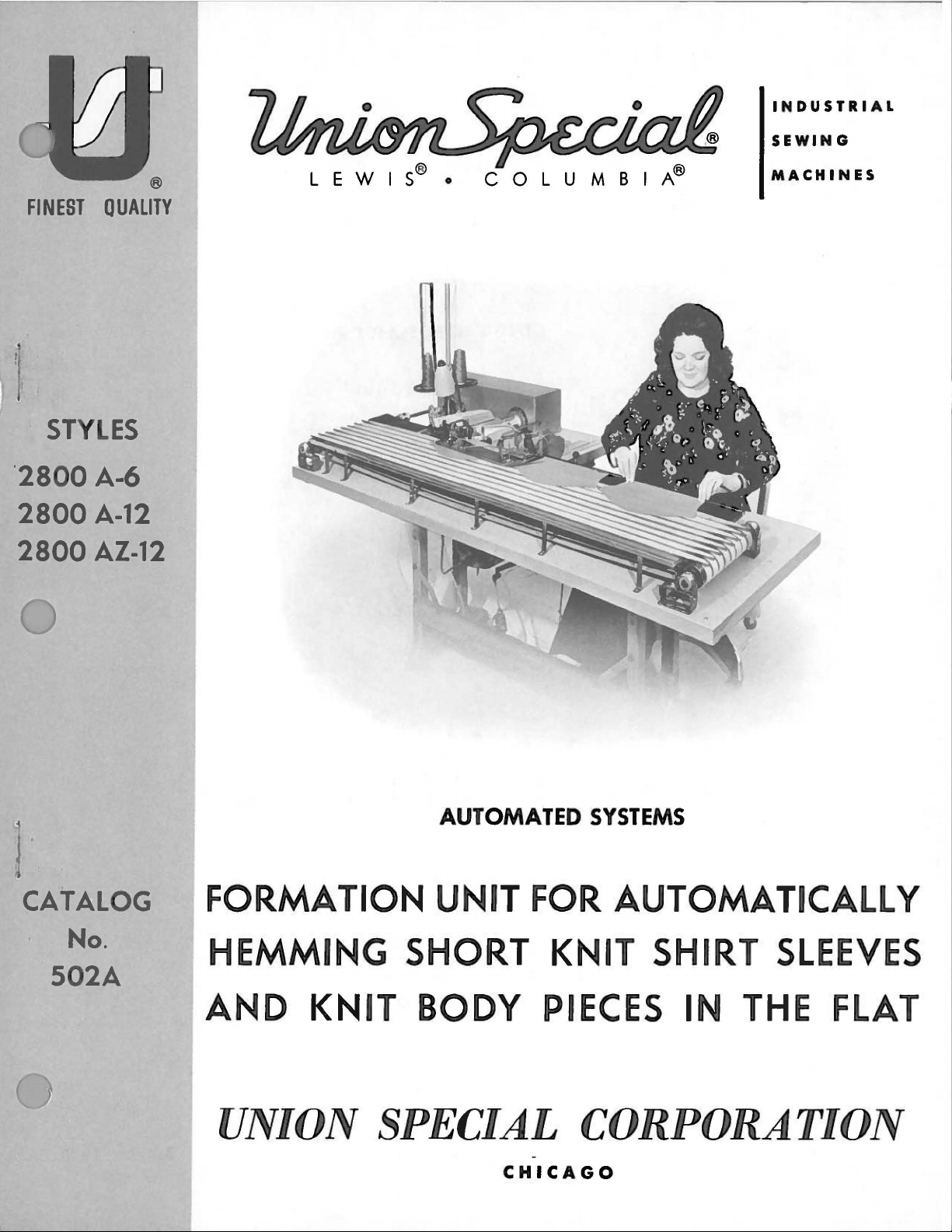

Page 1

INDUSTRIAL

FINEST

STYLES

'2800

2800

2800

®

QUALITY

A-6

A-12

AZ-12

ZVni<m~

SEWING

L E W I

S®

• C 0 L U M B I

A®

MACHINES

AUTOMATED

CATALOG

No.

FORMATION UNIT

FOR

HEMMING SHORT KNIT SHIRT

502A

AND

KNIT

BODY

PIECES

UNION SPECIAL

-

CHICAGO

SYSTEMS

AUTOMATICALLY

SLEEVES

IN

THE

FLAT

CORPORATION

Page 2

Catalog

INSTRUCTIONS

No.

AND

502A

2800

A-6

Union

Rights

LIST

CLASS

2800

First

Special

Reserved

OF

Styles

A-12

@

1975

By

PARTS

2800

Edition

Corporation

in

All

2800

Countries

AZ-12

UNION

SPECIAL

INDUSTRIAL

Printed

CORPORATION

SEWING

CHICAGO

in

U.S.

MACHINES

A.

March,

1978

Page 3

CONTENTS

SECTION

I.

II.

III.

IV.

V.

GENERAL

A.

B.

INFORMATION

UNIT

DESCRIPTION

SPECIFICATIONS

INSTALLATION

OPERATOR

A.

CARE

B.

ADJUSTMENTS

1.

2.

C.

MAINTENANCE

INSTRUCTIONS

AND

CONVEYOR

STITCH

DESCRIPTION

A.

CONVEYOR

B.

HEMMING

C.

AIR

BLOWERS

TECHNICAL

A.

WIRING

B.

UNIT

c.

ACCESSORIES

1.

2.

3.

DATA

DIAGRAM

OPERATING

"AIR-KLIPP"®

TRIM-MASTER

FOLDERS

.

HANDLING

FOR

• • .

OF

VARIOUS

..

PENETRATION

• • • . • .

AND

ADJUSTMENT

FOLDER

. . . .

SEQUENCE

. . . . . . • . .

CHAIN

KUT-VAC

WORK

WEIGHTS

.

OF

. . . . .

CUTTER

OF

CONTROLS

MATERIAL

PAGE

2

3

3

4

5

.

5

5

6

7

9

10

11

12

VI.

VII.

VIII.

PARTS

LIST

TROUBLE

A.

BITE

B.

BITE

C.

MATERIAL

FOOT

D.

FOLDING

SEWING

HEAD

SHOOTING

TOO

DEEP

IS

UNEVEN

REFUSES

NORMALLY

OF

CLOTH

• • . . . .

. . . .

OR

MISSES

TO

START

•.••••••

UNDER

PRESSER

. . . • • . • • .

. . . .

13

16

18

- 1 -

Page 4

Page 5

SECTION

I

GENERAL

INFORMATION

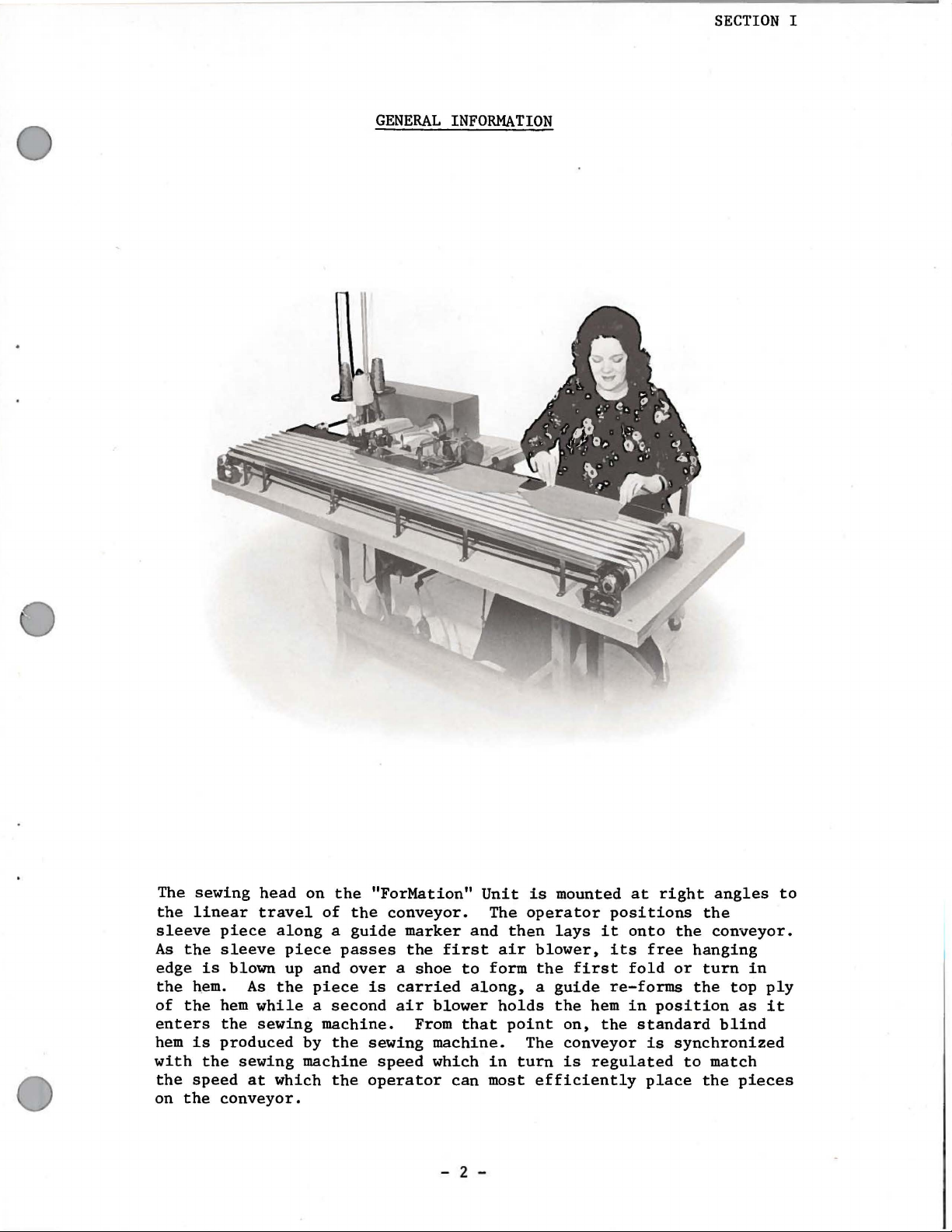

The

sewing

the

linear

sleeve

As

the

edge

is

the h.em.

of

the

enters

hem

is

with

the

the

speed

on

the

head

travel

piece

sleeve

blown up and

As

hem

while a second

the

sewing

produced

sewing

at

conveyor.

on

along a guide

piece

the

piece

by

machine

which

the

"ForMation"

of

the

passes

over a shoe

is

machine.

the

sewing

speed

the

operator

conveyor.

marker

the

first

carried

air

blower

From

machine.

which

can

- 2 -

Unit

and

to

along, a guide

that

The

then

air

form

holds

point

in

turn

most

is

mounted

operator

lays

blower,

the

the

on,

The

conveyor

is

efficiently

positions

it

its

first

re-forms

hem

the

regulated

at

right

onto

fold

in

the

free

or

position

standard

is

synchronized

place

angles

the

conveyor.

hanging

turn

the

top

blind

to

match

the

to

in

ply

as

it

pieces

Page 6

Page 7

SECTION

I

2800 A-6

2800 A-12

2800 AZ-12 -

39500

stitch

fl•at,

sport

DESCRIPTION

"ForMation"

for

knit

Specifications:

Treadle

Same

Same

flat

sleeves

RNZ -Differential

hemming on

warp

shirts.

and

"T"

operated

as

2800 A-6

as

2800 A-12

knit

body

light

ribbed

STYLE

Unit,

shirts,

pieces

weight

knit

OF UNIT

automatically

polo

3

phase

1

phase

except

except

OF

feed,

material

continuous

as

MACHINE

single-needle

rayon,

shirts,

- 60

- 60

24"

well

used

hems

HZ

HZ

wide

as

silk,

in

flat

and

sport

- 220

- 110

operation

conveyor

both

long

machine

cotton,

"T",

sleeve

volts

volts

polo,

shirts

control

for

and

for

wool,

and

pieces

hemming

short

blind-

nylon,

Shipping

Flopr

Minimum

Space

Information:

Height

Width

Length

Weight

Required:

Total

Work

SPECIFICATIONS

48"

48"

84"

lbs.

lbs.

6 x 9

- 12"

- 24"

375

450

3-1/2'

Area:

x

conveyor

conveyor

6'

- 3 -

Page 8

Page 9

SECTION

II

1.

Remove

top

2.

Unbolt

assembly

3.

Cut

out

is

4.

Set

off

5.

Bolt

needle

nearest

6.

Connect

unconnected

of

the

crate

cut.

thread

guide,

the

the

four

crate.

lower

off

steel

top

stand

that

1/2"

thread

the

the

INSTALLATION

wood

end

of

skids.

banding

and

then

on

farthest

flange

pull

front

two

matching

off

of

wires

2800 A-6

2800 A-12

2800 AZ-12

screws

table

that

stand

upright

from

using

guide

the

table

found

wires

INSTRUCTIONS

holding

legs

from

corsses

clear

already

the

front

the

pre-positioned

should

board.

at

base

using

the

perforated

skids

the

top

as

the

placed.

of

be

over

of

1/2"

wire

nuts

iron

and

lift

of

the

one

circumference

Use

only

the

machine.

bolts

the

cone

pipe

to

provided.

strapping

complete

crate.

one

so

that

of

the

to

Lift

band

pull

the

thread

two

7.

8.

Remove

lever

head

pivot

Remove

"L"

pivot

to

table

screw.

hold

shaped

screw.

top

down

bracket

This

during

bolt

which

bracket

shipment.

and

block

is

fastened

is

of

wood

only

Replace

used

behind

to

the

to

foot

handwheel.

foot

hold

lifter

lifter

sewing

lever

- 4 -

Page 10

Page 11

SECTION

III

III.

OPERATION

A.

Care

1.

Pieces

disarranged.

table

that

will

bundles

that

the

B.

Adjustments

After

handled

is

conveyor

slower

served

the

1.

INSTRUCTIONS

and

handling

to

and

the

ends

produce

causes

in

turn

roll

to

for

once

setting

by two

speed.

than

what

visually

presser

Conveyor

end

of

foot.

sleeve.

of

be

hemmed

Sleeves

placed

too

in a canvas

to

be

superior

the

causes

start

various

the

adjustments.

The

the

by

concentrating

slow -can

work

should

taken

hemmed

results.

ends

of

folder

properly

weights

machine

conveyor

sewing

not

be

tied

in

carefully

bin

or

are

not

Careless handling

the sle

trouble

under the

of

material

almost

The

most

should

machine

cause a widening

feeds.

attention

from the

box,

turned

eves

to

and

difficulty

pre

all

materials

important

run

bundles

taking

under

curl

sser

just

This

at

the

trim

nor

cutting

care

or ple

of

into a roll

in

getting

foot.

can

be

adjustment

a

trifle

can

be

ob-

cloth near

at the

ated

finish

2.

The

guide

thickness

compensated

1.

2.

C.

Maintenance

1.

2.

3.

Conveyor

hem

and a diminishing

progresses.

second

controlled

and

Bite

too

a.

Turn

Bite

a.

Unit

Oil

Bearing

is

Turn

should

in

too

most

machine

used

sizing

for

by

dee

p:

knurled

uneven

knurled

be

on

end

fast

adjustment

by

the

content

adjusting

thumb s

or

thumb

blown

should

of

-

causes

trim

knurled

crew

misses:

screw

out dai

be

the

rollers

pleats

as

will

thumb

cuases

screw.

in

in a counterclockwis

ly.

checked

in

the

length

be

the

screw.

varying

clockwise

every

should

the

week.

be

top

ply

of

the

sewing

Weight

bites

direction.

oil

ed

that

once

of

the

sleeve

machine hem

of

cloth,

can

be

e

direction.

weekly.

- 5 -

Page 12

Page 13

SECTION

IV

1.

Adjust

the

loosening

2. The

the

rotate

slower,

Note:

is

3.

For

slower

are

speed.

Note:

Check

4.

The

This

leakage,

conveyor

table

conveyor

end

running.

best

semi-stiff,

gear

oil

top.

the

of

the

adjusting

rotate

Do

not

results,

than

The

conveyor

the

sewing

reduction

is

it

CONVEYOR

belts

Make

wing

nuts

speed

force

the

obtainable

should

is

gear

knob

adjusting

the

machine

it

is

must

machine

drive

last

INSTRUCTIONS

so

that

this

and

adjusted

reduction

counterclockwise;

knot

adjusting

conveyor

feeds.

possible

never

bite

requires

at

almost

they

adjustment

moving

by

box.

clockwise.

knot.

should

For

to

run

after

any

garage.

indefinitely.

are

with

the

turning

To

Turn

always

certain

have

both

faster

changing

#90

oil

Unless

approximately

the

idler

pillow

adjust

block

the

black

conveyor

to

adjust

only

run a little

materials

run

than

the

to

the

there

while

at

the

conveyor

plug

1/2"

roller

base.

knob on

faster,

conveyor

conveyor

that

the

same

machine

so

marked.

is

oil

above

by

feeds.

speed.

5.

Oil

every

the

week.

self

aligning

bearing

- 6 -

with

a few

drops

of

machine

oil

Page 14

0

Page 15

SECTION

IV

1.

2.

TO

A.

B.

C.

TO

A.

B.

C.

PLACE

SET

FOLDER

Place

notch

the

At

left

notch

folder.

This

the

positioned

FOLDER

Swing

Sighting

note

hem

The

the

material

Loosen

IN

folder

on

folder

sewing

strip

slight

clearance

guide

clearance

of

in

same

EDGE

out

at

screws

machine

folder

acts

spring

by

sewing

"B".

FOLDER

OPERATING

on

conveyor

engages

hem

gently

until

to

position

in

keeping

GUIDE

machine

conveyor

between

should

being

"C"

hemmed

and

ADJUSTMENTS

POSITION

and

slide

the

small

guide.

spring

it

engages

the

same

keeps

the

"V"

CLEARANCE

presser

level

equal

"D"

from

folder

three

but

to

adjust

upright

the

the

left

the

notch

FROM

foot.

discharge

edge

times

in

no

to

right

steel

upright

end

right

engaged.

THE

MACHINE

guide

the

case

same.

till

pin

strip

pin

of

the

end

end

"A"

to

thickness

less

the

screw

with

on

the

folder

of

the

HEM

of

conveyor

machine

than

"V"

on

the

and

folder

GUIDE

of

1/16".

3.

•

D.

TO

A .

Too

much

of

SET

Loosen

for

after

little

clearance

bite.

WIDTH

hem

adjusting.,

clearance

OF

HEM

screws

width

and

and

the

sleeves

"E" and "F"

desired.

the

sleeves

and

Check

E F

will

then

set

interior

will

have

folder

"jam"

varying

folder

and

too

depths

center

clearance

piece

- 7 -

Page 16

Page 17

SECTION

IV

FOLDER

4.

DEPTH

A.

5.

PROPER

A.

B.

C.

6.

WIRE

ADJUSTMENTS,

OF

BITE

This

hem

bracket

POSITIONING

Place

the

sleeve

for

and

cut

off

Adjust

toward

The

width

of

the

on

the

it

results

UNCURLER

(Needle

adjustment

sleeve

noting

the

white

operator

sleeve

line.

CONTD.

adjusting

OF

edge

through

sleeve.

line

of

the

edge

Too

in

open hems

thread

is

SLEEVES

to

the

away from

to

trim

narrow a trim

showing on

made

using

screw.

be

hemmed

the

sewing

amount

trim

more.

is

and

the

that

the

ON

THE

on

machine

of

or

operator

governed

care

require

outside

regular

CONVEYOR

the

white

while

width

in

is a poor

of

to

by

the

which

repairing.

trim

of

sleeve)

sewing

the

straightness

it

economy

machine

line.

watching

trimming

less

and

is

placed

as

Run

A.

B.

C.

The

wire's

material

the

folder

beginning

Its

work must

In

principle,

whose

prevents

The

and

and

shape,

first

remove any

serves

purpose

from

to

of

a

pleat

blower

the

doubling

cause

the

hem.

be

coordinated

the

material

as

the

or

should

"end"

same

is

to

or

either

sleeve

double

bend

curl;

purpose

prevent

pleating

a

"jam"

with

is

blown

progresses

thickness

the

the

as

the

while

or a pleat

the

cloth

second

the

material

natural

first

back

through

from

back

blower

curl

going

over

through

at

air

blower.

the

the

developing.

over

keeps

progresses.

in

the

wire

folder,

the

wire

out

the

- 8 -

Page 18

Page 19

1.

Blowers

requirements.

loosening

2.

The

air

folder

end

3.

The

of

4.

Clean

loosen

the

can

first

to

firmly

wire

of

the

second

the

first.

lint

same

loosened

be

their

blower

and

and

sleeve.

blower

from

and

lint.

moved

Their

brackets.

has

definitely

enough

takes

fan

vanes

then

AIR

and

relocated

air

streams

an

adjustable

air

over

with a very

starting

BLOWERS

can

blow

to

as

the

blow

the

them

as

required

be

intake

material

out

the

sleeve

small

for

a moment

raised

cover.

curl

passes

stiff

for

individual

or

lowered

Allow enough

back

in

the

out

over

of

brush

to

clear

I

SECTION

by

the

leading

range

to

IV

5.

Oil

the

machine

Note:

work

as

motor

oil

Some

well

bearings

every

stiffer

or

better

three

materiaB

without

on

the

months.

blowers

that

using

do

with

not

the

regular

tend

to

blowers.

sewing

curl

will

- 9 -

Page 20

Page 21

......

0

I

L-

- - - -

---

B.C.

- _j

r

-----------

I I ? I I I

I

I

I

I

I

,,

"

'

'

'

'

M.S. I

'

'

'

'

'

'

/

/

/

/

/

/

/

/

/

v

,

r:

I

I

._

_I

~

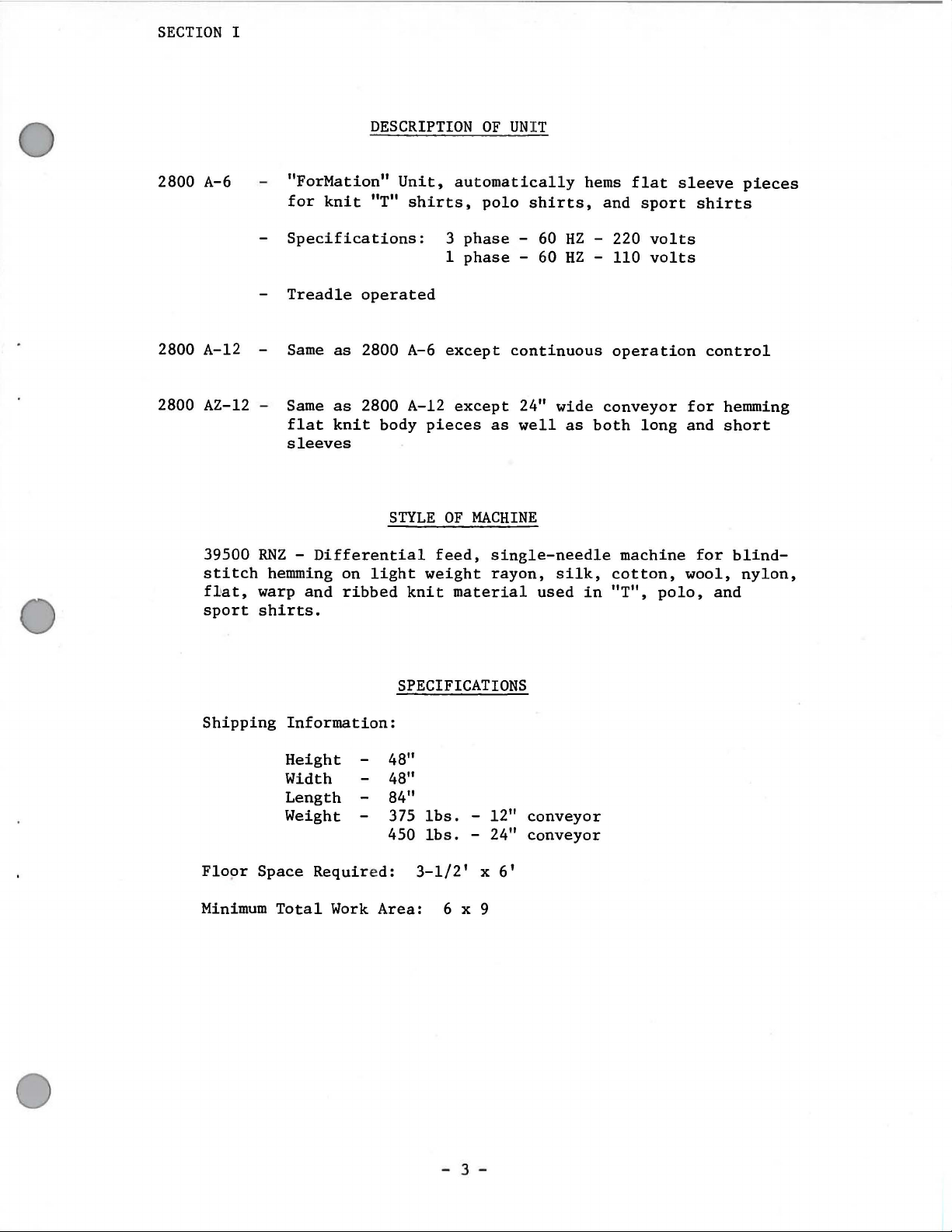

B - Blow

BC

- Blow

lA M RC -Run

MS

M

M

T F -

l - N

S2

SB

- Knot

- M

Fuse 1 Am

Unit

eedle

ain

Transformer

Fuse

er

er

Drive

Contr

Sensor

Switch

(3

'

•I' m I

I = I

'-----

Units

Control

p

Motor

ol

& Looper

Box

Step

2/10 Amp)

Junction

_______

Thread

Down

Box

Sensor

(24

Volts)

J

M.S. B.

3

PHASE

60

CYCLE

220

VOLTS

Cll

~

(")

~

H

0

z

<

Page 22

Page 23

V.

I.

II.

SEQUENCE

Turn

1.

Supplies

2.

Supplies

3.

Supplies

Turn

1.

Energize

OF

OPERATION

main

blower

control

power

power

power

switch

blowers.

switch

to

motor.

to

blower

to

automatic

to

on

to

on

position.

control

run

position.

box.

control

box.

SECTION

V

III.

Press

1.

2.

3.

4.

handle

Coil

Clutch

in

automatic

engages

on

automatic

linkage.

Knot

A.

sensor

Sequence

catching

1)

Switch

mercury

of

blades.

tilts

2) Mercury becomes

3) Power

4)

Coil

flows

de-energizes

shutting

Needle

A.

and

Sequence

looper

of

run

and

is

switch

operation

to

through

off

unit.

thread

operation

run

control

control

locked

when

horizontal

conducto~

and

sensor

when

box

into

is

normally

knot

switch

unlocks

thread

position.

circuit

to

micro-switch

box

to

becomes

run

position

open.

is

caught

is

coil.

mechanical

breaks.

down

position.

energized.

through

in

the

now

closed.

linkage

is

normally

mechanical

knot

open.

1)

Arm

on

side

of

2)

Circuit

3) Power

4)

Coil

shutting

is

now

flows

through

de-energizes

unit

off.

micro-switch

closed.

switch

and

unlocks

goes

to

coil.

mechanical

- 11 -

up.

linkage

Page 24

Page 25

SECTION

V

29480

The

available.

The

chain

Functionally,

start

system,

tube.

tinuous

by a

is

2899 A-14

Trim-Master

the

and

GZ

"Air-Klipp"

"Air-Klipp"

is

assured

and

finish

the

The

operation

treadle

depressed,

chain

disposes

between

chain

Compact

chain

at

the

of

chain

knife

mechanism

mounted

thus

Air

automatic

of

the

ACCESSORIES

cutter

design

cutter

the

start

material

the

seam.

is

sucked

when

machine

switch

conserving

Requirements:

chain

the

pieces

cloth

is

the

makes

is

air

and

carries

At

into

an

is

driven

is

which

the

cutter,

into

trimming

AVAILABLE

simplest,

it

easy

powered,

finish

the

that

opening

by

running.

turns

air

supply.

4

CFM

10-20

stationary

blades

from

to

on a

chain

point

the

the

PSI

and

the

most

install,

and

wide

to

through

at

main

The

air

automatically

sewing

efficient

adjust,

neat

variety

the

knife

the

the

front

feed

air

supply

on when

mounted

machine

close

mechanism

use

of

bar

and

the

trimmer

chain

and

severing

of

operations.

of a venturi

the

is

is

activated

sewing

trims

trim

cutter

maintain.

chain

in

treadle

draws

both

knife.

of

at

inlet

con-

off

ends

the

the

Folders

There

due

to

be

enclosed

are

the

several

wide

with

Electrical

folders

ranges

order.

available

of

material

Spec:

60

220

now

3

phase

cycle

volts

upon

request.

being

used.

These

Material

vary

in

capacity

samples

must

- 12 -

Page 26

SECTION

VI

FRONT

REAR

ROLLER

ROLLERASSEMBLY

ASSEMBLY

BEARING

ASSEMBLY

-

13

-

Page 27

SECTION

VI

Ref.

No.

1

2

3

4

5

Ref.

No.

Part

FU

FU

FU

FU

FU

Part

No.

1008

1009

1010

1011

1012

No.

FRONT

Front

Lower

Collar

Front

Roller

Belt

(Screw

Roller

Conveyor

REAR

PARTS

ROLLER

LIST

ASSEMBLY

Description

(Screw

for

Roller

FU

1008A)--------------

Separator--------------------------------

FU

1010A)---------------------------

Shaft-----------------------------------

Table-------------------------------------

ROLLER

ASSEMBLY

Description

Amt.

Req.

1

1

--1

1

1

Amt.

Req.

1

*2

3

4

I

5

Ref.

No.

1

2

3

4

FU

FU

FU

FU

FU

Part

FU

FU

FU

FU

1004

1005

1006

1007

1008

No.

1001

1002

1002A

1002B

Bearing

Conveyor

Belt

Separator

Rear

Rear

Self

Aligning

Bearing

Washer

.

Screw

Shield------------·-------------------------

Belt

(1"

width)------------------------------

Roller

Roller

BEARING

Track

Shaft-----------------------------------(Screw

(Screw

for

Roller

ASSEMBLY

for

FU

Tracks

1008A)--------------

Description

Bearing--------------------------------

Casing-------------------------------------

(For

(For

attachment

attachment

Bearing

Bearing

to

to

Mounting

FU

Mounting

1006A)-----

Bracket)--

Bracket)----

1 ,

8

8

1

1

Amt.

Req.

4

4

8

8

FU

FU

1002C

1003

Please

Nut

Mounting

specify

(For

width

attachment

Bracket

of

belt.

-

Bearing

for

Bearll1g-------------------------

to

13A-

5

6

*NOTE:

Mounting

Bracket)-------8

4

Page 28

SECTION

VI

MOTOR

CONVEYOR

SPEED

8

\

DRIVE

CONTROL

1

('

10

ASSEMBLY

REAR

DRIVE

-

14

PULLEY

-

Page 29

SECTION

VI

Ref.

No.

1

2

3

4

5

6

7

8

9

10

Part

FU

FU

FU

FU

FU

FU

FU

FU

FU

FU

No.

1024

1025

1026

1027

1028

1029

1030

1031

1032

1033

PARTS

MOTOR

Motor

Pitman

Rocker--------------------------------------------Rocker

Collar

Knock

Sew

Mowtting

Control

Spring----------------------------------------------1

Speed

Rod-----------------------------------------

Bolt-----------------------------------------1

(Screw

Off

Cam--------------------------------------

Rod--------------------------------------------

Bracket-----------------------------------

Handle--------------------------------------

CONVEYOR

SPEED

Control

FU

LIST

CONTROL

Description

Box-----------------------------

1028A)-----------------------------

DRIVE

ASSEMBLY

Amt.

Req.

1

1

1

1

1

1

-1

1

Ref.

No.

1

2

3

4

5

6

7

8

9

10

Ref.

No.

1

Part

FU

FU

FU

FU

FU

FU

FU

FU

FU

FU

Part

FU

No.

1013

1014

1015

1016

1017

1018

1018A

1018B

1019

1020

No.

1021

Description

Coupling

Handwheel

Gear

Gear

Belt------------------------------------------------1

Adjustment

Nut

(Outside)----------------------------------------1

Nut

(Inside)----------------------------------------Screws

Speed

Rear

Shield--------------------------------------1

Coupling----------------------------------1

Box------------------------------------------Box

Adjustable

Control----------------------------------

for

Speed

Control

REAR

Adjustable

Locking

DRIVE

Pulley---------------------------1

Control

Pulley-------------------------------1

Locking

Arm---------------------------1

PULLEY

Description

Arm----------------

Amt.

Req.

1

1

1

2

Amt.

Req.

-

2

3

FU

FU

1022

1023

Drive

Coupling

Shaft------------------------------------------1

(Screws

for

-

14A-

Coupling

FU

1023A)---------------1

Page 30

SECTION

VI

FOLDER

AND

BLOWER

UNITS

2

MICRO

SWITCH

-

15

-

Page 31

SECTION

VI

Ref.

No.

1

2

3

4

5

Ref.

No.

Part

FU

FU

FU

FU

FU

No.

1034

1035

1036

1037

1038

Part

No.

FOLDER

PARTS

AND

LIST

BLOWER

UNITS

Description

Folder---------------------------------------------

Blower--------------------------------------------Blower

Unit

Control

Box----------------------------Fuse 1 Amp---------------------------------------Folder

Positioning

KNOT

CATCHING

Bracket---------------------------

SWITCH

Description

Am

Req.

1

2

1

2

1

Amt.

Req.

t.

1

2

3

4

5

6

Ref.

FU

FU

FU

FU

FU

FU

Part

No. No.

1

2

3

FU

FU

FU

1044

1045

1045A

1045B

1046

1047

1039

1040

1040A

~ercury

Knot

Catching

Nuts

(For

Screws

Thread

Collar

~icro

Thread

Screws

(For

Guide---------------------------------------

Screw

Switch----------------------------------------

Guide--------------------------------------for

Switch-------------------------------------

Blades--------------------------------

Attaching

Attaching

(FU

MICRO

Thread

Knot

Catching

Knot

Catching

Blades)-------------

Blades)-----------

1047A)------------------------------4

SWITCH

De

scription

Guide-----------------------------

1

2

4

4

3

Amt.

Re

q.

2

1

2

4

5

6

FU

FU

1041

1042

1043

Tension

Tension

Tension

Assembly

Assembly

Assembly

~ountin

g

Plate--------------------(Needle)--------------------------(Looper)---------------------------1

-

15A-

FU

1

1

Page 32

Page 33

SECTION

VII

TROUBLE

This

degrees

or

adjustments

this

speed.

veyor

A.

B.

unit

stretch

area

runs

IF

THE

1.

2.

3.

IF

THE

1.

SHOOTING

of

This

Adjust

Folder

cloth

1/16"

tabletop

Too

hem

Adjust

is

designed

stretch

material

to

compensate

is

the

setting

just

BITE

sewing

base

goes

clearance

little

guide.

BITE

sewing

to

handle a wide

and

thickness.

to

another,

for

synchronization

is

most

slightly

IS

TOO

over

or

clearance

IS

UNEVEN

slower

DEEP

machine

shoe

shimming

Clearance

too

machine

over

OR

machine

it

this.

of

critical,

than

hem

edge

high

above

hem

throat

sewing

between

should

MISSES

hem

edge

variety

When

is

often

The most

the

and

the

guide

edge

plate

machine

folder

be

guide

of

changing

necessary

important

conveyor

should

sewing

with

sewing

guide.

1/16"

by

rubber

base

machine

raising

to

with

materials

from

speed

be

head.

knurled

Set

isolators.

shoe

1/8".

knurled

one

type

to

make two

adjustment

to

the

adjusted

thumb

throat

folder

or

lowering

edge

thumb

with

base

and

varying

of

weight

or

in

sewing

so

the

screw.

plate

shoe

conveyor

machine

screw.

more

head

con-

and

2.

3.

4.

5.

6.

7. Trimming

8.

C.

IF

1.

2. Sewing

Too

much

guide.

Is

the

Is

guide

Wide

Presser

THE

at

Trimming

slow.

too

fast.

shoe

and

same

in

MATERIAL

Sewing

tilt

clearance

Should

work

wire

beginning.

widens

Check

starts

folder

foot

contact

machine

(high

machine

be

cut

straight?

properly

as

sleeve

okay

Try

increasing

center

should

with

REFUSES

feed

in

front).

feed

between

1/16"

positioned?

Check

sleeve

for

and

piece.

have

the

TO

START

dog

dog worn

folder

to

1/8".

for

sideward

progresses.

sideward

then

diminishes

angle

as

little

cloth

UNDER

tilt

adjustment

or

base

show and

movement

Check

movement on

made by

pressure

at

all

times.

PRESSER

set

too

machine

of

conveyor

conveyor.

or

runs

intersection

as

possible

FOOT

PROPERLY

not

set

for

low.

cloth

off.

hem

for

Conveyor

of

folder

to

almost

edge

on

conveyor.

being

keep

maximum

too

is

base

the

- 16 -

Page 34

Page 35

3.

Folder

presser

too

foot.

far

from

presser

foot.

Folder

should

almost

SECTION

touch

VII

D.

4. Too

hem

5.

Presser

move

6.

Presser

instead

foot

7. Ends

before

8.

Leading

with

unit).

FOLDING

1.

Sleeves

wire

length.

2.

Blower

the

adjustable.

the

little

edge

guide

foot

of

own

foot

of

sideways

of

sleeves

operator

edge

a new

OF

CLOTH

must

must

Bend

turbines

cloth

leading

clearance

causing

hinge

weight.

bottom

alongside.

for

curled

sews

of

presser

unit

as

blow

help

being

the

The

end

remove

should

sewn

of

between

pinching.

tight.

coming down

Loosen

1/32"

from

same.

these

over

brass

second

the

(not

any

be

over

sleeve.

edge

Should

presser

clearance.

rought

foot

wire

blower

are

curl

kept

the

uncurler

properly

under)

as

to

clean.

brass

is

of

be

on

sewing

handling

the

the

suit

to

folder

perfectly

foot

not

rounded

brass

cloth

the

material

Use

wire.

blow

base

loose

machine

hinge

of

the

rounded

when

wire

progresses

just

The

air

out

any

shoe

so

hem

screw

cut

(only

shipped

and

being

enough

cut

small

and

machine

foot

edge

guide

and move

work

if

replaced

with

the

brass

along

sewn.

air

to

off

is

curl

can

a

its

blow

in

3.

Sleeves

folder

bottom

folder

clearance.

base

contacts

to

moving

shoe

discharge

sideways

makes

canvas

end

under

with

conveyor,

at

the

sewing

folder.

conveyor's

especially

machine.

Lessen

edge.

the

from

Check

angle

Make

centerpoint

interior

that

sure

the

folder

of

folder

-

17

-

Page 36

Page 37

SECTION

VIII

Sewing Head - 39500

Standard

39500

RN

except

Presser

Carbide

Edge Guide - 39503 J

STANDARD

RNZ -List

fitted

Foot

Lower

923

with:

- 39520 H

Knife

- 39503 J

modified

(see

MODIFIED

drawing)

Seam

Stitch

Needle

Needle

Looper

Specification

Eccentrics

Standard

- 154

Thread -70/2

Thread -70/2

Setting

GAS

Machine Speed up

Unit

Sewn

I

Off

at

- 503 EFc-1

Available

(Ecc.

- 8

39540

027

Soft

Soft

to

- 8000 R.P.M.

- 4200 R.P.M.

to

30

B-10-12)

S.P.I.

- 12

S.P.I.

- 18 -

Page 38

Page 39

Helpful,

cient

types

machine

Promotion

Sales

esting,

obligation

illustrated

authoritative

of

sewed

equipment

article

Department. Among

are the

bulletins

following

information

for

is

available

that

:

on

the

making

are available

from

virtually

Union

the

many inter-

most

Special's

without

effi-

any

HERE

ARE

HELPFUL

No.

240,

No.

249,

No.

250,

No. 251,

No. 252,

No.

253,

No. 254,

No.

256,

No.

259,

No.

260,

No.

262,

No.

263,

No.

264,

No.

265,

No.

266,

No.

267,

No.

268,

No.

269,

No.

271,

No.

273,

No.

610,

No.

710,

No.

730,

No.

740,

No.

750,

No.

1100,

No.

1105,

"Columbia

ing

Machines"

No.

1500,

"Men's,

"Rainwear"

"Men's

"Service

"Men's

"Overalls, Coveralls,

"Men's

"Knit

"Men's

"Work

"Cotton,

Bags"

"Men's

"Men's

"Women's

"Women's

"Corsets, Girdles, Brassieres"

"Children's

"Mattresses,

Upholstery"

"Awnings,

"Curtains & Drapes"

"Kiipp-it"

"MCS

"MCS

Hemmer"

"MCS

"Fusing

"Lewis

stitch,

"Button

"Alteration

Women's,

Dress

Shirts

Shorts

Knit

Outerwear"

Sports

Gloves"

Burlap,

Clothing"

Women's,

Wear"

Wear

Canopies, Tents,

ForMation

Automatic

Automatic

Presses"

Blindstitch,

Machines"

Sewers-

Blindstitch,

Children's

Shirts"

and

Pants"

and Pajamas"

and

Underwear"

Shirts"

Jute,

Children's

And

Wear"

Slip

Covers,

Unit"

Dual

Rib-Knit

Chainstitch,

Ticket

Saddle

Stitch,

Department

Dungarees"

and

High

Fashion"

Furniture

Underfront Shi

Tackers"

Mach i

Footwear"

Multiwall

Jackets"

Tarps"

Cuff

Machine"

Lock·

and

Tie

nes"

Paper

rt

Clos-

BULLETINS

TO

SEWING

HELP

YOU

PROBLEMS

and

CATALOGS

SOLVE

UNION SPECIAL

fiNIS!

QUALITY

CORPORATION

Page 40

..

Q

..

...

'

0

WORLD'S

....

lf

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

facilities throughout

aid

you

in

the selection of the right sewing

equipment for your

Special representatives

tory trained

promptly

tion, there

serve you.

ATLANTA, GA.

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES,

NEW YORK, N.

PHILADELPHIA, PA.

ILL.

TEXAS

and

and

is

Check with

CAL.

Y.

maintains sales

the

world. These offices

and

service

will

particular operation. Union

and

are

service men

able

to serve your needs

are

fac-

efficiently. Whatever your loca-

a Union Special Representative to

him

today.

MONTREAL,

TORONTO, CANADA

BRUSSELS,

LEICESnR, ENGLAND

LONDON, ENGLAND

PARIS,

STUnGART,

CANADA

BELGIUM

FRANCE

GERMANY

!t

I'

Representatives

Industrial

UNION SPECIAL

400

N.

FRANKLIN

and

distributors

cities

throughout

CORPORATION

ST., CHICAGO,

In

the

all

Important

world.

ILL.

60610

I

.

I

I

'

•

Loading...

Loading...