Page 1

LEWIS

ARTS and INSTRUCTIONS

F'OR

7 &

24

INVISIBLE

CLASS MACHINES

Models

17-10 24-12

STITCH

MACHINE

MAIN

121-

131

NEW

West

YORK

OFFICE

22nd

11,

N.

COMPANY

Street

V.,

U.

8.

A.

PRINTED

IN

U. &. A.

Page 2

iNDEX

Page

Adjusting

Automatic

Basting

Bight,

Bobbin, how

Bobbin

Bobbin

Breaking

Catalogue, how

Feed Plate Pressure,

Feed Poi

Foreign

and

Groups,

Gr

oups,

Ha

nd

Hook,

Hook,

Inserting

Instructions

Instructions

Models,

Model 24-1

Model 17-

Needles •.•......

Numerical List

Oiling and Cleaning

Ordering

Parts,

P

enetrat

Plunger

Plunger,

Plunger,

Presser

Sack

Setting

Skipping

Speed

Stitch

Straight Felli

Tensions,

Thread

Thread

Instructions

Tension

Work,

how

to

adjust

to

Case,

how

Case Rel

Thread,

nt,

raising

Shipments,

parts

of

Key

to.

list

of

Wheel

....

how

to

raising

Coats

of

Length.

repl

and

and

Removing

for

for

General

2,

Operating.

10,

Operating

Parts

Numerical

ion,

how

Barrel,

how

to

how

to

Fciot, removing

and

Up

of

Machine ....•..

Stitches, how

Machine

how

ng

how

to adjust .••••...

To

Use •.•.

Breakage,

Model 24-1

insert.

to

ease

how

to use

oil

.

..

.

.

ace

lowering ...

Adjusting ....

Ordering

Description

of

Parts.

......

List

to adjust

how

raise

remove

Overcoats

.....•.

to

Stitch,

how

...

Release

width ...

• . . . .

replace.

.•....

to

overcome

••••....

how

and

lowering

how

to

and

time.

Work

.

. • .

. . .

.

..

to

remove.

and

. . .

and

. .•..•.

to

ove

adjust ...

how

....

to

overcome

• .

..

2.

to

adjust

mount

Parts.

lower

••••

replacing

rcome

..

to

•••

. . .

head,

.

.

•

..

••

..

produce

.•.

5

to

27

24

22

12

'J

13,

14

.

..

.

and

c l

ean

hook

25,

16

26

5

13

21

6

3, 4

2

6

14,

15

15 ,

16

9.

10

5

to

2 7

5

5,

6

21

to

23

19

7,

8

72

to

75

6, 7

5, 6

72

to

75

22

18

19,

20

17,

18

13

20,21,23

6

26

.

7

10

19

12

8,

9

25,

26

Page 3

2.

INDEX

Page

3

Thread

Threading

Timing

Two

Unp

Wid

Main

He

Hook

Hook

Needle

Take-Up Lever •••

Thr

Skip

Cover .....

Feed,

Feed,

Feed

Feed

Plunger

Plungers

Knee

Work

Miscellaneous

Presser

Presser

Pre

Presser

Controller

Needle

to

One

acking

th

of

Shaft

ad

Shaft ...•

Drive

...

Drive

ead

Tension ..•

Stitch

Feed

Feed

Elevating

Driving •..

Press

Support

sser

guide,

m

aterials,

• . •

••.

with

Stitch. • •..•..

Machine •...•.•

Bight,

how

..••

.••

• .

•••

•.•

Plunger

•...

Plate

Plate and

...••....

Cradle

and

.. ..

.•..

••••..

Plate.

. . . • • ••.•. .•.

Fo

ot,

Model

Foot

for

Feet

for

Model

17-10 •..••....

Feet

for

Model

Spring .•.

•.•••..

Plunger

to

adjust

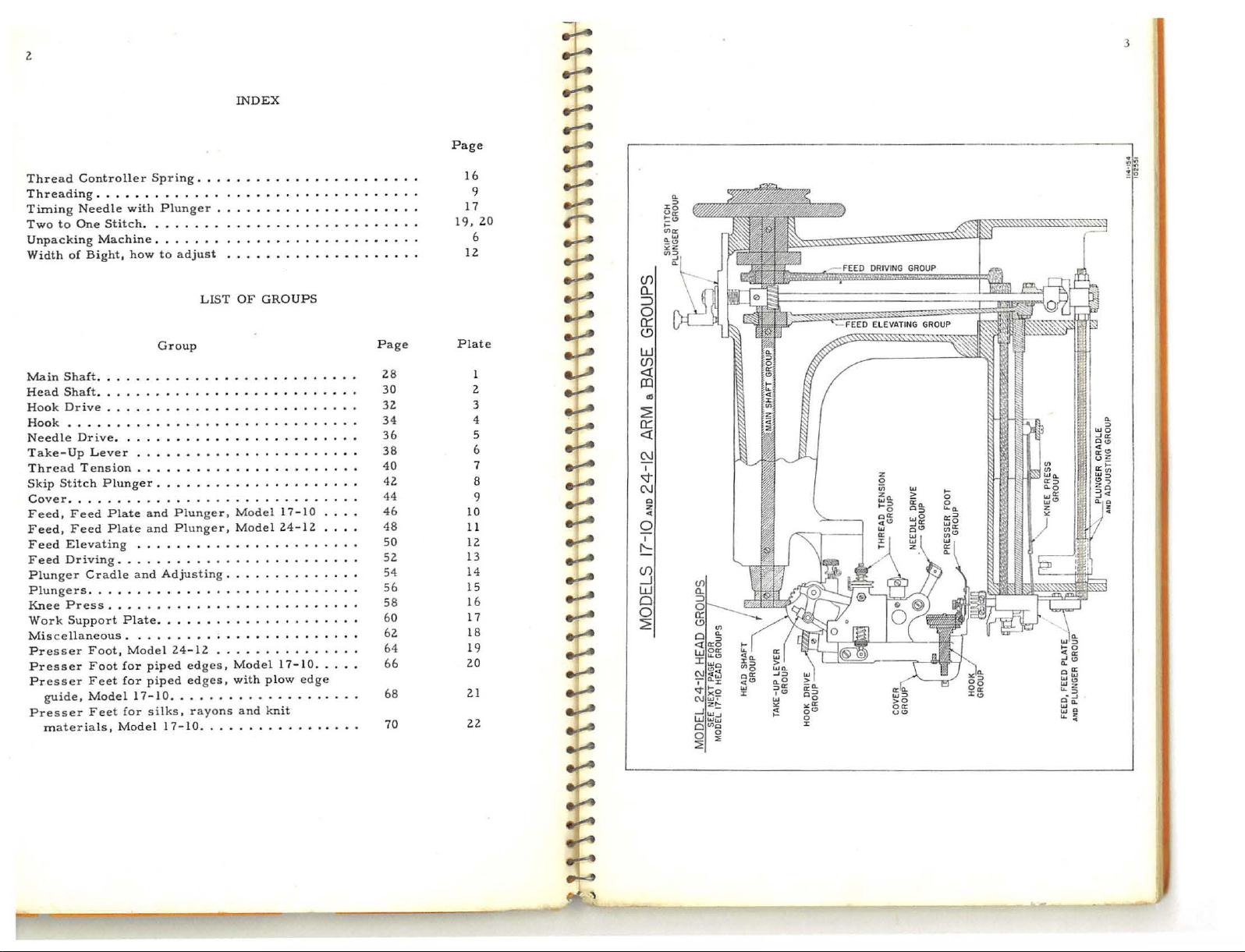

LIST

Group

.

.

•..

and

Plunger, Model

Plunger,

.•.•.....

Adjusting.

2.4-12. •.. . • . .

piped

edges,

piped

edges, with

silks,

rayons

17-10

.......

.

OF

GROUPS

Model 24-12.

..•

.

.•.••..•.•

Model 17-1

plow

•.•••.•.•

and knit

.•

17-10

....

edge

•••••

0.

16

9

17

19,

2.0

6

12.

(f)

(L

:)

0

0::

P

age

2.8

30

32.

34

36

38

40

42.

44

46

•.

48

50

52.

54

56

58

60

62.

64

66

68

.

70

Plate

2.

3

4

5

6

7

8

9

10

11

12.

13

14

15

16

17

18

19

2.0

2.1

2.2.

<.9

w

(f)

<!

co

ell

::2!

0::

<!

C\J

I

o;;t

C\J

Q

z

..

0

I

t::

(f)

_J

w

Cl

0

::2!

Page 4

5

TAKE

MODEL 17-

-UP

LEV

VER

ER

H

OOK

GRO

GROUP

CO

GROUP

UP

10

HEAD

THRE

___.>---

GROUPS

AD TENSION

GRO

UP

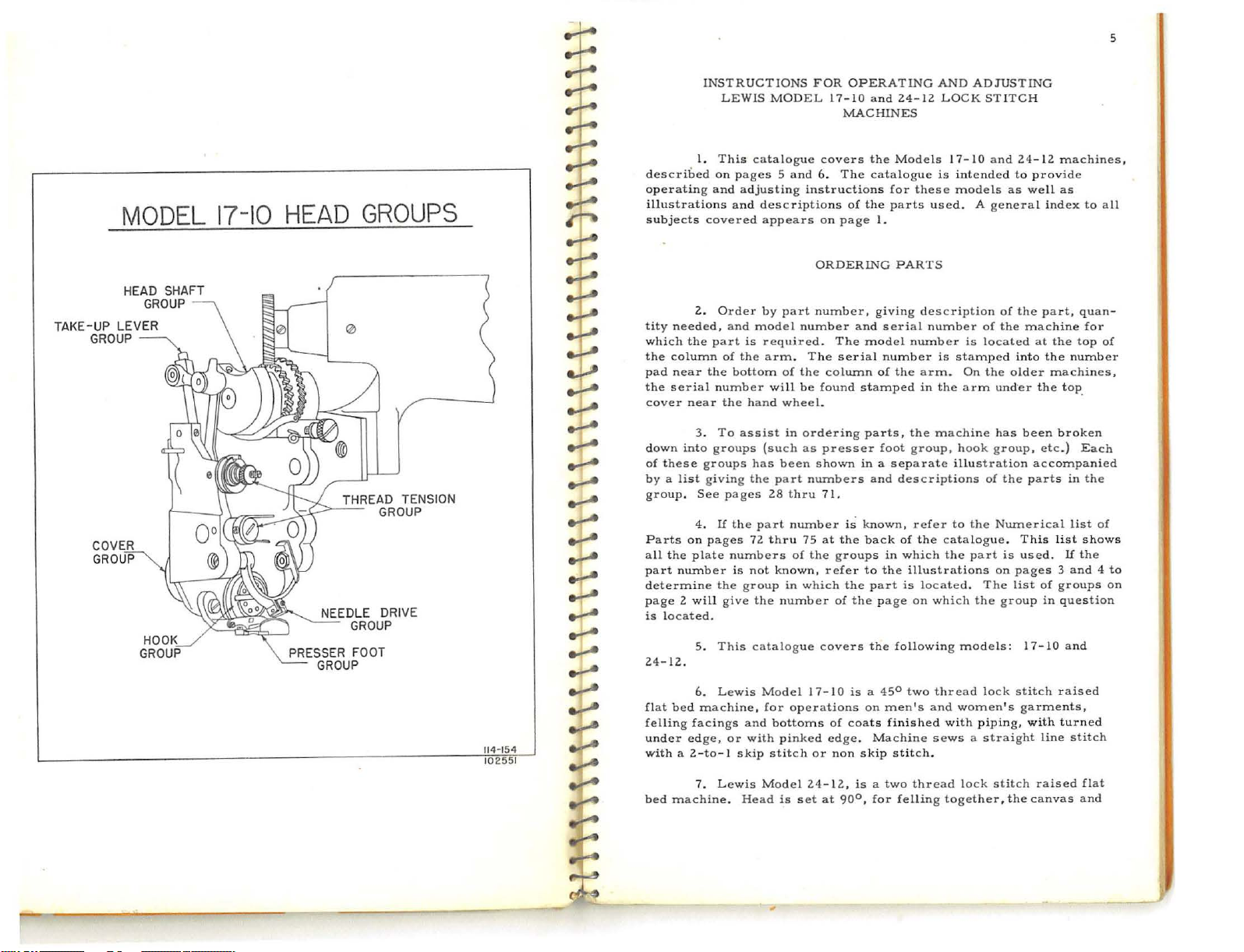

INSTRUCTIONS

LEWIS

1.

2.

needed,

the

column

near

serial

near

3.

into

list

4 .

on

plate

numb

5.

covered

part

t he

groups

giving

pages

.

This

on pages 5 and

and

Order

and

of

bottom

number

the

To

groups

pages

If

t

he

numbers

er

is

the

give

This

described

operating

illustrations and

subjects

tity

which

t

he

pad

the

cover

down

of

these

by

a

group. See

Parts

all the

pa

rt

determine

page 2 will

is

located

24-12.

MODEL 17-

catalogue

adjust

ing

descriptions

appears

by

part

model

is required.

the

arm. The

of

will

hand

wheel.

assist

in

(such

has

been

the

part

28

thru

part

num

72

thru

not

known,

group

in

the

number

catalogue

FOR

covers

6.

instructions

on

ORDERING

number,

numb

the

column of

be

found

ordering

as

presser

shown

numbers

71.

ber

75

at

of

the

refer

which

covers

OPERATING

10

and 24-1

MACHINES

the

The

catalogue

of

the

page

I.

giving

er

and

model

serial

stamped

parts,

in a separate

and

is

known, refer

the

back

to

the

part

the

page

the

serial

number

foot

in

t he

The

groups

of

AND

2 L

Models 17-

for

parts used

is inte

these

PARTS

description

number

number

is

the

arm.

in

the

the

machine

group,

descriptions

of

the

catalogue

which

the

illustrations

is

located. The

on

which

following

ADJUSTING

OCK

STITCH

10

and 24- 12

nded

models

. A

general index

of

is

located

stamped

On

the

arm

under

has

hook

group,

illustration

of

to

the

Numerical

part

on

the

models:

machines

to

provide

as

well

as

of

the part,

the

machine

into the number

older

been

the

parts

. This

is

used.

pages 3 and 4 to

list

gro

up

I 7- 10

quan

at

the

top

machines,

the

top_

broken

etc.)

Each

accompanied

in

list

list

If

the

of

groups

in

question

and

to

all

for

of

the

of

shows

,

-

on

114·154

1

0255

1

6.

Lewis

fl

a t

bed

felling facings

under

wit

bed

machine,

edge,

h a 2-to- 1

Lewis Model

7.

machine.

or

and

with

skip

Head

Mode

for

bottoms

pinked

stitch

is

l 17-10

operatio

of

edge. Machine

or

non

24-12,

set

at

is a 45°

ns

on

coats

skip

is a two

90°,

two

men's

and

finished with

stitch

.

thread

for

felling

thread

sews a straight

lock

women

piping,

lock

together,

' s

stitch

the

stitch

garments,

with

line

raised

canva

raised

t u

rned

stitch

s and

flat

Page 5

6

cloth

at

Sometimes

remove

Use

by

lifter

ot

carefully

that

Lift

take-up and

machine.

parts

before

by

at

the

hook

shipping

head

order.

red

frame

say

m

of

service

properly

the

8.

the

a n

ail

nails

or

and

her

small

you

will

the mac

9.

are

the

loosening

its

lowest

hook

and

freely.

machines

mechanism

To

paint,

of

the

1

0.

in a clockwise

ach

ine.

11.

first

importance.

and

edge

referred

To

remove

nails and

puller

screws

bobbin

parts

through

find

hine

tension

To

protect

covered

machine

thumb

point.

bobbin

Also

aid

showing

machine

The

Proper

satisfaction

oil

ed

of

sack

to

UNPACKING

the·

screws

to

avoid

driven throu

winder

will

be

the

material

all

the

out

of

studs

the

with

is

put

screw.

Use

case,

wipe

to

distant

and

pack

reassembly,

the

relative

and

hand

wheel

direction

OILING

lubrication

Lewis

and

cleaned.

coats

as a bluff

the

vaseline,

and

AND

machine

that

breaking

gh

are

attached

found

wrapped

used

parts

and

box

very

as

these

machine from

in

operation. Take

To

remove

gaso

line

so

as

needle

countries,

separately,

the

also

the

HAND

turns

when

Invisible

if

reasonable

The

to

castings

position

AND

and

foot,

overcoats

edge

.

SETTING

from

hold

the

the

machine.

the

outsi

to

the side

for pack

equ

ipment

carefully

parts

which

rusting

must

this

or

petrol

allow

and

other

it

so

of

timing

WHEEL

away from

seen

from

CLEANING

thorough

Stitch

care

machine

finished

UP

the

box,

take

brace

blocks

These

de

of

the

ing

that

to

be

off

cover

to

remove

is

necessary

to

gears

the

of

the

the

the

cleaning

Machines

is

should

exposed

insure

head

taken

of

b e

fore destroying

goes

avoid break

beyond

while

carefu

aluminum

the

ead

gears.

operator, that

hand

be

in a package.

project

the thr

as

and

with

a pl

off

the

in

position.

blocks are helrl.

box.

The

the

box,

and

Be

sure

with

the

the

head

in

transit,

lly

wiped

head

take-up

the

grease

to

pass

over

parts.

to

remove

delivery

are

marked

mechanism

wheel

of

the machine

will

give

in

keeping

oiled

and

ain

cover

knee

ing

must

When

end

clean

edge,

and

the

to

look

it,

machine.

the

of

the

all

off

cover

be

from

the

the

in

good

with

on

the

is

to

of

the

years

them

ed

so

is

of

::t:

-.!..-

...:...-

~

......

......

~

.-r-

--1

.-r-

--r

~

~

~

~

~

..;...e

.;:...e

~

~

..;;...e

~

rr--

.,:.r-e

r.:--

daily

as

lint

function

head

and

turning

ings,

gears,

these

drop

of

hours. The

to

the

than

ten

necessary

mechanism

the

presser

work

plate,

require

turning

base,

the

plate

every day

points

minute. A speed

in starting a

stitches

in

all

improperly.

ll.

In

wipe

the

hand

small

parts

oil

in

right

of

drops

13.

Besides

to

will

foot. This

or

14.

On

oiling

back

all

of

which

15.

It

near

16.

See that

to

will

cause

17.

Lewis

18.

Lewis

per

19.

Needles

necessary

and

off

etc.

back

hook

lubricate

the

is

avoid lint

new machine

minute.

dirt

accumulates

cleaning

the

parts

wheel

and

oil

daily.

of

the

shaft

the

hook. A drop

that

do

thoroughly

be

found

by

tur

nin

all

types

near

the

machine,

require

also

necessary

the

hand

the

the

machine

Model

of

900

Modell4-ll

for

s i

zes

in

the

moving

the

machine

with a clean

you

will

holes

On a

bobbin

should

not

reach

the

plunger

in

the

mechanism

g the

of

machines there

base,

several

daily

wheel

feed

points

accumulating. Accumulation

17-10

to

o

llOO

or

Lewis

with

either a taper

always remove

see

the

. A

few

new machine

case

oiled

of

oil

the

parts

oili

n g

and

bed

of

may

movable

lubrication

to

oil

Figure

{Figure

feed

SPEED

can

be

stitches

can

be

Invisible

race-way

the

0,

improperly.

be

machine

immediately

to

with a new

NEEDLES

cloth.

various

drops

through

well

feed

the

back

the

operated

operated from

of

it

placed

requ

head

mechanism.

machine

be

uncovered

on

are

below

parts

.

machine

Page

P)

per

operator

Stitch

point

Do

is

iring it.

the hin

lO.

minute

Machines

parts,

causing

the

cover

not

use

moving

oil

every

the

mechanism

movable

Page

up

or a ball

parts, bear-

should

necessary to

two

hole

in

will

do

imm

ediately

by

ges.

the

hand

will

be

at the

ll

are

of

lint

to

1500

is recomme

.

90

them

from

waste. By

be

placed

place

or

three

the

casting

more

good

it

is

also

The

feed

removing

parts

that

wheel.

found

in

top

underneath

cleaned

in

the

stitches

t·

to

1100

are

furnished

eye. Taper

7

to

the

on

a

be\ow

the

By

the

feed

per

nded

~

----

Page 6

8

point needles are recommended

difficult

m

to

si

is

fir

the

needle for

the bla

of

needl

a l

what

the

the needle.

in

ri

genuine

and

t o

ateria

ls and

hug

or

ble

required

s t

average

arger nee

ghted word

ride

to

form a good loop,

20.

importan

size of

de

of

2

1. A number

e ,

such

needle

thread

22. Needles

the

following

23 .

Lew

the

cor

penetr.ate. Ball Eye need

soft

finish

ed

with

the

.

The

selection

ce. The l

the

needle,

Lewis Class

the

needle is .035"

weight. For

as a number

dle, su

ch

is sel

ected,

or

yarn

that

for

sizes:

Taper Point

Not

Scarfed

29-123

29-123-1/2

29-124

29-124-l/2

Use

ONLY genuine LEWIS Needl

"LEWIS" stam

is

Invisible

rect

size

materials.

needles

it

of the pro

ast whole

thus

29 -

17

and

3-l/2

lighter than

3.

as a number 4 or a number 4-1/2.

be

sure

is

to

L ewis

Stitch

stamped

for

light materials and materials

les are

If

on

its

is a good

figure

133-1/2

24

Machines.

in

diamet

needle

For heavier than

that the

be used

17-l 0 and 24-1

ped

on

Machine

on

each sha

T

HREAD

the mate

return

indication

per size and

(and fract

is a numb

er.

will

be found

average

eye

to

run

the

shank

needles

nk.

recommended

rial

strok

e , making it

that a Ball Eye

kind

of n

ion

if

er

3-1/2 Ball

Th

e 3-1/2

satisfactory

material,

average

is large

freely through

2 m

Ba

ll

Not

2929

-13

29

- 133-l

29-134

29-134-1/2

es. Look

of

enough to

achines

Eye

Scarfed

132-l/2

3

/2

each needle. All

have

the

for

heavier

has a tendency

use a smaller

materia

for

impos-

needle

eed

le

is

indicated)

indicat

Eye

ed

for

l, use

No matter

permit

the

eye

are

furnishe

the

copy

name Lewis

of

that

work

of

is

-

9

25

r-t

__,....

"00

"

or

Chart

threading,

the

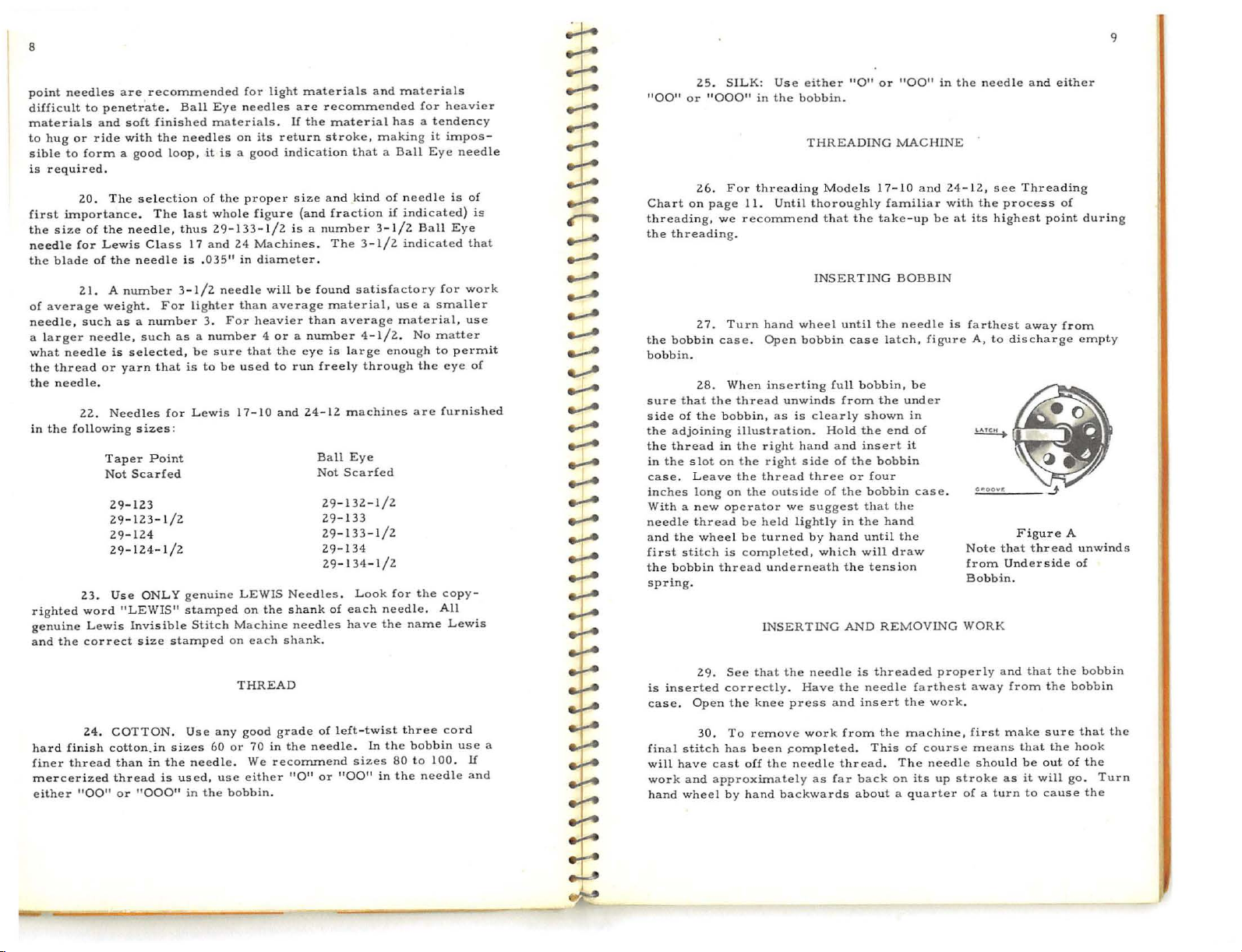

26.

on

threading

. SILK:

"00

For

page 11.

we

Use

0"

in

threading

recommend that

.

eithe

the

bobbin

THREADING

Until

thoroughly

r

"0"

.

Models

the

or

"00"

in

the need

MACHINE

17-10 and 24- 12,

familiar

take-up

with

be

at

its highest poi

le

and

see Thre

the process

either

ading

of

nt

during

._...

....-....

._..

........

........

.......

the bobb

bobbin

27. Turn hand wheel

in

case.

Open

.

-.,......

8.

When inserting

2

su

r e

~

d

.,_;.A

~

~

........

........

.,_A

~

--]

...:--

-+-

~

~

that the thread

side

of

the adj

the

in

case

i

Wi

needle

and the

first

the

spring

the

oining

thread

the slot

. L

nches long

th a new

thread

stitch

bobbin

.

bobbin,

illus

in

the right

on

the right

eave

the

on

the

operator

be

wheel

be

is

completed, which

thread

t r

thread

held

turned

underneath

I

NSERTING

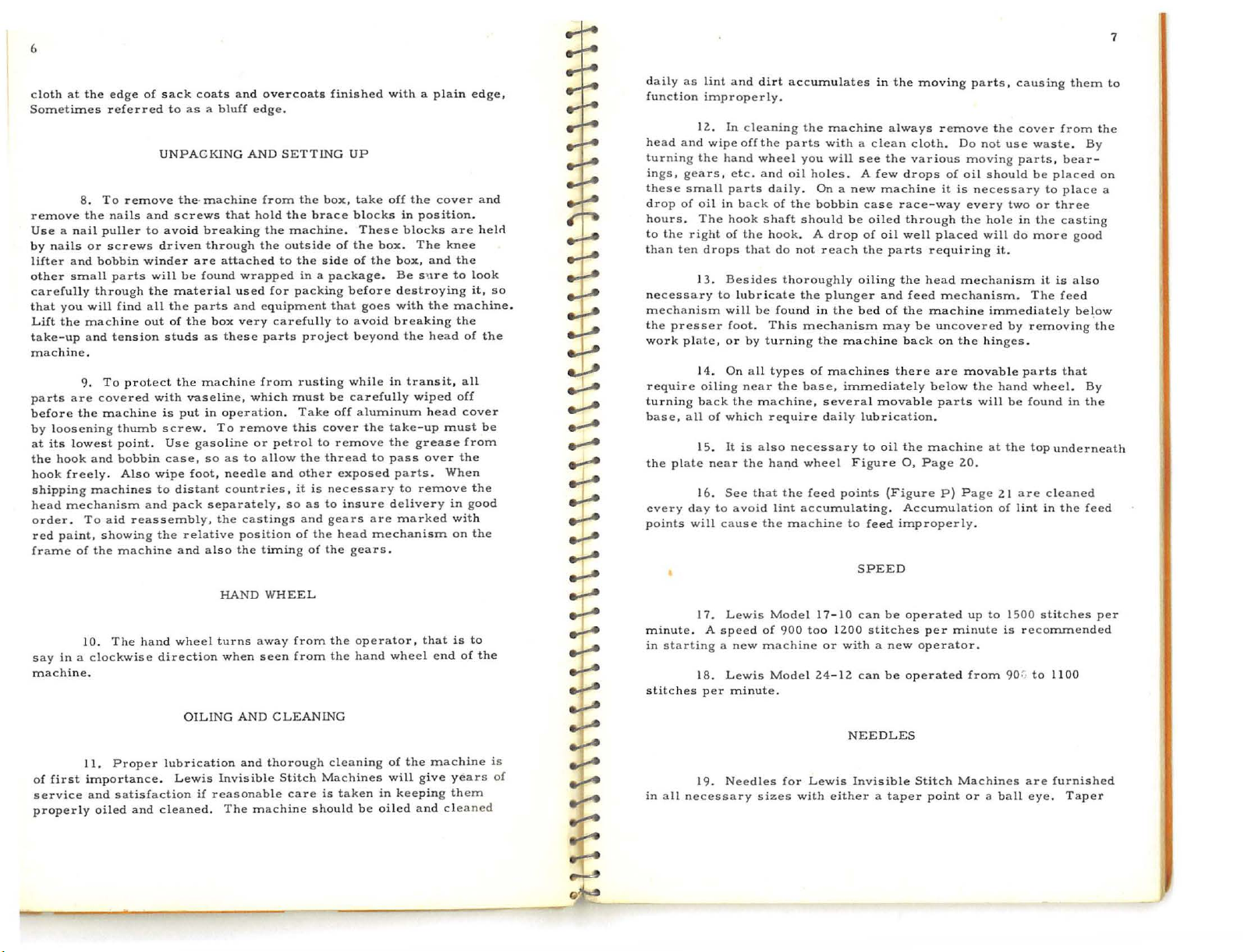

INSERTING BOBBIN

until

bobb

in

case

full

unwinds

as

is

ation. Hold

outside

we

lightly

from

clearly

hand

a nd

side

of

three

or

of

the

suggest that

in

by hand

the tens

AND

the needle is

latch, figure

bobbin,

the

shown

the

end

insert it

the

bobbin

four

bobbin

the

the

hand

until the

will

draw

ion

REMOVING

be

under

in

of

case

.

farthest

A,

to

discharge

Note

that thread unw

om

Und

fr

Bobbin.

WORK

away from

gu

r e A

F i

erside

empty

of

ind

s

:t:

29.

See

that

the

is

inserted

case.

correctly. Have the

Open

the

knee

needle

press

and

is

threaded

needle

insert the

properly

farthest away

work.

and

from

that

the

the

bobbin

bobb

in

ha

rd

finish cotton.in

finer

thread

merceri

either

"00"

24. COTTON. Use any

than

zed threa

or

in

the

d is

"000"

sizes

needle. We

used, use eithe

in

the

60

good

or

70

bobbin.

gra

de

in

of l

the need

recommend

r

"0"

or

eft-twi

le .

sizes

"00"

In

st

the

in

three cord

bobbin

80

to 100.

the

needle

use

a

If

and

final stitch

will

work

hand

30.

have

and

wheel

To

remove

has

been

cast

off

by

hand

the

backwards

approximately

work from

s:ompleted. This

needle thr

as

the

ead. The

far

back

about a quarter

machine,

of

on

its

course

needle

up

first

means

should

stroke

of a tu

make

that

be

out

a s

it

will

r n

to cause the

sur

the

e t

hook

of

go.

hat

the

the

Turn

Page 7

10

plunger

thread

carrier

the work

needle

mounted

b

stitch. The

progresses

presser foot unl

needle

Turn back

the

ing

To

pleted,

perntanent

the

showing what

oth

moving

to

shorten

to

from

and

and

threads

31.

thread

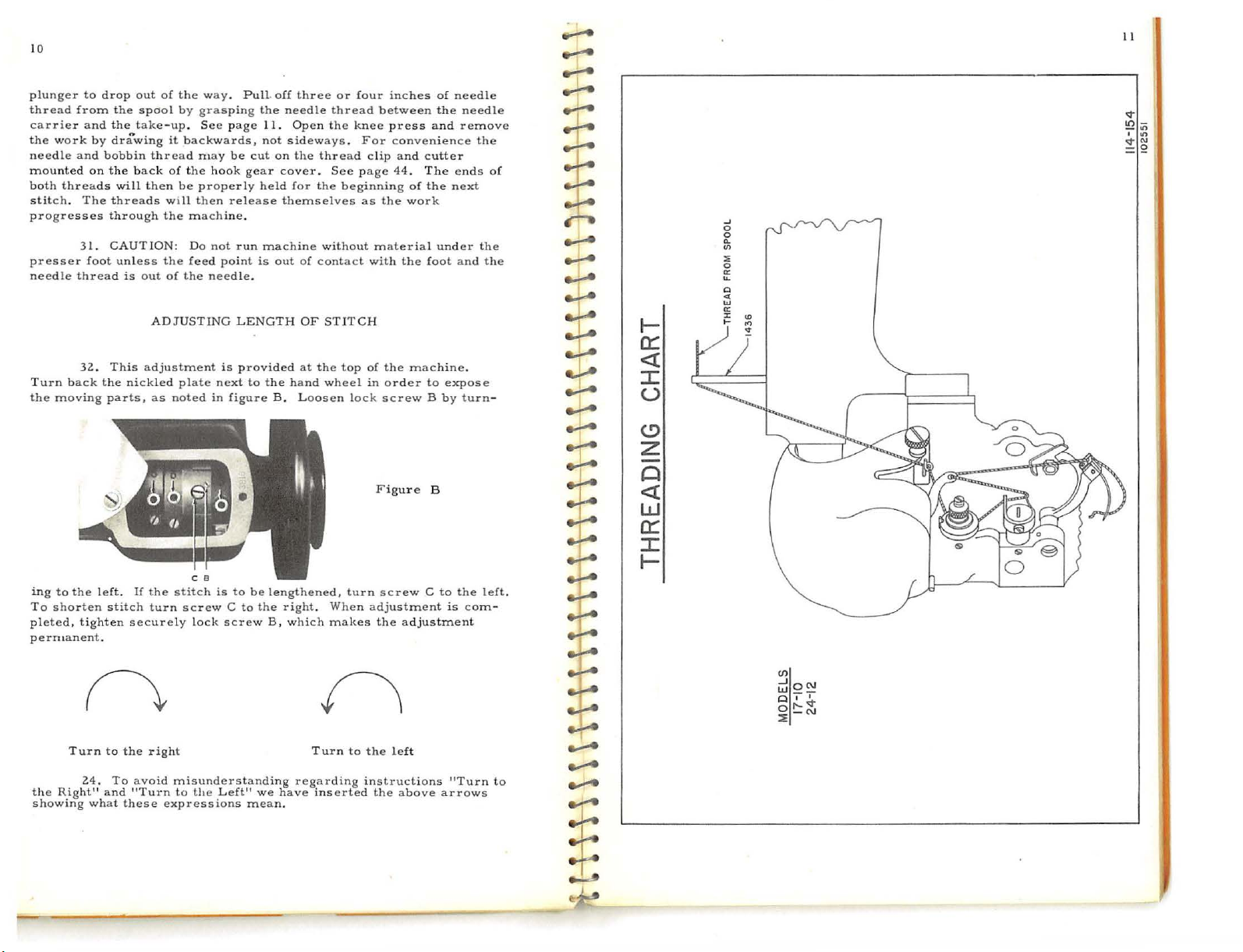

32.

the

tighten

Turn

24. To

Right"

drop

the

the

by

drawing

bobbin

on

the back

will

thr

through

CAUTION: Do

This adjustment

the

parts,

left.

stitch

.

to

and "Turn to

out

spool

take-up.

thread may

then

eads

ess

is

out

ADJUSTING

nickled

as

lf

the

turn

securely

the

right

avoid

these

of

the

way. Pull. off

by

grasping

See

it

of

be

will

the mac

the

of

plate

noted

misunderstanding

expressions

page

b a

ckwards,

be

the

hook

properly

then

release

hine.

not

feed

point

the

needle.

is

next

in

figure

is

lock

the

to

screw

Left" we

screw C to

the

needle

11.

Open

not

sidew

cut

on

gear

cover. See

held

for

themselves

run

machine

is

out

LENGTH

provided

to

the

hand wheel

B . L

be

lengthened, turn

the

right. When

B ,

which

have

mean.

three

or

four

thread

the knee

ays. For

the

thread

the

beginning

without

of

contact

OF

STITCH

at the

lop

oosen

makes

Turn

regarding instructions

inserted

inches

between

press

conven

clip and

page 44. T h e

lock

to

of

as

the

work

material

with

the

of

the

machine

in

order

screw B by

F i

gu

r e B

screw C to

adjustment

the adjustment

the left

the

above

of

th e

and

ien

cutter

the

under

foot

to

expose

arrows

needle

needle

remove

ce

the

ends

n e

xt

the

and

.

turn

the

is com-

"Turn

of

the

-

left.

to

~

~

....:---

~

~

--r

--1

~

:t:

....

--1

--1

--r

.,...

~

&.!-A

J...

~

._!...

..J....

.J.-.

+

~

:t:

.,:..e

~

.,:..e

~

~

~

.,:;.-e

:c

..,:.....

.,_.

.......

.......

t-

cr:

<(

::r:

u

(.!)

z

-

Q

<(

w

cr:

::r:

t-

...I

0

0

Q.

(/)

:l;

0

0::

lL

c

~

lLI

0::

J:

....

en

~Q~

Q I I

o

r-<t

::E

-N

II

<t

10-

_.,

I

<t"'

=~

<ll

I

tl

Page 8

12.

....;...

13

the

not,

tight,

the

draw

rades

machine

depth

guide

the

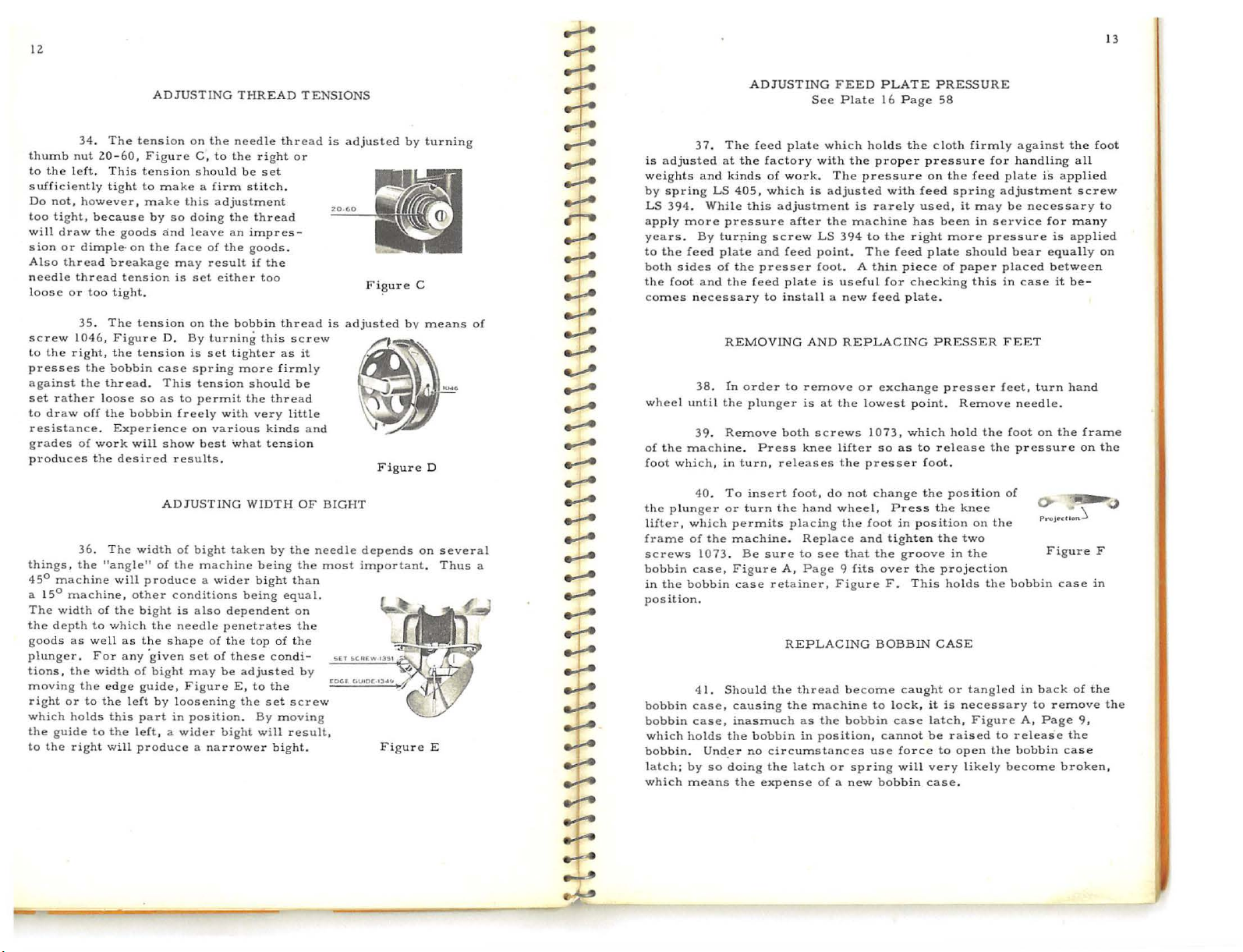

34. The

nut

left.

however,

because

draw

or

dimple· on

thread

thread

or

too tight

35. The

right, the

the

the

off

a nce.

of

the

36. The

achi

width

to

as

well

the

or

to

holds

to

right

2.0-60,

the

loose

work

of

width

the

thumb

to

sufficiently

Do

too

will

sion

Also

needle

loose

screw 1046,

to

presses

against

set rather

to

resist

g

produces

things, the

45°

a 15° m

The

the

goods

plunger. For

tions, the

moving

right

which

the

to

ADJUSTING

tension

Figure

This

tension

tight

to

make a firm

make

by

goods

breakage

tension

Figur

bobbin

thread. This

the

Experience

desired

"angle"

will

ne,

the

which

as

any 'given

edge

this

the

will

so

and

the

face

may result

is

.

tension

e D.

tension

case

so

as

bobbin

will

show

results

ADJU

width

of

the

produce a wider

other conditions

bight

the

the

shape

of

bight may

guide,

left

by loo

part

in

left, a wider

produce a narrower

on

C ,

sho

this

doing

leave

set

on

By

is

spring

tension

to

permit

freely

on

best

STING

of

bight

machine

is

also

needle

set

Figure

sening

position.

THREAD

the

needle

to

the

uld

be

stitch

adjustment

the

an

impres-

of

the

goods

either

the

bobbin

turning

set

tighter

more

should

the

with

various

'what

.

WIDTH

taken

being

dependent

penetrates

of

the top

of

these

be

adjusted

E,

the

bight

right

set

thread

if

the

too

this

thread

very

kinds

tension

by

being

bight

condi

to

the

set

By

will

bight.

TENSIONS

thread

or

.

.

thread

screw

as

it

firmly

be

little

and

OF BIGHT

the

the

than

equal.

on

the

of

the

-

by

screw

moving

result,

is

20

is

needle

most

adjusted

GO

adjusted

FigureD

depends

important.

Figure

~

by

by

turning

means

on

several

Thus

E

of

~

~

is adjust

weights

by

LS

~

...;-e

...;.-e

..,:..e

~

apply

years.

to

both

the

comes

37.

ed

and kin

spring

394. While

more

By

the

feed

sides

foot

and

necessary

::c

..,::..-

ADJUSTING

The

feed

at

the

ds

LS

405, which

this

pressure

turping

plate

and

of

the

presser fool

the

feed

REMOVING

plate

factory

of

work. The

adjustment

after

screw

feed

plate

to

inst

FEED

See

Plate

which

with

the

is

adjusted

is

the

machine

LS

394

point. The

. A

is

useful

all a new

AND

REPLACING

PLATE

16

holds

proper

pressure

with

rarely

to

the

feed

thin

for

feed

PRESSU

Page 58

the

c l

oth

pressure for

on

the feed

feed

used,

has

been

right

more

plate

piece

of

chec

king

plate.

PRESSER

firmly

spring

it may

in ser

should

paper

this

RE

against the

handling

plate

is

adjustment

be necessa

vice

for

pressure

placed

in

FEET

is

bear equally on

between

case

it be-

all

applied

screw

r y

many

applied

foot

to

~

38. rn

order

to

........

wheel

until

the

~

__..

__..

.....-...

~

~

...;...e

.,;..e

a

.,.;...e

.,_.A

__..

....,....

of

foot

the

lif

frame

screws

bobbin

in

position

39.

the mach

which,

40.

plung

ter, which

of

1073.

case, Fig

the

bobbin

.

plunger

Remove

ine.

in

turn,

To

insert

er

or

turn

permits placing

the

machine.

Be

ure

case

::t:

._;;..e

+-

.,:...e

:t:

...;.-e

~

~

~

~

~

~

bobbin

bobbin

which

bobbin. Under

latch;

whi

41.

case, causing

case,

holds

by

so

ch

means

Should

inasmuch

the

bobbin

no

doing the

the

remove

is

both

Press

knee

releases

foo

the

hand

Repl

sure

to

A ,

Page 9 fits

retainer

REPLACING

the

thread

the mach

as

in

circumstances

latch

expense

at

the

screws

lifter

the

t,

do

not

wheel,

the

ace

see

that

, F

igure

become

ine

the

bobbin

position,

or

of a new

or

exchange

lowest point. Remove

1073,

so

presser

change

Press

foot

and

tight

the groove

over

F.

BOBBIN

to

lock,

case

cannot

use

spring

bobbin

which

as

to

in

posi

en

the

This

caught

force

will

presser

rele

foot.

the

the

tion

the

projecti

holds the

CASE

or

it

is

latch,

be

to

very

case

hold

position

in

raised

open

.

ase

knee

two

necessary to

likely

feet, turn hand

needle.

the

foot

the

pressure

of

on

the

the

on

bobbin

tangled

Figure

to

release

the

bobbin

become

in

A,

on

Figure

back

remove

Page

the

case

the

case

broke

frame

on

of

9,

the

F

in

the

the

n,

Page 9

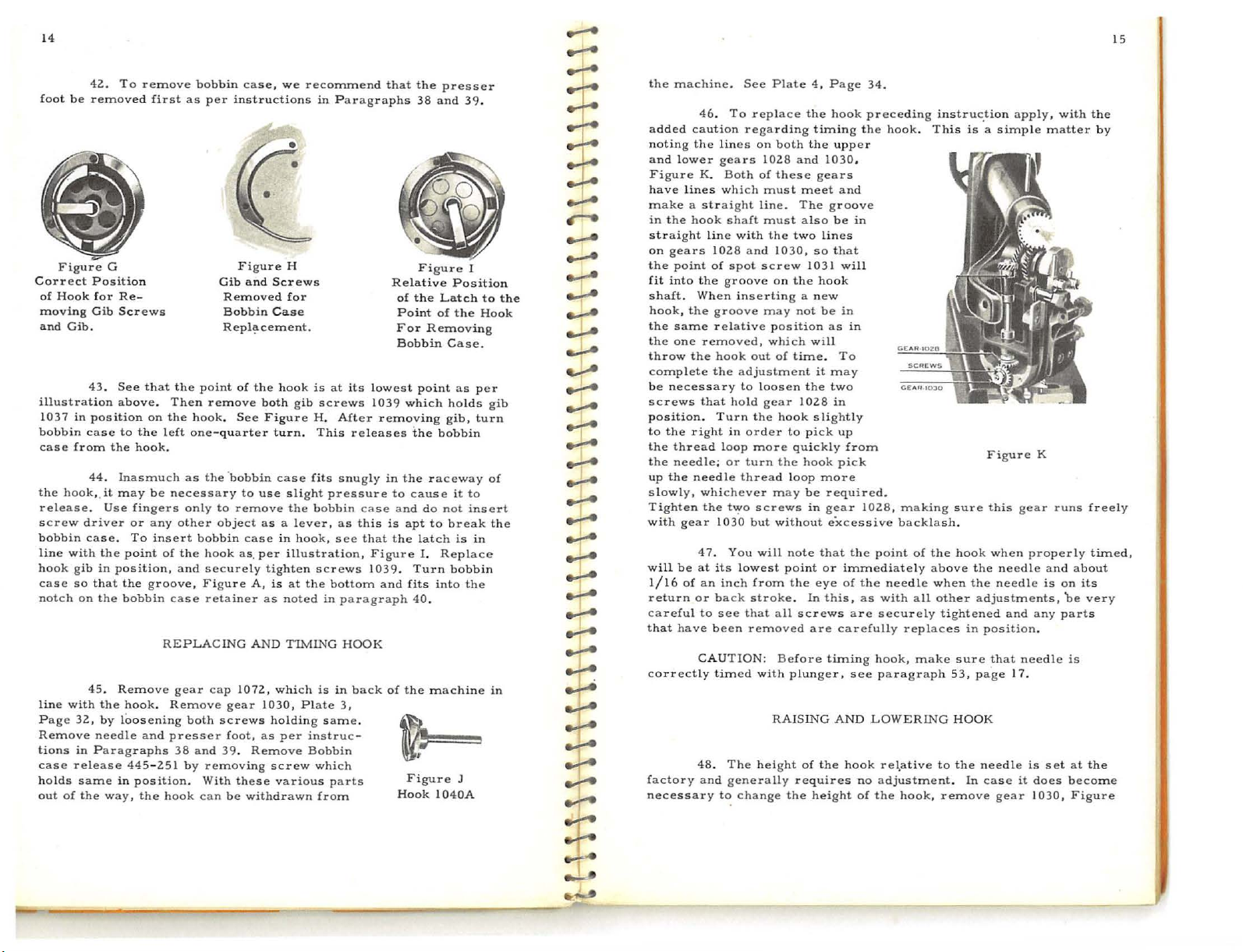

14

f

Correct Pos i

of

moving

and

illustration

1

bobbin

case from

the

release. Use

screw

b

line with

hook

case

n

line with

P

Remove

tions

case

holds

out

42..

oot

be

rem

Figu

re

G

Hook

for Re-

Gib

Gib.

43. See that

037

in pos

case

44.

hook

,.

it

driver

obb

in

case. To

the

gib

in

so

that

otch

on

the

45. Remove

age

the

32., by

needle

in Parag

release 445-2.51

same

of

the

way, the

To

remove

oved first

tio

n

Screws

above. Then rem

ition

on

to

the

the

hook.

Inasmu

may

fingers

or

any

point

position,

the

groove, Figu

bobbin

hook. Rem

loosening

and

raphs

in

position. With

bobbin

as

the point

the

hook

left

one

ch

as

be

necess

only

other

insert

bobbin

of

the

and

case

REPLACING

gear

ove

both

presser

38

and

by

hook

can

case, we

per

ins

tructions

Figure

Gib and

Removed

Bobbin Case

Repl~cement.

. S

-qu

the ·bobbin

ary

to

object

hook

secure

retainer

cap

screws

39.

removing

of the

ove

ee

arter

to

remove

case

as.

ly

re

A,

AND

1072.,

gear

foot,

Remove

these

be

withdrawn

Scr

hook

both gib

Figur

turn. This

case

use

as

a l

in

per

tighten

is

as noted

which

1030,

holding

a s

per

screw

various

recommend

in

Paragraphs

H

ew s

for

is

at

screw

e H.

After rem

fits

slight pressu

the bobb

illustration, Figure

at

TIMING

snugly

ever,

as

hook, see

screws

the

bottom

in

is

in

Plate

same.

instruc

Bobbin

which

parts

from

its

lowest p

s 1

039

releases

re

in

case

this

that

1039.

and fits

paragraph

HOOK

back

3,

-

that

Relative

in

to

is

the

of

the

presser

38

and

Fi

gure

the

Latch

of

Removing

oint

ng gib,

the bobb

cause

do

to

latch

I.

Replace

Turn

into

40

.

Figure

Position

the Hook

Case.

as

holds gib

it

not

break

is

bobbin

J

of

Point

For

Bobbin

which

ovi

the raceway

and

apt

the machine

Hook 1040A

39.

to the

per

turn

in

to

insert

in

the

of

the

in

~

.......

~

~

.......

..,:.-e

.,.:...e

~

.,....

.,_;....e

.....-..

~

~

....-...

..,

--r-

..,

..,

--1

..,:..e

..;-.-

~

.-i-4

~

--0

.,;..e

.,;...e

...;-e

..,::A

~

~

~

~

the

machine.

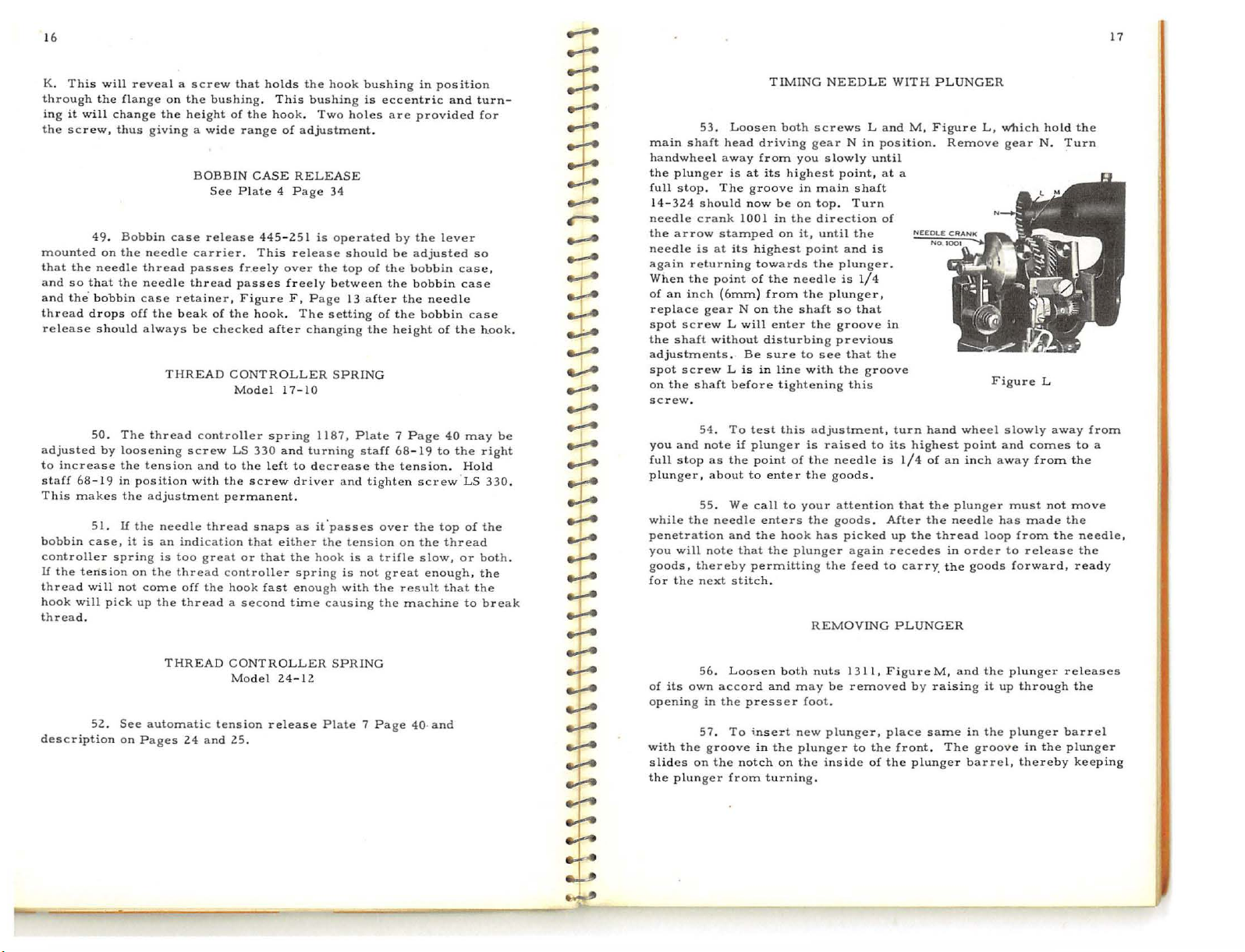

46. To

a

dded caution

noting

the

lin

a

nd

lower

Figure

have

make a strai

in

the

straight

on

gears

the point

fit

into

shaft.

hook,

t

he

the

throw

complete

be neces

screws

position. Turn

to

the right

the thread loop

t

he

up

the

slowly,

Tighten

with

will

1/16

return

careful to

that

correctly

factory

necessary

gears

K.

Both

lines

which

hook

shaft

line

102.8

of

spot

the

groove

When

the groove

same relative

one

removed,

the

hook

the

s a

ry

that

hold

in

needle;

be

have

or turn

needle

whichever

the

gear

t~o

1030

47. You

at

its lowest point

of

an

inch

or

back

see

been removed

CAUTION:

timed with

48.

The

and

generally requires

t~

See

Plate

repla

regarding

es

on

both

102.8 a

of these

must

ght

line. The

must

with

the

and

1030, so

screw

on

inser

ting a new

may

posit

which

out

of

adjustment

to loosen

gear

the

hook

order

more quick

the

thread

may

screws

but

without

will

from the

stroke.

that

all

Before tim

RAISING

hei

ght

change

4,

Page

ce

the

hook

timing

the

upper

nd

1030

gears

meet

and

groove

also

be

two

lines

that

1031

the hook

time.

to

loop

note

plunger,

the

will

not

be

in

ion

as

will

To

it

may

the

two

102.8

in

slightly

pick

up

ly

hook

p i

more

be required

in

gear

excessive

that

or immediately

eye

of

In

this,

screws

are carefully

AND

of

the

height

34.

preceding

the

hook. This

,

in

in

from

ck

.

102.8, m

the

the

as

are

ing

see paragraph

hook

no

of

aking

backlash

point

of the

above

needle

with

all

securely

replaces

hook,

make

LOWERING HOOK

re\ative

adjustment. In

the

hook,

instruc.tion

is a simple

sure

.

hook

when

other adjustments,

tightened

in

sure

53,

to

the

remove

Figure

this

when

the

needle and

the

need

and any

position

that need

page

needle is

case

gear

apply,

gear

properly

le

17 .

it

1030,

matte

K

is

.

set

does

with

runs

on

be

parts

le

the

r by

freely

timed,

about

its

very

is

at

the

become

Figure

15

~

.J_,

~

~~----~

------------~~

=

~~-

~--~------~--------

-

..

·-~~------------------------------------------------~-'

Page 10

16

K.

This

through

ing

it

the

screw,

mounted

that

the

and

so

and

the. bobbin

thread

release

adjusted

to

increase

staff 68This

makes

bobbin

controller

lf

the

tens

thread

hook

will

thread.

will

the

will

change

thus

49.

Bobbin

on

the needle

needle

that

the

drops

should

50.

The

by looseni

the

19

in posi

51. U the

case,

spring

ion

will

not

pick

reveal a screw

flange

on

the

the

height of

giving a wide

BOBBIN

case

thread

needle

case

off

always

tension and

the

it

is

on

come

up

carrier.

passes

thread

retainer,

the

beak

be

THREAD

thread

ng

screw

tion

with the scr

adjustment

needle

an

indication

is

too

the

thread

off the

the

thread a second

that

bushing.

See

release

of

checked

controller spring

thread snaps

great

holds

This

the

hook. Two

range

of

CASE

Plate 4 Pa

445-251

This

freely

over

passes

the

CONTROLLER

Model 17-

LS

to

permanent.

controller

hook fast

Figure

hook.

330

the

that

or

that

freely

F, Page

after

and

left

ew

either

the

time

the

hook

bushing

ge

34

is

the

between

setting

cha

nging

10

1187,

turning

it"passes

the

hook

causing

holes

operated

should

top

13

SPRING

and

tension

is a trifle

is

with

adjustment.

RELEASE

release

The

to decrease

driver

as

spring

enough

bushing

is

of

after

the

Plate 7 Page

staff

tighten

not great

in

eccentric

are

provided

by

the

be

adjusted

the

bobbin

the

bobbin

the

of

the

bobbin

height

68-19

the

tension. Hold

screw

over

the

on

the

slow,

the

result

the

machine

position

and

turn-

for

lever

so

case,

case

needle

case

of

the

hook.

40

may

to

the

right

LS

330.

top

of

the

thread

or

that

to

both

the

break

enough, the

be

...:-e

17

--1

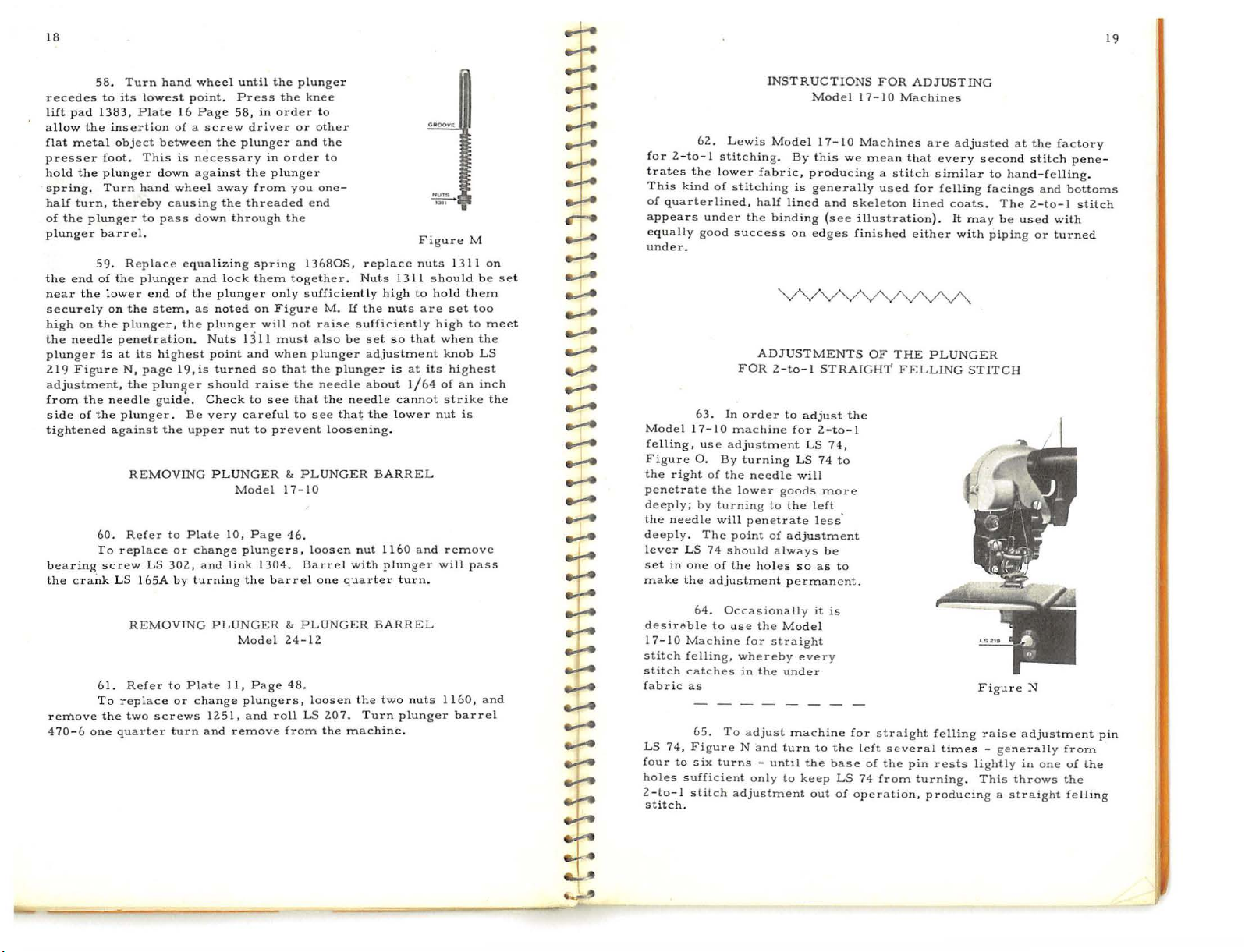

TIMING

53.

~

..4

.J,.

:}

.....-..

r-e

.......

......

.......

.......

.......

~

.,!....

.........

...-..

~

~

~

~

.,..

~

~

..,;-.-

.

.......

-r-

.,;-e

main

handwheel

the

plung

full

stop.

14-

324

needle

the

arrow

needle

again

When

of

an

replace

spot

the

shaft

adjustments.

spot

on

the

screw.

you

and

full

stop

plunger,

while

penetration

you

will

goods,

for

the next

Loosen

shaft head driving

away from

er

is

at

its

The

should

cra

is

returning

the

inch

screw L will

screw L is

shaft

54.

55.

the

thereby

groove

now

nk

1001

stamped

at

its

highest

towards

point

of

(6mrn} from

gear N on

without

note

as

about

needle enters

note

Be

before

To

test

if

plunger

the

to enter

We

and

that

permitting

stitch.

disturbing

in

point

call

the

be

in

on

the

the

enter

sure

line with

tightening

the

NEEDLE

both

screws L and

gea

r N

you

slow

highest

the

this

of

to

hook

point,

in

main

on

top.

direction

it,

until

point and

the

plunger

needle

plunger

is

the plunger,

shaft

so

the

groove

previous

to

see

that

the

adjustment, turn

is

raised

the

need

the

goods

your

atte

the

goods. After

has

picked

the

REMOVING

in posi

ly

shaft

Turn

the

1/4

that

groove

this

le

ntion

again

feed

WITH

until

at

of

is

.

in

the

to

its

is

.

up

recedes

to

PLUNGER

a

l/4

that

carry_

PLUNGER

M,

Figure

tion. Remove

hand

wheel slowly

highest

the

of

an

the

plung

the

needle has

thread

in

the

point

inch

order

goods

L,

Figure

away

er

loop

which

gear

and

must

made

from

to

release

forward,

hold

N.

L

away

comes

from

not

the

the

Turn

to

the

mov

the

needle,

the

ready

from

a

e

THREAD

CONTROLLER

Model

24-12

SPRING

..,....

~

...,;-4

.......

description

on

automatic

Pages

24 and

tension

25.

release

Plate 7 Page 40·

and

.,;.4

...,.

52.

See

:t:

+-

~

.,.l,

of

its

opening

with

the

slides

the

p l

56. Loosen

own

accord

in

the

57. To

groove

on

the

ung

er

from

presser

i.nsert

in

notch

both

and

may

new

the

on

turning.

nuts 131

be

foot

.

plunger,

plunger

the

inside

1,

Figure

removed

place

to

the

of

the

by

front.

plung

M,

raising

same

The

er

and

in

groove

barrel,

the

it

the

plung

up

through

plunger

thereby

in

er

the

releases

the

barrel

plun

ger

keeping

Page 11

18

19

pad

ll

ow

the

metal

the plunger

turn,

the

end

t he l

on

needle

Figure

the

of

crank

emove

70-6

58. Turn

plunger

59.

the

To

one

recedes

liit

a

flat

presser

hold

spring.

half

of

plunger

the

near

securely

high

the

plunger

219

adjustment,

from

side

tightened

bearing

the

r

4

to

1383,

insertion

foot.

Turn hand

thereby

barrel.

of

ower end

on

the

is

needle gui

against

60.

screw

61.

To

the

hand

its

lowest

Plate

16

object

Replace

the

plunge

penetration. Nuts

at

N,

plunger

Refer

replace

LS 165A

replace

two

quarter

of a screw

between

This

is

down

wheel

causing

to

pass

equalizing

plunger

the

the

Refer

of

stem,

r ,

the

its

highest

page 19,

plun&er

de.

. B e

the

REMOVING

to

or

LS

302,

by tur

REMOVING

to

or

screws

turn

wheel

until

the

point. Press

Page

58,

driver

the

plunger and

necessary

against

down

and

th e p

as noted

is

upper nut

Plate

cha

Plate

change

the

away

the

threaded

through

lock

lunger

plunger

1.3

point

and

turned

should

Check

to

very

careful to

PLUNGER & PLUNGER

Model

10,

Page 46.

nge

plungers,

and

link

ning

the

PLUNGER & PLUNGER

Model

11,

Page

plungers, loosen

1251,

and

and

remove

plunger

the

in

orde

or

in

order

plunger

from

you

the

spring

them

together. Nuts 1311

only

on

Figure

will

not

11

must

when

so

that

raise

the

see

that

to prevent

17-10

1304. Barrel

barrel

24-12

48.

roll

from

knee

r to

other

the

to

one-

end

13680S, replace

s u

fficiently high

M.

If

the

raise

sufficiently

also

be

plunger

the

needle

that

loosening.

nut 1160

with

quarte

the

207. Tu

the

machine

set

ustment

about

the lower

BARREL

plunger

BARREL

two

r n

plunger adj

the

needle

see

loosen

one

LS

Figu

nuts 1311

to hold

nuts

are

so

that

is

at

1/64

cannot

and

r tu r n.

nuts

plunger

.

should

set

high

when

knob

its

of

strike

nut

remove

will

1160,

r e M

them

too

to

the

highest

an

is

pass

barrel

on

be

meet

LS

inch

the

and

set

._!...

.......

....-..

e.-A

......

......

......

~

......

........

........

........

~

......

.,_;.4

......

......

~

......

.,!....

~

~

~

.-....

.,:;..4

.......

.......

..-....

~

~

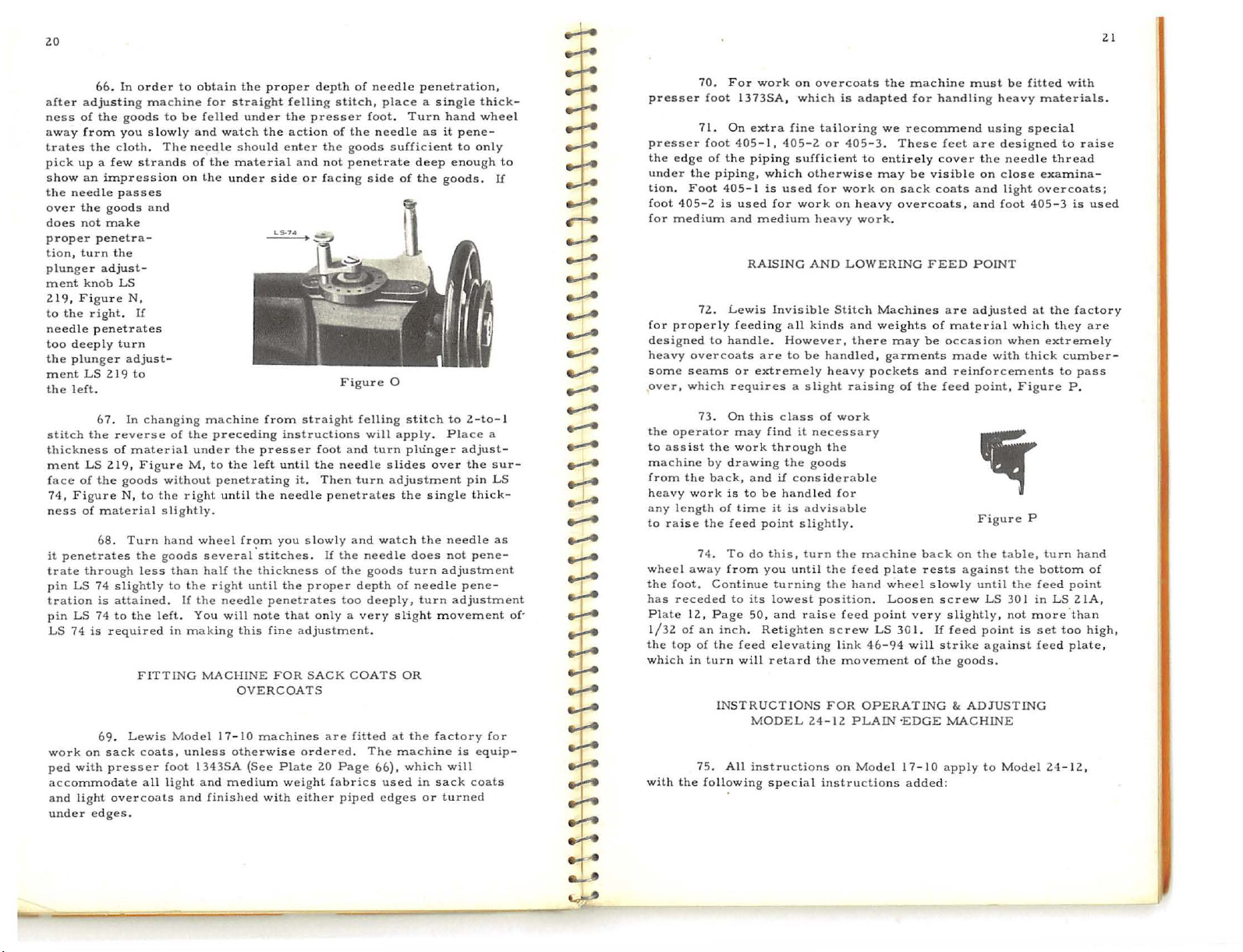

62. Lewis

for 2-to-1

trates

the lower

This

kind

of

quarterlined,

appears

equally

under

Model I 7-10

felling,

Figure

the

penetrate

deeply;

the

deeply.

lever

set

make

desirable

17stitch

stitch

fabric

LS

four

holes

2-to- 1

stitch

under

good

.

63.

use

0 . B y

right

of

by

needle

The

LS

74

in

one

the adjustm

64. Occasionally

10

Machine

felling,

catches

as

65.

74,

Figure N and

to

six

suffi

stitch

.

INSTRUCTIONS

Model

stitching.

fabric,

of stit

ching

half

the

binding

success

ADJUSTMENTS

FOR

2-to

In

order

machine

adjustment

turning

the

needle will

the

lower

turning

will

of

to

To

turns -until

cient only

to

penetrate

point

of

should

always

the holes so

ent

use

the

for

straight

whereby

in

the

adjust

adjustment

Model

17-10 Machines

By

this

we mean that

producing a stitch

is

generally

lined

and

skeleton

(see

on

edges

- 1

STRAIGHT

to

adjust

LS

s m

left

less'

it

to

the

out

the

74,

74

to

ore

be

as

to

is

the left

base

LS

of

operation, pr

for 2-to-

LS

good

the

adjustment

permanent

Model

every

under

machine for

turn

to

keep

FOR

used

shed

OF

straight

of

the

from

ADJUSTING

Machines

for

lined

either

THE

FELLING

several

pin

turni

are

adjusted

every

similar

felli

ng facings

coats. The 2-to-1

with

PLUNGER

STITC

fell

ing

times -generally

rests

lightly

ng .

oducing a straight

I 7- 10

illustration). It may

fini

1

.

74

second

to

be used

piping

Figure

raise

This

at

the facto

s t

itch

hand-felling

and

with

or

turned

H

N

adjustment

in one

throws

ry

pene

.

bottoms

stitch

from

of

the

the

felling

-

pin

Page 12

20

after

ness

away

trates

pick

s h

the

over

does

proper

t io

plunger

ment

219,

to

needle

too

the

ment

the

stitch

thickness

ment

face

74, Figure

ness

it

trate

pin

tration

pin

LS

work

ped

accommoda

a

under

66.

adju

of

the

from

the

up a few

ow

an

needle

the

not

penetra-

n,

turn

knob

Figure

the

right.

penetrates

deeply

plunger

LS

left

.

67. In

the reverse

LS

of

the

of

penetrates

through

LS

74

LS

74

74

is

on

with

nd light

edges.

In

order

sting

machine

goods

you

slowly

cloth. The

strands

impression

passes

goods

and

make

the

adjust

-

LS

N ,

If

turn

adjust-

219

to

changing

of

material

219,

Figure

goods

N,

to

Turn

the

less

slightly

attained.

to

the

left. You

FITTING

coats. unless

t e

all light

the r ighl

slightly.

material

68.

is

required

69. Lewis

sack

presser foot

overcoats

to

obtain

for

to

be

felled

and

watch

needle

of the

on

the

machine

of

the

preceding

under

M,

without

hand

goods

to

penet

until

wheel

several.stitches.

than

half

to

the

right

If

the

needle

M.ACI-IINE

1343SA

and

and

finished

will

ing

in mak

Model 17- 10

the

proper

straight

under

t h e

should

enter

material

under

side

from

instructions

the

presser

the

left

until

rating

the

needle

from

you

the

thickness

until the

penetrates

note

this

fine adjustm

FOR

OVERCOATS

machines

otherwise

(See

medium

Plate

weight

with

depth

of

felling stitch,

the

presser

action

the

and

not

or

facing

straight

foot

the

it. Then

slowly and

If

of

proper

that

only a very

SACK

ordered. The mac

20

either

foot.

of

the

goods

penetrate

side

Figure

felling

will

and

needle

turn

penetrates

the

needle

the

goods

depth

too

deeply,

ent.

COATS

are

fitted

Page 66),

fabri

cs

piped

needle

needle

turn

penetration,

place a single

Turn

hand

as

sufficie

0

apply.

slides

adjustment

watch

of

slight

at

used

edges

it

nt

deep

of

the

goods

stitch

to 2-to

Place

plunger adjust-

over

the

single thi

the

needle

does

not

turn adj

needle

turn

movement

OR

the

factory

hine

which

will

in

sack

or

turned

thick

wheel

pene

-

to

only

enough

.

If

-1

a

the

sur-

pin

LS

ck-

as

peneustment

pene

-

adjustment

for

is

equip-

coa

ts

to

-

of·

~

~

::t:

...,:..e

........

~

c.-A

.........

....._..

....._..

.........

~

.........

.......

.........

.......

---1

..,

.,:.....

~

J...

~

~

c,.:...e

:t.:

:t:

pre

presser

the

under

tion. Foot

fool

f

for

designed

heavy

s

over, which

the

to

m

from

heavy

any

to

wheel

the

has

Plate

1

the

which

with

70.

sser

foot l37

71.

foot

edge

the

405-2

or

medium and

72.

properly

overcoats

ome

seams

73.

operator

assist

achi

ne

by drawing

the

work

length

raise

the

74. To

away

foot. Continue

receded

12,

/32

of

an

top

of

in

turn

75.

the

following

For

work

3SA, which

On

extra

405-

of

the

piping,

405

is

used for

Lewis

feeding

to

handle. However,

or

requires a slight

On

may

the

work

back,

is

of

time

feed

from

to

Page 50,

inch.

the

feed

will

INSTRUCTIONS

All

fine

l ,

405-2

piping

which

-1

is

used

medium

RAISING

Invisible

all

are

to

extreme

this

class

find

through

the

and

if

to

be

handled

it

is

point

do

this,

you

turning

its

lowest

and

Retighten

elevating

retard the

MODEL

instructions

special instruct

on

overcoats

is

tailoring

or

sufficient

work

it

considerab

until

405-3.

otherwise

for

work

on

heavy

heavy

work.

AND

LOWERING

Stitch

kinds

and weight s

be

advisab

slightly

turn

raise

there

handled, garments

ly

hea

vy

raising

of

work

necessary

the

goods

for

le

.

the

the

feed

the

hand

position.

feed

screw

link 46-

movement

FOR

24-12

PLAIN ·EDGE

on

Model 17-

the

adapted for

to entirely

machine

OPERATING & ADJUSTING

machine

we reconune

These

may

be

on

sack

overcoats,

Machines

may

pockets

of

the

le

plate

wheel

Loosen

point

very

LS

30

I.

94

will

of

ions added:

back

mu

st

nd

using

are

on

and

and

POINT

adjusted

on

point,

Figure

the

against

until

LS

point

against

to

with thick

be

designed

need

close

light

foot

al

which

when

Figure

table, turn

the

the

30 I in

is

Model 24-12,

handling heavy

feet

cover the

visible

coats

FEED

are

of

materi

be

occasi

made

and reinforcements

feed

on

rests

slowly

screw

slightly, not

If

feed

strike

the

goods.

MACHINE

10

apply

fitted with

materials

special

to rai

le thread

exa

mina-

overcoats;

405

- 3 i s

at

the

factory

they

ext

rem

cumber

to

pass

P .

P

hand

bottom

feed

point

LS

21A

more.than

set

too

feed

plate,

21

.

se

used

are

e ly

-

of

,

high,

*

--r

·

......

~

Page 13

22

76.

We

and

not

by

hand.

a

nd

the

the prod

shown

which

joining

ormed

stitch

se adj

line

77.

inch

78.

vas

seam,

79. Pl

80.

by

8 1.

ustment

stitch

Baste

from

on

in

is

the canvas

taking

through one

with hand basti

and

5/16

the can

as

basting

Q,

of

f

one

canvas, giving

u

felling

recommend

Machine

of bast

ing

ng .

uction is

the

1n

placing

the left

Figure

which

ace

directly under

The

the

To adju st n

deeper

is

Furthermore,

far gre

sack coats

edge.

the

of

Q.

See

is

the

the

edge

NEEDLE

operation

t o

one

sti

- ha

appearance

pin

LS

74,

and

BASTING

all

edge

basting places

more even

ater

.

1/4

inch

F i

gure

work

on

th e

arm,

that

guide No.

seam

between

of

the

the

foot.

PENETRATION

of

felling

the

facing

tch

into

the

lf

the

thickness

of

eedle

penetrati

Figure

to

the

left

basting

than

machin

the stitches

ordina

e basting

from

the

work

·.

Q

the machine ,

which

is

on

1576

the canvas

garment

with a zig-zag

sketch

N.

the

canvas

canvas

shown

on

Turn

for less

in the

only and

of

the

in

the

to

penetration.

be done

rily

can

is

edge

and

pla

ce

the

outside

is

dir

groove

to

the

stitch.

goods

at

top

cloth

the right

by.

machine

closer together

be att

eco

overcoats

garme

of

the machi

above

facing

of

plate

front

Th

i~ stit

through

the

facing

to

make

aine

nomical

nt

the

Figure

is

w1th

the

more

the

ectly

and the

coat

alternatmg

and

of page 23.

on

d

with

sid

that

~h

the

side,

is

ne ,

e.

.J,..

±

.J...

.......

c,..;A

e,..:..e

...:--e

..,_.....

.......

.......

~

~

~

~

...-..

~

~

...,:....

~

~

adjustment

which,

crown

allows

ad

through

deep

against. The

unless

finish.

penetrate

ing

slide

are

coats

coats

SACK

~

:t=

._:...

__.

--r-

~

e-':'1

82. To

screw 1493,

in

turn,

adjusting

the

nee

83. On

justment

knob

fitted

1571A-Foot

1578)

1579)

I

584 Plu nger

s o

part

penetration

you

desire

84

.

If

the

LS

2 1

over the

85. Lewis

with

.

86. Parts

to

overcoats

COAT

Plunger

Comple

adjust needle

causes

screw 1493

dle

to

penetrate

overcoats

as

to

permit

of

the

undergoo

is

not

needle

canvas only, lower the

should

to

produce

the

needle

9, Figure

facing

goods

Model

presser foo

for

and

PAR

TS

te

Sprin

g

penetration

Figure

the

necessary

M,

cha

vice

Q ,

needle

to

the

more deeply

it

is esp

needle

ds

on

not ent

what

penetrates

to the left

.

24-12

machines, unless

t 1

571A

nging

Lewis

versa

TOPCOAT PARTS

1

1593A -Foot

1591)

I

592)

1310

Plunger

in

to

to

penetrate

left

ecially desira

to

the

or

er

is

the

and relating par

are

Plung

Complete

the

the

right

tends

to

into

pass

through

canvas

desirable, and

the

fore-part

termed

plunger

Model 24-

as a "pri

facing

by

sufficie

as follows:

er

Spring

canvas, turn

to

stop

the

deep

ly. Turn

the

canvas

to

make

canvas and

On

sack

should

on

sack

cked edge"

time

plunger

mit

se

for

machine

plunger

plunger,

it

work

nger Spring

less

raise

the

b l e

the

side.

at

the

turning

nt

to per

otherwi

ts

12

OVERCOAT PARTS

1

593SA -Foot

1591-1/2)

1592-1/2)

1310 Plu

crown

.

the

above

coats

be

guarded

coats

should

the

needle to

specified

on

from

Plunger