Page 1

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

Medley

4012-0XX

TM

• Index

Lexmark and Medley are trademarks

of Lexmark International, Inc.,

registered in the United States and/or

other countries.

Page 2

4012-0XX

Second Edition (July, 1995)

The following paragraph does not apply to the United Kingdom or any country

where such provisions are inconsistent with local law: LEXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; thesechangeswillbe

incorporated in later editions of the publication. Improvements or changes in the

products or the programs described in this publication may be made at any

time. Publications are not stocked at the address given below; requests for publications should be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., Department

D22A/035-3, 740 New Circle Road, Lexington, Kentucky 40550, U.S.A. Lexmark may use or distribute any of the information you supply in any way it

believes appropriate without incurring any obligation to you.

Lexmark and Medley are trademarks of Lexmark International, Inc.

ExecJet is a registered trademark of International Business Machines Corpora-

tion

© Copyright Lexmark International, Inc. 1995. All Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS.

Use, duplication or disclosure by the Government is subject to restrictions as

set forth in subparagraph(c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013 and in applicable FAR provisions:

Lexmark International, Inc., Lexington, KY 40550.

Page 3

4012-0XX

Contents 1

Preface........................................... vi

SafetyInformation................................... vii

GeneralInformation....................................1

Options............................................2

Maintenance Approach................................2

Abbreviations.......................................3

DiagnosticInformation .................................4

SymptomTable......................................5

ServiceChecks......................................7

CommunicationsServiceCheck .....................7

EnvelopeFeedServiceCheck.......................8

FirstPrintLineServiceCheck.......................8

MaintenanceStationServiceCheck ..................9

Operator Panel Service Check......................10

PowerServiceCheck.............................11

Printer Paper Feed Service Check. ..................12

Printer Paper Path Service Check . ..................15

PrintQualityServiceCheck........................16

PrintingProblemServiceCheck.....................18

Scanner Document Feed Service Check ..............19

Scanner Service Check ...........................20

TransportServiceCheck..........................21

DiagnosticAids ......................................22

CallMonitoring.....................................22

Error Report . . . ....................................22

FrameServicePosition...............................22

HexPrintMode.....................................22

MachineCheckout..................................23

MemoryTest.......................................23

Operator Panel Service Position........................23

Operator Panel Test .................................24

ResetButton.......................................24

PrintEngineTest...................................24

PurgeTest........................................25

ScannerFeedTest..................................25

SettingtheMachineSerialNumber.....................26

TestPrint .........................................26

iii

Page 4

4012-0XX

RepairInformation.....................................27

Handling ESD-Sensitive Parts ......................... 28

Adjustments....................................... 29

Bidirectional Alignment Adjustment. . ................ 29

RemovalProcedures................................ 30

Auto Sheet Feed (ASF) Assembly Removal ........... 30

ASFEnvelopeBucklerandPickRollerHubRemoval.... 31

ASF Right and Left Edge Guide Assemblies Removal . . . 31

BatteryOption.................................. 31

CarrierGuideRodRemoval....................... 31

CarrierRemoval ................................ 32

CarrierTransportBeltRemoval..................... 32

CarrierTransportMotorRemoval................... 33

CarrierTransportMotorFrameRemoval ............. 33

CoversRemoval................................ 34

FrontCover .................................34

RearCover..................................34

TopCover ..................................34

RightSideCover .............................34

LeftSideCover ..............................34

Operator Panel and Cover ......................34

EncoderStripRemoval........................... 35

End-of-FormsFlagRemoval....................... 35

ExitRollerAssemblyRemoval ..................... 35

EPROMRemoval............................... 36

FaxBoard,PrinterBoard,andLCUBoardRemoval..... 37

FeedArmAssemblyRemoval...................... 37

InsideIdlerGearsRemoval........................ 37

LargeFeedRollerAssemblyRemoval............... 38

LeftSideFrameRemoval......................... 38

Maintenance Drive and Rocker Assemblies Removal.... 39

MemoryOption................................. 39

MiddleFrameRemoval........................... 40

OutsideIdlerGearsRemoval...................... 40

Paper Ejectors Removal . ......................... 40

Paper Feed Motor Removal ....................... 40

Paper Guide Removal. . . ......................... 41

Paper Release Lever Removal ..................... 41

Power Supply Removal. . ......................... 42

PrintEngineRemoval............................ 42

Printhead Cable Removal ......................... 43

ReleasingPlasticLatches......................... 44

RightSideFrameRemoval........................ 45

iv

Page 5

4012-0XX

Repair Information, Removal Procedures (continued)

Rubber Backer Removal ..........................47

SmallFeedRollerAssemblyRemoval................47

StarRollerRemoval..............................47

Scanner and Speaker Removal . . . ..................48

SubframeRemoval...............................48

PartsandTestPointLocations..........................49

LCUBoard.....................................49

FaxBoard......................................50

PrinterBoard...................................52

Preventive Maintenance ...............................54

Lubrication Specifications..........................54

Scanner Cleaning Procedure.......................55

PartsCatalog ........................................56

HowToUseThisPartsCatalog.....................56

Assembly1:Covers ..........................57

Assembly2:Frame...........................59

Assembly3:OperatorPanel....................61

Assembly 4: Printer Paper Feed Assembly ........63

Assembly 4: Printer Paper Feed Assembly (cont.) . . . 65

Assembly5:Carrier ..........................67

Assembly6:CarrierTransport ..................69

Assembly 7: Maintenance Station ...............71

Assembly 8: Scanner .........................73

Assembly9:Electronics .......................75

Assembly 10: Automatic Sheet Feed (ASF) ........77

Assembly11:Options.........................79

Index ...............................................80

v

Page 6

4012-0XX

Preface

This manual is divided into the following chapters:

1. General Information contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

2. Diagnostic Information contains the symptom table and service checks used to isolate failing field replaceable units (FRUs).

3. Diagnostic Aids contains tests and checks used to locate or

repeat symptoms of printer problems.

4. Repair Information provides instructions for making printer

adjustments and removing and installing FRUs.

5. Parts and Test Point Locations uses illustrations to identify the

major components and test points on the printer.

6. Preventive Maintenance contains recommendations to help

prevent problems and maintain optimum performance.

7. Parts Catalog contains illustrations and part numbers for individual FRUs.

vi

Page 7

4012-0XX

Safety Information

The maintenance information for this product has been prepared

•

for use by a professional service person and is not intended to be

used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product. Professional service personnel should understand this and take necessary precautions.

• The safety features of some parts may not always be obvious.

Therefore, replacement parts must have the identical or equivalent characteristics as the original parts.

Sicherheitshinweise

Die Wartungsinformationen fuer dieses Produkt wurden zur

•

Verwendung durch einen Wartungsfachmann entwickelt und

sollten nicht von anderen benuetzt werden.

• Zusaetzliches Risiko eines elektrischen Schlags und

koerperlicher Verletzung existiert waehrend des

Auseinandernehmens und der Wartung des Geraets.

Fachpersonal sollte im vollen Verstaendnis der Lage

entsprechende VorsichtsmaBnahmen ergreifen.

• Ersatzteile muessen gleiche oder gleichwertige Merkmale wie

die Originalteile aufweisen, da Sicherheitsvorkehrungen nicht

immer offensichtlich sind.

Consignes De Securite

Les consignes d’entretien et de reparation de ce produit

•

s’adressent uniquement a un personnel de maintenance qualifie.

• Le demontage et l’entretien de ce produit pouvant presenter

certains risques electriques, le personnel d’entretien qualifie

devra prendre toutes les precautions necessaires.

• Les normes de securite de certaines pieces n’etant pas toujours

explicites, les pieces de rechange doivent etre identiques ou

conformes aux caracteristiques des pieces d’origine.

vii

Page 8

4012-0XX

Norme Di Sicurezza

Le informazioni riguardanti la manutenzione di questo prodotto

•

sono indirizzate soltanto al personale dell’assistenza autorizzato.

• Durante lo smontaggio e il manutenzionamento di questo

prodotto, e possibile il rischio accresciuto di scosse elettriche e

danni personali. Il personale di assistenza autorizzato,

consapevole di cio, deve adottare le precauzioni necessarie.

• E possibile che le funzioni di sicurezza di alcuni elementi non

siano cosi ovvie, quindi, i pezzi di ricambio devono avere

caratteristiche identiche o equivalenti a quelle dei pezzi originali.

Pautas De Seguridad

La informacion sobre el mantenimiento de este producto fue

•

escrita para el personal de mantenimiento cualificado y no para

cualquier otro usuario.

• Existen mayores riesgos de descargas electricas y danos

personales durante el desmontaje y la reparacion de la maquina.

El personal cualificado comprende esto y toma las precauciones

necesarias.

• Los dispositivos de seguridad de algunas partes quiza no

siempre puedan ser reconocidas a simple vista. Por lo tanto, las

partes de reemplazo deben poseer caracteristicas identicas o

equivalentes a las partes originales.

Sikkerhedsoplysninger

Oplysningerne om vedligeholdelse af dette produkt er forberedt

•

med henblik pa professionelt servicepersonale, og bor derfor ikke

benyttes af andre.

• Risikoen for elektrisk stod oges under demontering og service af

dette produkt, hvorfor der bor tages de nodvendige

forholdsregler.

• Sikkerhedsforanstaltningerne er ikke altid lige apenbare for alle

reservedele. Der bor derfor kun anvendes originale reservedele

eller reservedele med samme egenskaber som de oprindelige.

viii

Page 9

4012-0XX

Chinese Safety Information

Korean Safety Information

ix

Page 10

4012-0XX

General Information 8

This manual is used to service the Lexmark Medley 4012. Medley is

a multifunction product which can connect to an IBM-compatible personal computer. It acts as an all-in-one color-capable printer, G3 fax

machine, scanner, and convenience copier. It will send and receive

faxes, scan documents, print from the PC, and make convenience

copies. It uses 300 x 300 pels per inch inkjet technology for high

quality text and graphics. Print Quality Enhancement Technology

(PQET) smooths the edges of lines and characters.

Medley uses the same black or color print cartridges as the IBM

ExecJet II and ExecJet IIc by Lexmark.

Medley uses a 300 x 300 dpi scanner for fast, high quality scanning,

personal copying, and faxing. Scanning software for the PC is

included with the Medley.

There are three models: Medley 4c (4012-005) which does not

include a handset, Medley 4x (4012-006) which does include a

handset, and the Medley 4sx (4012-009) which is the same as the

4x but is shipped standard with the battery backup. Other than in the

Parts Catalog, there are no service differences.

All models can handle a variety of paper sizes as well as envelopes

and other media using an integrated automatic sheet feed and manual feed.

The machine contains the following circuit boards:

• Fax Board—controls the scanner and most of the machine’s

functions

• Printer Board—runs the printer motors, sensors, and printhead

• Line Connect Unit (LCU) Board—printer parallel port and tele-

phone connections

• Operator Panel Board

General Information 1

Page 11

4012-0XX

Options

The following options are available. Contact your point of purchase

for options available in your country.

• 1MB Memory Expansion

• 3MB Memory Expansion

• Battery Backup (standard on Medley 4sx)

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom table, service checks, and diagnostic aids to determine the

symptom and repair the failure.

Medley can be serviced without being connected to a host computer.

After you complete the repair, perform tests as needed to verify the

repair.

General Information 2

Page 12

4012-0XX

Abbreviations

CCD Charge Coupled Device

CE Customer Engineer

CSU Customer Setup

DRAM Dynamic Random Access Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

G3 Group 3 (Digital Facsimile Protocol)

LCD Liquid Crystal Display

LCU Line Connect Unit

LED Light-Emitting Diode

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PCA Printed Circuit Assemblies

PICS Problem Isolation Charts

PIXEL Picture Element

POST Power-On Self Test

PQET Print Quality Enhancement Technology

SRAM Static Random Access Memory

UPR Used Parts Replacement

V ac Volts alternating current

V dc Volts direct current

ZIF Zero Insertion Force

3

Page 13

4012-0XX

Diagnostic Information 9

Use the symptom table and service checks in this chapter to determine the failing part in a malfunctioning machine.

Diagnostic Information 4

Page 14

4012-0XX

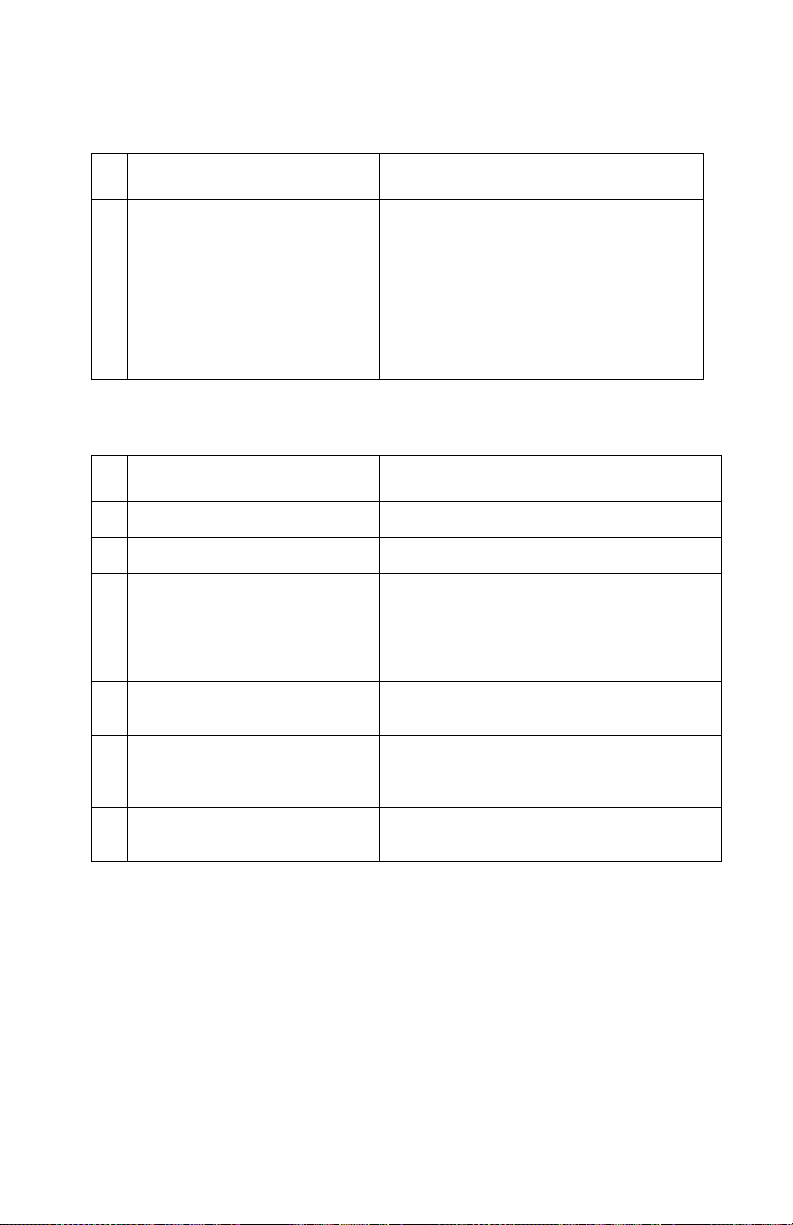

Symptom Table

Symptom Action

Printer Code 1,4 Replace the printer board EPROM;

Printer Code 1,6 Go to “Transport Service Check” on page

Printer Code 1,8 Replace the printer board EPROM;

Printer Code 1,10 Go to “Maintenance Station Service

Printer Code 1,12 Replace the printer board EPROM;

Printer Code 1,14 Go to “Maintenance Station Service

Printer Code 3,4 Go to “Transport Service Check” on page

Printer Code 3,8 Go to “Transport Service Check” on page

Printer Code 9,2 Replace the printer board EPROM;

Printer Code 9,4 Go to “Transport Service Check” on page

Power Problem

No LEDs or LCD pixels light up

during POR, no machine activity:

if necessary replace the printer board.

21.

if necessary replace the printer board.

Check” on page 9.

if necessary replace the printer board.

Check” on page 9.

21.

21.

if necessary replace the printer board.

21.

Go to “Power Service Check” on page 11.

Maintenance Station Problem

Maintenance station does not

move,orfailstocleanorcap the

printhead:

Carrier Transport Problem

No carrier movement, slow carrier movement, carrier stops:

Operator Panel Problem

Incorrect or no lit LEDs or LCD

display, or buttons do not work

properly:

5

Go to “Maintenance Station Service

Check” on page 9.

Go to “Transport Service Check” on page

21.

Go to “Operator Panel Service Check” on

page 10.

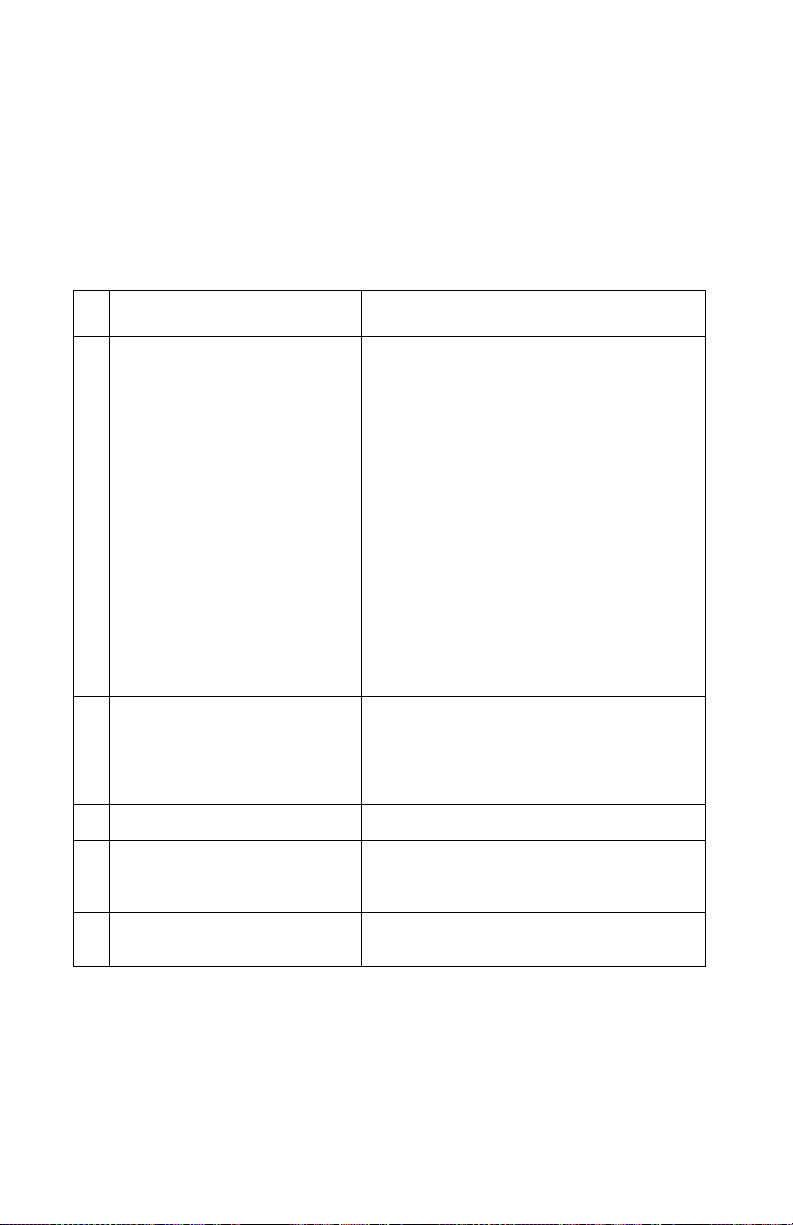

Page 15

4012-0XX

Symptom Action

Printer paper feed, misfeed, or

jam problem

Paper fails to stop at first print

line:

Go to “First Print Line Service Check” on

page 8.

Envelopes fail to feed:

Paper misfeeds, multifeeds,

jams, picks but fails to feed, or

fails to exit:

Paper skews:

Scanner paper feed, misfeed,or

jam problem

Printing Problem

Test prints, faxes, or printer jobs

do not print correctly (not a print

quality problem).

Print Quality Problem

Test prints, faxes, and printer

jobs print butoutputhasvoidsor

uneven density or is fuzzy,

smudged, or faint.

Scanning Problem

No scanned image or incorrect

scanned image:

Communications Problem

Cannot send fax,cannotreceive

fax, or cannot connect with

remote machine:

Go to “Envelope Feed Service Check” on

page 8.

Go to “Printer Paper Feed Service Check”

on page 12.

Go to “Printer Paper Path Service Check”

on page 15.

Go to “Scanner Document Feed Service

Check” on page 19.

Go to “Printing Problem Service Check” on

page 18.

Go to “Print Quality Service Check” on

page 16.

Go to “Scanner Service Check” on page

20.

Go to “Communications Service Check”

on page 7.

Diagnostic Information 6

Page 16

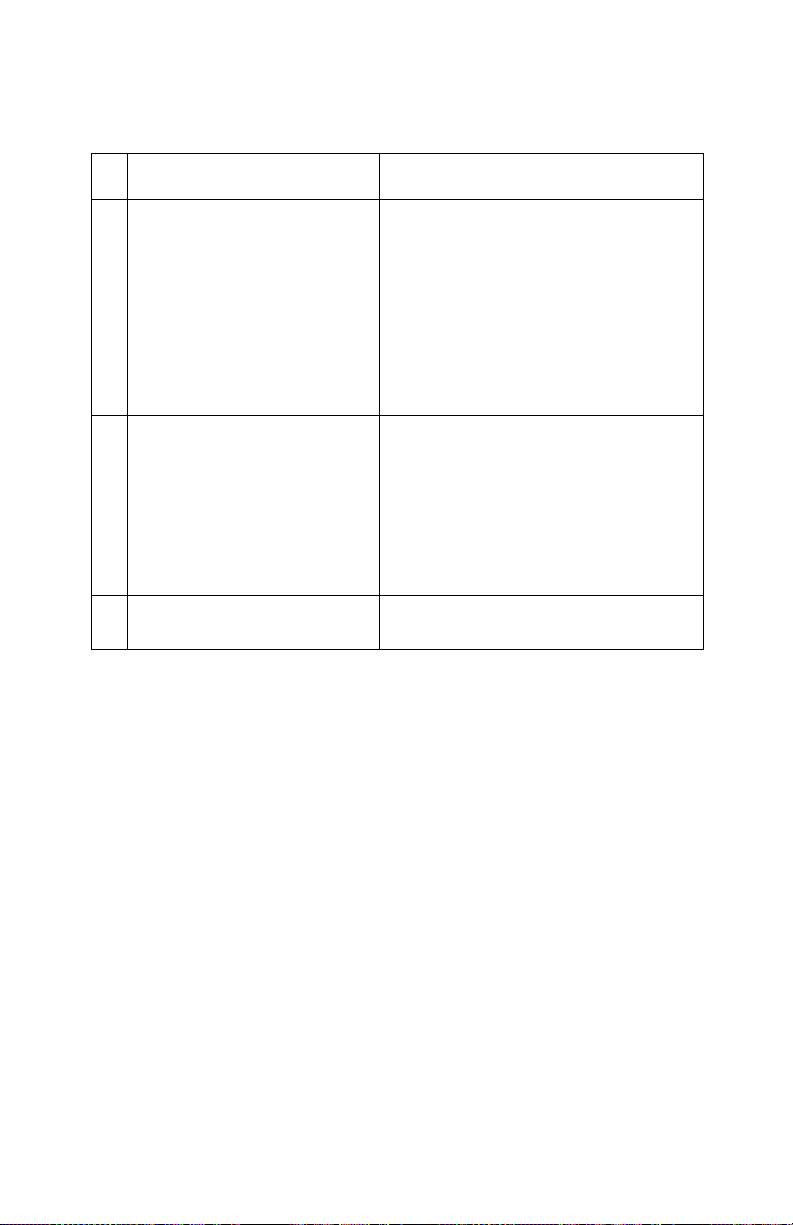

4012-0XX

Service Checks

Communications Service Check

FRU Action

1 Fax or LCU Card

Cannot make telephone connection to other fax machine.

2 Cannot receive faxes. Machine not set for auto-answer.

No dialtone

Verifycorrect dialing method (tone or

pulse).

TEL and LINE connections reversed.

Verifyphone number and availability of

other fax machine.

Turn Call Monitoring on and listen to the

speaker during dial. You should hear the

ring and a 0.5 second 1000Hz calling tone

from your machine, a 1 second pause,

then the 3 second 2100Hz fax response

tone and a 1650Hz-1850Hz “warbling”

handshaking tone from the called

machine.

Check the connections of LCU card J2 to

fax card J11. If the problem still exists,

replace the LCU board, and then if necessary,the fax board.

TEL and LINE connections reversed.

A telephone on the same line is already

off-hook.

Machine connected to the wrong telephone line.

Damaged telephone line to machine.

Check memory; faxes received during

paper jams are stored and printed after

jam is cleared.

Make sure “Receive into memory” is set to

No.

If handshaking between fax machines can

be established, the LCU board should be

OK. If necessary, replace the fax board.

7

Page 17

4012-0XX

Envelope Feed Service Check

FRU Action

1 Envelope Loading Be sure the envelope guides have been

turned to the envelope load positions.

Be sure the envelope guides are against

the envelopes.

Go to and perform the “Printer Paper Feed

Service Check” on page 12.

First Print Line Service Check

FRU Action

1 Printer End-of-Forms Flag Check the flag for binds or damage.

2 Printer End-of-Forms Sensor Check the sensor for dirt.

3 Printer Board Check the End-of-Forms sensor, measure

4 Feed Arm Assembly Check all parts of the feed arm assembly for

5 Software Setting Use Toolkit, one of the setup programs

the voltage at pin 2 of U28 on the printer

board. The voltage should change from 0 to

5 V dc as you block and unblock the End-ofForms sensor S1.

binds, wear, or damage.

installed on the PC, to adjust the TopofForm

setting.

6 Operator Panel Go to “Operator Panel Service Check” on

page 10.

Diagnostic Information 8

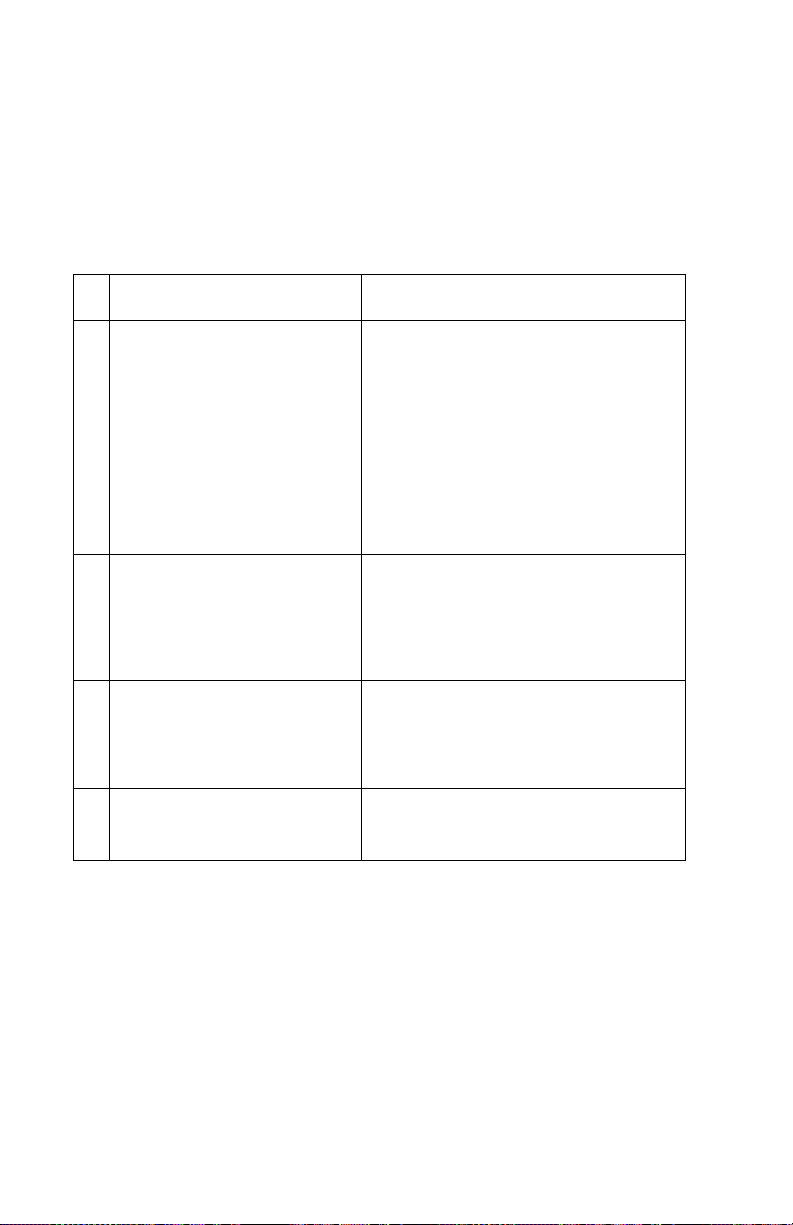

Page 18

4012-0XX

Maintenance Station Service Check

The maintenance station has two functions:

1. Cleans the printhead nozzles during the print operation.

2. Seals the printhead when it is not being used to prevent the nozzles from drying.

FRU Action

1 Maintenance Drive Assembly Warning: Disconnecting the maintenance

2 Printer Board Turn the machine off and disconnect J4 from

3 Maintenance Rocker Asm Check for binds or wear.

4 Wiper A worn wiper causes degraded print quality

5 Cap A worn cap causes the printhead nozzles to

motor while the machine is plugged in can

damage the printer board. Voltage is present

on the board even with the power switch off.

Disconnect J4 from the printer board. Check

for 18 ohms (±4 ohms) between pins 1 and 2

at the motor. If the reading is incorrect,

replace the maintenance drive assembly.

Check for motor pins shorted to the motor

housing. If you find a shorted pin, replace the

maintenance drive assembly. If the symptom

remains, replace the printer board.

A bind in the drive assembly can prevent the

motor from turning. Check for binds and

loose or worn parts in the drive assembly.

Also check the motor gear.

the printer board. Turn the machine on and

check for a pulse of 15 V dc between J4-1

and ground on the system board as the

printer goes through POST.

just after a maintenance cleaning. Check for

loose or worn wiper.

dry and clog. Check for loose or worn cap.

Note: If the failure remains, replace the printer board.

9

Page 19

4012-0XX

Operator Panel Service Check

FRU Action

1 PowerSupply Disconnect J2 from the fax board and

2 Operator Panel Board

Operator Panel Cable

3 Fax Board Turn the printer on. Check for +5 V dc at

check the following voltages on the power

supply cable:

J2-1 to GND = +5 V dc

J2-3 to GND = +34 V dc

If you do not have correct voltage, replace

the power supply. Be sure to unplug the

machine before you reconnect the power

supply to the fax board.

Perform the Operator Panel Test;see

“Operator Panel Test” on page 24.

If some of the buttons do not work, check

the contacts on the back of the keypads

and the surface of the lands on the operator panel board. Replace the keypads as

necessary.Check the continuity of the

operator panel cable before replacing the

operator panel board.

J4-3 on the fax board.

Diagnostic Information 10

Page 20

4012-0XX

Power Service Check

The operator panel power key does not control line power. With the

machine turned off the power supply is still active and there is voltage to both the fax and printer boards. To remove power you must

unplug the machine.

FRU Action

1 PowerSupply Disconnect J2 from the fax board, J11

2 Printhead Cable

Parallel Cable

3 Printer Board Disconnect the fax board from the printer

4 Fax Board Check for +5 V dc at the fax board J9-4,

from the printer board and check the following voltages on both power supply

cables:

Pin-1toGND=+5Vdc

Pin-3 to GND = +34 V dc

If you do not have correct voltage, replace

the power supply. Be sure to unplug the

machine before you reconnect the power

supply to the boards.

Unplug the machine. Disconnect one of

the listed components and plug in the

machine. Look for a symptom change.

Check the failing part for shorts and

replace as necessary. Repeat this procedure for the remaining listed parts.

board. Run the Print Engine Test. If the

test does not run and there are no

mechanical problems, replace the printer

board.

and check for +34 V dc at J9-2. If the voltages are incorrect replace the fax board.

11

Page 21

4012-0XX

Printer Paper Feed Service Check

If your machine does not have paper jam problems, go on to the service check. If your machine does have a paper jam problem, examine it for the following before you begin the service check.

• Check the entire paper path for obstructions.

• Make sure there is not too much paper in the Automatic Sheet

Feed (150 sheets or less depending on the thickness).

• Make sure the correct type of paper is in the machine.

• Check for static in the paper.

• Make sure the rear of the carrier guide is on top of the paper

guide.

FRU Action

1 Printer Board With J5 disconnected and power on,

check for +24 V dc between J5-3 and

ground, and between J5-4 and ground on

the printer board. If the voltage is not

present, check for motor pins shorted to

the motor housing. If you find a shorted

pin, replace the motor. If you still have a

failure after replacing the motor, replace

the printer board.

Diagnostic Information 12

Page 22

4012-0XX

FRU Action

2 Paper Feed Motor A noisy or chattering motor or a motor that

fails to turn, can be caused by:

• An open or short in the motor

• An open or short in the motor driver on

the printer board

• A bind in the paper feed mechanism

Warning: Disconnecting the paper feed

motor while the machine is plugged in can

damage the printer board. Voltage is

present on the board even with the power

switch off.

Check for 100 ohms (±20 ohms) between

the following pins on the motor:

Pin1toPin4

Pin2toPin4

Pin3toPin5

Pin3toPin6.

If the readings are incorrect, replace the

motor.Check for motor pins shorted to the

motor housing. If you find a shorted pin,

replace the motor. If the failure remains,

replace the printer board.

Although the paper feeds in a forward

direction only, the paper feed motor turns

in two directions. If the paper feed motor

turns in one direction only,replace the

printer board.

Binds in the paper feed motor or gear train

can cause intermittent false paper jam

errors. Remove the paper feed motor and

check the shaft for binds. Also check for

loose or worn motor gears.

3 Gears Check forbinds in the gear train and paper

feed mechanism. To do this, rotate the

largest gear by hand. If you notice a bind,

isolate it by removing the small idler gear

on the outside of the right side plate and

rotate the gears again. Replace any worn

or binding gears, rollers, or bearings.

13

Page 23

4012-0XX

FRU Action

4 Feed Arm Assembly At the beginning of the paper feed opera-

5 Auto Sheet Feed (ASF) Check the following for wear or damage:

6 End-of-Forms Flag Check for binds or damage.

7 Star Rollers Check for worn or binding rollers. Check

8 Ejectors After the paper exits from the exit rollers,

tion, the paper feed motor reverses

momentarily to allow the feed arm pawl to

drop off the home position notch in the

ASF side plate. If the pawl fails to drop off

the notch, check the feed arm assembly

for binds, and worn or broken parts.

• Pick Rollers

• Envelope Bucklers

• All parts inside the left and right edge

guides.

for broken star roller springs.

the paper feed motor reversescausing the

feed arm pawl to restore to the home position in the ASF side plate. At the same

time, the paper ejectors move the last

sheet of paper into the exit tray.If the ejectors do not move or restore, check them

for worn, loose, or broken parts; also

check for interference with the front cover.

Diagnostic Information 14

Page 24

4012-0XX

Printer Paper Path Service Check

Examine the machine for the following before you begin this service

check:

• Check the entire paper path for obstructions.

• Be sure the paper guides are not worn or broken and are posi-

tioned against the paper without binding or buckling the paper.

• Be sure the correct type of paper is in the m achine.

• Be sure the rear of the carrier guide is on top of the paper guide.

FRU Action

1 Large and Small Feed Rollers Check for wear and binds.

2 Large Feed Roller Springs Check for damage.

3 Auto Sheet Feed (ASF) Check for equal pressure between the left

4 End-of-Forms Flag Check for binds or damage.

5 Exit Roller Check for wear or binds.

6 Star Rollers Checkfor wear or binds. Check for broken

7 Ejectors Check the front cover; if it is installed

and right pick rolls and their pads; this can

be caused by the paper load shaft gears

being misaligned by one tooth in the ASF

frame.

Check the following for wear or damage:

• Envelope Bucklers

• All parts inside the left and right edge

guides.

star roller springs.

incorrectly it can interfere with the ejectors.

Make sure the front bottom cover is

installed correctly.Ifthe front bottom cover

is not installed correctly, the ejectors can

hang on the cover possibly causing severe

paper jams.

After the paper exits from the exit rollers,

the paper feed motor reversescausing the

feed arm pawl to restore to the home position in the ASF side plate. At the same

time, the paper ejectors move the last

sheet of paper into the exit tray.If the ejectors do not restore, check them for worn,

loose, or broken parts.

15

Page 25

4012-0XX

Print Quality Service Check

FRU Action

1 Print Cartridge Be sure the machine has a known good

2 Printhead Carrier Assembly Reseat the printhead cables in the printer

3 Printer Board

Printhead Cable

Rubber Backer

print cartridge.

board and check the following parts for

wear or damage:

• Print Cartridge Latch

• Latch Spring

•Carrier

Performthe“PurgeTest” on page 25. Look

for a break in the diagonal line at the bottom of the test pattern. A broken line indicates one or more print nozzles are

clogged. Run the test again to verify the

failure.If there are evenbreaks in the diagonal line similar to the pattern shown

below,replace the printer board.

If there is a single break or random breaks

in the diagonal line check the following:

Check the gold-plated contacts on the end

of the cable that connects to the carrier for

dirt and wear. Use only a clean dry cloth to

clean the contacts. Also check the cable

for damage. Youmay need to remove the

cable from the carrier to inspect it.

A worn rubber backer will result in poor

contact between the printhead cable and

the print cartridge. Check the rubber

backer for wear.

4 Maintenance Station Intermittent nozzle failures can be caused

by worn parts in the maintenance station.

Go to and perform the “Maintenance Sta-

tion Service Check” on page 9, then return

to this check.

Diagnostic Information 16

Page 26

4012-0XX

FRU Action

5 Paper Feed Ink smudging and smearing can be

6 Transport Blurred print and voids can be caused by

7 Bidirectional Alignment Uneven vertical lines can be adjusted by

caused by paper problems or problems in

the paper feed area. Check the following:

• Correct type of paper is in the machine.

Also check the paper for curl and wrinkles.

• Feed roller for wear, dirt, or looseness.

• Gears for wear or binds.

• Paper path for obstructions.

• Star rollers for binds or dirt.

The exit roller and star rollers keep tension on the paper by moving slightly

faster than the feed rollers. A binding

star roller can put vertical marks on the

paper.

• Subframe is properly snapped into position.

problems in the transport area. Check the

following:

• Transport belt for wear.

• Carrier guide and carrier guide rod for

wear or dirt.

• Idler pulley parts for wear, damage, or

looseness.

• Encoder strip for wear or dirt.

• Subframe is properly snapped into position.

performing the “Bidirectional Alignment

Adjustment” on page 29.

17

Page 27

4012-0XX

Printing Problem Service Check

If test prints, faxes, or printer jobs do not print correctly (not a print

quality problem), run the Print Engine Test.

FRU Action

1 Machine does not start the test: Make sure all the pins of connector J7 are

2 The machine responds butdoes

not complete the test:

3 The tests prints correctly: There is a problem with the print job, t he

shorted together and try to run the test

again.

If the test still does not start, go to “Power

Service Check” on page 11.

Refer to the appropriate service check for

the symptom.

parallel cable, the LCU board, the fax

board, the fax/LCU cables, or the printer/

fax cable. Check the cables and their continuity. If no problem is found, replace the

fax board and then the LCU board.

Diagnostic Information 18

Page 28

4012-0XX

Scanner Document Feed Service Check

Before beginning ser vice, examine the following:

• Are the pages damaged or dog-eared, are pages stuck together?

• Is the paper being fed too thin (less than 16 lb paper), or too thick

(greater than 24 lb paper)?

• Are the pages too small to feed properly?

• Too many pages being fed (greater than 20)?

• Are the scanner entr y guides set properly?

• Are both sides of the scanner front frame latched?

The scanner document feeder can be checked using the “Scanner

Feed Test” on page 25.

FRU Action

1 Feed Rollers & Restraint Pad Check for dirty, worn, or damaged rollers.

2 Paper Sensors The operator panel message should

3 Motor Fax board J3-5 and J3-6 should have

4 Gear Train Inspect the gear teeth for damage. Rotate

5 Fax Board or Connections Check scanner motor (J3) and paper sen-

Make sure the restraint pad and its spring

are in good condition. Make sure the pick

springs and all roller springs are undamaged. Refer to “Scanner Cleaning Proce-

dure” on page 55.

change when a document is fed into the

scanner. Check for fax board J6-3 to

change from 0 V dc to +5 V dc as the entry

sensor flag is toggled. Check for fax board

J6-6 to change from 0 V dc to +5 V dc as

the second sensor flag is toggled.

+15 V dc.

Warning: Disconnecting scanner motor

while the machine is plugged in can damage the fax board. Voltage is present on

the board even with the power switch off.

Unplug the machine before proceeding.

Disconnect the motor from the fax board.

Motor pins 1 through 4 should not have

continuity to each other or to ground.

the gear train to check for binds.

sor (J6) cable connections to fax board.

19

Page 29

4012-0XX

Scanner Service Check

FRU Action

1 LED Array A failed LED array results in either black or

2 Scanner and Fax Board If there is no image (all white image),

3 PC Scanner Software If the machine sends faxes properly but

very dark output. If a single LED fails, the

output will have a black or dark vertical

fuzzy stripe. The voltage at fax board J7-3

should be +12 V dc during a scan.

Replace the array if the voltage is correct.

check the connection of the scanner data

cable to both the scanner (J1) and the fax

board (J8). A scanner CCD unit failure

results in either a white image, a black

image, or an image with one or more thin

vertical black lines. Replace the scanner

CCD unit.

It is not possible to be certain whether an

all-black or all-white scan failure is due to

the CCD unit or the fax board. In general,

if the machine performs non-scanning

functions involving the fax board (for

example, receiving a fax, exchanging

stored data with the PC, or accepting data

entered from the operator panel) the fax

board is probablyOK.If replacing the CCD

unit does not correct the problem, reinstall

the old CCD unit and replace the fax

board.

does not create a scanned image file on

the PC, there is a problem with the PC

scanner software installation or configuration.

Diagnostic Information 20

Page 30

4012-0XX

Transport Service Check

FRU Action

1 Transport Motor Check the motor for binds, or loose motor

2 Printer Board Unplug the machine and disconnect J6

3 Transport Belt

Carrier Guide or Guide Rod

Idler Pulley Parts

Cable Clip

pulley.

Warning: Disconnecting the transport

motor while the machine is plugged in can

damage the printer board. Voltage is

present on the board even with the power

switch off. Unplug the machine before proceeding.

Disconnect the transport motor (J6) from

the printer board. Check for 8 to 18 ohms

between pins 1 and 2 on the motor cable.

If the reading is incorrect, replace the

motor.

Check for motor pins shorted to the motor

housing. If you find a pin shorted to the

housing, replace the motor. If the failure

remains, replace the printer board.

from the printer board. Plug the machine

in and check for a pulse of 3 to 5 V dc

between J6-1 and ground and between

J6-2 and ground on the printer board as

the machine goes through POST.

Check for worn, loose or broken parts.

Clean the carrier guide rod. Do not lubricate the rod or the carrier rod bearings.

Check for obstructions blocking carrier

movement.

4 Encoder Strip Check for wear and dirt.

5 Printhead Cables Be sure the printer board connectors J1

6 Maintenance Station A problem with the maintenance station

and J2 are fully seated. Check the cables

for damage.

can cause carrier movement problems at

the right margin:

Go to the “Maintenance Station Service

Check” on page 9.

21

Page 31

4012-0XX

Diagnostic Aids 3

Call Monitoring

Call Monitoring plays tones during the call connection. This is helpful

in diagnosing communication problems.

To invoke this aid, press Setup, then select SPK. Press an arrow key

to turn the speaker on or off, press OK to save the setting and then

press Stop.

Error Report

When a fax transmission cannot be completed, the machine prints

an Error Report. This is useful in determining whether service is

required to correct the communication problem.

Frame Service Position

For ease of access to the electronic boards, the frame can be pivoted out of the way without being removed. Remove the covers. Disconnect the cables from the frame on the right side of the printer and

faxboards. Unsnap the right front and right rear frame supports from

the machine base. Pivot the printer frame up 90°on the left feet.

Hex Print Mode

Perform this test with a black print cartridge installed. Use hex mode

to help evaluate data stream problems. All data (including both control and character data) print in hexadecimal digits instead of ASCII.

To activate, press Setup, then select PRT. Use the right arrow to

move the cursor to Diag and press OK. Select HEX. Then send the

PC job to be printed in hexadecimal.

Press Stop to return to ASCII mode, and press Stop again to exit

from the service menus.

Diagnostic Aids 22

Page 32

4012-0XX

Machine Checkout

Use the standard functions of the machine to verify the correct operation of its subsystems. Copying a document confirms that the scanner and the printer engine is working. Sending a fax verifies that the

scanner and the telephone connection are OK. Printing a job from

the PC verifies that the parallel port and the print engine are OK.

Receiving a fax to memor y confirms that the telephone connection

and the memory on the fax board are good.

Memory Test

Use the Memory Test for testing both system memory and document

memory.

1. Press Setup.

2. Press 2104 to enter the Service Functions menu.

3. Press the right arrow key to select Testing, then press OK.

4. Select MEM.

5. Press Stop several times to exit the test.

Operator Panel Service Position

To operate the machine with the covers removed, the operator panel

can be positioned on a table at the left of the machine and the cable

connected to the fax board.

23

Page 33

4012-0XX

Operator Panel Test

This test activates each LED in sequence and cycles all pels of the

LCD display. It also allows the servicer to test each button.

1. Press Setup.

2. Press 2104 to activate the Service Functions menu.

3. Press the right arrow to move the pointer to Testing, then press

OK.

4. Select PNL.

5. Press any button (except Stop) to start the button test. Followthe

instructions on the display to press and test each button.

6. Press Stop at any time to end the test. Press Stop s everal times

to exit the menus.

Reset Button

This recessed button on the operator panel is covered with a shield

and must be pressed with a small tool or straightened paper clip.

The Reset button does a hardware reset of the fax board and operator panel. Pressing Reset does not erase stored faxes or the contents of the phone book. The Reset button does not reset the printer

board; unplugging the machine resets the printer board.

Print Engine Test

Use the Print Engine test for testing the pr inter board and inkjet

printer engine independent of the other machine subsystems. T his

test can be run with the fax, LCU, or operator panel boards disconnected or defective.

1. Unplug the machine.

2. Remove the right cover and locate printer board header J7.

3. Short all four pins together with a screwdriver and plug the

machine in.

The test print will run continuously until the machine is unplugged.

The pins do not need to stay shorted after the test starts.

Diagnostic Aids 24

Page 34

4012-0XX

Purge Test

This test prints out a nozzle test pattern followed by several gray

lines and another nozzle test pattern. Use this test to check the function of all the nozzles in the print cartridge. This test also checks the

electronic connection to the print cartridge. During the test, the printhead cartridge goes through a maintenance cleaning at the maintenance station. Run this test with either the black or the color

cartridge installed.

1. Press Setup.

2. Select PRT.

3. Select PUR.

4. Press Stop several times to exit the menus.

Scanner Feed Test

This test exercises the scanner Automatic Document Feed to allow

you to verify the paper pick and scanner motor function. This test

feeds paper but does not test scanning.

1. Press Setup.

2. Press 2104 to activate the Service Functions menu.

3. Use the right arrow to select Testing and press OK.

4. Select ADF.

5. Insert one or more sheets into the scanner ADF and follow the

panel instructions.

6. Press Stop several times to exit the service menus.

25

Page 35

4012-0XX

Setting the Machine Serial Number

When the fax board is replaced, the machine serial number needs to

be saved into memory.

1. Press Setup.

2. Press 2104 to activate the Service Functions menu.

3. Press OK to enter the Service Setup menu.

4. Select SRN.

5. Enter the machine serial number (4012 followed by 10 characters) found on the rear label.

6. Press OK to save the number. Press Stop several times to exit

the service menus.

Test Print

From the operator panel, print the Setup Conditions report (press

Setup, then press the button for LST) to determine that the operator

panel, the fax board, the printer board, the ASF, and the print engine

areperformingcorrectly.

There are two other test prints available. Press Setup, then the button for PRT. Press the right arrow to select Diag and then press OK.

On this menu, FON pr ints the fonts available in the printer. TST

prints a test print which can show a non-functioning printhead nozzle. Press Stop several times to exit the service menus.

Diagnostic Aids 26

Page 36

4012-0XX

Repair Information 7

This chapter explains how to make adjustments to the printer and

how to remove defective parts. Read page 28 before handling electronic parts.

Warning: Medley has a soft power key which does not remove

machine power; it shuts down visible machine activity. When the

machine is plugged in power is always present on the fax board and

printer board. Before connecting or disconnecting any machine components always unplug the machine from the wall outlet.

Repair Information 27

Page 37

4012-0XX

Handling ESD-Sensitive Parts

Many electronic products use par ts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual precautions, such as turning off power before removing logic boards:

• Keep the ESD-sensitive part in its original shipping container (a

special “ESD bag”) until you are ready to install the part into the

machine.

• Make the least-possible movements with your body to prevent an

increase of static electricity from clothing fibers, carpets, and furniture.

• Put the ESD wrist strap on your wrist. Connect the wrist band to

the system ground point. This discharges any static electricity in

your body to the machine.

• Hold the ESD-sensitive part by its edge connector shroud

(cover); do not touch its pins. If you are removing a pluggable

module, use the correct tool.

• Do not place the ESD-sensitive part on the machine cover or on

a metal table; if you need to put down the ESD-sensitive part for

any reason, first put it into its special bag.

• Machine covers and metal tables are electrical grounds. They

increase the ri sk of damage because they make a discharge path

from your body through the ESD-sensitive part. (Large metal

objects can be discharge paths without being grounded.)

• Prevent ESD-sensitive parts from being accidentally touched by

other personnel. Install machine covers when you are not working on the machine, and do not put unprotected ESD-sensitive

parts on a table.

• If possible, keep all ESD-sensitive parts in a grounded metal cab-

inet (case).

• Be extra careful in working with ESD-sensitive parts when cold-

weather heating is used because low humidity increases static

electricity.

Repair Information 28

Page 38

4012-0XX

Adjustments

Bidirectional Alignment Adjustment

Perform this adjustment with the black print cartridge installed.

Note: For machines at software version 5.15.5.2 or lower (press

Setup LST to print the report listing the version number), this adjustment affects only Letter quality mode and Step 5 and its note do not

apply. If bidirectional alignment in Draft mode is a problem on a

machine at this level, enter Setup PRT Setup and either set Printing

Quality to Letter or set Printing Direction to Unidir.

1. Press Setup.

2. Select PRT, select Diag (diagnostics), and then select Bidi.

3. Open the top cover to see the alignment test print. A page loads

and the bidirectional alignment pattern prints. The pattern consists of three lines of vertical bars. The bars are aligned when

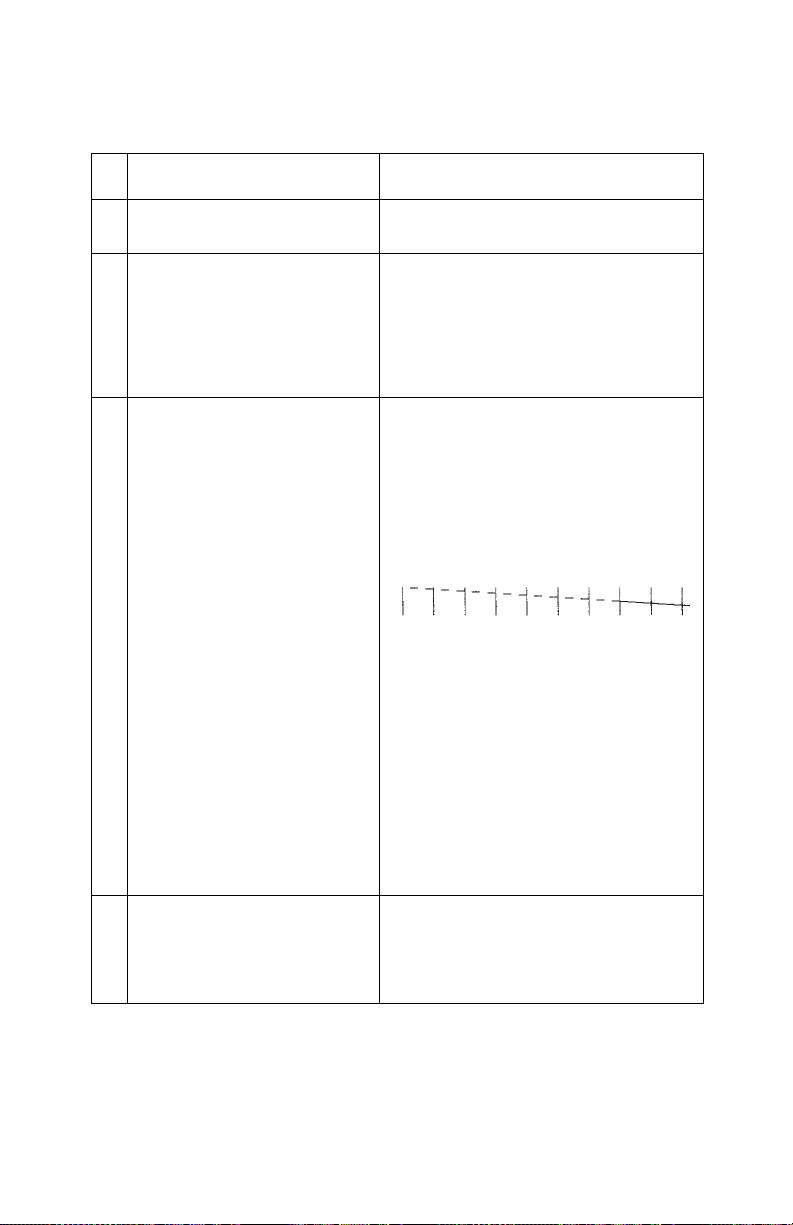

the adjustment is correct. The following sample requires the center vertical bars to be moved to the right.

4. The center bars can be aligned in increments of 1/1200

(0.02 mm). If the lines are not straight, press the left arrow key

(←) to move the center of the lines to the left, or press the right

arrow key (→) to move them to the right. Each time you press an

arrow key the three lines print.

5. When the alignment is correct, press the top right key under the

display to switch to Draft mode. Follow the same procedures as

above to align the bars in Draft mode.

Note: Single left and right arrows are printed while in Letter

mode, and triple left and right arrows are printed while in Draft

mode.

6. When the adjustment is complete press Stop to save the setting

then press Stop again to exit the Setup menu.

29

Page 39

4012-0XX

Removal Procedures

The following procedures are arranged according to the name of the

part discussed. When there is artwork to support a procedure, it follows the text.

Note: Unplug the machine before beginning any electrical service.

The power key does not remove power from the electronics.

Auto Sheet Feed (ASF) Assembly Removal

1. Remove the paper load lever.

2. Remove the left and right side covers.

3. Remove the clip from the right side subframe, if installed.

4. Remove the top cover.

5. Release the latches holding the subframe to the ASF.

6. Push in the two latches [A] that secure the ASF to the side

frame, then lift up the sheet feed to remove it from the machine.

A

A

When you reinstall the ASF, be sure the feed arm assembly is vertical, with the feed pawl at the top.

Repair Information 30

Page 40

4012-0XX

ASF Envelope Buckler and Pick Roller Hub Removal

1. Remove the ASF assembly.

2. Remove the inside C-clip from the pick roller shaft and pull the

shaft to the right far enough to remove the envelope bucklers

and pick rollers.

3. Remove the pick roller hubs from the bucklers.

ASF Right and Left Edge Guide Assemblies Removal

1. Remove the ASF assembly.

2. Remove the manual insert tray by prying one of the side frames

away from it.

3. Remove the inside C-clip from the pick roller shaft and pull the

shaft out to the right.

4. Remove the pick roller and buckler assemblies.

5. Remove the paper load lever and shaft by pulling them out from

the right side of the ASF assembly. Be careful not to lose the

small gear on the left end of the shaft. When you reinstall this

shaft, it must be parallel with the ASF housing.

6. Pivot the guide assembly up and pry it off the back plate.

Battery Option

1. Unplug the machine.

2. Open the access door on the left side cover. The battery option

is attached to the door.

3. Disconnect the battery option cable from the fax board.

4. Remove the battery board mounting screw.

Note: If the battery option is being replaced, install the jumper on

the new battery option board. If the battery option is being removed,

install the jumper at J9 (2 center pins) of the fax board. Failure to

install the jumper will cause a dead machine condition.

Carrier Guide Rod Removal

1. Open the top cover.

2. Remove the print cartridge.

3. With the carrier centered, carefully release the two carrier guide

rod latches and lift the shaft slightly.

4. Unlatch the two carrier guide rod latches by pushing the latches

to the rear.

5. Gently push the carrier to the extreme right and remove the carrier guide rod.

31

Page 41

4012-0XX

Carrier Removal

1. Open the top cover.

2. Remove the right side cover

3. Remove the print cartridge.

4. Disconnect the printhead cables from the printer board.

5. Cut the cable tie and remove the toroid.

6. Move the carrier in line with the opening in the carrier transport

motor frame.

7. Reach through the opening and pull the belt from the carrier.

8. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Move the rod to the left until the right end can

be lifted above the frame. Remove the carrier guide rod to the

right, above the carrier motor. Be careful not to damage the

encoder strip.

9. Pull the ends of the printhead cables into the machine, then

remove the cables from the four retainers in the paper guide

starting from the right.

Carrier Transport Belt Removal

1. Open the top cover and then remove the left and right side

covers.

2. Move the carrier in line with the opening in the carrier transport

motor frame.

3. Reach through the opening and pull the belt from the carrier.

4. Remove the belt from the carrier transport motor pulley.

5. Remove the belt from the idler pulley and pull it through the

opening in the left side frame.

Note: When you reinstall the belt be sure to insert the bottom of the

belt into both the lower and upper belt grips on the carrier. DO NOT

INSERT THE TOP OF THE BELT INTO THE UPPER GRIP

Repair Information 32

.

Page 42

4012-0XX

Carrier Transport Motor Removal

1. Open the top cover and then remove the left and right side

covers, then the lower front cover.

2. Disconnect the carrier transport motor (J6) from the printer

board.

3. Remove the two motor mounting screws and remove the motor.

Carrier Transport Motor Frame Removal

1. Remove the top cover and then the left and right side covers.

2. Remove the rear and front covers.

3. Disconnect J6 from the printer board.

4. Disconnect the four scanner connectors and the speaker connector from the fax board.

5. Remove the scanner and subframe.

6. Move the carrier in line with the opening in the carrier transport

motor frame.

7. Reach through the opening and pull the belt from the carrier.

8. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier guide rod through the

opening in the left side frame. Be careful not to damage the

encoder strip.

9. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames and pivot the carrier transport motor frame down

and out of the side frames.

33

Page 43

4012-0XX

Covers Removal

Front Cover

1. Remove the left and right side covers.

2. Flex the front cover to release the latches on each end.

3. Lift the cover to free the l ower latch and remove the cover.

Note: When reinstalling the front cover, make sure the lower latch

and side latches are installed properly to prevent the cover from

interfering with the paper ejectors.

Rear Cover

1. Remove the left and right side covers.

2. Flex the tabs on the subframe to release both latches.

3. Lift the cover to free the l ower latch and remove the cover.

Top Cover

1. Bend the subframe slightly to free the top cover pivot pin.

2. Remove the top cover.

Right Side Cover

1. Remove the paper load lever.

2. Open the operator panel cover and the top cover.

3. Remove the screw from inside the subframe just above scanner.

4. Lift on the top inner edge of the cover to free the top latches.

5. Rotate the cover to the right to free the lower latches.

Left Side Cover

1. Open the operator panel cover and the top cover.

2. Remove the screw from inside the subframe just above scanner.

3. Lift the top inner edge of cover to free the top latches.

4. Rotate the cover to the left to free the lower latches.

5. If the battery option is installed, disconnect its cable from the fax

board (J9).

Operator Panel and Cover

1. Remove the left and right side covers.

2. Flex the subframe to free one of the pivot pins.

3. Remove the two screws and the ESD shield.

4. Disconnect the operator panel cable from the back of the operator panel.

5. Unsnap the operator panel from the cover.

Repair Information 34

Page 44

4012-0XX

Encoder Strip Removal

The encoder strip can be easily damaged; use care when removing

or installing.

1. Open the top cover.

2. Move the carrier in line with the opening on the carrier transport

motor frame.

3. Reach through the opening and pull the belt from the carrier.

4. To unlock the carrier guide rod latches, rotate the rod top to rear.

Gently push the carrier guide rod latches at each end of the rod

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Place the carrier on top of the paper guide.

5. Remove the encoder strip from the left mounting peg. To do this,

push the right latch slightly to the left.

6. Remove the encoder strip from the right latch.

When you install the encoder strip, be sure it is fully seated on the

left mounting peg.

End-of-Forms Flag Removal

1. Remove the covers.

2. Disconnect the printer board connectors: J1, J2, J4, J5, and J6.

3. Disconnect the fax board connectors: J3 and J8.

4. Raise the machine frame into the service position.

5. Pivot the weighted end of the end-of-forms flag through the

opening in the middle frame.

6. Unsnap the flag by moving it to the rear.

Exit Roller Assembly Removal

1. Remove the covers.

2. Remove the carrier transport frame.

3. Pivot the paper ejector pusher toward the front then pull it to

remove the paper ejector from the shaft.

4. Removethe bushing from the left end of the exit shaft. Todo this,

pull the tab and rotate the bushing.

5. Slide the exit roller to the left and lift it out of the machine.

35

Page 45

4012-0XX

EPROM Removal

1. Unplug the machine before beginning any electrical service. The

power key does not remove power from the electronics.

2. Remove the top cover.

3. Disconnect the printhead cables from the printer board.

4. Disconnect connectors J4, J5, and J6 from the printer board.

5. Disconnect the scanner motor connector J3 from the fax board.

6. Release the latches at the right-front and right-rear legs of the

frame, then lift and pivot the frame 90° to the left into the service

position.

7. Gently pry the EPROM from the board.

8. To install the EPROM:

a. Ensure the orientation notch is to the right for the fax board or

to the front for the printer board. Refer to: “Parts and Test

Point Locations” on page 49.

b. Ensure that each module pin aligns with each socket, so

there are no bent pins.

c. Apply even pressure on the top of the module until it is seated

against the socket.

Repair Information 36

Page 46

4012-0XX

Fax Board, Printer Board, and LCU Board Removal

1. Unplug the machine before beginning any electrical service. The

power key does not remove power from the electronics.

2. Remove the left and right side covers, the front cover and the

rear cover,and disconnect J1, J2, J4, J5 and J6 from the printer

board.

3. Disconnect the scanner motor cable from J3 and scanner data

cable J8 from the fax board.

4. Unsnap the two print engine feet at the right side of the machine.

5. Pivot the print engine up around the l eft pivots, being sure no

cables are being strained, until the left side of the print engine is

resting on the table.

6. Disconnect the remainder of the cables required to remove the

board.

7. Cut the cable tie around the support posts.

8. Remove the EPROM (see “EPROM Removal” on page 36)for

installation on the new board. Remove the ground screw and

remove the board.

Note: If the printer board is replaced, check the bidirectional alignment. If the fax board is replaced, inspect the LCU board for physical

damage. Replace the LCU board if damage is present. The machine

serial number needs to be saved into memory, if the fax board is

replaced. Refer to “Setting the Machine Serial Number” on page 26.

Feed Arm Assembly Removal

1. Remove the covers.

2. Remove the ASF.

3. Remove the C-clip from the center of the large gear and remove

thefeedarmassembly.

Inside Idler Gears Removal

1. Remove the covers.

2. Remove the ASF.

3. Disconnect the printhead cables from the printer board.

4. Remove the paper guide.

5. Remove the C-clip from the feed ar m assembly and remove the

feed arm assembly.

6. Pull the idler gears off the mounting studs.

37

Page 47

4012-0XX

Large Feed Roller Assembly Removal

1. Remove the top cover.

2. Disconnect the printhead cables from the system board.

3. Disconnect connectors J4, J5, and J6 from the system board.

4. Disconnect scanner motor connector J3 from the fax board.

5. Release the latches at the right front and right rear legs of the

frame, then lift and pivot the frame 90° to the left into the service

position.

6. Disconnect the 3 springs from the bottom of the middle frame

assembly.

7. Remove the large feed roller assembly.

Left Side Frame Removal

1. Remove the covers.

2. Remove the print cartridge.

3. Remove the subframe.

4. Remove the ASF.

5. Disconnect the printhead cables from the printer board.

6. Disconnect connectors J4, J5, and J6 from the printer board.

7. Remove the machine from the base. To do this, release the

latches at the right-front and right-rear legs of the frame, then lift

and pivot the frame 90° to the left. Lift the frame to disengage

the left legs from the base.

8. Move the carrier in line with the opening in the carrier transport

motor frame.

9. Reach through the opening and pull the belt from the carrier.

10. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier guide rod through the

opening in the left side frame. Be careful not to damage the

encoder strip.

11. Pull the ends of the printhead cables into the machine, then

remove the cables from the four retainers in the paper guide

starting from the right.

12. Disengage the left paper guide latch by carefully moving the rear

of the left side frame to the left.

13. Disengage the right side of the paper guide from the latch and lift

it from the machine.

Repair Information 38

Page 48

4012-0XX

14. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames, then pivot the carrier transport motor frame down

and out of the side frames.

15. Place the machine on its back and push the left side frame latch

to the rear and remove the frame from the machine.

16. Unsnap the feet from the left side frame.

When you reinstall the paper guide, be sure the front edge goes

under the rear of the carrier guide. If the paper guide is on top of the

carrier guide, push down the front, bottom edge. The paper guide

will snap under the carrier guide.

To install the left side frame onto the middle frame, align the right

side frame latch with the latching surface on the middle frame before

you align the roller shafts and carrier guide. It may be easier to do

this with the machine on its right side.

Maintenance Drive and Rocker Assemblies Removal

1. Remove the covers.

2. Remove the ASF.

3. Remove the right side frame.

4. Gently unlatch the maintenance assembly latches.

5. Slide out the maintenance drive assembly and then the rocker

assembly.

When you reassemble the drive assembly, be sure the forks engage

the pins on the rocker assembly.

Memory Option

1. Unplug the machine.

2. Open the access door in the left side cover.

3. Lift up the memory board to remove it.

Note: The 1MB option consists of two modules and the 3MB

option has six modules.

4. From the operator panel, print the Setup Conditions report

(press Setup, then select LST) to verify the installed memory is

recognized by the machine.

39

Page 49

4012-0XX

Middle Frame Removal

1. Remove the covers.

2. Remove the print cartridge.

3. Remove the subframe.

4. Remove the ASF.

5. Disconnect the printhead cables from the printer board.

6. Disconnect J4, J5, and J6 from the printer board.

7. Remove the machine from the base. To do this, release the

latches at the right front and right rear legs of the frame, then lift

and pivot the frame 90° to the left. Lift the frame to disengage

the left legs from the base.

8. Remove the paper ejectors from the middle frame.

9. Remove the left side frame.

10. Remove the exit shaft.

11. Remove the small feed roller shaft.

12. Remove the large feed roller shaft and springs.

13. Remove the end-of-forms flag.

14. Remove the right side frame.

15. Remove the maintenance station.

Outside Idler Gears Removal

1. Remove the right cover.

2. Disconnect the printhead cables from the printer board.

3. Each gear is latched in place. Push up the latch and remove the

gear from the side frame stud by pulling the gear from the bottom.

Paper Ejectors Removal

1. Remove the covers.

2. Pivot the paper ejector pusher toward the front then pull it to

remove the paper ejector from the shaft.

3. Unsnap the paper ejectors from the middle frame.

Paper Feed Motor Removal

1. Remove the right cover.

2. Disconnect the paper feed motor connector from printer

board J5.

3. Remove the two mounting screws.

Repair Information 40

Page 50

4012-0XX

Paper Guide Removal

1. Remove the covers.

2. Remove the ASF.

3. Remove the subframe.

4. Disconnect the printhead cables from the printer board.

5. Pull the ends of the printhead cables into the machine, then

remove the cables from the four retainers in the paper guide

starting from the right.

6. Disengage the left paper guide latch by carefully moving the rear

of the left side frame to the left.

7. Disengage the right side of the paper guide from the latch and lift

it from the machine.

When you reinstall the paper guide, be sure the front edge goes

under the rear of the carrier guide. If the paper guide is on top of the

carrier guide, push down the front, bottom edge. It will snap under

the carrier guide.

Paper Release Lever Removal

1. Remove the left cover.

2. Pull the paper release lever forward.

3. Place a screwdriver into the slot [A] of the paper release lever.

Push the screwdriver down to release the latch, then remove the

lever.

41

A

Page 51

4012-0XX

Power Supply Removal

1. Unplug the machine before beginning any electrical service. The

power key does not remove power from the electronics.

2. Remove the left and right side covers.

3. Remove the front and rear covers.

4. Disconnect the scanner motor cable from J3 on the right side of

the fax board.

5. Disconnect the five cables connecting the printer board to the

print engine (J1, J2, J4, J5, J6).

6. Unsnap the two print engine feet at the right side of the machine.

7. Pivot the print engine up around the left pivots, being sure no

cables are being strained, until the left side of the print engine is

resting on the table.

8. Disconnect the power leads from the fax board (J2) and the

printer board (J11).

9. Remove the ground screw holding the power supply to the bottom shield.

Note: Make sure the ground screw is secure when reinstalling

the power supply.

10. Unsnap the front latch and lift the power supply from the

machine. Make sure the power supply insulator remains in place

when reinstalling the power supply.

Print Engine Removal

1. Unplug the machine before beginning any electrical service. The

power key does not remove power from the electronics.

2. Remove the left and right side covers.

3. Remove the front and rear covers.

4. Disconnect the six cables connecting the fax board to the print

engine (J3, J4, J5, J6, J7, J8); cut the cable tie on the scanner

cable.

5. Disconnect the five cables connecting the printer board to the

print engine (J1, J2, J4, J5, J6).

6. Unsnap the two print engine feet at the right side of the machine.

7. Pivot the print engine up around the left pivots, being sure no

cables are being strained, until the left side of the print engine is

resting on the table.

8. Lift the print engine to free the left pivot feet from the bottom

cover.

Repair Information 42

Page 52

4012-0XX

Printhead Cable Removal

1. Unplug the machine before beginning any electrical service. The

power key does not remove power from the electronics.

2. Open the top cover.

3. Remove the print cartridge.

4. Remove the carrier.

5. Remove the cable clip [A] from the left side of the carrier.

6. Remove the pointer from the front of the carrier.

A

7. Remove the two sensor mounting screws.

8. Push down the two latches that secure the cradle to the carrier

and pull the cradle up from the carrier.

9. Remove the printhead cable from the alignment pins.

The new cable comes without the folds in it. Place the new cable

next to the old cable and fold the new cable in the appropriate

places.

43

Page 53

4012-0XX

Releasing Plastic Latches

Many of the parts are held in place with plastic latches. To remove

such parts, press the hook end of the latch away from the par t to

which it is latched. The latches break easily. Release them carefully.

Never apply excessive force

Hook

when releasing the hook.

Repair Information 44

Page 54

4012-0XX

Right Side Frame Removal

1. Remove the covers.

2. Remove the print cartridge.

3. Remove the subframe.

4. Remove the ASF.

5. Disconnect the printhead cables from the printer board.

6. Disconnect connectors J4, J5, and J6 from the system board.

7. Remove the machine from the base. To do this, release the

latches at the right front and right rear legs of the frame, then lift

and pivot the frame 90° to the left. Lift the frame to disengage

the left legs from the base.

8. Move the carrier in line with the opening in the carrier transport

motor frame.

9. Reach through the opening and pull the belt from the carrier.

10. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier rod guide latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier rod guide through the

opening in the left side frame. Be careful not to damage the

encoder strip.

11. Pull the ends of the printhead cables into the machine, then

remove the cables from the four retainers in the paper guide

starting from the right.

12. Disengage the left paper guide latch by carefully moving the rear

of the left side frame to the left.

13. Disengage the right side of the paper guide from the latch and lift

the guide from the machine.

45

Page 55

4012-0XX

14. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames, then pivot the carrier transpor t motor frame down

and out of the side frames.

15. Place the machine on its back, then unlatch the right frame latch

from the middle frame and remove the side frame.

Note: For reassembly you may want to remove the carrier guide

and reinstall it after you install the paper guide.

When you reinstall the paper guide, be sure the front edge goes

under the rear of the carrier guide. If the paper guide is on top of the

carrier guide, push down the front bottom edge. It will snap under the

carrier guide.

To install the right side frame onto the middle frame, align the right

side frame latch with the latching surface on the mid frame before

you align the roller shafts and carrier guide. It may be easier to do

this with the machine on its left side.

Repair Information 46

Page 56

4012-0XX

Rubber Backer Removal

1. Open the top cover.

2. Remove the print cartridge.

3. Remove the printhead cable.

4. Remove the rubber backer from the carrier.

Small Feed Roller Assembly Removal

1. Remove the covers.

2. Remove the ASF.

3. Remove the paper guide.

4. Carefully remove the paper release lever.

5. Remove the bushing from the left end of the small feed roller

shaft. To do this, pull the tab and rotate the bushing.

6. Slide the small feed roller assembly to the left and lift it out of the

machine.

Star Roller Removal

1. Remove the covers.

2. Remove the subframe.

3. Move the carrier in line with the opening on the carrier transport

motor frame.

4. Reach through the opening and pull the belt from the carrier.

5. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches at each end of the rod

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Place the carrier on top of the paper guide.

6. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames and pivot the carrier transport motor frame down

and out of the side frames. Place the carrier transport motor

frame face down in front of the machine.

7. Removethe star roller by pushing it forward off the mounting peg

in the carrier transport motor frame.

47

Page 57

4012-0XX

Scanner and Speaker Removal

1. Unplug the machine before beginning any electrical service. The