Page 1

Lexmark T620 and T622

User’s Reference

January 2001

www.lexmark.com

Page 2

Page 3

Table of Contents

Chapter 1: Printer overview ..............................................................9

Chapter 2: Using the operator panel .............................................10

Understanding the operator panel .. ....... ...... ...... ....... .......................................... 10

Using the operator panel buttons ....................................................................... 11

Using the operator panel to change printer settings .......................................... 12

Printing the menu settings page ......................................................................... 13

Menus Disabled ................................................................................................. 13

Chapter 3: Disabling operator panel menus .................................14

Chapter 4: Using the Print and Hold function ..............................15

Printing and deleting held jobs ........................................................................... 15

Accessing held jobs from the operator panel ..................................................... 16

Recognizing when format errors occur .............................................................. 16

Repeat Print ....................................................................................................... 17

Reserve Print ..................................................................................................... 17

Verify Print .......................................................................................................... 17

Confidential jobs ................................................................................................. 17

Chapter 5: Canceling a print job ....................................................19

Chapter 6: Printing folio and statement size paper .....................20

Chapter 7: Choosing print material ...............................................21

Paper characteristics .......................................................................................... 21

Recommended paper ......................................................................................... 22

Unacceptable paper ........................................................................................... 23

Choosing preprinted forms and letterhead ......................................................... 23

Choosing prepunched paper .............................................................................. 24

Choosing paper .................................................................................................. 24

iii

Page 4

Choosing envelopes ........................................................................................... 25

Choosing labels .................................................................................................. 25

Choosing card stock ........................................................................................... 26

Choosing transparencies ................................................................................... 27

Chapter 8: Storing paper ................................................................28

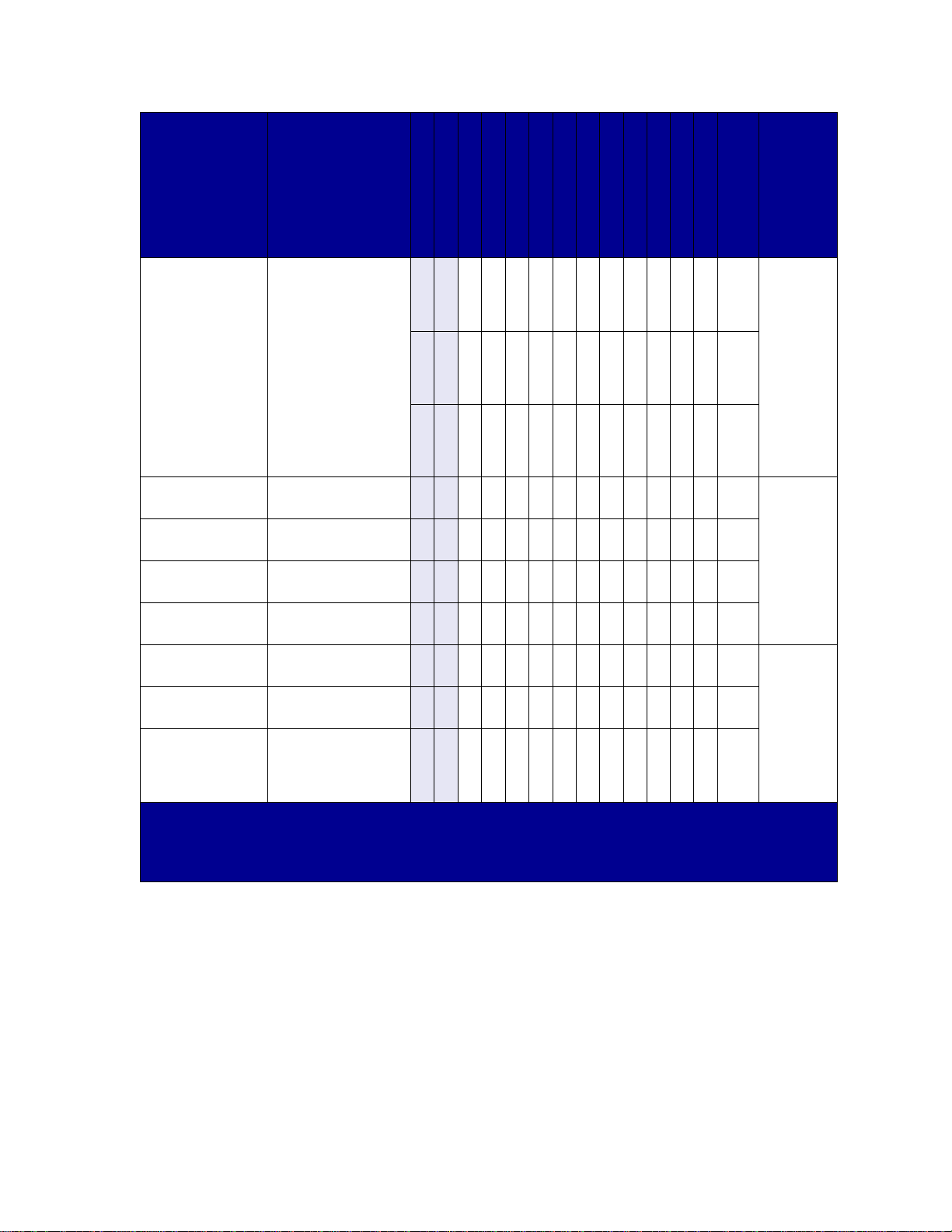

Chapter 9: Print material specifications ........................................29

Chapter 10: Loading print material ................................................36

Chapter 11: Loading a paper tray ..................................................37

Chapter 12: Loading the multipurpose feeder ..............................40

Capacity ............................................................................................................. 40

Paper dimensions .............................................................................................. 40

Trouble-free printing ................. ............................................. ...... ....... ...... ....... ... 40

Closing the multipurpose feeder .................................... .................................... 48

Chapter 13: Loading the envelope feeder .....................................49

Chapter 14: Loading the 2000-sheet drawer .................................53

Chapter 15: Tray linking .................................................................54

Chapter 16: Tips for avoiding paper jams .....................................55

Chapter 17: Replacing the print cartridge .....................................56

Chapter 18: Replacing the charge roll ...........................................57

Chapter 19: Replacing the transfer roll .........................................58

Chapter 20: Replacing the fuser assembly ...................................59

Chapter 21: Replacing the staple cartridge ..................................60

Chapter 22: Resetting the maintenance counter ..........................61

Chapter 23: Ordering supplies .......................................................63

iv

Page 5

Chapter 24: Storing supplies .........................................................66

Chapter 25: Checking an unresponsive printer ...........................67

Chapter 26: Clearing paper jams ...................................................68

200 and 201 Paper Jam

Remove Cartridge .............................................................................................. 70

202 Paper Jam

Open Rear Door ................................................................................................. 71

230 Paper Jam

Check Duplex ..................................................................................................... 74

24x Paper Jam

Check Tray x ...................................................................................................... 77

250 Paper Jam

Check MP Feeder .............................................................................................. 82

260 Paper Jam

Check Env Feeder ............................................................................................. 83

27x Paper Jam

Check Bin x ..................................................................................................... 85

28x Paper Jam ................................................................................................... 89

Chapter 27: Clearing staple jams ...................................................91

Chapter 28: Solving display problems ..........................................94

Chapter 29: Solving print problems ..............................................95

Chapter 30: Solving print quality problems ..................................97

Chapter 31: Solving option problems .........................................100

Chapter 32: Solving network printing problems ........................102

Chapter 33: Resolving other problems and questions ..............103

Chapter 34: Understanding printer messages ...........................104

Chapter 35: Using printer menus .................................................136

Chapter 36: Finishing Menu .........................................................137

v

Page 6

Chapter 37: Infrared Menu ............................................................143

Chapter 38: Job Menu ...................................................................147

Chapter 39: LocalTalk Menu .........................................................150

Chapter 40: Network Menu ...........................................................154

Chapter 41: Paper Menu ...............................................................158

Chapter 42: PCL Emul Menu ........................................................166

Chapter 43: Parallel Menu ............................................................171

Chapter 44: PostScript Menu .......................................................176

Chapter 45: Quality Menu .............................................................177

Chapter 46: Serial Menu ...............................................................179

Chapter 47: Setup Menu ...............................................................185

Chapter 48: Utilities Menu ............................................................191

Chapter 49: USB Menu ..................................................................195

Chapter 50: Removings options ..................................................198

Removing an output option .............................................................................. 199

Removing the envelope feeder ........................................................................ 201

Removing a paper tray or duplex unit .............................................................. 202

Removing printer or flash memory ................................................................... 203

Removing an option card ................................................................................. 204

Chapter 51: Disabling Power Saver .............................................205

Chapter 52: Printer specifications ...............................................206

Dimensions ...................................................................................................... 206

Duty cycle ......................................................................................................... 206

vi

Page 7

Notices ............................................................................................207

Edition notice ........ ....... ...... ....... ...... ....... ...... ...... ....... ........................................ 208

Trademarks ...................................................................................................... 208

Safety information ............................................................................................ 209

Cautions and warnings ...... ....... ...... ....... ...... ............................................. ....... . 209

Electronic emission notices ...... ...... ....... ...... ...... ....... ...... ....... ...... ..................... 210

Energy Star ..................................................................................................... 212

Laser notices .................................................................................................... 212

Index ................................................................................................ 215

vii

Page 8

viii

Page 9

1

Printer overview

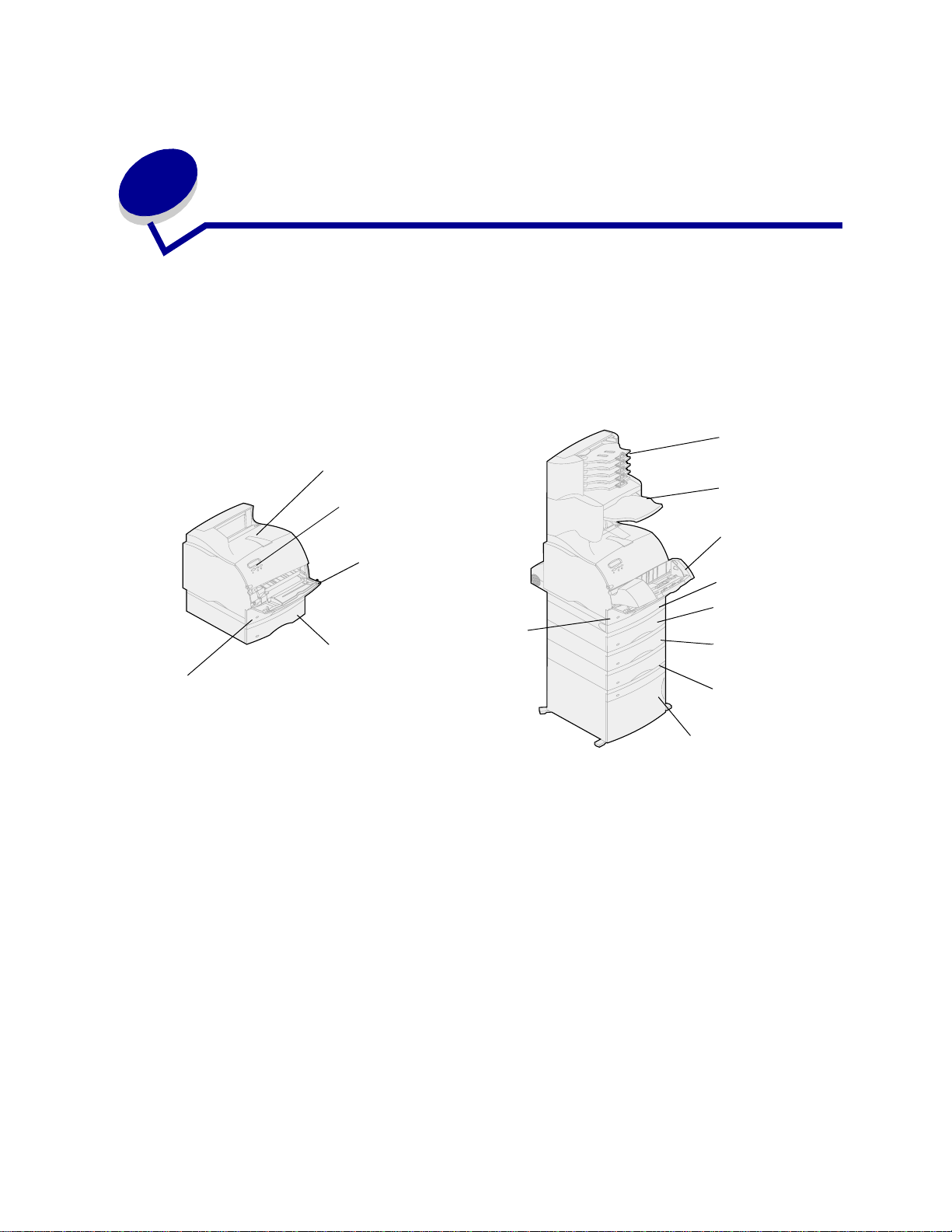

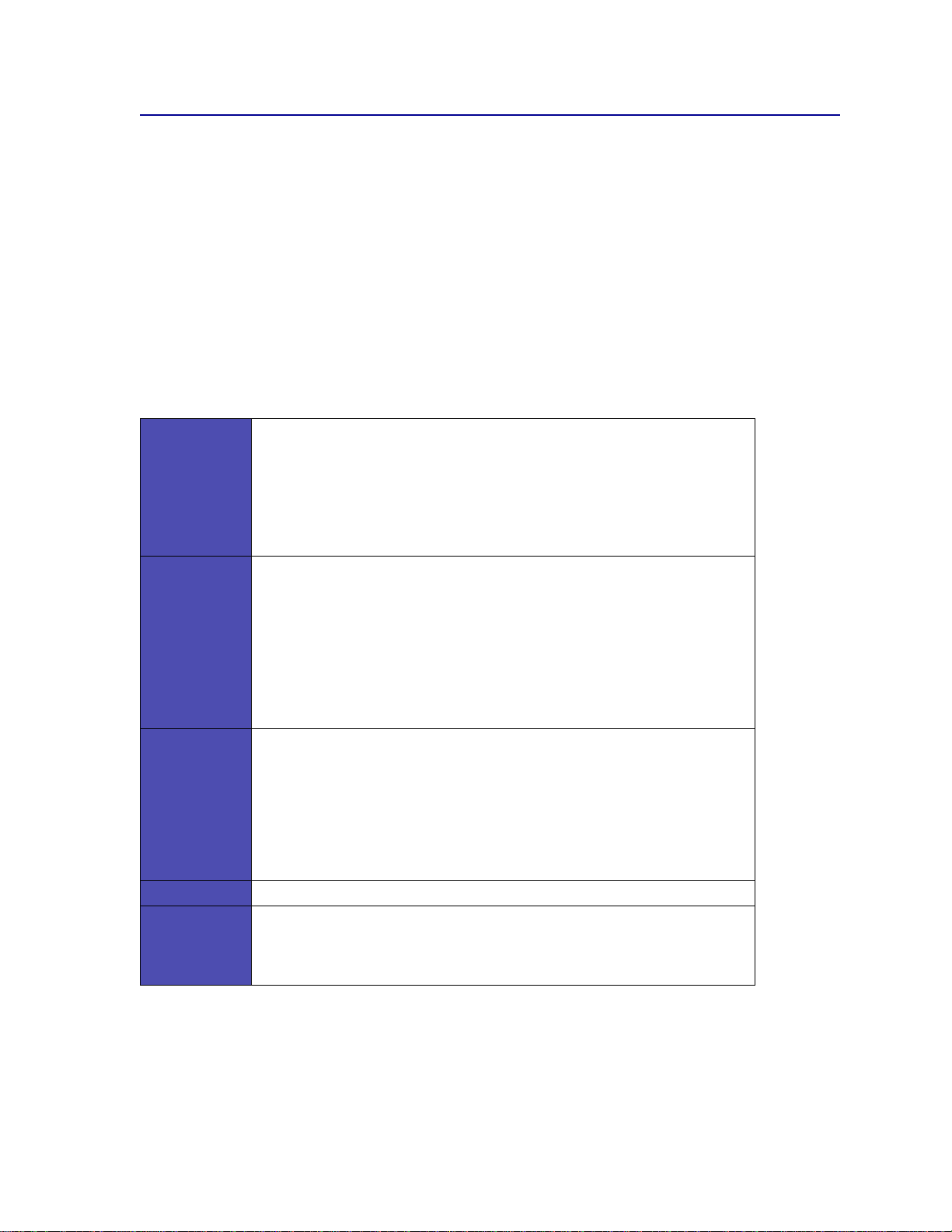

The following illustrations show a Lexmark™ T620 and T622 standard network model configuration

and a fully configured printer. If you have attached paper handling options to your printer, it may look

more like the fully configured model. For information on other possible configurations, refer to the

Setup Guide.

Standard network

model configuration

Tray 1

(integrated tray)

Standard output bin

Operator panel

Multipurpose feeder

Tray 1

(integrated tray)

Tray 2

(optional in

non-network models)

Fully configured

5-bin Mailbox *

Finisher*

Envelope feeder*

Duplex unit*

Tray 2*

(250 or 500 sheets)

Tray 3*

(250 or 500 sheets)

Tray 4*

(250 or 500 sheets)

* Optional

Tray 5*

(2000-sheet drawer)

9

Page 10

2

Using the operator panel

This section contains information about understanding the operator panel, changing printer settings,

and understanding operator panel menus.

You can change most printer settings from your software application or printer driver. Settings you

change from the application or printer driver apply only to the job you are preparing to send to the

printer.

Changes made to printer settings from a software application override changes made from the printer

operator panel.

If you cannot change a setting from your application, use the printer operator panel or the remote

operator panel available from MarkVision™. Changing a printer setting from the printer operator panel

or from MarkVision makes that setting the user default.

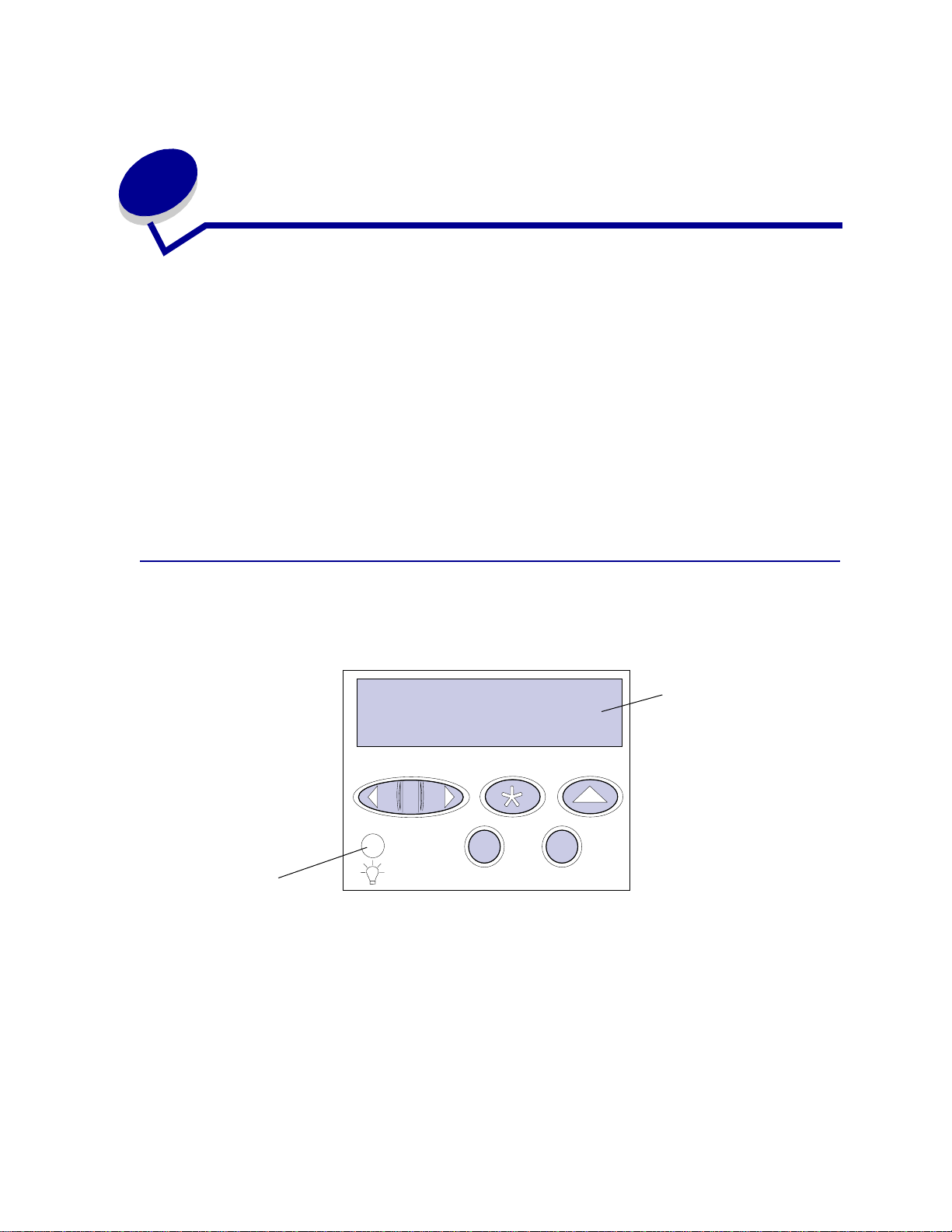

Understanding the operator panel

The printer operator panel has a 2-line by 16-character liquid crystal display (LCD), five buttons, and

one indicator light.

LCD

1

Light

Menu

2

Go

Select

5

3

Return

Stop

4

6

Indicator light

The indicator light gives information about the status of your printer. If the light is:

• Off, the printer is off

• On, the printer is on, but idle

• Blinking, the printer is on and is busy

10

Page 11

Using the operator panel buttons

Use the five operator panel buttons to open a menu, scroll through a list of values, change printer

settings, and respond to printer messages.

The numbers 1 through 6 appear beside the operator panel buttons; these numbers are used to enter

personal identification numbers (PIN) for Print and Hold jobs. For more information, see Using the

Print and Hold function.

The following information describes the functions of each button.

Note: Buttons act upon the information displayed on the second line of the operator

panel.

Go

Menu

Select

Press the

• Return to the Ready state if the printer is in an offline situation (the Ready

• Exit printer menus and return to t he Ready state.

• Clear operator panel error messages.

If you’ve changed printer settings from the operator panel menus, press Go

before sending a job to print. The printer must display Ready for jobs to print.

Each end of the button has a function. Press

• When Ready is displayed, to take the printer offline (out of the Ready state)

• When Busy is displayed, to take the printer to the Job Menu.

• When the printer is offline, press

For menu items with numeric values, such as Copies, press and hold Menu to

scroll through the values. Release the button when the number you want is

displayed.

Press

• Select the menu displayed on the second line of the operator panel.

• Save the displayed menu item as the default setting. The printer displays the

• Clear certain messages from the operator panel.

Go button to:

message does not display on the operator panel).

Menu:

and scroll through the menus.

Menu> to scroll through the menus.

– Press

Depending on the type of menu, this action:

– Opens the menu and displays the first item in the menu.

– Opens the menu item and displays the default setting.

Saved message and returns to the menu item.

<Menu to go to the previous item in the menus.

Select to:

Return Press Return to return to the previous menu level or menu item.

Press

Stop at the Ready, Busy , or W aiting message to temporarily stop all

Stop

activity and tak e the printer offlin e. T he ope rator panel status mes sage cha nges

to Not Ready.

Go to return the printer to the Ready, Busy , or Waiting state.

Press

11

Page 12

Using the operator panel to change printer settings

From the operator panel, you can select menu items and associated values to print your jobs

successfully. You can also use the panel to alter the setup and operating environment of the printer.

See Using printer menus for an explanation of all the menu items.

You can modify printer settings by:

• Selecting a setting from a list of values

• Changing an On/Off setting

• Changing a numerical setting

To select a new value as a setting:

1 From a Ready status message, press Menu. The menu names appear.

2 Continue to press and release Menu until you see the menu you need.

3 Press Select to select the menu or menu item displayed on the second line of the display.

– If the selection is a menu, the menu is opened and the first printer setting in the menu

appears.

– If the selection is a menu item, the default setting for the menu item appears.

(The current user default setting has an asterisk [*] beside it.)

Each menu item has a list of values for the menu item. A value can be:

– A phrase or word to describe a setting

– A numerical value that can be changed

– An On or Off setting

4 Press Menu to move to the value you need.

5 Press Select to select the value on the second line of the operator panel. An asterisk appears

beside the value to indicate that it is now the user default setting. The new setting appears for

one second, clears, displays the word Saved, and then displays the previous list of menu

items.

6 Press Return to go back to previous menus. Make additional menu selections to set new

default settings. Press

User default settings remain in effect until you save new settings or restore the factory defaults.

Settings you choose from your software application can also change or override the user default

settings you select from the operator panel.

Go if this is the last printer setting to change.

12

Page 13

Printing the menu settings page

Complete the following steps to print a list of the current user default settings and installed printer

options:

1 Make sure the printer power is on and the Ready status message appears.

2 Press Menu until you see Utilities Menu, and then press Select.

3 Press Menu until you see Print Menus, and then press Select.

The message Printing Menu Settings appears and remains until the page prints. The

printer returns to Ready when the page or pages finish printing.

If a message appears, see Understanding printer messages for more information.

The diagram in Using printer menus shows the menu items in each menu.

An asterisk (*) next to a value indicates the factory default setting. Factory defaults may differ for

different countries.

Factory defaults are the function settings in effect the first time you turn your printer on. These remain

in effect until you change them. Factory defaults are restored if you select the Restore value for the

Factory Defaults menu item in the Utilities Menu. See Utilities Menu for more information.

When you select a new setting from the operator panel, the asterisk moves next to the selected setting

to identify it as the current user default.

User defaults are the settings you select for different printer functions and store in printer memory.

Once stored, these settings remain active until new ones are stored or the factory defaults are

restored.

Note: Settings you choose from your software application may override the settings you

select from the operator panel.

Menus Disabled

If your printer is configured as a network printer available to a number of users, Menus Disabled ma y

appear when you press

operator panel to inadvertently change a printer default that has been set by the person managing the

printer. You can still use Print and Hold features, clear messages, and select items from the Job Menu

when printing a job, but you cannot change other printer settings. You can, however, use your printer

driver to override printer defaults and select settings for individual print jobs.

Menu from the Ready state. Disabling the menus prevents users from using the

13

Page 14

3

Disabling operator panel menus

To disable the operator panel menus so that changes cannot be made to the printer default settings:

1 Turn the printer off.

Note: Disabling the operator panel menus does not prevent access to the Job Menu or to

Print and Hold functionality.

2 Press and hold Select and Return and turn the printer on.

3 Release the buttons when you see Performing Self Test.

Config Menu appears on the first line of the display.

4 Press Menu until you see Panel Menus, and then press Select.

Disable appears on the second line of the display.

5 Press Select.

Locking Menus appears briefly.

6 Press Menu until you see Exit Config Menus, and then press Select.

The menus are disabled. If you press Menu, the message Menus Disabled appears.

To enable the menus:

1 Repeat steps 1 through 4.

2 Press Menu until you see Enable.

3 Continue with steps 5 and 6.

14

Page 15

4

Using the Print and Hold function

When sending a job to the printer, y ou can specify in the driver that you want the printer to hold the job

in memory. When you are ready to print the job, you must go to the printer and use the operator panel

menus to identify which held job you want to print.

Note: Print and Hold functions require a minimum of 16MB available printer memory . W e

recommend a minimum of 32MB available printer memory and a hard disk.

To learn more about this function, click a topic:

• Printing and deleting held

jobs

• Recognizing when format

errors occur

• Verifying print jobs

• Accessing held jobs from

the operator panel

• Repeating print jobs at a

later time

• Printing confidential jobs

• Reserving print jobs

Printing and deleting held jobs

Once held jobs are stored in printer memory, you can use the printer operator panel to specify what

you want to do with one or more of the jobs. You can select either Confidential Job or Held Jobs

(Repeat Print, Reserve Print, and Verify Print jobs) from the Job Menu. If you select Confidential Job,

you must enter the personal identification number (PIN) you specified in the driver when you sent the

job. See Confidential jobs for more information.

From either the Confidential Job or the Held Jobs menu items, you have five choices:

• Print All Jobs

• Print A Job

• Delete All Jobs

• Delete A Job

• Print Copies

15

Page 16

Accessing held jobs from the operator panel

1 To access held jobs from the operator panel:

– If the printer is Busy, press Menu and the Job Menu appears.

– If the printer is Ready, continue to step 2.

2 Press Menu until you see Held Jobs or Confidential Job on the operator panel display,

depending on the type of job you want to access.

3 Press Select.

User Name appears on the first line of the operator panel. The second line displays the names

of users currently associated with Print and Hold jobs.

4 Press Menu until you see your user name.

Note: If you are looking for a Confidential Job, you are prompted to enter your PIN. See

Confidential jobs for more information.

5 Press Select.

6 Press Menu until the action you want to take is on the second line of the operator panel (Print

A Job, Delete A Job, and so on).

7 Press Select.

– If you are looking for a particular job, press Menu to scroll through the list of available jobs,

and press Select when the correct job is displayed. An asterisk (*) appears next to the job

name indicating you have chosen to print or delete that job.

– If you are prompted to enter the number of copies you want to print, use the Menu button

to increase or decrease the number on the display, and then press Select.

8 Press Go to print or delete specific jobs you have marked.

The printer briefly shows messages indicating what Print and Hold functions it is performing.

Recognizing when format errors occur

If the symbol appears on the display, it indicates that the printer had trouble formatting one or more

of the held jobs. These formatting problems are most commonly the result of insufficient printer

memory or invalid data that might cause the printer to flush the job.

When a symbol appears next to a held job, you can:

• Print the job. Be aware, however, that only part of the job may print.

• Delete the job. You may want to free up additional printer memory by scrolling through the list

of held jobs and deleting others you have sent to the printer.

If formatting errors are a recurring problem with held jobs, your printer may require more memory.

16

Page 17

Repeat Print

If you send a Repeat Print job, the printer prints all requested copies of the job and stores the job in

memory so you can print additional copies later. You can print additional copies as long as the job

remains stored in memory.

Note: Repeat Print jobs are automatically deleted from printer memory when the printer

requires extra memory to process additional held jobs.

Reserve Print

If you send a Reserve Print job, the printer does not print the job immediately, but stores the job in

memory so you can print the job later. The job is held in memory until you delete it from the Held Jobs

menu. Reserve Print jobs may be deleted if the printer requires extra memory to process additional

held jobs.

See Printing and deleting held jobs for information.

Verify Print

If you send a Verify Print job, the printer prints one copy and holds the remaining copies you requested

from the driver in printer memory. Use Verify Print to examine the first copy to see if it is satisfactory

before printing the remaining copies.

See Printing and deleting held jobs if you need help printing the additional copies stored in memory.

Note: Once all copies are printed, the Verify Print job is deleted from printer memory.

Confidential jobs

When you send a job to the printer, you can enter a personal identification number (PIN) from the

driver. The PIN must be four digits using the numbers 1–6. The job is then held in printer me mo ry unti l

you enter the same four-digit PIN from the printer operator panel and choose to print or delete the job.

This ensures that the job does not print until you are there to retrieve it, and no one else using the

printer can print the job.

When you select Confidential Job from the Job Menu and then select your user name, the following

prompt is displayed:

Enter PIN:

=____

17

Page 18

Use the buttons on the operator panel to enter the four-digit PIN associated with your confidential job.

The numbers next to the button names identify which button to press for each digit (1–6). As you enter

the PIN, asterisks are displayed on the operator panel to ensure confidentiality.

Enter PIN

=****

1

If you enter an invalid PIN, the message No Jobs Found. Retry? appears. Press

PIN, or press

Stop to exit the Confidential Job menu.

Menu

2

Go

Select

5

3

Stop

Return

6

4

Go to reenter the

When you enter a valid PIN, you have access to all print jobs matching the user name and PIN you

entered. The print jobs matching the PIN you entered appear on the display when you enter the Print A

Job, Delete A Job, and Print Copies menu items. You can then choose to print or delete jobs matching

the PIN you entered. (See Printing and deleting held jobs for more information.) After printing the

job, the printer deletes the confidential job from memory.

18

Page 19

5

Canceling a print job

To cancel a print job:

1 Press Menu. Job Menu appears on the first line of the display and Cancel Job appears on the

second line.

Note: Job Menu is the only available menu item when the printer is in the Busy state.

2 Press Select.

Canceling Job briefly appears in the display. The printer finishes printing any page already

being printed, and then stops. The printer returns to the Ready state.

19

Page 20

Printing folio and statement size

6

paper

Folio and statement sizes are not available in the Paper Size menu until Size Sensing is turned off. To

turn off Size Sensing:

1 Press and hold the Select and Return buttons while you turn the printer on.

2 Release the buttons when Performing Self Test appears on the display.

The printer performs its power-on sequence, and then Config Menu appears on the first line of

the display.

3 Press Menu until you see Size Sensing, and then press Select.

Tray 1 Sensing appears on the second line of the display.

4 Press Menu to select the input option that will hold the folio or statement size paper, and then

Select.

press

The first line of the display shows the selected input option and the second line shows the

current setting.

5 Press Menu to change the setting to Off, and then press Select.

SAVED appears briefly on the display, and then is replace by Config Menu on the first line and

Size Sensing on the second line.

6 Press Menu until you see Exit Config Menu, and then press Select.

7 Activating Menu Changes appears briefly, f ollowed by P erf orming Self T est. The printer returns

to the Ready state.

20

Page 21

7

Choosing print material

The print quality and feed reliability of your printer and options can vary with the type and size of print

material you use. This section provides guidelines for each type of print material. For information on

card stock and labels, refer to the Card Stock & Label Guide located on Lexmark’s Web site at

www.lexmark.com.

Always print samples on the print material you are considering before buying large quantities.

Click a topic for more information:

• Paper characteristics

• Recommende d paper

• Unacceptable paper

• Choosing preprinted forms

• Choosing paper

• Choosing envelopes

• Choosing labels

• Choosing card stock

and letterhead

• Choosing transparencies

• Choosing prepunched paper

Paper characteristics

The following paper characteristics affect print quality and reliability. We recommend that you keep

these guidelines in mind when evaluating new paper stock.

For detailed information, refer to the Card Stock & Label Guide located on the Lexmark Web site at

www.lexmark.com.

Weight

The printer can automatically feed paper weights from 60 to 176 g/m2 (16 to 47 lb bond) grain long.

Paper lighter than 60 g/m

best performance, use 75 g/m

mm (7.2 x 10.1 in.), we recommend that the weight be greater than or equal to 90 g/m

2

(16 lb) might not be stiff enough to feed properly, causing paper jams. For

2

(20 lb bond) grain long paper. To use paper narrower than 182 x 257

21

2

(24 lb bond).

Page 22

Curl

Curl is the tendency of paper to curve at its edges. Excessive curl can cause paper feeding problems.

Curl usually occurs after the paper passes through the printer, where it is exposed to high

temperatures. Storing paper unwrapped in humid conditions, even in the paper tray, can contribute to

paper curling.

Smoothness

The degree of smoothness of paper directly affects print quality. If the paper is too rough, the toner

does not fuse to the paper properly, resulting in poor print quality. If the paper is too smooth, it can

cause paper feeding problems. Smoothness needs to be between 100 and 300 Sheffield points;

however, smoothness between 100 and 175 Sheffield points produces the best print quality.

Moisture content

The amount of moisture in the paper affects both print quality and the ability of the printer to feed the

paper properly. Leave the paper in its original wrapper until you are ready to use it. This limits the

exposure of the paper to moisture changes that can degrade its performance.

Grain direction

Grain refers to the alignment of the paper fibers in a sheet of paper. Grain is either grain long, running

the length of the paper, or grain short, running the width of the paper.

2

For 60 to 176 g/m

than 176 g/m

36 lb bond) paper, grain long fibers are recommended. For the multipurpose feeder, papers heavier

than 135 g/m

(16 to 47 lb bond) paper, grain long fibers are recommended. For papers heavier

2

(47 lb bond), grain short is preferred. For the multipurpose feeder, 60 to 135 g/m2 (16 to

2

(36 lb bond), grain short is preferred.

Fiber content

Most high-quality xerographic paper is made from 100% chemically pulped wood. This content

provides the paper with a high degree of stability resulting in fewer paper feeding problems and better

print quality. P aper containing fibers such as cotton possess characteristics that can result in degraded

paper handling.

Recommended paper

To ensure the best print quality and feed reliability, use 75 g/m2 (20 lb) xerographic paper. Business

papers designed for general business use may also provide acceptable print quality.

Always print several samples before buying large quantities of any type of paper. When choosing any

papers, consider the weight, fiber content, and color of the paper.

The laser printing process heats paper to high temperatures of 225°C (437°F) for Magnetic Ink

Character Recognition (MICR) applications, and 205°C (401°F) for non-MICR applications. Use only

papers that are able to withstand these temperatures with out disc olo ring, bleeding, or releasing

hazardous emissions. Check with the manufacturer or vendor to determine whether the paper you’ve

chosen is acceptable for laser printers.

22

Page 23

Unacceptable paper

The following papers are not recommended for use with the printer:

• Chemically treated papers used to make copies without carbon paper, also known as

carbonless papers, carbonless copy paper (CCP), or no carbon required (NCR) paper

• Coated papers (erasable bond)

• Multiple-part forms or documents

• Preprinted papers that require a registration (the precise print location on the page) greater

than ±0.09 in., such as optical character recognition (OCR) forms

In some cases, you can adjust registration with your software application to successfully print

on these forms.

• Preprinted papers with chemicals that may contaminate the printer

• Preprinted papers that can be affected by the temperature in the printer fuser

• Rough-edged or curled papers

• Synthetic papers

• Thermal papers

• Less than 60 g/m

2

(16 lb) recycled paper

• Recycled papers containing more than 25% post-consumer waste that do not meet DIN 19

309

Choosing preprinted forms and letterhead

Use the following guidelines when selecting preprinted forms and letterhead paper for the printer:

• Use grain long papers for best results.

• Use only forms and letterhead printed using an offset lithographic or engraved printing

process.

• Choose papers that absorb ink, but do not bleed.

• Avoid papers with rough or heavily textured surfaces.

Use papers printed with heat-resistant inks designed for use in xerographic copiers. The ink must

withstand temperatures of 225°C (437°F) without melting or releasing hazardous emissions. Use inks

that are not affected by the resin in the toner. Inks that are oxidation-set or oil-based should meet these

requirements. Latex inks might not meet these requirements. If you are in doubt, contact your paper

supplier.

23

Page 24

Choosing prepunched paper

Prepunched paper brands can differ in the number and placement of holes and in manufacturing

techniques.

Use the following guidelines when selecting and using prepunched paper:

• Test paper from several manufacturers before ordering and using large quantities of

pre-punched paper.

• Paper should be punched at the paper manufacturer and not drilled into paper already

packaged in a ream. Drilled paper can cause paper jams when multiple sheets feed through

the printer.

• Prepunched paper can include more paper dust than standard paper. Your printer may require

more frequent cleaning and your feed reliability may not be as good as that of standard paper.

• Weight guidelines for prepunched paper are the same as for nonpunched paper.

Choosing paper

Proper paper loading helps prevent paper jams and ensure trouble-free printing.

To help avoid paper jams or poor print quality:

• Always use new, undamaged paper.

• Before loading paper, know the recommended print side of the paper you’re using. This

information is usually indicated on the paper package.

• Do not use paper that you have cut or trimmed yourself.

• Do not mix paper sizes, weights, or types in the same paper source; mixing results in paper

jams.

• Do not use coated papers.

• Do not forget to change the Paper Size setting when you use a source that does not support

auto size sensing.

• Do not remove paper trays while a job is printing or Busy is displayed on the operator panel.

• Make sure the Paper Type, Paper Texture, and Paper Weight settings are correct. (See Paper

Menu for detailed information about these settings.)

• Make sure the paper is properly loaded in the paper source.

• Flex paper back and forth. Do not fold or crease the paper. Straighten the edges on a level

surface.

24

Page 25

Choosing envelopes

When printing on envelopes:

• To achieve the best possible print quality, use only high-quality envelopes that are designed for

use in laser printers.

• Use only new, undamaged envelopes.

• Load only one size of envelope at a time in the envelope feeder.

• Make sure the glue is not exposed.

• A combination of high humidity (over 60%) and the high printing temperatures may seal the

envelopes.

• Be sure to select Env Feeder or MP Feeder as the paper source in the Paper Menu and set

the correct envelope size.

The laser printing process heats envelopes to a temperature of 205°C (401°F). Use only envelopes

that are able to withstand these temperatures without sealing, excessive curling, wrinkling, or releasing

hazardous emissions. If you have any doubts about the envelopes you are considering using, check

with the envelope supplier.

2

For best performance, use envelopes made from 75 g/m

2

(28 lb bond) weight for the multipurpose feeder or 105 g/m2 (28 lb bond) weight for the envelope

m

feeder as long as the cotton content is 25% or less. Envelopes with 100% cotton content must not

exceed 90 g/m

2

(24 lb bond) weight.

(20 lb bond) paper. You can use up to 105 g/

To minimize jams, do not use envelopes that:

• Have excessive curl or twist

• Are stuck together or damaged in any way

• Contain windows, holes, perforations, cutouts, or embossing

• Use metal clasps, string ties, or metal folding bars

• Have an interlocking design

• Have postage stamps attached

• Have any exposed adhesive when the flap is in the sealed or closed position

• Have nicked edges or bent corners

• Have rough, cockle, or laid finishes

Choosing labels

The printer can print on many labels designed for use with laser printers. These labels are supplied in

letter size and A4 size sheets.

When printing on labels:

• Be sure to select Labels in the Paper Type menu item in the Paper Menu. (See Paper Ty pe for

detailed information about these settings.)

• Do not load labels together with paper or transparencies in the same paper tray; mixing print

materials can cause feeding problems.

25

Page 26

• Do not load partial sheets with areas exposed by missing labels; this can cause labels to peel

off during printing, jam, and contaminate your printer and your print cartridge with adhesive. It

can also void your printer and cartridge warranties.

• Avoid using labels that may release hazardous emissions when heated.

Note: Labels are one of the most difficult print materials for laser printers. The T620 and

T622 printers require a special fuser cleaner for label applications in order to

optimize feed reliability. See Ordering supplies for information on obtaining a

label fuser cleaner.

After continuously printing approximately 10,000 page sides of labels (or each time you replace the

print cartridge), complete the following steps to maintain printer feeding reliability:

1 Print five sheets of paper.

2 Wait approximately five seconds.

3 Print five more sheets of paper.

For detailed information on label printing, characteristics, and design, refer to the Card Stock & Label

Guide, available on Lexmark Web site at www.lexmark.com.

Choosing card stock

Card stock is single-ply and has a large array of properties. The orientation of paper fibers, moisture

content, thickness, and texture can all affect printing on card stock. See Paper specifications for

information on the preferred weight for the grain direction of print materials.

When printing on card stock:

• Be sure to select Card Stock in the Paper Type menu item in the Paper Menu. (See Paper

Type for detailed information about these settings.)

• Be aware that preprinting, perforation, and creasing can significantly affect the print quality and

cause paper handling or jamming problems.

• Avoid using card stock that may release hazardous emissions when heated.

After printing approximately 10,000 page sides of card stock (or each time you replace the print

cartridge), complete the following steps to maintain printer feeding reliability:

1 Print five sheets of paper.

2 Wait approximately five seconds.

3 Print five more sheets of paper.

For more information, refer to the Card Stock & Label Guide, available on the Lexmark Web site at

www.lexmark.com.

26

Page 27

Choosing transparencies

The printer can print directly on transparencies designed for use in laser printers. Print quality and

durability depend on the transparency used. Always print samples on the transparencies you are

considering before buying large quantities.

The Paper Type setting should be set to Transparency to help prevent jams. (See Paper Type for

detailed information about this setting.) Check with the manufacturer or vendor to determine whether

your transparencies are compatible with laser printers that heat transparencies to 212°C (414°F). Use

only transparencies that are able to withstand these temperatures without melting, discoloring,

offsetting, or releasing hazardous emissions. For detailed information, refer to the Card Stock & Label

Guide, which is available on the Lexmark Web site at www.lexmark.com.

Transparencies can be fed automatically from the multipurpose feeder and all standard and optional

trays, except the 2000-sheet drawer, for all printer models. See Print material specifica tions for

information about transparency compatibility with output options.

Be careful when you handle transparencies. Fingerprints on the surface of the transparency cause

poor print quality.

27

Page 28

8

Storing paper

Properly storing the paper you buy helps ensure trouble-free printing. Use the following guidelines:

• For best results, store paper in an environment where the temperature is approximately 21

• Store cartons of paper on a pallet or shelf, rather than directly on the floor.

• If you store individual packages of paper out of the original carton, make sure they rest on a

• Do not place anything on top of the paper packages.

°

F) and the relative humidity is 40%.

(70

flat surface so the edges do not buckle or curl.

°

C

28

Page 29

9

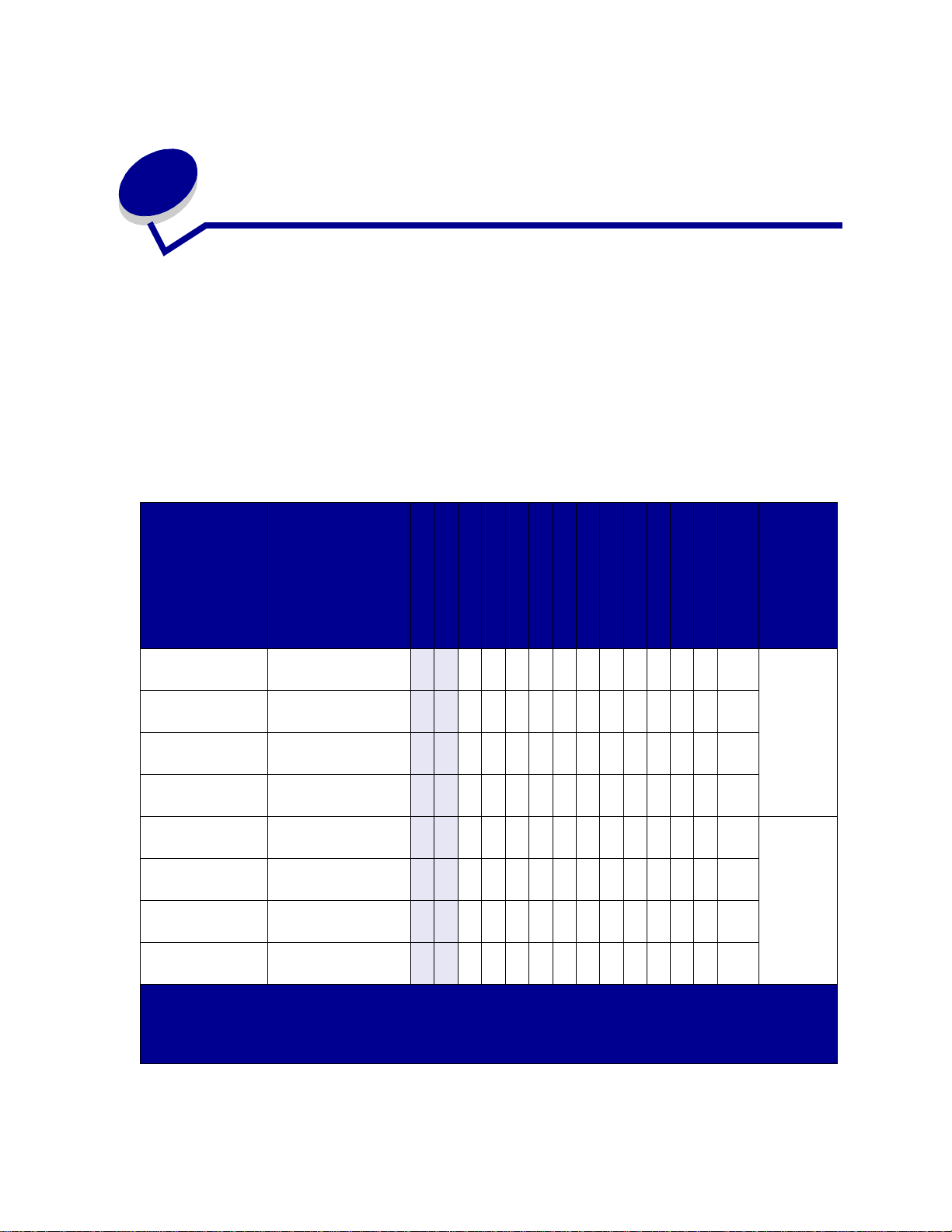

Print material specifications

The following tables provide information on standard and optional paper sources, as well as output

options, for your printer model, including the paper sizes you can select from the Paper Size menu and

supported weights.

Note: If you use a paper size not listed, select the next larger size.

For information on card stock and labels, refer to the Card Stock & Label Guide located on the

drivers CD.

Paper size Dimensions

A4 210 x 297 mm

A5 148 x 210 mm

JIS B5 182 x 257 mm

Letter 215.9 x 279.4 mm

Legal 215.9 x 355.6 mm

Executive 184.2 x 266.7 mm

2

Folio

Statement

1

This size setting formats the page for 215.9 x 355.6 mm (8.5 x 14 in.) unless the size is specified by the

software application.

2

This size does not appear in the Paper Size menu until T ra y Size Sensing is turned off. See Printing folio and

statement size paper for more information.

2

(8.27 x 11.7 in.)

(5.83 x 8.27 in.)

(7.17 x 10.1 in.)

(8.5 x 11 in.)

(8.5 x 14 in.)

(7.25 x 10.5 in.)

216 x 330 mm

(8.5 x 13 in.)

139.7 x 215.9 mm

(5.5 x 8.5 in.)

T622

T620

250-sheet drawer

250 UAT

500-sheet drawer

400 UAT

Multipurpose tray

2000-sheet drawer

Envelope feeder

Duplex unit

Standard output bin

Output expander

5-bin mailbox

High-capacity

output stacker

✓ ✓✓ ✓ ✓✓ ✓✓✓✓✓ See

✓ ✓✓ ✓ ✓✓ ✓✓✓ ✓

✓ ✓✓ ✓ ✓✓ ✓✓✓✓✓

✓ ✓✓ ✓ ✓✓ ✓✓✓✓✓

✓ ✓✓ ✓ ✓✓ ✓✓✓✓✓ See

✓ ✓✓ ✓ ✓✓ ✓✓✓✓✓

✓ ✓✓ ✓ ✓ ✓✓✓✓✓

✓ ✓✓ ✓ ✓ ✓✓ ✓

separate

Finisher

output

support

table.

separate

Finisher

output

support

table.

Finisher

29

Page 30

Paper size Dimensions

Universal

1

139.7 x 210 mm to

215.9 x 355.6 mm

(5.5 x 8.27 in. to 8.5

x 14 in.)

69.85 x 127 mm to

229 x 355.6 mm

(2.75 x 5 in. to 9.01 x

T622

T620

250-sheet drawer

250 UAT

500-sheet drawer

400 UAT

Multipurpose tray

2000-sheet drawer

Envelope feeder

Duplex unit

Standard output bin

Output expander

5-bin mailbox

High-capacity

output stacker

✓ ✓✓✓✓✓✓ ✓✓ ✓

✓ ✓✓✓

See

separate

Finisher

output

support

table.

14 in.)

148 x 182 mm to

215.9 x 355.6 mm

(5.83 x 7.17 in. to 8.5

✓ ✓✓✓✓✓✓ ✓✓✓ ✓

x 14 in.)

7 ¾ Envelope 98.4 x 190.5 mm

(3.875 x 7.5 in.)

9 Envelope 98.4 x 225.4 mm

(3.875 x 8.9 in.)

10 Envelope 104.8 x 241.3 mm

✓ ✓ ✓✓✓✓✓See

separate

✓ ✓ ✓✓✓✓✓

Finisher

output

support

✓ ✓ ✓✓✓✓✓

table.

(4.12 x 9.5 in.)

DL Envelope 110 x 220 mm

✓ ✓ ✓✓✓✓✓

(4.33 x 8.66 in.)

C5 Envelope 162 x 229 mm

(6.38 x 9.01 in.)

B5 Envelope 176 x 250 mm

(6.93 x 9.84 in.)

Other Envelope198.4 x 162 mm

to 176 x 250 mm

(3.87 x 6.38 in.

✓ ✓ ✓✓✓✓✓See

separate

✓ ✓ ✓✓✓✓✓

Finisher

output

support

table.

✓ ✓ ✓✓✓✓✓

to 6.93 x 9.84 in.)

1

This size setting formats the page for 215.9 x 355.6 mm (8.5 x 14 in.) unless the size is specified by the

software application.

2

This size does not appear in the Paper Size menu until T ra y Size Sensing is turned off. See Printing folio and

statement size paper for more information.

Finisher

30

Page 31

Print material

T622

T620

250-sheet drawer

500-sheet drawer

Multipurpose tray

2000-sheet drawer

Envelope feeder

Duplex unit

Standard output bin

Output expander

5-bin mailbox

High-capacity

output stacker

Paper ✓ ✓✓✓✓✓ ✓✓ ✓✓✓ See separate

Card stock

Transparencies

Vinyl labels

Paper labels

Polyester labels

Dual-web labels

*

Printing label applications on the T620 and T622 printers require a special label fuser cleaner which prevents

*

*

*

*

✓ ✓✓✓✓ ✓✓ ✓ ✓

✓ ✓✓✓✓ ✓ ✓ ✓

✓✓✓✓ ✓ ✓ ✓

✓ ✓✓✓✓ ✓ ✓ ✓

✓ ✓✓✓✓ ✓ ✓ ✓

✓ ✓✓✓✓ ✓ ✓ ✓

Finisher output

support table

duplexing. The label fuser cleaner is included with a special label cartridge for label applications. See

Ordering supplies for more information on obtaining a label fuser cleaner.

Print material weight

Print material Type

Paper Xerographic or

business paper

Card stock—

maximum

(grain long)

1

Index Bristol 163 g/m

Tag 163 g/m

Integrated tray and

optional

500-sheet drawer

60 to 176 g/m2 grain

long

(16 to 47 lb bond)

2

(90 lb) 120 g/m2 (67 lb) Not

2

(100 lb) 120 g/m2 (74 lb) Not

Multipurpose feeder

and optional

250-sheet drawer

60 to 135 g/m2

grain long

(16 to 36 lb bond)

Envelope

feeder

Not

recommended

recommended

recommended

Cover 176 g/m

2

(65 lb) 135 g/m2 (50 lb) Not

recommended

1

Grain short is preferred for papers over 176 g/m2.

2

Printing label applications on your printer requires a special label fuser cleaner which prevents duplexing.

3

Information on whether your vinyl label converter has passed Lexmark's criteria is available at Lexmark’s Web

site (www .lexmark.com); search for “converter list.” You can also check Lexmark’s Automated FAX system

(LEXFAX™).

4

28 lb bond envelopes are limited to 25% cotton content.

5

Includes envelopes fed from the multipurpose tray only.

Finisher

31

Page 32

Print material weight

Integrated tray and

optional

Print material Type

Card stock—

maximum

(grain short)

Transparencies Laser printer 138 to 146 g/m

1

Index Bristol 199 g/m

Tag 203 g/m

Cover 216 g/m

500-sheet drawer

2

(110 lb) 163 g/m2 (90 lb) Not

2

(125 lb) 163 g/m2 (100 lb) Not

2

(80 lb) 176 g/m2 (65 lb) Not

(37 to 39 lb bond)

Labels—maximum

2

Paper 180 g/m

2

(48 lb bond)

Dual-web paper 180 g/m

2

(48 lb bond)

Polyester 220 g/m

2

(59 lb bond)

Vinyl

3

300 g/m

2

(92 lb liner)

Integrated forms Pressure-

Envelopes

100% cotton content

maximum weight–24 lb

1

Grain short is preferred for papers over 176 g/m2.

2

Printing label applications on your printer requires a special label fuser cleaner which prevents duplexing.

3

Information on whether your vinyl label converter has passed Lexmark's criteria is available at Lexmark’s Web

site (www .lexmark.com); search for “converter list.” You can also check Lexmark’s Automated FAX system

(LEXFAX™).

4

28 lb bond envelopes are limited to 25% cotton content.

5

Includes envelopes fed from the multipurpose tray only.

sensitive area

(must enter the

printer first)

Paper base

(grain long)

Sulfite,

wood-free or up

to 100% cotton

bonds

140 to 175 g/m

75 to 135 g/m

(20 to 36 lb bond)

Not recommended 60 to 105 g/m

2

Multipurpose feeder

and optional

250-sheet drawer

2

138 to 146 g/m

(37 to 39 lb bond)

163 g/m

(43 lb bond)

163 g/m

(43 lb bond)

220 g/m

(59 lb bond)

260 g/m

(78 lb liner)

2

140 to 175 g/m

75 to 135 g/m

(20 to 36 lb bond)

(16 to 28 lb

4, 5

bond)

Envelope

feeder

recommended

recommended

recommended

2

Not

recommended

2

2

2

2

2

2

Not

recommended

Not

recommended

Not

recommended

Not

recommended

2

Not

recommended

Not

recommended

60 to 105 g/m

(16 to 28 lb

bond)

4

2

32

Page 33

Print material weight—output options

Print material Type 5-bin mailbox

Paper

(grain long)

Xerographic or

business paper

60 to 90 g/m

(16 to 24 lb

bond)

Card stock—

maximum

(grain long)

Index Bristol Not

recommended

Tag Not

recommended

Cover Not

recommended

Card stock—

maximum

(grain short)

Index Bristol Not

recommended

Tag Not

recommended

Cover Not

recommended

Labels—

maximum

Paper Not

recommended

Dual-web

paper

Not

recommended

Polyester Not

recommended

Vinyl Not

recommended

Integrated

forms

Envelopes Sulfite,

wood-free or up

Not

recommended

Not

recommended

to 100% cotton

bond

Output

expander

2

60 to 176 g/m

(16 to 47 lb bond)

163 g/m

(90 lb)

163 g/m

(100 lb)

176 g/m

(65 lb)

199 g/m

(110 lb)

203 g/m

(125 lb)

216 g/m

(80 lb)

180 g/m

(48 lb bond)

180 g/m

(48 lb bond)

220 g/m

(59 lb bond)

300 g/m

(92 lb liner)

175 g/m

60 to 105 g/m

(16 to 28 lb bond)

High-capacity

output stacker

2

60 to 176 g/m

(16 to 47 lb bond)

Finisher

2

See separate

Finisher media

weight table

2

163 g/m2

(90 lb)

2

163 g/m

2

(100 lb)

2

176 g/m

2

(65 lb)

2

199 g/m

2

(110 lb)

2

203 g/m

2

(125 lb)

2

216 g/m

2

(80 lb)

2

180 g/m

(48 lb bond)

2

180 g/m

2

See separate

Finisher media

2

weight table

(48 lb bond)

2

220 g/m

2

(59 lb bond)

2

300 g/m

2

(92 lb liner)

2

175 g/m

2

60 to 105 g/m

(16 to 28 lb bond)

2

2

Not

recommended

33

Page 34

Finisher output support

Paper size Standard

Dimensions

A4 210 x 297 mm

1

Offset Stapled

✓✓ ✓

(8.27 x 11.7 in.)

A5 148 x 210 mm

(5.83 x 8.27 in.)

JIS B5 182 x 257 mm

✓

(7.17 x 10.1 in.)

Letter 215.9 x 279.4 mm

✓✓ ✓

(8.5 x 11 in.)

Legal 215.9 x 355.6 mm

✓✓ ✓

(8.5 x 14 in.)

Executive 184.2 x 266.7 mm

✓

(7.25 x 10.5 in.)

2

Folio

216 x 330 mm

✓✓ ✓

(8.5 x 13 in.)

Statement

2

139.7 x 215.9 mm

(5.5 x 8.5 in.)

1

Paper passes to the output tray without being stapled or offset.

2

This size does not ap pear in th e Paper Size menu unt il Tray Size Sensing is turned off . See Printing f olio a nd

statement size paper for more information.

34

Page 35

Finisher media weight

Print material Type

Paper Xerographic or

business paper

Card stock—

Index Bristol 163 g/m

maximum (grain

long)

Tag 163 g/m

Standard

60 to 176 g/m

(16 to 47 lb bond)

(90 lb bond)

1

2

2

2

Offset Stapled

60 to 90 g/m

2

(16 to 24 lb bond)

60 to 90 g/m

(16 to 24 lb bond)

2

Not recommended Not recommended

Not recommended Not recommended

(100 lb bond)

Cover Not recommended Not recommended Not recommended

Card stock—

maximum (grain

short)

Index Bristol

199 g/m

(110 lb bond)

Tag 203 g/m

2

2

Not recommended Not recommended

Not recommended Not recommended

(125 lb bond)

Cover 176 g/m

2

Not recommended Not recommended

(65 lb bond)

Transparencies Laser printer 138 to 146 g/m

37 to 39 lb bond)

2

138 to 146 g/m

37 to 39 lb bond)

Labels Not recommended Not recommended Not recommended

Integrated forms Not recommended Not recommended Not recommended

1

Paper passes to the output tray without being stapled or jogged.

2

Not recommended

35

Page 36

10

Loading print material

This section provides information about loading the various input options. Proper paper loading helps

prevent paper jams and ensure trouble-free printing.

Before loading paper, you need to know the recommended print side of the paper you’re using. This

information is usually indicated on the paper package.

Click below for information on loading a particular option:

• Loading a paper tray

• Loading the multipurpose feeder

• Loading the envelope feeder

• Loading the 2000-sheet drawer

36

Page 37

11

Loading a paper tray

Complete these instructions to load print materials into any of the standard or optional trays.

1 Remove the paper tray.

2 Pull the width guide tab and slide the width guide to the far right side of the tray.

3 Squeeze the length guide lever and slide the length guide to the correct position for the size

paper you are loading.

Pull here

Length guide

lever

Length

guide

Width

guide

Pap er size

indicators

4 Place the paper into the paper tray with the recommended print side face down for

single-sided printing and face up for double-sided printing. Do not fill paper above the paper

capacity mark.

5 Pull the width guide tab and slide the width guide to the left until it lightly rests against the edge

of the paper stack.

Paper capac ity

mark

37

Page 38

6

Adjust the knob to show the size of the paper currently loaded.

Note: This setting serves as a visual reminder only; it has no effect on the operation of

the printer.

7 Reinstall the tray.

Loading letterhead

Letterhead must be loaded differently depending on what options you have installed on your printer.

Without a finisher installed

For simplex (single-sided) printing on letterhead, place the printed side face down a s shown.

38

Page 39

For duplex printing on letterhead, place the printed side face up as shown.

Note: The Paper Loading menu item lets you print simplex (single-sided) jobs on

letterhead (or other preprinted media) that has been loaded specifically for duplex

printing. See Paper Loading for more information.

With a finisher installed

For simplex (single-sided) printing on letterhead, place the printed side face down a s shown.

For duplex printing on letterhead, place the printed side face up as shown.

Note: The Paper Loading menu item lets you print simplex (single-sided) jobs on

letterhead (or other preprinted media) that has been loaded specifically for duplex

printing. See Paper Loading for more information.

39

Page 40

12

Loading the multipurpose f eeder

The multipurpose feeder can hold several sizes and types of paper, such as transparencies, postcards,

note cards, and envelopes. It is useful for single page printing on letterhead, colored paper, or other

special paper.

Keep in mind the following capacities, paper dimensions, and operating tips when loading the

multipurpose feeder.

Capacity

The maximum stack height is 10 mm (0.4 in.). The multipurpose feeder can hold approximately:

• 100 sheets of 75 g/m

• 10 envelopes

• 75 transparencies

2

(20 lb) paper

Paper dimensions

The multipurpose feeder accepts paper within the following dimensions:

• Width—69.85 mm (2.75 in.) to 229 mm (9.01 in.)

• Length—127 mm (5 in.) to 355.6 mm (14 in.)

Trouble-free printing

• Load only one size of paper or envelopes at a time in the multipurpose feeder.

• To achieve the best possible print quality, use only high-quality print media that is designed for

use in laser printers. For more guidelines on paper, see Choosing print material.

• To prevent paper jams, do not add or remove paper when there is still paper in the

multipurpose feeder. This applies to other types of print materials, too.

• Never add print materials to the multipurpose feeder while the printer is printing from the

multipurpose feeder. Doing so may cause a paper jam.

• Print material should be loaded with the recommended print side up and the top of the print

material going into the multipurpose feeder first.

40

Page 41

• Do not place objects on the multipurpose feeder. Also, avoid pressing down or applying

excessive force on it.

• Do not remove any paper tray while a job is printing from the multipurpose feeder or Busy is

displayed on the operator panel. Doing so may cause a paper jam.

Note: The multipurpose feeder may be used with the optional envelope feeder installed.

The icons on the multipurpose feeder show you how to load the multipurpose feeder with paper, how

to turn an envelope for printing, and how to load letterhead paper for simplex and duplex printing. If a

finisher is installed, it will affect how letterhead documents are loaded for duplexing. See Loading

letterhead for detailed instructions on loading documents printed on letterhead.

Simplex

letterhead

Note: The Paper Loading menu item in the Paper Menu lets you print simplex

(single-sided) jobs on letterhead (or other preprinted media) that has been loaded

specifically for duplex printing. For more information, see Paper Loading.

To load the multipurpose feeder:

Duplex

letterhead

Envelope

1 Push the lower release latch. The multipurpose feeder door drops open.

41

Page 42

2

Locate the metal bar in the recessed area on the multipurpose feeder. Pull the bar out far

enough to accommodate the paper you will be using.

3 Slide the paper width guide to the far right.

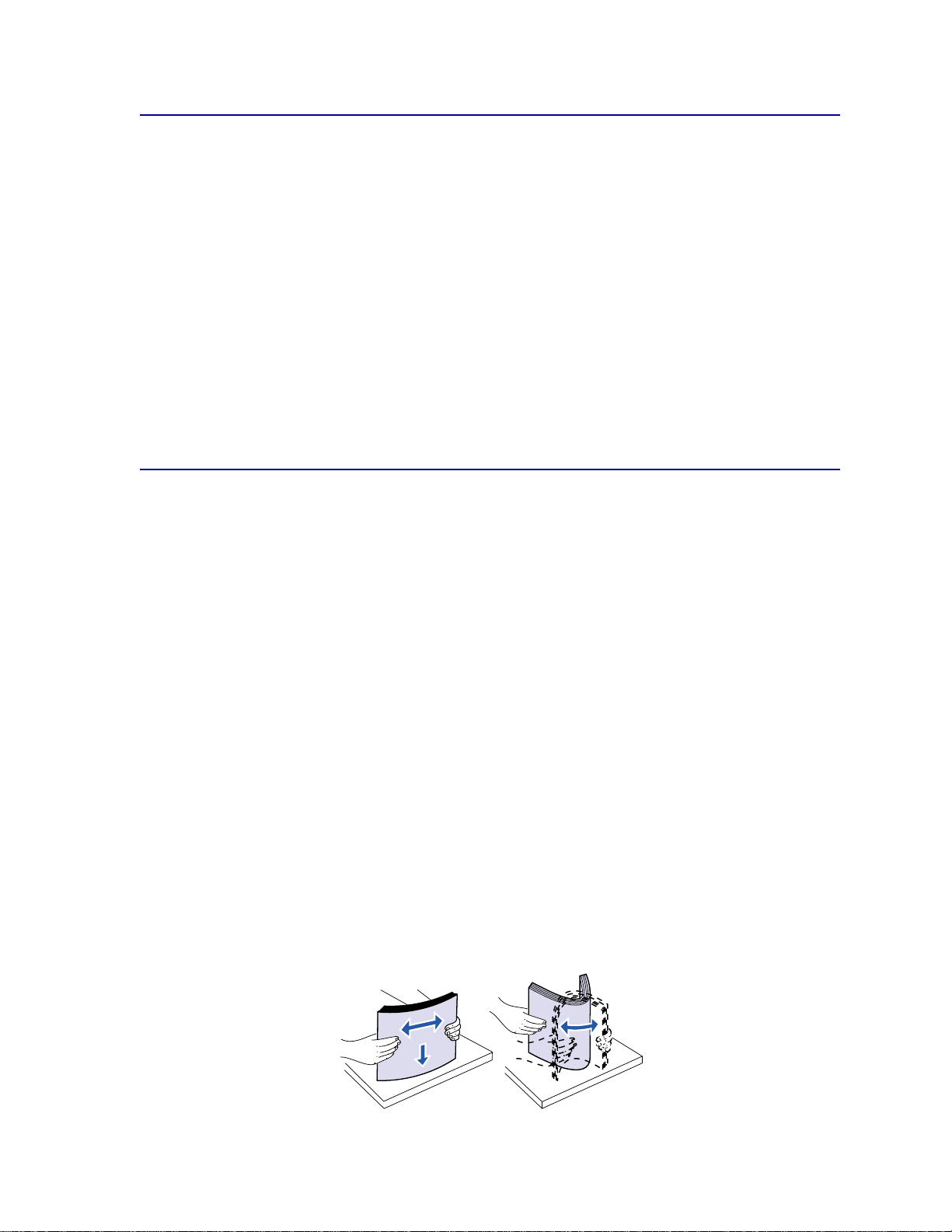

4 Prepare the print material for loading.

– Flex paper or fan envelopes back and forth. Do not fold or crease the paper. Straighten the

edges on a level surface.

42

Page 43

– Hold transparencies by the edges and avoid touching the print side. Fan the stack of

transparencies to prevent jams. Be careful not to scratch or leave fingerprints on the

transparencies.

5 Use the stack height limiter as a guide for stack height when loading print materials.

Stack height limiter

6 Load one type of print material in the multipurpose feeder. Do not mix types. Click a topic for

loading instructions:

– Loading paper and transparencies

– Loading envelopes

– Loading letterhead

43

Page 44

Loading paper and transparencies

a Load paper with the left edge of the stack against the stack height limiter and with the

recommended print side face up.

b Continue with step 7.

Loading envelopes

a Load envelopes flap side down with the stamp area and flap on the left. The end of the

envelope with the stamp area enters the multipurpose feeder first.

WARNING: Never use envelopes with stamps, clasps, snaps, windows, coated linings, or

self-stick adhesives. These envelopes may severely damage the printer.

Note: If envelopes jam while printing, try reducing the number of envelopes in the

multipurpose feeder.

b Continue with step 7.

44

Page 45

Loading letterhead

Load letterhead according to the options installed on the printer. Click the topic that describes your

printer configuration.

• Neither a duplex unit nor a finisher attached

• A duplex unit, but no finisher attached

• A finisher, but no duplex unit attached

• Both a duplex unit and a finisher attached

Neither a duplex unit nor a finisher attached

a

Load letterhead paper for single-sided printing with the logo face up as shown.

b Continue with step 7.

A duplex unit, but no finisher attached

a

Load letterhead paper for duplex printing with the logo face down as shown.

45

Page 46

b Continue with step 7.

Note: The Paper Loading menu item in the Paper Menu lets you print simplex

(single-sided) jobs on letterhead (or other preprinted media) that has been loaded

specifically for duplex printing. For more information, see Paper Loading.

A finisher, but no duplex unit attached

a

Load letterhead paper for single-sided printing with the logo face up as shown.

b Continue with step 7.

Both a duplex unit and a finisher attached

a

Load letterhead paper for duplex printing with the logo face down as shown.

b Continue with step 7.

Note: The Paper Loading menu item in the Paper Menu lets you print simplex

(single-sided) jobs on letterhead (or other preprinted media) that has been loaded

specifically for duplex printing. For more information, see Paper Loading.

46

Page 47

7

Gently slide the print material into the multipurpose feeder as far as it will go. Forcing the print

material may cause it to buckle.

8 Slide the paper width guide to the left until it lightly touches the stack of print material. Do not

bend the print material.

9 Select the paper source, size, and type from your software application and select paper size

and type from the printer operator panel.

a Make sure the Paper Size and Paper Type for the multipurpose feeder (MP Feeder Size

and MP Feeder Type) are set to the correct value for the print material you are loading.

(See Paper Size and Paper Type for detailed information about these settings.)

b Press Go to return to Ready.

Note: Software settings may override operator panel settings.

47

Page 48

Closing the multipurpose feeder

1 Remove print material from the multipurpose feeder.

2 Push the metal bar straight back to collapse the multipurpose feeder to its short-length

position.

3 Close the multipurpose feeder door.

48

Page 49

13

Loading the en velope f eeder

1 Gently adjust the envelope support for the size you are loading:

– Fully closed (pushed in toward the printer) for short envelopes

– Extended to the middle position for medium-length envelopes

– Fully open (extended to its full length) for long envelopes

WARNING: Do not place objects on the envelope feeder . Av oid pressing down on it or applying

excessive force.

2 Lift the envelope weight back toward the printer. It stays in place.

49

Page 50

3

Slide the envelope edge guide to the far right.

4 Flex a stack of envelopes back and forth and then straighten the edges on a level surface.

Press down the corners to flatten them.

Fan the envelopes. This prevents the edges of the envelopes from sticking together and helps

them feed properly.

Note: When you load envelopes, do not exceed the maximum stack height of 64.7 mm

(2.55 in.). The envelope feeder holds a maximum of 85 envelopes (75 g/m

bond).

2

, 20 lb

50

Page 51

5

Load the stack of envelopes flap side down with the stamp area and the flap on the left. The

end of the envelopes with the stamp area enters the envelope feeder first. Let the envelopes

at the bottom of the stack slide into the envelope feeder slightly more than the ones at the top

of the stack.

WARNING: Never use envelopes with stamps, clasps, snaps, windows, coated linings, or

self-stick adhesives. These envelopes may severely damage the printer. See

Choosing envelopes for more information.

Note: Do not try to load more envelopes by forcing them under the envelope feeder

weight. This results in jams.

6 Slide the envelope edge guide to the left until it lightly touches the stack. Make sure the

envelopes do not buckle.

7 Lower the envelope weight to the stack.

51

Page 52

8 Select the paper source, size, and type from your software application.

9 Select the paper size and type from printer operator panel:

a Make sure the Paper Size for the envelope feeder (Env Feeder Size) is set to the correct

envelope size you are loading. (See Paper Size for detailed information about this

setting.)

b Press Go to return to Ready.

Note: Software settings may override operator panel settings.

If envelopes jam, see Clearing paper jams.

52

Page 53

14

Loading the 2000-sheet drawer

For information on loading the optional 2000-sheet drawer, refer to the

2000-Sheet Drawer User’s Guide on the Lexmark PRODUCT Publications CD that came with your

printer.

53

Page 54

15

Tray linking

Tray linking enables the automatic linking feature for trays when you use the same size and type of

print material in multiple paper sources (trays).

For example, let’s say you have loaded two optional trays with the same size print material and both

are set to the same paper type. When one tray becomes empty, the printer automatically selects print

material from the other tray since the printer sees the trays as linked.

If you use different print material in the trays, each source with a different print material must have the

Paper Type set to a unique value to disable the automatic linking feature. If all the trays do not have the

same paper type when they are linked, you could mistakenly print a job on the wrong paper type.

54

Page 55

16

Tips for a v oiding paper jams

By carefully selecting print materials and loading them properly, you should be able to avoid most

paper jams. If jams do occur, follow the steps outlined in Clearing paper jams. If jams occur

frequently, make sure you follow these tips to avoid jams:

• See Loading print material to load paper properly. Make sure the adjustable guides are

positioned correctly.

• Do not overload the paper trays. Make sure the paper is under the paper capacity mark on the

inside of the paper tray.

• Do not remove paper trays while print jobs are in process.

• Flex, fan, and straighten the paper before loading it.

• Fan stacks of labels or transparencies before loading them into trays or the multipurpose

feeder. If jams do occur using the multipurpose feeder, try feeding one sheet at a time.

• Do not load wrinkled, creased, damp, or curled paper.

• Do not mix paper types or paper sizes in one tray.

• Use only recommended print materials. See Recommended paper.

• Make sure the recommended print side is face down for simplex printing when loading all

trays.

• Keep print materials stored in an acceptable environment. See Moisture content.

55

Page 56

17

Replacing the print cartridge

Order a new print cartridge when the Toner Low message first appears so you will have it when the

current one no longer prints satisfactorily. See Ordering supplies for information on ordering print

cartridges.

Note: Lexmark does not recommend that you use print cartridges from a third party. Print

quality and printer reliability cannot be guaranteed if you do. For best results, use

Lexmark supplies.

Complete the following steps to replace the print cartridge. Refer to the documentation that comes with

the print cartridge for detailed installation information.

1 Turn the printer off and unplug the printer power cord.

2 Open the front doors and remove the used print cartridge.

WARNING: Never touch the photoconductor drum on the underside of the print cartridge. Use

the handhold on the cartridge to avoid touching this area.

3 Clean the printer.

4 Install the new print cartridge and close the front door.

5 Replace the fuser cleaner if you are printing special label applications.

6 Plug the printer power cord into a properly grounded electrical outlet and turn the printer on.

7 Follow the instructions on the new print cartridge box to return the used print cartridge to

Lexmark for recycling.

When you return a used print cartridge, you contribute to a worldwide recycling effort at no

cost to you.

Note: The print cartridge warranty is voided by unauthorized refilling.

56

Page 57

18

Replacing the charge r oll

Order a new charge roll kit when toner fog or background shading appears on printed pages. See

Ordering supplies for information on ordering a charge roll.

Complete the following steps to replace the charge roll. Refer to the documentation that comes with

the charge roll for detailed installation information.

1 Turn the printer off and unplug the printer power cord.

2 Open the front doors and remove the print cartridge.

3 Remove the old charge roll.

4 Install the new charge roll.

5 Reinstall the print cartridge and close the front doors.

6 Plug the printer power cord into a properly grounded electrical outlet.

7 Reset the maintenance counter.

57

Page 58

19

Replacing the transfer r oll

Order a new transfer roll when light print, toner fog, or background shading appears on printed pages.

See Ordering supplies for information on ordering a transfer roll.

Complete the following steps to replace the transfer roll. Refer to the documentation that comes with

the transfer roll for detailed installation information.

1 Turn the printer off and unplug the printer power cord.

2 Open the front doors and remove the print cartridge.

3 Remove the old transfer roll.

4 Install the new transfer roll.

5 Reinstall the print cartridge and close the front doors.

6 Plug the printer power cord into a properly grounded electrical outlet.

7 Reset the maintenance counter.

58

Page 59

20

Replacing the fuser assembl y

Order a new fuser assembly when toner fog or background shading appears on printed pages. See

Ordering supplies for information on ordering a fuser assembly.

Complete the following steps to replace the fuser assembly. Refer to the documentation that comes

with the fuser assembly for detailed installation information.

CAUTION: The fuser assembly is hot! Turn the printer off and wait twenty minutes before

changing the fuser assembly.

1 Turn the printer off, unplug the printer power cord, and wait twenty minutes.

2 Remove the top cover and all installed output options. If a duplex unit is installed, remove it.

3 Remove the fuser cover.

4 Lift up and remove the fuser cleaner.

5 Open the rear access door and remove the redrive.

6 Remove the old fuser assembly.

Note: For best results, use Lexmark supplies with the printer. If you are in the U.S. or

Canada, call 1-800-438-2468 for information about Lexmark Authorized Supplies

Dealers in your area. In other countries, contact the place where you bought your

printer.

7 Install the new fuser assembly and replace the redrive.

8 Close the rear access door and replace the fuser cover .

9 If you have a duplex unit, reinstall it. Reinstall all output options and the printer top cover.

10 Plug the printer power cord into a properly grounded electrical outlet.

11 Reset the maintenance counter.

59

Page 60

21

Replacing the staple cartridge

When Staples Low or Staples E mpty appears on the operator panel display, complete the steps to

insert a new staple cartridge in the finisher. Refer to the illustrations inside the stapler access door for

more information. For information about ordering staple cartridges, see Ordering supplies.

Note: If Staple Alarm is set to Single, the printer stops printing and displays the Load

Staples message. Install a new staple cartridge or press

and continue printing. If Staple Alarm is set to Continuous, the printer displays the

Load Staples message and continues printing.

1 Open the stapler access door and remove the staple cartridge holder by pulling on the colored

tab.

Note: A partial sheet of staples will remain in the staple cartridge holder when this

message appears. Do not remove this sheet. Install a new staple cartridge to

properly feed the partial sheet of staples.

2 Remove the empty staple cartr idge.

Go to clear the message

3 Install the new staple cartridge.