Page 1

OGS 600

Optical guidance sensor

EN 01-2017/11 50137686

We reserve the right

to make technical changes

Original operating instructions

Page 2

© 2017

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.com

Leuze electronic OGS 600

TNT 35/7-24V

Page 3

Table of contents

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.1 Trace detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.2 Measurement time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.3 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.4 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.5 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.6 Output value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.7 Example: Guide trace detection with active "Trace width" filter . . . . . . . . . . . . . . . . . . . 13

3.3 Guide trace requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.1 Trace color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.2 Trace width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.3 Free space next to the trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5 Operating and display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 General mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Selecting a mounting location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Mounting accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Safety notices for the electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.1 Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Pin assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 OGS 600-…/D3-M12.8 with RS485 interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Leuze electronic OGS 600 1

Page 4

Table of contents

5.3.2 OGS 600-…/D2-M12.8 with RS422 interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.3 OGS 600-…/CN-M12 with CANopen and RS232 interface . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Switching inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.1 Function of the SW_IO and IO switching outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.2 Switching output SW_IO (pin 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.3 IO switching output/switching input (pin 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4.4 Function of the IO switching input (pin 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5 Connection to the PC via RS232/RS422/RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Configuration/diagnostic software . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1 Installing the required software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1.2 Installation of the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Starting the configuration/diagnostic software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 Short description of the configuration/diagnostic software . . . . . . . . . . . . . . . . . . . . . 30

7 Configuring the sensor – Overview of functions . . . . . . . . . . . . . . 31

7.1 Compensating the installation position of the sensor – Angle compensation teach . . 31

7.2 Configuring the guide trace – light, dark, retro-reflective . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Offset to the edge positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.4 Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.4.1 "Switch" function – Settings for type 2 switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.4.2 Index accesses for activation of the "Switch" function . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5 "Trace width" filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5.1 Teaching the trace width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.2 Manual configuration of the trace width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.3 Process data information for the "Trace width" filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.4 Index overview for the "Trace width" filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.6 "Minimum contrast" filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.6.1 Teaching the minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.6.2 Manual configuration of the minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.6.3 Warning for minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.6.4 Process data information for the "Minimum contrast" filter . . . . . . . . . . . . . . . . . . . . . . . 43

7.6.5 Index overview for the "Minimum contrast" filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.7 "Trace amplitude" filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.7.1 Teaching the trace amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.7.2 Manual configuration of the trace amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.7.3 Warning for trace amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.7.4 Process data information for the "Trace amplitude" filter . . . . . . . . . . . . . . . . . . . . . . . . 47

Leuze electronic OGS 600 2

Page 5

Table of contents

7.7.5 Index overview for the "Trace amplitude" filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.8 Index overview – More data on correct and incorrect traces . . . . . . . . . . . . . . . . . . . . 48

8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1 Communication protocol for serial interfaces (UART) . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.1 RS485/RS422 node address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.2 Error handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.3 Index access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1.4 Process data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.1.4.1 Status byte in the process data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1.4.2 Contrast byte in the process data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.1.4.3 Type 1 process data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1.4.4 Type 4 process data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.1.5 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2 Object directory for serial interfaces (UART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2.1 System commands for serial interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.3 CANopen communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3.1 General information on CANopen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3.1.1 Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3.1.2 Bus line (trunk line) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3.1.3 Address assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3.1.4 Baud rate setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.3.1.5 Communication mechanisms of the OGS 600 in the CANopen network. . . . . . . . . . . . . . . . . . 68

8.3.1.6 Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.3.1.7 EDS file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.3.1.8 SDOs and PDOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.3.1.9 Default 11 bit identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.3.1.10 Object structure of the OGS 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.3.1.11 Process data objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.1.12 Overview of the mapped data in the TxPDOs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.3.1.13 Overview of the mapped data in the RxPDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.3.1.14 Overview TPDOs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.3.1.15 Overview RPDOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.4 CANopen object directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.4.1 CANopen system commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.5 Performing a reset on the OGS 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9 Tips for initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1 Configuration of the sensor according to the trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1.1 Variant: All filters ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1.2 Changeover between different traces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.1.3 Trace markings for application-specific actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.2 Basic settings for the filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Leuze electronic OGS 600 3

Page 6

Table of contents

10 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.1 Decommissioning, maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.2 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.1 General technical data OGS 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.2 Dimensioned drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.2.1 Dimensioned drawing OGS 600-280/CN-M12 – long version . . . . . . . . . . . . . . . . . . . . . 89

11.2.2 Dimensioned drawing OGS 600-280/D…-M12.8 – long version . . . . . . . . . . . . . . . . . . . 90

11.2.3 Dimensioned drawing OGS 600-140/CN-M12 – short version . . . . . . . . . . . . . . . . . . . . 91

11.2.4 Dimensioned drawing OGS 600-140/D…-M12.8 – short version. . . . . . . . . . . . . . . . . . . 92

11.3 Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

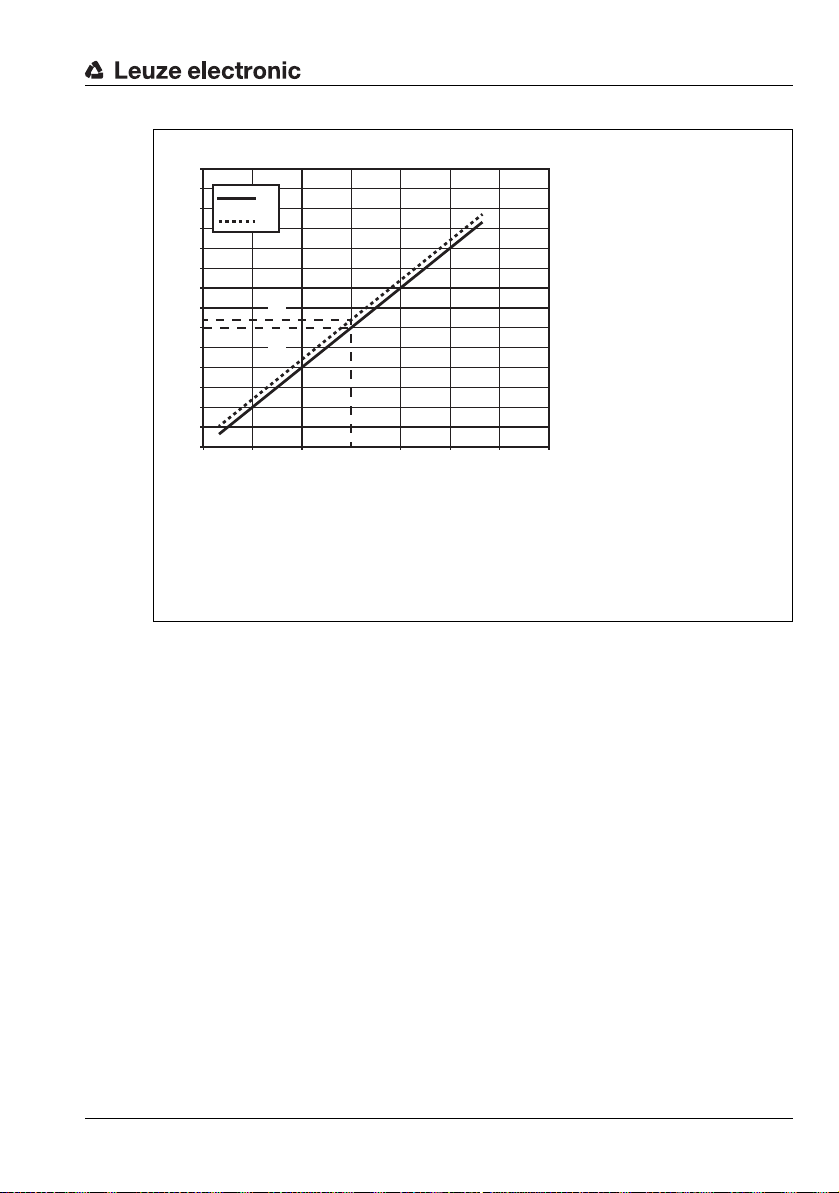

11.3.1 Sensor characteristic curve with one guide trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.3.2 Linearity error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

12 Order guide and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

12.1 Sensor part number code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

12.2 Order guide for sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

12.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.3.1 Connection cables for CANopen/RS232 devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.3.2 Connection cables for RS485/RS422 devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.3.3 RS485-USB adapter set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.3.4 Guide trace tapes, self-adhesive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13 Appendix – Sensor measurement values for RAL colors . . . . . . . . 98

Leuze electronic OGS 600 4

Page 7

1 About this document

This technical description contains information regarding the proper use of the OGS 600

optical guidance sensors.

1.1 Explanation of symbols

The symbols used in this technical description are explained below.

CAUTION

This symbol precedes text messages which must strictly be observed.

Failure to observe the provided instructions could lead to personal injury or damage to

equipment.

NOTE

This symbol indicates text passages containing important information.

1.2 Terms and abbreviations

AGV Automated Guided Vehicle

DTM Device Type Manager

EMC Electromagnetic compatibility

EN European standard

FDT Field Device Tool

FE Functional earth

GUI Graphical User Interface

IO or I/O Input/Output

OGS Optical Guidance Sensor

PD Process data

RO Read Only

RW Read/Write

PLC Programmable Logic Control

UART Universal Asynchronous Receiver Transmitter, here: RS232 / RS422 / RS485

WO Write Only

Table 1.1: Terms and abbreviations

About this document

TNT 35/7-24V

Leuze electronic OGS 600 5

Page 8

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The OGS 600 optical guidance sensor measures the contrast of a guide trace that is affixed

to the ground. The sensor supplies the vehicle's position data on the guide trace, which

determines the course of travel.

Areas of application

The OGS 600 optical guidance sensor is designed for the following area of application:

• Intralogistics – in-house material flow with automated guided vehicles (AGV).

CAUTION

Observe intended use!

The protection of personnel and the device cannot be guaranteed if the device is operated in a manner not complying with its intended use.

Only operate the device in accordance with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read the supplement and these operating instructions for the device before commis-

sioning the device. Knowledge of these documents is required in order to use the

equipment for its intended purpose.

Safety

NOTE

The optical guidance sensors of the OGS 600 series correspond to the following classification with respect to the integrated lighting:

Illumination red:

risk group 0 (exempt group) in acc. with EN 62471

NOTE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is

considered improper use.

Leuze electronic OGS 600 6

TNT 35/7-24V

Page 9

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• as stand-alone safety component in accordance with the machinery directive

• for medical purposes

NOTE

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried

out by competent persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at

work.

• They are familiar with the original operating instructions of the device.

• They have been instructed by the responsible person on the mounting and operation

of the device.

Safety

1)

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with

relevant standards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

1) Use as a safety-related component within a safety function is not permissible.

Leuze electronic OGS 600 7

TNT 35/7-24V

Page 10

3 Device description

A Integrated illumination – transmitter (small lenses)

B Receiver modules – receiver (large lenses)

C Groove with 2 sliding blocks for fastening the mounting bracket

D 2 x M12 connector, 5-pin

E 1 x M12 connector, 8-pin

A

B

C

D

OGS 600-280/CN-M12

OGS 600-140/D…-M12.8

E

3.1 Device overview

Device description

Leuze electronic OGS 600 8

Figure 3.1: Device overview

TNT 35/7-24V

Page 11

3.2 Performance characteristics

A

B

C

D

E

A Guide trace; here dark trace on light background

B Left edge of guide trace

C Right edge of guide trace

D Width of the sensor's measurement field

E AGV direction of travel

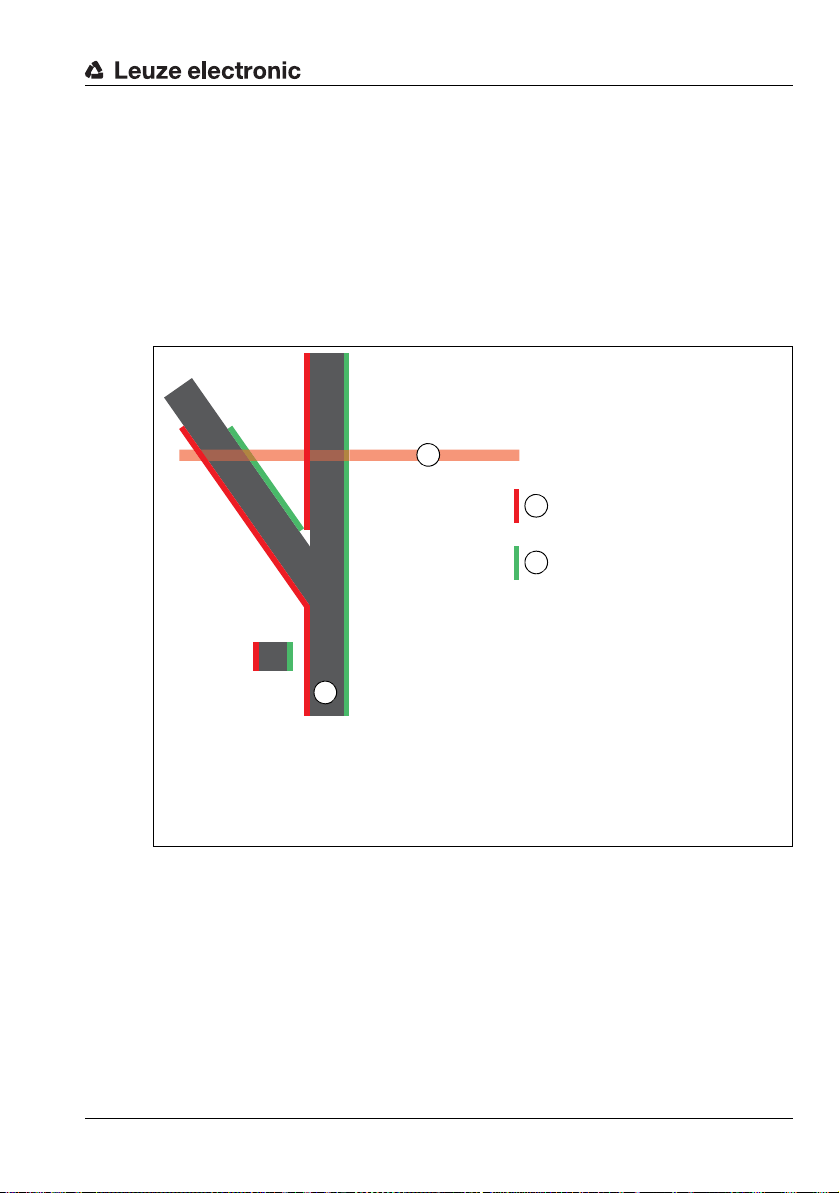

3.2.1 Trace detection

The sensor is designed to detect an optical guide trace on the floor and to output the position

of the guide trace relative to the sensor.

The sensor can detect a light trace on a dark background or, inversely, a dark trace on a

light background.

The sensor can detect up to 6 guide traces. Each guide trace consists of a left edge (shown

in red below) and a right edge (show in green below). This edge information is output for

each detected guide trace.

When a guide trace is detected, the sensor therefore outputs two pieces of information in

the process data for each trace:

• position of the left edge of the guide trace and

• position of the right edge of the guide trace

The difference between these two edge positions is the track width.

Device description

Figure 3.2: Schematic illustration of the guide trace under the optical guidance sensor

Leuze electronic OGS 600 9

TNT 35/7-24V

Page 12

3.2.2 Measurement time

The sensor delivers an updated measurement every 10ms.

3.2.3 Filter

The detection of incorrect floor markings can be minimized considerably by means of the

following filters, which can be activated separately: trace width, minimum contrast and trace

amplitude.

Filtered-out traces can be read out in separate parameters (see the chapter "Index overview

– More data on correct and incorrect traces").

Chapter 9 "Tips for initial commissioning" contains information on using the filters.

3.2.4 Switches

At each switch, the sensor outputs two or more traces. The users themselves decide which

trace they want to follow. The switch function is provided to ensure that the wide midpoint of

the type 2 switch (see chapter 7.4 "Switch") is detected properly when the trace width filter

is active.

Example:

When the vehicle moves over a seamlessly bonded switch (type 2) and a turn request is

given, the vehicle control unit can very early on follow the edge position in the direction in

which the vehicle is to turn.

If the vehicle is to turn left, the vehicle is guided by the left edge. The turn operation then

begins before the sensor has passed the midpoint of the switch and outputs two traces.

Device description

3.2.5 Faults

If floor markings occur which, despite activated filters, are detected as valid, then these

markings are output. The vehicle's control unit must ensure that position jumps in the output

traces are detected and that they are not followed.

Leuze electronic OGS 600 10

TNT 35/7-24V

Page 13

3.2.6 Output value

150 mm

17 mm 17 mm

AB

A Start of measurement field, output value 0

B End of measurement field, output value 1500 or 3000

300 mm

17 mm 17 mm

AB

The sensor outputs the position of the left edge and the right edge of the optical guide trace

in mm * 10. The output value range is therefore:

• Short version OGS 600-140…: 0 … 1500.

•Long version OGS 600-280…: 0 … 3000.

A trace is detected if it enters the sensor's measurement field by at least 17mm at the

left or right edge. This corresponds to an output value of:

• Short version OGS 600-140…: 170 … 1330.

•Long version OGS 600-280…: 170 … 2830.

Device description

Figure 3.3: Measurement field of the guidance sensor

The trace width is the absolute value of the difference between the right and left edge of the

trace.

Leuze electronic OGS 600 11

TNT 35/7-24V

Page 14

3500

A Measurement value for left edge of guide trace

B Measurement value for right edge of guide trace

C Output value: Position of left edge

D Output value: Position of right edge

x Position of left edge of guide trace under sensor

y Output value: Edge positions

3000

2500

2000

1500

1000

500

Device description

y

A

B

D

C

0

0 10050 150 200 250 300 350

Figure 3.4: Sensor characteristic curve with one trace (long version)

x

TNT 35/7-24V

Leuze electronic OGS 600 12

Page 15

Device description

A

B

C

D

A Guide trace; here dark trace on light background

B Left edge of guide trace

C Right edge of guide trace

D, E Trace too wide according to active "Trace width" filter

F Width of the sensor's measurement field

G AGV direction of travel

H Objects not detected as trace

G

E

F

F

H

H

If the "Trace width" filter detects an excessively wide trace, you can e.g.:

• activate the "Switch" function

• manually increase the upper tolerance for

the permissible trace width

3.2.7 Example: Guide trace detection with active "Trace width" filter

Leuze electronic OGS 600 13

Figure 3.5: Schematic illustration of the guide trace under the optical guidance sensor

TNT 35/7-24V

Page 16

3.3 Guide trace requirements

To ensure error-free detection of the optical guide trace on the floor, the guide trace must

meet the requirements described in the following sections.

3.3.1 Trace color

The illumination of the sensors emits red light. As a result, the contrast that the sensor sees

is different to that perceived by the human eye.

The following overview shows how the sensor sees different colors.

Device description

Color perceived by

human eye

White Traffic white 9016 21200 Leuze black

Black Jet black 9005 400 Leuze white 1)

Red Tomato red 3013 11800 Black

Orange Deep orange 2011 17400 Black

Yellow Melon yellow 1028 19800 Black

Green Emerald green 6001 1200 White

Blue Ultramarine blue 5002 700 White

1) Leuze trace tapes available as accessories:

OTB 40-BK250, black, 40mm wide, self-adhesive, 25m roll (part no. 50137874)

OTB 40-WH250, white, 40mm wide, self-adhesive, 25m roll (part no. 50137875)

Table 3.6: Color comparison between the sensor and the human eye.

NOTE

A detailed table with sensor measurement values can be found in the appendix (see

chapter 13 "Appendix – Sensor measurement values for RAL colors").

Floor/background Guide trace

RAL color RAL no. Measurement value of

the sensor:

Amplitude [LSB]

Suitable

trace color

1)

TNT 35/7-24V

Leuze electronic OGS 600 14

Page 17

3.3.2 Trace width

AB

C

A Guide trace; here dark trace on light background

B Free space next to guide trace

C Markings next to guide trace

B

C

The maximum width of the trace is limited only by the sensor's measurement field (see

figure 3.3). The trace must have a minimum width so that a sufficiently good contrast can be

achieved. The "Trace width" filter can be adjusted to the trace by means of a trace width

teach.

The recommended trace width is approx. 30 … 40mm.

Trace width OGS 600-280… OGS 600-140…

Maximum 266mm 106mm

Minimum 20mm 20mm

Table 3.1: Maximum/minimum trace widths

3.3.3 Free space next to the trace

To ensure error-free detection, there should not be any other marking within a distance of at

least 30mm from the actual trace.

At distances greater than 30mm from the trace, the floor can have any color.

> 30mm > 30mm

Device description

Leuze electronic OGS 600 15

Figure 3.7: Minimum distance between the guide trace and other objects on the floor

The same applies to an inverted layout with a light guide trace on a dark background.

TNT 35/7-24V

Page 18

3.4 Connection technology

All device connections are based on M12 connection technology, see chapter 5 "Electrical

connection".

NOTE

Shielding!

The shielding is connected via the M12 connector housing.

Use only shielded connection cables!

3.5 Operating and display elements

The optical guidance sensor does not have any operating elements or indicators.

The sensor is operated and its configuration checked only via the serial interface or via the

CAN bus.

Device description

Leuze electronic OGS 600 16

TNT 35/7-24V

Page 19

4 Mounting

20°

A

B

C

A Optical guidance sensor

B Reflection of reflecting surfaces

C Automated guided vehicle (AGV)

D Direction of travel

D

4.1 General mounting instructions

The device is mounted using the groove integrated in the profile. Two sliding blocks with M6

thread are included in the delivery and already inserted into the groove.

NOTE

Mount the sensor at an angle!

The sensor must be mounted at an angle of 20° to ensure that reflective surfaces have no

effect on the evaluation.

Mounting

Figure 4.1: Angled sensor mounting to prevent unwanted reflection

The sensor can be mounted using the mounting brackets included in the delivery (see

chapter 4.3 "Mounting accessories"). They ensure that the sensor is pointing at the floor at

the correct angle.

Leuze electronic OGS 600 17

TNT 35/7-24V

Page 20

4.2 Selecting a mounting location

Reliable detection of the guide trace primarily depends on how good the contrast is between

the trace and the background.

In order to select the right mounting location, several factors must be considered:

• The distance of the sensor to the trace to be detected should be 10 … 70mm.

• The guide trace must have a minimum width of 20mm.

• The linearity error of the output value depends on the distance to the floor.

• Diffuse reflection of the trace. Ideally, a jet black guide trace on a pure white background should be used.

4.3 Mounting accessories

The following items are included with the sensor:

• 2x M6 sliding blocks (inserted in the groove)

• 2x mounting brackets for mounting the sensor at an angle of 20°.

NOTE

Dimensioned drawings!

The dimensioned drawings with the installation dimensions of the sensor can be found in

Chapter 11.2.

Mounting

Leuze electronic OGS 600 18

TNT 35/7-24V

Page 21

5 Electrical connection

NOTE

The corresponding mating connectors and ready-made cables are available as accessories for all M12 connections. For further information, see chapter 12 "Order guide and

accessories".

5.1 Safety notices for the electrical connection

CAUTION

Before connecting the device, be sure that the supply voltage agrees with the value

printed on the name plate.

The device may only be connected by a qualified electrician.

Ensure that the functional earth (FE) is connected correctly. Unimpaired operation is

only guaranteed when the functional earth is connected properly.

If faults cannot be cleared, the device should be switched off and protected against

accidental use.

NOTE

Protective Extra Low Voltage (PELV)!

The OGS 600 optical guidance sensors are designed in accordance with protection class

III for supply by PELV (protective extra-low voltage with reliable disconnection).

Electrical connection

NOTE

Shielding connection!

The shielding is connected via the M12 connector housing.

Use only shielded connection cables!

NOTE

Degree of protection IP65 is achieved only if the connectors and caps are screwed into

place.

Leuze electronic OGS 600 19

TNT 35/7-24V

Page 22

5.2 Voltage supply

The OGS 600 guidance sensors are designed for a voltage supply of 18 … 30 VDC (PELV

– protective extra low voltage with reliable disconnection). The current consumption with

24 V DC is approx. 180 mA.

5.2.1 Shielding

NOTE

Shielded connection cables!

Only shielded connection cables should be used; they ensure that the housing of the

OGS 600 is connected to functional earth.

Use only shielded connection cables!

The shielding must be connected to earth potential on the connection side.

If unshielded connection cables are used, a separate cable must be routed from the

housing to the earth potential (additional earthing screw on the housing cover and in

the fastening groove).

Electrical connection

Leuze electronic OGS 600 20

TNT 35/7-24V

Page 23

5.3 Pin assignment

M12 plug

(A-coded)

M12 plug

(A-coded)

5.3.1 OGS 600-…/D3-M12.8 with RS485 interface

PWR/RS485, 8-pin M12 connector, A-coded

Pin Name Comment IN / OUT

1 VIN Operating voltage +18 … +30V DC IN

2 IO Switching input or switching output IN / OUT

3GND

4 SW_IO Switching output OUT

5 RX / TX + Signal line of RS485 interface IN / OUT

6 RX / TX - Signal line of RS485 interface IN / OUT

7 n. c. Not connected

8 n. c. Not connected

Thread FE Functional earth (housing)

Table 5.1: PWR/RS485 – Pin assignment for OGS 600 with RS485 interface

5.3.2 OGS 600-…/D2-M12.8 with RS422 interface

PWR/RS422, 8-pin M12 connector, A-coded

Pin Name Comment IN / OUT

1 VIN Operating voltage +18 … +30 VDC IN

2 IO Switching input or switching output IN / OUT

3GND

4 SW_IO Switching output OUT

5 TX + Signal line of RS422 interface OUT

6 TX- Signal line of RS422 interface OUT

7 RX + Signal line of RS422 interface IN

8 RX- Signal line of RS422 interface IN

Thread FE Functional earth (housing)

Table 5.2: PWR/RS422 – Pin assignment for OGS 600 with RS422 interface

Operating voltage 0VDC / reference

Operating voltage 0VDC / reference

Electrical connection

ground

ground

IN

IN

TNT 35/7-24V

Leuze electronic OGS 600 21

Page 24

Electrical connection

M12 plug

(A-coded)

M12 socket

(A-coded)

5.3.3 OGS 600-…/CN-M12 with CANopen and RS232 interface

PWR/RS232, 5-pin M12 connector, A-coded

Pin Name Comment IN / OUT

1 VIN Operating voltage +18 … +30 VDC IN

2 RxD Signal line of RS232 interface IN

3GND

4 SW_IO Switching output OUT

5 TxD Signal line of RS232 interface OUT

Thread FE Functional earth (housing)

Table 5.3: PWR/RS232 – Pin assignment for OGS 600 with CANopen/RS232 interface

CAN, 5-pin M12 socket, A-coded

Pin Name Comment IN / OUT

1 SHIELD CAN functional earth

2 n. c. Not connected

3 CAN_GND Reference level for CAN signal lines

4 CAN_High CAN bus A signal line IN / OUT

5 CAN_Low CAN bus B signal line IN / OUT

Thread FE Functional earth (housing)

Operating voltage 0VDC / reference

ground

IN

Table 5.4: CAN – Pin assignment for OGS 600 with CANopen/RS232 interface

Leuze electronic OGS 600 22

TNT 35/7-24V

Page 25

5.4 Switching inputs/outputs

NOTE

The devices with RS485 and RS422 interface have two IO pins:

• SW_IO (pin 4) switching output (configurable)

• IO (pin 2) switching input or switching output (configurable)

The devices with CANopen and RS232 interface have only one IO pin:

• SW_IO (pin 4) switching output (configurable)

5.4.1 Function of the SW_IO and IO switching outputs

The switching outputs are configured via index accesses only. The possible function range

is the same for both switching outputs. The switching outputs can be configured independently of each other.

Two functions are available which can be signaled via the switching output.

Trace monitoring

An upper and lower position value can be defined using two parameters. The limit values

are compared with the values of the detected trace.

If the left or the right edge of the detected trace is greater than the limit value, the switching

output is activated.

If more than one trace is detected, then the outermost edges are always used for monitoring.

The function has a hysteresis.

Electrical connection

Contrast monitoring

An upper and a lower value can be defined for contrast using two parameters. The limit

values are compared internally with the values of the contrast measured for the current

trace.

If the contrast is greater or less than the limit value, the switching output is activated.

NOTE

Deactivation of a switching output

Both switching outputs SW_IO and IO can also be deactivated independently of each

other.

Leuze electronic OGS 600 23

TNT 35/7-24V

Page 26

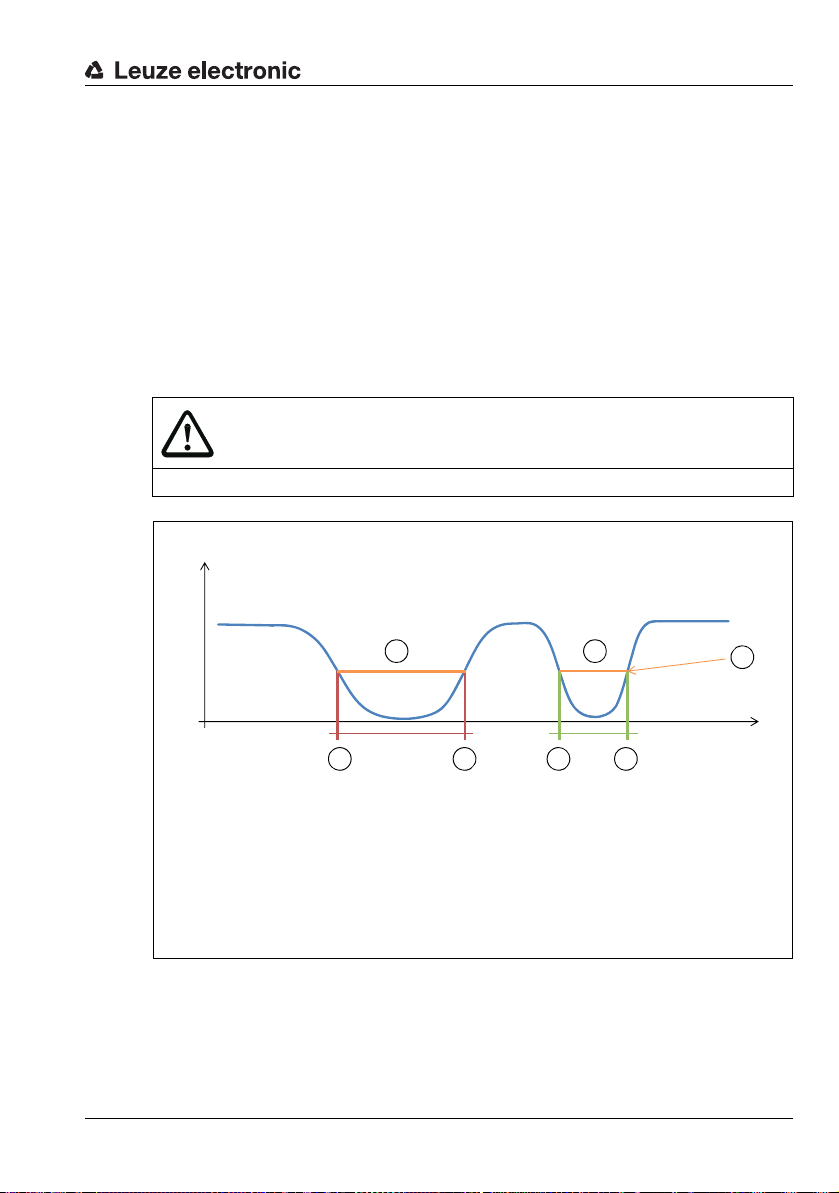

Switching behavior

1 High signal within switching points

2 High signal outside switching points

3 Hysteresis

4 Measurement value: object position or contrast

5 Upper switching point

6 Lower switching point

ON

1

OFF

ON

2

OFF

Electrical connection

3

6 5 4

Figure 5.1: Switching behavior of the switching outputs

NOTE

The switching outputs can be configured independently of each other as:

• Push-pull switching output

•PNP switching output

• NPN switching output

Leuze electronic OGS 600 24

TNT 35/7-24V

Page 27

5.4.2 Switching output SW_IO (pin 4)

The functions of the switching output are described in Chapter 5.4.1.

The switching output SW_IO is connected to pin 4 on all device models (see chapter 5.3

"Pin assignment"). The function of the switching output can be configured via indices.

Electrical connection

Name Index

Q1UserConfig 87d 2003h [6h]2 RW 0d 0d: not active

Q1SwitchPtMode 80

Q1UpperSwitchingPoint 77

Q1LowerSwitchingPoint 78

Q1Hysteresis 81

Q1LightDark 79

Qproperty 76

Index

UART

[subindex]

CANopen

2003h [4h]2 RW 0d 0d: deactivated

d

2003h [1h]2 RW 0d Upper limit.

d

2003h [2h]2 RW 0d Lower limit.

d

2003h [5h]2 RW 20d Hysteresis in absolute values.

d

2003h [3h]2 RW 0d 0d: output has high signal outside switching

d

2005h [0h]2 RW 0d 0d: switching output switches OFF

d

Index

length

[byte]

Access Default

data

Function / value [dec.]

1

: Out_PP (push-pull)

d

2

: Out_NPN

d

3

: Out_PNP

d

1

: trace monitoring

d

2

: contrast monitoring

d

Trace position in mm * 10

Contrast value in LSB

Trace position in mm * 10

Contrast value in LSB

Applies to both limits.

Unit: mm * 10 or LSB

points

1

: output has high signal within switching

d

points

1

: switching output switches ON

d

2

: switching output remains unchanged

d

Takes effect in the case of

• Activation/deactivation

• Global error

(UART index 200

], value 0001h) with detailed info in UART

[1

h

index 201

Table 5.5: Configuration options for switching output SW_IO (pin 4)

, and CAN index 2020h

d

and CAN index 2020h [2h]

d

TNT 35/7-24V

Leuze electronic OGS 600 25

Page 28

5.4.3 IO switching output/switching input (pin 2)

The functions of the switching output are described in Chapter 5.4.1.

The IO switching output is connected to pin 2 on the device models with RS485 and RS422

interface (see chapter 5.3 "Pin assignment"). The function of the switching output can be

configured via indices.

Electrical connection

Name Index

Q2UserConfig 88

Q2SwitchPtMode 85

Q2UpperSwitchingPoint 82

Q2LowerSwitchingPoint 83

Q2Hysteresis 86

Q2LightDark 84

Qproperty 76

Index

UART

[subindex]

CANopen

2004h [6h]2 RW 0d 0h: inactive

d

2004h [4h]2 RW 0d 0d: deactivated

d

2004h [1h]2 RW 0d Upper limit.

d

2004h [2h]2 RW 0d Lower limit.

d

2004h [5h]2 RW 20d Hysteresis in absolute values.

d

2004h [3h]2 RW 0d 0d: output has high signal outside switching

d

2005h [0h]2 RW 0d 0d: switching output switches OFF

d

Index

length

[byte]

Access Default

data

Function / value [dec.]

1

: Out_PP (push-pull)

h

2

: Out_NPN

h

3

: Out_PNP

h

104

: In_NPN deactivation input

h

105

: In_PNP deactivation input

h

304

: In_NPN activation input

h

305

: In_PNP activation input

h

1

: trace monitoring

d

2

: contrast monitoring

d

Trace position in mm * 10

Contrast value in LSB

Trace position in mm * 10

Contrast value in LSB

Applies to both limits.

Unit: mm * 10 or LSB

points

1

: output has high signal within switching

d

points

1

: switching output switches ON

d

2

: switching output remains unchanged

d

Takes effect in the case of

• Activation/deactivation

• Global error

(UART index 200

], value 0001h) with detailed info in UART

[1

h

index 201

d

Table 5.6: Configuration options IO switching output/switching input (pin 2)

, and CAN index 2020h

d

and CAN index 2020h [2h]

TNT 35/7-24V

Leuze electronic OGS 600 26

Page 29

5.4.4 Function of the IO switching input (pin 2)

The switching input is configured via index accesses only (see Table 5.6).

Two functions are available which can be activated via the switching input.

Activation

A high signal at the switching input activates the sensor illumination; a low signal deactivates

the sensor illumination.

Deactivation

A high signal at the switching input deactivates the sensor illumination; a low signal activates

the sensor illumination.

NOTE

Output behavior with deactivated sensor illumination

With the sensor illumination deactivated, the sensor does not deliver any measurement

values.

In this case, the output behavior of the switching output (pin 2, pin 4) with the trace monitoring or contrast monitoring function can be controlled via UART index 76

index 2005

This setting has no effect on the output of process data.

NOTE

Deactivation of the switching input

The switching input IO can also be deactivated.

) Qproperty.

h

Electrical connection

(CANopen

d

Leuze electronic OGS 600 27

TNT 35/7-24V

Page 30

5.5 Connection to the PC via RS232/RS422/RS485

A

B

C

A PC with OGS 600 software

B RS485-USB adapter (on request)

C Y-connection cable (on request)

D Optical guidance sensor

D

The devices can be configured via the RS232/RS422/RS485 interface using the Windows

software OGS600.exe or Sensor Studio.

All connections via the serial interfaces require a USB adapter which provides a virtual COM

port on the PC.

For the RS422/RS485 interface, a USB adapter and a Y-cable are available as accessories

for setting up the connection between the sensor, voltage supply and USB adapter.

Electrical connection

Figure 5.2: Connection of the OGS 600 to the PC using the RS485 interface

The adapter set and the Y-connection cable are available as accessories on request.

Information about installation and use of the software can be found in Chapter 6 "Configu-

Leuze electronic OGS 600 28

ration/diagnostic software" on page 29.

TNT 35/7-24V

Page 31

Configuration/diagnostic software

6 Configuration/diagnostic software

6.1 Installing the required software

6.1.1 System requirements

Operating system: Windows XP

Windows Vista

Windows 7

Windows 8

Windows 10

Computer: PC with USB interface version 1.1 or higher

Graphics card: Min. 1024 x 768 pixels or higher resolution

Required hard drive capacity: Approx. 10MB

Note!

It is recommended to update the operating system and the browser regularly and to install

the current Windows service packs.

6.1.2 Installation of the software

RS485-USB adapter

A driver must be installed for the USB RS485/422 interface adapter (available as an accessory). It can be found on the supplied CD. The file CDM21216_Setup.exe can be found on

the CD in the folder ..\Windows. This file must be executed by double-clicking. Admin rights

are required for correct installation.

Configuration software OGS 600

The control software for the OGS 600 does not need to be installed. This is a directly executable .exe file. No admin rights are required.

The software functions with all RS485, RS422, RS232 serial interfaces.

The software accesses the (virtual) COM port of the adapter.

Leuze electronic OGS 600 29

TNT 35/7-24V

Page 32

Configuration/diagnostic software

6.2 Starting the configuration/diagnostic software

To start the configuration software, double-click the file OGS600.exe.

6.3 Short description of the configuration/diagnostic software

The control software is intended to provide an overview of the sensor's functions. For this

purpose, measurement data and detected traces are visualized.

There is a function for recording raw values and data of the guide trace.

This can be used for configuring CANopen devices via the RS232 interface.

The control software offers the following functions

• Firmware update via UART boot loader

• Visualization of the measurement values

• Saving of measurement values

• Visualizing the detected guide traces

• Visualizing the filter settings

• Changing filter settings manually

• Performing the various teach modes for the filters

• Querying of the process data

• Reading out of valid and invalid traces

• Reading and writing indices

• Configuring the CANopen properties

Leuze electronic OGS 600 30

TNT 35/7-24V

Page 33

Configuring the sensor – Overview of functions

A

B

C

A Optical guidance sensor

B Long axis (150mm/300 mm)

C Light beam gate

D Distance

E Angle

D

E

7 Configuring the sensor – Overview of functions

7.1 Compensating the installation position of the sensor – Angle compensation teach

After installation of the device, it is recommended to perform a one-off compensation teach

in order to compensate the installation position. The compensation teach is especially

recommended if the contrast between the trace and environment to be evaluated is

extremely low. A low contrast is a value less than 5000 LSB.

Figure 7.1: Angle compensation teach for compensation of the installation position

Procedure

1. The sensor must be pointing at a light, homogeneous object.

A sheet of white paper is ideal for this purpose.

2. Perform the teach –> System Command (UART index 2

value: 193

Leuze electronic OGS 600 31

3. Read UserState (UART index 151

evaluation of the data –> wait until bit 1 (angle compensation OK) is set.

and CAN index 2000h [0h],

).

d

and CAN index 2011h [2h]),

d

d

TNT 35/7-24V

Page 34

Configuring the sensor – Overview of functions

AB

C

A Dark guide trace on light background

B Light guide trace on dark background

C Retro-reflective guide trace

7.2 Configuring the guide trace – light, dark, retro-reflective

The sensor must be preconfigured for the type of trace to be detected.

The following models exist:

• Dark guide trace on light background

• Light guide trace on dark background

• Retro-reflective guide trace

Figure 7.2: Guide trace types

Retro-reflective guide trace

The retro-reflective guide trace is a special variant of the light guide trace on a dark background. The amount of light reflected by the retro-reflective medium is greater than the

amount of light reflected by the background. For the sensor, this signal looks like a light

trace.

With this setting, the transmitting current of the LEDs for the sensor illumination is reduced

in order to fully utilize the dynamics of the electronics.

Leuze electronic OGS 600 32

TNT 35/7-24V

Page 35

Configuring the sensor – Overview of functions

Configuration of the guide trace type

Name Index

Dark trace type 2d 2000h [0h] 2 W 212d Dark trace, light background

Light trace type 2

Retro-reflective trace 2

Index

UART

[subindex]

CANopen

2000h [0h] 2 W 213d Light trace, dark background

d

2000h [0h] 2 W 214d Retro-reflective trace

d

Index

length

[byte]

Table 7.1: Configuration of the guide trace type

Querying of the guide trace type

Name Index

UserMode 75

Index

UART

[subindex]

CANopen

2002h [0h] 2 R Bit 0: 0 = light trace; 1 = dark trace

d

Index

length

[byte]

Table 7.2: Querying of the guide trace type

7.3 Offset to the edge positions

An offset can be added to the edge output values. This offset only has an effect on the output

of process data.

NOTE

If indices with edge positions are read out, they do not contain the offset.

The offset can be used to compensate off-center installation of the sensor.

Access Data

Access Data Function / value

[Dec.]

Function / value

Bit 8: 0 = inactive, 1 = retro-reflective trace

Name Index

UserOffset 109d 2010h [Ah] 2 RW 212d Offset for edge position

UART

Index

[subindex]

CANopen

Index

length

[byte]

Access Data

[Dec.]

Function / value

Unit: [ mm * 10 ]

Example:

Offset the process data output values from 0 … 3000 to -1500 … 1500.

-150mm offset: -150mm * 10 = -1500.

–> Write the value ’-1500’ in UserOffset (UART index 109

and CAN index 2010h [Ah]).

d

NOTE

If the offset is to be deactivated, the value 0 must be written.

Leuze electronic OGS 600 33

TNT 35/7-24V

Page 36

7.4 Switch

AB

C

D

A Switch type 1

B Switch type 2

C Minimum distance 30mm

D Midpoint of switch

E Left edge of guide trace

F Left edge of guide trace too wide

G Right edge of guide trace

H Right edge of guide trace too wide

"Trace width" filter = ON

GE

F H

At a switch, the sensor always outputs all detected traces.

NOTE

The users themselves must decide in which direction they want to turn.

There are two different switch types (see figure 7.3):

•Switch type 1 with parallel guide trace

•Switch type 2 with branching guide trace

Configuring the sensor – Overview of functions

Leuze electronic OGS 600 34

Figure 7.3: Type 1 and type 2 trace switches

The sensor supports both switch types.

TNT 35/7-24V

Page 37

Configuring the sensor – Overview of functions

A

B

CD

A Midpoint of a type 2 switch

B Dead zone

C Left edge of guide trace

D Right edge of guide trace

E Area with extremely low contrast

B - Dead zone:

Area in which there is no trace output. The

length depends on the angle of the branch.

Typical value: approx. 5 … 20mm.

E

NOTE

One switch can have three branches.

Switch type 2

The behavior at the midpoint of a type 2 switch depends on the trace width filter and the

angle of the branch.

For type 2 switches, it is recommended to use the "Switch" function (see chapter 7.4.1

""Switch" function – Settings for type 2 switches") in order to improve detection of the wide

trace at the midpoint of the switch, as well as to receive two trace values in the output as

soon as possible in the triangular, extremely low-contrast area after the switch.

Figure 7.4: Midpoint of type 2 switch

Leuze electronic OGS 600 35

TNT 35/7-24V

Page 38

Configuring the sensor – Overview of functions

7.4.1 "Switch" function – Settings for type 2 switches

NOTE

The "Switch" function changes several settings in the sensor.

These changes are only required for type 2 switches.

Activation of the SwitchNumber function (UART index 170d and CAN index 2012h) affects

the filters as follows:

• "Minimum contrast" filter is deactivated

• "Trace width" filter remains active/inactive -> adjustment of Tr ac eW id th Ma x

• "Minimum contrast" filter remains active/inactive

"Trace width" filter

If the "Trace width" filter is used, the maximum trace width of the filter is increased. The

minimum trace width remains unchanged.

The SwitchTraceWidthFactor factor (UART index 110

for calculating the new maximum trace width.

The calculation temporarily changes the TraceWidthMax parameter (UART index 100

CAN index 2010

[1h]) until the SwitchNumber switch function is deactivated.

h

The SwitchTraceWidthFactor factor is preset by default for a type 2 switch with one branch.

For switches with 2 branches (3 traces), the preset factor may be too small and may need

to be increased.

Calculation of the maximum trace width when the switch function is activated:

TraceWidthMax_Switch = TraceWidthMax + ( Trac e Wid thM a x * SwitchTraceWidthFactor / 100 )

The result of the calculation can be checked in TraceWidthMax. After deactivation of the

SwitchNumber function, the original value is entered in TraceWidthMax.

and CAN index 2010h [Bh]) is used

d

and

d

NOTE

If problems with the "Trace width" filter occur at a switch, the SwitchTraceWidthFactor

factor can be increased or reduced.

The change is retained after a voltage reset of the device. Resetting to the factory settings

(system command Factory Reset) restores the original value.

Why write trace number?

To ensure that the dead zone (see Figure 7.4) is as small as possible, internal parameters

for the guide trace are set on activation of the switch function when the first measurement is

performed after the query.

If the sensor detects more than one correct guide trace in the measurement cycle performed

during activation, then these traces are output via the process data.

The vehicle decides which guide trace is used. The sensor does not know the decision made

by the vehicle.

To allow optimum configuration to be performed, the sensor must be informed of the number

of the guide trace which is followed by the vehicle.

Leuze electronic OGS 600 36

TNT 35/7-24V

Page 39

Configuring the sensor – Overview of functions

The trace number is derived from the sequence in which the trace is output in the process

data (see Table 8.8).

If the trace number used by the vehicle control unit changes during an active switch function

or the second trace disappears, then the currently used trace number is transferred to the

sensor.

This does not cause the internal settings to change. These settings are only changed again

when the switch function is deactivated by writing a '0' and then reactivated.

NOTE

If a trace number which is not present is written, an error occurs. In this case, bit 13 is set

in the Status index (UART index 200

activated.

The switch function is active if bit 12 is set in the Status index (UART index 200

index 2020

).

h

Solution: Write the correct trace number.

Operational sequence of the "Switch" function

When should the SwitchNumber function be activated?

1. The system informs the vehicle that there is a switch ahead.

Ideally, this happens 10 … 200mm before the sensor reaches the midpoint of the

switch and the trace becomes wider.

2. The vehicle notes which guide trace it is currently following. The guide traces are

numbered in ascending order from 1 to 6.

The sequence is derived from the sequence in which the edges are output in the process data (see Table 8.8).

3. This trace number must be written to the SwitchNumber index (UART index 170

CAN index 2012

[0h]) or sent via the query with the process data with byte 2 PD-In1.

h

4. Internal adaptation of the values in the sensor to the trace which the vehicle is cur-

rently following takes place once only.

The effect on the output traces becomes apparent within the maximum time of one

measurement cycle (10ms) after the query is sent for the first time.

and CAN index 2020h). The switch function is not

d

and CAN

d

d

and

TNT 35/7-24V

Deactivation of the "Switch" function

1. Writing a ’0’ in SwitchNumber (UART index 170d and CAN index 2012h [0h])

or

2. Writing of ’0’ in byte 2 PD-In1 during the process data query.

Leuze electronic OGS 600 37

Page 40

Configuring the sensor – Overview of functions

7.4.2 Index accesses for activation of the "Switch" function

Name Index

SwitchNumber 170d 2012h [0h]2 W 0 0d = inactive

SwitchTraceWidthFactor 110

Index

UART

[subindex]

CANopen

2010h [Bh] 2 RW 150 Factor in % for increase in Tra ce -

d

Index

length

[Byte]

Access Default value

data [Dec.]

Info

1

= trace no. 1

d

2

= trace no. 2

d

3

= trace no. 3

d

4

= trace no. 4

d

5

= trace no. 5

d

6

= trace no. 6

d

WidthMax parameter when switch

function is activated

Table 7.3: Index accesses for activation of the "Switch" function

Type Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

Query PD 13

Node no./

identifier

PD type PD-In1

04h 0

h

(data in)

= off

d

1

= trace no. 1

d

2

= trace no. 2

d

3

= trace no. 3

d

4

= trace no. 4

d

5

= trace no. 5

d

6

= trace no. 6

d

PD-In2

(reserve)

CRC

0

h

CRC

Table 7.4: Settings for "Switch" function with process data query in byte 2

Leuze electronic OGS 600 38

TNT 35/7-24V

Page 41

7.5 "Trace width" filter

AB

CD

x Edge position

y Amplitude reception signal

A Left edge of guide trace

B Right edge of guide trace

C Trace too wide according to active "Trace width" filter

D Trace OK

E Teac h th r esh old

E

AB

If the sensor is to output only traces which correspond to a certain trace width, the "Trace

width" filter can be activated.

The filter value can be set to the trace by means of a teach or manually by entering the

values in the corresponding indices.

Traces filtered out by the filter can be read out via the TraceInvalidSubPixel index (UART

index 213

During the trace width teach, the TraceTeachThr parameter is calculated. The position of

the left and right edge is determined for the amplitude of this threshold. If a trace is detected

which does not allow the trace width to be calculated with the threshold determined during

the teach, then the threshold is adapted for this particular trace. The taught threshold is used

as soon as the amplitude of the found background-trace combination permits this.

The trace width depends on the value of this threshold.

and CAN index 2027h [1h]…[Ch]).

d

CAUTION

y

Configuring the sensor – Overview of functions

Figure 7.5: Application of the "Trace width" filter using a dark trace as an example

Leuze electronic OGS 600 39

x0 3000

TNT 35/7-24V

Page 42

Configuring the sensor – Overview of functions

7.5.1 Teaching the trace width

The TraceWidthTol parameter (UART Index 102d and CAN Index 2010h [3h]) is used during

the teach in order to define the upper and lower limit for the trace width on the basis of the

currently measured trace width.

Calculation of the values in the sensor:

Trace width = │Position of left edge - Position of right edge│

Trace Wi dt hM ax = Trace width + Tr ac eW id th Tol

Trace Wi dt hM in = Trace width - Trac eW id th Tol

7.5.2 Manual configuration of the trace width

If the trace width is to be configured manually, the values can be written directly to the

parameters TraceWidthMax (UART index 100

WidthMin (UART index 101

Remember to apply the factor 10 during conversion: 10

CAUTION

If a trace width teach is performed, manually configured trace width values are overwritten.

and CAN index 2010h [2h]).

d

7.5.3 Process data information for the "Trace width" filter

If the number of detected traces which, owing to the "Trace width" filter, are not output in the

process data is greater or equal to one, then bit 3 is set in process data byte 2 Status PD.

and CAN index 2010h [1h]) and Trace-

d

corresponds to 1mm.

d

Leuze electronic OGS 600 40

TNT 35/7-24V

Page 43

Configuring the sensor – Overview of functions

7.5.4 Index overview for the "Trace width" filter

Bit counting method: bit0 … bit15

Name Index

Activation of

"Trace width" filter

Deactivation of

"Trace width" filter

Trace width teach 2

TraceWidthMax 100

TraceWidthMin 101d 2010h [2h] 2 RW (290d) Minimum trace width

TraceWidthTol 102

TraceTeachThr 112

Status 200

UserMode 75

Index

UART

[subindex]

CANopen

2d 2000h [0h] 2 W 229d System command

2000h [0h] 2 W 230d System command

2

d

2000h [0h] 2 W 194d System command

d

2010h [1h] 2 RW (490d) Maximum trace width

d

2010h [3h] 2 RW (100d) Trace width tolerance

d

2010h [Dh] 2 R Determined during teach

d

2020h [1h] 2 R Bit no. 5 If the number of filtered-out traces is

d

2002h [0h] 2 R Bi t no. 2 If the bit is set, then the "Trace width"

d

Index

length

[byte]

Access Data / (default

value)

Info

For manual configuration

or result from teach

Value: [ mm * 10 ]

For manual configuration

or result from teach

Value: [ mm * 10 ]

Only required for teach

Value: [ mm * 10 ]

≥ 1, the bit is set.

See also process data status byte, bit

no. 3 (Chapter 8.1.4.1)

filter is active.

Table 7.5: Index accesses for the "Trace width" filter

Leuze electronic OGS 600 41

TNT 35/7-24V

Page 44

Configuring the sensor – Overview of functions

AB

C

D

x Edge position

y Reception signal amplitude

A Left edge of guide trace

B Right edge of guide trace

C Trace width

D Amplitude of background

E Amplitude of guide trace

F Contrast

G Warning threshold for minimum contrast

H Minimum contrast (TraceContrastMin)

J Verification of minimum contrast.

The second, right trace is not output because the minimum contrast is not fulfilled.

G

E

F

H

J

7.6 "Minimum contrast" filter

The filter for the minimum contrast queries whether the brightness of the background and

the brightness of the trace have a minimum difference.

This minimum difference can be taught based on a reference trace, or the value can be set

manually.

y

0 3000

Figure 7.6: Application of the "Minimum contrast" filter using a dark trace as an example

7.6.1 Teaching the minimum contrast

Leuze electronic OGS 600 42

The value of the TraceContrastTol parameter (UART index 105d and CAN index 2010h [6h])

is used for calculating a minimum threshold for the contrast using the contrast value

measured during the teach. The value appears as a percentage [%] in the index.

Calculation in the sensor:

Contrast = │Amplitude_environment - Amplitude_trace│

TraceContrastMin = Contrast - ( Contrast * TraceContrastTol /100 )

x

TNT 35/7-24V

Page 45

Configuring the sensor – Overview of functions

7.6.2 Manual configuration of the minimum contrast

If the minimum contrast is to be configured manually, it can be written directly to the TraceContrastMin parameter (UART index 103

CAUTION

If a minimum contrast teach is performed, a manually configured minimum contrast value

is overwritten.

7.6.3 Warning for minimum contrast

The warning threshold corresponds to a percentage deviation from the minimum contrast

TraceContrastMin (UART index 103

the minimum contrast is calculated using the TraceContrastWarning factor (UART

index 104

Calculation:

and CAN Index 2010h [5h]). There is no index for calling up this value directly.

d

TraceContrastWarning_threshold = TraceContrastMin + ( TraceContrastMin * TraceContrastWarning )

7.6.4 Process data information for the "Minimum contrast" filter

In the status byte of the process data, there are two bits for information relating to the

minimum contrast:

•Bit1: Minimum contrast warning

•Bit4: Minimum contrast error

Bit 1 Minimum contrast warning is set if the number of detected traces for which the

minimum contrast is less then the warning threshold, is greater than or equal to one.

Bit 4 Minimum contrast error is set if the number of detected traces for which the contrast is

less than TraceContrastMin, is greater than or equal to one.

and CAN index 2010h [4h]) as a value in [LSB].

d

and CAN index 2010h [4h]). The warning threshold for

d

Leuze electronic OGS 600 43

TNT 35/7-24V

Page 46

Configuring the sensor – Overview of functions

7.6.5 Index overview for the "Minimum contrast" filter

Bit counting method: bit0 … bit15

Name Index

Activate filter 2d 2000h [0h] 2 W 231d System command

Deactivate filter 2

Teaching the minimum

contrast

TraceContrastMin 103

TraceContrastWarning 104

TraceContrastTol 105

Status 200

Status 200

UserMode 75

Index

UART

[subindex]

CANopen

2000h [0h] 2 W 232d System command

d

2

2000h [0h] 2 W 195d System command

d

2010h [4h] 2 RW (5500d) Result from teach or manual entr y, unit:

d

2010h [5h]2 RW (20d) Factor for calculation of warning thresh-

d

2010h [6h]2 RW (30d) Tolerance is used in teach event, unit:

d

2020h [1h] 2 R Bit no. 6 1 = Minimum contrast error

d

2020h [1h] 2 R Bit no. 3 1 = Minimum contrast warning

d

2002h [0h] 2 R Bi t no. 3 If bit = 1, then "Minimum contrast" filter

d

Index

length

[byte]

Access Data / (default

value)

Info

[LSB]

old, unit [%]

[%]

See also process data status byte, bit

no. 4 (Chapter 8.1.4.1)

See also process data status byte, bit

no. 1 (Chapter 8.1.4.1)

is active.

Table 7.6: Index accesses for the "Minimum contrast" filter

Leuze electronic OGS 600 44

TNT 35/7-24V

Page 47

7.7 "Trace amplitude" filter

AB

C

D

x Edge position

y Reception signal amplitude

A Left edge of guide trace

B Right edge of guide trace

C Trace width

D Amplitude of background

E Amplitude of guide trace

F Invalid trace amplitudes (red area)

G TraceAmplitudeMin value

H TraceAmplitudeWarning value

G

E

F

H

The filter is based on the assumption that the guide trace tape processed in a system is the

same throughout. If this is the case, then the guide trace tape is a known constant. As a

result, all other markings with a different amplitude can be filtered out.

It is therefore recommended to select a guide trace tape which is as light as possible (white)

or as dark as possible (black) so that there are no markings which are darker or lighter than

the optical trace.

The filter for trace amplitude is the limit value TraceAmplitudeMin (UART index 106

CAN index 2010

trace signal is greater than the limit value. There is a warning threshold which is set using

the TraceAmplitudeWarning parameter (UART index 107

y

[7h]) which marks as incorrect all traces for which the amplitude of the

h

Configuring the sensor – Overview of functions

and

d

and CAN index 2010h [8h]).

d

0 3000

Figure 7.7: Application of the "Trace amplitude" filter using a dark trace as an example

Leuze electronic OGS 600 45

x

TNT 35/7-24V

Page 48

Configuring the sensor – Overview of functions

7.7.1 Teaching the trace amplitude

The TraceAmplitudeTol value (UART index 108d and CAN index 2010h [9h]) is used for

setting the TraceAmplitudeMin limit value (UART index 106

the "Trace amplitude" filter during the teach.

Calculation of dark guide trace:

TraceAmplitudeMin = Amplitude_trace [LSB] + Trace Amp l itu deTo l [LSB]

Calculation of light guide trace:

TraceAmplitudeMin = Amplitude_trace [LSB] - TraceAmplitudeTol [LSB]

7.7.2 Manual configuration of the trace amplitude

If the trace amplitude limit value is to be configured manually, it can be written directly to the

TraceAmplitudeMin parameter (UART index 106

[LSB].

CAUTION

If a trace amplitude teach is performed, a manually configured trace amplitude limit value

is overwritten.

7.7.3 Warning for trace amplitude

The warning threshold corresponds to a percentage deviation from the trace amplitude limit

value TraceAmplitudeMin (UART index 106

The warning threshold for the trace amplitude is calculated using the

TraceAmplitudeWarning factor (UART index 107

index for calling up the calculated value directly.

Calculation of dark guide trace:

TraceAmplitudeWarning_threshold = TraceAmplitudeMin [LSB] - ( TraceAmplitudeMin [LSB] * Tra c eA mpl itu deW ar nin g )

and CAN index 2010h [7h]) as a value in

d

and CAN index 2010h [7h]).

d

and CAN index 2010h [8h]). There is no

d

and CAN index 2010h [7h]) for

d

TNT 35/7-24V

Calculation of light guide trace:

TraceAmplitudeWarning_threshold = TraceAmplitudeMin [LSB] + ( TraceAmplitudeMin [LSB] * T raceAmplitudeWarning )

Leuze electronic OGS 600 46

Page 49

Configuring the sensor – Overview of functions

7.7.4 Process data information for the "Trace amplitude" filter

In the status byte of the process data, there are two bits for information relating to the trace

amplitude:

•Bit2: Trace amplitude warning

•Bit5: Trace amplitude error

The Trace amplitude warning bit is set if the number of detected traces for which the trace

amplitude is greater (dark guide trace) or less (light guide trace) than the warning threshold,

is greater than or equal to one.

The Trace amplitude error bit is set if the number of detected traces for which the contrast

is greater (dark guide trace) or less (light guide trace) than TraceAmplitudeMin, is greater

than or equal to one.

7.7.5 Index overview for the "Trace amplitude" filter

Bit counting method: bit0 … bit15

Name Index

Activate filter 2

Deactivate filter 2

Teaching the minimum

contrast

TraceAmplitudeMin 106

TraceAmplitudeWarning 107

TraceAmplitudeTol 108

Status 200

Status 200

UserMode 75

Index

UART

[subindex]

CANopen

2000h [0h] 2 W 233d System command

d

2000h [0h] 2 W 234d System command

d

2000h [0h] 2 W 196d System command

2

d

2010h [7h] 2 RW (2500d) Result from teach or manual change,

d

2010h [8h]2 RW (20d) Factor for calculation of warning thresh-

d

2010h [9h] 2 RW (1000d) During teach:

d

2020h [1h] 2 R Bit no. 7 1 = Trace amplitude error

d

2020h [1h] 2 R Bit no. 4 1 = Trace amplitude warning

d

2002h [0h] 2 R Bit no. 4 If bit = 1, then "Trace amplitude" filter

d

Index

length

[byte]

Access Data / (default

value)

Table 7.7: Index accesses for the "Trace amplitude" filter

Info

unit [LSB]

old, unit [%]

Tolerance for calculation of minimum

threshold, unit [LSB]

See also process data status byte, bit

no. 5 (Chapter 8.1.4.1)

See also process data status byte, bit

no. 2 (Chapter 8.1.4.1)

is active

TNT 35/7-24V

Leuze electronic OGS 600 47

Page 50

Configuring the sensor – Overview of functions

7.8 Index overview – More data on correct and incorrect traces

It is also possible to access the detected and filtered traces without accessing the process

data. In doing so, additional information on the traces can be retrieved: