l

OPERATOR’S MANUAL

Level 1® H-1200

Fast Flow Fluid Warmer

With:

H-31, Version B,

Air Detector/Clamp

< H-1200 115V

®

< H-1200 230V

6 2

s

l

Level 1® H-1200

Fast Flow Fluid Warmer

With:

H-31, Version B, Air Detector/Clamp

<

H-1200 115 V

<

H-1200 230 V

OPERATOR’S MANUAL

®

P/N 40-6917-51A

s

SECTION X • Title

ii

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

General Information

SECTION X • Title

General Information

Level 1® H-1200 Fast Flow Fluid Warmer

Part Number: 40-6917-51A

This revision supercedes all previous revisions.

Under copyright laws, this manual may not be reproduced in any form, in

whole, or in part, without prior written permission of Smiths Medical ASD,

Inc. (Smiths Medical).

Smiths Medical and Level 1 design marks and Level 1 are trademarks of

Smiths Medical. The symbol ® indicates the trademark is registered in the U.

S. Patent and Trademark oce and certain other countries. All other names

and marks mentioned are the tradenames, trademarks, or service marks of

their respective owners.

Every eort has been made to ensure that the information in this

manual is accurate and details provided are correct at the time of printing.

The company, however, reserves the right to improve the equipment

shown.

Mention of third-party products is for informational purposes only and

constitutes neither an endorsement nor a recommendation. Smiths Medical

assumes no responsibility with regard to the performance or use of

these products.

For further information, please call your local Smiths Medical distributor or

Smiths Medical direct at 1 800 258 5361 or +1 614 210 7300.

©2014 Smiths Medical.

All rights reserved.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

iii

Contents

Contents

1 About this Manual 1

2 Description 3

3 Indications for Use 4

4 Important Safety Information 5

CONTRAINDICATIONS 5

WARNINGS 5

CAUTIONS 8

5 Out of the Box – Assembly 9

Step 1 – Verify Components of the Level 1® H-1200 Fast Flow Fluid Warmer 10

Step 2 – Assemble I.V. Pole to the Warming Unit 11

Step 3 – Install the Pressure Chambers 12

Step 4 – Attach the I.V. Bag Hanger 13

Step 5 – Disinfect the Recirculating Solution Reservoir 13

Step 6 – Preliminary Preparation 14

Step 7 – Connect the Pneumatic Tubing 14

Step 8 – Install the Level 1® H-31, Version B, Air-Detector/Clamp 15

Step 9 – Perform Electrical Safety Tests 17

6 Principle of Operation 19

Fluid Warming 19

Pressurized Fluid Delivery 19

Air Detection/Clamping 19

7 Controls and Displays 20

Fluid Warmer Power and Alarm Test Panel 21

Fluid Warmer Display Panel 22

Reservoir Level Display 22

Pressure Chamber Control Panel 24

Interlocks 25

8 Operation 27

Modes of Operation 28

OFF Mode 28

ON/Automatic Operation Mode for Fluid Warmer 28

Alarm Test Mode 28

Over Temperature Test Mode 29

Temperature Display 29

Check Disposables Mode 29

Add Recirculating Solution Mode 30

Over Temperature Alarm Mode 30

Power ON Test for Air Detector/Clamp 31

Automatic Operation Air Detector/Clamp 31

Check Tubing Mode 31

Air Detected/Clamped Mode 32

Pressure Display 32

Pressurized Mode 32

Unpressurized Mode 32

iv

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

9 Operating Instructions 33

WARNINGS 34

9.1 Set Up for Use 34

A – Install the Disposable Administration Set 34

B – Prime the Disposable Administration Set 35

C – Prime the Patient Line 37

D – Test the Audible and Visual Alarms 37

E – Test the Air Detector/Clamp 38

9.2 Use of the Fluid Warmer 39

Step 1—Load the Pressure Chambers 40

Step 2—Pressurize the Pressure Chambers 40

Step 3—Make Patient Connection 40

Step 4—Replace the Gas Vent/Filter Assembly 40

Step 5—Change the Fluid Bag 41

9.3 Replace the Gas Vent/Filter Assembly 41

9.4 Activated Alarms 42

9.5 After Use 44

10 Troubleshooting 45

General Troubleshooting Guide 45

Slow Flow Rate Troubleshooting 46

11 Testing 47

Add Recirculating Solution Alarm 47

Check Disposables Alarm 47

Over Temperature Test 48

Fluid Warmer Alarm Signal Test 48

Performance Testing 48

Cold Start Test 48

Calibration Test 49

Calibration Test with DSTA-40 49

Proper Calibration of Recirculating Solution Temperature 49

Periodic Electrical Testing 50

Earth Leakage 50

Ground Continuity 50

12 Maintenance 51

Maintenance Performed Prior to Every Use 51

Clean the Exterior 51

General Inspection 52

Maintenance Performed Every 30 Days 52

Lubricate O-Ring Seals 52

Change Recirculating Solution with Distilled Water 53

Maintenance Performed Every 12 Months 53

Disinfect the Recirculating Solution Reservoir 53

Change Recirculating Solution with a

0.3% Hydrogen Peroxide/Distilled Water Solution 53

Change O-Rings 54

Clean Fan Filter 54

Inspect Air Detector/Clamp 54

Inspect the Reservoir and Float Switch Assembly 54

Testing Fluid Warmer Operation 54

Maintenance and Calibration Log 55

Scheduled Maintenance and Calibration Checklist 55

Contents

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

v

Contents

13 Limited Warranty 56

14 Service 58

Non-Warranty Work 58

Additional Documentation 58

Disposal Information 58

Service Contacts 59

15 Specications 60

System Specications 61

Standard Compliance 61

Physical 61

Environmental 61

Thermal 61

Electrical 61

Electromagnetic Environment Recommendations 61

Disposable Administration Set Specications 61

DI-50 61

D/DI-60HL 61

D/DI-70 62

D/DI-100 62

D/DI-300 62

16 Symbols 63

Index 66

vi

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 1

SECTION 1 • About this Manual

1 About this Manual

About this Manual

WARNING: These instructions contain important information for safe use

of the product. Read the entire operator’s manual, including Warnings and

Cautions, before using this product. Failure to properly follow warnings,

cautions and instructions could result in death or serious injury to the patient.

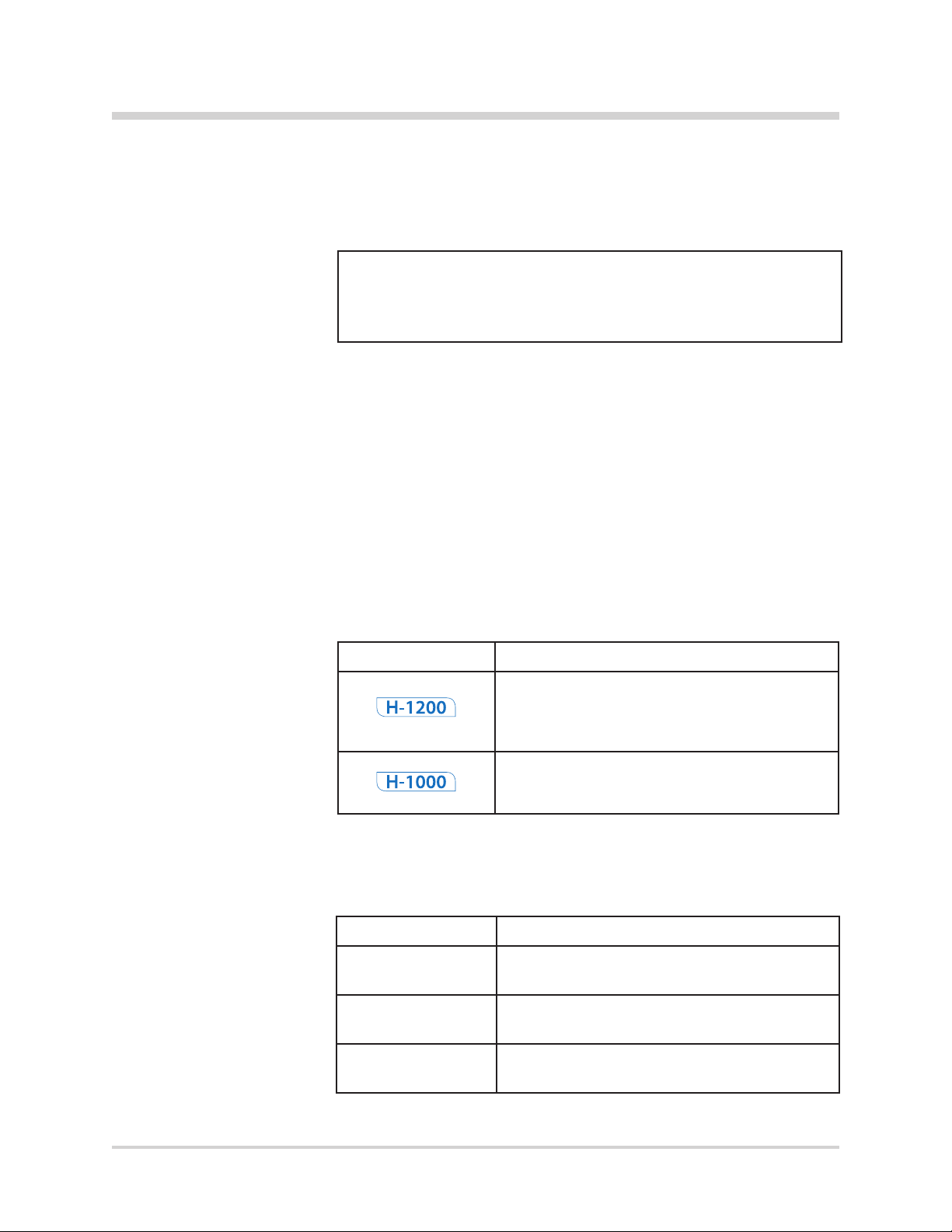

This Operator’s Manual describes the set-up, use, and maintenance of:

• Level 1® H-1200 Fast Flow Fluid Warmer

• Level 1® H-1000 Fast Flow Fluid Warmer with H-2 Pressure

Chambers (H-1025)

• Level 1® H-1000 Fast Flow Fluid Warmer with H-2 Pressure

Chambers and H-31, Version B, Air Detector/Clamp

The manual is intended for use by individuals trained in the healthcare

and biomedical professions.

This operator’s manual is also for users of the H-1000 Fast Flow

Fluid Warmer. All references to the “Level 1® H-1200 Fast Flow Fluid

Warmer” apply to the H-1000 Fast Flow Fluid Warmer except where

indicated by the symbols dened in the following table.

Symbol Description

Appears in the margin to identify information that

only applies to the H-1200 Fluid Warmer and the H-1000

Fluid Warmer equipped with the H-31, Version B,

Air Detector/Clamp

Appears in the margin to identify information that only

applies to the H-1000 Fluid Warmer (not equipped with

the H-31, Version B, Air Detector/Clamp)

Conventions Used in this Manual

This manual uses the following text and text conventions:

Convention Description

CONTRAINDICATION

WARNING

CAUTION

A Contraindication statement alerts the user to

conditions when the device should not be used.

A Warning statement alerts the user to conditions that

may cause death or serious injury to the patient or user.

A Caution statement alerts the user to conditions that

may cause malfunction, failure, or damage to the device.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

1

SECTION 1 • About this Manual

This manual is organized into the following sections:

2 and 3 Description and Indications for Use

These sections provide the purpose and indications for use of the

Level 1® H-1200 Fast Flow Fluid Warmer.

4 Important Safety Information

Lists the Contraindications, Warnings, and Cautions associated with

the use of the Level 1® H-1200 Fast Flow Fluid Warmer.

5 Out of the Box—Assembly

Guides the user through the installation of the Level 1® H-1200

Fast Flow Fluid Warmer and the Level 1® H-31, Version B,

Air Detector/Clamp.

6 Principle of Operation

Provides a functional description of the Level 1® H-1200 Fast Flow

Fluid Warmer.

7 Controls and Displays

Provides a description of the function and purpose of the

controls, displays, and indicators for the Level 1® H-1200 Fast Flow

Fluid Warmer.

8 Operation

Describes Operation, Indicator, and Alarm modes of the Level 1®

H-1200 Fast Flow Fluid Warmer.

9 Operating Instructions

Describes the Set Up, Use, and Alarm modes of the Level 1® H-1200

Fast Flow Fluid Warmer.

10 Troubleshooting

Contains information on troubleshooting the Level 1® H-1200

Fast Flow Fluid Warmer. This section also details troubleshooting

slow uid ow rates.

11 Testing

Describes Operational, Performance, and Electrical Tests that are

used to verify the proper operation of the Level 1® H-1200 Fast Flow

Fluid Warmer.

12 Maintenance

Regular maintenance procedures for every use, 30-day, and

12-month intervals are covered in this section.

13 Limited Warranty

Describes the Limited Warranty and its provisions.

14 Service

Explains Non-Warranty Work as well as listing Service Contacts.

15 Specications

Provides physical, environmental, and electrical specications of the

Level 1® H-1200 Fast Flow Fluid Warmer.

16 Symbols

Lists the symbols and their denitions used with the Level 1®

H-1200 Fast

Flow Fluid Warmer.

2

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 2

SECTION 2 • Description

2 Description

Description

®

The Level 1

uid warmer with pressure chambers, air detection, and automatic

clamping capability. I.V. uid and/or blood products are warmed

through the use of a sealed heat exchanger through which a

recirculating solution ows. Pressure Chambers apply pressurization

and deliver the uids at a fast ow rate. This non-invasive method

employs single-use, disposable administration sets that include a Gas

Vent/Filter Assembly and Heat Exchanger.

The Air Detector/Clamp monitors for the presence of air in the

disposable Gas Vent/Filter Assembly. When air is detected in the Gas

Vent/Filter Assembly, the Air Detector/Clamp closes o the patient

line and alerts operators to the presence of air with audible and visual

alarms. An ultrasonic signal continually passes through the uid lled

Gas Vent/Filter Assembly. As a bolus of air displaces the uid in the Gas

Vent/Filter Assembly, the ultrasonic signal is broken and the clamp

closes, stopping the air before it enters the patient line. Audible and

visual alarms are activated, notifying the user that the uid ow has

stopped. Clearing the bolus of air and restoring the uid ow are

quickly accomplished without disconnecting from the patient.

H-1200 Fast Flow Fluid Warmer (Fluid Warmer) is an I.V.

Disposable Administration Sets

The installation, set up, and replacement of Level 1® Fast Flow I.V.

Disposable Administration Sets (Disposable Sets) follows a fourstep sequence that corresponds to numbered blocks on the device.

Disposable Sets available for use on the Level 1® H-1200 Fast Flow

Fluid Warmer are listed below.

• DI-50

• D-60 / DI-60HL

• D-70 / DI-70

• D-100 / DI-100

• D-300 / DI-300

D-series Disposable Sets are for use in the U.S.A. DI-series Disposable Sets

are for use in markets outside of the U.S.A.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

3

SECTION 3 • Indications for Use

SECTION 3

Indications for Use

The Level 1® H-1200 Fast Flow Fluid Warmer (Fluid Warmer) provides

a rapid ow of warmed uids, such as crystalloid or blood product,

including red blood cells, as volume replacement for patients suering

from blood loss due to trauma or surgery.

The Fluid Warmer provides fast ow of warmed uid to re-warm patients

during surgery by trained medical personnel.

3 Indications for Use

4

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 4 • Important Safety Information

SECTION 4

4 Important Safety Information

CONTRAINDICATIONS

WARNINGS

Important Safety Information

This section covers information for prescribers and guidelines for safe

®

use of the Level 1

Not for use in warming platelets, cryo-precipitates, or

granulocyte suspensions.

Death or serious injury may occur to the patient or user if

these warnings are not followed:

H-1200 Fast Flow Fluid Warmer (Fluid Warmer).

CONTRAINDICATIONS

WARNINGS

• These instructions contain important information for safe use

of the product. Read the entire operator’s manual, including

Warnings and Cautions, before using this product. Failure to

properly follow warnings, cautions, and instructions could result

in death or serious injury to the patient or user.

• Remove all air from the uid bags before spiking and the uid

lines before connecting to the patient. Failure to do so can result

in infusion of air into the patient.

• Replace Gas Vent/Filter Assembly every three hours, or when

the lter becomes clogged, or when air is slowly vented.

Failure to do so will result in a reduction of ow rate. This

may result in inadequate patient treatment

• The replacement Gas Vent/Filter Assembly must be fully

primed before continuing infusion. Failure to do so may

allow air to be infused into the patient.

• Do not use the Fluid Warmer in high-energy elds such as:

MRI, X-RAY, portable and mobile RF communications equipment,

and other such devices. The Fluid Warmer may act as a

projectile in a strong magnetic eld, cause image artifacts, or

not function as intended.

• Do not bend the heat exchanger. Bending may damage the

heat exchanger allowing communication between the

recirculating solution and I.V. uid path, resulting in the I.V.

delivery of inappropriate uids.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

5

SECTION 4 • Important Safety Information

WARNINGS [continued]

• Blood and blood products could contain pathogenic

organisms. Failure to follow institutional policy and

procedures for biomedical-hazardous materials could lead to

exposure to harmful pathogens.

• When injecting medications into the uid path, do not inject

through the triple lumen tubing of the D/DI-60HL Disposable

Set. This may allow communication between the recirculating

solution and I.V. uid path.

• Exposed conductor on MAINS power cord can cause an

electrocution hazard. Remove device from service if MAINS

power cord has exposed wires.

• Do not re-use partially full uid bags. Fluid bags that have

been partially drained, un-spiked, and then reinstalled may

contain air, which if used can result in infusion of air into the

patient. Use only new uid bags from which the air has

been removed.

• Activation of the Over Temperature warning signal indicates

that warming has stopped and immediate operator

intervention is required. Failure to clear the over temperature

condition or to take the device out of service may result in death

or serious injury to the patient.

• The Fluid Warmer is not for use with irrigating tubing, which

may not t into the clamp slot of the Air Detector/Clamp

causing diminished ow or a failure to stop ow.

• The Fluid Warmer is for use only with Smiths Medical

supplied or approved parts, accessories, and D or DI series

Disposable Sets. The device may not function as intended with

the use of unapproved parts, accessories, or Disposable Sets.

• Grounding reliability can only be achieved when MAINS

power cords are connected to a properly grounded

receptacle. Risk of electrical shock exists if the equipment is

not connected to a properly grounded receptacle.

• Use of a bedside leukocyte reduction lter may cause a

sudden precipitous drop in blood pressure resulting in

respiratory distress, facial ushing, abdominal pain and

nausea, and loss of consciousness. Immediately stop

transfusion, and follow institution’s protocol for treatment of

transfusion reactions.

• Do not operate the Fluid Warmer in the presence of a ammable

anesthetic mixture with air, oxygen, or nitrous oxide. The risk of

6

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 4 • Important Safety Information

WARNINGS [continued]

explosion exists if the Fluid Warmer is operated in

a potentially explosive environment.

• No user-serviceable parts. All service must be performed by

Smiths Medical or competent personnel.

• Disposable Sets are supplied with a sterile uid path which may

be compromised if the caps are not in place. Do not use

Disposable Set if Luer and spike caps are not securely in place,

or if Luer connections are not secure as the uid path may not

be sterile and may cause death or serious injury to the patient.

• Disposable Sets are for single use only. To reduce the risk of

cross contamination, do not reuse Disposable Sets.

• If uid exits the Patient Line of the D/DI-60HL Disposable Set,

replace the Disposable Set.

• Do not use auto-transfusion bags. Auto-transfusion bags

may contain air that can result in infusion of air into the patient.

• Set-up, priming, and use require aseptic technique. Failure to

use aseptic technique may result in death or serious injury to

the patient.

• Do not use the Fluid Warmer if equipment or Disposable

Set malfunction is evident.

• No modication of this equipment is allowed.

WARNINGS for the Air Detector/Clamp

• The tubing must be properly placed in the Clamp Slot of the

Air Detector/Clamp. Failure to ensure that the tubing is

correctly positioned in the Clamp Slot may result in failure to

stop air infusion.

• Activation of the Air Detector/Clamp alarm during infusion

indicates that uid ow has stopped and that immediate

operator intervention is required to restore uid ow.

Failure to reinstate ow (after purging any air or foam) may

result in death or serious injury to the patient.

• Do not turn OFF the Fluid Warmer when the Air Detector alarm

is active. If the Fluid Warmer is powered OFF in an active alarm

state, the Air Detector/Clamp will open and the Air Detector

will become disabled. This could allow any air within the patient

line to be delivered to the patient resulting in serious injury

or death.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

7

SECTION 4 • Important Safety Information

WARNINGS for the Air Detector/Clamp [continued]

• The functional test for the Air Detector/Clamp accessory

must be performed before each use. If any visual indicator

does not illuminate or the audible signal does not sound,

do not use the Fluid Warmer. Remove the device from service

immediately. Fully functional visual and audible alarm systems

are essential for the safe use of the Air Detector/Clamp.

CAUTIONS

Malfunction, failure, or damage to the device may occur if these

cautions are not followed:

• Never use organic solvents (e.g., acetone), strong acids, or

bases to clean any portion of the Fluid Warmer.

• Do not place the Fluid Warmer directly under a faucet or use a

faucet sprayer to rinse. Never spray cleaning or other uids into

openings on the Fluid Warmer or into the external connectors.

CAUTIONS

• When loading uid bags into Pressure Chambers, choose a

hanging hook that allows the bag port to hang freely in the

indented slot at the bottom of the chamber door. If bag ports

are positioned above this slot, diminished ow could occur.

• Federal law (U.S.A.) restricts this device to sale by or on the

order of a physician.

• Medical devices require specic material characteristics to

perform as intended. These characteristics have been veried

for single use only. Any attempt to re-process the device for

subsequent re-use may adversely aect the integrity of the

device or lead to deterioration in performance.

8

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 5

SECTION 5 • Out of the Box—Assembly

5 Out of the Box – Assembly

Out of the Box—Assembly

This device must be assembled and tested by authorized Smiths Medical

personnel, an authorized distributor of Smiths Medical, or competent

personnel prior to placing the device into service.

The following steps describe how to assemble and do preliminary set up

of the Level 1® H-1200 Fast Flow Fluid Warmer (Fluid Warmer).

Refer to Step 8 if you need to install the Level 1® H-31, Version B, Air

Detector/Clamp to the Level 1® H-1000 Fast Flow Fluid Warmer.

Step 1 Verify components of the Fluid Warmer

Step 2 Assemble I.V. Pole to Warming Unit

Step 3 Install Pressure Chambers

Step 4 Attach the I.V. Bag Hanger

Step 5 Disinfect the Recirculating Solution Reservoir

Step 6 Preliminary Preparation

Step 7 Connect the Pneumatic Tubing

Step 8 Install the Level 1® H-31, Version B,

Air Detector/Clamp

Step 9 Perform Electrical Safety Tests

Read through the instructions completely prior to setting up the device.

Note: After unpacking the system, recycle packaging material according to

hospital policy for recyclable materials.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

9

SECTION 5 • Out of the Box—Assembly

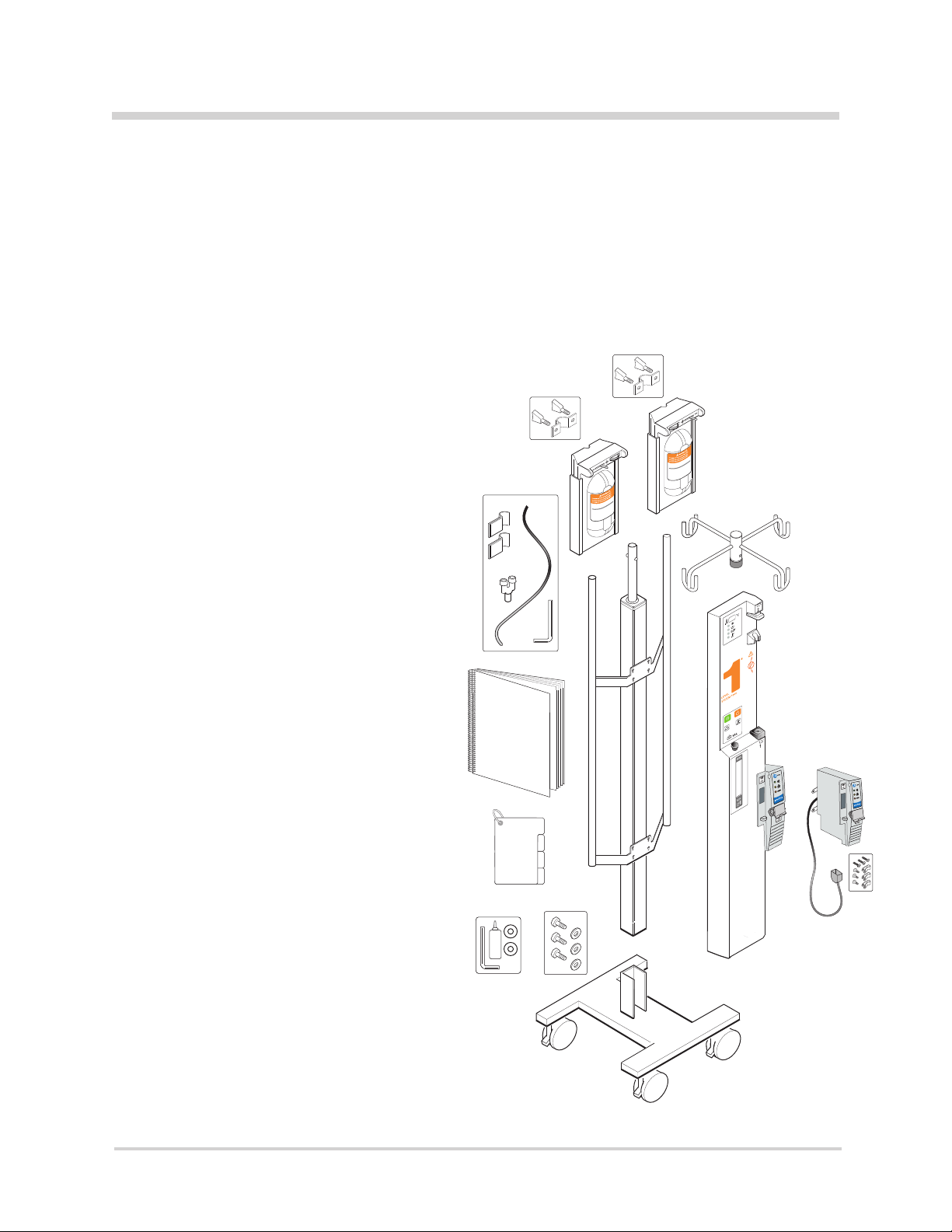

Step 1 – Verify Components of the Level 1® H-1200

Fast Flow Fluid Warmer

Note: The Level 1® H-31, Version B, Air Detector/Clamp is shipped as a

separate accessory only for installation on an existing Level 1® H-1000

Fast Flow Fluid Warmer.

Check the contents of all packaging to verify that the following

components are present. If any parts are missing or damaged, do

not use the Fluid Warmer. Do not substitute parts not supplied by

Smiths Medical. Contact Smiths Medical for replacement parts.

Below is a listing of the component parts for the Level 1® H-1200

Fast Flow Fluid Warmer.

Components Checklist

in order of appearance in illustration

Qty Component

2 Pressure Chambers / Contents:

(2) “U” brackets

(4) Thumbscrews

1 I.V. Bag Hanger

1 Fluid Warming Unit

1 H-31, Version B, Air

Detector/Clamp

1 Accessory Pack

(3) Pan-head screws

(3) Power Cord Clips

(3) Flat-head screws

1 Operator’s Manual

1 Quick Reference Guide

1 I.V. Pole with Flanking Brackets

1 Accessory Pack / Contents:

(2) Plastic “J” Clamps

(1) Y Connector

(1) Black Tubing

(1) Hex Wrench

1 O-Ring Kit / Contents:

(1) Silicone

(2) O-Rings

(1) Hex Wrench

(1) Instructions for Use

3 Bolts

3 Washers

1 I.V. Pole Base

10

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 5 • Out of the Box—Assembly

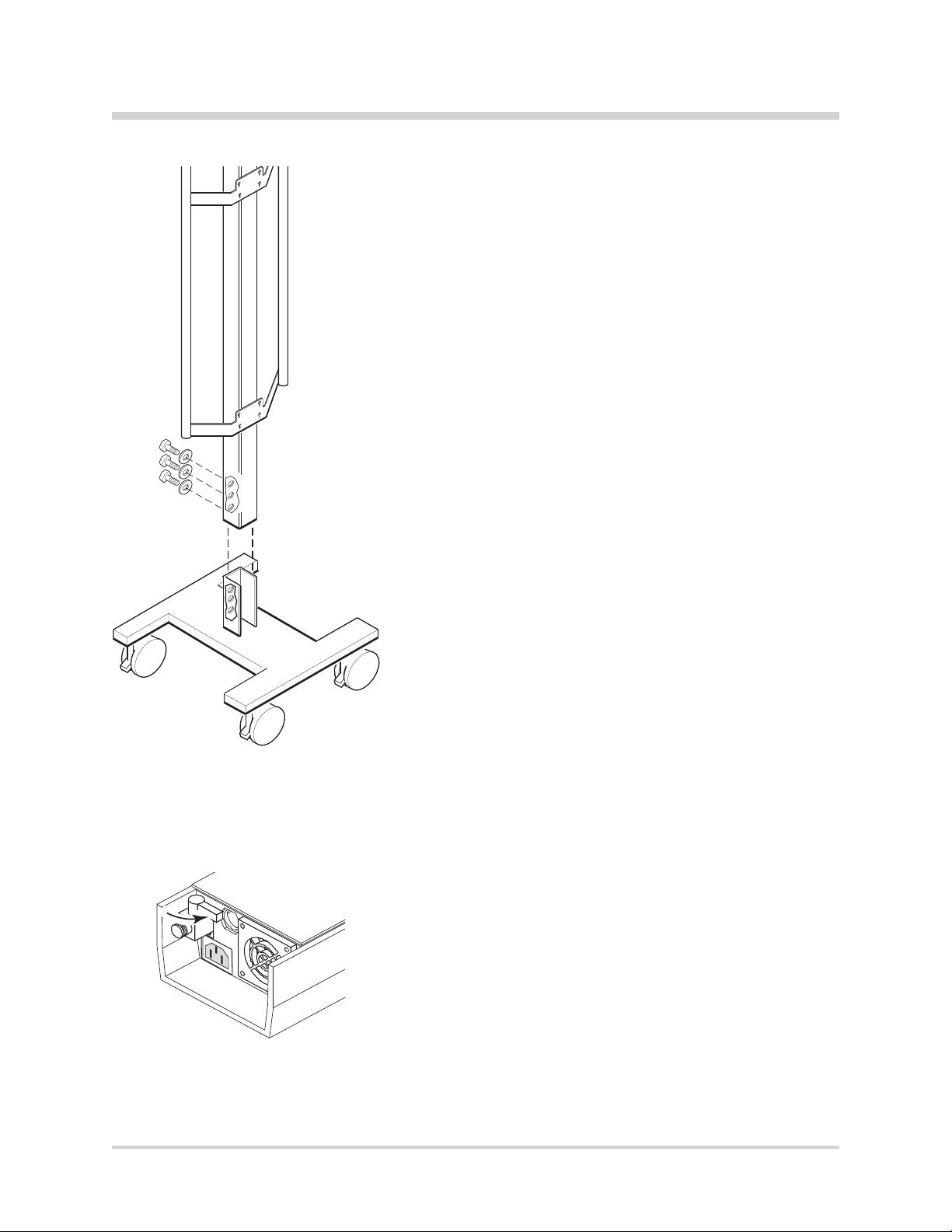

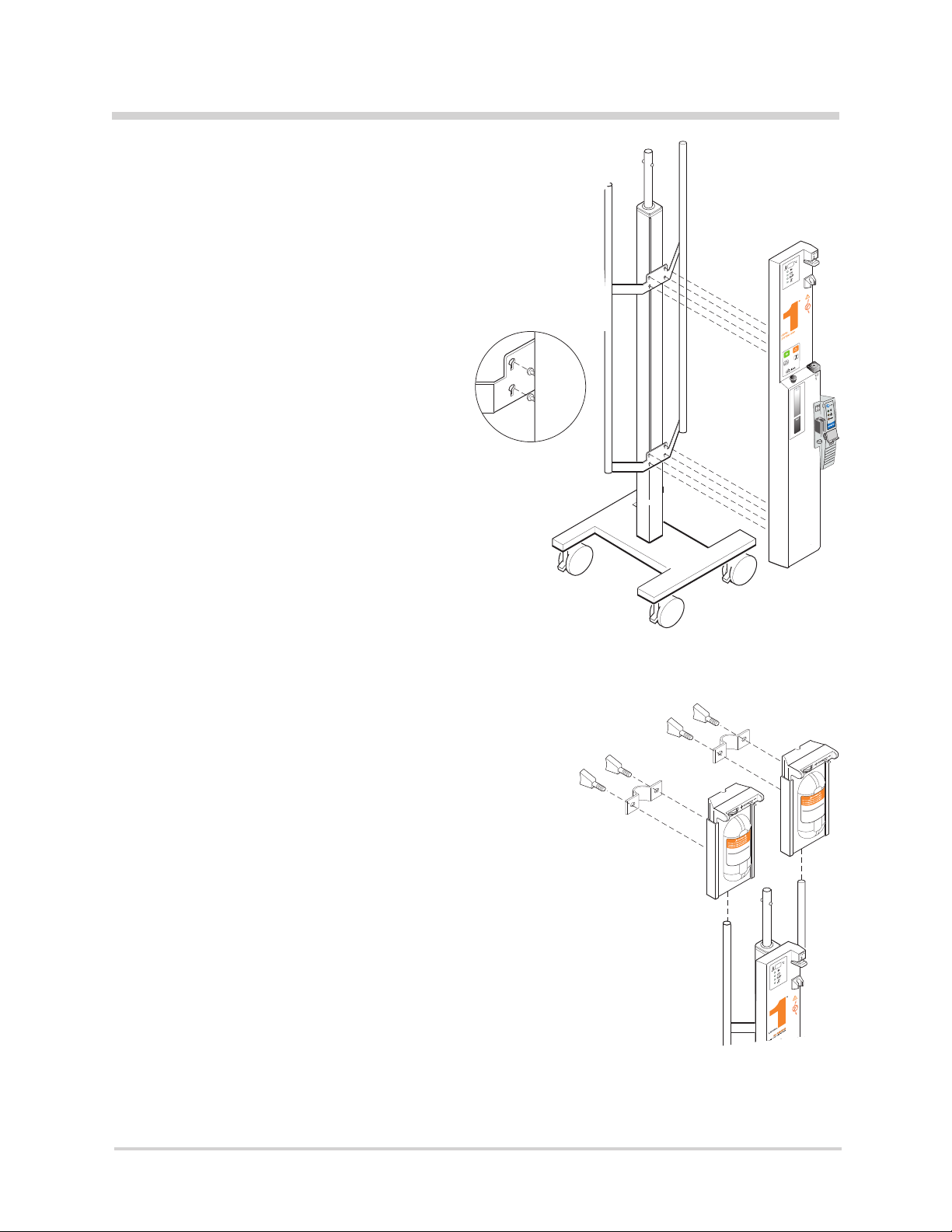

Step 2 – Assemble I.V. Pole to the Warming Unit

There are three steps involved in assembling the I.V. Pole to the

Warming Unit. The steps are: 1. Assemble the I.V. Pole to the Base,

2. Close the Drain Valve, and 3. Attach the Warming Unit to the Flanking

Brackets. Each step is detailed in a short procedure.

2.1 Assemble the I.V. Pole to the Base

1 Locate the I.V. Pole Base (a).

2 Locate the dark-gray extruded I.V. Pole (b) with Flanking

Brackets.

b

d

e

3 Place the I.V. Pole Base upright on its wheels, (c) and lock the

wheels to prevent movement during set up.

4 Locate three bolts (d) and washers for the

pole base.

5 Align the three holes (e) in the I.V. Pole with the three screw

holes on the pole base.

6 Slide the I.V. Pole down over the pole base, (f) keeping holes

f

aligned.

7 Guide three bolts and washers through the holes (g) at the base

of the pole and tighten.

g

c

a

2.2 Close the Drain Valve

h

Turn valve, located on the bottom of the device, perpendicular

to stem (h) of the Warming as shown.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

11

SECTION 5 • Out of the Box—Assembly

2.3

Attach the Warming Unit to the Flanking Brackets

1 Align the eight hex screws on the back of the WarmingUnit

with the eight keyhole notches on the anking bracket.

2 Slide screw heads down into keyhole notches.

3 Tighten all eight hex screws with the supplied hexwrench

and secure in place.

Attach the Quick Reference Guide

2.4

to the Fluid Warmer by sliding the ring on the

Quick Reference Guide over one of the poles

on the Flanking Bracket.

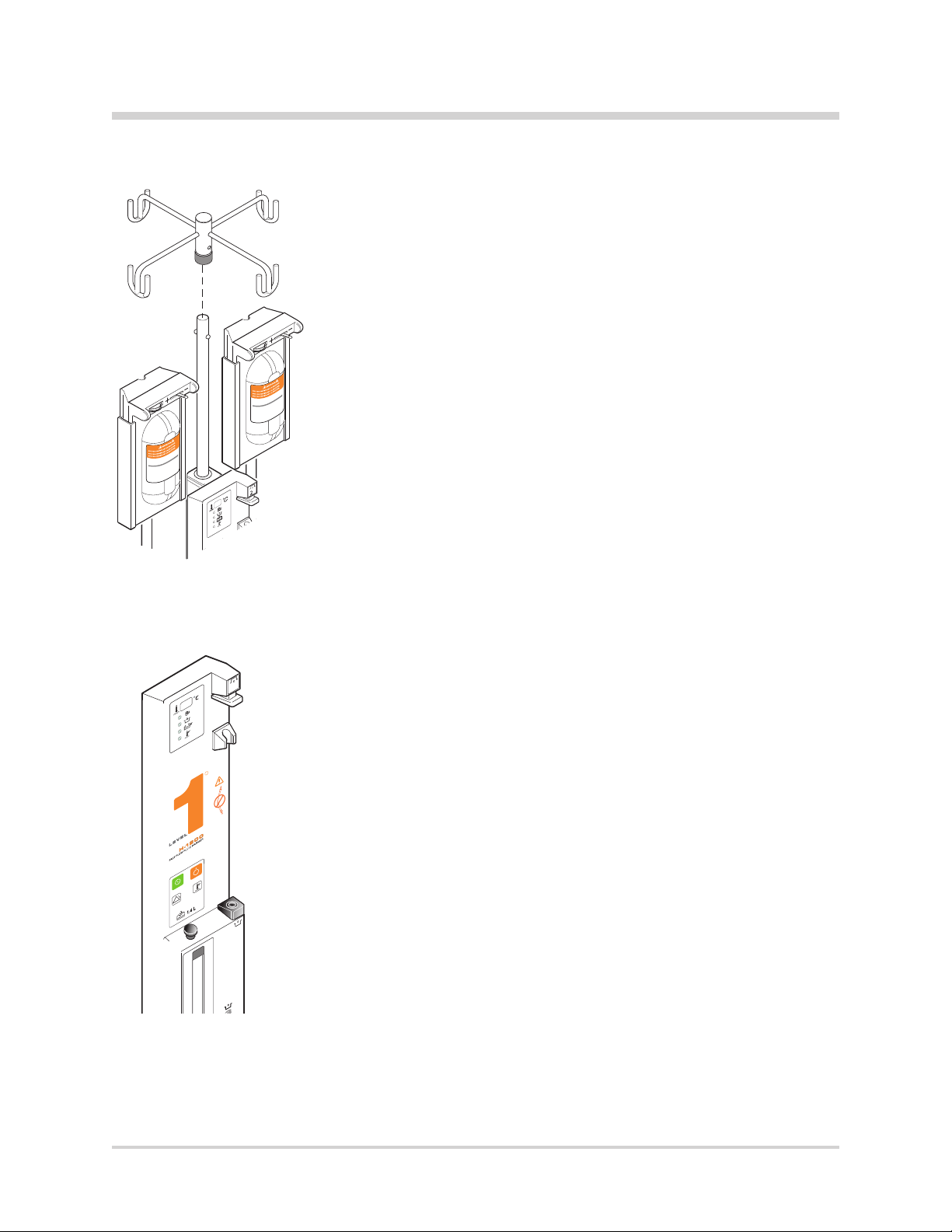

Step 3 – Install the Pressure Chambers

1 Locate the two Pressure Chambers.

2 Locate the U-brackets and thumbscrews supplied with

the Pressure Chambers.

3 Attach the U-brackets with thumbscrews to the back of

thePressure Chambers, as shown. Keep thumbscrews

and brackets loose.

4 Slide one Pressure Chamber with attached U-bracket over

the top of each anking pole.

5 Align the U-bracket slightly below the top of the anking

pole. Tighten the thumbscrews securely.

12

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

MIN

MAX

1

2

SECTION 5 • Out of the Box—Assembly

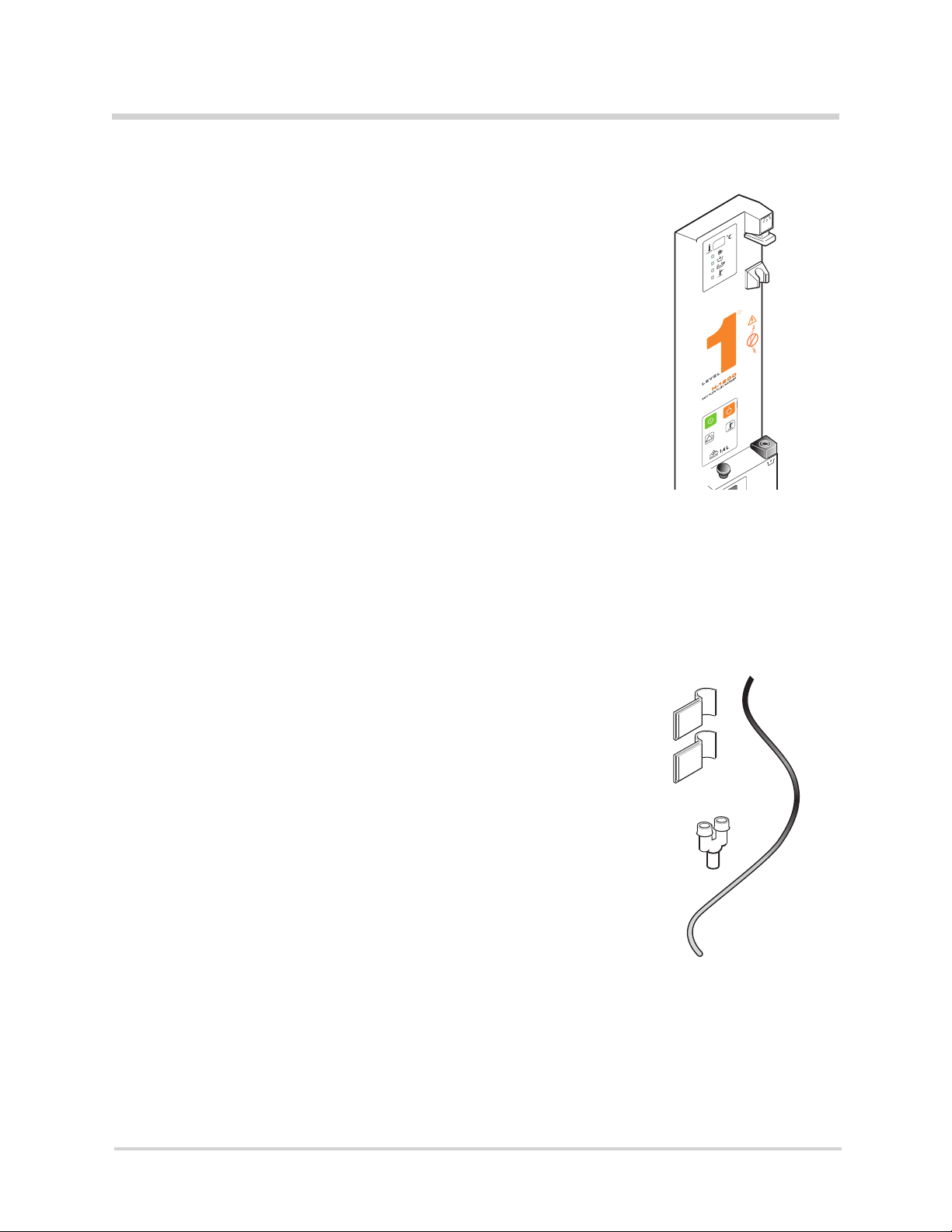

Step 4 – Attach the I.V. Bag Hanger

1 Slide the I.V. Bag Hanger on top of the I.V. Pole.

2 Align with tabs.

3 Press down and snap into place.

Step 5 – Disinfect the Recirculating

Solution Reservoir

1 Remove the ll-port plug (a) on the reservoir.

2

c

R

b

1

a

MAX

2 Prepare a 0.3% hydrogen peroxide/distilled water solution

for the reservoir. Mix 140 ml of 3% hydrogen peroxide

solution and 1,260 ml of distilled water.

3 Fill the reservoir with 1.4 liters of 0.3% hydrogen peroxide/

distilled water solution.

4 Replace the ll-port plug.

5 Insert a Disposable Set into the Fluid Warmer.

6 Insert the power cord into a properly grounded receptacle.

7 Turn the Fluid Warmer ON. Let the solution circulate for a

30-minute disinfection period.

8 Turn the Fluid Warmer OFF.

9 Empty the reservoir.

10 Remove the Disposable Set and discard according to

established hospital procedures.

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

13

MAX

1

2

SECTION 5 • Out of the Box—Assembly

Step 6 – Preliminary Preparation

1 Remove the ll-port plug (a) on the front of the warming unit

and ll the reservoir to the maximum level with 1.4 liters of one

of the following solutions:

• 0.3% Hydrogen Peroxide/Distilled Water Solution

Mix 140 ml of 3% hydrogen peroxide and 1,260 ml of

distilled water.

Note: If this option is selected, the maintenance requirement to

change the recirculating solution is once every 12 months.

Always use a 0.3% hydrogen peroxide/distilled water solution

when relling the reservoir.

• Distilled Water

Note: If this option is selected, the maintenance requirement to

change the recirculating solution is once every 30 days.

2 Replace the ll port plug.

3 Lubricate O-Rings in #1 Block (b) and #2 Block (c). Place a small

amount of silicone lubricant, provided in the supplied O-Ring

Kit, on a cotton swab and apply all around the inside of each

O-Ring.

c

2

R

b

a

1

Step 7 – Connect the Pneumatic Tubing

1 Locate the Accessory Pack with the black pneumatic tubing (a),

two “J” clamps (b), and one “Y” Connector (c).

a

b

c

14

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

SECTION 5 • Out of the Box—Assembly

2 Locate the orange protective plug in the red ring connector (d)

located on the back of the device. Remove the plug by

depressing the red plastic ring as you pull the plug out of the

connector.

f

e

g

3

Take the pneumatic tubing and press one end of the tubing rmly into

the ring connector

4

Take the “Y” connector and press the other end of the pneumatic

tubing into the bottom of the “Y” connector, as shown

(d)

until it can go no further.

(e)

, until it can

go no further.

5

Press the pneumatic tubing from the Pressure Chamber into place

(f)

on the top of the “Y” connector until it can go no further. Repeat

this procedure with the pneumatic tubing from the other Pressure

h

Chamber.

6

Remove the protective backing sheet on one “J” clamp, exposing the

adhesive side.

7

d

Carefully position the “J” clamp and press the adhesive side against the

gray I.V. Pole in the approximate locations

(g)(h)

shown.

F1

Press down rmly to secure in place.

Repeat this procedure for the other “J” clamp.

8

Press the pneumatic tubing into place on the “J” clamps.

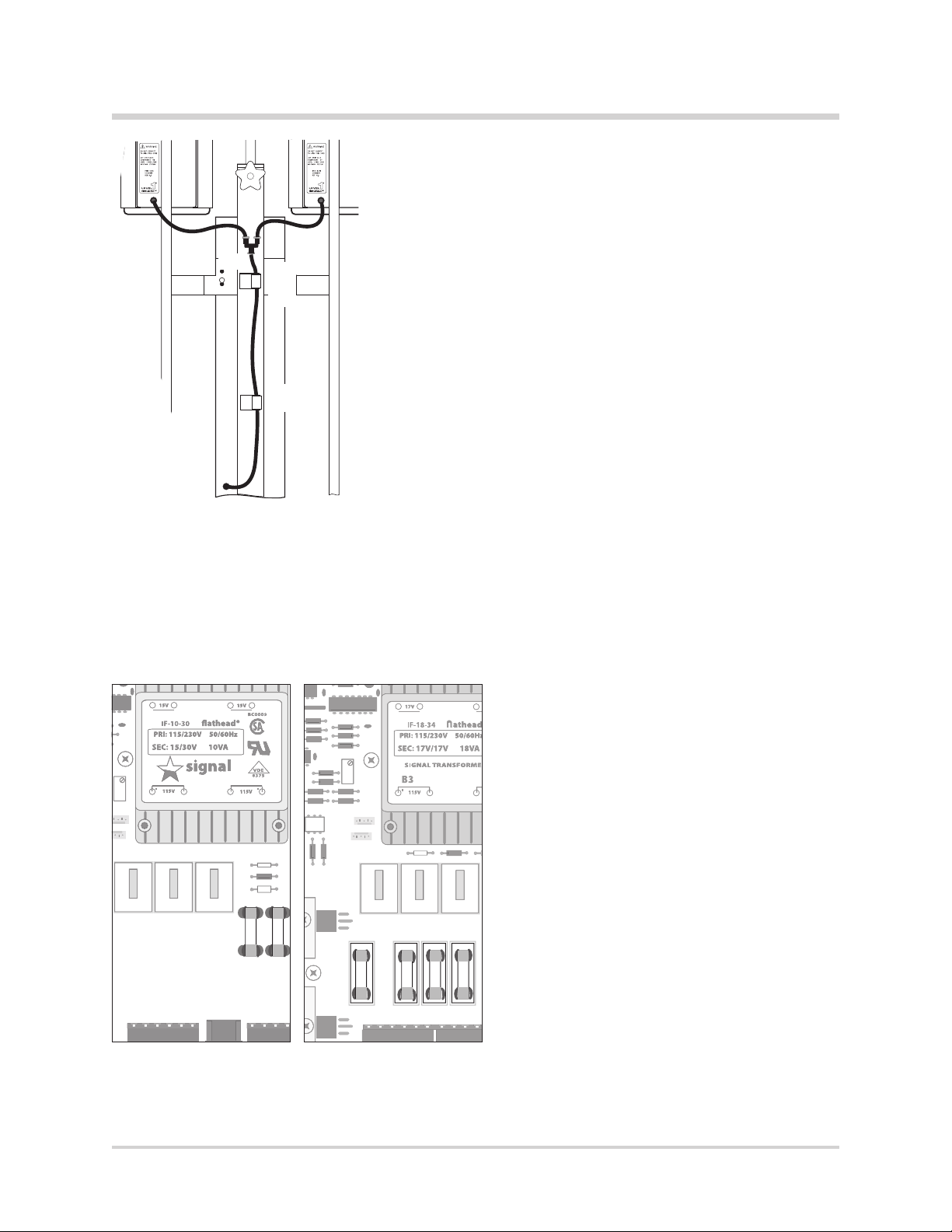

Step 8 – Install the Level 1® H-31, Version B,

Air-Detector/Clamp

Before installing the Air detector, determine if the

Fluid Warmer was manufactured before 2004. If

it is, inspect the “F1” fuse to conrm that it is the

correct value and type. The year of manufacture

can be determined by the serial number label

which is located on the bottom right side of the

unit, or for older units on the inside. If the rst four

characters of the serial number are numbers, then

the numbers represent the year of manufacture (e.g.

20040100 would be manufactured in 2004). If the

rst character of the serial number is the letter “J”,

then the year of manufacture is prior to 2004 (the

letter “S” indicates the year 2007 or later). For units

manufactured prior to 2004, perform the following.

1 Disconnect the power.

Two Fuse Conguration

F1

Four Fuse Conguration

FAST FLOW FLUID WARMER

2 Remove the 18 screws from the rear of the

Fluid Warmer and remove the back panel.

3 Locate the “F1” fuse on the electronic

assembly. See gures to locate the “F1” fuse

for either a two fuse conguration or a four

fuse conguration.

|

Operator’s ManualH-1200

15

SECTION 5 • Out of the Box—Assembly

• For 100 - 120V Fluid Warmers,

Remove the fuse and verify that T6.3AL250V (time lag,

6.3 amp, 250V fuse), is printed on one of the silver end

caps, if not replace the fuse with a new fuse marked

T6.3AL250V.

• For 220 - 240V Fluid Warmers,

Remove the fuse and verify that T3.15AL250V (time lag,

3.15 amp, 250V fuse), is printed on one of the silver end

caps, if not replace the fuse with a new fuse marked

T3.15AL250V.

4 Replace the back panel and insert all but 6 of the screws (a)

as indicated in Step 1 below. Then proceed to install the

Air Detector/Clamp.

a

d

a

a

e

a

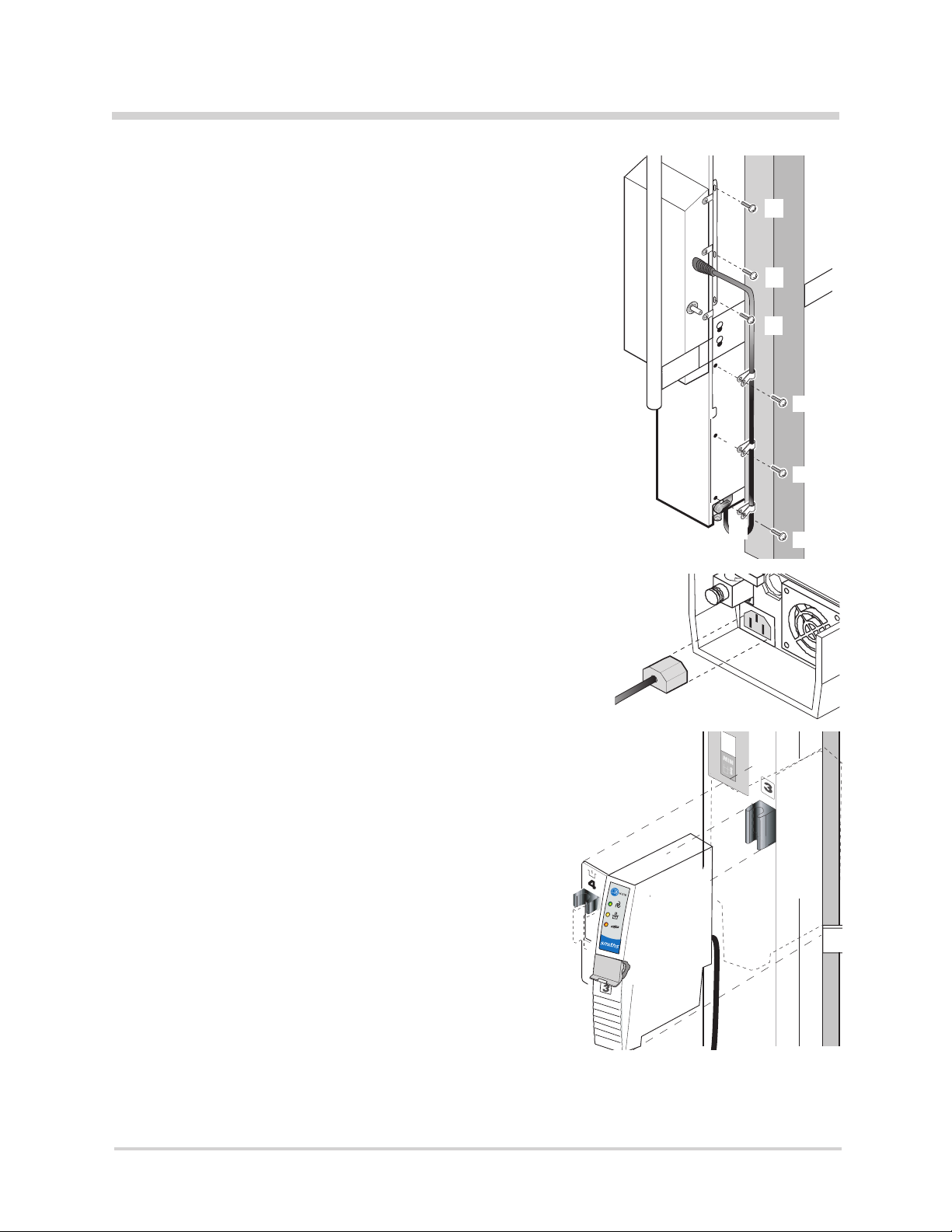

To install the Air Detector/Clamp,

1 Remove 6 screws (a) from the rear of the Fluid Warmer,

lower left side, from locations shown in gure.

2 Plug in the power cord (b) of the Level 1® H-31, Version B,

Air Detector/Clamp into the auxiliary MAINS outlet located

on the bottom of the Fluid Warmer.

Note: If you turn the Fluid Warmer o and the Air Detector/Clamp

does not turn o, contact Smiths Medical or your local Smiths

Medical distributor.

3 Loosen the three screws holding the mounting bracket to the

rear of the Air Detector/Clamp (do not remove).

4 Align the slot on the Air Detector/Clamp with #3 Block on the

Fluid Warmer (c). Fit in place over the block.

Note: Do not bend the mounting bracket while holding the

Air Detector/Clamp against the uid Warmer.

5 Carefully align the mounting bracket on the rear of the

Air Detector/Clamp with three screw holes, shown (d).

Ensure that the gasket seal on the Air Detector/Clamp is

ush with the Fluid Warmer. Insert three at-head screws

and tighten, securing the Air Detector/Clamp to the

Fluid Warmer. Tighten the three screws on the

mounting bracket on the Air Detector/Clamp.

e

a

e

a

b

c

6 Locate three power cord clips (e) included with the

Air Detector/Clamp and snap onto power cord. Align

clips with the three screw holes as shown, insert

screws, and tighten.

7 Install and prime a Level 1® Fast Flow I.V. Disposable

Administration Set, and test the audible and visual

alarms and Air Detection/Clamp as described in

Section 9 Operating Instructions.

16

FAST FLOW FLUID WARMER

|

Operator’s ManualH-1200

Loading...

Loading...