input source=Tray 1, Tray 2, Tray 3, or MP

Feeder. Size=Letter, Legal, B5, A4, A5, Exec,

Univ., Folio, or Stmt.

The following actions may be taken:

• Load media in the indica ted source.

•Press Menu until Busy/Waiting displays.

Select one of the following:

–Cancel Job

–Reset Printer

If the message cannot be cl eared, go to “Input

tray(s) service check” on page 2-64.

Page 49

4048-1xx

User attendance messages (continued)

Message Explanation

Load <input source>

<type><size>

No Jobs Found

Retry?

Res Reduced

<warning>

Input source=Tray 1, Tray 2, Tray 3, or MP

Feeder. Type=Bond, Cardstock, Colored,

Enve lope, Labels, Ltrhead, Plain, Preprint,

Trnsprncy. Size=letter, legal, B5, A4, A5, Exec,

Univ., Folio, or Stmt.

The foll owing actions ma y be taken:

• Load media in the indicated source.

• Press Menu until Busy/Waiting displays.

Select one of the fol lowing:

–Cancel Job

–Reset Pri nter

If the message cannot be cleared, go to “Input

tray(s) service check” on page 2-64.

When a PIN (personal identi fication number) is

added to a Confidential Prin t job and there are

no jobs associat ed wit h the PIN number .

The foll owing actions ma y be taken:

• Press Go to enter another PIN.

• Press Return or Stop to exit the PIN entry

operation.

This message displays only when the

Resolution Reduc ti on setting is enabl ed. The

following actions may be taken:

• Press Stop to take the printer offline. No more

data is processed, but the printer processes

all the paper currently in the paper path.

• Press Menu to access the Busy/Waiting

menu group. Select one of the following:

–Cancel Job

–Reset Printer.

31 Missing or

Defective Cart.

The cartridge may be mi ssing and the front door

closed. Return the cartridge. Or, the cartridge

may be defective. Replace the cartridge.

Diagnostic information 2-15

Page 50

4048-1xx

User attendance messages (continued)

Message Explanation

32 Unsupported

Print Cartridge

34 Short Paper

35 Res Save Off

Deficient Memory

Error 32 displays when the top cover is closed

and an unsupported print cartridge is detected.

It may take the printer 10-20 seconds to

determine if the print cartridge is supported.

Depending on the setting of the Machine Class

ID , the printer may be allowed t o print pages

during this 10-20 second interval. If pages are

allowed t o print, t hen the y are not rep rinted once

a good print cartridge is inserted. Replace the

cartridge.

The printer determines the paper length is too

short to print the formatted data. This occurs

when the printer does not kno w t he actual paper

size loade d in t he tray. Make sure the Paper Siz e

setting is correct for the size paper that is being

used.

The following actions may be taken:

•Press Go to clear the message and continue

printing.

•Press Menu until Busy/Waiting displays.

Select one of the following:

–Cancel Job

–Reset Printer

The printer lacks sufficient memory to enable

Resource Save. The following actions may be

taken:

•Press Go to clear the message. The printer

disables Res ource Save.

• Install additional memory.

• Set link buffers to Auto, return to Ready and

enable Resource Save and res et the link

buffers.

2-16 Service Manual

Page 51

4048-1xx

User attendance messages (continued)

Message Explanation

37 Insufficient

Collation Area

37 Insufficient

Defrag Memory

This message displ ays when th e printer memory

is insufficient to perform the Flash Memory

Defragment operation.

Note: This message is posted prior to the

actual start of the defragment operation. The

printer code determines i f enough printer

memory is available to complete the defragment

operation. The user should not be concerned

with losing resources stored in the flash option.

The foll owing actions ma y be taken:

• Press Go to clear the message.

• Press Menu until Busy/Waiting appears.

The following actions are available:

–Cancel Job

–Reset Pri nter

This message displ ays when th e printer memory

is fragmente d. Defragmentation i s required and

additional me mory is required to complete the

task.

• Press Go to clear the message.

Defragmentation will not contin ue and no

changes are made to memory and no

resources are los t.

• Press Menu until Busy/Waiting appears.

The following functions may be available:

–Cancel Job

–Reset Pri nter

The user may clear memory for a

defragmentation by:

• Deleting fonts, macr os, and other data in

RAM.

• Installing additional memory.

Diagnostic information 2-17

Page 52

4048-1xx

User attendance messages (continued)

Message Explanation

37 Insufficient

Memory

Held Jobs may be

lost

38 Memory Full

This message displays when there is not

enough memory available to continue

processing a job and Print and Hold f eature is in

use. The printer frees memory by deleting the

oldest Reserve Print and Verify Print jobs. It

deletes only the amoun t needed to continue the

incoming job. Some or all of the jobs may not be

restored. If, while printing the curr ent job, it runs

out of memory again, another message is not

posted.

•Press Go to clear the message. Some of the

Print and Hold jobs on the disk will not be

restored. They remain on the disk, but cannot

be acc e ssed.

•Press Menu until Busy/Waiting appears.

The function, Reset Printer, may be

available.

This message displays when the printer is

processing an inco ming job and there is

insufficient memory a vailable to continue

processing t he job. The f ollo win g ac tions ma y be

taken:

•Press Go to clear the message. P e rfo rm the

defragment operation:

–S implify the pr in t jo b.

–Delete fonts, macr os, and other data in

RAM

–Install additional memory

•Press Menu to display Busy/Waiting. The

foll owing functions m ay be available:

–Cancel Job

–Reset Printer

39 Complex Page

2-18 Service Manual

This message displays when the page is too

complex to print . The followi ng actions may be

taken:

•Press Go to clear the message and continue

the job. Some dat a lo s s may occ ur. Simp lify

the print job and reprint, if necessary.

•Press Menu until Busy/Waiting appears.

The following selections are possible:

–Cancel Job

–Reset Printer

Page 53

4048-1xx

User attendance messages (continued)

Message Explanation

40 Unsupported

Firmware Card

41 Unsupported

Firmware Card

50 PPDS

Font Error

51 Defective

Flash

A firmware card containing network code is

installed on a non-network printer or a nonnetwork card is installed on a network printer.

Press and hold Go while powering the printer.

The unsupported card will be ignored. Remove

the card.

A firmware car d containing u nsupported code is

detected. Press and hol d Go while powering the

printer . The unsupported card will be ignor ed.

Remove the card.

This message displ ays when the PPDS

interpreter has encount ered a font error.

Note: This error may only occur when the

printer is fo rmatting PPDS prin t dat a.

The foll owing actions ma y be taken:

• Press Go to clear the message and continue

processing the job.

• Press Menu until Busy/Waiting appears.

The follo w ing are available:

–Cancel Job

–Reset Pri nter

This message displays when the printe r detects

a defecti ve flash. This err or may occur at power

on, or during flash format and write operations.

Press Go to clear the message. The flash is

marked as ba d and normal operation continues .

Flash operations are not allowed until the

problem is resolved.

52 Flash Full

This message displays when there is not

enough free space in t he fl ash memory to hold

the resources t hat have been requested to be

written to flash.

The foll owing actions ma y be taken:

• Press Go to clear the message and continue

processing the job.

• Press Menu until Busy/Waiting appears.

The follo w ing are available:

–Cancel Job

–Reset Pri nter

Diagnostic information 2-19

Page 54

4048-1xx

User attendance messages (continued)

Message Explanation

53 Unformatted

Flash

54 Std Network

Software Error

55 Unsupported

Flash in Slot x

56 Std Parallel

Port Disabled

This message displays when the printer detects

an unformatted flash at power on. Press Go to

clear the message. The flash is marked as bad

and normal operation con ti nues. Flash

operations are not allowed until the flash is

formatted.

This error displays when a network port is

detected, but the printer cannot establish

communications with it.

Press Go to clear the message . The printer

disables al l comm unications to the network

interface.

An unsupported flash option is inst alled in the

solutions port. Turn off the printer and remove

the unsupported flash option in the specified

slot.

This error is displayed when data is sent to the

printer across the parallel port, but the parallel

port has been disabled. Once this message is

displayed, reporting of further errors is

suppressed until the menus are entered, or th e

printer is reset. The following actions may be

taken:

•Press Go to clear the message. The printer

discards any data received on the parallel