Page 1

First Edition (March, 1996)

The following paragraph does not apply to the United Kingdom or any country where such

provisions are inconsistent with local law: LEXMARK INTERNATIONAL, INC. PROVIDES

THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of express or implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions of the publication. Improvements or changes in the products or the programs

described in this publication may be made at any time. Publications are not stocked at the

address given below; requests for publications should be made to your point of purchase.

A form for reader’s comments is provided at the back of this publication. If the form has

been removed, comments may be addressed to Lexmark International, Inc., Department

F95/035-3, 740 New Circle Road, Lexington, Kentucky 40511, U.S.A. Lexmark may use

or distribute any of the information you supply in any way it believes appropriate without

incurring any obligation to you.

Lexmark, MarkNet, MarkVision, Optra and WinWriter are trademarks of Lexmark

International, Inc.

IBM and ExecJet are registered trademarks of the International Business Machines

Corporation in the United States and/or in other countries. ExecJet is under license from

International Business Machines Corporation.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 1996. All Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Greenwich, CT 06836.

Page 2

Contents

4026-0XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Power-On Self Test (Post). . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Service Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Diagnostics Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Printer Diagnostic Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Service Diagnostic Test Page . . . . . . . . . . . . . . . . . . . . . . 1-16

User Mode Print Test Page . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Hex Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Restoring Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

4027-04W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power-On Self Test (POST). . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Diagnostic Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Customer Test Page (From WPS) . . . . . . . . . . . . . . . . . . . 2-10

Customer Test Page (Stand Alone) . . . . . . . . . . . . . . . . . . 2-10

Developed Image Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

WPS.INI File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

4033 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Power Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Reset, LAN Connected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Symptoms after Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Diagnostic Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Sample Print Test (Models 20X and 30X) . . . . . . . . . . . . . . 3-5

Wrap Test for Adapter Ports. . . . . . . . . . . . . . . . . . . . . . . . . 3-5

LAN Connection Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Printer and LAN checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Printer checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

LAN checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Contents

iii

Page 3

4037 / 4047-05E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Power-on Self Test (POST). . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Print Test (Main Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Developed Image Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Diagnostics Print Test 1. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Diagnostics Print Test 2. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Page Count Display Or Initialize . . . . . . . . . . . . . . . . . . . . 4-10

Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Button Lockout Mode (4047 Only). . . . . . . . . . . . . . . . . . . 4-12

LCD Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Sensor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Print Head Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Print Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . 4-14

Advanced Setup Menu (Early 4037 Models Only). . . . . . . 4-15

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Fastbytes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Hex Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Fuser Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Parts Catalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4039-1XX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Failures With Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Alphabetical List of Diagnostic Aids. . . . . . . . . . . . . . . . . . . 5-9

Operator Panel Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Network Connections and Checks . . . . . . . . . . . . . . . . . . 5-20

LAN Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Laser Printer Reference Handbook

iv

Page 4

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Envelope Restraint Spring . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Paper Restraint Spring. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Printhead Skew - Level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Printhead Skew - Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

4040 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance Approach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Diagnostic Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Error Code/Message Tables . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Operator Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Symptom Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Diagnostic Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Interlock Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Diagnostics Mode Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Envelope Feeder Separation Guide and Lower Separation Roll-

er Gap Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Paper Drawer Cassette Side Registration Adjustment. . . . 6-27

Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

System Board Connector Signals . . . . . . . . . . . . . . . . . . . 6-28

Paper Deck Switches, Sensors, Clutches, Solenoid, Motors. . .

6-37

Paper Deck Printed Circuit Boards. . . . . . . . . . . . . . . . . . . 6-37

Paper Deck Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Option Controller Interface Connectors . . . . . . . . . . . . . . . 6-41

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Contents

v

Page 5

4047-05W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Customer Test Page (From WPS). . . . . . . . . . . . . . . . . . . 7-10

Customer Test Page (Stand Alone). . . . . . . . . . . . . . . . . . 7-10

Developed Image Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Service Diskette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Diagnostics Test Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Diagnostics Test Page 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Envelope Print Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Hex Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Set Page Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Printhead Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Print Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . 7-16

Fuser Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Parts Catalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

4049-XXX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . 8-10

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Diagnostics Mode Menu Structure . . . . . . . . . . . . . . . . . . 8-13

Diagnostics Mode Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Auto Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Auto Clean Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Auto Clean Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Charge Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Disk Test/Clean. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Duplex Feed 1 Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Duplex Feed 2 Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Envelope Enhance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Envelope Print Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Flash Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Fuser Temperature And Warm-Up Time. . . . . . . . . . . . . . 8-21

Laser Printer Reference Handbook

vi

Page 6

LCD Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Maintenance Kit Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Memory Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Paper Feed Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Parallel Confidence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Permanent Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Print Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Print Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Print Test 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Print Test 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Print Test 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Quick Disk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Top Margin and Duplex Quick Tests . . . . . . . . . . . . . . . . . 8-28

Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Wrap Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Developed Image Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

LAN Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Print Test Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Print Test with RIP Board Removed. . . . . . . . . . . . . . . . . . 8-31

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Contents

vii

Page 7

5045 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Diagnostic/Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . 9-3

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Diagnostics Mode Menu Structure . . . . . . . . . . . . . . . . . . . 9-7

Diagnostics Mode Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Disk Test/Clean. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Flash Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

LCD Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Memory Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Permanent Page Count. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Print Test 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Print Test 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Print Test 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Quick Disk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Wrap Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Density Adjustment Panel . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

LAN Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Attendance/Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Service Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Screen/Color Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Toner Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Ordering Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Handling The Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Optional Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Using Print Density Adjustment (PDA)Panel. . . . . . . . . . . 9-22

Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Temperature/Humidity Sensor. . . . . . . . . . . . . . . . . . . . . . 9-23

117 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Print Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Laser Printer Reference Handbook

viii

Page 8

4026-0XX 1

Optra E

4026-0XX

4026-0XX

1-1

Page 9

Notes:

Laser Printer Refer ence Handbook

1-2

Page 10

4026-0XX

Diagnostics

Start

CAUTION:

interlock switch and the printhead shutter actuator at the same

. To perform some of the servic e checks and tests, such as

time

troubleshooting paper feed problems, you need to actuate the top cover

interlock switch with the covers opened or removed and power applied

to the machine. It is important for personal safety that you

FOR ANY REASON

is on.

Remove power from the printer before you connect or disconnect any

cable or electronic board or assembly for personal safety and to prevent

damage to the printer.

Use the service error code, user error message, symptom table, service

checks, and diagnostic aids to determine the corrective action

necessary to repair a malfunctioning pr int er.

The lights on the operator panel can indicate either a user error

message or service error message. When a service error occurs the

printer stops printing and all operator panel LEDs blink in a continuous

patt e rn, indicating a se rvice e rror, until the pri n t e r is powe r e d o ff. If all

operator panel LEDs are blinking, go to the “Service Error Codes” on

page 1 -5.

When a user error message occurs, one or two operator panel LEDs

are on solid or blinking. Go to the “User Error Message Table” on

page 1 -8.

If your machine does not have a service error code and does not

complete POST, go to the “POST Symptom T able” on page 1-11. If your

machine completes POST without an error, and you have a symptom,

go to the “Symptom Table” on page 1-12. Locate your symptom and

take the appropriate action.

If a service error code appears while you are working on the machine,

go to the “Service Error Codes” on page 1-5 and take the indicated

action for that error.

If your printer did not successfully complete POST, locate the symptom

in the “POST Symptom Table” on page 1-11 and take the appropriate

action.

NEVER

manually actuate or disable the top cover

DO NOT,

, disable the printhead shutter actuator when power

4026-0XX

4026-0XX

1-3

Page 11

If the printer completes all these steps and no error indications are

displayed, the printer has successfully completed the POST. If the

printer has completed POST without an error and a symptom exists, go

to the “Symptom Table” on page 1-12.

Power-On Self Test (Post)

4026-0XX

The printer performs the following Power-On Self Test when powered

on:

1. All LEDs come on solid.

2. The fan turns on for 2 seconds.

3. All the LEDs turn off.

4. The engine board checks the status of the cover interlock switch.

5. The LEDs begin to turn on then off continuously.

6. The fan turns off.

7. The engine board checks the status of the paper exit sensor.

8. The engine board checks the status of the thermistor.

9. The fuser lamp turns on.

The printer may be idle for up to 40 seconds as the fuser warms

to operating temperature. Printer idle time is shorter if the fuser is

already warm.

10. The polygon motor (printhead motor) turns on.

11. The main motor turns on.

12. The paper feed gears turn.

13. The print cartridge drive gear engages.

14. The paper feed take-up shaft and D-roll assembly rotates to

home position. (The paper feed lift plate assembly is in the down

position).

15. All the LEDs turn off.

16. Model 4026-06A, 06D - The Ready LED turns on solid and the

Data LED blinks. Go to Step 17.

Model 4026-06B, 06E - The Ready LED turns on solid and the

Data LED blinks.

• The controller board checks flash ROM installation.

• The controller board verifies that flash is formatted.

• The controller board attempts to format flash if unformatted.

• The Data LED blinks du ring format.

• The printer continues POST after format is complete.

• If format fails, a “Flash Memory Failure” error displays.

Laser Printer Refer ence Handbook

1-4

Page 12

17. The main drive motor turns off.

18. The polygon motor (printhead motor) turns off.

19. The Data LED turns off.

20. The Ready LED stays on solid.

If the printer completes all these steps and no error indications are

displayed, the printer has successfully completed the POST.

Service Error Codes

When a service error occurs the printer stops printing and all operator

panel LEDs blink in a continuous pattern, indicating a service error, until

the printer is powered off.

Press and release the operator panel button to display the service error

code. Locate the blinking LEDs in the following table and take the

indicated action.

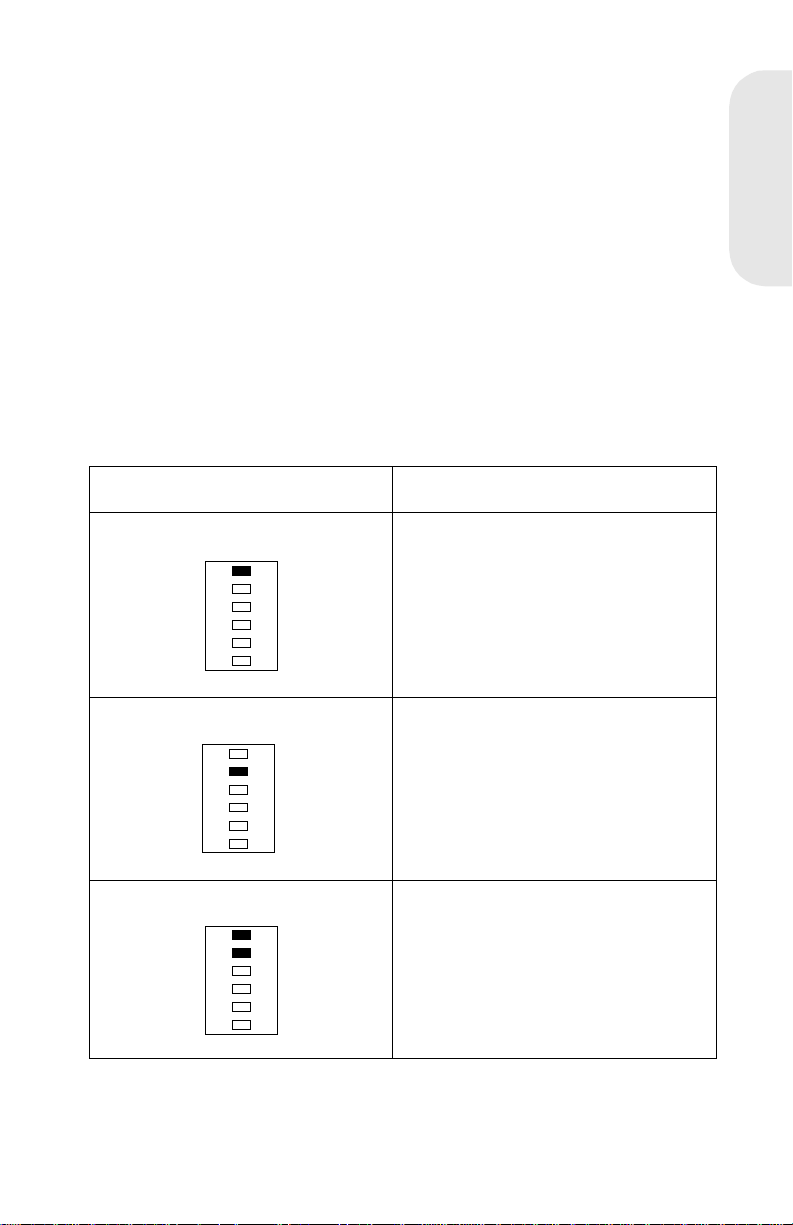

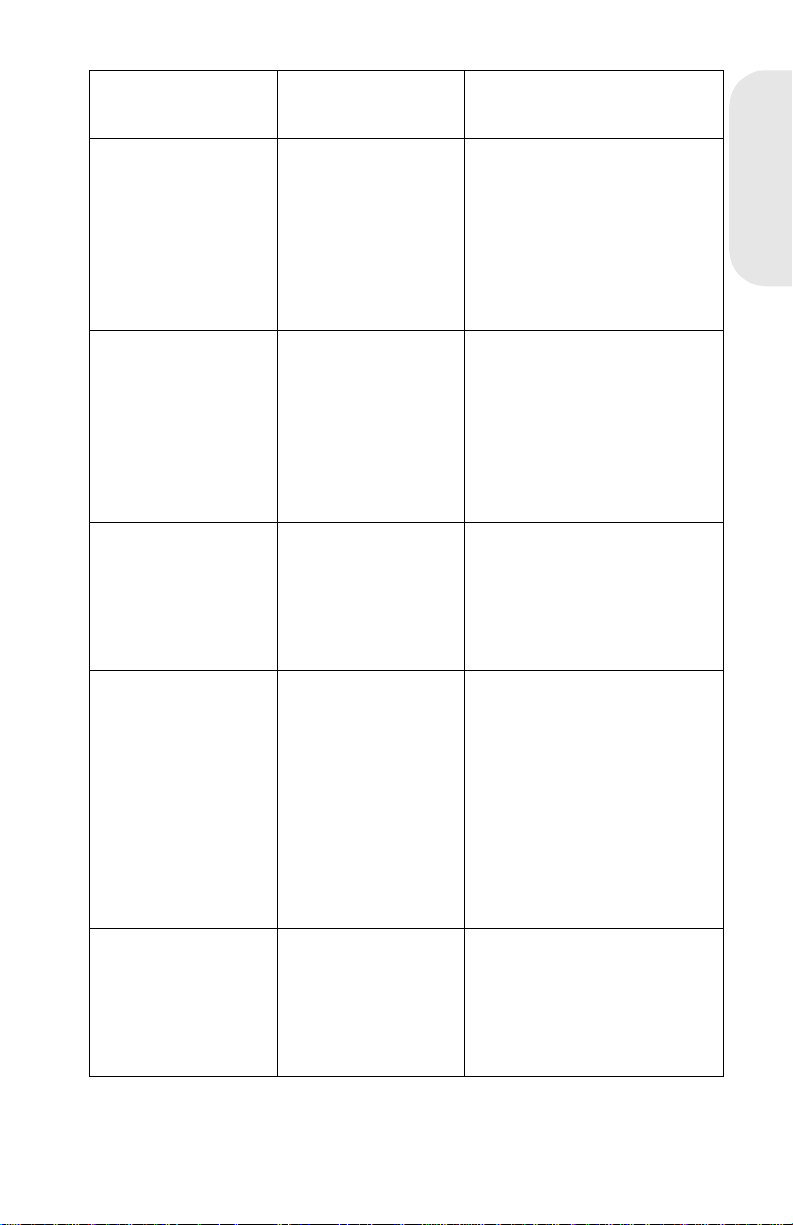

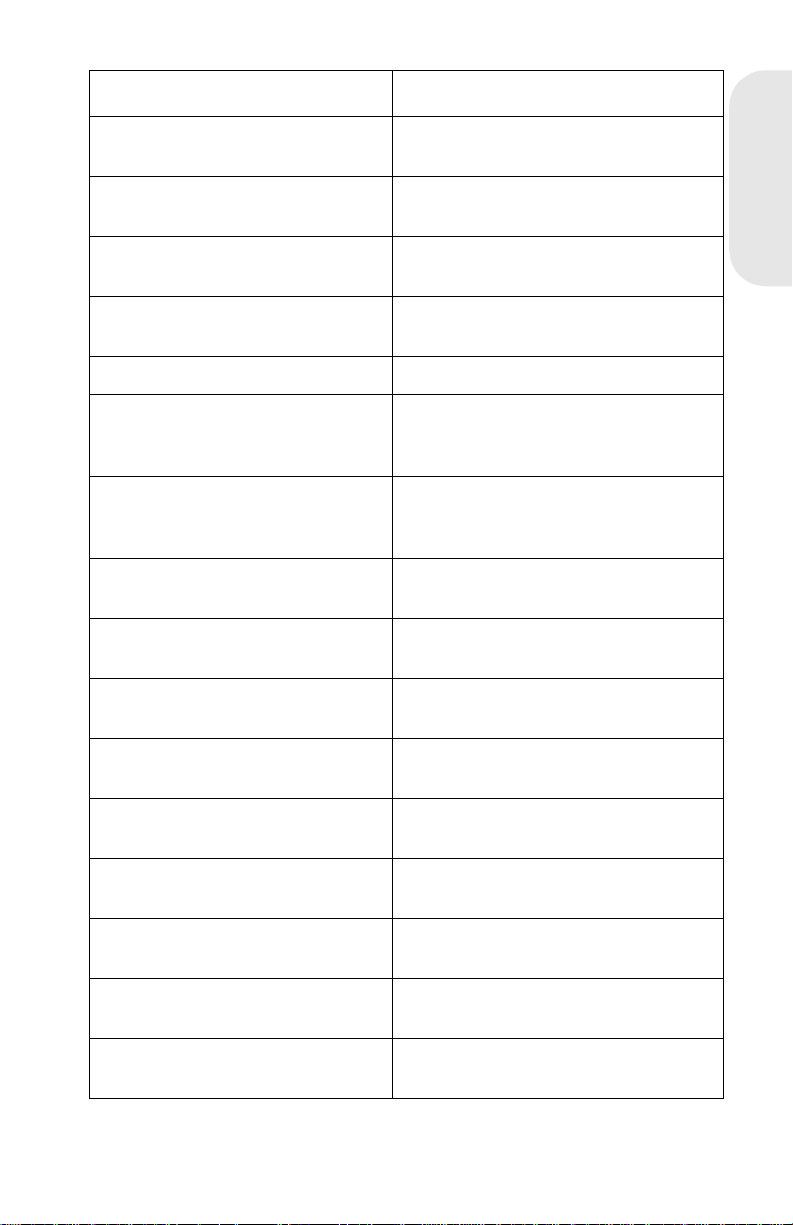

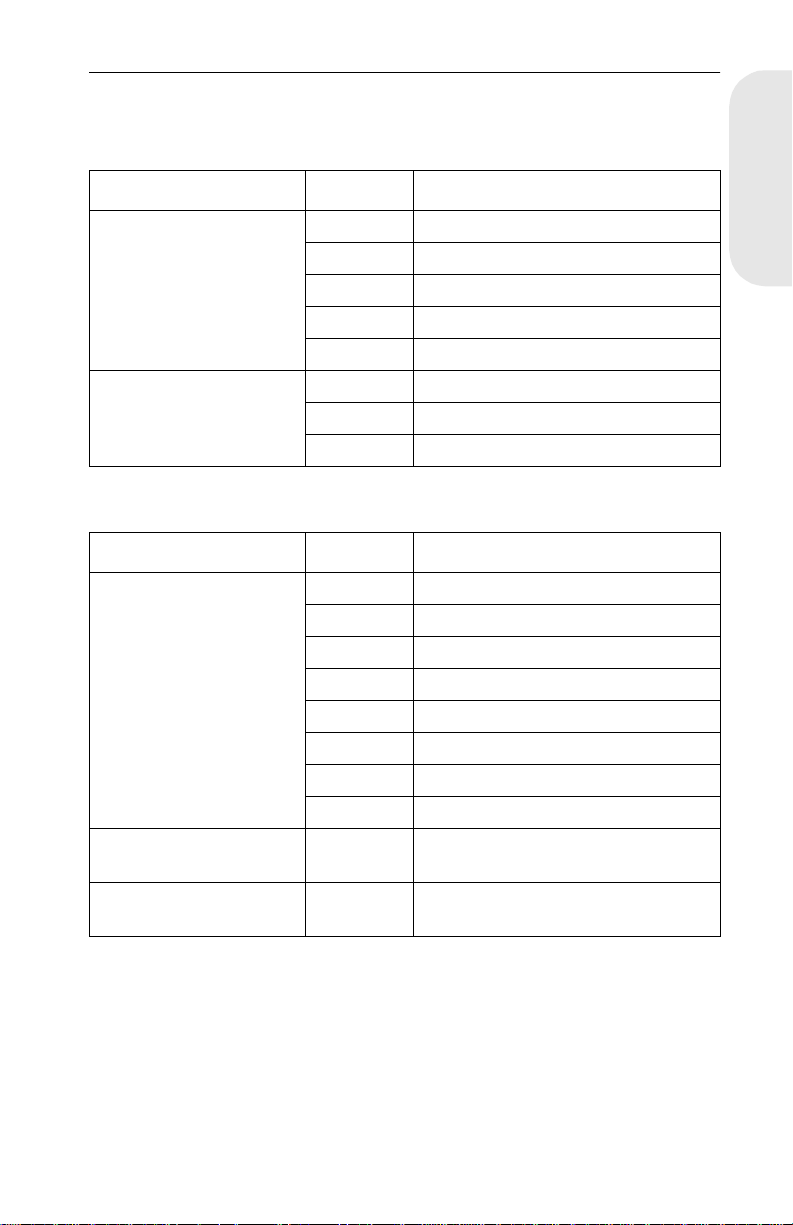

Blinking Operator Panel LED Action

Software Service Error Code Run the Printer Diagnostic Test to

diagnose between the ROM SIMM

and the control ler board. If no other

error cod e displays after the test

completes, replace the controller

board.

4026-0XX

Fuser Failure Error Refer to t he Cold Fus er Service

Check in the Service Man ual.

Mirror Motor Error The Polygon Mirror Motor is not

rotating during printing. Replace the

engine board. If t his does not c orrect

the problem, replace the printhead

assembly.

4026-0XX

1-5

Page 13

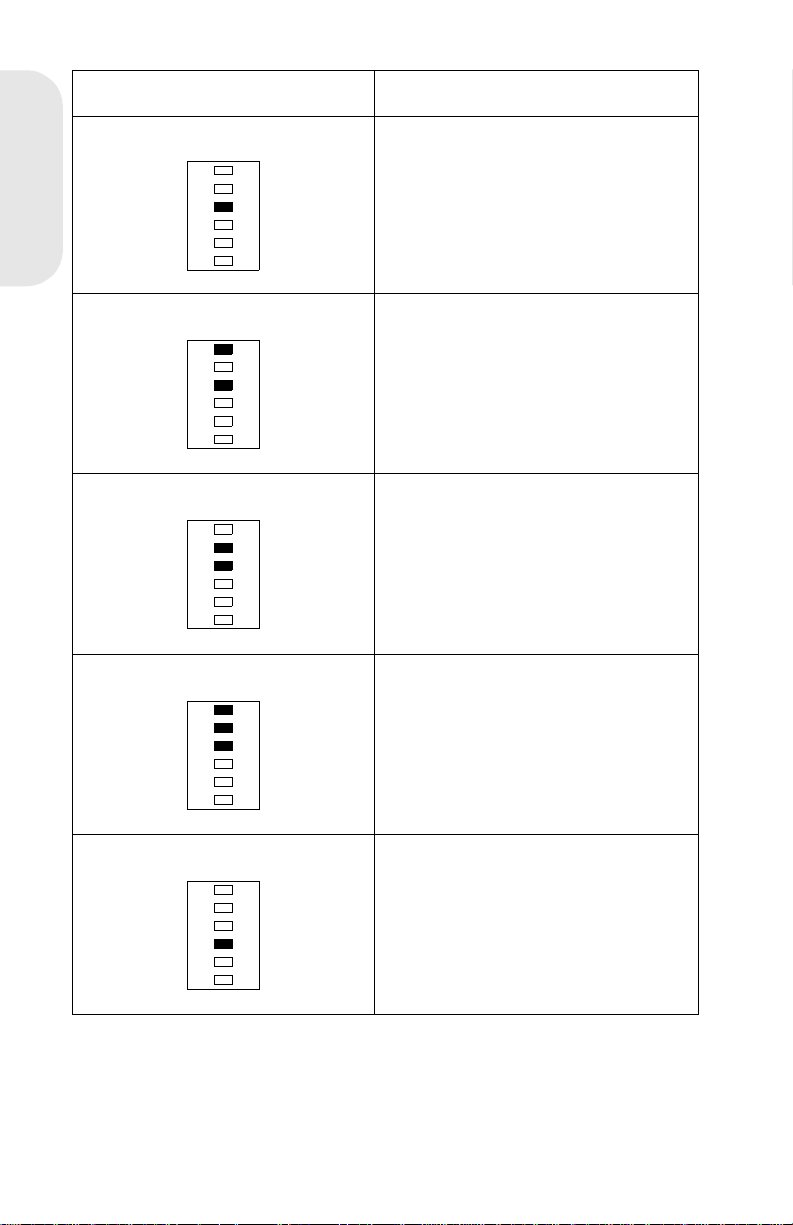

Blinking Operator Panel LED Action

Laser Diode Failure Replace the printhead assem bly. If

this does not correct the problem,

replace the engine board.

4026-0XX

Controller Card Failure Replace Controller board

Optional Memory Error Replace the op ti onal memory SI MM.

If this does not correct the problem ,

replace the controller board.

Fan Failure Error Refer to the Fan Service Check in

the Service Manual.

ROM Checksum Error Replace the ROM SIMM. If thi s does

not correct the problem, replace the

controller board.

Laser Printer Refer ence Handbook

1-6

Page 14

Blinking Operator Panel LED Action

Base Memory Error Replace Controll er board

NVRAM Fai lure Error Replace Controller board

ASIC Register Failure Error Replace Controller board

ASIC SRAM Fail ure Er ror Replace Controll er boar d

4026-0XX

Flash Memory Failure Error Replace the ROM SIMM w/Flas h. If

this does not cor rect the problem,

replace the controller board.

4026-0XX

1-7

Page 15

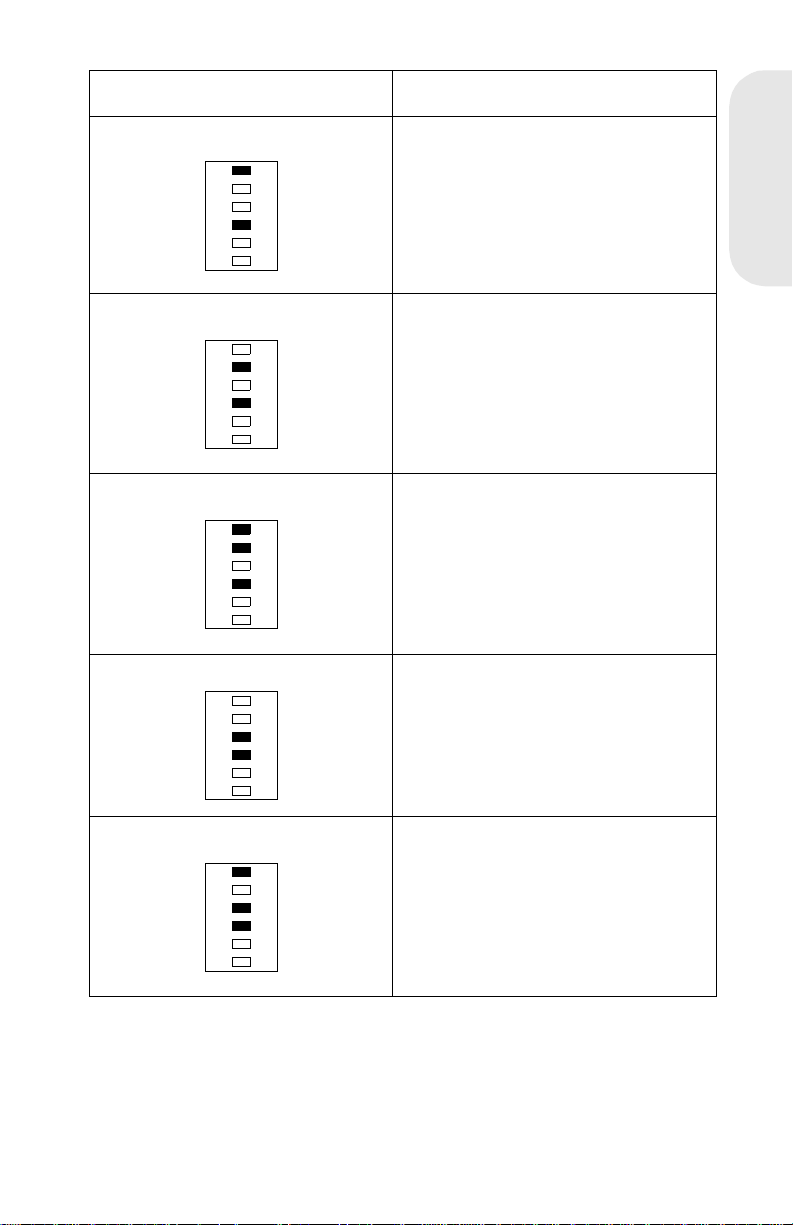

Blinking Operator Panel LED Action

Font Checksum Fail ure Error Replace the ROM SIMM . If thi s does

not correct the problem, replace the

controller board.

4026-0XX

Engine Board Communications

Failure Error

Controller SRAM Failure Error Replace Controller board

Replace the engine boar d. If this

does not correct the problem,

replace the controller board.

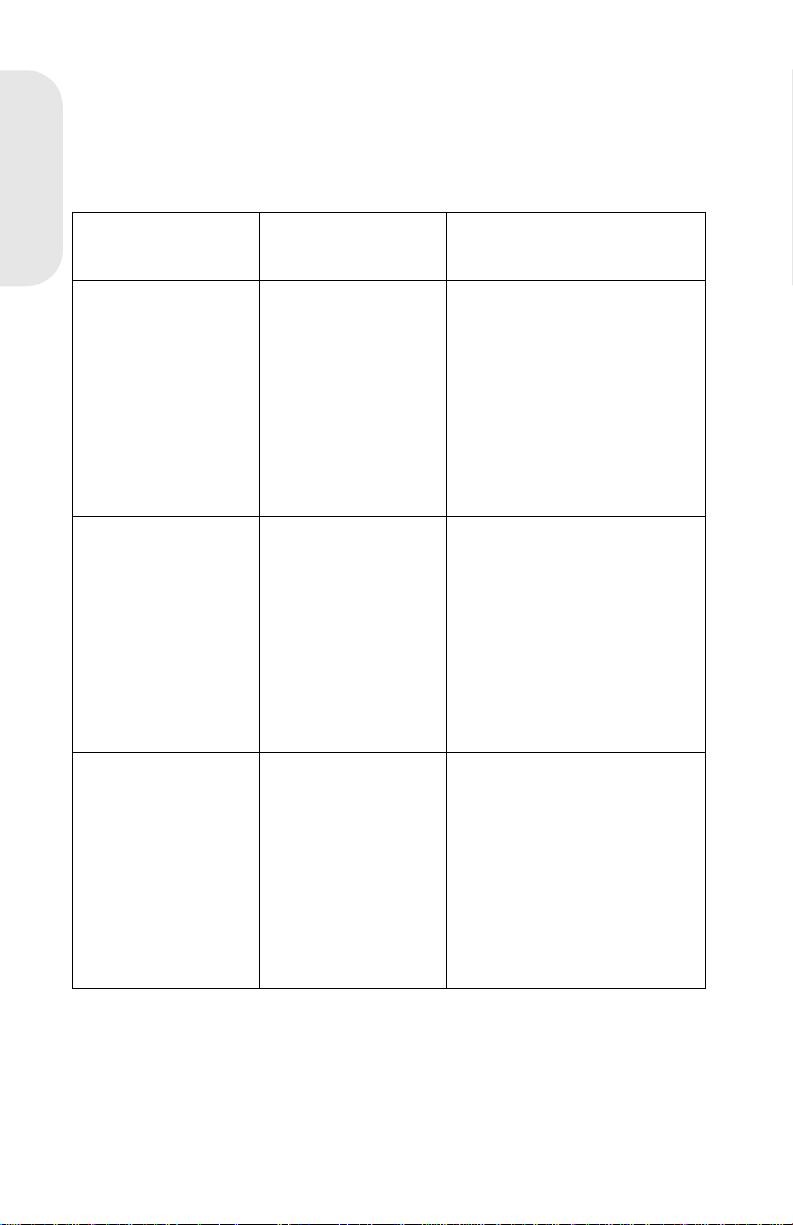

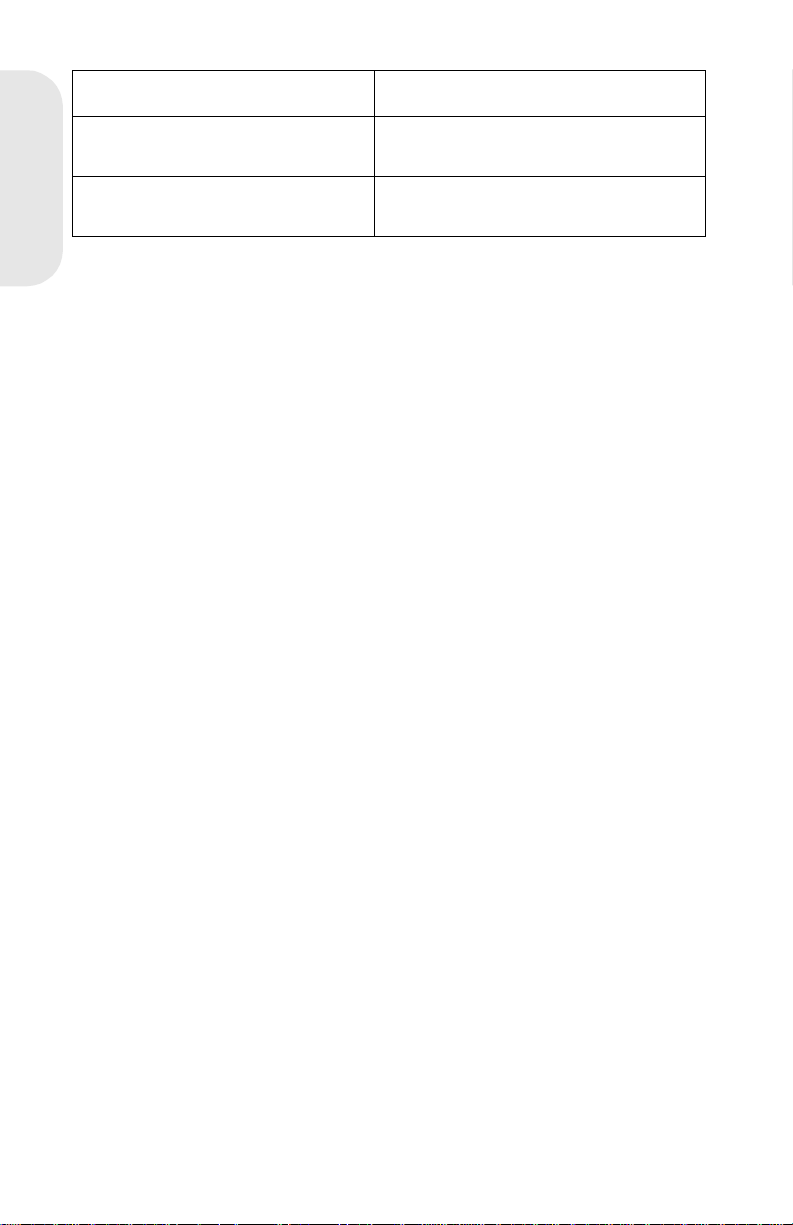

User Error Message Table

When a user error message occurs the printer stops printing and one or

two operator panel LEDs are on solid or blinking until the printer is

powered off. Locate the printer’s LED Status in the following table and

take the indicated action.

User Error

Message

LED Status Action

Paper Jam Paper Jam on solid Open cover and clear any

paper jams. Close the top

cover. If the error message

is still present , refer to the

Paper Feed Service Check

in the Service Manual.

Laser Printer Refer ence Handbook

1-8

Page 16

User Error

Message

Load Manual

Paper /Envel ope

LED Status Action

Load Paper blinks

and Press Button

on solid

Load media into the manual

slot and push the oper ator

panel button to resume

printing or do a front panel

reset by pressing and

holding the operator panel

button for more than three

seconds.

4026-0XX

Load Paper/Load

Env elo pe

Top Cover Open Error on solid Close the top cover. If the

Memory Full/

Complex Page/

Resolution

Reduction

Warning/Data

Transmission Error

Load Paper on

solid and Press

Button on soli d

Error on solid and

Press Button on

solid

Load media in the

appropriate pap er tr ay and

push the operator panel

button to r esum e printing or

do a front panel reset by

pressing and hol ding the

operator panel button for

more than three seconds.

error LED remains on solid

and POST does not

continue, refer to t he Cover

Interlock Service Check in

the Service Manual.

The printer memory is full or

the page is too complex to

print. The printer is forced to

reduce the resol ution of a

formatted page to 300 dpi

before pri nting, or the printer

is unable to maintain the

required data transfer rate.

Refer to the “User

Secondary Error Message”

Table in the Service Manual.

Flash Memory Full Error blinks and

Press Button on

solid

This condition only occurs

when the Flash SIMM is

installed. (4026-06B, 06E)

Refer to the “User

Secondary Error Message”

Table in the Service Manual.

4026-0XX

1-9

Page 17

User Secondary Error Message Table

Press and release the operator panel button two times to display the

user secondary error LED status. Each press and release action must

be performed within a half second. Locate the printer’s LED status in

the following table and take the indicated action.

4026-0XX

User Error

Message

LED Status Action

Complex P age Ready, Error, and

Press Button on

solid

Memory Full Ready, Data,

Error, and Press

Button on solid

Resolution

Reduction

Ready, Data

blinking and the

Error , Press But ton

on solid

Switch the printing mode to

a differ ent pri nting mode

using the Lexmark driver for

Windows, or push the

operator panel button to

resume printing, or do a

front panel reset b y pre ssing

and holding the oper ator

panel button for more than

three seconds.

Change the pri nting mode to

Quick Print Plus or reduce

the complexity of the job or

the resolution, or push the

operator panel button to

resume printing, or do a

front panel reset b y pre ssing

and holding the oper ator

panel button for more than

three seconds.

Switch from the GL/2 or

raster mode to Quick Print

Plus mode using the

Lexmark driv er f or Windows ,

or press the operator panel

button to resume printing,

or do a front panel reset by

pressing and holding the

operator button for more

than three seconds.

Laser Printe r Reference Handbook

1-10

Page 18

User Error

Message

Data Transmission

Error

LED Status Action

Data, Error, and

Press Button on

solid

Switch to Print Accelerator

using the Lexmark driver for

Windows if 2MB of memory

or more is installed, or

switch to the GL/2 printing

mode using the Lexmark

driver for Windows, or push

the operator panel button to

resume printing, or do a

front panel reset b y pressing

and holding the oper ator

panel button for more than

three seconds.

4026-0XX

Flash Memory Full Error blinking and

Press Button on

solid

This condition only occurs

when the Flash memory is

full.

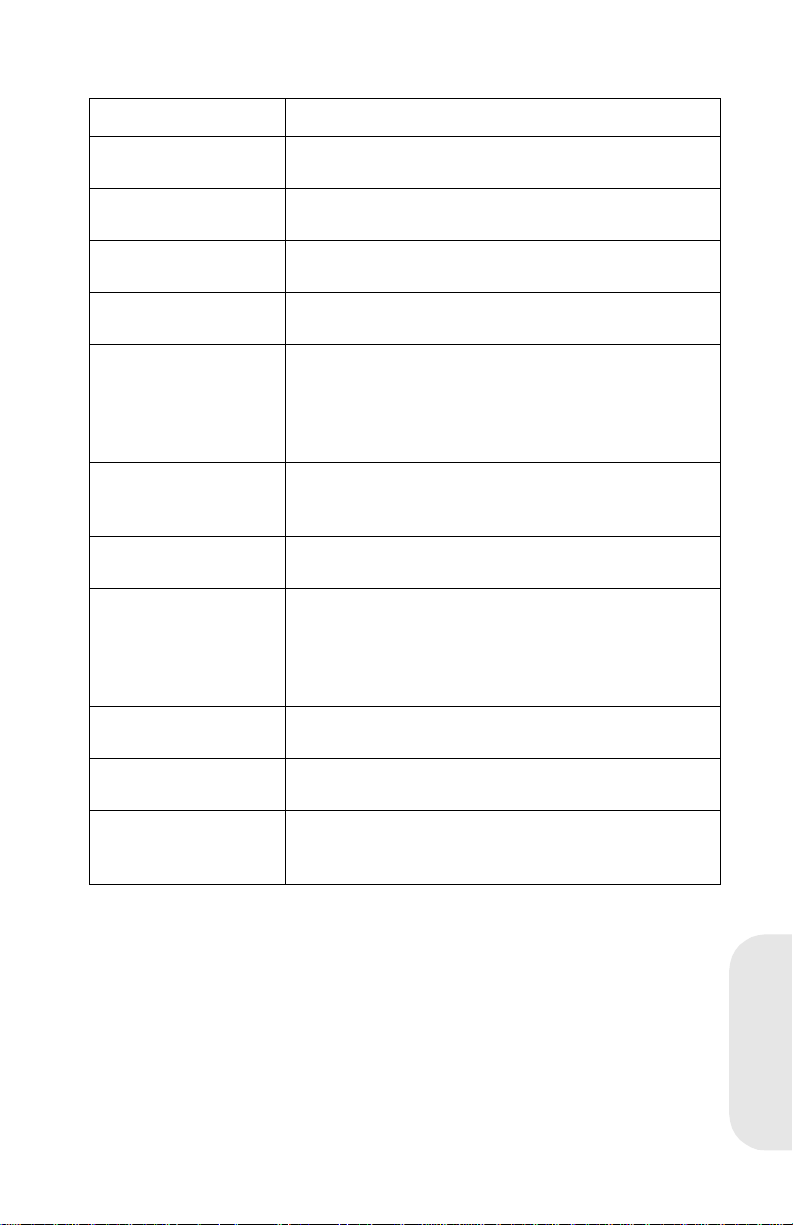

POST Symptom Tabl e

Symptom Action

POST completes e xcept one or

more LEDs do not come on.

None of the LEDs come on. Refer to t he Operator Panel Service

The printer is dead (No LEDs

come on, no motor turns)

The fan does not come on. Refer to the Fan Service Check in t he

The fuser l am p does not c om e on. Refer to the Cold Fuser Service

The polyg on motor does n ot come

on.

Refer to the Ope rator Panel Service

Check in the Service Man ual.

Check in the Service Man ual.

Refer to the Low Voltage Power

Supply Service Check in the Service

Manual.

Service Manual.

Check in the Service Man ual.

Replace the printhead assembly. If

this does not fix the problem, repl ace

the engine board.

The main drive motor does not

come on.

Refer to the Main Drive Motor Service

Check in the Service Man ual.

4026-0XX

1-11

Page 19

Symptom Action

The paper feed gears do not turn. Refer to the Paper Feed Service

Check in the Service Manual.

The paper feed solenoid picks

4026-0XX

and tries to feed paper.

The toner/print cartridge gear s do

not tur n .

Refer tot he Paper Fe ed Service

Check in the Service Manual.

Refer t o the Main Driv e Motor Service

Check in the Service Manual.

Symptom Table

Locate your symptom in the following table and take the appropriate

action

Symptom Action

Dead printer Refer to the Lo w Voltage Power

Supply Service Check in the Service

Manual.

Fan not w orki ng Refer to the Fan Se rvice Check in the

Service Manual.

Fan noisy Refer to the Fan Service Check in the

Service Manual.

Fuser parts melted Refer t o the Col d Fuser Service

Check in the Service Manual.

Fuser Lamp doesn’t light Refer to the Cold Fuser Service

Check in the Service Manual.

Toner not fused to the paper Refer to the Cold Fuser Service

Check in the Service Manual.

Blank page Refer to the Print Quality Service

Check in the Service Manual.

Black page Refer to the Print Quality Service

Check in the Service Manual.

High or heavy background Refer to the Print Quality Service

Check in the Service Manual.

Offset print (image ar ound

characters)

Laser Printe r Reference Handbook

1-12

Refer to the Print Quality Service

Check in the Service Manual.

Page 20

Symptom Action

Poor image (charact ers washed

out)

Paper jams Refer to the Paper Feed Service

Main Drive Motor noisy Refer t o the Main Drive Motor Service

Main Drive Motor does not move Refer to the Main Dri ve M otor Service

Main Drive Motor runs backward Replace the Engine board.

Paper is not picked or never

leaves the primary tray

Paper is not picked or never

leaves the optional paper tray

(Tray 2)

Paper feeds continuously Refer to t he Paper Feed Servi ce

Paper fails to exit printer or st ack

in output bin

Paper skew Refer to t he Paper Feed Servi ce

Refer to the Print Quality Service

Check in the Service Man ual.

Check in the Service Man ual.

Check in the Service Man ual.

Check in the Service Man ual.

Refer to t he Paper Feed Frame

Assembly S ervice Ch eck in the

Service Manual.

Refer to the Optional Pape r Tray 2

Service Check in the Service Manual.

Check in the Service Man ual.

Refer to the Paper Feed Service

Check in the Service Man ual.

Check in the Service Man ual.

4026-0XX

Toner on the back of the page Refer to t he Transfer Assem bly

Service Check in the Service Manual.

Po or pri nt quality Refer to the Print Quality Service

Check in the Service Man ual.

Incorrect characters print Refer to the Print Quality Service

Check in the Service Man ual.

Printer not communicating with

host

White or black lines or bands Refer to the Print Quality Service

Paper wrinkled or bent Refer to the Paper Feed Service

Refer to the Parallel Port Service

Check in the Service Man ual.

Check in the Service Man ual.

Check in the Service Man ual.

4026-0XX

1-13

Page 21

Symptom Action

Top cov er wi ll not close Refer to the Cov er Interlock Service

Check in the Service Manual.

Light print Refer to the Print Quality Service

4026-0XX

Check in the Service Manual.

Laser Printe r Reference Handbook

1-14

Page 22

Diagnostics Aids

Printer Diagnostic Test

The following tests run sequentially when performing this test:

Standard Memor y Test

Optional Memor y Test

Microcode Check

LED Test

Read/Write ASIC Register Test

Read/Write ASIC SRAM Test

Read/Write controller board SRAM Test

Perform the following steps to run the Printer Diagnostic Test:

1. Tur n t he prin ter off.

2. Open the top cover.

3. Press and hold the operator panel button as you turn on the

printer. Release the button once the printer’s indica tor lights

come on.

4. Wait until the Error LED (top cover open indication) comes on.

5. Close the top cover.

6. The Ready LED comes on solid and the Data LED blinks. (This is

the printer Busy Mode indication).

7. If all the diagnostic tests run correctly, the Ready LED goes off

and the Data LED continues to blink. If a test fails, the error light

pattern for the service error code displays on the operator panel.

4026-0XX

4026-0XX

1-15

Page 23

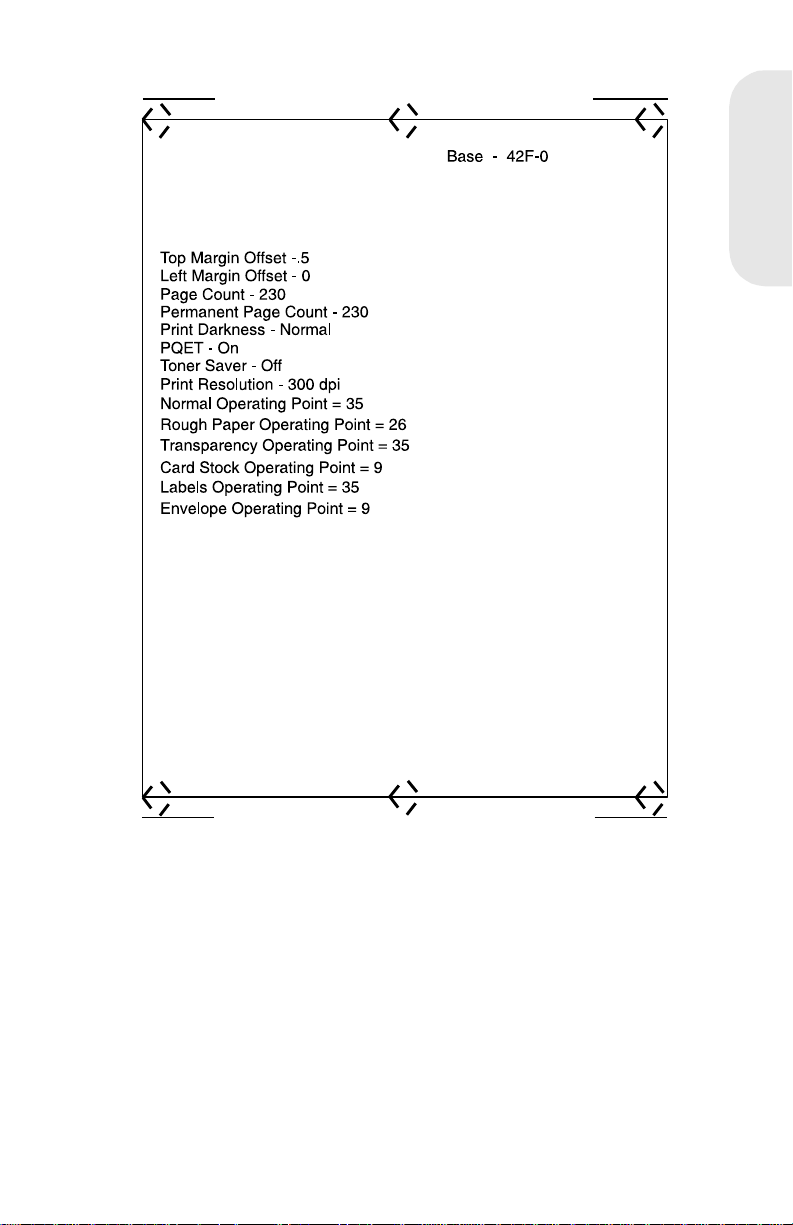

Service Diagnostic Test Page

The service diagnostic test page includes registration marks to aid in

adjusting print registration and also includes the installed printer base

code level. The service test page displays the user default v alues for t he

following:

4026-0XX

Top M argin Offset

Left Margin Offset

Printer Page Count

Permanent Page Count

Print Da rk n es s Setting

PQET Setting (on/off)

Tone r Saver (on/off)

Print Re s olu t ion

Perform the following steps to print the Service Diagnostic Test Page:

1. Tur n the pr inter off.

2. Open the top cover.

3. Press and hold the operator panel button as you turn on the

printer.

4. Wait until the Error LED comes on solid.

5. Close the top cover.

6. The Ready LED is on solid and the Data LED blinks continuously.

7. When the test is complete the Ready LED goes off and the Data

LED continues to blink.

8. Press the operator panel button briefly.

9. The Ready and Data LEDs blink and the Service Diagnostic T est

Page prints. The test page requires several seconds to start

printing.

10. When the test page has finished printing the Ready LED comes

on solid and Data LED goes off.

Note:

automatically exits the diagnostic mode and returns to the normal

mode.

After the diagnostic test page prints, the printer

Laser Printe r Reference Handbook

1-16

Page 24

4026-0XX

4026-0XX

1-17

Page 25

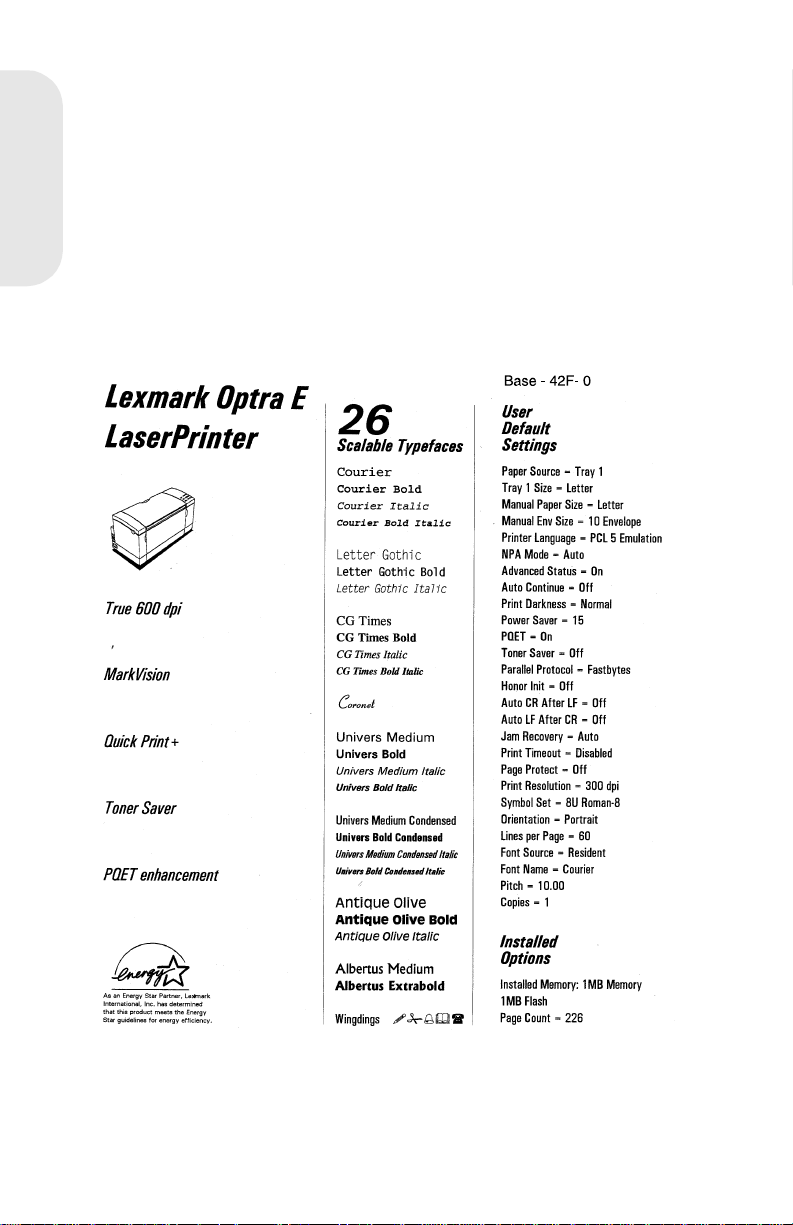

User Mode Print Test Page

The User Mode Print Test Page displays the user default values,

installed options, printer features, various typefaces, and the installed

printer base code level.

1. Be sure the Ready LED is on solid (printer is in the ready state).

4026-0XX

2. Press and release the operator panel button.

3. The Ready and Data LEDs blink continuously.

4. The test page prints and the operator panel Ready LED comes

on solid and the Data light turns off.

5. The printer returns to the ready state.

Laser Printe r Reference Handbook

1-18

Page 26

Configuration Mode

The configuration mode gives the ability to set the following printer

functions through the operator panel:

Hex Trace

NPA Mode (Parallel)

Parallel Protocol

Advanced Status

PPDA Activated

Auto CRLF/LFCR

Perform the following steps to enter the configuration mode:

1. Tur n t he prin ter power off.

2. Open the top cover.

3. Turn the printer power on.

4. Top Cover Open (Error LED on) is displayed on the operator

panel.

5. Double-click the operator panel button.

Note:

solid. The Data, Load Paper, Paper Jam, Er ror and Press Button are off.

Note:

mode. Repeat the steps to re-access the configuration mode.

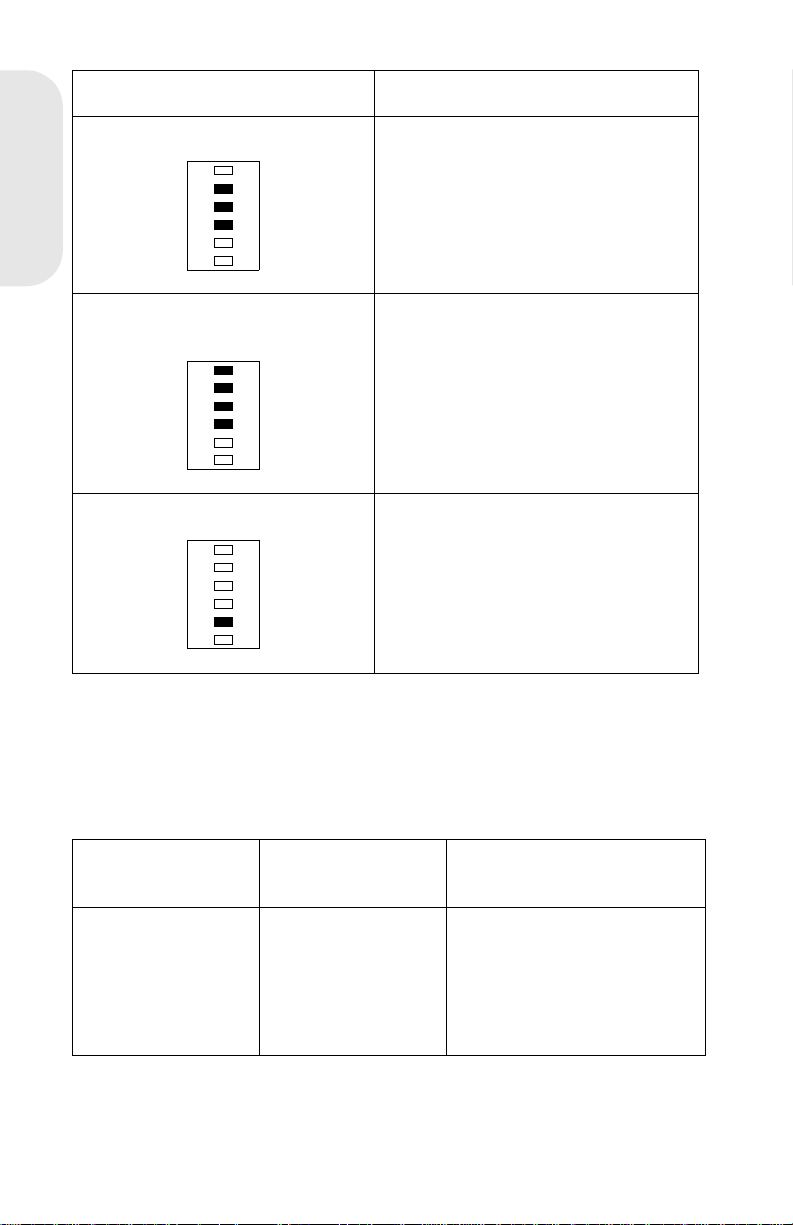

Configuration Mode Operator Panel Overlay

The following overlay indicates the operator panel LED and button

designations when in the configuration mode.

The printer is in the configuration mode. The Ready LED is on

Closing the top cover causes the printer to exit the configuration

4026-0XX

Hex Trace

NPA Mode

Parallel Protocol

Advance St a tus

CRLF/LFCR

Off/On/Auto

Press three secon ds to save

4026-0XX

1-19

Page 27

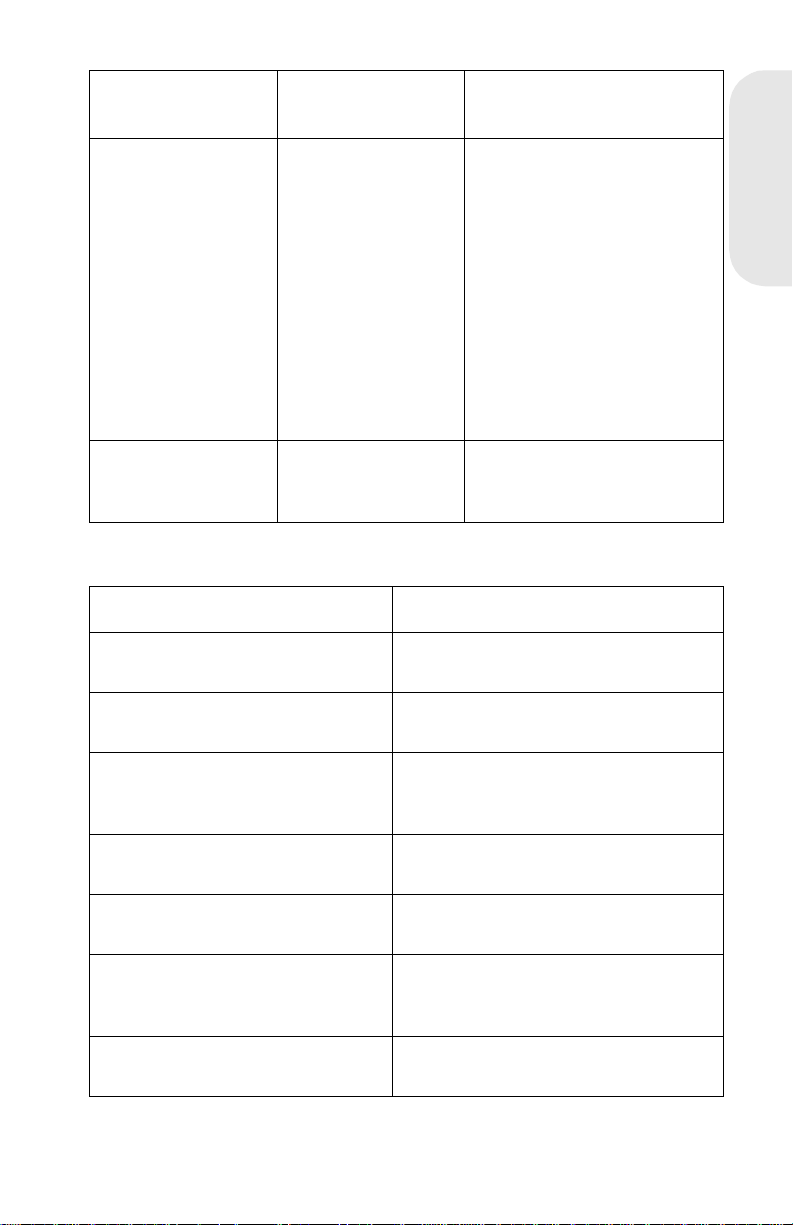

Operator Panel Configuration Mode Button Definition

Term Description Result

Brief Button Press Press the operator

4026-0XX

Long Button Press Press and hold the

Double-Click Button

Press

panel but ton n o longer

than three seconds.

operator panel button

for more than three

seconds.

Press and release t he

operator panel button

two times. E ac h

press and release

action must be

performed within a

half second.

This action moves

through the

configurat ion mode

value list.

This action sel ects

and save s the value

for the menu it em

displayed. To indicate

that the setting i s

save d, it is displayed

on the operator pane l.

This action moves

through the

configurat ion mode

value list.

Laser Printe r Reference Handbook

1-20

Page 28

Hex Trace

Use Hex Trace to isolate the cause of print problems. When a job is

printed, the printer operator panel displays the Hex Trace indication,

(Ready LED blinking), showing that the printer remains in the Hex Trace

mode. Tu rn the printer power off or do a front panel reset (long button

press) to exit the Hex Trace mode.

Perform the following steps to enter the Hex Trace mode:

1. Enter the configuration mode.

2. Do a brief button press.

3. The Ready LED is on and the Press Button (Off/On/Auto) is on or

off indicating the value selected. A brief button press causes the

printer to cycle through the valid settings for Hex Trace and the

Press Button LED turns on or off.

Operator Panel LED Status Action

4026-0XX

Off/On/Auto LED and Hex Trace

LED is off

Off/On/Auto LED and Hex Trace

LED is on

A long button pr ess causes the

printer to exit configurat ion mode

and enter the normal printi ng mode

or a demo printing mode.

A double-click button press causes

the next menu item, NPA mode, to

display

A long button pr ess causes the

printer to e xi t the config urat ion mode

and enter Hex Trace mode.

A double-click button press causes

the next menu item, NPA mode, to

display .

4. Press and hold the button until the Saved setting indication, (all

LEDs on solid) is posted.

5. When the Error LED comes on, close the top cover.

6. The printer completes POST with the Ready LED blinking

indicating the printer is in the Hex Trace mode.

7. Do a double-click to proceed to the next mode. Do an operator

panel reset or turn the printer off to exit the Hex Trace mode.

4026-0XX

1-21

Page 29

Restoring Factory Defaults

Restoring factory defaults returns the printer settings to the original

factory sett ing s.

Perform the following steps to invoke factory defaults:

1. Turn the printer power off.

4026-0XX

2. Open the top cover.

3. Tur n t he printer power on. The printer star ts POST.

4. The operator panel Error LED comes on solid.

5. Press and hold the operator panel button until all the LEDs are

on solid indicating the printer is restoring factory defaults.

6. Release the button. The printer indicates the operation is

complete by turning all the LEDs off except the Error LED.

7. The configuration mode can be selected by doing a brief button

press or closing the top cover which causes the printer to enter

either the normal mode or the demo mode.

Laser Printe r Reference Handbook

1-22

Page 30

Connectors

Low Voltage Power Supply

Connector Pin No. Signal

CN1 Engine Board

CN2 Fuser Lamp/

Thermal Fuse

1 +24 V dc

2GND

3GND

4 +5 V dc

5FUSER LAMP*

1HEAT N

2 NO CONNECTION

3HEAT L

High Voltage Power Supply

Connector Pin No. Signal

CN1 Engine Board

T

TRET

1HV C

2HV T*

3 HV SEL 2*

4 HV SEL 1*

5HV B

6 BIAS MON

7GND

8 +24 V dc

T HV to TRANSFER CORONA

CHARGE

TRET HV to TRANSFER CORONA

HOUSING

4026-0XX

4026-0XX

1-23

Page 31

Engine Board

CN1A Controller Board

Pin No. Signal Pin No. Signal

1 NO CONNECTION 16 CMD*

4026-0XX

2 NO CONNECTION 17 CTBSY*

3 NO CONNECTION 18 PRINT*

4 NO CONNECTION 19 SRCLK*

5GND 20GND

6 RESET* 21 GND

7 GND 22 VIDEO*

8 GND 23 +5 V dc

9GND 24GND

10 HSYND* 25 +5 V dc

11 EPRDY* 26 GND

12 PRRDY* 27 +5 V dc

13 TDD* 28 CPRDY*

14 ETBSY* 29 +5 V dc

15 STS* 30 TEST*

Connector Pin Signal

CN2A Thermistor

CN3A Paper Entry

Sensor and Paper

T ake-up Solenoid

Laser Printe r Reference Handbook

1-24

1 THERMISTOR

2 +5 V dc

1 ANODE (PC1)

2GND

3PC1*

4 NO CONNECTON

5 +24 V dc

6 FEED1*

Page 32

Connector Pin Signal

CN4A HVPS

CN5A Laser Diode

Drive Board

CN6A Main Motor

CN7A LVPS

CN8A Paper Exit

Sensor

1HV C

2HV T*

3 HV SEL2*

4 HV SEL1*

5 HV B

6 BIAS MON

7GND

8 +24 V dc

1 S SCAN

2CO

3 LD APC2 (LDVR2)

4 LD APC1 (LDVR1)

5GND

6 L DATA*

7 +5 V dc

1 PHASE A

2 PHASE A*

3 PHASE B

4 PHASE B*

1 +24 V dc

2GND

3GND

4 +5 V dc

5FUSER LAMP*

1 ANODE (PC3)

2GND

3PC3*

4026-0XX

4026-0XX

1-25

Page 33

Connector Pin Signal

CN9A 2nd Paper Tra y

(Option)

4026-0XX

CN10A Polygon

Motor

CN11A Fan Motor

1 +24 V dc

2 FEED 2*

3 NO CONNECTION

4+5 V dc

5GND

6 P EMP2

7 PSIZED

8 2NDBIN*

9 MM/INCH

10 CHECK0*

11 CHECK1*

12 CHECK2*

1 NO CONNECTION

2 +24 V dc

3GND

4+5 V dc

5 POLYGON CONTR OL

1FAN*

2 +24 V dc

Laser Printe r Reference Handbook

1-26

Page 34

Second Paper Tray Sensor Board (Option)

Connector Pin No. Signal

CN1A Engine Board

CN3A Paper Take-up

Solenoid - 2nd Paper

Tray (Option)

1 CHECK2*

2 CHECK1*

3 CHECK0*

4 MM/INCH

5 2NDBIN*

6 PSIZEO

7 P EMP 2

8GND

9 +5 V dc

10 NO CONNECTION

11 FEED2*

12 +24 V dc

1 +24 V dc

2 FEED2*

Controller Board

4026-0XX

Connector Pin No. Signal

J5 Op er ator Panel

1GND

2 +5 V dc

3OP DAT

4OP CLK

5 OP BTN 1

6 OP BTN 2

4026-0XX

1-27

Page 35

J4 Engine Board

Pin No. Signal Pin No. Signal

1 NO CONNECTION 16 CMD

2 NO CONNECTION 17 CTBSY

4026-0XX

3 NO CONNECTION 18 PRINT

4 NO CONNECTION 19 SRCLK

5GND 20GND

6 RESET* 21 GND

7 GND 22 R VIDEO*

8 GND 23 +5 V dc

9GND 24GND

10 RHSYNC* 25 +5 V dc

11 EPRDY* 26 GND

12 PRRDY* 27 +5 V dc

13 TOD* 28 CPRDY

14 ETBSY* 29 +5 V dc

15 STS* 30 NO CONNECTION

Connector Pin No. Signal

J3 Pullup Power

J2 Parallel Port

Pin No. Signal Pin No. Signal

1 RSTROBE* 19 GND

2D0 20GND

3D1 21GND

4D2 22GND

5D3 23GND

6D4 24GND

7D5 25GND

Laser Printe r Reference Handbook

1-28

1+5 V dc

2 +5 V dc JUMPER

3 NO CONNECTION

Page 36

J2 Parallel Port (Continued)

Pin No. Signal Pin No. Signal

8D6 26GND

9D7 27GND

10 RACK* 28 GND

11 RBUSY 29 GND

12 RPERROR 30 GND

13 RSELOUT 31 RINIT*

14 RAUTOFD* 32 RFAULT*

15 GND 33 GND

16 GND 34 GND

17 GND 35 GND

18 PLH 36 RSELECTIN*

Paper Exit Sensor

Connector Pin No. Signal

CN3S Engine Board 1 ANODE (PC3)

2GND

3PC3*

4026-0XX

Paper Entry Sensor

Connector Pin No. Signal

CN1S Engine Board

1PC1*

2GND

3 ANODE (PC1)

Paper Feed Solenoid

Connector Pin No. Signal

CN2S Engine Board

1 +24 V dc

2 FEED1*

4026-0XX

1-29

Page 37

Parts Catalog

Covers

P/N Description

4026-0XX

69G8341 Left Side Cover

69G9969 Cover, Cable

69G8301 Top Cover

69G8306 Fan Cover

69G8305 Fan

69G9990 Label, S/N Bla nk

69G8340 Exit Paper Tray

69G8303 Cover Release Assembly

69G8302 Printhead Interlock Actuat or

69G8396 Operator Panel Assembly inc. English Overlay

69G9981 Operator Panel Assembly inc. Overlay W.T. Kit

69G8342 Right Side Cover with shield

69G9690 Logo, Optra E

69G8344 Input Paper Tray

69G8343 Front Cover

69G8337 Gear, 15T

69G8338 Bushing

69G9999 Board, PWB-R

69G9971 Exit Paper Feed Roller/Clip Assembly

69G8336 Exit Paper Feed Roller/Shaft Assembly

11A7443 Logo, Optra Ep (Models 06D and 06E)

Frame

Part

Number

69G9962 Motor, Main Drive

69G9691 Left Side Pla te Motor Bracket

69G8345 Left Side Pla te

69G8346 Guide, photoconductor unit

69G8347 Guide, Toner Cartridge/Photoconductor Unit

11A7420 Bracket, Printhead Mounting

69G8358 Terminal, Rt Side Ground LVPS to Bd Cage

69G8360 Terminal, Rt Side Photoconductor Unit Ground

69G8361 Terminal, Rt SIde, Photoconductor Unit Charge Bias

69G8362 Terminal, Rt Side Toner Cartridge

Laser Printe r Reference Handbook

1-30

Description

Page 38

Frame (Continued)

Part

Number

69G8357 Spring, Rt Side Frame, Cartridge Latching

69G8359 Terminal, Rt Side Ground HVPS to Bd Cage

69G9982 Terminal, Ground

11A7424 Terminal, Left Side Plat e to LVPS

11A7425 Terminal, Left Side Plat e to Li ft Plate

69G8377 Clutch Cam Assembly

69G8379 Bushing

69G8393 D-Roll Shaf t

69G9991 Pin, D-Roll Shaft

69G8375 D-Roll

69G8363 Rubber Foot

Description

Printhead

Part

Number

69G8364 Printhead Assembly 600 dpi

Description

Paper Feed Input Tray

Part

Number

69G8365 Paper Feed I nput Tray Assembly

69G8367 Pressure Spring

69G8394 Guide Plate, Manual Feed

69G8366 Guide, Movable Paper

11A7419 Lift Plate Assembly

Description

4026-0XX

4026-0XX

1-31

Page 39

Paper Feed Frame

Part

Number

69G8368 Paper Feed Frame Assembly

69G8369 Gear, 16T Paper Feed

4026-0XX

69G8371 Sensor, Paper Entry

11A7409 Cable, Input Sensor/Solenoid to Engine Board

69G8372 Flag, Paper Entry Sensor

69G8373 Separator, Paper

11A7442 Paper Feed Pressure Roller Assembly

69G8374 Terminal, Solenoid Ground

69G8370 Solenoid, Paper Feed

Description

Fuser

Part

Number

69G8312 Fuser Assembly, 120 V ac

69G8313 Fuser Assembly, 220/230 V ac

69G8328 Lower Fuser Assembly

69G8331 Sensor, Paper Exit

11A7408 Cable, Paper Exit Sensor

69G8332 Flag, Paper Exit Sensor

11A7423 Spring, Exit Sensor Flag

69G8333 Separator, Paper Hot Roll

11A7421 Separator Roll

69G8314 Thermal Fuse

69G8327 Terminal, Fuser Lamp Right Side

69G8329 Terminal, Thermal Fuse

69G9973 Spring, Backup Roll

11A7422 Holder, Backup Roll Spring

69G8315 Fuser Lamp, 120 V ac

69G8316 Fuser Lamp, 220/230 V ac

69G9694 G-Ring, Hot Rol l

69G9695 Bearing, Hot Roll

69G9978 Backup Roll

69G9977 Hot Roll

69G8317 Thermistor

69G8330 Separator, Paper

69G8325 Cable, Fuser Lamp

69G9979 Terminal, Fuser Lamp/Thermal Fuse

Description

Laser Printe r Reference Handbook

1-32

Page 40

Fuser (Continued)

Part

Number

69G8326 Terminal, Fuser Lamp Left side

69G8318 Upper Fuser Assembly

69G9697 Lever, Fuser Driv e

69G8323 Spring , Inside

69G9698 Arm, Fuser Driv e

69G8324 Spring, Outside

69G9699 Holder, Fuser Drive

11A7431 Transfer Corona cleani ng tool

Description

Electronics

Part

Number

69G8380 Power Supply, 110 V ac

69G8382 Power Supply, 220/230 V ac

1339526 Power Cord; U.S.

69G8381 Fuse, 125 V ac, 5 A

69G9976 Fuse, 250 V ac, 3.15 A

69G9972 Rear Frame

69G8356 Cover, High Voltage Power Supply

69G8383 Board , Hig h Voltage Power Supply

11A7410 Cable, HVPS to Engine Board

69G8385 Cable, 2nd Paper Drawer

11A7406 Cable, Transfer Assembly to HVPS

11A7417 Termi nal, Rear Frame Ground to Control Board Cage

11A7418 Cover, LVPS Edge

69G8386 Controller Board Brac ket W/O Cage

69G9985 Controller Board Cage

11A7439 Controller Boar d W/O R O M SIMM, Mod els 06A, 06B

69G8262 Controller Board, W/O ROM SIMM, Models 06D, 06E

11A7433 Screw, 4-40 Control Board To Board Cage

69G9983 ROM SIMM, Model 06A (W/O Flash)

69G9984 RO M SIMM W/F lash, Model 06B, 06E

11A7272 ROM SIMM, Model 06D, W/OFlash

11A7271 ROM SIMM, Model 06E, W/Flash

69G8384 Engine Board

Description

4026-0XX

4026-0XX

1-33

Page 41

Transfer Assembly

Part

Number

69G8307 Transfer Assembly

69G8310 Right Transfer Frame Guide

4026-0XX

69G8311 Spring, Right Transfer Guide

69G9968 Transfer Corona Assembly

69G9967 Spring, Left Transfer Guide

69G8308 Left Transfer Frame Guide

69G8309 Gear, 18/21T

Description

Option - Second Paper Drawer

Part

Number

69G9929 Frame, Base

69G9927 Foot, square rubber

11A7416 Foot, round rubber

69G9926 Right Side Cover

69G9937 Lift Plat e Assembly

69G9928 Tray, Paper

11A7428 Pad

11A7429 Label, Paper Set

69G9933 Adjustable Paper Guide

11A7430 Regulating Plate, paper guide

69G9938 Spring, Lif t Plate

69G9925 Left Side Cover

69G9931 Holder, Roller

69G9930 Rolle r

69G9942 Stud, Solenoid Mounting

69G9965 Lever , Lift Plate Release

69G8370 Solenoi d

69G9958 Lever, Knockoff

69G9963 Button, Lift Plate Release

69G9943 Bracket

69G9945 Gear, 13/45T

69G9944 Gear, 41T

69G9946 Clutch Assembly, complete

69G9947 Gear, 28T

69G9949 Ratchet

11A7414 Collar, clutch

Description

Laser Printe r Reference Handbook

1-34

Page 42

Option - Second Paper Drawer (Continued)

Part

Number

69G9955 Shaft, D-Roll

69G9991 Pin, D-Roll Shaft

69G9957 Bushing, D-Roll Shaft

69G9956 D-Roll

69G9953 Gear, 14T

69G9952 Bushing, Paper Feed Shaft, Outside

69G9950 Paper Feed Shaf t W/Roller

69G9951 Bushing, Paper Feed Shaft, Inside

69G9959 Holder, Sensor Flag

69G9960 Sensor Flag

69G9935 Ground Term inal

69G9934 Sensor/Interface Board

69G9940 Cover, Front.

69G9939 Paper Feed Assembly, complete

11A7427 Guide Plate

Description

Option - SIMMS

Part

Number

1364936 Memory SIMM, 1MB

1364906 Memory SIMM, 2MB

1364907 Memory SIMM, 4MB

Description

4026-0XX

Miscellaneous

Part

Number

69G9986 Parts Packet, C-Clips

69G9987 Parts Pack et, Springs

69G9988 Parts Packet, Fuser Gears

69G9989 Parts Packet, Paper Feed Gears

69G9974 Parts Packet, Screws

11A7436 Parts Packet, Second Paper Dra wer Springs

11A7434 Parts Packet, Second Paper Dra wer Screws

Description

4026-0XX

1-35

Page 43

4026-0XX

Laser Printe r Reference Handbook

1-36

Page 44

4027-04W 2

Winwriter 200

4027-04W

4027-04W

2-1

Page 45

Notes:

Laser Printer Refer ence Handbook

2-2

Page 46

4027-04W

Diagnostics

Start

Caution:

switch and the print head shutter actuator at the same time

To perform some of the ser vice checks and tests, such as

troubleshooting paper feed problems, you will need to actuate the top

cover interlock switch with the covers opened or removed and power

applied to the machine. It is imperative that you

REASON

Use the error code/message table, symptom table, and diagnostic aids

in this chapter to determine the corrective action necessary to repair a

malfunctioning printer.

If an error code or message is displayed on the host display, locate it in

the Error Message Table on the next page and take the appropriate

action.

If an alert message appears on the host display and the printer status

light is flashing rapidly and continuously, go to the “Printer Status Light

Table” on page 2-5.

If your machine does not have an error code/message and does not

complete POST, go to “Printer Status Light Table” on page 2-5. If your

machine makes it through POST without an error, and you have a

symptom, go to “Symptom Table” on page 2-8, locate your symptom

and take the appropriate action.

If an error code/message appears while you are working on the

machine, go to the Error Message Tab le and take the indicated action

for that error.

Note: For all 9XX errors the 4027-04W front cover LED will blink fast,

and the error code will be displayed on the host display. The last error

will be logged in the WPS.INI file.

NEVER

, defeat the print head shutter actuator when power is applied.

manually actuate or defeat the top cover interlock

.

DO NOT, FOR ANY

4027-04W

4027-04W

2-3

Page 47

Error Message Table

Error Code/

Message

[Error 920 Fuser

Temp]

[Error 930] Mirror

Motor]

[Error 940 Laser

Failure]

[Error 950

Controller Board]

4027-04W

[Error 951

Controller Board]

[Error 952

Controller Board]

[Error 953] Replace the cont roller board.

[Error 954] The engine board det ected an inv alid command.

[Error 970 Fan

Failure]

Action

Refer to the Cold Fuser Service Check in the

Service Manual.

The Polygon motor is not rotating during printing.

Replace the engine board. If this does not fix the

problem, repl ace the print head assembly.

Replace the print head assem bly. If this does not fix

the problem, replace the engine board.

Defective ASIC. Replace the controller board.

Basecode Check sum Err or. Replac e the controller

board.

DRAM failure. Replace the controller board.

Check: Engine Boar d, LVPS-to-Engine Board

Cable.

[Error 960 Memory] Base DRAM failure. Remov e the memory option. If

the problem remains, replace the controller board. If

you still have the problem, replace the memory

option.

[Error 980 ROM

Checksum]

[Memory Full]

(WPS Msg)

[Complex Memory

Page]

(WPS Msg)

Laser Printer Refer ence Handbook

2-4

Replace EPR OM s, or MROM if i nstalled. If this does

not fix the problem, replace the contr oller board.

This error occurs when the page memory is full.

Inform the customer that more memory is needed

for the appl ication, or that some of the dat a m ust

come off the page.

This error occurs when too complex a page is

printed. Some dat a could b e mis placed on the page .

More memory is needed for the application.

Page 48

.

Printer Status Light Table

Status Action

Add XXX Paper

(Audible: Add

paper to printer)

Clear Paper Jam

(Audible: Paper

jam)

Cover Open

(Audible: Close

printer cover.)

Note:

The printer status light will blink slowly and continuously until the

Printer is out of paper. Add paper, then if the error

remains, refer to the Paper Feed Take-Up Shaft

Service Check in the Service Manual.

Refer to t he Paper Feed Servi ce Check in the

Service Manual.

Close the top c over. If the error remains, refer to the

Cove r Int erl ock Service Check in the Service

Manual.

problem is corrected. An alert message or audio message may occur if

selected in WPS Setup.

4027-04W

4027-04W

2-5

Page 49

Power-On Self Test (POST)

When you turn the printer on, it performs a Power-On Self Test. Check

for correct POST functioning by observing the following:

1. The status LED comes on solid.

2. The fan turns on for 2 seconds.

3. The engine board checks the top cover interlock switch.

4. The engine board checks the fuser thermistor.

5. The engine board checks the exit sensor.

6. The fuser lamp turns on.

Note:

warms to operating temperature. Printer idle time is shorter if the

fuser is already warm.

7. The fuser lamp turns off.

4027-04W

8. The polygon motor turns on.

9. The main motor turns on.

10. The paper feed gears turn.

11. The print cartridge drive gear engages.

12. The paper feed solenoid picks.

13. The paper feed take-up shaft assembly rotates to home position.

(The paper feed lift assembly is in the down position.)

14. The status LED remains on.

If the printer completes all these steps and no error messages are

displayed, the printer has successfully completed the POST. If your

printer has completed POST, go to the Symptom Table.

If your printer did not complete POST, locate your symptom in the

POST Symptom Tab le on the following page, and take the appropriate

action.

The printer may be idle for up to 60 seconds as the fuser

POST Symptom Table

Symptom Action

POST completes,

but the LED does

not come on

Dead machine Refer to the Low Voltage Power Supply Service

Fan not w orki ng Refer to the Fan Service Chec k in the Service

Laser Printer Refer ence Handbook

2-6

Refer to the Operator Panel Service Check in the

Service Manual.

Check in the Service Manual.

Manual.

Page 50

POST Symptom Table

Symptom Action

Fuser Lamp does

not light

Main motor not

working

Polygon motor not

working

Paper Feed Gears

not turning

Paper Feed

Solenoid not

picking up

Status Light starts

blinking quickly

before POST has

completed

Status Light starts

blinking slowly

before POST has

completed

Refer to the Cold Fuser Service Check in the

Service Manual.

Refer to the Main Motor Service Check in the

Service Manual.

Replace the engin e board. If you still have the

problem, replace the print head assem bly.

Refer to t he Paper Feed Servi ce Check in the

Service Manual.

Refer to the P aper Take-Up Solenoid Service Check

in the Service Manual.

A 9XX error code should appear i n the WPS dial og

box on the host displ a y. Check the Print Manager f or

the error code. If it is not there, go to the “WPS .INI

File” on page 2-11.

Check the host display for an alert message in the

WPS dialog box.

4027-04W

4027-04W

2-7

Page 51

Sympto m Table

Symptom Action

Dead machine Refer to the Low Voltage Power Supply Service

Check in the Service Manual.

Fan not w orki ng Refer to the Fan Service Chec k in the Service

Manual.

Fan noisy Refer to the Fan Service Check in the Servic e

Manual.

Fuser parts melted Refer to the Hot Fuser Service Check in the Service

Manual.

Fuser Lamp

4027-04W

doesn’t light

Toner not fused to

the paper

Blank Page Refer to the Print Qual ity Service Check in the

Paper Jams Refer to the Paper Feed Service Check in the

Main Motor noisy Refer to the Mai n Motor Service Check in the

Main Motor

doesn’t move

Main Motor runs

backward

Paper isn’t picked

or never leaves

the tray

Paper feeds

continuously

Paper fails to exit

printer or stack

Refer to the Cold Fuser Check in the Service

Manual.

Refer to the Cold Fuser Check in the Service

Manual.

Service Manual.

Service Manual.

Service Manual.

Refer to the Main Motor Service Check in the

Service Manual.

Replace the engine boar d.

Refer to the Paper Fe ed Take-Up Shaft Service

Check in the Service Manual.

Replace the engine boar d.

Refer to the Paper Feed Service Check in the

Service Manual.

Paper skew Refer to the Registration Service Check in the

Service Manual.

Registration Refer to the Registration Service Check in the

Service Manual.

Laser Printer Refer ence Handbook

2-8

Page 52

Symptom Table

Symptom Action

Toner on the back

of the page

Po or pri nt quality Refer to the Print Quality Service Check in the

Incorrect

characters print

Printer not

communicating

with host

Horizontal black

band

Paper wrinkled or

bent

Top cover will not

close

Refer to the Transfer Service Check in the Service

Manual.

Service Manual.

Refer to the Print Qu ali ty Service Check in the

Service Manual.

Refer to the Parallel Port Service Check in the

Service Manual.

Refer to the Print Qu ali ty Service Check in the

Service Manual.

Refer to t he Paper Feed Servi ce Check in the

Service Manual.

Refer to the Top Cover Service Chec k in the Service

Manual.

4027-04W

4027-04W

2-9

Page 53

Diagnostic Aids

Customer Test Page (From WPS)

Use this test to check print and graphics quality. Running the print test

resets temporary settings to the printer default settings and deletes all

macros and downloaded fonts.

To ru n the Print Test:

1. Tur n the pr inter on.

2. Select [Test Printer] from the WPS Setup Screen in Print

Manager.

3. One test page prints.

The printer returns to the default settings after the test page prints.

4027-04W

Customer Test Page (Stand Alone)

Use this test to check print and graphics quality. Running the print test

resets temporary settings to the printer default settings and deletes all

macros and down-loaded fonts.

To ru n the Print Test:

1. Open the top cover .

2. Tur n t he printer on.

3. After the printer status light starts blinking, close the top cover.

4. One test page prints after POST completes.

The printer returns to the default settings after the test page prints.

Developed Image Test

This test allows you to examine the image on the photoconductor and

may be used to diagnose print quality problems. You may need to do

this procedure several times to get the timing correct.

To run the Developed Image Test :

1. Run the Customer Test Page (Stand Alone).

2. Tur n t he printer off while it is printing.

3. Remove the print cartridge and look at the image on the

photoconductor.

Laser Printe r Reference Handbook

2-10

Page 54

WPS.INI File

This file can be used to check for the last error code, date and time of

the last error sent from the printer to WPS.

1. Select File Manager from the Microsoft Windows Main Menu

(double click with mouse).

2. Select Fixed Disk WPS installed on.

3. Select Windows from DIR list.

4. Select WPS.INI from Files list (double click with mouse).

5. The Notepad program displays the WPS.INI file. Scroll down until

you see:

SERVICEERROR=9xx

SERVICED ATE=MM/DD/ YY TIME HH:MM:SS AM OR PM

4027-04W

4027-04W

2-11

Page 55

Connectors

Low Voltage P ower Supply

P/N Signal

CN1 Fan

CN2 Main Motor

4027-04W

CN3 Engine Board

CN4 Cover SW

1F

2 +12VDC

1M

2M

3M

4Motor

5 SW12VDC

1 GND +5.1VDC

2 +5.1VDC

3 GND +12VDC

4 SW12VDC

5 Fuser Lamp

6 Fan Motor

7 Main Motor

8 Main Motor

9 Main Motor

10 Main Motor

1 +12VDC

2 SW12VDC

an Motor

otor

otor

otor

Laser Printe r Reference Handbook

2-12

Page 56

High Voltage Power Supply

P/N Signal

CN1 PF Solenoid

CN2 Engine Board

Engine Board

CN1 LVPS

CN2 Thermistor

CN3 Exit Sensor

1 SOL ON

2 +12VDC

1 GND1

2

3 +5.1VDC

5 +12VDC

6 GND2

7

8

9 SOL ON

P/N Signal

1 GND1

2 +5.1VDC

3 GND2

4 +12VDC

5 Fuser Lamp

6Fan On

7 Main Motor

8 Main Motor

9 Main Motor

10 Main Motor

1 Thermistor

2 +5.1VDC

1 +5.1VDC

2 GND1

3 Exit Sensor

4027-04W

4027-04W

2-13

Page 57

P/N Signal

CN4 HVPS

CN5 Printhead

4027-04W

1 GND1

2 Input Sensor

3 +5.1VDC

4 +12VDC

5 GND2

6Drum Chg On

7Ter Roll On

8 DOC Blade

9PF SOL ON

1POL LOCK

2 P/H Select

3 POLY MTR CLK

4 POLY MTR ON

5 GND2

6 +12VDC

7 +5.1VDC

8LDATA

9‘ GND1

10 LDVR1

11 LDVR2

12 LDLVL

13 SSCAN

CN6 Controller Board

P/N Signal P/N Signal

1LED1 16CMD

2 N/C 17 CTBSY

3N/C 18Print

4 GND1 19 SRCLK

5 GND1 20 GND1

6 Reset 21 GND1

7 GND1 22 Video

Laser Printe r Reference Handbook

2-14

Page 58

CN6 Controller Board (Continued)

P/N Signal P/N Signal

8 GND1 23 +5.1VDC

9 GND1 24 GND1

10 RHYSNC 25 +5.1VDC

11 EPRDY 26 GND1

12 PRRDY 27 +5.1VDC

13 TOD 28 CPRDY

14 ETBSY 29 +5.1VDC

15 STS 30 N/C

P/N Signal

4027-04W

CN9 Op Panel

1 GND1

2LED1

3N/C

Controller Board

P/N Signal

J1 Op tional SIMM

1

.

.

.

.

40

J2 Parallel Port

P/N Signal P/N Signal

1 RSTROBE 19 GND

2D8 20GND

3D1 21GND

4D2 22GND

5D3 23GND

6D4 24GND

7D5 25GND

4027-04W

2-15

Page 59

J2 Parallel Port (Continued)

P/N Signal P/N Signal

8D6 26GND

9D7 27GND

10 RACK 28 GND

11 RBUSY 29 GND

12 RPERROR 30 GND

13 RSELOUT 31 RINIT

14 RAUTOFD 32 RF AULT

15 GND 33 GND

16 GND 34 GND

4027-04W

17 GND 35 GND

18 PLH 36 RSELECTIN

P/N Signal

J3 Pullup

1 +5.1VDC

2 5V Jumper

3N/C

Laser Printe r Reference Handbook

2-16

Page 60

J4 Engine Board

P/N Signal P/N Signal

1LED1 16CMD

2 N/C 17 CTBSY

3 N/C 18 PRINT

4 GND 19 SRCLK

5GND 20GND

6 Reset 21 GND

7GND 22Video

8GND 23+5.1VDC

9GND 24GND

10 RHSYNC 25 +5.1VDC

11 EPRDY 26 GND

12 PRRDY 27 +5.1VDC

13 TOD 28 CPRDY

14 ETBSY 29 +5.1VDC

15 STS 30 N/C

4027-04W

4027-04W

2-17

Page 61

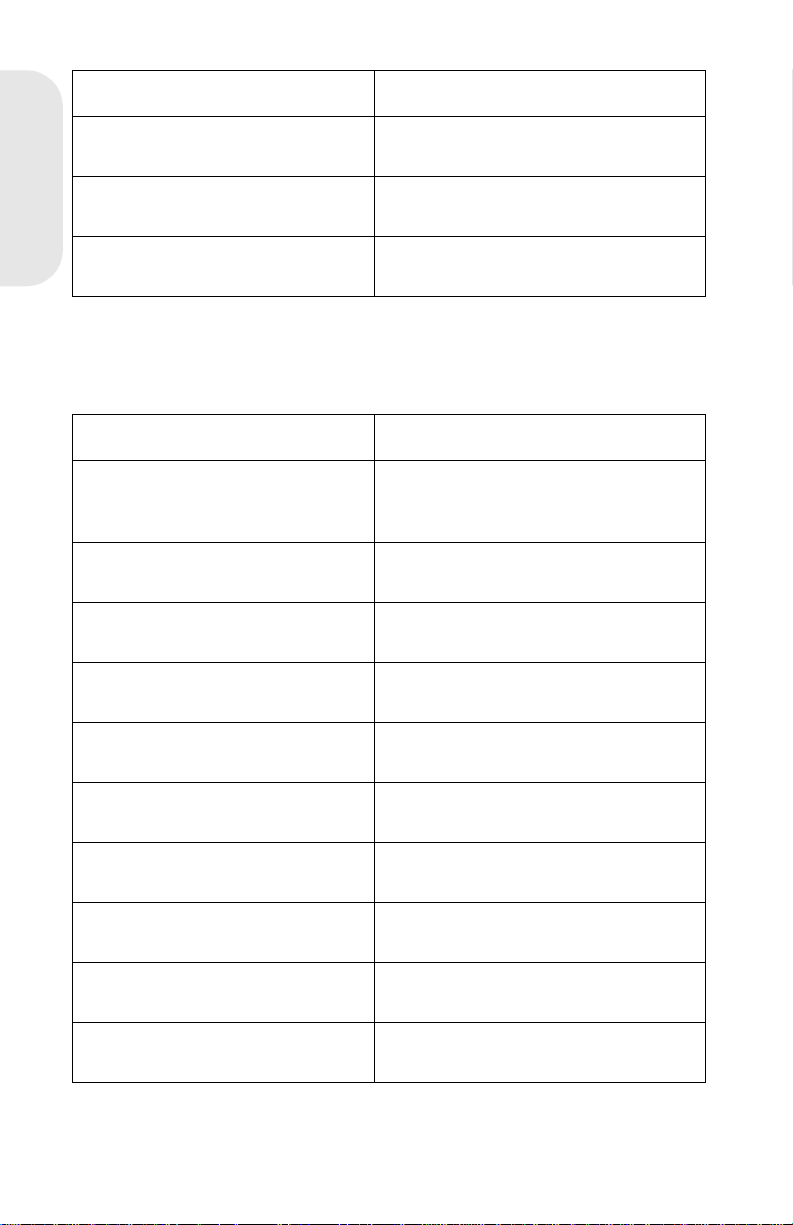

Parts Catalog

Parts Packet

P/N Description

1427269 Screw Parts Packet

Covers

P/N Description

1427161 Top Cover Asm

1427162 Anti Stati c Brush

1427163 Paper Tray, Exit

1427164 Left Side Cover

4027-04W

1427165 Right Side Cover

1427166 Front Cov er

1427267 Cover, Op Panel, with LED

1427167 Paper Tray, FNT

Left Side Frame

P/N Description

1427168 Left Si de Frame Asm

Right Side Frame

P/N Description

1427169 Right Side Frame Asm

1427170 Main Motor

1427171 Switch , Cover Interlock

1427172 Switch Bracket

Frame, Base

P/N Description

1427173 Frame Base

1427174 Rubber Feet

Rear Frame

P/N Description

1427175 Frame, Rear

1427176 Duct, Fan

1427177 Fan Motor

Laser Printe r Reference Handbook

2-18

Page 62

Print H ead

P/N Description

1427178 Print Head, with PWB-O

1427179 Print Head Bracket

Paper Feed Lift Plate

P/N Description

1427180 Paper Feed Lift Plate Asm

1427181 Pressure Spring

Paper Feed/Transfer

P/N Description

1427182 Paper Feed Asm 100/220/240V

1427183 Paper Feed Asm 120V

1427186 Ac tuator Sensor

1427187 Paper Take-up Shaft Asm

1427188 So lenoid

1427265 H.V. Board, for 220/240VAC P.F. Asm.

1427266 H.V. Board, for 120VAC P.F. Asm.

Screw, Type 3704 P/P 1427269

1427149 Bu shing

1427148 Gear, Clutch 45/48T

1427298 Separator, Paper

1427159 Spring , Clu tch

1427158 Ra tchet, Clutch

1427157 Co ll ar

1427156 Ro ll er, Paper Feed, incl uding rollers and shaft

1427299 Joint, Pape r Feed

1427147 Pin, Paper Take-Up Shaft

4027-04W

4027-04W

2-19

Page 63

Fuser

P/N Description

1427189 Fuse Asm, 120V

1427190 Fuser Asm, 220/240V

1427197 Frame/Thermal Fuse Asm

1427191 Fuser Lamp, 120V

1427192 Fuse Lamp, 220/240V

1427193 Thermistor

1427194 Sensor, Photo

1427195 Actuator, Sensor Flag

1427196 Torsion Spring

Electronics

4027-04W

P/N Description

1427198 Power Supply, 120V

1427199 Power Supply, 220/240V

1427251 Fuse, 220/240V, 1.6A

1427252 Fuse, 100/120V, 3A

1339526 Line Cord, U.S .

1427255 Controller Card, w/o EPROM

1427256 EPR OM, Control Card

1427059 Bracket, Contro l Car d Mtg.

1427264 Engine Board

1427262 Controller Cage

1427263 Card Cage Cover

Laser Printe r Reference Handbook

2-20

Page 64

4033 3

4033

4033

3-1

Page 65

Notes:

Laser Printer Refer ence Handbook

3-2

Page 66

4033

Diagnostics

Start