Page 1

®

INDUSTRIAL

SEWING

FINEST

CLASSES

17

and

24

QUALITY

LEWIS

•

COLUMBIA

LIST

17-100

17-130

OF

F

MACHINES

PARTS

OR

24 - 120

24- 130

CATALOG

NO.

T194-8

MACHINE COMPANY

CHICAGO

Page 2

Catalog

Noo

T194-8

Union

Rights

LIST

17-100

17-130

First

Copyright

Special

Reserved

OF

Styles

Edition

by

PARTS

24-120

24-130

1961

Machine

in

All

Co.

Countries

MACHINE

INDUSTRIAL

CHICAGO

Printed

COMPANY

SEWING

in

MACHINES

U.S.Ao

June,

1973

Page 3

IDENTIFICATION

OF

MACHINES

Each

the

style

The

boss

This

All

references

from

The

17-100

for

overcoats

line

stitch.

17-130

otherwise,

Union

plate

serial

in

the

catalog

the

operator1 s

operating

A

45°,

felling

stitch

Fitted

on

head

to

one

facings

finished

and

with

same

Special

the

number

of

the

applies

direction,

position

direction

needle,

can

automatic

as

Lewis

column

of

of

each

machine.

APPLICATION

specifically

such

while

of

DESCRIPTION

two

and

bottoms

with

piped

be

adjusted

tension

Style

17-100.

machine

the

machine.

machine

as

seated

the

handwheel

thread

edges

carries

to

Styles

right

OF

raised

of

quarter

or

to

produce

release

a

is

stamped

OF

CATALOG

17-100,

and

left,

at

the

machine.

is

away

MACinNES

flat

bed

lined

turned

a 2

for

sewing

style

in

front

from

lockstitch

and

under

to 1 skip

number

the

left

17-130,

and

the

half

edges.

thin,

light

which

main

24-120

back,

is

shaft

etc."

stamped

and

operator.

blindstitch

lined

sack

Makes a straight

stitch

or a non-skip

weight

materials"

bushing

24-130.

are

taken

machine,

coats

and

in

24-120

for

A

felling

finished

24-130

bluff

The

Same

edge.

machine

Use a good

at

1000

fact

Most

they

Fahrenheit.

of

are

Remove

oiling

See

cause

places.

Clean

that

the

lint

the

machine

90°,

one

needle,

together

with a plain

as

Style

should

grade

the

of

oiling

painted

work

feed

and

support

dirt

points

to

the

or

24-120

be

straight

places

red.

from

are

feed

two

thread

canvas

bluff

and

edge.

except

oiled

twice

mineral

on

the

plate,

the

kept

head

moving

clean.

improperly.

raised

flat

cloth

Stitches

for

overcoats.

OILING

daily,

oil

before

of a Say

machine

cover

parts

Accumulation

at

the

bolt

are

and

daily

bed

lockstitch

edge

up

the

viscosity

readily

arm

to

of

sack

to

1/4

Stitches

morning

identified

cover

insure

of

lint

blindstitch

coats

inch

up

to

and

afternoon

of

90

for

easier

trouble

in

the

and

from

1/2

to

because

free

feed

machine,

top

bluff

inch

starts.

125

seconds

of

access

operation.

points

coats

edge.

from

the

to

will

SPEED

The

recommended

The

recommended

speed

speed

for

for

Styles

Styles

17-100

24-120

and

and

17-130

24-130

is

is

1200

1100

R.

R.

P.M.

P.M.

Page 4

Use

"Lewis"

only

on

genuine

the

shank.

Union

Special

NEEDLES

Lewis

needles.

They

are

stamped

with

the

word

Needles

The

is a ball

following

The

is a uniform

following

Selection

type

of

for

recommended

eye

sizes:

recommended

blade

sizes:

of

material

produce a good

these

needle

needle

proper

used.

stitch

machines

needle

with

a • 035

NEEDLE

29-132-1/2

29-133

29-134

29-134-1/2

needle

with

NEEDLE

29-123

29-124

29-124-1/2

needle

Thread

formation.

are

for

TYPE

for

a.

TYPE

size

available

Styles

inch

Styles

035

inch

is

determined

should

with

either a uniform

17-100

diameter

24-120

and

blade.

and

diameterblade.

by

pass

freely

17-130

It

SIZE

0 025

0 030

0 040

.045

24-130

SIZE

• 030

• 040

.045

size

of

through

is

is

is

It

is

thread

needle

blade

Type

also

Type

also

or

ball

29-133-1/2.

available

29-123-1/2.

available

and

weight,

eye

in

order

in

in

eye.

It

the

It

the

and

to

To

have

sample

label.

needle,

A

Where

numbers

Success

Union

Special

Machine

according

precision.

Genuine

trade

mark

Prices

are

forwarded

otherwise

needle

or

complete

construction

represent

in

the

Lewis

Company,

to

the

Maximum

needles

is

your

are

strictly

f.

directed.

orders

the

order

type

promptly

number

would

permits,

the

same

USE GENUINE

operation

Needles

its

subsidiaries

most

approved

of

and

efficiency

are

packaged

guarantee

net

cash

and

o.

b.

shipping

A

charge

and

accurately

should

read:

"100

be

Needles,

IDENTIFYING

each

parts,

part

regardless

NEEDLES

these

Repair

machines

and

authorized

Parts

scientific

and

durability

of

with

the

labels

highest

TERMS

are

subject

point.

is

made

Parcel

to

cover

forwarded.

PARTS

is

stamped

of

AND

REPAIR

can

as

furnished

distributors.

principles,

are

assured.

marked

quality

to

in

change

Post

postage

filled,

an

Use

Type

29-133-1/2".

with

its

catalog

PARTS

be

secured

and

are

Lewis

materials

without

shipments

and

insurance.

empty

the

description

part

in

which

by

the

They

made

~

and

notice.

are

container,

number.

they

only

with

Union

are

designed

with

workmanship.

All

shipments

insured

a

on

the

Part

appear.

genuine

Special

utmost

..

This

unless

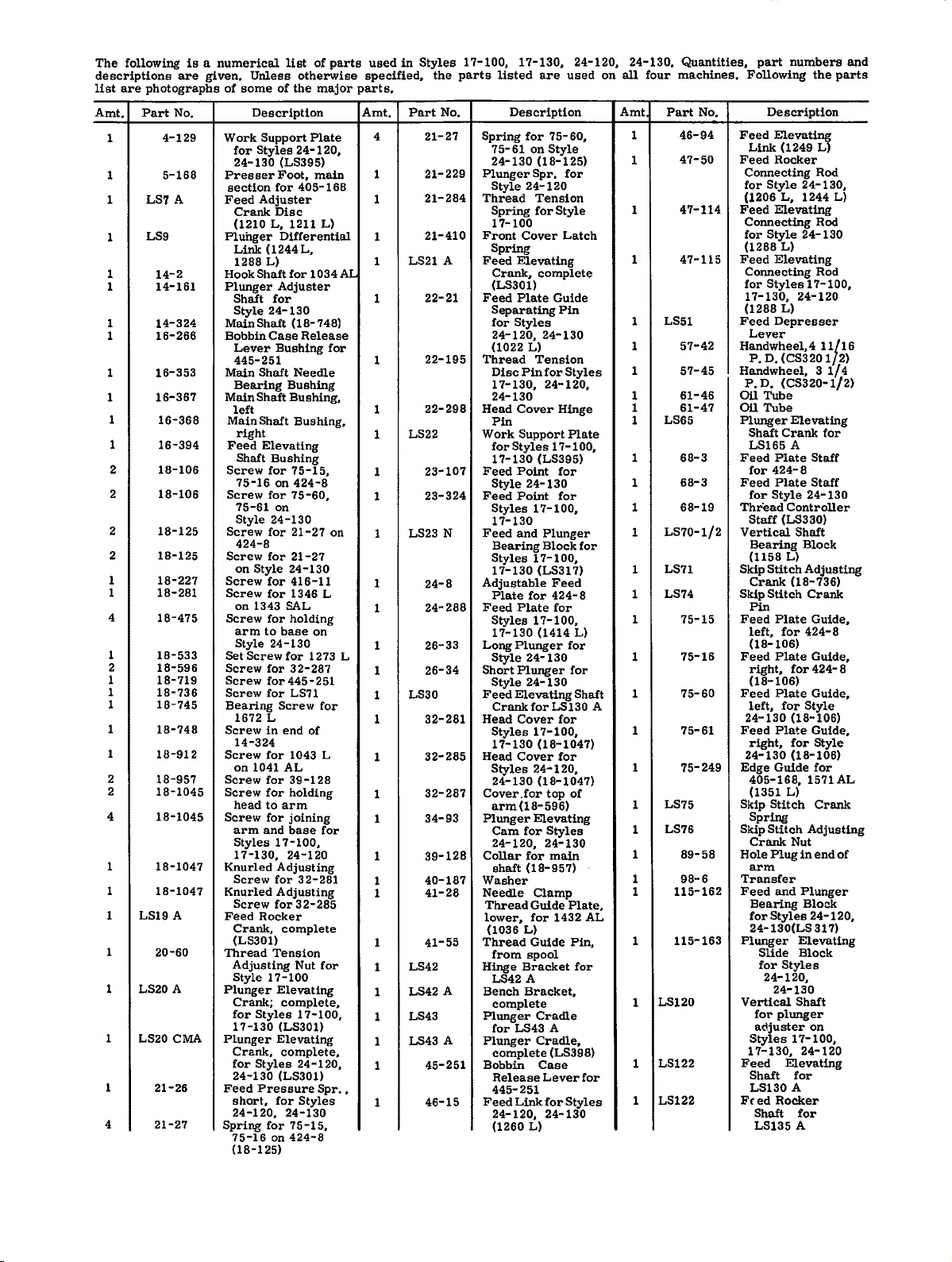

Page 5

The

following

descriptions

list

are

photographs

Part

Amt.

1

1

1

LS7

LS9

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

4

1

2

1

1

1

1

1

2

2

4

1

1

1 LS19 A

1

1 LS20 A

1

LS20 CMA

1

4

is a numerical

are

No.

4-129

5-168

A

14-2

14-161

14-324

16-266

16-353

16-367

16-368

16-394

18-106

18-106

18-125

18-125

18-227

18-281

18-475

18-533

18-596

18-719

18-736

18-745

18-748

18-912

18-957

18-1045

18-1045

18-1047

18-1047

20-60

21-26

21-27

given.

of

Work

for

24-130

Presser

section

Feed

Crank

(1210

Pluhger

Link

1288

Hook

Plunger

Shaft

Style

MainShaft

Bobbin

Lever

445-251

Main

Bearing

Main

left

Main

Feed

Screw

Screw

Screw

Screw

Screw

Screw

Screw

arm

Set

Screw

Screw

Screw

Bearing

Screw

14-324

Screw

on

Screw

Screw

head

Screw

arm

Styles

17-130,

Knurled

Screw

Knurled

Screw

Feed

Crank,

(LS301)

Thread

Adjusting

Style

Plunger

Crank;

for

17-130

Plunger

Crank,

for

24-130

Feed

short,

24-120.

Spring

75-16

(18-125)

Unless

some

Description

Support

Styles

for

Adjuster

Disc

L,

(1244

L)

Shaft

for

24-130

Case

Bushing

Shaft

Shaft

Shaft

right

Elevating

Shaft

Bushing

for

75-16

on

for

75-61

on

Style

24-130

for

424-8

for

on

Style

for

for

on

1343 SAL

for

to

Style

24-130

Screw

for

for

for

1672 L

in

for

1041

for

for

to

for

and

17-100,

for

for

Rocker

Tension

17-100

Styles

Styles

Pressure

for

for

on

list

of

otherwise

of

the

major

Plate

24-120,

(LS395)

Foot,

main

405-168

1211

L)

Differential

L,

for

1034

Adjuster

(18-748)

Release

for

Needle

Bushing

Bushing,

Bushing,

75-15,

424-8

75-60,

21-27

21-27

24-130

416-11

1346 L

holding

base

on

for

1273 L

32-287

445-251

LS71

Screw

for

end

of

1043 L

AL

39-128

holding

arm

joining

base

for

24-120

Adjusting

32-281

Adjusting

32-285

complete

Nut

for

Elevating

complete,

17-100,

(LS301)

Elevating

complete,

24-120,

(LS301)

Spr

Styles

24-130

75-15,

424-8

parts

AL

on

••

used

specified,

parts.

Amt.

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

in

Styles

Part

21-27

21-229

21-284

21-410

LS21 A

22-21

22-195

22-298

LS22

23-107

23-324

LS23 N

24-8

24-288

26-33

26-34

LS30

32-281

32-285

32-287

34-93

39-128

40-187

41-28

41-55

LS42

LS42 A

LS43

LS43 A

45-251

46-15

the

No.

17-100,

parts

listed

Description

Spring

75-61

24-130

Plunger

Style

Thread

Spring

17-100

Front

Spring

Feed

Crank6 complete

(LS301)

Feed

Separating

for

Styles

24-120,

(1022 L)

Thread

Disc

17-130,

24-130

Head

Pin

Work

Styles

for

17-130

Feed

Style

Feed

Styles

17-130

Feed

Bearing

Styles

17-130

Adjustable

Plate

Feed

Styles

17-130

Long

Plunger

Style

Short

Style

Feed

Elevating

CrankforLS130

Head

Styles

17-130

Head

Styles

24-130

Cover

arm(18-596)

Plunger

Cam

24-120,

Collar

shaft

Washer

Needle

Thread

lower,

(1036

Thread

from

Hinge

LS42 A

Bench

complete

Plunger

for

LS43 A

Plunger

complete

Bobbin

Release

445-251

Feed

Link

24-120,

(1260

17-130,

are

for

75-60,

on

Style

(18-125)

Spr.

24-120

Tension

for

Style

Cover

Elevating

Plate

Guide

Pin

24-130

Tension

Pin

for

24-120,

Cover

Hinge

Support

17-100,

(LS395)

Point

for

24-130

Point

for

17-100,

and

Plunger

Block

17-100,

(LS317)

Feed

for

424-

Plate

for

17-100,

(1414 L)

24-130

Plunger

24-130

Cover

for

17-100,

(18-1047)

Cover

for

24-120,

(18-1047)

.for

top

Elevating

for

Styles

24-130

for

main

(18-957)

Clamp

Guide

for

1432

L)

Guide

spool

Bracket

Bracket,

Cradle

Cradle,

(LS398)

Case

Lever

for

24-130

L)

24-120,

used

for

Latch

Styles

Plate

for

8

for

for

Shaft

of

Plate,

AL

Pin,

for

for

Styles

on

A

24-130.

all

four

Amt

1

1

1

1

1 LS51

1

1

1

1

1 LS65

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

LS120

1

LS122

1

LS122

1

Quantities,

machines.

Part

No.

46-94

47-50

47-114

47-115

57-42

57-45

61-46

61-47

68-3

68-3

68-19

LS70-1/2

LS71

LS74

75-15

75-16

75-60

75-61

75-249

LS75

LS76

89-58

98-6

115-162

115-163

part

numbers

Following

Feed

Link

Feed

Connecting

for

(1206

Feed

Connecting

for

(1288

Feed

Connecting

for

17-130,

(1288 L)

Feed

Lever

Handwheel,4

P.

D.

Handwheel, 3 1/4

P.

D.

Oil

Tube

Oil

Tube

Plunger

Shaft

LS165 A

Feed

for

Feed

for

Thread

Staff

Vertical

Bearing

(1158

Skip

Crank

Skip

Pin

Feed

left,

(18-106)

Feed

right,

(18-106)

Feed

left,

24-130

Feed

right,

24-130

Edge

405-168,

(1351 L)

Skip

Spring

Skip

Crank

Hole

arm

Transfer

Feed

Bearing

for

24-130(LS

Plunger

Slide

for

24-120,

Vertical

for

adjuster

Styles

17-130,

Feed

Shaft

LS130

Feed

Shaft

LS135

the

Description

Elevating

(1249

L)

Rocker

Style

Style

Styles

Stitch

Stitch

Stitch

Rod

24-130,

L,

1244

Elevating

Rod

24-130

L)

Elevating

Rod

17-100,

24-120

Depresser

(CS320 1 2)

(CS320-1/2)

Elevating

Crank

Plate

Staff

424-8

Plate

Staff

Style

24-130

Controller

(LS330)

Shaft

Block

L)

Adjusting

(18-736)

Crank

Plate

Guide,

for

424-8

Plate

Guide,

for

424-8

Plate

Guide,

for

Style

(18-106)

Plate

Guide,

for

Style

(18-106)

Guide

for

1571

Stitch

Crank

Adjusting

Nut

Plug

in

end

and

Plunger

Block

Styles

24-120,

31

Elevating

Block

Styles

24-130

Shaft

plunger

on

17-100,

24-120

Elevating

for

A

Rocker

for

A

11/16

for

parts

L)

7)

and

AL

of

Page 6

Amt.

Part

LS122

1

LS123

1

4

LS130

1

1

LS135

1

LS165

1

LS201

1

LS207

LS210

1

LS214

1

2

LS215

LS219

1

LS220

1

LS225

1

CS231

1

CS231

1

2 CS232

LS294

1

LS295

1

3

LS299

LS301

1

LS302

1

LS314

1

LS314

1

LS316

1

CS317

1

CS317-1/2

1

2

LS317

LS317

2

2

CS320

LS324

1

CS328

1

LS330

1

CS335

1

CS337

1

LS393

1

LS394

1

LS395

1

No.

125-23

A

A

A

A

1/2

De

scription

Feed

Rocker

Shaft

for

Plunger

Oil

Feed

Feed

complete,

for

Elevating

Shaft

for

Cup

Elevating

complete,

(1249

L)

Rocker

Styles

17-130

Plunger

Feed

Shaft,

with

Elevating

complete,

crank

Rocker

Bushing

Roll

for

plunger

elevating

on

Styles

24-130

Feed

Lock

LS324

Center

LS43

Plunger

Nut

Feed

Block

Nut

Nut

Nut

Cam

{LS397)

Skip

Lock

Clamp

Bearing

Screw

Screw

Plunger

Spot

Set

Clamp

Clamp

Set

wheel

Feed

Clamp

Set

Screw

Screw

Screw

Screw

Clamp

(1251 L)

Elevating

Eccentric

(1005

L,

Nut

for

Bearing

A 1

Adjuster

~ob,

complete

(LS220,

for

LS219

Spring

Guide

for

18-1047

for

1558

Styles

17-130,

24-120,

for

LS324,

LS396

on

24-120,

for

producing

2

to 1 skip

Stitch

Roll

(LS393)

Nut

LS397,

LS19

LS20

1304 L on

17-100,

(1160

for

LS398

Screw

A,

CMA, LS21 A

Screw

L)

for

for

on

Styles

24-120,

Adjuster

Knob

Shaft

LS219

A

Screw

57-45

Screw

Screw

LS23

N

Screw

115-162

Screw

Depresser

Lever

Stud

CS232)

Screw

LS672

Screw

for

for

for

fo::-

Screw

4-129

Crank

448-

6

LS165

with

Shaft,

with

17-100,

Shaft

cam

24-120,

1147

CS335)

A

Slide

Pin

SL

24-130

Styles

24-130

stitch

Cam

for

LS20

Styles

17-130

LS541

1555

17-130,

24-130

for

for

for

57-45

for

for

for

hand-

(LS214,

for

for

68-19

LS219

CS510

LS295

LS405

for

A

Shaft,

cram

crank,

slot

L)

for

on

A,

for

L

A

Amt.

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Part

No.

LS395

LS396

LS397

LS398

401-6

401-14-1/2

LS403

LS403

S

405-168

LS405

416-11

424-8

424-77

445-234

445-251

448-6

470-6

478-10

478-13

CS510

FP539

LS541

666-65

LS670

LS671

LS672

A

LS674

LS675

892 L

1001 L

1002

L

1002L-1/2

1002L-1/2

1003

L

1004

L

1005

L

1005

L

Description

Clamp

Screw

for

LS22

Plunger

Pivot

Pivot

Head

Head

24-120,

Plunger

Plunger

Presser

Long

Adjustable

Feed

Adjustable

Plate

Take-up

Bobbin

Feed

Plunger

Pulley

Main

End

Clamp

Plunger

Oil

Spiral

Vertical

Cam

Plunger

Bearing

Screw

Needle

Spot

Spot

Spot

Set

Needle

Set

Set

Elevating

Cam

Stud

on

24-120,

(CS232)

Screw

LS294

Screw

LS43

for

17-130

for

(18-1045)

Styles

24-130

for

(LS299)

for

A (LS299) 1

Style

Styles

24-130

Adjuster

Spring

for

24-120,

Spring

17-100,

Styles

24-130

Adjuster

for

Styles

17-130

Foot,

complete,

24-130

(LS394)

Bushing,

marked"B",

complete,

Style

(1073 L)

Feed

Plate,

24-120

for

for

Spring

Hook

complete

(18-227)

for

Feed

Style

24-130

Lever,

complete,

24-120,

complete { 18complete

for

24-130

Case

Rocker

Styles

for

24-130

Release,

719)

Crank,

with

24-120,

Sleeve,

complete,

Styles

24-130

for

24-120,

(1251

L)

Needle

Bearing

Shaft

Bearing

for

1415 L on

Retaining

(LS314) 1 1025 L

Needle

Thrust

Washer

1139 L (CS337)

Screw

for

1417

Adjuster

Spring

Wick

Gear

and

L,

1031

Plunger

Driving

L,

1031

Roll

Block,

(CS328)

Frame

17-100,

Center

A (1005

for

1573 L

AL

Crank

L,

1003

for

Screwfor

for

SL

for

Driving

for

for

for

14-161

Gear

1001 L

1146 L

1001 L

LS210

LS675

LS120

(1025

Shaft

(1025

complete

Styles

17-130

LS43

on

405-168,

1571

(1002

Screw

Screw

1146

Screw

Screw

Screw

Style

Styles

shaft

AL

L)

L)

for

for

L)

L)

Stud

Amt.

Part

2

1005

1

1005

1005

1

1

1005

1 1005 L

1 1006 L

1006

1007 L

1

1008 L

1

1 1009 L

1 1009 L

2

1009 L

2 1039 L

1010

1

1 1011 L

1012 L

1

1014

1

1 1016 L

1018

1

1

1019 L

2

1020 L

1021 L

1

1022 L

1

1022 L

1

1023 L

1

1024 L

1

1025 L

1

1025 L

1

2 1025 L

1026 L

1

2

1027 L

1028

1

1029 L

1

1023 L

2

1029 L

1

1030 L

1

3

1031 L

1031 L

1

1033 L

1

1034

1

1035 L

1

1036 L

1

No.

L

L

L

L

SL

L

L

AL

L

AL

Description

Set

Screw

SetScrew

SetScrew

Set

Screw

SetScrew

Needle

Connecting

for

Styles

17-130

Needle

Connecting

for

Styles

24-130

Needle

Needle

Driving

(1009

Nut

for

Nut

for

Nut

for

Nut

for

Needle

Bearing

left

(1008

Needle

Bearing

right

(1012

Nut

for

Clamp

Screw

1432

AL

Needle

Thread

Plate,

for

1432

(1036

Take-up

complete,

17-100,

Take-

up

Bearing

(1020

Set

Screw

1212 L

Collar

for

{1022 L)

Set

Screw

Set

Screw

on

Styles

24-130

Take-up

Block

Spiral

Gear

Timing

(1025

1031

L)

Set

Screw

Set

Screw

Set

Screw

for

Style

Set

Screw

Hook

Timing

on

Style

Hook

Timing

Collar

Hook

Timing

Bevel

Set

Screw

Set

Screw

Set

Screw

Hook

Shaft

Gear

1031

L)

Spot

Screw

LS671,

Spot

Screw

on

Styles

17-130,

Hook

for

Ho~k.

without

or

gib,

Needle

Guard

(1036

L)

Screw

for

405-168,

for

for

for

for

for

Carrier

17-100,

Carrier

24-120,

Carrier

Carrier

Stud

L)

1008

1010 L

1244

1288

Carrier

Stud,

L)

Carrier

Stud,

1011 L

Clamp

Guide

upper,

AL

L)

Lever,

for

17-130

Lever

Shaft

L)

for

1019

for

for 2 2-

24-120,

Lever

for

Hook

L,

1029

for

for

for 1 024L

24-120

for

17-100

(1029

Gear

for 1 024L

for

for

Bevel

(1029

for

1030

for

17-100,

24-130

1034

for

1040A-1

and

Thread

for

1040

177 8 L

1571

1001 L

1146 L

1146

1200

1201L

Link

Link

L

L

L

L)

for

Styles

1019

L

1021 L

21

Slide

L,

LS670

LS671

1028

Shaft

Shaft

L)

Shaft

(1025L)

1027 L

1030 L

L,

LS670,

L

1024

AL

guard

A-1

on

AL

SL

L

L,

L

L

L

L

Page 7

Amt.

Part

1036

3

·1036

1

1037

1

2

1039

1040

1

1041

1

1043

1

1046 L

1

1047

1

1049

1

1053

1

1054

1

1055

1

1056

1

1057 L

1

1057

1

1058

1

2

1058

1059

1

1060

1

1072

1

1072

1

2 1073 L

1073 L

2

1074

1

1075

1

1075

1

1075

1

1081 L

1

1132

1

2

1134

1139

1

1143 L

1

1144

1

1146

1

No.

L

L

L

L

A-1

AL

L

L

L

L

L

L

L

L

L

L

L

L

L

AL

L

L

L

L

L

L

L

L

L

L

Description

Screw

on

1040

Screw

for

41-28

on

1432

Hook

Gib

1040

A-1

Screw

on

1040

Hook,

bobbin

Bobbin

complete

1040

Tension

1041

Tension

1043

Bobbin

Bobbin

Spring

445-251

Stop

Pin

Spring

Spring

Bobbin

Lever

Bobbin

for

1343

(1058

Bobbin

Retainer

405-168,

(1058

Screw

on

405-168,

1571

Screw

on

1343

Needle

left

Needle

right

Hook

Gear

for

1072

Hook

Gear

complete

Screw

Screw

presser

Thread

cutter

(1075

Screw

for

on

405-168,

Screw

on

1072

Screw

1348

1343

Set

Screw

1182

17-100

Tension

Spring,

Styles

24-120,

Tension

Adjusting

Styles

24-120,

Head

Main

Head

Main

Drive

Styles

17-130

Head

Main

Drive

Styles

24-130

Head

Main

Hook

Drive

for

Styles

17-130

(1002L-1

for

1035

A-1

clamping

and

1016

AL

for

L(l039L)

for

1037

A-1

complete

case

Case

for

A-1

L

Spring

AL

(1046

Screw

Lon

1041

Case

Release

Pin

for

445-251

for

445-251

Pin

for

Case

Release

Case

Retainer

SAL

L)

Case

for

1571

L,

1577

for

1057

AL

for

1057

SAL

B$ir

Bushing,

Bar

Bushing,

Cover

AL

Cover,

(1073

for

1072

for

attaching

feet

Clip

and

for

1072

L)

1598

1571

for

107

AL

for

BL-1/4

SAL

for

AL

on

Staff

front,

17-130,

24-130

Staff

Nuts

17-130,

24-130

Shaft

Shaft

Gear

for

17-100,

Shaft

Gear

for

24-120,

Shaft

Gear

17-100,

2,

I

L 1

L

L

L

L

with

for

L)

for

AL

for

1054

L

AL

L)

L

L 1

L)

AL

AL

L-1/

AL

4 L

on

Style

for

for

1005

L)

Amt.

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4 1

1

1

2

2

1

1

1

1

1

1

1

1

2 1251 L

1

Part

No.

1146

SL

Head

Hook

Styles

24-130(1002L-1/2,

1005

L

L

L

L

L

AL

L

L

L

L

L

L

SpotScrew

Screw

Nut

Nut

Nut

Nut

Nut

Pigtail

Eyelet

Tension

complete,

17-100

Tension

Washer

Thread

Staff

Thread

Spring

Thread

Staffstop

Screw

Gear

Main

for

Styles

17-130

(1005

Gear

for

on

24-130

(1005

Spot

1200

Spot

1201 L

Feed

Connecting

for

17-100, 17-130,

24-120

1244

Screw

Screw

Screw

Screw

LS7 A

Set

Feed

Eccentric

(1020

Screw

Feed

Eccentric

Screw

1205

Screw

Feed

Crank

LS135

Plunger

Knob

LS219

Feed

Pin

Feed

Crank

LS130

Plunger

Shaft

for

Stud

(1160

Screw

(1160

Screw

470-6

Spring

1677

1147

1158

1160 L

1160 L

1160

1160

1160

1181 L

1182

1183 L

1185 L

1186 L

1187 L

1188

1189 L

1200 L

1201 L

1203 L

1203 L

1205

1206 L

1206 L

1206 L

1206 L

1210 L Spot

1211 L

1212

1213 L

1214

1244

1244 L

1246

1246 L

1246 L

1246L-1/2

1246L-1/2

1249 L

1249 L

1254 L

Description

Main

Shaft

Drive

Gear

24-120,

L)

for

for

for

for

for

for

for

Barrel

for

on

Shaft

driving

L,

on

driving

Styles

L,

Screw

L

Screw

Rocker

Styles

L)

for 4 7for

for

for

Screw

Screw

Adjuster

L,

for

Adjuster

for

L

for

Rocker

Rocker

for

Elevating

Crank

LS165

for

for

for

AL

LS210

LS70-1/2

LS302

1249

L 1

1251 L

1260

L 1

1303 L

Thread

Staff,

for

Style

(1081

L)

Disc

for

68-19

Controller

Controller

Controller

(1189 L)

1188

head

17-100,

1203 L)

Main

Shaft

head

24-120,

1203 L)

for

for

Rod

(1206

L,

50

47-114

47-115

1205

for

for

LS7

1213

1212

Spring

LS9,

47-50

Shaft

Pin

for

A 1

Adjuster

Pin

for

A

Crank

448-

6

Pin

for

A

Elevating

Pin

A

LS130

A

L)

46-

94

L)

LS207,

Pin

for

Amt.

for

L 2

on

L

A

L)

L

Shaft

Part

1256

1

1256

1

1257

1257L-1/2

1260

1

1260 L

1

1261 L

1

1262 L

1

1 1272 L

1273 L

1

1284

1288

1

1288

1

1288

1

1303 L

1

1304

1

1309

1

2

1311 L

2 1311 L

1321 L

1

1

1321L-1/2

2

1326

1327

4

1327

4

1328

2

1335

1

1 1343

1343

1

1346 L

1

1348BL-1/4

1351 L

1

3 1351 L

1357

1

1368

1

1373

1

1413

1

2

1414

1

1415

No.

L

L

L

L

L

L

L

L

L

L

L

L

L

L

AL

SL

SAL

L

OSL

BL

L

L

L

Description

Feed

Retaining

Spring

for

point

17-100,

24-130

Feed

Spring

1589

Feed

CrankforLS135

Feed

for

Screw

(1160

Screw

(1160

Feed

Styles

17-130

Feed

Pin

Feed

Nut

Feed

Block

Collar

448-6,

Screw

Screw

Screw

Bearing

1304 L on

17-100

(1160

Plunger

for

17-130

1303

Plunger

Spring,

Styles

17-130

Nut

Nut

Bushing,

LS43

Bushing,

LS43

Hinge

(1327

Screw

on

Screw

Hinge

(1327

Head

17-100

Presser

section

Presser

complete,

17-100,

(1073

Needle

1343

Needle

1343SAL

Screw

on

Screw

1575

405-168,

Plunger

17-100,

(1311

Plunger

Spring

17-100,

Edge

1343SAL

Feed

for

Screw

Feed

1417

feed

on

Styles

17-130,

Retaining

for

AL-1/2

Rocker

Rocker

448-6

for

46-15

L)

for

1261 L

L)

Link

for

17-100,

(1260

Link

Hinge

Spring

Spring

(18-

533)

for

LS130

LS135

for

LS9

for

17-114

for

47-115

Stud

and

L)

Frame

Styles

17-100,

(LS302,

L)

Barrel

heavy,

17-100,

for

1357

for

1578

left,

A

right,

A

for

LS42

L)

for

1326

LS42

A

for

1328

on

base

L)

for

Style

Foot,

for

1343

Foot,

for

17-130

L)

Guard

SAL(18-281)

Guide

(1075

for

1373

1343

SAL

for

75-249,

L,

on

1571

for

17-130

L)

Equalizing

for

Styles

17-130

Guide

(1351

Plate

1417

AL

for

24-288

Plate

Yoke

AL

(FP539)

Shaft

Crank

L)

Slide

A

for

Styles

17-130

Link

for

L

L

for

A

L

L

main

SAL

Styles

for

for

BL

AL

Styles

for

Stem

A

A,

for

L)

L)

for

Page 8

Amt.

1

1

1

1

1

1

1

1

1

1

1

Part

1417

1420

1432

1493 L

1551 L

1552

1553

1554

1555

1556

1557

No.

AL

L

AL

L

L

L

L

L

L

Description

Feed

Plate

Clamp

1432

Clamp,

Lon

AL

Timing

Styles

and

on

Shaft

17-130,

(1558 SL)

Staff

for

and

for

(LS314)

nut

Yoke,

for

17-130

AL

(1014

Screw

405-168,

17-130,

24-130

Cam

Styles

24-120,

Styles

24-120,

Cam

Styles

24-120,

Nut

1557

for

1556

complete,

17-100,

Needle

for

Needle

complete

Adjusting

1573

1571

Hook

for

24-120,

Gear

for

automatic

release

17-130,

24-130

Tension

Styles

24-130

Tension

rear,

17-130,

24-130

Gear

Latch

17-130,

24-130

Adjusti~

1553 L

Lock

Styles

Pin

L)

for

Shaft

Shaft

tension

for

24-120

Spring,

Shaft

for

L)

L

Amt.

Part

1

1558

1

1571 L

1571

1

1 1573 L

1

1575 L

1577 L

1

1578 L

1

1579 L

1

1

1584

1 1586 L

1

1589L-1/2

1

1589AL-1/2

No.

SL

AL

L

Description

Pilot

Screw

1553 L (CS231)

Presser

section

Presser

complete,

Style

(1073

Crown

1571

(892

Needle

405-168,

(1351

Screw

on

405-168,

1571

Plunger,

Style

Plunger,

for

Style

Plunger

Style

Rear

Support

Styles

24-130

Feed

1589Alt-1/2

Feed,

for

Style

(1260

Foot,

for

1571

Foot,

for

24-120

L)

for

405-168,

AL

L,

1493

Guard

1571AL

L)

for

1057

AL

lon~,

24-120

short,

14-120

Spring

24-130

Work

for

24-120,

Point,

complete,

14-120

L)

for

main

AL

L)

for

L

for

13UL)

for

for

Amt.

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Part

·No.

1598L-1/4

1669 L

1670

L

1671 L

1672 L

1672

L-1

1672

L-2

1672

L-3

AL

1677

1778

L

4129-15

4129-18

54274

p

61477

De

scription

Needle

Guide

for

405-168,

1571AL

Feed

Bell

Feed

Linkfor1677

Bearing

1677

Feed

Block

• 500

(18-745)

• 505

marked

• 510

marked

• 515

marked

Feed

complete,

Retaining

for

on

1571

Knee

Knee

complete,

4129-15

Washer

Bobbin

complete

(1075

Elevating

Crank

Elevating

Screw

AL

Spring

Roll,

inch

inch

"1"

inch

"11"

inch

"111"

Elevating

1493 L

405-168,

AL

Lift

Press

Winder,

L)

(1251L)

AL

for

Slide

dia.

dia.

dia.

dia.

Link,

(1671

L)

Spring

(1036

L)

Assembly

Pad,

for

NOTE:

The

catalog

following

*Standard

Numbers

parts.

listing

substitutions

MACHINE

17-100,

17-100,

17-100,

17-100,

equipment

in

parentheses

shows

can

STYLE

17-130

17-130

17-130

17-130

24-

120

24-120

24-120

24-130

24-130

24-130

on

the

presser

be

made

machine.

following

foot

to

compensate

parts•

and

plunger

PRESSER

1343

*1343

1373

1373

*1571

1593

1593

405-167

*

405-168

405-169

description

combinations

for

variations

FOOT

AL

SAL

AL

SAL

AL·

AL

SAL

indicate

in

weights

the

screws,

with

which

of

PLUNGER

1357

L

1357

L

1357

L

1357

L

1578

L

1579

L

1591 L

1592

L

1591-1/2

1592-1/2

26-31

26-32

26-33

26-34

26-35

26-36

nuts,

the

materials

L

L

etc.

standard

used.

Turned

Light

Light

Extra

Light

Heavy

used

machines

MATERIAL

and

Medium

Extra

Heavy

Medium

Heavy

Medium

to

attach

Under

Medium

to

Heavy

are

Edges

or

hold

equipped.

these

The

Page 9

1343

1373

075 L

(

2)

1357

1309 L

L

1343

SAL

Complete Assembly

24-288

Page 10

1571

Complete

1057

AL

Assembly

058 L

573 L

1778

1036

892

L

75-16

1598

351 L

L-1/4

(2)

589

L-l

/2

424-8

Complete

Assembly

Page 11

405-168

(Complete

Assembly)

23-1

07

892

2 6- 3 3·

r--

--==-

~

~

~

~

~

26-34

1584

1598

L

L-1/4

(

2)

~

II

75

-60

-

.---4

-

~,75-

-1

:

7a-77

&I

l-----:21-27

I

61

8-

106

68- 3

~

~18-125

(

(2)

(2)

4)

Page 12

1025

L

.

~

#l1._)

-

---

1031

·

1025

.

L

L

.:!:..!10~2::.::::9_L

_

Page 13

1010

L

1022

1021

L--;;

Ll

'-------

1019

L

1008

L

1056

L -

1432

Complete

~1016

CJ!I--41-

28

1420

AL

L

L

1011

L-

u:.-----

1014

L

Page 14

20

-6v

---11"

1181

L_r'

11~

1556

3

L

1554

L-

(2

L.--

- .•

;:::...,.

._

5:

2_

..,.

1183 L

- 15

21-284~

53

L

1182

AL--

llB~

L~

--

l18

7 L

68-19

1186 L

1188 L

1181;:1

L

1552 L

=r;_LS314

Page 15

~

lli4

L

~

-1009

LS19 A

Complete

YYYYYY'fYYVV[-cLS7

L

11

58

L (

2)

5 ;.I.

LS135 A

448-6

1260

l

1262

L

L

1160

~

j:'

~1206

lB-

736

L

'LS120 -r

LS672 A

Complete

14-161

Page 16

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

facilities throughout

aid

you

SPECIAL

in

the

maintains sales

the

world. These offices

selection of

and

the

right sewing

equipment for your particular operation. Union

Special representatives

trained

tory

promptly

there

tion,

and

and

is

a Union Special Representative

serve you. Check with him

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

MASS.

YORK,

ILL.

N.

Y.

PA.

efficiently.

are

and

service men

able

to serve your

Whatever

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

service

will

are

fac-

needs

your loca-

to

CANADA

ENGLAND

ENGLAND

GERMANY

400

Representatives

MACHINE

N.

FRANKLIN

industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

In

the

all

important

world.

ILL.

60610

Loading...

Loading...