Page 1

Lexium Servo Drive

17D Series

User Guide

Version 2.0 June 2003

31001643_K01_000_04

Page 2

Page 3

Preface

Preface The data and illustratio ns found in this bo ok are not bindi ng. We reserv e the right to

modify our products in line with our policy of continuous product development. The

information in this document is subject to change without notice and should not be

construed as a commitment by Schneider Electric.

Schneider Electric assum es no res po ns ibi lit y for any e rrors that m ay appe ar in this

document. If you have any suggestions for improvements or amendments or have

found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means,

electronic or mechanical, including photocopying, without express written

permission of the Publisher, Schneider Electric.

CAUTION!

All pertinent state, regional, and local safety regulations must be observed when

installing and using this product. For reasons of safety and to assure compliance

with documented s ystem dat a, repai rs to c ompo nents shou ld be performed only by

the manufacturer.

Failure to observe this precaution can result in injury or equipment damage.

MODSOFT® is a registered trademark of Schneider Electric

The following are trademarks of Schneider Electric:

Modbus Modbus Plus Modicon 984 Quantum

DIGITAL® and DEC® are registered trademarks of Compaq Computer Corp.

IBM® and IBM AT® are registered trademarks of International Business Machines

Corporation.

Microsoft® and MS-DOS® and Windows® are registered trademarks of Microsoft

Corporation.

©Copyright 2003, Schneider Electric

890 USE 120 00 iii

Page 4

Preface

iv

890 USE 120 00

Page 5

Contents

Chapter 1 - Introduction 1

At a Glance...................................................................................................... 1

Document Scope ....................... ...... ...... ..... ...... ........................................ 1

What’s in this Chapter ............................................................................... 1

About this User Guide .................................................................................... 2

Who Should Use this User Guide ............................................................. 2

How this User Guide Is Organized ............................................................ 2

Related System Components ......................................................................... 4

Single-Axis Motion Control System ........................................................... 4

UniLink Commissioning Software for 17D ................................................ 4

Related Documentation .................................................................................. 5

Documents ................................................................................................ 5

Hazards, Warnings and Guidelines ................................................................ 6

Hazards and Warnings ............................................................................. 6

Additional Safety Guidelines ..................................................................... 9

Qualified Personnel ................................................................................... 9

Standards and Compliances ............................ ...... ........................................ 10

European Directives and Standards ......................................................... 10

EC Directive Compliance .......................................................................... 10

UL and cUL Compliance ........................................................................... 11

Conventions .................................................................................................... 12

Acronyms and Abbreviations .................................................................... 12

890 USE 120 00 v

Page 6

Contents

Chapter 2 - Product Overview 15

At a Glance...................................................................................................... 15

Introduction ............................................................................................... 15

What’s in this Chapter ............................................................................... 15

The 17D Series Servo Drive Family ............................................................... 16

Introducing the 17D Drive Family ............................................................. 16

Drives Available ..................................... ..... ...... ...... .................................. 16

Implementing the Drives ........................................................................... 16

Applicable Servo Motor Types .................................................................. 16

Connection to different mains supply networks ........................................ 17

Electrical Considerations .......................................................................... 18

17D Drive Family Portrait .......................................................................... 19

17D Drives Front View .............................................................................. 20

Equipment Supplied .................................................................................. 21

Equipment Available ................................................................................. 21

17D System Configuration Diagram ......................................................... 22

Overview of Usability Features........................................................................ 23

Digital Control ........................................................................................... 23

Usability Enhancements ........................................................................... 24

Restart lock -AS- (A00 drives only) ........................................................... 25

Overview of 17D Internal Electronics.............................................................. 26

17D Internal Electronics Block Diagram ................................................... 26

General Characteristics ............................................................................ 27

Primary Power .......................................................................................... 27

Bias Power ................................................................................................ 27

EMI Suppression ............................. ...... ..... ...... ...... .................................. 27

Internal Power Section .............................................................................. 28

DC Link Capacitor Reconditioning ............................................................ 28

Integrated Safe Electrical Separation .......................... ...... ..... ...... ...... ...... 28

LED display ............................................................................................... 29

Overview of System Software ........................................................................ 30

Setup ........................................................................................................ 30

Setting Parameters ................................................................................... 30

Automatic Card Recognition ..................................................................... 30

Default Settings ............................... ...... ..... ...... ........................................ 30

UniLink Commissioning Software ............................................................. 31

vi

890 USE 120 00

Page 7

Contents

Chapter 3 - Mounting and Physical Dimensions 33

At a Glance...................................................................................................... 33

What’s in this Chapter................................................................................ 33

Installation Safety Precautions ....................................................................... 34

Power Supply Overcurrent Protecti on .... ..... ...... ...... ..... ............................. 36

Earth Connections .................................................................................... 36

Cable Separation ...................................................................................... 36

Air Flow ..................................................................................................... 36

Drive Mounting and Physical Dimensions ...................................................... 37

17D Height, Width and Depth Dimensions ............................................... 37

17D Drive and Mounting Area Dimensions ............................................... 38

External Regen Resistor Assembly Dimensions ....................................... 39

External regen resistor assembly .............................................................. 40

Motor Choke Assembly Dimensions ......................................................... 41

Chapter 4 - Wiring and I/O 43

At a Glance...................................................................................................... 43

Introduction 43

What’s in this Chapter................................................................................ 44

Wiring and I/O Initial Considerations .............................................................. 45

Initial Considerations ................................................................................. 45

Grounding ................................................................................................. 45

Wiring Overview ............................................................................................. 46

Overview of 17D Wiring Connections ....................................................... 46

Connection diagram for LEXIUM 17D ....................................................... 47

Pin assignments for LEXIUM 17D ............................................................ 48

Cable Shield Connections .............................................................................. 49

Connecting Cable Shields to the Front Panel ........................................... 49

Cable Shield Connection Diagram ............................................................ 50

Power Wiring .................................................................................................. 51

AC Mains Power Supply Connection ........................................................ 51

Bias Supply Connection............................................................................. 51

Serial Power Connections.......................................................................... 52

External Regen Resistor Connection......................................................... 53

Regen Circuit Functional Description ........................................................ 53

Lexium BPH Servo Motor Connection (excluded BPH055) ...................... 54

Lexium BPH 055 Servo Motor Connection................................................ 55

890 USE 120 00 vii

Page 8

Contents

Lexium SER Servo Motor Connection ...................................................... 56

Servo Motor (with Optional Dynamic Brake Resistors and Contactor)

Connection................................................................................................ 57

Servo Motor Holding-Brake Control Functional Description ..................... 58

Signal Wiring .................................................................................................. 60

Lexium BPH Resolver Connection (excluded BPH055) ........................... 60

Lexium BPH055 Resolver Connection ..................................................... 61

Lexium SER Resolver Connection ........................................................... 62

Lexium BPH Encoder Connection ............................................................ 63

Lexium SER Encoder Connection ............................................................ 64

Incremental Encoder Emulation ............. ................................................... 65

Incremental Encoder Output Functional Description ................................ 65

SSI Encoder emulation ............................................................................. 66

SSI Encoder Output Functional Description ............................................. 66

Diagram of master-slave operation ........................................................... 67

Incremental encoder emulati on .............................................. ...... ...... ..... . 67

SSI encoder emulation ............................................................................. 67

External Incremental encoder connection ................................................ 68

External SSI encoder connection ............................................................. 69

Analog I/O Connection ................................................................................... 70

Analog Inputs .............................................. ...... ...... ..... ............................. 70

Servo Motor Rotation Direction ................................................................. 70

Analog Outputs ........................................... ...... ...... ..... ...... ..... .................. 71

Fault Relay and Digital I/O Connection .......................................................... 72

Digital Inputs and Outputs ........................................................................ 72

Using Functions Pre-programmed into the Drive ...................................... 73

Serial Communications Connection................................................................ 74

Serial Communications Connection Diagram ........................................... 74

CANopen Interface ................................................................................... 75

CAN bus cable ................................. ...... ................................................... 76

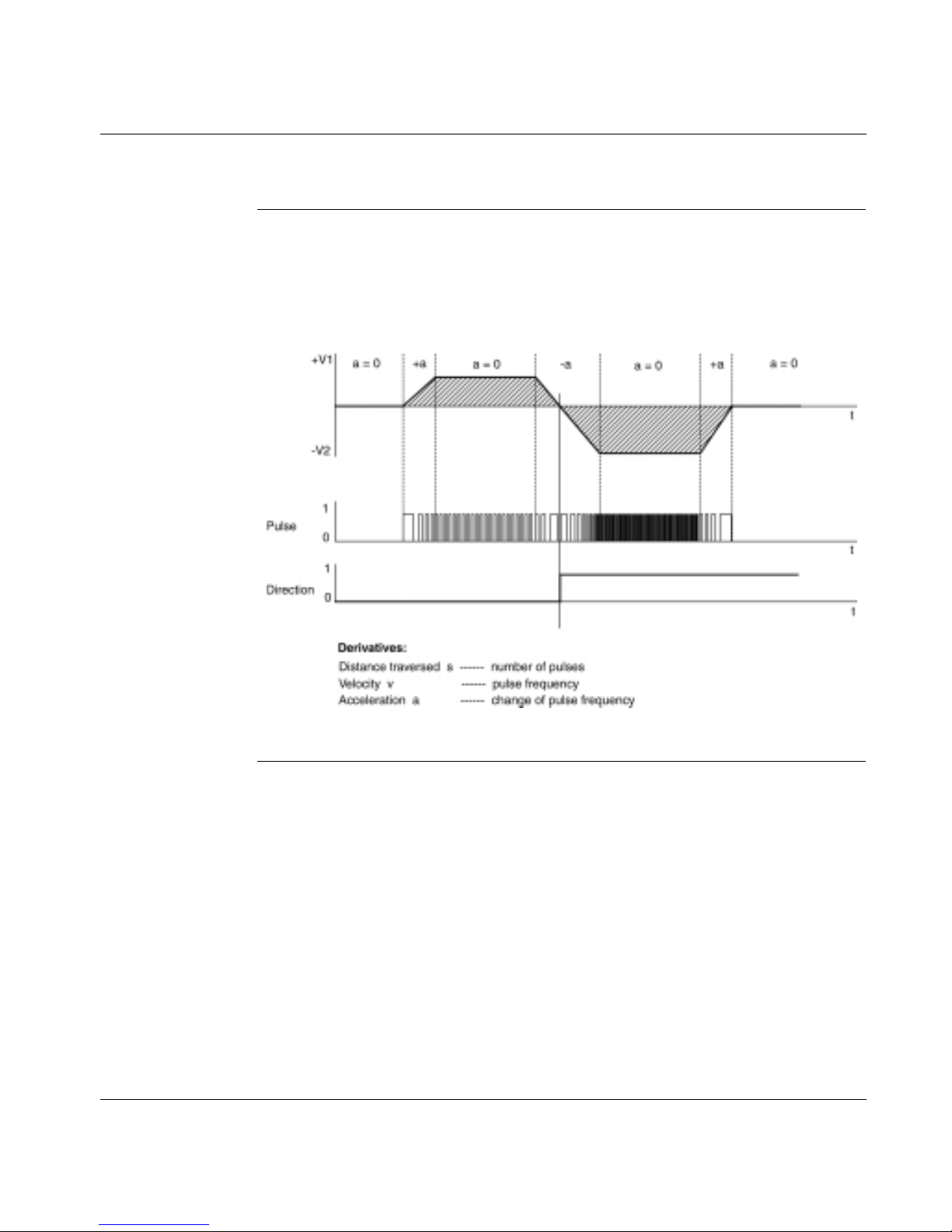

Stepper Motor Control Interface Connection................................................... 77

Stepper-Motor Control Interface Connection Functional Description ....... 77

Stepper-Motor Control Interface Connection Diagram ............................. 77

Stepper-Motor Speed Profile and Signal Diagram .................................... 78

viii

890 USE 120 00

Page 9

Contents

Chapter 5 - System Operation 79

At a Glance...................................................................................................... 79

What’s in this Chapter................................................................................ 79

Powering Up and Powering Down the System ............................................... 80

Power-on and Power-off Characteristics .................................................. 80

Stop Function ............................................................................................ 81

Emergency Stop strategies ....................................................................... 82

Wiring example ......................................................................................... 83

Description of the restart lock -AS- (MHDA••••A00 drives only) ..................... 84

Advantages of the restart lock .................................................................. 84

Description of the restart lock -AS- ................................................................. 85

Functional description ............................................................................... 85

Block diagram............................................................................................ 86

Signal diagram (sequence)........................................................................ 87

Installation / Commissioning...................................................................... 88

Connection diagram .................................................................................. 89

Application examples ................................................................................ 90

Control circuit example ................................................ ...... ..... .................. 91

Procedure for Verifying System Operation ..................................................... 92

Overview ................................................................................................... 92

Quick Tuning Procedure ........................................................................... 93

Parameter setting ...................................................................................... 95

Multi-axis system ....................................................................................... 95

Front Panel Controls and Indicators ............................................................... 96

Keypad Operation...................................................................................... 96

LED Display .............................................................................................. 97

Chapter 6 - Troubleshooting 99

At a Glance...................................................................................................... 99

What’s in this Chapter ............................................................................... 99

Warning Messages ......................................................................................... 100

Warning Identification and Description ..................................................... 100

Error Messages ........................................... ..... ...... ...... ..... ...... ....................... 101

Error Identification and Description............................................................ 101

Troubleshooting .............................................................................................. 105

Problems, Possible Causes and Corrective Actions ................................. 105

890 USE 120 00 ix

Page 10

Contents

Appendix A - Specifications 107

At a Glance...................................................................................................... 107

What’s in this Appendix ............................................................................ 107

Performance Specifications ............................................................................ 108

Performance Specifications Table............................................................. 108

Environmental and Mechanical Specifications ............................................... 109

Environmental Specifications Table .......................................................... 109

Mechanical Specifications Table .............................................................. 110

Electrical Specifications .................................................................................. 111

What’s in this Section ............................................................................... 111

Electrical Specifications - Power..................................................................... 112

Line Input Specifications Table ................................................................. 112

Bias Input Specifications Table ................................................................. 113

Limit supply values of the servodrive MHDA associated with a

BHP motor with brake .............................................................................. 113

External Fuse Specifications Table .......................................................... 114

Motor Output Specifications Table ............................................................ 115

Internal Power Dissipation Specifications Table ....................................... 116

Electrical Specifications - Regen Resistor ...................................................... 117

Regen Circuit Specifications ..................................................................... 117

Electrical Specifications - Signal .................................................................... 118

Motor Overtemperature Input Specifications Table .................................. 118

Resolver Input Specifications Table ......................................................... 118

Encoder Input Specifications Table .......................................................... 119

Emulated Encoder Output (Incremental Format) Specifications Table ..... 119

Encoder Output (Incremental Format) Timing Diagram ............................ 120

Encoder Output (SSI Format) Specifications Table .................................. 120

Encoder Input (Slave) Specifications Table .............................................. 121

Discrete Input Specifications Table .......................................................... 121

Discrete Output Specifications Table ........................................................ 122

Fault Relay Output Specifications Table ................................................... 122

Brake Output Specifications Table ........................................................... 122

Analog Input Specifications Table ............................................................ 123

Analog Output Specifications Table .......................................................... 123

Serial Communications Specifications Table ............................................ 124

Wire Specifications (Recommended) ............................................................. 125

Wire Specifications ................................................................................... 125

x

890 USE 120 00

Page 11

Contents

Appendix B - Parts List 127

At a Glance...................................................................................................... 127

What’s in this Appendix ............................................................................. 127

Lexium 17D Drives ......................................................................................... 128

Drives Available ........................................................................................ 128

External 24 Vdc supply ................................................................................... 129

External 24Vdc supply .............................................................................. 129

Drive Cables ................................................................................................... 130

Drive to Motor Cables ............................................................................... 130

RS-232 Serial Communications Cable Part Table .................................... 130

Encoder Output Cables Parts Table ......................................................... 130

Regen Resistor Assemblies ............................................................................ 131

Regen Resistor Assembly Part Table........................................................ 131

Servo Motor Choke.......................................................................................... 132

Servo Motor Choke Part Table (when cable length exceeds 25m)............ 132

Spare Parts ..................................................................................................... 133

Spare Parts Table ..................................................................................... 133

Appendix C - Drive-to-Controller Wiring Diagrams 135

At a Glance...................................................................................................... 135

What’s in this Appendix ............................................................................. 135

Typical Motion Controller Interface Connections ............................................ 136

Motion Controller Interface Diagram ......................................................... 136

Wiring a 17D Drive to Premium CAY Motion Modules ................................... 137

Premium CAY Single Axis Drive Option Diagram ..................................... 137

Premium CAY Multi-Axis Breakout Module Wiring Diagram ..................... 138

Premium CAY Multi-Axis and Breakout Module Diagram, First of 4 Axes. 139

Wiring a 17D Drive to a MOT 201 Motion Module .......................................... 140

MOT 201 Control Wiring Diagram ............................................................. 140

MOT 201 Encoder Wiring Diagram: Option 1 ........................................... 141

MOT 201 Encoder Wiring Diagram: Option 2 ........................................... 142

Wiring a 17D Drive to Quantum 140 MSx Motion Modules ............................ 143

Quantum 140 MSx Control and Encoder Wiring Diagram ........................ 143

890 USE 120 00 xi

Page 12

Contents

Wiring a 17D Drive to B885-11x Motion Modules .......................................... 144

B885-11x Control Wiring Diagram ............................................................ 144

B885-11x Encoder Wiring Diagram: Option 1 ........................................... 145

B885-11x Encoder Wiring Diagram: Option 2 ........................................... 146

Appendix D - Cable Connection Wiring Diagrams 147

At a Glance...................................................................................................... 147

What’s in this Appendix ............................................................................ 147

Wiring a Sub-D Connector with Shielding (drive side) .................................... 148

Wiring the Sub-D Connector .............................................. ..... .................. 148

Wiring the feedback connector of the motors ................................................. 150

Wiring the feedback connector of the BPH motors (excluded BPH055) ... 150

Wiring the feedback connector of the BPH055 motors ............................. 151

Wiring the feedback connector of the SER motors ................................... 152

Wiring the Motor Power Connector (Drive end).............................................. 153

Wiring the Motor Power Connector ................... ...... ..... ............................. 153

Wiring the BPH Motor Power Connector (excluded BPH055 )................... 154

Wiring the BPH055 Motor Power Connector ...................................... ...... 155

Wiring the SER Motor Power Connector ............................................ ..... . 156

Serial Communication Interface Connection (X6) RS 232 ............................. 157

Serial Communication Interface Cable Connectors .................................. 157

Appendix E - Servo Loop Diagrams 159

At a Glance...................................................................................................... 159

What’s in this Appendix ............................................................................ 159

17D Current Controller Overview ................................................................... 160

17D Current Controller Diagram................................................................ 160

17D Velocity Controller Loop .......................................................................... 161

17D Velocity Controller Loop Diagram ..................................................... 161

17D Analog Input Loop Diagrams................................................................... 162

Overview ................................................................................................... 162

17D Analog Input Mode 0 Loop Diagram.................................................. 162

17D Analog Input Mode 1 Loop Diagram ................................................. 163

17D Analog Input Mode 3 Loop Diagram.................................................. 164

17D Analog Input Mode 4 Loop Diagram ................................................. 165

17D Analog Input Mode 5 Loop Diagram ................................................. 166

xii

890 USE 120 00

Page 13

Contents

Appendix F - Expansion Options 167

At a Glance...................................................................................................... 167

What’s in this Appendix ............................................................................. 167

Expansion Cards ............................................................................................ 168

Overview ................................................................................................... 168

Fitting expansion card................................................................................ 168

I/O Expansion Cards ...................................................................................... 169

24 Vdc Discrete I/O Expansion Card......................................................... 169

IConnector and LED Location Diagram..................................................... 169

Light-Emitting Diodes (LEDs)..................................................................... 170

Terminal Assignments .............................................................................. 170

Controlling Pre-programmed Motion Tasks............................................... 172

Programming the PLC .............................................................................. 172

Motion Task Coordination.......................................................................... 172

Motion Task Application Examples ........................................................... 1 73

Example of a Motion Task Number............................................................ 173

Connection Diagram ................................................................................. 174

Appendix G - External Regen Resistor Sizing 175

At a Glance...................................................................................................... 175

What’s in this Appendix ............................................................................. 175

Overview ................................................................................................... 176

Determining When Energy Is Absorbed .................................................... 176

Determining External Regen Resistor Size..................................................... 177

Power Dissipation Calculatio n Proce dure .......................... ..... ...... ...... ..... . 177

Drive Energy Absorption Capability .......................................................... 178

Example Regen Resistor Power Dissipati on Ca lc ula tio n.......................... ..... . 179

Example Motor and Drive Specific ati ons ........................... ..... ...... ...... ..... . 179

Example Step 1...................... ..... ...... ...... ................................................... 180

Example Step 2 .......................... ...... ...... ..... .............................................. 181

Example Step 3 .......................... ...... ...... ..... .............................................. 181

Example Step 4 .......................... ...... ...... ..... .............................................. 182

Example Step 5 .......................... ...... ...... ..... .............................................. 182

Example Step 6 .......................... ...... ...... ..... .............................................. 182

Example Step 7 .......................... ...... ...... ..... .............................................. 182

Example Step 8 .......................... ...... ...... ..... .............................................. 183

890 USE 120 00 xiii

Page 14

Contents

xiv

890 USE 120 00

Page 15

Introduction

1

At a Glance

Document Scope This user guide contains complete installation, wiring interconnection, power

application, test and maintenance information on the Lexium 17D series servo

drive.

What’s in this

Chapter

This chapter provides general information about this user guide and contains the

following topics:

Topic Page

About this user guide 2

Related system components 4

Related documentation 5

Hazards, warnings, and guidelines 6

Standards and compliances 10

Conventions 12

1

Page 16

About this User Guide

Who Should Use

this User Guide

This user guide is written for any qualified person at your site who is responsible for

installing (mounting and interconnecting), operating, testing and maintaining your

Lexium 17D servo drive and the servo system equipment with which it int erfaces. In

addition, the following precautions are advised:

l Transportation of the servo drive to, or from, an installation site should only be

performed by personnel knowledgeable in handling electrostatically sensitive

components.

l Commissioning of the equipment should only be performed by personnel

having extensiv e know ledg e of, and experi ence wi th, elec trical and se rvo dri ve

technologies .

Y ou a re expec ted to h ave some overall u nderst anding of what your 17D servo drive

does and how it will function in a high-performance, single-axis motion control

system. Accordingly, be sure you read and understand the general information,

detailed descriptions and associated procedures presented in this manual, as well

as those provided in other relevant manuals, before installing your 17D. (See

Related System Components

later in this chapter.)

If you have questions, please consult your Schneider Electric customer

representative.

How this User

Guide Is

Organized

2

This manual is organized as follows.

Chapter/Appendix Description

Chapter 1

About this User Guide

Chapter 2

Lexium 17D Product Overview

Chapter 3

Mounting and Physical Dimensions

An introduction to this manual — who should use

this manual, how this manual is organized,

related publications, hazards and warnings.

General descriptions of the 17D servo drives,

descriptions of components that are supplied by

Schneider in a typical 17D system, and a block

diagram for internal electronics.

Physical dimensions and information for

mounting the servo drive, Regen resistor and

servo motor choke.

Continued on next page

Page 17

About this User Guide, cont inued

How this User

Guide Is

Organized,

continued

Chapter/Appendix Description

Chapter 4

Wiring and I/O

Chapter 5

System Initialization, Commissioning

and Operation

Chapter 6

Troubleshooting

Appendix A

Specifications

Wiring diagrams for the power connections and

wiring diagrams and descriptions for all signal

wiring connections — encoder, resolver, analog

I/O, discrete I/O, and serial communications

cable.

Detailed procedures and associated descriptions

on how to initialize, commission and operate a

typical 17D system.

Description of faults, probable causes and

recommended corrective actions.

Specifications for the servo drives, including

general, electrical, signal, and power

specifications.

Appendix B

Parts List

Appendix C

Drive to Controller Wiring Diagrams

Appendix D

Cable Connection Wiring Diagrams

Appendix E

Servo Loop Diagrams

Appendix F

Expansion Options

Appendix G

External Regen Resistor Sizing

Part numbers related to the 17D servo drive

system.

Wiring diagrams that show signal wiring between

a 17D servo drive and MOT 201, Quantum MSx,

B885-11x, and Premium CAY motion modules.

Procedures and associated diagrams that show

how to wire Sub-D and power cable connectors

as well as the serial communication cable used

with the drive.

Illustrations of the 17D servo drive and singleaxis motion module servo loops.

Description and procedure for using the I/O

expansion card with the drive.

Description and procedure for determining the

power dissipation requirement for the external

Regen resistor.

3

Page 18

Related System Components

Single-Axis

Motion Control

System

UniLink

Commissioning

Software for 17D

The 17D servo drive is typically only one component in a larger, single-axis motion

control system. A single axis comprises one motion module, one servo drive, and

one motor.

Compatible Schneider motion modules include:

l Quantum 140 MSx series motion modules

l Compact MOT 201 motion modules

l B885-11x series motion modules

l Premium CAY motion modules

To configure your single-axis system, you will be using the UniLink

axis

commissioning software, which Schneider supplies.

UniLink allows you to configure your 17D servo drive axis and tune the motor

quickly and easily. With its graphical user interface and oscilloscope tuning

features, UniLink provides an easy point-and-click method for configuring motion

setup parameters. UniLink minimizes or eliminates cumbersome programming

tasks.

For complete information on UniLink, please see the UniLink online help.

4

Page 19

Related Documentation

Documents Related documentation that covers all these system components is illustrated

below.

You will need these:

Unilink

Online Help

(included

in software)

Depending on which motion module you have, you will also need one of these:

MOT 201,

202 Motion

Modules

User Guide

GI-BMOT-20X

If you have a Premium motion module CAY, you will also need this:

PL7 Junior/Pro

Premium PLCs

Specific

Functions

TLX DS 57 PL7 40

If you have a BPH motor, you will also need this:

Quantum

140MSx 101

Single Axis

Motion

Module

Reference

Guide

840 USE 105 X

Premium PLCs

Installation

Manual

V4

TSX DM 57 40

Lexium BPH

Serie

servo motors

Motors Reference

Guide

B885-1xx

Motion

Modules

User Guide

GI-B885-1XX

* included in AM0 CSW 001V•00 (CDROM)

*AMOMAN001U

5

Page 20

Hazards, Warnings and Guidelines

Hazards and

Warnings

Read the following precautions very carefully to ensure the safety of personnel at

your site. Failure to c ompl y will re sult in dea th, seri ous in jury o r equipm ent da mage.

DANGER!

ELECTRIC SHOCK HAZARDS

l During operation, keep all covers and cabinet doors closed.

l Do not open the servo drives; depending on degree of enclosure protection,

the servo drives may have exposed components.

l Control and power connections on the drive may be energized even if the

motor is not rotating.

l Never attempt to disconnect the electrical connections to the servo drive with

power applied. Failure to comply may result in arcing at the contacts.

l Wait at least five minutes after disconnecting the servo drive from the mains

supply voltage before touching energized sections of the equipment (for

example, contacts ) or discon necting el ectrical con nections . Capacitors can st ill

have dangerous voltages present up to five minutes after switching off the

supply voltages. To ensure safety, measure the voltage in the DC Link circuit

and wait until it has fallen below 40V before proceeding.

l Check to ensure all energized connecting elements are protected from

accidental contact. Lethal voltages up to 900V can be present. Never

disconnect any electrical connections to the servo drive with power applied;

capacitors can retain residual and dangerous voltage levels for up to five

minutes after switching off the supply power.

Failure to follow any one of these instructions will result in death, serious

injury or equipment damage.

6

Continued on next page

Page 21

Hazards, Warnings and Guidelines, continued

WARNING!

THERMAL HAZARD

During operation, the front panel of the servo drive, which is used as a heat sink,

can become hot and may reach temperatures above 80°C. Check (measure) the

heat sink temperature and wait until it has cooled below 40°C before touching it.

Failure to observe this precaution can result in severe injury.

WARNING!

OVERCURRENT, OVERLOAD AND OVERHEATING PROTECTION

Separate motor overcurrent, overload and overheating protection is required to be

provided in accordan ce wit h the Ca nad ian Elec tric al Code, Part 1 and the National

Electrical Code.

Failure to observe this precaution can result in severe injury.

Continued on next page

7

Page 22

Hazards, Warnings and Guidelines, continued

CAUTION!

SAFETY INTERLOCKS

Schneider recommends the installation of a safety interlock with separate contacts

for each motor. Such a system sh ou ld be hard wired with over–travel lim it s w itc he s

and a suitable emergency stop switch. Any interruption of this circuit or fault

indication should:

l Open the motor contacts

l Shunt dynamic braking resistor s across each motor, if they are present.

Failure to observe this precaution can result in equipment damage.

CAUTION!

ELECTROSTATIC COMPONENTS

The servo drives contain electrostatically sens itive components that may be

damaged by improper handling. Appropriately discharge yourself before touching

the servo drive and avoid contact with highly insulating materials (artificial fabrics,

plastic film, and so on). Place the ser vo drive o n a conductive surface.

Failure to observe this precaution can result in equipment damage.

Continued on next page

8

Page 23

Hazards, Warnings and Guidelines, continued

Additional Safety

Guidelines

Qualified

Personnel

Read this documentation and adhere to the safety guidelines contained herein

before engaging in any activities involving the servo drives.

l Ensure that all wiring is in a ccorda nce with the Nati ona l Ele ctr ica l Code (NEC)

or its nationa l equiv alent (CSA, C ENELEC , etc.), as well a s in ac cordan ce wi th

all prevailing local codes.

l Exercise extreme caution when using instruments such as oscilloscopes, chart

recorders, or volt–ohm meters with equipment connected to line power.

l Handle the servo drives as prescribed herein. Incorrect handling can result in

personal injury or equipment damage.

l Adhere to the technical information on connection requirements identified on

the nameplate and specified in the documentation.

l The servo drives may only be operated in a closed cabinet or enclosure.

Nevertheless, operating co nditions must be always respected ( as defined

in Appendix A):

- operating temperature range

- pollution degree 2 as defined in EN 50178

- assembly.

Only properly qualified personnel having extensive knowledge in electrical and

servo drive technologies should install, commission and/or maintain the Lexium

17D servo drives.

9

Page 24

Standards and Compliances

European

Directives and

Standards

EC Directive

Compliance

The Lexium 17D servo drives are incorporated into an electrical plant and into

machinery for industrial use.

When the servo drives are built into machines or a plant, do not operate the servo

drive until the machine or plant fulfills the requirements of these European

Standards:

l EC Directive on Machines 89/392/EEC

l EC Directive on EMC (89/336/EEC)

l EN 60204

l EN 292

In connection with the Low Voltage Directive 73/23/EEC, the associated standards

of the EN 50178 series in conjunction with EN 60439-1, EN 60146 and EN 60204

are applied to the servo drives.

The manufacturer of the machine or plant is responsible for meeting the

requirements of the EMC regulations.

Compliance with the EC Directive on EMC 89/336/EEC and the Low Voltage

Directive 73/23/EEC is mandatory for all servo drives used within the European

Community.

10

The Lexium 17D servo drives were tested by an authorized testing laboratory and

determined to be in compliance wi th the directives identified above.

Continued on next page

Page 25

Standards and Compliances, continued

UL and cUL

Compliance

UL Listed (cUL Certified) servo drives (Underwriters Laboratories Inc.) comply with

the relevant American and Canadian standards (in this case, UL 840 and UL

508C).

This standard describes the minimum requirements for electrically operated power

conversion equipment (such as frequency converters and servo drives) and is

intended to eliminate the risk of injury to personnel from electric shock or damage

to equipment from fire. Conformance with the United States and Canadian

standard is determi ned by an i nde pe nde nt U L (cUL) fire inspector through the type

testing and regular checkups.

UL 508C

UL 508C describes the minimum requirements for electrically operated power

conversion equipment (such as frequency converters and servo drives) and is

intended to eliminate the risk of fire caused by that equipment.

UL 840

UL 840 describ es air a nd insu lation c reepage spacing s for ele ctrical equip ment and

printed circuit boards.

11

Page 26

Conventions

Acronyms and

Abbreviations

The acronyms and abbreviations used in this manual are identified and defined in

the table below.

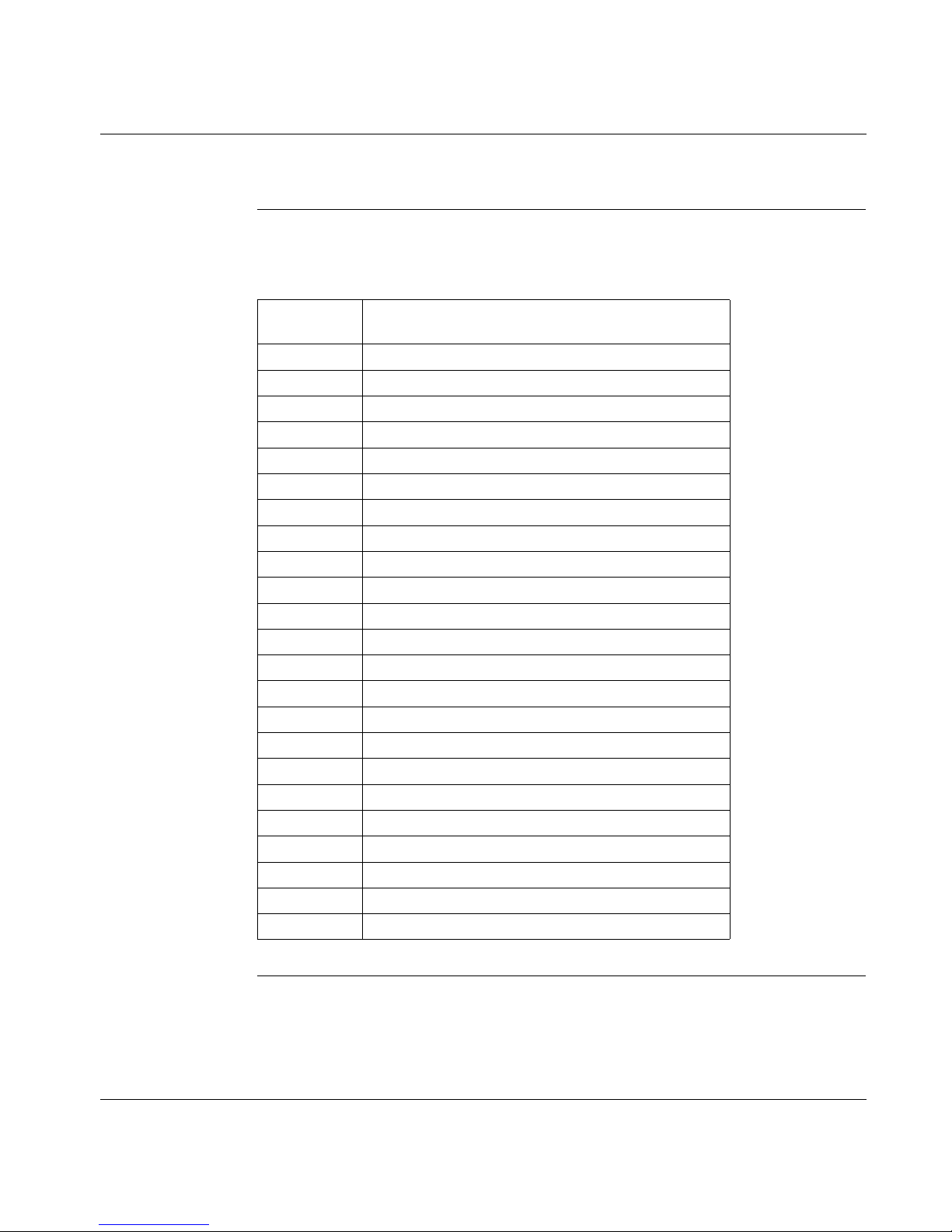

Acronym or

Abbreviation Description

CE European Community (EC)

CLK Clock signal

COM Serial communication interface for a PC-AT

cUL Underwriters Laboratory (Canada)

DIN German Institute for Norming

Disk Magnetic storage (diskette, hard disk)

EEPROM Electrically erasable programmable read only memory

EMC Electromagnetic compatibility

EMI Electromagnetic Interference

EN European norm

ESD Electrostatic discharge

IEC International Electrotechnical Commission

IGBT Insulated Gate Bipolar Transistor

ISO International Standardization Organization

LED Light Emitting Diode

MB Megabyte

MS-DOS Microsoft Disk Operating System for PC-AT

PC-AT Personal computer in AT configuration

PEL V Protected extra low voltage

PWM Pulse-width modulation

RAM Random Access Memory (volatile)

Regen Regen resistor

RFI Radio Frequency Interference

12

Continued on next page

Page 27

Conventions, continued

Acronyms and

Abbreviations,

continued

Acronym or

Abbreviation Description

PLC Programmable Logic Controller

SRAM Static RAM

SSI Synchronous Serial Interface

UL Underwriters Laboratory

Vac Voltage, Alternating Current

Vdc Voltage, Direct Current

13

Page 28

14

Page 29

Product Overview

2

At a Glance

Introduction This chapter contains a product overview of the Lexium 17D series servo drives

and includes:

l Available drive models and related system components

l Feedback and performance information

l Power and signal electronics

l Software and axis configuration

What’s in this

Chapter

This chapter contains the following topics:

Topic Page

The 17D series servo drive family 16

Overview of usability features 23

Overview of 17D internal electronics 26

Overview of system software 30

15

Page 30

The 17D Series Servo Drive Family

Introducing the

17D Drive Family

Drives

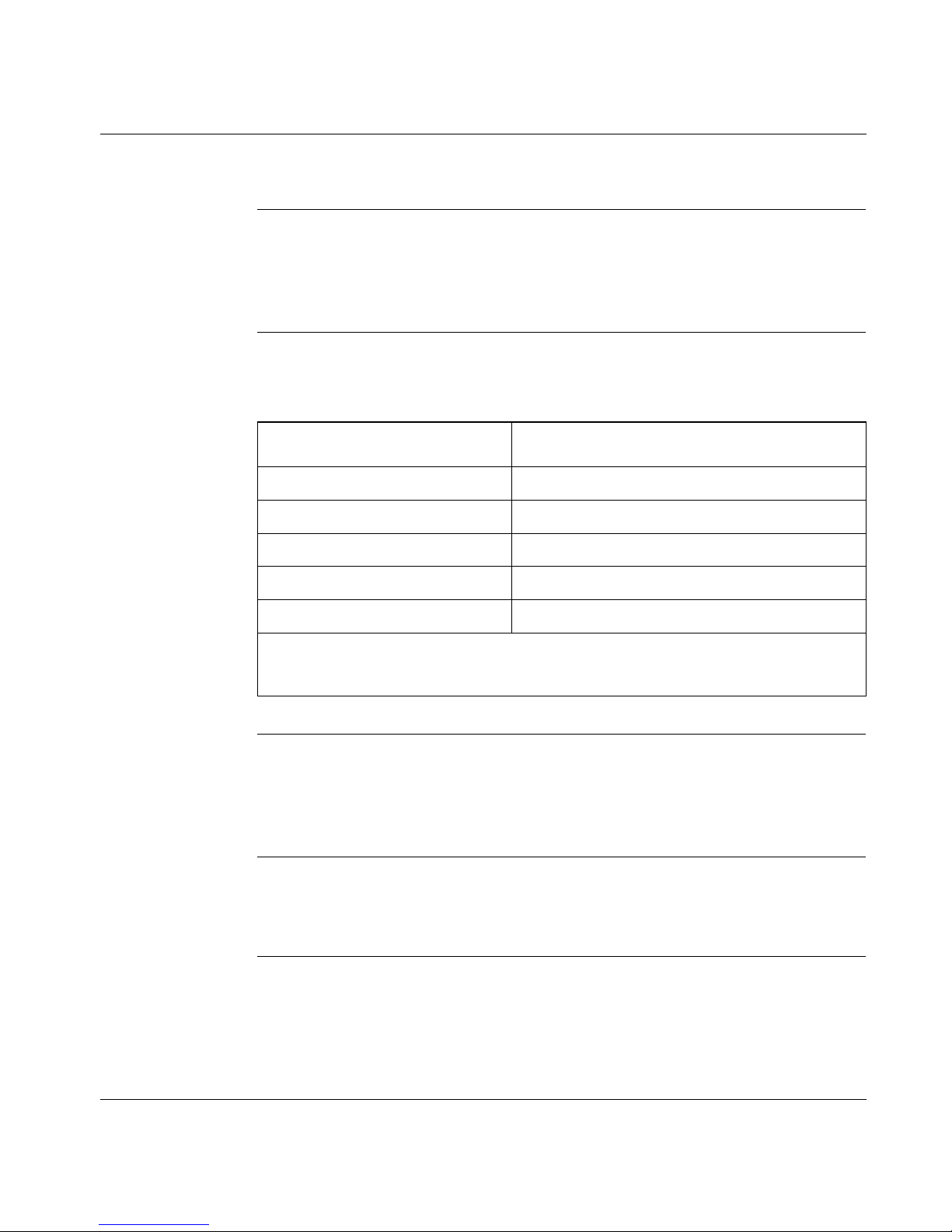

Available

Each member of the Lexium 17D series family is comprised of a three-phase

brushless servo amplifier, power supply and high-performance digital controller all

housed in a single enclosure.

The 17D drives are available in five models which are correlated to different output

current levels as identified in the following table.

Output Current Intermittent (Peak) 17D Drive

4A

8A

17A

28A

56A

Note:

A00 means that restart lock -AS- is included.

N00 standard version

MHDA1004

MHDA1008

MHDA1017

MHDA1028

MHDA1056

•00

•00

•00

•00

•00

Implementing

the Drives

The Lexium 17D servo drives are intended for incorporation into electrical

equipment or ma ch ine r y a nd can only be commissioned as in tegral components of

those types of devices.

Applicable Servo

Motor Types

16

The Lexium 17D se rvo drives are intended to drive BPH and SER series brushless

servo motors.

Continued on next page

Page 31

The 17D Series Servo Drive Family, continued

Connection to

different mains

supply networks

On this page you’ll find all possible connection variations to different mains supply

networks.

WARNING !

An isolating transformer is always required for 400...480V mains networks

without earth(ground) and for networks with asymmetrical earth(ground).

208...230V

208...230V

208...480V

L1

L2

L3

PE

L1

L2

L3

PE

L1

L2

L3

PE

208V with 60Hz only

230...480V with 50Hz or 60Hz

1:1400...480V

1:1400...480V

L1

L2

L3

PE

L1

L2

L3

PE

208...230V

208...230V

208...230V

L1

L2

L3

PE

L1

L2

L3

PE

L1

L2

L3

PE

1:1400...480V

1:1400...480V

1:1400...480V

Continued on next page

L1

L2

L3

PE

L1

L2

L3

PE

L1

L2

L3

PE

17

Page 32

The 17D Series Servo Drive Family, continued

Electrical

Considerations

The Lexium 17D family of servo amplifiers is to be used on earthed three-phase

industrial mains supply networks (TN-system, TT-system with earthed neutral

point, not more than 5000 rms symmetrical amperes).

Periodic overvoltages between outer conductor (L1, L2, L3) and housing of the

servo amplifier ma y not exceed 1000V (peak value). Transient overvoltages (<

50µs) between the outer conductors may not exceed 1000V. Transient

overvoltages (< 50µs) between outer conductors and housing may not exceed

2000V.

The Lexium 17D drives are incompatible with the IT system because interference

suppression filters are inte rnal an d conne cted to earth. If th e user w ants to conne ct

Lexium drives to an IT system, he may:

l use an in sulation star trans former in order to re-create a local TT or TN s ystem.

This way allows the rest of the wiring to stay an IT system (only warning in

case of the first fault.)

l use a spec ial Residual C urrent Circ uit Breaker ( RCCB) that is able to w ork with

dc and high peak currents. This device detects unbalance of phases with

regard to earth.

Warnin g: W hen th e fi rst fau lt occ urs, the RCCB has to switch off qui ckly po w er

of the drives. Set of the res idual curren t val ue mu st be carefu lly d one an d mus t

be started with the lowest available value (for example: 30mA.)

Following equipment of Merlin Gerin can be used:

l Vigirex, model RH328AF (Reference: 50055)

18

l One of these magnetic cores:

- model TA, 30mm in internal diameter (Reference: 50437)

- model PA, 50mm in internal diameter (Reference: 50438)

- model IA, 80mm in internal diameter (Reference: 50439)

If the servo amplifiers are used in residential areas, or in business or commercial

premises, then additional filter measures must be implemented by the user.

The Lexium 17D family of servo amplifiers is only intended to drive specific

brushless sync hron ous s erv om otors from the Lexium BPH series , w ith c los ed -loo p

control of torque, speed and/or position. The dielectric withstand voltage of the

motors must be at least as hight as the DC-link voltage of the servo amplifier.

Use only copper wire. Wire size may be deter minate d from EN 60 204 (or table 3 1016 of the NEC 60°C or 75°C column for AWG size).

We only guarantee the conformance of the servo amplifiers w ith the standards for

industrial areas, if the component s (mot ors, cables , ampli fiers etc ) are del ivered by

Schneider Automation.

Continued on next page

Page 33

The 17D Series Servo Drive Family, continued

17D Drive Family

Portrait

The following photograph shows a representative member of the 17D drive family.

The complete family consists of five models partitioned into two physical sizes.

Models MHDA1004

have dimensionally identical physical housings while Model MHDA1056

wider housing. (See Chapter 3 for detailed dimensional information.)

•00, MHDA1008•00, MHDA1017•00 and MHDA1028•00

•00 has a

Model without AS function

Continued on next page

19

Page 34

The 17D Series Servo Drive Family, continued

17D Drives Front

View

The following photograph shows a typical 17D front view without AS function.

20

Continued on next page

Page 35

The 17D Series Servo Drive Family, continued

Equipment

Supplied

Equipment

Available

Each 17D servo drive includes the following har dware.

l Mating connectors X3, X4, X0

, X0B, X7 and X8

A

l Read me first.

l Mating connector X10 for AS functi on, de livere d only w ith MH DA••••A 00 drive s.

Note: The mating Sub-D connectors and servo motor connector X9 are supplied

with the appropriate cable.

The following items are optionally available to you from Schneider for use with the

17D servo drives:

l Lexium BPH series br ushless servo motors

l Servo motor power and feedback cables

Note: Power and feedback cables are available in lengths from 5...75 m and are

supplied by Schnei der w i th th e c onn ec tor fo r the se rvo mo tor a ttac he d to t he c ab le

and with the connector for the drive unasse mbled and un attached to the cable. The

10 m length cable is supplied (from stock) by Schneider with connectors attached

to each end of the cable.

l Optional S ervo motor choke (for motor power c able lengths exceeding 25m)

l Optional External Regen resistor

l Serial communications cable (between drive and PC)

l Pre-configured cables for various Telemecanique and Modicon motion

controllers.

l Optional expansion cards.

l Optional communication cards and accessories (SERCOS, MODBUS +,

FIPIO, PROFIBUS DP)

Continued on next page

21

Page 36

The 17D Series Servo Drive Family, continued

17D System

Configuration

Diagram

The following illustration shows a typical 17D system configuration.

22

Page 37

Overview of Usability Features

Digital Control The 17D drive provides complete digital control of a brushless servo system. This

includes:

l A digital field-oriented current controller operating at an update rate of 62.5 µs

l A fully programmable digital PI-type speed controller operating at an update

rate of 250 µs

l If required by user application, an integrated, digital, position controller with

configurable trajectory generation operating at an update rate of 250 µs is also

available. Up to 180 indep endent moti on tas ks c an be confi gured and s tored i n

the drive depending upon the application requirements.

l An integral step/direction input is provided for use with an external indexer

which al lows the 17D drive and the applicable BPH motor to be used as a

stepper motor/drive replacement.

l Full digital evaluation of motor position feedback (primary feedback) from

either a standard two-pole resolver or a high precision Sin-Cos type encoder

(hiperface).

l Full digital emulation of either a standard incremental encoder or a SSI

encoder is also available fr om positio n information derived from the primary

feedback device. The drive may also be configured as a slave to follow a

master incremental encoder with a programmable gear ratio.

Continued on next page

23

Page 38

Overview of Usability Features, continued

Usability

Enhancements

The following features are incorporated into the 17D drive to facilitate the set-up

and operation of the servo system:

l Two analog +/-10 V inputs can be programmed for a multitude of functions

depending upon the application. Both inputs incorporate automatic offset

compensation, dead-band limitation and slew-rate limitation.

l T wo +/-1 0 V analog mo nitor outpu ts can be programm ed to support a multitu de

of internal drive control loop variables via the analog voltage output levels.

l Four fully programmable 24 V discrete inputs; two of which are typically

defined as hardware limit swi tches.

l Two fully programmable 24 V outputs and a separate 24 V brake output

capable of driving a maximum of 2 Amps.

l An integrated and fully isolated RS-232 connection for communication with a

PC; used to set configur ati on par ameters and tune the system with the Unilink

configuration software.

l Integrated CANopen (default 500 kBauds)

l A separate 24V bias supply input which may be connected through a UPS to

preserve system data in the event of an interruption in the AC mains supply.

l Restart lock AS (A00 drives only).

24

Page 39

Overview of Usability Features, continued

Restart lock -AS(A00 drives only)

The restart lock -AS- is exclusively intended to provide safety for personnel, by

preventing the restart of a system. To achieve this personnel safety, the wiring of

the safety circuits must meet the safety requirements of EN60204, EN292

and EN 954-1.

The -AS- restart lock must only be activated,

l When the motor is no longer rotating

(setpoint = 0V, speed = 0rpm, enable = 0V).

Drives with a suspended load must have an additional safe mechanical

blocking (e.g. by a motor-holding brake).

l When the monitoring contacts (KSO1/2 and Fault RA/RB for all servo

amplifiers are wired into the control signal loop (to recognize a cable break).

The -AS- restart lock may only be controlled by a PLC if the control of the internal

safety relay is arranged for redundant monitoring.

The -AS- restart lock must not be used if the drive is to be made inactive for the

following reasons

l Cleaning, maint ena nc e and repai r opera tions

l Long inoperative periods

In such cases, the entire system should be disconnected from the supply by

the personnel, and secured (main switch).

l Emergency-stop situations.

In an emergency-stop situation, the main contactor is switched off (by the

emergency-stop button or the Fault RA/RB contact in the safety circuit).

25

Page 40

Overview of 17D Internal Electronics

17D Internal

Electronics

Block Diagram

The following block diagram illustrates the 17D internal electronics and depicts

internal interfaces for power, signal I/O, and communication.

LEXIUM

2

Analog1 in +

Analog1 in -

-AS-

Analog2 in +

Analog2 in -

-AS-

17D

-AS-

+Rb ext

+Rb int

- Rb

X10

KSI+

KSI-

KS01

KS02

26

X9

X2

-AS-

X1

-AS-

X9

Continued on next page

Page 41

Overview of 17D Internal Electronics, continued

General

Characteristics

The Lexium 17D servo drives are available in five peak output current ratings (4.2,

8.4, 16.8, 28 and 56 A) that are partitioned into two groups based on the width of

the package; the 70 mm drive s are rated to ha ndle cu rrents up to 28 A and the 120

mm wide drive is rate d to han dle current s up to 56 A. All Lexium drives o perate wi th

an input voltage which may range from 208 V -10% 60 H z , 230 V -10% 50 Hz

through 480 V +10% 50-60 Hz.

Each drive provides:

l Direct shield connection points

l Two analog setpoint inputs

l Integrated and electrically isolated RS-232 communications

Primary Power A single phase input supply may be used for commissioning and set-up and for

continuous operating with various smaller drive/motor combinations. See the

Lexium 17/ BPH motor torque speed curves for details.

Fusing (e.g. fuse cut-out) is provided by the user.

Bias Power The 17D drive requires 24 Vdc bias power from an external, electrically isolated

supply (SELV).

EMI Suppression EMI suppression for the 17D drives is integrally provided by filters on both the

primary power (EN550011, Class A, Group 1) input as well as on the 24 Vdc bias

supply (Class A) input.

Continued on next page

27

Page 42

Overview of 17D Internal Electronics, cont i nued

Internal Power

Section

DC Link

Capacitor

Reconditioning

The Internal power section of the 17D drive includes the following:

l Power input: A rectifier bridge directly connected to the three-phase earthed

supply system, integral power input filter and inrush current limiting circuit.

l Motor power output: PWM current-controlle d voltage sou rce IGBT -inv erter with

isolated current measurement

l Regen ci rcu it: D y nam ic d is trib uti on of Regen power between s ev eral drives on

the same DC Link circuit. An internal Regen resistor is standard; external

Regen resistors are available as required by your application.

l DC Link voltage: 300...700 V dc, nominal (900 Vdc, intermittent) and can be

operated in parallel.

If the servo drive has been stored for longer than one year, then the DC Link

capacitors will have to be reconditioned as follows:

Step Action

1 Ensure that all electrical connections to the drive are disconnected.

2 Provide 230 Vac, single-phase power to connector XO

L1 / L2) on the servo drive for about 30 minutes to recondition the

capacitors.

(terminals

A

Integrated Safe

Electrical

Separation

The 17D drive ensures safe electrical separation (in accordance with EN 50178)

between the power input/motor connections and the signal electronics through the

use of appropriate i ns ula tio n-c reep age dis tances and electrical isolation. Th e dri ve

also provides so ft-start cha racteri stics, o vervoltage a nd over temperatu re detectio n,

short-circuit protection and input phase-failure monitoring. When using BPH and

SER series servo moto rs in conjunction with Schneider’s pre-assembled cables,

the drive also monitors the servo motor for overtemperature.

28

Continued on next page

Page 43

Overview of 17D Internal Electronics, continued

LED display A three-character LED display on the front of the 17D drive indicates drive status

after the 24 Vdc bias supply is turned on. If applicable during operation, error and/

or warning codes are displayed.

29

Page 44

Overview of System Software

Setup Configuration software is used for setting up and storing the operating parameters

for the Lexium 17D series driv es. The dri ve is co mmissi one d with the as sista nce of

the UniLink software and, during this process, the drive can be controlled directly

through this software.

Setting

Parameters

You must adapt the servo drives to the requirements of your installation. This is

usually accomp lished by connect ing a PC (p rogrammin g unit) to th e drive’ s RS-2 32

serial interface the n runni ng the Schnei der-sup plied UniLink configu ration s oftw are.

The UniLink software and the associated documentation are provided on a CDROM. Use the UniLink software to alter parameter s; you can instantl y observe the

effect on the drive when there is a continuous (online) connection to the drive. In

addition, actua l values are simulta neously received from the drive and display ed on

the PC monitor.

During the configu ration p roc ess, th e Unili nk sof tware wi ll sho w the motors that are

correctly matched to the current rating of the drive being configured.

Automatic Card

Recognition

Any interface modu le s (exp ansio n cards) tha t may be built in to the drive or that you

install are automatically recognized by the drive’s internal firmware. Any additional

parameters required for position control or motion-block definition are made

available automatically in the UniLink configuration software.

Default Settings Motor-specific default settings for all the reasonable combinations of drive and

servo motor are incorpo rated into the drive’ s firmware. In mo st applicatio ns, you will

be able to use thes e default values to get your drive running without any problems.

(Refer to the UniLink online help for additional information on default values.)

30

Page 45

Overview of System Software, continued

UniLink

Commissioning

Software

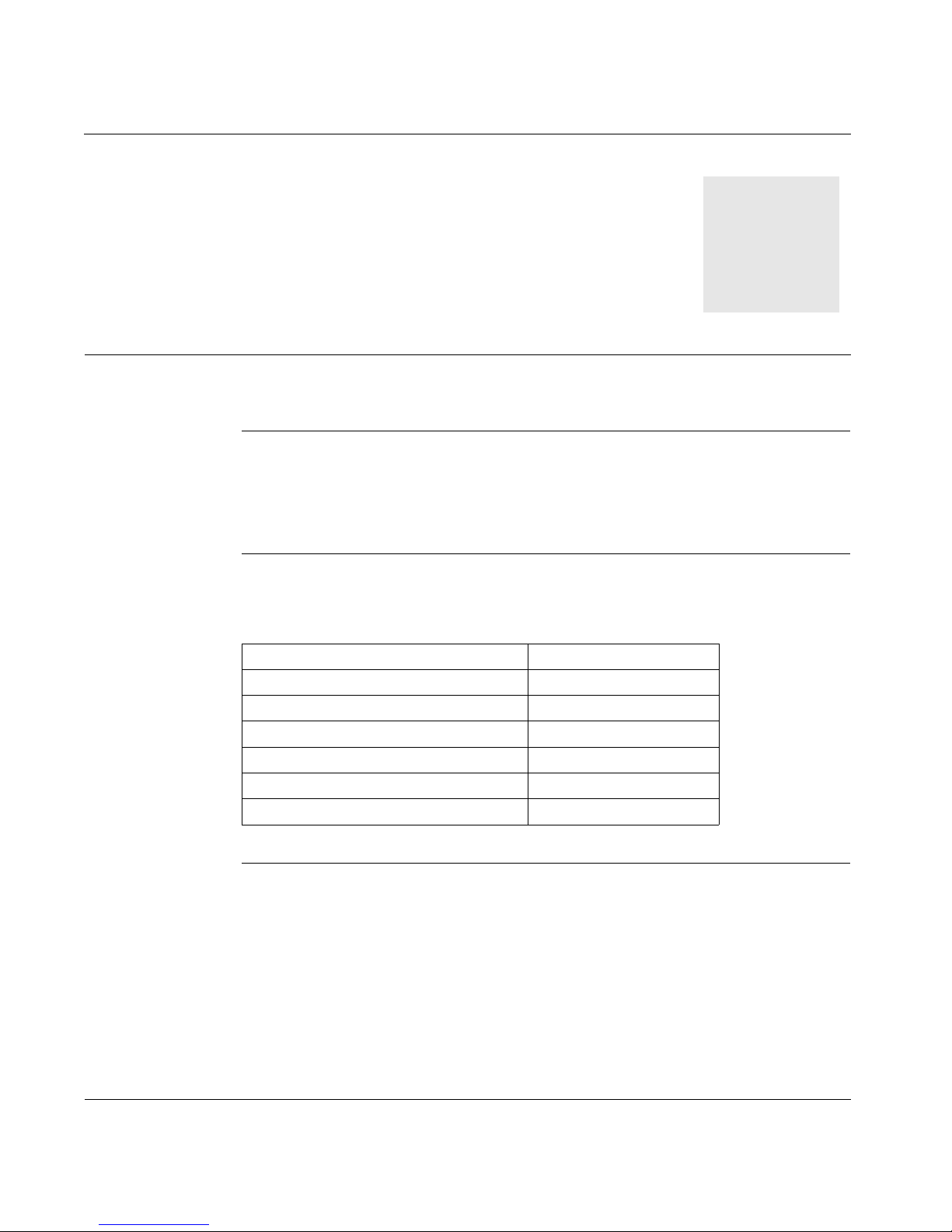

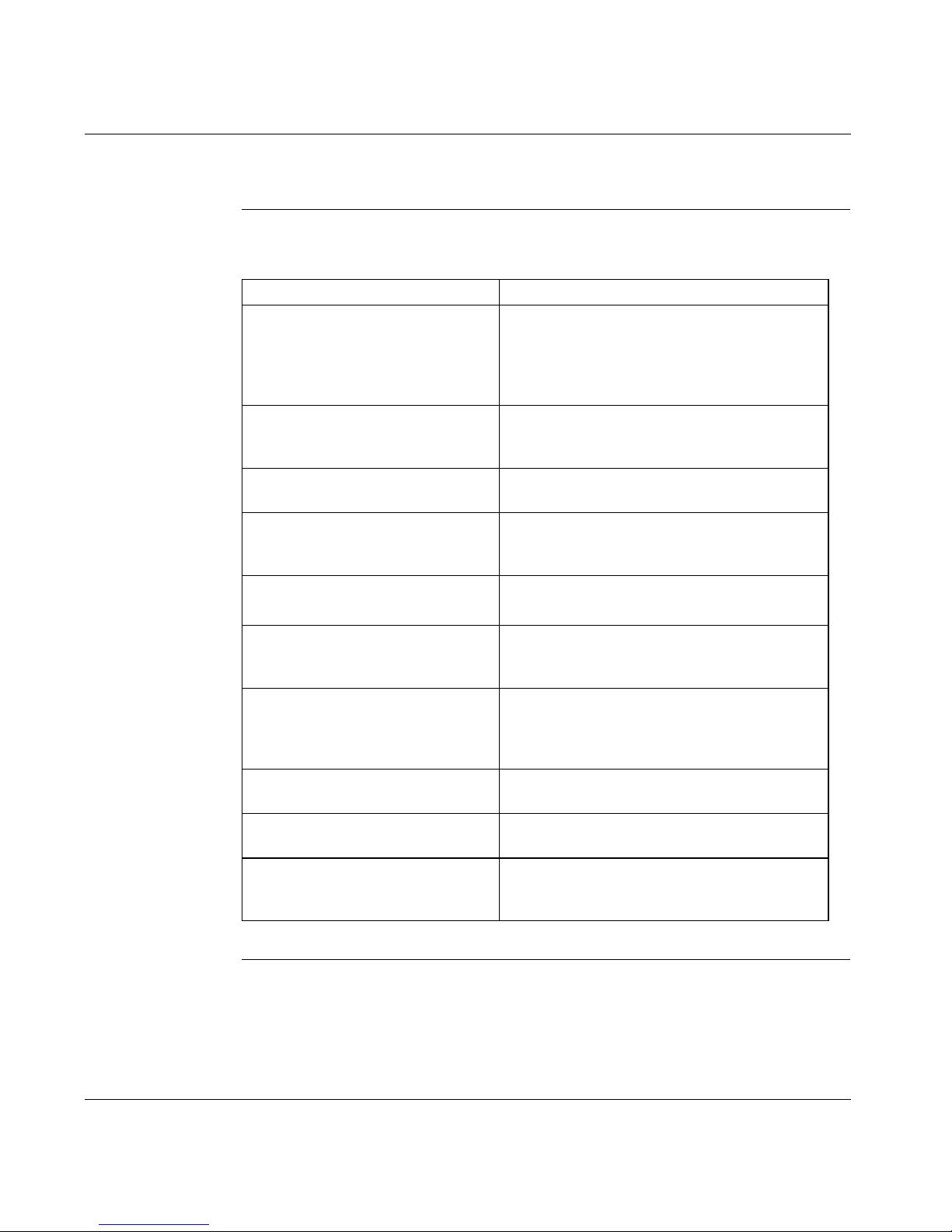

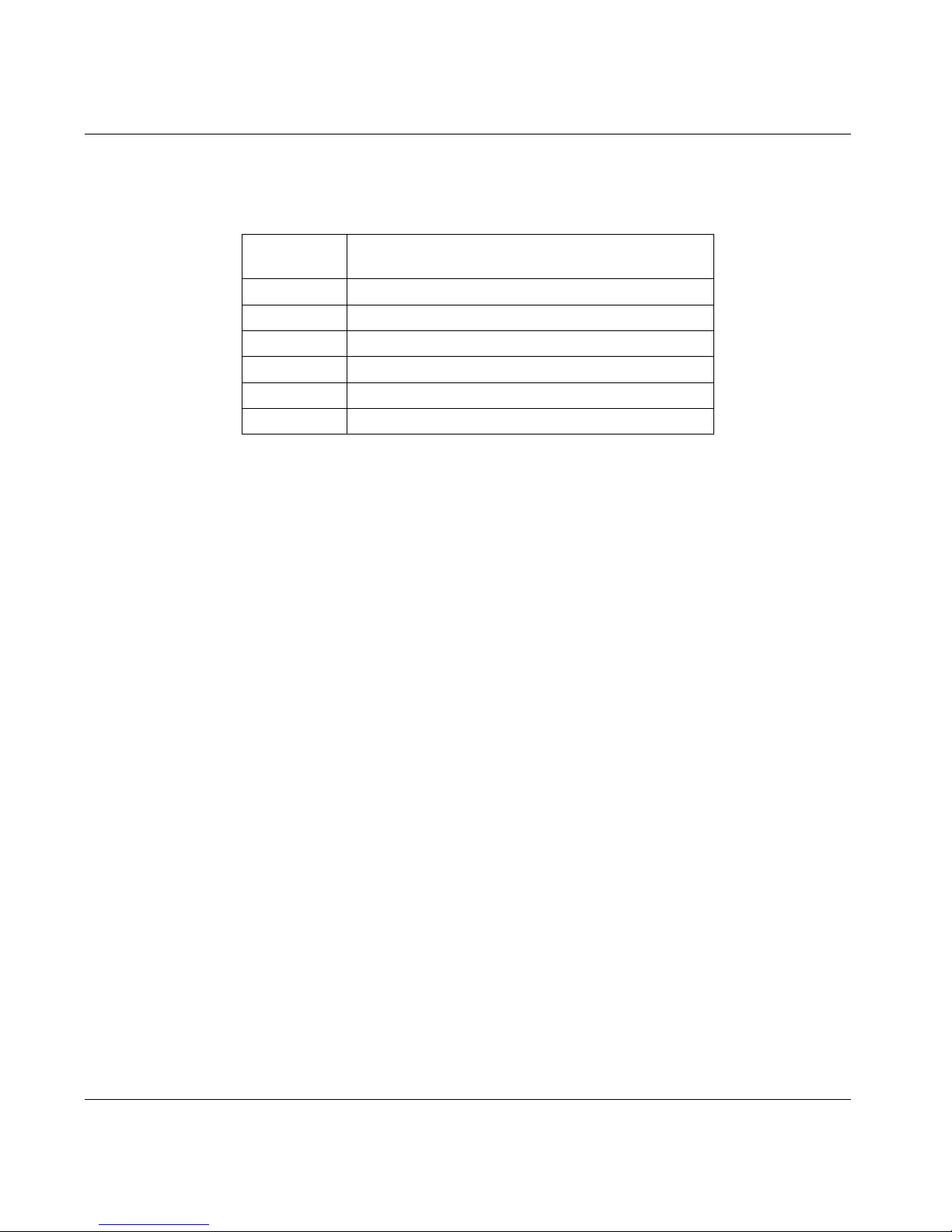

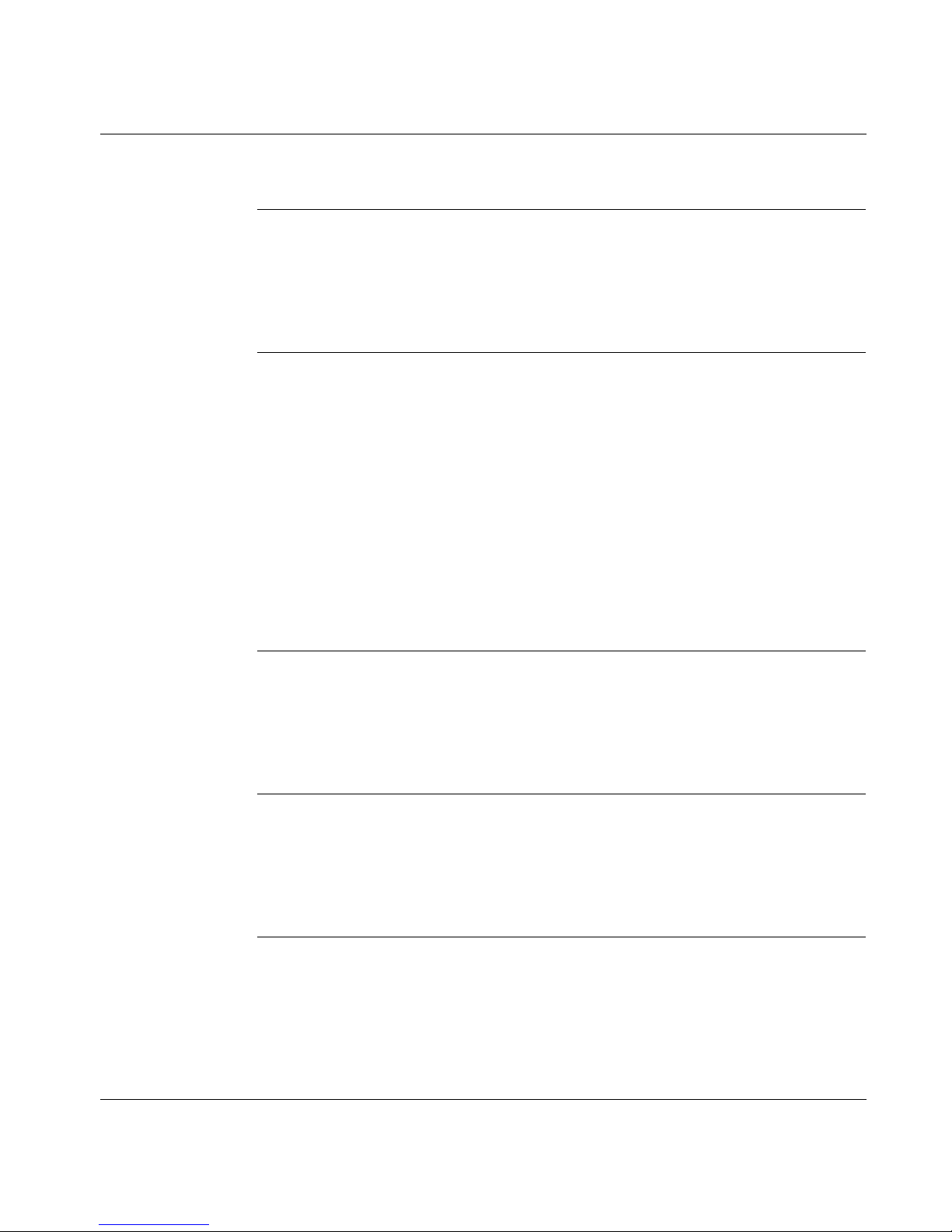

The minimum PC system requirements needed for the UniLink commissioning

software are specified in the following table:

Item Minimum Requirement

Operating System Windows 95

Windows 98

Windows 2000

Windows ME

Windows NT 4.0

Hardware:

Processor

Graphics adapter

RAM

Hard drive space

Communications

486 or higher

VGA

8 Mbytes

5 Mbytes available

One RS-232 Serial Port

31

Page 46

32

Page 47

At a Glance

Mounting and Physical

Dimensions

3

What’s in this

Chapter

This chapter provides information on the mounting requirements for, and physical

dimensions of, the Lexium 17D series servo drives and includes the following

topics:

Topic Page

Installation safety precautions 34

Installation considerations 36

Drive mounting and physical dimensions 37

External Regen resistor mounting and dimensions 39

Choke mounting and dimensions 41

33

Page 48

Installation Safety Precautions

CAUTION!

MECHANICAL STRESS

Protect the drive from physical impact during transport and handling. In particular,

do not deform any exterior surfaces; doing so may damage internal components or

alter critical insulation distances.

Failure to observe this precaution can result in injury or equipment damage.

CAUTION!

ELECTRICAL STRESS

At the installatio n s ite , ensure the maximum permissi ble rate d v oltage at the Mains

and bias input connectors on the drive are not exceeded. (See EN 60204-1,

Section 4.3.1.) Excessive voltages on these terminals can result in destruction of

the Regen circuit and/or the drive’s electronics.

Failure to observe this precaution can result in injury or equipment damage.

CAUTION!

ELECTRICAL CONNECTIONS

Never disconnect the electrical connections to the servo drive while power is

applied.

Failure to observe this precaution can result in injury or equipment damage.

Continued on next page

34

Page 49

Installation Safety Precauti ons, continued

CAUTION!

CONTAMINATION AND THERMAL HAZARD

Ensure the 17D drive is mounted within an appropriately vented and closed

switchgear cabinet that is free of conductive and corrosive contaminants. Ensure

the ventilation clearances above and below the drive conform to requirements.

(Refer to Chapter 3 for additional information.)

Failure to observe this precaution can result in injury or equipment damage.

DANGER!

ELECTRIC SHOCK HAZARD

Residual voltages on the DC link capacitors can remain at dangerous levels for up

to five minutes af ter switchin g off the mains su pply volt age. Ther efore, meas ure the

voltage on the DC Link (+DC/-DC) and wait until the voltage has fallen below 40 V.

Control and power connections can still be energized, even when the motor is not

rotating.

Failure to observe these instructions will result in death or serious injury.

35

Page 50

Installation Considerations

Power Supply

Overcurrent

Protection

Earth

Y ou are responsible for prov iding over current protec tion (via circui t breakers and/ or

fuses) for the Vac mains supply and the 24 Vdc bias supply that are connected to

the drive.

Ensure the drive and associated servo motor are properly connected to earth.

Connections

Cable Separation Route power and control (signal) cables separately. Schneider recommends a

separation of at least 20 cm. This degree of separation improves the EMC

performance of the system. If a servo motor power cable includes wires for brake

control, those wires have a separate shield which must be connected to earth at

both ends of the cable.

Air Flow Ensure that there is an adequate flow of cool, filtered air into the bottom of the

switchgear cabinet co ntai ning the drive.

36

Page 51

Drive Mounting and Physical Dim ensions

17D Height,

Width and Depth

Dimensions

The following diagram shows height, width and depth dimensions for the 17D drive.

Model:

MHDA1004/00

MHDA1008/00

MHDA1017/00

MHDA1028/00

325 mm

Model:

MHDA1056/00

275 mm

m

m

*)

3

7

2

(

5

6

2

7

0

m

m

5

6

2

m

m

)

*

3

7

2

(

275 mm

325 mm

1

2

0

m

m

* Dimensions with mating connectors installed

Continued on next page

37

Page 52

Drive Mounting and Physical Dimensions, continued

17D Drive and

Mounting Area

Dimensions

The following diagram shows depth dimensions and mounting area requirements

for the 17D drive.

Cable duct

45 mm 5 mm 305 mm

50 mm

00

/

MHDA1056

45 mm

00

/

MHDA1056

40 mm70 mm70 mm70 mm40 mm

00

/

MHDA1004

00

/

MKDA1008

00

/

MHDA1017

00

/

MHDA1028

00

/

MHDA1004

00

00

/

/

MKDA1008

MHDA1017

Cable duct

00

/

MHDA1028

38

Cabinet door

2,5 mm

(min.)

273 mm

Mounting panel

265 (273 mm*) mm

M5

Lexium 17D

* Dimensions with mating connecto rs installed

Page 53

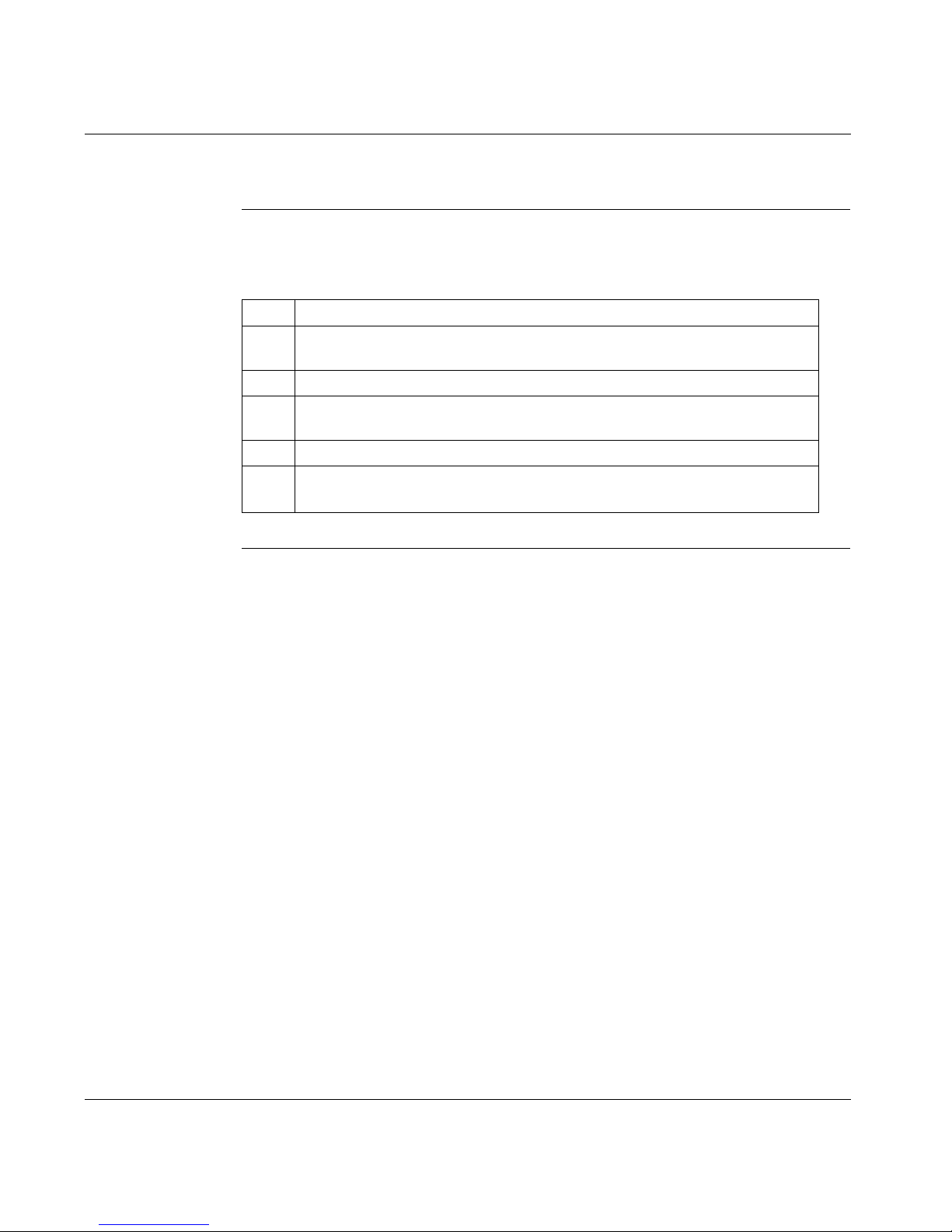

External Regen Resistor Mounting and Physical Dimensions

External Regen

Resistor

Assembly

Dimensions

The following diagram shows the dimensions for all three external Regen resistor

assemblies.

F

E

A

B

C

E

D

+Rb

-Rb

PE

ext

G

Regen Resistor

Assembly

Part Number

ext

AM0RFE001V025

AM0RFE001V050

AM0RFE 001V150

Power

R

Ω

33

33

1500

33

A B C D E F G Weight

mm mm mm mm mm mm mm Kg

W

342 352 410 64 45 4,8 x 8 77 1,5

250

413 428 485 93 64 6,5 x 12 120 4, 0

600

513 528 585 186 150 120 8,0

6,5 x 12

39

Page 54

External Regen Resistor Mounting and Physical Dimensions, continued

External regen

resistor

assembly

CAUTION !

Surface t emperature can

exceed 20 0°C. Observe

the requested free s pace.

Do not moun t on

combustible material !

100

Air flow

60

3030

40

Page 55

Motor Choke Mounting and Dimensions

3

Motor Choke

Assembly

Dimensions

The following diagram shows the dimensions for the motor choke assembly.

250

153.3

62

160

35

113

4.

N.B. : All dimensions are in millimeters

(mm).

35

Réf. Irms max. F max. L

AM0FIL001V056

3 x 20 A 8.3 kHz 1,2 mH

155

M4

41

Page 56

42

Page 57

Wiring and I/O

4

At a Glance

Introduction This chapter describes and illustrates all power wiring connections, all signal wiring

connections, an d I/O wi rin g co nne ctions on the 17D drive. Power and signal wir ing

connections are:

l AC mains power through a 4-position, plug-in, terminal block connector, X0

l Bias power through 4-position, plug-in, terminal block connector, X4

l Servo motor power throug h a 6-pos ition, plug-in, term inal bl ock conne ctor, X9

l Optional Regen power resistor through a 4-position, plug-in, terminal block

connector, X8

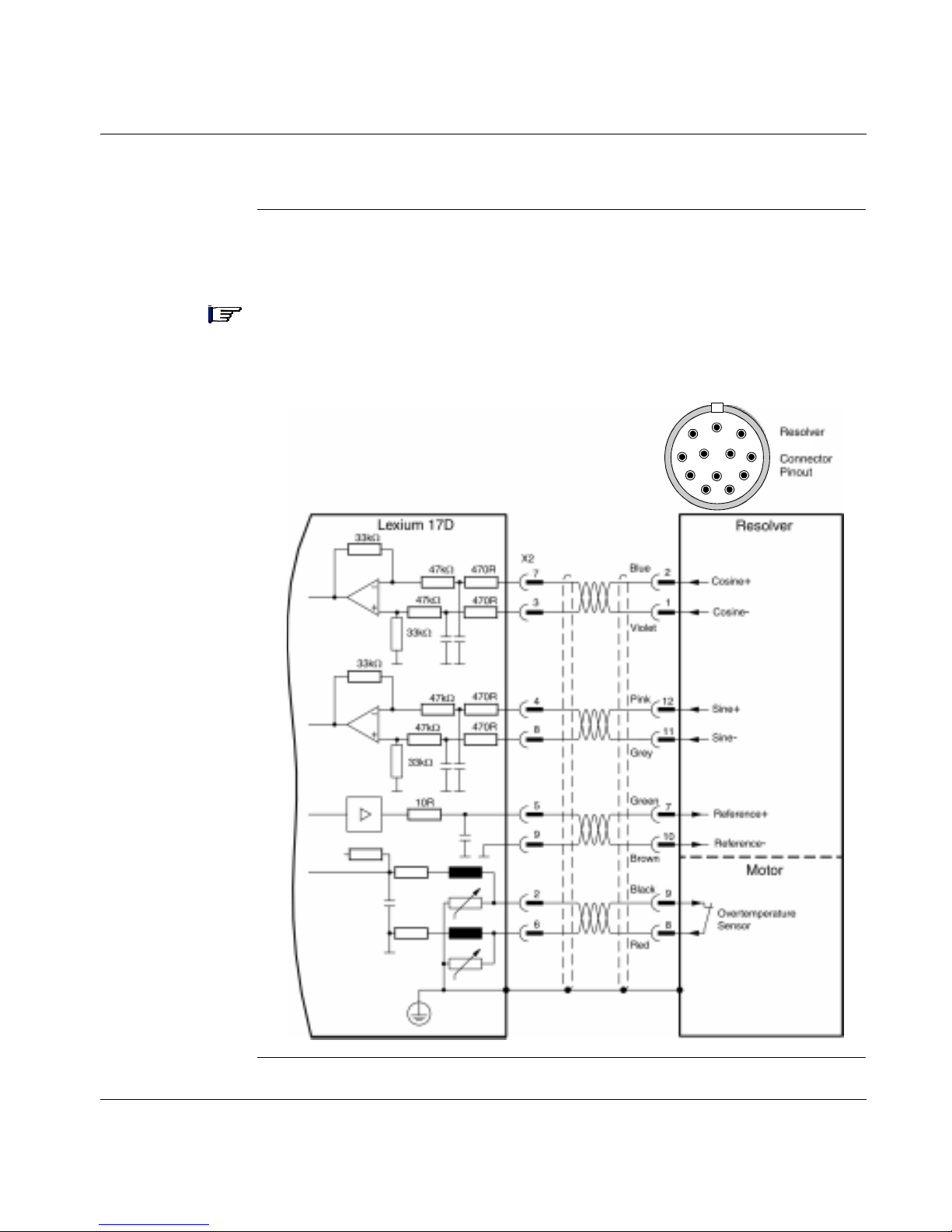

l Resolver feedback input through a 9-pin, plug-in, Sub-D connector, X2

l Encoder feedback input through a 15-pin, plug-in, Sub-D connector, X1

l Auxiliary encoder/command interface through a 9-pin, plug-in, Sub-D

connector, X5

l Master-Slave drive interface through a 9-pin, plug-in, Sub-D connector, X5

l Analog/digital I/O through an 18-position, plug-in terminal block connector, X3

l Serial communications interface through a 9-pin, plug-in, Sub-D connector,

X6

l Stepper-motor control interface through an 9-pin, plug-in, Sub-D connector,

X5

l Restart lock through a 4-position, plug-in, terminal block connector, X10 (A00

drives only)

Continued on next page

A

43

Page 58

At a Glance, continued

What’s in this

Chapter

This chapter contains the following topi cs.

Topic Page

Wiring and I/O initial considerations 45

Wiring overview 46

Cable shield connections 49

Power wiring 51

Signal wiring 60

Analog I/O connections 70

Fault Relay and Digital I/O connections 72

Serial communications connections 74

Stepper-motor control interface connections 77

44

Page 59

Wiring and I/O Initial Consider ations

Initial

Considerations

Some descriptions and illustrations contained in this chapter are provided as

examples. Actual implementation depends on the application of the equipment;

thus, appropriate variations are allowed provided they neither violate any safety

precautions nor jeopardize the integrity of the equipment.

DANGER!

ELECTRIC SHOCK HAZARD

Before you wire and connect cables, ensure the mains po wer supply, the 24 Vdc

bias power supply and the power supplies to any other connected equipment, are

OFF. Ensure any cabinet to be accessed is first electrically disconnected, secured

with a lock-out and tagged with warning signs.

Failure to observe these safety instructions will result in death or serious

injury.

Grounding Ensure the drive mounting plate, servo motor housing and Analog Com for the

controls are connected to common panel earth ground point.

Continued on next page

45

Page 60

Wiring Overview

Overview of 17D

Wiring

Connections

The following diagram shows the wiring connections for the 17D drive.

CAUTION:

Do not connect a Modbus serial port to the X6 connector!

Pin1 carries +8 Vdc which would be shorted out by a Modbus cable.

Instead, use a 3-core cable (not a null-modem link cable) with only

pins 2, 3 and 5 wired.

Failure to observe this precaution can result in equipment damage.

X0A, X0

B -

Note: The connectors descri bed above appea r in many wiring diagrams throug hout