Lewis 43-240, 43-250, 43-270 User Manual

®

INDUSTRIAL

SEWING

FINE

ST

ST

YLES

43-

240

43-

25

43-270

QUALITY

0

LEWIS

•

COLUMBIA

MACHINES

CATALOG

CLASS

43

No.

194-13

'

CHAINSTITCH

BLINDSTITC

MACHINE

CHICAGO

H

MACHINES

COMPANY

The

Union

Special

Lewis

FOREWORD

Class

43

offers

a

line

of

single

thread

chainstitch

blindstitch

also

sweaters

enable

The

and

cooperate

offers

All

parts

It

is

the

following

describe

Union

machines

a

bottom

,

knit

are

our

constant

customer

pages

the

Special

in

planning

with

feed

dresses

made

to

secure

contain

parts

for

representatives

and

top

and

only

and

similar

by

precision

aim

to

all

valuable

Class

estimating

bottom

machine

garments.

furnish

possible

43.

will

feeds

for

methods

carefully

advantages

operating

be

requirements.

for

making

insuring

found

coat

work

mock

complete

prepared

from

and

adjusting data,

in

all

manufactur

and

full

fashion

interchangeability.

information

the

use

of

work

Union

and

ing cente

on

furs.

marks

which

Specials.

illustrate

rs

It

on

will

to

~

Enginee

MACHINECOMPANY

rin

g De

partment

Catalog

INSTRUCTIONS

No.

FOR

194-13

ADJUSTING

LIST

43-240

First

AND

OF

Styles

43-250

Edition

OPERATING

PARTS

43-270

Union

Rights

Copyright

by

Special

Reserved

19

Machine

in

All

6 4

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

October.

1969

SEWING

CHICAGO

i n

3

MACHINES

U.S.

A.

Co.

Each

is

stamped

stamped

Union

in

in

the

Special

the

lug

style

also,

Lewis

plate

on

IDENTIFICATION

machine

on

the

the

front

carries a style

front

of

the

of

the

column,

nF

MACHINES

column.

number,

The

which,

serial

in

this

number

class

of

each

of

machines,

machine

is

This

to

direction,

position

The

while

operating

High

Base

Angle

Machine,

of

Inserting

is 9 Inches.

43-240

For

for

padding collars

light,

plies

43-250

Similar

penetration

the

finest

which

needle

43-270

For

light, _nedium

ped

with

needle

Use

only

on

the

shank.

The

type

catalog

are

are

available

The

following

catalog

applies

such

seated

direction

Production,

Non-Skip 1 to 1 Stitch,

90

Degrees

and

Removing

blindstitch

medium

for

quality

to

Style

from

furs.

prevents

{size . 035).

making

lower

{size • 045),

genuine

number

given

in

in

all

types

specifically

as

right

at

the

Single

to

Line

Work,

felling

and

and

heavy

work.

43-240

skin

Upper

and

unnecessary

mock

and

heavy

feed

full

only.

Union

of

the

the

machine

the

required

and

APPLICATION

and

left,

machine.

of

the

handwheel

DESCRIPTION

Thread,

of

Feed,

Work

bridle

lapels,

and

materials,

Seam

specification

except

side.

Skins

lower

fullness,

fashion

materials.

Seam

Special

Lewis

needles

style

sizes

sizes

are

to

the

styles

forward

and

is

OF

Single

Curved

Needle

Calibrated

Support

and

for

Plate,

edge

tacking

tape

Upper

104-SSm-1,

equipped

are

stitched

feed

adjustments

Seam

marks

on

Every

specification

NEEDLES

needles.

recommended

description.

in

both

uniform

available:

OF

CATALOG

of

machines

back,

away

from

MACHINES

Needle,

Travels

Penetration

Maximum

on

men's

the

canvas

and

lower

for

fur

work,

without

allow

specification

sweaters,

stitch

evenly

104-SSm-1

They

for

each

Needles

blade

listed

etc, , are

the

operator.

Chainstitch,

Left

to

Work

medium

to

facing

feeds

Type

Presser

distorting

perfect

104-SSm-1,

knit

dresses

spaced

are

stamped

style

for

the

and

ball

herein,

taken

Blindstitch,

Right

and

Adjustment,

Space

weight

on

seamed

give

positive

29-123

1/2

foot

or

feeding

and

for

quality

modified,

with

of

machine

Lewis

eye.

All

from

Penetrates

Knee

to Rig

suit

needle

regulated

cutting

at

lining

Type

knitted

work,

Type

the

word

covered

Class

references

the

operators

Lifter

ht

of

coats.

edge

control

{size.

the

and

29-123

garments

29-134

"LEWIS"

43

machines

Cylinder

at

an

for

Needle

Also

coats

of

all

035).

depth

hairs

skins.

1/2

of

Equip-

1/2

by

this

of

of

of

Selection

material

a

good

When

To

needle,

Type

29-123

being

stitch

sewing,

have

or

the

Uniform

29-123

29-123

29-124

29-124

Uniform

Scarfed

29-34

of

the

sewn.

formation,

immediately

needle

~e

number

1/2

'.

Blade

Blade

proper

Thread

orders

1/2

1/2

needle

or

promptly

should

Blade

.

. 035

•

, 045

Blade

.

size

yarn

discard

be

Dia

•

11

030

11

11

040

II

Dia,

040"

is

determined

should

pass

any

and

accurately

forwarded,

freely

needle

A

Ball

Eye

29-132

29-133

29-133

29-134

29-134

29-135

by

through

which

filled,

complete

4

1/2

1/2

1/2

1/2

size

may

Blade

Dia.

, 025

.

030"

•

035

•

040

, 045

•

055

of

thread

needle

have a hooked

an

empty

order

would

II

11

11

II

11

used

eye

in

container,

read:

and

order

or

"100

weight

to

blunt

a

Needles,

of

produce

point.

sample

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

This

views

seen

will

number

the

used

indicated

assembly.

The

complete

this

the

of

in

be

Numbers

position

in

Component

4115-72

1307

121-3

It

will

reason

At

the

book.

part

catalog

various

their

found a listing

of

pieces

ordering

by

Example:

L

be

is

sub-

back

This

number

has

sections

actual

required

in

the

first

of

that

parts.

parts

indenting

Feed

noted

assembly

in

that

replacement

of

the

will

is

known.

position

been

of

column

part

in

Always

of

sub-

their

and

Plunger

Plunger

the

above

should

book

facilitate

arranged

of

the

in

the

the

parts

in

the

the

assemblies

descriptions

Plunger

Barrel--------------------------------

Frame--------------------------------

example

of

be

will

be

locating

to

simplify

mechanism

machine.

with

particular

are

reference

illustration.

use

the

part

Bearing

that

this

part

ordered.

found a numerical

the

are

On

their

view

Reference

number

which

under

Block,

the

individually

illustration

ordering

part

being

numbers

can

the

plunger

repair

shown

the

so

page

numbers,

be

description

complete----------

index

shown.

only,

numbers

listed

furnished

bearing

is

not

and

opposite

of

parts.

that

the

parts

the

description

and

merely

should

in

the

second

for

repairs

of

the

block

recommended,

all

the

description

is

parts

Exploded

may

illustration

and

indicate

never

column.

main

not

shown

when

the

are

sub-

1

1

1

listed.

so

the

only

be

be

in

Where

Part

Union

Machine

according

precision.

trade

forwarded

wise

numbers

Success

Special

Genuine

mark

Prices

directed.

the

construction

represent

in

the

Lewis

Company,

to

the

Maximum

needles

is

your

are

net

f. o.

b.

A

USE

GENUINE

operation

Needles

its

subsidiaries

most

shipping

charge

approved

efficiency

are

packaged

guarantee

cash

the

and

point.

is

IDENTIFYING

permits,

same

subject

made

part,

NEEDLES

of

these

and

scientific

and

with

of

the

Parcel

to

Repair

and

durability

highest

to

cover

each

machines

TERMS

part

regardless

AND

Parts

authorized

principles,

labels

change

Post

postage

PARTS

is

REP

can

as

are

marked

quality

without

shipments

stamped

of

cc;talog

AIR

be

furnished

distributors.

assured.

LEWIS

in

materials

notice.

and

insurance.

with

PARTS

secured

and

are

are

its

in

which

only

by

the

They

made

~

and

All

insured

part

Union

workmanship.

shipments

unless

they

with

are

with

number.

appear.

genuine

Special

designed

utmost

•

This

are

other-

5

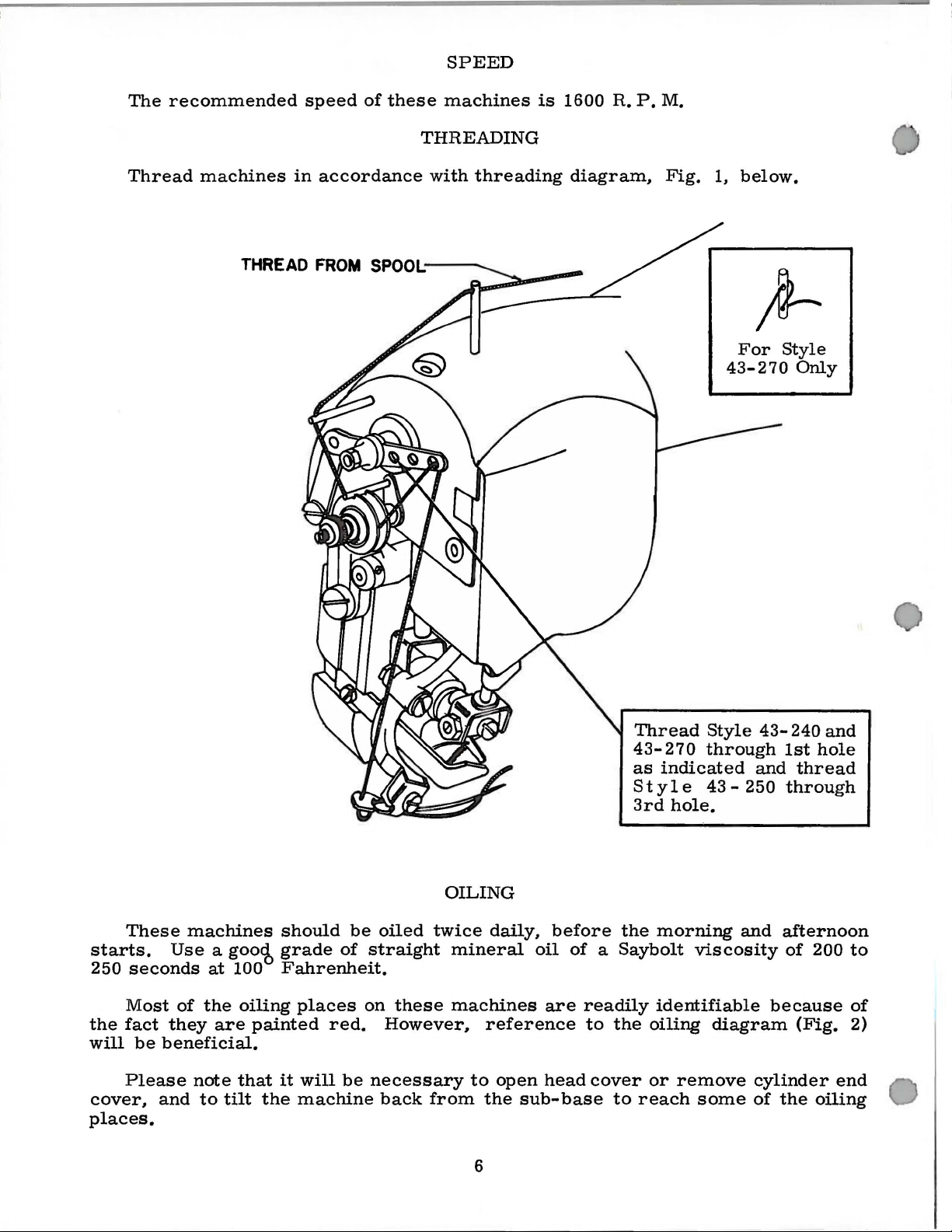

The

recommended

speed

of

SPEED

these

machines

THREADING

is

1600

R.

P.M.

Thread

machines

THREAD

in

accordance

FROM

with

threading

SPOOL;--..__

diagram,

Fig.

1,

below.

For

43-270

Style

Only

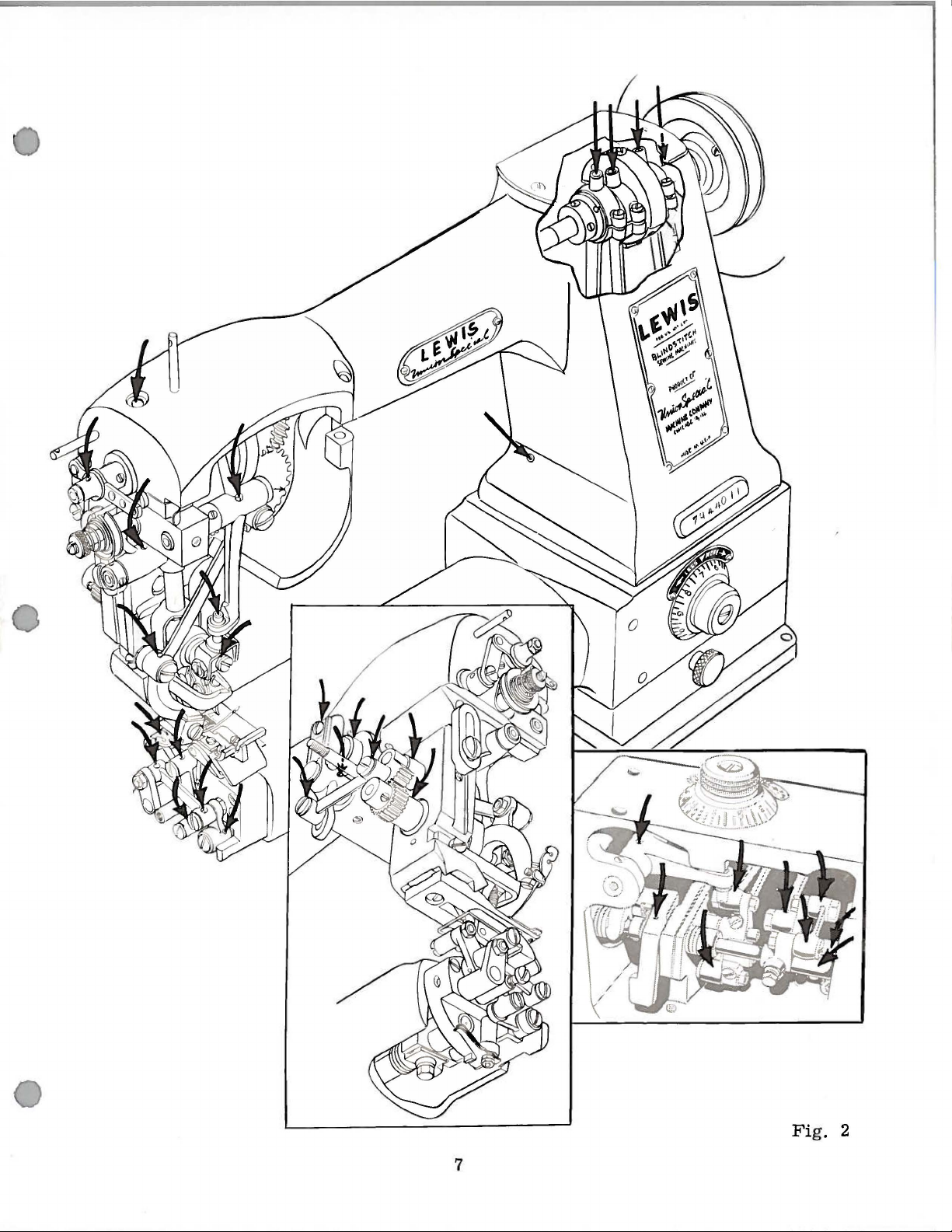

These

starts.

250

seconds

Most

the

fact

will

be

Please

cover,

places.

machines

Use

a goo<b

at

100

of

the

they

are

beneficial.

note

and

to

tilt

oiling

painted

that

the

grade

it

should

be

of

Fahrenheit.

places

on

red.

will

be

machine

oiled

twice

straight

these

However,

necessary

back

from

OILING

daily,

mineral

machines

reference

to

open

the

6

before

oil

of a Saybolt

are

readily

head

sub-base

to

the

cover

to

Thread

43-270

as

indicated

Style

3rd

hole.

the

morning

identifiable

oiling

or

reach

Style

through

43-

viscosity

diagram

remove

some

43-

1st

and

250

through

and

afternoon

of

because

cylinder

of

the

240

and

hole

thread

200

(Fig.

oiling

to

of

2)

end

7

Fi

g. 2

ADJUSTING

INSTRUCTIONS

REMOVING

the

arm

cover

TIMING

the

shaft.

looper

gear

if

the

the

wheel

same

right

timing.

in

operating

(the

turned

arrow

time

pointing

the

The

main

looper

Therefore,

cam

should

arrow

left

side

is

arrow

side

open

second

in

on

the

slightly

two

screws

NEEDLE

turned

operating

the

arrow

EXCESS

Fig.

plate

shaft

cam

and

be

in

on

of

drive

is

of

gear

front

direction

screw

cam

Fig.

WITH

(B)

on

line.

gear

in

the

in

line

around

will

on

above

in

drive

the

(A).

gear

PLAY

3

back

drive

into

PLUNGER

gear

are

spotted

arrow

the

right

The

(C)

points

gear

(A),

operating

with

To

cover

and

until

as

direction)

then

(C)

horizontal

gear

5

IN

CONNECTING

position.

(A.

Fig.

on

the

on

the

hub

side

of

the

timing

or

to

as

is

the

the

direction

the

arrow

check

the

the

be

should

for

turn

handwheel

spot

handwheel

in

the

looper

in a horizontal

coincide

as

(A)

and

slide

Oil

set

at

be

necessary

shake

ing

rod

top

of

arm

out

of

position

Tighten

rod

until

wheel

which

screw

Repeat

connecting

rod

screws

4)

and

main

of

the

drive

correct

line

on

hand-

this

on

the

proper

screw

is

cam

with

in

Fig.

gear

mesh.

until

Do

this

the

not

position.

arrow

a

horizontal

the

left

screw

shaft.

alignment

Fig.

gear

(C)

4).

(A)

to

position

the

spot

the

arrow

until

line

arrows

with

screw

RODS

clearance

the

factory.

that

may

adjusting

(Fig.

screw

machine

is

being

is

away

until

the

the

same

rod

(B)

(B.

position

the

5.

If

to

the

Turn

handwheel

spot

turn

the

points

position.

so

the

lines

Retighten

of

If

the

to

the

the

left

gear

on

the

alignment.

spot

and

set

for

Due

to

remove

develop.

screws

3).

Swing

for

access

(A)

in

plunger

begins

turned

from

operator.

machine

procedure

and

feed

and

(C)

Fig.

5)

is

pointing

arrow

on

adjustment

right

in

until

looper

handwheel

to

up

Now,

the

gear

turn

right

teeth

with

the

the

arrows

arrows

right

(A)

or

so

once

right

spot

main

line

up

and

on

main

the

screw

the

connecting

to

normal

any

excessive

Access

is

through

the

to

adjusting

drive

to

bind

in

operating

again

for

driving

respectively.

Fig.

4

toward

to

the

the

cam

is

necessary,

the

gears

in

operating

cam

is

after

gear

and

is

Slide

drive

mesh

the

spot

screws.

on

gears

do

not

again

as

required.

screw

shaft

and

Repeat

the

spot

shaft,

in

then

drive

wear

to

connect-

opening

arm

cover

screws.

connecting

while

direction.

Then,

turns

feed

elevating

connecting

the

front.

right.

at a position

no

direction

to

the

the

spot

(C)

until

slightly

gear

and

the

on

the

Now,

(A

line

up.

and

turn

lines

up

again

this

procedure

screw

tighten

gear

rods

it

may

play

plate

hand-

loosen

freely.

Swing

The

At

this

loosen

longer

front.

is

the

above

(A)

spot

main

check

and

C.

slide

gear

Re-

with

check

is

spot

(A).

is

or

in

in

to

in

8

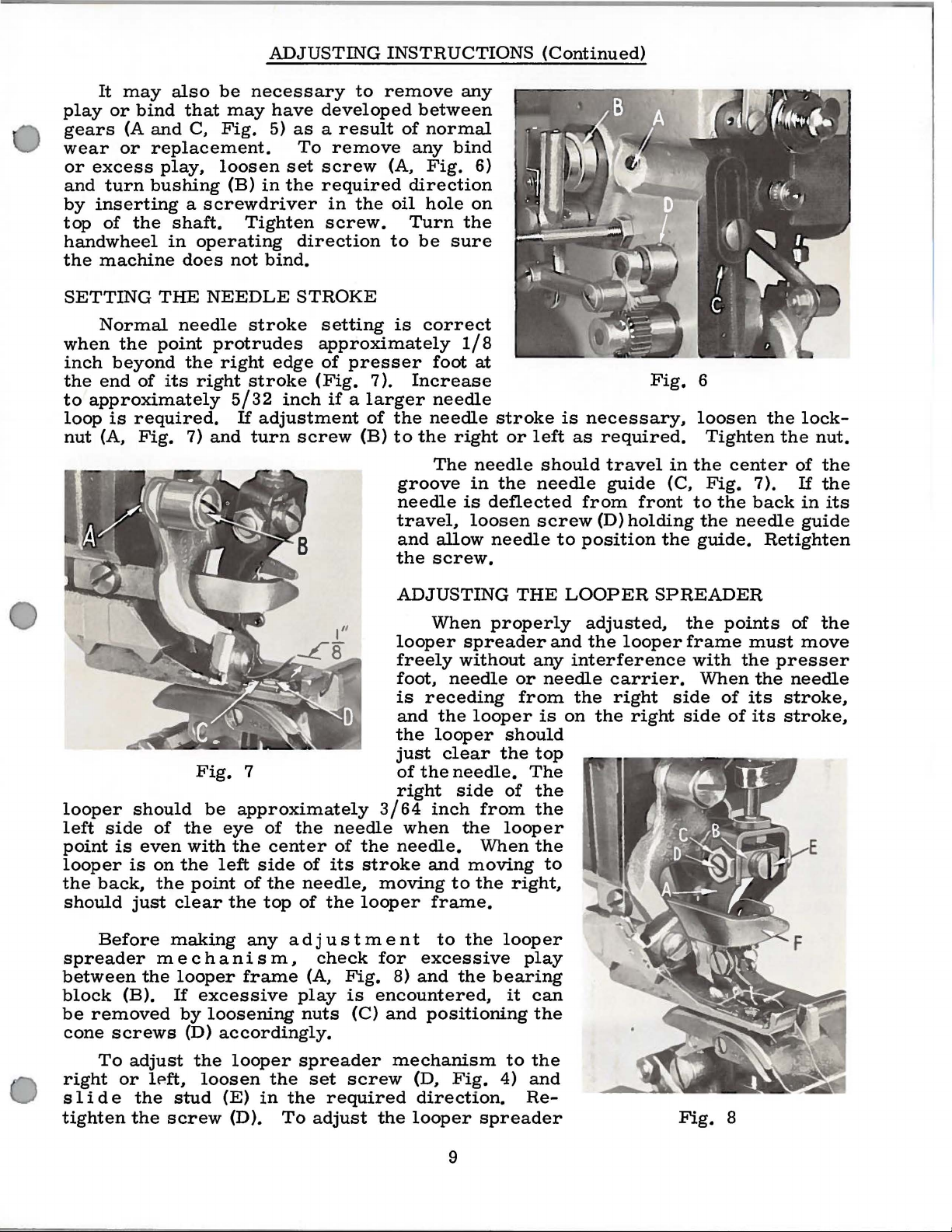

It

may

play

or

gears

wear

or

and

by

top

or

excess

turn

inserting a screwdriver

of

handwheel

the

machine

also

bind

(A

and

that

C,

replacement.

play,

bushing

the

shaft.

in

operating

does

be

may

Fig.

loosen

ADJUSTING

necessary

have

5)

set

(B)

in

the

Tighten

not

bind.

to

developed

as a result

To

remove

screw

required

in

the

screw.

direction

INSTRUCTIONS

remove

any

between

of

normal

any

bind

(A,

Fig.

6)

direction

oil

hole

on

Turn

to

be

the

sure

(Continued)

SETTING

Normal

when

inch

the

to

loop

nut

looper

left

point

looper

the

should

the

beyond

end

of

approximately

is

required.

(A,

Fig.

should

side

is

even

is

back,

just

THE

needle

point

its

of

the

on

the

the

clear

NEEDLE

protrudes

the

right

right

5/32

7)

and

Fig.

be

eye

with

the

left

point

the

STROKE

stroke

setting

approximately

edge

stroke

If

adjustment

turn

(Fig.

inch

screw

of

if a larger

7

approximately

of

the

needle

side

of

center

the

top

of

of

its

needle,

of

the

is

presser

7).

of

the

(B)

to

groove

needle

travel,

and

the

ADJUSTING

looper

freely

foot,

is

and

the

just

of

right

3/64

the

needle.

stroke

moving

looper

correct

foot

Increase

needle

needle

the

right

The

allow

screw.

When

needle

receding

the

looper

clear

the

needle.

inch

when

and

to

frame.

1/8

at

stroke

or

needle

in

the

is

deflected

loosen

needle

properly

spreader

without

looper

should

the

side

of

from

the

looper

When

moving

the

right,

left

should

needle

screw

THE

any

or

needle

from

is

top

The

the

the

the

to

is

necessary.

as

required.

travel

guide

from

(D)

to

position

LOOPER

adjusted,

and

the

interference

carrier.

the

right

on

the

Fig.

in

(C,

front

holding

the

SPREADER

looper

side

right

side

6

loosen

Tighten

the

Fig.

to

the

the

guide.

the

points

frame

with

When

of

the

center

7).

back

needle

Retighten

must

the

the

its

of

its

lock-

the

nut.

of

the

If

the

in

its

guide

of

the

move

presser

needle

stroke,

stroke,

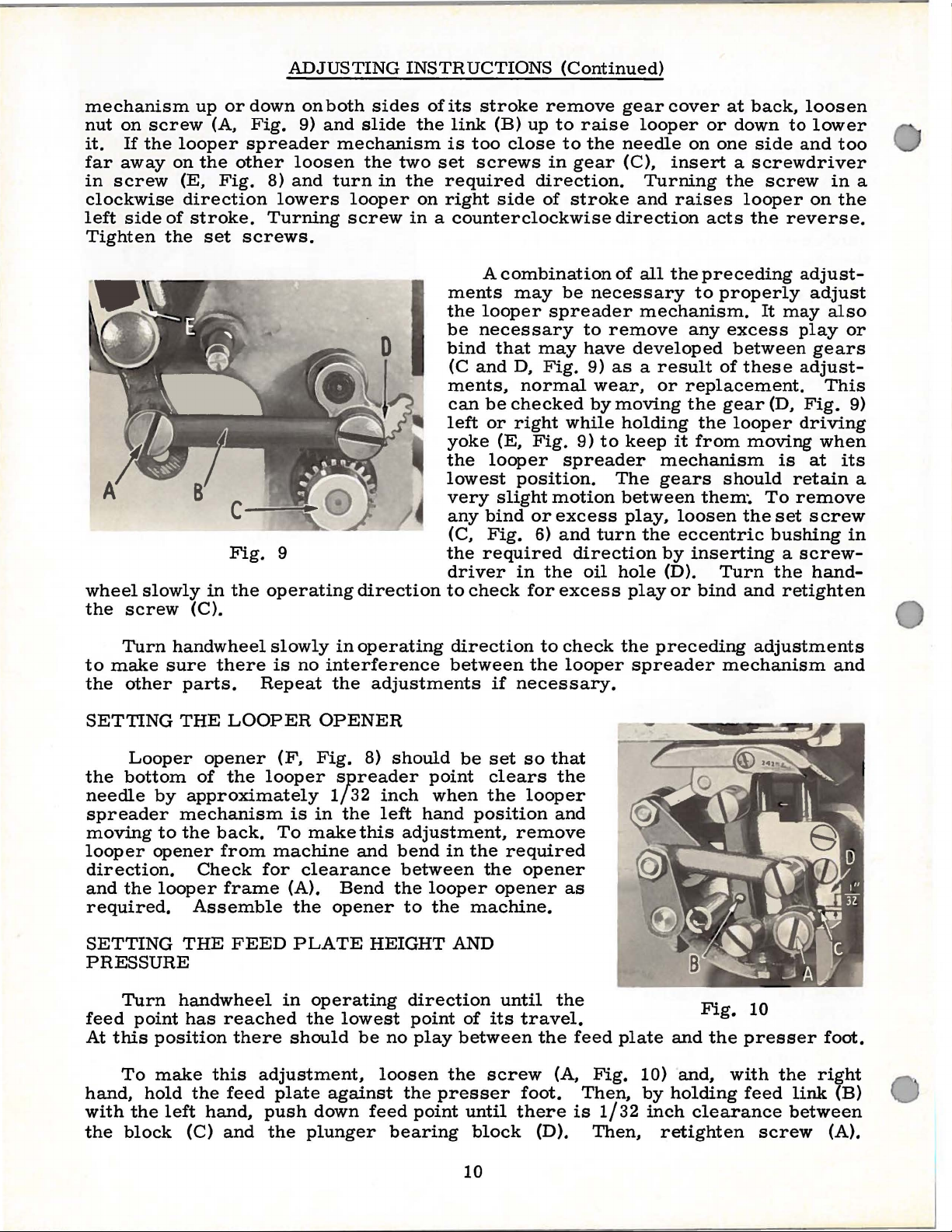

Before

spreader

between

block

be

removed

cone

screws

To

right

s 1

or

ide

tighten

making

mechanism,

the

looper

(B).

If

by

adjust

lP.ft,

the

stud

the

screw

frame

excessive

loosening

(D)

accordingly.

the

looper

loosen

(E)

(D).

any

adjustment

the

in

the

To

check

(A,

Fig.

play

nuts

is

(C)

spreader

set

screw

required

adjust

to

the

for

excessive

8)

and

the

encountered,

and

positioning

mechanism

(D.

Fig.

direction.

the

looper

9

looper

play

bearing

it

can

the

to

the

4)

and

Re-

spreader

Fig.

8

ADJUSTING

INSTRUCTIONS

(Continued)

mechanism

nut

on

screw

it.

If

the

far

away

in

screw

clockwise

left

side

of

Tighten

wheel

the

the

slowly

screw

up

or

(A,

looper

on

the

(E,

Fig.

direction

stroke.

set

C

Fig.

in

the

(C).

down

Fig.

spreader

other

8)

lowers

Turning

screws.

9

operating

on

both

9)

and

loosen

and

turn

sides

slide

mechanism

the

looper

screw

the

two

in

the

on

in a counterclockwise

D

direction

of

its

link

is

too

set

required

right

ments

the

be

bind

(C

ments,

can

left

yoke

the

lowest

very

any

(C,

the

driver

to

check

stroke

(B)

screws

side

A

looper

necessary

that

and

be

or

(E,

looper

slight

bind

Fig.

required

remove

up

close

direction.

of

combination

may

may

D,

Fig.

normal

checked

right

Fig.

position.

or

6)

in

the

for

to

raise

to

the

in

gear

stroke

be

necessary

spreader

to

remove

have

9)

wear,

by

while

9)

to

spreader

motion

excess

and

turn

direction

oil

excess

gear

needle

direction

of

as a result

moving

holding

The

between

hole

cover

looper

on

(C),

insert a screwdriver

Turning

and

raises

all

the

to

mechanism.

any

developed

or

replacement.

the

keep

play,

it

mechanism

gears

loosen

the

eccentric

by

(D).

play

or

from

inserting a screw-

at

back,

or

down

one

side

the

screw

looper

acts

the

preceding

properly

It

excess

between

of

these

gear

the

looper

moving

should

them~

Turn

bind

To

the

and

loosen

to

lower

and

on

reverse.

adjust-

adjust

may

play

gears

adjust-

This

(D,

Fig.

driving

when

is

at

retain

remove

set

screw

bushing

the

hand-

retighten

too

in

the

also

or

9)

its

in

a

a

Turn

to

make

the

other

SETTING

the

bottom

needle

spreader

moving

looper

direction.

and

the

required.

SETTING

PRESSURE

Turn

feed

At

this

To

hand,

with

the

block

handwheel

sure

Looper

by

to

opener

looper

point

position

make

hold

the

left

slowly

there

parts.

THE

opener

of

approximately

mechanism

the

back.

from

Check

frame

Assemble

THE

handwheel

has

reached

this

the

hand,

(C)

and

is

Repeat

LOOPER

(F,

the

looper

To

machine

for

FEED

there

adjustment,

feed

plate

push

the

in

no

interference

the

OPENER

Fig.

SJlreader

1/32

is

in

make

clearance

(A).

the

opener

PLATE

in

operating

the

should

against

down

plunger

operating

adjustments

8)

should

inch

the

left

this

and

bend

Bend

lowest

the

HEIGHT

be

no

loosen

feed

bearing

direction

between

be

point

when

hand

adjustment,

between

looper

to

the

direction

point

play

the

presser

point

the

position

in

the

the

machine.

AND

of

between

the

screw

until

block

the

if

necessary.

set

so

clears

looper

remove

required

opener

opener

until

its

travel.

the

foot.

there

(D).

to

that

the

and

the

(A,

check

looper

as

feed

Fig.

Then,

is

1/32

Then,

the

preceding

spreader

plate

10)

by

inch

retighten

mechanism

Fig.

and

the

and,

holding

clearance

adjustments

10

presser

with

feed

screw

the

link

between

and

foot.

right

(B)

(A).

10

Loading...

Loading...