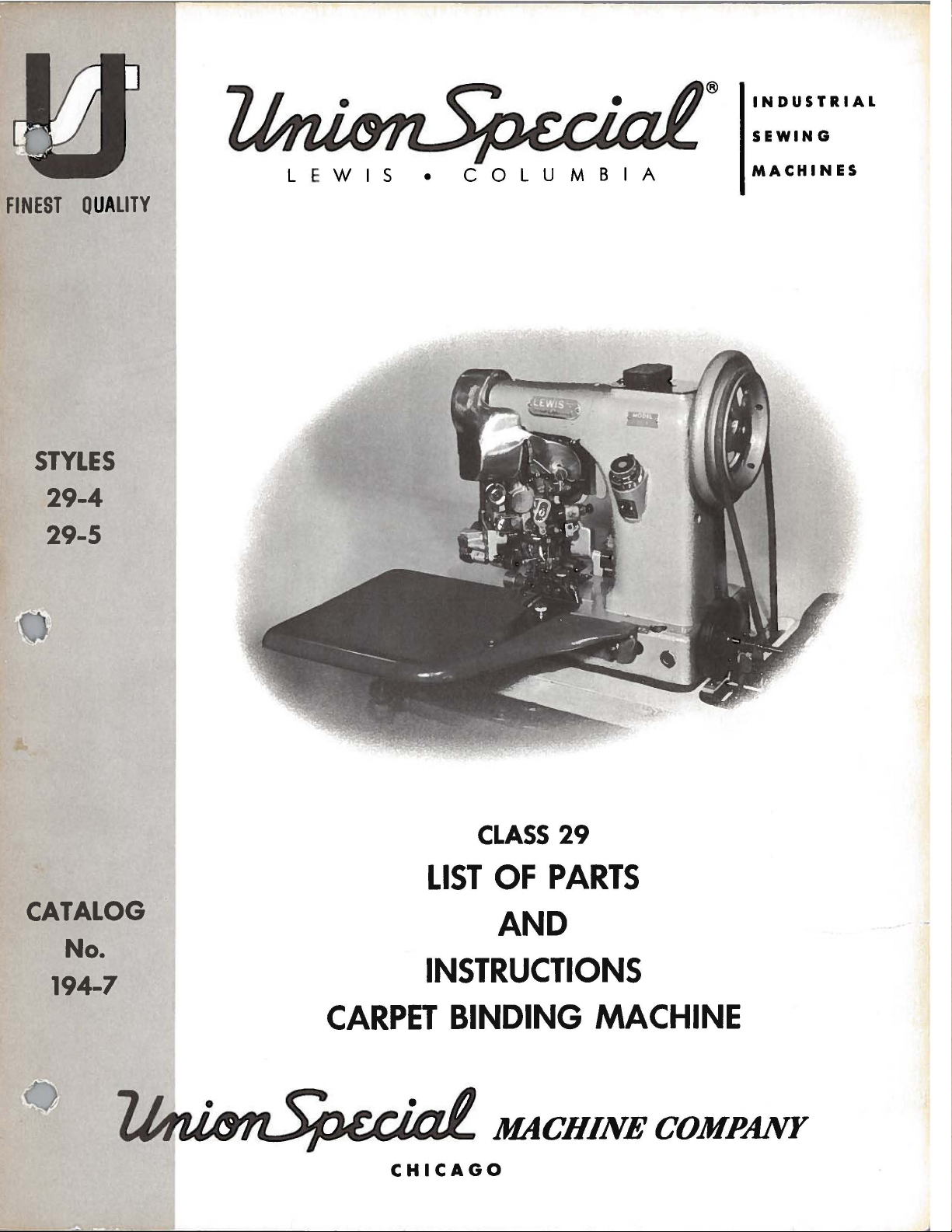

Lewis 29-4, 29-5 User Manual

®

INDUSTRIAL

SEWING

FINEST QUA

STYLES

29-4

29-5

LITY

L E

WIS

•

COLUMBIA

MACHINES

CATALOG

CLASS

LIST

OF

29

PARTS

AND

No.

INSTRUCTIONS

194-7

CARPET

CHICAGO

BINDING

MACHINE

FOREWORD

There

demand

greater

has

come

At

has

made

binding.

the

LEWIS

The

binding

81200

the

AZ.

Lewis

machine

The

mounted

powerful~

spring

gripping

has

by

the

variety

into

first~

it

Our

Carpet

first

to

the

The

Carpet

for

LEWIS

on

consisting

pressed

the

with a feeding

The

carpet

sewing

carpet

in

the

re-rolled

continues

the

LEWIS

binding

the

edge

and

been a great

people

of

sizes

wide

these

necessary

attention

Binding

operation

carpet.

binding

binding

Class

top

of

rolls

binding

rate

is

rolled~

of

along

Carpet

has

been

the

opposite

for

to

use

broadloom

carpets

for

was

in

This

is

Binding

carpets

29

the

table~

of

the

directly

and

carpet~

of

four

binding

on

Binding

stretched

change

rugs

be

were

the

that

carried

bound

carpet

called

Machine.

sewing

operation

then

carried

Machine

results

machines

requiring

two

top

rotary

under

pull

{4)

stitches

placed

to

the

on

the

conveyor~

Machine

over

edge

is

bound.

in

the

more

by

carpets

by

dealers

to

this

binding

up

to

the

in

prompt

are

the

top

the

carpet~

per

the

carpet

the

carpet

nearly

the

carpet

that

hand~

necessity

on

is

usually

and

backing

industry

fit

can

be

but

to

speed

carpets

over

of

the

room~

dealers.

cut

the

and

done

the

edge

the

deliveries

45

no

hole

feeds

feeds.

inch

degree

with

lying

at

for

1400

the

very

The

right-hand

powerful

on

R.

conveyor -about

on

the

and

and

carpet

the

is

Union

corner

pulled

and

Special

along

blindstitched~

in

recent

which

With

to

any

demand

up

their

this

size.

for

methods

resulted

is

to

sew

on a Union

and

is

carpet.

and

satisfied

machines

machine.

coarse

teeth

top

a

conveyor~

P.

M.

18

inches

Style

of

the

carpet

on

the

years

through

necessitates

change

faster

service

of

in

our

producing

one

edge

Special

blindstitched

Using

the

customers.

that

The

feed

is

acting

against

rotating

by

the

machine

is

unrolled

81200 AZ;

is

then

conveyor;

the

carpet

a

there

carpet

of

the

Style

by

LEWIS

are

very

feeds~

for

the

placed

after

is

The

machine

edge~

carpet

the

including

The

machine

binding

needle

thread.

and

winding a coarse

Machine.

equipped

More

with

oil

is

equipped

stretching

will

handle

No.

30

thread

production

pads

for

device

threads

It

is

recommended

or

finer

on

paper

can

lubricating

with a device

for

laying

as

coarse

for

the

bobbin.

bobbins

be

gained

the

by

thread.

2

for

rolling

the

binding

as

that

No. 16

suitable

using

No.

Some

for

these

the

binding

tightly

16

and

to

No.

thread

the

LEWIS

bobbins.

Engineering

up

and

in

place.

as

fine

as

24

thread

be

manufacturers

Carpet

The

machine

Department

over

the

finest

used

Binding

the

in

are

is

Catalog

No.

INSTRUCTIONS

FOR

194-7

The

furnished

ADJUSTING

LIST

29-4

parts

at

listed

list

First

AND

OF

Styles

in

prices

OPERATING

PARTS

29-5

this

for

Edition

catalo

repairs

g

are

only.

Copyri

g

ht

1965

by

Union

Rights

Special

Reserved

Machine

in

All

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

September~

1965

SEWING

CHICAGO

in

3

MACHINES

U.S.A.

Co.

IDENTIFICATION

OF

MACHINES

Each

of

machines,

The

below

This

herein.

are

taken

direction

High

Machine.

the

line

operated

4

1/4

29-4

carpets

29-5

and

mechanism

hard

plunger

has a contoured

Standard

Union

serial

the

plunger

catalog

All

of

Production,

of

for

inches.

For

Same

also

to

is

references

from

the

handwheel

Needle

feed.

inserting

the

second

or

rugs.

as

29-4,

reduces

sew

which

needle

Special

stamped

number

regulator.

applies

the

operator's

Two

travels

Calibrated

and

operation

Standard

except

marking

greatly

carpets.

minimizes

top

Type

Lewis

in

of

to

reduces

with a deeper

machine

the

style

each

APPLICATION

specifically

direction,

is

DESCRIPTION

Thread,

from

removing

This

29-127.

machine

position

away

right

penetration

of

blindstitching

needle

wider

on

carpet

new

needle

carries

plate

to

such

from

feed

the

Single

to

adjustment.

work.

Type

wheels,

the

mechanism

blunting.

a

style

on

the

front

is

stamped

OF

CATALOG

the

Standard

as

right

while

OF

left

carpet

backing breakage

notch,

seated

operator.

MACHINES

Curved

and

Maximum

carpet

29-137.

which

backing.

The

to

number,

of

in

Styles

and

at

Needle,

penetrates

Work

work

binding

increases

produces

plunger

greatly

the

column.

the

base,

of

left,

front

the

machine.

Lockstitch,

at

support

space

A

new

and

a

dwell

is

reduce

which,

machines

an

to

the

cracking on some

smaller

in

this

class

on

the

right

as

listed

and

back,

Blindstf1:ch

angle

plate.

to

right

the

under side

feeding power

plung

er

{paus

in

needle blunting.

etc.

Operating

of

45

Treadle

of

needle

driving

e )

of

ar ea

side

,

to

of

the

and

Use

only

"LEWIS"

The

by

this

The

Selection

material

ood

a g

When sewin

point.

To

sample needle,

the

label.

on

the

type

catalog are g

following

used.

stitch

have needle

formation.

A comple

genuine

shank.

number

types

of

proper

Thread

g,

immediately

or

the

NEEDLES

Union

of

iven

Needle

orders promptly

te

order

Special

the

needles

in

the

and

sizes

Type

29-127

29-136

29-137

needle size

should pass freely through t

Type numb

would read:

Lewis needle

recommend

machine

are

discard any needle whi

er s

styl

availabl

Size

•

070

•

060

•

070

is

det

and accurately filled,

hould

"100

s.

They

ed

for

each

e description.

e:

Blade

Uniform

Ball ey

all

ey e

B

er m

ined by size

he

needle eye in

ch

be f

orwarded

Nee

dle

s,

are stamped

style of

e

of

thread

may

have a hook

an

em

. Us e the description

Typ

e 29- 137".

with the

mach

or der

ine cov

and weight

pty

contain

to

ed

word

er ed

produc

or blu

er,

of

e

nt

a

on

4

ADJUS

CHA

TING

NGI

INSTRUCTIONS

NG NEEDLES

When

carrier

improper

six

machine

table.

hole

removing

with

operation.

To

gasoline

allow

e

xposed

as far

Immediately dis

needl

Class

holes.

to

This

will

To

vaseline.

remov

have

th

protect the

e

or petrol

the

thread

part

ch

ang

ing needle. make

as

it will

e pe

netrat

29 m achines

two

to per

table. Set m achine from

is the m ost c

to

be

e f

oot

or

which

T

ake off the a

this cov

to remove th

to pass ov

s.

go. and tight

card any

ion wi

are

mit the be

onvenient position for

drill

ed

load

ing work.

machi

er the t

ne

must

luminu

er the

needle

ll res

set on

lt

wh

en

fro

m r usting

be c

aref

m head

ake

- up (H.

e gr

su

r e that the

en cla

which may have a hooked

ult

SETTI G

a s

to operate from

using treadle

ully

ease from the

hook freely

mp scr

.

olid board. and

four to

wh

wipe

cov

er

by loo

Fig

.

.

needle

ew completely.

UP

the

five

inches

handling the

for

ile

in transit.

d off

1)

Also wipe

mu

befo

sen

st

hook

is inserted in

or

it

is

only necessary

transmitter

from the

work.

dr

opping

re the

ing

thumb scre

be

at its

and

off

low

all par

bobbin cas

foot,. needle

blunt

and

front edge

An

er rolle

ts

machine

w (H.

lowest

the nee

ed poi

four

are

point.

nt..,

to

to

additional

r.

covered

is put

Fig. 13

e.

so

and

dle

bore

bolt

of

the

when

Use

as

other

as

in

).

to

Fig

. 1

•

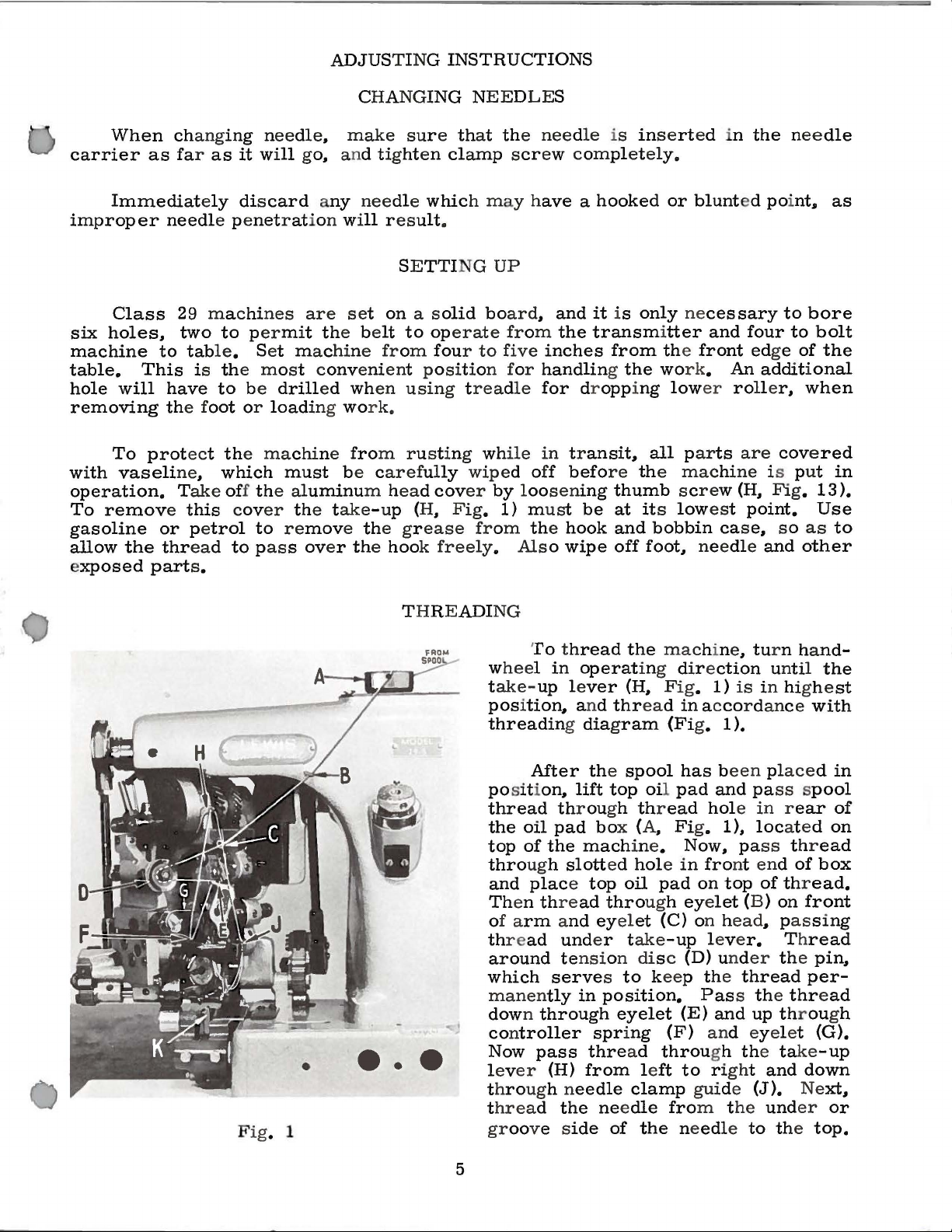

THREADING

•••

To thread

w

heel in

t

ake-

pos

ition,. and

threading diagram

After the

posit

thread

the

oil

top

of

through

and

place top

Th

en thre

of a

rm and eyel

th

r e

ad

around tensi

which

manen

down through

controller

Now

lev

er

throug

t

hread the nee

groove s

operat

up lever

ion,.

lift

throu

pad box (A. Fig.

the

slott

ad

und

serves to keep the thread

tly

in

pass

(H)

h n

eedle

ide

the

ing dir e

(H,.

thread

spool

top oil

gh thr

mach

ine.

ed

hole in

oil

through eye

et

er t

ake

on dis c (D) und

position.

eyelet

spring

thre

ad

from left

clamp

dle

of

the needle to the

mac

hine. tur n ha

ction

Fig

.

1)

in acco

(Fi

g. 1 ).

has been placed in

pad

and pass spool

ead

hole in rear

1).

Now. pass thr

fro

pad

on

top

let

(C) on h

-up

leve

Pass the thread

(E)

and

(F) and eyel et

throu

gh the take

to right and

gui

de

fro

m t

unt

is

in highe

r dance

loc

ated

nt end

(B )

ead

r.

he

of

of thr

on

,. pas

Th

er the pin,.

up through

(J).

und

er

nd-

il

the

with

ead

box

ead.

front

sing

read

per-

(G).

-up

down

Ne

xt,.

or

top.

st

of

on

5

THREADING

(Continued)

When

under

mend

To

to

the

One

loading

loaded

used

the

disc

loading

sew

in

needle

in

the

passing

the

take-up

that

the

avoid

Left"

of

the

tension

the

and

the

the

next

thread

lever

take-up

misunderstanding

we

have

the

characteristics

work

following

thread

into

disc

hook

material

carpet.

lever

Turn

inserted

the

located

manner:

thread

holder,

as

from

(H).

be

to

the

the

machine.

on

may

then

it

is

INSERTING

eyelet

Until

Right

the

When

not

thoroughly

at

its

regarding

above

THREAD

of

this

There

gear

one

be

carried

cut.

necessary

(C)to

highest

instructions

arrows

HOLDER

machine

is a thread

cover

end

This

THE

tension

familiar

point

showing

in

the

of

the

through

allows

to

BOBBIN

disc

during

Turn

is

back

carpet

the

hold

(D),

with

to

the

"Turn

what

that

both

holder

of

and

placed

operator

the

threads

see

threading,

the

process

Left

to

the

these

hands

in

the

the

is

completed

that

the

of

Right"

expressions

are

form

machine.

between

to

use

both

when

thread

we

threading.

and

needed

of a spring

and

the

beginning

goes

recom-

"Turn

mean.

It

can

run-off,

tension

hands

for

be

in

to

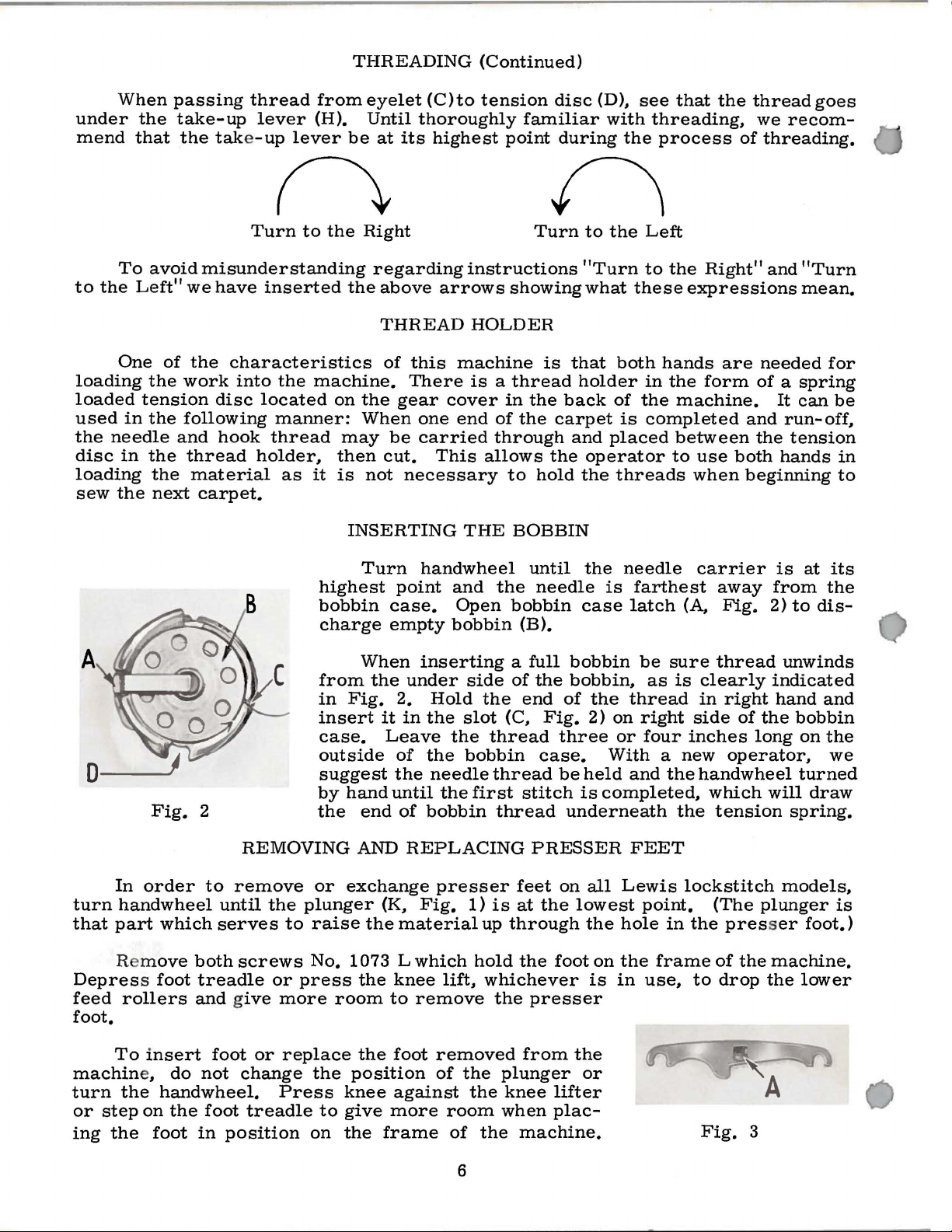

Fig.

In

order

turn

handwheel

that

part

which

R m

ove

Depress foot

feed

foot.

rollers

2

REMOVING

to

remove

until

serves

both

screws

treadle

and give

the

to

or

more

highest

bobbin

charge

from

in

Fig.

insert

case.

outside

suggest

by

hand

the

or

exchange

plunger

raise

No.

1073

press

room

Turn

case.

empty

When

the

it

Leave

the

until

end

AND

(K,

the

the

knee

to

handwheel

point

under

2.

in

of

of

REPLACING

material

Lwhich

and

Open

bobbin

inserting

side

Hold

the

slot

the

the

bobbin

needle

the

first

bobbin

presser

Fig.

remove

1)

hold

lift,

the

thread

up

whichever

until

the

needle

bobbin

(B).

a

full

of

the

end

(C,

thread

stitch

thread

PRESSER

feet

is

at

through

the

the

presser

the

case

bobbin

bobbin,

of

the

Fig.

2)

three

case.

be

held

is

underneath

on

all

the

lowest

the

foot

on

is

needle

is

farthest

latch

thread

on

or

With a new

and

completed,

FEET

Lewis

hole

the

in

be

sure

as

is

right

four

the

the

point.

in

frame

use,

(A,

side

inches

lockstitch

the

to

carrier

away

Fig.

thread

clearly

in

right

handwheel

which

tension

(The

presser

of

drop

from

2)

indicated

hand

of

the

long

operator,

will

plunger

the

machine.

the

is

at

the

to

dis-

unwinds

and

bobbin

on

the

we

turned

draw

spring.

models,

foot.)

lower

its

is

To

machin

turn

or

step

ing

the

insert

e,

the

handwheel.

on

foot

do

the

foot

not

foot

in

position

or

replace

change

Press

treadle

the

to

on

the

foot

position

knee

give

the

against

more

frame

removed

of

the

the

room

of

the

6

from

plunger

knee

when

lifter

plac-

machine.

the

or

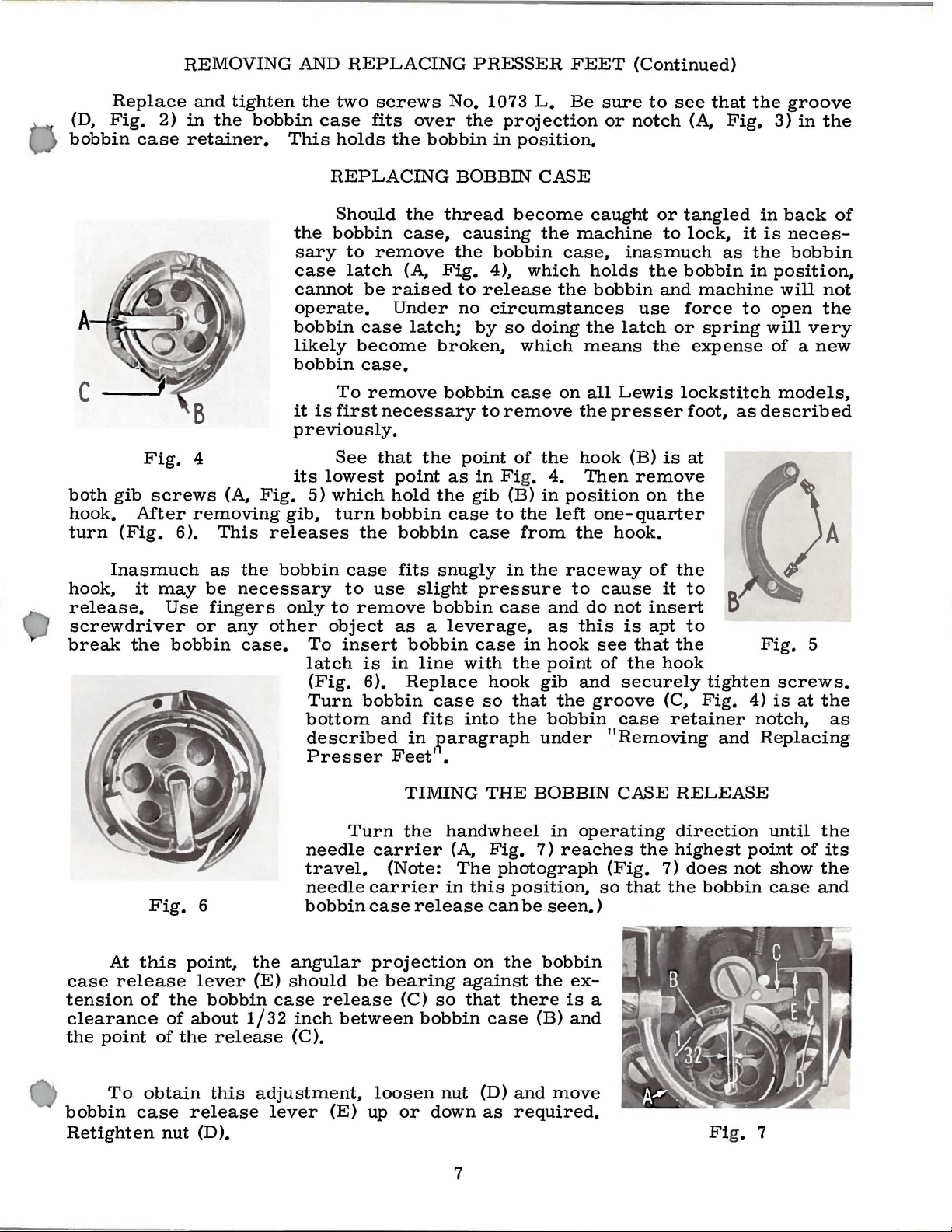

Fig.

3

REMOVING

AND

REPLACING

PRESSER

FEET

(Continued)

Replace

(D,

Fig.

bobbin

A

C

both

gib

hook.

turn

case

Fig.

screws

After

(Fig.

and

2)

in

retainer.

4

removing

6).

tighten

the

(A,

This

the

bobbin

This

the

sary

case

cannot

operate.

bobbin

likely

bobbin

it

previously.

its

Fig.

gib,

releases

two

screws

case

is

lowest

5)

fits

holds

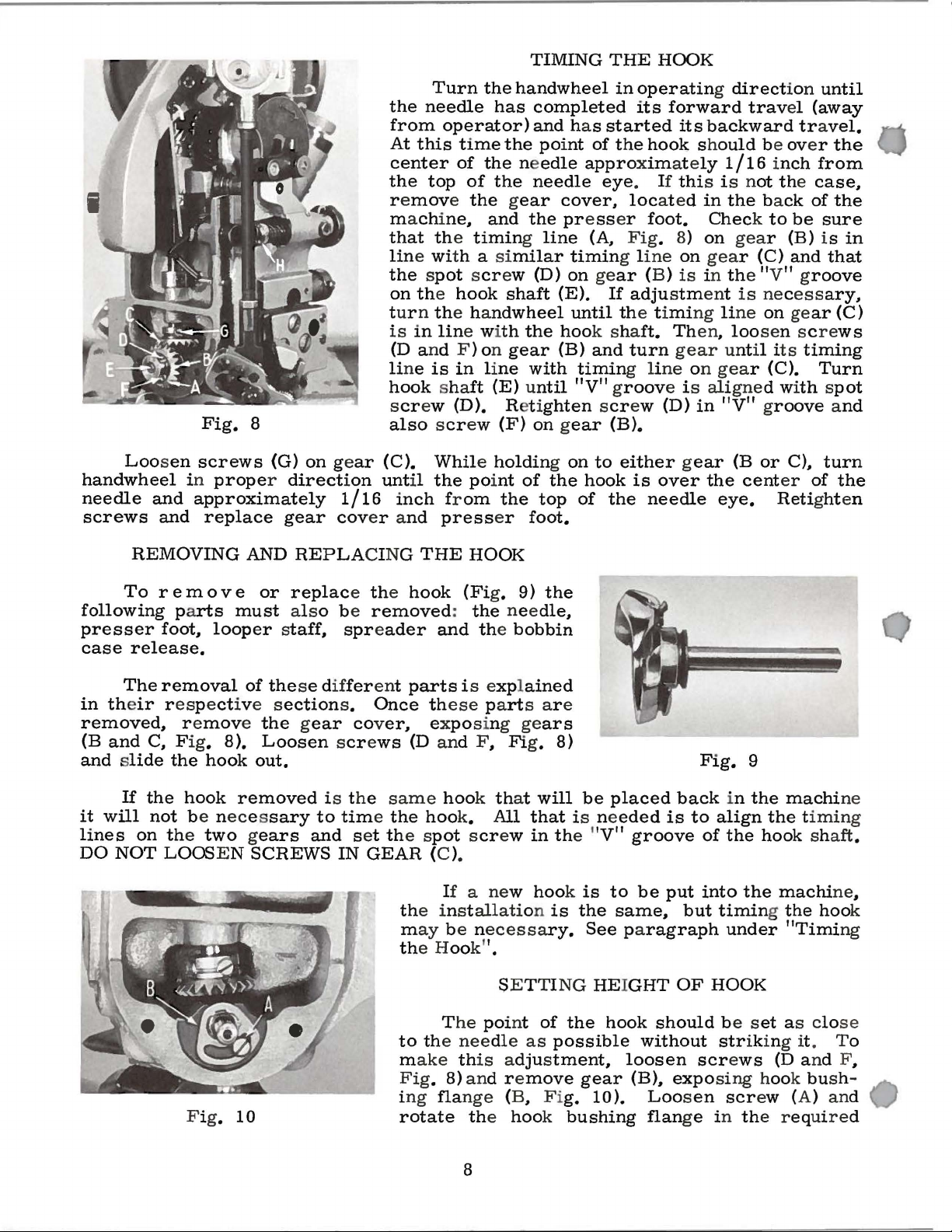

REPLACING

Should

bobbin

to

remove

latch

be

case

become

case.

To

remove

first

necessary

See

that

which

turn

bobbin

the

over

the

bobbin

the

case,

(A,

raised

Under

latch;

the

point

hold

bobbin

No.

1073

the

BOBBIN

thread

causing

the

Fig.

broken,

bobbin

the

4),

to

release

no

circumstances

by

to

point

as

in Fig.

gib

case

case

L.

projection

in

position.

CASE

become

the

bobbin

which

the

so

doing

which

case

remove

(B)

to

of

the

from

on

the

4.

in

left

Be

sure

or

caught

machine

case,

holds

bobbin

the

latch

means

all

Lewis

the

presser

hook

Then

position

one-

the

hook.

to

see

notch

inasmuch

use

(B)

remove

quarter

or

tangled

to

the

bobbin

and

force

or

the

lockstitch

is

on

the

(A,

lock,

expense

foot,

at

that

the

Fig.

it

as

the

in

machine

to

spring

as

groove

3)

in

the

in

back

is

neces-

bobbin

position,

will

not

open

will

of a new

described

the

very

models,

A

of

Inasmuch

hook,

release.

screwdriver

break

case

tension

clearance

the

it

the

At

release

point

Fig.

this

of

may

Use

bobbin

point,

the

of

about

of

the

as

be

fingers

or

any

6

lever

bobbin

release

the

bobbin

necessary

only

other

case.

the

(E)

1/32

To

latch

(Fig.

Turn

bottom

described

Presser

needle

travel.

needle

bobbin

angular

should

case

inch

(C).

case

to

to

remove

object

insert

is

6).

bobbin

Turn

carrier

case

projection

be

release

between

fits

snugly

use

slight

bobbin

as a leverage,

bobbin

in

line

with

Replace

case

and

fits

into

in

~aragraph

Feet'

carrier

(Note:

bearing

•

TIMING

the

handwheel

(A,

The

in

release

(C)

so

bobbin

this

against

that

in

the

pressure

case

case

in

the

hook

so

that

the

THE

on

BOBBIN

Fig.

can

case

7)

photograph

position,

be

the

the

there

(B)

raceway

to

and

do

as

this

hook

point

gib

and

the

bobbin

under

in

operating

reaches

seen.)

bobbin

ex-

is

and

of

cause

not

insert

is

apt

see

that

of

the

securely

groove

case

"Removing

CASE

the

(Fig.

so

that

a

the

it

to

to

the

hook

tighten

(C,

Fig.

retainer

and

RELEASE

direction

highest

7)

does

the

bobbin

Fig.

screws.

4)

is

notch,

Replacing

until

point

not

show

case

at

of

5

the

as

the

its

the

and

To

bobbin

Retighten

obtain

case

nut

this

release

(D).

adjustment,

lever

(E)

loosen

up

or

nut

down

7

(D)

and

as

required.

move

Fi

g. 7

TIMING

THE

HOOK

Loosen

handwheel

needle

screws

and

and

Fig.

screws

in

8

(G)

proper direction

approximately

replace

gear

on gear

1/16

cov

Turn

the

needle

from

At

this

center

the

top

r e

move the gear

machine~

that the

line wi

the

operator)

time

of

the needle

of

timing line

th a similar

the spot scr

on the

hook

tur n the ha

is

in

lin

e wi

(D

and F ) on

li

ne

is

in

line

hook

sha

ft

screw (D). Ret i

also scr

(C).

until

ew

While holding on

the poi

inch from

er a

nd

press

handwheel

has

completed

and

the poi

the

needle

and

the presser

ew (D)

shaft

ndwheel

th

the

gear

with

(E) until

ghten scr

(F)

on gear

nt

of

the

top

er

foot.

in

operating direct

its

forward

has

started

nt

of

the

approxim

eye

cover~

loc

its

hook should

at e

ly

.

If

thi

s i s n

ated

in

foot.

(A

Fig

. 8)

1

timing li

on gear

(E).

If

ne

(B) is in the "V" g

adjustment

on

on

until the timing line

hoo

k sha

(B)

and

timing li

"V" groov

ft.

Then~

turn

gear until its

ne

on

e i s ali

ew (D)

in

(B).

to

either gear

the

hook

of

the

is

over

needle

ion

until

trav

el

(away

backward tra

be over

1/16 inch

ot the

the back

Check to

gea

r (B) i s

gea

r (C)

from

case~

of

be

and

roove

is

necess

on gear

loosen screws

timing

gea

r (C).

gne

d wi

Turn

th spot

"V" groove and

(B

or

C)1 turn

the

cent

er

of

eye.

Retight

vel.

the

the

sure

in

that

ary~

(C)

the

en

REMOVING

To r em

following parts

presser

case

in the

removed~

(B

and

and slide

it

will

lines

DO

NOT

foot~

release.

The

removal

ir respect

r e

C~

Fig. 8).

the

If

the

hook

not

be neces

on the

LOOS E N

move the gear

hook

two gears

AND

o v e

must

looper

of

ive s

removed

REPLA

or

replace the hook

also be

CING

removed

staff1 spreader

the

se different

ection

s.

cover,

Loosen screws

out.

is the

sary

SCREWS

to

time the

and

IN

set the s

GEAR

THE

HOOK

(Fi

:

the

g. 9)

nee

and the

parts

i s expl

Once these part

exposing gears

(D and F1 Fi

same

hook th

hoo

k.

pot scr

All

ew

(C ).

If

a new

th

e inst

m

ay

th

e Hook"

be n

allati

ecess

.

SETTI NG

the

dle

bobbin

ained

s ar e

g.

8)

at

will

that

in the "

hook is

on

is

ary.

1

be

placed

is ne

eded

V"

groove

to

be

the

same1 but

See paragraph

HEIGHT

back

is

put

OF

Fig.

to

in

align

of

the

into

9

the

the

timing the

under

HOOK

machi

the timing

hook shaft

machi

ne

hoo

"Timi

ng

ne

.

1

k

T

he

poi

nt

of

Fig.

10

to the

m

Fig

ng

i

rotate

needle

as

possible

ake this adjustment1 loosen

. 8) and r e

fla

nge

move

(B1 Fi

g.

the hook bushing

8

the

gear

hook

should

without

be s

str

screws

(B)1 exposing hook bu

10).

Loosen

flan

scr

ge in the required

et

as close

iking it. To

(D

and F

sh-

ew (A) and

1

SETTING

HEIGHT

OF

HOOK

(Continued)

direction

cannot

in

the

Replace

The

(H,

Fig.

set

sufficiently

make

needle

Fig.

more

against

so

very

grades

stitch

and

plunger,

this

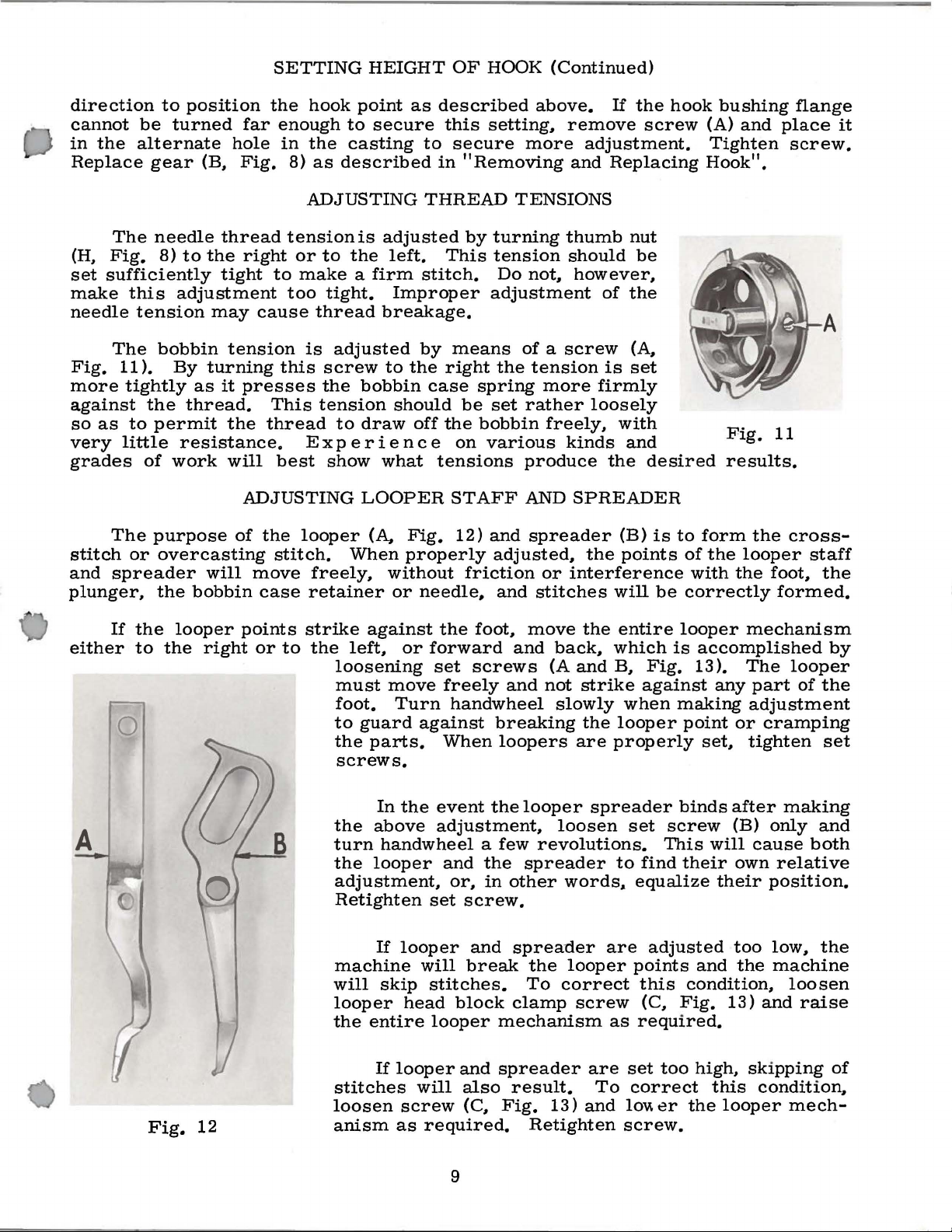

The

11

tightly

as

to

little

The

or

spreader

to

position

be

turned

alternate

gear

needle

8)

to

adjustment

tension

bobbin

).

By

as

the

thread.

permit

resistance.

of

work

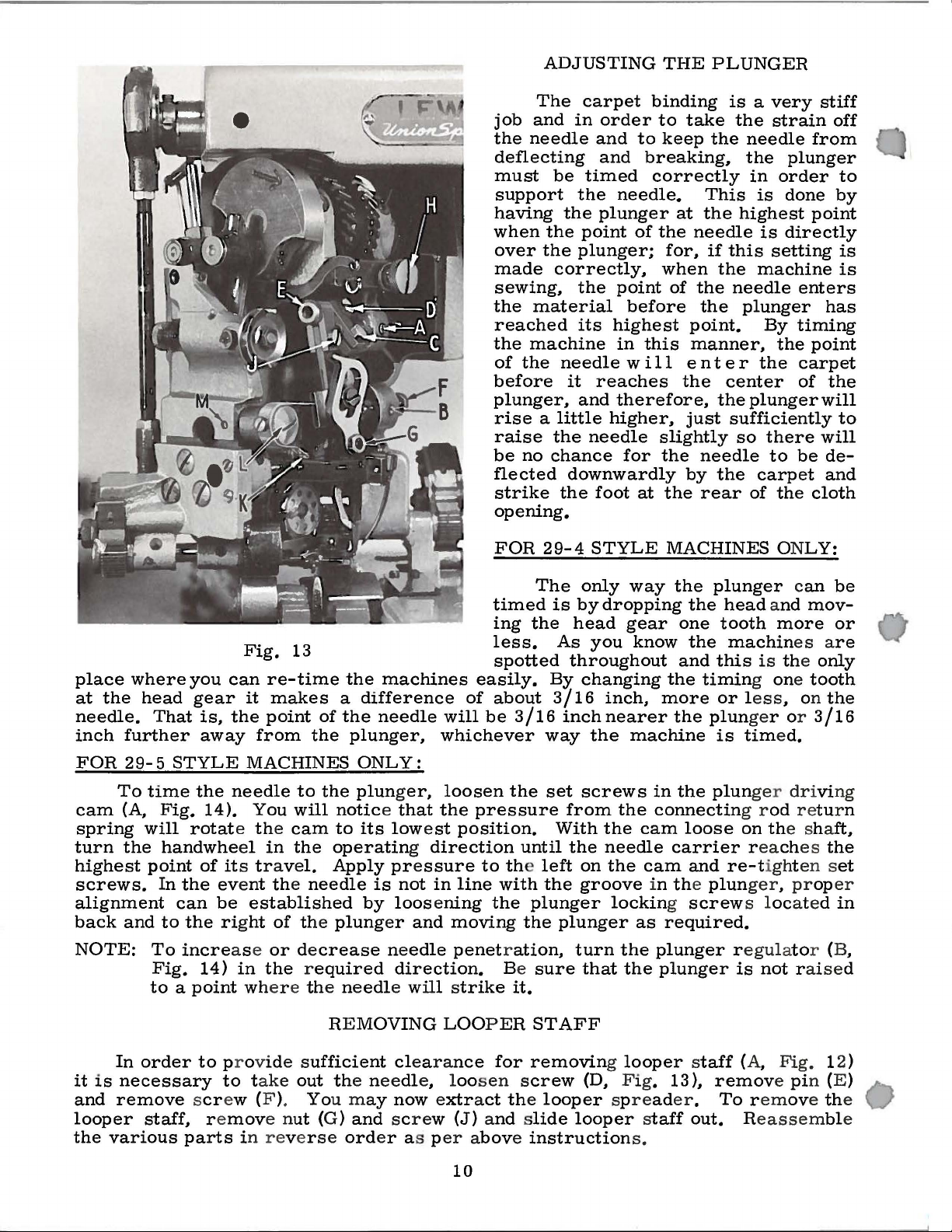

purpose

overcasting

the

bobbin

far

hole

(B,

Fig.

thread

the

right

tight

may

cause

tension

turning

it

presses

the

will

ADJUSTING

of

the

will

move

case

the

hook

enough

in

the

8)

as

ADJUSTING

tension

or

to

to

make a firm

too

tight.

thread

is

this

screw

the

This

thread

Ex

best

looper

stitch.

freely,

retainer

tension

show

point

to

secure

casting

described

is

adjusted

the

left.

Improper

breakage.

adjusted

to

bobbin

should

to

draw

p e r i

en

what

LOOPER

(A,

When

without

or

as

described

this

to

secure

in

"Removing

THREAD

by

This

stitch.

by

means

the

right

case

be

off

the

c e

on

tensions

STAFF

Fig.

properly

12)

friction

needle.

above.

setting,

more

TENSIONS

turning

tension

Do

not,

adjustment

of a screw

the

tension

spring

set

bobbin

various

and

adjusted,

rather

produce

AND

and

more

freely,

spreader

or

stitches

If

the

remove

adjustment.

and

thumb

should

however,

firmly

loosely

kinds

SPREADER

the

interference

screw

Replacing

nut

be

of

the

(A,

is

set

with

and

the

desired

(B)

is

points

will

hook

to

of

with

be

correctly

bushing

(A)

and

Tighten

Hook".

Fig.

results.

form

the

the

looper

the

flange

place

screw.

11

cross-

staff

foot,

formed.

it

the

either

A

If

the

to

Fig.

looper

the

right

12

points

or

to

B

strike

the

left,

loosening

must

foot.

to

guard

the

screws.

the

turn

the

adjustment,

Retighten

machine

will

looper

the

stitches

loosen

anism

against

move

parts.

In

above

handwheel a few

looper

If

skip

entire

If

the

or

forward

set

Turn

against

the

event

adjustment,

set

looper

will

stitches.

head

looper

looper

will

screw

as

required.

foot,

screws

freely

handwheel

When

the

and

the

or,

in

screw.

and

break

block

and

also

(C,

move

and

back,

(A

and

and

not

slowly

breaking

loopers

looper

spreader

other

spreader

the

To

clamp

mechanism

spreader

result.

Fig.

Retighten

are

loosen

revolutions.

words,.

looper

correct

screw

13)

the

entire

which

B,

strike

when

the

looper

properly

spreader

set

to

are

as

are

set

To

correct

and

loVI.

screw.

looper

is

accomplished

Fig.

against

find

equalize

points

this

(C,

required.

13).

making

point

binds

screw

This

their

adjusted

and

condition,

Fig.

too

high,

er

the

any

or

set,

after

(B)

will

own

their

too

the

13)

this

looper

mechanism

by

The

looper

part

of

the

adjustment

cramping

tighten

only

cause

relative

position.

low,

machine

and

skipping

condition,

set

making

and

both

the

loosen

raise

mech-

of

9

ADJUSTING

The

carpet

job

and

in

the

needle

deflecting

must

support

having

when

over

made

sewing,

the

reached

the

of

before

plunger,

rise a little

raise

be

flected

strike

opening.

be

the

the

the

correctly,

material

machine

the

needle

it

the

no

chance

downwardly

the

timed

the

point

plunger;

the

its

and

order

and

and

needle.

plunger

of

point

before

highest

in

w i 11

reaches

therefore,

higher,

needle

for

foot

THE

binding

to

take

to

keep

breaking,

correctly

at

the

needle

for,

when

of

the

point.

this

at

manner,

en

the

just

slightly

the

by

the

PLUNGER

is a very

the

the

needle

the

in

This

the

if

the

needle

rear

is

highest

is

this

setting

the

machine

needle

plunger

By

t e r

the

center

the

plunger

sufficiently

so

there

to

the

carpet

of

strain

from

plunger

order

done

point

directly

enters

timing

the

point

carpet

of

be

the

cloth

stiff

off

to

by

is

is

has

the

will

to

will

deand

place

at

needle.

inch

FOR 2 9-5 STYLE

cam

spring

turn

highest

screws.

alignment

back

NOTE:

the

further

To

(A,

the

and

where

head

you

gear

That

time

will

point

To

Fig.

to a point wher e the ne

is,

away

the

Fig.

14).

rotate the cam

handwhe

of its trave

In

the eve

can

be

to

the rig

incre

14)

Fig.

can

the

needle

el

ase

in

13

re-time

it

makes

point

from

MACHINES

to

You

will notice that

in

the

l.

nt the

established

ht

needle

of the

or decrease

the required

the

machines

a

difference

of

the

needle

the

plunger,

ONLY:

the

plunger,

to

its

lowest

operating direction

Apply pre

is

by

loosening

plung

er

ne

direction.

edl

e will s

not

and

edle

ssure

in

will

whichever

loosen

the

moving

penetration,

FOR

timed

ing

less.

spotted

easily.

of

about

be

3/16

the

pressure

position.

until

to the left

line

with

the

Be

trike

it.

29-4

The

is

the

As

throughout

By

3/16

inch

way

set

from

With

the

the

plunger

the

plunger

sure

STYLE

only

by

head

changing

screws

on

groove

turn

that

way

dropping

gear

you

know

inch,

nearer

the

machine

the

the

cam

needle

the

cam

in the

locking screw

as

the

the

MACHINES ONLY:

the

plunger can

the

head and

one

tooth

the

machin

and

this

the

timing one tooth

more

in

connectin

carrier reaches

required.

plunger regulato

plunger

or less

the

plunger or

is

the

plunger driving

loose

and

re-tigh

plun

more

es are

is the

, on

tim

ed.

g r

od

r etur n

on the sha

t en s

ger, proper

s located

is

not

r aised

be

mov-

or

only

the

3/16

ft,

the

et

in

r (B,

RE

In

it

is

necessary

and

remove scr

looper

the

various

order

staff,

to

r e

parts

pr ovide s

to take

ew (F ).

mov

e n

ut

in rever

MOVING

ufficient clearance

out the needl

You may now extract the

(G)

and screw (J) and slide

se

ord

er a s p

LOOPER

e, loos

er above instruction

10

STAFF

for

removing looper staff

en screw

looper

(D, F ig. 13

spreader.

looper staff

s.

(A,

Fig.

),

remove pi

To remove the

out. Reassemble

12)

n (E)

Loading...

Loading...