Leuze electronic SOLID-2, SD2R20, SD2T20, SD2T30, SD2R30 Connecting And Operating Instructions

...Page 1

SOLID-2

Safety Light Curtain

607374 - 2015/04

Subject to change wit-

hout prior notice

CONNECTING AND OPERATING INSTRUCTIONS

Original Instructions

Page 2

Notes on Connecting and Operating Instructions

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

This connecting and operating instructions manual contains information on the proper use

of SOLID-2 Safety Light Curtains in accordance with its intended purpose.

All the information contained herein, in particular the safety notes, need to be carefully

observed.

Notes regarding safety and warnings are marked by this symbol .

Notes regarding important pieces of information are marked by the symbol .

This connecting and operating instructions manual must be stored carefully. It must be

available for the entire operating time of the SOLID-2.

The Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Acquaintance with these instructions is an element of the knowledge required for proper

use.

© Reprints and reproduction, in whole or in part, are permitted only with the explicit

permission of

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen - Teck / Germany

Telefon +49 (0) 7021 / 573-0

Fax +49 (0) 7021 / 573-199

info@leuze.de

www.leuze.com

2 SOLID-2 Leuze electronic

Page 3

Contents

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Symbols and terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Selecting a SOLID-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.1 SOLID-2 Safety Light Curtains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Approved purpose and foreseeable improper operation . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.1 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Competent personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Responsibility for safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Additional safety instructions for access guarding with SOLID-2 . . . . . . . . . . . . . . . . . . 11

3 System design and selectable functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 The opto-electronic protective device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Functions of the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Transmission channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Internal or external testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Selectable function of the Receiver Standard and Extended . . . . . . . . . . . . . . . . . . . . . 14

3.3.1 Transmission channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Additional functions of the Receiver Extended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 Start/restart interlock (RES) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.2 Contactor monitoring (EDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Transmitter status displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Receiver status displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.1 7-segment display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 LED displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Calculating minimum distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.1 Safety distance for safeguarding danger points . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.2 Safety distance for safeguarding danger areas . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.3 Safety distance and beam heights for access guarding . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.4 Minimum distance from reflective surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Mounting notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3 Mechanical mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Mounting types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4.1 Standard mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4.2 Option: Mounting with swiveling brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4.3 Option: Side mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 M12 connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1.1 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1.2 Receiver Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1.3 Receiver Extended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Leuze electronic SOLID-2 3

TNT 35/7-24V

Page 4

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

7.1 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1.1 Transmitter display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1.2 Receiver display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 Aligning transmitter and receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.1 Optimized aligning with the aid of the Receiver’s 7-segment display . . . . . . . . . 39

8 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1 Testing before setting the protective device in service the first time . . . . . . . . . . . . . . . . 40

8.2 Regular tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Daily testing with the test rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.4 Cleaning the front screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.1 What should I do if an error occurs? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2.1 Transmitter diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2.2 Receiver diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.3 AutoReset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.1.1 Protective field data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.1.2 Safety relevant technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.1.3 General system data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.1.4 Transmitter signal inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.1.5 Receiver Extended signal inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.1.6 Receiver transistor safety switch outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

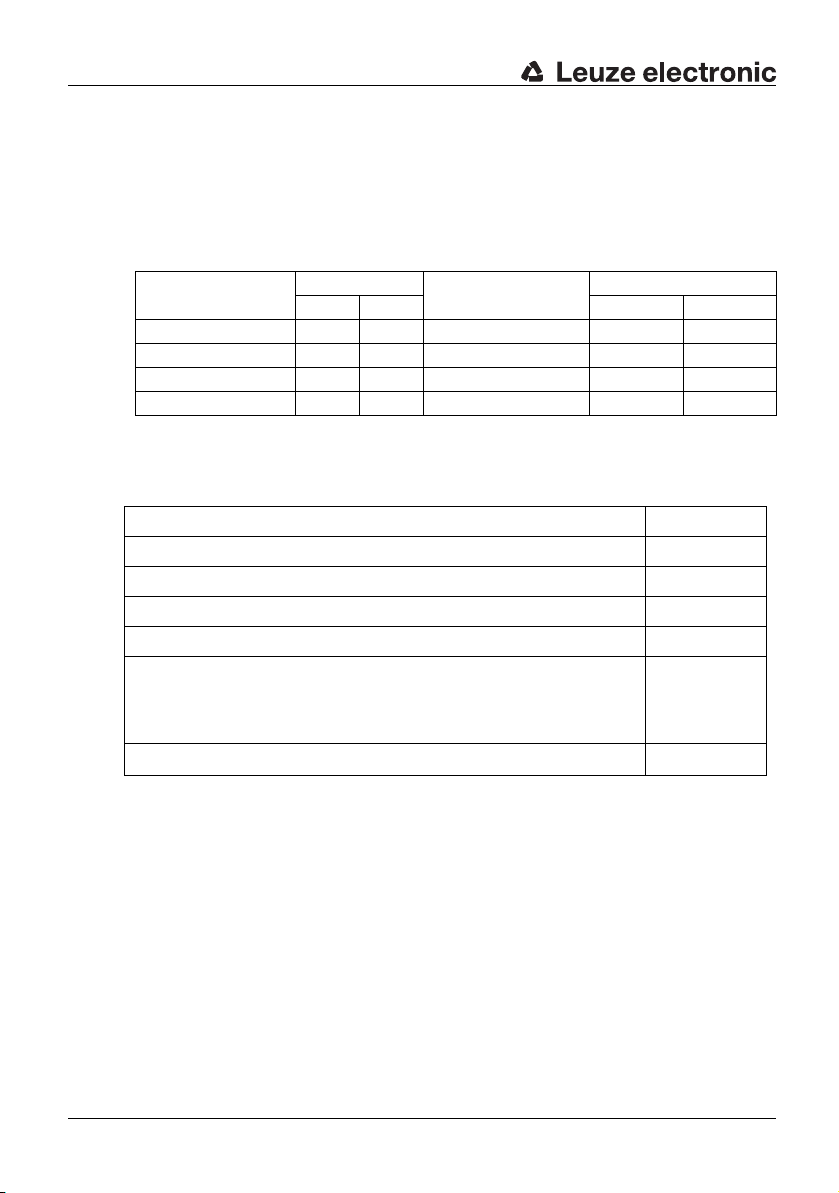

10.2 Dimensions, weights and response times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2.1 Safety Light Curtains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2.2 Dimensions of mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.1 SOLID-2 scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.2 Order numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.4 Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.4.1 Checklist for safeguarding danger points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

11.4.2 Checklist for safeguarding danger areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11.4.3 Checklist for access guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4 SOLID-2 Leuze electronic

Page 5

1 General

SOLID-2 Safety Light Curtains are type 2 Active Opto-electronic Protective Devices,

(AOPDs) in accordance with EN/IEC 61496-1, EN/IEC 61496-2, PL c in accordance with

ISO 13849-1, designed to Safety Integrated Level 1 (SIL 1) as per EN IEC 61508.

All SOLID-2 Safety Light Curtains are equipped with integrated cyclical testing and

display elements (LEDs and 7-segment display).

placing a unit in service or performing diagnostics.

The SOLID-2 is equipped with 2 OSSDs (transistor outputs) with M12 connectors as

standard features.

In addition to the features of the Standard version, the Extended version also offers a

selectable start/restart interlock and contactor monitoring feature.

To provide the best possible solutions for specific applications, SOLID-2 series devices

are available in various resolutions and protective field heights.

1.1 Certifications

Company

Leuze electronic GmbH & Co. KG in D-73277 Owen - Teck, Germany, has a certified

quality assurance system in compliance with ISO 9001.

General

This is especially convenient when

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Products

SOLID-2 Safety Light Curtains are developed and manufactured in compliance with

applicable European directives and international standards.

EC prototype testing in accordance with

EN IEC 61496 Part 1 and Part 2

TÜV PRODUCT SERVICE GmbH, IQSE

Ridlerstrasse 65

D-80339 Munich

Leuze electronic SOLID-2 5

TNT 35/7-24V

Page 6

General

1.2 Symbols and terms

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Symbols used:

Warning notice. This symbol indicates possible dangers.

Please pay especially close attention to these instructions!

Table 1.2-1: Symbols

A note, which also refers to a course of action, provides information

about special attributes or describes set-up procedures

Notice on important information

Symbols of the Transmitter SD2T

General transmitter symbol

Transmitter not active

Transmitter active

Symbols for Receiver SD2R

General receiver symbol

The receiver’s active protective field is not free. Outputs in OFF state

The receiver’s active protective field is free. Outputs in ON state

The receiver’s active protective field is free. Outputs in OFF state

Signal output

Signal input

Signal input and/or output

6 SOLID-2 Leuze electronic

Page 7

General

Terms used in this manual:

AOPD Active Opto-electronic Protective Device

AutoReset After an error indication, for example because of a faulty

Contactor monitoring

(EDM)

OSSD1, OSSD2 Safety-related switch output

RES Start/REStart interlock

Response time of AOPD The time lag between penetration into the active protective field

Scan All beams, beginning with the synchronization beam, are

Start/restart interlock

(RES)

TC1 Transmission channel 1

TC2 Transmission channel 2

Table 1.2-2: Terms

external wiring, the AOPD attempts to start again. If the

error is no longer present, the AOPD returns to normal state.

Also called External Device Monitoring (EDM), monitors

dynamically the positive-guided normally closed contacts of

downstream relays, contactors or valves

Output Signal Switching Device

of the AOPD and the actual switching off of the OSSDs

pulsed by the transmitter in cycles one after the other

Prevents automatic start after the supply voltage has been

turned on, or after the protective field has been penetrated

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Leuze electronic SOLID-2 7

TNT 35/7-24V

Page 8

General

SD2trr-xxxx v*

SOLID-2

t - Type of device

T: Transmitter

R: Receiver

r - Resolution

20: 20 mm

30: 30 mm

40: 40 mm

90: 90 mm

xxxx- Protective field height

150 ..... 1800 mm (for 20, 30 and 40 mm resolution)

600..... 3000 mm (for 90 mm resolution)

v- Function version

E: Extended version (with selectable start/restart

interlock and contactor monitoring)

Standard version (automatic start/restart without

contactor monitoring)

*) In the Standard version this place in the product

designation is not used

1.3 Selecting a SOLID-2

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

1.3.1 SOLID-2 Safety Light Curtains

Fig. 1.3-1: Selecting a SOLID-2 Safety Light Curtain

8 SOLID-2 Leuze electronic

Page 9

2Safety

Before using the safety sensor, a risk evaluation must be performed according to valid

standards (e.g. EN

result of the risk assessment determines the required safety level of the safety sensor (see

Table 2.1-1). For mounting, operating and testing, document "SOLID-2 Safety Light

Curtain" as well as all applicable national and international standards, regulations, rules

and directives must be observed. Relevant and supplied documents must be observed,

printed out and handed to the affected personnel.

Before working with the safety sensor, completely read and understand the documents

applicable to your task.

In particular, the following national and international legal regulations apply for the startup, technical inspections and work with safety sensors:

• Machinery directive 2006/42/EC

• Low voltage directive 2006/95/EC

• Electromagnetic compatibility directive 2004/108/EC

• Use of Work Equipment Directive 89/655/EEC supplemented by Directive 95/63 EC

• OSHA 1910 Subpart 0

• Safety regulations

• Accident-prevention regulations and safety rules

• Ordinance on Industrial Safety and Health and Labor Protection Act

• Device Safety Act

Notice!

For safety-related information you may also contact the local authorities (e.g., industrial

inspectorate, employer's liability insurance association, labor inspectorate, occupational

safety and health authority).

Safety

ISO 14121, EN ISO 12100-1, ISO 13849-1, IEC 61508, EN 62061). The

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

2.1 Approved purpose and foreseeable improper operation

Warning!

A running machine can cause severe injuries!

Make certain that, during all conversions, maintenance work and inspections, the system is

securely shut down and protected against being restarted again.

2.1.1 Proper use

The safety sensor must only be used after it has been selected in accordance with the

respectively applicable instructions and relevant standards, rules and regulations regard

ing labor protection and occupational safety, and after it has been installed on the

machine, connected, commissioned, and checked by a competent person.

When selecting the safety sensor it must be ensured that its safety-related capability

meets or exceeds the required performance level PL

Leuze electronic SOLID-2 9

ascertained in the risk assessment.

r

TNT 35/7-24V

-

Page 10

Safety

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

The following table shows the safety-related characteristic parameters of the SOLID-2

Safety Light Curtain.

Type in accordance with IEC/EN 61496 Type 2

SIL in accordance with IEC 61508 SIL 1

SILCL in accordance with IEC/EN 62061 SILCL 1

Performance Level (PL) in accordance with ISO 13849-1: 2008 PL c

Category in accordance with ISO 13849 Cat. 2

Average probability of a failure to danger per hour (PFHd)

For protective field heights up to 900 mm, all resolutions

For protective field heights up to 1800 mm, all resolutions

For protective field heights up to 2850 mm, all resolutions

Service life (TM) 20 years

8.2 x 10-8 1/

8.9 x 10-8 1/

On request

h

h

Table 2.1-1: Safety-related characteristic parameters of the SOLID-2 Safety Light

• The safety sensor protects persons at access points or at points of operation of

machines and plants.

• The safety sensor with vertical mounting detects the penetration by fingers and hands

at points of operation or by the body at access points.

• The safety sensor only detects persons upon entry to the danger zone; it does not

detect persons who are located within the danger zone. For this reason, a start/restart

interlock is mandatory.

• The safety sensor with horizontal mounting detects persons who are located within the

danger zone (presence detection).

• The construction of the safety sensor must not be altered. When manipulating the safety

sensor, the protective function is no longer guaranteed. Manipulating the safety sensor

also voids all warranty claims against the manufacturer of the safety sensor.

• The safety sensor must be tested regularly by competent personnel.

• The safety sensor must be exchanged after a maximum of 20 years. Repairs or the

exchange of parts subject to wear and tear do not extend the service life.

Curtain

2.1.2 Foreseeable misuse

In principle, the safety sensor is not suitable as a protective device in case of:

• danger of objects being expelled or hot or dangerous liquids spurting from the danger

zone

• applications in explosive or easily flammable atmospheres

10 SOLID-2 Leuze electronic

Page 11

2.2 Competent personnel

Prerequisites for competent personnel:

• he has a suitable technical education

• he knows the rules and regulations for occupational safety, safety at work and safety

technology and can assess the safety of the machine

• he knows the instructions for the safety sensor and the machine

• he has been instructed by the responsible person on the mounting and operation of the

machine and of the safety sensor

2.3 Responsibility for safety

Manufacturer and operating company must ensure that the machine and implemented

safety sensor function properly and that all affected persons are adequately informed and

trained.

The type and content of all imparted information must not lead to unsafe actions by users.

The manufacturer of the machine is responsible for:

• safe machine construction

• safe implementation of the safety sensor

• imparting all relevant information to the operating company

• adhering to all regulations and directives for the safe starting-up of the machine

The company operating the machine is responsible for:

• instructing the operating personnel

• maintaining the safe operation of the machine

• adhering to all regulations and directives for occupational safety and safety at work

• regular testing by competent personnel

Safety

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• safety sensor is not used as intended

• safety notices are not adhered to

• reasonably foreseeable misuse is not taken into account

• mounting and electrical connection are not properly performed

• Proper function is not tested (see Chapter 8)

• changes (e.g., constructional) are made to the safety sensor

2.5 Additional safety instructions for access guarding with SOLID-2

Warning!

SOLID-2 Safety Light Curtains with a resolution of 20, 30 or 40 mm detect hands, arms or

bodies of a person entering the protective field, and therefore, it can be placed closer to the

danger point or points than Safety Light Curtains with a resolution of 90 mm. In this case,

Leuze electronic SOLID-2 11

TNT 35/7-24V

Page 12

Safety

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

the height of the highest and lowest beam above the reference plane must be selected in

accordance with EN ISO 13857.

Valid for all design types: In case of access guarding applications, the start/restart

interlock function is obligatory due to the fact that only access to the danger zone, but not

the area between the protective field and the danger points is monitored.

The start/restart button for unlocking the device must be mounted in such a way that it

cannot be reached from inside the danger zone and the entire danger zone is fully visible

form its installation position.

12 SOLID-2 Leuze electronic

Page 13

System design and selectable functions

a

b

3 System design and selectable functions

3.1 The opto-electronic protective device

Working principle

SOLID-2 consists of a transmitter and a receiver. Beginning with the first beam (the

synchronizing beam) directly after the display panel, the transmitter pulses beam for

beam in rapid sequence. The synchronization between transmitter and receiver is

performed optically.

Fig. 3.1-1: Working principle of the opto-electronic protective device

The receiver recognizes the specially coded pulse packages of the transmitter beams

and opens the corresponding receiver elements in sequence in the same rhythm. A

protective field is consequently formed in the area between transmitter and receiver.

Its height depends on the geometrical dimensions of the protective device and its width is

determined by the distance selected between the transmitter and receiver within the

permissible detection range.

Functions such as start/restart interlock or contactor monitoring can optionally be

performed by the Receiver Extended version.

3.2 Functions of the Transmitter

3.2.1 Transmission channel

The infrared beams are modulated with specially coded pulse packages so that the are

distinct from ambient light, thus ensuring undisturbed operation.

Welding sparks or warning flash lights from passing forklifts do not having any effect on

the protective field.

If two protective fields are located directly next to each other for two adjacent machines,

however, measures must be taken to ensure the optical protective devices do not affect

each other.

Both transmitters should first be assembled “back to back“ so that the beams radiate in

opposite directions. This prevents one system from affecting the other.

a=Transmitter

b=Receiver

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Leuze electronic SOLID-2 13

Page 14

System design and selectable functions

a

b

Another possible way to suppress mutual influence is to switch one of the two protective

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

3.2.2 Internal or external testing

devices from transmission channel 1 to 2 and thus to differently formed pulse packages.

This solution should be considered when more than two optical safety systems must be

arranged

a=AOPD “A“ transmission channel 1

b=AOPD “B“ transmission channel 2, not affected by AOPD “A“

Fig. 3.2-1: Transmission channel selection

Both the transmitter and the receiver of the optical protective system in question must be

switched from transmission channel 1 to 2. For additional information, see Chapter 6.

If external testing is desired, the test input of the transmitter must be wired in accordance

with the connection and operating instructions of the selected testing safety interface. The

testing safety interface will turn the transmitter off and back on, verifying that the selected

single OSSD of the receiver is turned off and on in accordance. For more details, see

Chapter

In most cases, however, internal cyclical testing is sufficient. For this purpose, the

transmitter‘s test input must be connected with +24V DC. Both OSSDs must be integrated

into the safety circuit as a two-channel system.

next to each other.

6.1.1.2.

3.3 Selectable function of the Receiver Standard and Extended

3.3.1 Transmission channel

If the transmitter is switched to transmission channel 2, the corresponding receiver must

also be set to transmission channel 2

14 SOLID-2 Leuze electronic

. See Chapter 6.

Page 15

System design and selectable functions

3.4 Additional functions of the Receiver Extended

3.4.1 Start/restart interlock (RES)

If the start/restart interlock function is activated, it prevents the safety circuits from being

released automatically when the machine is turned on or the power supply is switched on

or is restored after a power outage. The receiver only switches to the ON state by pressing

and releasing the start/resart button within a time window.

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Fig. 3.4-1: Start/restart interlock function in effect when the supply voltage is turned

If the protective field is interrupted, the start/restart interlock function ensures that the

receiver will remain in the OFF

rece

iver will then not be switched back to the ON state until the start/restart button is

pressed and released again.

Fig. 3.4-2: The start/restart interlock function after the protective field has been

Activate the start/restart interlock:

✟ with the circuitry in the Receiver Extended (see Chapter 6.1.3)

✟ or in the downstream machine control unit

✟ or in the downstream safety PLC

Once the internal start/restart interlock is activated as described in Chapter 6.1.3, this

function is monitored dynamically. The receiver cannot be switched back to the ON state

until the start/restart button is pressed and released again within a time window of 300

to 5

s, with the protective field free.

on

state after the protective field is released again. The

penetrated

ms

TNT 35/7-24V

Leuze electronic SOLID-2 15

Page 16

System design and selectable functions

3.4.2 Contactor monitoring (EDM)

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

If the “Contactor monitoring” function is activated, it dynamically monitors contactors,

relays or valves downstream from the SOLID-2. Precondition here are switching elements

with positive-guided feedback contacts (normally closed).

Fig. 3.4-3: Contact monitoring function, combined in this example with a start/

You can implement the contactor monitoring function with:

✟ The internal contactor monitoring in the Receiver Extended (see Chapter 6.1.3)

✟ or via a downstream safety PLC

If the internal contactor monitoring function is activated, it works dynamically, i.e. in

addition to verifying that the feedback loop is closed before turning on the OSSDs the

system checks whether the feedback circuit has opened within 500 ms of being enabled

and whether it has closed again within 500 ms when turning off the

the case, the OSSDs will assume an OFF state again shortly after turning on.

message appears at the 7-segment display, E 30.

restart interlock

OSSDs. If this is not

A error

16 SOLID-2 Leuze electronic

Page 17

4 Display elements

ab

4.1 Transmitter status displays

When the transmitter’s green LED1 is lit, this indicates that the supply voltage is available.

Fig. 4.1-1: Transmitter, LED status displays

Display of the current state of the transmitter:

Indication Meaning

LED1 green LED2 off Supply voltage present, TC1 selected

LED1 green LED2 green Supply voltage present, TC2 selected

LED1 green LED2 red Supply voltage present, TC1 or TC2 selected, external

LED1 red LED2 any state Device fault

Table 4.1-1: Transmitter, LED status displays

a = LED1 (green/red)

b = LED2 (green/red)

test signal activated

Display elements

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Leuze electronic SOLID-2 17

Page 18

Display elements

bd

c

a

4.2 Receiver status displays

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

4.2.1 7-segment display

LED1 and the 7-segment display report on the operating states of the Receiver Standard.

LED2 is added in case of Receiver Extended.

Fig. 4.2-1: Receiver, status displays

After the electrical supply voltage is turned on, the following data appear on the receiver’s

7- segment display:

7-segment

display

1 or 2 Indication of transmission channel TC1 or TC2

a=Symbol for OSSDs

b=LED1 = red/green

c=Symbol for interlocking state

d=LED2 = yellow

Meaning

Permanent display after startup

Table 4.2-1: Receiver, 7-segment permanent displays

7-segment

Meaning

display

Temporary event displays, 1 s per display

E xx Locking status display “error“, which can be eliminated by the user

E xx = Error code (for example contactor monitoring error E 30, see Chapter 9). The display shows repeating the sequence of E, 3 (1st position)

and 0 (2nd position).

F xx Locking status display „device fault“ and an internal fault code.

Receiver must be replaced.

1 or 2

flashing

Table 4.2-2: Receiver, 7-segment temporary event display

Flashing transmission channel number → weak signal display, device not

adjusted optimally or contaminated front screens

18 SOLID-2 Leuze electronic

Page 19

4.2.2 LED displays

4.2.2.1 Receiver Standard, LED status displays

LED Color Meaning

LED1 red/

green

Table 4.2-3: Receiver Standard, LED status displays

red = OSSDs safety outputs in the OFF state

green = OSSDs safety outputs in the ON state

No display = Device without supply voltage

4.2.2.2 Receiver Extended, LED status displays

If the internal start/restart function is not activated, the Receiver Extended indicates only

the status of the OSSDs safety outputs in the same way like the Receiver Standard,

described under

The following table is valid, if the internal start/restart function is activated.

LED Color Meaning

LED1 red/

LED2 yellow ON = Internal start/restart interlock activated; The OSSDs

green

4.2.2.1.

red = OSSDs safety outputs in the OFF state

green = OSSDs safety outputs in the ON state

No display = No supply voltage to the device

safety outputs are switched to the OFF state. If the

protective field is free,

the device can be unlocked by pressing and

releasing the start/restart button in a time window of

300 ms to 5 s.

OFF = If the OSSDs are in ON state (LED1 green):

Internal start/restart interlock function is not activated.

If OSSDs are in OFF state (LED1 red):

Internal start/restart function is activated and the

protective field is not free.

Display elements

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

TNT 35/7-24V

Table 4.2-4: Receiver Extended, LED status displays when start/restart interlock

Leuze electronic SOLID-2 19

function is activated

Page 20

Display elements

4.2.2.3 Receiver Extended, LED displays and protective field states when the internal

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

start/restart interlock function is activated:

LED1 LED2 Protective

field

green OFF free LED1

red OFF interrupted LED1 red = OSSDs safety outputs in the OFF state

red yellow free LED1 red = OSSDs safety outputs in the OFF state

Table 4.2-5: Receiver Extended with selected internal start/restart interlock function

The following illustrations show the behaviour of the LEDs and OSSDs in start/restart

interlock operating mode.

a b c d e

Meaning

green

LED2 OFF = Start/restart interlock not active, see Fig.

LED2 OFF = Start/restart interlock not active.

LED2

yellow

= OSSDs safety outputs in the ON state

4.2-2 a

As long as the protective field is interrupted, it is not possible to start/restart the device, see Fig. 4.2-2 b

= Start/restart interlock active. The OSSDs

safety outputs are only turned on again af

ter pressing and releasing the start/restart

button in a time window of 300 ms to 5 s,

see Fig. 4.2-2 c-e

-

LED1: green

LED2: OFF

OSSDs: ON

Fig. 4.2-2: Start/restart interlock function after intrusion into the protective field

20 SOLID-2 Leuze electronic

LED1: red

LED2: OFF

OSSDs: OFF

LED1: red

LED2: yellow

OSSDs: OFF

LED1: green

LED2: OFF

OSSDs: ON

Page 21

5 Installation

This section contains important information on installing the SOLID-2. The effects of its

effective protection are only guaranteed if the following installation requirements are

observed. These installation specifications are based on the respective applicable

versions of European standards such as EN 999 and EN

countries outside of the EU, the valid requirements in those countries must also be

observed. The installation depends greatly on the type of protection being provided.

Because of this, the situations of:

• Safeguarding danger points

• Safeguarding danger areas

• Access guarding

are considered separately below. The applicable distance from the protective device to

reflective surfaces in the surrounding area are presented for all types of protection based

on these situations.

5.1 Calculating minimum distances

Light curtains can only perform their protective function if they are mounted with a

sufficient safety distance. The calculation formulas for the safety distance depend on the

type of protection. In the harmonized European standard EN 999, “Positioning of

protective devices with regard to approach speed of parts of the human body“, the

installation situations and calculation formulas for safety distance are described for the

types of protection named above.

The formulas for the required distances to reflective surfaces are based on the European

standard for “Active opto-electronic protective devices“ prEN IEC 61496-2.

Installation

ISO 13857. If SOLID-2 is used in

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

5.1.1 Safety distance for safeguarding danger points

Calculation of the safety distance for a SOLID-2 Safety Light Curtain with resolution of 20,

30 or 40 mm to safeguard danger points:

The safety distance S for safeguarding danger points is derived in accordance with EN

999 from the formula:

S [mm] = K [mm/s] x T [s] + C [mm]

Leuze electronic SOLID-2 21

TNT 35/7-24V

Page 22

Installation

b

c

d

f

e

a

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

S = Safety distance in mm

If the result is less than 100 mm, a distance of at least 100 mm must still be

maintained.

K = Approach speed in mm/s

In the close range of 500 mm, 2000 mm/s is used for the calculation. If the distance greater than 500 mm is calculated, K = 1600 mm/s may be used.

However, in this case a minimum safety distance of 500 mm is applied.

T = Total time of the delay in seconds;

Total of:

the response time of the protective device t

the response time of the safety interface, if any t

and the machine‘s stopping time t

Machine

a)

AOPD

c)

Interface

b)

C = 8 x (d-14) in mm

Additional amount depending on depth of penetration into the protective field

before switching of the AOPD

d = Resolution of the AOPD

a)

see Chapter 10.2

b)

see specifications of the safety interface

c)

Specifications of the machine or stopping time measurement

a = Safety distance (S)

b = Measures to prevent penetration from above

c = Measures to prevent penetration from the sides

d = Measures to prevent penetration from the rear

e = Measures to prevent penetration from below

f = 75 mm – Maximum distance to avoid walking

behind*

Fig. 5.1-1: Safety distance (a) for safeguarding danger points

*) If because of the safety distance this value cannot be achieved, other measures e.g.mechanical

barriers must provide this distance.

S [mm] = 2000 [mm/s] x (t

AOPD

+ t

Interface

+ t

) [s] + 8 x (d-14) [mm]

Machine

22 SOLID-2 Leuze electronic

Page 23

Calculation example for safeguarding danger points:

c

b

d

a

A light curtain with a resolution of 20 mm, protective field height 1500 mm is used on a

machine with a stopping time of 150 ms. The response time of the safety interface is

20

ms.

Stopping time of the machine t

Response time t

Response time t

AOPD

= 20 ms

Interface

= 150 ms

Machine

= 49 ms

Resolution d of the AOPD = 20 mm

T = 0.150 s + 0.049 s + 0.020 s = 0.219 s

S = 2000 x 0.219 + 8 x (20 -14) = 486 mm

Make certain during assembly that it is not possible to reach over, around or under or to

walk behind the

protective device.

5.1.2 Safety distance for safeguarding danger areas

Calculation of the safety distance and required resolution for a Safety Light Curtain to

secure danger areas.

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

a = Safety distance (S)

b = Measures to prevent access from the sides

c = Height above the reference plane

d = max. distance < 75 mm*

Fig. 5.1-2: Safety distance (a) and height (c) for safeguarding danger areas

*) If this value can not be achieved because of the safety distance, other measures, e.g. mechanical

barriers, must guarantee for that required maximum distance of 75 mm.

Leuze electronic SOLID-2 23

TNT 35/7-24V

Page 24

Installation

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

The height of the protective field H above the reference plane and the resolution d of the

AOPD are related to each other as follows:

Hmin [mm] = 15 x (d -50) [mm] or d [mm] = H/15 + 50 [mm]

H = Height of the protective field above the reference plane, maximum 1000 mm

Heights equal to or less than 300 mm are considered too low for adults to crawl

under

d = Resolution of the AOPD

The safety distance S for safeguarding danger areas is derived in accordance with EN

999 from the formula:

S [mm] = K [mm/s] x T [s] + C [mm]

S = Safety distance in mm

K = Approach speed of 1600 in mm/s.

T = Total time of the delay in seconds;

Total of:

the response time of the protective device t

the response time of the safety interface, if any t

and the stopping time of the machine t

Machine

AOPD

c)

a)

Interface

b)

C = (1200 mm – 0,4 H), but not less than 850 mm (arm’s length)

H = Height of the protective field above the floor

a)

see Chapter 10.2

b)

see specifications of the safety interface

c)

Specifications of the machine or stopping time measurement

S [mm] = 1600 [mm/s] x (t

AOPD

+ t

Interface

+ t

) [s] + (1200 – 0,4 H) [mm]

Machine

24 SOLID-2 Leuze electronic

Page 25

5.1.3 Safety distance and beam heights for access guarding

a

b

c

d

Determination of the beam heights and calculation of the safety distance of Safety Light

Curtains with a resolution of 20, 30 or 40

limited space between the protective field and a danger point.

mm for use as access guarding, for example with

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

a = Safety distance (protective field/danger

point),

b = Height of the lowest beam above reference

plane, see Table 5.1-1

c = Height of the highest beam, see Table 5.1-1

d = Measures to prevent access from the sides

Fig. 5.1-3: Access guarding with Safety Light Curtain, resolution of 20, 30 or 40 mm

Warning!

Please consider the additional safety instructions for access guarding with SOLID-2 in

Chapter 2.5.

Beam heights with use of Safety Light Curtain to guard access in accordance with

EN 999 and EN ISO 13857:

Design Resolu-

ion

Lowest beam above

reference plane

Highest beam above reference plane

Additional

amount C

(see formula

Chapter 5.1.1)

SD2-20-xxxx 20 mm As per EN ISO 13857 As per EN ISO 13857 48 mm

SD2-30-xxxx 30 mm As per EN ISO 13857 As per EN ISO 13857 128 mm

SD2-40-xxxx 40 mm As per EN ISO 13857 As per EN ISO 13857 208 mm

SD2-90-xxxx 90 mm 300 mm 1200 mm 850 mm

Table 5.1-1: Beam heights above the reference plane and additional amount C for

access guarding applications

Leuze electronic SOLID-2 25

TNT 35/7-24V

Page 26

Installation

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Calculation formula for safety distance S based on EN 999:

Calculation of the safety distance for a Safety Light Curtain with a resolution of up to

40

mm, used to guard access. The safety distance S is calculated as described by

EN

999 according to the formula:

S [mm] = K [mm/s] x T [s] + C [mm]

S = Safety distance in mm

K = Approach speed in mm/s

In the close area of 500 mm, the speed is calculated at 2000 mm/s. If the distance is greater than 500 mm, K can be calculated as 1600 mm/s. In this case,

however, a minimum of 500 mm applies to the safety distance.

T = Total time of the delay in seconds;

Total of:

the response time of the protective device t

the response time of the safety interface, if any tI

and the stopping time of the machine t

Machine

AOPD

c)

a)

nterface

b)

C = 8 x (d-14) in mm

Additional amount depending on the depth of penetration into the protective

field before turning on the AOPD

d = Resolution of AOPD up to a maximum of

40

mm

a)

see Chapter10.2

b)

see specifications of the safety interface

c)

Specifications of the machine or stopping time measurement

S [mm] = 2000 [mm/s] x (t

AOPD

+ t

Interface

+ t

) [s] + 8 x (d-14) [mm]

Machine

If the resolution is greater than 40 mm for example for SOLID-2 Safety Light Curtains with a

resolution of 90 mm, an additional amount is required:

C = 850 mm (arm’s length)

The safety distance is thus calculated according to the following formula:

S [mm] = 1600 [mm/s] x (t

AOPD

+ t

Interface

+ t

) [s] + 850 [mm]

Machine

Warning!

Please consider the additional safety instructions for access guarding with SOLID-2 in

Chapter 2.5.

26 SOLID-2 Leuze electronic

Page 27

5.1.4 Minimum distance from reflective surfaces

c

b

a

4°± 25%

4°± 25%

130

a

b

Reflective surfaces in the area of opto-electronic protective devices can indirectly deflect

beams from the transmitter into the receiver. This can cause an object in the protective

field not to be detected! All reflective surfaces and objects (for example material

containers, sheets) must be kept at a minimum distance „a“ . The minimum distance

depends on the distance „b“ between the transmitter and the receiver.

a = Minimum distance

b = Reflective surface

c = Protective field width

Fig. 5.1-4: Minimum distances from reflective surfaces

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

a=Required distance from reflective surfaces [mm]

b=Width of protective field [m]

Fig. 5.1-5: Minimum distances from reflective surfaces as a function of the width of

the protective field

Safety light curtains of the SOLID-2 product line are equipped with an optics of less beam

aperture than required by EN IEC 61496-1, -2. Thus, less distances between reflecting

surfaces and protective field are needed than typically required.

Warning!

Replacing with safety light curtains of different production lines fulfilling the minimum

requirements of the above mentioned standards may request higher distances.

Leuze electronic SOLID-2 27

TNT 35/7-24V

Page 28

Installation

5.2 Mounting notes

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Special notes on mounting a SOLID-2 Safety Light Curtain for safeguarding danger

points (

✟ Calculate the safety distance according to the formula in Chapter 5.1.1.

✟ Ensure that it is impossible to reach under, over, around or walk behind the protective

field.

✟ Observe the maximum distance between machine table and protective field of 75 mm,

with reference to a table height of 750 mm. If this is not possible because the safety

distance is too big, e.g. a mechanical barrier must be provided.

✟ Observe the minimum required distance to reflective surfaces.

Special notes on mounting a SOLID-2 Safety Light Curtain for safeguarding danger areas

(

see Fig. 5.1-2):

✟ Calculate the safety distance according to the formula in Chapter 5.1.2.

✟ The resolution determines the minimum height of the protective field above the floor.

The calculation formula can also be found in Chapter

✟ Ensure that the maximum height of the protective field above the reference plane of

1000 mm is not exceeded and only heights equal to or less than 300 mm are

considered impossible for an adult to crawl under (also see EN 999).

✟ It must not be possible to step into the danger area from the sides. Suitable hard guards

must be provided.

✟ Consider the position of the last light beam before the machine. It must not be possible

to stand undetected between this light beam and the machine.

Special notes on mounting a SOLID-2 Safety Light Curtain for access guarding (see

Fig. 5.1-3):

✟ Calculate the safety distance according to the formula in Chapter 5.1.3.

✟ The highest and the lowest light beam and thus the height of the protective field for

Safety Light Curtains with a resolution of 20, 30 or 40

requirements described in EN

✟ Access guarding systems must only be operated with start/restart interlock. Activate the

start/restart interlock internal or of a downstream safety interface and

sure it is working.

✟ Ensure while installing the start/restart button, that it must only be impossible to press

this button from the inside the danger zone. Make sure, that from the location of the

button there is a complete overview over the danger zone.

see Fig. 5.1-1):

5.1.2.

mm is determined from the

ISO 13857.

check to make

28 SOLID-2 Leuze electronic

Page 29

5.3 Mechanical mounting

What should generally be taken into consideration during installation?

✟ Make certain that the transmitter and receiver are mounted on even surfaces.

✟ The transmitter and receiver must be positioned at the same height and their

connection plugs must be pointing in the same direction.

✟ Use screws for mounting that can only be loosened with a tool.

✟ Fasten and secure the transmitter and receiver so that they cannot be swiveled or

moved. Securing transmitter and receiver so they cannot be moved or swiveled is

especially important in the close area with a narrow protective field.

✟ The safety distance between the protective field and the danger zone must be

observed.

✟ Make certain that access to the danger point/danger area is only possible through the

protective field. Additional access routes must be secured separately (for example by

hard guards, additional safety light curtains or doors with locking devices).

5.4 Mounting types

5.4.1 Standard mounting

Four standard mounting brackets (two each for transmitter and receiver) are included with

delivery.

Installation

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

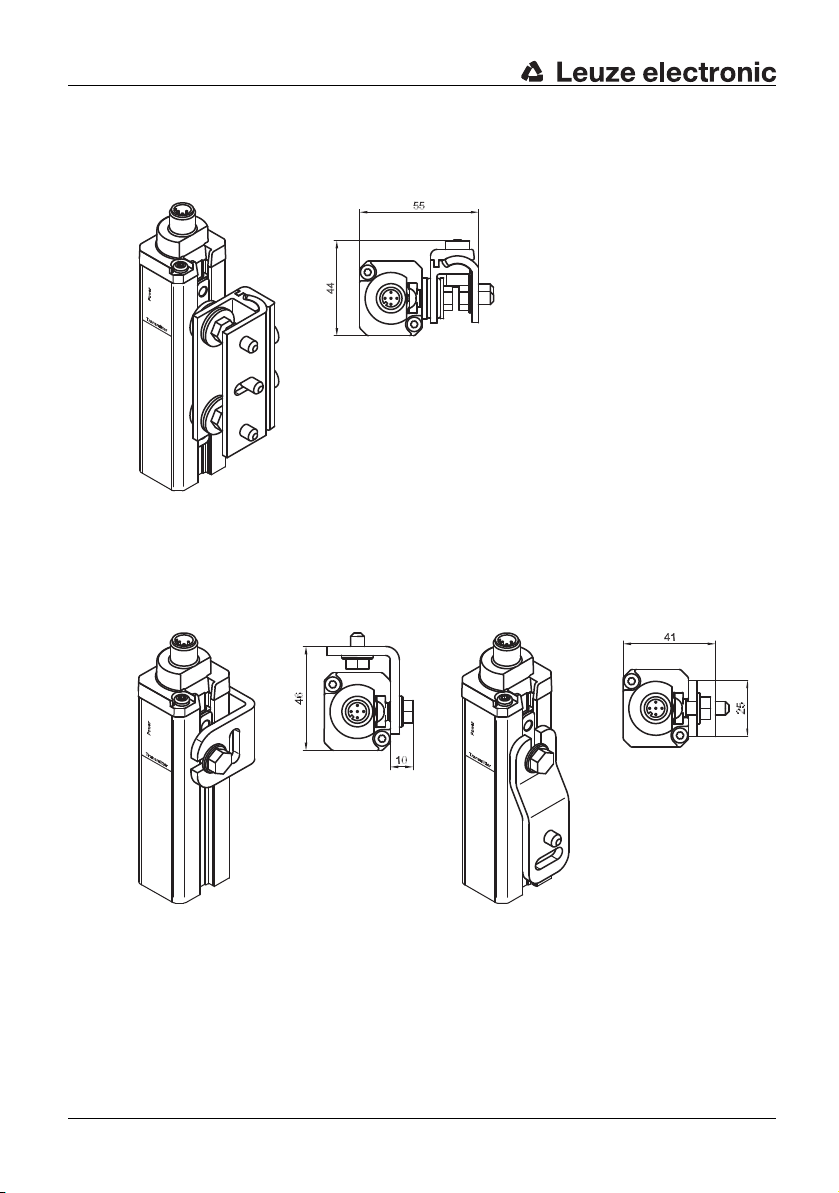

Fig. 5.4-1: Standard mounting bracket examples

Leuze electronic SOLID-2 29

TNT 35/7-24V

Page 30

Installation

L-mounting bracket

Z-mounting bracket

5.4.2 Option: Mounting with swiveling brackets

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

5.4.3 Option: Side mounting

Four swivel mounting brackets with shock absorbers can be ordered optionally. They are

not included with delivery.

Fig. 5.4-2: Swiveling mounting bracket with shock absorber

Optionally, mounting is possible with L- or Z-mounting brackets (with sliding nuts and

screws) using the side groove. They are not included with delivery.

The swivel range is ± 8°.

Fig. 5.4-3: Mounting examples, L-mounting bracket and Z-mounting bracket

30 SOLID-2 Leuze electronic

Page 31

6 Electrical connection

• The electrical connection must be performed by experienced personnel. Knowledge of

all safety instructions in these connecting and operating instructions is part of this

competence.

• The external supply voltage of 24V DC ± 20 % must guarantee safe isolation from mains

voltage and be able to bridge a power outage period of at least 20 ms. Leuze

electronic offers suitable power supplies (see list of accessories in the Appendix).

• The power supply selected must not support any other parts of the machine with power

other than the safety components connected. It must provide at least 1 A. Transmitter

and receiver must be fused against overcurrent.

• It is vital during the electrical installation for the power of the machine or system to be

protected is switched off and locked, so that the dangerous movements cannot be

started unintentionally. Only after the safety function on the protective device is entirely

checked, its connection to the machine is permissible. For more details see

and 11.4.

6.1 M12 connection

Transmitter and Receiver Standard are equipped with M12, 5-pin plugs while the Receiver

Extended providing additional functions is equipped with a M12, 8-pin plug.

6.1.1 Transmitter

Fig. 6.1-1: SD2T 5-pin (view of the pins)

1 = brown

3 = blue

4 = black

5=grey

Electrical connection

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Chapter 8

Pin Color Assignment Inputs/outputs

1 brown Supply voltage +24V DC for TC1 or 0V for TC2

2 white nc.

3 blue Supply voltage 0V for TC1 or +24V DC for TC2

4 black Test in Test input

5 grey/

connector

enclosure

Table 6.1-1: Transmitter, connection assignment

Leuze electronic SOLID-2 31

Shield Functional earth

Connected to +24V DC

→ internal test activated

Connected to 0V or disconnected

→ external test activated

TNT 35/7-24V

Page 32

Electrical connection

+24V DC

b

a

2 K

External test signal

8 - 150 ms

c

OSSD output

6 ms 6 ms

d

+24V DC

+24V DC

The polarity of of the power supply at Pin1 and Pin3 determines the selected optical

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

6.1.1.1 Internal cyclical testing

6.1.1.2 External test signal

transmission channel. If +24V DC is present on Pin1 and 0V on Pin3 transmission

channel

1 is selected. If 0V is present on Pin1 and +24V DC on Pin3 transmission

channel

2 is selected.

Make certain to select the same transmission channel for both, for transmitter and

receiver.

Warning!

For optimal shielding cables must be used, where the shield is led on the knurled nut of the

connecting cable socket (such cables are listed under accessories in Chapter

To activate internal cyclical testing, connect Pin4 of the transmitter to +24V DC.

Warning!

While using the internal cyclical testing both of the OSSDs must by used to open the safety

circuit redundant.

To use the external testing option, connect the test output of the corresponding testing

safety interface with Pin4 of the transmitter. In case of using the external testing procedure

in combination with a testing safety interface, only one of the OSSDs needs to be

connected to the testing safety interface.

Note:

External testing takes precedence over the internal testing.

11.3).

Test input Pin4 Transmitter: +24V DC test = not activated

high impedance or 0V test = activated

32 SOLID-2 Leuze electronic

a = transmitter

b = test input pin4

Fig. 6.1-2: Transmitter, external testing

c = high impedance or 0V

d = high impedance

Page 33

6.1.2 Receiver Standard

Fig. 6.1-3: SD2R 5-pin (view of the pins)

Pin Color Assignment Inputs/outputs

1 brown ⇐ Supply volta-

2 white Output OSSD2, switching semicontactor output

3 blue ⇐ Supply volta-

4 black Output OSSD1, switching semicontactor output

5 grey/

connector

enclosure

Table 6.1-2: Receiver Standard, connection assignment

Warning!

The Receiver Standard does not offer the functions start/restart interlock and EDM. These

functions have to be carried out by the downstream machine control unit if required by the

safety category.

1 = brown

2 = white

3 = blue

4 = black

5=grey

+24V DC for TC1 or 0V for TC2

ge

0V for TC1 or +24V DC for TC2

ge

⇐ Shield Functional earth

Electrical connection

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Note:

For optional shielding cables must be used, where the shield is led on the knurled nut of the

connecting cable socket (such cables are listed under assessories in Chapter 11.3).

The polarity of of the power supply at Pin1 and Pin3 determines the selected optical

transmission channel. If +24V DC is present on Pin1 and 0V on Pin3 transmission channel

1 is selected. If 0V is present on Pin1 and +24V DC on Pin3 transmission channel 2 is

selected.

Note:

Make certain to select the same transmission channel for both, for receiver and transmitter.

Leuze electronic SOLID-2 33

TNT 35/7-24V

Page 34

Electrical connection

SOLID-2 / SD2R

+24V

+24V

Tes t

OSSD1

SOLID-2 / SD2T

OSSD2

0V

FE

FE

0V

Var. B

Var. A

4

142

-A1

1 234

-A2

1 2

3

14

-W1 -W2

5

-W2

SH3

-W1

5

SH3

-K3 -K4-K4

-K3

0V

PE

+24V

PE.

+24V

0V.

n.c.

14 24 42

13 23 41

A1

A2

-K3

121

2

L+ L+

L- L-

-S1

-K3

-K4

+24V

0V

MSI-SR4

A1

-A3

A2

S22 S12 S31 S33 S34 S35

2 AOPD-

1 AOPD+

33

34

A1

A2

-K4

2 AOPD+

IV-0

RES-0

RES-I

1

2

*

*

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

Fig. 6.1-4: Connection example SOLID-2 with MSI-SR4 Safety Relay

34 SOLID-2 Leuze electronic

Page 35

6.1.3 Receiver Extended

Fig. 6.1-5: SD2R 8-pin (view of the pins)

Pin Color Assignment Inputs/outputs

1 white Operating

2 brown Supply voltage +24V DC for TC1 or 0V for TC2

3 green Operating

4 yellow nc

5 grey Output OSSD1, switching semicontactor output

6 pink Output OSSD2, switching semicontactor output

7 blue Supply voltage 0V for TC1 or +24V DC for TC2

8 black/

connector

enclosure

1 = white

2 = brown

3 = green

4 = yellow

5=grey

6=pink

7=blue

8 = black

Input BA1

mode selection

Input BA2

mode selection

Shield Functional earth

Electrical connection

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Table 6.1-3: Receiver Extended, connection assignment

6.1.3.1 Selection of the transmission channel

The polarity of of the power supply at pin2 and pin7 determines the selected optical

transmission channel:

If +24V DC is present on pin2 and 0V on pin7 transmission channel 1 is selected.

If 0V is present on pin2 and +24V DC on pin7 transmission channel 2 is selected.

Note:

Make certain to select the same transmission channel for both, for transmitter and receiver.

For optimal shielding cables must be used, where the shield is led on the knurled nut of

the connecting cable socket (such cables are listed under accessories in Chapter

11.3).

6.1.3.2 Operating mode selection RES and contactor monitoring (EDM)

The Receiver Extended has to be connected via the 8-pin M12 connector. The operating

modes S/R and EDM can be activated in several combinations using the pins BA1 (pin1)

and BA2 (pin3) .

Leuze electronic SOLID-2 35

TNT 35/7-24V

Page 36

Electrical connection

BA1

BA2

+24V DC

GND

BA1 BA2

GND

BA2BA1

+24V DC

k2

k1

BA1 BA2

GND

k1

k2

OSSD2

0V

FE

FE

0V BA1

SOLID-2 E / SD2R E

+24V

Tes t

n.c.

+24V

SOLID-2 E/ SD2T MSI-RM2

n.c.

OSSD1

BA2

Var. B

Var. A

A1

A2

-K3

65

1

2

1

2

3SH

8

-W1

7SH

-W2

-S1

A2

5

14B36Y1

1

B1

4

-A3

11

3

12 22

2

-K4

-K3

A1

A2

-K4

21Y2

-W1

41

5

-W2

7

21

-A2

4

3

24

1

-A1

3

2

-K3 -K4-K4

-K3

0V

PE

+24V.

0V

+24V

PE

0V

L+L+

L- L-

Warning!

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

The adaptation of the operating mode is only be carried out in the switched off state of the

receiver. If the adaptation is made during operation, the new values will not be accepted

until the power supply was switched off.

Without RES Without EDM

BA1

0V Start/restart button

pin1

BA2

+24V DC 0V n.c. Via start/restart

pin3

Connection

Table 6.1-4: Receiver Extended, operating mode selection

6.1.3.3 Connection example

With RES

Without EDM

to BA2

Without RES

With EDM

EDM feedback

loop k1/k2 at

+24V

DC

With RES

With EDM

EDM feedback

loop k1/k2 at BA2

button to 0V

Fig. 6.1-6: Connection example SOLID-2E with MSI-RM2 Safety Relay

36 SOLID-2 Leuze electronic

Page 37

7 Commissioning

Warning!

Before placing the SOLID-2 in operation for the first time on a power-driven production

machine, an experienced and commissioned person with suitable training must check the

entire setup and the integration of the opto-electronic protective device into the machine

control system.

Before connecting the supply voltage for the first time and while the transmitter and

receiver are being aligned, it must be ensured that the outputs of the protective device do

not have any effect on the machine. The switching elements that finally set the dangerous

machine in motion must be safely switched off and secured form restarting.

The same precautionary measures apply after every change in operating mode made to

the protective device, after repairs or during maintenace work.

Only after it has been determined that the optical protective device functions are correct it

can be integrated into the machine’s control circuit!

7.1 Startup

Warning!

Without internal start/restart interlock function and the protective field is free the OSSDs

immediately switch to the ON state!

Make certain that the transmitter and receiver are protected against overcurrent (for fuse

size see Chapter

power supply must have a load current reserve of at least 1 A and the ability to bridge a

power outage for at least 20 ms, and it must guarantee secure mains supply isolation.

10.1.2). There are special requirements for the supply voltage: The

Commissioning

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

7.1.1 Transmitter display

After the power supply is turned on and the selftest is completed, the LEDs indicate the

current operating status (see Chapter

Warning!

If the transmitter’s LED1 lights permanently red, the 24V DC supply voltage and the wiring

must be checked. If the error remains after it is turned on again, discontinue the setup

process immediately and send in the malfunctioning transmitter to be checked.

4.1).

7.1.2 Receiver display

After the receiver is turned on or restarted, the number of the selected transmission

channel appears.

Warning!

In the event of an error or fault, the receiver’s 7-segment display reports it with ”E xx“ or ”F

xx“. The error code in Chapter 9 provides information on whether it is an error (E xx) in

external wiring or an internal device fault (F xx). For internal faults, immediately interrupt

the installation and send in the malfunctioning receiver to be checked.

Leuze electronic SOLID-2 37

TNT 35/7-24V

Page 38

Commissioning

bd

c

a

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

However, if errors are found and cleared in the external wiring, the receiver will be

restored to normal operation mode and startup can be continued.

Warning!

The Receiver Standard and the Receiver Extended without selected start/restart interlock

does not show the yellow LED2 lit after turning on and the OSSDs immediately switch to

the ON-state if the protective field is free. In this case, a downstream safety interface must

provide the start/restart interlock function:

LED Without internal RES, transmitter/

receiver aligned and protective field

free

Without internal RES, transmitter/

receiver not aligned or protective field

not free

LED1 green ON = OSSDs in the ON state red ON = OSSDs in the OFF state

LED2 OFF = RES interlock not availab-

le or not activated

OFF = RES interlock not available

or not activated

Table 7.1-1: Receiver Standard or Receiver Extended with start/restart interlock not

activated, LED displays

The LEDs display of the Receiver Extended with activated internal start/restart interlock

function after it is turned on (for activation see Chapter

LED With internal RES, before unlocking

by the start/restart button while the

protective field is free

6.1.3.2):

With internal RES, after unlocking the

start/restart button while the protective

field is free

LED1 red ON = OSSDs in the OFF state green ON = OSSDs in the ON state

LED2 yellow ON = RES locked OFF = RES unlocked

Table 7.1-2: Receiver Extended with start/restart interlock activated, LED displays

a=Symbol for OSSDs

b=LED1 = red/green

c=Symbol for interlocking state

d=LED2 = yellow

Fig. 7.1-1: Receiver Extended, LED display

38 SOLID-2 Leuze electronic

Page 39

Commissioning

7.2 Aligning transmitter and receiver

Transmitter and receiver must be mounted in place at the same height or, if they are used

horizontally, at the same distance from the reference level.

7.2.1 Optimized aligning with the aid of the Receiver’s 7-segment display

The distinction between protecting field is free (channel number is shown continuously)

and the weak signal mode (channel number is flashing) can be used as a convenient

alignment tool.

When the components are already almost aligned it is recommended to improve the

alignment e.g. by turning the receiver. Turn the receiver with slightly loosened brackets

until the 7-segment display starts to blink. Memorize this position. Now turn the receiver in

the opposite direction until the display lights constantly and further, until it is blinking

again. Now turn the receiver back in between the two positions determined. Screw the

receiver firmly into place to prevent turning. Proceed with the transmitter in the same

manner.

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Leuze electronic SOLID-2 39

TNT 35/7-24V

Page 40

Testing

8 Testing

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

8.1 Testing before setting the protective device in service the first time

Testing by an experienced technician before initial startup must ensure that the optical

protective device and any other safety components that might be present have been

selected in accordance with the required specifications, especially the European Machine

and Machine Utilization Directive, and that they provide the necessary protection when

properly operated.

✟ Use the regulations listed above, where required, with the help of the checklists

provided in the Appendix of these instructions, to check that the protective devices are

properly installed, that they are properly wired into the controls and that they work in all

machine operating modes. When selecting the checklist, note the type of protection

(danger point, danger area or access guarding).

✟ The same testing requirements apply if the machine in question has not been operated

for a longer period of time and after major modifications or repairs if this could affect the

safety of the machine.

✟ Observe the specifications regarding the instructing of operation personnel by experi-

enced technicians before work is started. Instruction of personnel is the responsibility of

the machine owner.

Leuze electronic offers a specialist service, which undertakes the required testing and

monitoring tasks in accordance with the European regulations (www.leuze.de). The results

of these tests are documented for the machine owner consistent with ISO

8.2 Regular tests

Regular tests must also be carried out in accordance with local regulations. They are

designed to discover changes (e.g. in machine stopping times) or manipulations to the

machine controls or protective device.

✟ You must have the effectiveness of the protective device checked by an experienced

technician at suitable intervals, but at least once per year.

✟ The applicable checklist in the Appendix may also be used during regular testing.

Leuze electronic also provides a specialist service for regular tests.

9000.

8.3 Daily testing with the test rod

SOLID-2 Safety Light Curtains are subject to a cyclical testing. Nevertheless it is very

important to check the protective field for its effectiveness daily to ensure that the

protection stays effective at every point after an operation mode or tool change.

Warning!

Use the appropriate test rod (Accessory) but never your fingers, hand or arm for checking

the system!

✟ When selecting the test rod’s diameter, use the nameplate of the receiver indicating the

resolution as a guideline.

✟ If for Receiver Extended the internal start/restart interlock function is selected and the

AOPD is released, LED1 lights up green. When the test rod is inserted, LED1 switches

40 SOLID-2 Leuze electronic

Page 41

Testing

a

to red and LED2 stays in the OFF state. During the test procedure, the yellow LED2

must not light up at any point. Only after the test rod is removed out of the protective

field, the LED2 is allowed to turn to yellow.

a = Beginning of test

Fig. 8.3-1: Testing the protective field with the test rod

✟ If the AOPD is being operated without the internal start/restart interlock, it is sufficient to

watch LED1 on the receiver during the testing procedure. When the test rod is inserted

into the protective field, this LED1 must switch from “green” to “red” and must not switch

back to “green” at any point during the test procedure.

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

Warning!

If the test does not yield the desired result, the cause could be a protective field height that

is too low or reflections from reflective metals or tools brought into the area. In this case the

installation of the safety light curtain must be checked by a specialist. If the cause cannot

be clearly defined and remedied, the machine or system must not beoperated any more!

8.4 Cleaning the front screens

The front screens on the transmitters and receivers must be cleaned regularly depending

on how dirty they are. A blinking 7-segment display with the protective field is free (LED1

is green) indicates a “weak signal reception”, cleaning is then required.

If cleaning the screens does not improve this, the detection range and alignment must be

checked.

We recommend using a mild cleanser for cleaning the front screens. The screens are

resistant to thinned acids or alkalis and resistant to organic solvents within limits.

Leuze electronic SOLID-2 41

TNT 35/7-24V

Page 42

Troubleshooting

9 Troubleshooting

DEUTSCH ENGLISH FRANÇAIS ITALIANO ESPAÑOL NEDERLANDS

9.1 What should I do if an error occurs?

9.2 Diagnostics

9.2.1 Transmitter diagnostics

The following information is used for rapid troubleshooting in the event of a malfunction.

If the AOPD shows an error on the display, the machine must be stopped immediately and

checked by an experienced technician. If it is found that the error cannot be clearly

defined and remedied, your local Leuze office and or the Leuze electronic hotline can

assist.

Operational malfunctions often have simple causes that you can remedy yourself. The

following tables will help you do this.

Symptom Measure to eliminate error

LED

is not lit

LED1 is lit red

continuously

Table 9.2-1: Transmitter diagnostics

Check + 24 V DC supply voltage

Check connection cable

Replace transmitter if necessary

Check the test input, hardware fault, replace transmitter if necessary

9.2.2 Receiver diagnostics

The receiver distinguishes between error codes (E xx) and fault codes (F xx). Only error

messages (E) provide information about events or states that you can eliminate. If the

receiver shows a fault code (F), it must be replaced. Consequently, only error codes (E)

are shown in the table below:

Code Cause / significance Measure to eliminate error

LEDs and 7-segment displays are not

lit

8 Lights continuously Hardware error Replace receiver

F xx Internal hardware fault Replace receiver

E 00 Source of failure in the ambient area Eliminate the source of the failure

E 01 Short circuit between OSSD1 and

OSSD 2

Table 9.2-2: Receiver diagnostics

42 SOLID-2 Leuze electronic

Check the + 24 V DC supply voltage

Check the connection cable, replace

the receiver if necessary

Eliminate short circuit

Page 43

Troubleshooting

Code Cause / significance Measure to eliminate error

E 06 Short circuit between GND and

OSSD1

E 07 Short circuit between +24V DC and

OSSD1

E 08 Short circuit between GND and

OSSD2

E 09 Short circuit between +24V DC and

OSSD2

E 14 Power supply undervoltage Check power supply/load

E 17 Operating mode setting incorrect or

start/restart button longer than 60

pressed

E 18 Test signal time-limit exceeded Test signal > 150 ms; check external

E 22 Power supply overvoltage Check the power supply

E 30 EDM error Check connection of feed back con-

Table 9.2-2: Receiver diagnostics

Eliminate short circuit

Eliminate short circuit

Eliminate short circuit

Eliminate short circuit

Invalid wiring combination, check the

wiring and/or button

s

test signal

tacts. Switch off power supply for setting back the system.

DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

9.3 AutoReset

After an error or a fault has been detected and displayed, an automatic restart occurs

within

• about 2 seconds for the transmitter