Lexmark 1200 Service Manual

Optra Color 1200

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

TM

5050-001

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

5050-001

First Edition (October, 1998)

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTERNATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED,INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULARPURPOSE. Some states do not

allow disclaimer of express or implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22/035-3,

740 New Circle Road N.W., Lexington, Kentucky 40550, U.S.A. Lexmark may use or

distribute any of the information you supply in any way it believes appropriate without

incurring any obligation to you. You can purchase additional copies of publications related

to this product by calling 1-800-553-9727. In other countries, contact your point of

purchase.

Lexmark,FontVision, MarkVision, and Optra are trademarks of Lexmark International,

Inc., registered in the United States and/or other countries.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 1998.

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

5050-001

Contents

SafetyInformation.......................................ix

Safety Notice ...........................................ix

GeneralInformation....................................1-1

Maintenance Approach ................................1-1

Tools ..............................................1-1

Serial Number .......................................1-2

Abbreviations .......................................1-3

Standard Features ....................................1-4

Options.............................................1-5

Printer Supplies ......................................1-6

Cross Section of Printer ................................1-6

Operational Theory ......................................1-8

Electrophotographic Process ............................1-8

Photoconductor Drum ................................1-10

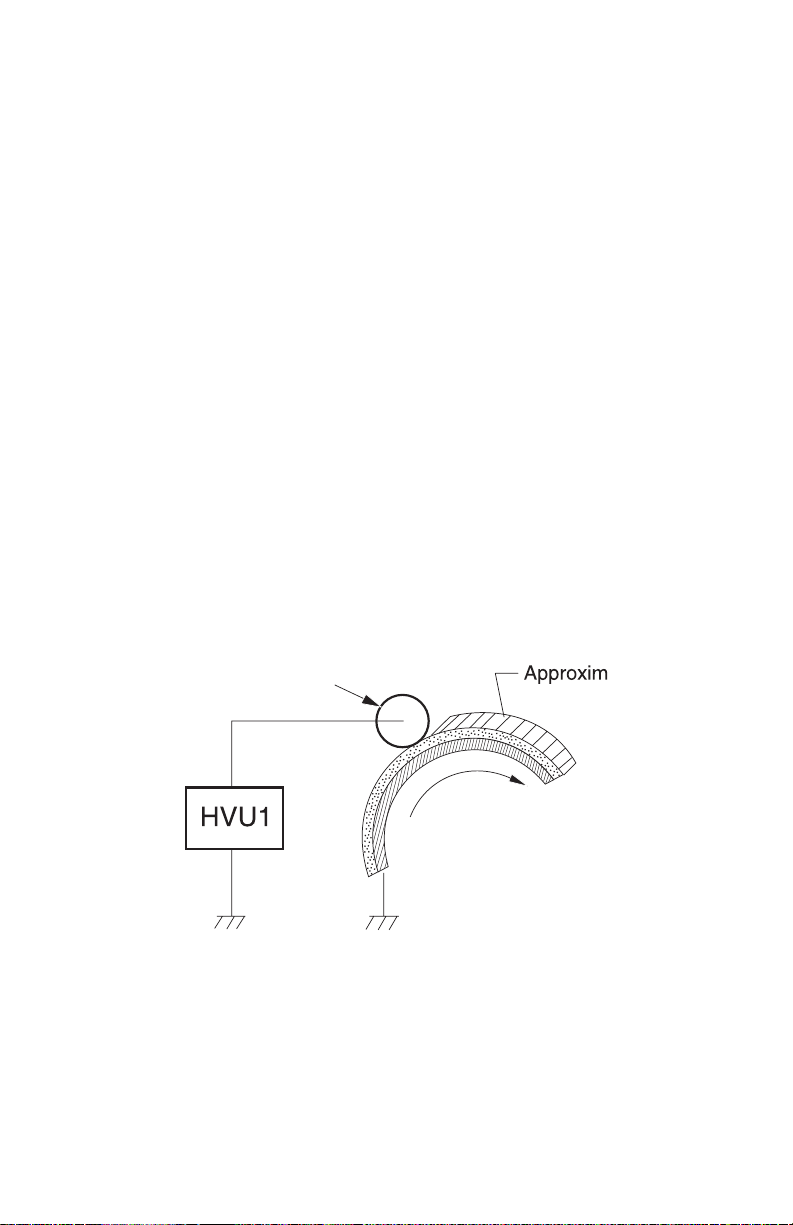

Electrical Charge Unit ................................1-10

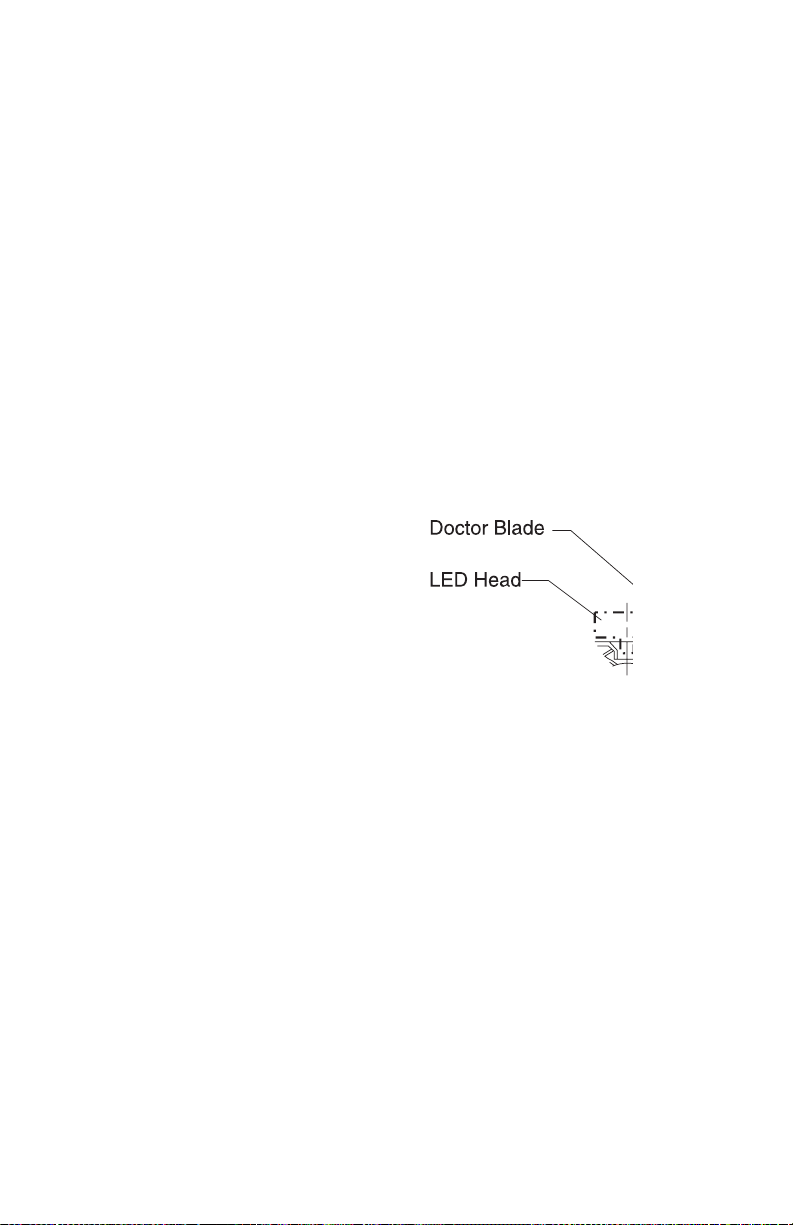

Exposure Assembly ..................................1-11

Developer Assembly .................................1-11

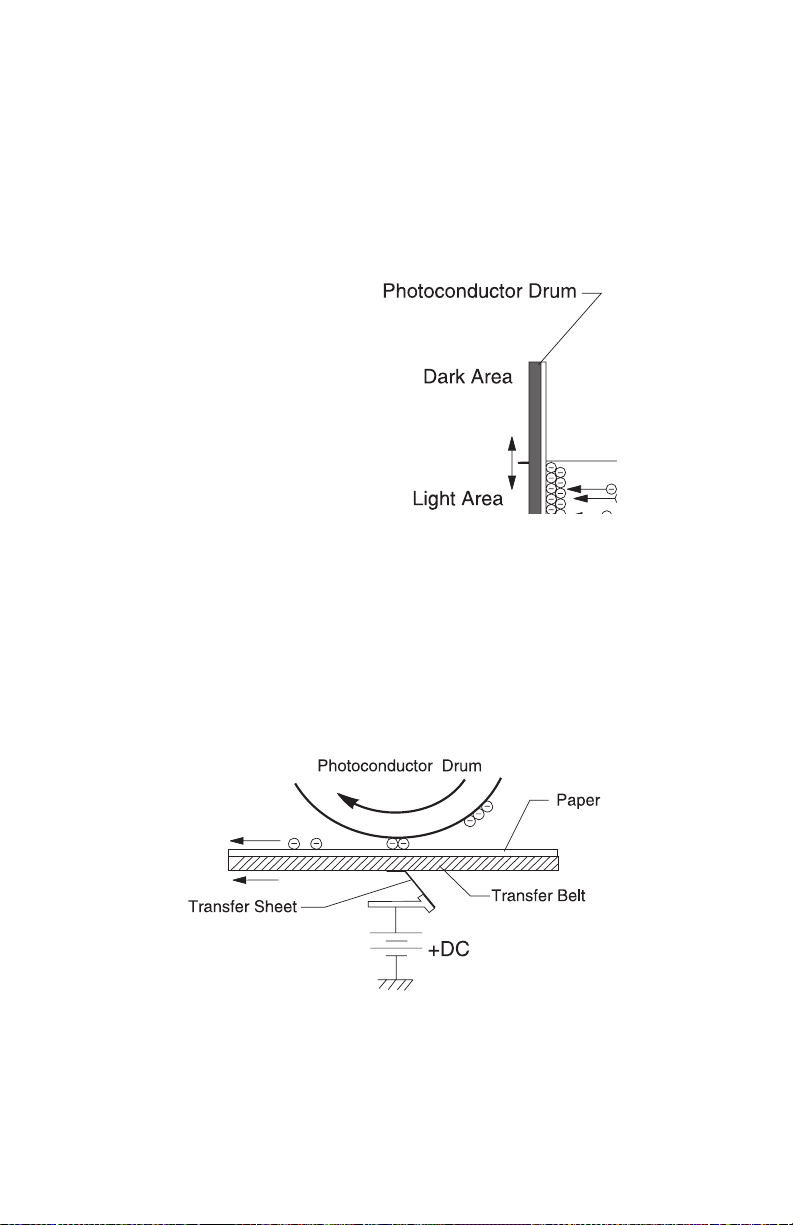

Transfer Assembly ...................................1-12

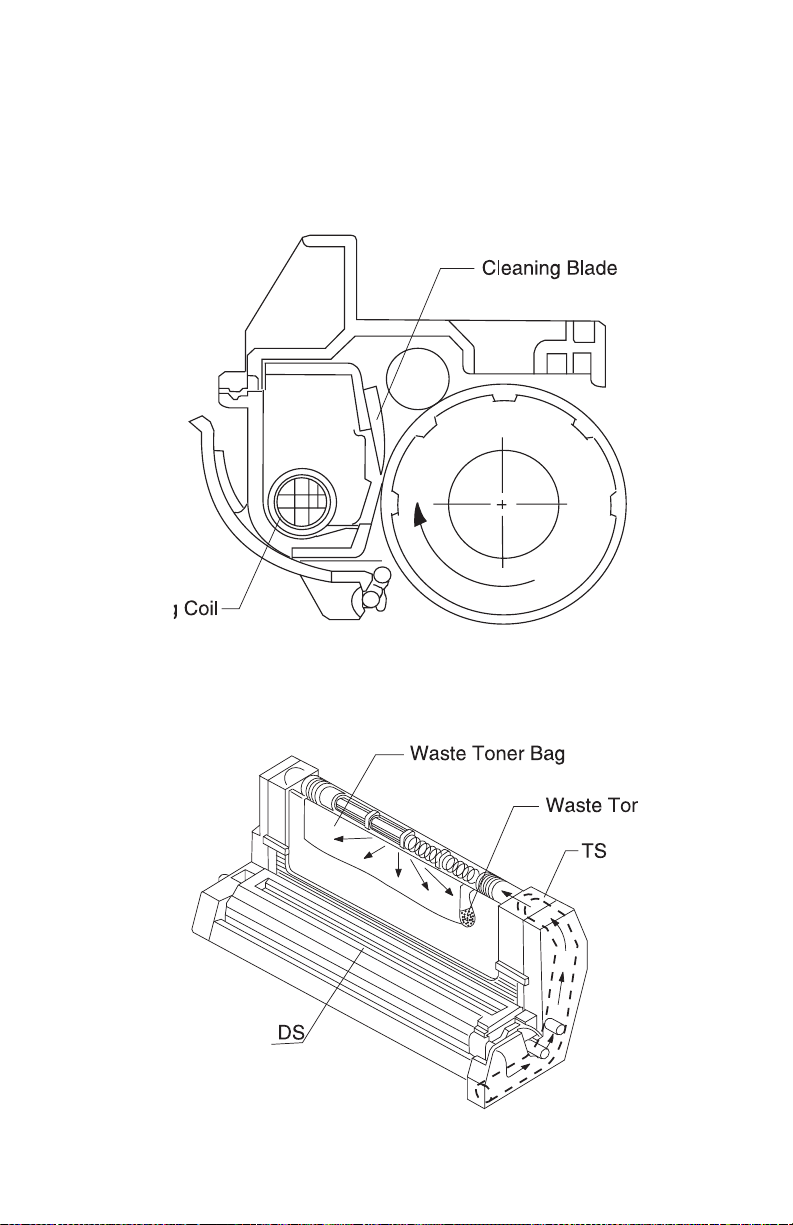

Cleaning Assembly ..................................1-13

Paper Feed, Transfer, and Fusing .......................1-14

Print Modes ........................................1-26

Clearing Paper Jams ...................................1-27

Printing From the Multipurpose Feeder ...................1-28

DiagnosticInformation .................................2-1

Part Numbers........................................2-1

Adjustments and Procedures Following Parts Replacement....2-1

Start .................................................2-2

Initial Check .........................................2-2

Printer Messages .......................................2-3

Service Error Message Table............................2-4

Status Messages ....................................2-11

Attendance Messages ................................2-14

Symptom Table .....................................2-24

Service Checks .......................................2-28

Fuser Service Check .................................2-28

Color Print Unit Missing Service Check ...................2-29

Drive 1 DC Motor Service Check........................2-29

Drive 2 Stepper Motor Service Check ....................2-30

iii

5050-001

Transport Belt/BUD Service Check.......................2-30

Optional Paper Feed Service Check......................2-31

Paper Jam Service Check..............................2-31

Paper Carrying Service Check ..........................2-33

Paper Exit FU/FD Service Check ........................2-35

Paper Low/Empty Tray 1, 2, 3 Service Check...............2-36

Paper Tray Missing/Size Service Check ...................2-36

Remove Paper Sensor Service Check ....................2-37

Power Supply Service Check ...........................2-37

Marks on Paper Service Check..........................2-38

Image Quality Troubleshooting ............................2-39

Print Quality Problems.................................2-39

Sensor Service Check ................................2-46

DiagnosticAids ........................................3-1

Power-On Self Test Sequence ...........................3-1

Using the Operator Panel ...............................3-2

Operator Panel Buttons.................................3-3

Printing the Menu Settings ..............................3-4

Operator Menu Disabled ...............................3-4

Menu Overview .......................................3-4

Diagnostic Mode ......................................3-6

Diagnostic Menu Group ................................3-6

Setting Printer top Margin ..............................3-10

Color Calibration of Printer .............................3-13

Print Tests ...........................................3-15

Input/Output Source Print Tests .........................3-15

Print Quality Pages ...................................3-16

LCD Hardware Test...................................3-17

Button Test .........................................3-17

DRAM Memory Test ..................................3-17

Std Parallel Wrap Test and Parallel X Wrap Test ...........3-18

Serial Wrap Tests ....................................3-19

Quick Disk Test .....................................3-20

Disk Test/Clean .....................................3-21

Setting the Page Count ...............................3-23

Viewing the Permanent Page Count .....................3-23

Viewing and Resetting the Drum Counters ................3-24

Calibrating the Transparency Sensor .....................3-24

Viewing the Error Log .................................3-25

Clearing the Error Log ................................3-26

US / Non-US ........................................3-27

Exiting Diagnostics Mode ..............................3-27

iv Service Manual

5050-001

Test Print 1.........................................3-28

Test Print 2.........................................3-29

RepairInformation.....................................4-1

Precautions for Disassembly and Cleaning ................4-1

Handling the Printed Circuit Boards with MOS ICs ...........4-1

Precautions for Handling the Drum Cartridge ...............4-2

Parts not to be touched ................................4-3

Adjustment Procedures ..................................4-3

Transfer Belt Tracking Adjustment .......................4-3

Thermistor Rank Adjustment ............................4-5

LED Head Light Quantity Adjustment .....................4-5

Top Margin for Color Mode .............................4-5

Top Margin for Black and White Mode ....................4-6

Overhead Projection Sheet Detection Sensor Adjustment .....4-6

Printhead Adjustments (X, Y, and Theta) ..................4-6

Removal Procedures ...................................4-10

LED Head Removal .................................4-10

Transfer Belt Unit Removal ............................4-11

Paper Remaining Sensor Removal ......................4-12

Belt Unit Drive Frame, BUD Motor, BUD Sensor Removal ....4-12

Engine Board (PG14 ENG BB) Removal..................4-14

Cover Removals.....................................4-15

Head Controller Board (P614 HDCONT) Removal ..........4-21

Operator Panel Removal ..............................4-22

MPF Removal ......................................4-23

Paper Feed Roller Removal ...........................4-24

MPF Roller .........................................4-25

FPadRemoval .....................................4-26

Registration Sensor Removal ..........................4-26

MPF Paper Empty Sensor Removal .....................4-27

Humidity Sensor Removal .............................4-27

Printer Controller (614 PRCONT) Removal ...............4-28

HVU1(U) Removal ..................................4-29

Drive 2 (U) and Face Up/Face Down (FUD) Solenoid Removal 4-29

Fuser Removal .....................................4-30

Fuser Thermostat, Fuse, and Thermistor Removals .........4-34

Fuser Press Roller Removal ...........................4-37

Fuser Pawl Removal .................................4-39

Fuser Heater Removal ...............................4-42

Fuser Heat Roller and Gear H, Gear 30 Removal ..........4-44

Heater Drive Board, 230 V Only ........................4-45

HVU 2 Removal ....................................4-46

v

5050-001

Power Supply Switch Removal .........................4-46

Power Supply Board (P614-MPS) Removal ................4-47

Size Sensor Board (P611-PSZ) Removal .................4-48

Toner Remaining Sensor, Drum Gear Sensor Removal.......4-48

Drive 1 Removal .....................................4-50

Drum Drive Gear Sensor (P614-DGS) Removal ............4-51

Registration Roller Removal ............................4-52

OHP Sensor Removal ................................4-57

Paper Exit Sensor Removal ............................4-59

Output Bin Full Sensor Removal ........................4-59

RIP Controller Card Removal ...........................4-61

Paper Face Up/Face Down (FUD) Delivery Sensor Removal . .4-61

Optional Paper Feeder Removal Procedures .................4-62

Outer Cover Removal .................................4-62

Size Sensor Board (P611-PSZ) Removal .................4-63

Drive Board (P614-2/3 DRIV) Removal ...................4-64

Paper Feed Motor 2 (PM42) Removal ....................4-64

Paper Feed Roller Removal ............................4-65

Paper Remaining Sensor Removal ......................4-66

Paper Feed Clutch, Solenoid, and Transfer Roller Removal . . .4-67

ConnectorLocations....................................5-1

Paper Handling .......................................5-1

Cross Section of Printer ................................5-2

Electronic Board Layout ................................5-4

Electrical Components .................................5-5

Sensors.............................................5-6

Power Supply Board (614-MPS-E) ........................5-7

High Voltage Unit 1 Board (614-HVU1).....................5-8

High Voltage Unit 2 Board (P614-HVU2) ...................5-9

Optional Paper Feed Controller Board (P614-2/3 DRIV) ......5-10

Printhead Controller Board (P614-HD CONT) ..............5-11

Printer Controller Board (P614-PRCONT) .................5-12

Size Sensor Board (P611-PSZ) .........................5-13

RIP Controller Card ..................................5-14

Preventive Maintenance .................................6-1

Maintenance Kit ......................................6-1

Periodic Maintenance ..................................6-2

Lubricants and Cleaners ...............................6-2

PartsCatalog ..........................................7-1

How to Use This Parts Catalog ............................7-1

Assembly 1: Covers ......................................7-2

vi Service Manual

5050-001

Assembly 2: Paper Exit...................................7-6

Assembly 3: Upper Unit ..................................7-8

Assembly 4: Base 1.....................................7-14

Assembly 5: Base 2.....................................7-18

Assembly 6: Feeder ....................................7-26

Assembly 7: Electrical...................................7-30

Assembly 8: I/F Controller................................7-36

Assembly 9: Fuser......................................7-38

Assembly 10: Cassette ..................................7-42

Assembly 11: Optional Feeder Base........................7-44

Assembly 12: Optional Feeder Paper Feed ..................7-50

Assembly 13: Optional Features...........................7-52

vii

5050-001

viii Ser vice Manual

5050-001

Safety Information

Safety Notice

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not

always be obvious. Lexmark is not responsible for the use of

other replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injur y during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation

d'autres pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Safety Information ix

5050-001

• Il prodotto è stato progettato, testato e approvato in

conformità a severi standard di sicurezza e per l’utilizzo con

componenti Lexmark specifici. Le caratteristiche di sicurezza

di alcune parti non sempre sono di immediata comprensione.

Lexmark non è responsabile per l’utilizzo di par ti di ricambio

di altri produttori.

• Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale di assistenza

autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit

gültigen Sicherheitsanforderungen zu erfüllen. Die

sicherheitsrelevanten Funktionen der Bauteile und Optionen

sind nicht immer offensichtlich. Sofern Teile eingesetzt

werden, die nicht von Lexmark sind, wird von Lexmark

keinerlei Verantwortung oder Haftung für dieses Produkt

übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

x Service Manual

5050-001

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede

que las características de seguridad de algunas piezas no

sean siempre evidentes. Lexmark no se hace responsable

del uso de otras piezas de recambio.

• La información sobre el mantenimiento de este producto

está dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existemayorriesgodedescargaeléctricaydedaños

personales durante el desmontaje y la reparación de la

máquina. Elpersonal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

• Este produto foi concebido, testado e aprovado para

satisfazer os padrões globais de segurança na utilização de

componentes específicos da Lexmark. As funções de

segurança de alguns dos componentes podem não ser

sempre óbvias. A Lexmark não é responsável pela utilização

de outros componentes de substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto.Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Safety Information xi

5050-001

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest

producte. El personal professional ha d’estar-ne assabentat i

prendre les mesures convenients.

xii Service Manual

5050-001

Safety Information xiii

5050-001

xiv Ser vice Manual

5050-001

1. General Information

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, and service checks to determine the symptom and

repair the failure. You may find that the removals in the Repair

Information chapter will help you identify parts.

After you complete the repair, perform tests as needed to verify the

repair.

Tools

The removal and adjustment procedures described in this manual

require the following tools and equipment:

• Magnetic tip Phillips screwdrivers, large and small

• Flat-blade screwdrivers

• Analog volt ohmmeter (a digital volt ohmmeter may also be

used)

• Needle nose pliers

• Tweezers, C-ring pliers

• Magnifier (10 times or equivalent)

• 6-angle wrench (1.5 mm).

When you make voltage readings, always use frame ground unless

another ground is specified.

General Information 1-1

5050-001

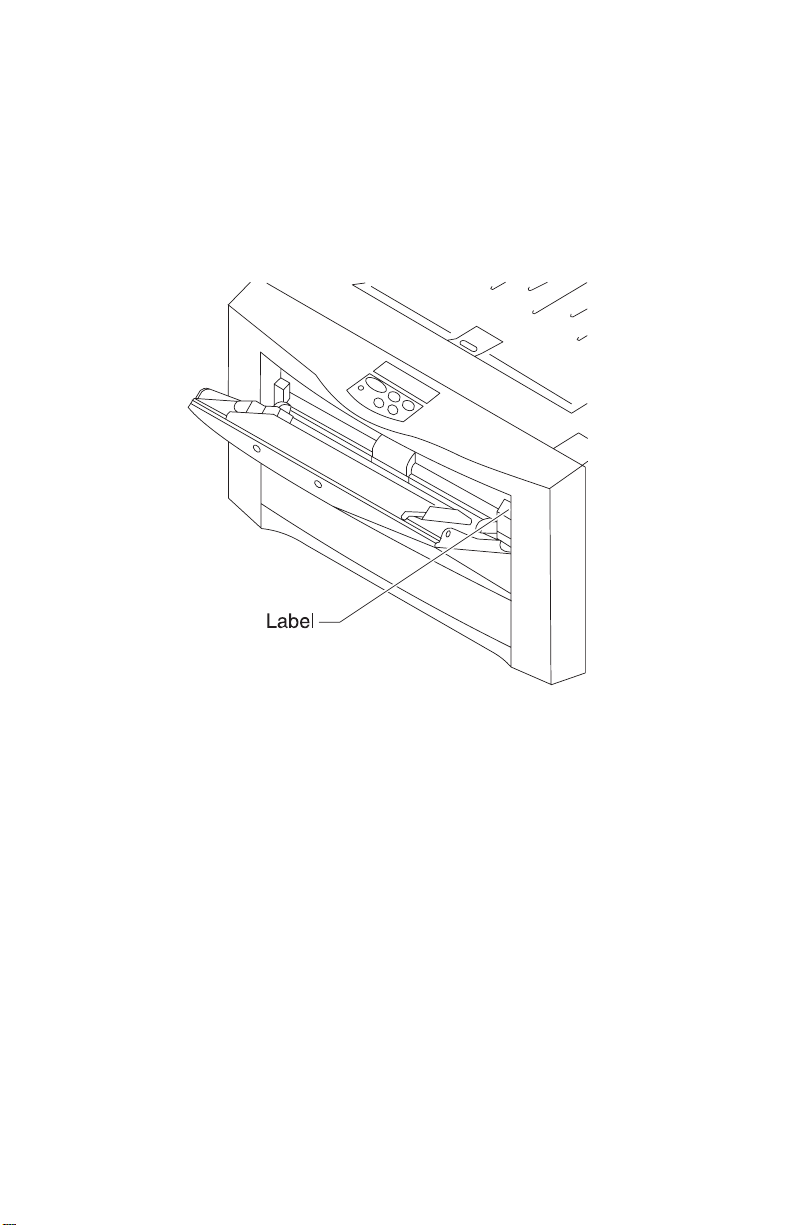

Serial Number

Lower the multipur pose feeder and refer to the label on the right.

The serial number is also listed on the menu settings page you can

print from the Tests Menu.

1-2 Service Manual

5050-001

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EEPROM Electrically Erasable Programmable Read-

Only Memory

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PICS Problem Isolation Charts

PIXEL Picture Element

POR Power-On R eset

POST Power-On Self Test

PQET Print Quality Enhancement Technology

RIP Raster Image Processor

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

VAC Volts alternating current

VDC Volts direct current

General Information 1-3

5050-001

Standard Features

Print method Dry electrophotographic process using LED printheads

Print

addressability

Maximum print

speed

Fonts 1. 75 resident scalable fonts:

Paper input • 250-sheet tray

Paper output • Top output bin: 250 sheets (collated)

Paper sizes

supported

Printer memory 32MB (two 16MB 50 ms EDO SIMMS)

600 dpi

• 12 ppm (letter and A4 paper) (Color)

• 12 ppm (Mono)

• PostScript Level 2 emulation: 39 Optra compatible plus

36 additional

• PCL emulation: 45 LaserJet compatible plus

30 additional

2. PCL bitmap fonts:

• LinePri nter

•POSTNETBarcode

3. FontVision

4. World class international font support:

• 77 symbol sets, including support for

• Canadian, French, Brazilian,

• Portuguese, Cyrillic, and Greek

• Multipurpose feeder

• Rear output bin: 100 sheets (uncollated)

A4, A5, JIS B4, JIS B5, A3, letter, legal, 11 x 17

Some printer models may ship with more memory.

TM

font manager utility with 110 fonts

Flash memory 4MB (for permanent storage of fonts, logos, and forms)

Interface Parallel (standard Centronics protocol that complies with

bidirectional IEEE 1284B)

Internalsolutions

ports

Printer software MarkVision

• 2 ports for network adapters, tri-port adapters, or

parallel port adapters

• 1 connector for hard disk

• 2 pairs of memory connectors

TM

utility that lets you manage your printer

from your computer. Supported in the following

environments: Windows 95, Windows NT 4.0,

Windows 3.1x, OS/2 Warp, Macintosh, UNIX.

1-4 Service Manual

5050-001

Options

Optional drawer Support unit and 250-sheet tray; up to two drawers may

be installed underneath the printer

250-sheet tray Replacement tray

Memory • 32MB option (two 16MB memory cards)

• 64MB option (two 32MB memory cards)

• Maximum installed memory: 128MB

Hard disk option 2.5-inch hard disk to store fonts, forms, job statistics, and

Hard disk

adapter ribbon

cable

MarkNet S

internal network

adapters

Tri-port adapter Provides support for the following interfaces:

Parallel port

adapter

Infrared adapter For use with the tri-port adapter; receives infrared beam

Serial interface

adapter

Parallel cables High speed bidirectional 10-foot and 20-foot 1284-B

spooled jobs

For installing compatible Lexmark or third-party hard

disks

Adapters available to support the following topologies:

• Ethernet 10BaseT and 10Base2

• Ethernet 10/100BaseTX

• Token-Ring (connects the printer to a Token-Ring

network via DB9 or RJ45)

• Serial RS-232C/RS-422A (which can also be

configured to support a class 1 fax modem)

• High speed Infrared local connections

• LocalTalk network connection

Provides additional parallel port

from an IrDA-compatible workstation

Converts the printer’s parallel port to a serial port

parallel cables; 9.8-foot 1284 A-C parallel cable

Serial cable 50-foot serial cable

General Information 1-5

5050-001

Printer Supplies

Toner cartridges Black, magenta, cyan, or yellow

cartridges

Photoconductors • Black photoconductor (with fuser

coating roll)

• Cyan, magenta, and yellow

photoconductors (packaged

together)

Transparencies A4 and letter size

6,500 pages each

(5% coverage)

13,000 pages each

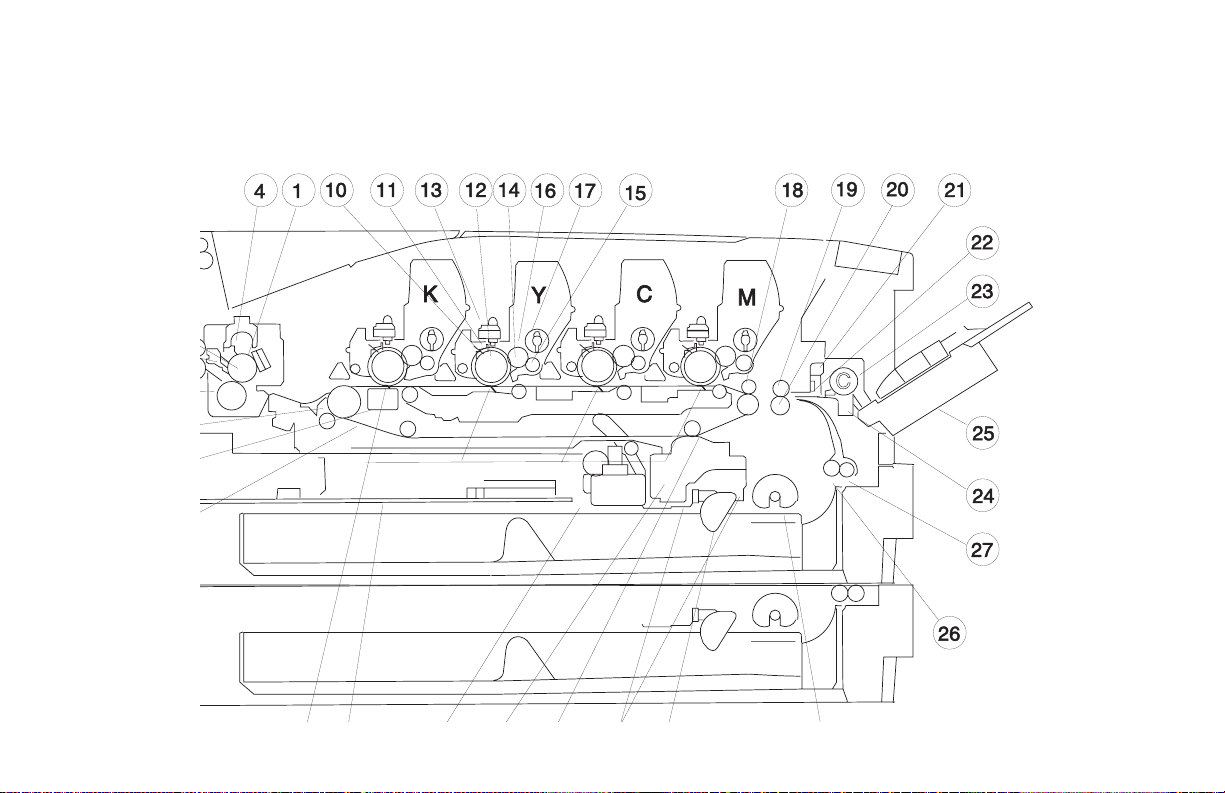

Cross Section of Printer

1 FuserRoller 18 Absorption Roller

2 PressRoller 19 Registration Upper Roller (Metal)

3 Heater 20 Registration Roller (Rubber)

4 FuserOil Roller 21 Registration Sensor

5 Paper Exit Sensor Lever 22 Registration Sensor Lever

6 Belt Drive Roller 23 MPF Roller

7 BeltThermistor 24 Feeder Friction Stop Pad

8 Transfer Belt 25 MPF Assembly

9 Transfer Sheet 26 Paper Carrying Roller

10 Cleaning Blade 27 Paper Noise-Cut Roller

11 Charging Roller 28 Pick-up Paper Feed Roller

12 Photoconductor Drum 29 Paper Remaining Detection

Lever

13 LED Printhead 30 Paper Remaining Detection

Sensors

14 DevelopmentRoller 31 Transport Belt Blade

15 DeveloperSupply Roller 32 Transport Belt Waste Bottle

16 DeveloperDoctor Blade 33 Belt Unit Drive Motor

17 DeveloperAgitator 34 Interface RIP Controller Card

1-6 Service Manual

5050-001

General Information 1-7

5050-001

Operational Theory

This printer makes a color image by overlapping each color toner in

dot units and fusing them to the paper. The process is divided into

two steps. The first step is the electrophotographic process which

forms the image on the PC. The second step consists of Feeding,

Transferring, Fusing which feeds the paper, transfers the image to

the paper and fuses the toner.

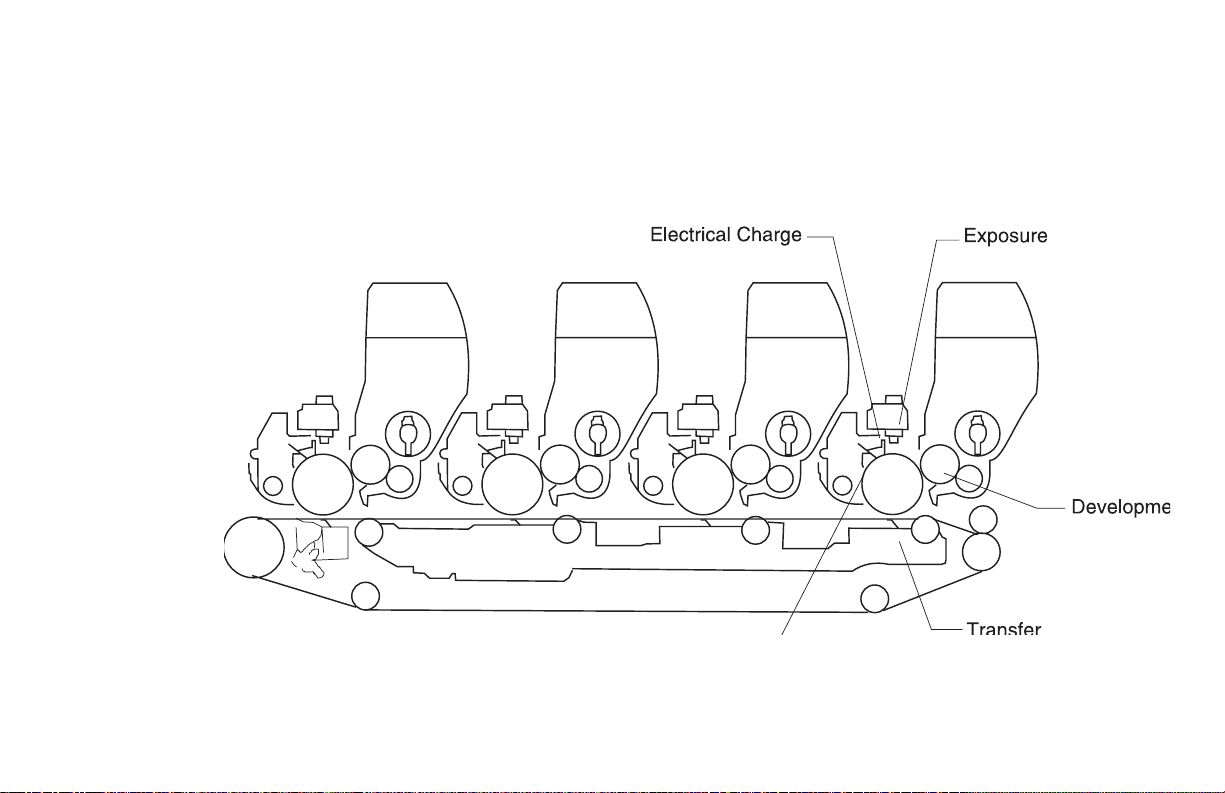

Electrophotographic Process

As the photoconductor drum rotates it is electrically charged, the

image is exposed to the PC drum, the image is developedwith toner,

the image is transferred to the paper, and the PC drum is cleaned.

1-8 Service Manual

5050-001

General Information 1-9

5050-001

Photoconductor Drum

The photoconductor drum uses aluminum as the base material and

a layer of organic photo conductor (OPC) on the surface. A

characteristic of this layer is that only the part that the light shines on

becomes conductive.

Electrical Charge Unit

The charge roller of the electrical charge unit evenly charges the

surface of the drum. The static latent image forms on the photosensitive drum.

1-10 Ser vice Manual

5050-001

Exposure Assembly

The exposure assembly uses an LED head to form an electrostatic

image by emitting light onto the charged drum. The length of time

the light is on is contained in non-volatile memory (EEPROM) in the

printer controller because the light emitting time of each LED is

different in every head. When the LED head is replaced, the light

emitting time must be reset. If you replace the LED head, be sure to

also replace the EEPROM.

Developer Assembly

The toner agitator stirs the toner in the cartridge.The toner supply

roller provides toner to the development roller.The doctor blade is

pressed to the development roller which is conductive rubber.

As the development roller rotates, toner feeds between the

developer roller and the doctor blade. This friction charges the toner

negatively. As the toner comes in contact with the photoconductor

drum, it sticks to the electrostatic latent image.

General Information 1-11

5050-001

Transfer Assembly

Paper is held to the transfer belt electrostatically. The belt rotates at

the same speed as the photoconductor drum. The absorption roller

applies a positive charge to the paper. T he toner formed on the

photoconductor drum transfers to the paper because of the positive

charge from the transfer sheet under the transfer belt.

1-12 Ser vice Manual

5050-001

Cleaning Assembly

The cleaning blade scrapes off the remaining toner on the

photoconductor drum after the toner image has been transferred to

the paper.

A rotating coil in the waste toner conveyance assembly conveys the

scraped-off toner to the waste toner bag.

General Information 1-13

5050-001

Paper Feed, Transfer, and Fusing

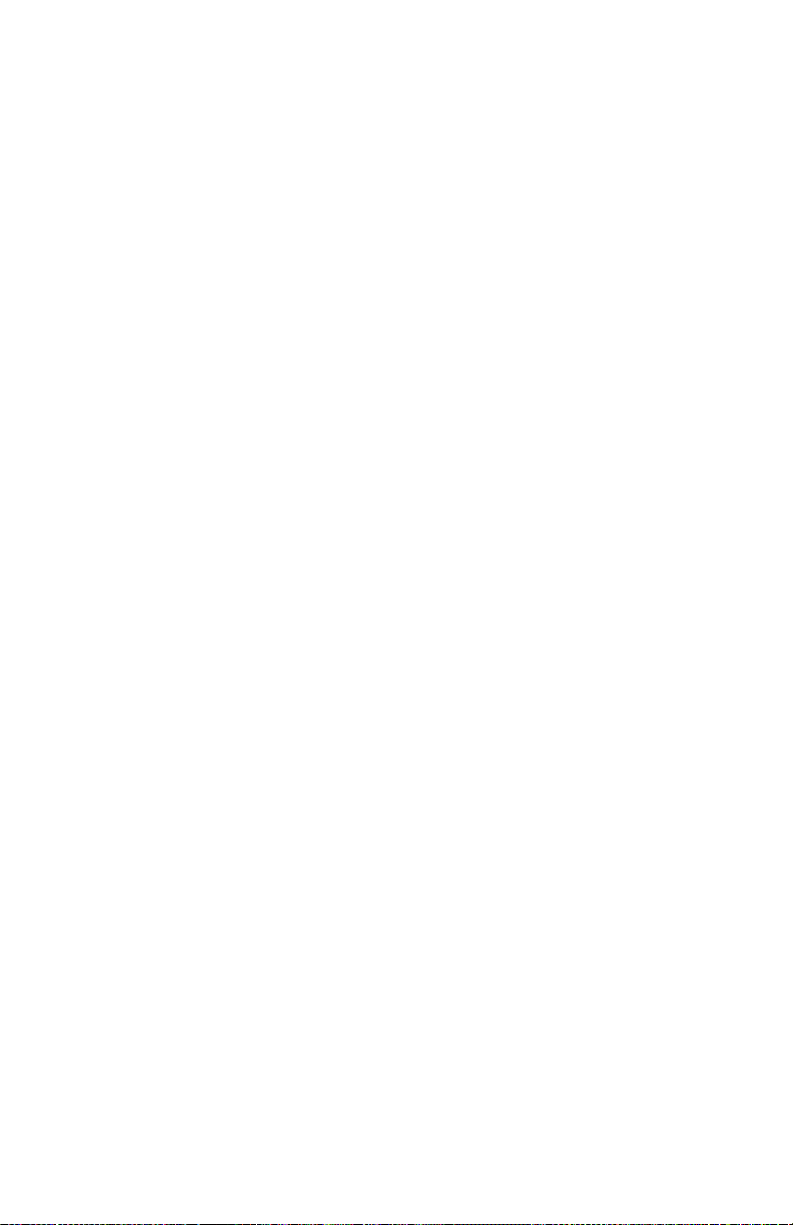

Two drives perform the entire paper feed in this printer, drive 1 and

drive 2. There is a separate motor in the second paper feeder to

drive the paper feed.

Drive 1

Drive 1 consists of a brush-less dc motor and gear unit. Drive 1

carries paper from the paper feed unit to the registration unit and

also drives the electrophotographic process. The motor starts

running after it receives an ON signal from the printer controller.The

motor then sends a synchronizing signal to the printer controller.

When monochrome mode is selected, clutch 2 interrupts the

electrophotographic process for color printing.

Do not disassemble the gears in drive 1 because the phase

adjustment has been preset. Do not turn the PC when it is out of the

machine as the gears will lose timing to work as a matched set.

Drive 2

Drive 2 consists of a hybrid stepping motor and gear assembly. It

drives the fuser and exit assembly. There is no synchronizing signal

for this motor.

1-14 Ser vice Manual

5050-001

General Information 1-15

5050-001

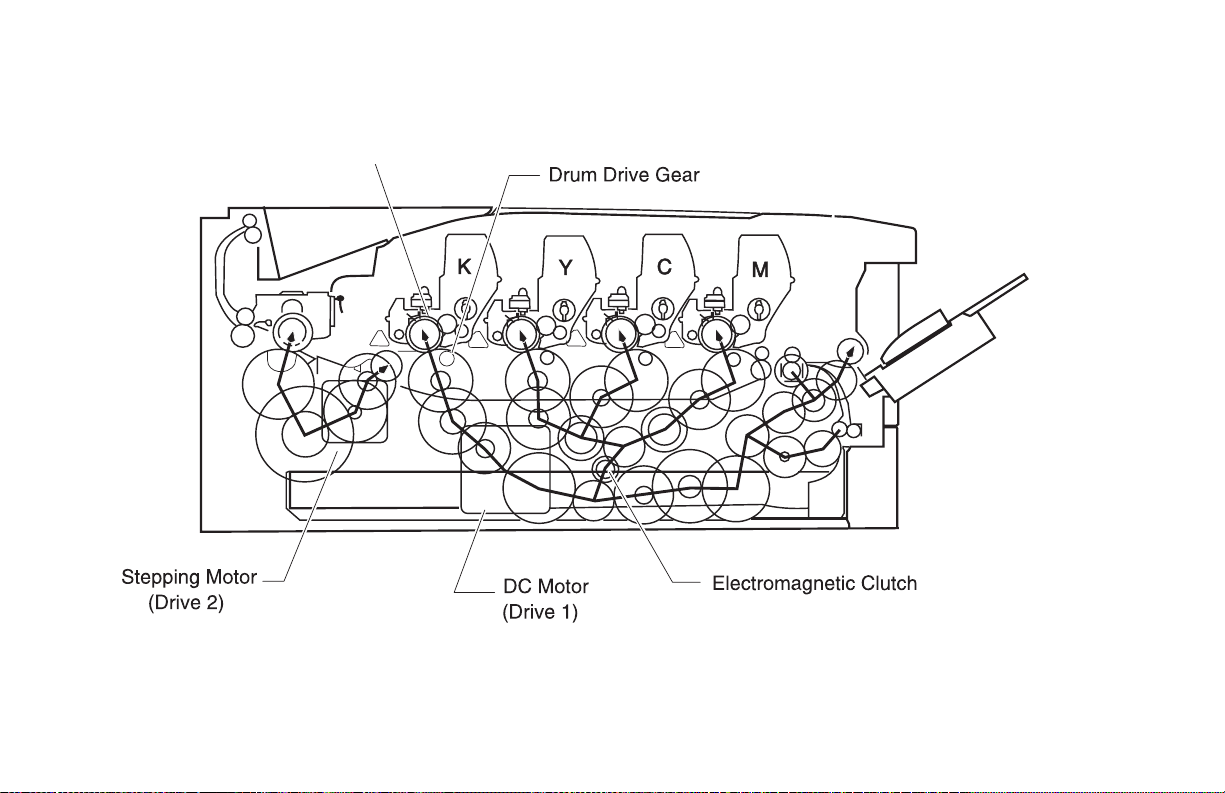

Paper Cassette Feeder

The printer controller sends a signal to the paper feed solenoid

which turns on and drives the paper feed roller connected to drive 1

by a spring clutch. The paper in the cassette is picked one sheet at a

time.

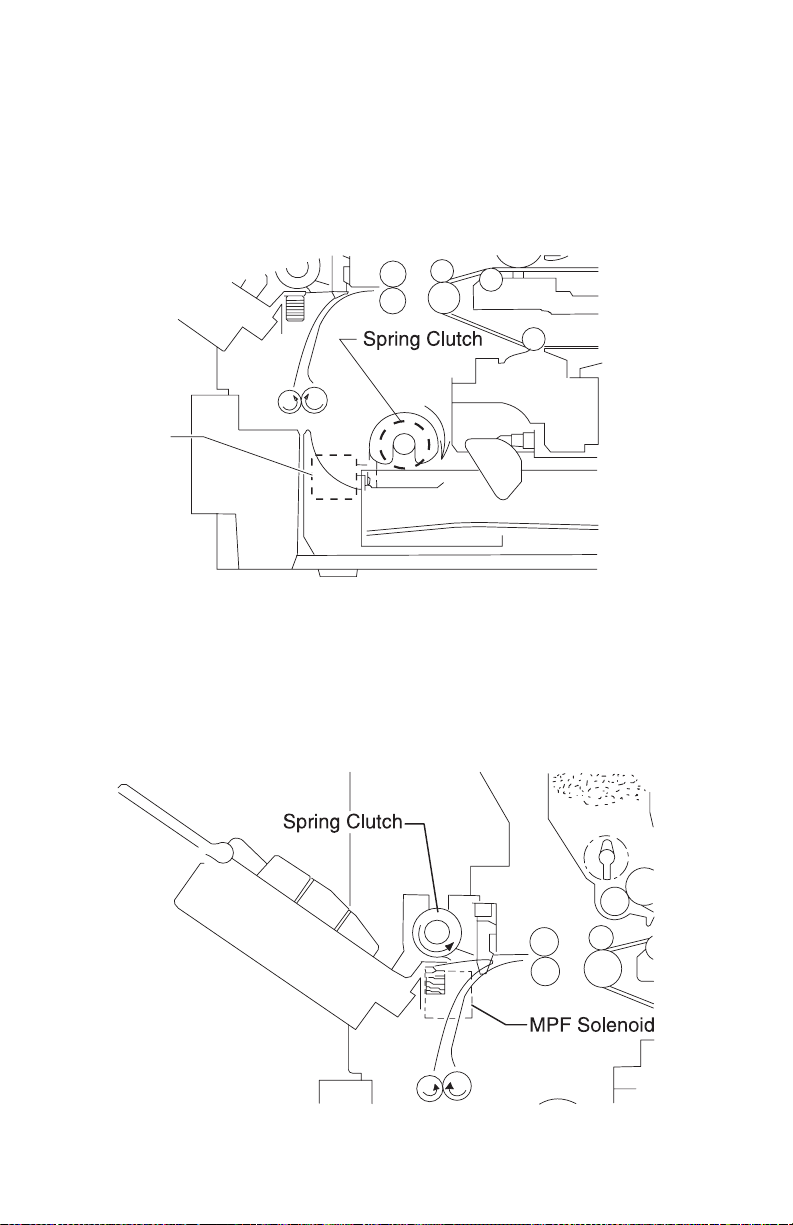

Multipurpose Feeder

After it r eceives a signal from the printer controller,the MPF solenoid

turns on and drives the MPF roller connected to drive 1 by a spring

clutch. The paper in the multipurpose feeder is picked up one sheet

at a time.

1-16 Ser vice Manual

Loading...

Loading...