Lexmark 3200, 4036-306 Service Manual

3200MFP

Service Manual

4036-306

Lexmark International, Inc.

Table of Contents

1. OVERVIEW....................................................................................................................................................... 1-1

1.1 GENERAL NOTES FOR SERVICING .................................................................................................................... 1-1

1.2 GENERAL PRODUCT DESCRIPTION .................................................................................................................. 1-2

1.3 PRODUCT FEATURES..................................................................................................................................... 1-2

1.4 PRODUCT SPECIFICATIONS............................................................................................................................. 1-3

1.5 OASIS 982 ..................................................................................................................................................1-3

1.6 FIREWIRE ................................................................................................................................................... 1-3

1.5 DEVICE CONFIGURATION ............................................................................................................................... 1-4

Outer View ......................................................................................................................................................... 1-4

Mechanical Configuration................................................................................................................................. 1-5

Wiring Configuration......................................................................................................................................... 1-7

1.6 THEORY OF OPERATION ............................................................................................................................. 1-8

Introduction .......................................................................................................................................................1-8

Mechanical Section Operation ..........................................................................................................................1-8

System Description............................................................................................................................................. 1-9

2. INSTALLATION................................................................................................................................................. 2-1

2.1 PRECAUTIONS OF INSTALLATION ....................................................................................................................2-1

2.2 UNPACKING PROCEDURE ............................................................................................................................... 2-1

2.3 UNLOCKING YOUR SCANNER.......................................................................................................................... 2-2

2.4 CABLE CONNECTION..................................................................................................................................... 2-3

2.4.1 Power Cable Connection ...................................................................................................................... 2-3

3. PROBLEM SOLVING......................................................................................................................................... 3-1

3.1 DIAGNOSTICS ............................................................................................................................................. 3-1

3.1.1 Diagnostic Flowcharts.......................................................................................................................... 3-1

3.2 ERROR CODE ........................................................................................................................................... 3-18

4. MAINTENANCE ............................................................................................................................................. 4-1

4.1 CLEANING .................................................................................................................................................. 4-1

4.1.1 Cover and Glass.................................................................................................................................... 4-1

4.1.2 ADF unit ...............................................................................................................................................4-2

4.2 MAINTENANCE TOOLS ............................................................................................................................... 4-3

4.3 REPLACEMENT COMPONENTS OUTER VIEW............................................................................................... 4-3

4.3.1 Main Control PCBA.............................................................................................................................. 4-3

4.3.2 Optical chassis unit............................................................................................................................... 4-4

4.3.3 Lamp Inverter circuit............................................................................................................................ 4-5

4.3.4 Lamp (Flatbed) ..................................................................................................................................... 4-6

4.3.5 Motor unit (Flatbed) ............................................................................................................................. 4-7

4.3.6 Belt (Flatbed)........................................................................................................................................ 4-8

4.3.7 ADF unit ...............................................................................................................................................4-9

4.3.8 Control Panel PCBA............................................................................................................................. 4-9

4.3.9 Parts That Must Not Be Disassembled................................................................................................ 4-10

4.4 SPARE PARTS REPLACEMENT................................................................................................................... 4-11

4.4.1 Notes on Replacement......................................................................................................................... 4-11

4.4.2 ADF Snap-in Pad Module Removal and Mounting ............................................................................ 4-11

4.4.3 Document Cover Removal ..................................................................................................................4-12

4.4.4 ADF Cover Removal & Mounting....................................................................................................... 4-13

4.4.5 ADF Optical Chassis Removal ........................................................................................................... 4-14

4.4.6 ADF Unit Removal.............................................................................................................................. 4-15

4.4.7 ADF Inverter Removal........................................................................................................................ 4-16

4.4.8 ADF Lamp Removal............................................................................................................................4-17

ii

4.4.9 Upper Housing Removal..................................................................................................................... 4-18

4.4.10 Flatbed Optical Chassis Removal .................................................................................................. 4-19

4.4.11 Flatbed Lamp Removal .................................................................................................................. 4-20

4.4.12 Flatbed CCFL Inverter PCBA Replacement .................................................................................. 4-21

4.4.13 Motor (Flatbed) Removal............................................................................................................... 4-22

4.4.14 The Control Panel PCBA Removal ................................................................................................4-23

4.4.15 Main Control PCBA Replacement.................................................................................................. 4-24

4.4.16 LED & Sensor PCBA Replacement ................................................................................................ 4-25

4.5 PCBA VOLTAGE TEST .............................................................................................................................4-26

4.5.1 Check power supply output voltage .................................................................................................... 4-26

4.5.2 Main control PCBA input power (+5V) failure check ........................................................................ 4-26

4.5.3 LED display PCBA check ................................................................................................................... 4-26

4.6 LUBRICATION ............................................................................................................................................. 4-28

4.6.1 Mechanical unit lubrication................................................................................................................ 4-28

5. PARTS .............................................................................................................................................................. 5-1

5.1 SPARE PARTS AND AFR................................................................................................................................. 5-1

iii

1. Overview

1.1 General Notes for Servicing

1.2 Product Description

1.3 Product specifications

1.4 Device Configuration

1.5 Theory of Operation

This manual is intended to be used by the maintenance engineers. It describes the areas to be

maintained, the installation, the disassembly, and the main trouble shooting guides.

Please take your time to read this manual thoroughly to obtain comprehensive knowledge about the

3200MFP before serving the unit.

1.1 General notes for servicing

(1) Before trying to disassemble the 3200MFP, make sure the power supply cord of the 3200MFP is

disconnected from the power outlet. Under any circumstance, do not remove or install the

connectors on the 3200MFP with the power supply turned ON.

(2) Use caution not to drop small parts or screws inside the unit when disassembling and

reassembling. If left inside, they might cause the malfunction of the unit.

(3) Do not pull the connector cable when disconnecting it. Hold the connector.

(4) When carrying the scanning head unit, put it in an anti-static bag.

(5) Keep the document table glass surface always clean. If contaminated, use a dry clean cloth for

cleaning.

(6) Use caution not to injure your fingers or hands when disassembling or reassembling the unit.

1-1

1.2 General Product Description

3200MFP is a multifunction solution that offers integrated print, copy, fax and color network-scanning

capabilities for increased small workgroup productivity. The 3200MFP is easy to use and provides lowcost access to key office functions, including fax from workstation, network color copying, scanning,

and electronic document routing.

You can hand your document over to 3200MFP, and in a few steps, 3200MFP scans it to the network and

delivers it wherever, to whomever you want. With 3200MFP, inefficient steps to the mailroom, copier,

fax machine and to your workstation are a thing of the past.

1.3 Product Features

• Ease of Use

The control panel on the front of 3200MFP looks like a panel on a regular copier with the standard

phone keys added. The operating steps follow the same procedure as that of a regular copier or

fax machine.

• A Digital Copier and a Full-function Fax Machine

When 3200MFP is connected to a Lexmark printer, it is able to perform convenient digital copying.

When 3200MFP is connected to telephone line, it is able to perform a full fax function - to send

and to receive faxes.

• Network Scanning

The 3200MFP employs two Color Charged-Coupled Devices (CCD) as the scanning method.

Through a network port at the rear of the 3200MFP, the product is able to perform network

scanning.

• Duplex Scanning through the Auto Document Feeder (ADF)

To increase workgroup productivity, the 3200MFP is featured with the advance duplex scanning

capability. The scan speed reaches to 20 PPM at 300 dpi resolution while the auto document

feeder can hold up to 50 pages of document at one time.

1-2

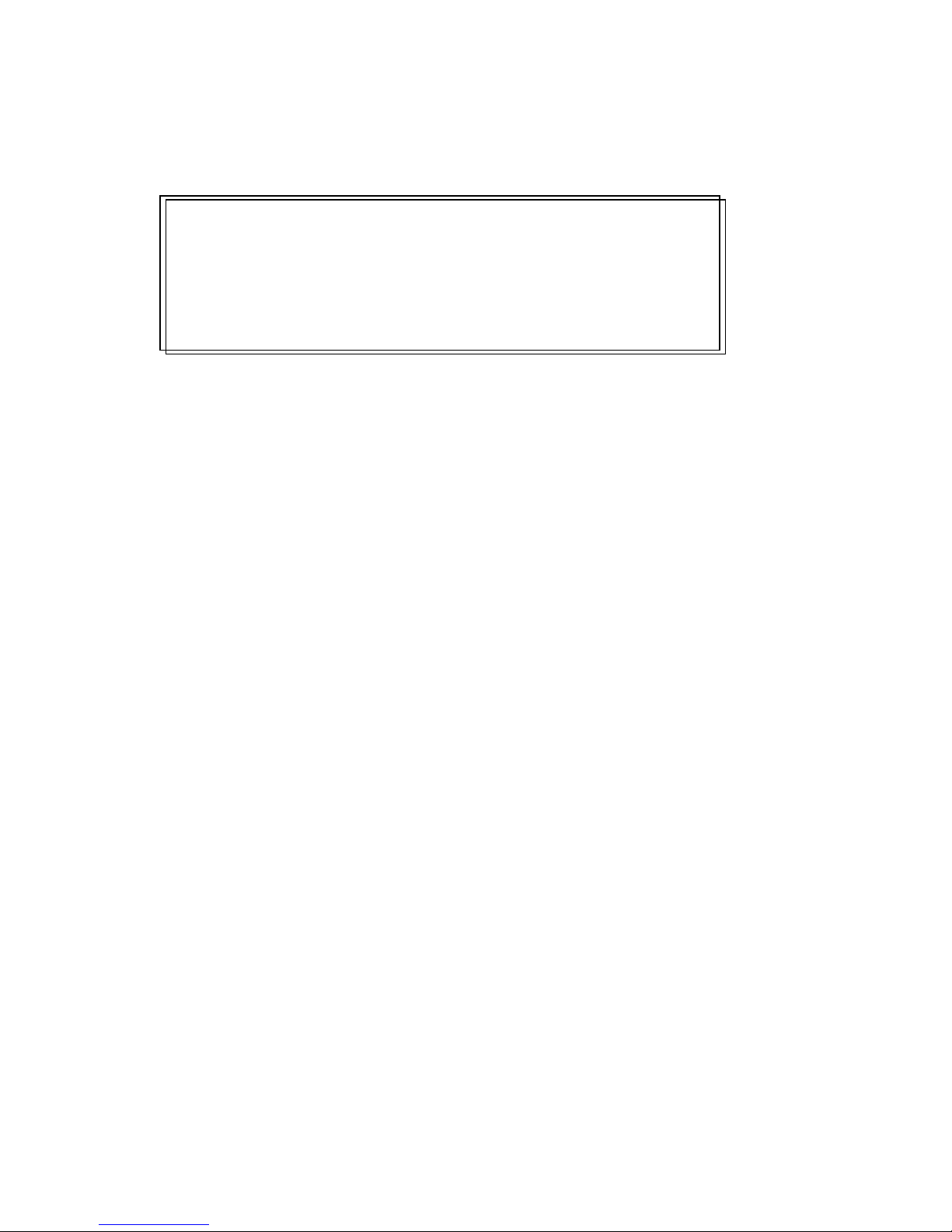

1.4 Product Specifications

The 3200MFP is designed to meet the following product specifications:

Function 3200MFP

ADF mono @ 300 22 ppm

ADF Mono @ 600x300 18 ppm (22 ppm possible?)

ADF color @ 300 15 ppm

ADF color @ 600 5 ppm

ADF type Straight

ADF dimensions 570x430x190mm

22.2x16.7x7.4

ADF optical resolution 600 x 600

Interpolated up to 4800 x 4800

ADF document size 4.5x5.5 to 8.5x14inch

ADF document depth 0.05 to 0.15 mm

0.002 to 0.006 inch

ADF paper capacity 50 sheets

Paper feed Single side: Face down

ADF jam rate 1/2000

ADF miss feed 1/2000 1/1500

ADF multiple feed 1/500 1/400

ADF dog ear 1/500

Flat bed optical resolution 600 x 600

Interpolated up to 4800 x 4800

Scanning modes

1.5 Oasis 982

Power consumption 60W

Weight 15 lb.

Duty Cycle 10,000 pages/month

Pad life (replaceable) 40,000 scans

MSBF 50,000

Life of lamp 50,000 hr.

Scanner life (warranty) 600,000 scans or 5 years flatbed

400,000 scans or 5

years ADF

Time to first page <13.0 sec. Flatbed

< 14.5 sec. ADF

Class of machine Class A

ON/OFF Switch Yes

Interface

1.6 Firewire

Table 1-1 Product Specifications

1-3

1.5 Device Configuration

This section describes the device configuration of the multifunction product.

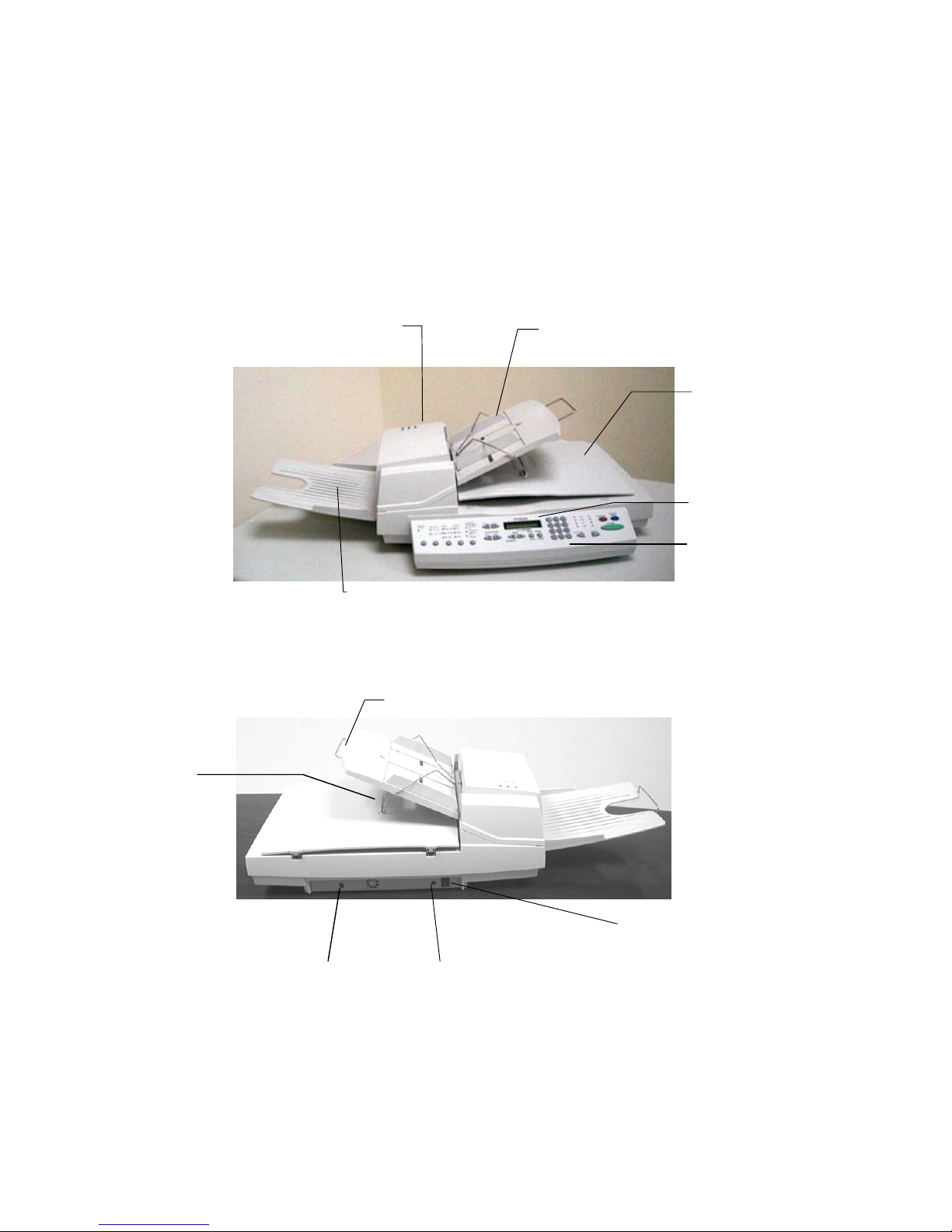

Outer View

Extension

Auto Document

Feeder

Paper Feed

Tray

Document

cover

LCD-display

Control

Panel

Output

Paper Tray

Extension

1394 Port

Power Switch

Power Port

Figure 1.1 3200MFP Outer View

1-4

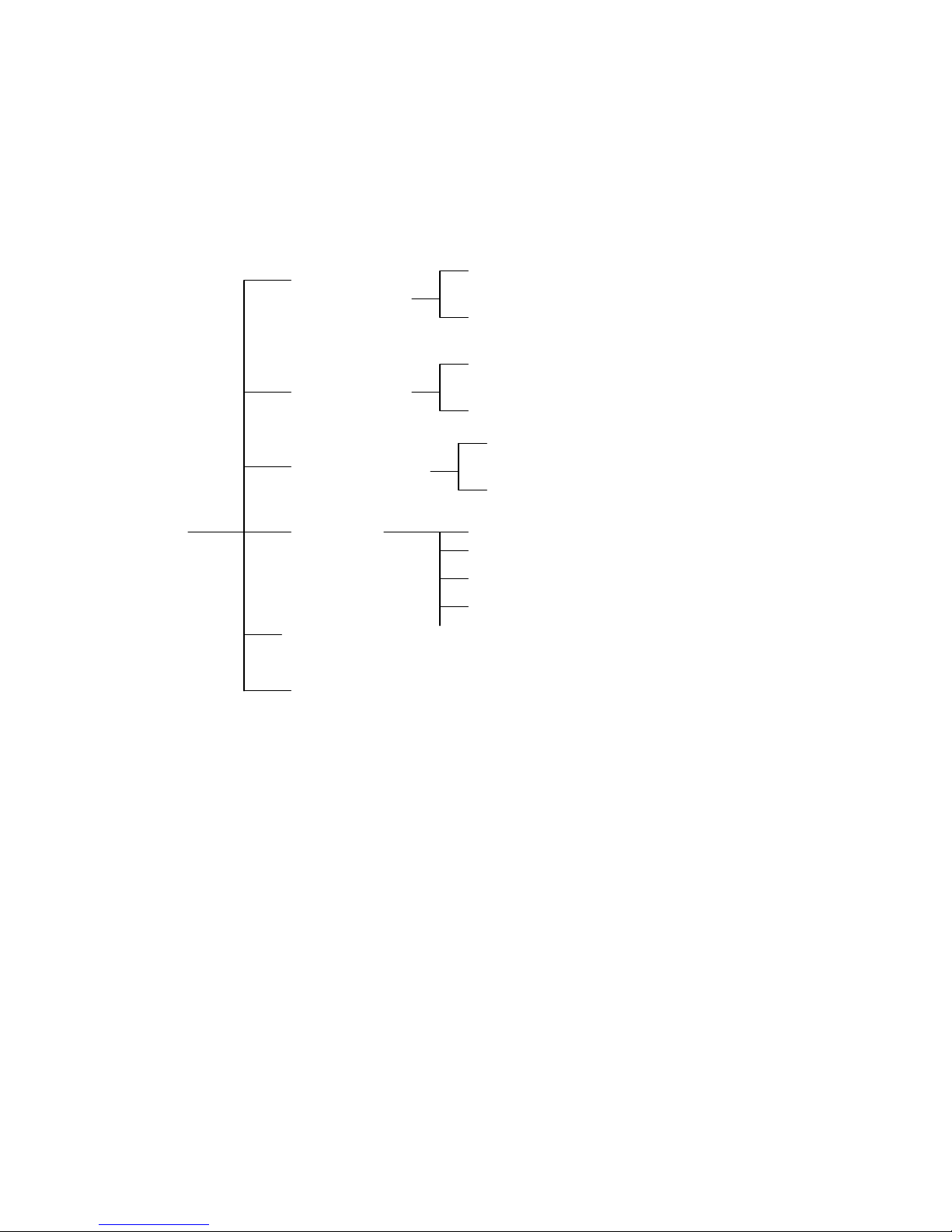

Mechanical Configuration

The equipment consists of the following components:

Image

Scanner

Document Cover

and Paper Tray

Upper Cover

ADF Unit

Lower Unit

Main Control

PCBA

Output Paper

Tray

Document Cover

ADF Paper Feed Tray

Upper Housing Unit

ADF Cover

Optical Chassis (ADF)

ADF Module

Bottom housing unit

Motor unit

Panel Cover

Panel PCBA

Optical Chassis (Flatbed)

1-5

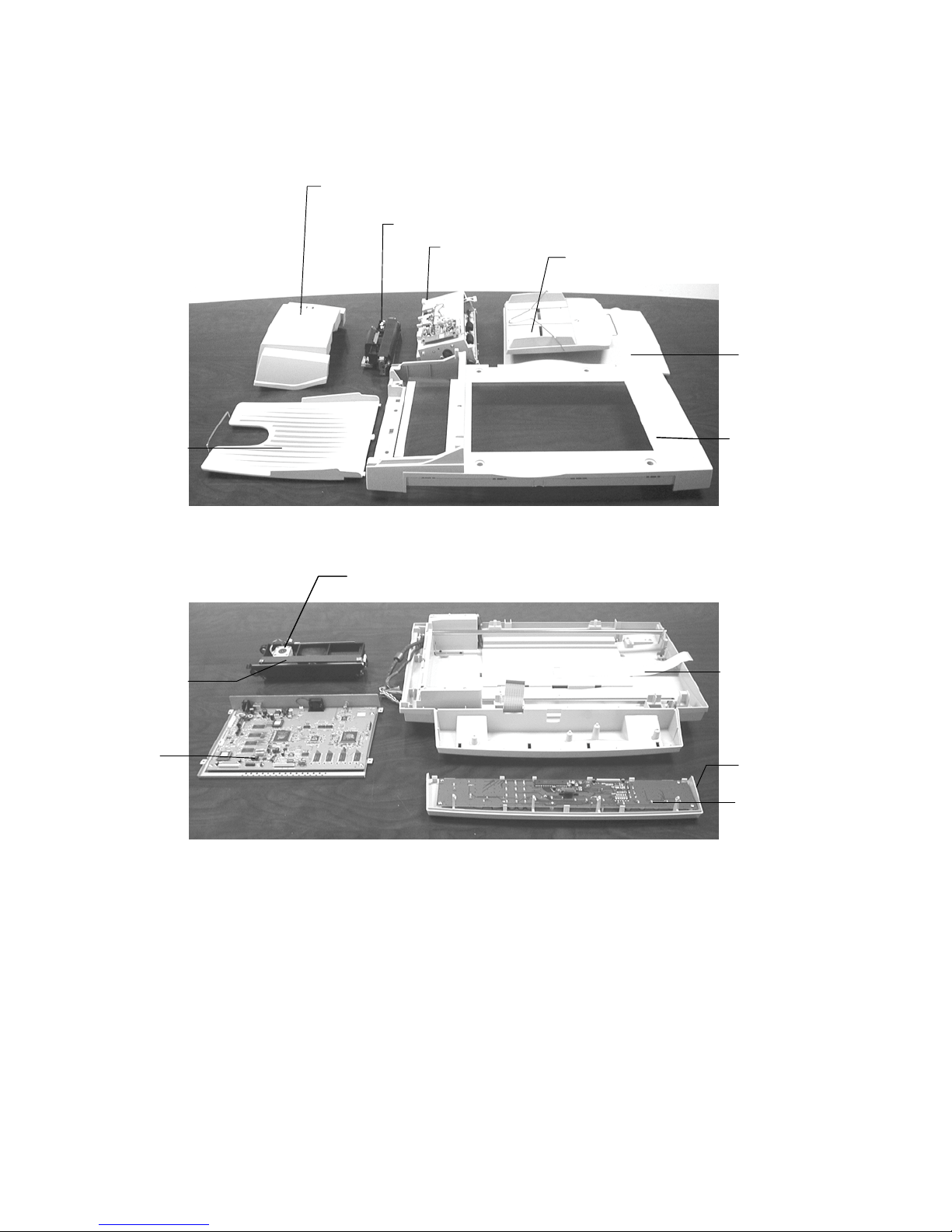

ADF Cover

Optical Chassis (ADF)

ADF Module

ADF Paper Feed Tray

Document

Cover

Output

Paper Tray

Optical

Chassis

Main Control

PCBA

Upper

Housing Unit

Motor Unit

Bottom

Housing

Panel Cover

Panel PCBA

1-6

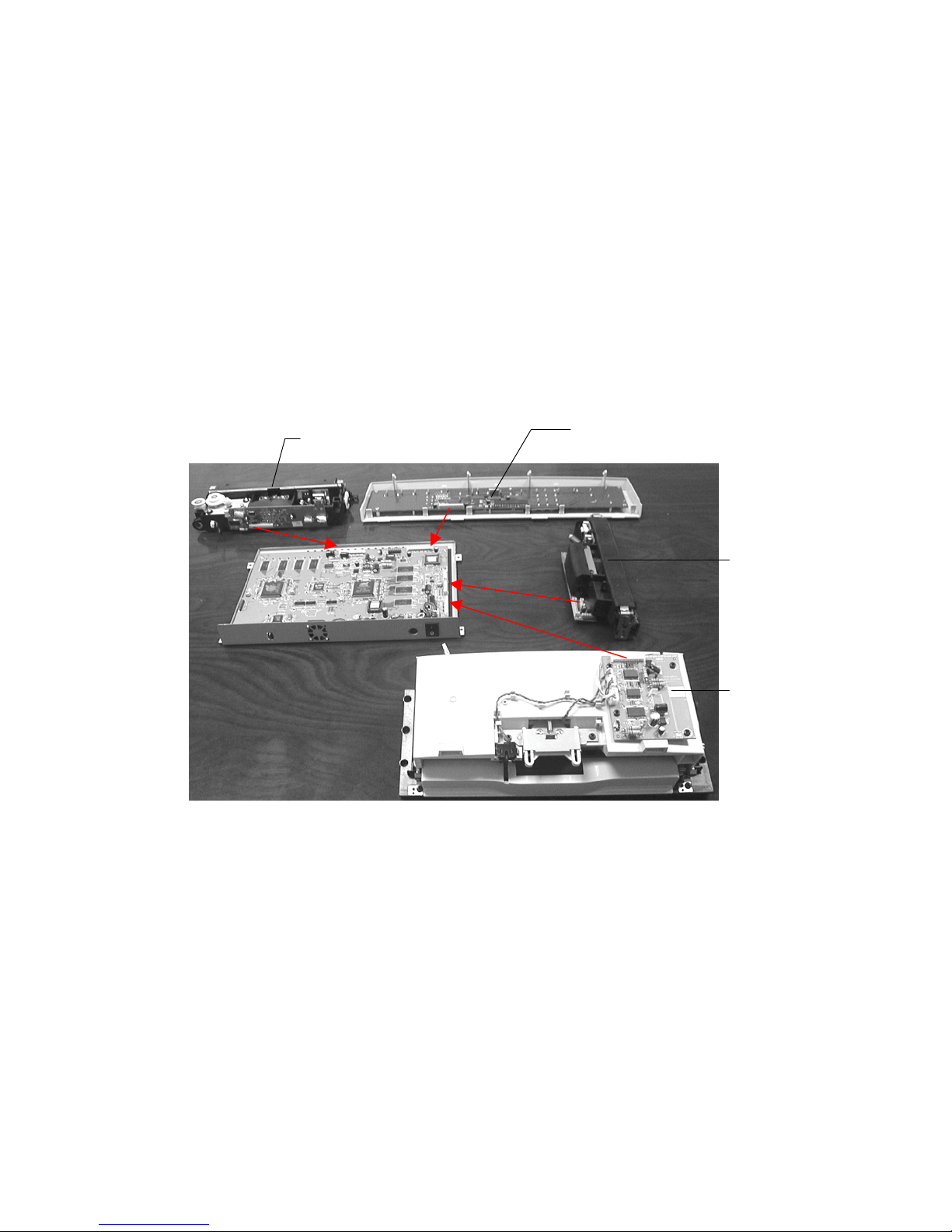

Wiring Configuration

CCD Board 1

Figure 1.2 Wiring Configuration

Control

Panel Board

CCD Board 2

LED Board

1-7

1.6 Theory of Operation

Introduction

This section explains the theory of operation of this scanner.

The microprocessor in this scanner controls the following functions.

• Interface

• Scanning module drive

• ADF drive

• Reading mode (reading density, document size, half-tone) selection.

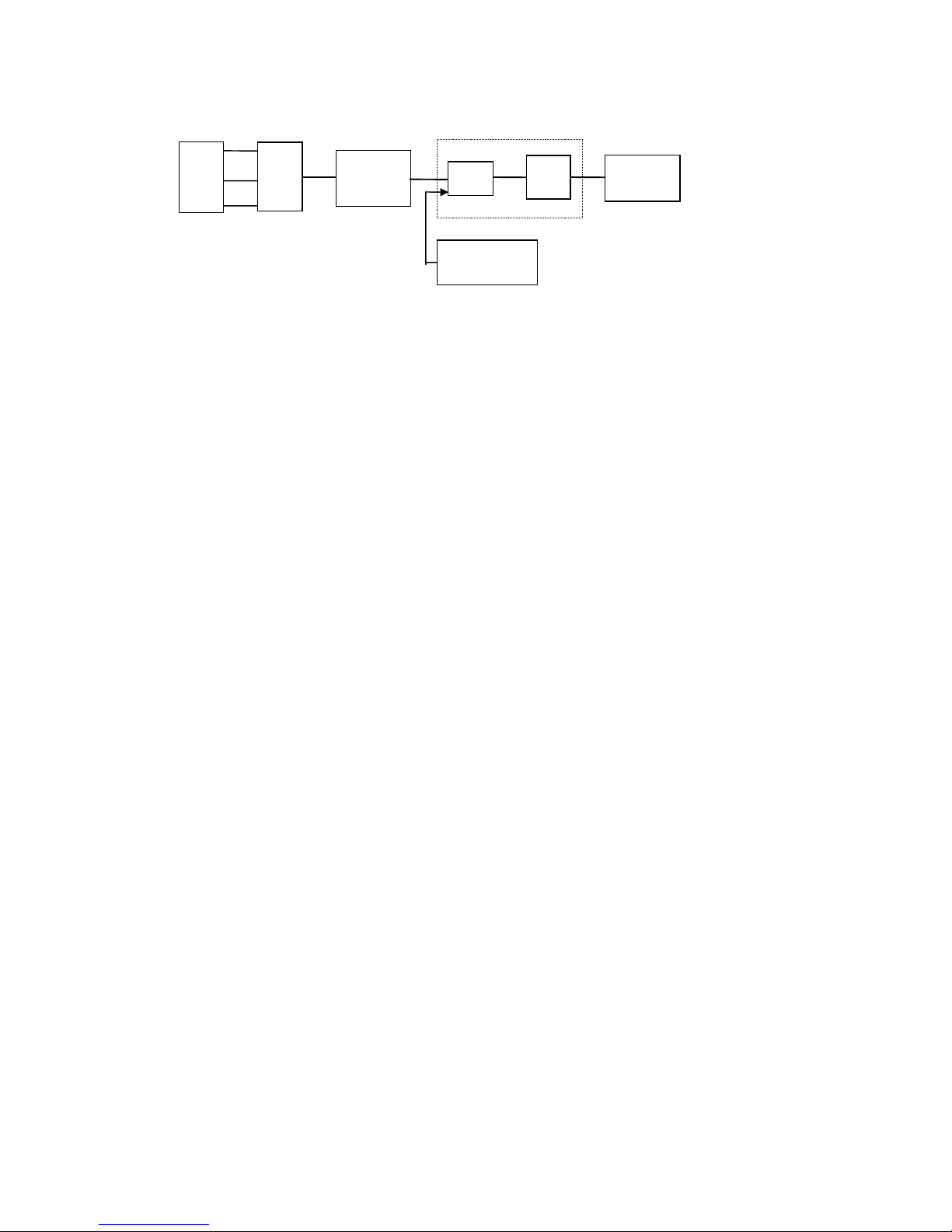

Figure 1.3 shows the operation mode sequence.

Reading mode setting

ADF drive/scanning module drive Reading

Mechanical Section Operation

Scanning module drive

The carrier is driven by a 2-phase stepping motor. The stepping motor has a rotation of

1.8°(full step). And the use of micro-stepping control technique can work the motor to move

the scanning module at 1/300 inch/step.

ADF mechanism operation

The ADF is driven by a 2-phase stepping motor. The stepping motor has a rotation of 1.8°

(full step). The use of micro-stepping control technique enables the motor to move the paper

on the ADF at 1/300 inch/step.

Figure 1.3 Operation sequence

1-8

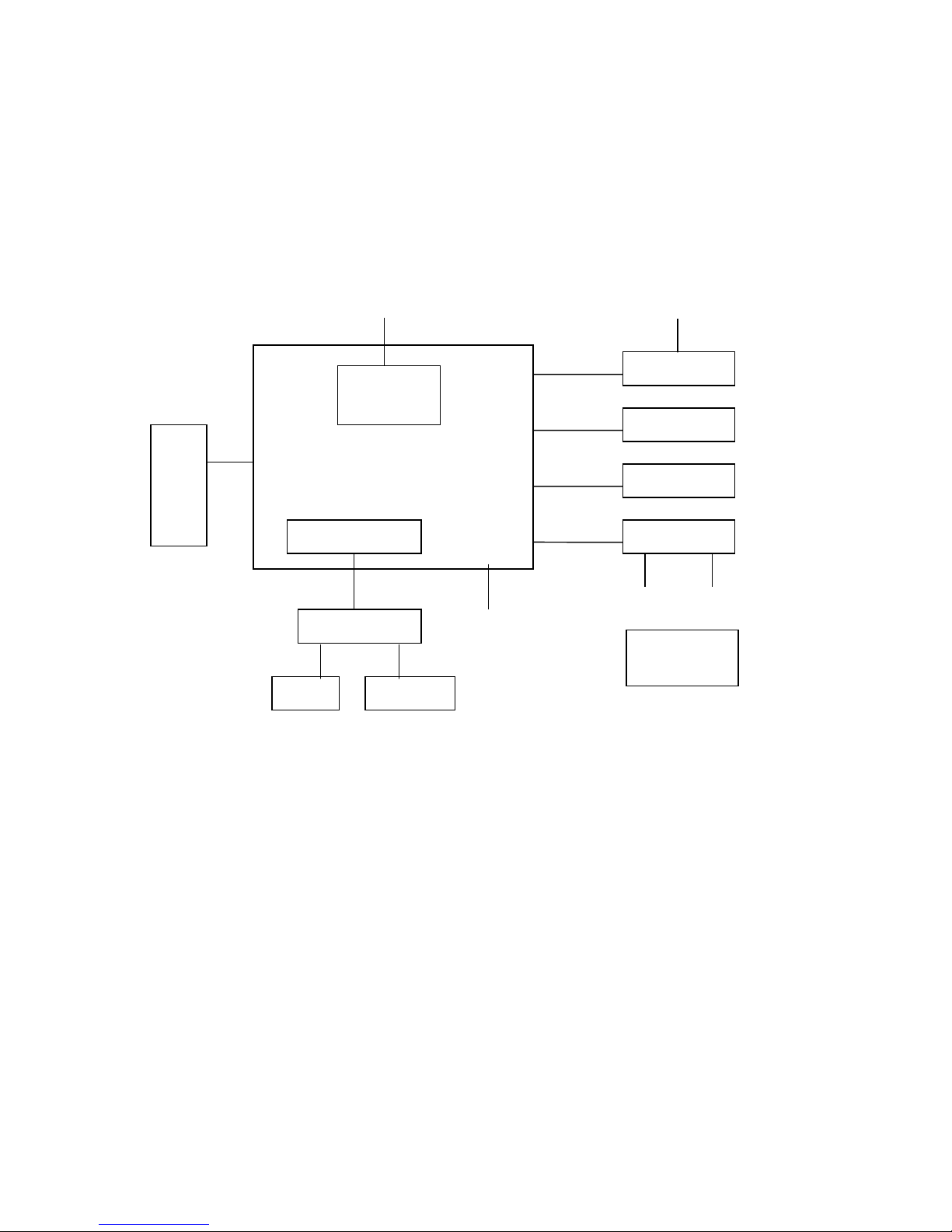

System Description

The 3200MFP is a duplex scanner which can scan synchronously both top and bottom size in a

document. It includes one main control board, two optical modules, one ADF module and one

LCD panel.

System Diagram

Figure 1.4 shows the system block diagram.

The main control board controls all the modules built up the 3200MFP. It includes a RISC.

ARM9(internal) as the main controller, one Flash Memory as program area , two ASIC for

flatbed and ADF image processing and each have external 64MB SRDRAM for data processing ,

two A/D converter for processing flatbed and ADF CCD signals input, two sets of motor

drivers for driving flatbed and ADF motors, one 1394 controller for data interfacing with

printer.

The power is an external 24V/2500mA power adapter for the whole system.

There are some different values inside the 3200MFP.

+24V Power directly comes from the power adapter and used for flatbed and ADF motor.

+12V Power converted from 7812 to supply flatbed and ADF CCD

+5V Power converter from 34063 to supply flatbed and ADF A/D converters and all 5V

logic.

+3.3V Power converted from LM 2576/3.3V to supply RTL8811, 1394 controller, two image

processing ASICs and some 3.3V logics.

1-9

r

Control

Panel

To printer

1394

Controller

Main board

Control

section

110/240 VAC

Power supply

LED display

Sensor input

Video Circuit

Optical unit

Flatbed

moto

Lamp unitInverter

Figure 1.4 System Block Diagram

ADF section

ADF motor ADF sensor

ADF's video

circuit

1-10

1394 interface:

This scanner and the printer are connected via the 1394 interface.

Video circuit:

The video circuit of this scanner includes: CCD driving circuit, CCD signal processing circuit.

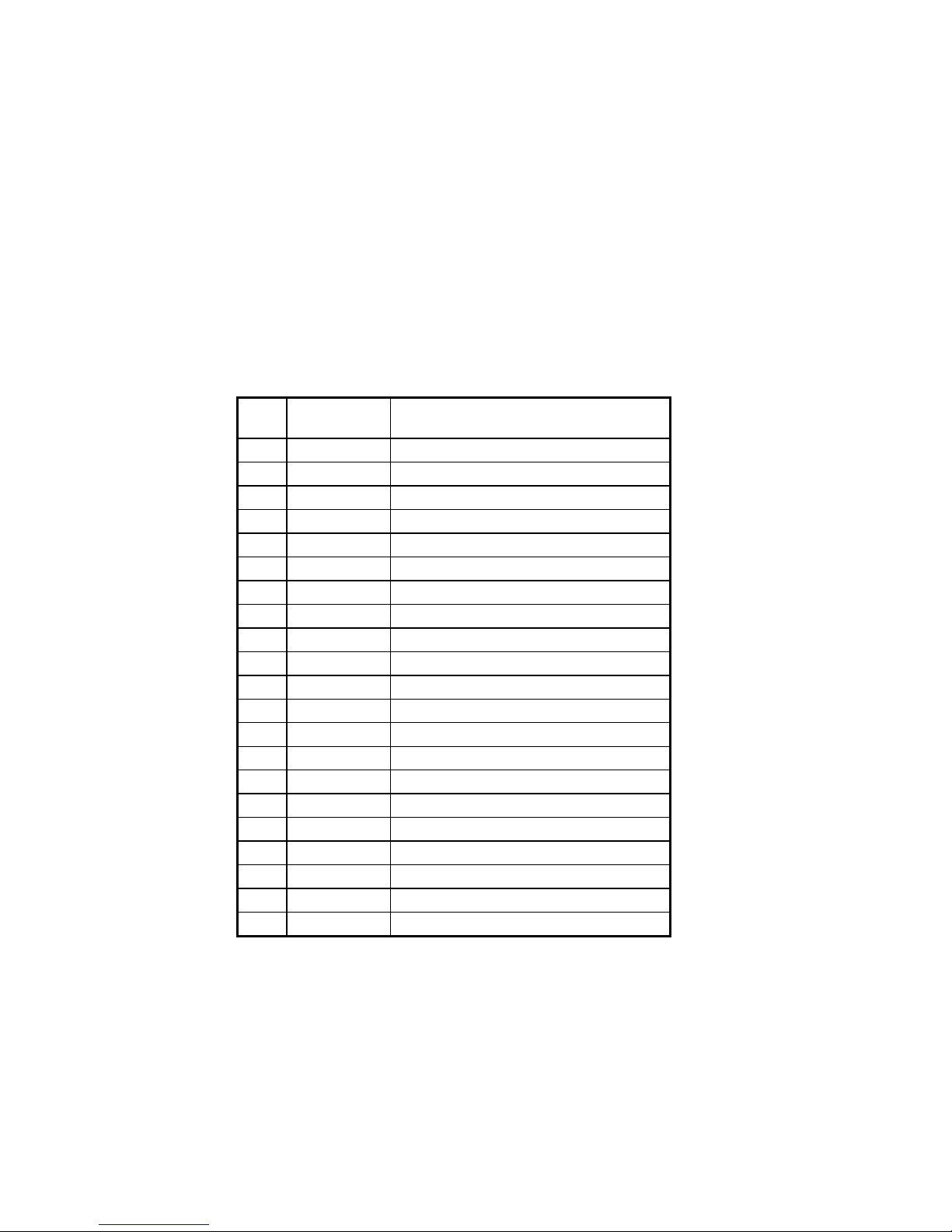

1 CCD Driving Circuit

Pin Assignment for Flatbed Video Circuit J3:

The CCD driving circuit is used to generate correct signals to the CCD, so that the CCD

may generate the correct image data.

Pin

Name Function

No.

1 H.G Inverter Ground

2 H.G Inverter Ground

4 Lamp V Inverter Power Supply

5 Lamp V Inverter Power Supply

6 +5V +5V Power Supply

7 SH Channel Shift Gate

8 Home Sensor Sensor Signal

9 D.G Digital Ground

10 PH2 CCD Clock Phase

11 PH1 CCD Clock Phase

12 D.G Digital Ground

13 Clamp CCD Clamp Signal

14 RS CCD Reset Gate

15 B/W CCD B/W Control Switch

16 +12V +12V Power Supply

17 VOR CCD red Channel Output Signal

18 A.G Analog Ground

19 VOG CCD Green Channel Output Signal

20 A.G Analog Ground

21 VOB CCD Blue Channel Output Signal

22 A.G Analog Ground

1-11

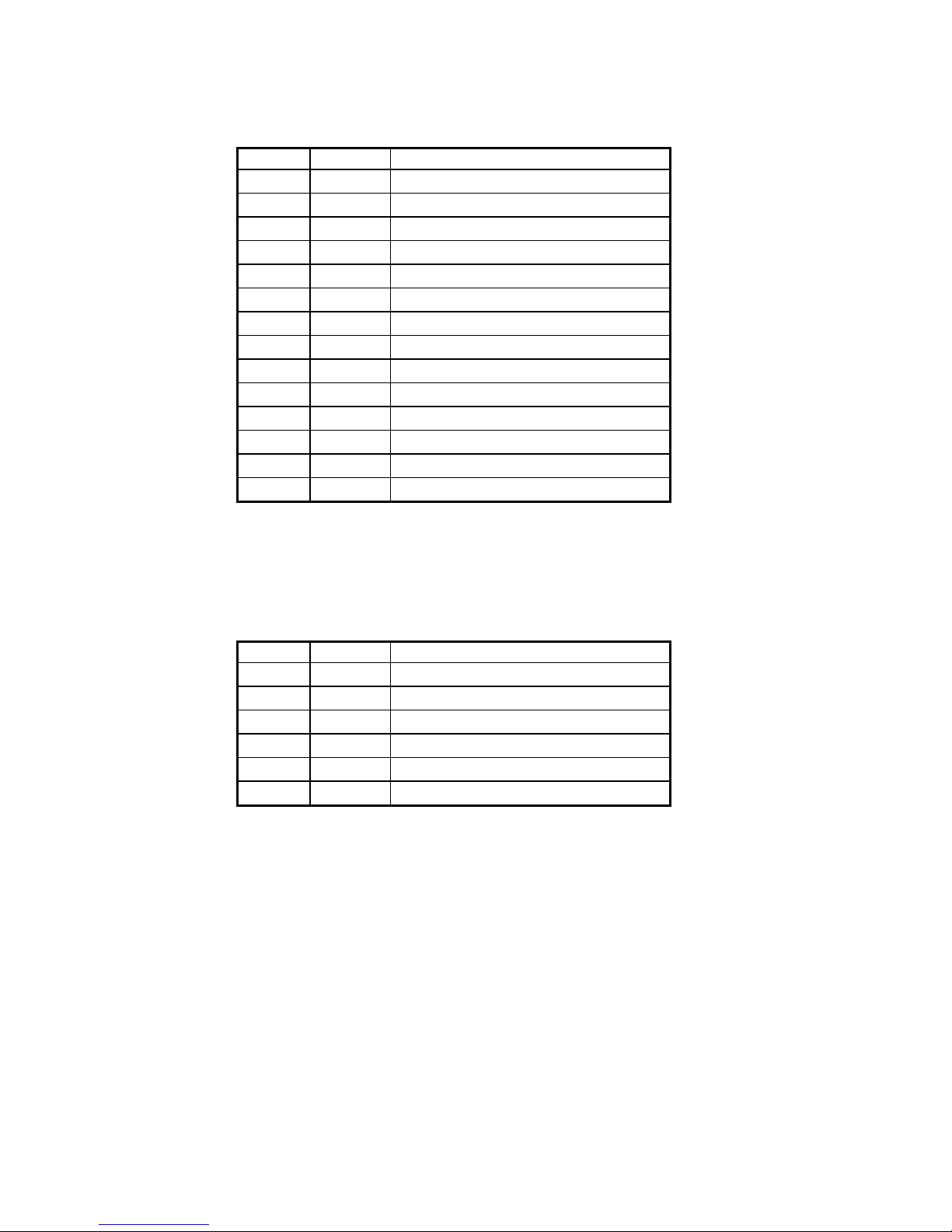

Pin Assignment for ADF Video Circuit J9:

Pin No. Name Function

1 H.G. Inverter Ground

2 +24V Analog +24V Power Supply

3 GND +5V GND

4 +5V +5V Power Supply

5 B/W CCD B/W Control Switch

6 SH Channel Shift Gate

7 RS CCD Reset Gate

8 Clamp CCD Clamp Signal

9 GND +5V GND

10 PH2 CCD Clock Phase

11 PH1 CCD Clock Phase

12 H24G +24V Ground

13 A.G Analog Ground

14 +24Va Analog +24Va Power Supply

Pin Assignment for ADF Video Circuit J8:

Pin No. Name Function

1 A.G Analog Ground

2 VOR CCD Red Channel Output Signal

3 A.G Analog Ground

4 VOG CCD Green Channel Output Signal

5 A.G Analog Ground

6 VOB CCD Blue Channel Output Signal

1-12

2. CCD signal processing circuit

R

CCD

G

B

MUX

Video Noise

Suppression

Circuit

PGA*

Level

Shift

A/D

Converter

DC Offset

Adjust Circuit

The video noise suppression circuit is to eliminate the reset noise and low frequency noise of

CCD and then PGA performs video gain control. The “level shift” circuit is used to bias the

PGA output to satisfy the reference bottom requirement of the A/D converter. The “DCOFFSET Adjust” circuit is used to adjust the bias level of video signal.

* PGA: Programmable gain amplifier

1-13

Sensor input

The sensor input includes home position sensor and ADF cover sensor.

1. Home position sensor

The home position is detected when the carrier passes between the LED and the photo transistor.

2. ADF cover sensor

The operation of the ADF cover sensor is the same as that of the home position sensor.

The home position of the carrier motor is detected by photo sensor. The photo

transistor transmission to the photo sensor receiver circuit is shown below .

+5V +5V

R R

Figure 1.5 Home position sensor

1-14

2. Installation

2.1 Precautions of Installation

2.2 Unpacking Procedure

2.3 Unlocking Your Scanner

2.4 Cable Connection

This chapter explains the unpacking procedure, installation procedure and confirmation of

operation.

2.1 Precautions of Installation

Pay attention to the following matters before unpacking and installation.

• Do not install in a place where vibration may occur.

• Keep the scanner out of direct sunlight. Do not install near a heat source.

• Do not place the scanner around materials which shut off the circulation of air.

• Do not install in a humid or dusty place.

• Do not use the wall socket with connecting devices which may generate noise, for example,

air-conditioner, etc.

• Use a suitable AC power source.

• Place the scanner on a level surface.

2.2 Unpacking Procedure

Unpack the scanner according to the following procedure.

• Remove the packing material.

• Remove the scanner from the shipping container.

• Remove the scanner from the PVC bag.

• Check the items

• For any missing items, please contact your nearest dealer or distributor.

2-1

2.3 Unlocking Your Scanner

The scanner is designed with the lock switch on the bottom to protect the scanning unit during

transportation. Please unlock the scanner first before using it.

1. Place the scanner on its side as shown in Figure 2.2

2. Locate the lock switch near the control panel. Move the lock switch to the "Unlock" position

as shown in Figure 2.3.

3. Remove the shipping retainer from its slot.

4. Insert the shipping retainer in the use position and fasten with the same screw as shown in Figure

2.3.

5. Place the scanner in its normal operating position.

Figure 2.2 Unlock the Scanning Unit

2-2

2.4 Cable Connection

Two cables are required to operate the scanner: the 1394 signal cable and the power cable. The

power cable connects the scanner to the power source. The 1394 signal cable connects the

scanner to the host for image transfer.

2.4.1 Power Cable Connection

1. Remove the power cable from the PVC bag.

2. Turn the power switch to the “off” position (“0” depressed).

3. Connect the female plug of the power cable to the scanner connector, and press it firmly

into place. (See Figure 2.4)

4. Connect the other end of the power cable to the power outlet, and press it firmly into

place.

1394 Port

Figure 2.4 Cable connection

Power Jack

2-3

Loading...

Loading...