Lexmark 5022-xxx, 5022 Series Media Specifications

5022-xxx

Media specifications

Paper and specialty media guidelines

Media guidelines

Media characteristics

The foll owing media characteristics affect print quality and reliability. Consider these characteristics when

evaluating new media stock.

Weight

The printer can automa ti cally feed media weights from 60 to 176 g/m

lighter than 60 g/m

2

90 g/m

g/m

Curl

Curl is the tendency for media to curl at its edges. Excessive curl can cause media feeding problems. Curl can

occur after the med ia passes through the printer, where it is expos ed to hi gh temperatures. Stori ng media

unwrapped in hot, hum id, cold, or dry conditions, even in the trays, can contribute to media curling prior to

printing and can cause feeding problems.

(24 lb bond) grain long medi a. Fo r media smaller than 182 x 257 mm (7.2 x 10.1 in.), we reco mmend 90

2

or heavier media .

2

(16 lb) might not be sti ff enough to feed properly, causing jams. For best performance, use

2

(16 to 47 lb bond) grain lo ng. Media

Smoothness

Media smoothne ss directly affec ts print quality. If media is too rough, toner cannot fuse to it properly. If media is

too smooth, it can cause media fee din g or print qual ity issues . Alw a ys u se media bet wee n 100 and 300 Shef fiel d

points; however, smoothness between 150 and 200 Sheffield points produces the best print quality.

Moisture content

The amount of moisture in media affects both print quality and the ability of t he prin ter to feed the media

correctly. Leave medi a in i ts original wr apper u ntil it is t ime to us e i t. Thi s limit s the e xp osur e of medi a to mo isture

changes that can degrade its performance.

Condition medi a before printing by storing it in its original wrapper in the same environment as the printer for 24

to 48 hours before printing. Extend the time several days if the storage or transportation environmen t is very

different from the printer environment. Thick media ma y also require a longer conditioning period.

Grain direction

Grain refers to the alignment of the medi a fi bers in a sheet of media. Grain is eith er grain long, running the

length of the media, or grain short, running the width of the media. For 60 to 90 g/m

use grain long fibers.

Fiber content

Most high-quality xerographic media is made from 100% chemically treated pul ped wood. This content provides

the media with a high deg re e of stabi lity re sulti ng in f e wer media f eedi ng prob lem s and bett er print qual ity. Media

containing fibers such as cotton possesses characteristics that can negatively affect media handling.

2

(16 to 24 lb bond) media,

1-6 Service M anual

5022-xxx

Unacce p tab l e media

The foll owing media types are not recommended for use with the printer:

• Chemically treated media used to make copies without carbon paper, also known as carbonless papers,

carbonless copy paper (CCP), or no carbon required (NCR) paper

• Preprinted media with chemicals that may contaminate the printer

• Preprinted media that can be affected by the temperature in the printer fuser

• Preprinted media that requires a regis tr ation (the precise print location on the page) greater than ±2.3 mm

(±0.09 in.), such as optical character recognition (OCR) forms

In some cases, registration can be adjusted with a program to successfully print on these forms.

• Coated media (eras able bond), synthetic media, thermal media

• Rough-edged, rough, or heavily te xtured surface med ia, or curled m edia

• Recycled media containing more than 25% post-consumer waste that does not meet DIN19 309

• Media weighing l ess than 60 g/m

2

(16 lb)

• Multiple -p a rt forms or do c uments

Selecting media

Using appropriate media prevents jams and helps ensure trouble-free printing.

To help avoid jams and poor print quality:

• Always use new, undam aged media.

• Before lo ading medi a, know t he re commended print side of the media. This information is usual ly indicat ed

on the media package.

• Do not use media that has been cut or trim m ed by hand.

• Do not mix media sizes , types, or weights i n the same source; mixing result s in j am s.

• Do not use coated media unl ess they are specifical ly designed for elect rophotographi c prin ti ng.

Selecting preprinted forms and letterhead

Use these guidelines when selecting preprinted forms and letterhead:

• Use grain long papers for best results for 60 to 90 g/m

2

weights.

• Use only for m s and letterhead printed using an offset lithographic or engraved printing process.

• Av oid papers with rough or heavi ly textured surfaces.

Use papers printed with heat -resistant inks designed for use in xerographic copiers. The ink must be able to

withstand tempe ratures up to 180°C (356°F) without me lt ing or releasing hazardous emissions. Use inks that

are not affected b y the resin in toner. Inks that are o xidation-set or oil-based generally meet these requirements;

latex inks might not. When in doubt, contact the paper supplier.

Preprinted papers such as letterhead must be abl e to wi thstand temperatures up to 180°C (356°F) without

melting or releasing hazardous emissions.

General inf ormation 1-7

5022-xxx

Using media

Using letterhead

Check with the man ufacturer or vendor to determine whether the chosen preprinted letterhead is acceptable for

laser printers.

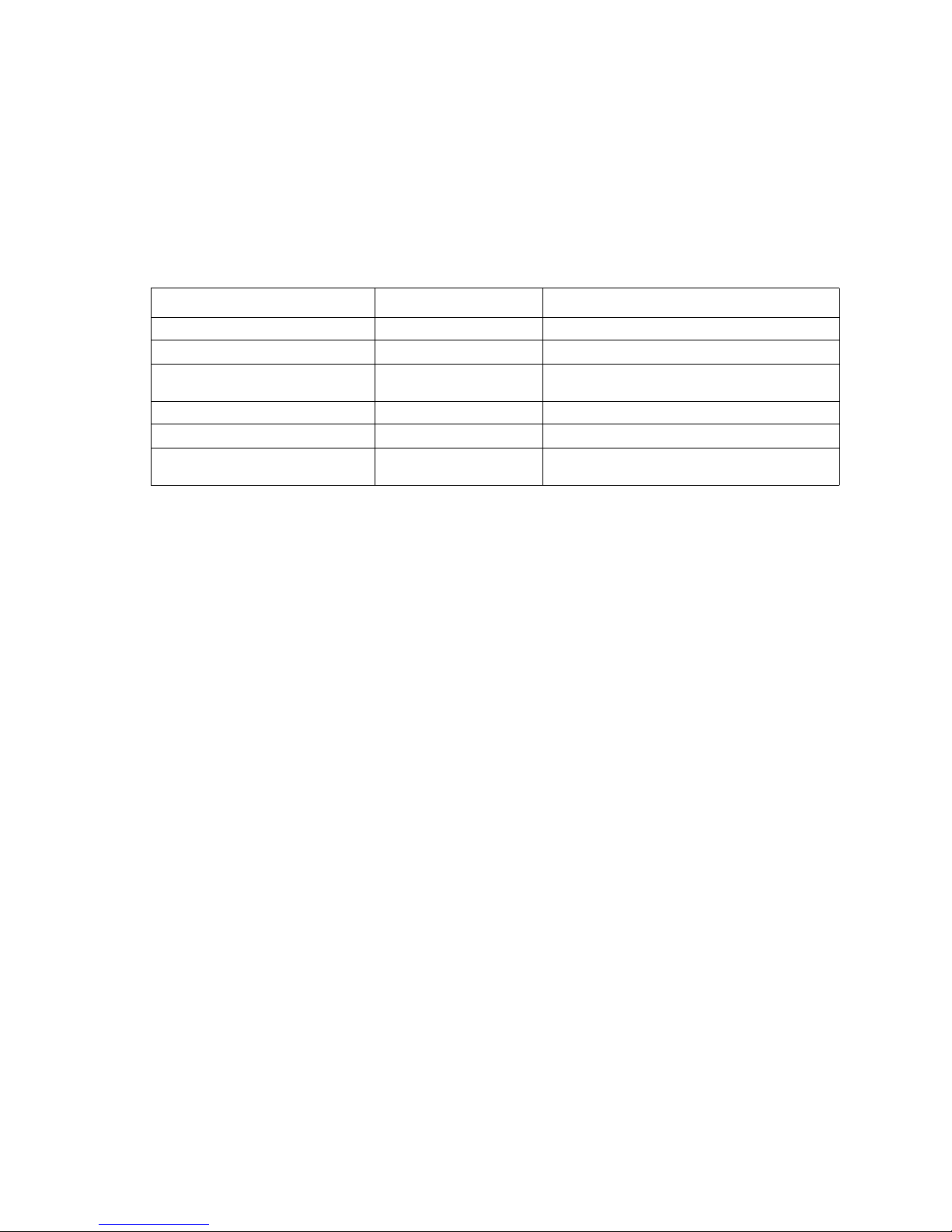

Page orientation is important when printing on letter head. Use the followi ng table for help when lo ading

letterhead.

Process or paper source Print side Top of page

Tray 1 Letterhead f aceup Letterhead goes to ward the front of the tray

Tray 2 Letterhead f aceup Letterhead goes to ward the front of the tray

Duplex (two-sided) printing from

trays 1 and 2

Multipurpose feeder Letterhead f acedown Letterhead top edge enters first

Manual feeder Letterhead f acedown Letterhead top edge enters first

Duplex (two-sided) printing from

the multipurpose feeder

Letterhead f acedown Letterhead goes to ward the rear of the tray

Letterhead f aceup Letterhead top edge enters last

Using tran sparencies

Print samples on the transparencies being considered for use before buying large quantities.

When printing on transparencies:

• Fr om MarkVisi on™ Professional , th e print er software, or the control panel, set the Pap er Type to

Transparency.

• Feed transparencies from the standard tray (Tray 1) or the multipurpose feeder.

• Use transparencies designed specifically for laser printers. Check with the manufacturer or vendor to

ensure transparencies are able to withstand temperatures up to 180°C (356°F) without melting,

discoloring, offsetting, or releasing hazardous emissions .

• Use transparencies that are 0.12–0.14 mm (4.8–5.4 mil) in thicknes s or 161–179 g/m

2

in weight.

• Print quality and dur ability depend on the transparencies used.

• To prevent print quality problems, avoid getting fingerprints on t he transparencies.

• Before loading transparencies, fan the stack to prevent sheets from sticking together.

• We recommend Lexmark part number 12A8240 for let ter-size and Lexm ark part numbe r 12A8241 for

A4-size transparencies.

Using envelopes

Print samples on the envelopes being considered for use before buying large quantities.

•

When printing on envelopes:

• Fr om the control panel, set the Paper Source based on the source in use. From the control panel, the

printer so ft ware, or Mark Vision Professional, set t he Paper Type to Envelope, and select t he envelope size.

• Use env elopes designed specific all y for laser print ers. Check with the manufacturer or vendor to ensure

the envelopes can withstand temper atures up to 180°C (356°F) without sealing, wrinkling, curling

exces sively, or rele asing hazardous emissio ns.

• For the bes t performance, us e en vel opes made from 90 g/ m

bond) weight for envelopes as long as the cotton content is 25% or le ss. All-cotton envelopes must not

exceed 90 g/m

2

(24 lb bond) weight.

2

(24 lb bond) paper. Use up to 105 g/m2 (28 lb

• Use only new envelopes.

1-8 Service M anual

Loading...

Loading...