Page 1

LEWIS

PARTS

CATALOGUE

200

200-1

200

200-3

LEW

IS SEWING

and

-2

INSTRUCTIONS

194-4

Class

MODELS

Machines

200-4

200-6

2

00

-7

MACHINE COMPANY

Page 2

CLASS

INDEX

ZOO

Page

Adjusting

Button

Cams

General

Looper

Model

Needles

Needle

Needle

Oiling

Parts,

Parts

Speed

Stitch

Shank

Machine,

Clamp

for

200-6

Bar

Guard

Machine

Instructions

List

of

Combinations

Buttons

Adjustments

Button

Instructions.

Adjustments

and

•......•...

Adjustments

. .

..

•.....

Machine

•..

Plates A to

Clamp

.

200-7

Special

for

ordering

•

Available

•••.••.

.

.

D .

Instructions

.•

4

to

10

to

18

13

14

33-57

12

17

7

15

ll

18

14

8

8

9

8

Stop

Motion

Threading

Thread

Thread

Thread

Thread

Two

Treadle

and

. • •••.

Nipper

Positioning

Take-Off

Tension

Adjustments.

Operation

Clutch

Controls.

Adjuatments

•••.•••

Finger

Adjustments

••

••

.••

10

8

16

14

17

16

17

Page 3

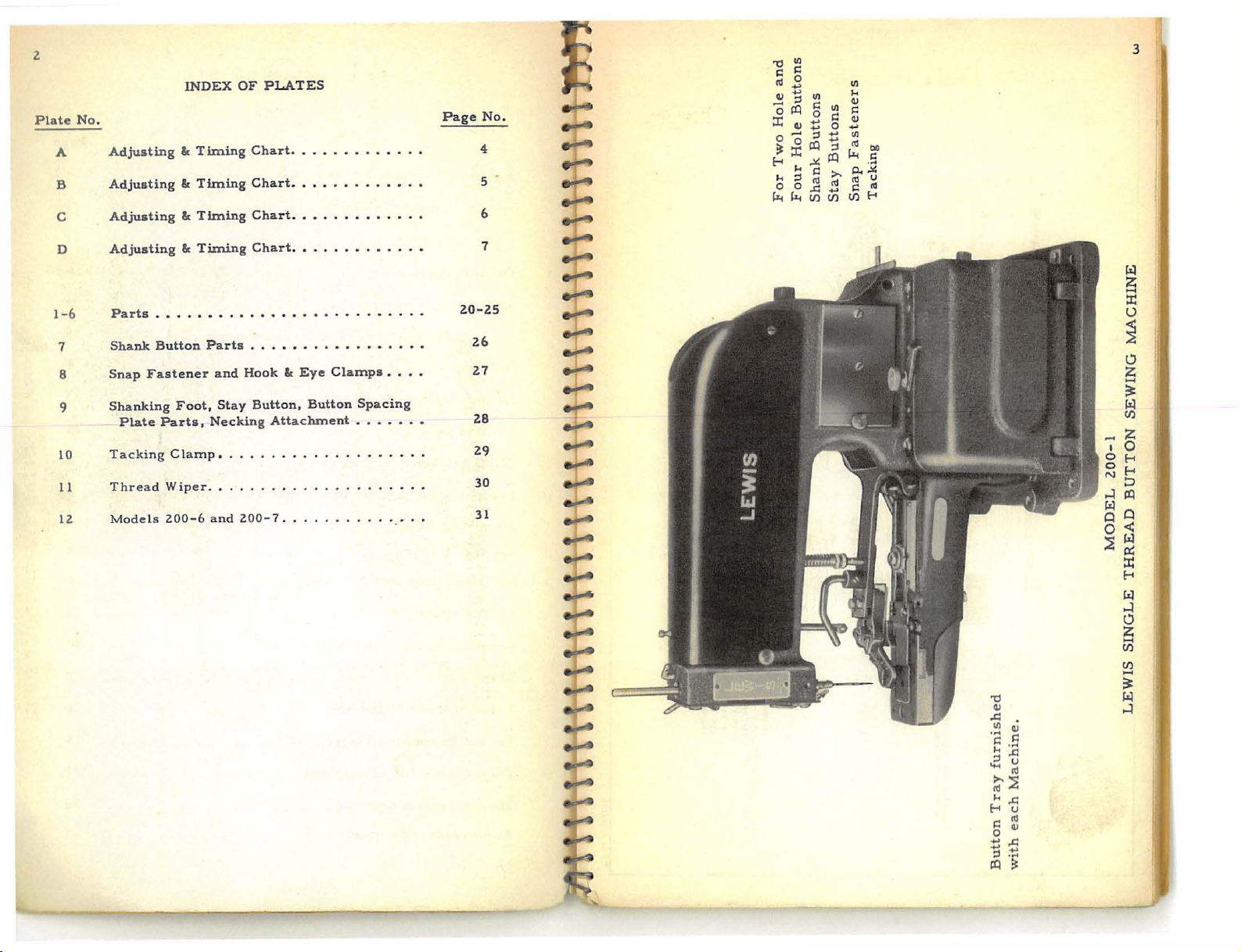

z

3

Plate

A

c

1-6

B

D

7

8

10

11

9

lZ

No.

Adjusting

Adjusti

Adjuating

Adjusting

Parts

••.••••.

Shank

Button

Snap

Fastener

Shanking

Plate

Ta

cking

Thread

Models

INDEX

!.

ng

!.

!.

!.

Foot,

Parts, Necking

Clamp

Wiper

200-6 and

OF

PLATES

Timing

Timing

Timing

Timing Chart .••..••.•...•

Chart.

Chart

Chart

•

•••••••

Parts

. . • • • • • • • • • • • • • • •

and

Hook

Stay

Button,

Attachment

•.

...

200-7

Page No.

• . • • • • . • • . . . 4

. • . • • • • • • • • . • 5

..•

•.••

&c

..

Eye

Button

•.

..••••

Clamps

••...

Spacing

•.•

. .

• • • .

••

••

•

2.0

6

7

-2.5

2.6

2.7

2.8

2.9

30

31

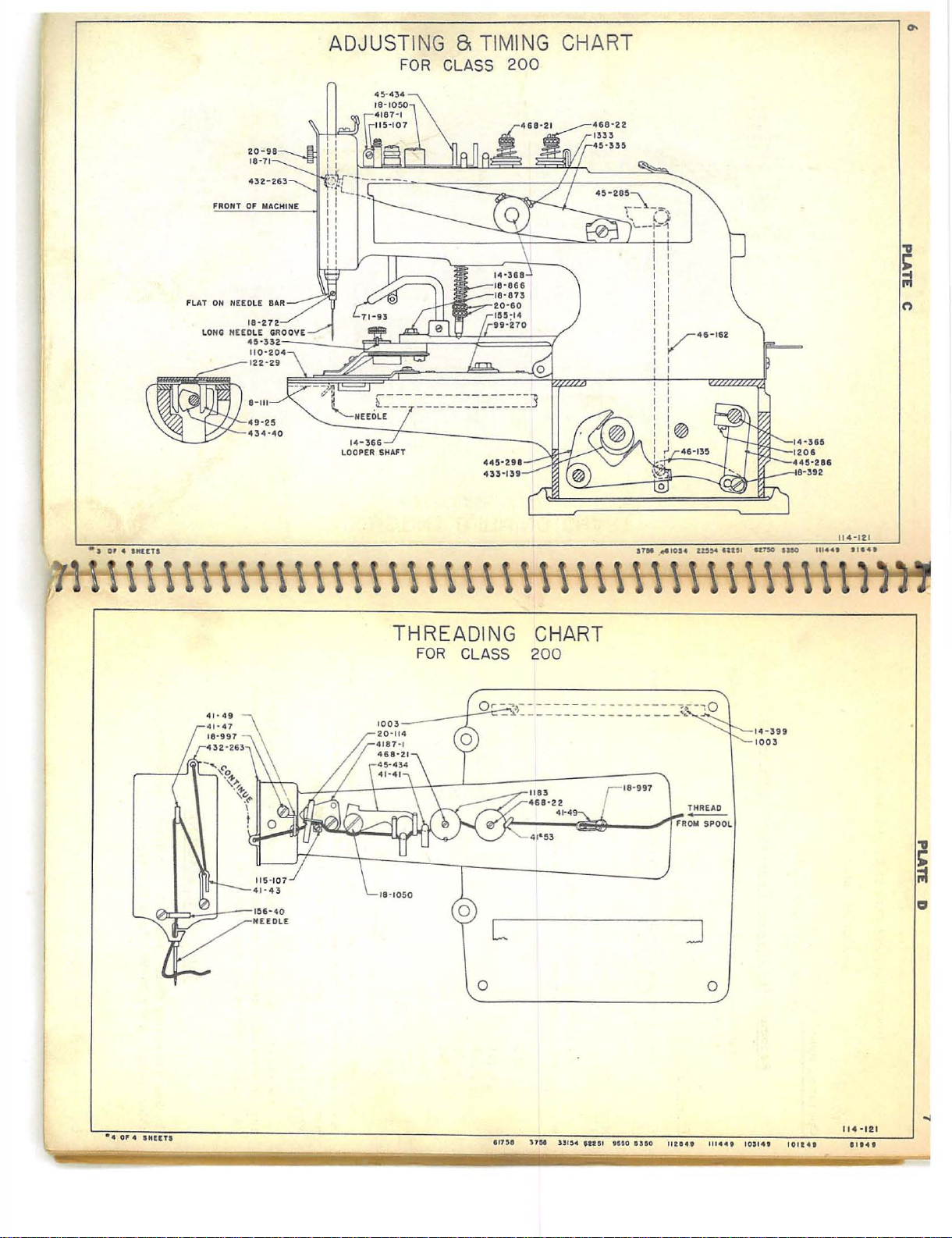

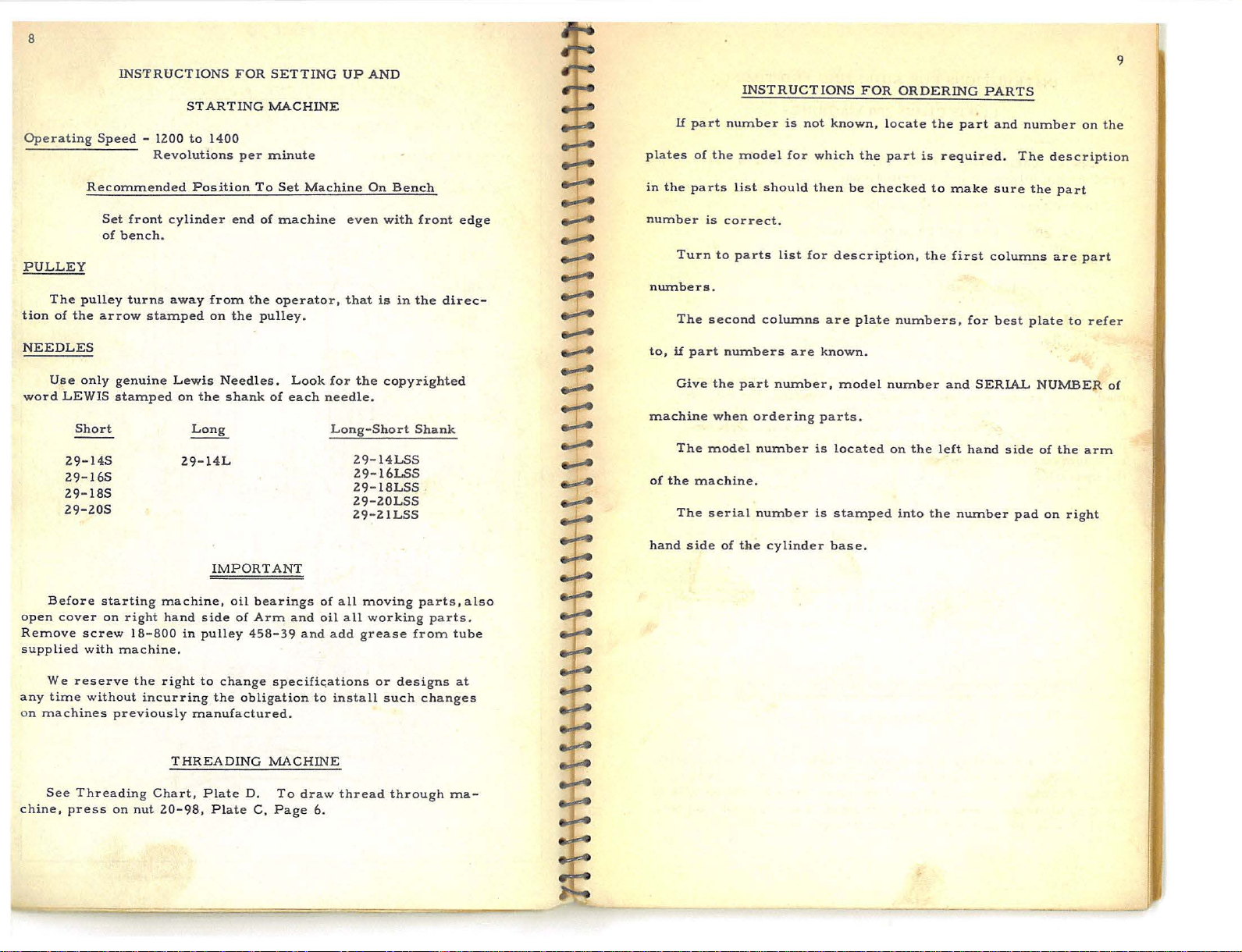

Page 4

FRONT

OF

MACHINE

ADJUSTI

FOR

NG a TIMING

CLASS

200

CHART

v

46-162

I

I

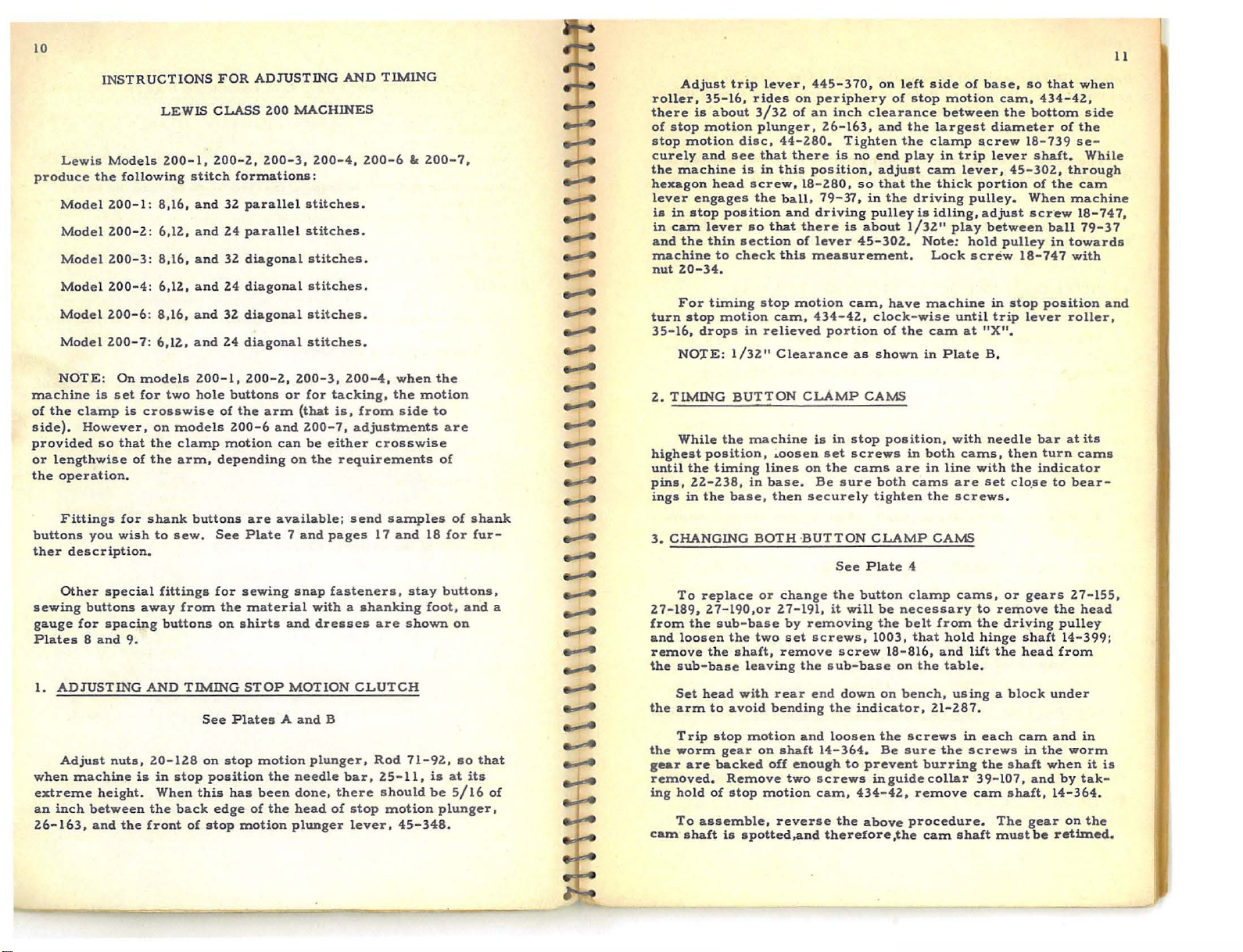

THREADING

FOR

CLASS

CHART

200

IT • .e1034 US,..

11

II

U I

U:f$0

I

DO

14-399

1003

4•121

111

441

f l

l4t

•4

0'

4 I H

IITI

• 4

••

-~--

---

117!UI

17MI

331~4

flU!

t!S&O

I

U50

111141

114

111

441

101141

101141

·121

1

114

I

Page 5

8

Operating

INSlfRUCTIONS

Speed

- 1200

Revolutions

FOR

STARTING

to

1400

per

SETTING

MACHINE

minute

UP

AND

plates

9

INSTRUCTIONS

If

part

of

number

the

model

is

for

not

FOR

known, locate

which

the part

ORDERING

the

part

is

required.

PARTS

and

The

number

descript

on

the

ion

PULLEY

The

tion

of

the

NEEDLES

Use only

word

LEWIS

29

29-16S

29-18S

29-

Before

op

en

cover

Remove

supplied

Recommended

Set

front

of

bench

pulley

Short

-14S

tur

arrow

genuine

stamped

20S

starting

on

right hand side

screw

18-800

with machi

cyli

.

ns

away

stam

Lewis

machine,

ne.

Position

nder end

from

ped

on

on

the

Z9-14L

in

pull

the

Needles.

shank

IMP

ORTAN

oil

of

ey

To

Set

of

machi

the

operator,

pulley.

of

bearings

Arm

458-39

Machine

ne

Look

for

each

needle.

Long-Short

T

of all moving

and

oil

and

add

On

Bench

even

with

that

is

in

the

copyrighted

29-14LSS

29-16LSS

29-18LSS

29-20LSS

29-ZlLSS

all working

grease

front edge

the

direc-

Shank

parts, also

parts.

from

tube

.......

.......

.,.._..

.......

.......

~

~

........

........

.....

.......

.,_....

......

.......

.,__...

.......

........

.......

.-.....

.,..

....-.

._:;...e

...-.....

in

the

number

Turn

numb

The

to

,

if

Give

machine

The

of

the

The serial

ha

nd

parts list

is

correct

to

parts list

ers.

second

part

numb

the

part

when

model number

machine

side

of

the

should

.

columns

ers

are

number,

ordering

•

numb

er

cylinder

then

for

description,

are

known

model

parts

is

located

is

stamped

base

be

checked

the

plate numbers,

.

number

•

on the l

into

.

to

make

first

and

eft hand

the

number

sure

columns

for

best plate

SERIAL

t he

NUMBER of

side

of

pad

on

part

are

the

part

to

arm

right

refer

We

any

time

on

machines

See

chine, pr

reserve

without

Threading

ess

prev

on

the

right

incurring

iously

Cha

nut

20-98,

to

change

the

manufactured.

THREA

rt,

Plate

Plate

obligation

DING

D.

C,

specifications

to

install

MACHINE

To

draw thread

Page

6.

or

designs

such

through

at

changes

ma-

Page 6

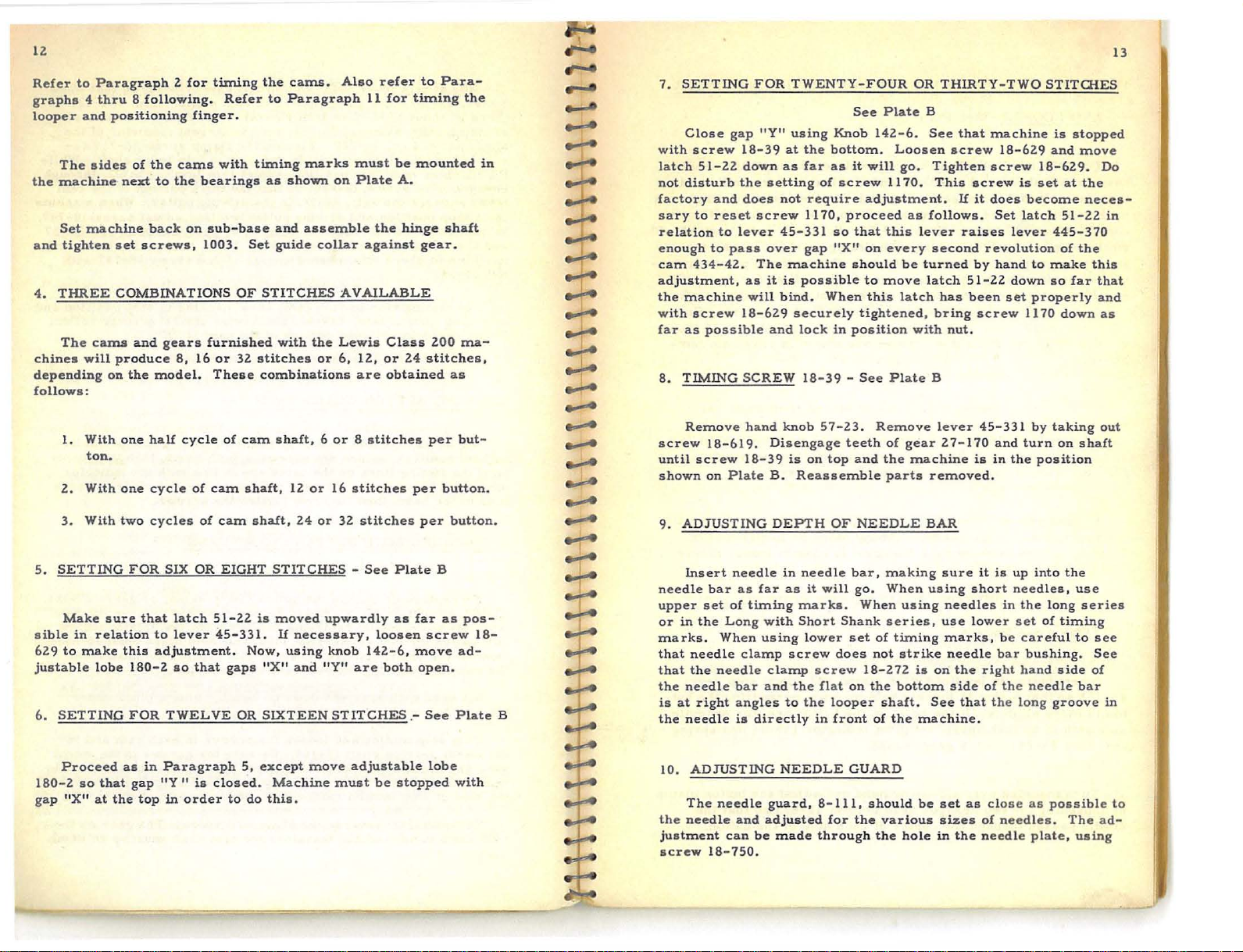

10

INSTRUCTIONS

L e

wis

produce

machine

of

side).

provided

or

the

buttons

ther

sewing

gauge

Plates 8 and

1.

when

extreme

an

26-163,

the

Model

Model

Model

Model 200-

Model

Model

NOTE:

is

the

clamp

However,

so

lengthwise

operation.

Fittings

you

description.

Other

special

buttons

for

spacing but

ADJUSTING

Adjust

machine

height.

inch

between

and

LEWIS CLASS

Models

200-1:

Z.00-2:

Z.00-3:

200-6:

200-7:

set

nuts, 20-1Z.8

following

8,16,

6,12,

8,16,

4:

6,1Z.,

8,16,

6,1Z.,

On

models

for

is

crosswise

on

that

the

of

the

for

shank

wish

to

fittings

away

9.

AND

is

in

When

the

the

front

Z.00-1,

two

models

clamp

arm,

sew. See

from

tons

TIMING

stop

back

Z.OO-Z,

stitch

and

and

and

and

and

and

200hole

buttons

for

See

on

position

this

edge

of

stop

FOR

depending

on

ADJUSTING

Z.OO

Z00-3

formations:

32

parallel

24

parallel

32

diagonal

24

diagonal

32

diagonal

24

diagonal

1,

Z00-2,

buttons

of

the

arm

200-6

and

motion

the

stop

has

can

are

available;

Plate 7 and

sewing

material

shirts and

STOP

Plates A and

motion

the

been

of

the

motion

AND

MACHINES

, Z00-

4,

stitches.

stitches.

stitche5.

stitches.

stitches

stitches.

Z00-3,

or

on

snap

MOTION

need

done,

head

plunger

Z00-4,

for

tacking,

(that

is,

200-7,

be

either

the

requirements

send

pages

fasteners,

with a shanking

dresses

B

plunger,

le bar ,

t h

ere

of

stop

lever,

TIMING

Z00-6

8t

.

when

the

from

side

adjustments

crosswise

samples

17

and

stay

are

shown

CLUTCH

Rod

71-92,

25-11,

should

motion

45-348

200-7,

the

motion

to

are

of

of

18

for fur -

buttons,

foot,

is

at

be

5/16

plunger,

.

on

so

shank

and

that

its

of

11

.....

~

~

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

Adjust

roller,

there

of

stop

stop

curely

the

machine

hexagon

lever

is

in

in

cam

and

the

machine

nut

Z0-34

For

turn

35-16,

NOTE: 1/32

35-16,

is

about

motion

motion

and

head

engages

stop

lever

thin

to

timing

stop

drops

trip

lever,

rides

3/32

plunger,

disc, 44-280.

see

that

is

in

screw,

the

position

so

that

section

check

•

stop

motion

in

relieved

11

cam,

Clearance

445-370,

on

periphery

of

an

there

this

position,

18-Z.80,

ball.

and

driving

there

of

lever

this

measurement.

motion

434-42,

inch

26-163,

Tighten

is

no

79-37,

is

cam,

portion

as

on

of

clearance

and

end

adjust

so

that

in

the

pulley

about

45-302.

have

clock-wise

of

shown

left

stop

the

the

play

the

driving

is

l/3Z."

the

side

motion

between

largest

clamp

in

trip lever

cam

thick

idling,

play

Note:

Lock

machine

until

cam

in

Plate

of

base,

acrew

lever,

portion

pulley.

adjust

between

hold

screw

at

"X"

B •

so

cam,

the

bottom

diameter

18-739

shaft.

45-30Z,

of

When

scr·ew

pulley

18-747

in

stop

trip

lever

•

that

434-42,

of

through

the

machine

ball

in

towards

with

position

roller

when

side

the

se-

While

cam

18-747,

79-37

and

,

.......

.......

.......

Z..

TIMING

BUTTON CLA

MP

CAMS

......

.......

......

......

......

While the

highest

until

pins,

ings

the

22-Z.38,

in

........

3.

.......

CHANGING

.......

.......

To

a

.......

.......

.......

.......

.......

Z7-189,

from

and

remove

the

.......

.......

the

.......

.......

.......

......

~

the

gear

removed.

ing

cam

replace

the

loosen

sub-base

Set

arm

Trip

worm

are

hold

To

assemble,

shaft

machine

position,

timing

in

the

base,

27-190,or

sub-base

the

the

shaft,

leaving

head

with

to

avoid

stop

motion

gear

backed

Remove

of

stop

is

spotted

is

on

Be

securely

by rem

set

screws,

the

end

and

14-364.

enough

two

screws

cam,

,and

in

set

the

sure

See

it

will

oving the

screw

sub-base

down

the

loosen

to

the

therefore

.oosen

lines

base.

then

BOTH ·BUTTON

or

change the

27-191,

two

remove

rear

bending

on

shaft

off

motion

reverse

stop

position,

screws in

cams

are

both

tighten

CLAMP

Plate

4

button

indicator,

434-42,

clamp

be

necessary

belt

1003,

18-816,

on

on

bench,

the

screws

Be

sure

prevent

inguidecollar

above

procedure.

,the

both

in

cams

the

CAMS

from

that

and

the

21-287.

the

burring

remove

cam

line

hold

table

with

needle

cams,

then

with

set

to

remove

the

hinge

lift

the

•

each

screws

the

39-107,

cam

The

must

the

clo.se

•

or

gears 27- 155,

driving

shaft

head

cam

in

shaft

shaft,

gear

are

screws

cams,

using a block

in

shaft

bar

at

turn

indicator

to

the

pulley

14-399;

from

under

and

the

when

and

by

14-364.

on

be

retim.ed.

its

cams

bear-

head

in

worm

it

tak-

the

is

Page 7

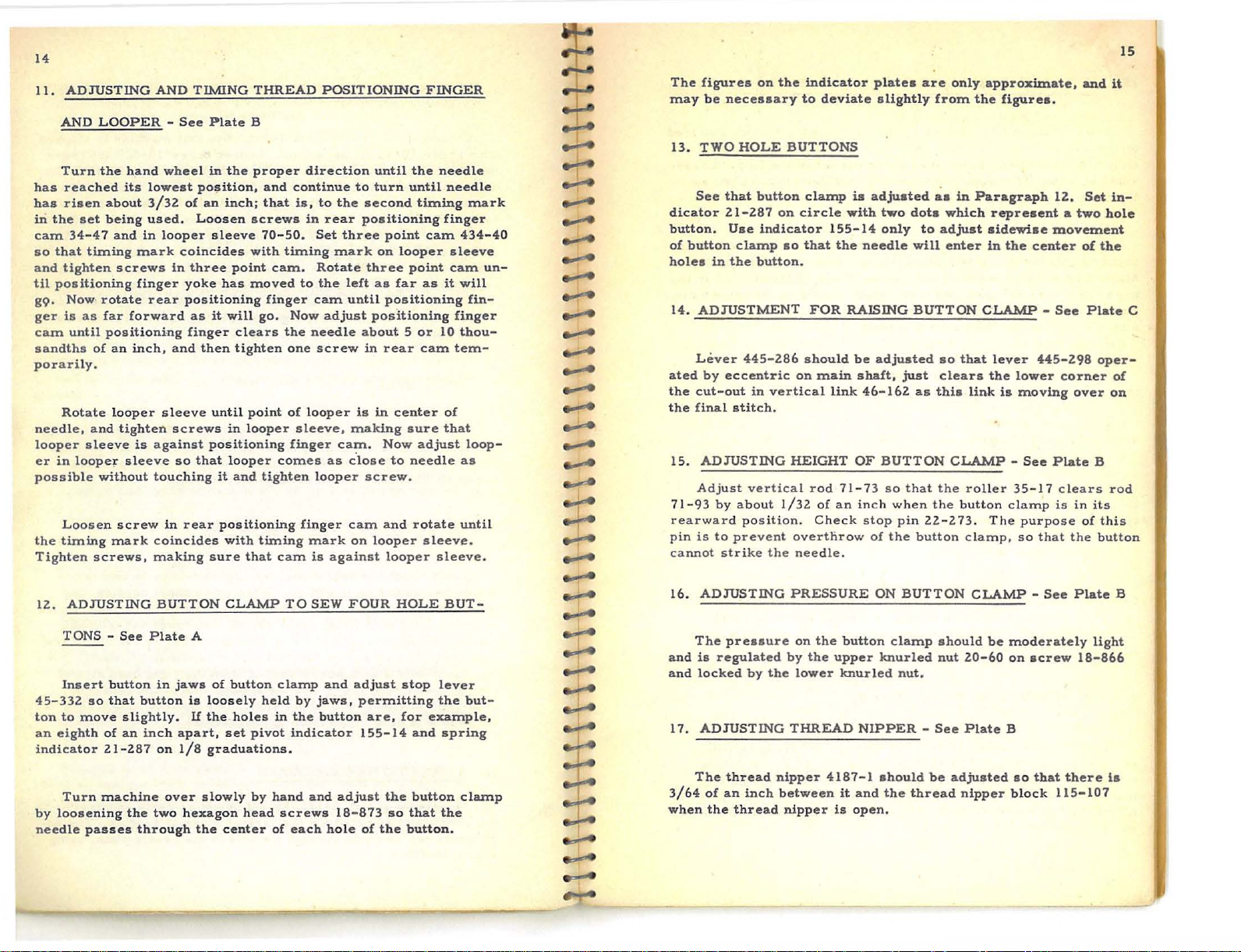

lZ

Refer

t o

Paragraph Z for

graphs 4 thru 8 following.

looper

the

and

4.

chines will

depending on

follows:

5.

s

629

justable

The

machine

Set

tighten

THREE

The

1.

2.

3.

SETTING

Make

ible

to

6.

SETTING

and

positioning

sides

of

next

machine back

set

screws,

COMBINATIONS

cams

and

produce

the

With

one

ton.

With

one

With

two

FOR

sure

that

in

relation

make

this

lobe

180-2

FOR

finger.

the

cains

to

the

on

gears

8,

16

model.

half

cycle

cycle

of

cycles

SIX

OR

latch

to

lever

adjustment.

so

that

TWELVE

timing

Refer

with

bearings

sub-base

1003.

OF

furnished

or

32

These

of

cain

of

cam

EIGHT

51-22

45-331.

gaps "X"

OR

the

cams.

to

Paragraph

timing

Set

cam

shaft,

shaft

Now,

marks

as

shown

on

and

assemble

guide

collar

STITCHES

with

the

stitches

combinations

is

SIXTEEN

or

shaft, 6 or 8 stitches

12

or

16

,

24

or

STITCHES-

moved

If

necessary,

using

and "Y"

upwardly

knob

STITCHES.-See

Also

refer

11

for

must

be

Plate

the

against

AVAILABL

Lewis

6,

32

Class

12,

or

are

obtained

stitches

stitches

See

loosen

142-6,

are

both

Plate

as

timing

mounted

A.

hinge

24

per

far

move

open

to

Para-

shaft

gear.

E

ZOO

stitches

per

button

per

B

as

screw

the

ma-

as

but-

button

pos-

18-

ad-

.

Plate

in

,

,.....

,....

~

......

.-...

e-i4

....,...

:t:

:t:

..-...

~

~

~

~

~

~

.......

7.

SETTING

Close

with

screw

lat

ch

51-22

not

disturb

factory

sary

relation

enough

c

am

adjustment,

the

wit h

far

8.

and

to

reset

to

434-42.

machine

screw

as

possible

TIMING

gap

t o

pass

FOR

"Y"

18-39

down

t h e

setting

does

screw

lever

over

The

as

it

will

18-629

and

SCREW

TWENTY-FOUR

See

using

Knob

at

the

bottom.

as

far

as

it will

of

screw

not

require

1170,

proceed

45-331

machine

is

bind. When

so

gap

"X"

possible

securely

lock

in

18-39

that

should

tightened,

position

-

See

OR

Plate

142-6.

Loosen

go.

1170.

adjustment.

as

this

lever

on

every

be

turned

to

move latch

this

latch

with

Plate

THIRTY-TWO

B

See

that

machine

screw

Tighten

This

follows.

second

has

bring

B

If

raises

nut.

scre

screw

it

does

revolution

by

51-22

been

screw

18-629

is

Set

lever

hand

down

set

STITCHES

is

a.

w

18-629

set

become

latch

445-370

to make

so

properly

117

0

nd move

at the

51-22

of

down

stopped

.

Do

neces-

the

this

far

that

and

as

13

in

.......

Remo

ve

hand

knob

.......

.......

......

.

~

screw

until

shown

18-619.

scr

ew

on

Disengage teeth of

18-39

Plate

B.

57-23.

is

on

top

Reassemble

and

Remove

gear

the

machine

parts

lever

45-331

27-170

is

removed.

and

in

turn

the

by

taking

on

position

out

shaft

.......

.

.......

9.

ADJUSTING

DEPTH

OF

NEEDLE

BAR

......

......

.J.,..

........

.,...

.,-.

.,_.

:t:

B

-;--

.-......

Insert

needle

upper

or

marks.

that

that

the

is

the

bar

set

of timing

in

the

Long

When

needle

the

needle

needle

at right angles

needle

needle

as

far

using

cla

mp

bar

is

directly

in

as

with

clamp

and

to

needle

it will

marks.

Short

lower

screw

screw

the

th e

Shank

does not

flat

looper

in

front

bar,

go.

When

set

18-272

on

of

the

of

making

When

series,

timing

shaft. See

the

using

strike

is

bottom

machine

sure

using

use

on

it

short

needles

low

marks,

needle

the right

side

of

that

.

is

er

be

bar

the

up

needl

in

set

the

the

careful

hand

long

into

the

es, use

long

of

timing

bushing.

side

nee

dle

groove

series

to

of

bar

see

See

in

Proceed

180-2

gap "X"

so

that

at

the

as

gap

in

Paragraph

"Y"

top

in

is

order

5,

closed.

to

except

do

Machine

this.

move

adjustable

must

be

lobe

stopped

with

:t

:t:

J,...

.,_...,.

.......

10.

ADJUSTING

The

the

needle

justment

screw

needle

and

can

18-750

NEEDLE

guard,

adjusted

be

made

.

GUARD

8-111,

for

through

should

the

various

the

hole

be

set

sizes

in

the

as

close

as

possible

of

needles.

needle plate,

The

using

to

ad-

Page 8

14

11.

ADJUSTING

AND

LOOPER -See

Turn

the

has

reached

has

risen

iri

the

set

cam

34-47

so

that

timing

and

tighten

til

positioning

g9.

Now· rotate

ger

is

as

cam

until

sandths

porarily.

needle, and

looper

er

possib

the

Tighten

12.

45-332

ton

an

indicat

by

needle

of

Rotate

sleeve

in

loope~

le

without

Loosen

timing

screws,

ADJUSTING

TONS -See

Insert

so

to

move

eig

hth

or

Turn

machine

loosening

passes

AND

hand

its

lowest

about

3/32

being

used. Loosen

and

in

mark

screws

finger

rear

far

forward

positioning

an

inch,

looper

tighten

is

against

sleeve

touching

screw

mark

coincides

making

BUTTON

Plate

button

that

of

21-287

in

button

slightly.

an

inch

on

the

two

through

TIMING

Plate

wheel

in

po~?ition,

of

an

looper

sleeve

in

over

sleeve

coincides

in

three

yoke

positioning

as

it

finger

and

then

until

screws

positioning

so

that

rear

sure

A

jaws

is

loosely

If

the

apart,

I/8

graduations.

slowly

hexagon

the center

THREAD

B

the

proper

inch;

screws

70-50.

with

point

has

moved

will

go.

clears

tighten

point

in

looper

looper

it

and

tighten

positioning

with

timing

that

CLAMP

of

button

held

holes

set

pivot

by

head

and

that

timing

cam.

finger

the

comes

cam

TO

clamp

in

hand

screws

of

POSITIONING

direction

continue

is,

to

in

rear

Set

Rotate

to

the

cam

Now

adjust

needle

one

screw

of

looper

sleeve,

finger

as c.lose

looper

finger

mark

is

against

SEW

and

by

jaws,

the

button

indicator

and

each

hole

to

the

second

positioning

three

mark

left

until

about 5 or

in

is

making

cam.

screw.

cam

on

FOUR

adjust

permitting

155-14

adjust

18-873

of

until

the

turn

until

point

on

looper

three

point

as

far

positioning

positioning

rear

in

center

sure

Now

to

needle

and

rotate

looper

looper

HOLE

stop

are,

for

and

the

button

so

that

the

button

FINGER

needle

needle

timing

finger

cam

sleeve

cam

as

it

10

cam

of

that

adjust

sleeve.

sleeve.

BUT-

lever

the

example,

spring

the

.

mark

434-40

will

fin-

finger

thou-

tem-

loop-

as

until

but-

clamp

un-

~

~

.,.;..e

...-..

.,.;..e

........

~

.......

.......

.......

........

.......

.....-..

~

__.....

.......

.-....

.......

.......

~

...-..

.......

......

~

....-..

..-...

..-....

.......

.......

.......

~

.......

~

.......

.......

......

.......

:t:

~

:t:

......

.......

.......

The

figures

may

be

13.

TWO

See

dicator 2 l-.287

button. Use

of

button

holes

14.

ADJUSTMENT

Lever

ated

by

the

cut-out

the

final

15.

ADJUSTING

Adjust

71-93

rearward

pin

is

cannot

16. ADJUSTING

The

and

is

and

locked

17

. A.

The

3/64

of

when

the

on

necessary

HOLE

that

button

indicator

clamp

in

the

button.

445-.286

eccentric

in

stitch.

vertical

by

about

position.

to

prevent

strike

pre

ssure

regulated

by

DJUSTING

thread

an

inch

thread

the

indicator

to

BUTTONS

clamp

on

circle

so

that

should

on

vertical

HEIGHT

1/32

overtnrow

the

needle

PRESSURE

on

by

the

lower

THREAD

nipper

between

nipper

deviate

FOR

main

rod

of

Check

the

the

4187-l

is

adjusted

with

155-14

the

needle

RAISING

be

shaft,

link

46-16.2

OF

71-73 so

an

inch

stop

of

.

button

upper

knurled

NIPPER-

it

and

is

open.

plates

slightly

two

dots

only

will

BUTTON

adjusted

just

as

BUTTON

that

when

pin

the

button

ON

BUTTON

clamp

knurled

nut.

should

the

thread

are

only

from

the

as

in

Paragraph

which

to

adjust

enter

so

that

clears

this

link

CLAMP -See

the

roller

the

button

22-2

73.

clamp,

CLAMP -See

should

nut

20-60

See

Plate

be

adjusted

nipper

approximate,

figures

represent a two

sidewbe

in

the

CLAMP -See

lever

the

is

The

be

•

12.

movement

center

445-298

lower

moving

Plate

35-17

clears

clamp

B

is

purpose

so

that

moderately

on

acrew

so

that

block

115-107

corner

the

there

and

Set

of

the

Plate

oper-

over

B

in

its

of

this

button

Plate

light

18-866

15

it

in-

hole

C

of

on

rod

B

ls

Page 9

16

18.

AUTOMATIC

The

on

tension

clamp

vent

follows:

is

highest

needle

the

the

Turn

moving

rection

sion

staff

When

thread

19.

THREAD

The

the

automatic

this

regular

threads.

The

fore

the

~ease

the

This

adjustment

lever

45-32.7

ZO.

THREAD

The

eno

ugh

cycle

so

made.

off

so

when

completed

thread

staff

thread

looper

the

machine

upwards

position.

bar lever

until

the

468-Zl.

this

setting

tension

regular

thread

Normally,

opener

end

of

thread

to

purpose

thread

that

the

This

much

thread

THREAD

tension

468-Z

tight until

from

and

Loosen

45-335,

thread

Tighten

release

TENSION

thread

thread

tension

for

the

each stitching

at

the

is

made

open

TAKE-OFF -See Plate

of

through

first stitch

lev

er

should

that

.

TENSION

release

1,

and

requires a moderate

the

stealing

in

has

tension

only a light

the

thread

the

proper

is

from

the

and

is

released

both

been

requires

tension

may

regular

time

the

by

tension

take-off

the

tension

be adju

tails

thread.

two

turn

release.

loosening

of

operates

looper

5/16

hexagon

screws

properly

no

staff

require

tension

thread

cycle

button

discs. See

the next

of

thread

RELEASE-

the

has

This

direction

to

3/8

shaft

14-368

by

the

1333.

made,

further

468-2.2.

As

adjustment

is

tension

.

It

should

clamp

screw

B.

lever

at

the

stitching

sted

so

are

tension

taken

the

tension

until

of

an

head

screws

in

tension

the

adjustment.

is

mounted

in

any

required.

operates

be

starts

18-750

Plate

45-434,

end

of

that

it

left

See

Plate

discs

tight

tension

loop,

is

timed

the

needle

inch

from

1333

the

proper

discs

on

automatic

behind

sewing

adjusted

one stitchin

cycle

does not

on

B.

for

to

and

is

the

machine,

different

just

raise.

sliding

to

may

button

C

mounted

to

to

pre-

as

bar

its

in

the

di-

ten-

be-

to

re-

pull

g

be

pull

.......

......

.......

......

__...

~

.......

....-.

~

~

~

......,.

~

.......

.......

~

...-..

......

~

~

......

~

......

~

......

~

~

~

......

......

......

.,.....

~

~

.,_...

.......

~

......

~

::t:

.,_.

+

This

block

Zl.

TWO

In

the

clamp

Connect

bearing

from

the

of

vertical

machine

In

some

The

obser

ved

ZZ.

NEEDLES

Use

must be

graph

Z3.

FOOT

An

This

second

to

the

chain

from

e

nd

of

Plate

C. A hole

this

chain

sewing

thread.

button

lever

115-106

TREADLE

case

it

and

link

screw

second

link

thru

general,

cases,

following

when

long

reset

9 .

TREADLE

additional

left

of

this

the

vertical

may

shank

The

clamp.

is

adjusted

in

the

appropriate

OPERATION

is

desired

thus

use

46-135

which

buttons

needles

treadle

it,

buttons

second

to

18-392.

46-162.. A hole

buttons

sewing

using

be

but

treadle

the

SHANK

as

is a description

for

the

foot

treadle

should

in a position

second

link

is

provided

attached. Note

still

foot

by

loosening

direction

-

to

eliminate

two

foot

treadles,

the

f~ont

hole

do

not

loosen

is

attached

is

provided

chain

may

be

BUTTONS -See

up

to

50

!ignes

large

as

55

of

shank

buttons

sewing

lower

treadle

46-162.,

treadle

set

is

be

placed

convenient

in

uses

shank

used

is

attached

that

the

that

the

is

of

base

automatic

for

screw

See

the

in

lever 445-2.86. Move

screw

to

the

passed.

can

!ignes

the

.

buttons.

timing

for

beside

for

lifts the

of

the

the

18-750

along

Plate

automatic

proceed

12.06.

hole

in

in

the

Plate

be

handled,

can

be

important

marks.

sewing

the

the

to

the hole

button

the

machine

normal

lift

purpose

the

C

raising

as

the

base

7

sewed.

points

The

shank

main

operator.

clamp.

set

to

break

of

and

nipper

follows:

The

lower

of

although

needle

See

Para-

buttons.

treadle

in

the

thru

ting

opening

moving

bar

of

chain

end

the

to

be

bar

The

lower

See

which

for

the

17

•

in

and

the

:t:

I

Page 10

18

24.

HEIGHT

A:n.

operator

when

theo

ing

the

To

button

ed

on

the

machine.

25. ADAPTERS,

There

clamps

tons . A

Unless

ple

buttons

ju

st

what

26.

FEED

The

there

is

the front

21.

SETTINP

OF

adjustment

can

open

machine

block

115-127

guard

against

strikes

button

See

are a great

and

work

different

the

correct

should

is

required.

PLATE

feed

plate

slightly

edge

BUTTON

is

the

has

the

needle,

clamp

Plate

CLAMPS

support

set

be

for

less

of

the

FOR

provided

button

stopped.

mounted

the

lifting

B.

many

may

number

sent

sewing

than 1/64

opening

Models

SPECIAL

SIX

OR

CLAMP -See

for

controlling

clamp

with

This

on

the

button

there

AND

different

blocks

be

required

of these

to

the

in

EIGHT

clamp

is

an

lever

WORK

available

agent

shank

of

an

the

work support

Z00-6

INSTRUCTIONS

STITCHES-

Plate

B

the

the

second

adjustment

front

of

the

being

raised

adjustable

on

the

rear

top left

SUPPORT

combinations

for

sewing

for

different

parts

is

known,

so

that

he

buttons should

inch

between

and

200

- 7

See

amount

foot

is

made

machine.

so

stop

42-21

BLOCKS

of

shank

shank

several

can

determine

be

the

block.

Plate

the

treadle

by

mov-

high

that

mount-

of

the

adapters,

but-

buttons.

set

so

needle

12

sam-

that

and

the

:J::

:f

~

.,_.

:E

:E

._!-.

.,.;..e

~

:f

~

~

.......

~

:r:

..-!'4

~

........

......

~

......

a.

Plate

two

hole

b.

Plate

sired

NOTE:

the

machine is

29.

SETTING

Pull

tor

21-287

To

set

4110-329

button

To

set

4ll0-329

spacing

Adjustment

slide

and

the

clamp

all

the

position.

the

clamp

all

the

.

of

in

normal

MACHINE

plate

4110-329

indicator

motion

way

motion

way

slide

155-14

out.

Use

in.

stop

FOR

crosswise

Put

indicator

lengthwise

Use

plate

position.

FOUR

all

the

for

spring

spring

4ll0-329

HOLE

way

desired

of

the

arm,

indicator

155-14

out,

for

of

the

a r

indicator

must

only

BUTTONS -See

and

use

spacing.

pull

21-287

desired

m,

push slide

21-287

be

spring

slide

spacing.

for

made

iri

the

de-

when

Plate

indica-

19

12

:!:

not

Refer

used

to

when

Paragraph

sewing

5 Pa

four

ge

hole

12.

NOTE:

buttons.

Six

or

eight

stitches

are

..-...

2

8.

SETTING

TACKING-

The

or

lengthwise

motion

MACHINE

See

Plate

of

the

clamp

of

the

arm

FOR

lZ

:

can

TWO

HOLE BUTTONS AND

be

set

so that

it

is

either

FOR

crosswise

..-.....

:t:

I

Page 11

CLASS

200

0

"'

"D

s

"'

...

\\\\\\\1\\1

~\\\\\\\\\\\

CLASS

200

\1\\1;;

114-84

\tt

4

IN

GEAR

27•189

"D

s

"'

......

&&

..

111141 101141 IOS4t

114-

ll14t

Page 12

18-330

20-98

41· 47

CLASS

200

I'll

I'll

.,

s

"'

w

CLASS

200

L----;co~•••••~•~tut;,;.--

----------------

----

----------

------

----------

----------------

----~~

------------------

----------~--------------~l:~~_j

1

11'5

1 I

141

~

Page 13

CLASS

200

•s

OP I IMI!TS

\ \

41

•49

\\\\\\

\

\\\\\\\\\\

CLASS

200

\

----

112141

111441 I

OS

I4t

\\

FROM

21·287

1

41·3

110·206

21·321

12

787

45·

1160

~~--~~~

14·399

32

THRE

35

333

·1 9 1

\\t

AD

SPOOL

SPRING

..

·

Page 14

----

--

~==~------

11

5·1~3

115·151

CLAMP

18·733

22·224

------

----------

SHANK

4~

430·55

430·61

USE

F

OR

STO.

FOR

MUST

NEEDLE

THE

LOWEST

LOHG

SHANK

29·14L

29•16LSS

29·18LSS

29·20LSS

430·62

CLEAR

BAR

NEEDLES

BUTTONS

----

------~~----------------------

BUTTON

CLASS

PARTS

200

aflrSi

BUSHING

WHEN

1 i

~~

)h. ....

IS

SET

USING

LINES

OH

.,.,

18·330~

17·155

18·750

.

•

BAR

.

L.J.

1

1r

' -··-----

'""'

---··---

-·~----

39

95

9o-34

'~~

90·6

;~:~~:

··-

- ·

---

71·

72

835

-

-{_5·17

_ ____/""""-

1005

21·317

20·60

18·965

99•308

..

.__

__

_

••

)

1

9o-49Jt®

AOJUSTA8LE

.-

90·47

00

/8-

490·49

--~

132

.,

§;;

AOAP~R

-t

"'

...

~

45-4

19

\\

\\1\

\\\1\

158

-25

158-21

18-75

1

8-125

45-458

18-931

45-332

99-316

99-316-1

18-930

\\\\11\\\\\1

($~

(t\~

114

- 123

1\\t

110&0

.,

>

itt

CD

430-77

SNAP

FASTENER

CLAMP

430-86

HOOK 8

EYE

CLAMP

72258

611158

114-176

37118

N

~

Page 15

475-231

BUTTON

SHEET I OFI

SHANKING

FOOT

424-299

NECKING ATTACHMENT

18-986

CLASS

99-

STAY

Blr'f'i'ON

24-304

313-

200

HOLDER

GAUGE

GAUGE

72258

407-10

FOR

SPACING

(LEFT SIDE)

407

-11

FOR

SPACING BUTTONS

(RIGHT SIDE)

7258

BUTTONS

37'SS

U!!4

114-150

82551

TACKING

MODELS

MODELS

CLAMP

1

22-46

200-1,

200-6.200-7

(MODELS

200-2,

COMPLETE

200-6,

200-7

WITH

ONLY)

200-3,200-4,200-5

USE

TACKING CLAMP

THREAD

USE

TACKING CLAMP

430-75-1

BREAKING

430-75

FINGER

114-162

,

§

...

0

Page 16

0

""'

THREAD WIPER FOR

BUTTON SEWI

LEWIS

NG

MACHINES

200

INSTRUCTIONS

SET

ROD

oF•

19/32"

SET

STOP

CLA"P

ADJUST COLLAR

SO

LOOP

NEEDLE. TIGHTEN SET

ADJUST

BACK

IN

FRONT

SEW

ONE

TO

CHECK

IB•I

THREAD

WIPER

CLASS

FOR

71•99

TO

FR~

42·21

AND

WILL NOT

OH

SPRI

WIPER

FORWARD

OF

LOOP

ON

Of

THR

OR

TWO

ADJ

UST

036

ASSEMBLY

(INCLUDES

ADJUSTING

LIFT

CLAMP

FEED

PL ATE,

STOP

OVERTHROW.

39·C255

HG

21·~11

SCREW

WIPER

SPRING

EAD,

BUTTONS,

..

ENT,

BEFORE

BOP

TO A MAXI"'U"'

PIN 22·

WHEH

CLA"P

IS 3/ 81 TO

IN

OR

BACKWARD SO

21·411 PASSES

TURNING

SEWING

68·29

3~79

21·411

No.

71·99)

THREAO WIPER

273

SO

IS

DOWN,

RIGHT

"ACHIHt:

BY

OF

MANUALLY

POWER.

COLLAR.

44!!-432

...

...

MODELS

200-6

AND

200-7

10·

114

\tt

30 4

-170

1

75S

"a

s

"'

..

N

S

HU:T

I C# I

61751 lltn

114

· 1

tll0~4

J28S4

64

Page 17

33

Part

No.

5-5Z5-ll/3Z

7-10

7-11

8-111

8-1Z6

8-13Z

14-36Z

14-363

14-364

14-365

14-366

14-368

14-399

14-455

BUTTON

MODELS

Plate

9

9

9

1,4,5

4,5

7

Z,4

1,Z,4,5

l,Z,4,5

l,Z,4,5

l,Z,4

l,Z,3

1,3,6

7

PARTS

Z00-4,

LIST

SEWING

Z00-1,

Z00-6

Shanking

Gauge

Gauge

Guard

Guard

Shaft

St

for

for

for

for

71-9Z.

Adjustable

for

Pulley

Cam

Shaft

op

Motion

Looper

Shaft

for

Hinge

Shaft

Covers

Shaft

for

Opening

FOR

ZOO-Z,

and

Foot.

spacing

spacing

Needle,

stop

Guard

lift

Shaft

in

Shaft

Needle

3Z-191

holding

Lever

LEWIS

MACHINES

Z00-3

Z00-7

Description

buttons,

buttons,

in

motion

for

lever

445-Z98

in

base.

base.

T r

ip

Lever

in

base

.

Lever

in

both

sides

and

3Z-19Z.

Shank

45-37Z.

left

right

cylinder

plunger

90-49, 90-54.

45-335

Button

Shaft

of

base.

rod

in

base.

in

Sub-base

Clamp

hand.

hand

base.

in

arm.

.

for

16-Z88

16-Z89

16-Z90

16-Z91

16-Z

9Z

16-Z95

16-Z96

16-Z97

1'6-315

4

4

4

4

1,4

1,3

Z,3,6

Z,3

Bushing

Shaft

14-363

Bushing

Shaft

14-363.

Bushing

Shaft

14-364.

Bushing

Shaft

14-364.

Bushing

Shaft

14-366.

Bushing

14-368.

Bushing

Z5-ll.

Bushing

Z5-11.

Bushing

15. Sold

43Z-Z63

in

right

.

in

left

side

in

right

in

left

side

in

front

in

arm

(Upper)

{Lower)

in

Cover

Assembled

only.

side

of

base

of

base

side

of

base

of

base

of

base

for

for

Needle

in

arm

for

in

arm' for Needle

43Z-Z63

in

Front

for

for

Looper

Lever

Needle

for

for

Pulley

for

Cam

Bar

Cover

Pulley

Cam

Shaft

Bar

Bar

138-

Page 18

34

Part No.

16-334

17-124

17-147

17-155

11-1

n 2

18-39

18-71

18-75

18-125

l8-Cl86

18-272

18-280

18-286

18-307

18-318

18-330

18-391

18-392

PARTS

BUTTON

MODELS

Plate

4

1,5

4

7

1,4

2,3

5,8

8

11

2,3

4,5

2

7

10

1,2,3,

6,7

2

1,2,5

200-4,

LIST

FOR

SEWING

200-1,

200-6

Bushing

14-366.

Bearing

Plate

Link

Stud

in

Positioning

base.

Stud

for

Opening

Stud

for

Hinge

Screw

in

stop

base.

Screw

of

Screw

40

Hinge

Flat

430-77,

Screw

Screw

Screw

Hexagon

45-348

Screw

Screw

block

Screw

122-45

Screws

and

Screw

clamp,

Screws

50,

Shoulder

base, and

base,

to

Button

to

for

in

in

for

Needle

Screw

for

for

in

in

for

for

for

and

for

for

Shank

for

arm.

LEWIS

MACHINES

200-2,

and

in

Stud

Lever

holding

Block

Cover

motion

for

Clamp

Needle

Scr

Feed Plate, Shank

Front

Screw

200-3

200-7

Descriftion

rear

of

in

top

46-137.

445-349

Finger

Shank

115-12

432-202.

for adjustable

cam

side of

stop

Stud

46-137

lifting

clamping

Bar 2 5-11.

for

Clamps,

430-86

110-404.

Collar

ew

for attaching

motion,

Covers

attaching

holding

122-46

Stop

42-21

End

17-155

buttons.

cap

of

for

Gear

Stop

Bar

on

base

of

base

122-29,

7,

434-42,

27-170

lever

Bearing

Lever

Snap

.

39-C255.

25-ll, for

32-198

work

thread breaking

to

Clamp

on

Cover

for

Top

Ball

46-135

top

for

for

Roll

Button

in

front

45-331.

Fastener

right

on

sup

Lever

432-263.

opening

and

of

base.

Looper

for

Slide

35-20

in

cylinder

Clamp

of

shoe

left

side

on

Block

45-332,

Needle.

45-302

side

side

porting

Buttons.

30-75.

45-285

Joint

46-175

Shaft

arm.

or

left

117-

Clamp

of

of

arm

fingers

button

4124-

for

lobe

of

side

on

to

base

in

~

~

~

ri-4

~

:r:

Part

No.

PARTS

BUTTON

MODELS

Plate

200-4,

LIST

FOR

LEWIS

SEWING

200-1, 200-2,

200-6

MACHINES

and

200-3

200-7

Description

35

.......

.......

~

r:4

~

~

18-547

18-562

18-619

.-i'1

~

~

~

...;-.e

..-!4

~

.......

18-623

18-629

18-634

18-677

~

18-730

~

..;-e

.,...

.

~

~

~

18-733

18-738

18-739

18-747

18-750

1,5

1,5

7

1,5

6

2,4,5

7

3

1,4,5

4,5

1,2,4,5,

& 7

Set

Screw

Bearing

Screw

arm.

Shoulder

46-138

Shoulder

162

to

Shoulder

side

of

Screw

on

Shank

Screw

latch

Screws

40,

in

Screws

Bracket

Allen

l

for

2

for

2

for

Grooved

2

for

1

for

Spiral

2

for

Spiral

Screw

Screw

Clamp

445-370,

Screw

Clutch

Screw

Nipper

for

adjusting

thread

Arm.

Screw

Tension

Screw

inder

in

Pin

for

Lever

Screw

on

top

screw

lever

Screw

base.

in

Collar

Button

in

Lever

51-22,

for

cylinder

for

50-215,

Set

Screw:

Lower

Worm

Worm

for

Clamp

in

Sub-base

Screw

on

for

adjusting

Pressure,

for

clamping

Operating

pull-off

for

adjusting

Disc

for

Needle

Base.

rear

of

22-219.

445-405,

for

of

base.

for

445-405,

for

39-95

Clamp.

45-331

left

aide

positioning

base.

Stop

Motion

on

Ball

Eccentric

27-189.

Collar

Gear

27-155.

Gear

27-169.

Gear

27-168.

for

for

for

Stop

left

side

right

Bar

block

115-106 for

Lever

on

468-22.

Guard

base

for

left

Links

46-136

connecting

on

left

Lever

Sub-base.

45-331

for

Spring

for

of

base.

Finger

TriP.

39-

107.

Shank

But

ton

Motion ·Trip

of base

Lev

er

45-302

aide

block

4115-104

138-15,

445-304

lever

45-327

8-111

holding

side

Link

side

clamping

Cam

Lever

33-137

Buttons.

Tray

.

of

base.

and

adjusting

on

top

to

in

Cyl-

of

and

46-

of

arm.

on

left

21-353

434-

.

4186-1,

Lever

{or

to

Screw

of

ope

n

Page 19

36

37

Part

18-750

18-752

18-766

18-800

18-809

18-812

18-814

18-816

18-818

18-819

18-821

18-823

18-826

18-827

18-835

18-854

18-866

18-873

No.

PARTS

BUTTON

MODELS

200-4,

Plate

1,2,4,5,7

2,3

12

4

2

3,4

1,5

3,6

1,5

4,5

6

1,6

1,4

, 5

1,2,6

1,2

2,5,7

LIST

SEWING

ZOO-I,

200-6

Screws

206

to

Screw

Screw

nipper

Screw

17-155,

Screws

4115-194

Knob

Screws

base

.

Screw

458-39.

Screw

vertical

Screws

190-1

Screw

Screw

Screw

slide

Spot

Screw

Lever

Screws

Screw

Nut

20-114.

Screw

left

side

Screw

for

front

Arm.

Screw

for

stop

Screw

on

top

Screw

Clamp

Screws

Clamp

FOR

MACHINES

200-2, 200-3

and

200-7

for

attaching

Base.

for

guard

for

holding

bar.

for

holding

for

Shank

for

holding

to

nipper

Screw

plate

for

for

block

for

grease

connecting

link

46-162,

to

attach

to

cylinder

for

Cam

for

locking

for

clamping

158-9,

for

45-348,

for

attaching

Stud

for

Top

for

spring

of

Arm.

on

Nipper

end

of

for

clamping

motion

for

Thread

of

arm.

for

adjusting

Holder

to

attach

Holder

LEWIS

Description

Indicator

8-111.

Lever

Block

Buttons.

blocks

bar.

right

side

115-137,

hole

in

curved

in

Base.

insert

for

base.

Roller

Stop

right

opening

Spring

434-42, left

99-270,

99-270.

35-15,

machine

Indicat~r

on

cylinder

Motion

side

Arm

Nipper.

front

of

Zl-379

Bars

138-15

Zl-3

adjustable

Nipper

pressure

under

Button

Clamp

45-327

115-127

115-106

Cover

top

Clutch

link

46-135

Looper

in

to

sub-base.

155-14

Plunger

of

base.

to

Base.

Arm.

in

block

and

79,

side

Block

on

Arm.

Plate

to

to

3Z-198.

rear

Pulley,

base.

base

Take

115-110,

138-ZZ

left

Shoe

of

115-107,

Button

to

Button

ll0-

Stud

and

of

to

Yoke

to

s

side

180-2

base.

of

~

..,.;..e

__.

__..

..-..

~

....:--

.......

~

__.

........

.-.

~

.....:-e

~

....:--

__.

......

~

......

__.

.,......

.......

~

..-.

......

.......

.......

.......

.--

.--

.......

__.

........

........

......,.

~

...:--

:f

Part

18-873

18-878

18-907

18-920

18-92

18-929

18-930

18-931

18-934

18-945

18-949

18-958

18-959

18-

965

18-966

18-967

18-968

1

8-969

No

5

PARTS

BUTTON

MODELS

200-4,

•

Plate

1

1,4

2,3

5

2,4

5,8

5,8

5,8

4

5,8

4

4

7

2,5

4

2,4

4,5

LIST

SEWING

200-1,

200-6

Screws

Shank

Bearing

side

Screw

up)

Screws

Cap

base.

Hinge

Flat

Clamp

Bearing

158-Zl

Fastener

Shoulder

158-21

Fastener

Shoulder

Lever

Knurled

L

ever

Snap

430-86.

Screw

er

36-18,

Spot

right

Screw

Pawl

side

Screw

Button

Screws

top

of

Allen

44-280

Spot

Screw

33-137,

Allen

434-42,

FOR

MACHINES

200

and

for

Button

Screw

of

base.

for

41-47,

for

Screws

Screws

Button

430-77,

Screws

in

Flat

Clamp 430-77,

Screw

in

Flat

Clam

Screw

445-349,

Screw

45-332

Fastener

in

Collar

in

Screw

for

side

of

for

Stop

166-7

of

base.

for

regulating

Clamp.

for

Graduated

Cylinder

Set

Screw

.

for

in

bas

Set

Screws

left

LEWIS

-Z,

200-3

200-7

Description

attaching

Clamp.

for

clamping

to

Needle

Needle

for

Ball

for

Clamps,

and

for

Button

for

Button

p, 430--77,

for

in

for

on

Flat

Clamp

1284

front

Stop

base.

Motion Lat

in

steel

Base.

for

Needle

e.

(2)

side

of

Bracket

Gear

Thread

Bar

Plates.

Joint

45-346

and

in

Clamp

Slots

Clamps,

Slide

Clamps,

positioning

cylinder

clamping

Button

430-77,

for

end

of

Motion

disc

Pressure

Plate

Stop

Drive

for

Stop

base.

27-171,

Guide (Take-

25-11

4124-49,

and

in

Snap

430-86.

of

Slides

Clamp

Blocks

Clamp

base.

adjusting

Clamps,

clamping

Cylinder

Disc

ch

51-20

44-280,

110-205

Motion

Eccentric

Motion

50-238

on

•

45-347

Fastener

Snap

430-86.

158-11,

Snap

430-86.

finger

Clamp

Base.

44-280,

on

on

Shank

Disc

on

left

in

in

158-ll,

Loop-

and

right

on

Cam

~

~--------~-----------=~------------~~

Page 20

38

Part

18-974

18-982

18-984

18-986

18-987

18-995

18-996

18-997

18-1022

18-1023

18-1036

18-1050

20-13

20-34

20-35

20-60

20-80

No.

PARTS

BUTTON

MODELS

200-4,

Plate

1,2,3,6,9

4

4

9

9

1,6

2

2,6

12

12

11

1,2,6

1,6

4,5

2

1,2,6,

&:

7

z

LIST

FOR

SEWING

200-1, 200-2,

Z00-6

Screws

End

for

Screw

Screw

from

Set

Cams,

Screw

5-525-11/32.

Screw

5-525-11/32.

Screw

Nipper

Allen

Models

Collar

Screw

41-49.

Link

Bearing

446-173.

Screw

Bearing

Nuts

4187-l.

Nut

Lever

Lock

Knurled

Tension

top

Nuts

pressure

under

Nuts

Spring

Nut

lock

and

for

Cover

spacing

in

to

turning.

Screws

in

for

for

for

4187-l.

Set

200-2

39-131.

for

Locking

Screws

for

Screw

for

for

Adjusting

45-302,

Nut

Nut

Springs

of

arm.

for

arm.

for

for

on

top

Ball

MACHINES

424-299.

keep

base.

Screw

Screw

for

adjusting

on

Screw

Joint

LEWIS

200-3

200-7

Description

Thread

432-263.

buttons

Friction

for

Button

clamping

Positioning

Spring

Thread

Thread

sewing

of

21-366

for

and

200-4,

Guides

Screw

for

Wiper

for

18-995

Screw

on right

Stud

17-172

for

adjusting

21-284

Spring

Button

18-965

Shank

Connecting

4124-50.

Snubber

Screw

407-10,

Disc

Clamp

Shanking

Shanking

Worm

on

top

Links

45-434.

in

side

and

Clamp

for

156-40

for

407-11.

44-288

Vibrating

Foot

for

Thread

27-190

and for

41-48

of

base.

46-173

Spring

Nipper

18-747

of

.

Thread

113Z

21-317

Holder,

P r

essure

Buttons.

Rod

71-74

Gauge

Foot

and

and

Clamp.

for

base.

on

for

on

on

to

~

~

.......

......

.-.

....r1

~

.-f4

.....:---

~

~

~

~

.,..

..-r

..,..

_..r4

~

.......

~

......

~

...-...

......

~

~

~

..;-e

~

..;.--

...;-e

:t:

:t:

..,;..,e

......

~

....;..-

~

.,...

.-....

Part

Z0-81

Z0-98

Z0-109

Z0-114

20-123

20-127

20-128

21-70

21-96

21-229

21-Z8

21-Z87

21-295

21-310

21-315

Zl-317

21-321

No.

4

BUTTON

MODELS

Plate

2

l,Z,3

&:

6

1,Z,5

2,6

5,8

4

4,5

12

1,6

4

l ,Z

1,2

,5,

6,12

3,6

l,Z

5

1,2,

7

6

PARTS

Z00-4,

Slotted

Snap

430-86.

Nut

98Z

Nuts

aide

Spring

Spring

45-285,

Spring

releasing

Thread

Tension

Handle

136

Button

Spring

32-192.

Spring

on

Spring

Clamp,

Clamp

Spring

Clamp

arm.

Spring

tion

LIST

FOR

LEWIS

SEWING

Z00-1, Z00-2, Z00-3,

Z00-6

Nut

(left

necting

4124-49.

Knurled

for

releasing

ver.

Fulcrum

Plate,

Nut

on

Nipper

Flat

Button

for

in

of

to

top

on

and

hand

Rod

Thumb

Nut

on

top

Screw

.

Nut

Fastener

locking

steel

for

Stop

base.

for

ball

for

Button

in

in

end

clutch.

Tension

Staff

and

regulate

Clamp

for

holding

for

Thread

of

arm.

for

closing

Snap

430-86.

for

regulating

Holders

for

Lever

sub-base

MACHINES

Z00-7

Description

thread)

71-74

Nut

Thread

for

of

base.

Stud

for

locking

Clamps

Clamp

Screws

Disc

Motion

79-31.

rear

left

of

Pulley

Spring

468-21

Indicator

lengthwise

on

Fastener

99-270

45-333

•

to

on

Button

18-8Z3

430-63

44-280,

Clamp

side

on

Spring

rear

Covers

Nipper

Jaws

pressure

on

lock

Plunger

Nipper,

Clamp

screw

430-77,

18-959

Rod

Lifting

of

Shaft

(front)

top

of

arm.

of

Clamp

and

to

bottom

Ball

Joint

in

Slide

for

opening

18-931

and

430-63-1,

Clamp

and

for

Stop

71-92,

arm.

14-363

in

of

arm

on

Link

movement

32-191,

Block

115-107,

Flat

Button

430-77,

on

99-308,

trip

stop mo-

of

Con-

Z6-147

front

18-

Motion.

right

Lever

for

Thread

•

46-

Button

under

39

co-

in

of

~

Page 21

40

Part

No.

21-322

21-336

21-337

21-353

21-359

21-360

21-361

21-362

21-366

21-379

21-407

21-411

21-414

2

1-416

22-175

22-195

221-205

22-219

22-221

22-224

22-235

PARTS

BUTTON

MODELS

Plate

4

5

5

7

4,5

4

4,5

4,

5

2

11

1

,2

4,5

6

6

5

1,5

1,5,7

200-4,

~c

Spring

LIST

SEWING

200-1,

200-6

Spring

for

locating

side

of

Spring

346,

right

Spring

34

7,

left

Spring

on

Shank

Spring

right

side

Spring

45-348,

Outside

348

for

Inside

348

for

Spring

4187-1,

Spring

rear

left

Spring

Thread

Thread

on

top

Spring

Dowel

Locating

top

of

Locating

337

on

Bearing

228

for

for

Lever

sidewise

Pin

for

Staff

468-21

Hinge

270

and

ing

Nipper

FOR

MACHINES

200-2,

and

on

Screw

base.

for

holding

Jaw

for

holding

Jaw

for

Clamp

Button

(rear)

of

for

restoring

right

Spring

Rod

Spring

Rod

for

applying

top

for

Nipper

side

Clip

Wiper

Tension

of

arm

P i

ns

Pin

arm,

Pins

Jaws

Pin

moving

45-290

on

releasing

Pin

for

99-308.

Pin

LEWIS

200-3,

Z00-7

Description

Shoe

of

of

Flat

Clamp.

on

base

side

in

71-92,

in

Stop

71-92,

left

side

of

for

Pin

Spring.

Spring

.

for

stop

for

Arm

for

for

of

Flat

for

Lever

Button

rear

on

top

Button

in

Block

on

left

18-835

in

Flat

stop

.

arm.

Tension

top

for

Cam

434-42,

button

button

Opening

of

Stop Motion

Bars

Spring

for

Tension

side

in

Button

in Lever

Button

Motion

Stop

base.

right

side

Motion

right

side

pressure

of

arm.

138-15

22-224.

in

motion,

and

Base.

Discs 1183

21-336

Button

with

Clamp lengthwise

moving

of

base

of

arm.

Clamp

4115-1

of

arm.

Knob

142-6

left

Lever

Clamp.

Lever 45-372

Motion

468-22,

Clamps.

curved

in

Holders

04

Clamps.

Rod

Lever

of

base.

Lever

of

base

on

Nipper

and

(30

and

Button

.

Tension

for

45-

45-

71-92,

Lever

45-

138-22

rear,

used).

slot

adjust-

45-

.

on

21-

45-

Clamp

99-

and

~

.,_:.,

....;..-

~

.......

.,....

...,..

~

~

~

~

~

~

~

.......

.,.-:4

~

.-:-.e

....:--

~

.....

...+-

......

~

__.

.....

......

......

~

~

:t:

~

.,.,.,.

......

......

~

...;..e

~

.....:-4

...:--

~

~

Part