PL-4509-01, Rev01, DCO# 16-191

1/2

Technical Support:

Levitronix

Phone for US: 888-569 07 18

CAUTION

have been tested to be

robust against gamma radiation with a dose up to

with care, especially after

gamma radiation with doses above 25 kGy, since the

Kinem.

[cSt]

Liquid

[°C]

LFS-03SU

0.800

1

20

LFS-06SU

8.000

1

20

LFS-10SU

20.000

1

20

LFS-15SU

50.000

1

20

LFS-20SU

80.000

1

20

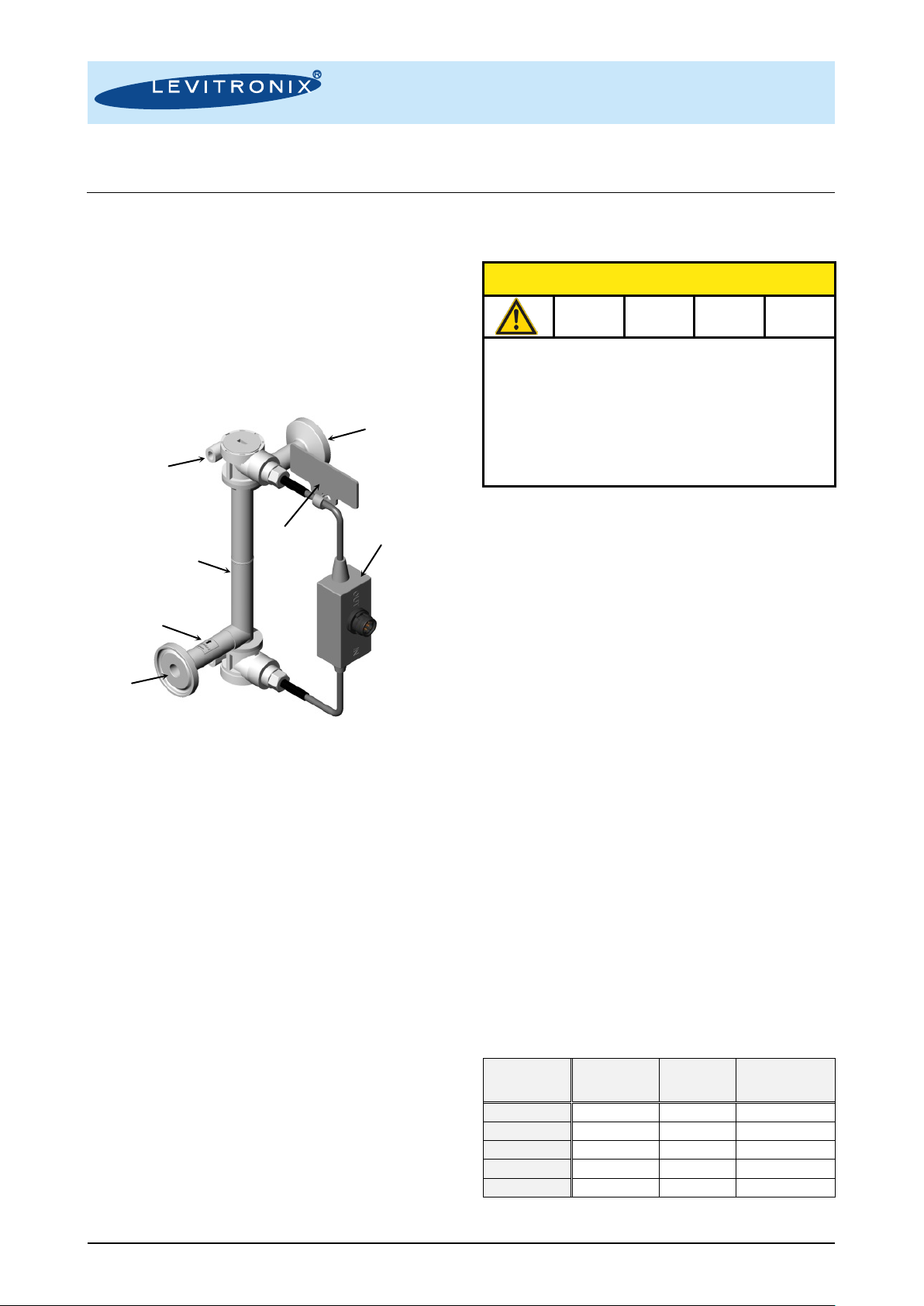

Calibration

Parameter

Tag

Measurement Path

Connector

Box

Label with Serie # and

Flow Direction Arrow

Inlet

Outlet

Fixation Hole

Instructions for Use of LEVIFLOW® LFS-SU Flowsensors

www.levitronix.com

Technical Service Department

Technoparkstr. 1, CH-8005 Zurich, Switzerland

1 Description and Preparation

1.1 Description

The LEVIFLOW® LFS-SU flowsensors are

designed for non-invasive flow measurements in

single-use applications of the Life Science

industries. T he wetted materials of the sens ors are

made out of biocompatible polypropylene (FDA,

USP-VI, BSE/TSE and An imal free), which can be

gamma sterilized.

Figure 1: Single-use flowsensor (e xa m pl e LFS-06SU)

Before using the flowsensor make yourself fam iliar

with the following instructions.

1.2 Inspection Prior to Use

The flowsensor should be inspected prior to use for

any damage. Do not use the flowsensor if any

damage is found. Contact Levitronix

return of any suspected flowsensor.

1.3 Traceability for Troubleshooting

For full traceability of the flowsensor the serial

number located on the s ensor bod y (see Figure 1)

shall be used. The s erial num ber is also printed on

the biocompatibility decl aration and the calibration

sheet delivered with each sensor.

®

1.4 Levitronix

For sensor parameter setting and calibration

parameter transfer to the converter (not necessar y

for sensors with a param eter chip) the Levitronix

Configuration Software with version V1.30 or

newer is needed. For detai ls regarding installation

of software and establishing RS485 connection

consult the LEVIFLOW

manual (see Doc# PL-4501-00).

Configuration Software

®

Configuration Software

®

regarding

Phone for outside US: +1 888-569 07 18

E-Mail: support@levitronix.com

2 General Warnings and Cautions

Gamma Sterilization

The LFS-SU flowsensors

40 kGy.

Handle the flowsensors

radiation exposure decreases the flexibility of the

flowsensor material.

3 Procedure for Installation

3.1 Mechanical/Electrical Installation

Connect the sensor to the converter t ogether with

the relevant adaptor cables. Take specific care

about the flow direc tion indi cated w ith t he arr ow on

the flow sensor (see Figure 1). For details about

mechanical and el ectrical ins tallation and desig n of

an adequate hydraulic circuit, consult the user

manual (Doc# PL-4509-00).

3.2 Setting of Sensor Type Parameters

The sens or type (or size) specific parameters can

be set or updated on the converter at the first

installation or whenever the sensor type is

changed.

Note: Sensors which are labeled with “Type: PC”

on the calibration tag have an integrated

parameter chip and parameters are transferred

automatically to the converter.

®

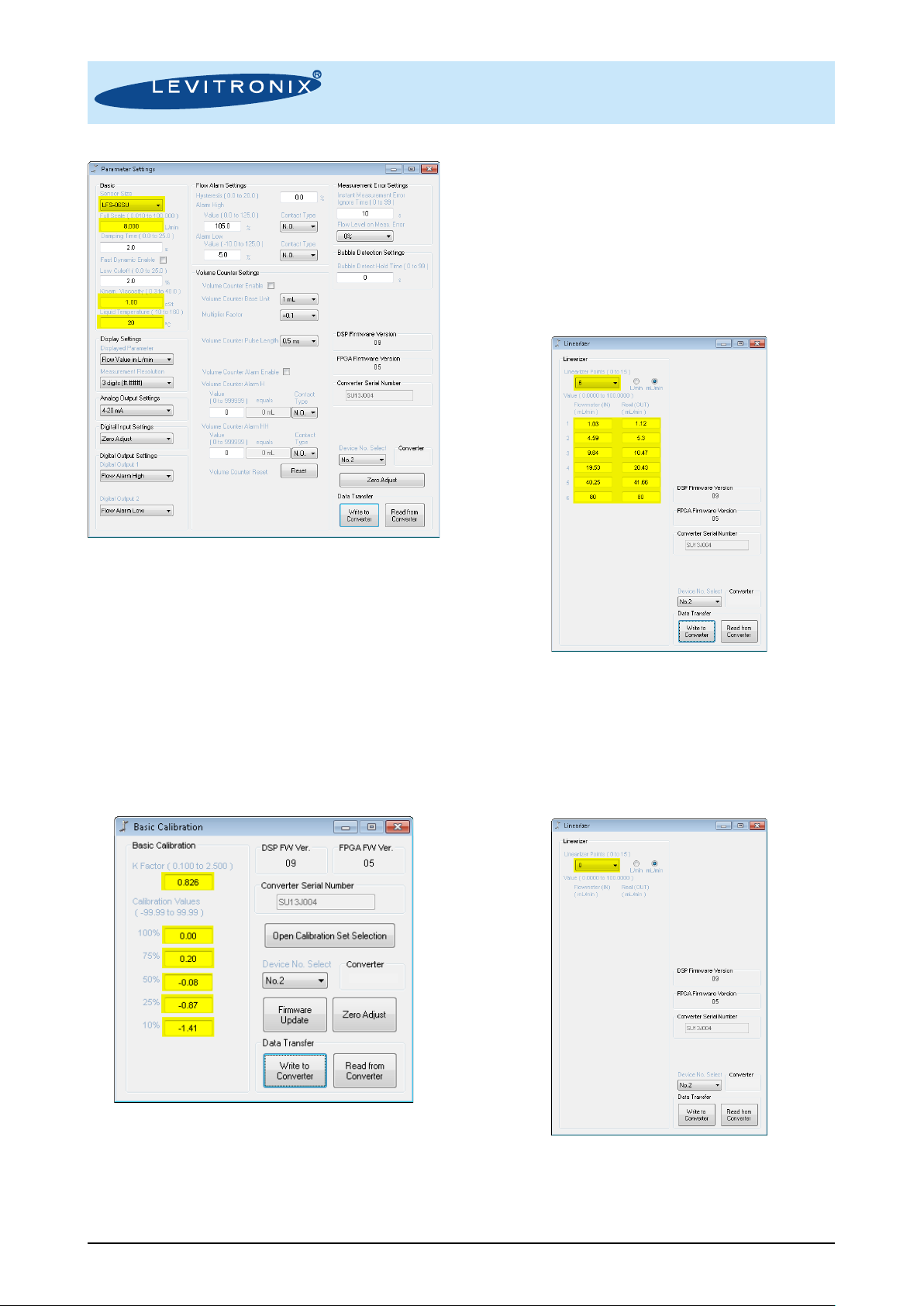

Start the LEVIFLOW

open the “Parameter Settings” menu (Figure 2).

Make sure that “Sens or Size”, “Full Scale”, “Kinem.

Viscosity” and “Liq uid Temperature“ are set t o the

values designated for the used sensor type.

Table 1 tab le sho ws the sta ndard values. F or other

configuration consult the specific sensor

specification.

Sensor

Type

®

Full Scale

[L/min]

Table 1: Standard sensor type parameters

Configuration Software and

Viscosity

Temperature

PL-4509-01, Rev01, DCO# 16-191

2/2

LFC-1C-PC

LFC-1C-PC

LFC-1C-PC

LFC-1C-PC

Instructions for Use of LEVIFLOW® LFS-SU Flowsensors

www.levitronix.com

3.4 Transfer of Linearizer Values

In some cases (for example for the LFS-03SU)

additional linearizer values are defined to increase

accuracy. These values are available on the

backside of calibration parameter tag or on the

calibration sheet del ivered with each s ensor. Open

the “Linearizer” menu (see Figure 4) of the

configuration software and transfer the linearizer

values.

Figure 2: “Parameter Settings” menu of configuration software

(Example for LFS-06SU)

3.3 Transfer of Basic Calibration Values

Next step is to transfer the calibration values.

These values are a vailabl e on th e sensor tag or on

the calibration sheet delivered with each sensor.

Open the menu “Basic Calibration” of the

configuration software (see Figure 3). Update the

“K Factor” and the 5 “Calibration Values”.

Store the settings to the converter by using the

“Write to Converter” button.

Figure 4: “Linearizer” menu of configuration software

(Settings for example with LFS-03SU)

If no linearizer values are defined on the back side

of the calibration parameter tag (for example for

LFS-06SU and LFS-20SU), write “0” linearizer

points to the “Linearizer Points” item (see

Figure 5).

Figure 3: “Basic Cali br ati o n ” menu of c onfiguration softwar e

Figure 5: “Linearizer” menu of configuration software

Store the settings to the converter by using the

“Write to Converter” button.

(Setting for no linearizer values)

Loading...

Loading...