Page 1

Lexmark Optra™ Series

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4049-XXX

• Index

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

4049-XXX

Third Edition (November, 1996)

The following paragraph does not apply to the United Kingdom or any country

where such provisions are inconsistent with local law: LEXMARK

INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THEIMPLIEDWARRANTIESOF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer of express or implied warranties in certain transactions, therefore,

this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will be

incorporated in later editions of the publication. Improvementsor changes in the

products or the programs described in this publication may be made at any

time. Publications are not stocked at the address given below; requests for

publications should be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., D22A/035-3, 740

New Circle Road NW, Lexington, Kentucky 40550, U.S.A. Lexmark may use or

distribute any of the information you supply in any way it believes appropriate

without incurring any obligation to you.

Lexmark is a trademark of Lexmark International, Inc., registered in the United

States and/or other countries.

©Copyright Lexmark International, Inc. 1995, 1996

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS.

Use, duplication or disclosure by the Government is subject to restrictions as

set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS252.227-7013 and in applicable FAR provisions:

Lexmark International, Inc., Lexington, KY 40550.

Page 3

4049-XXX

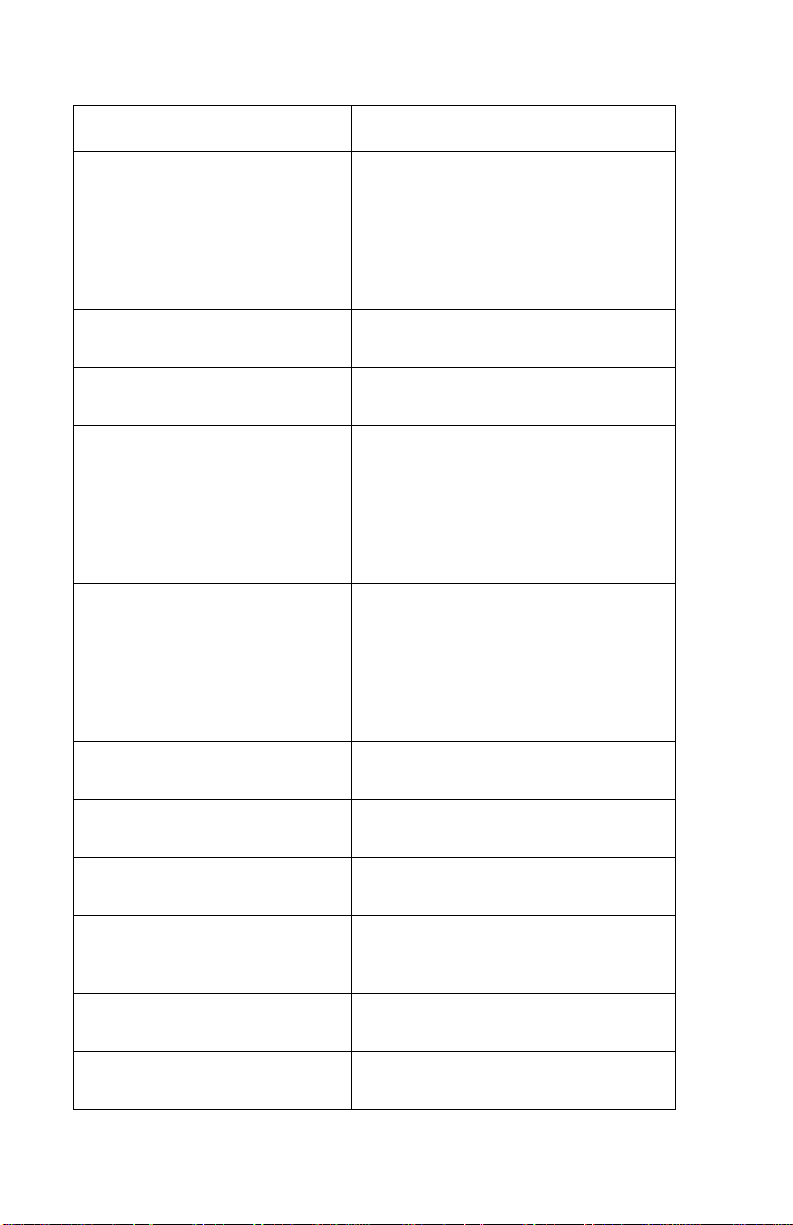

Table of Contents

NoticesandSafetyInformation...........................ix

LaserNotice....................................... ix

Laser..............................................x

Avisrelatifàl’utilisationdelaser.........................x

Avvertenzesuiprodottilaser .......................... xi

Avisossobreelláser................................. xi

DeclaraçãosobreLaser.............................. xii

Laserinformatie..................................... xii

Lasermeddelelse ...................................xiii

Huomautuslaserlaitteesta............................xiii

Laser-notis....................................... xiv

Laser-melding..................................... xiv

AvíssobreelLàser.................................. xv

Japanese Laser Notice...............................xv

ChineseLaserNotice............................... xvi

KoreanLaserNotice................................ xvi

Trademarks....................................... xvii

SafetyInformation..................................xviii

Preface ............................................xxiii

GeneralInformation...................................1-1

PowerConsumption................................ 1-2

Options.......................................... 1-2

Maintenance Approach.............................. 1-3

Tools Required For Service .......................... 1-3

Abbreviations..................................... 1-4

iii

Page 4

4049-XXX

DiagnosticInformation ................................2-1

Start............................................ 2-1

Power-OnSelfTest(POST) ........................ 2-10

SymptomTable.................................. 2-11

Banding ..................................... 2-12

Background.................................. 2-12

BlackPage .................................. 2-13

BlankPage.................................. 2-14

BlurredorFuzzyPrint.......................... 2-15

DeadMachine................................ 2-15

Duplex...................................... 2-16

Fan(927Error)............................... 2-18

Fuser Theory . ................................ 2-19

Fuser: 920, 921, or 922 Error .................... 2-19

Fuser:923or924Error......................... 2-20

Honeycomb.................................. 2-20

HorizontalVoidorStreak........................ 2-20

LANProblems................................ 2-21

LightPrint ................................... 2-21

NetworkCard977Errors........................ 2-21

NetworkWrapTests........................... 2-22

OutputBinSensor............................. 2-22

Operator Panel Problem . ....................... 2-22

Paper Feed Problem, 500-Sheet Option or 200-Sheet Second

Drawer,Non-Rt............................... 2-23

Paper Feed, Base Printer ....................... 2-23

Paper Feed, Duplex Unit . ....................... 2-25

Paper Feed Problem, Envelope+ Feeder/

100-Sheet Auxiliary Feeder...................... 2-26

Paper Feed Problem, 200-Sheet Second Drawer, Rt . . 2-26

Paper Feed Problem, Dual Rear Feeder............ 2-27

MachineLevelInformation: ...................2-27

Paper Feed Problem, High Capacity Feeder......... 2-29

Printhead.................................... 2-30

Paper Size Sensing Problem..................... 2-31

RegularlySpacedMarks........................ 2-32

ResidualImage............................... 2-32

Random Marks ............................... 2-32

Skew, all edges ............................... 2-33

Skew,topandbottomonly...................... 2-33

Stalled (diamonds on display) .................... 2-34

VerticalVoidorStreak.......................... 2-34

iv Service Manual

Page 5

4049-XXX

DiagnosticAids ......................................3-1

Diagnostics Mode .................................. 3-1

Diagnostics Mode Menu Structure . ................. 3-1

Diagnostics Mode Tests . . . .......................... 3-3

AutoClean.................................... 3-3

Auto Clean Frequency . .......................... 3-3

AutoCleanDelay............................... 3-4

ButtonTest.................................... 3-4

ChargeRoll ................................... 3-4

Defaults...................................... 3-5

DiskTest/Clean................................ 3-5

DuplexFeed1Test............................. 3-6

DuplexFeed2Test............................. 3-6

Envelope Enhance .............................. 3-7

EnvelopePrintTest............................. 3-7

ErrorLog ..................................... 3-8

FlashTest..................................... 3-8

FuserTemperatureAndWarm-UpTime............. 3-8

FuserTemperature...........................3-9

FuserWarm-UpTime.........................3-9

LCDTest..................................... 3-9

Maintenance Kit Count. ......................... 3-10

MemoryTests................................. 3-10

PageCount .................................. 3-10

Paper Feed Tests.............................. 3-10

Parallel Confidence . . . ......................... 3-11

Permanent Page Count ......................... 3-11

PrintContrast................................. 3-11

PrintRegistration.............................. 3-12

PrintTest1................................... 3-13

PrintTest2................................... 3-13

PrintTest3................................... 3-14

QuickDiskTest............................... 3-14

QuickTest................................... 3-14

SensorTest.................................. 3-15

TopMarginandDuplexQuickTests............... 3-15

Transfer..................................... 3-16

WrapTests................................... 3-16

v

Page 6

4049-XXX

OtherTests..................................... 3-17

DevelopedImageTest ......................... 3-17

LANInformation............................... 3-17

PrintTestPage............................... 3-18

PrintTestwithRIPBoardRemoved............... 3-18

RepairInformation....................................4-1

Handling ESD-Sensitive Parts ........................ 4-1

Adjustments...................................... 4-2

Envelope Restraint Spring On

The Envelope+ Feeder Adjustment. . ............... 4-2

Paper Restraint Spring On T he 100-Sheet

Auxiliary Feeder Adjustment ...................... 4-2

Envelope+ Feeder Magnet And

100-Sheet Auxiliary Feeder Magnet Adjustment. ...... 4-3

Dual Rear Feeder Gear Alignment Adjustment. . ...... 4-4

FuserDriveGearBacklashAdjustment ............. 4-5

Fuser Solenoid Adjustment ....................... 4-7

Paper Feed Magnet Adjustment ................... 4-8

Printhead Skew Adjustment ...................... 4-9

RemovalProcedures.............................. 4-10

Covers...................................... 4-10

RightCoverRemoval .......................... 4-10

FrontCoverRemoval .......................... 4-10

LeftCoverRemoval............................ 4-12

TopCoverRemoval............................ 4-12

14 in. 200-Sheet Paper Tray Top Cover ............ 4-14

14 in. 500-Sheet Paper Tray Top Cover ............ 4-14

D-rollAssemblyRemoval....................... 4-14

DriveMotorRemoval........................... 4-14

EngineBoardRemoval......................... 4-15

ExitSensorBoardRemoval ..................... 4-16

Fan/RedriveRemoval.......................... 4-17

FuserRemoval............................... 4-18

FuserInputGuideRemoval...................... 4-19

FuserLampRemoval.......................... 4-20

Fuser/SensorCableRemoval.................... 4-21

Fuser Solenoid Removal. ....................... 4-22

FuserShroudAssemblyRemoval................. 4-23

HVPSRemoval............................... 4-24

INAorHardDiskRemoval ...................... 4-26

Input Sensor Board Removal .................... 4-26

LowerFrameAssemblyRemoval................. 4-28

vi Service Manual

Page 7

4049-XXX

Removal Procedures (continued)

LVPSRemoval................................ 4-29

LVPSCoverRemoval .......................... 4-30

Operator Panel Removal ........................ 4-31

Paper Feed Rollers Removal ..................... 4-31

Paper Feed Magnet Assembly Removal ............ 4-32

Paper Size Switch Removal...................... 4-33

Printhead Removal............................. 4-34

RIPBoardandInnerEMCShieldRemoval.......... 4-35

TonerSensorRemoval ......................... 4-35

Torquer Motor Removal ......................... 4-35

TransferRollRemoval.......................... 4-36

TransferRollHousingRemoval................... 4-37

Upper Frame Removal. ......................... 4-38

Duplex Option Top Cover And Table Cover Removal . . 4-39

DuplexOptionExitCardAndCoverRemoval........ 4-40

Duplex Option Bottom Cover

AndEntrySensorCardRemoval.................. 4-41

DuplexOptionSystemCardAndMotorRemoval..... 4-42

Dual Rear Feeder - Edge Guide Asm. .............. 4-43

Dual Rear Feeder - Gear Plate Asm. ............... 4-43

Dual Rear Feeder - Right Cover. . . ................ 4-43

200-Sheet Second Drawer, Rt .................... 4-44

High Capacity Feeder Paper Feed Rollers........... 4-45

High Capacity Feeder Cover ..................... 4-47

ConnectorLocations ..................................5-1

MajorAssemblyLocations........................... 5-1

GearTrain.................................... 5-2

HVPS........................................ 5-3

TransferRollerHousing.......................... 5-3

Engine Board Connectors ........................ 5-4

RIPBoard..................................... 5-6

BoardInstallationHardware....................... 5-7

MirrorMotor/FanCable.......................... 5-7

Operator Panel/Output Bin Sensor Cable ............ 5-8

Printhead Connector Locations . . . ................ 5-10

Duplex Autoconnect Cable....................... 5-10

Printer Ground Straps . ......................... 5-11

High Capacity Feeder Board Connectors............ 5-12

vii

Page 8

4049-XXX

Preventive Maintenance ...............................6-1

SafetyInspectionGuide............................. 6-1

LubricationSpecifications........................... 6-1

Scheduled Mechanical Maintenance................... 6-3

Printhead Window Cleaning Procedure. . ............... 6-4

CleaningTheTransferRoller......................... 6-4

PartsCatalog ........................................7-1

HowToUseThisPartsCatalog................... 7-1

Covers........................................7-2

LowerFrame...................................7-4

UpperFrame...................................7-6

Printhead......................................7-8

Paper Feed . . .................................7-10

Paper Feed Alignment Gears .....................7-14

Paper Feed Drive ..............................7-16

Standard Paper Tray (200-Sheet) . . . ...............7-18

Paper Tray (500-Sheet). . ........................7-20

Base for Paper Drawer (500-Sheet) . ...............7-22

Second Paper Drawer, (200-Sheet) . ...............7-24

Optional Paper Drawer (500-Sheet) . ...............7-26

Fuser........................................7-28

Electronics....................................7-32

TransferRoll..................................7-36

DuplexOption.................................7-38

Envelope+ and 100-Sheet Auxiliary Feeder ..........7-40

Dual Rear Feeder ..............................7-42

High Capacity Feeder . . . ........................7-44

Options ......................................7-46

Miscellaneous .................................7-47

Index ...............................................X1

viii Service Manual

Page 9

4049-XXX

Notices and Safety Information

References in this publication to products, programs, or services do

not imply that the manufacturerintends to make these availablein all

countries in which it operates. Any reference to a product, program,

or service is not intended to state or imply that only that product, program, or service may be used. Any functionally equivalent product,

program, or service that does not infringe any existing intellectual

property rights may be used instead. Evaluation and verification of

operation in conjunction with other products, programs, or services,

except those expressly designated by the manufacturer, are the

user’s responsibility.

Laser Notice

The printer is certified in the U.S. to conform to the requirements of

DHHS 21 CFR Subchapter J for Class I (1) laser products, and elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 825.

Class I laser products are not considered to be hazardous. The

printer contains internally a Class IIIb (3b) laser that is nominally a 5

milliwatt gallium arsenide laser operating in the wavelengthregion of

770-795 nanometers. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed

service c ondition.

Notices and Safety Information ix

Page 10

4049-XXX

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die

Anforderungen der Bestimmung DHHS (Depar tment of Health and

Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1).

In anderen Ländern gilt der Drucker als Laserprodukt der Klasse I,

der die Anforderungen der IEC (International Electrotechnical

Commission) 825 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des

Druckers befindet sich ein Laser der Klasse IIIb (3b), bei dem es

sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen

der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbetrieb, bei der Wartung

durch den Benutzer oder bei ordnungsgemäßer Wartung durch den

KundendienstLaserbestrahlung, die die Klasse I übersteigen würde,

Menschen keinesfalls erreicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est certifiée conforme aux

provisions DHHS 21 CFR alinéa J concernant les produits laser de

Classe I (1). Pour les autres pays : cette imprimante répond aux

normes IEC 825 relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comme des produits

non dangereux. Cette imprimante est équipée d’un laser de Classe

IIIb (3b) (arséniure de gallium d’une puissance nominale de 5

milliwatts) émettant sur des longueurs d’onde comprises entre 770

et 795 nanomètres. L’imprimante et son système laser sont conçus

pour impossible, dans des conditions normales d’utilisation,

d’entretien par l’utilisateur ou de révision, l’exposition à des

rayonnements laser supérieurs à des rayonnements de Classe I .

x Service Manual

Page 11

4049-XXX

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme

ai requisiti del DHHS 21 CFR Sottocapitolo J per i prodotti laser di

classe 1 ed è certificata negli altri Paesi come prodotto laser di

classe 1 conforme ai requisiti della nor m a CEI 825.

I prodotti laser di classe non sono considerati pericolosi. La

stampante contiene al suo interno un laser di classe IIIb (3b)

all’arseniuro di gallio della potenza di 5mW che opera sulla

lunghezza d’onda compresa tra 770 e 795 nanometri. Il sistema

laser e la stampante sono stati progettati in modo tale che le

persone a contatto con la stampante, durante il normale

funzionamento, le operazioni di servizio o quelle di assistenza

tecnica, non ricevano radiazioni laser superiori al livello della classe

1..

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los

requisitos para los productos láser de Clase I (1) establecidos en el

subcapítulo J de la norma CFR 21 del DHHS (Departamento de

Sanidad y Servicios) y, en los demás países, reúne todas las

condiciones expuestasen la norma IEC 825 para productos láser de

Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La

impresora contiene en su interior un láser de Clase IIIb (3b) de

arseniuro de galio de funcionamiento nominal a 5 milivatios en una

longitud de onda de 770 a 795 nanómetros. El sistema láser y la

impresora están diseñados de forma que ninguna persona pueda

verse afectadapor ningún tipo de radiación láser super ior al nivelde

la Clase I durante su uso normal, el mantenimiento realizado por el

usuario o cualquier otra situación de servicio técnico.

Notices and Safety Information xi

Page 12

4049-XXX

Declaração sobre Laser

A impressora está certificada nos E.U.A. em conformidade com os

requisitos da regulamentação DHHS 21 CFR Subcapítulo J para a

Classe I (1) de produtos laser. Em outros locais, está certificada

como um produto laser da Classe I, em conformidade com os

requisitos da norma IEC 825.

Os produtos laser da Classe I não são considerados perigosos.

Internamente, a impressora contém um produto laser da Classe IIIb

(3b), designado laser de arseneto de potássio, de 5 milliwatts

,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de

forma a nunca existir qualquer possiblidade de acesso humano a

radiação laser superior a um nível de Classe I durante a operação

normal, a manutenção feita pelo utilizador ou condições de

assistência prescritas.

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een

laserprodukt van klasse I. Voor de Verenigde Staten zijn deze eisen

vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in

IEC 825.

Laserprodukten van klasse I worden niet als ongevaarlijk

aangemerkt. De printer is voorzien van een laser van klasse IIIb

(3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt met

een golflengte van 770-795 nanometer. Het lasergedeelte en de

printer zijn zo ontworpen dat bij normaal gebruik, bij onderhoud of

reparatie conform de voorschriften, nooit blootstelling mogelijk is

aan laserstraling boven een niveau zoals voorgeschreven is voor

klasse 1.

xii Service Manual

Page 13

4049-XXX

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i

overenstemmelse med kravene i IEC 825.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren

indeholder internt en Klasse IIIB (3b)-laser, der nominelt er en 5

milliwatt galliumarsenid laser, som arbejderpå bølgelængdeområdet

770-795 nanometer. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over

Klasse I-niveau ved normal dr ift, brugervedligeholdelse eller

obligatoriske servicebetingelser.

Huomautus laserlaitteesta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) laserlaitteiden DHHS

21 CFR Subchapter J -määrityksen mukainen ja muualla luokan I

laserlaitteiden IEC 825 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle.

Kirjoittimessa on sisäinen luokan IIIb (3b) 5 milliwatin

galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä.

Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei

altistu luokan I määrityksiä voimakkaammalle säteilylle kirjoittimen

normaalin toiminnan, käyttäjän tekemien huoltotoimien tai muiden

huoltotoimien yhteydessä.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina

näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Notices and Safety Information xiii

Page 14

4049-XXX

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21

CFR, underparagraf J för laserprodukter av Klass I (1). I andra

länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt

kraven i IEC 825.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en

inbyggd laser av Klass IIIb (3b) som består av en laserenhet av

gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770795 nanometer.Lasersystemet och skrivaren är utformade så att det

aldrig finns risk för att någon person utsätts för laserstrålning över

Klass I-nivå vid normal användning, underhåll som utförs av

användaren eller annan föreskriven serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR,

underkapittel J, for klasse I (1) laserprodukter, og er i andre land

godkjent som et Klasse I-laserprodukt i samsvar med kravene i IEC

825.

Klasse I-laserprodukter er ikke å betrakte som farlige. Skriveren

inneholder internt en klasse IIIb (3b)-laser, som består av en

gallium-arsenlaserenhet som avgir stråling i bølgelengdeområdet

770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk, vedlikehold som utføres av brukeren, eller foreskrevne

serviceoperasjoner.

xiv Service Manual

Page 15

4049-XXX

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora

compleix els requisits de DHHS 21 CFR, apartat J, pels productes

làser de classe I (1), i segons ha estat certificat en altres llocs, és un

producte làser de classe I que compleix els requisits d’IEC 825.

Els productes làser de classe I no es consideren perillosos. Aquesta

impressora conté un làser de classe IIIb (3b) d’arseniür de gal.li,

nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona

de 770-795 nanòmetres. El sistema làser i la impressora han sigut

concebuts de manera que mai hi hagi exposició a la radiació làser

per sobre d’un nivell de classe I durant una operació nor mal, durant

les tasques de manteniment d’usuari ni durant els serveis que

satisfacin les condicions prescrites.

Japanese Laser Notice

Notices and Safety Information xv

Page 16

4049-XXX

Chinese Laser Notice

Korean Laser Notice

xvi Service Manual

Page 17

4049-XXX

Trademarks

Optra and Lexmark are trademarks of Lexmark International, Inc.,

registered in the United States and/or other countries.

AppleTalk and LocalTalk are trademarks of Apple Computer, Inc.,

registered in the United States and other countries.

PCL is a registered trademark of the Hewlett-Packard Company.

PCL 5 is Hewlett-Packard Company’s designation of a set of printer

commands (language) and functions included in its printer products.

This printer is designed and manufactured byLexmark International,

Inc., to be compatible with the PCL 5 language. This means the

printer recognizes PCL 5 commands used in various applications

programs, and that the printer emulates the functions corresponding

to the commands.

Details relating to compatibility are included in the 4049 Technical

Reference manual.

Other trademarks are the property of their respective owners.

Notices and Safety Information xvii

Page 18

4049-XXX

Safety Information

•

This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not always

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precautions.

Consignes de Sécurité

•

Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres

pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

xviii Service Manual

Page 19

4049-XXX

Norme di sicurezza

•

Il prodotto è stato progettato, testato e approvato in conformità a

severi standard di s icurezza e per l’utilizzo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune par ti

non sempre sono di immediata comprensione. Lexmark non è

responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

•

Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Notices and Safety Information xix

Page 20

4049-XXX

Pautas de Seguridad

•

Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

siempre evidentes.Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

•

Este produto foi concebido, testado e aprovado para satisfazer

os padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outros componentes de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

xx Service Manual

Page 21

4049-XXX

Informació de Seguretat

•

Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

Notices and Safety Information xxi

Page 22

4049-XXX

xxii Service Manual

Page 23

4049-XXX

Preface

This manual is divided into the following chapters:

• “General Information” contains a general description of the

printer, available options, and the maintenance approach used

to repair it. Special tools and test equipment are listed in this

chapter.

• “Diagnostic Information” contains error code table, symptom

table, and service checks used to isolate failing field replaceable

units (FRUs).

• “Diagnostic Aids” contains tests and checks used to locate or

repeat symptoms of printer problems.

• “Repair Information” provides instructions for making printer

adjustments and removing and installing FRUs.

• “Connector Locations” uses illustrations to identify the major

components and test points on the printer.

• “Preventive Maintenance” contains safety inspection guidelines,

lubrication specifications, and maintenance information to

prevent problems and maintain optimum performance.

• “Parts Catalog” contains illustrations and part numbers for

individual FRUs.

Preface xxiii

Page 24

4049-XXX

1. General Information

The Optra™ Laser Printers are designed to attach to IBM-compatible PC’s and to most computer networks. There are multiple models,

all with standard PostScript Level 2 emulation and PCL 5 emulation.

+

From a service standpoint models Lxi

+

, model Lxi is the same as Lx, and model Rn+is the same as R+.

Lx

Models Lxi

+

,Lxn+, Lxi, and Rn+are not mentioned elsewhere in this

manual.

plus

The

models have a different ROM SIMM, RIP board, and top

cover,and all have a maximum speed of 16 ppm. There are no other

hardware differences. Processing speed and efficiency have been

improved, and scheduled maintenance has been eliminated.

and Lxn+are the same as

1-1

Page 25

4049-XXX

Power Consumption

R/L/Rt/R+/Rt

Power Saver Mode 21W 20W

Printing (average) 260W 310W

Max. AC draw 110V 6.8A 9.8A

Max. AC draw 220V 3.4A 5.0A

+

Rx/Lx/Lx

+

Options

The following options are available. Some options are not available

in every country. Contact your point of purchase foroptions available

in your country.

Memory upgrade options of 2MB, 4MB, 8MB, 16MB and 32MB

Flash memor y options of 1MB, 2MB and 4MB

Integrated network options

Token-Ring

Ethernet

AppleTalk

SCS

IPDS

200 and 500-sheet paper trays of A5, letter, and legal size.

500-sheet second drawer (with letter-size paper tray)

Envelope+ feeder

100-sheet auxiliary feeder

Duplex option

Font cards (bitmapped or scalable fonts)

100MB Hard Disk

Dual Rear Feeder

Stat Alert Light

High Capacity Feeder (1500 sheets)

General Information 1-2

Page 26

4049-XXX

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, service checks, and diagnostic aids to determine

the symptom and repair the failure. Begin with “Start” on page 2-1.

This printer can be serviced without being connected to a host computer.

After you complete the repair, perform tests as needed to verify the

repair.

Tools Required For Service

Flat-blade screwdriver

#1 Phillips screwdriver

#2 Phillips screwdriver

5.5 mm nut driver

8 mm wrench

Needlenose pliers

Diagonal pliers

Spring hook

Feeler gauges

Analog or digital multimeter

Parallel wrap plug 1319128

Serial wrap plug 1329048

Twinax/serial debug cable 1381963

Coax/serial debug cable 1381964

1-3

Page 27

4049-XXX

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EEPROM Electrically Erasable Programmable Read-

Only Memory

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PICS Problem Isolation Charts

PIXEL Picture Element

POR Power-On Reset

POST Power-On Self Test

PQET Print Quality Enhancement Technology

RIP Raster Image Processor

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

VAC Volts alternating current

VDC Volts direct current

General Information 1-4

Page 28

4049-XXX

2. Diagnostic Information

Start

Remove power from the printer before you connect or disconnect

any cable or electronic board or assembly for personal safety and to

prevent damage to the printer.

Two-digit codes are messages for the user, but if they recur frequently or at inappropriate times they may be symptomatic of a service problem.

Use the service error code, symptom table, service checks, and

diagnostic aids to determine the corrective action necessary to

repair a malfunctioning printer.

2-1

Page 29

4049-XXX

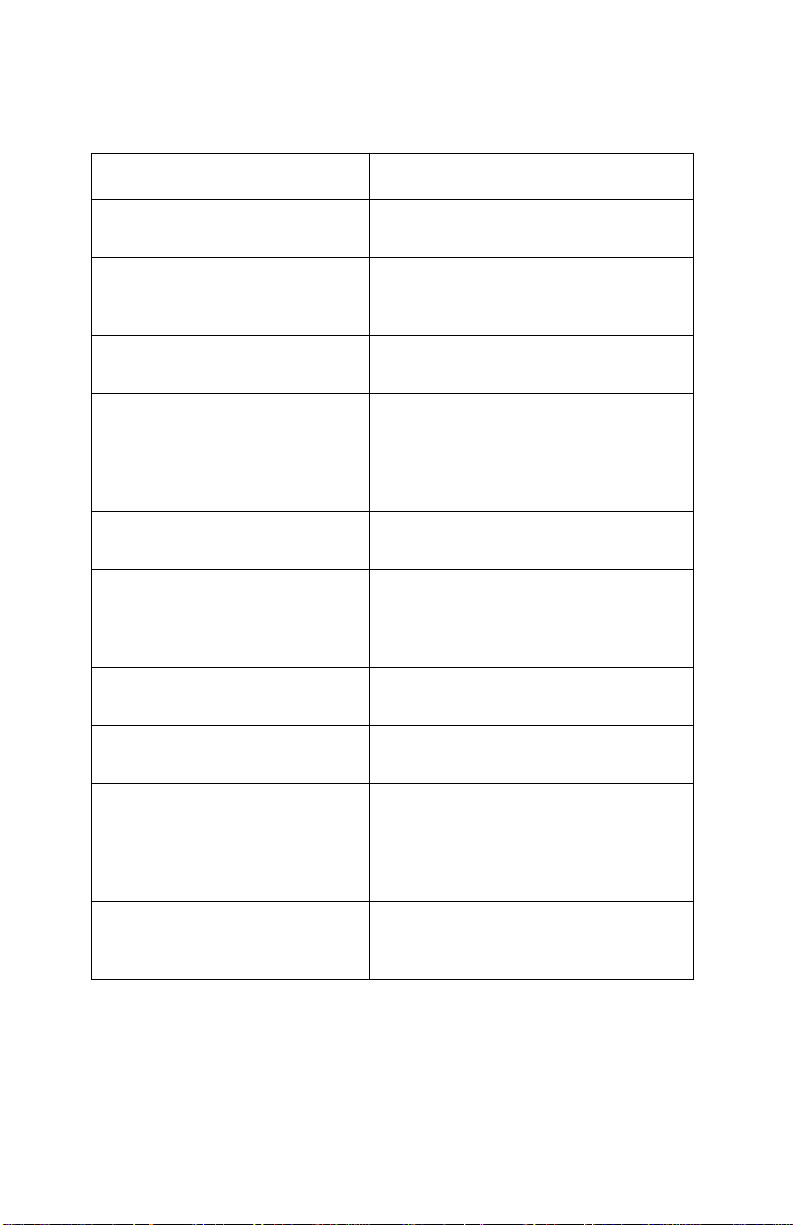

Refer to the diagnostics Error log for the last six machine errors.

Error Code Explanation

20 Paper Jam The input sensor was not unmade in

time.

21 Paper Jam The exit sensor was not made in

time after the input sensor was

made.

22 Paper Jam The exit sensor was not unmade in

time.

23 Paper Jam Jam at the duplex unit. Paper is

either not leaving the duplex entry

sensor in time or not making or

unmaking the duplex exit sensor in

time. See “Duplex” on page 2-16

24 Short Paper The defined paper size is too short

to print data as formatted.

25 Incorrect Manual Feed Input sensor made at wrong time.

May be due to the paper feeding

manually while motors running and

previous page in path.

26 Duplex Tray Missing Duplex unit is installed butpaper tray

is not sensed.

27 Change Envelope/Paper Envelopes/paper loaded are wrong

28 Load Envelope/Paper Input sensor not made after pick

29 Output Bin Full The output bin sensor has not been

size.

attempt. Tray is empty or not

installed, paper jam in entry throat,

or printer is requesting a manual

feed.

unmade.See “Output Bin Sensor” on

page 2-22.

Diagnostic Information 2-2

Page 30

4049-XXX

Error Code Explanation

30 Top Cover Open or Print

Cartridge Missing

32 Wrong Print Cartridge

installed

37 Insufficient Collation Memory

38 Memory Full Memory used to store pages is full.

39 Complex Page Page too complex to print.To verify

Make sure the spring-mounted pin

on the printhead shroud is installed

properly andthat it is detected by the

ramp on the print cartridge as the

cover closes. The pin should enter

the tower on the HVPS and depress

the cover switch.

The installed print cartridge is not

supported by the Optra printer.

Memoryistoofulltocollatetheprint

job.

To verify that the printer recognizes

all the installed memory, go to the

user menus and print the “Print

Menus” test page. Make sure the

memory shown on the printout

matches the installed memory.

that the printer recognizes all the

installed memory, go to the user

menus and print the “Print Menus”

test page. Make sure the memory

shown on the printout matches the

installed memory.

43 Font Card Not Supported Font card format not supported by

printer.

44 Defective Font Card Defective font card installed in font

slot.

47 Font Card Removed While

Printing

51 Defective Flash The printer detects a defective Flash

52 Flash Full Not enough flash memory for data

53 Unformatted Flash Flash problem at POR or while

Printer needs data on removed card.

SIMM. If the error recurs replace the

Flash SIMM.

requested to be stored.

attempting to write.

2-3

Page 31

4049-XXX

Error Code Explanation

54 Serial Error Framing or parity error on serial.

56 Serial Port Disabled or,Par-

allel Port Disabled

57 Check Duplex Connection The duplexunit has been electrically

58 Duplex Not Attached Duplex is no longer connected, and

59 Duplex Cover Open Top cover of duplex unit is sensed

62 Disk Full Not enough disk space for data that

63 Unformatted Disk Format the disk.

64 Defective Disk The printer will ignore a disk it

Data has been sent to a port which

has been disabled in the Setup

Menu. The port can be reactivated

by entering the customer setup

menu and selecting Serial Setup or

Parallel Setup, Serial Buffer or Parallel Buffer,and changing the setting

from Disabled to Auto.

disconnected from the printer but the

printer top cover is not open. Check

theauto-connect plugson the duplex

unit and the printer.

printer top cover is closed.

open.

has been requested to be written to

disk.

senses as defective. Run the Quick

Disk Test. If the test fails, the disk is

defective or the data on track 1 is

bad. If the Quick Disk Test passes

but the disk does not work, run the

Disk Test/Clean (2 hour test).

Replace the disk if instructed by the

operator panel.

7X Network Card Codes These user codes are documented

in various network card user manuals. See “Network Wrap Tests” on

page 2-22

80 Scheduled Maintenance Printer has reached 200,000 prints

without maintenance count reset.

Refer to “Scheduled Mechanical

Maintenance” on page 6-3.

Diagnostic Information 2-4

Page 32

4049-XXX

Error Code Explanation

81 Engine Code CRC Microcode to be programmed into

the engine board during a machine

upgrade has failed a CRC check.

The microcode data will be discarded and must be retransmitted

from the host computer.

88 Toner Low Toner sensor detects low toner.

90X Software Error Unrecoverable software error. If one

of these errors appeared during

POST, o r while the printer was idle

(not printing or receiving data), or

whiletryingtoprintoneoftheinter-

nal test pages, replace the RIP

Board. If the error appeared while

sending a job from the host com-

puter to the printer, turn the printer

off, then turn it on and try again. If

the error appears again, callthe next

level service support for assistance.

917 Transfer Roll Error Cannot start servo operation. Verify

correct cable connections from the

engine board to the HVPS. Make

sure there is continuity between the

transfer roller and its contact on the

HVPS; replace the transfer roll if the

continuity is correct. If there is no

continuity, make sure the HVPS con-

tact returns to its upward limit when

depressed, and make sure the left

bearing of the transfer roll is making

proper contact. If the error persists,

replace the HVPS and cable.

918 Transfer Roll Error Servo Failure. Verify correct cable

connections from the Engine board

to the HVPS. Make sure there is

continuity between the transfer roller

and its contact on the HVPS; replace

the transfer roll if the continuity is

correct. If there is no continuity,

make sure the HVPS contact returns

to its upward limit when depressed,

and make sure the left bearing of the

transfer roll is making proper con-

tact.

2-5

Page 33

4049-XXX

Error Code Explanation

920 Fuser Error Fuser is below temperature while

printing. See “Fuser: 920, 921, or

922 Error” on page 2-19.

921 Fuser Error Fuser is below standby temperature

when idle. See “Fuser: 920, 921, or

922 Error” on page 2-19.

922 Fuser Error Fuser failed to reach standby tem-

perature. See “Fuser: 920, 921, or

922 Error” on page 2-19.

923 Fuser Error Fuser is too hot while printing or

when idle. See “Fuser: 923 or 924

Error” on page 2-20.

924 Fuser Error Open detected in thermistor circuit.

See “Fuser: 923 or 924 Error” on

page 2-20.

927 Fan Stalled See “Fan (927 Error)” on page 2-18.

928 Erase Lamps Erase lamp assembly missing or dis-

connected.

931 Printhead Error No first hsync. See “Printhead” on

page 2-30.

932 Printhead Error Lost hsync.See “Printhead” on page

2-30.

934 Printhead Error Lost lock condition. See “Printhead”

on page 2-30.

935 Printhead Error Mirror motor unable to reach operat-

ing speed. See “Printhead” on page

2-30.

941 ROM SIMM ROMSIMM failedCRC;code dataor

font data. Run the diagnostic Mem-

ory Test for ROM. Replace the SIMM

if the test fails or the problem recurs

after POR; replace the RIP Board if

the SIMM does not fix the problem.

944 RIP Board RIP processor failure. Replace the

RIP Board.

Diagnostic Information 2-6

Page 34

4049-XXX

Error Code Explanation

945 RIP Board ASIC 1 failure. Replace the RIP

Board.

946 RIP Board ASIC 2 failure. Replace the RIP

Board.

947 Engine Board Engine ASIC RAM failure. Replace

the engine board.

948 Engine Board Engine ASIC electronics failure.

Replace the engine board.

950 RIP Board SRAM failure. Replace the RIP

951 Engine Board PQET SRAM failed verification test.

952 Engine Board Unable to zero PQET SRAM.

953 Engine Board NVRAM failure. Replace the engine

954 Engine Board Printhead crystal not functioning cor-

960 Memory Error Bad or missing DRAM in the base

961 Memory Error Bad DRAM in the optional DRAM

970 Network Card 1 Network card 1 processor failure.

Board.

Replace the engine board.

Replace the engine board.

board.

rectly. Replace the engine board.

DRAM slot. Reseat the DRAM and

run the diagnostic Memory Test for

DRAM. POR the printer. If the test

fails or the problem recurs, replace

the DRAM SIMM.

slot. Reseat the DRAM and run the

diagnostic Memory Testfor DRAM.

POR the printer.If the test failsor the

problem recurs, replace the DRAM

SIMM.

Replace network card 1.

970 Network Card 2 Network card 2 processor failure.

Replace network card 2.

971 Network Card 1 Network card 1 RAM failure.

Replace network card 1.

2-7

Page 35

4049-XXX

Error Code Explanation

971 Network Card 2 Network card 2 RAM failure.

Replace network card 2.

972 Network Card 1 Network card 1 ROS/FLASH failure.

Replace network card 1.

972 Network Card 2 Network card 2 ROS/FLASH failure.

Replace network card 2.

973 Network Card 1 Network card 1 EEPROM/NVRAM

failure. Replace network card 1.

973 Network Card 2 Network card 2 EEPROM/NVRAM

failure. Replace network card 2.

974 Network Card 1 Network card 1/ Network interface

error. Replace network card 1.

974 Network Card 2 Network card 2/Network interface

error. Replace network card 2.

976 Network Card 1 Network card 1 software error.Verify

that the network card is installed and

grounded correctly. If this error

returns after a POR, there is a soft-

ware or microcode incompatibility

problem. Do not replace the card.

Contact your next level of support.

976 Network Card 2 Network card 2 software error.Verify

that the network card is installed and

grounded correctly. If this error

returns after a POR, there is a soft-

ware or microcode incompatibility

problem. Do not replace the card.

Contact your next level of support.

977 Network Card 1 Network card 1 is installed but is not

communicating with the RIP Board.

See “Network Card 977 Errors” on

page 2-21.

977 Network Card 2 Network card 2 is installed but is not

communicating with the RIP Board.

See “Network Card 977 Errors” on

page 2-21.

978 Network Card 1 General network 1 card hardware

error. Replace network card 1.

Diagnostic Information 2-8

Page 36

4049-XXX

Error Code Explanation

978 Network Card 2 General network 2 card hardware

error. Replace network card 2.

979 Network Card 1 General network 1 card software

error. Verify that the network card is

installed and grounded correctly. If

this error returns after a POR, there

is a software or microcode incompatibility problem. Do Not replace the

card. Contact your next levelof support.

979 Network Card 2 General network 2 card software

error. Verify that the network card is

installed and grounded correctly. If

this error returns after a POR, there

is a software or microcode incompatibility problem. Do Not replace the

card. Contact your next levelof support.

990 Duplex Option Duplex error.See “Duplex” on page

2-16.

991 Duplex System Card Failure

993 Duplex Comm. Failure Communications between the

Duplex system board failure.

Replace the duplex system board.

duplex unit and the printer have

failed. See “Duplex” on page 2-16.

2-9

Page 37

4049-XXX

Power-On Self Test (POST)

When you turn the printer on, it performs a Power-On Self Test.

Check for correct POST functioning by observing the following:

1. One and one half rows of pels appear on the display and then

clear.

2. Diamonds fill the display and then clear.

3. The fuser lamp and the fan turn on. [Performing Self Test]

appears on the display.

Note:

warms to operating temperature. Printer idle time is shorter if

the fuser is already warm.

Note:

on for about five seconds just before the Ready screen appears.

4. The ready screen appears on the display.

Note:

5. The dr ive motor and the mirror motor start. The fan starts to run

at high speed.

6. The drive motor runs for approximately ten seconds. The fan

runs at high speed, then switches to low speed.

If the printer completes all these steps and no error messages are

displayed, the printer has successfully completed the POST.

The printer may be idle for up to 60 seconds as the fuser

If the duplex unit is installed, the duplexdrive motor turns

Diagnostics menu appears if you are in diagnostic mode.

Diagnostic Information 2-10

Page 38

4049-XXX

Symptom Table

Symptom Go To

Dead Machine “Dead Machine” on page 2-15.

Machine Hangs Displaying

Diamonds

Repeats a pattern of 5 beeps

and a pause.

Operator Panel “Operator Panel Problem” on page

Paper Feed, Base Printer “Paper Feed, Base Printer” on page

Paper Feed, Duplex Unit “Paper Feed, Duplex Unit” on page

Paper Feed Problem, 500Sheet Option or 200-Sheet

Second Drawer, Non-Rt

Paper Feed Problem, Envelope+ Feeder/100-Sheet Auxiliary Feeder

Paper Feed Problem, Dual

Rear Feeder

Paper Feed Problem, 200Sheet Second Tray, Rt

Machine Hangs Displaying Diamonds Service Check.

“Operator Panel Problem” on page

2-22.

2-22.

2-23.

2-25.

“Paper Feed Problem, 500-Sheet

Option or 200-Sheet Second

Drawer, Non-Rt” on page 2-23 or

“Paper Feed Problem, 200-Sheet

Second Drawer, Rt” on page 2-26.

“Paper Feed Problem, Envelope+

Feeder/ 100-Sheet Auxiliary Feeder”

on page 2-26.

“Paper Feed Problem, Dual Rear

Feeder” on page 2-27.

“Paper Feed Problem, 200-Sheet

Second Drawer, Rt” on page 2-26.

Paper Feed Problem, High

Capacity Feeder

Automatic Paper Size Sensing

Problem

LAN Problems “LAN Problems” on page 2-21.

Blank Page “Blank Page” on page 2-14.

Black Page “Black Page” on page 2-13.

Random Marks “Random Marks” on page 2-32.

“PaperFeedProblem, HighCapacity

Feeder” on page 2-29

Automatic Paper Size Sensing Problem Service Check.

2-11

Page 39

4049-XXX

Symptom Go To

Regularly Spaced Marks “Regularly Spaced Marks” on page

2-32.

Skew, all edges “Skew, all edges” on page 2-33.

Skew, top and bottom only “Skew,top and bottom only” on page

2-33.

Light Print “Light Print” on page 2-21.

Blurred or Fuzzy Print “Blurred or Fuzzy Print” on page

2-15.

Residual Image “Residual Image” on page 2-32.

Honeycomb “Honeycomb” on page 2-20.

Background “Background” on page 2-12.

Horizontal Void or Streak “Horizontal Void or Streak” on page

2-20.

Vertical Void or Streak “Vertical Void or Streak” on page

2-34.

Banding “Banding” on page 2-12.

Banding

Banding appears as light and dark horizontal lines on a page that is

supposed to be uniformly gray. It is due to variation in the speed of

the paper as it moves from roll to roll during developmentor transfer.

It is undetectable when printing text and is most noticeable on fine

dot or horizontal line patterns such as the second page of Print

Test 2 or Print Test 3. Inspect the gear train and the paper feed rollers for wear, damage, dirt, or binds.

Background

Areas that are supposed to stay blank are getting small amounts of

toner deposited on them. Clean the erase lamps and the printhead

window.

Verify that all the erase lamps are working by powering on or off with

the top cover open. Verify that there is +24VDC on engine board

Diagnostic Information 2-12

Page 40

4049-XXX

J9-1 and between +15 and +20VDC on engine board J9-2. Shorting

engine board J9-2 to ground should turn on all the erase lamps.

Check the erase lamp cable continuity. Replace the transfer roll

housing if the voltage and the cable are good.

Inspect the contacts on the HVPS; make sure each spring-loaded

contact returns when pressed and released.

Rough Paper mode can cause background on some papers; if

Rough Paper mode is on, turn it off and run the print test again.

Printing on coated paper or using refilled print cartridges can also

cause background.

Run the Print Test with the RIP Board removed and check the following voltages; then stop the test and check the voltages again:

Connector

Voltage while

Printing

Voltage while Idling

J13-1 Less than 5 VDC 0 VDC

J13-2 Less than 5 VDC 0 VDC

J13-3 (Fluctuates

0VDC

between pages)

+1.5 VDC

J13-8 Less than 1 VDC +6 VDC

If any voltages are not correct replace the engine board.

If no problem is found, enter the diagnostics mode and change the

Charge Roll setting.

Users who run large jobs with very dense graphics in high humidity

environments may get some print quality improvement from increasing the Transfer setting; users with more normal jobs will see no difference.

Make sure the HVPS contacts to the transfer roll housing are in good

condition.

Black Page

Black output is usually caused by an incorrect high voltage in the

printing process, resulting in toner development on the entire photo-

2-13

Page 41

4049-XXX

conductor drum. Check the condition of each HVPS contact and

make sure they spring back when pressed. Check the continuity of

the HVPS cable.Make sure the following voltages are correct; if they

are not, replace the engine board.

Connector Voltage

J13-5 to J13-4 +24 VDC

J13-6 to J13-4 +24 VDC

Run the Print Test with the RIP Board removed. Make the following

voltage checks while printing and again while idling. If the voltages

are not correct, replace the engine board.

Connector

Voltage while

Printing

Voltage while

Idling

J13-1 to J13-4 +4.5 VDC 0 VDC

J13-2toJ13-4 +4VDC 0VDC

If no other trouble is found replace the HVPS.

Blank Page

Inspect the printhead shutter for proper operation and make sure the

actuator on top of the cartridge is present and extends into the printhead shroud when the printer top cover is closed. A failed printhead

will cause a 931 Service e rror rather than blank output.

Check the continuity of the HVPS cable. The HVPS and transfer roll

contacts should be clean and spring back when pressed. Make sure

the transfer roll contact under the left bearing is making contact with

the HVPS.

Diagnostic Information 2-14

Page 42

4049-XXX

Run the Print Test with the RIP Board removed. Make the following

voltage checks:

Connector

Voltage while

Printing

J13-1 to J13-4 Less than 5

Voltage while

Idling

0VDC

VDC

J13-2 to J13-4 Less than 5

0VDC

VDC

J13-3 to J13-4 (Fluctuates

0VDC

between

pages) +1.5

VDC

J13-8 to J13-4 Less than 1

+6 VDC

VDC

If the voltages are not correct replace the engine board.

Blurred or Fuzzy Print

This can be caused by a damaged gear train or by paper slippage in

the feed roll or transfer roll. Also see Banding.

Inspect the HVPS contacts; make sure each spring-loaded contact

returns when pressed and released. Inspect the transfer roll housing

contacts for damage or contamination. Check the gear train for damage, binds, or wear.

When using the 100-sheet auxiliary feeder, some blurring mayoccur

at the point where the feeder’s friction rollers release the paper.

Dead Machine

Possible causes: no voltagereaching the printer, LVPS failure, blown

LVPS fuse, failure of the On/Off switch or switch linkage, or a

shorted electrical component.

Check for the indicated voltages at the LVPS connection to the

engine board. If no voltages are present, remove the LVPS cover

and check fuse F1 and the power switch before replacing the LVPS.

If some voltages are present but all are not correct, disconnect all

cables except the LVPS from the engine board. POR and verify that

2-15

Page 43

4049-XXX

the LVPS voltages are correct. Turn the power back off and, one at a

time, reconnect the engine board cables, powering on in between

each connection and checking the voltages. The connection which

causes the voltages to be wrong indicates which component is bad.

Repair or replace the failing component or cable as necessary.

Duplex

The duplex unit should home — the front shafts should turn and the

input deflector should move — immediately when you install the

duplex unit with the printer already powered on, or just before the

[Ready] screen is displayed when you POR the printer with the

duplex unit installed. This means the duplex unit and the printer are

communicating and thus the printer engine board, duplex unit system board, and the cables between them are all good.

If the duplex unit does not home immediately but homes after 5 or 6

seconds, the duplex unit is receiving +34 VDC from the printer but is

not communicating with the printer. The duplex unit homes on its

own as a signal that it is functional.

If the duplex unit does not home at all, it is either damaged or is not

receiving +34 VDC from the printer.

To check the connection from the printer engine board to the duplex

system board, removethe printer RIP Board. Removethe duplex top

cover and table cover, and reinstall the duplex unit. Engine board J32 should have continuity with the duplex system board J5-1, J3-3

with J5-2, and so on. With power on, you should have the following

voltages:

Connector Voltage to Ground

Engine Board J3-3 +34 VDC

J3-5 +5 VDC

J3-7 +5 VDC

Duplex System

Board

J5-2 +34 VDC

J5-4 +5 VDC

J5-6 +5 VDC

Diagnostic Information 2-16

Page 44

4049-XXX

If you do not find a cable or voltage problem replace the duplex system board. If this does not fix the problem, replace the printer engine

board.

A 993 error indicates that communication between the printer and

duplex unit had been established but has been lost. Check the cable

as above; if the error persists replace the duplex system board.

23 Paper Jams: Examine the paper path in the duplex unit and in

the fuser exit area for paper or other obstructions. Make sure the

duplex unit is positioned correctly on the printer, and that the gear at

the bottom of the duplex unit meshes with the gear on the top of the

paper tray. Check that the paper is fed with no skew or binds from

the duplexer into the metal channel at the right edge of the tray

cover. The tray roller should move the paper forward when the tray

gear is turned, but allow the paper to be pulled by the D-roll when it

picks. Make sure the belt to the duplex DC motor is in place. Make

sure the duplex table cover (floor) is correctly snapped in place at its

front and rear and that the gear block assembly is correctly snapped

into the bottom cover. Run duplex diagnostics tests #1 and #2 to

make sure there is no slippage in the paper path. Make sure the

flags of the duplex unit i nput and exit sensors move freely.

While the 23 is displayed, press and hold the Return button while

pressing the second button from the top, and note the 7th and 8th

digits from the left. If they are 01 or 03, there is a problem with the

duplex input sensor signal. Remove the duplex top cover and table

cover and reinstall the duplex unit on the printer. Measure the voltage on J5-12 of the duplex system board; it should fluctuate from 0

to +5 VDC as you toggle the sensor. Check the sensor cable continuity. If the sensor and the cable are good, replace the duplex system board.

If the 7th and 8th digits are 04, there is an exit sensor problem.

Remove the duplex top cover and table cover and reinstall the

duplex unit on the printer. Remove the paper tray so you can reach

the sensor. Measure the voltage on J5-8 of the duplex board; it

should fluctuate from 0 to +5 VDC as you toggle the sensor. Check

the sensor cable continuity. If the sensor and the cable are good,

replace the duplex system board.

2-17

Page 45

4049-XXX

Fan (927 Error)

The fan should run continuously when the printer is powered up,

unless the printer is in Power Savermode. Check that the fanrotates

freely when spun manually and that the cable connections to the fan

are OK. The voltage at engine board J 2-7 should be approximately

+24 VDC when the top cover is up. Short J2-7 to ground (J2-6) to

test the fan; if the fan does not run, check the continuity of the fan

cable before replacing the fan. A bad fan can pull down the +24 V

line even if it runs; check that J2-8 has between +21 and +26 VDC

when the fan is running. If the voltage is under 21 VDC, replace the

fan; if the voltage is correct and there is still a 927 error, replace the

engine board.

Diagnostic Information 2-18

Page 46

4049-XXX

Fuser Theory

The fuser lamp operates off line voltage from the LVPS. The thermistor is in contact with the fuser hot roll. The system board reads

the thermistor resistance and toggles a TRIAC in the LVPS which

cycles the lamp on and off to maintain the proper hot roll temperature. Inside the fuser shroud there is a thermal fuse which is in

series with the lamp; if the TRIAC fails and leaves the lamp on continuously, the fuse melts and shuts off power to the lamp.

The thermistor output voltage is proportional to the fuser temperature and is on engine board J8-4. The voltage cycles from approximately 2.0 to 2.3 VDC as the lamp goes on and off during idle, and

will be around 2.7 VDC during continuous printing when the Fuser

Temperature is set to Normal. In Power Saver mode the lamp is left

off until a job is printed.

The engine board signalto the LVPS TRIACis on J4-16. The voltage

is 0 VDC when the lamp is to be on and +5 VDC when the lamp is to

be off. The lamp can be tested by briefly connecting this pin to

ground.

Fuser: 920, 921, or 922 Error

A 922 error during a POR caused by low line voltage can usually be

cleared by doing another POR.

If the fuser lamp is lighting very dimly, check for a 220 V lamp

installed in a 110 V machine.

Check all the connectors to the exit sensor card and the lamp power

connections at the left end of the fuser. Make sure the thermistor is

making contact with thehot roll. Check the continuity of the lamp, the

thermal fuse, and the fuser power cable. Check the thermistor resistance at engine board J8-3 to J8-4; it should be from 100K Ohms to

260K Ohms when cold; it may be as low as 2.3K Ohms when hot but

increases quickly as the fuser cools. There should be no connection

from either pin to ground.

If the thermal fuse is open, the fuser and the fuser wiper may be

damaged. Before replacing the fuser and the fuser wiper, check the

voltage at engine board J4-16 as you POR again. It should stay at 0

until the 922 Error is displayed and then go to +5 VDC; if it does not,

replace the engine board, the fuser, and the fuser wiper. Next, mea-

2-19

Page 47

4049-XXX

sure the voltage to the fuser lamp during a POR; it should be line

voltage until the 922 Error is displayed, if it does not, replace the

LVPS, the fuser, and the fuser wiper.

If the voltage to the fuser lamp is the not the same as the line voltage, replace the LVPS.

If the lamp, fuser power cable, thermal fuse, thermistor and lamp

voltage are OK, check J4-16 to see if the engine board is sending

the correct signal to the TRIAC. At POR this signal should go to +5

VDC and then immediately drop to 0 VDC until the fuser is warm; if it

does not, replace the engine board. If the signal is OK, replace the

LVPS.

Fuser: 923 or 924 Error

Check the connection and continuity of the cable from the fuser exit

sensor board to engine board J8. Check the thermistor condition

and connection.

Check the thermistor resistance at engine board J8-3 to J8-4. It

should be from 100K Ohms to 260K Ohms when cold; it may be as

low as 2.3K Ohms when hot, but increase quickly as the fuser cools.

Honeycomb

(Areas of the page are covered by faint 6 mm circles.)

This print defect is usually caused by the print cartridge. If it is not

the problem, verify that the tab on the transfer roll housing is touching the contact on the HVPS; the transfer roll housing should have

continuity to ground. Make sure the HVPS ground lead to the side

frame is in place and making good contact.

Horizontal Void or Streak

This is usually due to the cartridge not being installed correctly.

Check the printhead area for obstructions, and check the mechanical workings of the pr int cartridge and printhead shutter. If nothing is

found see “Blank Page” on page 2-14 and follow those instructions.

Diagnostic Information 2-20

Page 48

4049-XXX

LAN Problems

You cannot find a printer or network problem, but jobs still do not

print.

If the network card checks out successfully, the problem may be with

the hardware or software outside of the network card. Below are

some suggestions to the customer for checking hardware and software for possible problems. Refer the customer to the LaserPrinter

Network Printer Utility Guide to find the problem.

• Make sure the network protocol you want is enabled from the

printer operator panel.

• Verify proper print queue and printer driver configuration.

• Verify the adapter port has been associated.

• Verify correct installation of the software utility.

• Single route broadcast not supported across network bridge, if

bridge is used.

• Server problem;check print server installation and configuration

using the appropriate system guide to operations.

Light Print

Light print is frequently caused by a worn out print cartridge. Clean

the transfer roll by powering on and off two or three times, leaving

the printer on for about two minutes each time. Other causes are the

same as for “Blank Page”. See “Blank Page” on page 2-14.

Make sure Print Darkness on the customer menu is set to Normal or

Dark. Increasing the diagnostics mode Print Contrast setting will

darken print further.

PostScript emulation output may appear lighter than PCL emulation

output or a test print; this is not a defect. Verify on the Print Test that

the print is too light before performing service.

Network Card 977 Errors

All network card errors are recorded as 977 in the error log. If there

are 977 errors in the log, POR several times and take the appropriate action for the displayed error code.

2-21

Page 49

4049-XXX

If the displayed error is 977, verify that the network card is installed

and grounded correctly. Remove the network card and check for +5

VDC at pin B24 of RIP board J6 or J12 (whichever the network card

was connected to). If the voltage is incorrect replace the engine

board; if there is +5 VDC replace the network card.

Network Wrap Tests

Token-Ring with Shielded Twisted-Pair Cable: Disconnect the

LAN cable from the electr ical outlet, leaving it connected to the

printer network card.

Ethernet 10BASE2: Attach a 50 Ohm BNC terminator cap to each

end of the T-connector. The customer may be able to provide this

cap.

There is no wrap test for Token-Ring with Unshielded Twisted-Pair

cable or for Ethernet 10Base -T.

POR the printer. If the printer completes POR successfully, the

printer, network card, and the port to the LAN are working correctly.

see

If the customer still has a problem printing,

page 2-21.

“LAN Problems” on

Output Bin Sensor

Examine the bin area for obstructions or damage. Run the diagnostic sensor test.

Make sure the plastic bails and guide are in good condition and that

they guide the sensor flag out of and into the sensor as paper

passes into the bin. On the sensor, the voltage from pin 2 to pin 3

(pin 1 is the bottom pin) should change from 0 to +5 VDC as the sensor is blocked and unblocked.Pin 1 should always measure +5 VDC.

Replace the sensor, the sensor card or the operator panel/bin sensor cable as necessary.

Operator Panel Problem

Note:

the menus by powering on the printer with the Return button and the

top button pressed. Repeat the POR procedure to disable the

menus again after service.

If the printer is in “Menus Disabled” mode, you can activate

Diagnostic Information 2-22

Page 50

4049-XXX

Possible causes: failed LCD or operator panel card, cable or connector problem, or engine board problem.

Replace the operator panel if POR stops with half rows of pels displayed.

Run the diagnostic tests for the LCD and for the buttons. If only

some buttons or pels work, replace the operator panel.

If the printer beeps 5 times at POR, or if the operator panel is blank:

check for +5 VDC at pin 4 of the cable connector at the operator

panel, and also at engine board J1-4. Replace the operator panel or

the cable if they are the problem. If the voltage at the engine system

board is incorrect, check that the LVPS is providing +5 VDC at J4-7,

J4-9, and J4-11, and replace the LVPS if its output voltages are

wrong.

Paper Feed Problem, 500-Sheet Option or 200-Sheet Second Drawer, Non-Rt

Remove the module and inspect the tray, the module D-roll and the

gear train. Make sure the gear train is meshing with the drive gear at

the bottom of the printer. Look for other mechanical problems or

damage. Make sure the printer and module auto-connectors mate

properly when the module is installed.

Check for +34 VDC at engine board J15-2. You can test the torquer

motor by shorting engine board J15-1 to ground (J15-3).

Paper Feed, Base Printer

Note:

torquer motor or a solenoid.

Run the print test or the diagnostic paper feed test and carefully

examine the area of the problem.

If paper is not feeding, make sure the paper is in the tray correctly

and is not damaged or stuck together. With 500-sheet trays, make

sure the tension wheel is set high enough to give good contact

between the D-roll and the paper stack.

If paper is not feeding, make sure the gear train is rotating. The main

motor should be on during most of POR and during any attempt to

2-23

The printer paper pick mechanism may have either a

Page 51

4049-XXX

feed paper. Remove the RIP board and run Print Test with RIP

Board Removed. During the test check for 19±2 Vdc on the engine

board J6-1, J6-2, J6-3, and J6-4. If the voltage is wrong, replace the

engine board.

Remove the motor and gear assembly from the printer and reconnect it to the engine board. Reconnect all the other engine board

connectors and reinstall at least one engine board mounting nut to

make sure the engine board is grounded. POR the printer. If the

motor does not run during POR replace the motor. If the motor is

OK, look for a bind elsewhere in the gear train.

Intermittent problems may be caused by a thermal problem in the

motor. Run an extended print test; if the gear train stops suddenly

replace the motor.

If paper is not feeding or is feeding continuously with no gaps

between pages, remove the paper tray and the RIP board. Press

switches 1 and 3 on the paper size switch assembly. Watch the Droll as you run the Print Test with RIP Board Removed. One of the

following will occur:

• The D-roll will make one complete revolution and stop with the

flat side down. This indicates that the mechanism is working

correctly. If the flat side is not facing down, or if the printer had

error code 20 or 28, turn the D-roll, if it rotates easily more than

10°, either the D-roll or gear 11 is damaged and should be

replaced.

• The D-roll will turn continuously:

a. Torquer: There is a possible short to ground of the lead

between the torquer gear and engine board J14-2, or the

timing marks on the torquer gear and the D-roll gear are misaligned. Examine the condition of the torquer leads and

replace the torquer motor if necessary.The timing marks are

visible when the engine board is removed. If no problem is

found, replace the engine board.

b. Solenoid: There is a possible short to ground of the lead

between the solenoid and engine board J14-2, or the solenoid is out of adjustment. Examine the condition of the solenoid leads. Adjust the solenoid air gap (see “Paper Feed

Magnet Adjustment” on page 4-8) or replace the solenoid if

necessary. If no problem is found, replace the engine board.

• The D-roll will not move at all. Either the engine board signal is

Diagnostic Information 2-24

Page 52

4049-XXX

incorrect or the torquermotor or solenoid is defective.Adjust the

solenoid air gap (see “Paper FeedMagnet Adjustment” on page

4-8). On torquer machines, make sure the torquer gear is not

slipping on the shaft. Engine board J14-1 should always be +34

VDC; J14-2 should be +34 VDC when the torquer or solenoid is

not picking. Short engine board pin J14-2 to ground and listen

carefully for the torquer or solenoid; it will move slightly and

make a noise. If it does, replace the engine board.

• The D-roll will move slightly but will not complete an entire revo-

lution. This indicates a bind or defect in the gear train, or a misalignment of the torquer motor gear timing marks.

If paper is jamming, clean the paper path of obstructions or repair

any damaged parts. Very thin or thick paper, labels, transparencies,

or card stock has a higher jam rate than regular xerographic paper.

Check the condition of the paper in the tray and verify that the tray is

installed correctly. If the paper feeds but stops undamaged in the