Page 1

Lexmark Optra TM W810

Laser Printer

• Table of Contents

•Start Diagnostics

• Safety and Notices

4023-001

• Trademarks

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trade ma rks of Lexmark

International, Inc., registered in the

United States and/or ot her countries.

Page 2

4023-001

Edition: March 24, 2006

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTERN ATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING , BUT NOT LIMITED TO, THE IMPLIED W A RRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not all o w di sc la im er o f e xp res s o r im plie d w ar r ant i es in ce rta in t r ansa ct io ns , t he refore, t hi s

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

A form for reader’s comments is provided at the back of this publication. If the form has

been removed, comments may be addressed t o Lexmark International, Inc., Department

D22/032-2, 740 West New Circle Road, Lexington, Kentucky 4055 0, U.S.A. Lexmark may

use or distribute any of the information you supply in any way it believes appropriate

without incurring any obligation to you.

Lexmark, MarkNet, MarkVision, Optra and OptraImage are trademarks of Lexmark

International, Inc., registered in the United Sta tes and/or other co untries .

Other tradema rks are the property of their respective owner s.

© Copyright Lexmark International, Inc. 1999, 2004

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Right s in Technical Data and Computer Software clause at

DFARS 25 2.227-7013 and in applicable FAR provisions: Le x mark International, Inc.,

Lexington, KY 40550.

U.S.A. P/N: 12G3978

Page 3

4023-001

Table of Contents

Notices and Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Printer (Main) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Printer/Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

General Description of Each Section . . . . . . . . . . . . . . . . . . . . . . . . . .9

Paper Feed Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Printhead Unit (Exposure Section). . . . . . . . . . . . . . . . . . . . . . . . . .9

Imaging Cartridge (Charging, Development Section) . . . . . . . . . . .9

Image Transfer Section (Release Section) . . . . . . . . . . . . . . . . . . .9

Fusing Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cleaning Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Paper Exit Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

General Flow for Printing Process . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Paper Feed Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Taking Up Paper–Tray 1 (1st Paper Cassette) . . . . . . . . . . . . . . . 11

Tray 1 Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1st Cassette Tray 1 Paper Size Detection. . . . . . . . . . . . . . . . . . .15

Tray 2 (2nd Paper Cassette) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Taking up Paper–Tray 2 (2nd Paper Cassette) . . . . . . . . . . . . . . .16

Tray 2 Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Edge Guide and Trailing Edge Stop. . . . . . . . . . . . . . . . . . . . . . . .20

Paper Lifting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Cassette-in-Position Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Paper Near Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Paper Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Paper Separating Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Paper Take-Up Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Paper Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Printhead Unit (Exposure section) . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Imaging Cartridge (Charging/Development Section) . . . . . . . . . . . . .28

Development Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

iii

Page 4

4023-001

Toner Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Image Transfer Section (Release Section) . . . . . . . . . . . . . . . . . . . . 34

Optical Erase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Fusing Sectio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Temperature Control Using The Thermistor . . . . . . . . . . . . . . . . . 36

Thermostat (TS1) and Heater Lamp Fuse (TF1). . . . . . . . . . . . . . 36

Fusing Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fus ing PPM Cont rol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Paper Exit Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Paper Path Through Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Detection of a New Imaging Cartridge . . . . . . . . . . . . . . . . . . . . . . . . 39

Right Door Interlock Switch (S2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Duplex Unit Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Parts Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cross-Sectional View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Switchback Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Transport and Duplex Paper Take-Up Mechanism . . . . . . . . . . . . 43

Paper Deck 2500-Sheet (LCC) Option . . . . . . . . . . . . . . . . . . . . . . . 45

Cross-Sectional View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Vertical Transport Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . 45

Paper Take-Up Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Paper Take-Up Retry Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Paper Separating Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Paper Pressure Releasing Mechanism. . . . . . . . . . . . . . . . . . . . . 53

Paper Take-Up Roll Retracting Mechanism . . . . . . . . . . . . . . . . . 54

Edge Guides and Trailing Edge Stop . . . . . . . . . . . . . . . . . . . . . . 54

Paper Size Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

LCC-in-Position Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Lifting Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Paper Near Empty Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Paper Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Paper Dehumidifying Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Mailbox/Transport Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Parts Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Paper Transport Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Paper Entrance Switching Mechanism . . . . . . . . . . . . . . . . . . . . . 64

Paper Transport Mechanism (Horizontal Transport Unit) . . . . . . . 64

Paper Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Paper Full Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Paper Output Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Finisher Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

iv Service Manual

Page 5

4023-001

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Paper Transport Path Switching Mechanism. . . . . . . . . . . . . . . . .69

Paper Transport Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Punch Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Finisher Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

CD Aligning Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Shifting Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Finisher Tray Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Paper Holding Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Elevator Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Stapling Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Horizontal Transport Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Service Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operator Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Symptom Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Print Quality Symptom Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Paper Feed Symptom Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Other Printer Malfunction Symptom Table. . . . . . . . . . . . . . . . . . .31

LCC 2500-Sheet Tray 4 Symptom Table. . . . . . . . . . . . . . . . . . . .32

Mailbox Symptom Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Finisher Symptom Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Printer Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

No Power Service Check (923) . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Fuser (Abnormal Temperature) Service Check (923) . . . . . . . . . .34

Fuser (Temperature Low) Service Check (920/922) . . . . . . . . . . .35

Toner Feed Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Print Quality Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Black Page Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

White Spots Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Toner Smudges On Backside Service Check . . . . . . . . . . . . . . . .37

Low Image Density Service Check . . . . . . . . . . . . . . . . . . . . . . . .38

Foggy Background Service Check. . . . . . . . . . . . . . . . . . . . . . . . .39

White/Black Lines Service Check . . . . . . . . . . . . . . . . . . . . . . . . .40

Offset Image Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Blank Print Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Image Space Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Paper Feed Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Paper Feed Pickup Tray 1 (250-Sheet) Service Check . . . . . . . .44

Paper Feed Pickup Tray 2&3 (500-Sheet) Service Check . . . . . . 44

Paper Feed Synchronizing Roll/Registration Service Check . . . .45

Paper Feed Fuser/Exit Service Check . . . . . . . . . . . . . . . . . . . . .46

v

Page 6

4023-001

Paper Feed In Duplex Service Check . . . . . . . . . . . . . . . . . . . . . 46

Paper Feed In Horizontal Transport Service Check . . . . . . . . . . . 48

Paper Feed Mailbox Service Check . . . . . . . . . . . . . . . . . . . . . . . 48

Paper Feed Finisher Service Check . . . . . . . . . . . . . . . . . . . . . . . 50

Paper Feed LCC (2500-Sheet Tray 4) Service Check . . . . . . . . . 51

Paper Feed Hole Punch Service Check . . . . . . . . . . . . . . . . . . . . 52

Finisher Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Finisher Power Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Finisher Elevator Tray Service Check (993) . . . . . . . . . . . . . . . . . 53

Finisher Tray Drive Service Check (994) . . . . . . . . . . . . . . . . . . . 54

Finisher Shift Plate Drive Service Check (995) . . . . . . . . . . . . . . . 54

Finisher Paper Aligning Service Check (996) . . . . . . . . . . . . . . . . 54

Finisher Stapler Drive Service Check (997) . . . . . . . . . . . . . . . . . 56

Finisher Paper Holding Tray Drive Service Check (998). . . . . . . . 56

Finisher Upper Entrance Service Check . . . . . . . . . . . . . . . . . . . . 57

Mailbox Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Mailbox Power Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Mailbox Bin 1–10 Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . 59

Mailbox Transport Drive Service Check (935). . . . . . . . . . . . . . . . 59

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operator Menu Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Diagnostics Mode Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . 1

Printing Menu Settings Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Quick Test Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Diagnostics–Print Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Print Quality Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hardware Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Duplex Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Input Tray Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Output Bin Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Finisher Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Base Printer Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Device Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Disk Test/Clean. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Flash Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mailbox Internal Diagnostic Test. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Repa ir Informatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Disassembly and Cleaning Precautions . . . . . . . . . . . . . . . . . . . . . 1

vi Service Manual

Page 7

4023-001

Handling the Printed Circuit Boards with MOS ICs . . . . . . . . . . . . .1

Image Cartridge/PC (I/C) Handling Precautions . . . . . . . . . . . . . . .2

Parts Not To Be Touched. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Printer (Main) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Resetting Maintenance Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Resetting Hole Punch Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Resetting Fuser Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Resetting Transfer Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Printer Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pre-disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Outer Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

1st Cassette/250-Sheet (Tray1) Paper Take-Up Roller Removal .16

250-Sheet Cassette (Tray 1) Paper Take-Up Rolls Removal . . . .16

250-Sheet Cassette (Tray 1) Paper Take-Up Rolls Cleaning . . . .17

500-Sheet Cassette (Tray 2 and 3) Vertical Transport Roller/Rolls

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

500-Sheet Cassette (Tray 2 and 3) Paper Lifting Springs Replace-

ment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

500-Sheet Cassette (Tray 2 and 3) Paper Size Detecting Board

(PWB-S2) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Image Transfer Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . .21

Image Cartridge/PC (I/C) Thermistor (TH2) Removal . . . . . . . . . .22

Image Transfer Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Synchronizing Roller Sensor (PC2) Removal . . . . . . . . . . . . . . . .23

Pre-transfer Guide Plate Register Plate (PWB-R2) Removal . . . .24

Synchronizing Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Cooling Fan Motor (M3) and I/C Filter Removal . . . . . . . . . . . . . .26

Fusing Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Paper Exit Sensor (PC3) and Actuator Removal . . . . . . . . . . . . . .27

Heater Lamp Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Heater Lamp (H1) Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Fusing Roller Thermistor (TH1) Removal . . . . . . . . . . . . . . . . . . .29

Fusing Roller Thermostat (TS1) Removal . . . . . . . . . . . . . . . . . . .30

Paper Exit Full Sensor (PC12) Removal . . . . . . . . . . . . . . . . . . . .31

Eraser Duct Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . .32

Erase Lamp (LA1) Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Fuser Frame Resistor Board (PWB-R1) Removal . . . . . . . . . . . . .34

1st Ca ssette Paper Em pty Sensor (PC4) Removal. . . . . . . . . . . .35

Image Cartridge/PC (I/C) Cooling Fan Motor (M9) Removal. . . . . 36

High Voltage Unit (HV1) Removal . . . . . . . . . . . . . . . . . . . . . . . . .37

vii

Page 8

4023-001

Printer Main Engine Board (PWB-A) Removal . . . . . . . . . . . . . . . 38

Printhead Unit Assembly (PH) Removal . . . . . . . . . . . . . . . . . . . . 40

Right Door Switch (S3) Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Supply Unit (PU1) Removal . . . . . . . . . . . . . . . . . . . . . . . . 44

CPM (Power Supply Safety) Switch and PWB-L Removal . . . . . . 45

Power Unit Cooling Fan Motor (M4) Removal. . . . . . . . . . . . . . . . 46

Ozone Fan Motor (M8) and Ozone Filter Removal . . . . . . . . . . . . 47

1st Paper Cassette (Tray 1) Paper Size Detecting Board Removal .

48

Bottle Cover Sensor (PC10) Removal. . . . . . . . . . . . . . . . . . . . . . 49

Agitating Motor (M10) Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Main Hopper Motor (M6) and Sub Hopper Motor (M7) Removal . 51

Transport Motor (M2) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Image Cartridge/PC (I/C) Drive Motor (M1) Removal . . . . . . . . . . 53

Right Door Interlock Switch (S2) Removal . . . . . . . . . . . . . . . . . . 54

Toner Detecting Read Switch (S4) Removal. . . . . . . . . . . . . . . . . 55

1st Cassette (Tray 1) Paper Near Empty Sensor (PC5) Removal 57

1st Cassette (Tray 1) Set Sensor (PC6) Removal . . . . . . . . . . . . 58

1st Cassette (Tray 1) Paper Take-Up Solenoid (SL1) Removal . . 59

Double Feed Detection Sensor Board (PWB-H) Removal . . . . . . 60

500-Sheet Cassette (Tray 2 and 3) Control Board (PWB-A2) Remov-

al . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

500-Sheet Cassette (Tray 2 and 3) Paper Take-Up Roller Removal

63

500-Sheet Cassette (Tray 2 and 3) Paper Empty Sensor (PC22) Re-

moval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

500-Sheet Cassette (Tray 2 and 3) Paper Near Empty Sensor (PC25)

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

500-Sheet Cassette (Tray 2 and 3) Right Door Detecting Sensor

(PC23) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

500-Sheet Cassette (Tray 2 and 3) Paper Take-Up Solenoid (SL2)

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Duplex Unit Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Duplex Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Duplex Unit Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Paper Deck 2500-Sheet Tray 4 (LCC) Removal Procedures . . . . . . 70

Exterior Parts Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Paper Take-Up Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Paper Take-Up Rolls Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Feed Roll, Separator Roll and Torque Limiter Assembly Removal 79

Paper Take-Up Roll Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Feed Roll and Separator Roll Cleaning. . . . . . . . . . . . . . . . . . . . . 80

Vertical Transport Roller/Rolls Cleaning . . . . . . . . . . . . . . . . . . . . 81

viii Service Manual

Page 9

4023-001

Roll with a Torque Limiter Cleaning. . . . . . . . . . . . . . . . . . . . . . . .81

Finisher Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

External Covers Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Punch Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Stapler Unit Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Rear Cable Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Front Cable Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Front Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Mailbox Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Storage Unit Cover Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Horizontal Transport Unit Cover Removal . . . . . . . . . . . . . . . . . . .92

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Printer with Opti o n s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Printer Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Electrical Components (cont.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Printer Main Engine Board PWB-A . . . . . . . . . . . . . . . . . . . . . . . . .8

RIP Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

High Voltage Board (HV1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Power Unit (PU1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Network Interface Card (NIC). . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Paper Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Fixed Paper Size Cassette (Tray 1 only) . . . . . . . . . . . . . . . . . . . .12

Universal Cassette (Tray 2,3 and 500-Sheet Option) . . . . . . . . . .12

Cross-Sectional View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Paper Cassette Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Paper Cassette Electrical Components . . . . . . . . . . . . . . . . . . . . .14

Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Duplex Cross-Sectional View. . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Duplex Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Duplex Electrical Components. . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Paper Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Paper Deck Cross-Sectional View . . . . . . . . . . . . . . . . . . . . . . . . .19

Paper Deck Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Paper Deck Electrical Components . . . . . . . . . . . . . . . . . . . . . . . .21

Finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Finisher Cross-Sectional View. . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Finisher Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Finisher Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . .26

ix

Page 10

4023-001

Finisher Main Board PWB-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

External View (Front: When Connected To Printer) . . . . . . . . . . . 29

External View (Rear: When Connected To Printer) . . . . . . . . . . . . 29

Mailbox External View (Each Section) . . . . . . . . . . . . . . . . . . . . . 30

Mailbox Horizontal Transport Unit: Cross-Sectional View. . . . . . . 30

Mailbox Horizontal Transport Unit: Electrical Components. . . . . . 31

Mailbox Horizontal Transport Unit: Mechanical Components . . . . 31

Mailbox Storage Unit: Cross-Sectional View. . . . . . . . . . . . . . . . . 32

Mailbox Storage Unit: Electrical Components. . . . . . . . . . . . . . . . 33

Mailbox Storage Unit: Mechanical Components . . . . . . . . . . . . . . 34

Mailbox Storage Unit: Main Board PWB-A . . . . . . . . . . . . . . . . . . 34

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How To Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly 1: Printer Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Assembly 2: Printer Frames (A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly 3: Printer Frames (B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Assembly 4: Printer Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Assembly 5: Printer Fuser (A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Assembly 6: Printer Fuser (B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Assembly 7: Printer Manual Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Assembly 8: Printer Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Assembly 9: Printer Electrical Components . . . . . . . . . . . . . . . . . . . . 26

Assembly 10: Printer Paper Take-up . . . . . . . . . . . . . . . . . . . . . . . . . 28

Assembly 11: Printer Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Assembly 12: Printer Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Assembly 13: 500 Sheet Unit Housing. . . . . . . . . . . . . . . . . . . . . . . . 38

Assembly 14: 500 Sheet Unit Paper Take-up . . . . . . . . . . . . . . . . . . 42

Assembly 15: 500 Sheet Unit Paper Tray Unit (A). . . . . . . . . . . . . . . 46

Assembly 16: 500 Sheet Unit Paper Tray Unit (B). . . . . . . . . . . . . . . 48

Assembly 17: Printer Controller Card. . . . . . . . . . . . . . . . . . . . . . . . . 50

Assembly 18: Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Assembly 19: Paper Deck Housing . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Assembly 20: Paper Deck Paper Take-up (A) . . . . . . . . . . . . . . . . . . 58

Assembly 21: Paper Deck Paper Take-up (B) . . . . . . . . . . . . . . . . . . 62

Assembly 22: Paper Deck Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Assembly 23: Paper Deck Paper Tray (A) . . . . . . . . . . . . . . . . . . . . . 70

Assembly 24: Paper Deck Paper Tray (B) . . . . . . . . . . . . . . . . . . . . . 72

Assembly 25: Finisher Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

x Service Manual

Page 11

4023-001

Assembly 26: Finisher Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Assembly 27: Finisher Paper Transport (A) . . . . . . . . . . . . . . . . . . . .80

Assembly 28: Finisher Paper Transport (B) . . . . . . . . . . . . . . . . . . . .82

Assembly 29: Finisher Paper Aligning. . . . . . . . . . . . . . . . . . . . . . . . .86

Assembly 30: Finisher Assistance Tray . . . . . . . . . . . . . . . . . . . . . . .92

Assembly 31: Finisher Elevator Tray. . . . . . . . . . . . . . . . . . . . . . . . . .96

Asse m bly 32: F i nisher Punch U nit . . . . . . . . . . . . . . . . . . . . . . . . . .100

Assembly 33: Finisher Stapler Unit/Finisher Tray. . . . . . . . . . . . . . .1 02

Assembly 34: Finisher/Mailbox Horizontal Transfer (A) . . . . . . . . . .106

Assembly 35: Finisher/Mailbox Horizontal Transfer (B) . . . . . . . . . .108

Assembly 36: Mailbox Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Assembly 37: Mailbox Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 14

Assembly 38: Mailbox Paper Transport (A). . . . . . . . . . . . . . . . . . . .118

Assembly 39: Mailbox Paper Transport (B). . . . . . . . . . . . . . . . . . . .122

Assembly 40: Mailbox Paper Transport (C) . . . . . . . . . . . . . . . . . . .124

Assembly 41: Mailbox Paper Transport (D) . . . . . . . . . . . . . . . . . . .126

Assembly 42: Mailbox Paper Transport (E). . . . . . . . . . . . . . . . . . . .128

Assembly 43: Mailbox Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Assembly 44: Optional Features (No illustration) . . . . . . . . . . . . . . .132

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

xi

Page 12

4023-001

xii Service Manual

Page 13

4023-001

Notices and Safety Information

Laser No tices

The following laser notice labels may be affixed to this printer as

shown:

Notices and Safety Information xiii

Page 14

4023-001

Laser Not ice

The printer is certified in the U.S. to conform to the requirements of

DHHS 21 CFR Subchapter J for Class I (1) laser products, and

elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 60825.

Class I laser products are not considered to be hazardous. The

printer contains internally a Class IIIb (3b) laser that is nominally a 5

milliwatt gallium arsenide laser operating in the wavelength region of

770-795 nanometers. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed

service condition.

Laser

Avis relatif à l’utilisation de laser

German

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die

Anforderungen der Bestimmung DHHS (Department of Health and

Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1).

In anderen Ländern gilt der Drucker als Laserprodukt der Klasse I,

der die Anforderungen der IEC (International Electrotechnical

Commission) 60825 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des

Druckers befindet sich ein Laser der Klasse IIIb (3b), bei dem es

sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen

der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbetrieb , bei der Wartung

durch den Benutzer oder bei ordnungsgemäßer Wartung durch den

Kundendienst Laserbestrahlung, die die Klasse I übersteigen würde,

Menschen keinesfalls erreicht.

French

Pour les Etats-Unis : cette impri man te est certifiée conforme aux

provisions DHHS 21 CFR alinéa J concernant les produits laser de

Classe I (1). Pour les autres pays : cette imprimante répond aux

normes IEC 60825 relatives aux produits laser de Classe I.

xiv Service Manual

Page 15

4023-001

Les produits laser de Classe I sont considérés comme des produits

non dangereux. Cette imprimante est équipée d’un laser de Classe

IIIb (3b) (arséniure de gallium d’une puissance nominale de 5

milliwatts) émettant sur des longueurs d’onde comprises entre 770

et 795 nanomètres. L’imprimante et son système laser sont conçus

pour impossible, dans des conditions normales d’utilisation,

d’entretien par l’utilisateur ou de révision, l’exposition à des

rayonnements laser supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme

ai requisiti del DHHS 21 CFR Sottocapitolo J per i prodotti laser di

classe 1 ed è certificata negli altri Paesi come prodotto laser di

classe 1 conforme ai requisiti della norma CEI 60825.

I prodotti laser di classe non sono considerati pericolosi. La

stampante contiene al suo interno un laser di classe IIIb (3b)

all’arseniuro di gallio della potenza di 5mW che opera sulla

lunghezza d’onda compresa tra 770 e 795 nanometri. Il sistema

laser e la stampante sono stati progettati in modo tale che le

persone a contatto con la stampante, durante il normale

funzionamento, le operazioni di servizio o quelle di assistenza

tecnica, non ricevano radiazioni laser superiori al livello della classe

1.

Avisos so bre el láser

Se certifica que, en los EE.UU., esta impresora cumple los

requisitos para los productos láser de Clase I (1) establecidos en el

subcapítulo J de la norma CFR 21 del DHHS (Departamento de

Sanidad y Servicios) y, en los demás países, reúne todas las

condiciones expuestas en la norma IEC 60825 para productos láser

de Clase I (1).

Spanish

Italian

Los productos láser de Clase I no se consideran peligrosos. La

impresora contiene en su interior un láser de Clase IIIb (3b) de

arseniuro de galio de funcionamiento nominal a 5 milivatios en una

longitud de onda de 770 a 795 nanóme tros. El sistema láser y la

impresora están diseñados de forma que ninguna persona pueda

verse afectada por ningún tipo de radiación láser superior al nivel de

Notices and Safety Information xv

Page 16

4023-001

la Clase I durante su uso normal, el mantenimiento realizado por el

usuario o cualquier otra situación de servicio técnico.

Declaração sobre Laser

A impressora está certificada nos E.U.A. em conformid ade com os

requisitos da regulamentação DHHS 21 CFR Subcapítulo J para a

Classe I (1) de produtos laser. Em outros locais, está certif icada

como um produto laser da Classe I, em conformidade com os

requisitos da norma IEC 60825.

Os produtos laser da Classe I não são considerados perigosos.

Internamente, a impressora contém um prod uto lase r da C lass e IIIb

(3b), designado laser de arseneto de potássio, de 5 milliwatts

,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de

forma a nunca existir qualquer possiblidade de acesso humano a

radiação laser superior a um nível de Classe I durante a operação

normal, a manutenção feita pelo utilizador ou condições de

assistência prescritas.

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een

laserprodukt van klasse I. V oor de Verenigde Staten zijn deze eisen

vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in

IEC 60825.

Dutch

Portugese

Laserproduk ten van klasse I worden niet als ongevaarlijk

aangemerkt. De printer is voorzien van een laser van klasse IIIb

(3b), dat wil zeggen een gallium arsenide- laser van 5 milliwatt met

een golflengte van 770-795 nanometer. Het lasergedeelte en de

printer zijn zo ontworpen dat bij normaal gebr uik, bij onderhoud of

reparatie conform de voorschriften, nooit blootstelli ng mogelijk is

aan laserstraling boven een niveau zoals voorgeschreven is voor

klasse 1.

xvi Service Manual

Page 17

4023-001

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i

overenstemmelse med kravene i IEC 60825.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren

indeholder internt en Klasse IIIB (3b)-laser, der nominelt er en 5

milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet

770-795 nanometer. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over

Klasse I-niveau ved normal drift, brugervedligeholdelse eller

obligatoriske servicebetingelse r.

Danish

Notices and Safety Information xvii

Page 18

4023-001

Huomautu s las er laitteesta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) laserlaitteiden DHHS

21 CFR Subchapter J -määrityksen mukainen ja muualla luokan I

laserlaitteiden IEC 60825 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle.

Kirjoittimessa on sisäinen luokan IIIb (3b) 5 milliwatin

galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä.

Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei

altistu luokan I määrityksiä voimakkaammalle säteilylle kirjoittimen

normaalin toiminnan, käyttäjän tekemien huoltotoimien tai muiden

huoltotoimien yhteydessä.

LUOKAN 1 LASERLAITE

V AROITUS! Laitteen käyttäminen muulla kuin tässä käyttöohjeessa

mainitulla tavalla saattaa altistaa käyttäjän turvallisuusluokan 1

ylittävälle näkymättömälle lasers äteilylle.

KLASS 1 LASER APPARAT

VARNING! Om apparaten används på annat sätt än i denna

bruksanvisning specificerats, kan användaren utsättas för osynlig

laserstrål ning, som överskrider gränsen för laserklass 1.

Finnish

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina

näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och

spärren är urkopplad. Betrakta ej strålen.

xviii Service Manual

Page 19

4023-001

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21

CFR, underparagraf J för laserprodukter av Klass I (1). I andra

länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt

kraven i IEC 60825.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en

inbyggd laser av Klass IIIb (3b) som består av en laserenhet av

gallium-arsenid på 5 milliwat t so m arbe t ar i våglängdsområdet 770795 nanometer. Lasersystemet och skrivaren är utformade så att det

aldrig finns risk för at t n ågon person utsätts för laserstrålning över

Klass I-nivå vid normal användning, underhåll som utförs av

användaren eller annan föreskriven serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR,

underkapittel J, for klasse I (1) laserprodukter, og er i andre land

godkjent som et Klasse I-laserproduk t i samsvar med kravene i IEC

60825.

Klasse I-laserprodukter er ikke å betrakte som farlige. Skriveren

inneholder internt en klasse IIIb (3b)-laser, som består av en

gallium-ar senlaserenhet som avgir stråling i bølgelengdeområdet

770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk, vedlikehold som utføres av brukeren, eller foreskrevne

serviceopera sjoner.

Swedish

Norwegian

Notices and Safety Information xix

Page 20

4023-001

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora

compleix els requisits de DHHS 21 CFR, apartat J, pels productes

làser de classe I (1), i segons ha estat certificat en altres llocs, és un

producte làser de classe I que compleix els requisits d’IEC 60825.

Els productes làser de classe I no es consideren perillosos. Aquesta

impressora conté un làser de classe IIIb (3b) d’arseniür de gal.li,

nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona

de 770-795 nanòmetres. El sistem a làser i la impressora han sigut

concebuts de manera que mai hi hagi exposició a la radiació làser

per s obre d’un nivell de classe I durant una operació normal, durant

les tasques de manteniment d’usuari ni durant els serveis que

satisfacin les condicions prescrites.

Catalàn

Japanese Laser Notice

xx Service Manual

Page 21

4023-001

Chinese Laser Notice

Korean La ser Notice

Notices and Safety Information xxi

Page 22

4023-001

Safety Information

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not alway s

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury dur ing disassem bly and ser v icing of this product.

Professional service personnel should understand this and take

necessary precautions.

Consignes de Sécurité

French

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiqu es. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres

pièces de rechange.

• Les consignes d'entretien et de répa ration de ce produit

s'adressent uniquement à un personnel de m aintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

xxii Service Manual

Page 23

4023-001

Norme di sicurezza

Italian

• Il pr odotto è stato progettato, testato e approvato in conformità a

severi standard di sicurezza e per l’utiliz zo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune parti

non sempre sono di immediata comprensione. Lexmark non è

responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

German

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Pautas de Seguridad

Spanish

• Este producto se ha diseñado, verificado y aprobado para

cumplir lo s más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

Notices and Safety Information xxiii

Page 24

4023-001

siempre evidentes. Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La in formaci ón sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser conscien te de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

Portugese

• Este produto foi concebido, testado e aprovado para satisfazer

os padrões globais de segurança na utilização de componentes

específicos da Le xmar k. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outros componentes de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serv iços e não de vem s er

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessári os.

Informació de Seguretat

Catalàn

• Aquest producte està dissenyat, compr ovat i apro vat per tal

d'acomplir les estrictes nor me s de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La in formaci ó pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

xxiv Service Manual

Page 25

4023-001

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

Chinese

Korean

Notices and Safety Information xxv

Page 26

4023-001

xxvi Service Manual

Page 27

4023-001

1. Gen e r a l Informat io n

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, and service checks to determine the symptom and

repair the failure. You may find that the removals in the Repair

Information chapter w ill help you identify parts.

After you complete the repair, perform tests as needed to verify the

repair.

Tools

The removal and adjustment procedures described in this manual

require the following tools and equipment:

• Magnetic tip Phillips screwdrivers, large and small

• Flat-blade screwdrivers

• Analog volt ohmmeter (a digital volt ohmmeter may also be

used)

• Needle nose pliers

• Tweezers, C-ring pliers

When you make voltage readings, always use frame ground unless

another ground is specified.

General Information 1-1

Page 28

4023-001

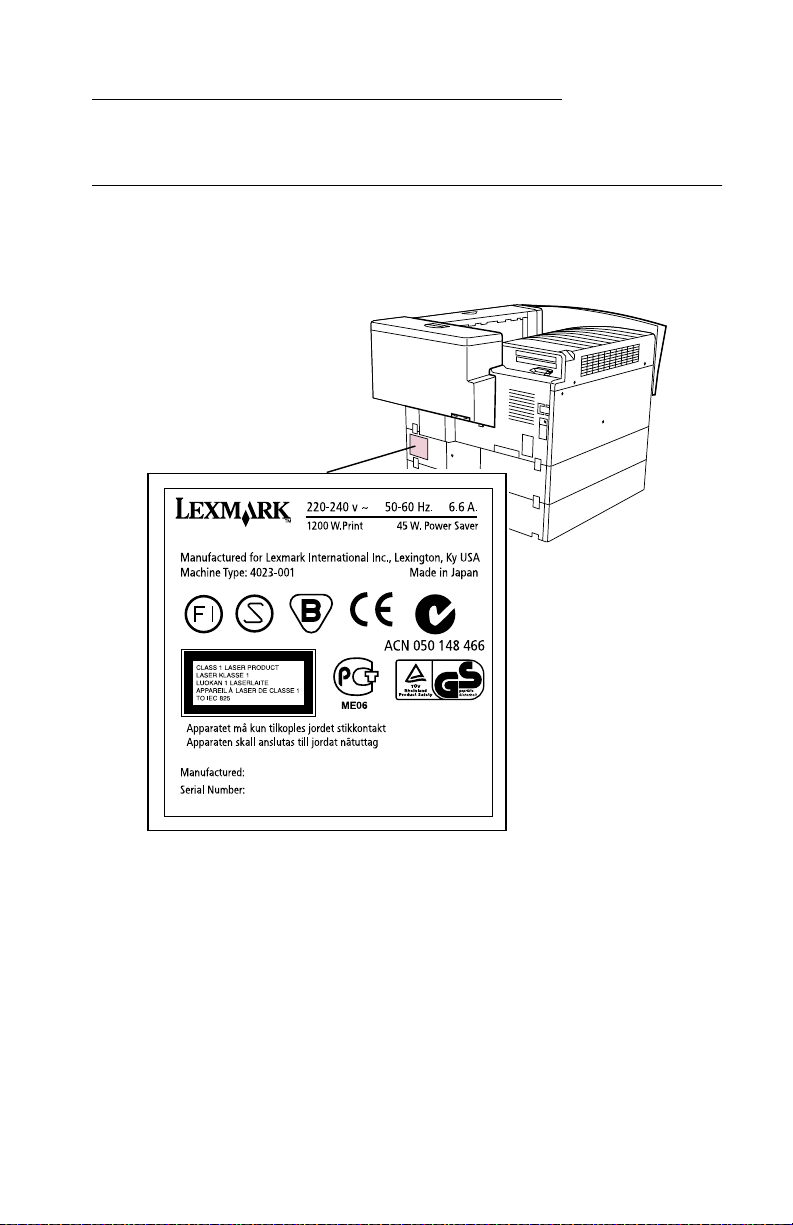

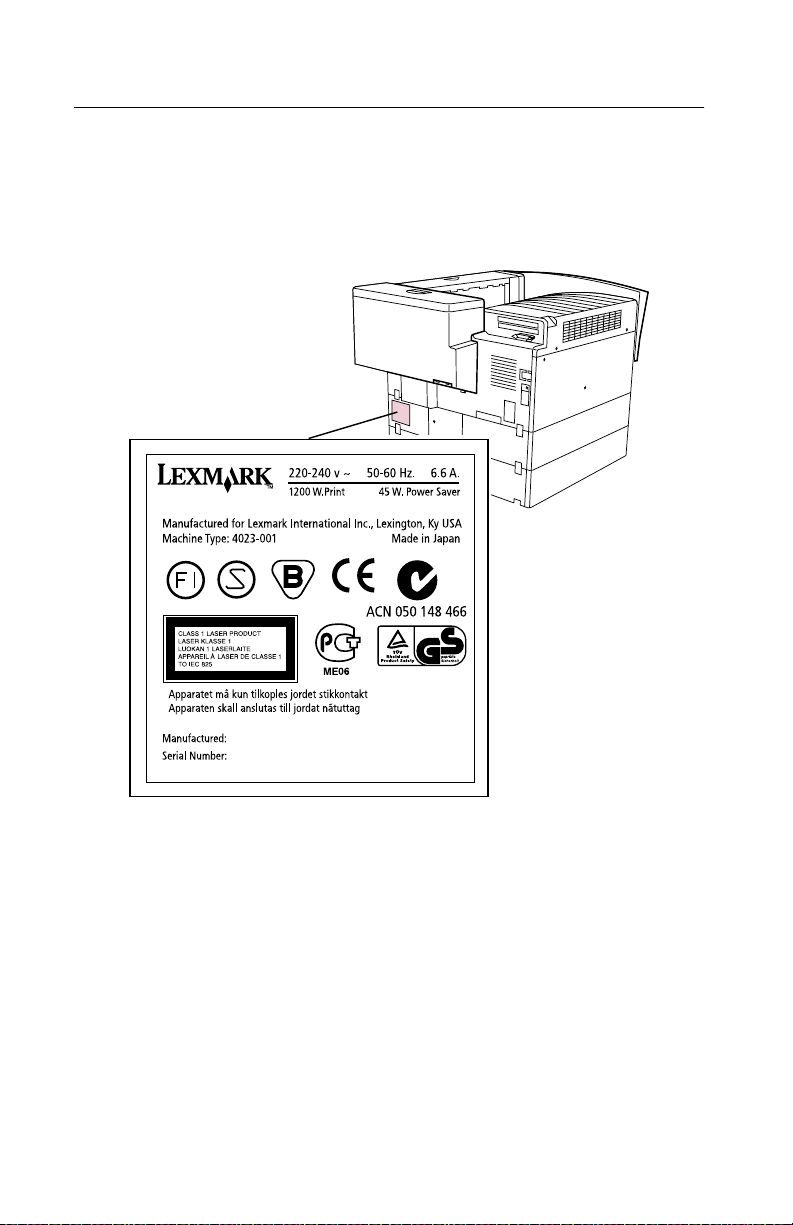

Serial Number

The serial number is located in the bottom left corner of the label

illustrated below:

1-2 Service Manual

Page 29

4023-001

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EEPROM Electrically Erasable Programmable Read-

Only Memo ry

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Fi eld Replacea ble Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Vol tage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PICS Problem Isolation Charts

PIXEL Picture Element

POR Power-On Reset

POST Power-On Self Test

PQET Print Quality Enhancem ent Technology

RIP Raster Image Processor

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

VAC Volts alternating current

VDC Volts direct current

General Information 1-3

Page 30

4023-001

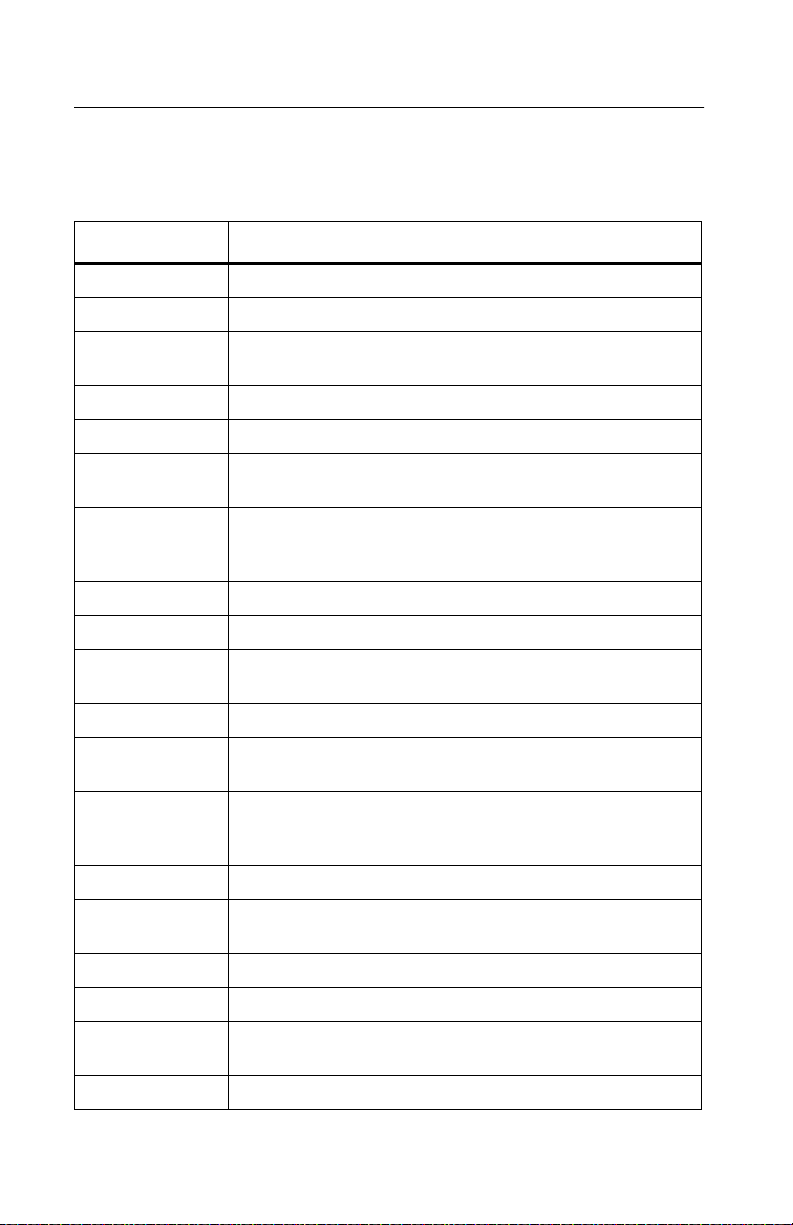

Standard Feat ures

Printer (Main)

Feature Description

Print speed 35 ppm (letter/A4) High Speed Printing

Power supply AC120V, AC220–240V ±10%

Power

consumption

Tempera tur e 10 to 35°C

Controller Lexmark Control ler (High Performance)

RIP page

storage

Printer

management

software

Operator panel Operator panel access for menus

Universal Drawer 250 sheet 11x17/A3/letter/legal/ A4

500 sheet input

drawers

Copy collation Multiple copy collation in the printer RAM

Dimensions 1.75 ft. (535 mm) Width x 2.06 ft. ( 628 mm) Depth x 1.40

Printing system Electrostatic dry powdered imaging system +

Exposure system Laser diode + polygon m irror scanning

Paper feeding

system

1200W

45W or less (low power)

Hard disk option can be partitioned to be used for

intermediate RIP page storage

Markvision

management

Two (2) 500 sheet input drawers (11x17/A3/letter/legal/

A4)

ft. (428 mm) Height

Imaging cartridge

Two-com ponent imaging cartridge

Six-way system Tray 1 (multipurpose) (250 sheet s)

TM

for network and/or desktop printer

Charging system Comb electrode with scorot ron system

Development MTHG system

Density

correction

Density control Developing bias adj usting system

ATDC sensor

1-4 Service Manual

Page 31

4023-001

Feature Description

Image transfer

system

PC drum Organic photoconductor (OPC)

Cleaning system Blade system

Separating

system

Fusing system Heat roller fusing system

Paper exit

system

Roller t ransform system

Paper separator

Printer

Face do wn (300 sheets maximum A4/C/Lett er C)

Mailbox

2000 sheets

Finisher

2500 sheets

500 sheets standard bin

2000 sheets fini sher bin

General Information 1-5

Page 32

4023-001

Options

Option Description

EDO DRAM

Memory

Options:

Hard disk Hard disk option

Tri-port interface

card

MarkNet

Adapters

Parallel

connector

Paper handling 500 sheet input tray and drawer

OptraImage

TM

S

32MB EDO Memory

64MB EDO Memory

Hard disk adapter cable

Serial, LocalTalk and IR A,B,C

Token-ring

Ethernet (10BT/100BTx)

Ethernet (10BT/2)

Ethernet (10BT/100BTx) SCSI

Coax/twinax adapter for SCS

Parallel/USB A,B,C

2500 sheet input tray (worldwide)

2000 sheet mailbox

2500 sheet finish er (3 and 4 hole

punching capability, 5k stapling capacity)

TM

Ethernet 10/100, SCSI

scanner and fax

Optra W810

Versions*

A,B,C

A,B,C

B,C

A,B,C

A,B,C

Supplies Photoconductor kit

Toner cartridge

Staples

Cables 10-foot par allel cable

20-foot par allel cable

50-foot serial cable

10-foot 1284 A-C parallel cable

*Versions are:

A–W810

B–W810n

C–W810dn

1-6 Service Manual

A,B,C

A,B,C

Page 33

4023-001

Printer/Options

Parts Identification

General Information 1-7

Page 34

4023-001

Printer Configuration

The following diagram shows the major parts of the printer and

paper path. The printer consists of the paper feed section, printhead

unit (exposure section), imaging cartridge (charging section and

development section), image transfer section, fusing section,

cleaning section and paper exit section.

1 Paper Exit Roller 12 Double Feed Sensor

2 Paper Exit Sensor (PS3) 13 Tray1 (1st Paper Cassette)

3 Lower Fusing Roller 14 1st Paper Cassette Near Empty Sensor

4 Upper Fusing Roller (Heater Lamp) 15 1st Paper Cassette Empty Sensor (PC4)

5 Image Transfer Roller 16 ATDC Sensor

6 Synchronizing Roller 17 Sleeve Roller

7 Synchronizing Roller Sensor (PC2) 18 P C Drum Charger

8 Manual Unit 19 PC Drum

9 Tray2 (2nd Paper Cassette) 20 Imaging Cartridge

10 2nd Paper Cassette Near Empty Sensor

(PC25)

11 2nd Paper Cassette Empty Sensor (PC22) 22 Laser Beam

(PC5)

21 Print Head Unit (PH)

1-8 Service Manual

Page 35

4023-001

General Des crip tio n of Each Sectio n

Paper Feed Section

Paper feeds from tray 1 (1st paper cassette), tray 2 or 3 (500-sheet

paper cassette). When the printer receives a print command, the

transport motor M2 turns, paper take-up solenoid turns ON, and the

paper take-up roller in the 1st paper cassette feeds a sheet of paper.

The synchronizing roller sensor (PC2) detects the fed paper and the

paper is then fed to the synchronizing roller fo r printing. When paper

trays (500-sheet cassette (tray 2 or 3), 250-sheet universal cassette

(tray 1)), or 2500-sheet drawer is installed, paper feeds from the

respective paper source.

Printhead Unit (Exposure Section)

The laser diode in the printhead unit emits a laser beam. The

scanning beam creates an electrostatic latent image on the surface

of the PC drum in the imaging cartridg e.

Imaging Cartridge (Charging, Development Section)

The imaging car tr idge consist s of the charging section and

development section. The I/C drive motor (M1) drives the moving

parts of the imaging cartridge.

Image Transfer Section (Release Section)

The toner image on the PC drum transfers to the paper when

passing over the transfer roll. The paper electrostatically releases

from the PC drum.

Fusing Section

Using a heated roller , the fusing section permanently fixes the toner

image onto the paper. A heat sensitive element (thermistor)

attached to the upper fusing roller controls the fusing temperature.

Cleaning Section

The cleaning blade removes excess toner from the paper and

transfers the toner to the waste toner box.

General Information 1-9

Page 36

4023-001

Paper Exit Section

After the paper passes the fusing section, the paper exit roller ejects

the paper out the top of the printer. The paper exit sensor (PC3)

senses the ejection of the paper.

Optional manual and duplex unit installed:

The duplex unit switchback motor pulls the trailing edge of the

printed paper inside the duplex unit. The duplex unit transport motor

then feeds the paper to the manual unit where the paper remains

until the second print command.

General Flow for Printing Process

Print command

Polygon Motor ON

Cleaning The transfer roll er becomes negatively

Starting processing The I/C (imaging cartridge) drive motor (M1)

Paper take-up The transport motor (M2) starts turning.

Laser emission A laser beam is emitted at constant power.

Scanning the image dat a

Paper feeding

Dev eloping the image data T one r is applied to the PC drum to produce a

Transfer the image data The toner image on the surface of the PC

Fusing the toner The toner is permanently fixed onto the

Cleaning Excess toner and electric potential on the

Paper ejection The paper ejects.

The motor in the printhead unit starts

turning.

charged to prevent the negat ively-charged

toner from sticking to the PC Drum.

starts turning.

The paper take-up solenoid turns on to feed

paper.

A laser beam scans the sur face of the PC

drum to produce a latent elect rostatic image.

The syc hroniz ing r olle r sen sor (PC2) d etects

the presence of paper. The sychronizing

clutch then turns on which turns on the

sychronizing roller for feeding paper.

visibl e toner image.

drum is transferred onto the paper.

paper.

PC drum are eliminated .

1-10 Service Manual

Page 37

4023-001

Paper Feed Section

Taking Up Paper–Tray 1 (1st Paper Cassette)

Power is transmitted from the transport motor (M2) as follows to take

up paper from the 1st paper cassette:

1. The transport motor (M2) tur n s counterclockwise.

2. The idle gear turns clockwise and the 1st cassette paper takeup solenoid (SL1) turns ON.

3. The paper take-up roller turns counterclockwise and paper is

taken up.

1 PC Drum 5 Synchronizing Roller

2 Image Transfer Roller 6 Paper Take-Up Roller

3 Transport Motor (M2) 7 Paper

4 Synchronizing Roller

Sensor (PC2)

General Information 1-11

Page 38

4023-001

Tray 1 Sensors

1 1st Cassette Paper Near Empty Sensor (PC5) 5 Synchronizing Roller Sensor (PC2)

2 1st Cassette Set Sensor (PC6) 6 Double Feed Sensor

3 1st Cassette Paper Take-up Solenoid (SL1) 7 Paper Take-up Roller

4 Separator Pad 8 1st Paper Cassette Empty Sensor (PC4)

1st Cassette Tray 1 Set Sensor (PC6)

PC6 (1) sensor detects installation of the 1st paper cassette in tray

1.

.

1 1st Cassette Set Sensor (PC6)

2 1st Paper Cassette

1-12 Service Manual

Page 39

4023-001

1st Cassette Tray 1 Paper Empty Sensor (PC4)

PC4 (1) detects paper empty status of the 1st paper cassette.

.

1 1st Paper Cassette Empty Sensor (PC4)

2 Paper

1st Cassette Tray 1 Paper Near Empty Sensor (PC5)

PC5 detects when the 1st cassette is near empty.

1 1st Paper Cassette Near Empty Sensor (PC5)

2 Paper

3 Paper Lifting Plate

General Information 1-13

Page 40

4023-001

1st Cassette Tray 1 Double Feed Sensor

The double feed sensor (located on the double feed detecting

sensor board (PWB-H)) detects the possibility of double feed. This

sensor uses a photo reflector.

The double feed sensor detects whether the leading edge of paper

to be taken up next runs 10 mm or more from the paper nip point. If

paper runs 10 mm or more, double feeding may occur if the paper is

taken up in the normal printing interval. To avoid this, the printer

prolongs the printing intervals as long as the double feed sensor

detects a double feed status. This results in the reduction of the

number of sheets fed per minute.

Light reflects: Output=L Light does not reflect: Output=H

1 Paper

2 Paper Take-up Roller

3 Double Feed Sensor

1st Cassette Tray 1 Synchronizing Roller Sensor (PC2)

This sensor detects that the paper is fed inside the printer.

1 Synchronizing Roller Sensor (PC2)

2 Paper

1-14 Service Manual

Page 41

4023-001

1st Cassette Tray 1 Paper Size Detection

Five DIP switches indicate the paper size for the 1st paper cassette.

Four of the switches indicate length and one width. The DIP

switches are located on the 1st cassette paper size board (PWBS1).

The ON(1)/OFF(2) settings of the length dip switches set the analog

input voltage. The input voltage and the normal input data from the

width dip switch port determine paper size.

The precise paper size cannot be identified by detection and must

be selected from the operation panel.

When no cassette is set, all switches are set to off.

General Information 1-15

Page 42

4023-001

Tray 2 (2nd Paper Cassette)

1 2nd Cassette Paper Empty Sensor (PC22) 4 2nd Cassette Right Door Detecting Sensor

2 2nd Cassette Paper Near Empty Sensor (PC25) 5 Paper Take-Up Roller

3 2nd Cassette Paper Take-up Solenoid (SL21)

(PC23)

Taking up Paper–Tray 2 (2nd Paper Cassette)

Power transmits from the transport motor (M2) as follows to take up

paper from the 2nd paper cassette:

1. The transpor t motor (M2) turns counterclockwise.

2. The idle gear turns clockwise.

3. The 1st cassette paper take-up gear turns counterclockwise.

4. The 1st cassette idle gear turns clockwise and the transport

clutch (CL1) turns ON.

5. Power is transmitted to the 2nd paper cassette.

a. The 2nd cassette paper take-up solenoid (SL21) turns ON.

b. Paper take-up roller turns counterclockwise.

c. Paper is taken up.

1-16 Service Manual

Page 43

4023-001

1 PC Drum 6 Paper

2 Image Transfer Roller 7 Paper Take-up Roller

3 Transport Motor (M2) 8 Transport Clutch (CL1)

4 Synchronizing Roller Sensor

(PC2)

5 Transport Gear

9 Synchronizing Roller

General Information 1-17

Page 44

4023-001

Tray 2 Sensors

2nd Cassette Detection

This sensor detects installation of the 2nd paper cassette in tray 2.

The paper size indicated by the 2nd cassette paper size board

(PWB-S2, -S3) is also checked. The length dip switch setting

determines paper size.

2nd Cassette Paper Empty Sensor (PC22)

PC22 detects the paper empty status of the 2nd paper cassette.

Paper empty status occurs when paper runs out in the 2nd paper

cassette.

1 2nd Cassette Paper Near Empty Sensor (PC22)

2 Paper

1-18 Service Manual

Page 45

4023-001

2nd Cassette Paper Near Empty Sensor (PC25)

PC25 detects paper near empty status of the 2nd cassette.

1 2nd Cassette Paper Near Empty Sensor (PC25) 3 Paper Lifting Plate

2 Paper

2nd Cassette Right Door Detecting Sensor (PC23)

PC23 detects if the 2nd cassette right door is open or closed. The

right door is normally closed except when removing jammed paper.

1 2nd Cassette Right Door Detecting Sensor (PC23)

2 Right Door

General Information 1-19

Page 46

4023-001

Edge Guide and Trailing Edge Stop

Universal Cassette/500-Sheet Tray 2 & 3

The edge guide and trailing edge stop of the universal cassette slide

to accommodate different paper sizes.The edge guide and trailing

edge stop of the fixed paper size cassette are attached in fixed

positions.

Fixed Paper Size Cassette

Paper Lifting Plate

Two paper lifting springs in each cassette constantly raise the paper

lifting plate.

1-20 Service Manual

Page 47

4023-001

Cassette-in-Position Detection

The rib on the cassette frame presses the cassette set switch on the

back panel of the printer, indicating the cassette is inserted. The

position of the rib on the cassette frame is different between the

fixed paper size and universal cassette. This lets the printer detect

which cassette is inserted.

General Information 1-21

Page 48

4023-001

Paper Near Empty Detection

Height of the paper lifting plate determines paper-near-empty

condition. Since the amount of paper available during the take-up

sequence varies, detection occurs when the paper take-up roll is in

the retracted position.

1-22 Service Manual

Page 49

4023-001

Paper Empty Detection

When the cassette runs out of paper, the actuator of the paper

empty sensor drops into the cutout of the paper lifting plate. This

exposes the sensor, signaling that the cassette is out of paper.

General Information 1-23

Page 50

4023-001

Paper Separating Mechanism

Each cassette has fingers that separate the top sheet of paper from

the rest of the paper stack during paper take-up. When the paper

take-up roll starts to turn, the turning force transmits to the top sheet

of paper. The transmitted force overcomes the block of the fingers,

causing the top sheet of paper to ride over the fingers and feed out

of the cassette into the printer. The paper transport force obtained

through friction with the top sheet of paper is weak and does not

allow the second sheet of paper to ride over the block of the fingers.

1-24 Service Manual

Page 51

4023-001

Paper Take-Up Roll

Two paper take-up rolls are mounted in both the fixed paper size

cassette and universal cassette. As the take-up solenoid energizes,

the spring tension increases, meshing the drive and clutch gear

which transmits drive to the paper take-up rolls.

General Information 1-25

Page 52

4023-001

Paper Feed

The paper taken up by the paper take-up section feeds to the

transfer section after registration compensation.

Registration Compensation

Registration compensation eliminates paper skew by controlling the

paper take-up roller and synchronizing roller rotation timing.

The taken-up paper passes the synchronizing roller sensor (PC2)

and reaches the synchronizing roller. The printer delays the

synchronizing roller to align the leading edge of the paper with the

stopping synchronizing roller. The leading edge of the paper slacks

a little as shown in the figure. The synchronizing clutch (CL1)

activates and the paper take-up roller turns for a moment to securely

feed the paper to the inside of the printer.

1 Slack of Paper 4 Synchronizing Roller Sens or (P C2)

2 Synchronizing Roller 5 Paper

3 Transport Motor (M2) 6 Paper Take-up Roller

Paper Feeding

1. The transpor t motor (M2) turns counterclockwise.

2. The idle gear turns clockwise. The synchronizing clutch (CL1)

turns. The I/C drive motor (M1) drives the PC drum.

As the PC Drum turns, the transfer roller also turns.

1-26 Service Manual

Page 53

4023-001

The synchronizing roller feeds paper to the PC drum and transfer

roller. The PC drum and transfer roller pinch the paper and feed it to

the fusing section.

1 PC Drum 4 Synchronizing Clutch (CL1)

2 Image Transfer Roller 5 Paper

3 Transport Roller 6 Synchronizing Roller

General Information 1-27

Page 54

4023-001

Printhead Unit (Exposure section)

The printhead unit incorporates a laser diode that emits a laser

beam corresponding to the print image data.

The scanning laser beam scans the PC drum from left to right,

producing an electrostatic latent image on the surface of the PC

drum.

Imaging Cartridge (Charging/Development Section)

The printer main body I/C drive motor (M1) transmits power to the

gears of the imaging cartridge. The I/C drive motor (M1) turns

clockwise (as viewed from the front of the printer).

1-28 Service Manual

Page 55

4023-001

Part Name Function

1 Waste toner box Collects excess toner.

2 Transf er screw Transfers exc ess toner to the

3 Rotary blade Transfers the waste toner

4 Separating claw Ensures paper release fro m the

5 Cleaning blade Removes excess toner from the

6 Sheet erase Negatively charges the PC Drum

7 PC drum Charged roller that applies image

8 Sleeve roller Transfers toner to the su rface of

9 Screw Mixe s toner and carrier inside the

10 ATDC Sensor Adjusts the toner density.

waste toner box.

collected by the cleaning blade to

the waste toner box.

PC Drum.

PC Drum (waste toner) aft er

transfer to the paper.

to eliminate the remaining elect ric

polarity after tr ansfer to the paper.

to paper.

the PC Drum via a rotating resin

sleeve and then dev elops it.

toner hopper.

11 Toner fil ler opening Toner is supplied from the sub-

hopper.

12 Charger Charges the PC Drum.

General Information 1-29

Page 56

4023-001

Development Section

Development

The development section feeds toner to the electrostatic latent

image on the surface of the PC drum to produce a visible toner

image.

A screw circulates the toner in the toner hopper. The toner mixes

with the carrier to produce the developer. The ATDC sensor detects

the ratio of toner to carrier, and voltage controls the toner density.

The developer is then supplied to the sleeve roller.

The sleeve roller negatively charges the toner. The toner adheres to

the electrostatic latent image due to the reduced negative voltage in

the image area. The toner does not adhere to the area where the

laser beam has not been applied. This occurs because the charge

brush maintains the negatively charged voltage in the non-image

area.

1-30 Service Manual

Page 57

4023-001

1 Laser Beam 4 ATDC Sensor

2 PC Drum 5 Screw

3 Sleeve Roller 6 Developer

General Information 1-31

Page 58

4023-001

Toner Empty Detection

Three empty-toner conditions are detected: sub-hopper empty, toner

bottle near empty, and toner bottle empty.

Sub-Hopper Empty

The toner detection plate lead switch checks the toner level by

detecting the position of the toner detection plate.

The toner bottle supplies toner to the rotating mixing plate. The

rotating mixing plate spreads the toner evenly in the sub-hopper .

The toner pushes upward on the toner detection plate. The position

of the toner detection plate indicates the amount of toner in the subhopper.

A toner empty status occurs when the toner detection plate lowers

enough for the lead switch to detect the plate. However, the lead

switch is not activated when the toner supply motor stops or the

bottle motor rotates. When the sub-hopper empty status occurs, the

bottle motor activates to supply toner to the sub-hopper from the

toner bottle.

.

1 Toner Detection Plate 3 Rotating Mixing Plate

2 Toner Detection Plate Read

Switch

1-32 Service Manual

Page 59

4023-001

Toner bottle near empty

The toner bottle empty status is detected when the toner bottle

rotates and feeds toner to the sub-hopper. The bottle rotation

counter checks the number of bottle rotations. If the number of

rotations exceeds 10, the near empty status occurs. The bottle

supplies toner after the near empty status occurs.

Toner bottle empty

The toner bottle empty status in the imaging cartridge occ urs when

the ATDC sensor detects a toner density (ratio of toner to carrier)

below 10%. When this occurs, the appropriate toner density cannot

be maintained. The bottle motor and toner supply motor stop. The

toner empty status is recorded and will not reset until the toner

cartridge is replaced.

A TDC Sensor

The developer, circulated by a screw, passes over the ATDC sensor.

The sensor measures the ratio of toner to carrier (T/C ratio) in the

developer . This ratio is converted to a charge and input to PWB-A.

When the sensor detects a low T/C ratio, T/C recovery mode begins.

General Information 1-33

Page 60

4023-001

Image Transfer Section (Release Section)

The transfer roller transfers the toner image on the surface of the PC

Drum onto the paper.

Normally the paper separates from the PC drum without any outside

interference. When the paper fails to separate from the PC drum, the

separating claw releases the paper by force.

1 PC Drum

2 Image Transfer Roller

3 Paper

1-34 Service Manual

Page 61

4023-001

Optical Erase

During the optical erase, light from the eraser lamp irradiates the PC

drum, eliminating the negative charge applied by the cleaning blade

during PC drum cleaning. This prevents blac k lines from being

created on the front and rear ends and both sides of the image.

1 Cleaning Blade

2 Optical Erase

General Information 1-35

Page 62

4023-001

Fusing Section

Fusing

Toner-transferred paper feeds from the transfer section to the fusing

section when power from the transport motor (M2) transmits to the

upper fusing roller.

The fusing roller heater lamp (H1, built in the roller) heats the upper