Leuze Electronic MC388-S1C2-A, MC388-S1C5-A, MC388-S1C10-A, MC388-S1R2-A, MC388-S1 R5-A User guide

...Page 1

MC3x

Magnetically Coded Sensors with MSI-MC3x Safety Relays

EN 2012/10 - 700021

We reserve the right to

make technical changes

SAFE IMPLEMENTATION AND OPERATION

Original operating instructions

Page 2

© 2012

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.de

Leuze electronic MC3x 2

Page 3

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Other applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Approved purpose and foreseeable improper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Responsibility for safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Device overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Start/restart interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Automatic start/restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Contactor monitoring (EDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Selecting the position and arrangement of sensor and actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Mounting and aligning sensor and actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.1 Checklist - correct mounting of sensor and actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.3 Mounting the Safety Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Terminal assignments of the Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1.1 MSI-MC310 Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.2 Sensor pin assignment (1NC/1NO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.3 MSI-MC311 Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 Sensor pin assignment (2NO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.3 Connection examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3.1 Connection examples with MC3xS1x sensors and MSI-MC310 Safety Relay . . . . . . . . . . . . . . . . 31

7.3.2 Connection examples with MC3xS2x sensors and MSI-MC311 Safety Relay . . . . . . . . . . . . . . . . 33

7.4 Connecting to the machine control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.5 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.6 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.7 Unlocking start/restart interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1 Before the initial start-up and following modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.1 Checklist – before the initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2 To be performed periodically by competent persons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3 To be performed daily by the operating personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3.1 Check list – daily or at change of shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Leuze electronic MC3x 3

Page 4

10 Rectifying the fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.1 What to do in case of failure? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.2 Rectifying the fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11 Disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

12 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

13.1 Magnetically Coded Sensors, actuator, contact set 1NC/1NO . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

13.2 Magnetically Coded Sensors, actuator, contact set 2NO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13.3 MSI-MC310 Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.4 MSI-MC311 Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

14 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

16 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Leuze electronic MC3x 4

Page 5

1 About this document

1.1 Other applicable documents

The information on the MC3x Magnetically Coded Sensor is divided into two documents. Document “MC3x

Application information” contains only the most important safety notices.

For safe implementation, testing and operation, you must download document “MC3x Magnetically Coded

Sensors with MSI-MC3x Safety Relay, safe implementation and operation” from

• http://www.leuze.com/

or request it from

• service.protect@leuze.de or

• Tel. +49 8141 5350-111

Table 1.1: Documents on the MC3x Magnetically Coded Sensors with Safety Relay

Purpose and target group Title Source

About this document

Detailed information for all

users

Basic information for technicians and operating company

MC3x Magnetically Coded Sensors

with MSI-MC3x Safety Relay

Safe implementation and operation

MC3x Magnetically Coded Sensors

with MSI-MC3x Safety Relay

Application information

1.2 Used symbols and signal words

Table 1.2: Warning symbols and signal words

Symbol indicating dangers to persons

NOTICE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger

avoidance are not followed.

CAUTION Signal word for minor injury

Indicates dangers that may result in minor injury if the measures for danger

avoidance are not followed.

WARNING Signal word for serious injury

Indicates dangers that may result in serious or fatal injury if the measures for

danger avoidance are not followed.

On the Internet, download from:

http://www.leuze.com/

Print document part no. 70002

included in the delivery contents

of the Magnetically Coded Sensor

DANGER Signal word for life-threatening danger

Indicates dangers with which serious or fatal injury is imminent if the measures

for danger avoidance are not followed.

Table 1.3: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

Leuze electronic MC3x 5

Symbols for action steps

Text passages with this symbol instruct you to perform actions.

Page 6

About this document

Table 1.4: Terms and abbreviations

EDM External Device Monitoring

OSSD Output Signal Switching Device

RES Start/REStart interlock

PDF-M Magnetically Coded Sensors (Proximity Devices with defined behavior under

Fault conditions) with automatic monitoring (Self-Monitoring)

PDF-S Magnetically Coded Sensors (Proximity Devices with defined behavior under

Fault conditions) with Single fault tolerance

PFH

d

MTTF Mean time to a dangerous failure

PL Performance Level

2NO Two contacts in "open" state without the presence of an actuator

xxx Placeholder for version

1.3 Checklists

The checklists (see chapter 8 „Testing“) serve as a reference for the machine manufacturer or supplier.

They replace neither testing of the complete machine or system prior to the initial start-up nor their periodic

testing by a competent person. The checklists contain minimum testing requirements. Depending on the

application, other tests may be necessary.

Probability of a dangerous Failure per Hour

Probability of dangerous Failure per Hour

Mean Time To Failure

Leuze electronic MC3x 6

Page 7

2 Safety

Before using the MC3x Series, a risk evaluation must be performed according to valid standards (e.g.

EN ISO 12100-1, EN ISO 13849-1, EN ISO 14121). The result of the risk assessment determines the

required safety level of the Safety Relay, sensor and actuator.

The realizable category of integration in control circuits acc. to EN ISO 13849-1 is dependent on the used

contact block, wiring and evaluation.

For mounting, operation and testing, document “MC3x Magnetically Coded Sensors with MSI-MC3x

Safety Relay”, the application information as well as all relevant national and international standards, regu-

lations, rules and directives must be observed. Relevant and supplied documents must be observed,

printed and handed to the affected personnel.

Before working with Safety Relay, sensor and actuator completely read and understand the documents

applicable to your task.

In particular, the following national and international legal regulations apply for the start-up, technical

inspections and work with safety components:

• Machinery directive 2006/42/EC

• Electromagnetic compatibility directive 2004/108/EC

• EN 1088, Interlocking devices associated with guards

• EN 60204-1, Electrical equipment of machines

• EN 60947-5-3, Requirements for proximity switches

• Use of Work Equipment Directive 89/655/EEC supplemented by Directive 95/63 EC

• OSHA 1910 Subpart 0

• Safety regulations

• Accident-prevention regulations and safety rules

• Ordinance on Industrial Safety and Health and Labor Protection Act

• Device Safety Act

Safety

For safety-related information you may also contact the local authorities (e.g., industrial inspec-

torate, employer's liability insurance association, labor inspectorate, occupational safety and

health authority).

2.1 Approved purpose and foreseeable improper operation

WARNING

A running machine can cause severe injuries!

Make certain that, during all conversions, maintenance work and inspections, the system is securely

shut down and protected against being restarted.

Leuze electronic MC3x 7

Page 8

2.1.1 Proper use

• Safety Relay, sensor and actuator are intended for use in protective door monitoring in accordance

with EN 1088 and EN 60947-5-3.

• They are used for the safety-related monitoring of moveable guards and, thus, for the protection of

persons at entry or access areas of points of operation on machines and systems (e.g., protective

door, sliding gate, protective hoods).

• Safety Relay, sensor and actuator must only be used after they have been selected in accordance

with the respectively applicable instructions and relevant rules, standards and regulations regarding

labor protection and safety at work, and after they have been mounted on the machine, connected,

commissioned, and checked by a competent person.

• When selecting the Safety Relay, sensor and actuator, it must be ensured that their safety-related

capability meets or exceeds the required Performance Level ascertained in the risk assessment. For

the table of safety-related characteristic parameters, see chapter 13 „Technical data“.

• The MC3x sensors may only be operated with the approved MC3x actuators and MSI-MC3x Safety

Relays. Proper function with respect to safety can be ensured only if compatible components are

used.

• Safety Relay, sensor and actuator must be in perfect condition and periodically inspected by competent persons.

• If the point of operation can be reached within the stopping time of the dangerous process, a Safety

Locking Device must be used instead of the Magnetically Coded Sensor.

• The guard must be dimensioned and mounted in such a way that reaching or stepping around is not

possible.

• MC3x only reports persons upon opening of the guard, not whether persons are located in the danger zone. For this reason, a start/restart interlock in the safety chain is essential for access safeguarding.

• Sensor and actuator must be connected to the fixed or moveable guard in a permanent and tamperproof manner. The mounting conditions must be observed (see chapter 6 „Mounting“).

• The sensors and their actuators are to be protected against strong physical shocks and vibrations.

Observe the permissible environmental conditions for storage and operation (see chapter 13

„Technical data“).

• Sensor and actuator must be protected against foreign bodies (e.g., iron filings and blasting agents).

• The normally closed contacts of the MSI-MC310 are used to signal the state. Use as safety-related

contacts is not permitted.

• Sensor and actuator must be connected in such a way that a dangerous process can only be activated while the guard is closed and so that a stop command that ends the dangerous process is triggered upon opening of the guard.

• Cable gland, insulation materials and connecting wires of the appropriate protection rating are to be

used.

• Safety Relay, sensor and actuator must be replaced after a maximum of 20 years (see chapter 13

„Technical data“). Repairs or the exchange of parts subject to wear and tear do not extend the ser

vice life.

• Damaged components must be replaced immediately.

• Sensor or actuator must neither be tampered with nor may their correct position be changed.

• External magnets must not be used nor may the contacts be bridged.

• No structural changes may be made to Safety Relay, sensor or actuator. When manipulating, the

protective function is no longer guaranteed. In addition, all guarantee claims against the manufacturer shall no longer apply.

Safety

-

2.1.2 Foreseeable misuse Any use other than that defined under the “approved purpose” or which goes beyond that use of the Safety

Relay, sensor and actuator is considered improper use!

Leuze electronic MC3x 8

Page 9

Safety Relay, sensor and actuator must not be used under the following conditions, .e.g.:

• The safety of multiple persons is dependent on the function of Safety Relay, sensor and actuator

(e.g. nuclear power plants, trains, aircraft, motor vehicles, incinerators, medical devices)

• Where subjected to strong physical shocks or in potentially explosive or easily flammable atmospheres

• Danger posed by ejected objects or the spraying of hot or hazardous liquids from within the danger

zone

• Presence detection of persons in danger zones

• Looping into the safety circuit parts that are not relevant to safety

• The combination of non-approved parts with Safety Relay, sensor or actuator

• Combination with non-compatible controls (current limiting, logic)

• Mounting positions that enable reaching or stepping around

• Using the sensor or actuator as limit stop

• Insufficiently stable mounting locations or unsecured mounting of sensor or actuator

• Mounting on ferromagnetic materials.

2.2 Competent persons

Prerequisites for competent persons:

• They have a suitable technical education.

• They know the rules and regulations for occupational safety, safety at work and safety technology

and can assess the safety of the machine.

• They know the instructions for the safety components and the machine.

• They have been instructed by the responsible person on the mounting and operation of the machine,

the Safety Relay and the sensor with actuator.

Safety

2.3 Responsibility for safety

Manufacturer and operating company must ensure that the machine and Safety Relay, sensor and actu-

ator used function properly and that all affected persons are adequately informed and trained.

The type and content of all imparted information must not lead to unsafe actions by users.

The manufacturer of the machine is responsible for:

• safe machine construction

• safe implementation of Safety Relay, sensor and actuator

• imparting all relevant information to the operating company

• adhering to all regulations and directives for the safe starting-up of the machine

The operating company is responsible for:

• instructing the operator

• maintaining the safe operation of the machine

• adhering to all regulations and directives for occupational safety and safety at work

• regular testing by competent persons

2.4 Exemption of liability

Leuze electronic GmbH & Co. KG is not liable in the following cases:

• Safety Relay, sensor and actuator are not used as intended

• Reasonably foreseeable misuse is not taken into account

• Safety notices are not adhered to

• Mounting and electrical connection are not properly performed

• Proper function is not tested (see chapter 8 „Testing“).

• Combination of sensor and actuator with controls,

• which have not been designed to be safety-oriented

Leuze electronic MC3x 9

Page 10

• for which the current limits are not compatible

• which have not been programmed to be compatible with the respective contact set

• although a PDF system certified in accordance with EN 60947-5-3 was provided

Safety

Leuze electronic MC3x 10

Page 11

3 Device description

1

2

3

1

1

2

2

The sensor system consists of the MC3x sensor, the MC3xA actuator and the corresponding MSI-MC3x

Safety Relay.

The sensor contains a special combination of reed contacts that are contactlessly activated by the coded

magnetic field of the actuator. For guards that are accessible from behind, a reset button (RES) can be

connected to the MSI-MC3x for manual starting. Evaluation of the RES signal is monitored edge-depen-

dent.

If, for example, a door is opened, the actuator mounted here is separated from the sensor, which is located

on the stationary part of the guard. If the change in the position of the actuator reaches the maximum value

of the defined distance, the switching state is detected by the Safety Relay connected to the sensor and

is signaled to the control via two fail-safe OSSD contacts.

As a result, risky machine movements can only be executed while the guard is closed or if a stop command

is executed while the guard is being opened.

Moreover, additional switching elements can be integrated in the safety circuit. The monitoring of relays or

contactors is possible via their feedback contacts K3, K4 in the start circuit of the MSI-MC3x.

Due to the closed design of the sensors, they can also be used in critical environmental conditions (e.g.,

in areas where there is exposure to dust).

The system offers a high degree of safety and satisfies the following standards:

• Performance Level (PL) e (EN ISO 13849-1: 2008)

• Safety category 4 (EN ISO 13849-1:2008)

Depending on the application, various MC3x series are available.

Device description

1 Sensor

2 Actuator

3 Safety Relay

Figure 3.1: MC3x series with MSI-MC3x

Leuze electronic MC3x 11

Page 12

3.1 Device overview

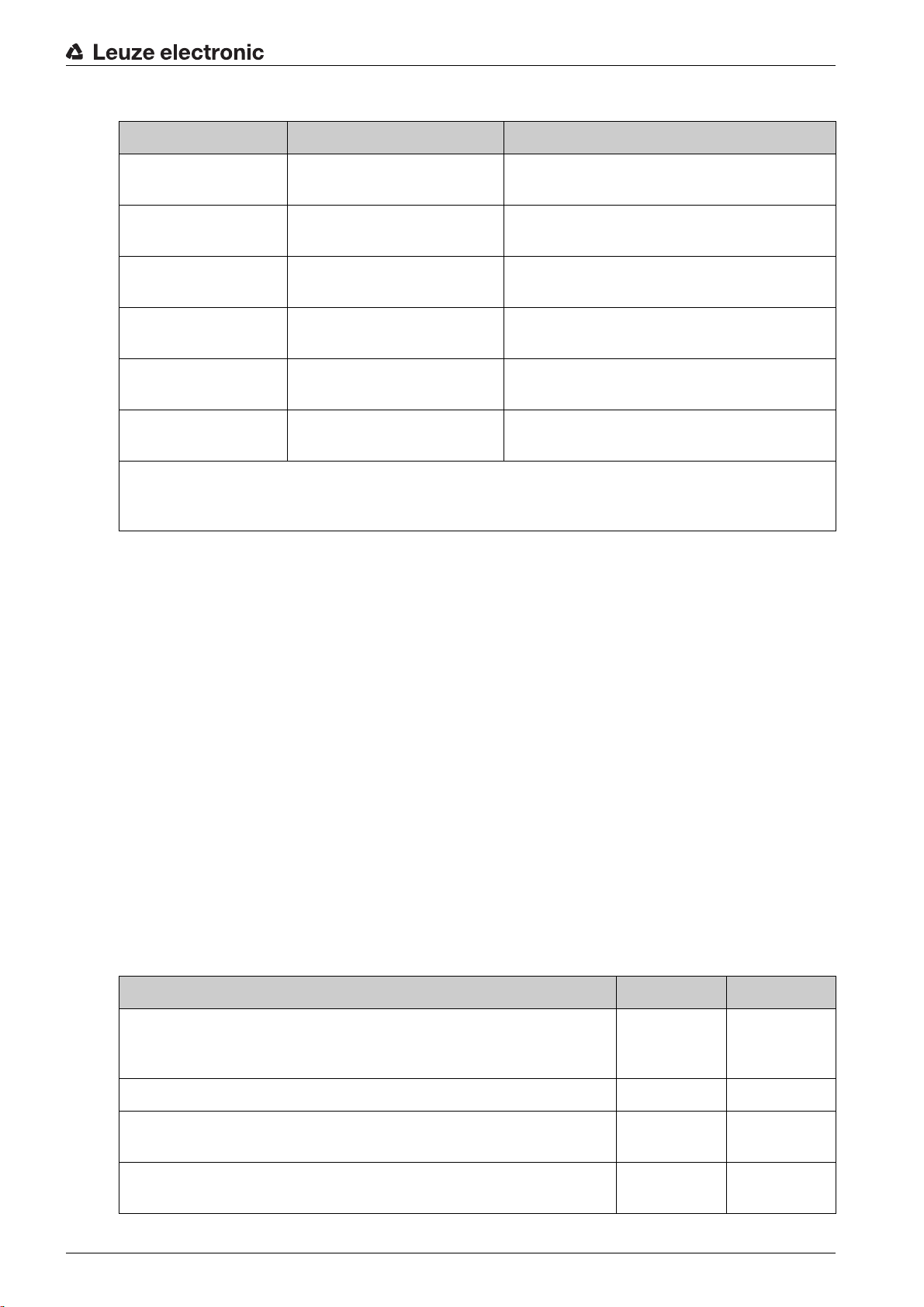

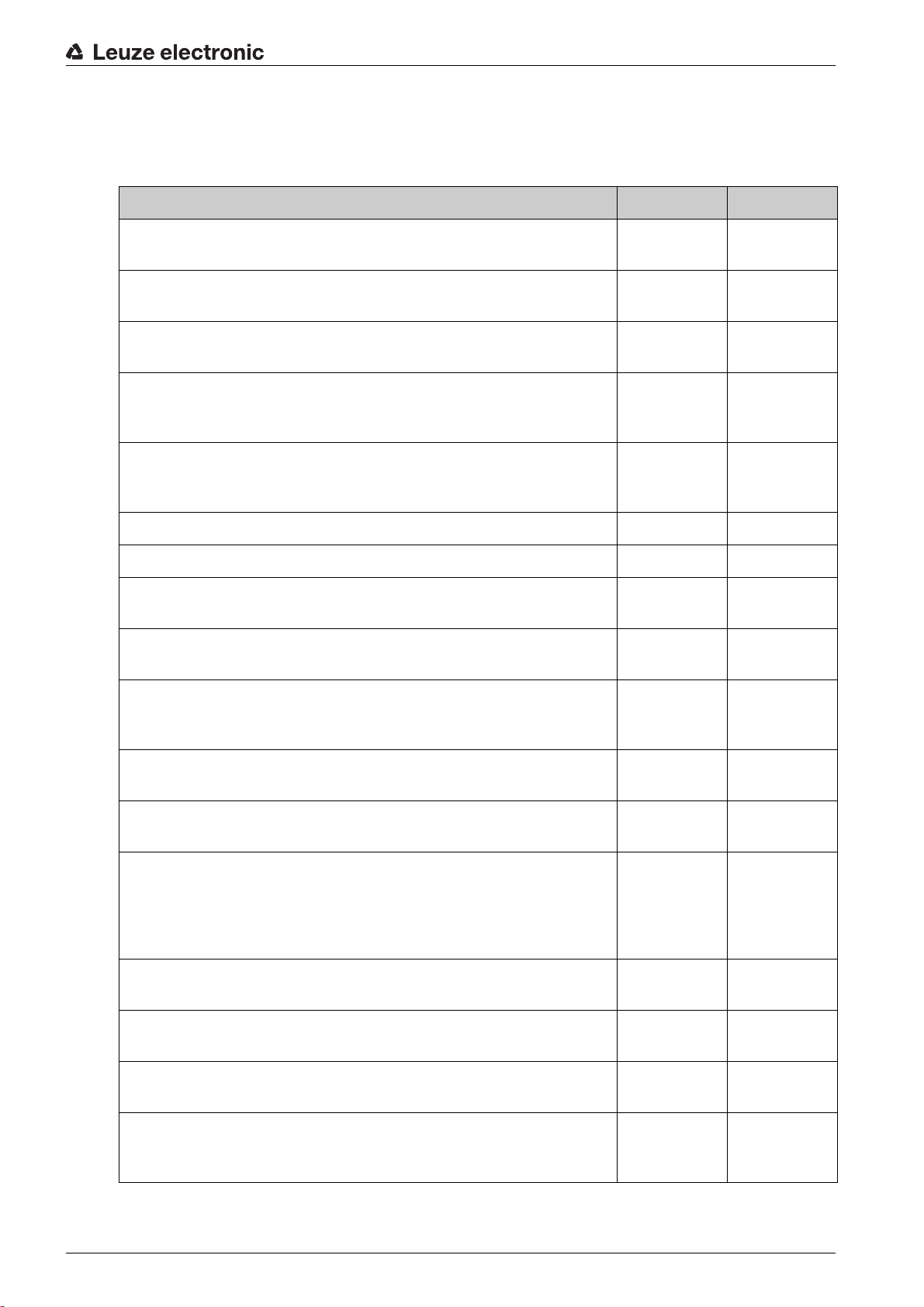

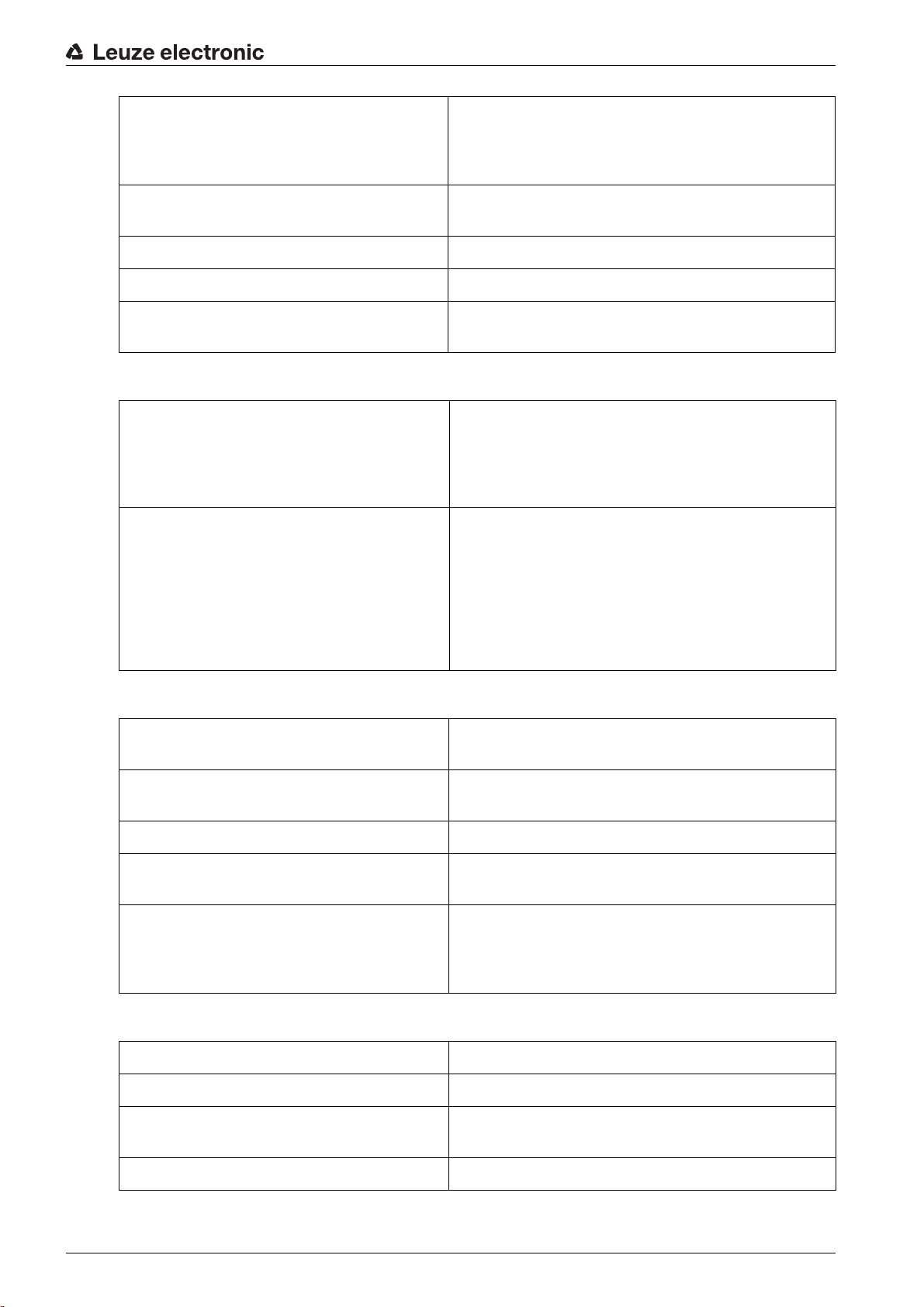

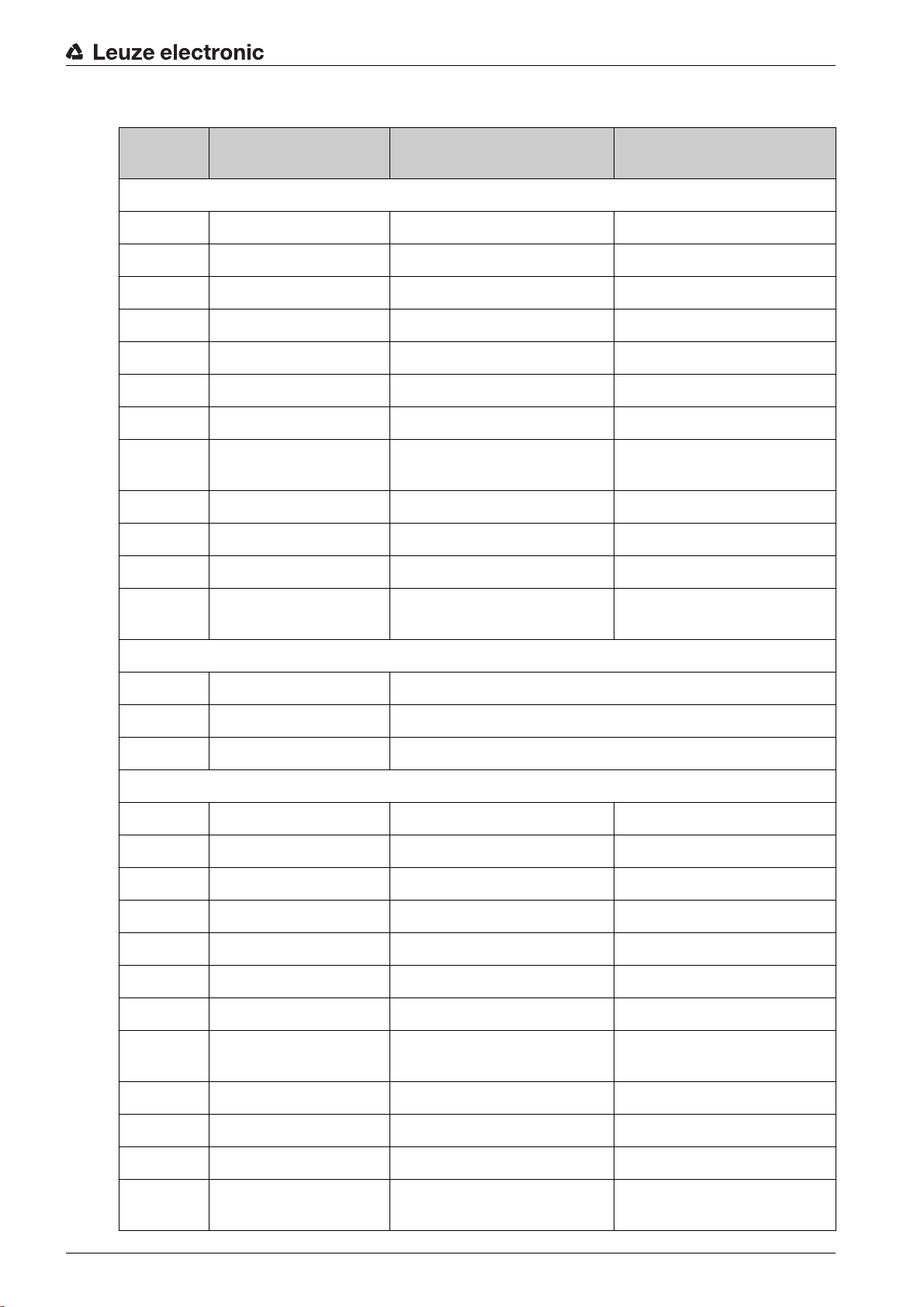

Table 3.1: Overview of the product variants of the MC3x series with contact set 1NC/1NO

Device description

Sensor Housing Switching distance

Sao /OFF/ Sar

MC388-S1x Cuboid

< 6 mm, > 13 mm, > 30 mm 2 m-, 5 m-, 10 m-PVC con-

max. 88 mm x 25 mm

MC336-S1x Cuboid

< 3 mm, > 8 mm, > 11 mm 2 m-, 5 m-, 10 m-PVC con-

max. 36 mm x 26 mm

Connection

nection cable with wire-end

sleeves

2 m, 5 m, 10 m PUR connection cable with wire-end

sleeves

0.2 m PVC connection

cable with M12 plug

M8 plug

nection cable with wire-end

sleeves

2 m, 5 m, 10 m PUR connection cable with wire-end

sleeves

0.2 m PVC connection

cable with M12 plug

M8 plug

MC330-S1x Cylinder

max. 30 mm, round

< 6 mm, > 12 mm, > 14 mm 2 m-, 5 m-, 10 m-PVC con-

nection cable with wire-end

sleeves

2 m, 5 m, 10 m PUR connection cable with wire-end

sleeves

0.2 m PVC connection

cable with M12 plug

M8 plug

Table 3.2: Overview of the product variants of the MC3x series with contact set 2NO

Sensor Housing Switching distance

Connection

Sao /OFF/ Sar

MC388-S2x Cuboid

max. 88 mm x 25 mm

< 9 mm, > 19 mm, > 22 mm 2 m-, 5 m-, 10 m-PVC con-

nection cable with wire-end

sleeves

0.2 m PVC connection

cable with M12 plug

M8 plug

Leuze electronic MC3x 12

Page 13

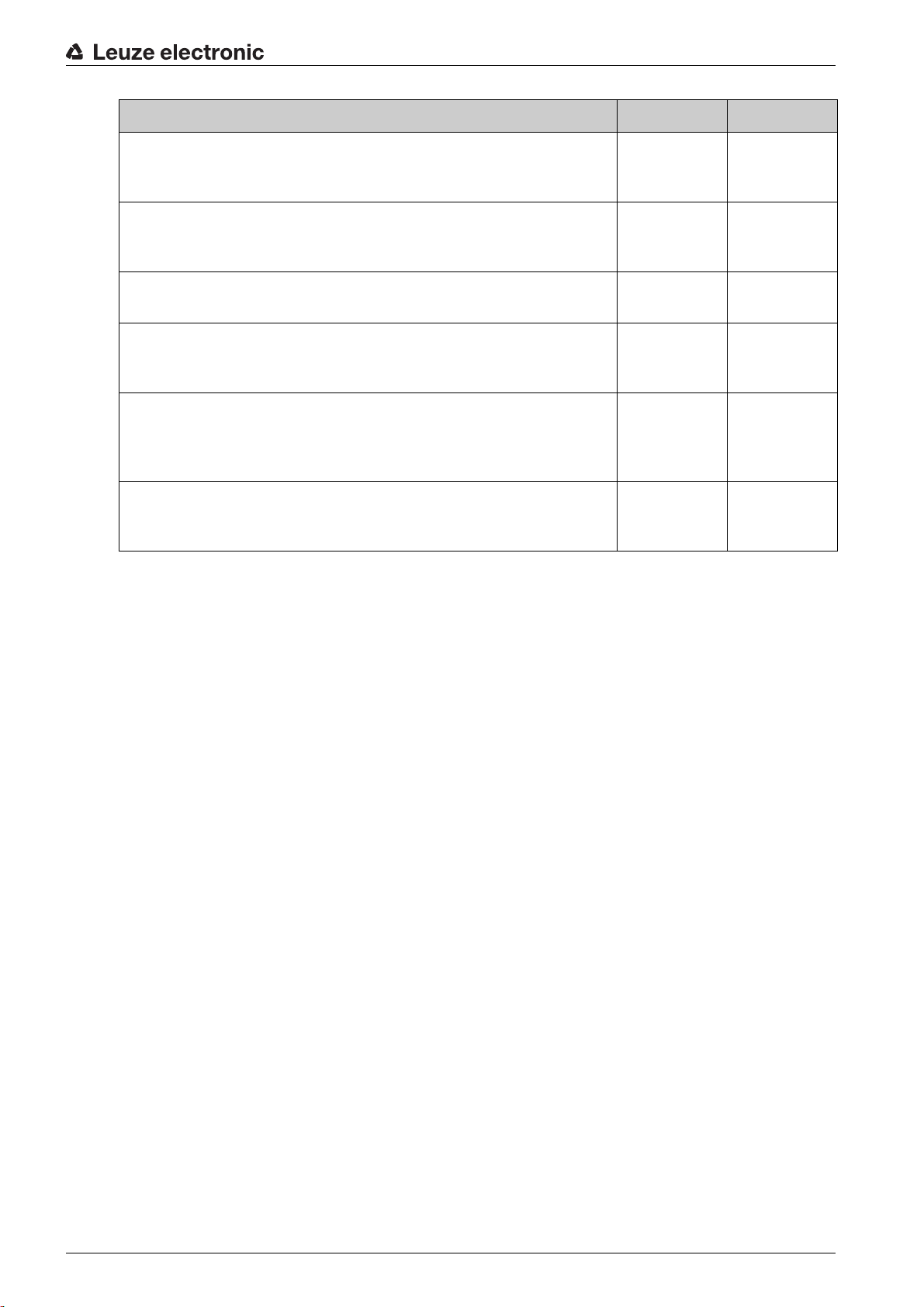

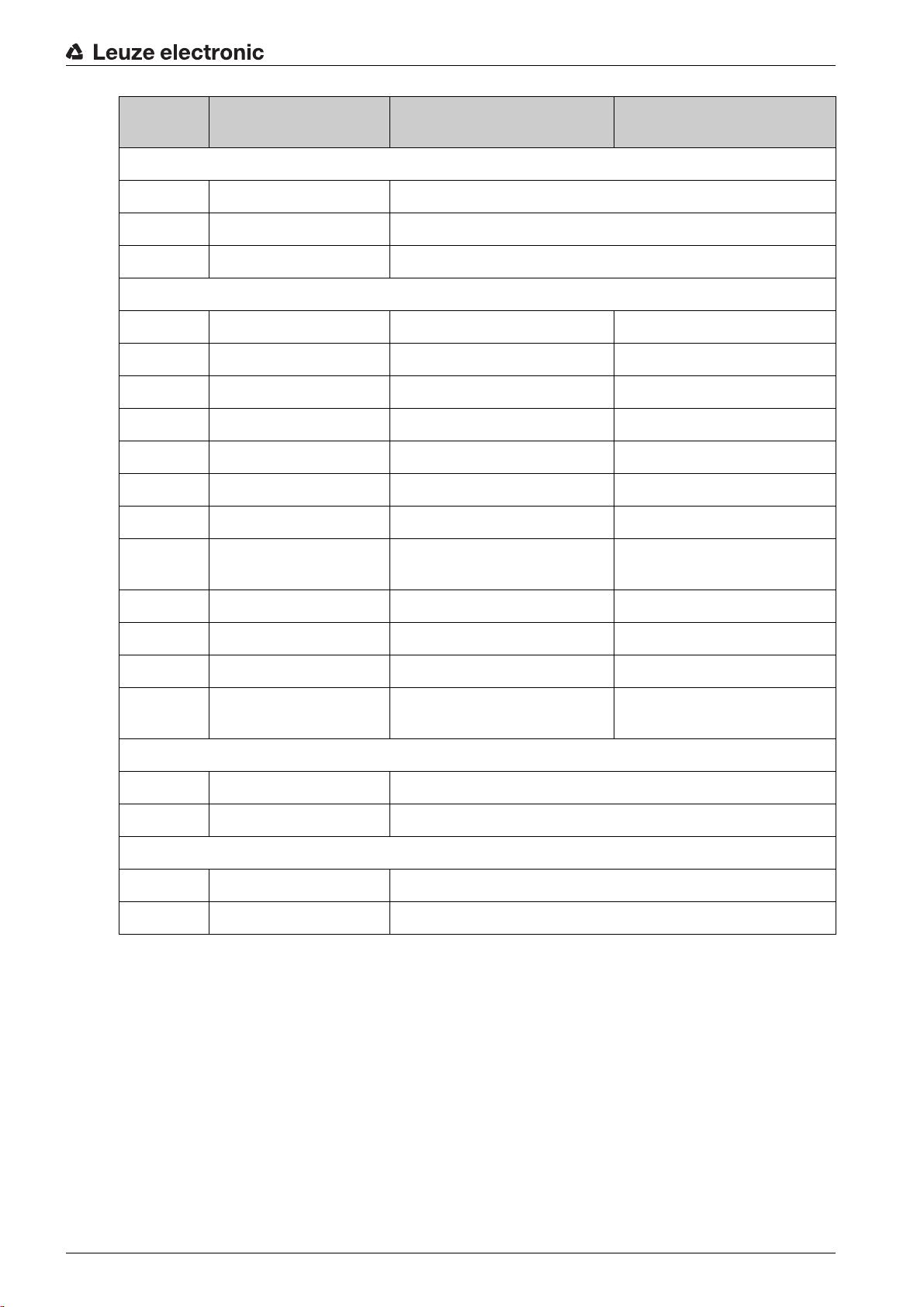

Device description

Sensor Housing Switching distance

Connection

Sao /OFF/ Sar

MC336-S2x Cuboid

max. 36 mm x 26 mm

< 7 mm, > 17 mm, > 20 mm 2 m-, 5 m-, 10 m-PVC con-

nection cable with wire-end

sleeves

0.2 m PVC connection

cable with M12 plug

M8 plug

MC330-S2x Cylinder

max. 30 mm, round

< 6 mm, > 15 mm, > 18 mm 2 m-, 5 m-, 10 m-PVC con-

nection cable with wire-end

sleeves

0.2 m PVC connection

cable with M12 plug

M8 plug

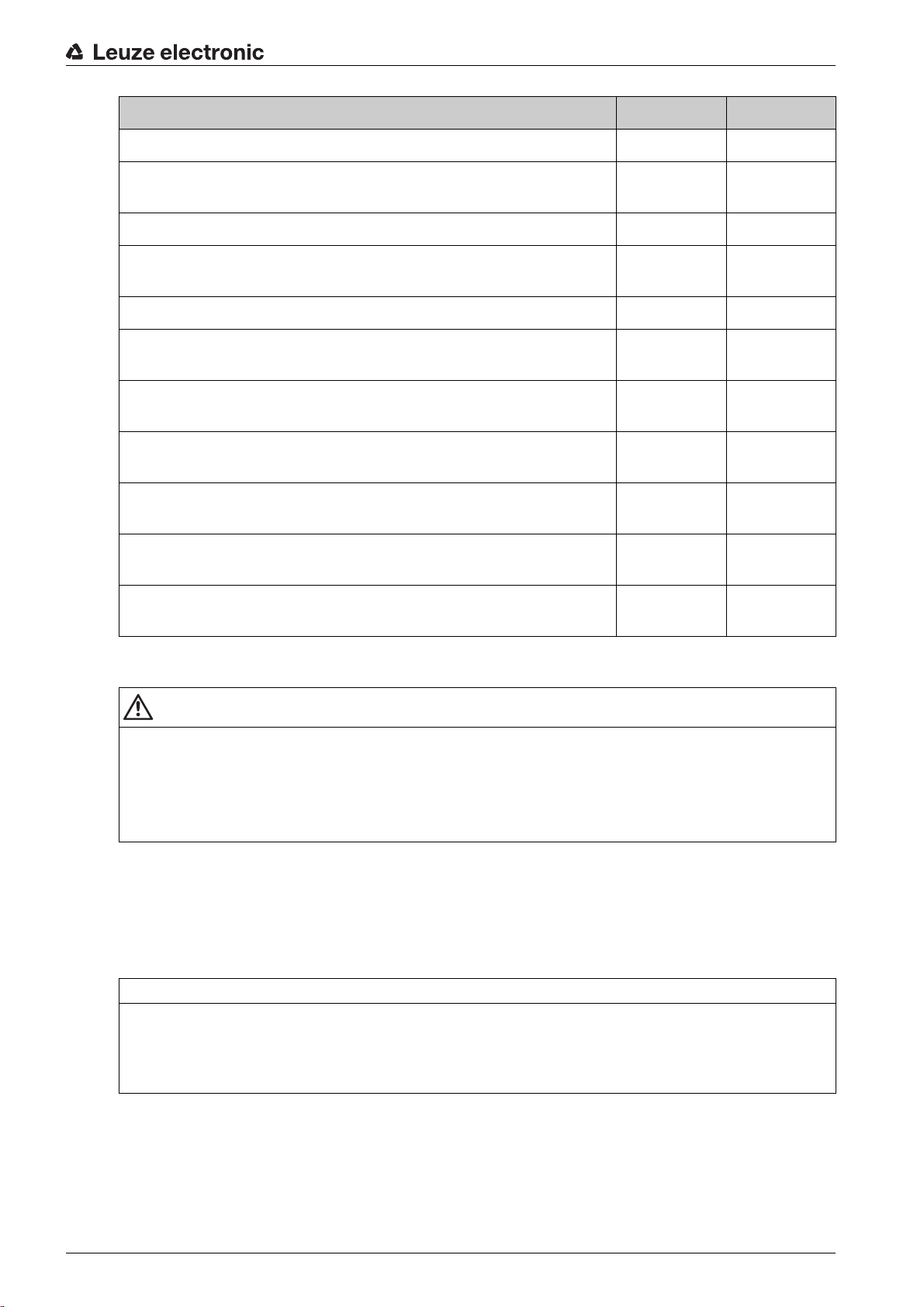

Table 3.3: Overview of MSI-MC3x Safety Relays

Safety Relays Functions Output contacts Safety

MSI-MC310 Evaluation of MC3xS1x

sensors (1NC/1NO), RES,

EDM

Safety-related relay contacts 2 normal open contacts (N/O) / non-safetyrelated relay

contact 1 normal closed

contact (N/C)

Up to PL e and cat. 4

(EN 13849-1) with connection of one sensor

Up to PL e and cat. 3

(EN 13849-1) with connection of more than one sensor

MSI-MC311 Evaluation of MC3xS2x

sensors (2NO), RES, EDM

Safety-related relay contacts 2 normal open contacts (N/O)

Up to PL e and cat. 4

(EN 13849-1) with connection of one sensor

Up to PL e and cat. 3

(EN 13849-1) with connection of more than one sensor

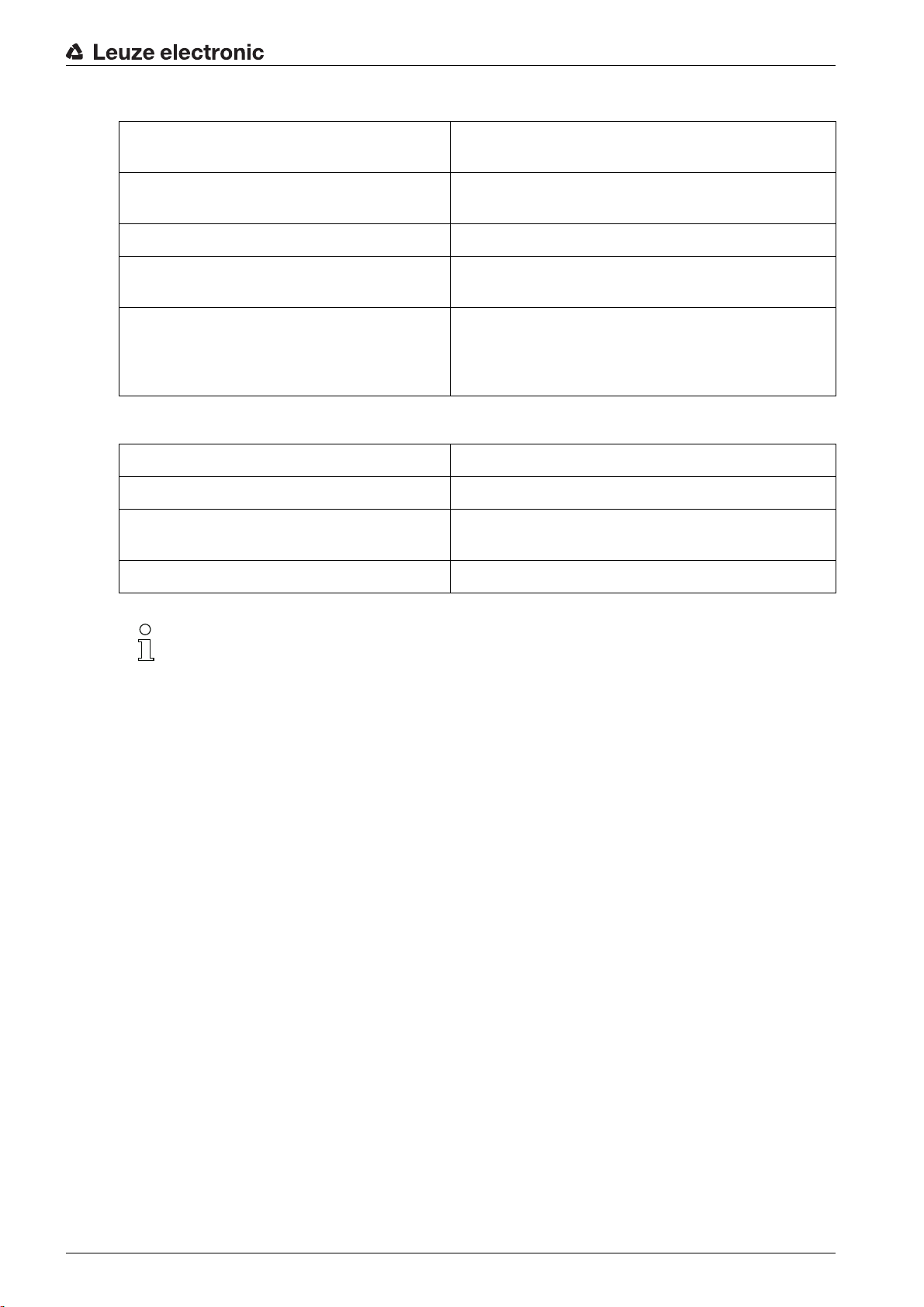

Figure 3.2: Design MC388x Figure 3.3: Design MC336x Figure 3.4: Design MC330x

Leuze electronic MC3x 13

Page 14

1 Connection terminals

24

S11

31

OUT

A2

A1

23

SR

13

A

S22

S33

S34

S12

32

14

MSI-MC310

Supply

K2

K1

1

2

3

4

5

1

2

3

4

5

1

2

3

2 Voltage indicator

3 Status K1

4 Status K2

5 Connection terminals

Figure 3.5: MSI-MC310 and MSI-MC311 Safety Relays

Device description

LED State Meaning

Supply Green illuminated Voltage supply switched on

K1 Green illuminated Input condition for K1 fulfilled

K2 Green illuminated Input condition for K2 fulfilled

Figure 3.6: Designation locations, MC3x series sensors

1 Date of manufacture

2 Order number

3 Designation

Leuze electronic MC3x 14

Page 15

4 Functions

Table 4.1: Overview of the safety functions

Short description of the functions

Stop function Safety-related; initiated by the guard

Start/restart interlock Prevents automatic restart; forces manual confirmation via a reset button

Automatic start/restart Automatic operation without use of a reset button

RES (restart) Manual start by means of a reset button for guards that are accessible

EDM External Device Monitoring (contactor monitoring)

Display technology LEDs, display for K1, K2 input condition as well as for voltage supply

OSSDs Safety-related switching outputs (relays)

4.1 Start/restart interlock

(Connection of the reset button between pin OUT / 24 V and pin SR of the MSI-MC310)

(Connection of the reset button between pin A2 and pin SR1 / SR2 of the MSI-MC311)

The start/restart interlock prevents automatic release of the safety circuits and automatic start-up of the

system (e.g., if the protective door closes again or an interruption of the voltage supply is restored).

The system may not be manually released with the reset button until no persons are located in the danger

zone (see chapter 7.7 „Unlocking start/restart interlock“).

Functions

(RES)

from behind

4.2 Automatic start/restart

(Bridge between pin OUT / 24 V and pin A of the MSI-MC310)

(Bridge between pin SR1 / SR2 and pin EDM of the MSI-MC311)

The automatic start/restart interlock enables immediate release of the safety circuits and automatic start-

up of the system (e.g., if the protective door closes again or an interruption of the voltage supply is

restored).

This operating mode is only permitted if it is not possible to reach or step behind the guard (see chapter 7.7

„Unlocking start/restart interlock“).

4.3 Contactor monitoring (EDM)

(Connection in the start circuit between pin OUT and pin SR of the MSI-MC310)

(Connection in the start circuit between pin S12 and PIN EDM of the MSI-MC311)

The MSI-MC310 / MSI-MC311 monitors the feedback circuits of the connected relays or contactors.

The two OSSDs are not activated until:

• all actuators of the connected sensors are in the specified distance range

• all connected sensors are activated

• opening of the contacts (reset button, EDM contacts) causes the signal at pin SR to drop out

Leuze electronic MC3x 15

Page 16

5 Applications

The MC3x series is used in position monitoring of moveable guards, e.g. (sliding) gates, flaps or hoods.

WARNING

Unexpected machine start-up may cause severe injuries.

If the guard is accessible from behind, e.g., in the case of access guarding of danger zones, only the

opening of the door is detected; persons present within the danger zone are not detected after the door

is closed.

Only operate access guarding in the start/restart interlock operating mode or take additional safety

measures.

Applications

Figure 5.1: Access guarding on a PCB production line, implemented on a door with MC330x sensors

Leuze electronic MC3x 16

Page 17

Applications

Figure 5.2: Access guarding on a filling system, realized on a door with MC388x sensors

Figure 5.3: Access safeguarding on a small painting robot, implemented on a hood with MC336x sen-

sors

Leuze electronic MC3x 17

Page 18

Applications

Figure 5.4: Access safeguarding on a food production line, implemented on a sliding gate with MC336x

sensors

Figure 5.5: Access safeguarding on a beverage filling system, implemented on a raisable window with

MC336x sensors

Leuze electronic MC3x 18

Page 19

6 Mounting

WARNING

Improper mounting may result in serious injury!

The protective function of the sensors is only ensured if used in the intended area of application and if

they are mounted professionally.

Mounting may only be performed by competent persons.

Observe the relevant standards, regulations and these instructions.

Do not use the sensor in areas under the influence of strong magnetic fields.

After mounting, check the sensors for proper function

6.1 Selecting the position and arrangement of sensor and actuator

WARNING

Improper mounting may result in serious injury!

The protective function of the sensors is only ensured if, after the guard is opened, the dangerous

process can be safely stopped before it is reached by a person.

Mount the sensors with an adequate safety distance to the danger zone.

Take all delay times into account (e.g., the response times of the control elements, the stopping time

of the machine)

Mounting

Select the mounting locations so that the following conditions are satisfied acc. to EN 1088:

• For doors/flaps that swing open, the position of sensor and actuator is opposite the hinge side.

• The position of sensor and actuator allows the cut-out distance Sar to be reached upon opening of

the moveable guard.

• The position of sensor and actuator makes it impossible to reach or step behind the moveable guard.

• Make certain that the gap dimension between the fixed and moveable part of the guard is not wide

enough for reaching or stepping behind.

• The position of sensor and actuator makes it impossible for a person to reach the dangerous area

during the stopping time of the machine after the guard is opened.

• The position protects the sensor from physical shocks and vibrations that exceed specifications (see

chapter 13 „Technical data“).

• Adjacent Magnetically Coded Sensors must be separated by at least 50 mm.

• The position of sensor and actuator must not lie within the range of influence of blasting agents or

magnetic particles.

• Mounting on ferromagnetic materials (e.g., iron, nickel, cobalt) is to be avoided.

• When mounting on stainless steel surfaces, spacers are to be used and the safety-related switching

distances are to be inspected.

• The position of sensor and actuator must facilitate form-fitting mounting.

• Accessible to qualified personnel for testing and replacement

• Cannot be manipulated by operators though removal, turning, short-circuiting (e.g., by means of covered mounting)

NOTICE

Faulty or incorrect alignment will result in an operating fault.

The alignment of sensor and actuator within the scope of start-up is to be performed only by trained

personnel.

Observe the data sheets and mounting instructions of the individual components.

Aligning on the basis of the markings, approach directions

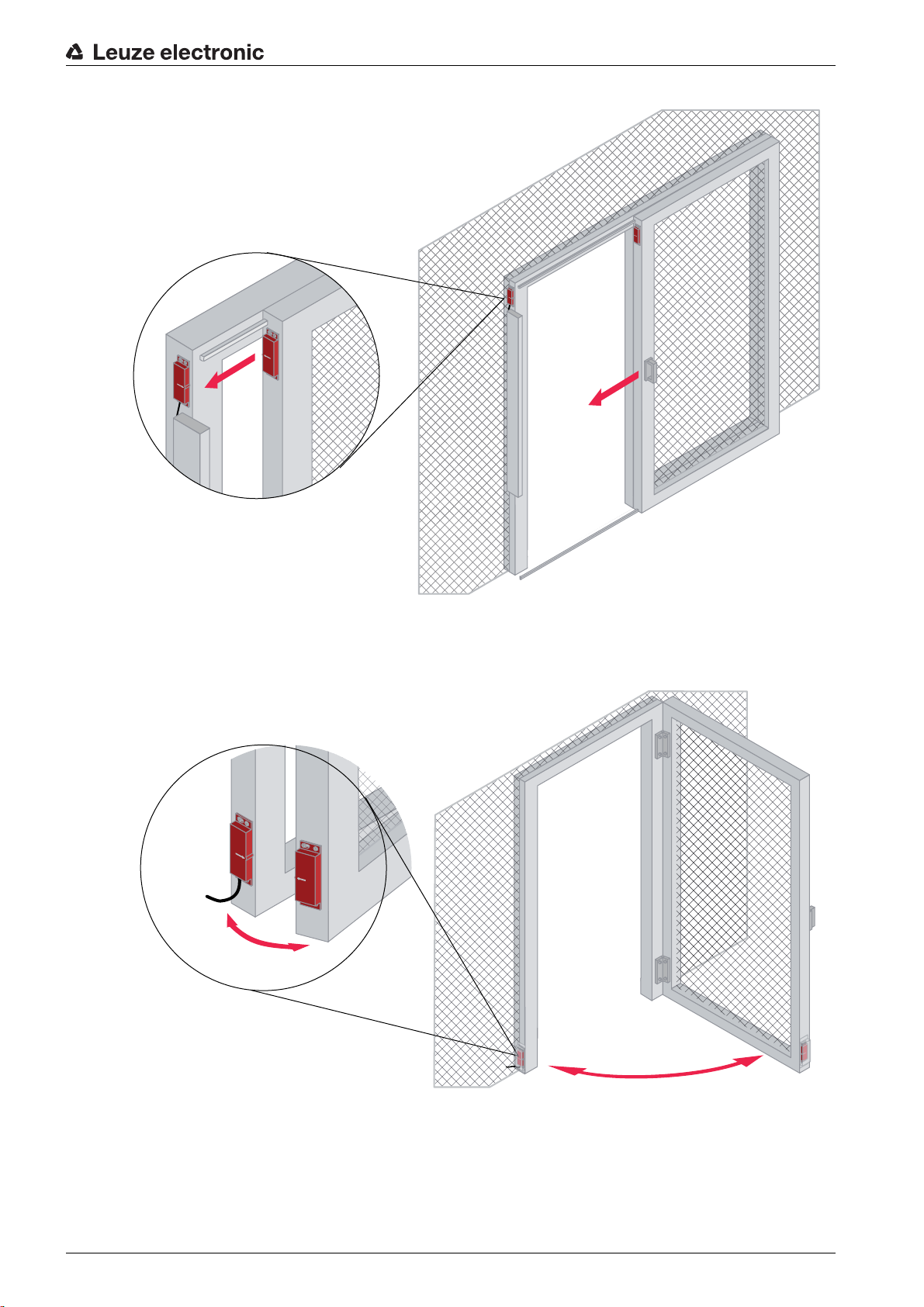

In the following example, the MC388x sensor is mounted on the front of a sliding gate. The switching condi-

tion is activated by the actuator approaching from below.

Leuze electronic MC3x 19

Page 20

Mounting

Figure 6.1: Approach direction from below

In the following example, the MC388x sensor is mounted on the front of a swinging door and is protected.

The switching condition is activated by the actuator approaching on the same level.

Figure 6.2: Approach direction on the same level

In the following example, the MC336x sensor is mounted on a small sliding window and is protected. The

switching condition is activated by the actuator approaching on the same level.

Leuze electronic MC3x 20

Page 21

Mounting

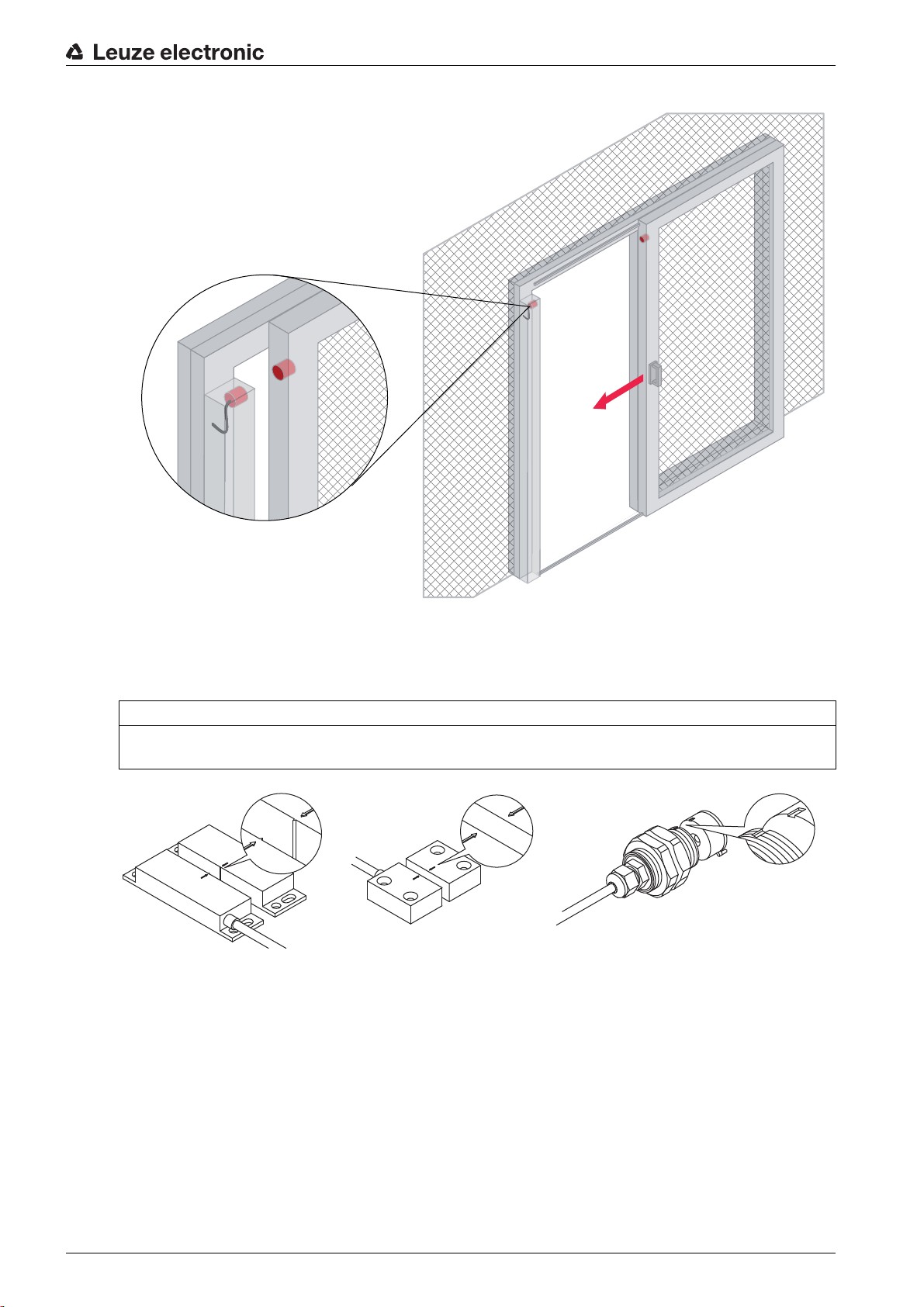

Figure 6.3: Approach direction on the same level

In the following example, the MC336x sensor is mounted on a vertically moving sliding window and is

protected. The switching condition is activated by the actuator approaching from the side.

Figure 6.4: Approach direction, from side

In the following example, the MC330x sensor is mounted recessed on the front of a sliding gate. The

switching condition is activated by the actuator approaching on the same level.

Leuze electronic MC3x 21

Page 22

Mounting

Figure 6.5: Approach direction on the same level

6.2 Mounting and aligning sensor and actuator

NOTICE

Observe the switching distances and ensure that the markings on sensor and actuator line up while the

guard is closed.

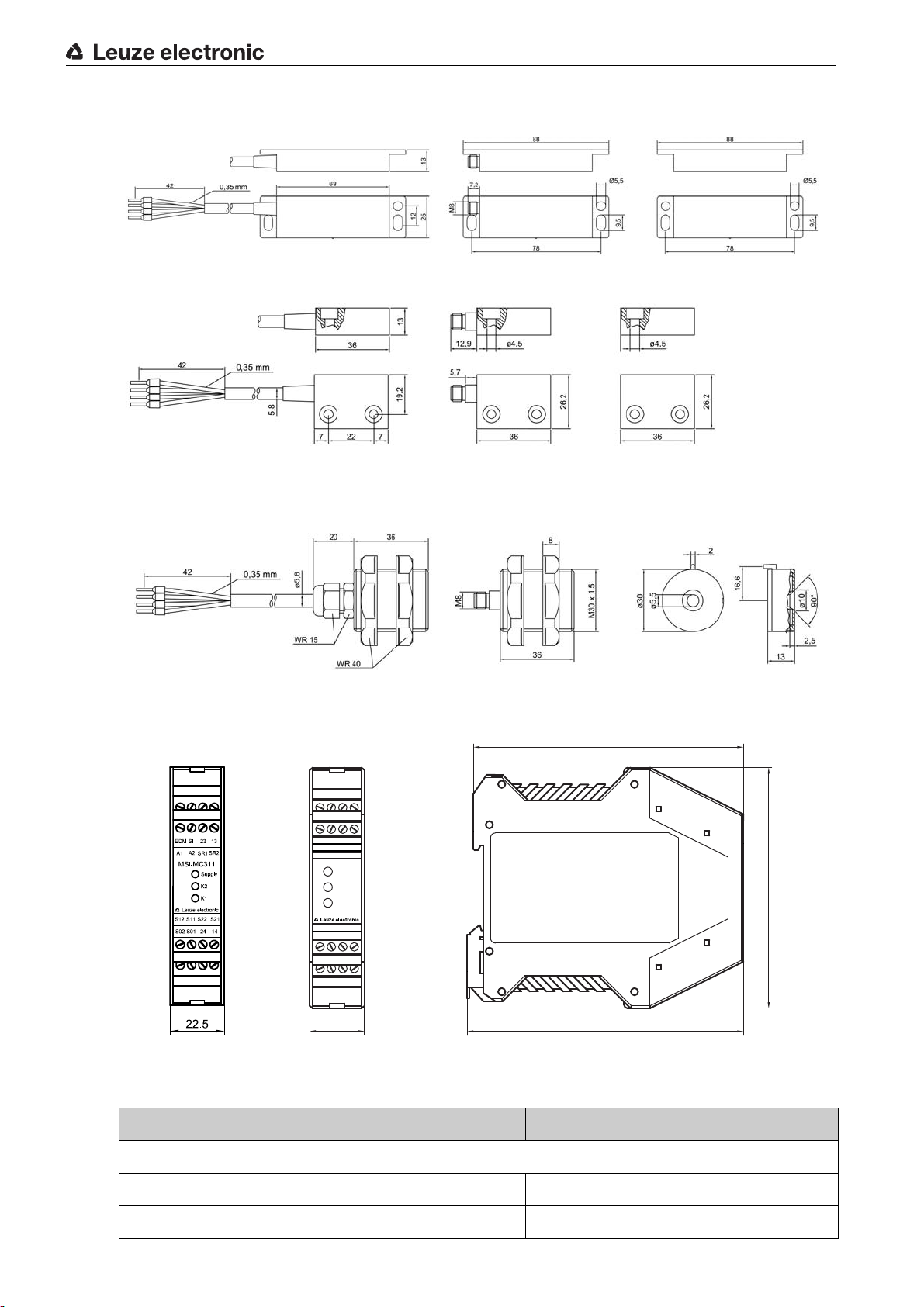

Figure 6.6: MC388x Figure 6.7: MC336x Figure 6.8: MC330x

Proceed as follows:

Select the position of the sensor on the fixed part of the guard (see chapter 6.1 „Selecting the position

and arrangement of sensor and actuator“).

Select the position of the actuator on the moveable part of the guard (see chapter 6.1 „Selecting the

position and arrangement of sensor and actuator“).

Drill the bore holes acc. to the specified dimensions (see chapter 14 „Dimensions and weights“).

For round actuators, take into account the anti-twist protection by providing an appropriate recess.

Loosely screw the sensor and actuator at the defined positions. Use the washers.

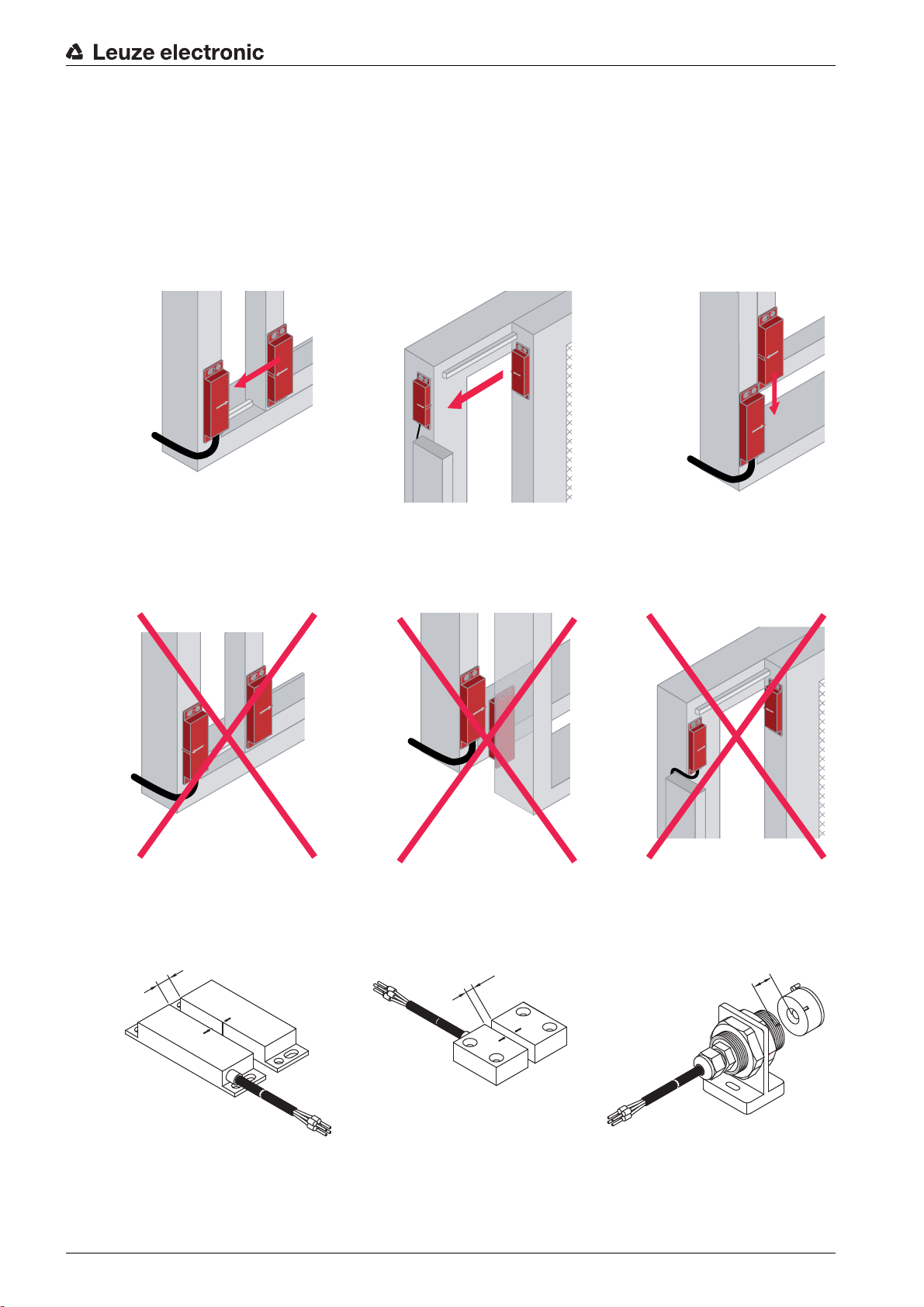

Align sensor and actuator with one another so that when the guard is closed, the markings (e.g., arrows,

notches, lines) are aligned, i.e., are opposite one another. A lateral offset reduces the switching distance.

Leuze electronic MC3x 22

Page 23

Mounting

a

a

Align sensor and actuator with one another so that while the guard is closed, they do not touch one

another (minimum distance: 1 mm).

Do not consider sensor and actuator to be limit stops.

Make certain that the cut-in and cut-out points (Sao, OFF, Sar see table 6.1) can be reached without

mechanical tension in the moveable guard.

Secure sensor and actuator within the specified distance values "Sao" and "OFF".

After aligning, permanently fasten sensor and actuator with locking screws (to 10 Nm).

Correct alignment

Figure 6.9: The markings are

Figure 6.10: The markings

aligned on the

same level.

Incorrect alignment

Figure 6.12: The markings are

Figure 6.13: The markings

not aligned with

one another.

Switching distances from sensor to actuator

are aligned from

below.

are not aligned.

Figure 6.11: The markings

are laterally

aligned.

Figure 6.14: The markings

are not

aligned.

a

Figure 6.15: MC388x

a see table switch-

ing distance

a see table

switching distance

a see table switching

distance

Figure 6.17: MC330x

Figure 6.16: MC336x

Leuze electronic MC3x 23

Page 24

Table 6.1: Switching distances of sensor and actuator

Sensor type Housing Switching distance Sao / OFF / Sar

Mounting

MC388-S1-A Cuboid

< 6 mm, > 13 mm, > 30 mm

88 mm x 25 mm

MC336-S1-A Cuboid

< 3 mm, > 8 mm, > 11 mm

36 mm x 26 mm

MC330-S1-A Cylinder

< 6 mm, > 12 mm, > 14 mm

30 mm, round

MC388-S2-A Cuboid

< 9 mm, > 19 mm, > 22 mm

88 mm x 25 mm

MC336-S2-A Cuboid

< 7 mm, > 17 mm, > 20 mm

36 mm x 26 mm

MC330-S2-A Cylinder

< 6 mm, > 15 mm, > 18 mm

30 mm, round

Sao = assured cut-in distance

OFF = cut-out point

Sar = assured cut-out distance

Proceed as follows:

Align the actuator so that the distance between sensor and actuator is within the specifications (Sao and

OFF) while the guard is closed.

The fitting position of sensor and actuator can be freely selected.

If necessary, provide a constraining guide for the moveable part of the guard. The edges of the move-

able and fixed part of the guard must be aligned (e.g., door and frame).

Do not use the sensor as a limit stop, but rather provide a separate mechanical limit stop.

Install a locking or snap mechanism for the moveable part of the guard to prevent it from swinging open.

If it is expected that the moveable part of the guard will warp, the mounting position of sensor and actu-

ator can be adjusted to offset this somewhat if necessary. Check the resulting gap dimensions to determine, e.g., whether it allows a person to reach behind.

Fasten sensor and actuator with rivets or tamperproof screws on a form-fitting surface so that they can-

not be detached.

If necessary, mount sensor and actuator so they are covered.

Note the minimum approach speed (see chapter 13 „Technical data“).

6.2.1 Checklist - correct mounting of sensor and actuator Area of application: Mounting

Tester: Technician who mounts the MC3x

Checklist for mounting Yes No

Are sensor, actuator and Safety Relay properly selected, i.e., not

mixed, and used acc. to the assignment (see chapter 15 „Ordering

information and accessories“)?

Are sensor and actuator mounted in a form-fitting manner?

While the guard is closed, is the distance from sensor and actuator

within the specified values Sao and OFF?

Do the markings on sensor and actuator align while the guard is

closed?

Leuze electronic MC3x 24

Page 25

Checklist for mounting Yes No

Is it ensured that sensor and actuator do not serve as a limit stop?

Are sensor and actuator fastened in such a way that they cannot be

moved and turned?

Is a separate limit stop with locking or snap mechanism mounted?

Is the distance to other Magnetically Coded Sensors and their actuators

maintained?

Are sensor and actuator accessible for inspection and replacement?

Is access to the point of operation/to the danger zone possible only

through the monitored, moveable part of the guard?

Can the point of operation be reached only after the dangerous movement has stopped?

Have measures been taken to prevent the guard from being bypassed

by crawling under or reaching or jumping over?

Is it impossible to actuate the start/restart button from within the danger

zone?

Mounting

Can the entire danger zone be seen from the installation site of the

start/restart button?

Are the edges of the moveable and fixed part of the guard aligned (e.g.,

door and frame); no warping or deformation?

6.3 Mounting the Safety Relay

WARNING

Improper mounting may result in serious injury!

The protective function of the Safety Relay is only ensured if appropriately and professionally mounted

for the respective, intended area of application.

Only allow competent persons to install the Safety Relay.

Observe the relevant standards, regulations and these instructions.

Prerequisites for mounting:

• Cabinet with appropriate protection rating (at least IP 54, NEMA 3)

• 35 mm-DIN top-hat supporting rail in accordance with DIN EN 50022

• Snap the Safety Relay onto the DIN rail.

• The Safety Relay can be connected to the sensors.

NOTICE

The Safety Relay may be damaged if mounted improperly!

The MSI-MC310/311 is not suitable for free wall mounting .

Depending on the environmental conditions at the end user, a suitable protective housing type must

be determined and used.

Leuze electronic MC3x 25

Page 26

7 Electrical connection

WARNING

Risk of death by electric shock!

Depending on external wiring, dangerous voltages may be present at the switching outputs.

During all work at the electrical system or electronics, make certain that each voltage supply has been

interrupted and protected against being restarted.

The following must be observed for the current supply of the Safety Relay:

• The supply voltage must be 24 V DC (see chapter 13 „Technical data“).

• Acc. to EN 61558-2-6, the cables at the inputs are to be separated from mains by either a safety isolating transformer with limited output voltage in the case of failure or by means of appropriate isolation measures.

WARNING

Improper electrical connection may result in serious injury!

Only allow competent persons to perform the electrical connection.

Make certain that supply and signal lines are laid separately from power lines.

Provide appropriate spark extinction for contactors/sequence relays in the cabinet.

Observe the installation and operating information for the products that are to be connected via the

Safety Relay (e.g., drive motors, brakes, etc.).

Electrical connection

The following conditions apply for the electrical connection:

• The Safety Relay must be integrated in the control circuit acc. to EN ISO 13849-1/-2:2009.

• The cables must be laid separately/in a protected manner, acc. to EN ISO 13849-1/-2:2009.

• Shutdown of the supply voltage for operational purposes is not permissible.

• If only one sensor is used, the free inputs must be bridged.

• It is not permissible to connect the sensor lines in parallel with third-party components.

• The mixed connection of protective extra low voltage and low voltage (e.g., 240 V

14, 23/24, 31/32 is not permissible.

• To prevent welding of the MSI output contacts, an external fuse is required acc. to the technical

specifications of the MSI-MC3x (see chapter 13.3 „MSI-MC310 Safety Relay“ or see chapter 13.4

„MSI-MC311 Safety Relay“) and for any other connected components.

• The OUT terminal (MSI-310) is not for operating external devices, but is rather intended only for supplying potential-free contacts.

7.1 Terminal assignments of the Safety Relay

WARNING

Selecting the wrong functions may result in serious accidents!

Activate restart interlock if it is possible to reach or walk behind.

For access guarding, make certain that the restart interlock cannot be unlocked from within the danger

zone but that the danger zone can be viewed from the reset button (RES).

Select the functions so that the Safety Relay is used as intended (see chapter 2.1 „Approved purpose

and foreseeable improper operation“).

~) at terminals 13/

There are 16 terminals on the Safety Relay for connecting the cables. The connection of the Safety Relay

is divided into sensor groups, additional functions, OSSDs and supply voltage.

Leuze electronic MC3x 26

Page 27

7.1.1 MSI-MC310 Safety Relay

24

S11

31

OUT

A2

A1

23

SR

13

A

S22

S33

S34

S12

32

14

MSI-MC310

Supply

K2

K1

Electrical connection

Figure 7.1: MSI-MC310, terminal assignments

Table 7.1: MSI-MC310, terminal designations

Terminal des-

Function Description

ignation

A1, A2 Input Voltage supply

S11 Output For sensor 1, contact NO + sensor 2/x, contact NO

S12 Input Sensor 1, contact NO

S22 Input Sensor x, contact NO

S33 Output Sensor 1, contact NC + sensor 2/x, contact NC

S34 Input Sensor 1, contact NC + sensor 2/x, contact NC

OUT Output For start- and EDM circuit

SR Input For start- and EDM circuit

A Input For “automatic” operating mode with or without EDM

13/14 Relay contacts OSSD 1, safety-related release circuit 1

23/24 Relay contacts OSSD 2, safety-related release circuit 2

31/32 Relay contacts EDM-, signaling circuit

Table 7.2: MSI-MC310, evaluation and bridging

Evaluation Safety level Connection, terminal Bridging, if the adjacent termi-

nal group is not needed

1 sensor PL e, cat. 4, PDF-M S11

1 sensor S33

Leuze electronic MC3x 27

® NO ® S12 S11 ® bridge ® S22

® NC ® S34

Page 28

Electrical connection

1

4

2

3

1

3

2

4

Evaluation Safety level Connection, terminal Bridging, if the adjacent termi-

nal group is not needed

2 sensors PL e/d, cat. 3, PDF-S S11

2 sensors S33

x sensors PL e/d, cat. 3, PDF-S S11

x sensors S33

® NO(1) ® S12 and

S11

® NO(2) ® S22

® NC(1) ® S34 and

S33

® NC(2) ® S34

® NO(1) ® NO(2) to

NO(x)

® S12

® NC(2) ® S34 to S33

® NC(x) ® S34

Table 7.3: MSI-MC310, evaluation and operating mode

Evaluation Operating mode Connection, terminal

Reset button

RS OUT

® (RES) ® SR

(RES)

Reset button

RS, EDM OUT

® (RES) ® EDM ® SR

(RES) and

contactor

Contactor Autom. start, EDM OUT

Autom. start OUT

® EDM ® A

® bridge ® A

® bridge ® S22

S11

7.1.2 Sensor pin assignment (1NC/1NO) The MC3x sensors (1NC/1NO) are equipped with either M8, M12 connectors or with a PVC or PUR

connection cable, in various lengths and with wire-end sleeves.

1Brown

2White

3Blue

4Black

Figure 7.2: Wire assignment, colors of the connection cable, state without activation by actuator

Pin 1 Brown

Pin 2 White

Pin 3 Blue

Pin 4 Black

Figure 7.3: Pin assignments of the M8 connector

Leuze electronic MC3x 28

Page 29

Pin 1 Brown

2

4

3

1

Pin 2 White

Pin 3 Blue

Pin 4 Black

Figure 7.4: Pin assignments of the M12 connector

7.1.3 MSI-MC311 Safety Relay

Electrical connection

Figure 7.5: MSI-MC311, terminal assignments

Table 7.4: MSI-MC311, terminal designations

Terminal des-

Function Description

ignation

A1, A2 Input Voltage supply

S11 Input Contact 1, NO

S12 Output Contact 1, NO

S21 Input Contact 2, NO

S22 Output Contact 2, NO

SR1 Input Start circuit 1

SR2 Input Start circuit, bridged

SI Relay contact input Status

S01 Relay contact output Status off

S02 Relay contact output Status on

Leuze electronic MC3x 29

Page 30

Electrical connection

1

4

2

3

Terminal des-

Function Description

ignation

EDM Input EDM circuit

13/14 Relay contacts OSSD 1, safety-related release circuit 1

23/24 Relay contacts OSSD 2, safety-related release circuit

Table 7.5: MSI-MC311, evaluation and bridging

Evaluation Safety level Connection, terminal

1 sensor PL e, cat. 4, PDF-M S11

2 sensors PL e/d, cat. 3, PDF-S S11

x sensors PL e/d, cat. 3, PDF-S S11

® NO ® S12

S21

® NO ® S22

® NO(11) ® NO(21) ® S12

S21

® NO(12) ® NO(22) ® S22

® NO(11) ® NO(21) ® NO(x1) ® S12

S21

® NO(12) ® NO(22) ® NO(x2) ® S22

Table 7.6: MSI-MC311, evaluation and operating mode

Evaluation Operating mode Connection, terminal Bridging

Reset button

RS, single-channel A2

(RES)

Contactors K3, K4EDM S12

Autom. start EDM

7.2 Sensor pin assignment (2NO)

The MC3x sensors (2NO) are equipped with either M8, M12 connectors or with a PVC or PUR connection

cable, in various lengths and with wire-end sleeves.

1Brown

2White

3Blue

4Black

Figure 7.6: Wire assignment, colors of the connection cable, state without activation by actuator

® (RES) ® SR1 SR1 ® bridge ® SR2

® K3, K4® EDM

® bridge ® SR1

EDM

® bridge ® SR2

Leuze electronic MC3x 30

Page 31

Pin 1 Brown

1

3

2

4

2

4

3

1

Pin 2 White

Pin 3 Blue

Pin 4 Black

Figure 7.7: Pin assignments of the M8 connector

Pin 1 Brown

Pin 2 White

Pin 3 Blue

Pin 4 Black

Figure 7.8: Pin assignments of the M12 connector

Electrical connection

7.3 Connection examples

Prerequisites for the electrical connection:

• The maximum temperature of the application does not exceed that specified in the technical data of

the sensors (see chapter 13 „Technical data“)

• Contact assignments are adhered to

Lay sensor connection cable and connect according to the assignment specifications and the applica-

tion-specific circuit diagram.

Connect the MSI-MC3x according to the application-specific circuit diagram.

Setting the device into service

NOTICE

Improper electrical connection may result in serious injury!

The mixed connection of protective extra low voltage and low voltage at terminals 13/14, 23/24 and

31/32 (MSI-3x) is not permitted.

Finger-safe acc. to DIN VDE 0106 part 100, maximum stripped length of the connection cables: 8 mm

To prevent welding of the respective output contacts, an external fuse must be connected upstream.

All reactive loads connected to the supply voltage are to be provided with interference-suppression cir-

cuits.

For reactive loads on terminals 13/14, 23/24, 31/32 (MSI-3x), an appropriate protective circuit is to be

provided.

Shutdown of the supply voltage for operational purposes is to be made impossible.

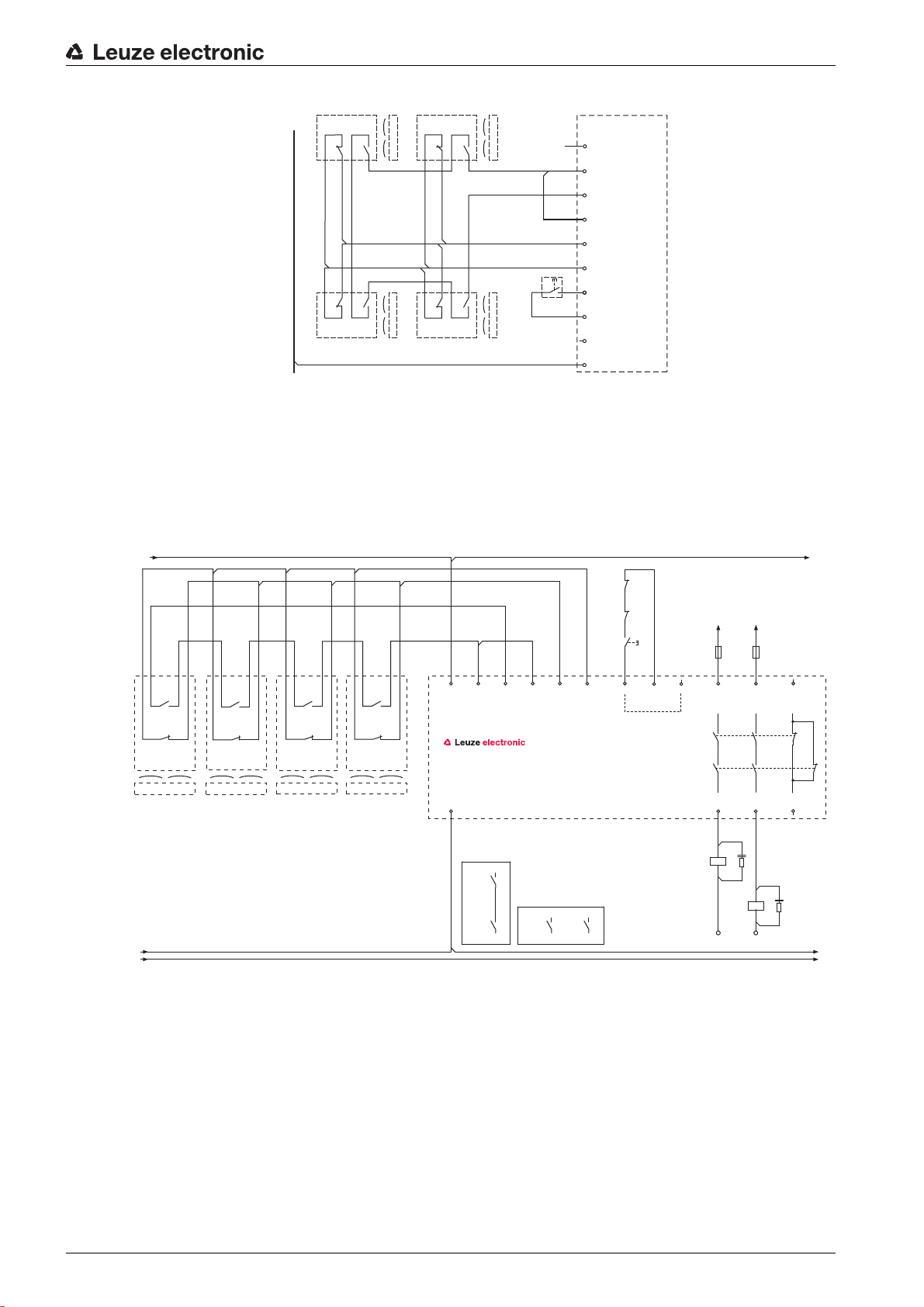

7.3.1 Connection examples with MC3xS1x sensors and MSI-MC310 Safety Relay The following examples show possible connection combinations of Magnetically Coded Sensors on the

Safety Relay for contact set 1NC/1NO.

All available safety inputs must be occupied. Bridges are to connect the remaining inputs where no

sensors are connected .

Leuze electronic MC3x 31

Page 32

Electrical connection

The following wiring diagram shows the connection of an MC3xS1x for achieving safety category 4 and

Performance Level e. For access safeguarding, it also includes the “start/restart interlock” operating mode

and a reset button.

0V

MC3xS1x

K3

+24V

K4

MSI-MC310

A1

S11

S12

S22

S33

S34

OUT

SR

A

A2

Figure 7.9: Example 1: Two-channel connection of an MC3xS1x with start/restart interlock and contactor

monitoring (EDM), contact drawing without activation by actuator

The following wiring diagram shows the connection of two MC3xS1x for achieving safety category 3 and

Performance Level e or d. If the guard cannot be reached or stepped around the “Automatic start/restart”

operating mode is permissible for the benefit of an efficient system design.

0V

MC3xS1x

MC3xS1x

K3

MSI-MC310

+24V

K4

A1

S11

S12

S22

S33

S34

OUT

SR

A

A2

Figure 7.10: Example 2: Connection of two MC3xS1x with automatic start/restart interlock and contactor

monitoring (EDM), contact drawing without activation by actuator

The following wiring diagram shows the connection of four MC3xS1x on two doors for achieving safety

category 3 and Performance Level e or d.

Leuze electronic MC3x 32

Page 33

Electrical connection

0V

MSI-MC310

S11

S12

S22

OUT

S34

A2

S33

+24V

A1

A

SR

MC3xS1x

MC3xS1x

MC3xS1x

MC3xS1x

Var. B

Var. A

MSI-MC310

0V

-K3

-A1

-A2

-K4

-K4

-K3

0V

PE

PE

0V

13 23A1 S11 S12 S22 S33 S34 OUT

31

-S1

-K3

-K4

+24V

A2 14 24

A1

A2

-K3

L- L-

32

*

A1

A2

-K4

1

2

1

2

L+ L+

+24V

+24V

SR A

MC3xS1x

MC3xS1x

MC3xS1x

MC3xS1x

No. x

No. 3

No. 2

No. 1

*

Figure 7.11: Example 3: Connection of four MC3xS1x with start/restart interlock, contact drawing without

activation by actuator

The following wiring diagram shows the connection of several MC3xS1x for achieving safety category 3

and Performance Level e or d in the case of access safeguarding (start/restart interlock, EDM). Up to 30

moveable guards can be monitored in this way. Safeguarding in the switch-off circuit must satisfy the spec-

ifications for K1, K2 as well as those of the downstream contactors.

*) Spark extinction circuit, suitable spark extinction provided

Figure 7.12: Example 4: Connection of several MC3xS1x with start/restart interlock and contactor moni-

toring (EDM), contact drawing without activation by actuator

7.3.2 Connection examples with MC3xS2x sensors and MSI-MC311 Safety Relay The following examples show possible connection combinations of Magnetically Coded Sensors on the

Safety Relay for contact set 2NO.

All available safety inputs must be occupied. Bridges are to connect the remaining inputs where no

sensors are connected .

The following wiring diagram shows the connection of an MC3xS2x for achieving safety category 4 and

Performance Level e. For access safeguarding, it also includes the “start/restart interlock” operating mode

and a reset button

Leuze electronic MC3x 33

Page 34

Electrical connection

0V

MSI-MC311

S11

S12

EDM

S22

A2

S21

+24V

A1

SR2

SR1

MC3xS2x

K3

K4

0V

MSI-MC311

S11

S12

EDM

S22

A2

S21

+24V

A1

SR2

SR1

MC3xS2x

K3

K4

MC3xS2x

Figure 7.13: Example 1: Two-channel connection of an MC3xS2x with start/restart interlock and contactor

monitoring (EDM), contact drawing without activation by actuator

The following wiring diagram shows the connection of two MC3xS2x for achieving safety category 3 and

Performance Level e or d. If the guard cannot be reached or stepped around the “Automatic start/restart”

operating mode is permissible for the benefit of an efficient system design.

Figure 7.14: Example 2: Connection of two MC3xS2x with automatic start/restart and contactor monitor-

ing (EDM), contact drawing without activation by actuator

The following wiring diagram shows the connection of several MC3xS2x for achieving safety category 3

and Performance Level e or d in the case of access safeguarding (start/restart interlock, EDM). Up to 30

moveable guards can be monitored in this way. Safeguarding in the switch-off circuit must satisfy the spec-

ifications for K1, K2 as well as those of the downstream contactors.

0V

MC3xS2x

Leuze electronic MC3x 34

Figure 7.15: Example 3: Connection of four MC3xS2x with start/restart interlock, contact drawing without

activation by actuator

MC3xS2x

MC3xS2x

MC3xS2x

MSI-MC311

+24V

K3

K4

A1

S11

S12

S21

S22

EDM

SR1

SR2

A2

Page 35

7.4 Connecting to the machine control

The safety-related parts of the control include, in addition to the Safety Relay, sensor and actuator

described above, the subsequent control elements up to the power-transfer elements that are to be

stopped safely and timely. Special attention must be given here to the adherence to the required safety

category. Important information on this topic can be found in harmonized European standard

EN ISO 13849-1.

Essential prerequisite for the safe operation is the possibility of electrically influencing the interruption of

the dangerous movement as well as a sufficiently short machine stand-still time. These must be incorpo-

rated in the calculation of the safety distance as must the response times of the safety-related chain

(Safety Relay, sensors, contactors, etc.).

Setting the device into service

WARNING

Improper use of the Safety Relay may result in serious injury!

Make certain that the entire device and the integration of the protective device was inspected by com-

petent and instructed persons.

Make certain that a dangerous process can only be started while the guard is closed.

Prerequisites for start-up:

• Safety Relay, sensor and actuator are mounted according to these instructions and connected

according to the wiring plan

• operating personnel have been trained in the correct use

• The dangerous process is switched off, outputs of the MSI-MC3x are disconnected and the system is

protected against being restarted

During start-up, test the function of the sensors and the Safety Relay (see chapter 8 „Testing“).

Prior to the initial start-up on a power-driven machine, make certain that a competent person inspects

the connection of the connected guard at the Safety Relay as well as the integration of the complete

system in the machine control.

Before switching on the supply voltage for the first time, make certain that the outputs of the Safety

Relay have no effect on the machine.

Make certain that the switching elements that put the machine which poses a danger into motion are

safely switched off or disconnected and are protected against being restarted.

Electrical connection

The same safety measures apply after each function change, after repairs or during maintenance

work.

7.5 Switching on

Requirements for the supply voltage (power supply unit):

• Safe mains separation is ensured (acc. to IEC 60742).

• Current reserve of at least 2 A available

The start/restart interlock function (where foreseen) connected and activated.

The guard is closed and has not been stepped around.

Check whether the green power LED on the MSI-MC3x illuminates constantly.

Check whether LEDs K1 and K2 of the MSI-MC3x switch off upon opening of the guard

The MSI-MC3x Safety Relay and the sensor are ready for use.

7.6 Reset

The reset button can be used to unlock the start/restart interlock (where foreseen). In this way, the respon-

sible person can restore normal operation of the system following process interruptions (triggering of the

protective function, failure of the voltage supply) (see chapter 7.7 „Unlocking start/restart interlock“).

Leuze electronic MC3x 35

Page 36

7.7 Unlocking start/restart interlock

WARNING

Premature unlocking of the start/restart interlock may result in serious injury.

If the start/restart interlock is unlocked, the system can start-up.

Before unlocking the start/restart interlock, make certain that no people are in the danger zone.

LEDs K1 and K2 do not illuminate as long as the restart is disabled.

Make certain that the guard is closed.

Make certain that there are no people in the danger zone.

Press and release the reset button.

The MSI-MC3x switches to the ON state, LEDs K1 and K2 illuminate.

Electrical connection

Leuze electronic MC3x 36

Page 37

8 Testing

WARNING

A running machine may result in serious injury!

Make certain that, during all conversions, maintenance work and inspections, the system is securely

shut down and protected against being restarted.

The Safety Relays and sensors are maintenance-free. Nevertheless, they must be replaced after a

maximum of 20 years.

Always completely replace the sensors together with actuator.

For the tests, observe nationally applicable regulations.

Document all tests in a comprehensible manner.

8.1 Before the initial start-up and following modifications

Acc. to IEC TS 62046 and national regulations (e.g., EU directive 89/655 EEC amended by 95/63/EC),

tests are to be performed by competent persons in the following situations:

• Prior to the initial start-up

• Following modification to the machine

• After longer machine downtime

• Following retrofitting or reconfiguring the safety device (Safety Relay, sensors and their actuators,

etc.)

Testing

WARNING

Unpredictable machine behavior during initial start-up may result in serious injury!

Make certain that there are no people in the danger zone.

Test the effectiveness of the shutdown function in all operating modes of the machine acc. to the follow-

ing checklist (see chapter 8.1.1 „Checklist – before the initial start-up“).

Document the test of the safety device (including alignment and positioning of sensors, their actuators,

Safety Relay, etc.) along with the wiring diagram of the MSI-MC3x and the data for safety and minimum

distances in a comprehensible manner.

Before they begin work, train the operating personnel on their respective tasks. The training is the

responsibility of the operating company.

Check whether the safety device (sensors, their actuators, Safety Relay, etc.) was correctly selected in

accordance with the locally applicable regulations and directives.

Attach notices in the respective national language of the operating personnel on the machine in a highly

visible location, e.g., by printing out the corresponding chapter (see chapter 8.3 „To be performed daily

by the operating personnel“).

Check whether the safety device (sensors, their actuators, Safety Relay, etc.) is operated acc. to the

specified environmental conditions (see table 13.3).

Check whether the Safety Relay, sensor and actuator are operated according to their specified environ-

mental conditions (see chapter 13 „Technical data“). Make certain that the MSI-MC3x is protected

against overcurrent.

Perform a visual inspection for damage and test the mechanical and electrical function (see chapter 8.2

„To be performed periodically by competent persons“).

Minimum requirements for the power supply unit:

• Safe mains separation

• At least 2 A current reserve

Not until proper monitoring of the guard is ascertained may it be integrated in the control circuit of the

system.

Leuze electronic MC3x 37

Page 38

8.1.1 Checklist – before the initial start-up Tester: Competent person

Table 8.1: Checklist – before the initial start-up

Check Yes No

Were all safety directives and standards relevant to this machine type

observed?

Does the Declaration of Conformity of the machine include a listing of

these documents?

Do the Safety Relay, sensor and actuator satisfy the safety-related

capability (PL, category) as required by the risk assessment?

Circuit diagram: Are both safety-related switching outputs (OSSDs)

integrated in the downstream machine control acc. to the required

safety category?

Circuit diagram: Are the switching elements (e.g. contactors, relays)

with positive-guided contacts that are controlled by the MSI-MC3x

Safety Relay monitored by a feedback circuit (EDM)?

Testing

Have the cables been laid separately/in a protected manner?

Does the electrical wiring match the circuit diagrams?

Have the required protective measures against electrical shock been

effectively implemented?

Has the maximum stopping time of the machine been remeasured and

recorded in the machine documents?

Is the required safety distance between the guard (moveable part of the

guard) and the nearest point of operation maintained, taking into

account all response times?

Are all of the machine's points of operation accessible only through the

monitored moveable part of the guard?

Are all additional protective devices (e.g. safety guards) correctly

mounted and protected against tampering?

Is the reset button for releasing the start/restart interlock of the MSIMC3x mounted outside of the danger zone in accordance with specifications in such a way that it cannot be reached from within the danger

zone? Can the entire danger zone be seen from the place at which the

reset button is installed?

Are sensor and actuator correctly aligned and are all fastening screws

and plugs secure?

Are all parts of the safety device undamaged and without signs of tampering?

Has the effectiveness of the protective function been checked for all

operating modes of the machine by means of a function test?

Does opening of the monitored moveable part of the guard cause the

dangerous process to stop in such a way that the dangerous process

cannot be reached during the stopping time?

Leuze electronic MC3x 38

Page 39

Check Yes No

Upon disconnection of the MSI-MC3x from the supply voltage, does the

dangerous process stop? If reaching or stepping around is possible, is it

necessary to actuate the reset button to reset the machine after the

supply voltage is restored?

Are the sensors and the Safety Relay effective during the entire dangerous process of the machine and do they cause the dangerous movement to stop?

Are the notices for recommended daily testing of the safety device legible to the operating personnel and are they located in a highly visible

location?

Store this checklist with the machine documents.

8.2 To be performed periodically by competent persons

The reliable interaction of guard and machine must be periodically tested in order to detect changes to the

machine or impermissible tampering with the guard. Testing intervals are determined by nationally appli-

cable regulations (recommendation acc. to IEC TS62046: 6 months).

Have all tests performed by competent persons.

Observe the nationally applicable regulations and the time periods specified therein.

Testing

8.3 To be performed daily by the operating personnel

We recommend that the safety device be checked daily or at change of shifts and at each change of

machine operating mode acc. to the following checklist (see chapter 8.3.1 „Check list – daily or at change

of shift“) so that damages or impermissible tampering can be detected.

WARNING

If the daily check is carried out incorrectly, further operation of the machine can lead to severe injuries!

Replace damaged components immediately.

The machine must no longer be operated if you answer one of the items in the following checklist (see

chapter 8.3.1 „Check list – daily or at change of shift“) with no.

Have the entire machine inspected by a competent person (see chapter 8.1 „Before the initial start-up

and following modifications“).

Stop the dangerous process.

Check sensor and actuator for damage or tampering.

Open doors, hoods, flaps, etc., from a location outside of the danger zone and make certain that the

machine cannot be started while the guards are open.

Make certain that no one is present in the danger zone.

Close the guard and start the machine.

Make certain that the dangerous state stops as soon as the guard is opened.

8.3.1 Check list – daily or at change of shift Tester: Authorized operator or instructed person

Leuze electronic MC3x 39

Page 40

Check Yes No

Are sensor and actuator in the correct position and are the housing

markings aligned?

Are all fastening screws tightened; are all connectors fastened?

Are sensor and actuator, connection cable, plug and reset button

undamaged and without signs of tampering?

Are sensor and actuator free of deposits (e.g., ferromagnetic filings)?

Are all point of operation of the machine accessible only through monitored moveable guards or equivalent protective devices?

Are all additional protective devices mounted correctly (e.g., safety

guard)?

Is it impossible to walk or reach behind?

Does the start/restart interlock (where foreseen) prevent the automatic

start-up of the machine after switching on or activating

• the Magnetically Coded Sensor

• the Safety Relay?

Is the dangerous process brought to an immediate standstill upon opening of the guard? Does the dangerous process end before the point of

operation can be reached?

Testing

Leuze electronic MC3x 40

Page 41

9 Cleaning

NOTICE

Operating faults due to impairment caused by ferromagnetic particles.

Sensor and actuator must be free of ferromagnetic soiling.

Use no cleaning agents that contain solvents.

Prerequisites for cleaning:

• The system is safely shut down and protected against being restarted.

• Remove metal dust, iron filings, etc.

Clean sensor and actuator depending on degree of contamination

• with, e.g., a vacuum cleaner or a clean cloth

• with solvent-free cleaning agents

Cleaning

Leuze electronic MC3x 41

Page 42

10 Rectifying the fault

10.1 What to do in case of failure?

After switching on the Safety Relay, display elements (see chapter 3.1 „Device overview“) assist in

checking the proper function and troubleshooting.

In case of failure, use the LEDs to recognize the fault and initiate rectification measures.

NOTICE

If the MSI-MC3x does not switch on with closed guard, a component may be defective.

Switch off the machine and protect it against being restarted.

Analyze and eliminate the cause of the fault using the following table.

If you are unable to rectify the fault, contact the Leuze branch responsible for you or call the Leuze

electronic Hotline (see chapter 12 „Service and support“).

10.2 Rectifying the fault

Rectifying the fault

Power sup-

Display OSSDs Cause Measure

ply unit

On “Supply” LED on K1, K2 off Guard open Close the guard.

On “Supply” LED on K1, K2 off Sensor incorrectly

Correct the sensor again.

aligned

On “Supply” LED on K1, K2 off Actuator missing Mount the corresponding actua-

tor.

On “Supply” LED on K1, K2 off Sensor defective Replace the respective sensor.

On “Supply” LED off K1, K2 off Fuse U

On “Supply” LED off K1, K2 off MSI-MC310 defec-

defective Replace fuse Ub.

b

Replace the Safety Relay.

tive

Off “Supply” LED off K1, K2 off No operating volt-

Switch on the power supply unit.

age

??? “Supply” LED off K1, K2 off Power supply unit

Replace the power supply unit.

defective

On “Supply” LED on K1, K2 on External fuse in

Replace the external fuse.

switch-off circuit

defective

On “Supply” LED off K1, K2 off External short circuit

U

b

On “Supply” LED on K1, K2 on External cross con-

nection in the

Rectify the short circuit and

replace the fuse.

Rectify the cross connection and

replace the fuse.

switch-off circuit

Leuze electronic MC3x 42

Page 43

11 Disposing

For disposal observe the applicable national regulations regarding electronic components.

Disposing

Leuze electronic MC3x 43

Page 44

12 Service and support

Telephone number for 24-hour standby service:

+49 (0) 702 573-0

Service hotline:

+49 (0) 8141 5350-111

Monday to Thursday, 8.00 a.m. to 5.00 p.m. (UTC+1)

Friday, 8.00 a.m. to 16.00 p.m. (UTC +1)

E-mail:

service.protect@leuze.de

Return address for repairs:

Service Center

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Service and support

Leuze electronic MC3x 44

Page 45

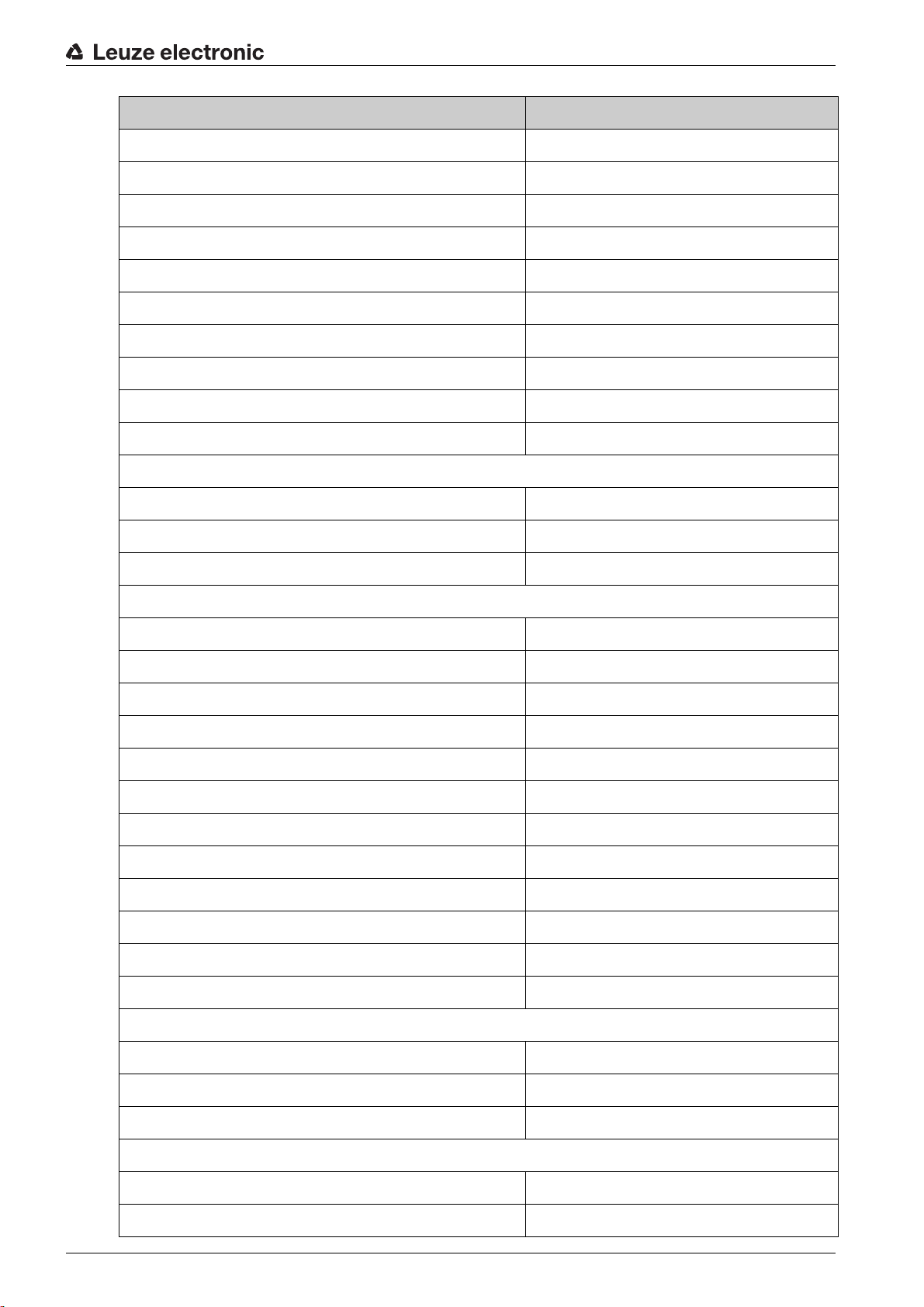

13 Technical data

13.1 Magnetically Coded Sensors, actuator, contact set 1NC/1NO

Table 13.1: Safety-relevant technical data

Actuator, external Magnetically coded, compatible with respective sensor

series

Safe switching distances and off distance if markings are aligned:

Sao = assured cut-in distance

OFF = cut-out point

Sar = assured cut-out distance

388 series: Sao (ON), (OFF), Sar < 6 mm, > 13 mm, > 30 mm

336 series: Sao (ON), (OFF), Sar < 3 mm, > 8 mm, > 11 mm

330 series: Sao (ON), (OFF), Sar < 6 mm, > 12 mm, > 14 mm

Technical data

Switching tolerance (without ferromagnetic

± 1 mm

materials in immediate vicinity)

Certification TÜV-SÜD, cULus

Contact type Reed contacts (magnetically sensitive)

Contact allocation 1NC/1NO

Mechanical life time 10 million switching cycles

Max. switching voltage 27 V AC/DC

Switched current Ie max. 0.5 A

Short circuit protection By means of MSI-MC310 Safety Relay

Installation point Arbitrary, provided housing markings are aligned

Min. distance to other magnetic sensors 50 mm

Approach actuation directions In longitudinal axis, left and right

In vertical axis, up and down

In depth, to and from sensor

Min. approach speed of actuator towards sen-

50 mm/s

sor

Response time 3 ms

Table 13.2: Connection

Number of connection cable infeeds 1 (connection cable or M8 plug)

Connection type Connection cable with wire-end sleeves or M8 plug,

each molded to housing

Conductor cross-section (stranded) 4 x 0.35 mm

Leuze electronic MC3x 45

²

(connection cable)

Page 46

Table 13.3: Environment

Ambient temperature, operation -20 … +70 °C

Vibration, sensitivity acc. to EN 60947-5-3:2005

Shock, sensitivity acc. to EN 60947-5-3:2005

Technical data

Dirt level, external,

3

in accordance with EN 60947-1

EMC compliance EN 60947-5-3:2005

EN 61000-6-3:2007

EN 61000-6-2:2005

EN 55011:2003

Table 13.4: Housing

Sensor material Plastic, glass fiber reinforced (PPS)

Actuator material Plastic, glass fiber reinforced (PPS)

Dimensions (dimensional drawings) see chapter 14 „Dimensions and weights“

Protection rating acc. to EN 60529 IP 67

13.2 Magnetically Coded Sensors, actuator, contact set 2NO

Table 13.5: Safety-relevant technical data

Actuator, external Magnetically coded, compatible with respective sensor

series

Safe switching distances and off distance if markings are aligned:

Sao = assured cut-in distance

OFF = cut-out point

Sar = assured cut-out distance

388 series: Sao (ON), (OFF), Sar < 9 mm, > 19 mm, > 22 mm

336 series: Sao (ON), (OFF), Sar < 7 mm, > 17 mm, > 20 mm

330 series: Sao (ON), (OFF), Sar < 6 mm, > 15 mm, > 18 mm

Switching tolerance (without ferromagnetic

± 1 mm

materials in immediate vicinity)

Certification TÜV-SÜD, cULus

Contact type Reed contacts (magnetically sensitive)

Contact allocation 2NO with upstream fuse

Mechanical life time 10 million switching cycles

Max. switching voltage 27 V AC/DC

Switched current Ie max. 100 mA

Short circuit protection By means of MSI-MC311 Safety Relay

Installation point Arbitrary, provided housing markings are aligned

Min. distance to other magnetic sensors 50 mm

Leuze electronic MC3x 46

Page 47

Approach actuation directions In longitudinal axis, left and right

In vertical axis, up and down