Optra™ N Finisher Option

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4040-FIN

• Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

4040 Finisher

Second Edition (November 1997)

The following paragraph does not apply to the United Kingdom or any country

where such provisions are inconsistent with local law: LEXMARK INTERNATIONAL,

INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIESOF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Some states do not allow disclaimer of express or implied warranties in certain

transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions of the publication. Improvements or changes in the products or the programs

described in this publication may be made at any time. Publications are not stocked at the

address given below; requests for publications should be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., Department D22A/035-3,

740 New Circle Road NW, Lexington, Kentucky 40550, U.S.A. Lexmark may use or

distribute any of the information you supply in any way it believes appropriate without

incurring any obligation to you.

Lexmark and Optra are trademarks of Lexmark International, Inc.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 1996, 1997. A ll Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

4040 Finisher

Contents

Notices................................................vi

SafetyInformation.................................... vi

GeneralInformation....................................1-1

Maintenance Approach............................... 1-1

StaplerTest.................................... 1-1

Tools............................................. 1-2

Abbreviations...................................... 1-3

DiagnosticInformation .................................2-1

Start............................................. 2-2

InitialCheck.................................... 2-2

OperatorErrorMessageTable...................... 2-3

ServiceErrorMessageTable....................... 2-6

SymptomTable................................. 2-7

TestingtheFinisher.............................. 2-7

Power On Reset (POR) Sequence. .................. 2-8

ServiceChecks.................................... 2-10

AlignmentPlateShiftMotorServiceCheck........... 2-10

DistanceDetectingSensorServiceCheck............ 2-10

Paper Delivery Motor Service Check ................ 2-11

Paper Delivery Service Check ..................... 2-11

Paper Feed Motor Service Check . ................. 2-12

Paper Jam, 41, Paper Input Service Check. . . ........ 2-12

Paper Jam, 42, Reversing Paper Sensor Service Check. 2-13

Paper Jam, 43, Delivery Paper Sensor Service Check . . 2-13

Paper Jam, 44, Staple Tray Paper Sensor Service Check 2-14

PowerServiceCheck............................ 2-14

ReversingRollerServiceCheck.................... 2-16

ShutterServiceCheck........................... 2-16

StaplerMotorServiceCheck...................... 2-17

StaplerShiftMotorServiceCheck.................. 2-17

SwingGuideServiceCheck....................... 2-18

TrayElevationMotorServiceCheck................ 2-18

TrayHeightServiceCheck........................ 2-19

Contents iii

4040 Finisher

RepairInformation.....................................3-1

Adjustments....................................... 3-1

DistanceSensorAdjustment....................... 3-1

Cover Removal Procedures. . ......................... 3-2

ExternalCovers................................. 3-2

FrontDoorRemoval............................. 3-3

RearCoverRemoval............................. 3-3

TopDoorRemoval .............................. 3-4

RightCoverRemoval ............................ 3-4

TopCoverRemoval.............................. 3-5

FrontCoverRemoval ............................ 3-6

TrayRemoval.................................. 3-7

TopGuideRemoval.............................. 3-7

BottomGuideRemoval........................... 3-8

Paper Transport Removal Procedures . . ................ 3-9

StapleTrayRemoval............................. 3-9

StapleTrayDeliveryMotorRemoval................ 3-10

StapleTrayAlignmentPlateShiftMotorRemoval ..... 3-11

StapleTrayDeliveryRoller1Removal.............. 3-11

Face-upSolenoidRemoval....................... 3-13

StapleAssemblyRemoval........................ 3-14

TrayAssemblyDriveRemoval.................... 3-16

Paper Feed Motor Removal ...................... 3-18

ReversingRollerRemoval........................ 3-19

Electrical Components Removal Procedures............. 3-20

DriverBoardRemoval........................... 3-20

Power Supply Removal. . ........................ 3-21

InterfaceBoardRemoval......................... 3-22

TestStapleSwitchBoardRemoval................. 3-23

Locations ............................................4-1

PartsoftheFinisher................................. 4-1

Cross Sectional View............................. 4-3

Switches...................................... 4-4

Sensors....................................... 4-5

SolenoidsandMotors............................ 4-6

PrintedCircuitBoards............................ 4-7

DriverBoard ................................... 4-8

Connectors . . .................................. 4-9

Finisher Driver Board Inputs and Outputs............ 4-11

iv Service Manual

4040 Finisher

PartsCatalog .........................................5-1

HowtoUseThisPartsCatalog......................... 5-1

ExternalCovers..................................5-2

ExternalCovers(Cont).............................5-4

Stapler,MainBody................................5-6

Stapler,MainBody...............................5-10

StaplerTray,MainBody...........................5-14

StaplerTray,MainBody(Cont).....................5-16

SwingGuideAssembly ...........................5-20

StaplerTray....................................5-22

TrayDrive......................................5-24

Upper Feeder ...................................5-26

CenterGuide...................................5-28

Stapler........................................5-30

ElectronicBoardsandPowerCords .................5-32

AttachmentParts................................5-34

WiringDiagram........................................6-1

Index................................................X-1

Contents v

4040 Finisher

Notices

References in this publication to products, programs, or services do

not imply that the manufacturer intends to make these available in all

countries in which it operates. Any reference to a product, program,

or service is not intended to state or imply that only that product,

program, or service may be used. Any functionally equivalent

product, program, or service that does not infringe any existing

intellectual property rights may be used instead. Evaluation and

verification of operation in conjunction with other products,

programs, or ser vices, except those expressly designated by the

manufacturer, are the user’s responsibility.

Safety Information

•

This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not always

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precautions.

vi Service Manual

4040 Finisher

Consignes de Sécurité

•

Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres

pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Norme di sicurezza

•

Il prodotto è stato progettato,testato e approvatoin conformità a

severi standard di sicurezza e per l’utilizzo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune parti

non sempre sono di immediata comprensione. Lexmark non è

responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Notices vii

4040 Finisher

Sicherheitshinweise

•

Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Pautas de Seguridad

•

Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

siempre evidentes. Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

viii Service Manual

4040 Finisher

Informações de Segurança

•

Este produto foi concebido, testado e aprovado para satisfazer

os padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outros componentes de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Informació de Seguretat

•

Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

Notices ix

4040 Finisher

x Service Manual

4040 Finisher

1. General Information

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, and service checks to determine the symptom and

repair the failure.

After you complete the repair, perform tests as needed to verify the

repair.

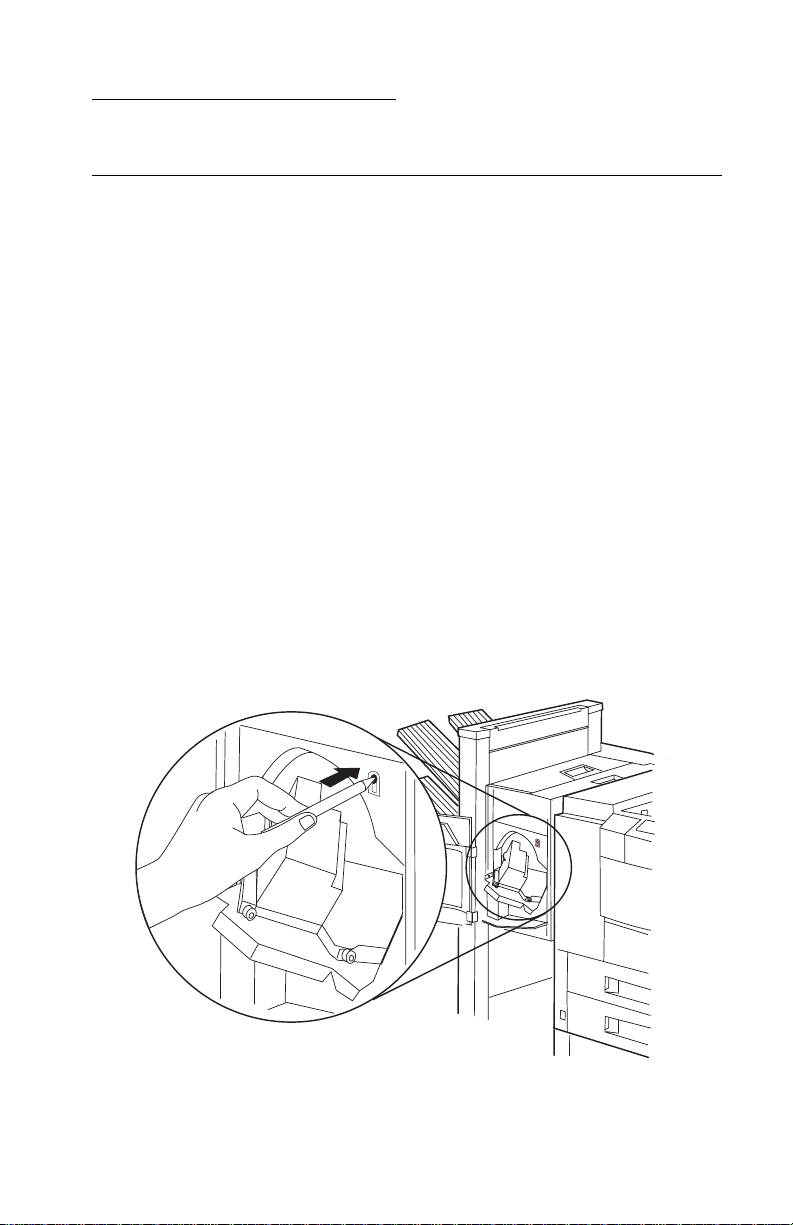

Stapler Test

The stapler test must be run after a new staple cartridge has been

installed.

1. Be sure Side is selected from the output bin menu so jobs are

directed to the finisher, and Staple is set to Staple 1 or Staple 2.

2. Use the tip of a ballpoint pen or similar object to press the test

button.

General Information 1-1

4040 Finisher

3. Close the stapler access door. Press Continue to Perform Staple Test appears on the operator panel display.

4. Select CONTINUE from the printer operator panel. Performing

Staple Test appears on the display. When the test page is delivered to the finisher, the finisher puts several staples along one

edge of the page. This primes the stapler for future jobs and

improves stapling reliability.

Tools

The removal and adjustment procedures described in this manual

require the following tools and equipment:

• Magnetic tip Phillips screwdrivers, large and small

• Flat-blade screwdriver

• Analog volt ohmmeter (a digital volt ohmmeter may also be

used).

• Oiler

• Grease

• Cleaning tissue

• Ruler

When you make voltage readings, always use frame ground unless

another ground is specified.

1-2

4040 Finisher

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EEPROM Electrically Erasable Programmable Read-

Only Memory

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PICS Problem Isolation Charts

PIXEL Picture Element

POR Power-On R eset

POST Power-On Self Test

PQET Print Quality Enhancement Technology

RIP Raster Image Processor

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

VAC Volts alternating current

VDC Volts direct current

General Information 1-3

4040 Finisher

2. Diagnostic Information

Use the serial number from the indicated label to identify the

machine for reporting service related activity.

The diagnostic information in this chapter leads you to the failing

part. Before you replace an entire assembly, determine if just the

defective part is available in the parts catalog. Some diagnostic procedures indicate the parts catalog location of the part to be checked

by including the assembly number and reference number in parenthesis. Some part numbers are also included. Use the error code

tables, symptom table, service checks and the diagnostic aids chapter to determine the symptom and repair the failure. After you complete the repair, perform the appropriate tests to verify the repair.

2-1

4040 Finisher

If an error is displayed, locate it in the following Operator Error Message Table, or the Service Error Message Table and take the appropriate action.

If an error message appears while you are working on the finisher,

go to the error message table and take the indicated action.

If you are in doubt whether the problem is with the printer or the finisher, unplug the finisher and see if the printer performs normally.

Start

Initial Check

Before you star t troubleshooting, check the following:

Installation Environment

• The power supply line voltage is plus or minus 10% of the rated

line voltage.

• The machine is securely installed on a level surface in a well-

ventilated place.

• The room temperature is between 10 and 32°C (50 and 90°F)

and the relative humidity between 20 and 80%.

• Avoid sites generating ammonia gas, high temperature or high

humidity (near water faucets, kettles, humidifiers), cold spaces,

near open flames, and dusty areas.

• Avoid sites exposed to direct sunlight.

Print Paper Checks

• Be sure the recommended paper for this printer is being used.

• Check the paper for dampness. Make a trial print with paper

from a newly opened package, and check the result.

Other

If you move the finisher into a warm room from a cold location such

as a warehouse, various problems can occur due to condensation if

it is immediately unpacked. If condensation should appear, either

wipe the relevant parts with a dry cloth, or leave the finisher power

onfor10to20minutes.

Diagnostic Information 2-2

4040 Finisher

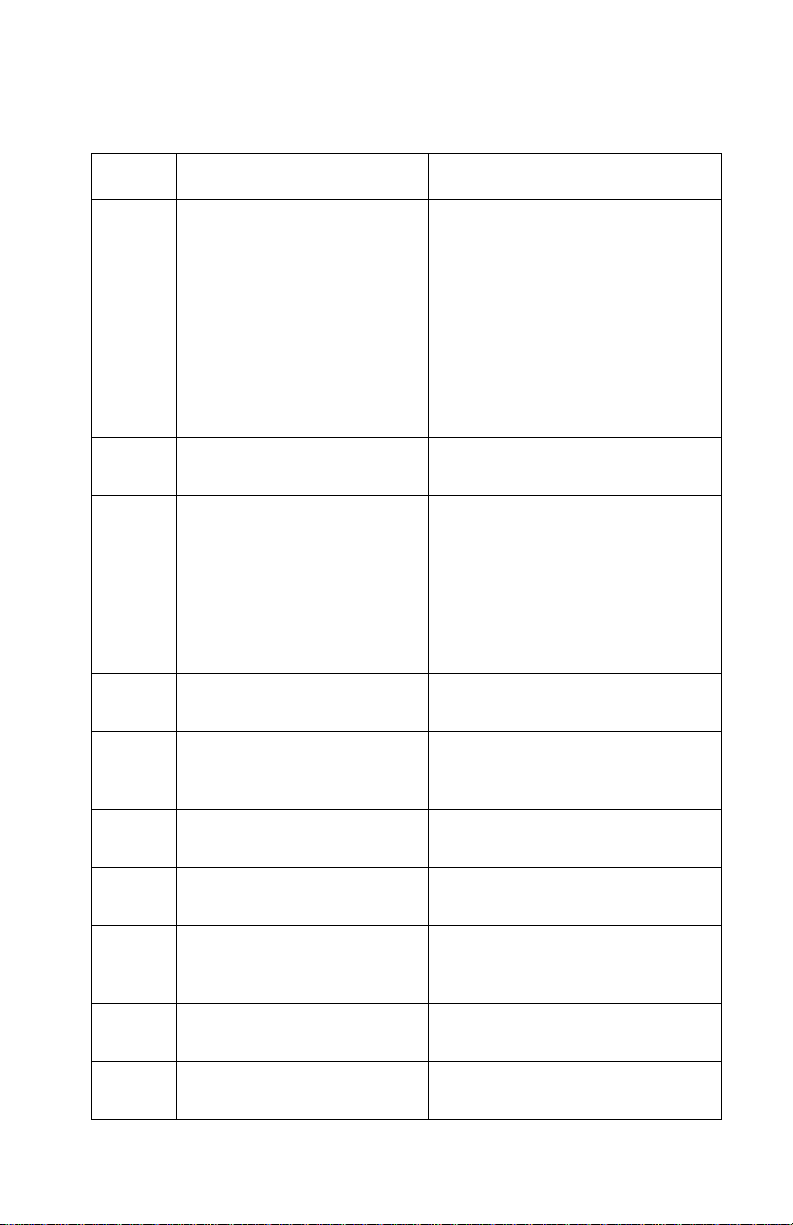

Operator Error Message Table

If you have a paper jam, be sure to clear all paper from the finisher,

paper deck, and printer. If you are unable to clear an operator error

code for a paper jam; note the location of the paper jam and check

the paper sensor for that station. See “Switches” on page 4-4 or

“Sensors” on page 4-5. If the sensors are working properly, see the

“Service Checks” on page 2-10 for other mechanical failures. If no

paper is present you must open a finisher cover to clear the error

code.

Message Action

30 Finisher Door Open (MS1,

MS7)

31 Finisher Interlock Open (PI-15) Be sure the finisher is positioned

41 Paper Jam (PI-1) There is a paper jam in the input

42 Paper Jam (PI-2) There is a paper jam at the right

Be sure the finisher top cover, right

access door, and stapler access

door are completely closed. If the

error does not clear, check the door

switches and replace if necessary.

snugly against the printer and the

latches on either side of the finisher

are snapped in place. If the error

does not clear, check the interlock

sensor. Replace if necessary.

area, right access door. If the error

code does not reset after you clear

the paper jam, go to the “Paper Jam,

41, Paper Input Service Check” on

page 2-12. If there is still a problem

after that, go to the “Symptom Table”

on page 2-7.

access door. If the error code does

not clear after you clear the paper

jam, go to the “Paper Jam, 42,

Reversing Paper Sensor Service

Check” on page 2-13.Ifthereisstill

a problem after that, go to the

“Symptom Table” on page 2-7.

2-3

4040 Finisher

Message Action

43 Paper Jam (PI-3) There is a paper jam at the top

cover. If the error code does not

clear after you clear the paper jam,

go to the “Paper Jam, 43, Delivery

Paper Sensor Service Check” on

page 2-13. If there is still a problem

after that, go to the “Symptom Table”

on page 2-7.

44 Paper Jam (PI-4) There is a paper jam at the staple

tray or output bins1, 2, or 3. If the

error code does not clear after you

clear the paper jam, go to the “Paper

Jam, 44, Staple Tray Paper Sensor

ServiceCheck”onpage2-13.If

there is still a problem after that, go

to the “Symptom Table” on page 2-7.

45 Staple Jam The printer has detected a staple

jam in the finisher. See the User’s

Guide.

47 Finisher Bin X Full Empty the output bin identified in the

message and select CONTINUE.

48 Top Output Bin Full Empty the top output bin and select

CONTINUE. If this doesn’t correct

theproblem,gototheOptraN

Service Manual.

49 Output Bins Full All three output bins are full. Empty

all three bins as well as the top

output bin, if Top Bin Linking is set

on. Then select CONTINUE.

If this doesn’t correct the problem,

go to the “Distance Detecting Sensor

ServiceCheck”onpage2-10.

Diagnostic Information 2-4

4040 Finisher

Message Action

89 Staples Low The finisher has 10 or fewer staples

remaininginthestaplecartridge.

The Staple Alarm must be set to

Single or Continuous for this

message to appear.If Auto Continue

is On when the printer detects this

error, the printer waits 30 seconds

fortheconditiontobecorrectedand

then continues normal operation.

Select CONTINUE to resume

printing.

90 Staples Empty The finisher is out of staples. The

Staple Alarm must be set to Single

or Continuous for this message to

appear. Select CONTINUE to

resume printing.

2-5

4040 Finisher

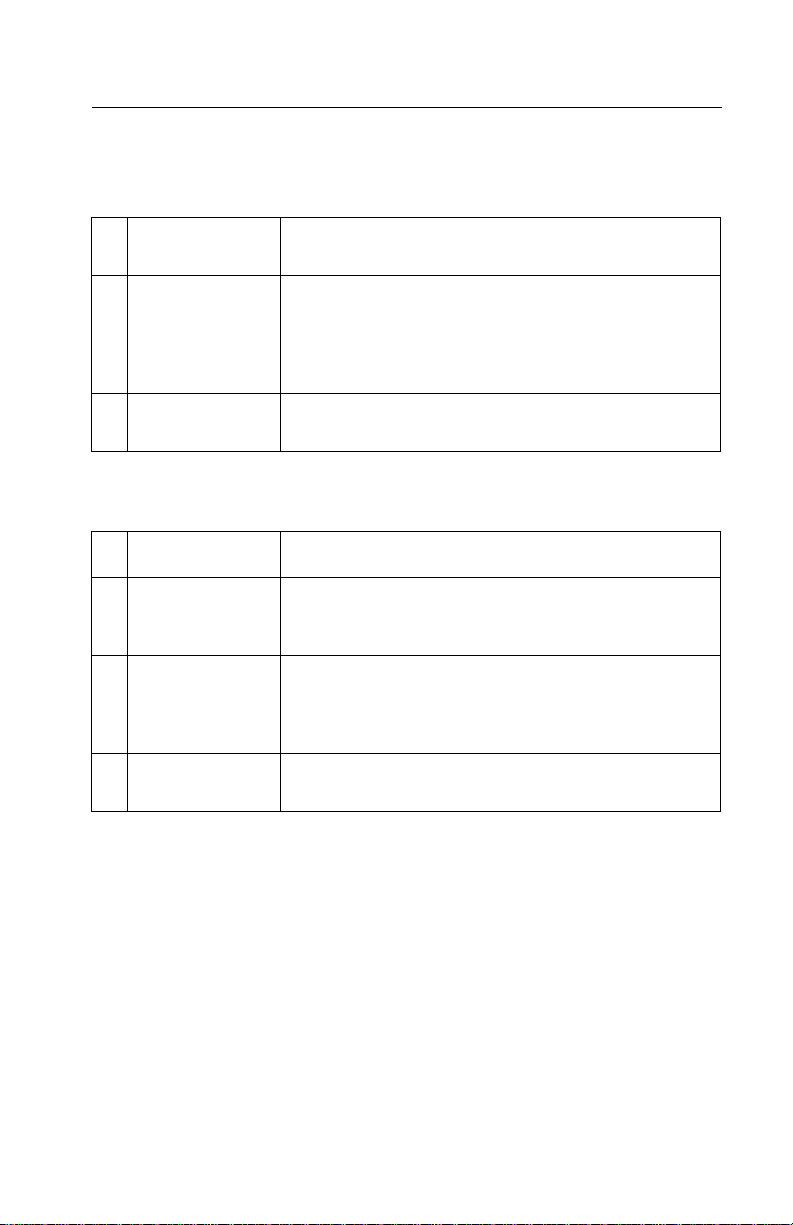

ServiceErrorMessageTable

Error Symptom or Message Action

938 Finisher Option Controller

Card, No response

951 The delivery motor requires

service.

952 The stapler a ssembly

requires service.

954 The adjusting plate requires

service.

955 The finisher output bin

assembly has had a vertical

movement failure.

Be sure the power cord and

interface cable are securely

plugged in. POR the printer. If

there is still a failure, replace the

finisher option controller card (PN

11D00326) located on the printer

controller board.

If there is still a problem, replace

thefinisherdriverboard(PN

11D0294).

Go to the “Paper Delivery Motor

Service Check” on page 2-11.

Be sure the stapler is clear of jams

and the staple cartridge is

properly installed and tested.

PORA the machine if the stapler is

not in the home position. If there is

still a problem,go to the “Stapler

Motor Service Check” on page

2-16.

Go to the “Stapler Shift Motor

Service Check” on page 2-16.

Go to the “Tray Height Service

Check” on page 2-18.

956 The shutter requires service. Go to the “Shutter Service Check”

on page 2-15.

957 The swing guide requires

service.

958 The paper full sensor

requires service.

959 The stapler motor requires

service.

962 The shift motor requires

service.

Go to the “Swing Guide Service

Check” on page 2-17.

Go to the “Distance Detecting

Sensor Service Check” on page

2-10.

Go to the “Stapler Motor Service

Check” on page 2-16.

Go to the “Stapler Shift Motor

Service Check” on page 2-16.

Diagnostic Information 2-6

4040 Finisher

Symptom Table

Symptom Action

Dead finisher. “Finisher Output Option

Missing” displays on the printer operator

panel when you enter the paper menu

selection.

Paper fails to enter finisher and the

paper feed motor does not run.

The paper feedmotor runs but the paper

fails to complete reversing or face down

delivery.

Paper fails to exit swing guide or stapler

tray.

Check the power cords and

interface cables. Go to the

“Power Service Check” on page

2-14.

Go to the “Paper Feed Motor

ServiceCheck”onpage2-12.

Go to the “Reversing Roller

ServiceCheck”onpage2-15.

Go to the “Paper Delivery

ServiceCheck”onpage2-11.

Testing the Finisher

To run paper through the finisher from the printer:

1. Select MENUS.

2. Select PAPER MENU.

3. Scroll until you have the option you want and be sure it is on and

saved.

4. Return to Ready.

5. Select MORE.

6. Select TEST MENU.

7. Select Print Fonts, or Print Test Page.

8. Do not use Continuous for staple or offset because there is no

end of job.

9. Be sure to reset the customer settings when you have completed the repair.

2-7

4040 Finisher

Power On Reset (POR) Sequence

When sensors, motors, or solenoids malfunction during POR no

errors are reported from the following sequence except for 1, 2, 3,

and 27. To be sure the finisher successfully completes POR you

must observe the sequence of events.

Confirm that the tray home position sensor (P18) is operating normally. Measure the voltage between connectors J12-5 and J12-6 on

the finisher driver board. It should be approximately 5 V when the

tray assembly is in the home position, and 0 V, in other positions.

1. The top cover/front cover are checked. If it is open, POR stops.

2. Residual paper is checked for. If paper is present, POR stops.

3. Checks whether the position of the tray assembly is within the

safety range or n ot. If it is not in the safety range, POR stops.

4. The swing guide closes.

5. The shutter closes.

6. The tray assembly returns to the home position.

7. The shutter opens.

8. The swing guide opens.

9. The alignment plate moves to the home position.

10. The alignment plate moves to the alignment position for A4-vertical size paper.

11. The alignment plate returns to the home position.

12. The alignment plate rotates for 1.5 seconds, and the paddle

solenoid turns on 0.75 seconds after the paper feed motor turns

on.

13. The left edge withdrawal solenoid turns off for 0.5 seconds, on

for 0.5 seconds, and off for 0.5 seconds.

14. The paper feed motor rotates for 4.0 seconds. The reversing

solenoid turns on 2.0 seconds after the paper feed motor turns

on.

15. The swing guide closes.

16. The shutter closes.

17. The tray assembly lifts until tray 3 is positioned at the paper

delivery slot.

18. The tray assembly returns to the home position.

19. Data is collected from the distance detecting sensor.

Diagnostic Information 2-8

4040 Finisher

20. The face-up flapper solenoid turns off for 0.5 seconds, on for 0.5

seconds, and off for 0.5 seconds.

21. The stapler assembly returns to the home position.

22. The stapler assembly moves to the stapling position A4R-size

paper, one point at the corner.

23. The stapler returns to the home position.

24. The staple motor rotates in reverse to return to the stapling

operation home position.

25. The staple motor rotates until the stapling operation goes out of

the home position.

26. The staple motor rotates in reverse until it enters the stapling

operation home position.

27. Checks for staples. If there are no staples, an error is indicated.

28. The shutter opens and the POR is complete.

2-9

4040 Finisher

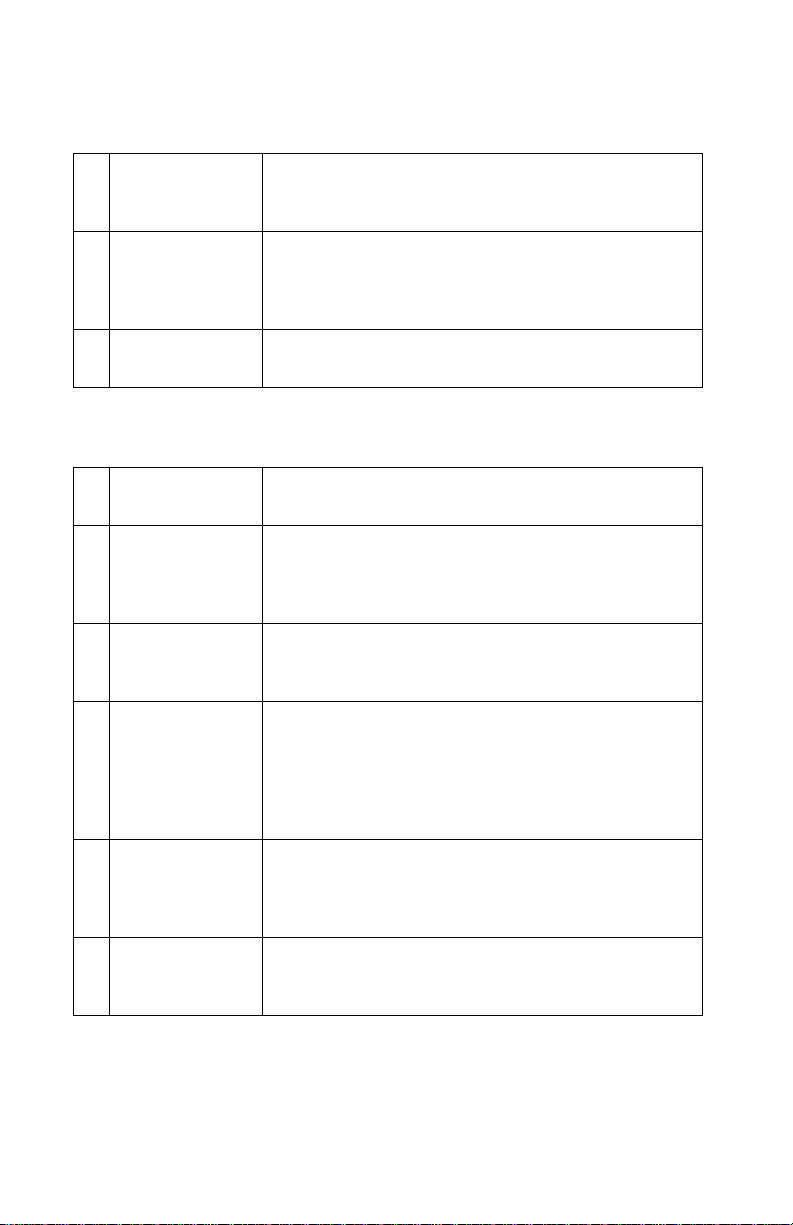

Service Checks

Alignment Plate Shift Motor Service Check

1 Connector Be sure J11 is properly connected to the finisher

2Alignment

Plate Shift

Motor, M2, (5-

21)

3FinisherDriver

Board (13-1)

driver board.

Unplug J11 from the finisher driver board. Measure

the resistance between J11-1 and J11-2/ -3/ -4/ -5

on the motor side. If it does not read approximately

16 Ohms, replace the alignment plate shift motor

(PN 11D0162).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Distance Detecting Sensor Service Check

FRU Action

1 Connector J6 Be sure the distance detecting sensor signal line

connector (J6) on the finisher driver board is

properly connected.

2Distance

Detecting

Sensor, PS1

(3-26)

3FinisherDriver

Board (13-1)

Measure the voltage between J6-4 (GND) and J6-2

(Vcc)/-3(Vin) on the finisher driver board. If it is not

5 V, replace the distance detecting sensor

(PN 11D0074).

If there is still a problem, replace the finisher driver

board (PN 11D0294.

Diagnostic Information 2-10

4040 Finisher

Paper Delivery Motor Service Check

1 Connector Be sure the J8 and J11 are properly connected to

the finisher driver board, and the stapler assembly

is properly installed and firmly plugged in.

2 PaperDelivery

Motor, M3, (5-

8)

3FinisherDriver

Board (13-1)

Unplug J11 from the finisher driver board. Measure

the resistance between J11-6 and J11-7 on the

motor side. If it does not read 42 Ohms, replace the

paper delivery motor (PN 11D0142).

If there is still a problem, replace the finisher driver

board (PN 11D0294.

Paper Delivery Service Check

1 Gears Check for and replace any broken or worn gears in

the swing guide and stapler tray assembly.

2 Delivery Roller

1andDelivery

Roller 2 (6-25,

6-44)

3 Delivery Roller

1DriveBelts

(6-26)

4 Staple Tray

Guide Stops

(6-41, 6-30)

Check delivery rollers 1 and 2 for wear or damage.

Replace as necessary (PN 11D0188, 11D0194).

Check the delivery roller 1 drive belts for damage

and proper tracking on delivery roller 1. Replace if

necessary (PN 11D0189).

Be sure the staple tray guide stops are not

damaged. Also be sure they are positioned

correctly. If they are positioned to the rear of the

normal pivot point, they will not pivot to the normal

rest position. Replace as necessary (PN 11D0207,

11D0202).

5 Reversing

Shafts (7-27)

6SwingGuide

Exit Pressure

Rollers. (7-7)‘

2-11

Be sure the swing guide reversing shafts are not

damaged. Also be sure they properly push paper

into the staple tray when offsetting or stapling jobs

(PN 11D0228).

Check for and replace any damaged swing guide

exit pressure rollers (PN 11D0216).

4040 Finisher

Paper Feed Motor Service Check

1 Connector Be sure the J10 is properly connected to the

finisher driver board.

2 Paper Feed

Motor, M1, (4-

43)

3FinisherDriver

Board (13-1)

Unplug J10 from the finisher driver board. Measure

the resistance between J10-1 and J10-4/ -6 and

between J10-2 and J10-3/ -5 on the motor side. If it

does not read 4.3 Ohms, replace the paper feed

motor (PN 11D0118).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

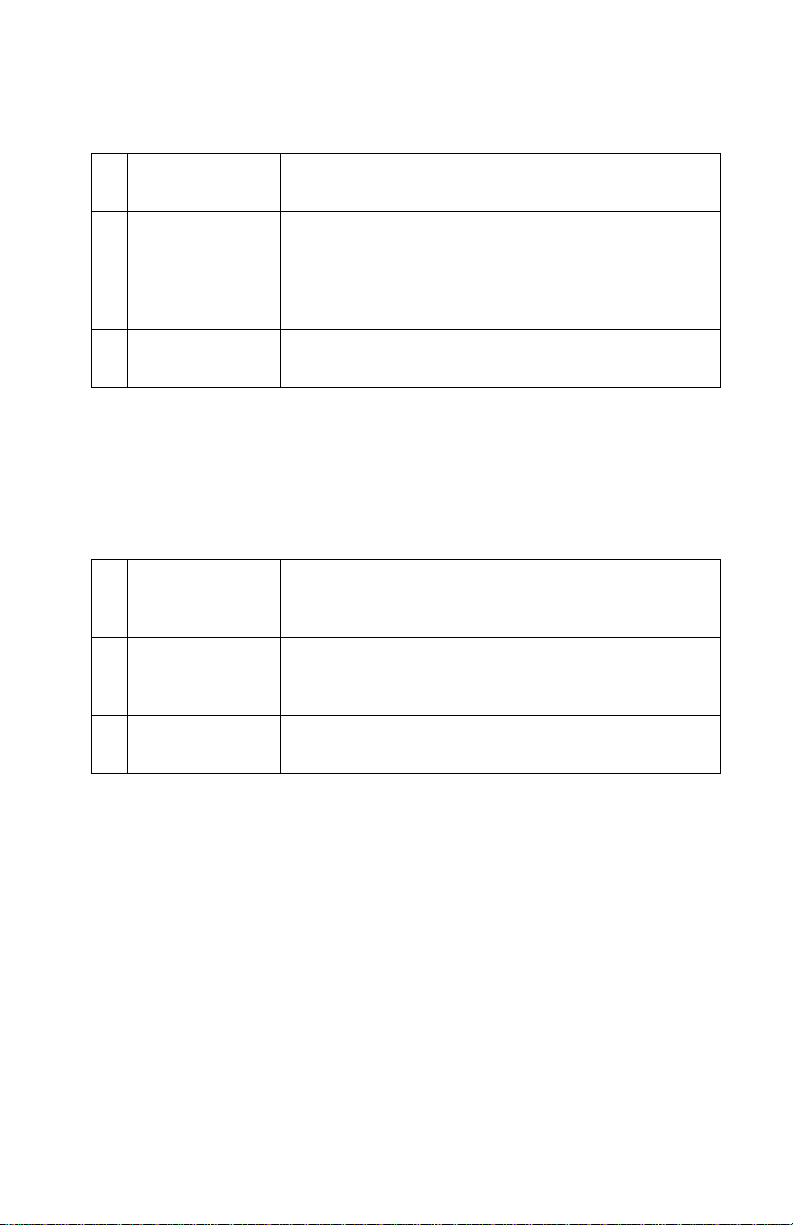

Paper Jam, 41, Paper Input Service Check

Clear all paper from the paper deck, printer, and finisher. If there is

no paper you must open and close one of the finisher covers to clear

the error.

1 Input Paper

Sensor Flag

(1-4)

2 Input Paper

Sensor, PI-1,

(3-10)

3FinisherDriver

Board (13-1)

Open the right access door and check the

operation of the flag (PN 11D0015) for the paper

input sensor (PI-1).

Check the voltage of J13-3 on the finisher driver

board. There should be 5 V when the sensor is

activated (PN 11D0071).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Diagnostic Information 2-12

4040 Finisher

Paper Jam, 42, Reversing Paper Sensor Service Check

Clear all paper from the paper deck, printer, and finisher. If there is

no paper you must open and close one of the finisher covers to clear

the error.

1 Reversing

Paper Sensor

Flag (4-27)

2 Reversing

Paper Sensor,

PI-2, (3-10)

3FinisherDriver

Board (13-1)

Open the right access door and check the

operation of the flag (PN 11D0121) for the

reversing paper sensor (PI-2).

Check the voltage of J12-3 on the finisher driver

board. There should be 5 V when the sensor is

activated (PN 11D0071).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Paper Jam, 43, Delivery Paper Sensor Service Check

Clear all paper from the paper deck, printer, and finisher. If there is

no paper you must open and close one of the finisher covers to clear

the error.

1 PaperDelivery

Sensor Flag

(5-15)

2 PaperDelivery

Sensor, PI-3

(5-13)

3FinisherDriver

Board (13-1)

Check the flag for the delivery sensor (PI-3) by

opening the top cover and rasing the upper paper

guide (label 1). Replace the flag if necessary.

Check the voltage of J9-11 on the finisher driver

board. There should be 0 V when the sensor is

activated (PN 11D0151).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Paper Jam, 44, Staple Tr ay Paper Sensor Service Check

Clear all paper from the paper deck, printer, and finisher. If there is

no paper you must open and close one of the finisher covers to clear

the error.

1 Staple Tray

Paper Sensor

Lever (6-24)

2-13

Check the delivery paper sensor leverby rasing the

swing guide up and s liding a sheet of paper over

the sensor lever. Replace the lever if necessary

(PN 11D0187).

4040 Finisher

2 Staple Tray

Paper Sensor,

PI-4, (5-1)

3FinisherDriver

Board (13-1)

Check the voltage of J9-3 on the finisher driver

board. There should be 0 V when the sensor is

activated (PN 11D0071).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

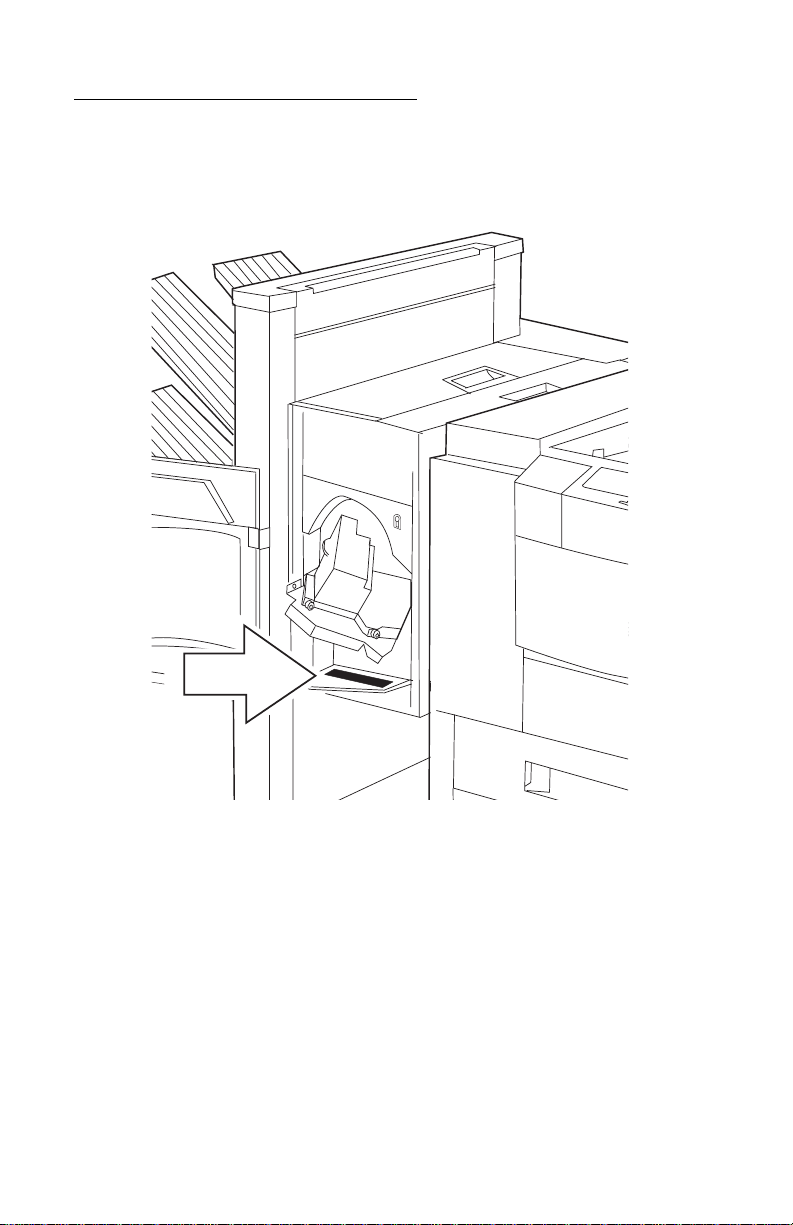

Power Service Check

Be sure the correct voltage is available at the power outlet, and the

power plug is firmly plugged into the printer, paper deck, and finisher.

FRU Action

1 Interface

Connector

2 • Option Con-

troller Board

• Printer Controller Board

3 Fuse Remove the power supply and replace the fuse

Be sure the interface cable (PN 11D0305)

connector is properly connected.

Turn the printer on. Measure the voltage between

J4-7 (PWRON-IN) and J4-11 (GND) on the finisher

board. If it does not measure approximately 5 V,

replace the option controller board (PN 11D0326).

If this does not fix the problem, replace the printer

controller board.

(PN 11D0343) if necessary.

4 PowerSupply

(3-1)

5FinisherDriver

Board (13-1)

Turn the printer off and remove the finisher power

cord. Be sure J1 is plugged into the finisher driver

board. Plug the power cord into the finisher power

supply and turn the printer on. Measure the DC

power supply through connector J1. Be careful not

to short it. If the voltage on J1-1 is not

approximately 5 V,and the voltage on J1-2, -4 does

not measure approximately +24 V, replace the

power supply (PN 11D0076).

Turn off the printer and check the lines and DC

loads from J1 on the finisher driver board. There

should be 0 V on J1-1 or J1-2, -4. If there is voltage,

replace the finisher driver board (PN 11D0294).

Diagnostic Information 2-14

4040 Finisher

Reversing Roller Service Check

1 Gears Check for, and replace any broken or worn gears.

2 Reversing

Solenoid, SL7

(4-20)

3 Paper Feed

Motor, M1 (4-

43)

4FinisherDriver

Board

5 Paper Deck

Driver Board

6Option

Controller

Board

7Printer

Controller

Board

Unplug J14 of the reversing solenoid. Measure the

resistance between J14-1 and J14-2 on the

solenoid side. If it does not read 125 Ohms, replace

the reversing solenoidm (PN 11D0114).

Set the DIP switch (SW1) on the finisher driver

board so that 3 is on. Press the push switch (SW3)

to execute mechanical checking. If the paper feed

motor does not rotate, replace it (PN 11D0118).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

If there is still a problem, replace the paper deck

driver board (PN 11A8461).

If there is still a problem, replace the option

controller board (PN 11D0326).

If there is still a problem, replace the printer

controller board (PN 11A8254).

Shutter Service Check

FRU Action

1 Connectors Be sure J7, J9, and J10 are properly connected to

the finisher driver board.

2 Shutter Close

Detection

Sensor, PI-5

(2-23)

3 Shutter Open

Detection

Sensor, PI-5

(2-23)

4FinisherDriver

Board (13-1)

Unplug J7 from the finisher driver board. Measure

the resistance between J7-1 and J7-2 on the switch

side. If it does not measure infinity with the shutter

down, replace the shutter close sensor

(PN 11D0071).

Measure the voltage between J9-8 and J9-9 on the

finisher driver board. If it is not 0 V with the shutter

up, or not approximately 5 V with the shutter down,

replace the shutter open sensor (PN 11D0071).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

2-15

4040 Finisher

Stapler Motor Service Check

1 Connector Be sure J8 is properly connected to the finisher

driver board.

2 Stapler Motor Unplug J8 from the finisher driver board. Measure

the resistance between J8-11 and J8-12 on the

motor side. If it does not read 10 Ohms, replace the

stapler motor assembly (PN 11D0344).

3FinisherDriver

Board (13-1)

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Stapler Shift Motor Service Check

1 Connector Be sure J8 is properly connected to the finisher

driver board.

2 Staple Shift

Motor, M4 (12-

5)

3FinisherDriver

Board (13-1)

Unplug J8 from the finisher driver board. Measure

the resistance between J8-5 and J8-1/-2/-3/-4 on

the motor side. If it does not read 16.5 Ohms,

replace the staple shift motor (PN 11D0269).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Diagnostic Information 2-16

4040 Finisher

Swing Guide Service Check

FRU Action

1 Connectors Be sure J5, J11, and J13 are properly connected to

the finisher drive board.

2SwingGuide

Close

Detecting

Switch, MS-2

(5-6)

3SwingGuide

Close Sensing

Switch, MS-6

(5-6)

4SwingGuide

Open Sensor,

PI-18 (5-1)

5FinisherDriver

Board (13-1)

Unplug J5 from the finisher driver board. Measure

the resistance between J5-9 and J5-10 on the

switch side. If the resistance is not 0 Ohms with the

swing guide down, or infinity with the swing guide

up, replace the swing guide close detecting switch

(PN 11D0139).

Unplug J5 from the finisher driver board. Measure

the resistance between J5-11 and J5-12 on the

switch side. If the resistance is not 0 Ohms with the

swing guide down, or infinity with the swing guide

up, replace the swing guide close sensing switch

(PN 11D0139).

Measure the voltage between J13-5 and J13-6 on

the finisher driver board. If it is not 0 V with the

swingguide down, and not 5 V with the swing guide

up, replace the swing guide open sensor

(PN 11D0071).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Tray Elevation Motor Service Check

1 Connector Be sure J7 is properly connected to the finisher

driver board.

2TrayElevation

Motor, M5 (9-

16)

3FinisherDriver

Board (13-1)

2-17

Unplug J7 from the finisher driver board. Measure

theresistancebetweenJ7-4andJ7-5onthemotor

side. If it does not read 5.5 Ohms, replace the tray

elevation motor (PN 11D0254).

If there is still a problem, replace the finisher driver

board (PN 11D0294).

Loading...

Loading...