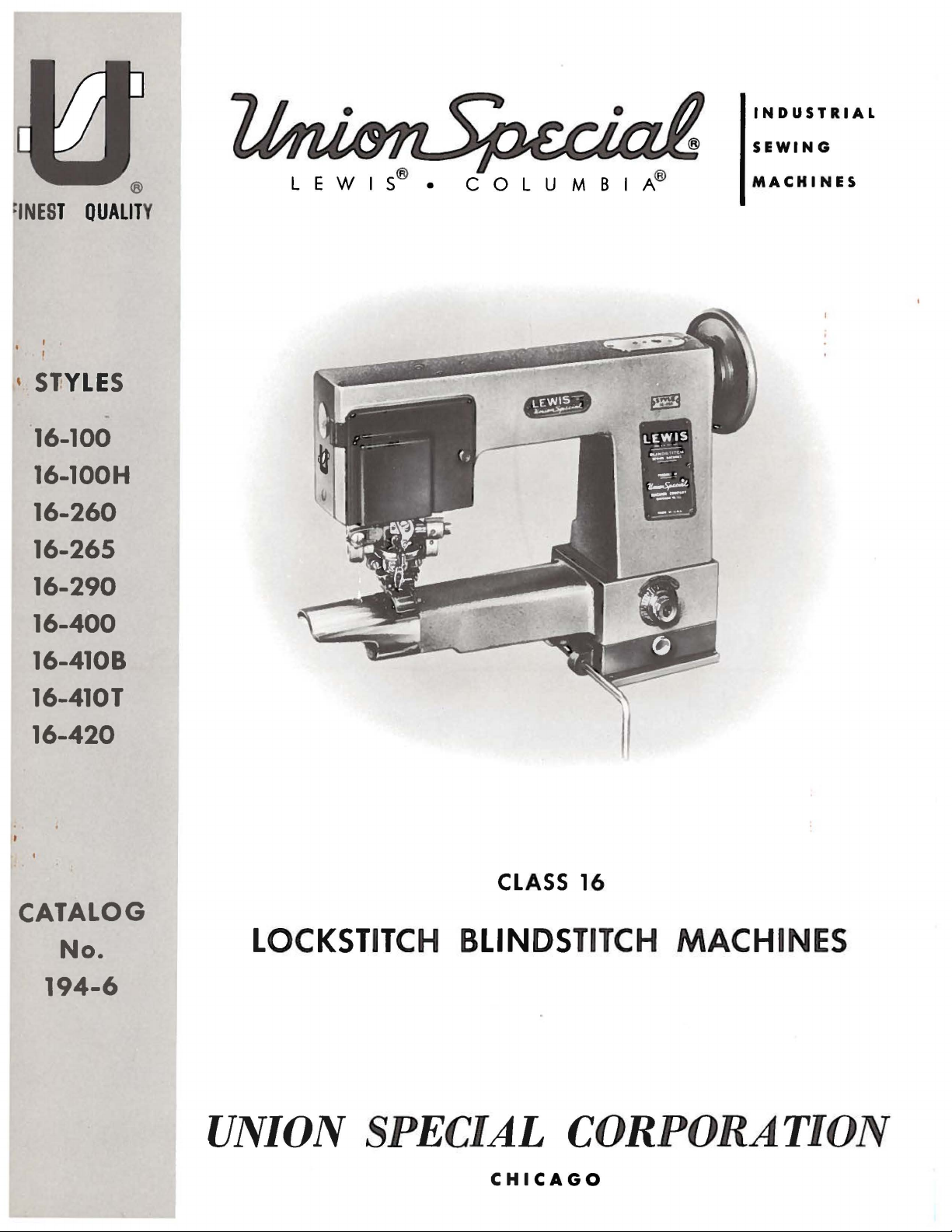

INDUSTRIAL

SEWING

I

NES

T

~

S11

YLE

16-100

16-100H

16-260

16-265

16-290

16-400

S

C 0 L U M B I A®

MACHINES

16-4108

16-410T

16-420

CATALOG

No.

194-6

LOCKSTITCH

CLASS

16

BLINDSTITCH

MACHINES

UNION SPECIAL

CHICAGO

CORPORATION

Catalog

INSTRUCTIONS

No.

FOR

194-6

16-100

16-100

16-260

ADJUSTING

LIST

H

First

AND

OF

Styles

16-265

16-290

16-400

Edition

OPERATING

PARTS

16-410

16-410

16-420

B

T

Union

Rights

UNION

INDUSTRIAl

Copyright

By

Special

Reserved

SPECIAL

SEWING

CHICAGO

Printed

1962

Corporation

in

All

Countries

CORPORATION

MACHINES

in

U.S.A.

2

April,

1981

The

Union

Special

Lewis

Class

FOREWORD

16

offers a complete

line

of

two

threadlockstitch

blindstitch

consideration.

All

parts

It

is

our

the

customer

following

describe

Union

cooperate

pages

the

in

machines,

are

made

constant

to

secure

contain

parts

Special

planning

for

universally

by

precision

aim

to

furnish

all

possible

valuable

Class

representatives

and

16.

estimating

demandedby

methods

carefully

advantages

operating

will

be

requirements.

manufacturerswhenqualityis

insuring

prepared

from

and

adjusting

found

complete

information

the

in

all

interchangeability.

use

of

Union

data,

manufacturing

and

which

Specials.

illustrate

a

will

enable

centers

first

The

and

to

UNION SPECIAL CORPORATION

3

IDENTIFICATION

OF

MACHINES

Each

of

machines,

The

serial

main

shaft

This catalog

references

from

High

the

The

operating direction

Production,

Cylinder

Calibrated

Removing

16-100

Single

suits

Also

Ideal

as

trouser

machine

travels

Union

Special

is

stamped

number

Lewis

in

of

each

bearing.

to

direction,

applies

specifically

such

operator• s position

Base

Penetration

Work.

needle

and

all

used

for

for

alteration

cuffs.

will

right

Two

Machine.

Maximum

types

under

sew

to

left

Thread,

Adjustment.

machine

of

knit

felling

rooms

Machine

straight

and

machine

the

style

machine

carries

plate

is

APPLICATION

to

as rig

ht

while seated

of

the

handwheel

DESCRIPTION

Single

Non-skip

1

Lower Fee

Work

Space

for

hemming

garments.

coat

collars

or

small

produces

lockstitch.

penetrates

at

a

style

on

the

stamped

OF

CATALOG

the

styles

and

left,

at

OF

forward

the

machine.

is

away

MACHINES

Curved

to 1 Stitch.

d.

to Rig

ht

medium

Particularly

or

felling

factories.

overcast

Work

an

support

angle

front

in

the

of

from

Needle,

Knee

of

Needle

desirable

Will

stitch.

of

45°

number,

of

the

column.

main

frame

machines

and

back,

the

Lockstitch,

Overcast

Lifter

10

weight

tape

edges

handle

By

plate

to

line

which,

at

the

listed

etc

operator.

or

Straight

for

Inserting

Inches.

trouser

cuff

for knitted

and

cylindrical

removing

not

included.

of

feed.

in

this

class

left

upper

herein.

.•

are

taken

Blindstitch,

Stitch.

s,

ladies•

dresses.

bridle

work

tape.

such

spreaders,

Needle

All

and

16-100

collars

plate

16-260

and

for

4

penetrates

spreaders

16-265

linings

similar

16-290

sleeves

Machine

Minimum

travels

straighd

for

16-400

topcoats

plate.

H

included.

Single

medium

quick

3/4

inches.

Single

Single

15

Single

Needle

Single

on

overcoats

needle

weight

inserting

at

is

needle

to

sleeves

garments.

needle

of

men• s sport

cylinder

sleeve

right

lockstitch

machines.

needle

of lig

travels -right

needle

machine,

and

similar

machine for felling

suit

coats

and removal

Work

an

possible,

support

angle

of

but

15°

machine,

at

cuffs

Work

on

support

machine

or suit

fitted

diameter

to

left

without

with

and

4

penetrates

spreaders

machine

ht

and

tropical

to

similar

heavy

and

of

plate

to

not

generally

similar

medium

for

felling

end

3/4

for

weight

left

to

weight garments.

sleeve

topcoats.

sleeves

not

included.

line

of

to

16-260

and

plate

wigan

coats

cov

er

for qui

inches.

at

is

possible,

felling

materials.

and

penetrates

16-100

exceptequippedforfell

linings to

Machine

and

linings.

Needle travels left

feed.

Sewing straight

recommended

except

heavy

not

of lig

Work

an

weight

included.

or

dummy strip sleeve lining

ht

and

ck

inserting

support

angle

but

under

collars

Includes

at

Removable

sleeves

cylinder fitt

Medium

for

equipped

overcoat

medium

pl9te

of

15

not

to

generally

on

men's

removabbe

an

angle

work

at

cuf

fs

ed

with

sleeve

lockstitch wit

15°

machines.

for

felling

s,

car

weight

and

removal

not

included.

line of

recommended

suit

work

of

25

to

i

ngunder

support

on

tropic

end

diamet

to rig

ht

sle

coats

to

materials.

of

Needle

feed.

Sewin

coats

support

line

of

cov

and

hout

eve

and

coat

wor

and

feed.

al

er

er

k.

g

4

DESCRIPTION

OF

MACHINES

(Continued)

16-410

and

Needle

Sewing

16-410

slacks

removable

angle

commended

*16-420

work

angle

These

starts.

seconds

Most

fact

they

Page

B

Single

pockets

travels

straight

T

Single

and

of

15

Similar

supp~rt

of

90

machines

Use a good

at

100

of

the

are

6,

will

be

needle

in

topcoats

right

lockstitch

needle

skirts

~ork

to

feed.

on

15°

to

16-100

plate

to

line

grade

Fahrenheit.

oiling

painted

beneficial.

machine

to

machine

of

heavy

support

Sewing

machines.

included.

of

feed.

should

of

places

red.

for

and

overcoats.

left

and

without

for

materials

plate.

straight

except

to

Needle

be

oiled

straight

on

these

However,

fell:ing

penetrates

spreaders

felling

Needle

sew

printing

travels

OILING

twice

mineral

machines

reference

medium

Includes

at

is

not

bottom

producing

travels

lockstitch

press

right

daily,

before

oil

of a Saybolt

are

readily

to

and

heavyweight

removable

an

angle

recommended

to

waistband

hand

right

to

felled

left

without

felt

to

left

the

identifiable

the

oiling

wo6k

of

15

on

curtain

effect.

and

penetrates

spreaders

ink

rolls.

and

penetrates

morning

viscosity

•

diagram,

bellows

facings

support

to

line

of

15°machines.

on

trousers.

Includes

is

not

Removable

and

afternoon

of

90

to

because

Fig.

plate.

feed.

at

an

re-

at

an

125

of

the

1,

on

Please

and

to

tilt

Referring

points

marked

The

lubricated

from

Union

Point

are

lubricatedwith

be

removed

The

note

that

the

machine

to

the

·~

".

and

two

points

·~"are

with a light

Special

''B"

on

under

the

a

and

the

recommended

it

will

back

oiling

one

grease

diagram

standard

grease

speed

be

necessary

from

diagram,

marked

for

the

needle

about

part

No.

refers

wheel

replenished,

of

these

to

remove

the

sub-base

it

will

"B".

bearings

once a week.

28604

to

the

P.

cover

bearing

if

necessary.

SPEED

machines

NEEDLES

to

be

noted

over

grease.

is

head

reach

on

Tubes

that

the

the

cover,

some

there

upper

of

hook

Periodically,

1500

R.

P.M.

cylinder

of

are

main

grease

driving

the

may

the

end

oiling

two

lubrication

shaft,

be

gears.

cover

cover,

places.

and

are

ordered

which

should

*

in

Not

both

Needles

uniform

Available.

for

the

blade

Lewis

and

Class

ball

16

eye.

machines

5

are

available

in

all

the

required

sizes

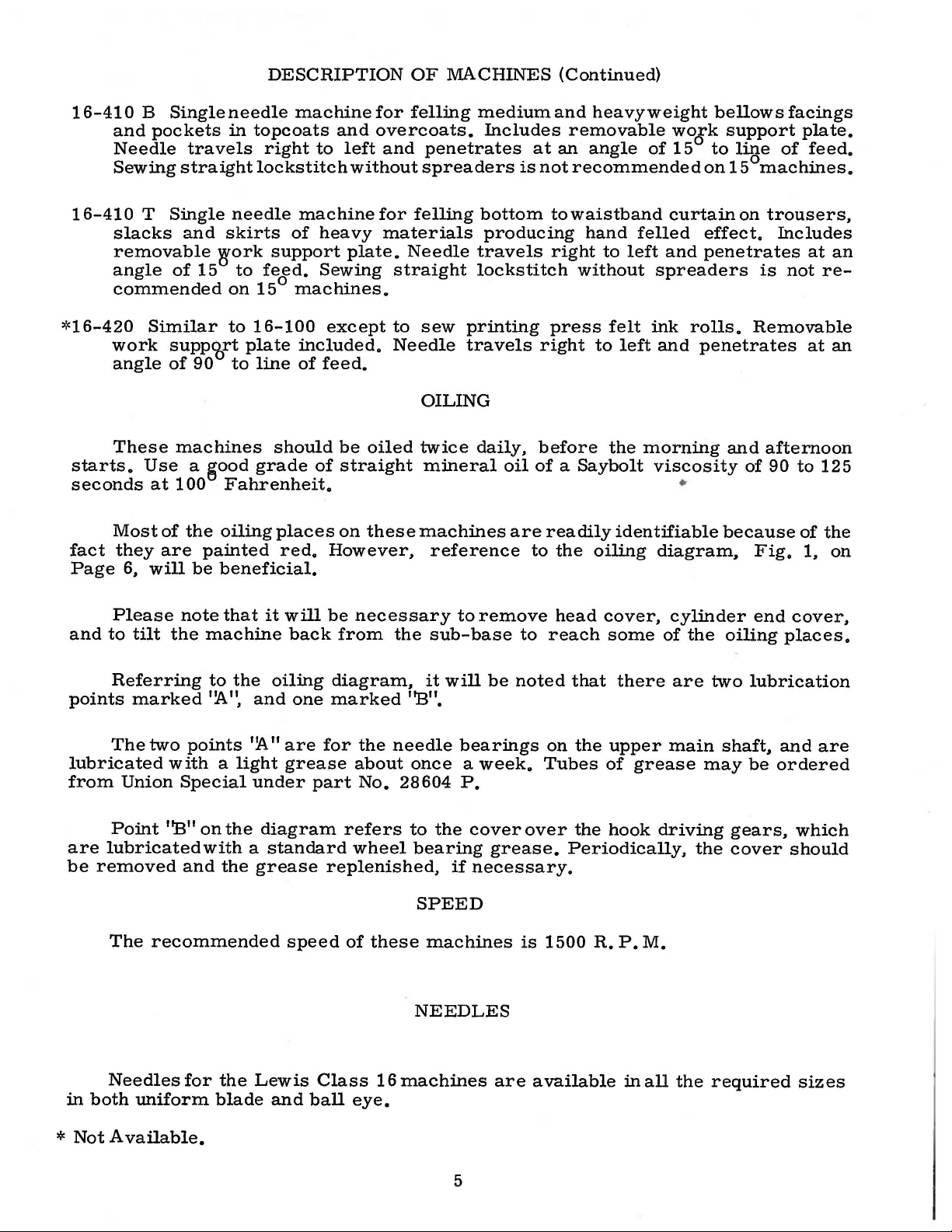

Fig.

1

6

STYLES

16-4108

16-410T

16-420

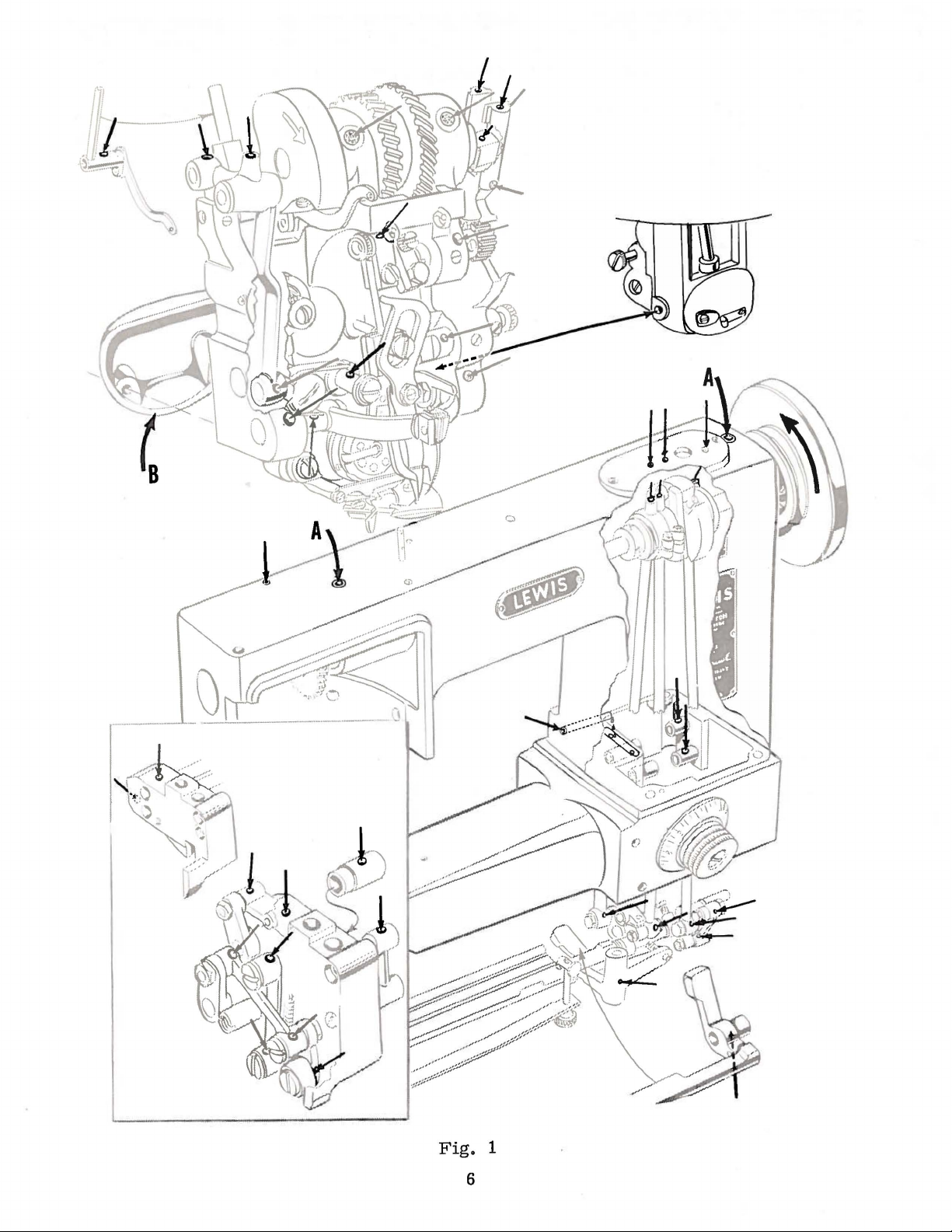

Fig.

2

7

NEEDLES

(Continued)

The following

Select

sure

that

Immediately

To

sample

read:

"100

Thread

Please

16-420

16-265

accurate

tracing

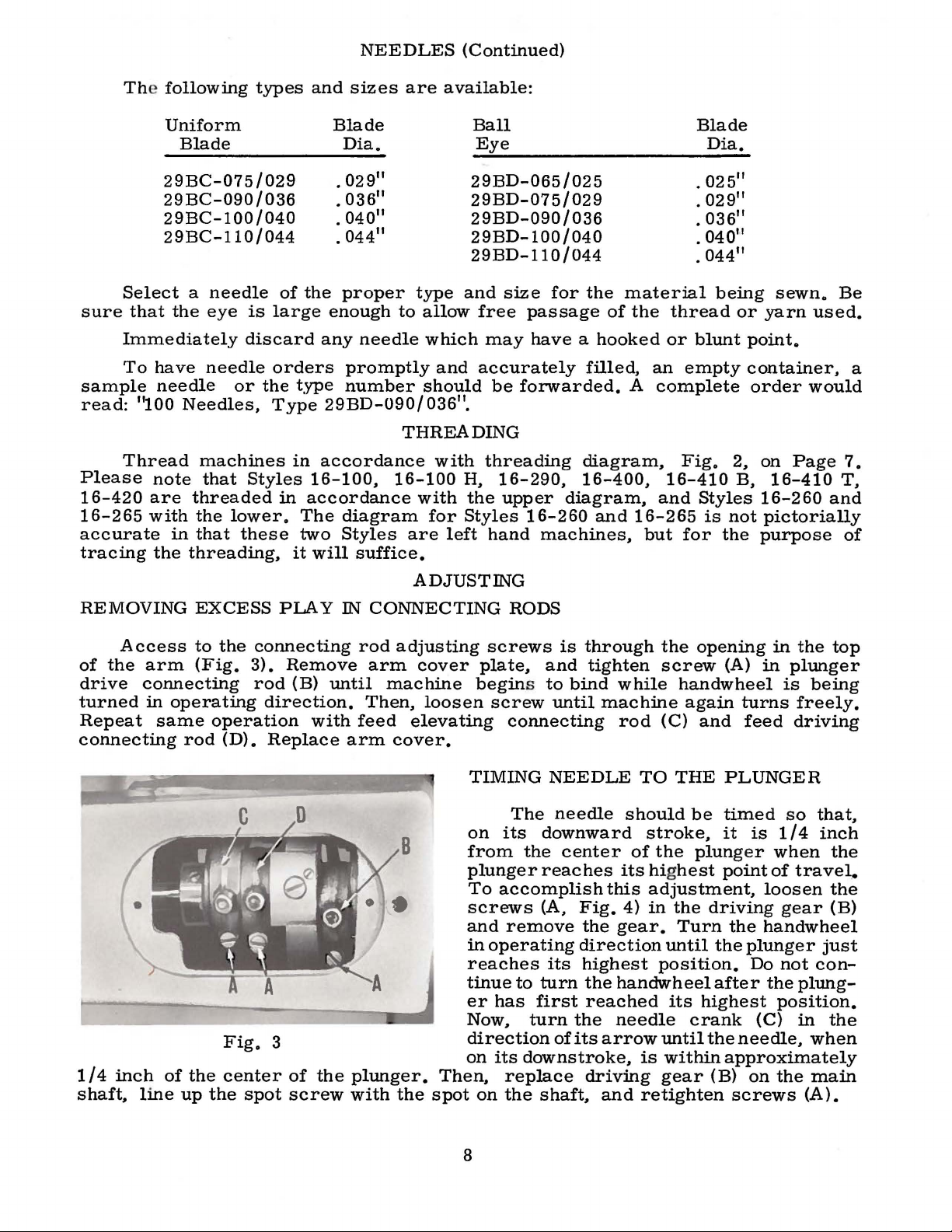

Uniform

Blade

29BC-075/029

29BC-090/036

29BC-100/040

29BC-110/044

a

needle

the

eye

have

needle

needle

or

Needles,

machines

note

are

with

the

that

threaded

the

in

that

threading,

lower.

these

types

of

is

large

discard

orders

the

type

Type

in

Styles

in

it

and

sizes

Blade

Dia.

11

. 02 9

11

.

036

11

.

040

11

.

044

the

proper

enough

any

needle

promptly

number

29BD-090/

accordance

16-100,

accordance

The

diagram

two

Styles

will

suffice.

are

available:

Ball

Eye

29BD-065/025

29BD-075/029

29BD-090/036

29BD-100/040

29BD-110/044

type

to

allow

which

and

and

free

may

accurately

should

036".

THREADING

with

16-100

with

for

are

H,

the

Styles

left

threading

hand

size

for

passage

have a hooked

be

forwarded.

16-290,

upper

diagram,

16-260

machines,

the

material

of

the

filled,

A

diagram,

16-400,

and

16-265

but

Blade

Dia.

. 02 5

. 02 9

.

036

.

040"

.

044

being

thread

or

blunt

an

empty

complete

Fig.

16-410

and

Styles

is

for

11

11

11

11

or

yarn

point.

container,

order

2,

on

B,

16-260

not

pictorially

the

purpose

sewn.

used.

would

Page

16-410

Be

a

7.

T,

and

of

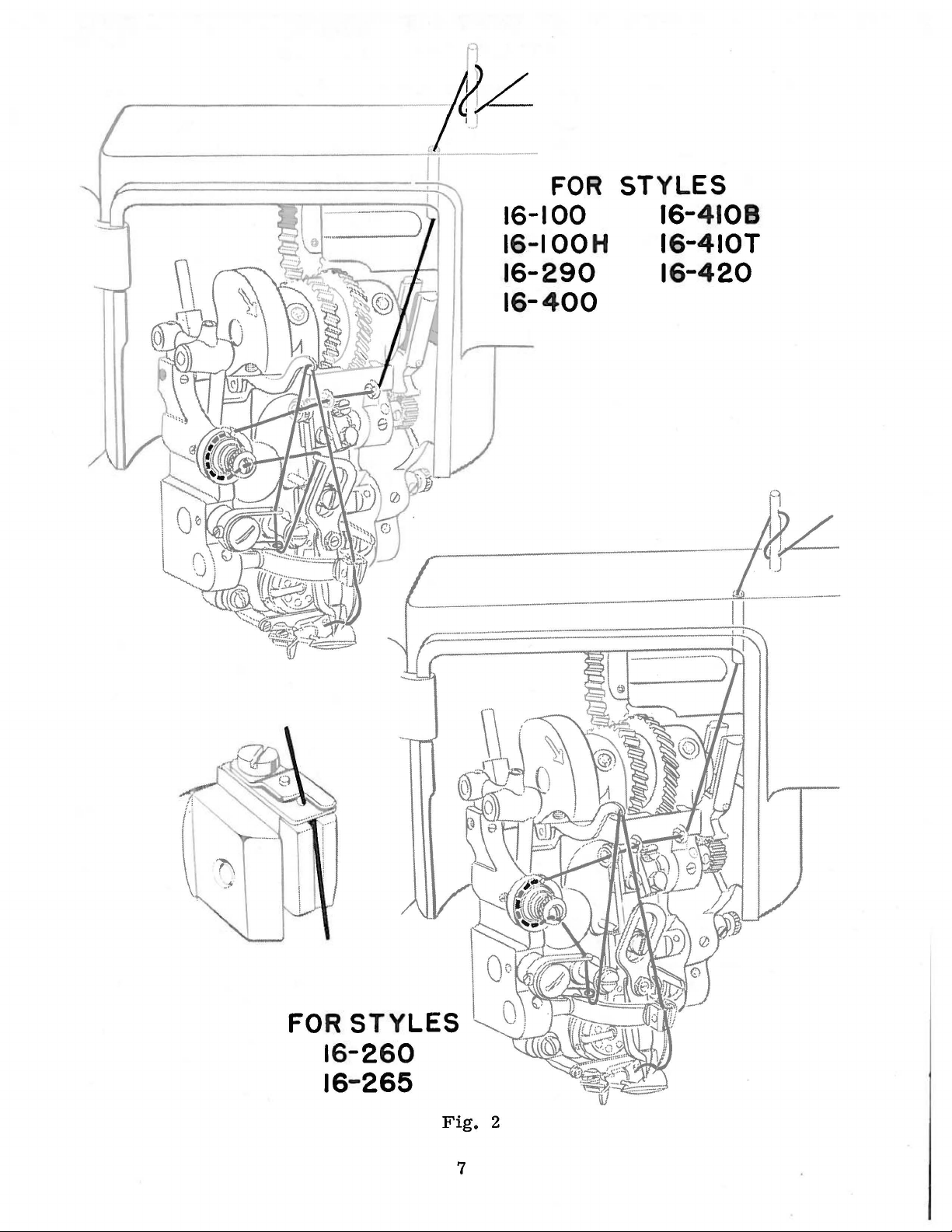

REMOVING

Access

of

the

arm

drive

turned

Repeat

connecting

in

same

connecting

1/4

inch

shaft,

of

line

EXCESS

to

the

(Fig.

operating

operation

rod

(D).

Fig.

the

center

up

the

PLAY

connecting

3).

Remove

rod

(B)

direction.

with

Replace

3

of

spot

screw

until

the

ADJUSTING

IN

CONNECTING

rod

adjusting

arm

cover

machine

Then,

feed

arm

loosen

elevating

cover.

plunger.

with

the

spot

RODS

screws

plate,

begins to

screw

connecting

TIMING

The

on

its

from

plunger

To

accomplish

screws

and

remove

in

operating

reaches

tinue

er

has

Now,

is

and

until

NEEDLE

needle

downward

the

center

reaches

(A,

its

to

turn

first

turn

through

tighten

bind

while

machine

rod

its hig

this

Fig.

4)

the

gear.

direction

highest

the

handwheel

reached

the

needle

the

screw

(C)

TO

THE

should

stroke,

of

the

adjustment,

in

the

until

position.

its

directionofitsarrowuntiltheneedle,

on

its

Then,

on

replace

the

downstroke,

driving

shaft,

and

is

within

gear

retighten

opening

(A)

handwheel

again

and

turns

feed

PLUNGER

be

timed

it

is

plunger

hest

point

driving

Turn

the

the

plunger

Do

after

highest

crank

approximately

(B)

on

screws

in

the

in

plunger

is

being

freely.

driving

so

that,

1/4

inch

when

of

trave~

loosen

gear

handwheel

just

not

con-

the

plung-

position.

(C)

in

when

the

main

(A).

top

the

the

(B)

the

8

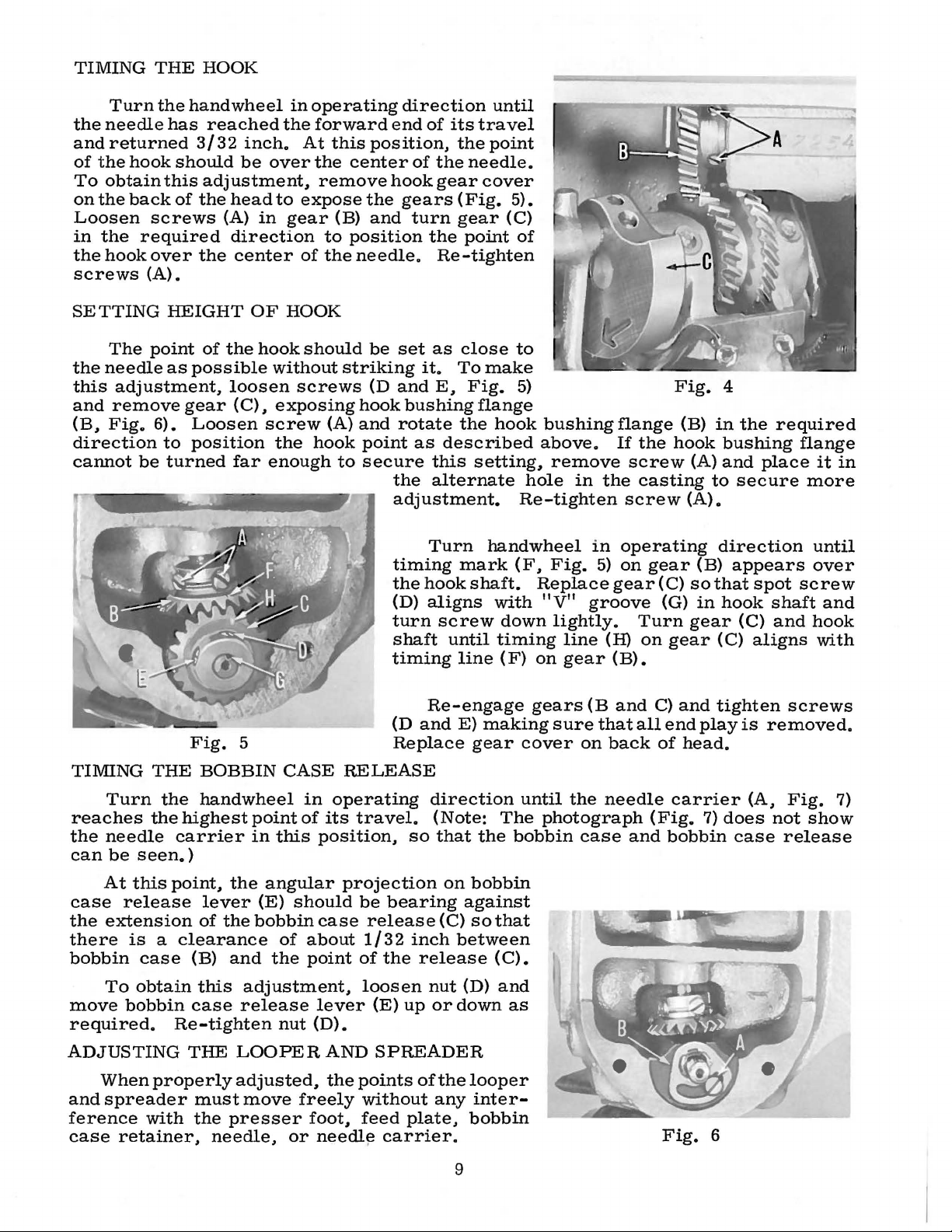

TIMING

THE

HOOK

Turn

the

needle

and

returned

of

the

hook

To

obtain

on

the

back

Loosen

in

the

required

the

hook

screws

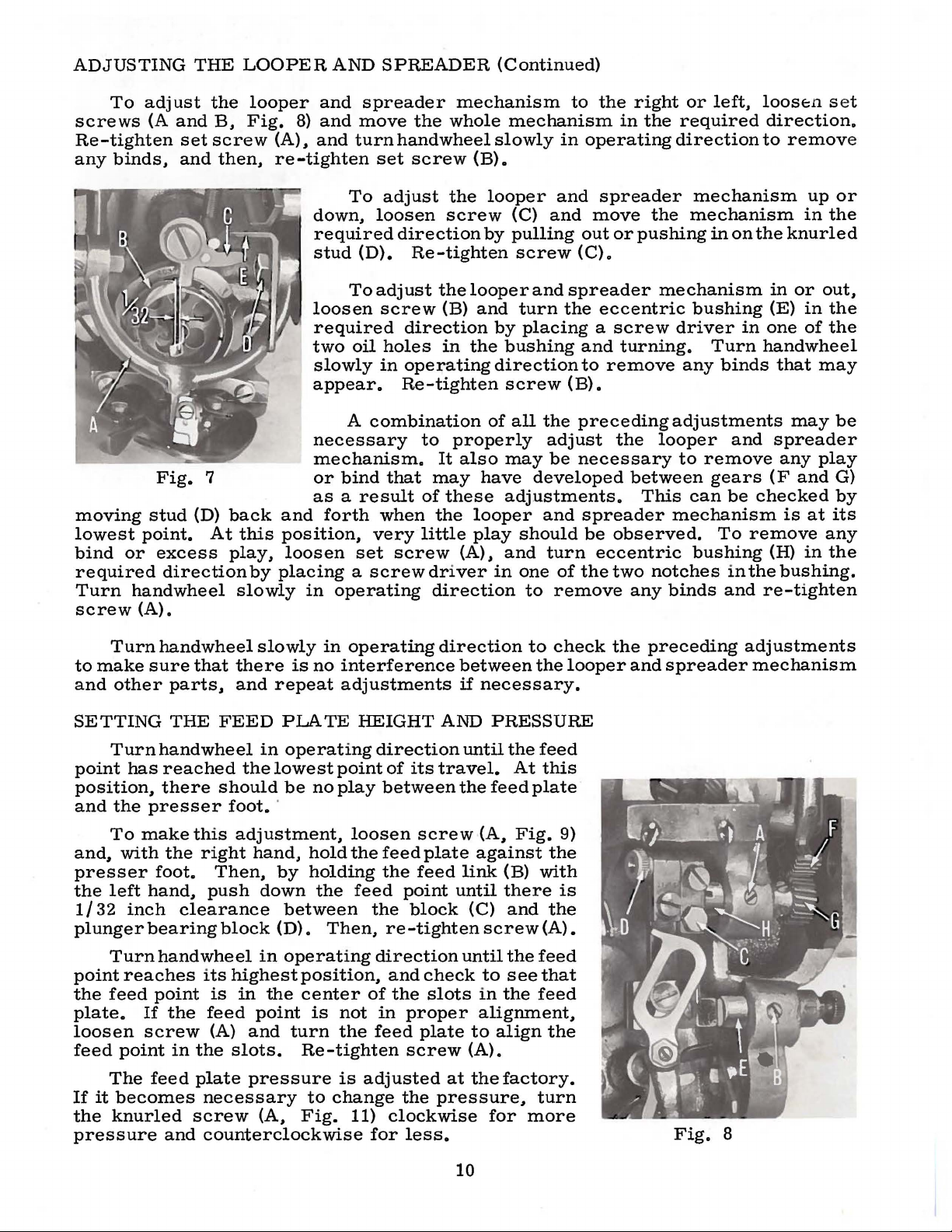

SETTING

(A).

The

the

needle

this

adjustment,

and

remove

(B.

Fig.

direction

cannot

be

the

hand

has

3/3 2 inch.

should

this

of

the

screws

over

the

HEIGHT

point

as

possible

gear

6).

Loosen

to

position

turned

wheel

reached

be

the

over

adjustment,

head

(A)

in

to

gear

direction

center

OF

HOOK

of

the

hook

without

loosen

(C).

exposing

screw

the

far

enough

in

operating

forward

At

this

the

remove

expose

(B)

to

of

the

should

screws

{A)

hook

to

end

position.

center

hook

the

and

position

needle.

be

set

striking

(D

and

hook

and

rotate

point

secure

the

adjustment.

timing

the

{D)

turn

shaft

timing

direction

of

its

the

of

the

needle.

gear

gears

turn

the

(Fig.

gear

point

Re-tighten

as

close

it.

To

E.

Fig.

bushing

the

as

described

this

alternate

Turn

mark

hook

shaft.

aligns

screw

until

line

until

travel

point

cover

5).

(C)

of

to

make

5)

flange

hook

above.

setting.

hole

Re-tighten

handwheel

(F.

Replace

with

down

timing

(F)

on

bushing

remove

in

in

Fig.

"V"

5)

groove

lightly.

line

gear

flange

If

the

screw

the

casting

screw

operating

on

gear

gear

Turn

(H)

on

{B).

Fig.

hook

{C)

{G)

gear

(B)

(A)

(A).

(B)

so

in

gear

4

in

the

bushing

and

place

to

secure

direction

appears

that

spot

hook

shaft

(C)

(C)

aligns

required

flange

it

more

until

over

screw

and

and

hook

with

in

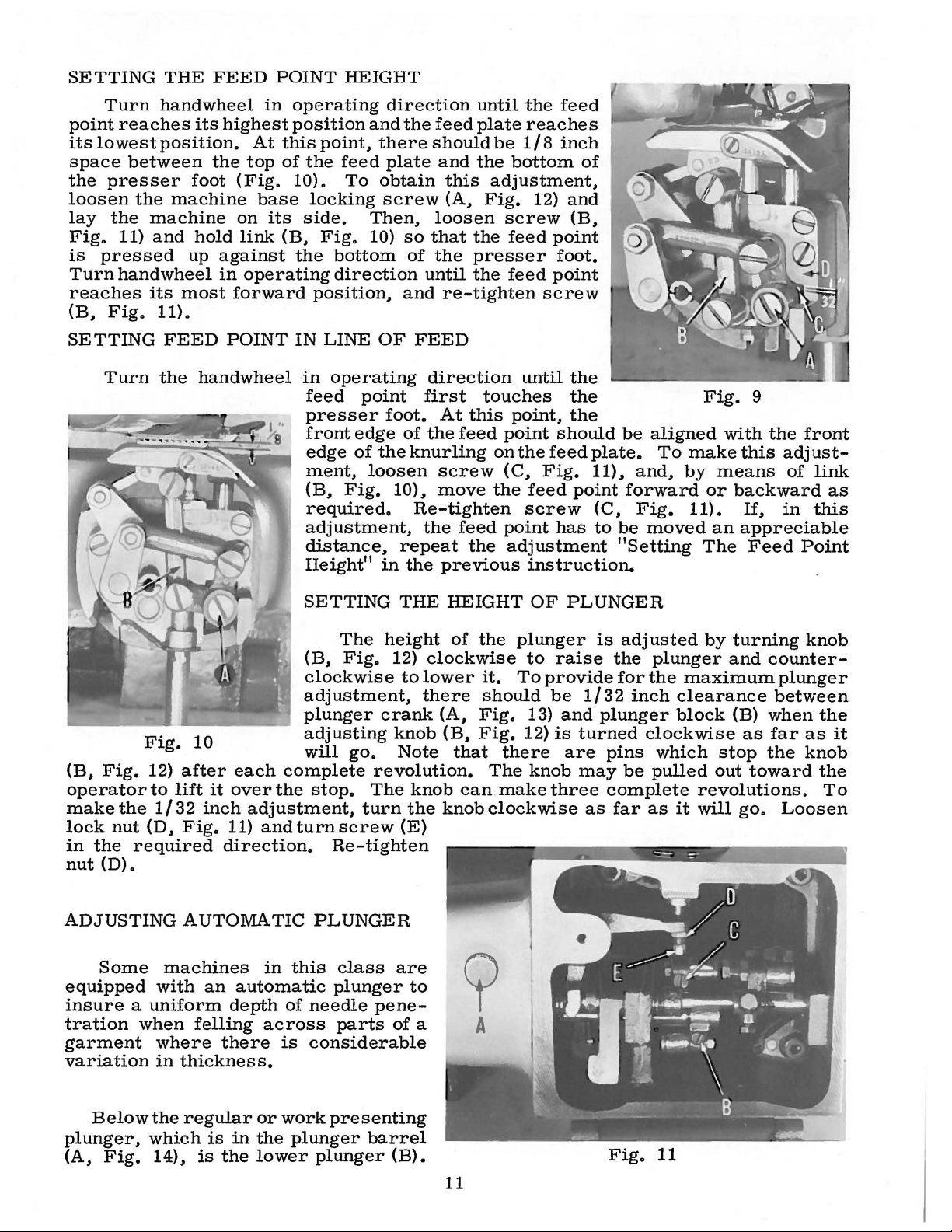

TIMING

reaches

the

needle

can

At

case

the

extension

there

bobbin

To

move

THE

Turn

the

the

be

seen.)

this

release

is a clearance

case

obtain

bobbin

required.

ADJUSTING

When

and

spreader

ference

case

properly

with

retainer.

Fig.

5

BOBBIN

handwheel

highest

carrier

point.

the

lever

of

the

(B)

and

this

adjustment.

case

release

Re-tighten

THE

LOOPER

adjusted.

must

the

move

presser

needle.

CASE

point

in

this

angular

(E)

should

bobbin

of

the

nut

or

RELEASE

in

operating

of

its

travel.

position.

projection

be

case

about

point

of

lever

(D).

AND

the

points

freely

foot,

needl~

Re-engage

(D

and

Replace

direction

(Note:

so

that

bearing

release

1/32

the

loosen

{E)

SPREADER

without

feed

{C)

inch

release

nut

up

or

of

the

any

plate.

carrier.

E)

making

gear

the

on

bobbin

against

so

between

(D)

down

looper

inter-

bobbin

cover

until

The

bobbin

that

(C).

and

as

gears

sure

(B

that

on

the

needle

photograph

case

and

all

back

and

C)

and

end

of

head.

carrier

(Fig.

bobbin

Fig.

tighten

play

7)

does

case

6

is

removed.

(A.

not

release

screws

Fig.

show

7)

9

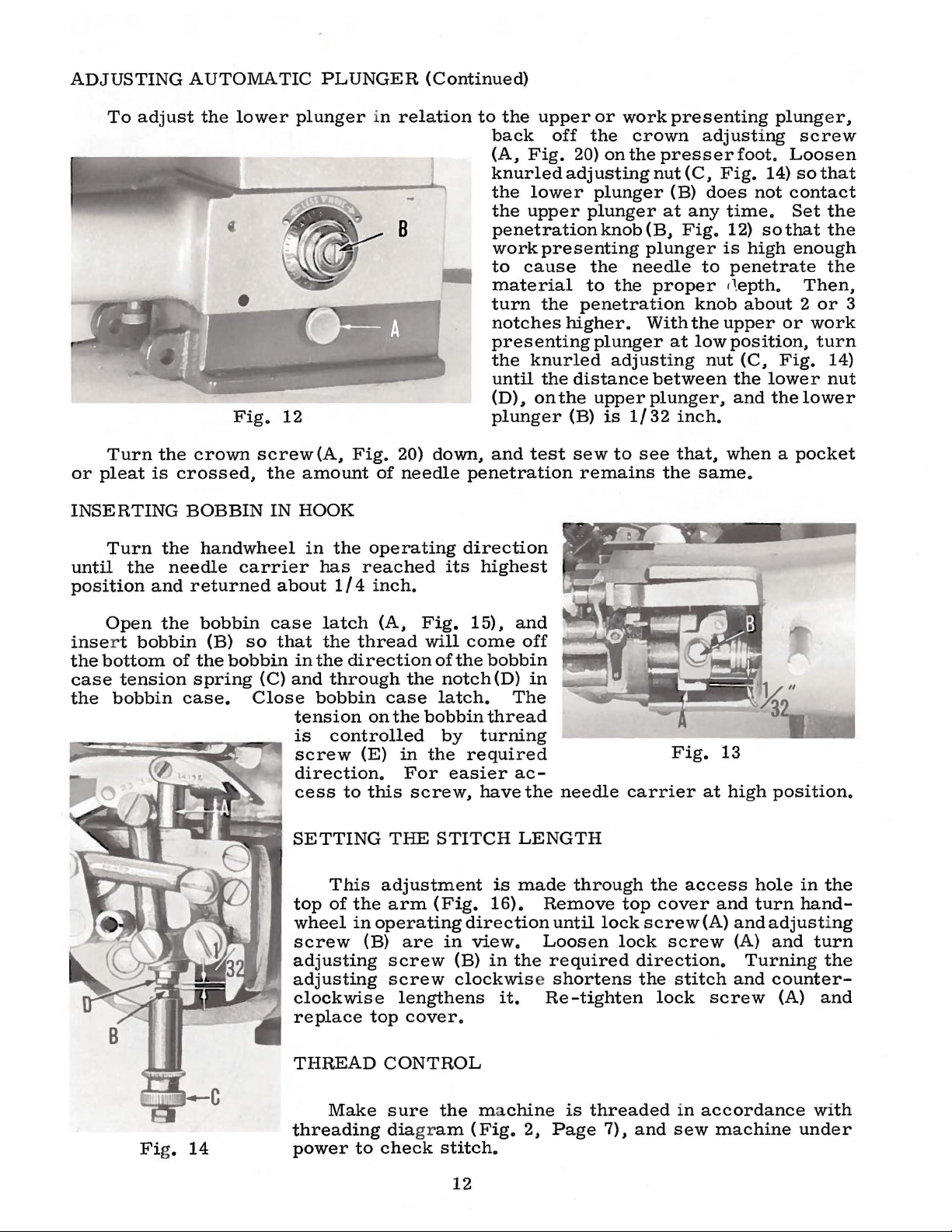

ADJUSTING

To

adjust

screws

(A

Re-tighten

any

binds.

Fig.

moving

lowest

bind

required

Turn

screw

stud

point.

or

excess

direction

handwheel

(A).

THE

and

set

and

(D)

the

B.

screw

then.

7

back

At

this

play.

slowly

LOOPER

looper

Fig.

(A).

8)

AND

and

and

and

re-tighten

down.

required

stud

loosen

required

two

slowly

appear.

necessary

mechanism.

or

bind

as a result

and

forth

position.

loosen

by

placing a screw

in

operating

SPREADER

spreader

move

turn

To

hand

set

screw

adjust

the

loosen

direction

(D).

To

Re-tighten

adjust

screw

direction

oil

holes

in

operating

Re-tighten

A

combination

that

when

very

set

screw

mechanism

whole

wheel

(B).

the

screw

the

looper

(B)

in

the

to

properly

It

also

may

of

these

the

looper

little

play

(A).

driver

direction

(Continued)

mechanism

slowly

looper

(C)

by

pulling

in

and

and

screw

and

and

turn

by

placing a screw

bushing

direction

screw

of

all

the

adjust

may

be

have

developed

adjustments.

and

should

and

turn

in

one

of

to

remove

to

the

in

operating

spreader

move

out

or

(C).

spreader

the

eccentric

and

turning.

to

remove

(B).

preceding

the

necessary

spreader

be

observed.

eccentric

the

two

right

the

or

required

direction

the

mechanism

pushing

mechanism

driver

any

adjustments

looper

to

between

This

can

mechanism

notches

any

binds

left.

loose:n

direction.

to

mechanism

in

on

the

in

bushing

Turn

binds

(E)

in

one

handwheel

that

and

spreader

remove

gears

To

bushing

be

remove

in

the

and

checked

(F

(H)

re-tighten

s et

remov

up

or

in

the

knurled

or

out.

in

the

of

the

may

may

be

any

play

and

G)

by

is

at

its

any

in

the

bushing.

e

Turn

to

make

and

sure

other

SETTING

Turn

point

has

position.

and

the

presser

To

make

and.

with

presser

the

left

hand.

1/32

plunger

inch

bearing

Turn

point

the

plate.

loosen

feed

reaches its

feed

If

screw

point

The

If

it

becomes

the

knurled

pressure

handwheel

that

parts.

THE

FEED

handwheel

reached

there

should

this

the

right

foot.

Then.

push

clearance

block

hand

wheel

point

the

is

feed

(A)

in

the

feed

plate

necessary

screw

and

counterclockwise

slowly

there

and

is

repeat

PLATE

in

operating

the

lowest

be

foot.

·

adjustment.

hand.

by

down

between

(D).

in

operating

highest

in

the

position.

center

point

and

turn

slots.

Re-tighten

pressure

to

(A.

Fig.

in

operating

no

interference

adjustments

HEIGHT

point

no

play

loosen

hold

the

holding

the

feed

Then.

of

is

not

the

is

adjusted

change

11)

for

direction

of

its

between

screw

feed

plate

the

feed

point

the

block

re-tighten

direction

and

check

the

slots

in

proper

feed

plate

screw

the

pressure.

clockwise

less.

direction

between

if

necessary.

AND

PRESSURE

until

travel.

the

feed

(A.

against

link

until

(C)

screw

until

to

in

alignment.

to

align

(A).

at

the

factory.

for

to

the

the

At

plate

Fig.

(B)

there

and

the

see

the

feed

turn

more

check

feed

this

9)

the

with

is

the

(A).

feed

that

the

the

looper

preceding

and

spreader

Fig.

adjustments

mechanism

8

10

SETTING

THE

FEED

POINT

HEIGHT

Turn

point

its

space

the

loosen

lay

Fig.

is

Turn

reaches

(B,

SETTING

reaches

lowest

between

presser

the

the

11)

pressed

hand

Fig.

Turn

handwheel

its

position.

the

foot

machine

machine

and

hold

up

against

wheel

its

most

11).

FEED

the

handwheel

in

highest

At

top

(Fig.

base

on

its

link

in

operating

forward

POINT

operating

position

this

point,

of

the

feed

10).

locking

side.

(B,

Fig.

the

bottom

direction

position,

IN

LINE

in

operating

feed

presser

front

edge

ment,

(B,

Fig.

required.

adjustment,

distance,

Height"

and

To

Then,

10)

point

edge

of

loosen

direction

the

feed

there

obtain

screw

OF

the

in

should

plate

loosen

so

that

of

the

until

and

FEED

direction

first

foot.

of

the

knurling

10).

Re-tighten

the

repeat

the

until

plate

be

and

the

this

adjustment,

(A,

Fig.

screw

the

presser

the

re-tighten

touches

At

this

feed

point

on

screw

move

previous

feed

the

(C,

the

point

the

feed

reaches

1/8

inch

bottom

12)

feed

feed

until

point,

the

feed

screw

adjustment

instruction.

of

and

(B,

point

foot.

point

screw

the

the

the

should

feed

Fig.

point

has

be

plate.

11).,

forward

(C,

to

be

"Setting

aligned

To

and,

Fig.

moved

Fig.

make

by

means

or

11).

an

The

9

with

the

this

adjust-

of

backward

If,

in

appreciable

Feed

front

link

as

this

Point

Fig.

(B,

Fig.

operator

make

lock

in

nut

ADJUSTING

equipped

insure a uniform

tration

garment

variation

the

nut

the

(D).

Some

required

when

10

12)

after

to

lift

1/32

(D,

in

inch

Fig.

AUTOMATIC

machines

with

where

an

felling

thickness.

each

it

over

adjustment,

11)

andturnscrew

direction.

in

automatic

depth

across

there

SETTING

(B,

clockwise

adjustment,

plunger

adjusting

will

complete

the

stop.

Re-tighten

PLUNGER

this

class

plunger

of

needle

parts

is

considerable

The

height

Fig.

crank

go.

revolution.

The

turn

pene-

THE

12)

clockwise

to

lower

there

knob

Note

knob

the

(E)

are

to

of

a

HEIGHT

of

the

it.

should

(A,

Fig.

(B,

Fig.

that

The

can

knob

clockwise

?

A

OF

plunger

to

To

13)

12)

there

knob

make

PLUNGER

is

raise

provide

be

1/32

and

plunger

is

turned

are

may

three

as

adjusted

the

plunger

for

the

inch

clockwise

pins

complete

be

far

which

pulled

as

by

turning

and

maximum

clearance

block

it

(B)

as

stop

out

revolutions.

will

go.

counter-

plunger

between

when

far

the

toward

Loosen

knob

the

as

it

knob

the

To

Belowthe

plunger,

(A,

Fig.

regular

which

14),

is

is

in

the

or

work

the

plunger

lower

presenting

barrel

plunger

(B).

11

Fig.

11

ADJUSTING

To

adjust

AUTOMATIC

the

lower

•

Fig.

plunger

12

PLUNGER

in

relation

8

(Continued)

to

the

back

(A,

knurled

the

the

penetrationknob(B,

work

to

material

turn

notches

presenting

the

until

(D),

plunger

upper

off

Fig.

20)

adjusting

lower

upper

presenting

cause

the

penetration

higher.

knurled

the

distance

on

the

(B)

or

work

the

crown

on

the

plunger

plunger

the

needle

to

the

plunger

adjusting

upper

is

1/32

presenting

adjusting

presser

nut ( C,

(B)

at

any

Fig.

plunger

to

proper

knob

With

the

at

low

between

plunger,

inch.

foot.

Fig.

does

time.

12)

is

high

penetrate

,l.

epth.

about 2 or

upper

position,

nut

(C,

the

and

plunger,

Loosen

14)

not

contact

Set

sothat

enough

or

Fig.

lower

the

screw

so

that

the

the

the

Then,

work

turn

14)

nut

lower

3

Turn

or

pleat

INSERTING

Turn

until

position

Open

inse

r t

the

bottom

case

the

the

is

the

the

and

the

bobbin

tension

bobbin

crown

crossed,

BOBBIN

handwheel

needle

returned

bobbin

(B)

of

the

spring

case.

screw

the

IN

carrier

about

case

so

that

bobbin

(C)

Close

(A,

Fig.

amount

HOOK

in

the

has

reached

1/4

latch

the

thread

in

the

direction

and

through

bobbin

tension

is

controlled

screw

direction.

cess

SETTING

top

wheel

screw

adjusting

adjusting

clockwise

replace

to

This

of

the

in

(E)

20)

of

needle

operating

inch.

(A,

Fig.

will

the

case

on

the

bobbin

in

the

For

this

screw,

THE

adjustment

arm

operating

(B)

are

screw

screw

lengthens

top

cover.

down,

ofthe

notch(D)

latch.

by

STITCH

(Fig.

in

and

test

penetration

direction

its

highest

15),

and

come

required

easier

direction

view.

(B)

clockwise shortens

off

bobbin

in

The

thread

turning

ac-

have

the

LENGTH

is

made

16).

in

the

it.

needle

Remove

until

Loosen

required

Re-tighten

sew

to

remains

carrier

through

top

lock

lock

see

that,

the

same.

Fig.

at

the

access

cover

screw(A)

screw

direction.

the

stitch

lock

when a pocket

13

high

position.

hole

in

and

turn

hand-

and

adjusting

(A)

and

Turning

and

counter-

screw

(A)

the

turn

the

and

Fi

g.

14

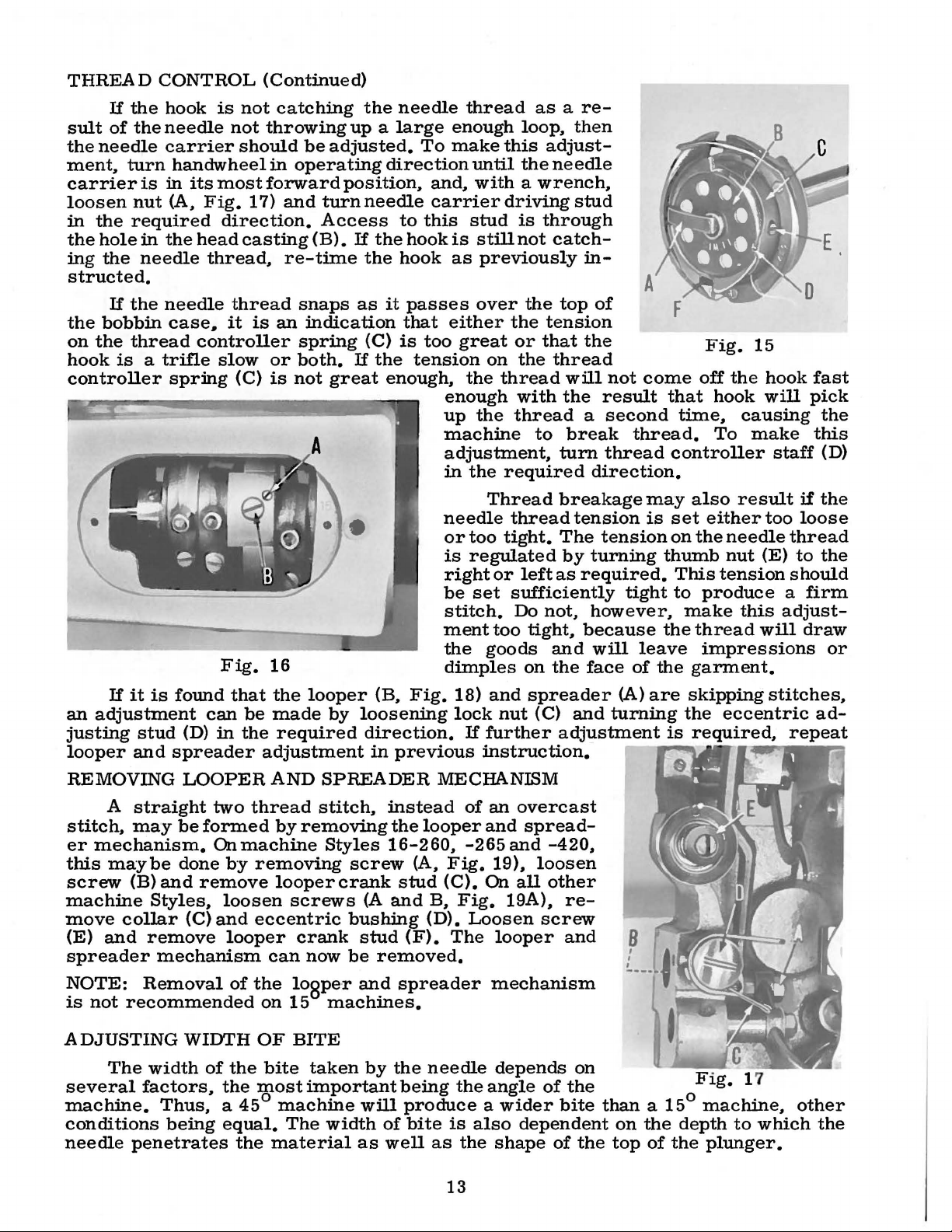

THREAD

Make

threading

power

CONTROL

sure

diagram

to

check

the

ma

(Fig.

stitch.

12

chine

2,

Page

is

threaded

7),

and

in

accordance

sew

machine

with

under

THREAD

If

the

sult

of

the

the

needle

ment.

carrier

loosen

in

the

ing

structed.

the

on

hook

controller

turn

is

nut

the

required

hole

in

the

needle

If

the

bobbin

the

thread

is a trifle

CONTROL

hook

needle

carrier

in

(A.

the

needle

case,

spring

is

not

not

should

handwheelin

its

most

Fig.

direction.

head

casting

thread.

thread

it

controller

slow

(C)

(Continued)

catching

throwing

be

adjusted.

operating

forward

17)

and

turn

Access

(B).

re-time

snaps

is

an

indication

spring

or

both.

is

not

great

the

needle

up a large

direction

position.

needle

to

If

the

hook

the

hook

as

it

passes

that

(C)

is

If

the

tension

enough.

thread

enough

To

make

until

and.

with a wrench.

carrier

this

stud

is

still

as

previously

over

either

too

great

on

the

enough

up

the

machine

adjustment.

in

the

as a re-

loop.

this

adjust-

the

needle

driving

is

through

not

catch-

the

top

the

tension

or

that

the

thread

thread

with

thread

to

turn

required

then

stud

in-

of

the

will

the

result

a

second

break

thread

direction.

not

thread.

A

come

that

time.

controller

Fig.

off

hook

To

15

the

hook

will

causing

make

staff

fast

pick

the

this

(D)

If

it

is

an

adjustment

justing

looper

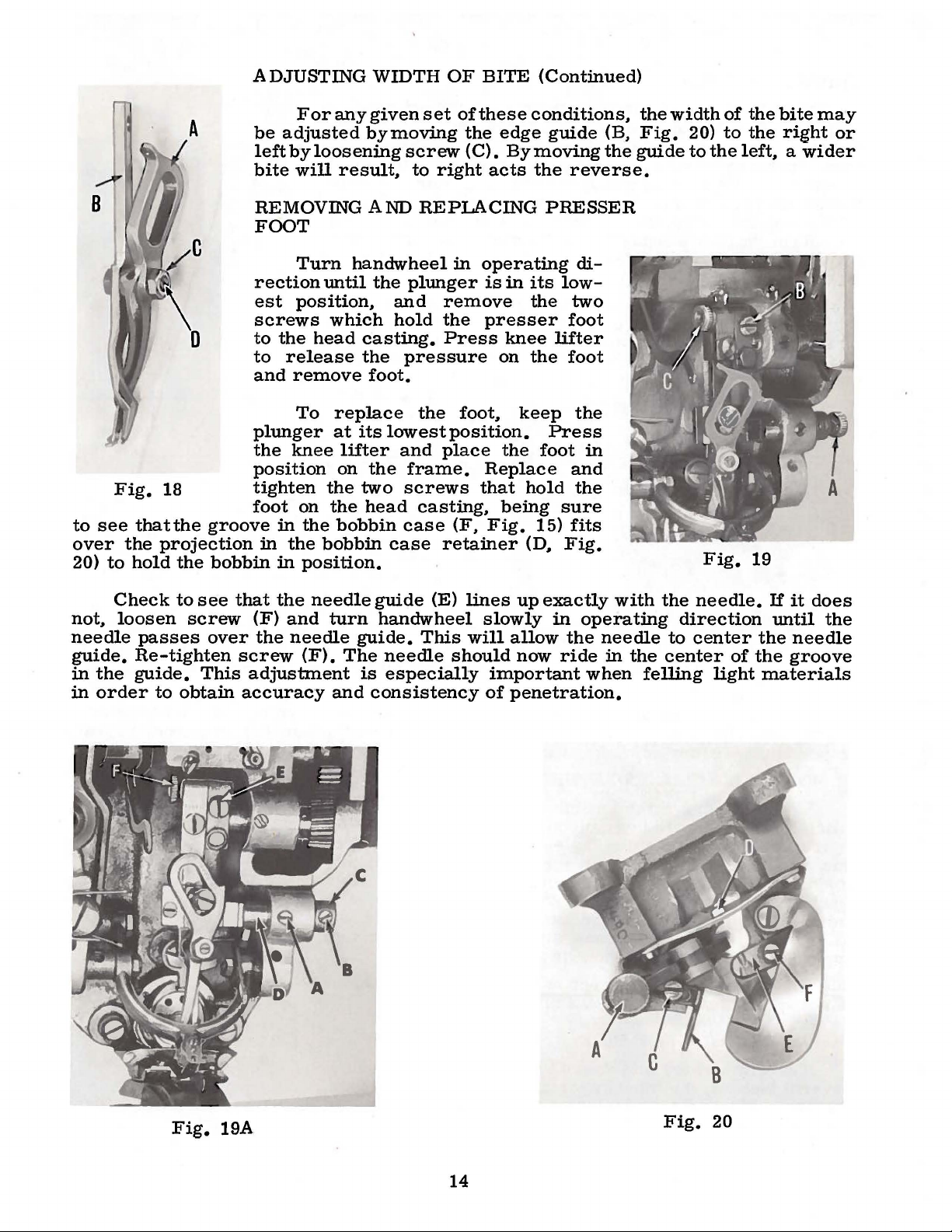

REMOVING

stitch.

er

this

screw

machine

move

(E)

spreader

NOTE:

is

not

stud

and

straight

A

may

mechanism.

maybe

(B)

and

Styles.

collar

and

remove

mechanism

Removal

recommended

Fig.

found

(D)

spreader

LOOPER

be

done

can

in

two

formed

On

by

remove

loosen

(C)

and

looper

that

of

16

the

be

made

the

required

adjustment

AND

thread

by

removing

machine

removing

looper

screws

eccentric

crank

can

the

lospe

on

15

looper

SPREADER

stitch.

Styles

now

machines.

by

loosening

direction.

in

screw

crank

(A

bushing

stud

be

·r

and

(B.

instead

16-260.

removed.

needle

or

is

right

be

stitch.

ment

the

dimples

Fig.

18)

lock

previous

MECHANISM

the

looper

(A.

Fig.

stud

(C).

and

B.

Fig.

(D).

(F).

The

spreader

Thread

thread

too

tight.

regulated

or

left

set

sufficiently

Do

too

tight.

goods

on

and

spreader

nut

(C)

If

further

instruction.

of

an

overcast

and

spread-

-265

and

19).

loosen

On

all

19A).

Loosen

looper

mechanism

breakage

tension

The

tension

by

turning

as

required.

not.

however.

because

and

will

the

face

and

adjustment

-420.

other

re-

screw

and

may

is

thumb

tight

the

leave

of

the

(A)

are

turning

B

,

,

,

also

set

either

on

the

needle

nut

This

tension

to

produce

make

thread

impressions

garment.

skipping

the

eccentric

is

required.

result

too

(E)

this

will

stitches.

if

the

loose

thread

to

the

should

a

firm

adjust-

draw

or

ad-

repeat

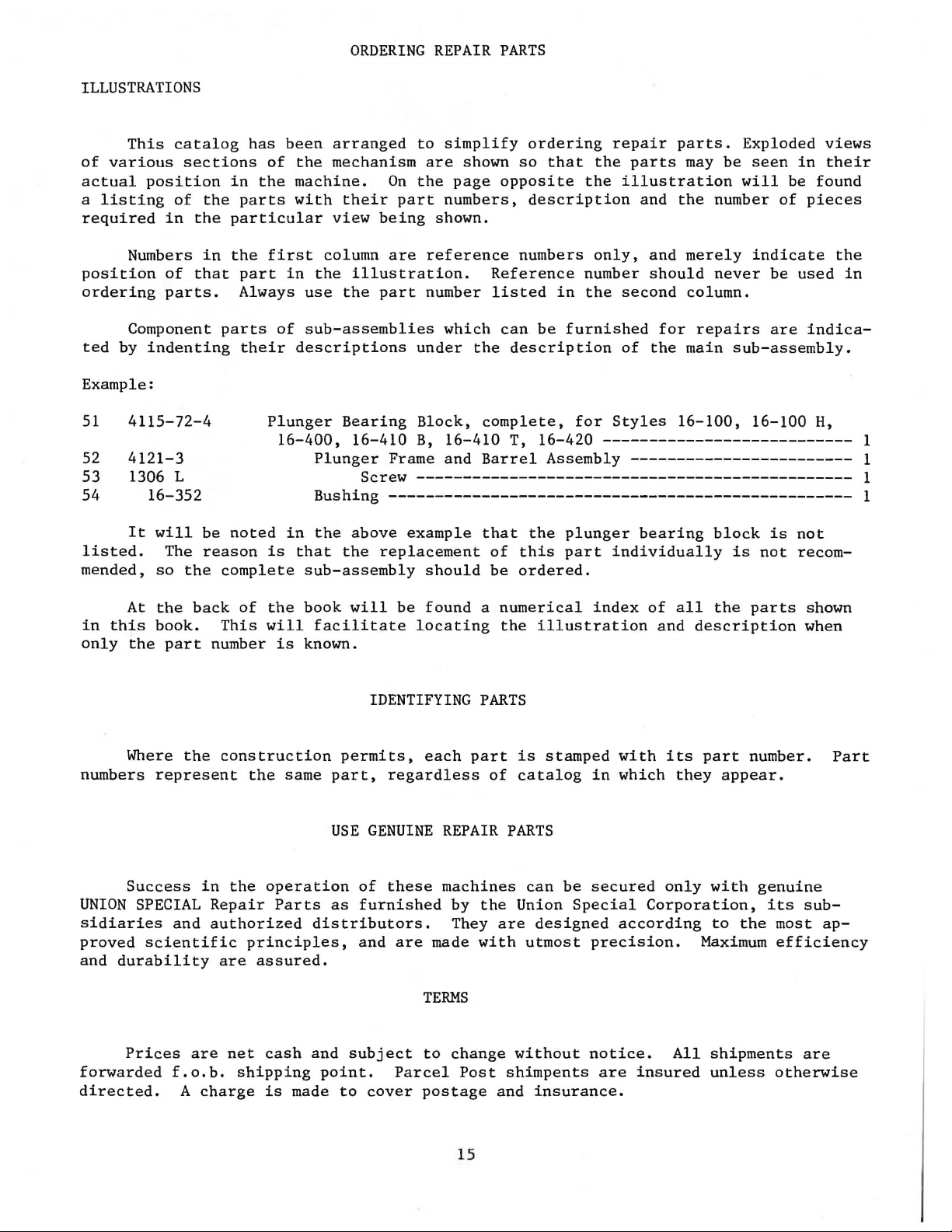

ADJUSTING

The

several

machine.

conditions

needle

penetrates

WIDTH

width

factors.

of

the

Thus. a 45°

being

equal.

the

the

OF

BITE

bite

most

machine

The

material

taken

important

by

will

width

as

the

needle

being

produce a wider

of

bite

well

as

13

the

is

the

depends

angle

also

shape

of

bite

dependent

of

on

the

than a 15°

on

the

top

the

of

Flg.

machine.

depth

the

plunger.

.

7

1

other

to

which

the

ADJUSTING

WIDTH

OF

BITE

(Continued)

to

see

over

20)

Fig.

the

to

18

thatthe

projection

hold

the

A

groove

bobbin

Foranygivenset

be

adjusted

left

by

loosening

bite

will

result~

REMOVING

FOOT

Turn

rection

est

screws

to

to

and

plunger

the

position

tighten

foot

in

until

position~

which

the

head

release

remove

To

replace

at

knee

lifter

on

the

on

the

in

the

bobbin

the

bobbin

in

position.

bymoving

screw

to

AND

REPLACING

handwheel

the

plunger

and

hold

casting.

the

pressure

foot.

the

its

lowest

and

the

frame.

two

screws

head

casting~

case

case

oftheseconditions~

the

(C).

right

edge

acts

guide

Bymovingthe

the

reverse.

thewidthof

(B.

Fig.

guide

PRESSER

in

operating

is

remove

the

presser

Press

on

foot~

position.

place

the

Replace

that

being

(F~

Fig.

retainer

in

its

the

knee

the

keep

hold

(D~

low-

lifter

Press

foot

sure

15)

Fig.

di-

two

foot

foot

the

in

and

the

fits

20)

to

Fig.

thebitemay

to

the

the

left~

19

right

a

wider

or

Check

not~

loosen

needle

guide.

in

the

in

order

to

see

screw

passes

over

Re-tighten

guide.

to

This

obtain

that

the

(F)

and

the

needle

screw

(F).

adjustment

accuracy

needle

turn

guide.

The

and

guide

(E)

handwheel

This

needle

is

especially

consistency

lines

slowly

will

should

important

of

up

exactly

in

operating

allow

now

the

ride

needle

when

penetration.

with

in

the

the

center

felling

needle.

direction

to

center

light

If

the

of

the

materials

it

until

needle

groove

does

the

Fig.

19A

14

Fig.

20

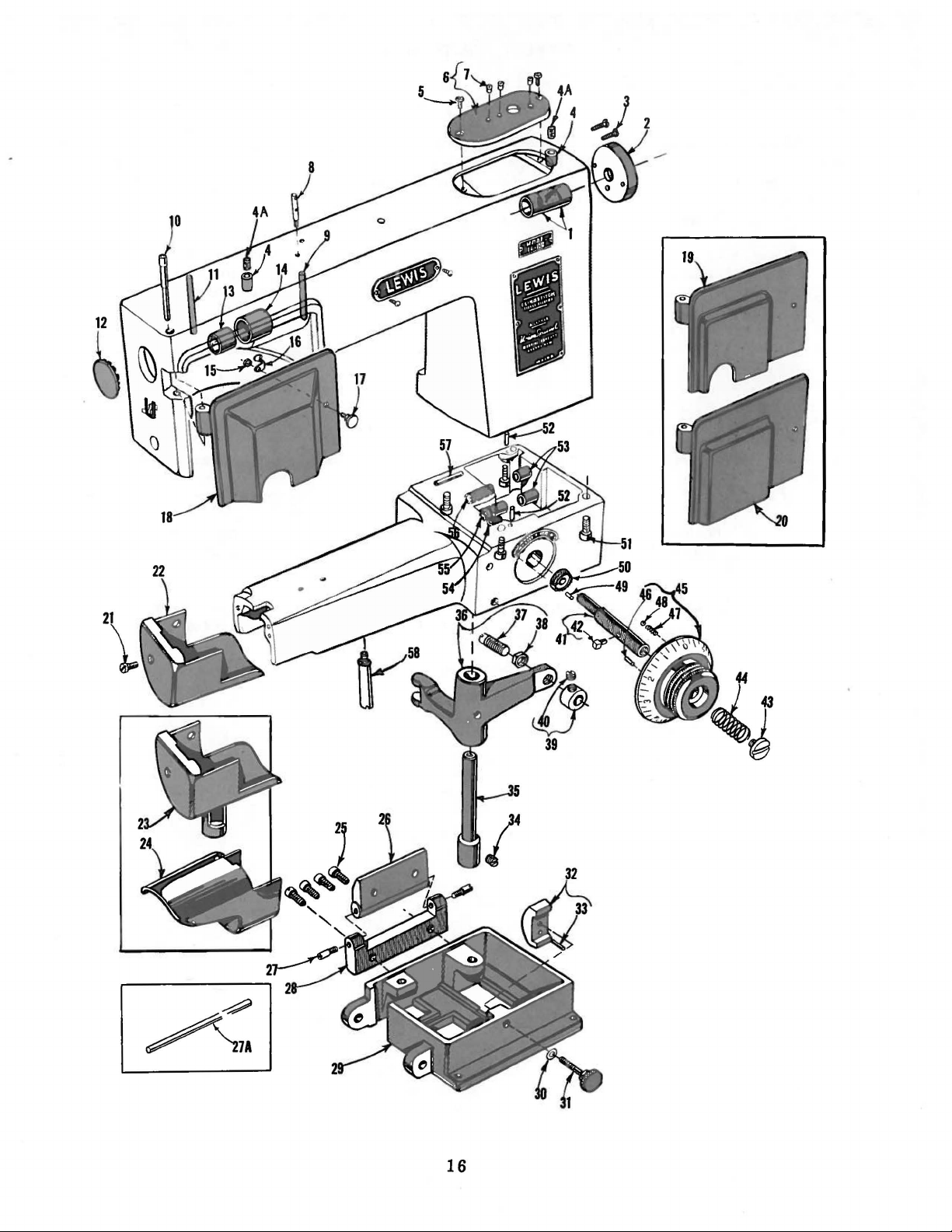

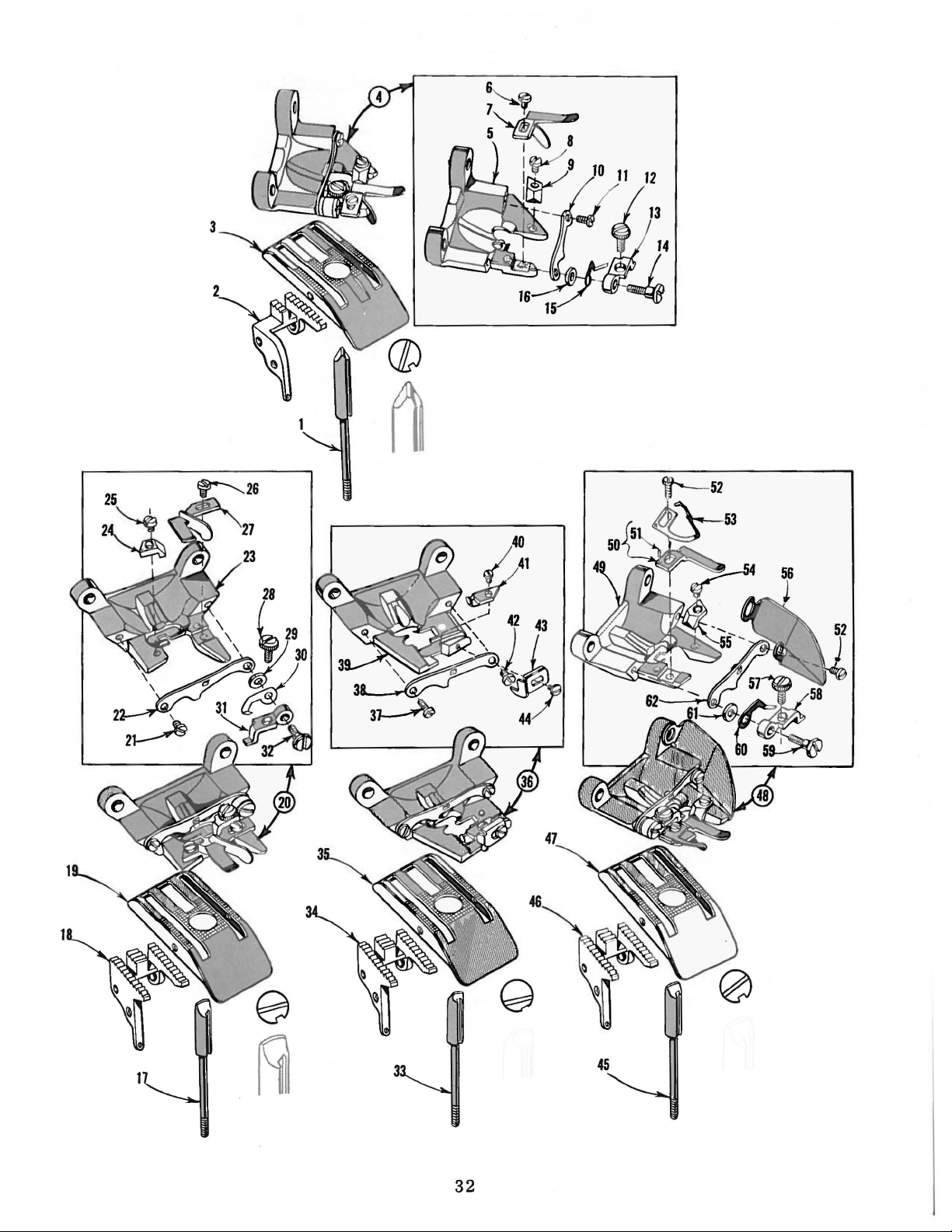

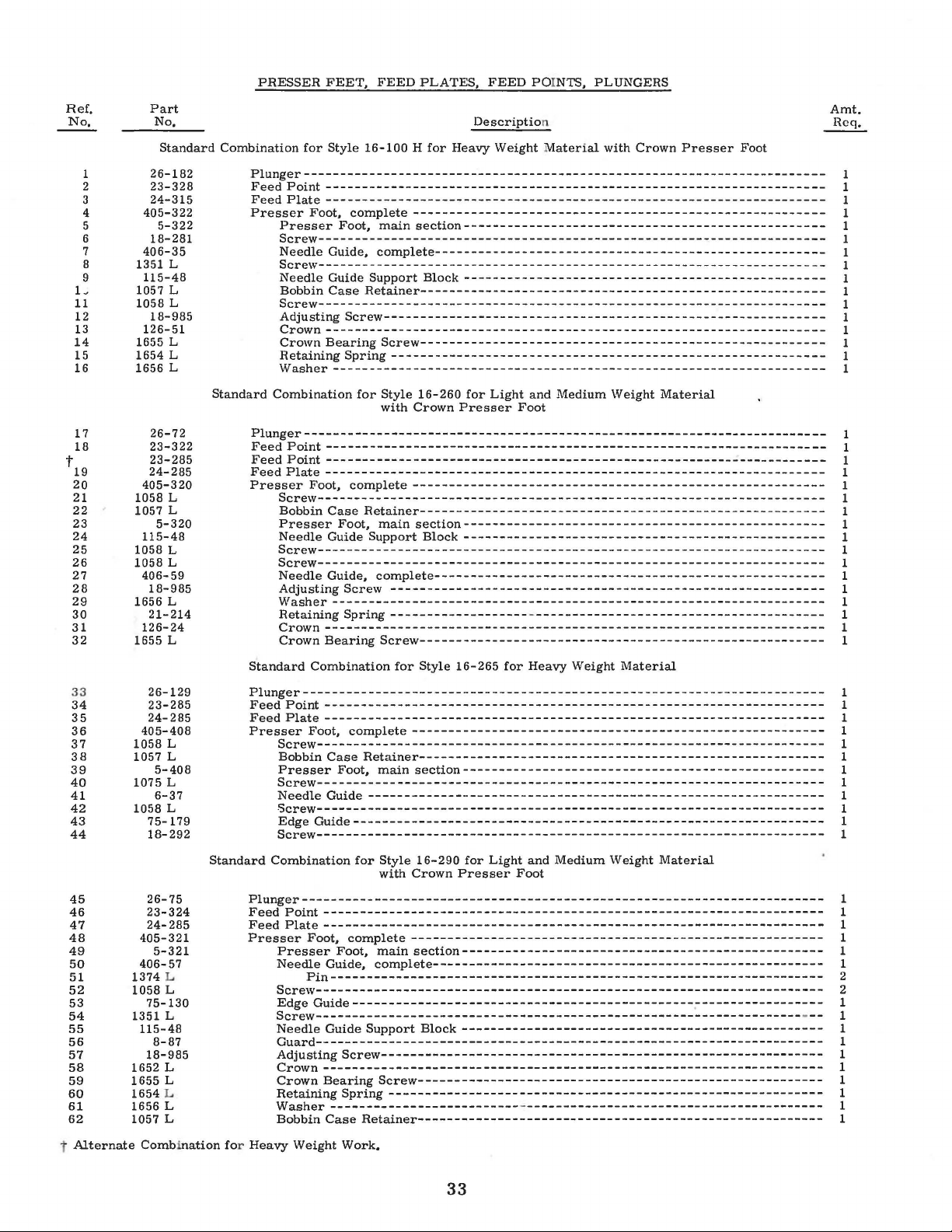

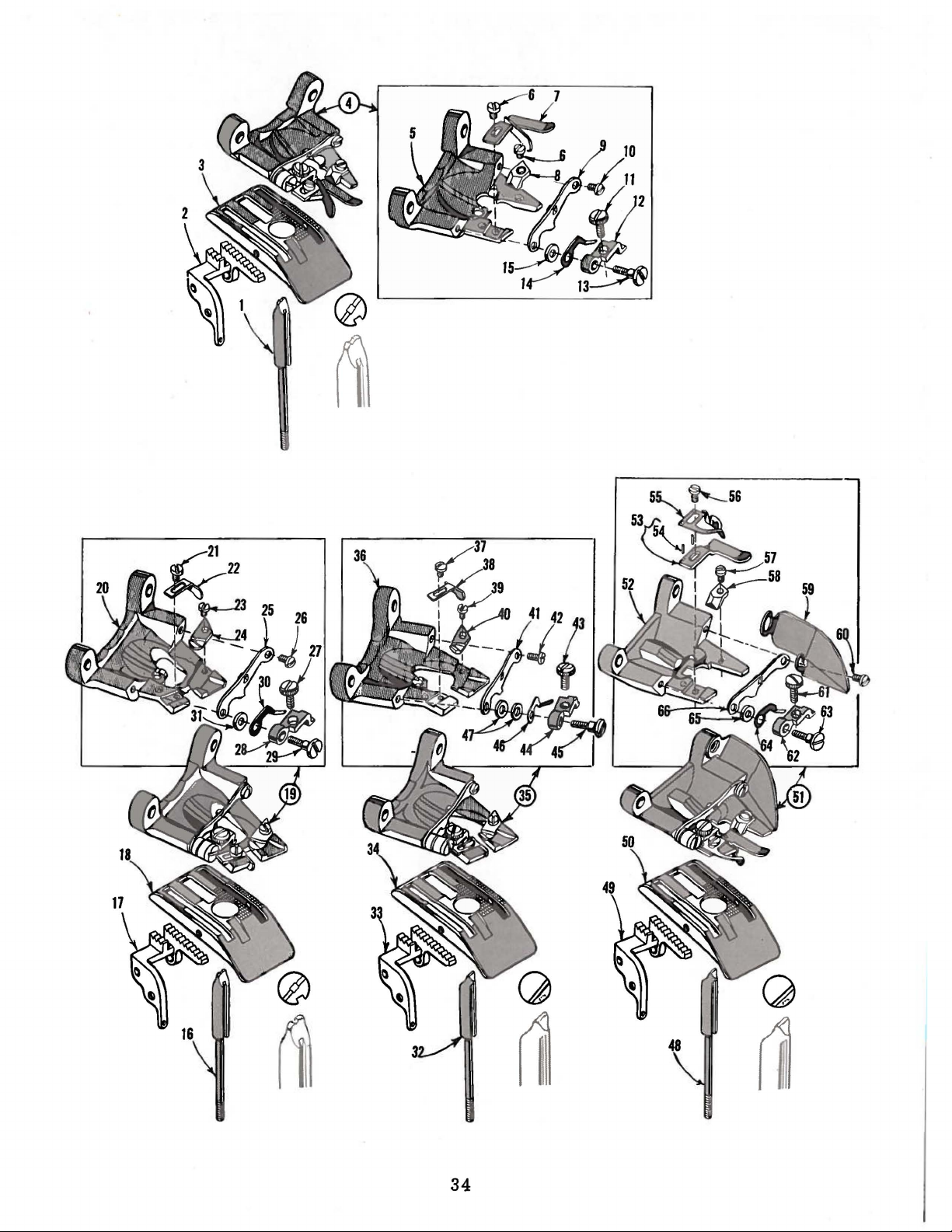

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

This

of

various

actual

a

listing

required

Numbers

position

ordering

Component

ted

by

Example:

51

4115-72-4

52

4121-3

53

54

listed.

mended,

1306 L

It

catalog

sections

position

of

the

in

the

in

of

that

parts.

indenting

16-352

will

The

so

be

reason

the

has

of

in

the

parts

particular

the

first

part

Always

parts

noted

complete

of

their

Plunger

16-400,

is

been

in

in

arranged

the

mechanism

machine.

with

descriptions

that

their

view

column

the

illustration.

use

the

sub-assemblies

Bearing

16-410

Plunger

Screw

Bushing

the

above

the

sub-assembly

to

simplify

are

shown

On

the

page

part

being

are

part

Frame

--------------------------------------------------

replacement

numbers,

shown.

reference

number

which

under

Block,

B,

-----------------------------------------------

example

should

the

16-410

and

ordering

so

opposite

description

numbers

Reference

listed

can

be

description

complete,

T,

16-420

Barrel

that

of

be

the

this

ordered.

repair

that

Assembly

the

the

only,

number

in

the

furnished

for

Styles

---------------------------

plunger

part

individually

parts.

parts

illustration

and

the

and

should

second

for

of

the

16-100,

------------------------

bearing

may

be

number

merely

never

column.

repairs

main

sub-assembly.

block

is

Exploded

seen

in

will

be

of

indicate

be

used

are

16-100

is

not

not

recom-

views

their

found

pieces

the

in

indica-

H,

1

1

1

1

At

in

this

only

numbers

UNION

sidiaries

proved

and

forwarded

directed.

the

Where

Success

SPECIAL

scientific

durability

Prices

the

back

book.

part

number

the

represent

in

Repair

and

authorized

are

f.o.b.

A

charge

of

the

This

will

is

construction

the

same

the

operation

Parts

principles,

are

assured.

net

cash

shipping

is

made

book

will

facilitate

known.

IDENTIFYING

permits,

part,

USE

GENUINE

of

as

furnished

distributors.

and

and

subject

point.

to

cover

be

found a numerical

locating

PARTS

each

regardless

these

are

TERMS

to

Parcel

postage

part

REPAIR

machines

by

the

They

made

with

change

Post

of

the

illustration

is

stamped

catalog

PARTS

can

Union

are

designed

utmost

without

shimpents

and

insurance.

index

in

be

secured

Special

precision.

notice.

are

of

all

and

with

which

according

its

they

only

Corporation,

All

insured

the

parts

description

part

Maximum

number.

appear.

with

genuine

its

to

the

shipments

unless

shown

when

Part

sub-

most

otherwise

ap-

efficiency

are

15

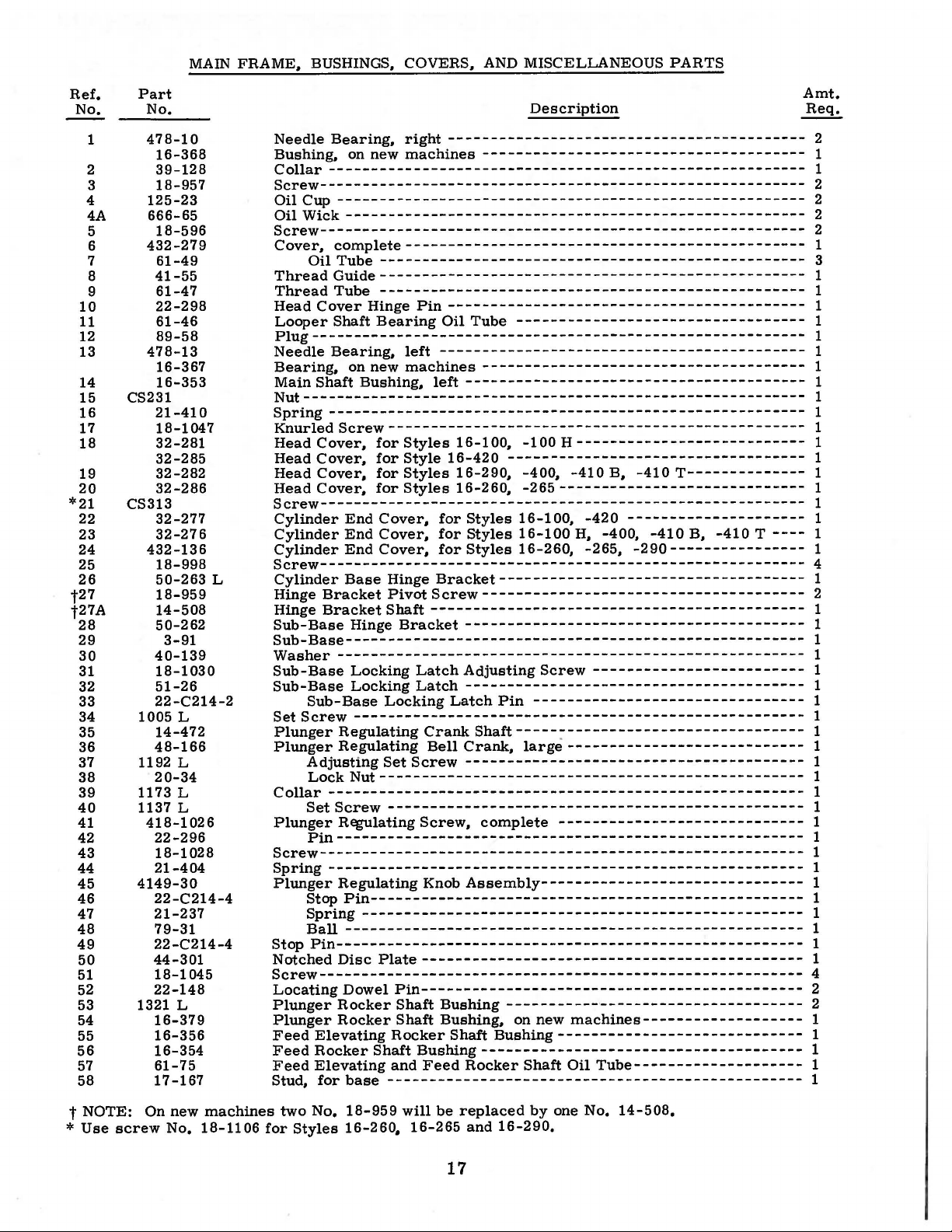

16

MAIN

FRAME.

BUSHINGS.

COVERS.

AND

MISCELLANEOUS

PARTS

Ref.

No.

1

2

3

4

4A

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

*21

22

23

24

25

26

t27

t27A

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Part

No.

478-10

16-368

39-128

18-957

125-23

666-65

18-596

432-279

61-49

41-55

61-47

22-298

61-46

89-58

478-13

16-367

16-353

CS231

21-410

18-1047

32-281

32-285

32-282

32-286

CS313

32-277

32-276

432-136

18-998

50-263

18-959

14-508

50-262

40-139

18-1030

51-26

22-C214-2

1005

14-472

48-166

1192 L

20-34

1173

1137

418-102

22-296

18-1028

21-404

4149-30

22-C214-4

21-237

79-31

22-C214-4

44-301

18-1045

22-148

1321 L

16-379

16-356

16-354

61-75

17-167

3-91

L

L

L

Description

Needle

Bushing.

Collar

Screw--------------------------------------------------------Oil

Oil

Screw--------------------------------------------------------Cover.

ThreadGuide-------------------------------------------------Thread

Head

Looper

Plug----------------------------------------------------------

Needle

Bearing.

Main

Nut-----------------------------------------------------------

Spring

Knurled

Head

Head

Head

Head

Screw---------------------------------------------------------

Cylinder

Cylinder

Cylinder

Screw---------------------------------------------------------

L

6

Cylinder

Hinge

Hinge

Sub-Base

Sub-Base------------------------------------------------------

Washer

Sub-Base

Sub-Base

SetScrew-----------------------------------------------------

Plunger

Plunger

Collar

Plunger

Screw--------------------------------------------------------Spring

Plunger

Stop

Notched

Screw---------------------------------------------------------

Locating

Plunger

Plunger

Feed

Feed

Feed

Stud.

Bearing.

on

--------------------------------------------------------

Cup

-------------------------------------------------------

Wick------------------------------------------------------

complete-----------------------------------------------

Oil

Tube

Tube

Cover

Shaft

Bearing.

on

Shaft

-------------------------------------------------------Screw-------------------------------------------------

Cover.

Cover.

Cover.

Cover.

End

End

End

Base

Bracket

Bracket

Hinge

------------------------------------------------------Locking

Locking

Sub-Base

Regulating

Regulating

Adjusting

LockNut--------------------------------------------------

--------------------------------------------------------

SetScrew-------------------------------------------------

Regulating

Pin-------------------------------------------------------

-------------------------------------------------------Regulating

Stop

Pin---------------------------------------------------

Spring

Ball

------------------------------------------------------

Pin-------------------------------------------------------

Disc

Dowel

Rocker

Rocker

Elevating

Rocker

Elevating

for

base

right

------------------------------------------

new

machines

--------------------------------------------------

--------------------------------------------------

Hinge

new

Bushing.

----------------------------------------------------

Pin

Bearing

left

machines

left

for

Styles

for

Style

for

Styles

for

Styles

Cover.

Cover.

Cover.

Hinge

Pivot

Screw--------------------------------------

Shaft

--------------------------------------------

Bracket

Latch

Latch

Locking

Crank

Bell

Set

Screw

Screw.

Knob

Plate

---------------------------------------------

Pin---------------------------------------------

Shaft

Shaft

Rocker

Shaft

Bushing--------------------------------------

and

Feed

-------------------------------------------------

--------------------------------------

------------------------------------------

Oil

Tube

----------------------------------

-------------------------------------------

--------------------------------------

----------------------------------------

16-100.

16-420

16-290.

16-260.

for

Styles

for

Styles

for

Styles

Bracket------------------------------------

----------------------------------------

Adjusting

----------------------------------------

Latch

Shaft-----:-----------------------------

Crank.

----------------------------------------

Assembly-------------------------------

Bushing

Bushing.

Shaft

Rocker

-100 H ---------------------------

-----------------------------------

-400.

-265

16-100.

16-100

16-260.

Pin--------------------------------

complete

-----------·-----------------------on

Bushing-----------------------------

-410

B.

-----------------------------

-420

H.

-265.

Screw

large----------------------------

-----------------------------

new

machines-------------------

Shaft

Oil

-410

---------------------

-400.

-290----------------

-------------------------

Tube--------------------

T--------------

-410

B.

-410 T ----

Amt.

Req.

2

1

1

2

2

2

2

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

2

2

1

1

1

1

1

NOTE:

t

*

Use

On

screw

new

No.

machines

18-1106

for

two

Styles

No.

18-959

16-260.

will

16-265

be

replaced

and

by

16-290.

one

17

No.

14-508.

15

1

3"-1

TORQ~.

17-19

£0-22

TO

ern.

lbs.

kg;_

)

18

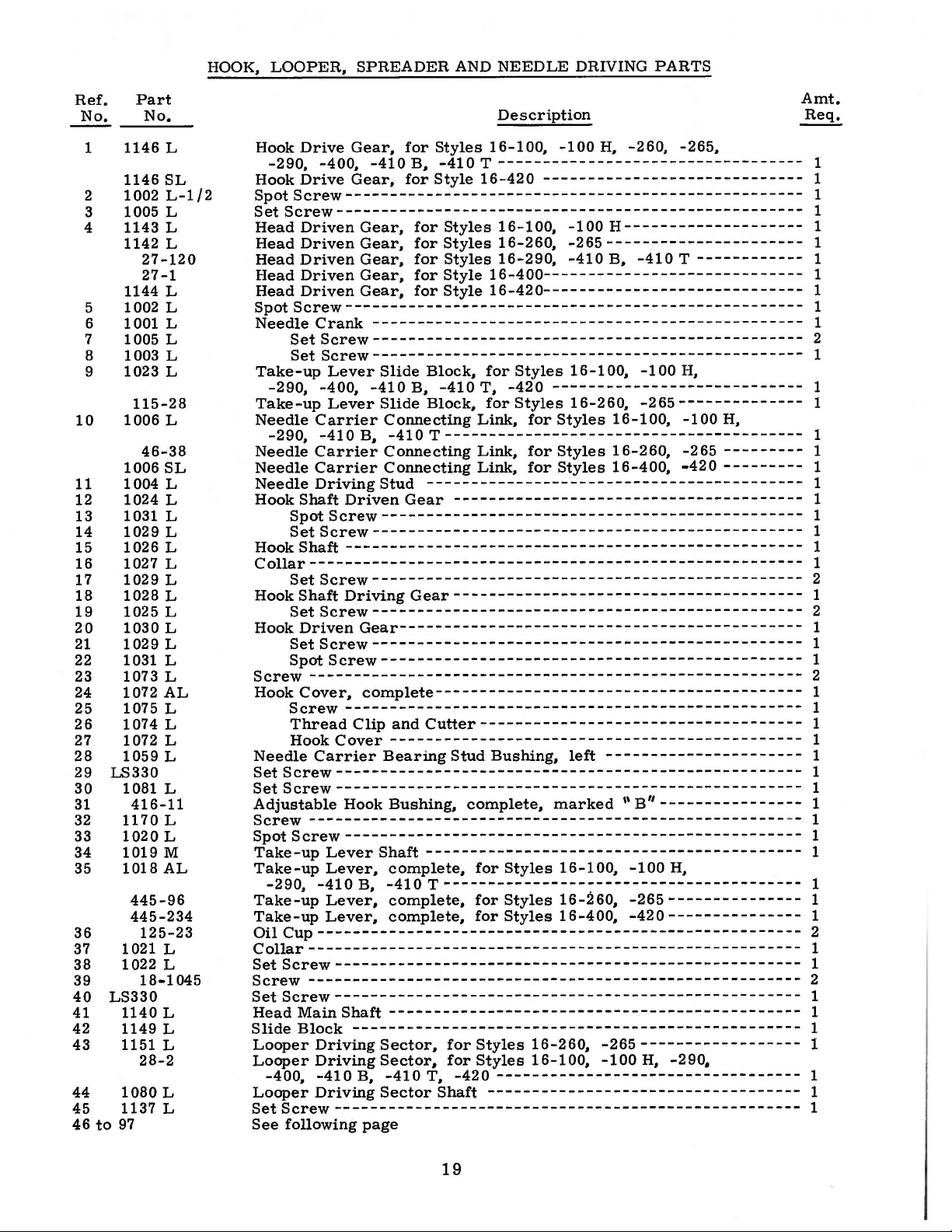

HOOK,

LOOPER,

SPREADER

AND

NEEDLE

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

LS330

LS330

1151 L

1080

1137 L

to

97

Part

No.

1146

1146

SL

1002

1005 L

1143 L

1142 L

27-120

27-1

1144 L

1002 L

1001 L

1005 L

1003 L

1023 L

115-28

1006

46-38

1006

SL

1004

1024

1031 L

1029

1026

L

1027 L

1029

L

1028

L

1025 L

1030

L

1029

L

1031 L

1073

L

1072

AL

1075 L

1074

L

1072 L

1059

L

1081 L

416-11

1170

L

1020

L

1019

M

1018

AL

445-96

445-234

125-23

1021 L

1022

L

18-1045

1140

L

1149

L

28-2

L

L

L-1/2

L

L

L

L

Description

Hook

-290,

Hook

Drive

Drive

-400,

Gear,

-410

Gear,

for

Styles

B,

-410 T ----------------------------------

for

Style

16-100,

16-420

-100

H,

-----------------------------

-260, -265,

SpotScrew---------------------------------------------------

Set

Screw----------------------------------------------------

Head

Driven

Head

Driven

Head

Driven

Head

Driven

Head

Driven

Spot

Screw---------------------------------------------------

Needle

Set

Set

Take

-up

-290,

Take-up

Needle

-290,

Needle

Needle

Needle

Hook

Shaft

Spot

Set

HookShaft

Collar-------------------------------------------------------

Set

Hook

Shaft

Set

Gear,

Gear,

Gear,

Gear,

Gear,

Crank

Screw------------------------------------------------

for

for

for

for

for

Styles

Styles

Styles

Style

Style

16-100,

16-260,

16-290,

-100

H--------------------

-265----------------------

-410

B,

16-400----------------------------16-420-----------------------------

------------------------------------------------

Screw------------------------------------------------

Lever

-400,

Lever

Carrier

-410

Carrier

Carrier

Driving

Slide

Block,

-410

B,

Slide

-410

Block,

Connecting

B,

-410 T ---------------------------------------Connecting

Connecting

Stud

------------------------------------------

Driven

Gear

for

T,

for

Link,

Link,

Link,

Styles

-420

Styles

16-1

---------------------------16-260,

for

Styles

for

Styles

for

Styles

---------------------------------------

00,

16-100,

16-260,

16-400,

Screw-----------------------------------------------

Screw------------------------------------------------

---------------------------------------------------

Screw------------------------------------------------

Driving

Gear---------------------------------------

Screw------------------------------------------------

HookDrivenGear---------------------------------------------

Set

Screw------------------------------------------------

Spot

Screw-----------------------------------------------

Screw

HookCover,

------------------------------------------------------complete-----------------------------------------

Screw---------------------------------------------------

Thread

Hook

Needle

Set

Screw----------------------------------------------------

Clip

and

Cutter------------------------------------

Cover----------------------------------------------

Carrier

Bearing

Stud

Bushing,

left

----------------------

SetScrew---------------------------------------------------Adjustable

Screw

SpotScrew---------------------------------------------------

Take-up

Take-up

-290,

Take-up

Take-up

Oil

Cup------------------------------------------------------

Hook

Bushing,

complete,

marked

----------------------------------------------------Lever

Lever,

-410

Lever,

Lever,

Shaft------------------------------------------

complete,

B,

-410 T ---------------------------------------complete,

complete,

for

for

for

Styles

Styles

Styles

16-100,

16-260,

16-400,

''

-100

-265---------------

-420---------------

Collar------------------------------------------------------Set

Screw----------------------------------------------------

Screw

Set

Head

Slide

Looper

Looper

Looper

-------------------------------------------------------

Screw----------------------------------------------------

Main

-400,

Block

Driving

Driving

-410

Driving

Shaft

----------------------------------------------

--------------------------------------------------

B,

Sector,

Sector,

-410

Sector

T,

Shaft

for

for

-420

Styles

Styles

16-260,

16-100,

----------------------------------

-----------------------------------

-265------------------

-100

SetScrew---------------------------------------------------See

following

page

-410 T ------------

-1

00 H,

-265--------------

-100

H,

-265

---------

-420

---------

1

B'

----------------

H,

H,

-290,

Amt.

Req.

- - 1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

1

19

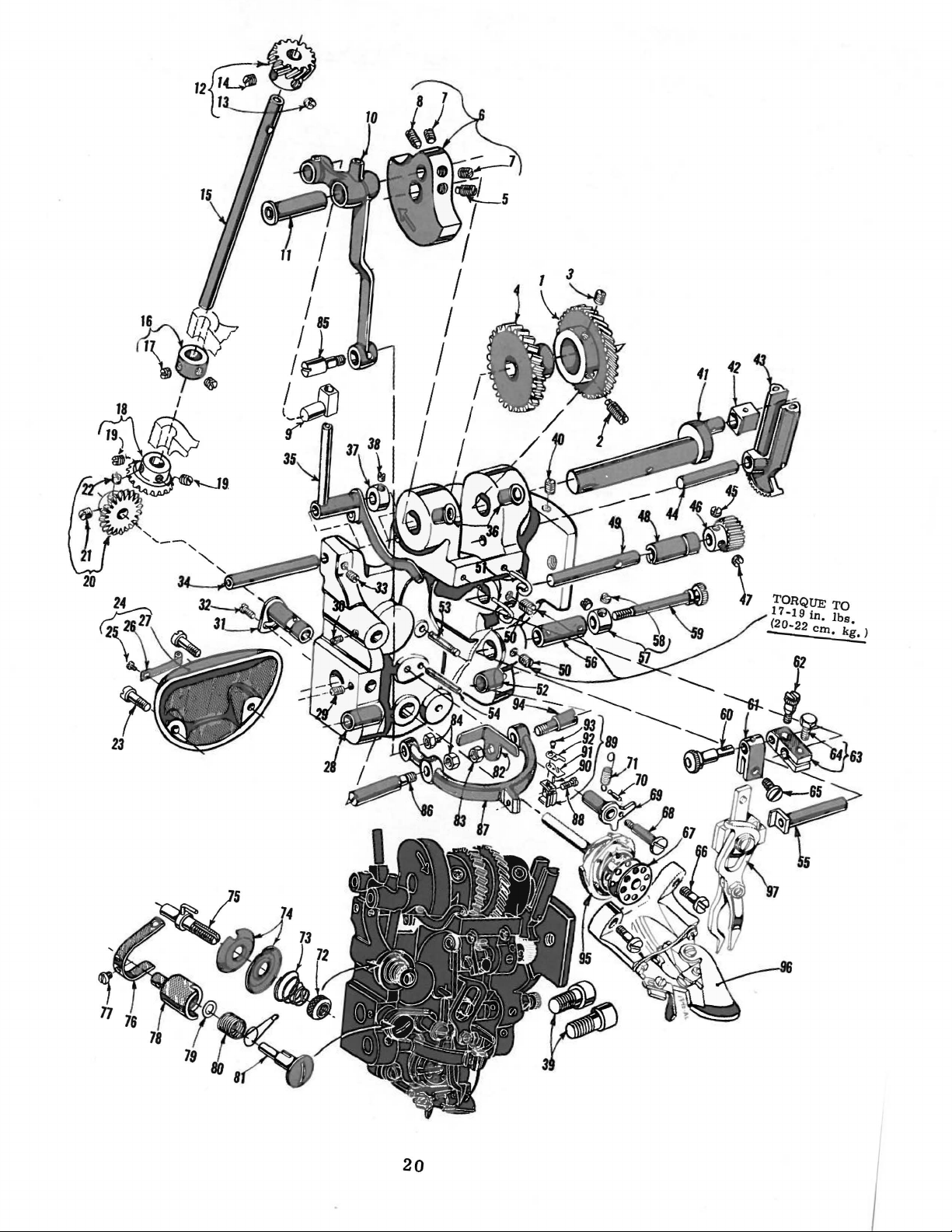

TORQUE

17-19in.

(20-22

-

czn.

TO

lbs.

kg.

)

--

20

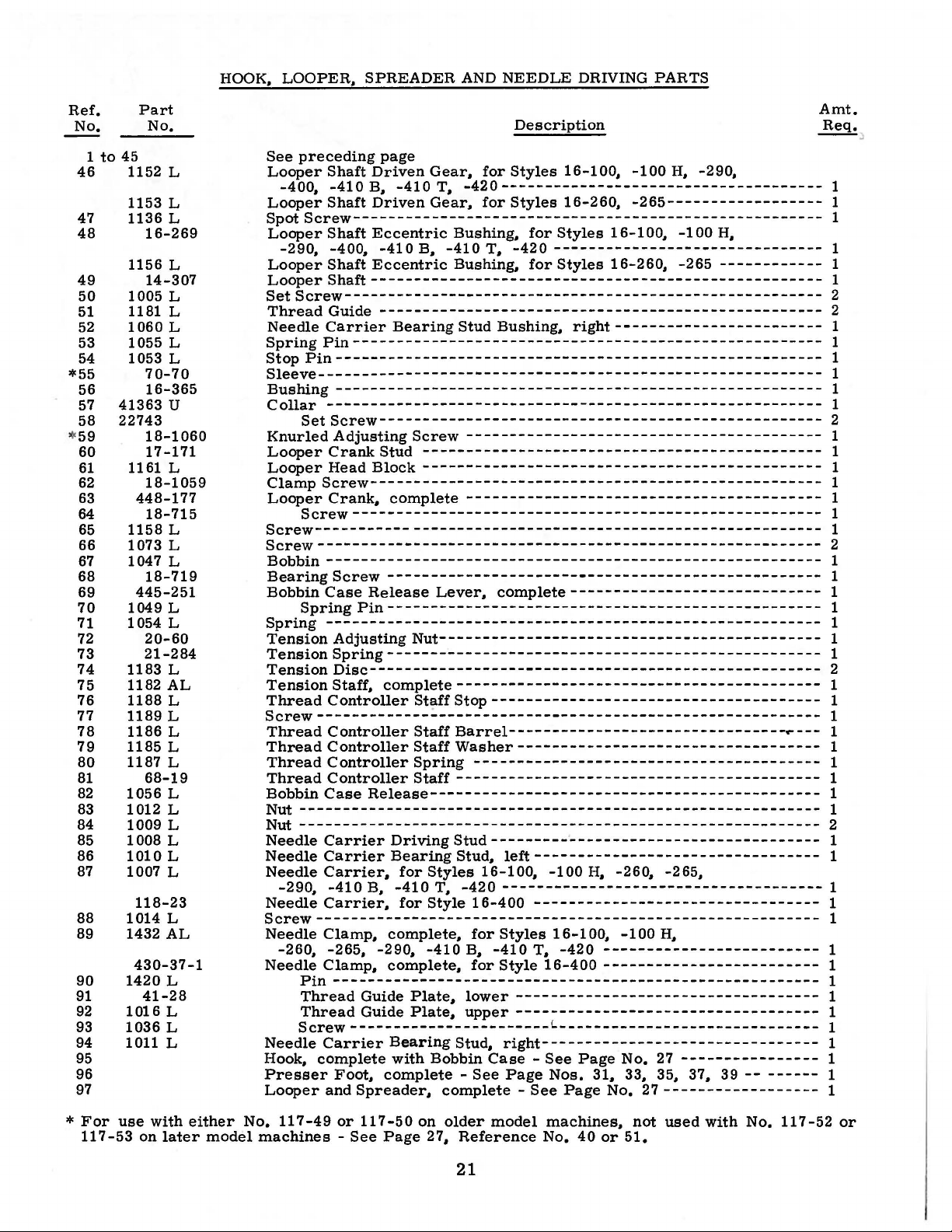

HOOK, LOOPER, SPREADER

AND

NEEDLE DRIVING PARTS

to

Part

No.

45

Ref.

No.

1

46 1152 L

1153 L

47

48

1136 L

16-269

1156 L

49

14-307

50 1005

51

52

53

54

*55

56

57

1181 L

1060 L

1055 L

1053 L

70-70

16-365

41363 u

58 22743

*59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

18-1060

17-171

1161 L

18-1059

448-177

18-715

1158 L

1073 L

1047 L

18-719

445-251

1049L

1054 L

20-60

21-284

74 1183 L

75

76

77

1182

1188 L

1189 L

78 1186 L

79 1185 L

80 1187 L

81

82

83

84

85

86

87

68-19

1056 L

1012 L

1009 L

1008 L

1010 L

1007 L

118-23

88

89

1014 L

1432

430-37-1

90 1420 L

91

92

93

94

41-28

1016 L

1036 L

1011 L

95

96

97

L

AL

AL

Description

See

preceding

Looper

-40~

Looper

Shaft

-410B,

Shaft

page

Driven

-410

Driven

Gear,

Gear,

for

T,

Styles

-420------------------------------------for

Styles

16-100, -100

16-260,

-265------------------

H,

SpmScrew------------------------------------------------------

Looper

-290, -400, -410 B,

Looper

Shaft

Shaft

Eccentric

Eccentric

Bushing,

-410

T,

Bushing,

for

Styles

-420

-------------------------------

for

Styles

16-100,

16-260, -265

-100

LooperShaft----------------------------------------------------

SetScrew-------------------------------------------------------

Thread

Needle

Guide---------------------------------------------------

Carrier

Bearing

Stud Bushing,

right------------------------

SpringPin------------------------------------------------------

Pin--------------------------------------------------------

Stop

Sleeve---------------------------------------------------------Bushing

Collar

--------------------------------------------------------

---------------------------------------------------------

SetScrew--------------------------------------------------Knurled

Looper

Looper

Clamp

Looper

Adjusting

Crank

Head Block

Screw----------------------------------------------------

Crank,

Screw

-----------------------------------------

Stud----------------------------------------------

----------------------------------------------

complete

-----------------------------------------

Screw------------------------------------------------------

Screw---------------------------------------------------------Screw----------------------------------------------------------

Bobbin

BearingScrew

Bobbin

---------------------------------------------------------

Case

--------------------------------------------------

Release

Lever,

complete-----------------------------

SpringPin--------------------------------------------------

Spring

Tension

--------------------------------------------------------Adjusting

Nut-------------------------------------------TensionSpring-------------------------------------------------TensionDisc----------------------------------------------------

Tension

Thread

Staff,

complete

Controller

------------------------------------------

Staff

Stop--------------------------------------

Screw----------------------------------------------------------

Thread

Thread

Thread

Thread

Bobbin

Nut

Nut

Needle

Needle

Needle

-290, -410 B,

Needle

Controller

Controller

Controller

Controller

Case

Staff

Barrel--------------------------------..----

Staff

Washer----------------------------------Spring

Staff

----------------------------------------

------------------------------------------

Release---------------------------------------------

------------------------------------------------------------

-----------------------------------------------------------Carrier

Carrier

Carrier,

Carrier,

Driving

Bearing

for

Styles

-410

T,

for

Style

Stud--------------------------------------

Stud,

left---------------------------------

16-100, -100

-420

-------------------------------------

16-400

---------------------------------

H,

-260, -265,

Screw----------------------------------------------------------

Needle Clamp,

-260, -265, -290, -410 B,

Needle

Needle

Hook,

Presser

Looper

Clamp,

Pin

--------------------------------------------------------

Thread

Thread

Screw-----------------------L------------------------------

Carrier

complete

Fom,

and

complete,

complete,

Guide

Guide

Plate,

Plate,

Bearing

with Bobbin

complete

Spreader,

for

Styles

-410

for

Style

lower

upper

Stud,

Case

-See

complete

16-100, -100

T,

-420

16-400

-------------------------

-------------------------

H,

-----------------------------------

-----------------------------------

right--------------------------------

-See

Page

No.

27

Page

Nos. 31, 33, 35, 37, 39 --------

-See

Page

No.

27

------------------

-290,

H,

------------

----------------

Amt.

Req.

--

1

1

1

1

1

1

2

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

.)

*For

use

117-53 on

with

later

either

model

No.

117-49

machines

or

117-50

-See

Page

on

27,

older

model

Reference

machines,

No. 40

21

or

nm

51.

used

with No. 117-52

or

22

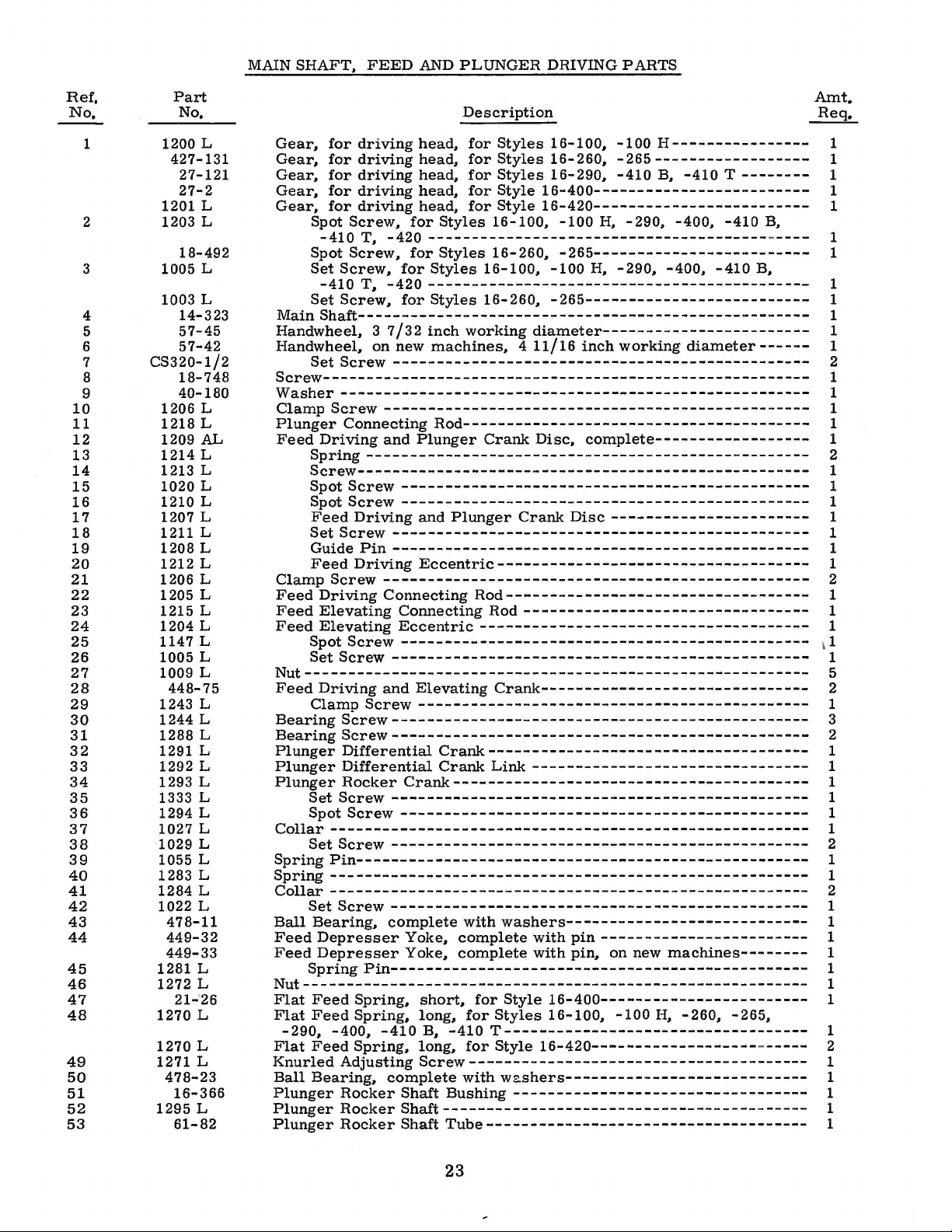

MAIN

SHAFT,

FEED

AND

PLUNGER

DRIVING

PARTS

Ref,

No,

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

Part

No,

1200

L

427-131

27-121

27-2

1201

L

1203

L

18-492

1005

L

1003

L

14-323

57-45

57-42

CS320-1/2

18-748

40-180

1206

L

1218

L

1209

AL

1214

L

1213

L

1020

L

1210

L

1207

L

1211

L

1208

L

1212

L

1206

L

1205

L

1215

L

1204

L

1147

L

1005

L

1009

L

448-75

1243

L

1244

L

1288

L

1291

L

1292

L

1293

L

1333

L

1294

L

1027

L

1029

L

1055

L

1283

L

1284

L

1022

L

478-11

449-32

449-33

1281

L

1272

L

21-26

1270

L

1270

L

1271

L

478-23

16-366

1295

L

61-82

Description

Gear,

Gear,

Gear,

Gear,

Gear,

MainShaft---------------------------------------------------Handwheel, 3 7/32

Handwheel,

Screw-------------------------------------------------------VVasher