Leuze electronic SD4T 14, SOLID-4, SD4R 20, SD4T 30, SD4T 40 Connecting And Operating Instructions

...Page 1

SOLID-4

Safety Light Curtain

604049 - 2011/02

Subject to change

without prior notice

CONNECTING AND OPERATING INSTRUCTIONS

Original Instructions

Page 2

Notes on Connecting and Operating Instructions

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

This connecting and operating instructions manual contains information on the proper use of

SOLID-4 Safety Light Curtains in accordance with its intended purpose. It is included with

delivery.

All the information contained herein, in particular the safety notes, must be carefully

observed.

This connecting and operating instructions manual must be stored carefully. It must be

a

ailable for the entire operating time of the optical safety device.

v

Notes regarding safety and warnings are identified with the symbol.

Notes regarding important pieces of information are identified with the symbol.

Leuze electronic GmbH + Co. KG is not liable for damage resulting from improper use

of

its equipment. Familiarity with these instructions is an element of the knowledge

required for proper use.

© Reprints and reproduction, in whole or in part,

permission o

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen - Teck / Germany

Phone+49 (0) 7021 / 573-0

Fax +49 (0) 7021 / 573-199

info@leuze.de

www.leuze.com

f

are permitted only with the explicit

2 SOLID-4 Leuze electronic

Page 3

Contents

1 General................................................................................................................................ 6

1.1 Certifications ........................................................................................................................6

1.2 Symbols and terms ........................................................................................................................7

1.3 SOLID-4 selection................................................................................................................9

2 Safety ................................................................................................................................10

2.1 Approved purpose and foreseeable improper operation....................................................10

2.1.1 Proper use..........................................................................................................................10

2.1.2 Foreseeable misuse...........................................................................................................11

2.2 Competent personnel...................................................................................................................12

2.3 Responsibility for safety .....................................................................................................12

2.4 Exemption of liability ..........................................................................................................12

2.5 SOLID-4 Safety Light Curtains with a resolution of 14 mm to 40 mm..........................................13

2.6 SOLID-4 Safety Light Curtains with a resolution of ≥ 40 mm.............................................13

2.7 Additional safety instructions for access guarding with SOLID-4.......................................14

3 System setup and possible uses....................................................................................15

3.1 The opto-electronic protective device ................................................................................15

3.2 Cascading option .........................................................................................................................16

4 Functions..........................................................................................................................18

4.1 Selectable functions of the SD4T Transmitter....................................................................18

4.1.1 Transmission channel ........................................................................................................18

4.2 Selectable functions of the SD4R-E Receiver....................................................................18

4.2.1 Transmission channel ........................................................................................................18

4.2.2 Start/restart interlock (RES) ...............................................................................................19

4.2.3 Contactor monitoring (EDM) ..............................................................................................20

4.3 Functions of receiver SD4R ...............................................................................................21

4.4 Diagnostics function: Dirt and error signal output ..............................................................21

4.5 Test input ........................................................................................................................... 21

5 Display elements..............................................................................................................22

5.1 SD4T Transmitter status displays......................................................................................22

5.2 SD4R-E Receiver status displays ................................................................................................23

5.2.1 7-segment displays ............................................................................................................23

5.2.2 LED displays ......................................................................................................................24

5.3 SD4R Receiver status displays..........................................................................................24

5.3.1 7-segment display.............................................................................................................. 25

5.3.2 LED displays ......................................................................................................................25

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Leuze electronic SOLID-4 3

Page 4

Contents

6 Installation........................................................................................................................ 26

6.1 Calculating minimum distances .........................................................................................26

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

6.1.1 Safety distance for point of operation guarding ................................................................. 26

6.1.2 Safety distance for danger zone guarding ......................................................................... 28

6.1.3 Safety distance and beam heights for Safety Light Curtains as access guarding ............. 30

6.1.4 Minimum distance from reflective surfaces........................................................................ 32

6.2 Mounting notes .................................................................................................................. 33

6.3 Mechanical mounting ......................................................................................................... 34

6.4 Mounting types ............................................................................................................................ 35

6.4.1 Standard mounting............................................................................................................. 35

6.4.2 Option: Mounting with swiveling brackets .......................................................................... 35

6.4.3 Option: Side mounting .......................................................................................................36

7 Electrical connection....................................................................................................... 37

7.1 M12 coupling...................................................................................................................... 37

7.1.1 Transmitter......................................................................................................................... 37

7.1.2 Receiver SD4R-E............................................................................................................... 38

7.1.3 Receiver SD4R .................................................................................................................. 41

7.2 Connection examples ........................................................................................................ 42

7.2.1 Connection example for transmission channel 1(TC1) ......................................................42

7.2.2 Connection example for transmission channel 2 (TC2) .....................................................43

7.2.3 SOLID-4 connection example with downstream relay module, MSI-RM2 ......................... 44

7.2.4 Connection example of SOLID-4 with downstream MSI-SR4 Safety Interface Device ..... 45

8 Startup .............................................................................................................................. 46

8.1 Switching on....................................................................................................................... 46

8.1.1 Display sequence with SD4T Transmitter.......................................................................... 46

8.1.2 Display sequence with SD4R-E Receiver..........................................................................47

8.1.3 Display sequence on receiver SD4R ................................................................................. 48

8.2 Aligning transmitter and receiver ....................................................................................... 48

8.2.1 Optimizing alignment by turning and/or tilting the transmitter and receiver ....................... 48

9 Testing ..............................................................................................................................49

9.1 Testing before first startup.................................................................................................49

9.2 Regular tests...................................................................................................................... 49

9.3 Daily testing with the test rod.............................................................................................49

9.4 Cleaning the front screens ........................................................................................................... 51

4 SOLID-4 Leuze electronic

Page 5

Contents

10 Troubleshooting...............................................................................................................52

10.1 What do I do if an error occurs?.........................................................................................52

10.2 Diagnostics......................................................................................................................... 52

10.2.1 SD4T Transmitter diagnostic..............................................................................................52

10.2.2 SD4R-E Receiver diagnostics............................................................................................52

10.3 AutoReset ....................................................................................................................................54

11 Technical data..................................................................................................................55

11.1 General data ...................................................................................................................... 55

11.1.1 Protective field data............................................................................................................55

11.1.2 Safety-relevant technical data............................................................................................55

11.1.3 General system data ..........................................................................................................55

11.1.4 SD4T Transmitter signal input............................................................................................56

11.1.5 SD4R-E Receiver signal inputs/outputs .............................................................................56

11.1.6 Safety-related transistor outputs ........................................................................................57

11.2 Safety Light Curtain/host dimensions, weights, response times ..................................................58

11.3 Safety Light Curtain/guest dimensions, weights, response times ......................................59

11.4 Number of beams for host / guest devices.........................................................................59

11.5 Bracket dimensions............................................................................................................ 61

12 Appendix...........................................................................................................................63

12.1 SOLID-4 scope of delivery.................................................................................................63

12.2 SOLID-4 ordering information ............................................................................................63

12.2.1 SOLID-4E Host ordering information .................................................................................65

12.2.2 SOLID-4 Guest ordering information..................................................................................66

12.3 SOLID-4 accessories ordering information ..................................................................................67

12.4 Checklists...........................................................................................................................69

12.4.1 Checklist for point of operation guarding............................................................................70

12.4.2 Checklist for danger zone guarding ...................................................................................71

12.4.3 Checklist for access guarding ............................................................................................72

12.5 EC Declaration of Conformity.......................................................................................................73

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Leuze electronic SOLID-4 5

Page 6

General

1 General

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

1.1 Certifications

SOLID-4 Safety Light Curtains are type 4 Active Opto-electronic Protective Devices (Active

Opto-electronic Protective Devices, AOPDs) in accordance with EN IEC 61496-1 and

prEN/I

All SOLID-4 Safety Light Curtains with a type SD4R-E Receiver hav

and contactor monitoring function that can be selected and deselected, as well as display

elements (LEDs and 7-segment) for convenient startup and diagnostics.

The SOLID-4 series is equipped with 2 OSSDs (t

with M12 connection system as standard features.

To provide the best possible solutions for specific applicat

available in various resolutions and protective field heights.

Company

Leuze electronic GmbH + Co. KG in D-73277 Owen - Teck, Germany, has a certified

qualit

Products

EC 61496-2.

ransis

y assurance system in compliance with ISO 9001.

e start/restart interlock

tor safety-related switching outputs)

ions, SOLID-4 series devices are

SOLID-4 Safety Light Curtains are develo

applicable European directives and standards.

EC Prototype Test in accordance with

EN IEC 61496-1 and prEN IEC 61496-2

carried out by:

TÜV PRODUCT SERVICE GmbH, IQSE

Ridlerstrasse 65

D-80339 Munich

6 SOLID-4 Leuze electronic

ped and manufactured in compliance with

Page 7

1.2 Symbols and terms

Symbols used

W

Please pay especially close attention to these instructions!

Sign indicating important information.

General

arning sign – This symbol indicates possible dangers.

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

➢ A note, which also refers to a course of action, provides informa-

tion about special attributes or des

Symbols for SOLID-4 Transmitter

General transmitter symbol

Transmitter not active

Transmitter active

Symbols for SOLID-4 Receiver

General receiver symbol

The receiver’s active protective field is not free, outputs in

O

The receiver’s active protective field is free. Outputs in ON-state

The receiver’s active protective field is free. Outputs in OFF-state

Signal output

Signal input

Signal input and/or output

Table 1.2-1: Symbols

F-state

F

cribes setting procedures.

TNT 35/7-24V

Leuze electronic SOLID-4 7

Page 8

General

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Terms used in this manual

Access guarding Detection of a person’s body on entry int

AOPD Active Opt

AOPD response time Time between penetration/entry into the active protective field of

AutoReset When an error indication occurs, caused, for example, by faulty

Contactor monitoring

(ED

M)

Danger zone guarding Requires detection in the foot/leg area

EDM External Device Monitoring

FC Feedback circuit for EDM

OSSD1

OSSD2

Point of operation

guarding

RES Start/REStart interlock.

Scan All beams, beginning with the synchronization beam, are pulsed

SD4 SOLID-4 consisting of transmitter and receiver

SD4R SOLID-4 Receiver

SD4R-E SOLID-4 Receiver with selectable start/restart interlock and con-

SD4T SOLID-4 Transmitter

SingleScan A switch-off is made if a beam is interrupted in the first scan of the

SOLID-4E SOLID-4 consisting of SD4T Transmitter and SD4R-E Receiver

Start/

restart interlock

(RES)

TC1/TC2 Transmission channel 1 and transmission channel 2

required.

o-electronic Protective Device

PD and when the OSSDs actually switch off.

the AO

exte

rnal wiring, the AOPD attempts to start again. If the error no

longer exists, the AOPD returns to the normal state.

The contactor monitoring monitors the normally closed contacts

of downstream positive-guided contactors and relays.

Safety-related switching output

put Si

Out

Requires

by the t

tactor monitoring function (EDM)

Light

RES prevents automatic start after the supply voltage has been

t

u

entered.

gnal Switching Device

finger, hand or arm detection

ransmitter in cycles one after the other.

Curt

ain.

rned on and after the protective field has been penetrated/

o the danger zone is

Table 1.2-2: Te

8 SOLID-4 Leuze electronic

rms/terminology, SOLID-4 Safety Light Curtains

Page 9

1.3 SOLID-4 selection

General

SOLID-4

t - Type of device

T: Transmitter

R: Receiver

rr - Resolution/range

14: 14 mm / 0.3 – 6 m

20: 20 mm / 0.7 – 14 m

30: 30 mm / 0.5 – 9 m

40: 40 mm / 0.9 – 20 m

90: 90 mm / 0.9 – 20 m

hhhh – Protective field heights

150 ... 1,800 mm

v – Functions (only with receiver)

E: With selectable start/restart interlock and monitoring

func

tion

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

k – Version/mode (only

Without

H

G

L

SD4trr-hhhhvk

Fig. 1.3-1: Select

Leuze electronic SOLID-4 9

U

a SOLID-4 Safety Light Curtain

ing

Standard model

Host

Guest

L-Shape

U-Shape

available with function "E")l

TNT 35/7-24V

Page 10

Safety

2 Safety

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Before using the safety sensor, a risk evaluation must be performed according to valid

standards (e.g. EN ISO 14121, EN ISO 12100-1, ISO 13849-1, IEC 61508, EN 62061).

Th

e result of the risk assessment determines the required safety level of the safety sensor

(see Table 2.1-1). For mounting, operating and testing, document "SOLID-4 Safety Light

Curtain" as well as all applicable national and international standards, regulations, rules

and direct

printed out and handed to the affected personnel.

Before working with the safety sensor, c

applicable to your task.

In particular, the following national and international legal regulations apply for the start-up,

te

• Machinery directive 2006/42/EC

• Low voltage directive 2006/95/EC

• Electromagnetic compatibility directive 2004/108/EC

• Use of Work Equipment Directive 89/655/EEC supplemented by Directive 95/63 EC

• OSHA 1910 Subpart 0

• Safety regulations

• Accident-prevention regulations and safety rules

• Ordinance on Industrial Safety and Health and Labor Protection Act

• Device Safety Act

Notice!

For safety-related information you may also contact the local authorities (e.g., industrial

n

i

safety and health authority).

i

ves must be observed. Relevant and supplied documents must be observed,

mpletely read and understand the documents

o

chnical inspections and work with safety sensors:

spectorate, employer's liability insurance association, labor inspectorate, occupational

2.1 Approved purpose and foreseeable improper operation

Warning!

A running machine can cause severe injuries!

Make certain that, during all conversions, maintenance work and inspections, the system is

securely shut down and protected against being restarted again.

2.1.1 Proper use

The safety sensor must only be used after it has been selected in accordance with the

respectively applicable instructions and relevant standards, rules and regulations regarding

labor protection and occupational safety, and after it has been installed on the machine,

connected, commissioned, and checked by a competent person.

When selecting the safety sensor it must be ensured that its safety-related capability meets

or e

10 SOLID-4 Leuze electronic

the required performance level PL

xceeds

ascertained in the risk assessment.

r

Page 11

Safety

The following table shows the safety-related characteristic parameters of the SOLID-4

Safety Light Curtain.

Type in accordance with IEC/EN 61496 Type 4

SI

L in accordance with IEC 61508 SIL 3

SILCL in accordance with IEC/EN 62061 SILCL 3

Performance Level (PL) in accordance with ISO 13849-1: 2008 PL e

Category in accordance with ISO 13849 Cat. 4

Average probability of a failure to danger per hour (PFH

For protective field heights up to 900 mm, all resolutions

For protective field heights up to 1800 mm, all resolutions

For protective field heights up to 2850 mm, all resolutions

Service life (T

) 20 years

M

)

d

-9 1

6.0 x 10

7.3 x 10-9 1/

On request

/

h

h

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Table 2.1-1: Safety-related characteristic parameters of the SOLID-4 Safety Light

Curtain

• The safety sensor protects persons at access

machines and plants.

• The safety sensor with vertical mounting detect

points of operation or by the body at access points.

• The safety sensor only detects persons upon entry

persons who are located within the danger zone. For this reason, a start/restart interlock

is mandatory.

• The safety sensor with horizontal mounting detect

danger zone (presence detection).

• The construction of the safety sensor must not be altered. When manipulating the safety

, the protective function is no longer guaranteed. Manipulating the safety sensor

sensor

also voids all warranty claims against the manufacturer of the safety sensor.

• The safety sensor must be tested regularly b

• The safety sensor must be exchanged after a maximum of 20 years. Repairs or the

change of parts subject to wear and tear do not extend the service life.

ex

2.1.2 Foreseeable misuse

In principle, the safety sensor is not suitable as a protective device in case of:

• danger of objects being expelled or hot or dangerous liquids spurting from the danger

zone

applications in explosive or easily fl

•

points or at points of operation of

s the penetration by fingers and hands at

to the danger zone; it does not detect

s persons who are located within the

y competent personnel.

TNT 35/7-24V

ammable atmospheres

Leuze electronic SOLID-4 11

Page 12

Safety

2.2 Competent personnel

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Prerequisites for competent personnel:

• he has a suitable technical education

• he knows the rules and regulations for occupational safety, safety at work and safety

chnology and can assess the safety of the machine

te

• he knows the instructions for the safety sensor and the machine

• he has been instructed by the responsible person on t

machine and of the safety sensor

2.3 Responsibility for safety

Manufacturer and operating company must ensure that the machine and implemented

safety sensor function properly and that all affected persons are adequately informed and

trained.

The type and content of all imparted information must not lead to unsafe actions by users.

The manufacturer of the machine is responsible for:

• safe machine construction

• safe implementation of the safety sensor

• imparting all relevant information to the operating company

• adhering to all regulations and directives for the safe starting-up of the machine

The operator of the machine is responsible for:

• instructing the operating personnel

• maintaining the safe operation of the machine

• adhering to all regulations and directives for occupational safety and safety at work

• regular testing by competent personnel

he mounting and operation of the

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• safety sensor is not used as intended

• safety notices are not adhered to

• reasonably foreseeable misuse is not taken into account

ly performed

• mounting and electrical connection are not

• proper function is not tested (see Chapter 9).

• changes (e.g., constructional) are made to the safety sensor

12 SOLID-4 Leuze electronic

proper

Page 13

Safety

2.5 SOLID-4 Safety Light Curtains with a resolution of 14 mm to 40 mm

are used for point of operation guarding, preferably in a vertical position.

(See Fig. 6.1-1). Depending on the resolution selected, they can detect:

Device type Resolution Detection with

SD4T 14-.. /

SD4R 14-..

SD4T 20-.. /

SD4R 20-..

SD4T 30-.. /

SD4R 30-..

SD4T 40-.. /

SD4R 40-..

Table 2.5-1: SOLI

Warning!

Safety Light Curtains with > 40 mm resolution are not suitable for protection of points of

operation

for which finger, hand or arm resolution is required.

14 mm F

20 mm Hand 0.

30 mm Hand 0.

40 mm Arm 0.

D-4 Safety Light Curtains for point of operation guarding

persons age

14

and over

inger 0.3 to 6 m Point of operation

Range Preferred area of

application

guarding

7 to 14 m Point of operation

guarding

5 to 9 m Point of operation

guarding

9 to 20 m Point of operation

guarding

2.6 SOLID-4 Safety Light Curtains with a resolution of ≥ 40 mm

are preferably used for danger zone guarding (see Fig. 6.1-2). Predominantly in a

horizontal position, the presence of

monitored.

Device type Resolution Detection with

SD4T 40-.. /

SD4R 40-..

SD4T 90-.. /

SD4R 90-..

Table 2.6-1: SOLI

40 mm F

90 mm F

D-4 Safety Light Curtains for danger zone guarding

people within the protective field is continuously

persons age

14

and over

rom the feet

upwards

rom the thigh

upwards

Range Preferred area of

application

0.9 to 20 m Danger zone

guarding

0.9 to 20 m Danger zone

guarding

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Note!

As an alternative to horizontal installation of Safety Light Curtains for danger zone

guarding, a

category 3/PL d acc. to ISO 13849 is sufficient (information on ROTOSCAN Safety Laser

S

anners can be obtained via our branch offices and partners or at www.leuze.de).

c

Leuze electronic SOLID-4 13

Safety Laser Scanner with configurable protective field can be used if safety

Page 14

Safety

2.7 Additional safety instructions for access guarding with SOLID-4

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Warning!

SOLID-4 Safety Light Curtains with a resolution of 14, 20, 30 or 40 mm detect hands, arms

or bodies of a pers

danger zone than Safety Light Curtains with a resolution of 90 mm. In this case, the height

of the highest and lowest beam above the reference plane must be selected in accordance

with EN ISO 3857.

on entering the danger zone, and therefore can be placed closer to the

It applies for all versions that people are only det

the danger zone, however, is not detected! When one or more beams are interrupted by a

person, the machine control unit must therefore go into safe interlock.

The start/restart interlock function is theref

restart button for unlocking the device must be mounted in such a way that it cannot be

reached from inside the danger zone and the entire danger zone is fully visible from its

installation position. For this, see also Chapter 6.1.3.

ec

ted during the access, their presence in

ore obligat

ory for access guarding! The start/

14 SOLID-4 Leuze electronic

Page 15

System setup and possible uses

a

b

3 System setup and possible uses

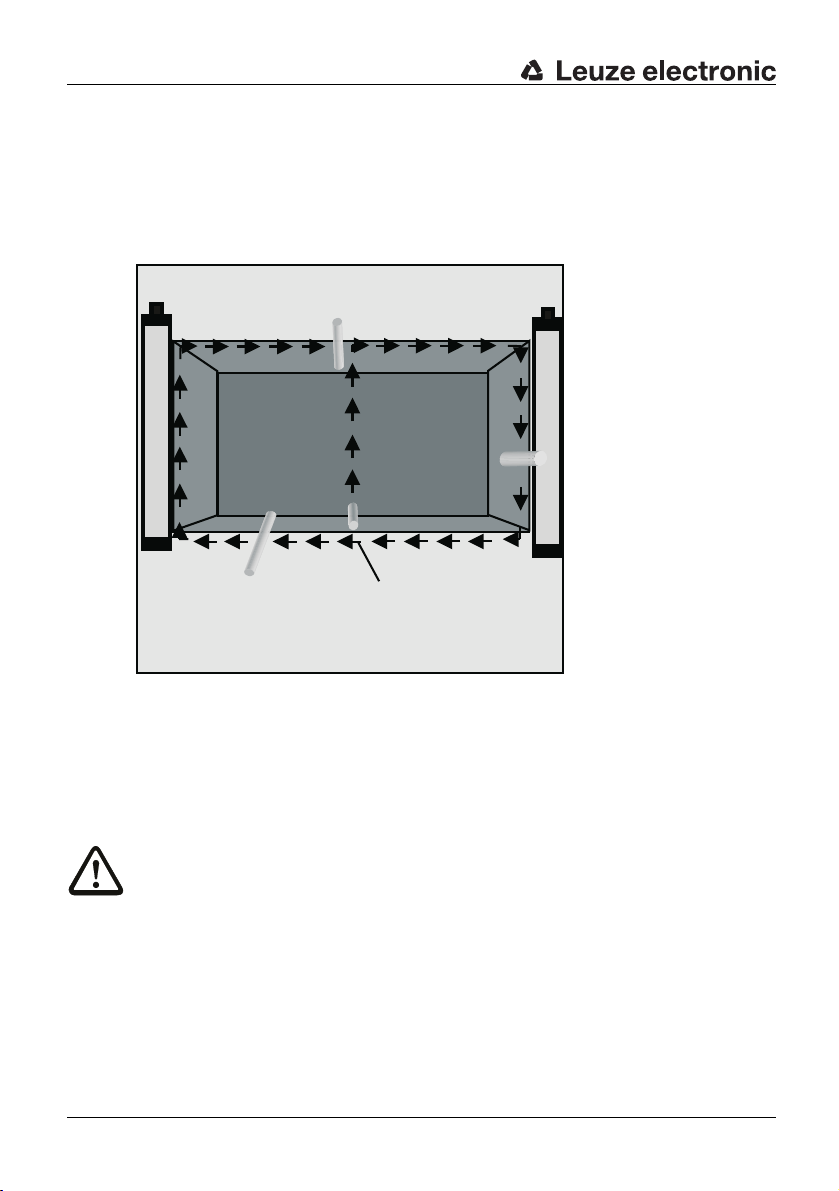

3.1 The opto-electronic protective device

Mode of operation

SOLID-4 consists of an SD4T transmitter and an SD4R

beam (the synchronizing beam) directly after the display panel, the transmitter pulses

beam for beam in rapid sequence. The synchronization between transmitter and receiver is

performed optically.

a = Transmitter

b = Receiver

Fig. 3.1-1: Working principle of the opto-electronic protective device

The SD4R receiver recognizes the specially f

and opens the corresponding receiver elements in sequence in the same rhythm. A

protective field is consequently formed in the area between the transmitter and receiver,

the height of which depends on the geometrical dimensions of the optical protective device,

the width of which depends on the distance selected between the transmitter and receiver

within the permissible range.

Basic functions, such as start/restart interlock

be performed by the electronics of receiver model SD4R-E. As a result, no downstream

Safety Interface Device is generally necessary if receiver model SD4R-E is chosen.

rmed pulse bundles of the transmitter beams

o

and/

receiver. Beginning with the first

or contactor monitoring, can optionally

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Leuze electronic SOLID-4 15

Page 16

System setup and possible uses

c

a

b

d

c

a

b

d

e

3.2 Cascading option

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

To implement multiple linked protective fields, SOLID-4E Safety Light Curtains can be

switched one after the other by cascading via plug-in cable connections or as fixedconnected L or U-shapes.

a = SDT transmitter, host (H)

b = SDT transmitter, guest (G)

c = SDR receiver, host (H)

d = SDR receiver, guest (G)

Fig. 3.2-1: Cascaded system setup with cable connection

a = SDT transmitter, host (H)

b = SDT transmitter, guest (G)

Fig. 3.2-2: Cascaded system setup as fixed-connected L or U-shape

Cascading devices makes it possible to implement adja

c = SDR receiver, host (H)

d = SDR receiver, guest (G)

e = Optional guest for U-shape

cent protective fields, for rear area

protection without any additional expense for control and connection, for example. The host

system is responsible here for all processor tasks, displays and the receiver-side interfaces

to the machine and control devices.

16 SOLID-4 Leuze electronic

Page 17

System setup and possible uses

The following limits must be observed:

• The height of the protective field for the first Light Curtain (host) must be at least 225mm.

• Ensure that the required range of the cascaded system is within the maximum range of

all individual component

• The maximum number of beams of all components must not exceed 240. For the number

of

beams n, for the individual components, please refer to the tables in Chapter 11.

• The connection cables between the individual components are part of the guest. The

standard

An additional terminating plug must be used to be able to operate a host-guest without

connect

Note!

With cascaded devices the response time of the entire system is always produced by the

response

Warning!

With fixed-connected L and U-shapes, the resoluti

greater than the resolution of the individual devices used (see L and U-Shape datasheet).

Devices with different resolutions can be combined for the variant with connection cable.

On

ly devices with the same resolution can be combined for the variant with fixedconnected L and U-shape. All cascadable devices are only available as extended version

with integrated start/restart interlock, contactor monitoring and reversible transmission

channels.

Warning!

The safety distance must be calculated in accordance with the set resolution and the

res

ponse

length is 300 mm. The connection to the host is made with an M12 plug.

ed guest (see Chapter 12.3).

time of the individual devices used.

time of the entire system (see Chapter 6).

s.

on at the point of intersection can be

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Leuze electronic SOLID-4 17

TNT 35/7-24V

Page 18

Functions

a

b

4 Functions

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

4.1 Selectable functions of the SD4T Transmitter

4.1.1 Transmission channel

The infrared beams are modulated with specially shaped pulse bundles so that they are

distinct from ambient light and undisturbed operation is consequently ensured. Welding

sparks or warning flash lights from passing forklifts do not having any effect on the

protective field.

If two protective fields are located directly next

measures must, however, be implemented so that the optical protective devices do not

affect each other.

Both transmitters should first be set up "back to back" so that the beams run in opposite

direct

ons. It is consequently impossible for them to affect each other.

i

Another possible way to suppress mutual influences is to

devices from transmission channel 1 to 2, thereby switching them to differently formed

pulse bundles. This solution should be considered when more than two optical protective

devices must be arranged next to each other.

to each other for two adjacent machines,

switch one of the two protective

a = AOPD "A" transmission channel 1

b = AOPD "B" transmission channel 2, not affected by AOPD "A"

Fig. 4.1-1: Transmission channel selection

The change from transmission channel 1 to 2

the receiver of the optical protective device in question. You will find more detailed

information in Chapter 7.

ust be made both on the transmitter and

m

4.2 Selectable functions of the SD4R-E Receiver

4.2.1 Transmission channel

If the corresponding transmitter is switched to transmission channel 2, the receiver must

also be set to transmission channel 2. For this, see also Chapter 7.

18 SOLID-4 Leuze electronic

Page 19

4.2.2 Start/restart interlock (RES)

0

I

0

I

The start/restart interlock function prevents the safety circuits from being released

automatically when the machine is turned on or the power supply is restored after a power

outage. Only by pressing and releasing the start button within a time window is the receiver

switched to the ON-state.

Functions

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Fig. 4.2-1: Start

/restart interlock function in effect when the supply voltage is turned

on

If the protective field is penetrated, the start

restart interlock function ensures that the

/

receiver will remain in the OFF state after the protective field is released again. The

receiver will then not be switched back to the ON state until the start button is pressed and

released again within a time window of 0.3 to 4 seconds.

Note!

The start button may not be pressed for longer than 10 seconds. An error message

appear

Fig. 4.2-2: Start

this is exceeded.

s if

/restart interlock function after interrupting the protective field

Warning!

Without the start/restart interlock, the receiver outputs immediately switch to the ON state

aft

er the machine has been turned on or the power supply has been restored and after the

protective field has been freed! The operation of the protective device without start/restart

interlock is only permitted in a few exceptional cases and under the conditions of controlling

protective devices in accordance with EN ISO 12100-1 and EN ISO 12100-2. It must in

part

i

cular be ensured here that it is impossible to walk or slip through the protective field.

In the case of access guarding applications, the start/restart interlock function is obligatory

due t

o the fact that only access, and NOT the area between the protective field and the

points of operation is monitored.

TNT 35/7-24V

Warning!

Before unlocking the start/restart interlock, the operator must be absolutely certain that

nobody

Leuze electronic SOLID-4 19

inside the danger zone.

is

Page 20

Functions

Activate the start/restart interlock:

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

4.2.3 Contactor monitoring (EDM)

➢ with corresponding connection of the SOLID-4E receiver (see Chapt

➢ or in the downstream safety interface (e.g. M

control functions)

➢ or in the downstream machine control unit

➢ or in the downstream safety PLC

f the internal start/restart interlock is activated as described in Chapter 7, the interlock

I

functions are monitored dynamically. T

ON-state after the start button has been pressed and released again. A further precondition

here is, of course, that the active protective field is free.

If both the SOLID-4E-internal and a subsequent start

SOLID-4E will only perform a reset function with its assigned start button (confirmation).

Warning!

The contactor monitoring of the SOLID-4E can be activated with corresponding connection

(see Chapter 7)!

SI series also for Leuze electronic muting or

he SD4R-E receiver is only switched back to the

restart interlock are activated, the

/

er 7)

The "Contactor monitoring" function dynamically monit

downstream from the SOLID-4E. Precondition here are switching elements with positiveguided feedback contacts (normally closed).

Fig. 4.2-3: Cont

You can implement the contactor monitoring function

➢ wi

th corresponding connection of the SOLID-4E receiver (see Chapt

➢ or the external contactor monitoring of

(e.g. Leuze electronic MSI series)

➢ or the contactor monitoring of the downstream safety PLC

ional, connected via a safety bus)

(opt

If the contactor monitoring function is activated (see Chapter 7), it works dynamically, i.e. in

addition to verifying that the feedback circuit is closed before turning on the OSSDs, the

sys

em checks whether the feedback circuit has opened within 500 ms of being enabled

t

and whether it has closed again within 500 ms when turning off the OSSDs. If this is not the

case, the OSSDs return to the OFF state again after being briefly switched on. An error

code appears on the 7 segment display (F34) and the receiver goes to the error locking

status, from which it can only be returned to normal operation by switching the supply

voltage off and back on again.

or monitoring function, combined in this example with RES

act

interlock

the downstream safety interface

ors contactors, relays or valves

er 7)

20 SOLID-4 Leuze electronic

Page 21

4.3 Functions of receiver SD4R

No functions can be selected on receiver SD4R.

Attention!

Without start/restart interlock, the outputs of the receiver switch to the ON state immediately after the device is switched on or afte

each release of the protective field! The protective device may only be operated without

start/restart interlock in certain exceptional cases and under the conditions of controlling

protective devices acc. to EN ISO 12100-1, EN ISO 12100-2. In this case, care must be

t

a

ken to ensure that it is impossible to step or slip past the optical protective device.

Notice!

To guarantee proper operation, the transmitter that

must be set to transmission channel 1.

r the supply voltage is restored and following

communicates with receiver SD4R

4.4 Diagnostics function: Dirt and error signal output

For diagnostic purposes SOLID-4 has a short circuit-proof "Weak Beam/Error Indication"

signal output for forwarding to the machine control unit. Information on connection of the

signal output and a connection example can be found in Chapter 7.

4.5 Test input

As a type 4 AOPD, SOLID-4 has a constant self-monitoring function that independently

detects errors in the system as well as cross and short circuits on the output cables of the

machine interface. An external test signal is not required for this. To test the downstream

contactors, an external control (e.g. protective combination) via a test signal (= pin4 of the

transmitter to 0 V or free) can switch off the OSSD outputs of the receiver and test the dropout

of

the switching elements. The test time signal time is a maximum 3 seconds. After the

test the OSSDs also go to the ON-state with activated start/restart interlock, provided the

protective field is not interrupted.

Functions

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Leuze electronic SOLID-4 21

TNT 35/7-24V

Page 22

Display elements

a

b

5 Display elements

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

5.1 SD4T Transmitter status displays

If the transmitter’s green LED1 is lit, this indicates that the supply voltage is present.

Fig. 5.1-1: Transmitter status displays

Display Meaning

LED1 green LED2 off Operating voltage present, TC1 selected

LED1 green LED2 green Operating voltage present, TC2 selected

LED1 green LED2 red Operating voltage present, TC1 or TC2 selected,

LED1 red LED2 any Device fault

a = LED1 (green/red)

b = LED2 (green/red)

e

rnal test signal activated

ext

Table 5.1-1: Transmitter, LED status displays

22 SOLID-4 Leuze electronic

Page 23

5.2 SD4R-E Receiver status displays

b

d

a

c

F

x

Two LEDs and one 7-segment display report the receiver's operating status.

Fig. 5.2-1: SD4R-E Receiver status displays

5.2.1 7-segment displays

After the electrical supply voltage is turned on, the following data appear on the receiver’s

7- segment display:

7-segment display Meaning

8. Hardware reset when turned on

S Self test running (for approx. 1.5 s)

1 Normal operation, channel 1

2 Normal operation, channel 2

F = Device fault

x = Fault number, alternating with "F"

1 or 2 flashing Flashing transmission channel number → W

Table 5.2-1: SD4R-E R

optimally aligned or dirty

eceiver 7-segment display

a = Symbol for OSSDs

b = LED1 (green/red)

c = Symbol for RES

d = LED2, yellow

Display elements

eak signal,

device not

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Leuze electronic SOLID-4 23

Page 24

Display elements

b

a

5.2.2 LED displays

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

LED Color Meaning

LED1 Red RED = OSSDs safety outputs in the OFF state

LED1 Green GREEN = OSSD safety outputs in the ON state

LED2 Yellow ON = Internal RES interlock activated; the OSSD safety outputs are

OFF = If the OSSDs are in ON state (LED1 = green): Internal RES is

Table 5.2-2: SD

Note!

If all LED displays are in the OFF state at the same time, there is no supply voltage.

4R-E Receiver LED displays

5.3 SD4R Receiver status displays

One LED and one 7-segment display report the receiver's operating status.

wit

ched to the OFF state. If the protective field is free, the de-

s

vice can be unlocked by pressing and releasing the start/restart button in a time window of 300 ms to 4 s.

unloc

If OSSDs are in OFF state (LED1 = red): Internal RES is

lock

or not selected.

ked

d the protective field is not free.

ed an

a=ymbol for OSSDs

b=LED1 (green/red)

Bild 5.3-1: SD4R Receiver status displays

24 SOLID-4 Leuze electronic

Page 25

5.3.1 7-segment display

F

x

After switching-on the supply voltage, the following data appears on the 7-segment display

of the receiver:

7-segment display Meaning

8. Hardware reset at the moment of turn-on

S Self test running (for approx. 1.5 sec)

1 Normal operation, channel 1

1 or 2 flashing Flashing number of the transmission channel → weak

Table 5.3-1: 7-segment

5.3.2 LED displays

LED Color Meaning

LED1 red RED = OSSD safety outputs in the OFF state

LED1 green GREEN = OSSD safety outputs in the ON state

Table 5.3-2: LED displays –

Notice!

If all LED displays are simultaneously in the O

Display elements

F = device fault

x = fault number; display alternates between this and "F"

vice not optimally aligned or dirty

display receiver SD4R

r

eceiver SD4R

FF state, no supply voltage is present.

signal,

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

de-

Leuze electronic SOLID-4 25

TNT 35/7-24V

Page 26

Installation

6 Installation

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

6.1 Calculating minimum distances

This section contains important information on installing the SOLID-4. The SOLID-4's

protective function is only guaranteed if the following installation specifications are

observed. These installation specifications are based on the respective applicable versions

of European standards, such as EN 999 and EN ISO 13857. If a SOLID-4 is used in

count

ries out

observed.

Installation is dependent on the type of protection as described in Chapter „Safety“.

Bec

ause o

• Point of operation guarding

• Danger zone guarding

• Access guarding

are considered separately below. The applicable dist

reflective surfaces in the surrounding area is presented for all types of protection based on

these situations.

Light Curtains can only perform their protective function if they are mounted with a

sufficient safety distance.

The calculation formulas for the safety distance depend on the type of protection. In the

harmoni

approach speed of parts of the human body", the installation situations and calculation

formulas for safety distance are described for the types of protection named above.

The formulas for the required distances to reflective surfaces are based on the European

st

andard f

side of the EU, the valid requirements in those countries must also be

f this, the situations of:

zed European standard EN 999, "Positioning of protective devices with regard to

or "Active opto-electronic protective devices" prEN IEC 61496-2.

ance f

rom the protective device to

6.1.1 Safety distance for point of operation guarding

Calculation of the safety distance for a SOLID-4 Safety Light Curtain with resolution of 14,

20, 30 or 40 mm for point of operation guarding:

The safety distance "S" for point of operation guarding is calculated in accordance with EN

999 with t

S [mm] = K [mm/s] x T [s] + C [mm]

26 SOLID-4 Leuze electronic

he formula:

Page 27

S = Safety distance in mm

f

d

b

a

e

c

the result is less than 100 mm, a distance of at least 100 mm must still be maintained.

If

K = Approach speed in mm/s

In the close area of 500 mm, 2,000 mm/s is used for the calculation. If the distance is greater than 500 mm, K = 1,600 mm/s can be used for the calculation. In this case, however, a

minimum of 500 mm applies for the safety distance.

T = Total delay time in seconds;

total from:

The response time of the protective device, t

The response time of the safety interface, if any, t

The machine’s stopping time, t

Machine

c)

a)

AOPD

Safety interface

b)

C = 8 x (d-14) in mm

Additional amount depending on the depth of penetration into the protective field before

turning on the AOPD

d = Resolution of the AOPD

a)

See Chapter 11.2

b)

See safety interface technical data

c)

See technical data of the machine or stopping time measurement

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

a = Safety distance (S)

b = Measures to prevent penetration from above

c = Measures to prevent penetration from the sides

d = Measures to prevent penetration from the rear

e = Measures to prevent penetration from below

Fig. 6.1-1: Safety distance (a) for point of operation guarding

*) If this value cannot be achieved because of the safety distance, other measures, e.g. mechanical

barriers, must guarantee the required maximum distance of 75 mm.

f = 75 mm – Maximum distance to avoid walking behind*

TNT 35/7-24V

Warning!

≤

If AOPDs with additional control functions are used, the resolution must be

minimum distance must be S

≥

150 mm.

30 mm and the

S [mm] = 2000 [mm/s] x (t

AOPD

+ t

Safety interface

+ t

) [s] + 8 x (d-14) [mm]

Machine

Leuze electronic SOLID-4 27

Page 28

Installation

a

c

d

Calculation example for point of operation guarding:

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

6.1.2 Safety distance for danger zone guarding

A Safety Light Curtain with a resolution of 20 mm, protective field height 1500 mm is used

on a machine wit

h a stopping time of 150 ms. The response time of the safety interface is

20 ms.

Stopping time of the machine t

Response time t

Response time t

= 25 ms

AOPD

Safety interface

Machine

= 20 ms

Resolution d of the AOPD = 20 mm

T = 0.150 s + 0.025 s + 0.020 s = 0.195 s

S = 2000 x 0.195 + 8 x (20 -14) =

Warning!

Make certain during assembly that it is not po

walk behind the protective device.

Calculation of the safety distance and required resolution for a Safety Light Curtain for

danger zone guarding.

= 150 ms

438 mm

ssible t

o reach over, around or under or to

a = Safety distance (S)

b = Measures to prevent access from the sides

c = Height above floor

d = 50 mm – Maximum distance to avoid walking behind*

Fig. 6.1-2: Safety distance (a) and height (c) for danger zone guarding

*) If this value cannot be achieved because of the safety distance, other measures, e.g. mechanical

barriers, must guarantee the required maximum distance of 50 mm. From 375 mm height above the

floor 75 mm are permissible.

28 SOLID-4 Leuze electronic

Page 29

Installation

The height of the protective field H above the reference plane and the resolution d of the

AOPD are related to each other as follows:

H

[mm] = 15 x (d -50) [mm] or d [mm] = H

min

H

= Minimum height of the protective field above the reference plane,

min

maximum height = 1000 mm

Heights equal to or less than 300 mm are considered too low for adults to crawl

under

d = Resolution of the AOPD

/15 + 50 [mm]

min

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

The safety distance "S" for danger zone guarding is

ed in accordance with EN 999

calculat

using the formula:

S [mm] = K [mm/s] x T [s] + C [mm]

S = Safety distance in mm

K = Approach speed of 1600 in mm/s.

T = Total delay time in seconds;

total from:

The response time of the protective device, t

The response time of the safety interface, if any, t

The machine’s stopping time, t

Machine

c)

a)

AOPD

Safety interface

C = (1200 mm – 0,4 H), but not less than 850 mm (arm’s length)

H = Height of the protective field above the floor

a)

See Chapter 11.2

b)

See safety interface technical data

c)

See technical data of the machine or stopping time measurement

S [mm] = 1600 [mm/s] x (t

AOPD

+ t

Safety interface

+ t

) [s] + (1200-0.4 H) [mm]

Machine

b)

TNT 35/7-24V

Leuze electronic SOLID-4 29

Page 30

Installation

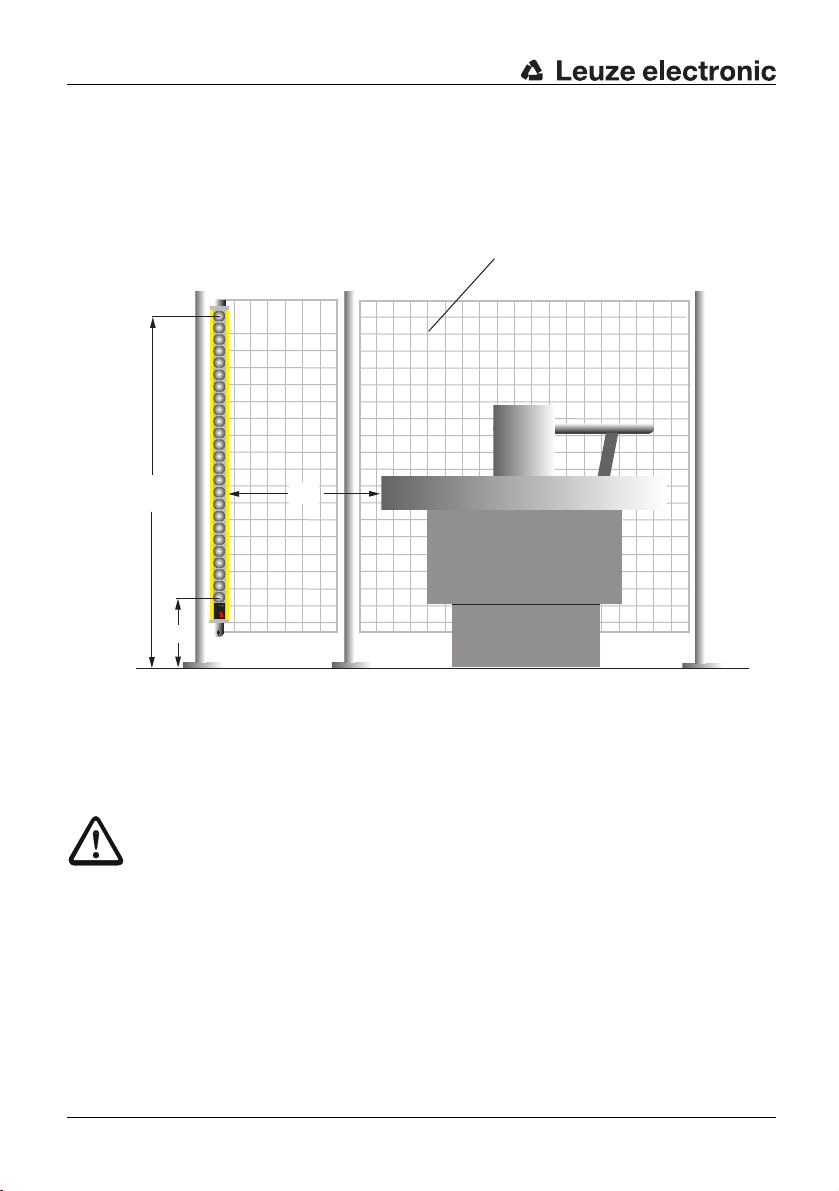

a

d

c

b

6.1.3 Safety distance and beam heights for Safety Light Curtains as access

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

guarding

Determination of the beam heights and calculation of the safety distance of Safety Light

Curtains with a resolution of 14, 20, 30 or 40 mm for use as access guarding, for example

with l

imited space between the protective field and point of operation.

a = Safety distance (protective field/point of operation)

b = Height of the lowest beam above the reference level, see table 6.1-1

c = Height of the highest beam, see table 6.1-1

d = Measures to prevent access from the sides

Fig. 6.1-3: Access guarding with Safety Light Curtain, resolution of 14, 20, 30 or

40 mm

Warning!

Please also observe the additional safety instructions for access guarding with SOLID-4 in

Chapter 2.7.

30 SOLID-4 Leuze electronic

Page 31

Installation

Beam heights with use of Safety Light Curtains for access guarding in accordance

with EN 999 and EN ISO 13857:

Version Resolu-

tion

SD4-14-hhhh 14 mm As per EN ISO 13857 As per EN ISO 13857 0 mm

SD4-20-hhhh 20 mm As per EN ISO 13857 As per EN ISO 13857 48 mm

SD4-30-hhhh 30 mm As per EN ISO 13857 As per EN ISO 13857 128 mm

SD4-40-hhhh 40 mm As per EN ISO 13857 As per EN ISO 13857 208 mm

SD4-90-hhhh 90 mm 300 mm 1200 mm 850 mm

Lowest beam above

reference plane

Highest beam above

reference plane

Additional

amount C

(see formula)

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Table 6.1-1: Beam height

s above the reference plane and additional amount C for

access guarding applications

Calculation formula for safety distance S based on EN 999:

Calculation of the safety distance for a Safety Light Curtain with a resolution of up to 40

mm

, used for access guarding. The safety distance S is calculated as per EN 999

according to the formula:

S [mm] = K [mm/s] x T [s] + C [mm]

S = Safety distance in mm

K = Approach speed in mm/s

In the close area of 500 mm, 2,000 mm/s is used for the calculation. If the dis-

s

tance is greater than 500 mm, K = 1,600 mm/

can be used for the calculation.

In this case, however, a minimum of 500 mm applies for the safety distance.

T = Total delay time in seconds;

total from:

The response time of the protective device, t

The response time of the safety interface, if any, t

c)

The machine’s stopping time, t

Machine

a)

AOPD

Safety interface

b)

C = 8 x (d-14) in mm

Additional amount depending on the depth of penetration into the protective field

before t

urning on the AOPD

d = Resolution of AOPD up to a maximum of 40 mm

a) See Chapter 11.2

b) See technical data of the safety interface

c) See technical data of the machine or stopping time measurement

S [mm] = 2000 [mm/s] x (t

AOPD

+ t

Safety interface

+ t

) [s] + 8 x (d-14) [mm]

Machine

TNT 35/7-24V

Leuze electronic SOLID-4 31

Page 32

Installation

a

c

b

If the resolution is greater than 40 mm, for example for SOLID-4 Safety Light Curtains with

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

6.1.4 Minimum distance from reflective surfaces

a resolution of 90 mm, an additional amount is required:

C = 850 mm (arm’s length)

The safety distance with 90 mm is therefore calculated according to the following formula:

S [mm] = 1600 [mm/s] x (t

AOPD

+ t

Warning!

Please also observe the additional safety instructions for access guarding with SOLID-4 in

Chapter 2.7.

Warning!

When using access guarding, it must be ensured that t

active and that unlocking from inside the danger zone is not possible.

Warning!

Reflective surfaces near optical protective devices c

beams into the receiver. This can cause an object in the protective field not to be detected!

Therefore, all reflective surfaces and objects (material containers, cans, etc.) must be kept

at a minimum distance from the protective field. The minimum distance depends on the

distance "b" between the transmitter and the receiver.

Safety interface

+ t

Machine

) [s] +850 [mm]

he start/restart interlock function is

an indirectly deflect the transmitter's

a = Distance

b = Protective field width

c = Reflective surface

Fig. 6.1-4: Minimum distances from reflective surfaces

With the calculation of the minimum distance to reflective surfaces it must be ensured that

wit

h

a protective field width of 3 m or less, at least a minimum distance of 131 mm is

achieved.

using the

With protective field widths over 3 m the minimum distance "a" is calculated

following formula:

a [m] = 0.044 x b [m]

32 SOLID-4 Leuze electronic

Page 33

a = Distance [mm]

130

b

a

b = Protective field width [m]

Fig. 6.1-5: Minimum distances from reflective surfaces as a function of the width of

the protective field

6.2 Mounting notes

Special notes on mounting a SOLID-4 Safety Light Curtain for point of operation

guarding:

➢ Calculate the safety distance according to the formula in Chapt

➢ Ensure that it is impossible to reach under, over,

Curtain.

➢ Observe the maximum distance between machine table and protective field of 75 mm,

h reference to a table height of 750 mm. If this is not possible because the safety

wit

distance is too big, a mechanical barrier must be provided.

➢ Observe the minimum required distance to reflective surfaces.

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

er 6.1.1.

around or walk behind the Safety Light

TNT 35/7-24V

Leuze electronic SOLID-4 33

Page 34

Installation

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Special notes on mounting a SOLID-4 Safety Light Curtain for danger zone guarding:

➢ Calculate the safety distance according to the formula in Chapt

determines the minimum height of the protective field above the floor.

➢ Ensure that the maximum height of the protective field above the reference plane of

1000 mm

impossible for an adult to crawl under (also see EN 999).

➢ It must not be possible to step into the danger zone from the sides. Suitable hard guards

must

➢ When mounting the device, ensure that it is impos

optical components (thereby allowing entrance into the danger zone).

Note!

Positioning behind corresponding cutouts on the hard

stepping onto transmitter or receiver housings.

is not exceeded and only heights equal to or less than 300 mm are considered

be provided.

sible to pass onto the housings of the

er 6.1.2. The resolution

guards on the sides prevents

➢ Consider the

stand undetected between this light beam and the machine.

Special notes on mounting a SOLID-4 Safety Light Curtain for access gu

➢ Calculate the safety distance according to the formula in Chapter 6.

➢ The highest and the lowest light beam and therefore the height of the protective field for

ety Light Curtains with a resolution of 14, 20, 30 or 40 mm is determined by the

Saf

requirements in acc. with EN ISO 13857.

➢ Access guarding may only be operated with the start/restart interlock function. Activate

t

he internal RES interlock function of the SD4R-E or the RES interlock function of the

downstream interface and check their effectiveness.

➢ Ensure while installing the start/restart button, that it is impossible to press this button

f

rom inside the danger zone. Make sure that the complete danger zone can be seen from

the location of the button.

position of the last light beam before the machine. It must not be possible to

6.3 Mechanical mounting

What should generally be taken into consideration during installation?

➢ Ensure that transmitter and receiver are mounted on an even surface at the same height.

➢ Use screws

➢ Fix the transmitter and receiver in position so that they cannot be shifted. Securing

ransmitter and receiver so they cannot be moved or swiveled is especially important in

t

the close area with a narrow protective field.

➢ The connections of transmitter and receiver must be pointing in the same direction.

➢ The safety distance between the protective field and the point of operation must be

observ

➢ Ensure that access to the point of operation/

protective field. Additional access points must be guarded separately (e.g. by hard

guards, additional Light Curtains or doors with locking devices).

for mounting that can only be loosened with a tool.

ed.

arding:

1.3.

danger zone is only possible through the

34 SOLID-4 Leuze electronic

Page 35

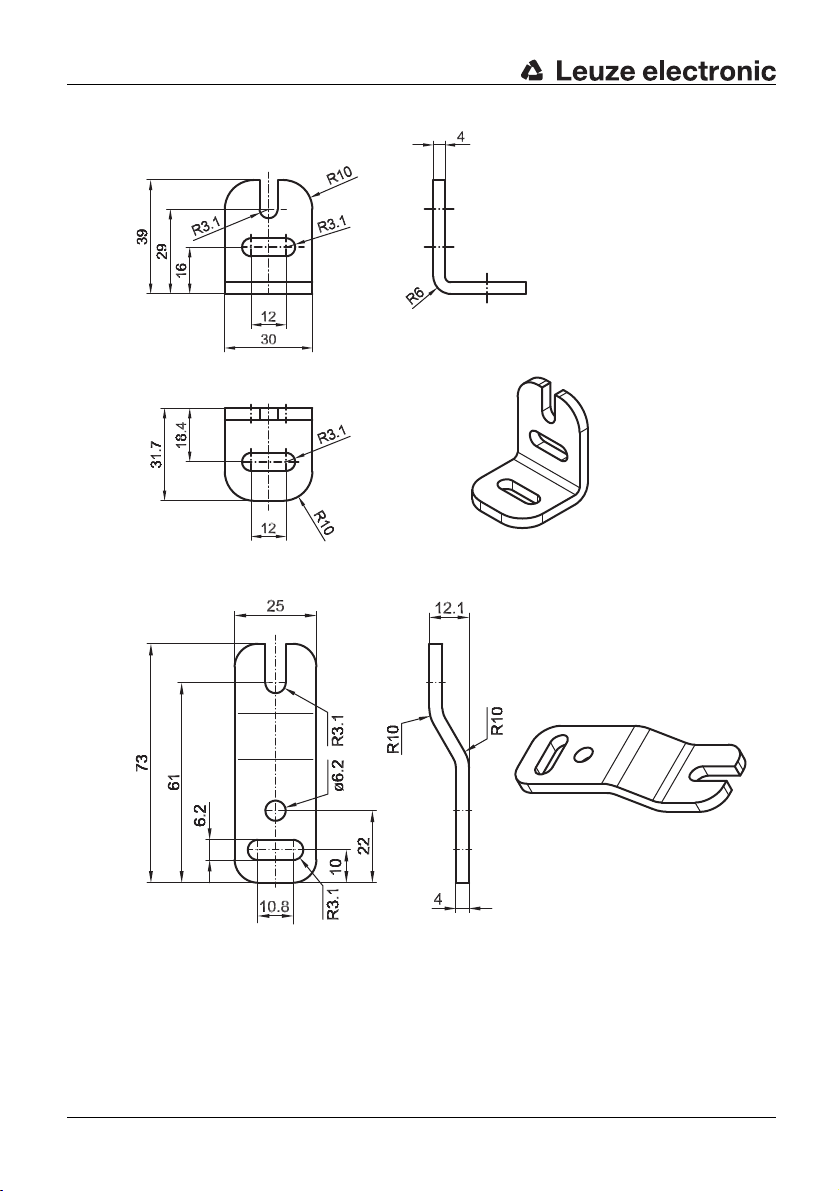

6.4 Mounting types

6.4.1 Standard mounting

Four brackets that can rotate 360° (two each for transmitter and receiver) are included with

delivery.

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Fig. 6.4-1: 360° rot

ation bracket, mounting examples

6.4.2 Option: Mounting with swiveling brackets

Four swivel mounting brackets with shock absorbers can be ordered optionally. They are

not included with delivery. The swivel range is ± 8°.

Fig. 6.4-2: Swiveling bracke

t with shock absorber

TNT 35/7-24V

Leuze electronic SOLID-4 35

Page 36

Installation

6.4.3 Option: Side mounting

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Mounting is optionally possible with mounting brackets with sliding nuts on the side slot.

They are not included with delivery.

L-mounting bracket Z-mounting bracket

Fig. 6.4-3: Mounting examples, L-mounting bracket and Z-mounting bracket

36 SOLID-4 Leuze electronic

Page 37

7 Electrical connection

FE

2

• The electrical connection must be performed by experienced personnel. Knowledge of all

safety notes contained in these operating instructions is part of this competence.

• The external supply voltage of 24 V DC +/- 20% must guarantee safe isolation from the

ns voltage in accordance with IEC 60742 and be able to bridge a power outage

mai

period of at least 20 ms. Leuze electronic offers suitable power supplies (see list of

acc

ssories in the Appendix Chapter 12). Transmitters and receivers must be supplied

e

from a shared power supply and must

• Basically both safety switching outputs OSSD1 and OSSD2 must be looped into the

king circuit of the machine.

wor

• Signal outputs may not be used for switching safety-relevant signals.

• The start/restart button for unlocking the restart interlock must be mounted in such a way

at it cannot be reached from the danger zone and the entire danger zone is fully visible

th

from its installation position.

• It is vital during the electrical installation that the power of the machine or system to be

protect

ed is switched off and locked, so that the dangerous movements cannot be

started unintentionally.

7.1 M12 coupling

Transmitter and receiver are equipped with an M12 coupling; the transmitter with a 5-pin

M12 coupling and the receiver with an 8-pin M12 coupling.

Warning!

To ensure safe operation of the SOLID-4, onl

Chapter 12.3 – Accessories may be used.

Electrical connection

used against overcurrent (see Chapter 7.2).

be f

y the connecting cables listed in

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

7.1.1 Transmitter

Fig. 7.1-1: SD4T 5-pin (view of the pins)

Leuze electronic SOLID-4 37

TNT 35/7-24V

Page 38

Electrical connection

FE

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Pin Cable

1 Brown Supply voltage 24 V DC for TC1 and 0 V for TC2

2Whitenc

3 Blue Supply voltage 0 V for TC1 and 24 V DC for TC2

4 Black Test in Test input

5 Gray Device internally

Mounting

plug

housing

Table 7.1-1: Transmitter, connection assignment

The polarity of the power supply from Pin1 and Pin3 determines the selected optical

transmission channel. If 24 V DC is present on Pin1 and 0 V on Pin3, transmission

channel 1 is selected. If 0 V is present on Pin1 and 24 V DC on Pin3, transmission

channel 2 is selected.

Note!

Make certain you select the same transmission channel for both, for transmitter and

recei

For optimum shielding, connecting cables with which t

of the housing coupling must be used (suitable cables are listed under accessories in

Chapter 12.3).

colors

Braided

shield

er.

v

Assignment Inputs/outputs

Connected to 24 V DC

→ Normal operation

to 0 V or free

→ External test activated

Functional earth

wired on housing

Shield Functional earth

he shield is routed on the knurled nut

7.1.2 Receiver SD4R-E

Fig. 7.1-2: SD4R-E 8-pin (view of the pins)

38 SOLID-4 Leuze electronic

Page 39

Electrical connection

Pin Color Assignment Function

1 White Input:

2 Brown Supply voltage 24 V DC for TC 1 and 0 V for TC 2

3 Green Input:

4 Yellow Input:

5 Gray Output OSSD1, transistor switching output

6 Pink Output OSSD2, transistor switching output

7 Blue Supply voltage 0 V for TC 1 and 24 V DC for TC 2

8 Red Device internally

Mounting

plug housi

Table 7.1-2: SD4R-E

ng

Braided

shield

Start/restart

Signal output:

Weak signal/

erro

r

Operating

m

feedback

ode/

circuit, EDM

Operating mode

wired on

hous

i

ng

Shield Functional earth

Receiver connection assignment

Start/restart normally open contacts

against

24

Weak signal/error:

24 V DC light reception, strong,

0 V light reception weak or error

Contactor monitoring (EDM):

24 V DC: Without EDM

0 V: With EDM and FC closed

High impedance: With EDM and FC open

Start/restart interlock

(RES):

24 V DC: With RES

Jumper to Pin1: Without RES (note: signal

out

Functional earth

V DC

put

remains functional)

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

7.1.2.1 Transmission channel selection

The polarity of the power supply from Pin2 and Pin7 determines the selected optical

transmission channel.

If 24 V DC is present on Pin2 and 0 V on Pin3, transmission channel 1 is selected. If 0 V is

pres

on Pin2 and 24 V DC on Pin7, transmission channel 2 is selected.

ent

Note!

Make sure that you select the same transmission channel for both transmitter and receiver.

For optimum shielding, connecting cables with which

of the housing coupling must be used (suitable cables are listed under accessories in

Chapter 12.4).

Leuze electronic SOLID-4 39

the shield is routed on the knurled nut

TNT 35/7-24V

Page 40

Electrical connection

7.1.2.2 Operating mode selection, start/restart interlock (RES) and contactor

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

monitoring (EDM).

The SD4R-E Receiver must be connected via an 8-pin M12 coupling. The RES/EDM

functions can be activated via the operating mode selections, Pin3 and Pin4.

Warning!

The operating mode switchover must only be made in the switched-off state. Operating

mode swit

removed by interrupting the voltage supply.

Pin3 24 V DC 24 V DC 0 V via closed feed-

Pin4 Jumper to Pin1 24 V DC Jumper to Pin1 24 V DC

Note on

Pin

Table 7.1-3: S

chovers (RES/EDM) during operation cause a fault (F32/F33), which can only be

1

Without EDM

Without RES

Signal output,

weak signal/

LID-4 SD4R-E Receiver operating mode selection

O

Without EDM

With RES

Start button, nor-

error

mally open contact to 24 V DC

and signal out

weak signal/error

With EDM

Without RES

back circuit

Signal output, weak

signal/

er

ut,

p

ror

With EDM

With RES

0 V via closed feedback circuit

Start button, normally open contact

to 2

4 V DC and

signal output

weak signal/error

,

40 SOLID-4 Leuze electronic

Page 41

7.1.3 Receiver SD4R

FE

2

Electrical connection

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Fig. 7.1-3: SD4R 5-pin (view of

Pin Color Assignment Function

1 Brown Supply voltage 24 V DC

2 White Output OSSD1, transistor switching output

3 Blue Supply voltage 0 V

4 Black Output OSSD2, transistor switching output

5 Gray Device internally

Mounting

plug housi

Table 7.1-4: SD4R Receiver

Notice!

When using an SD4R receiver, make certain to select transmission channel 1 on the

esponding transmitter.

corr

For the best-possible shielding, use connecting cabl

knurled nut of the housing coupling (suitable cables are listed under accessories,

Chapter 12.4).

ng

Braided

shield

he pins)

t

wired on

hous

ng

i

Shield Functional earth

connection assignment

Functional earth

es on which the shield extends to the

TNT 35/7-24V

Leuze electronic SOLID-4 41

Page 42

Electrical connection

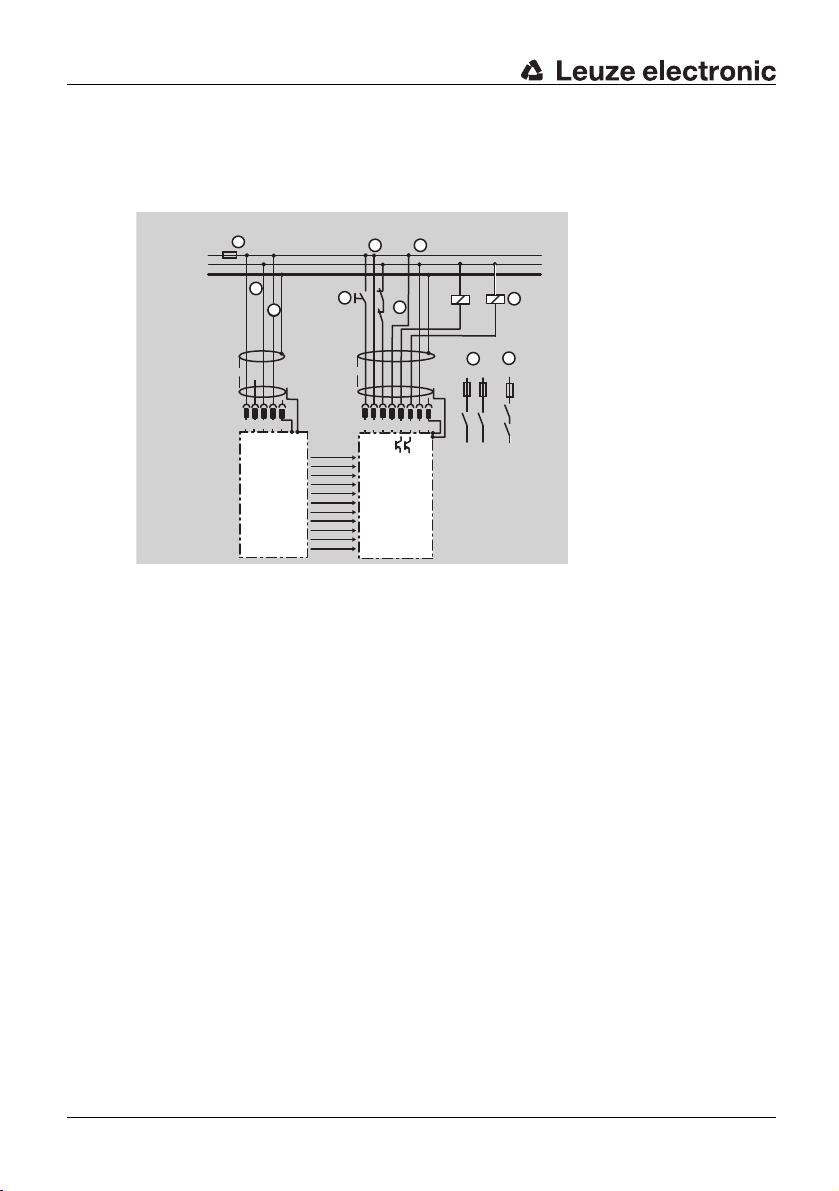

1

2

3 4

5

1

2 3

4

5

k1

k2

SOLID-4

SD4R-E

SOLID-4

SD4T

K1

K2

+24 V DC

GND

FE

nc

F

6 7

8

k1 k2

k1

k2

e

f

h

g

f

f

a

b

d

c

7.2 Connection examples

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

7.2.1 Connection example for transmission channel 1(TC1)

a = EDM feedback circuit

b = Positive-driven relays, spark suppression is pro-

vided by the receiver

c = Release circuit, 2-channel*

d = Release circuit, 1-channel*

e = External testing selected

f = Polarity for transmission channel 1

g = Start/restart button

h = 2 A fine-wire fuse, melting fuse

*) Always use both of the contacts in the release circuit; protect against overcurrent.

Fig. 7.2-1: SD4R-E Receiver, TC 1, with RES, with EDM

42 SOLID-4 Leuze electronic

Page 43

Electrical connection

1

2 3 4 5

1

2 3 4 5

k1

k2

SOLID-4

SD4R-E

SOLID-4

SD4T

K1

K2

+24 V DC

GND

FE

nc

f

F

6

7 8

k1

k2

k1

k2

h

e

g

f

f

a

c d

b

7.2.2 Connection example for transmission channel 2 (TC2)

When selecting TC 2, the polarity of the supply voltage on the transmitter and the receiver

must be reversed.

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

a = EDM feedback circuit

b = Positive-driven relays, spark suppression is

provi

c = Release circuit, 2-channel*

ded by the receiver

d = Release circuit, 1-channel*

e = External testing selected

f = Polarity for transmission channel 2

g = Start/restart button

h = 2 A fine-wire fuse, melting fuse

*) Always use both contacts in the release circuit.

Fig. 7.2-2: SD4R-E Receiver, TC2, with RES, with EDM

Leuze electronic SOLID-4 43

TNT 35/7-24V

Page 44

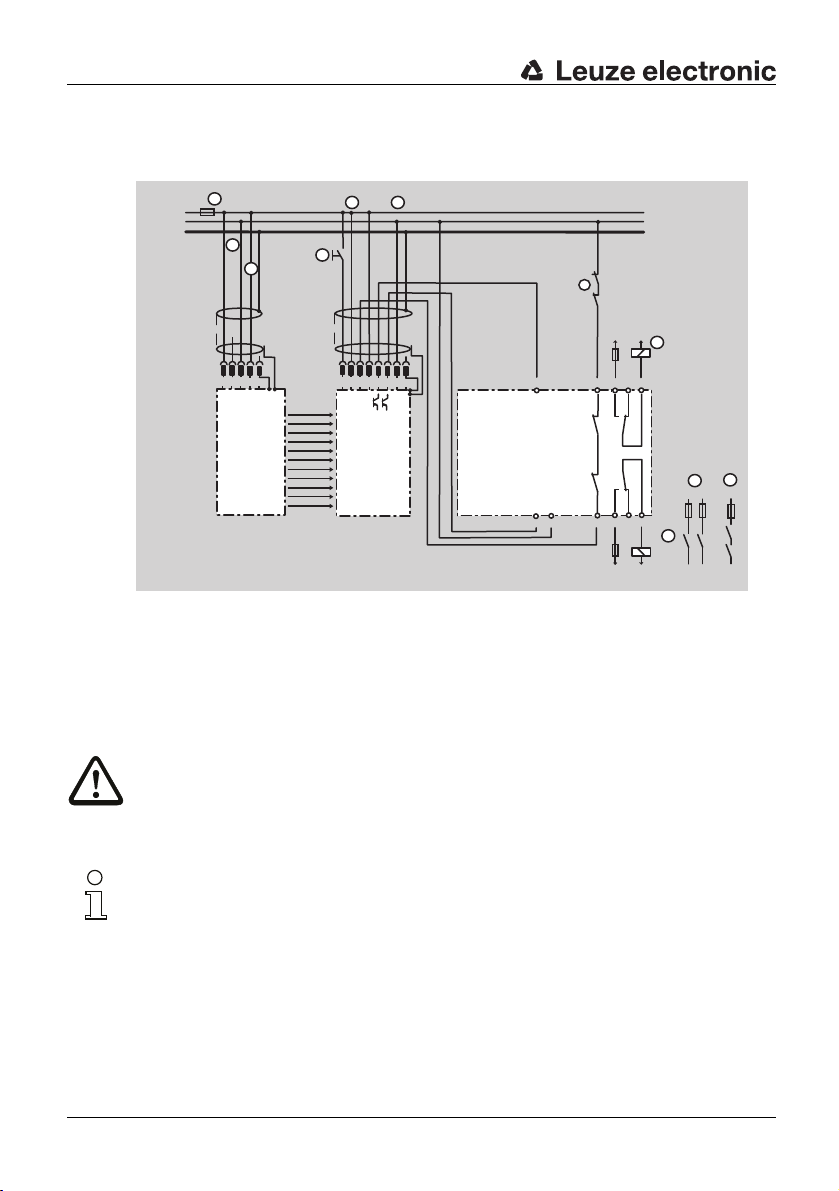

Electrical connection

1

2 3

4

5

1

2

3 4 5

SOLID-4

SD4R-E

SOLID-4

SD4T

+24 V DC

GND

FE

nc

6 7 8

K5

K4

k4 k5

k5

k4

k5

k4

a

Y1

Y2

B3

A2

B1

14

12

11

24

2221

L+PhL-

N

F

h

L+

Ph

LN

MSI-RM2

f

e

g

f

f

b

b

c d

7.2.3 SOLID-4 connection example

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

with downstream relay module, MSI-RM2

a = EDM feedback circuit

b = Positive-driven relays, spark suppression

required

c = Release circuit, 2-channel*

*) Always use both contacts in the release circuit.

Fig. 7.2-3: SD4R-E Receiver, TC1, with RES, with EDM and MSI-RM2

d = Release circuit, 1-channel*

e = External testing selected

f = Polarity for transmission channel 1

g = Start/restart button

h = 2 A fine-wire fuse, melting fuse

Warning!

If K4 and K5 are installed in the same switching rack as the MSI-RM2, each relay must be

44 SOLID-4 Leuze electronic

ed via a separate connecting cable with the MSI-RM2. The connecting cables must

connect

be routed in a strong conduit so that mechanical damage is prevented. Also be sure to

follow the MSI-RM2 connection and operating instructions.

Note!