Page 1

•

LEWIS

PARTS and INSTRUCTIONS

400

N.

Catalogue

150

ll/J"ZU.m.Jl;.ic.c:':I.Q.:£.

Franklin

Class Machines

Models

150-1

150-5

150-6

150-6TS

150-7

PRODUCT

St.

194-5

150-9

150-15

150-16

150-17

150-20

150-23

OF

®

MACHINE

COMPANY

Chicago,

Ill.

60610

PRINTED

IN

U.

S.

A.

Page 2

1

•

Adjusting

Adjusting

Belt

Cylinder

Feeds

Flared

Feed

Feed

Loop

Loops

••••.•

Plates

Plate

LEWIS

Chart

Looper

Parts

••

. . . . . . . . . . . . . . . . . . . . .

Base

•

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

for

3/8"

Parts

and

CLASS

INDEX

and

5/16"

their

150

Adjustments.

. . . . . . . . . . . . . . . . . . . . . . . . .

Skirts.

. . . . . . . . . . . . . . . . . . . . . . . . .

.•

Holders.

. . . . . . . . . . . . . . . . . . . . .

MACHINES

wide

PAGE

13,

14

16-19

93,94

12

11,114

11

115

116

•

Folders

General

Hemming

Plate

Feed

Instructions

Instructions

Instructions

Instructions

Model

Model

Additional

Plates

........

Instructions

8.

Plates ..•.....

Numbers

150-1

for

Flared

Parts

for

Belt

-

General •..••

for

Ordering

for

Using

and

.•

. . . . . . . . . . . . .

Parts

Model

.

Skirts:

to

adjust

Serial

for

150-1

. . . . . . . . . . . . . . . . . . . .

•••

. . . . .

Parts

pressure

.,

.................

Loop

Machine

Parts

Catalogue

Model

•.•...•

Numbers

..

. . . . .

for,

See

of

. . . . . . . . . . .

a •

. . . . . . . . . . . . .

. . . . . . . . . . . .

••

,

150-1

. .

. .

11 7

7-19

.

11,

5 3

91,92

7-19

5

5

5

44-54

54

46-53,110

Model

Additional

See

150-5

Plates

•.••••.•••••.••

Parts

for

for

Model

Model

150-1

150-5

•••••

. .

. .

.

.....

56

56

46-53,110

Page 3

2

Model

Additional

Instructions

Plates

Model

Additional

Instructions

Plates

Model

Additional

Instructions

Plates

Model

Additional

Plates

150-6 ..............

150-6TS

150-7

150-9

Parts

for

for

Model

••••••••.••••..

Parts

for

for

Model l 50-6TS

.•....

Parts

for

for

Model

..•....•.....

Parts

for

Model

LEWIS

for

Model

150-6

for

Model

.........••

for

Model

150-7

for

150-9.

CLASS

INDEX

Model

150-6

•••••••••

Model

150-6TS

Model

150-7

•••••••

Model

150-6

•••••

150-6TS

•••••••

150-7

•••

150-9

•

150

MACHINES

.

•

•

. . . . . .

. .

•

. .

. .

. . .

. . .

..

PAGE

58-60

60

57

59,

111

61-65

64,65

61

63,111

66-71

70,

71

67,68

•

69,113

72-76

75-76

74,111

•

•

Model

Additional

Plates

Model

Additional

Instructions

Plates

Model

Additional

See

Model

Model

Additional

Instructions

Plates

150-15

150-16

150-17

Plates

150-20

150-23,

for

for

for

.••.••••.••...•.

Parts

Model

Parts

Model

Parts

for

for

150-15

................

for

for

Model

150-16

..........•.....

for

Model

Model

••••••••

Model

150-16

••••••••••

Model

150-1

150-15

150-16

. . . . . .

150-1

••••••

•

. . .

. . . . .

.

••••••

. . . .

7 •

. . . ....

. . . . . . .

. . . . . .

. .

. . .

•

.....

. . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

Model

for

for

Model

150-23

Model

150-23

.••••••

150-23

. .

. .

. .

•

. . .

. .

. . .

77-80

80

79,111

81-93

86-90,93

91-92

82-85,112

96

97

46-53,111

81-94

98-109

106-109

98-100

102-105,113

•

•

Needles

Oiling

Parts

. . . . .

Machine

List

including

. . . . . . . . . . . . . . . . . . . . . .

e • • e e e e • e e e e • e O e e O • 0 e • e e e

all

Models

. . . . . . . . . . . . . .

8

9

20-43

Page 4

3

LEWIS

•

Plate

Presser

Regulating

Ridge

Ridge

Retainer

Speed

Serial

Numbers

Forming

Forming

of

Numbers

-

See

Feet .........

Length

Disc

Disc

or

Cloth

Machine

Clamp

•••••

and

Models.

of

Stitch

. . . . . . . . . . . . . . . . . . . . .

Regulator

Model

CLASS

INDEX

.

• • • • • • • • • • • • • • • • 0

See

150

MACHINES

below

•••••••••

. . . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . . . . .

• • • • • • • • • • • • •

Cl

• • • • •

. . . . . . . . . . . . . . . . . . .

Numbers.

. . . . . . . . . . .

PAGE

9,118,119

12

9,10,120

10

19,20

9

5

•

Thread

Threading

Timing

Unpacking

•••••••.

Machine

and

Adjusting

Machine

. . . . . . . . . . . . . . . . . . . . . . .

.......

Charts.

•••••••

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

13,

8

7

14

7

Page 5

4

PLATE

NO.

1

IA

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

LEWIS

T

irning

T

irning

Parts

Parts

Parts

Parts

Parts

Parts

Parts

Parts

Additional

Additional

l

50-6TS

Additional

Additional

Additional

Additional

Additional

Additional

Additional

Additional

Additional

Additional

Additional

150-1

Additional

150-6, 150-9,

Additional

Additional

150-7

Chart

Chart

For

For

For

For

For

For

For

For

and

and

CLASS

.••••••

•••••••

Model

Model

Model

Model

Model

Model

Model

Model

Parts

Parts

•••.••......••.•.••••.

Parts

Parts

Parts

Parts

Parts

Parts

Parts

Parts

Parts

Parts

Parts

150-5

Parts

Parts

Parts

150-23

150-1

150-1

150-1

150-1

150-1

150-1

150-l

For

For

For

For

For

For

For

For

For

For

For

For

For

For

150-15

For

For

150

INDEX

PLATES

150-1

Model

Models

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Models,

•.••••••••••

Models,

and

Model

Models,

• • • • • • • • • • • • • • • •

MACHINES

. . . . . . . .

. . . . .

. . . .

. . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

150-6

150-6,

150-7

150-9

150-15

150-16

150-16

150-16

150-23

150-23

150-23

150-23

150-17

150-16

••••••

••••••

••••••

•••••

•••••

•••••

•••••

. . . . .

. . . .

•••••

••••

PAGE

NO.

13

14

46

47

48

49

50

51

52

53

59

63

69

74

79

33

84

85

102

103

104

105

110

111

112

113

•

Page 6

-~-

'

5

•

The

in

compiling

used

class

under

machine

show

in

150

Additional

each

To

the

INSTRUCTIONS

TO

Model

the

Machines.

find

for

page

The

of

Model

the

Model

model

150-1

this

a

which

machine.

catalogue

150-1,

parts

number.

part

the

number,

No.

FOR

ORDER

Machine

are

used

needed,

is

to

part

referring

located

USING

PARTS

is

the

that

used

is

is

in

make

note

wanted,

to

on

CATALOGUE

basic

the

all

each

model

the

top

of

machine

majority

the

models

Model

number

and

the

model.

the

head

of

of

are

listed

on

index

used

parts

the

the

will

•

***************************************

The

in

Turn

obtain

part

to

section

referred

at

is

the

The

the

Serial

arm

No.

under

of

each

the

machine

top

cover.

is

stamped

***************************************

State

when

part

common

Model

ordering

to

the

number.

bottom

parts

are

to

the

at

No.

plate

to

Model

of

the

listed

additional

the

bottom

and

parts.

showing

If

part

page

and

Serial

cannot

150-1,

of

parts

plate

parts

of

page

No.

drawings

orto

drawing

used

of

of

be

the

listed.

parts

machine

of

machine

located,

model

in

each

over

the

listed.

then

referred

model

models

to

the

If

part

for

description

January,

number

and

1971

is

best

known

plate

turn

for

to

General

locating

part.

parts

list

Page 7

6

such

standard,

plates,

subjects:

as

presser

22, 23,

The

see

plate

lists

24,

drawings

feet,

on

and

folders

last

25.

show

and

pages

Refer

only

etc.

of

catalogue,

to

index

the

For

standard

parts

also

for

following

parts

other

see

than

Feeds.

Feed

Folders.

Presser

Ridge

Plates.

Feet.

Forming

Disc.

•

•

.)

•

Page 8

7

•

GENERAL

ADJUSTMENT,

UNPACKING

To

and

remove

position.

blocks

the

the

sure

fore

ment

box

parts

dust,

are

box.

other

very

The

small

to

look

destroying

that

carefully

project

Set

especially

INSTRUCTIONS

MACHINE

remove

the

nails

Use a nail

held

goes

by

knee

parts

carefully

it,

with

beyond

up

the

from

AND

150

the

machine

and

puller

nails

lifter

so

to

machine;

will

through

that

the

avoid

the

the

or

machine.

FOR

OPERATION

MACHINES

from

screws

to

screws

is

attached

be

you

breaking

head

looper.

avoid

found

the

will

of

the

clean

that

THE

OF

the

hold

breaking

driven

to

the

wrapped

material

find

all

Lift

the

the

machine.

away

INSTALLATION,

LEWIS

box,

the

the

through

side

in a package.

used

the

machine

tension

accumulated

take

brace

machine.

of

the

for

parts

studs

CLASS

the

out

off

the

blocks

outside

box,

packing

and

equip-

of

as

these

lint

cover

in

These

of

and

Be

be-

the

and

•

Place

with

machine,

knee

for

pad

the

the

the

transmitter,

lift

lever

Mark

the

screw

under

three

packing

HAND

away

at

the

THREADING

let

just

on

the

through

the

needle

through

machine

WHEEL

The

from

pitch

From

back

left

the

the

The

the

case.

top

the

line

of

side,

tension

bar,

eye

the

machine

machine

is

1/2"

the

three

holes;

machine

bolts

rim

operator

of

the

the

spool

the

tension

then

then

of

the

and,

should

from

bore

and

that

of

or

belt

lift

discs;

through

needle.

on

assemble

the

holes

the

fasten

were

hand

clockwise.

groove.

stand,

disc,

thread

then

the

the

be

edge

for

hole

wheel

pass

then

over

through

hole

bench

the

set

the

for

the

used

turns,

with

knee

on

the

of

the

machine

the

belt;

machine

to

hold

The

the

thread

between

the

pin

the

in

the

the

lift

table

table.

to

when

pulley

the

which

pig-tail

needle

pulley

lever

so

screws

place

the

the

machine

facing

is

through

tension

passes

clamp,

to

that

and

the

table,

the

2"

eyelet

lined

f.elt

diameter

the

up

the

the

bore

using

into

pulley,

eye-

disc

over

then

Page 9

8

REMOVING

plates

will

signs

changes

NEEDLE

by

Taper

Not

29-492 1 /2

and

break

at

any

on

number:

Point

Scarfed

WORK

See

that

retract

the

We

reserve

time

machines

SIZES

The

the

the

thread.

without

needles

needle

disc

the

previously

are

Taper

0

15

is

and

right

incurring

furnished

Front

29-343

29-343

29-344

29-344

out

of

the

give

the

to

change

the

manufactured.

in

the

Point

Scarf

½

½

cloth.

work a quick

specifications

obligation

following

Lower

to

15°

the

jerk

or

install

sizes,

Sharp

Front

29-493

29-493

29-494

29-494

feed

which

ti

de-

such

order

Point

Scarf

½

½

Ordinarily,

purpose.

to

meet

righted

THREAD

cotton

either

REGULATING

the

cylinder

showing

turn

and

dial

for

the

to

A

all

Use

word

Use

thread

"00"

The

the

raising

word

obtain

sizes

full

range

requirements.

ONLY

"LEWIS"

any

in

or

"000".

DEPTH

needle

base

word

"Less

less

genuine

good

sizes

penetrating

of

the

"More"

the

ridge

II

needle

which

29-343

of

needle

stamped

grade

70

to

OF

NEEDLE

machine

and

forming

penetration

sizes

LEWIS

on

of

left-twist

100.

indicates

If

adjustment

and

indicates

½

and

29-344

are,

needles.

the

silk

PENETRATION

is a dial

disc

the

in

however,

shank

three

thread

is

the

direction

for a deeper

direction

the

work.

will

Look

of

each

cord

is

located

with

serve

available

for

the

needle.

hard

used,

graduations,

to

select

on

top

in

which

penetration;

turn

the

the

copy-

finish

of

to

Page 10

-1'

1

9

•

SKIPPING

Examine

over.

stitches.

REPLACING

and

needle

IMPORT

SPEED

3000

recommended

Speed

Replacing

Insert

tighten

guide.

ANT

The

stitches

may

STITCHES

point

needle

NEEDLE

needle

set

screw.

--

OIL

LEWIS

per

minute.

in

starting

be

increased

of

needle

will

generally

into

needle

Needle

MACHINE

Class

to

a

150

A

new

suit

speed

to

see

carrier

should

DAILY

machines

of

machine

operator

if

remedy

bear

can

1800

or

or

it

is

blunt

skipping

as

far

as

slightly

be

operated

to

2000

with a new

class

or

possible

on

the

stitches

of

work.

turned

of

up

to

is

operator.

•

TIMING

screws.

PRESSER

ble

and

foot

up

.010"

needle

RIDGE

slot

in

150-17.

in

play

justing

first

tension.

guide

in

the

relation

question.

to

be

All

basic

FOOT

Place

with

or

down

FORMING

The

For

Before

the

the

loosened

new

the

Observe

freely.

disc

presser

to

the

other

cradle

pivot

driving

needle

point

so

that

DISC

must

foot,

needle,

models,

setting

140-11.

bearing

and

parts

in

directly

the

point

that

(Refer

be

adjusted

and

Models

the

screw

the

tension

the

shank

so

refer

disc

Any

are

needle

over

of

of

to

Plate

that

150-1,

to

be

end

18-869,

of

properly

carrier

the

needle

the

needle

needle

lA)

to

be

the

nose

150-6,

special

sure

play

Set

Spring

timed

passes

in

the

of

instructions

that

there

can

be

Screw

21-377

as

far

guide

is

under

center

the

disc

150-6TS,

is

taken

1003

released.

with

as

adjust

scant

over

of

no

up

must

spot

possi-

the

the

the

is

set

150-7,

on

end

by

ad-

model

Page 11

10

Adjust

cradle

hand,

1003

setting

even

loosen

crank

disc

slot

needle

disc

the

disc

1158

set

the

shaft.

Pivot

must

then

to

lock

Adjust

is

with

To

set

448-131

so

that

in

presser

will

joins

in

crank

collar

when

the

the

is

Screw

move

lock

18-869

tension

end

adjust

screw

when

be

periphery

at

its

448-131

to

pivot

the

of

the

and

the

foot

1/16"

most

take

18-869

very

screw

in

spring

end

nut

disc

1022

set

point

and

from

up

just

freely.

in

place.

21-377

of

screw

20-120.

to

in

collar

disc

advanced

and

at

of

all

to

of

center

where

the

set

end

enough

Check

place

for

center

slot,

the

disc.

position.

screw

play

by

with

adjusting

of

39-118

at

needle

of

the

the

small

This

1022

in

to

take

by

moving

tightening

nut

slot

in

and

the

same

is

at

disc,

radius

setting

Tighten

in

the

ridge

up

20-120.

tensions

the

presser

clamp

time

the

the

collar

play

cradle

forming

set

Normal

screw

set

center

point

on

nose

is

made

clamp

39-118

but

screw

the

by

18-909

foot,

1158

the

of

the

of

the

of

when

screw

and

disc

is

the

•

m

hand

shaft

ling

engages

nut

RIDGE

Base

needle

The

less

be

ulator

raised

ridge

side

feed

the

20-80

word

depth

of

To

plate

and

remove

disc,

the

and

FORMING

The

raises

penetration

"More"

of

The

in

forming

in

the

the

remove

holder,

the

care

slot

in

tighten

DISC

dialed

and

lowers

indicates

needle

regulator

order

disc.

"More"

regulator.

the

ridge

remove

washer

must

the

regulator

in

to

be

disc.

firmly.

REGULATOR

the

the

work

penetration.

also

protect

The

adjustment

direction

forming

the

40-144

taken

Assemble

located

ridge

being

more

limits

the

as

nut

and

that

the

{Refer

on

forming

done

depth,

the

needle

is

far

as

disc,

20-80

disc.

key

the

top

disc

to

and

amount

point

made

possible

depress

on

When

in

washer

to

Plate

of

the

to

form

"Less"

that

from

by

the

end

of

flange

40-144

Cylinder

get

a

blind

the

striking

turning

to

stop

left

disc

reassemb-

107-44

and

lA)

the

correct

stitch.

indicates

disc

the

pin

can

the

reg-

in-

6,

.,)

•

A

with

disc.

the

needle

needle

guide

must

and

be

point

in

the

of

needle

needle

carrier

over

the

and

ridge

in

contact

forming

Page 12

•

and

adjust

the

ridge

ridge

.010"

assemble

place.

hexagon

sure

ed

more

FEED

loosening

over

lowest

allel

weight

low

in

of

front

the

with

the

forming

which

tension

Now

remove

screw

forming

is

the

18-924

These

headed

ridge

machine,

point,

materials;

presser

The

of

The

the

the

two

forming

cylinder

and

two

then

bottom

the

18-923

disc

disc

will

equivalent

screw

screws

adjusting

adjustment

in

reverse

feed

is

binding

away

set

the

of

for

foot

about

set

that

shaft

lift

the

to

two

and

are

screw

for

disc

is

base,

adjustable

heavy

screws

from

feed

the

turn

direction

presser

work,

3/64".

screw

contacts

is

mounted

needle

thicknesses

set

located

18-922.

the

spring

made

in

relative

holding

you,

until

so

that

the

18-924

the

cradle

and

off

of

tightly

inside

tension

by

turning

clockwise

for

to

the

the

it

is

foot,

for

feed

(See

adjust

the

of

to

of

less

the

feed,

feed

1/32"

light

must

lock

Plate

140-11

so

needle

newspaper.

screw

the

main

for

correct

nut

20-120,

direction

tension.

presser

and

motion

below

and

be

brought

No.

lA)

in

which

that

the

guide

Re-

18-923

locat-

to

get

foot

turning

is

at

and

par-

medium

11

in

pres-

by

the

be-

•

inch.

FEED

of

the

springs.

from

material

the

paper

applied

feed

slightly

moving

looper,

in

The

PLATES

The

presser

There

moves

resulting

Check

before

For

for

each

the

fullness

on

the

feed

·Feed

foot

when

with

point

sewing

feed

hem.

is

and

must

the

to

see

of

adjustable

Plates

feed,

be

needle

the

needle,

in

skip

that

needle

flared

plate

in

this

press

when

enough

penetrates

stitches.

Feed

penetrates

skirts

can

type

from

the

on

pressure

a

loop

Plates

with

be

varied

of

hem

three

work

its

to

against

feeding

applied

the

material,

will

not

clamp a piece

material.

wide

so

the

if

the

eight

the

stroke

to

be

formed

hems,

machine

operator

stitches

bottom

by

hold

for

of

the

pressure

holds

two

the

if

the

for

news-

will

per

work

back

Page 13

12

ADJUSTING

located

open

on

per

which

hand

slot

serve

the

es

CYLINDER

Plate

ate

the

position

the

timing

are

on

the

the

shaft,

inch,

will

wheel

to

lengthen

through

feed

per

inch,

the

ridge

disc

bracket

marks

Eccentric

top

disc

lA)

to

with

LENGTH

The

stitch

top

of

the

cover

with

press

engage a slot

over

as

is

BASE

The

forming

insert

Parts

spot

50-222.

that

of

numerals

down

and

stitch,

the

opening

you

directly

PARTS

parts

and

in

the

screws

must

433-151

OF

is

regulated

arm

the

the

away

and

turn

under

in

the

disc,

remove

Cylinder

Parts

match

and

STITCH

of

the

machine,

machine

which

feed

knob

in

the

feed

from

in

until

AND

and a timing

you

toward

the

top

the

the

THEIR

Cylinder

depress

the

Base

assembled

the

Gear

27-165.

by

the

to

observe

indicate

located

mechanism;

while

you

to

of

the

numeral,

indicator.

ADJUSTMENT

Base

the

feed

work

from

where

mark

in

timing

knob

near

the

on

holding

shorten

arm,

indicating

and

plate

the

possible

has

this

mark

426-47,

the

the

feed

number

top

of

now

the

stitch,

the

base

and

machine.

been

bracket

in

the

head.

indicator·

the

turn

knob

number

the

{See

of

arm

retract

are

milled

that

bracket

Plate

First,

of

stitches

machine,

the

in

and

stitch-

opera-

held

have

3,

the

ob-

on

in

in

•

'..,

.

"

removing

Rod

447-118

18-664

bearing

Shaft

assembling,

all

to

adjust

sing

of

feed

14-429

against

lA.

far

48-127

and

Stud

14-458

coincide,

feed

cylinder

plates

so

the

Be

sure

as

possible,

turns

Bracket

Stud

take

Gear

by

if

Crank

the

Crank

plates.

base.

in

that

contact

Check

17-145

from

bracket

865

out

27-166

the

the

the

machine

448-131

ridge

48-127

The

contact

two

feed

plttes

the

and

without

50-222

which

Lever

Spot

gear

forming

Loosen

thicknesses

surface

turn

45-352.

from

of

the

and

Screws

teeth

will

is

is

adjustment

screw.CS

with

are

above

over

interfering

can

be

will

the

hole

Eccentric

are

function

clamped

disc.

for

adjusting

presser

of

of

feed

in

contact

setting

hand

removed

disconnect

Next

base

in

Ball

433-151

1025

and

engaged

properly.

to

(See

Plate

is

made

331

foot,

newspaper

plate

by

depressing

wheel,

with

adjacent

from

remove

by

slipping

Joint

18-624,

so

the

disc

Shaft

through

in

crank

adjust

holders.

with

and

the

the

end

the

4124-51.

are

that

shaft

lA)

14-429

48-127

surface

will

bottom

the

see

parts.

machine

of

Connecting

three

the

headless

held

on

therefore

the

timing

and

for

a

hole

(A)

just

pinch

See

(A)

of

presser

feed

that

crank,

Screws

to

when

marks

is

used

depresin

front

and

with

of

plate

plates

by

the

•

foot.

as

Page 14

TURN

MORE

AND

IN

DIRECTION

OSCILLATION

LARGER

THREAD

•

OF

ARROW FOR

TO

NEEDLE

LOOP

AMP

SCREW

EEDL1ECCENTRIC

BALL

~

TUD

ADJ. t

NEEDLE SHAFT

CRANK

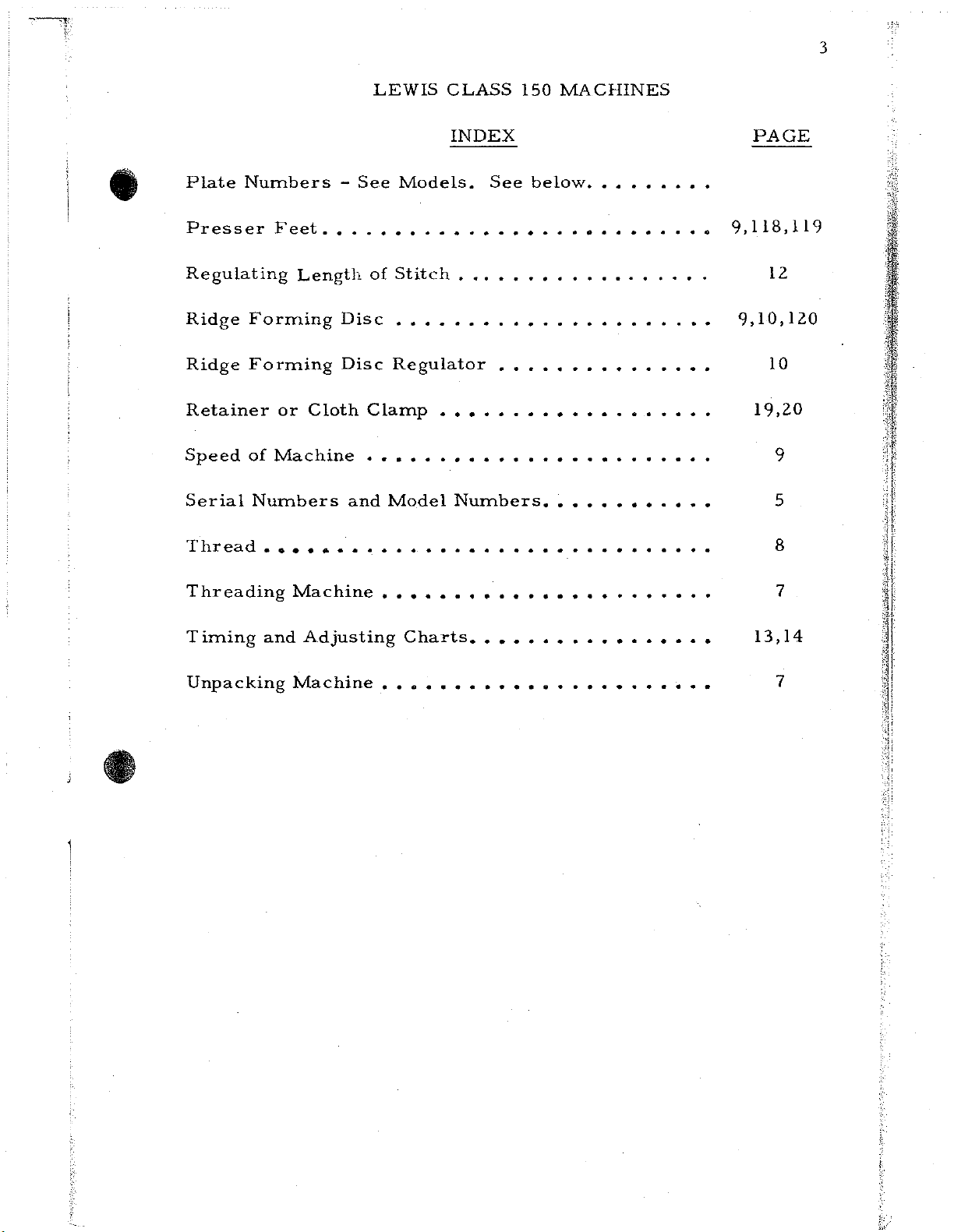

LEWIS CLASS 150 SINGLE THREAD MACHINE

ADJUSTING CHART

ADJ. 5

and

LOOPER

ADJ. 6

ECCENTRIC

SLEEVE-,

NEEDLE

/--CLAMP

I

CARRIER

SCREW

,~/,.--

"

[

-=-

,.

/

~ftt>

/

CLAMP

NEEDLE

•

SCREW

SHAFT

CRANK

FIG. 1

I

1

koT

FOR

IS

'--LOOPER

SCREW

TIMING NEEDLE AND

SET

AT

THE

LOOPER

LOOPER

PIN

CRANK_/

IN

ECCENTRIC

FACTORY

POSITION

MARK WITH EDGE

"V"

OF

TIMING

GROOVE

YOKE

YOKE

HOLES-

~

~

=

-----

-----

BALL

FIG.4

LOOPER CARRIER

ADJ, 4

1

j

-----

,

..

----

32

4

FIG. 5

LOOPER

JOINT

FIG.2

LOOPER

MACHINE TURNS

DIRECT!ON

MAIN SHAFT

!

-;,:f--voKE

CRANK

OF

rt-LOOPER

CLAMP SCREW

FEED

IN

ARROW

LOOPER

CLAMP

BALL

PLATE

SCREW

A

.,,--HOLE

8

FIG. 6

FORMING

MUST CLEAR CHAINING

LOOPER

CENTER

LOOPER CARRIER

FINGER

OF

RIDGE

DISC

NOT

OVER

ADJ. 3

LOOPER

FIG. 3

PRESSER

1

~,

3

SLOT

FIG. 7

NEEDLE

SURFACE

~DJ.4

SETTING

SEE

NEEDLE

RETAINER

167-80

"g

...

~

"'

""

SLOT

w

Page 15

TIMING

LEWIS CLASS 150 SINGLE THREAD MACHINE

8r

ADJUSTING

CHART

,i,.

-

FEED

PLATE

(LEFT)-~

40-144

20-80

RIDGE

FORMING DISC

HOLDER

--107·44

I003t·

..

,1

'

~!

'

/

_J

'i,_'.J

_,;:ii

,--n1=1ni!hi'51.

I

1/.::0,

1

~~

.PJtJ

\ 140·11

\...14·429_/

RIDGE

ic;t~

I,

,;;-

r.-·1:_

21·377-

___J

FORMING

REGULATOR----

---v5tf-

102

39·

18·90920-120-

I8·664-----M

14

-39-105-

2L-

118-1;,

DISC

-3

9 5

· '

1

..

~--i

II58L,

865L.J

4124-51.J

_,-18·924

-18·922

448·131

'

SCREW

IN

CYLINDER

48-127

k=,r{,

,~--

4 8 -127

0

DRIVER

BASE

---I284L

--50-222

l-~----433-I51

HOLE

REAR WALL

OF

MACHINE

18

• 6 2 4

21-344-.

39·117·,.

,,

~

-I

,,,

...

>

•

•

50·222

~

NEE

ROD

LIFTER_j

14-400

--,"·---

..

•

• 12 5

•

.

....

A

Page 16

15

Lifter

14-395

forming

14·-429.

press

holding

TIMING

Needle:

justing

in

best

and

disc

Shaft

knee

THE

the

Crank

position

Collar

setting

and

Collar

Collar

14-400

lifter

MACHINE

A

No. 4 taper

needle

48-150

39-105

tension

feed

1284

39-117

and

out

pas

it

is

for

is

plates

is

used

is

for

of

contact

point

ion.

for

adjusting

operator.

used

of

Spring

to

sewing

for

used

setting

needle

for

taking

to

take

tension

with

the

taking

21-344

position.

up

up

depressing

should

position

up

for

end

end

of

Spring

be

end

thrust

returning

thrust

thrust

lever.

used

of

the

of

of

of

knee

21-344

when

Knee

Shaft

ridge

Shaft

for

ad-

•

the

following

justing

Adjustment

when

hand

over

straight

1.

carrier

point

setting

screw.

Adjustment

slot -See

Loosen

carrier

needle

clear

Check

chart).

the

wheel,

until

with

of

surface.

the

will

the

to

To

2

To

needle

the

screw

up

and

the

clamp

the

To

Figure

needle

-

See

just

needle

see

secure

steps

Plate

set

the

is

follow

driver

down

machine

screw

needle

See

3

set

the

Figure.

clear

shoulder

that

the

must

point

at

the

mg

with

in

and

is

1/16"

Figure

needle

7 -

the

carrier

2 -

the

setting

correct

be

I.

steps

slot

the

the

taken

of

the

extreme

must

in

the

the

two

above

moye

following

in

needle

of

to

3/32"

3.

in

clamp

or

presser

for

the

Tighten

the

out

adjustment

and

settings

needle

end

of

be

taken:

needle

dots

at

pas

it

ion,

needle

from

correct

steps

screw

so

that

slot

at

"A" -See

foot

the

needle

in

the

its

eccentric

the

loosen

carrier

the

the

needle

position

and

and

move

the

at

point

for

the

made.

correct

stroke

Turn

bottom.

edge

setting

rear

"B"

about

needle

towards

the

ball

the

so

of

carrier

in

must

the

side

Figure

still

{See

position

machine

stud

See

needle

that

the

needle

the

needle

needle

of

.005".

is

1/16"

swing

ad-

the

is

Figure

the

clamp

be

rnade:

the

7 -

and

Page 17

16

to

3/32"

the

needle

LOOPER

importance.

-

allow

carrier

must

remove

l/64"

-

be

or

from

carrier

The

The

See

understood

The

the

correct

(See

looper

space

Figure

replace

looper

needle

clamp

setting

adjusting

is

mounted

between

2 -

in

case

this

assembly.

carrier

setting

screw.

chart).

and

for

surface

of

the

in

looper

the

correct

any

assembly

looper

Plate

the

looper

shoulder

assembling

reason

consists

of

is

l.

it

presser

of

the

carrier

and

end

is

necessary

of:

foot.

greatest

assembly

of

looper

of

this

Tighten

unit

to

•

•

sembling

positively

screw.

that

the

distance

est

the

looper

looper

and

which,

Adjustment

side

6.

or

yoke,

for

when

Looper

Clamp

Looper

Looper

The

these

located

The

The

reference

4

Means

looper

parts

looper

ball,

will

looper

the

Yoke -in

Screw

Ball

Carrier

carrier

into

on

the

carrier

from

be

looper

to

for

the

the

4-1/32".

has

to

the

adjusting

the

shaft

edge

side

means

is

taking

which

and

machine.

of

the

is

assembled

of

of

the

See

for

drawing,

the

the

are

the

looper

Now,

looper

the

looper

looper

adjusting

the

are

looper

loop

looper

yoke

carrier

to

the

ball

following

numbered

position

from

yoke

are

the

looper

looper

yoke

pin

nearest

chart -Figures

the

pin

holes

set

before

ball

by a spot

yoke

hole

near-

to

adjustments,

as

follows:

on

the

right

needle.

as-

is

so

the

5

•

hand

Adjustment

side

or

Adjustment

to

right

Means

when

Means

or

5

the

6

right

for

needle

for

to

left.

adjusting

is

between

adjusting

the

the

looper

the

prongs

position

position

of

of

the

on

the

looper

the

left

looper.

from

hand

left

Page 18

17

•

Adjustment

must

6

2

TIMING

the

turn

wheel

slot

with

chine

and

and

two

be

the

3.

set

the

towards

in

the

the

which

7

Means

Before

in

accordance

needle

The

THE

machine

two

LOOPER

Timing

screws

needle

dots

There

will

for

setting

setting

looper

the

over

the

rear

eccentric

at

is a "V"

be

adjusting

the

with

must

is

and

looper

on

the

by

the

of

the

bottom -See

at

the

top

the

looper,

instructions

be

as

can

be

is

relative

looper

hand

the

machine

ball

stud

notch

of

cut

the

looper

the

described

timed

crank.

wheel

is

Figure

in

shaft.

in

looper

for

at

to

To

by

until

straight

the

main

and

Figure

in

only

the

needle.

time

turning

the

1,

out.

carrier

5

and

adjustments

one

place.

Loosen

the

looper,

the

screw

up

adjustment

shaft

driver

and

of

assembly

Figure

1,

hand

down

1.

the

ma-

•

ure

4.

crank

shaft.

minus

chine

ADJUSTING

following

here

loop

the

eye

needle.

coincides

This

relative

with

given:

from

point

and

steps

of

the

There

Turn

timing

Clamp

the

two

AND

To

secure

The

looper

the

needle.

The

position

this

point

is a timing

the

looper

with

the

mark

to

the

edge

the

looper

set

SETTING

the

should

is

prong

of

the

crank

left

will

of

screws.

correct

be

taken

first

for

the

3/32"

long

mark

hand

not

the

crank

THE

and

adjusted

long

from

prong

on

the

until

the

edge

of

vary

more

"V".

to

the

main

LOOPER

adjustment

in

the

as

prong

the

inner

just

clearing

looper

timing

the

than

of

same

the

looper

of

the

end

crank -See

mark

"V"

on

the

1/32"

shaft

of

the

looper,

sequence

is

looper

of

the

the

scarf

on

the

main

plus

the

ma-

the

as

taking

is

to

needle

of

Fig-

or

the

have

the

Page 19

18

ments

are

To

taken

secure

and

this

made:

setting,

the

following

steps

and

adjust-

top

of

the

slowly

of

4,

the

permits

right -and

ment

ner

just

clamp

clamp

tion,

passing

ing

chaining

the

these

until

the

needle.

Figures

looper

the

6,

until

end

of

clears

screw

screw -See

until

chaining

1/32" -See

finger,

previous

should

Turn

hand

wheel

the

Loosen

2

and

just

clears

Loosen

looper

slide

the

the

needle

Check

the

scarf

-

See

Continue

the

short

adjustments

be

the

hand

will

long

prong

the

5 -

and

the

eccentric

the

looper

long

eye.

to

see

of

Figure

Figure

to

prong

finger,

Figure

or

if

the

re-made.

wheel

looper

roll

the

sleeve

prong

that

the

rotate

if

7.

clearance

have

be

moved

of

the

yoke

the

scarf

clamp

sleeve

eccentric

of

point

needle.

5,

and

2.

the

of

the

foot

If

the

in

clockwise

away

looper

clamp

looper

of

the

screw -See

the

looper

of

Tighten

the

hand

looper

has

chaining

short

is

not

been

from

is

screw -See

until

needle.

to

be

moved

sleeve

is

the

long

looper

wheel

is

prong

greater

correctly

direction;

the

over

the

-

Figure

3/32"

prong

the

eccentric

in

clockwise

at

nearest

finger,

does

than

operator

the

center

long

Figure

from

from

of

looper

not

not

1/32",

made,

that

is,

very

line

Adjustment

prong

2 -

this

left

to

2,

adjust-

the

in-

the

looper

yoke

sleeve

direc-

point

exceed-

clear

and

when

the

then

the

t:

•

of

tion

until

the

looper

not

enter

prong

the

looper

looper

short

crotch

the

prongs

until

instead

ing

corrective

the

the

will

eccentric

prong

of

the

the

point

of

Continue

short

slot

in

looper

clear

eccentric

clears

Care

looper

of

the

Continue

of

so

doing

steps

to

rotate

prong

the

the

sleeve

the

must

looper.

to

the

strikes

of

the

foot.

slot

edge

sleeve -Adjustment

be

when

needle

are

in

of

the

edge

taken

the

turn

required:

If

the

the

least

the

should

the

the

the

foot,

of

the

now

needle

hand

crotch

hand

looper

short

looper

amount

looper

as

wheel

enter·

wheel

has

prong

adjust

slot

the

should

of

in

passed

of

so

in

6,

Figure

possible

slot.

needle

be

in

clockwise

between

the

looper

clockwise

the

the

looper

that

the

the

foot

2.

so

may

entering

the

-

direc-

edge

short

by

moving

Move

that

strike

between

direction

prongs

the

of

does

the

the

the

but

follow-

f;

•

Page 20

19

•

Figure

the

needle

er,

clearing

the

two

-

Figure

5,

Figure

distance

tighten

tion

until

center

prong

needle

of

must

tenth

SETTING

ment

of

the

needle.

be

paragraphs

4,

Loosen

4,

and

turn

does

The

needle

the

In

case

prongs -to

2,

and

turn

2,

until

from

the

line

the

and

corrected

Figure

the

sleeve

Continue

the

point

of

the

looper

that

THE

the

In

LOOPER".

5.

the

crank

not

strike

two

prongs

the

correct

the

the

needle.

clamp

to

of

needle.

is

point

case

-

this

inclusive

Do

two

set

slightly

the

must

needle

prongs

rotate

the

3/32"

not

enter

about

this,

looper

When

screw -See

long

Check

of

the

the

above

is

done

under

Be

turn

screws

in a clockwise

crotch.

between

an

should

loosen

eccentric

of

the

this

the

hand

prong

to

from

the

long

conditions

as

the

sure

the

looper

on

the

Tighten

equal

not

enter

the

looper

setting

Figure

wheel

of

the

see

that

inner

prong

described

heading

to

roll

looper

the

prongs

amount.

about

sleeve

sleeve -Adjustment

are

has

2,

in a clockwise

looper

the

end

just

do

"ADJUSTING

the

eccentric

crank -See

direction

the

set

midway

clamp

about

clears

not

in

looper -Adjust-

been

is

point

of

eye

exist,

the

an

over

fifth

sleeve.

screws

of

the

equal

made,

of

the

of

the

they

until

screw

the

the

scarf

to

•

loop-

of

direc-

long

AND

•

cerned,

threads

However,

ding

silks

of

the

ser

er

position

Figure

direction

to

the

RETAINER

presser

needles

firmly

ing

no

is

may

or

hemming

and

needle

foot -Figure

1 -

needle

as

hold

the

material.

loop

will

The

machine,

now

ready

cause a slight

these

cotton,

1/16"

by

re-adjusting

the

timing

towards

resulting

OR

CLOTH

The

Cloth

foot

must

possible

the

work

form,

to

sew.

adjustments

the

more

however,

from

3,

instead

dots

the

hand

in a larger

CLAMP

Retainer

at

all

and

set

on

to

If

the

work

resulting

as

far

variation

heavy

it

the

the

on

wheel

times

the

as

Different

will

give

may

needle

of

3/32",

needle

the

located

be

relative

disc

is

carried

in

missed

the

looper

material

from

the

materials.

be

advisable

setting

without

ball

ball

stud

to

obtain

thread

in

adjusted

to

the

while

stitches.

and

needle

or

different

the

above

best

results

When

to

surface

changing

stud -Adjustment

should

slightly

loop.

the

cloth

a·s

close

ridge

the

needle

along

with

adjustments.

hemming

set

the

on

be

turned

more

opening

to

forming

is

the

are

when

point

the

pres-

the

loop

throw

of

the

disc

penetrat-

needle,

con-

pad-

-

1,

in

the

to

Page 21

20

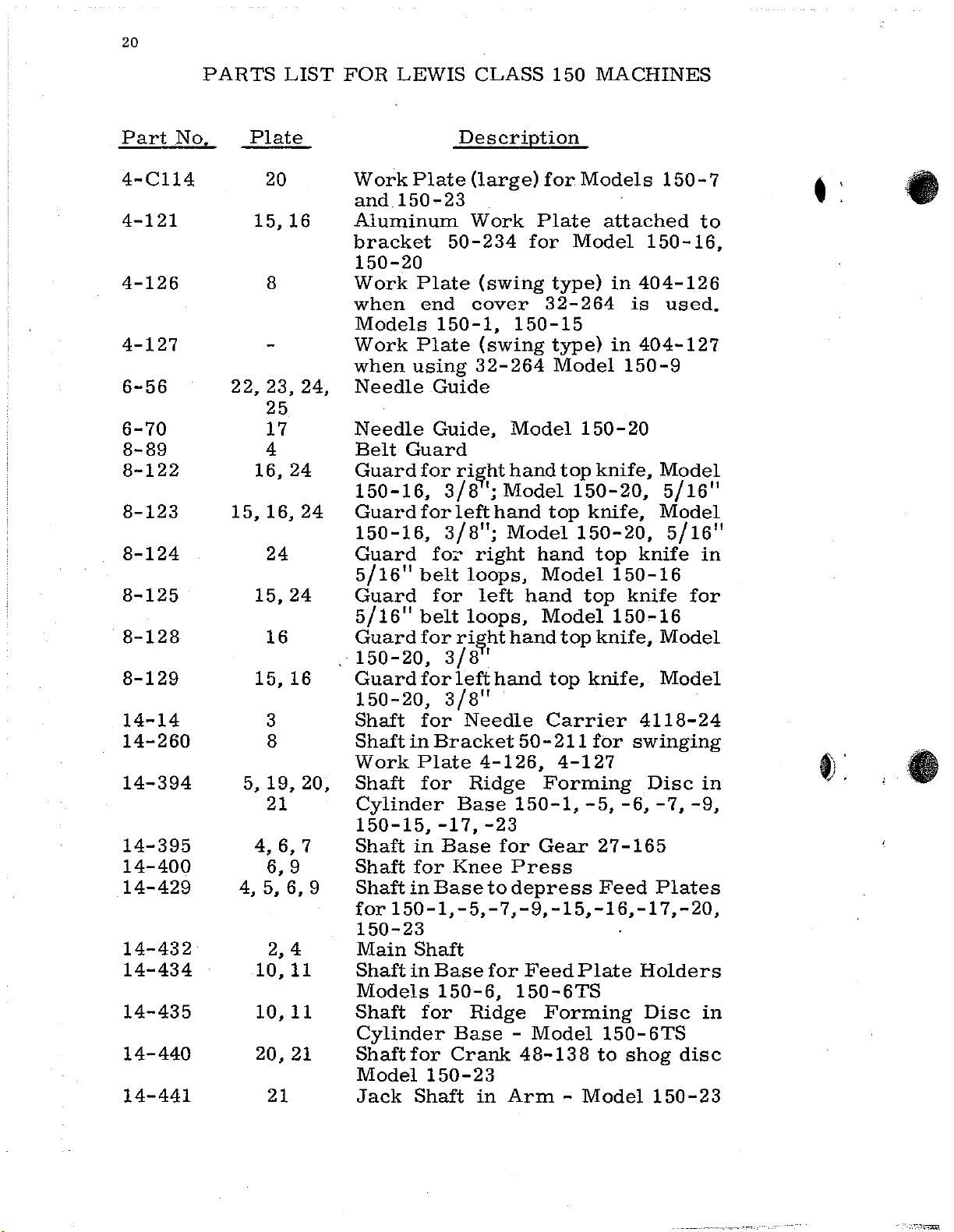

Part

4-Cll4

4-121

4-126

4-127

6-56

6-70

8-89

8-122

8-123

8-124

8-125

8-128

8-129

14-14

14-260

14-394

14-395

14-400

14-429

14-432

14-434

14-435

14-440

14-441

PARTS

No.

Plate

20

15,

8

22,

23, 24,

25

17

4

16,

15,

16,

24

15,24

16

15,

3

8

5,

19,

21

4,

6,

6,

4,5,6,9

2, 4

10,

10,

20,

21

LIST

16

24

24

16

20,

7

9

11

11

21

FOR

LEWIS

Work

and

Aluminum

bracket

150-20

Work

when

Models

Work

when

Needle

Needle

Belt

Guard

150-16,

Guard

150-16,

Guard

5/16"

Guard

5/16

Guard

150-20,

Guard

150-20,

Shaft

Shaft

Work

Shaft

Cylinder

150-15,-17,-23

Shaft

Shaft

Shaft

for

150-23

Main

Shaft

Models

Shaft

Cylinder

Shaftfor

Model

Jack

Plate

150-23

50-234

Plate

end

150-1,

Plate

using

Guide

Guide,

Guard

for

ri~ht

3/8

for

left

3/8";

fo~·

belt

for

11

belt

for

ri~ht

3/8

for

left

3/8"

for

in

Bracket

Plate

for

Base

in

Base

for

Knee

in

Base

150-1,-5,-7,-9,-15,-16,-17,-20,

Shaft

in

Base

150-6,

for

Base -Model

Crank

150-23

Shaft

CLASS

Description

(large)

Work

(swing

cover

(swing

32-264

';

Model

hand

right

loops,

left

loops,

I

hand

Needle

4-126,

Ridge

for

to

for

Ridge

in

150

for

Plate

for

type)

32-264

150-15

type)

Model

Model

hand

top

Model

hand

Model

hand

Model

hand

top

Carrier

50-211

Forming

150-1,

Gear

Press

depress

Feed

150-6TS

Forming

48-138

Arm -Model

MACHINES

Models

attached

Model

in

in

150-20

top

knife,

150-20,

knife,

150-20,

top

150-16

top

150,-16

top

knife,

knife,

for

4-127

-5,

-6, -7,

27-165

Feed

Plate

150-6TS

to

150-7

150-16,

404-126

is

used.

404-127

150-9

Model

5/16

Model

5/16"

knife

knife

4118-24

swinging

Holders

shog

for

Model

Model

Disc

Plates

Disc

disc

150-23

to

in

in

-9,

in

•

11

•

• •

Page 22

21

•

•

Part

14-458

16-39

16-148

16-194

No.

16-196

16-214

16-239

16-255

16-279

16-317

16-322

16-329

17-87

17-111

17-113

17-114

17-145

17-146

17-149

17-150

17-153

17-157

18-38

PARTS

Plate

4,

2, 4

17,

2, 5

2, 4

20, 21

17,

4,

2,

15,16,24

4,

LIST

7,

9

3

3

3

22, 24,

25

6

21

21

22,

24,

25

25

25

2

6

3

2

2, 3

9

15,

24

FOR

LEWIS

Description

Shaft

Lever

Needle

Head

Needle

Head

BushinginArm

length

BushingforMain

end

Bushing

ing

Bushing

Bushing

justing

CS317

Bushing

17-114

and

Bushing

End

Bushing

shogging

Bushing

end

Eccentric

adjusting

Eccentric

126-43

405-514

Stud

Foot

150-7

Eccentric

446-118

Stud

Rods

Stud

70-53

Stud

for

Stud

Stud

Cylinder

Eccentric

for

Screw

attachingll0-236,

mer

in

Base

45-352

Shaft

Shaft

of

stitch

of

Arm

in

Cloth

in

(eccentric)

Gear

in

for

in

Cylinder

for

of

Arm

disc

for

of

Arm,

and

and

for

Crown

405-409-1

in

Lever

447-118

for

in

Looper

Looper

for

Feed

for

Base,

Disc

Locking

for

bracket,

Presser

Retainer

in

Stud

Cloth

Stud

Looper

CLASS

for

Bushing

Bushing,

for

Base

27-215,

Head

adjusting

Base

Main

base

Model

Main

Model

in

Retainer

for

126-47

405-558

Stud

45-352

and

Drive

Bearing

Lever

Plunger

Model

Stud

for

Indicator

Model

150

MACHINES

oscillating

Front

Rear

26-47

Shaft

for

for

Shaft,

Bushing

126-36

and

in

14-432

Feet

Shaft

adjusting

447-125

Ball

Mechanism

for

Knee

in

Arm

use

Eccentric

height

for

Hand

for

14-440

150-23

Hand

150-23

on

presser

405-522

Head

for

Joint

Crank

in

Head

Link

150-16,150-20

adjusting

155-9

110-237to

150-16

disc

End

of

end

of

to

change

Head

adjust-

Lift

Rod

for

Ad-

set

screw

Stud

of

feed

14-429

Wheel

for

Wheel

16-214

on

Presser

for

Connecting

46-157

for

Crowns

feet

Model

Link

Sleeve

48-1~5

Latch

and

for

trim-

in

Page 23

22

Part

18-70

18-71

18-74

18-CllO

18-121

18-125

18-C186

18-261

18-270

18-277

18-281

18-292

18-295

18-307

18-318

18-326

18-330

18-345

18-355

18-391

No,

18-375

18-400

18-416

18-492

18-493

18-500

PARTS

1 7,

22,

12,18,19,

2,

17,

LIST

Plate

3

2

3

13,

8

11

13,

13

22,

8

23

23,

10,

3,

21,

6

13,

25

4

16

3,

16

22,

25

2

6

9

14

14

24

25

11

17

25

14

15

24,

FOR

LEWIS

Clamp

Clamp

Spot

Screw

carrier

Screw

50-223

405-538,

Screw

s·crew

Set

Screw

ing

folders,

Screw

Screw

Screw

Screws

110-230

and

150-6TS

Screw

presser

Bearing

base,

Screw

ket

150-16,

Screw

44base,

Screw

knee

Screw

for

150-15

Screw

405-514,

Screw

regulator

Screws

3/8

Screw

4124-56

Screws

3/8

Screw

eccentric

Spot

Screw

Set

stud

Models

50-160,

275

Models

lift

bracket

inch;

inch

Screw

Screw

17-157

CLASS

Description

Screw

Screw

for

to

in

for

for

in

in

for

for

for

for

for

for

for

for

for

in

for

for

in 4 79-8 to

4118-15

attaching

presser

Models

shaft14-260for

Spring21-332

for

Models

attaching

end

work

attaching

to

presser

holding

feet

Screw

holding

-20

attaching

to

plunger

clamping

shaft

cover 3 2-107

50-223,

presser

405-522,

107-51

in

cylinder

for

top

Model

447-97-1

and

447-23,

for

top

bushing

stud 1 7-

for

70-28

in

base

150

needle

for

looper

feet

150-9

collar

of

eccentric

plate

for

feed

150-6

presser

and

150-7

in

base

405-558

ridge

knives,

150-20,

knives,

87

eccentric

sleeve

for

MACHINES

carrier

locate

folder

405-497, 405-537,

and

Model

39-C255

150-9,

1733 L to

for

holding

roll

forming

feet,

chaining

and

for

26-152

and

in

16-214

plate

150-6TS

22-257,

ridge

150-23

39-117

of

arm

on

Models

foot

base

Model

5/16

head,

Model

Model

in

presser

433-93

for

locking

Models

forming

4118-

yoke

foot

forming

head,

449-27

on

looper

bracket

150-15

work

150-6TS

for

locat-

150-15

50-280

stud

folders

fingers

in

cylinder

to

in

cylinder

collar

150-9

405-409-1,

150-16,

inch

screws

150~16

150-20,

for

holding

foot

in

knee

eccentric

17-

150-6

brac-

Model

screw

24

plate

87

plate

disc

and

disc

head

press

L

to

to

in

•

•

Page 24

23

~

:

•

•

Part

18-561

18-565

18-602

18-622

18-623

18-624

18-628

18-643

18-644

18-647

18-657

18-662

18-664

18-674

18-700

18-701

18-702

18-715

18-732

18-737

18-738

18-744

18-749

PARTS

No

.

LIST

Plate

20

2

15

13

22

4

7,

8

17,

22,

23,

25

2

7

13, 14, 15,

17,

24

2

2,

4,

7

2

2,

4,

21

5

3

15

2

2

2,

15

25

9

FOR

LEWIS

Screw

Model

Screw

Screw

limitlengthofstitchModel

Screw

150-9

Screw

ser

Screw

inder

Screws

and

Screw

Foot

Screw

Screw

inder

Screw

Models

for

Screw

Sleeve

Screw

Base

bottom

Screw

Head

Spot

Eccentric

Spot

in

HexHead

Crank

Screw

under

Screw

Screw

in

Screw

Yoke

Model

Knurled

Presser

Screw

for

150-23

for

for

for

Foot

for

Base

21-375

for

for

Base

for

Plate

for

to

to

Screw

Screw

Cylinder

48-105

Head,

for

for

Head

449-27

150-16

for

CLASS

Description

4124-55

Aluminum

in

Stitch

Folder

Cloth

Eccentric

for

Feed

for

70-53

of

in

for

for

Needle

40-151

Spring

Clamping

150-9

110-295.

clamping

hold

Arm,

Cylinder

Stitch

433-144

for

Base

Spot

Knife

Feed

Looper

Pin

Screw

Feet

adjusting

Regulator

Spring

Retainer

and

in

Head

Head

and

Regulator

for

Ridge

Pivot

Screw

in

Head

Model

Driving

Shaft

and

for

for

Plate

in

Link

150-15.

adjusting

150

MACHINES

Ball

Guide

Bracket

Base

in

Drive

150-16,

Joint

Head

21-3

Stop

433-151

Springs

Arm

46-148

Folders

Model

Looper

to

Arm,

Forming

Arm

Bearing

for

22-8

holding

Crank

in

Base,

Cover

149-16

150-16,

85,

on

on

Presser

to

Screws

150-16

Adjusting

Cylinder

50-222

149-16

Needle

Link

150-20

Crank48-135

in

17-153

Crowns

48-150

-20

Model

Pres-

in

Cyl-

21-7

in

Cyl-

Foot,

Disc

117-41

Drive

46-155

Looper

to

5

(2)

to

in

in

on

Page 25

24

Part

18-

No.

750

18-750

18-

751

18-757

18-

764

18-766

18-767

18-869

18-

870

18-872

18-

892

18-895

18-900

18-906

18-909

18-C911

18-918

18-919

18-920

18-921

18-922

18-923

PARTS

2, 3

5, 6, 9

5,

4,

6,

LIST

Plate

10,

*

3

21

4

3

5

13,

5

5

5

20

5

14

12,

19

9,

5,9

5

4

4

11

18,

20

16

FOR

Screw

150-6

Screw

Hex

Eccentric

Hex

150-23

Screw

release

Screw

447-97-1

Screw

lever

Pivot

140-11

Hex

connect

Base

Shoulder

Holders

Stop

of

Hinge

on

Screws

Cylinder

Flat

4-Cll4,

Screw

Cradle

Base

Screw

Foot,

.

Taper

Cylinder

Hex

48-151

Flat

top

Flat

Plate

Adjusting

to

Adjust

height

LEWIS

for

and

for

Screw

Screw

on

hole

for

for

in

Bearing

and

Shoulder

Screw

Cylinder

Screws

top

of

for

Head

for

140-11

for

Model

Bearing

Clamp

in

Head