Page 1

INDUSTRIAL

SEWING

®

INEST QUALITY

ST

YLE

~50-

200

C 0 L U M B I A®

MACHINES

:ATALOG

LIST

OF

PARTS

No.

AND

194-12

INSTRUCTIONS

...

.,

UNION SPECIAL

CHICAGO

Price

$1.00

CORPORATION

Page 2

Catalog

INSTRUCTIONS

No.

FOR

194-12

ADJUSTING

Union

Rights

LIST

Style

First

Copyright

Special

Reserved

AND

OF

150-200

Edition

by

in

OPERATING

PARTS

1963

Corporat

All

Co

i

on

t!l.

ntries

UNION

SPECIAL

INDUSTRIAL

Printed

CORPORATION

SEWING

CHICAGO

in

U.S.A.

2

MACHINES

I

\~~

·'

'

Octob

er ,

1977

Page 3

Each

plate on

the top

UNION

the

head

cover.

SPECIAL

of

the

machine.

IDENTIFICATION

LEWIS

machine

The

serial

OF

MACHINES

carries a style

number

of

each

number

machine

which

is

stamped

is

stamped

in

the

in

arm,

the

style

under

This

catalog

Consult

catalog.

to direction

position

i

nturned

a trimmi

good

painted

catalog

Opposite

Th

is

catalog

while

Style

edge

ng

The

machine

grade

Most

red.

The

recommended

such

seated

150-200

finish

device,

of

straight

of

the oili

is a

supplement

No.

184-5,

the

illustrated

applies

as

right,

at

is a single

belt

front

should

mineral

ng

places

operating

machine

specifically

left,

the

machine.

needle,

loop

in

top

be

5/16

feed

oiled

oil

on

APPLICATION

to

catalog

Style

page

to

front,

DESCRIPTION

drive,

twice

of

aSaybolt

the

machine

speed

No.

150-20,

is

listedeach

the

Standard

back,

Operating

chainstitch,

or

3/8

inch

and a stationary

OILING

daily,

SPEED

of

this

NEEDLES

OF

194-5

for

part

Style

up

or

direction

OF

blindstitch

finished

before

viscosity

are

readily

machine

CATALOG

and

should

all

parts

by

number,

of

machine

down,

MACHINE

of

widths.

work

the

morning

of

90

identified

is

3000

etc.,

handwheel

be

used

not

illustrated

name

as

listed

are

given

is

machine for

This

support

and

to

125

seconds

because

R.

P.

M.

in

conjunction

or

described

and

amount

herein.

from

the

away

from

the

producing a double

machine

plate.

afternoon

of

at

is

st&rts.

100

the

equipped

fact

therewith.

in

this

required.

References

operators

operator.

with

Use

Fahrenheit.

they

are

a

Use

only

~

The

recommended

of • 036

Thread

or

would

go,

penetration

inch

Selection

should

To

have

the

Type

read: 11100

When

and

tighten

Immediately

genuine

w

.

(. 90

of

proper

pass

needle

number

changing

clamp

discard

will

result.

UNION

needle

mm).

needle

freely

orders

should

Needles,

needle,

screw

SPECIAL

It

is

also

Needle

29

BL-065/025

29

BL-075/029

29

BL-100/040

29

BL-110/044

through

promptly

be

Type

make

securely.

any

needle

for

this

available

Type

size

is

needle

and

forwarded.

29

BL-090/036''.

sure

which

needles.

machine

in

the

determined

eye

in

accurately

Use

CHANGING

that

it

is

may

have a hooked

THREADING

The

needles

is

Type

following

•

025

•

029

•

040

•

044

by

size

order

filled,

the

description

NEEDLES

inserted

are

packaged

29

BL-090/036.

sizes:

Size

inch

(. 65

mm)

inch

(.

75

mm)

inch

(1.

00

inch

(1.10

of

thread

to

produce a good

an

empty

on

in

the

needle ca

or

blunt point,

under

It

mm)

mm)

and

weight

stitch

container, a sample

the

label. A complete

r r i

our

has a blade

of

material

formation.

er

as

as i

mproper

brand

far

name

diameter

used

needle,

order

as

it

will

needle

.

To

highe

thread

st

position.

the

machine,

Thread

turn

hand whe

machine

as

indicated

el

in

operating

on

threading

direction

diagram

3

until the ne

on

next pag

edle

carrier

e.

is

in

its

Page 4

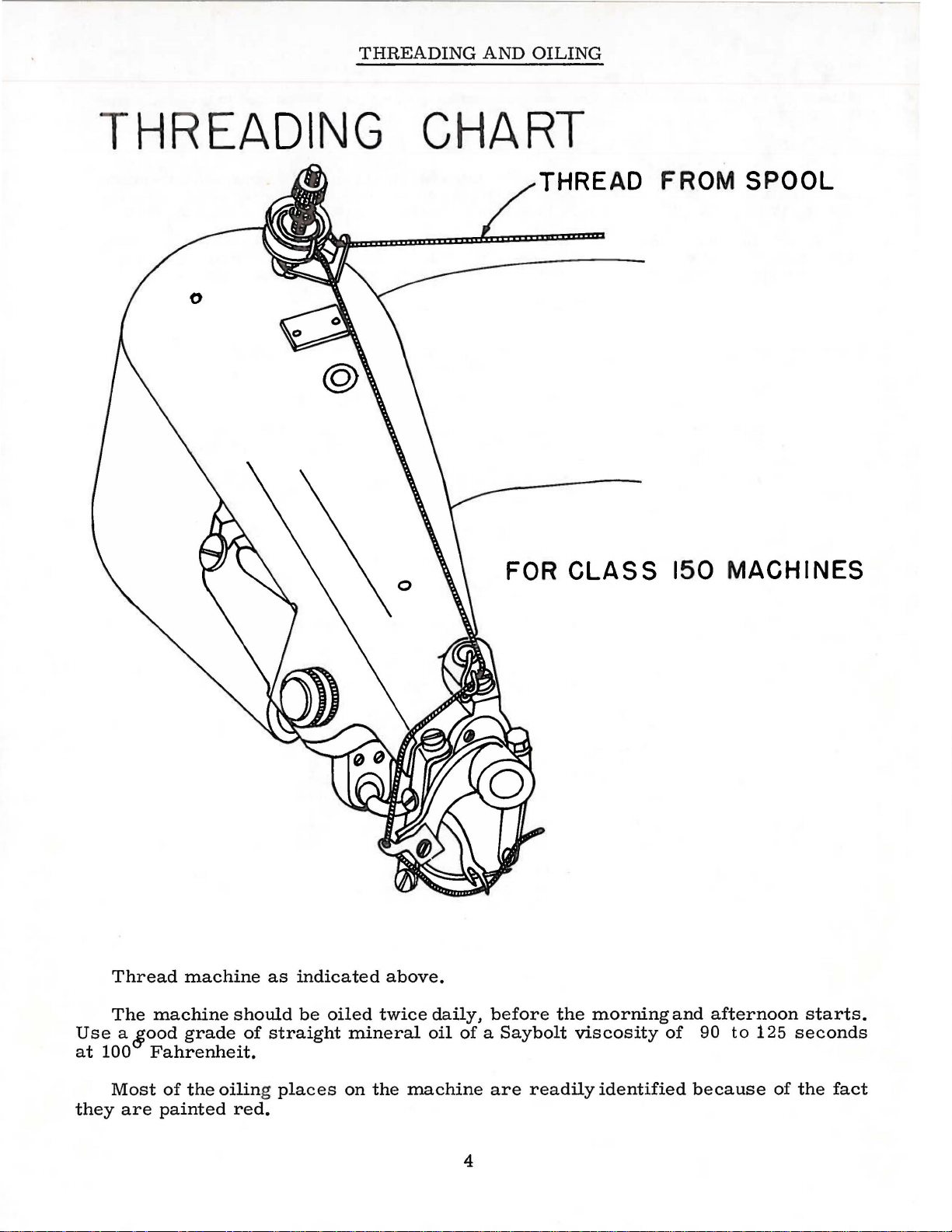

THREADING

AND

OILING

TH

RE

ADING

CHART

THREAD

FOR

CLASS

FROM

150

MACHINES

SPOOL

Thread

The

Use a &ood

at

100

Most

they

are

machine

machine

grade

Fahrenheit.

of

the

painted

should

oiling places

red.

as

of

straight

indicated

be

oiled

mineral

on

above.

twice

the

daily,

oil

of a Saybolt

machine

4

before

are

readily

the

morning

viscosity

identified

and

of

because

afternoon

90

to

125

starts.

seconds

of

the

fact

Page 5

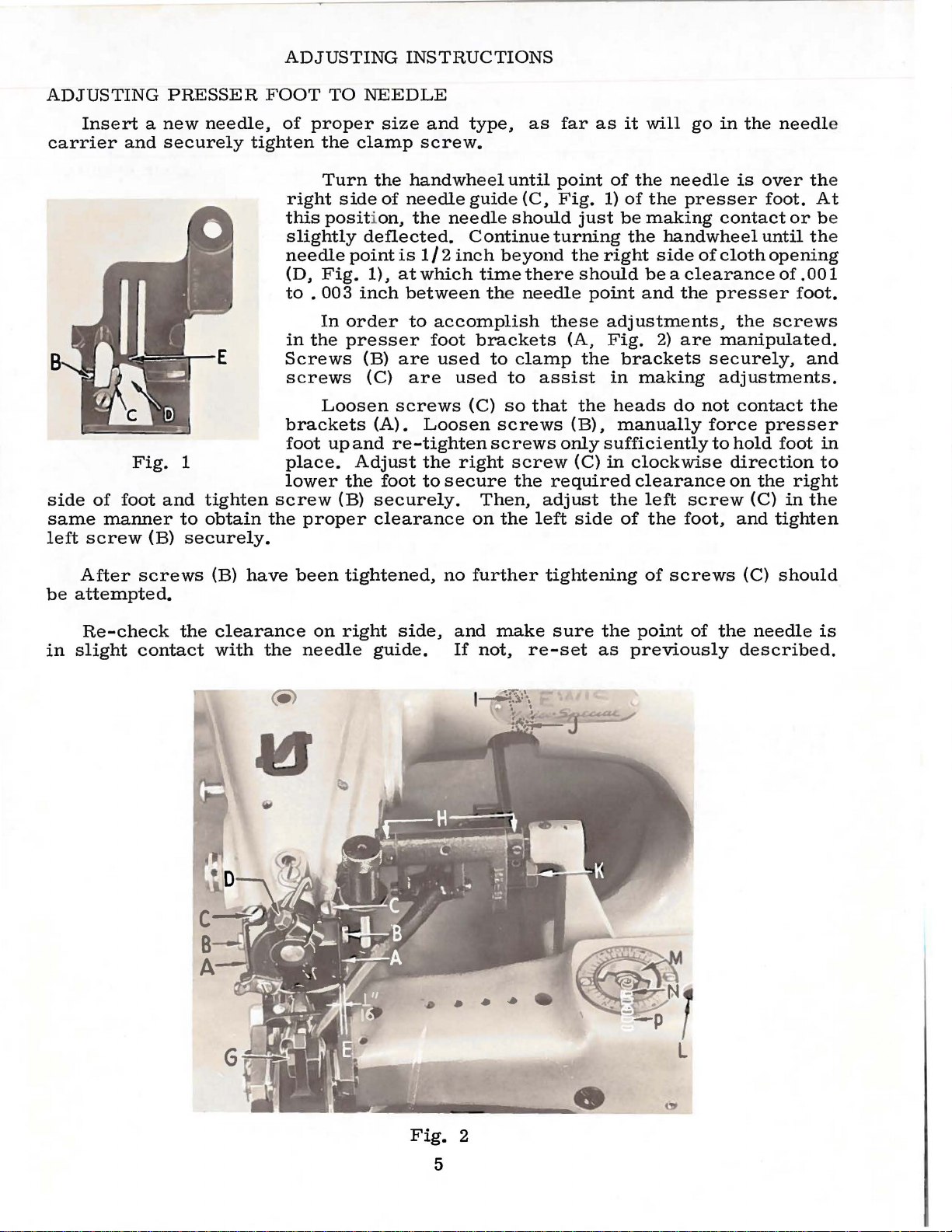

ADJUSTING

INSTRUCTIONS

ADJUSTING

Insert a new

carrier

side

same

left

of

foot

manner

screw

and

Fig.

PRESSER

securely

1

and

tighten

to

(B)

securely.

needle,

tighten

obtain

FOOT

of

right

this

slightly

needle

(D,

to

in

Screws

screws

brackets

foot

place.

lower

screw

the

proper

TO

NEEDLE

proper

the

clamp

Turn

side

position,

deflected.

point

Fig.

.

003

inch

In

order

the

presser

(B)

(C)

Loosen

up

and

Adjust

the

(B)

size

and

screw.

the

handwheel

of

needle

the

is

1/2

1),

at

which

between

to

foot

are

are

screws

(A).

securely.

clearance

Loosen

re-tighten

the

foot

to

type,

until

guide

needle

inch

accomplish

used

used

right

secure

should

Continue

beyond

time

the

brackets

to

clamp

to

(C)

so

screws

screws

screw

the

Then,

on

the

as

far

point

(C,

Fig.

turning

there

needle

these

(A,

assist

that

only

required

adjust

left

as

it

of

1)

of

just

be

the

the

right

should

point

adjustments,

Fig.

the

brackets

in

the

heads

(B),

manually

sufficiently

(C)

in

the

side

of

will

go

in

the

needle

the

presser

making

handwheel

side

be a clearance

and

2)

making

do

clockwise

clearance

left

the

contact

of

cloth

the

presser

are

manipulated.

securely,

adjustments.

not

force

to

direction

on

screw

foot,

the

needl

is

over the

foot.

until the

opening

of

the

screws

contact

presser

hold

foot

the

(C)

and

tighten

or

.001

foot.

and

the

right

in

the

e

At

be

in

to

After

be

attempted.

Re-check

in

slight

screws

the

contact

(B)

have

clearance

with

the

been

on

needle

tightened,

right

side,

guide.

no

and

If

.

further

make

not,

..

...

tightening

sure

re-set

of

the

point

as

previously

screws

of

the

(C)

should

needle

described.

is

Fig.

2

5

Page 6

ADJUSTING

INSTRUCTIONS

(Continued)

POSITIONING

Turn

extreme

the

needle

the

presser

To

allow

the

above

Turn

extreme

right

If

have

needle

screw

top

of

stud

to

15

the

ball

check

the

left

previously

retard

obtain

the

edge

this

to

at

in

head

{,A,

to

the

the

left

groove

carrier

setting

the

right

(E,

is

be

adjusted

its

the

(A,

Fig.

the

stud

position

side

described.

or

advance

foot.

results.

THE

NEEDLE

handwheel

position.

(B,

this

adjustment,

to

is

obtained.

handwheel

position.

Fig.

not

2)

the

in

extreme

needle

Fig.

4)

right

so

crank,

3).

that

of

down.

of

of

looper

this

in

In

this

Fig.

be

1)

moved

in

The

of

the

case,

the

following

left

the

position,

accessible

Turn

the

lower

vertical

Re-tighten

the

needle

opening

It

may

adjustment

operating

position

and

even

loosen

by

taping.

operating

point

presser

travel

manner.

the

needle

end

with

the

clamp

point

in

the

be

necessary

to

direction

the

with

needle

direction

of

needle

foot.

of

the

loosen

through

eccentric

of

its

punch

screw

in

presser

obtain

until

needle

the

left

clamp

Re-tighten

until

should

needle

the

With

clamp

will-

the

hole

balJ

slot

is

10

marks

and

re-

relation

foot

as

to

slightly

desired

point

side

screw

clamp

be

on

in

to

the

should

the

1/16

needle

of

the

(D,

Fig.

screw

needle

be

looper

inch

has

in

2)

(D,

has

from

reached

the

opening

just

Fig.

reached

center

enough

2) when

the

upper

the

of

in

to

the

CAUTION!

stud,

shaft

make

crank.

TIMING AND

is

Turn

at

the

the

bottom.

When

sure

adjusting

that

ADJUSTING

Fi

g. 4

handwheel

it

is

LOOPER

in

operating

the

needle

seated

needle

enters

loop

in

its

there

holder

and

(A,

eccentric

against

The

looper

motion

the

of

needle

Under

the

following

Insert

shank

is

1/64

(Fig.

In

the

on

the

Fig.

direction

ball

the

needle

motion

so

that

spot

of

the

thread

normal

conditions,

manner.

the

looper

corresponds

inch

5).

left

end

of

looper

5).

until

the

is

the

needle

is

being

in

its

with

space

the

main

crank,

"V

timed

long

at

formed.

this

holder

flat

on

between

shaft

there

1

groove

Fig.

in

relation

prong

the

of

time

timing

so

that

holder

looper

is

a

is a timing

in

the

3

the

the

is

the

and

seat

11 V 1

main

to

the

looper

largest

adjusted

flat

on

so

that

and

groove,

line

sha

ft

Loosen

so

that

shaft.

its

This

the

two

timing

settin

set screws

line

coincides

g

will

be

in

the

with

satisfactory

looper

the

for

6

crank

right

average

edge

(B,

Fig.

of

the

conditions.

4)

"V

and

1

position

groove

in

the

the

crank

main

Page 7

ADJUSTING

INSTRUCTIONS

(Continued)

Variations in

advance or reta

Again,

is

over

clear

of

the

presser

On

clear

return

The

sleeve

the

the

turn the

the

spot

spot

needle

foot

continuing

stroke,

adjustment

and

eye,

(E,

right

the

materials

rd

this timing

handwheel

in the

in

the

and

Fig.

the

side

should

of

looper

needle.

needle

the

1)

rotation

of

the

enter

the

holder

and

and

short

by

no

looper

looper

connecting

threads

to

obtain

in

operating

At

this

be

prong

more

of

the

opening

the

crotch

is

used

the

direction

point,

from

1/16

of

the

than

1/32

handwheel,

in

of

secured

rod.

may

desired

the

long

to

3/32

looper

inch

the

the

presser

the

looper

by

manipulation

Fig.

and

of

Lateral

loosening

pulling

Vertical

secured

make

results.

until

.

short

The

vertical

prong

inch

should

midway

looper

5)

positions

also

the

by

the

foot,

provides

adjustment

it

necessary

long

of

the

to

the

left

clear

prong

the

adjusting

or

turning

of

and

between

of

the

adjusting

the

or

clamp

height

prong

looper

of

the

the

the

looper

looper

a

limited

height

is

sleeve

adjustment

the

to

of

the

should

the

inner

bridge

looper

needle,

the

adjusting

sleeve

laterally,

adjustment.

secured

screw

in

sleeve.

slightl

looper

just

end

of

the

should

on

its

prongs.

(B,

amount

by

(C)

and

or

out.

is

y

in

the

looper

the

looper

required,

adjustment

REAR

operating

moving

the

foot.

of

The

to

is

inch.

To

right

the

feed

the

made

FEED

set

to

Set

feed

bottom

connecting

to

the

it

can

of

both

POINT

the

direction

the

edge

the

rear

point

surface

of

with

the

desired

be

rear

left

of

is

the

Fig.

secured

the

connecting

feed,

until

and

the

feed

1/4

should

presser

stitch

5

rod

height.

turn

the

is

cloth

point

inch

be

length

yoke

by

turning

point

1/16

opening

so

in

flush

foot.

(D)

If

rod

the

inch

that

back

set

and

by

turning

only a slight

the

adjusting

and

adjusting

handwheel

of

the

needle

to

the

in

the· presser

the

short

of

the

with

at

This

7

and

adjustment

stitches

The

looper

also

adjusts

to a greater

sleeve.

If

the

adjustment,

made

right

needle.

parallel

the

amount

sleeve.

sleeve.

in

the

prong

per

by

loosening

connecting

is

of

holder

the

looper

extent

looper

the

of

Final

than

is

initial

the

rod

height

setting

connecting

vertically,

the

adjusting

radically

adjustment

clamp

{E),

adjustment

involves

rod

but

out

of

is

screw

rolling

is

The

(A,

arm.

feed

Fig.

6)

holding

point

is

adjusted

the

feed

by

point

means

to

the

of

7

two

feed

screws

driving

Fig.

6

Page 8

FEE

D P

LATEN

ADJUS

TING

INSTR

UCTIONS (Continued)

When the feed point

a

gai

nst the

The

tension

on

There

the

needle

will

not

Check

needle

penetrates

Pressure

controlled

the

cylinder

platen

the

must

makes

be

formed

to

by

bottom

platen

see

on

the

(A,

counterclockwise

clockwise

RIDGE

The

should

opening

as

noted

Adjustment

to

the

ridge

distance

the

small

is

1/16

directly

acts

FORMING

yielding

be

located

in

the

in

subsequent

11

•

right,

the

former

from

radius

inch

over

the

presser

As

should

the

when

the

of the pre

is

controlled

be

enough

its

for

that

material.

the

two

Fig.

increases

reverse.

DISC

ridge

in

the

forward

point

of

the

the

disc.

is

on

its

feeding strok

sser

by

two

will

compensate

pressure

penetration.

the

looper,

the

feed

feed

nuts

in

the

7).

Turning

the

forming

the

center

foot

and

platen

applied

If

resulting

platen

back

them

tension,

disc

of

the

folder,

paragraph 11Folder

needle

be

position

set

of

the

nose

needle

is

traveling

so

that

needle

on

the

point

of

the

the

disc

e,

foot

springs

for

and feed

which

varying

to keep

the

material

in

skipped

clamps a piece

is

of

to

is

the

feed

point

should

thicknesses

the

material

moves

stitches.

of

newspaper

platen

under

be

adjusted

of

with

presses

spring

material.

from

the

moving

needle,

before

the

pressure.

so

that the

a

point

work

when

loop

of

E

NOTE:

forming

end

there

play

is

disc,

in

end

pages 9 and

In

order

the

set

screw

crank,

direction

center

center

nose

crank;

take

plate

ridge

disc

in

accessible

of

of

of

up

all

If

there

holders,

forming

assembly,

the

ridge

until

the

also

firmly.

Before

be

the

play

10.

to

adjust

(F,

the

the

presser

the

presser

disc

the

the

end

is a need

remove

disc

care

forming

adjusting

sure

cradle

see

Catalog

Fig.

through

point

and

set

play

assembly.

must

disc

that

(H.

the

7)

of

foot.

foot

the

screw

in

to

remove

the

the

there

Fig.

No.

disc,

in

the

the

the

needle,

Position

and

point

(F,

the

ridge

nut

(B,

be

taken

holder.

ridge

is

no

7).

If

194-5,

loosen

collar

hole

(L,

when

the

there

of

Fig.

is

the

7)

forming

the

ridge

Fig.

Remember

so

that

Then

(G,

Fig.

Fig.

2).

traveling

disc

manually

1/16

inch

needle.

in

collar

disc

forming

8)

on

the

when

the

key

re-assemble

8

7);

also

Turn

to

the

the

so

between

Re-tighten

(G,

Fig.

shaft.

disc

assembly,

ridge

former

re-assembling

in

the

flange

the

nut

Fig.

the

7

clamp

handwheel

right,

that

the

the

7)

is

it

small

clamp

and

shaft

the

engages

(B,

Fig.

screw

in

in

line

lines

radius

screw

set

the

depress

and

ridge

with

8)

in

operating

with

up

with

of

in

collar

the

remove

forming

the

and

tighten

the

the

the

the

the

to

feed

the

slot

Page 9

ADJUSTING

INSTRUCTIONS

(Continued)

P ressur

plunger

Generally~

be

tween the

shaft

RIDGE

(Fig.

FORMING

The

lowers

being

depth

sewn.

of

forming

in

place.

e is

rod

(C~

the correct

8).

dialed

the

ridge

needle

disc.

F

top

regulator

The

penetration.

Re-assemble

directly

ig.

8)

of

the

DISC

forminR

word

Fig.

applied

with

the

to

upper

pressure

plunger

holder

REGULATOR

(M~

Fig.

disc

More"

to

indicates

8

the

set

the

nut

is

obtained

and

2)

located

get

screw

yielding

(D)

and

the

the

correct

more

ridge

locking

when

underside

on

top

depth~

amount

in

from

disc.

turninR

in

possible

regulator.

over

and

the

the

(N,

Fig.

the

the

mounted

the

(N)

and

forming

in

there

of

the

needle

and

The

order

striking

The

the

The

the

ridge

case~

Fig.

2)

cradle

ridge

needle

set

disc

place

is

5/32

of

the

head

cylinder

penetration

"Less"

regulator

that

the

to

protect

adjustment

the

regulator

More"

to

stop

needle

the

center

needle

former.

remove

2)

and

underneath

(H~

forming

and

adjust

just

tightly

by

adjusting the

with

lower

inch

of

base

in

indicates

also

disc

can

the

needle

the

ridge

direction

pin

inside

point

of

the

should

If

the

adjust

that

Fig.

disc

screw

grazes

to

lock

nut

clearanc

the

plunger

raises

the

limits

be

forming

is

made

(M~

as

should

just

this

set

screw

contacts

7)

in

shaft

the

screw

(E).

and

work

less

the

raised

point

Fig.

far

of

the

rid

g e

graze

is

not

screw

(P~

which

so

that

rid

ge

(P)

e

by

2)

as

be

is

FOLDER

The

the

center

With

height

the

relationship.

needle

Rotate

extreme

mately

1/16

increasing

tighten

center

knife

should

the

over

block

be

NOTE:

the

opening

the

folder.

ADJUSTMENT

folder

line

the

is

left

should

of

front

traveling

the

end

inch

the

1/16

folder

the

the

top

handwheel

of

stroke.

from

inch

with

ridge

mounting

taken

If

in

If

to

the

the

this

move

ridge

presser

is

be

set

needle

feed

The

needle

to

the

the

dimension.

the

former

screws

the

former

not

the

so

that

and

located

and

folder

point

right.

in

operating

Insert

needle.

two

locking

and

in

(C~

block

has

foot~

the

case~

its

front

in

the

removed,

should

direction

the

folder

A

slightly

With

the

screws

the

opening

Fig.

7)

and

perpendicular

been

rid

position

correctly

ge

former

9

ridge

edge

center

check

just

and

wider

folder

(B~

of

move

to

former

is

approximately

of

the

the

clear

and

the

position

position

belt

resting

Fig.

the

the

should

presser

the

line

set

7 ).

block

in

relation

line

accordingly.

opening

ridge

ridge

the

the

front

loop

can

on

If

the

foot,

accordingly.

of

feed.

up

with

1/16

in

presser

former

forming

needle

edge

be

the

ridge

folder

loosen

to

the

the

inch

from

-

needle

disc

at

approxi-

obtained

former

does

the

Care

center

center

foot.

as

the

by

not

two

of

of

Page 10

A

DJUSTING

INSTRUCTIONS

(

ontinu

d)

FRONT

TOI

Ass

curely.

Release

clockwise.

Insert

•

003

inch

Apply

folder

of

the

base.

slot

The

obtain

this

NOTE:

the

main

Fig.

free

2)

of

in

any

direction,

maintained.

The

travel

position

slot.

loosen

the

lower

top

4

1/8

slot..

If

lock

feed

driving

of

the

S.P.I.

the

of

it

Normally,

With

the

driving

adjust

the

FEED

mble

front f ed

a

piece

clearance.

finger

While

in

the

center

setting,

It

may

shaft

the

when

eccentric

binds.

locates

of

the

feed

is

desirable

nut

(K,

rocker

arm

slot,

When

stitch

the

arm

arm located

feed

lift

feed

arm

of

pressure

doing

feed

dog.

prong

adjust

be

making

The

on a flat

the

front

driving

to

Fig.

slot.

in

slot.

the sti

the

length

is

set

as

follows:

to

feed

pressure

paper

to

between

the

so,

Tighten

of

feed

two

necessary

the

and

position

first

on

feed

arm

increase

2)

and

raise

To

shorten

When

tch

length

arm

is

is

approximately

in

the

in

the

arm

top

feed

raise

should

collars

to

above

screw

the

is

regulated

in

the

the sti

the

is

at

the

center

desired

with

by

rotating

feed

feed

screw

be

on

adjust

dog

dog

shank.

bar

securely

located

feed

top

screw

so

rocker

front

adjustment.

eccentric

(I),

when

main

so

shaft.

by

feed

driving

stitch

arm

tch

rocker

length,

arm

length

is

at

approximately

bottom

of

8 S.

of

the

slot.

position,

(G,

adjusting

and

folder to

holding

that

screw

in

in

center

feed

that

turning

It

is

the

in

..

the

the

P.

I.

Fig.

knob

this

(H.

Fig.

drive

Loosen

the

feed

the

essential

2).

Do

(B.

obtain

the

feed

(G,

Fi

g.

position.

of

opening

2)

accordingly.

eccentric

the

two

drive

handwheel

that

not tighten

Fig.

6)

counter-

approximately

dog

flat against

2)

is

at

the

in

folder.

located

screws

strap

this

operates

in

operating

timing

(I,

se-

top

To

on

J,

be

_"{otate

in

the

center

feeddog

gulating

underside

connecting

the

feed

Re-apply

justing

handwheel

of

3/32

block

of

rod

driving

knob

its

travel

to

1/8

(A,

Fig.

the

feed

regulator

arm.

sufficient

(B.

Fig.

until

inch

driving

Lock

6)

the

toward

and

9)

so

block

tension

to

insure

top

the

slide

that

arm..

in

this

front

operator.

the

it

(B

..

position.

to

feed

feed

feed

contacts

and

Fig.

bar

proper

dog

Raise

lift

locate

9)

against

by

feeding

is

re-

the

the

adaction.

TRIMMING

The

for

the

size

of

Referto

width

of

MECHANISM

width

upper

the

folder

chart

finished

of

and

belt

trim

lower

being

on

loops,

is

used

Page

determined

knives.

and

the

15

for

weight

The

material

the

parts

of

material

by

the

selection

to

use

of

being

be

removed

or

of

these

sewn.

type

10

spacer

spacers

of

folder.

and

Fig.

pins

added

and

is

9

spac

relative

when

er

plates

to

the

changing

Page 11

PPE

H KNI

VES

ADJUSTING

INSTRUCTIONS

(Continued}

Attach

attaching scr

pressure

space

NOTE:

no

gap

Adjust

tension

to

between

between

Fig.

10

applied

upp

er

ews (C,

the

chip

top

The

chip

the

tension

may

knives,

Fig.

deflector

of

folder

deflectors

deflectors

It

the

upper

slightly.

possible,

LOWER

Turn

stroke.

position

(The

resharpening.

turn

above

on

vary

elongated

Loosen

connecting

bottom

knives

with

chip

6 & 10}.

and

should

deflector,

and

cutting

should

and

knives

Normally

to

give

KNIVES

handwheel

Loosen

knives

nuts

by

turning

the

thickness

When

knives

the

upper

be

noted

from

maximum

knife

to

slots

}

on

rod

edge

and

securing

and

edges

be

assembled

knives.

that

the

the

clockwise

attaching

their

in

ball

until

of

top

two

of

correct

knives,

lock

in

place.

of

the

knives.

the

location

top

of

knives

clearance.

until

maximum

the

knives

joint

front

knife.

screws

cloth

connecting

edge

to

spacing

to

the

the

folder

are

positioned

lower

screws

low

of

lower

Tighten

(E,

Fig. 6 }.

be

trimmed.

plates

apply a slight

This

are

will

knife

position

of

the

base

knives

(D,

to

rod

nuts.

block

Fig.

knife

cutting

and

compensate

(D,

The

with

insure

so

can

be

as

far

are

6 & 10}

retighten.

Fig.

is

1/32

amount

four

upward

proper

there

edge

varied

up

at

top

7}

inch

is

of

as

of

and

for

and

of

Proper

the

collar

operate

collar

STITCH

The

near

shaft

down,

dow

shorten

ing

Release

n,

to

the

with

the

alignment

(E,

the

machine

in

position,

LENGTH

stitch

head.

numerals

which

turn

the

desired

the

the

stitch.

Fig. 7 }.

length

Open

will

knob.

engage

handwheel

amount

of

slowly.

being

is

the

which

As

you

Stitch

the

bottom

To

obtain

The

careful

regulated

top

cover

indicate

a

slot

away

turn,

of

stitches

range

knives

the

correct

knives

not

to

by

the

on

the

the

in

the

from

observe

per

of

the

to

will

disturb

knob

arm

number

feed

you

to

the

inch

machine

the

top

knives

alignment,

automatically

the

alignment.

(B,

Fig.

and

observe

of

stitches

mechanism.

lengthen

indicator

appears

is

until

from

is

obtained

loosen

align

3}

on

the

the

per

While

the

stitch

the

directly

6

to 8 stitches

collar

themselves.

arm

feed

inch.

number

under

of

indicator

Press

holding

and

by

positioning

screw

the

machine

the

the

toward

correspond-

the

indicator.

per

Lock

on

knob

knob

you

inch.

and

the

to

11

Page 12

3575

20-80

1

48-1

89

T

F

80

22- 321

- 20

.,

0

0

8-138

12

Page 13

The p

arts illustrat

r e pr es e nt

the

parts

ed

that

on the

are

preceding and following page,

used

on

Styl

e 150- 200

but are not used

that are d

on

escribed

Style

on

150-20.

this page

and

on page

15

On lhe prece

low

or be

ain

assembly.

m

·se C

atalo

P

art

No.

8-137

8-138

14-394

14-432

'~18-

400

18-533

t-<18-

533

18-764

18-873

18-951

18-1075

20-80

20-148

20-149

21-58

21-427

22-262

22-319

22-320

22-321

32-36

*

32-302

33-156

18-700

39-141

45-464

46-201

47-132

48-180

50-286

50-287

*

57-52

70-73

107-44

*

110-

285

*

110-314

115-160

115-161

119-81

119-82

AS126

158-26

158-27

444-318

18-318

20-122

21-341

26-1

52

44-318

99-304

667

D-24

*

1158

L

*

1160

L

~

'1750

L

*6042

A

22652

35751

D-12

F

*

88

89

38242

G

39543

N

*

20-

31

ding page,

the

box

g N

o. 194-5 for

A

<

part

are

ge Form

g Sc

numbers

indicated

all

parts

Sh

aft-----for

for

for

rew,

for

for

for

for

14-394----

for

18-1075--

g N

ut,

on

Sprin

Sprin

on

left-right

er

Shaft---

119-68

45-464

3 824 2 G - - - - -

for

115158-27

47-132----- - ------

for

g, for

g- - - -

and

Knife Guard,

Knife Guard,

Rid

~ain

Screw,

Screw,

Screw,

Plu

Screw,

Screw,

Screw,

Nut,

Nut,

Lockin

Tensi

Presser

Spring Pin------Presser

Pin,

P in,

Arm

Cover,

Auxiliary

Pin-----

for

driving lower

for

driving

Cover

Plate-----

for

50-286-------

Feed

Driving

Screw------

Drive

P in

Front

Front

Connect

Driving Crank,

Knife

Spring Support

Handwheel------------

Collar

Feed

Feed

ing

Support

Bar-------Rocker

Rod

Bracket

Bracket -----

Spring Barrel---------------Flange,

Top

Top

F e

Connect

Bottom

Bottom

\Va s h e

S

lide Plate,

Slide

Rid

Knife

Kni

fe

ed

Lift Reg

r,

Plate, rig

ge

Former

for

rid

ge

Spacing Plate,

Spacing

ulator

ing

Rod

Knife,

left-----------------

Knife, rig

for

18-873-

left---------

ht----------------------------------------

Assembly---------

Screw-------------------

Nut

-------------

Spring------------------

Plunger-------------Di

sc--------

Disc

Front

Screw,

Nut,

Screw,

\V

asher,

Screw,

Looper

Feed

Thrust

Nut,

Plunger

Feed

Rocker Shaft--------

for

50-287------------

for

865 L ----------------

for

119-68

for

22652

for

50-286

Rocker

Set

Screw----------------------------

Spot

Rocker

Shaft

Screw

Shaft--------------------------------------------------------

Bearing Washer,

for

No.

4118-15

contain

not illustrated

160

ed

this page

within

by

- - ---- ------

---------

---

----on Sty

- - - -

- - - ----

---

- - - -

le

150-200-5/16------------------

-- --

- - - - -

----

machine arm-

- --------

- ---- -

----

- - ----

---

- -------------

70-73--------

low

er

---

knives --------------------------

- - - - - - - ---- - - - -

a box

are

indentin

and describ

D

g the

escrip

components

ir desc

riptions

ed her e.

tion

- ---- ----------------

----

- - - - - - --

------

-----------

-------

- -- -------- - - -

-----

---

- - - - --

---

- ----------------------- ----------------

- - - - - - - - ------------

- -

------ ------------------------------------

--------------------

----------------------

- - - - - - -

---------------------------

------------------------------------

--------------

----------------------------------

- --------

- -------------------------

- - ---------- - - - - - - -

- ·

---

----------------------

----

----

- ----------------------------

----------- ------------------------

- --------knives,

lower

knive

--

---------

-

-------

---

- -

---

-----

-------------

on Style 150-200-3/8--------

s,

on

Style

150-200-5/16---------

- - - - -

---------------------------

- - -

---------------------

Eccentric ---------------------------

-

-------------

------

-----

--

---

- - -

----

----------------------------------------

for low

er

knives----

- -

---------

---

former

shaft---------------------------------------------

for

Plate,

for

- - - - ----

----------------------

----------------------------------------------

------

---

----

---

- - -

----------

- - -

- -------

----------

- - - - -----------------------------------------

--

----

---

-----------------------

----------------

--------------------------

---------------------------------

-

-----------------------------------

- -

---------------------------------

Style 150-200-5/.16----------------------------Sty

le

150-200-3/8------------------------------

------------------------------------------------------

Regulator

ht

-

------------

Holder--------

on

D-12

--------------------------------------------------------

Block

------------------------------------

--

-----------

- - -

--------------

-

-

-------

-

------------------------------------------

------------------------------------------------

-

----------------------------------------

-

-----------

- - - -----------------------------------------

-

------ -

- - - - ---------

- - -

----------------------------------------

-

-----------------------------------------

---

---------------------------------------

-

---------

- - -

Style

150-200-3/8--------------------------------

----------------------------------------

--------------------------------

Stop

Collar

-------------------------------------------

---------

- - ----

-

---------------------------

-------------------------------

-

-------------------------------

-------------------------------------

----------------------------------

-

---------------------------------

-

-------------------------------

-----------------------------------for

18-1075

-------------------------------

-------------------------------------------------

of

the

part

under

-

--------

-

-----------------

-

--------------

- -

-

------------------

-----

- - -- - -- -

-

----------------

-

-

--------------------

-

-------------------

--

----------------

- - -

-

----------------

-

------------------

-

-----------------

-

----------------

-

-----------------

-

--------------

number

listed

the description

-- -----------

- - -

-----------

---

----------

---------------

---------

---------------

-------------

-

--------

- - -

------------

-

------------

-

--------

-

---------

-

------

-

-

------

--

------

opposit

-

--

----

-

---

of

Am

Re

the

1

1

1

1

4

1

1

1

1

2

1

1

1

1

2

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

4

2

2

2

1

1

1

1

1

e

t .

q.

*Not

shown

on

the

picture

plate

on page

12.

13

Page 14

50-210

(.)

1132

1183 L

'

'./

I

L I

18-715

2

3-333

14

468-23

-1

Page 15

MISCE

LLANEOUS PART

S

Part

No

.

18-715

18-7

32

18-9

42

23-3

33

23-3

34

24-323

41-42

41-

4 9

50-210

405-

5 81

5-581

6-7

3

18-643

*

431-18

t431-185-

'~431-186-

t431-186-

468-23-1

468-2

1132

1160

1183

499-303

22894

below

to

sew

431-185-5116

5- 5/16

3/ 8

5/16

3/ 8

20-60

3

L

L

L

AB

If

a

customer des

indicates the

5

116

inch

.

Screw,

Screw,

Screw,

F

ront Feed

ee

F

Fee

d P

oint----

d P

late-------

for

for

for

ThreadGuide

ThreadGui

Fee

d P

Pr

late

esser F

Presser Foot

N

eedle

S

crew------

F

older,

F

older,

F

older,

F

older, mark

Tension

marked

marked "B", split

mark

Post, comple

N

ut--------- -----

Tens

ion

Tension S

Nut-

-----------------------------

Tension Dis

F

eed Plate Holder,

Screw,

parts to

belt

for

ires

to sew a different

be

loops

made

Descriptio

23-333

23-334

499-303

-----------------

-----------

--------------------

-

-------

Point---------------------

- ---- -

------------------

--

-- --

- -

---------------

-------------------------

de

- -- - - -

Holder Bracket--------------

oot,

Guide-

-------------

complete----------------

(not

identified

- - ----

----------------------------- --

on picture pl

- - - - ----

-- --------------------

"A" , sp

ed "C

ed "

D", solid type,

",

lit

solid

type,

type,

type,

5/16

3/8

for

for

inch fini s

te-----------------------

Staf

f - ----

-------------

pring---------------

---------

-

---------

- ---- -

c------------------

right-----------

folder-------------

removed

of lig

ht

and

to

weight

added

medium weig

- - ----

material

to

a s

tanda

n

-

---

----------

- - - - ---- -

--

- - -

---

- -

--------

---

---

----- ----

---

- - ---- ------- ----

-------

-- --

- -

----

-----

ate)-

- - ----

---

- - -

------- --

- ------- ----

----------

----------

-----------

---

- - - - - ------- - - ------

-------

- -

----------

- - ---- -------- - -

i

nch finish,

for

Style

h, for Sty

5

116

in

ch

3/8

i

nch finish- - -

finish-

-- ----- ----- - - - -

----

- --------

- - -------------------

-

--------------------

-------------

-

-------------

- - - - -

---

---

ht

--------

- - - -----

- - ----

, a

diff

r d 15

material

---

------

- - - -

----

---

- -

-- -----

er e

nt

usin

fold

g a

0-200-5116

----

--------

- - - - -

- - ---------

- -

---

-------- -

- - - ---- - - -----

- - - - -

-----------

------ -

----

- - -

---

- - - -

----

------

----

---

- ---- -

15

0-200-5116---

le 15

0-200-31

- - - - -

----

- --------------

-- --

- - - - -

---

-----

- -

-----------

---- - ----------

- - - -

--------

-------------

- - -

--------

er

or fini

ma

sh,

chine th

split type folder,

Amt.

R

----

- 1

---

------- 1

- 1

-----

---

- 1

- - 1

-----

------

- - -

- 1

--

--

8- - - - - 1

----

- -

---

- 1

----

- -

--

- 1

- -- 1

- 2

---

--

the chart

at

is

set

No.

eq.

1

1

1

1

1

1

1

1

1

1

1

1

1

2

up

Type

of

Material

Light

Light

to M

ed.

to Med. 43

Light to l\Ied.

Solid Fold

Ex

tr a L ig

ht

Split Fold

Extra Light 43

Solid F

Extra

Hea

vy

431-185-3/

:\

Split Folder

Extra He

avy

43

M

Solid Fold

Folder

431-185-318

M

arked

Split

fark

Solid

431-186-318

arked "D"

M

"B"

Folde

r

1-186-5116

ed

"C"

Fol

der

er

431-185-5/16

Marked "A "

er

1-186-5/16

M

arked "C"

old

er (1) 43

'la

rked

"B"

1-1 8 6-

arked

31 8

"D"

er

Fini

sh

318"

5116"

318"

11

5

116

11

5116

8

31 8"

318"

Remov

(4)

18-400

(1)

22-

(2)

(1)

(1)

(4)

(1)

(2)

(1) 43

(2)

(1)

(2)

(1)

(4) 18-400

(l)

(4) 18- 4

(1) 43

321

110-285

431-185-5116

431-18

18-400

22-321

110-28

1-185-5116

110-285

22-321

110-28

22-

321

1-1

431-185-5/16

00

1-18

e F

-5116

5 (2)

5

85- 5

116

5- 5/ 16

it

Wit

(4)

1750

(1)

22-320

(2)

110-31

(1}

431-18

o > 431-

(4)

(1}

< 1 >

(2}

(1}

(2}

(1)

(1)

(4}

(1}

(4)

(1)

186-

1750

22-320

110-314

431-186-

110-

314

22-320

110-314

22-320

431-186-5/16

1750

4

31-1

1750

431-186-

L

4

5- 3

L

L

85- 3

L

h

51 16

31

/8

3/ 8

/8

8

*

Folder

t

Folder can be used

can

be

used for

fo r lig

ext

ra lig

ht

and

ht and l'ght

medium

or xtra heavy weight

to medi

um weig

ht material, de

m ater i a

15

pend

ing

l, depending

on shim

on shi

s used .

ms use

d .

Page 16

_.o

...

..

'

0

WORLD'S

p.llf

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

facilities throughout

aid

you

in

the selection of the right sewing

equipment for your

Special representatives

tory trained

promptly

tion, there

and

and

is

a Union Special Representative to

serve you. Check with

ATLANTA,

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

ILL.

TEXAS

YORK, N.

Y.

PA.

maintains sales

the

world. These offices

and

service

will

particular operation. Union

and

are

service men

able

to serve your needs

are

fac-

efficiently. Whatever your loca-

him

today.

MONTREAL, CANADA

TORONTO, CANADA

BRUSSELS,

LEICESTER,

LONDON, ENGLAND

PARIS, FRANCE

STUnGART,

BELGIUM

ENGLAND

GERMANY

Representatives

industrial

UNION SPECIAL

400

N.

FRANKLIN

and

cities

distributors

throughout

ST.,

In

all

Important

the

world.

CORPORATION

CHICAGO,

ILL.

60610

Loading...

Loading...