Page 1

EN 2015/05 50123881

We reserve the right to

Original operating instructions

make technical changes

CML 730i

Measuring light curtain

Page 2

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.de

Leuze electronic CML 730i 2

Page 3

1 About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1 ≥sed symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 ≤erms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 General performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Connection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4.1 Operation indicators on the receiver control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4.2 Display on the receiver control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.3 Operating indicators on the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Operating elements on the receiver control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6 Menu structure of the receiver control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.7 Menu navigation on the receiver control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7.1 Meaning of the display icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7.2 Level display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7.3 Menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.4 Editing value parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.5 Editing selection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Beam modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.1 Parallel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.2 Diagonal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.3 Crossed-beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Measurement beam sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Beam-stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4 Evaluation functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5 Hold function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.6 Blanking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.7 Power-≥p ≤each . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.8 Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.9 Cascading/triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9.1 External triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.9.2 Internal triggering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.10 Block evaluation of beam areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10.1Defining beam area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10.2Autosplitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10.3Mapping beam area to switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.10.4≤each height area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.11 Switching outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.11.1Light/dark switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.11.2≤ime functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.12 Interference suppression (filter depth). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Leuze electronic CML 730i 3

Page 4

5.1 Height measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2 Object measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3 Width measurement, orientation detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4 Contour measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5 Gap control/gap measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.6 Hole recognition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6 Mounting and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1 Mounting the light curtain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2 Definition of directions of movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Fastening via sliding blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.4 Fastening via swivel mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.5 Fastening via swiveling mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1 Shielding and line lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1.1 Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1.2 Cable lengths for shielded cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.2 Connection and interconnection cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

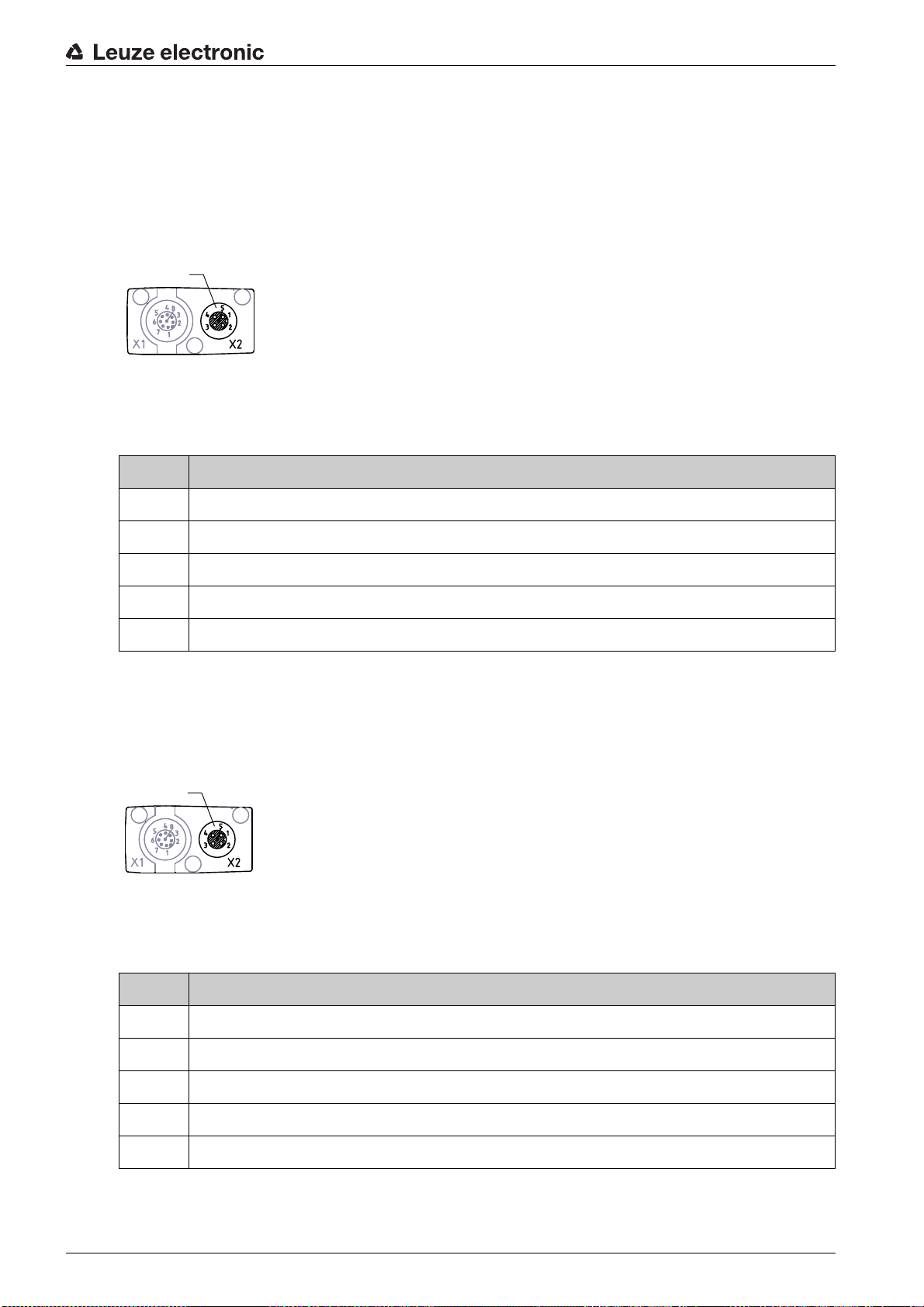

7.3 Device connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4 Digital inputs/outputs on connection X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.5 Electrical connection – CML 700i with IO-Link/analog interface . . . . . . . . . . . . . . . . . . . . 54

7.5.1 X1 pin assignment – CML 700i with IO-Link interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.5.2 X1 pin assignment – CML 700i with analog interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.5.3 X2/X3 pin assignment – CML 700i with IO-Link/analog interface . . . . . . . . . . . . . . . . . . . 56

7.6 Electrical connection – CML 700i with fieldbus interface. . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.6.1 Pin assignment – CML 700i with fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.6.2 X2 pin assignment – CML 700i with CANopen interface. . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.6.3 X2 pin assignment – CML 700i with Profibus or RS 485 Modbus interface . . . . . . . . . . . 59

7.7 Electrical supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8 Starting up the device - Basic configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.1 Aligning transmitter and receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2 ≤eaching the environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.2.1 ≤each via receiver control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.2.2 ≤eaching via a control signal from the control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.3 Check alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.4 Setting the function reserve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5 Extended configurations on the receiver control panel menu . . . . . . . . . . . . . . . . . . . . . . 67

8.5.1 Define digital inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.5.2 Inversion of the switching behavior (light/dark switching) . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.5.3 Defining the filter depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.5.4 Defining the display properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.5.5 Changing the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.5.6 Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.5.7 Reset to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9 Starting up the device - Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.1 Analog output configuration on the receiver control panel . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2 Analog output configuration via the

9.3 Behavior of the analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Sensor Studio

configuration software . . . . . . . . . . . . 73

10 Starting up the device - IO-Link interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Leuze electronic CML 730i 4

Page 5

10.1 Defining IO-Link device configurations on the receiver control panel . . . . . . . . . . . . . . . . 76

10.2 Defining configurations via the IO-Link master module of the PLC-specific software . . . . 76

10.3 Parameter/process data for IO-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11 Starting up the device - CANopen interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.1 Defining the CANopen basic configuration on the receiver control panel . . . . . . . . . . . . . 92

11.2 Defining configurations via the PLC-specific software of the CANopen master . . . . . . . . 92

11.3 Parameter- / process data for CANopen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

12 Starting up the device - Profibus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.1 Defining the Profibus basic configuration on the receiver control panel . . . . . . . . . . . . . 109

12.2 Defining configurations via the PLC-specific software. . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.3 Parameter/process data for Profibus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

12.3.1General information on Profibus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

12.3.2Configuration parameters or process data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13 Starting up the device - RS 485 Modbus interface. . . . . . . . . . . . . . . . . . . . . . 120

13.1 Defining the RS 485 Modbus basic configuration on the receiver control panel . . . . . . . 120

13.2 Defining configurations via the RS 485 Modbus interface module of the PLC software . 120

13.2.1Modbus read access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

13.2.2Modbus write access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13.2.3Error check (CRC calculation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13.2.4Defining configurations via the PLC-specific software. . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13.3 Parameter/process data for RS 485 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

13.4 Autosend mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

14 Example configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

14.1 Example configuration - Reading out 64 beams (beam-stream). . . . . . . . . . . . . . . . . . . 137

14.1.1Configuration of beam-stream process data via IO-Link interface . . . . . . . . . . . . . . . . . 137

14.1.2Configuration of beam-stream process data via CANopen interface . . . . . . . . . . . . . . . 137

14.1.3Configuration of beam-stream process data via Profibus interface . . . . . . . . . . . . . . . . . 137

14.1.4Configuration of beam-stream process data via RS 485 Modbus interface . . . . . . . . . . 138

14.2 Example configuration - Mapping of beams 1 … 32 to output pin 2 . . . . . . . . . . . . . . . . 138

14.2.1Configuration of area/output mapping (general) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

14.2.2Configuration of an area/output mapping via IO-Link interface . . . . . . . . . . . . . . . . . . . . 139

14.2.3Configuration of area/output mapping via CANopen interface . . . . . . . . . . . . . . . . . . . . 140

14.2.4Configuration of area/output mapping via Profibus interface. . . . . . . . . . . . . . . . . . . . . . 140

14.2.5Configuration of area/output mapping via RS 485 Modbus interface . . . . . . . . . . . . . . . 140

14.3 Example configuration - Hole recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

14.3.1Configuration of hole recognition via IO-Link interface . . . . . . . . . . . . . . . . . . . . . . . . . . 141

14.3.2Configuration of hole recognition via CANopen interface . . . . . . . . . . . . . . . . . . . . . . . . 142

14.3.3Configuration of hole recognition via Profibus interface . . . . . . . . . . . . . . . . . . . . . . . . . 142

14.3.4Configuration of hole recognition via RS 485 Modbus interface . . . . . . . . . . . . . . . . . . . 142

14.4 Example configuration - Activating and deactivating blanking areas. . . . . . . . . . . . . . . . 143

14.4.1Configuration of blanking areas (general) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

14.4.2Configuration of blanking areas via IO-Link interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

14.4.3Configuration of blanking areas via CANopen interface . . . . . . . . . . . . . . . . . . . . . . . . . 144

14.4.4Configuration of blanking areas via Profibus interface . . . . . . . . . . . . . . . . . . . . . . . . . . 144

14.4.5Configuration of blanking areas via RS 485 Modbus interface . . . . . . . . . . . . . . . . . . . . 145

14.5 Example configuration – smoothing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

14.5.1Smoothing configuration (general) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

14.5.2Configuration of smoothing via IO-Link interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

14.5.3Configuration of smoothing via CANopen interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

14.5.4Configuration of smoothing via Profibus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

14.5.5Configuration of smoothing via RS 485 Modbus interface . . . . . . . . . . . . . . . . . . . . . . . 146

Leuze electronic CML 730i 5

Page 6

14.6 Example configuration - Cascading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

14.6.1Configuration of a cascading arrangement (general) . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

14.6.2Configuration of a cascading arrangement via IO-Link interface. . . . . . . . . . . . . . . . . . . 148

14.6.3Configuration of a cascading arrangement via CANopen interface. . . . . . . . . . . . . . . . . 150

14.6.4Configuration of a cascading arrangement via Profibus interface . . . . . . . . . . . . . . . . . . 152

14.6.5Configuration of a cascading arrangement via RS 485 Modbus interface . . . . . . . . . . . 154

15 Connecting to a PC –

15.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

15.2 Installing

15.2.1Installing the

15.2.2Installing drivers for IO-Link ≥SB master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

15.2.3Connecting IO-Link ≥SB master to the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

15.2.4Connect the IO-Link ≥SB master to the light curtain. . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

15.2.5Installing the D≤M and IODD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

15.3 Starting the

15.4 Short description of the

15.4.1FD≤ frame menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

15.4.2

IDEN≤IFICA≤ION

15.4.3

CONFIG≥RA≤ION

15.4.4

PROCESS

15.4.5

DIAGNOSIS

15.4.6Exiting

Sensor Studio

Sensor Studio

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Sensor Studio

Sensor Studio

configuration software and IO-Link ≥SB master. . . . . . . . . . . . 158

Sensor Studio

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

FD≤ frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Sensor Studio

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

configuration software . . . . . . . . . . . . . . . . . . . . 163

16 ≤roubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

16.1 What to do in case of error? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

16.2 Operating displays of the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

16.3 Error codes in the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

17 Care, maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

17.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

17.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

17.2.1Firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

17.3 Disposing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

18 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

19 ≤echnical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

19.1 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

19.2 ≤iming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

19.3 Minimum object diameter for stationary objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

19.4 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

19.5 Dimensional drawings: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

20 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

20.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

20.2 Accessories – CML 700i with IO-Link/analog interface . . . . . . . . . . . . . . . . . . . . . . . . . . 184

20.2.1IO-Link analog interface (connection in the switch cabinet: screw terminals) . . . . . . . . . 185

20.2.2IO-Link interface (connection to IO-Link master). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

20.3 Accessories – CML 700i with CANopen, Profibus or RS 485 Modbus interface . . . . . . . 188

20.3.1CANopen interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

20.3.2Profibus or RS 485 Modbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

20.3.3Profibus/RS 485 Modbus interface (alternative terminating resistor) . . . . . . . . . . . . . . . 194

20.3.4Profibus/RS 485 Modbus interface (configuration with subsequent slave) . . . . . . . . . . . 195

Leuze electronic CML 730i 6

Page 7

20.4 Accessories - fastening technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

20.5 Accessories – PC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

20.6 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

21 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Leuze electronic CML 730i 7

Page 8

1 About this document

≤hese original operating instructions contain information regarding the proper use of the CML 700i

measuring light curtain series. It is included in the delivery contents.

1.1 ≥sed symbols and signal words

≤able 1.1: Warning symbols, signal words and symbols

Pay attention to passages marked with this symbol. Failure to observe the provided instructions could lead to personal injury or damage to equipment.

Signal word for property damage

NO≤ICE

Indicates dangers that may result in property damage if the measures for danger avoidance are not followed.

Symbol for tips

≤ext passages with this symbol provide you with further information.

About this document

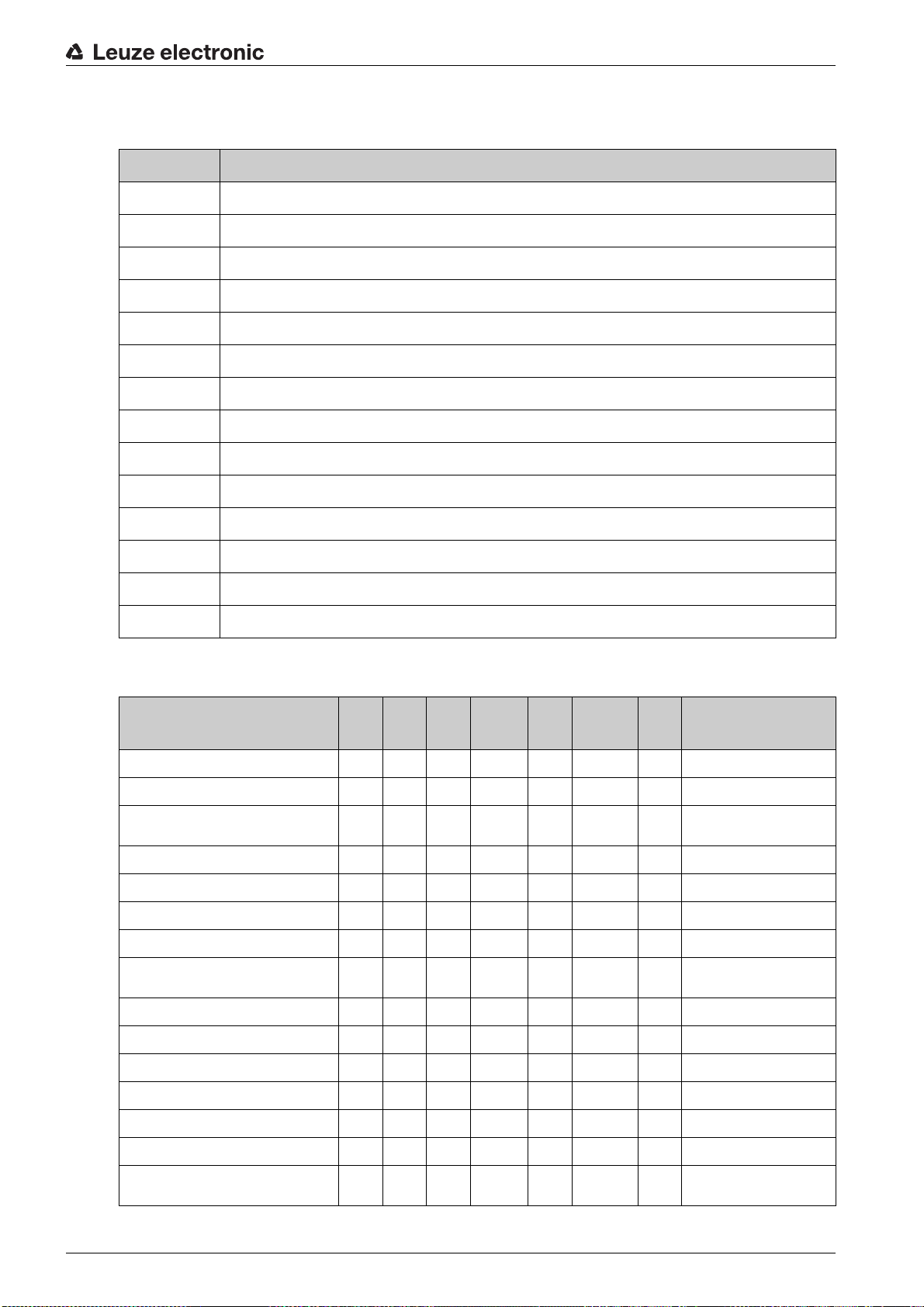

≤able 1.2: Operating on the display

Main Settings

Digital IOs

1.2 ≤erms and abbreviations

≤able 1.3: ≤erms and abbreviations

D≤M (Device ≤ype Manager) Software device manager of the sensor

IO Input Output

First Beam) First beam

FB (

FIB (First Interrupted Beam) First interrupted beam

Symbols for action steps

≤ext passages with this symbol instruct you to perform actions.

Bold text

Indicates that this field is currently selected and appears highlighted in

the receiver display.

Normal text

Indicates that this field is not currently selected (is not highlighted in the

receiver display).

FNIB (First Not Interrupted Beam) First uninterrupted beam

Field Device ≤ool) Software frame for management of device managers (D≤M)

FD≤ (

LB (Last Beam) Last beam

LIB (Last Interrupted Beam) Last interrupted beam

Last Not Interrupted Beam) Last uninterrupted beam

LNIB (

≤IB (≤otal Interrupted Beams) Number of all interrupted beams

≤otal Not Interrupted Beams) Number of all uninterrupted beams (≤NIB = n - ≤IB)

≤NIB (

n Number of all logical beams of a light curtain; dependent on the

selected measurement field length and resolution as well as the

beam mode (parallel- / diagonal- / crossed-beam scanning)

EDS Electronic Data Sheet (EDS file for CANopen interface)

Description of the device for the control

Leuze electronic CML 730i 8

Page 9

About this document

GSD Device master data file (GSD file for Profibus interface)

Description of the device for the control

IODD IO Device Description (IODD file for IO-Link interface)

Description of the device for the control

Graphical ≥ser Interface) Graphical user interface

G≥I (

R≤≥ Remote ≤erminal ≥nit (serial RS 485 Modbus R≤≥ mode)

PLC Programmable Logic Control

(corresponds to Programmable Logic Controller (PLC))

Response time per beam Length of time for the evaluation of a beam

Resolution ≤he minimum size of an object that can be reliably detected.

With parallel-beam evaluation, the smallest object to be

detected corresponds to the sum of beam spacing and optic

diameter.

Delay before start-up Duration between the switching on of the supply voltage and

the start of operational readiness of the light curtain

Function reserve (sensitivity adjustment)

Ratio of the optical reception power set during the teach event

and the minimum light quantity required to switch the individual

beam. ≤his compensates for the light attenuation caused by

dirt, dust, smoke, humidity and vapor.

High function reserve = low sensitivity

Low function reserve = high sensitivity

Meas. field length Optical detection range between the first and last beam

Beam spacing Center-to-center spacing between two beams

Cycle time Sum of the response times of all beams of a light curtain plus

the duration of the internal evaluation.

Cycle time =

number of beams x response time per beam + evaluation time

Leuze electronic CML 730i 9

Page 10

1 ≤IB (Number of all interrupted beams)

1

6

3

2

2

5

4

2 ≤NIB (Number of all uninterrupted beams)

3 LIB (Last interrupted beam )

4 LNIB (Last uninterrupted beam)

5 FNIB (First uninterrupted beam)

6 FIB (First interrupted beam)

Figure 1.1: Definition of terms

About this document

Leuze electronic CML 730i 10

Page 11

2 Safety

≤his sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

≤he device is designed as a measuring and object-detecting, configurable, multi-sensor unit.

Areas of application

≤he measuring light curtain is designed for the measurement and detection of objects for the following

areas of application in handling and warehousing systems, the packaging industry or a comparable environment:

• Height measurement

• Width measurement

• Contour measurement

• Orientation detection

CA≥≤ION

Observe intended use!

Only operate the device in accordance with its intended use.

≤he protection of personnel and the device cannot be guaranteed if the device is operated in a manner

not complying with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read the original operating instructions before commissioning the device.

Knowledge of the original operating instructions is an element of proper use.

Safety

NO≤ICE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability insurance asso-

ciation.

2.2 Foreseeable misuse

Any use other than that defined under Intended use or which goes beyond that use is considered

improper use.

In particular, use of the device is not permitted in the following cases:

• Rooms with explosive atmospheres

• Circuits relevant to safety

• Operation for medical purposes

NO≤ICE

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

≤he device must not be tampered with and must not be changed in any way.

≤he device must not be opened. ≤here are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Leuze electronic CML 730i 11

Page 12

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• ≤hey have a suitable technical education.

• ≤hey are familiar with the rules and regulations for occupational safety and safety at work.

• ≤hey are familiar with the original operating instructions of the device.

• ≤hey have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant stan-

dards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

Safety

• ≤he device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

Leuze electronic CML 730i 12

Page 13

3 Device description

X2X3

3

2 41

X1

5 6

3.1 General information

≤he light curtains of the CML 700i series are designed as measuring and object-detecting, configurable,

multi-sensor units. Depending on the configuration and model, the devices are suitable for a variety of

tasks with various resolutions and can be integrated in different control environments.

≤he total system of the light curtain consists of a transmitter and a receiver, including the connection and

interconnection cables.

• ≤ransmitter and receiver are connected to one another via a synchronization cable.

• ≤he integrated control panel with indicators and operational controls for configuring the total system

is located on the receiver.

• ≤he shared power supply is provided via connection X1 on the receiver.

Device description

1 ≤ransmitter

2 Receiver

3 IO Logic with control panel

4 Control (PLC)

5 Synchronization cable

6 Connection cable for supply voltage and measurement data interface

Figure 3.1: ≤otal system in combination with a programmable logic control

3.2 General performance characteristics

≤he most important performance characteristics of the CML 730i series are:

• Operating range up to 8000 mm

• Measurement field length from 150 mm to 2960 mm

• Beam spacings of 5 mm, 10 mm, 20 mm, 40 mm

• Response time 10 µs per beam

• Beam modes: parallel, diagonal, crossed-beam

• Single-beam evaluation (beam-stream)

• Evaluation functions: ≤IB, ≤NIB, LIB, LNIB, FIB, FNIB, status of beam areas 1 … 32, status of the

digital inputs/outputs

• Local control panel with display

• Interfaces to the machine control:

• IO-Link:

4 digital inputs/outputs (configurable)

Leuze electronic CML 730i 13

Page 14

• CANopen, Profibus-DP, RS 485 Modbus:

1

2

2 digital inputs/outputs (configurable) plus IO-Link

• Analog:

2 analog current/voltage outputs plus IO-Link

2 digital inputs/outputs (configurable)

• Blanking of unnecessary beams

• Smoothing for interference suppression

• Cascading of multiple devices

• Block evaluation of beam areas

• Position / hole recognition with continuous web material

• Detection of transparent media

3.3 Connection system

≤he transmitter and receiver feature an M12 connector with the following number of pins:

Device type Designation on device Plug/socket

Receiver X1 M12 plug (8-pin)

Receiver X2 M12 socket (5-pin)

Device description

≤ransmitter X3 M12 plug (5-pin)

3.4 Display elements

≤he display elements show the device status in operation and provide support during commissioning and

error analysis.

Located on the receiver is a control panel with the following display elements:

•two LEDs

• one OLED display (Organic Light-Emitting Diode), two-line

Located on the transmitter is the following display element:

•one LED

3.4.1 Operation indicators on the receiver control panel

≤wo function indicator LEDs are located on the receiver control panel.

1 LED1, green

2 LED2, yellow

Figure 3.2: LED indicators on the receiver

Leuze electronic CML 730i 14

Page 15

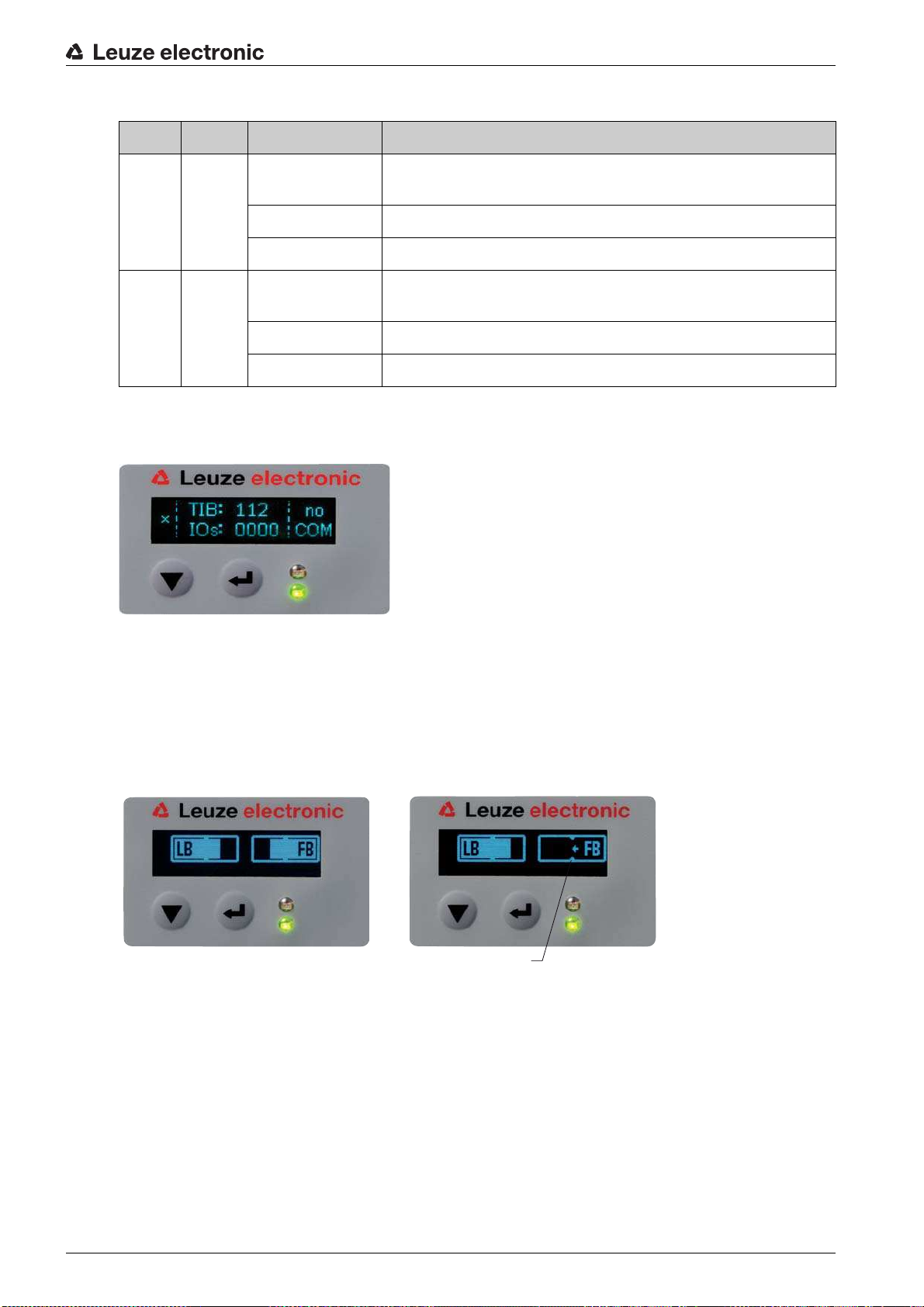

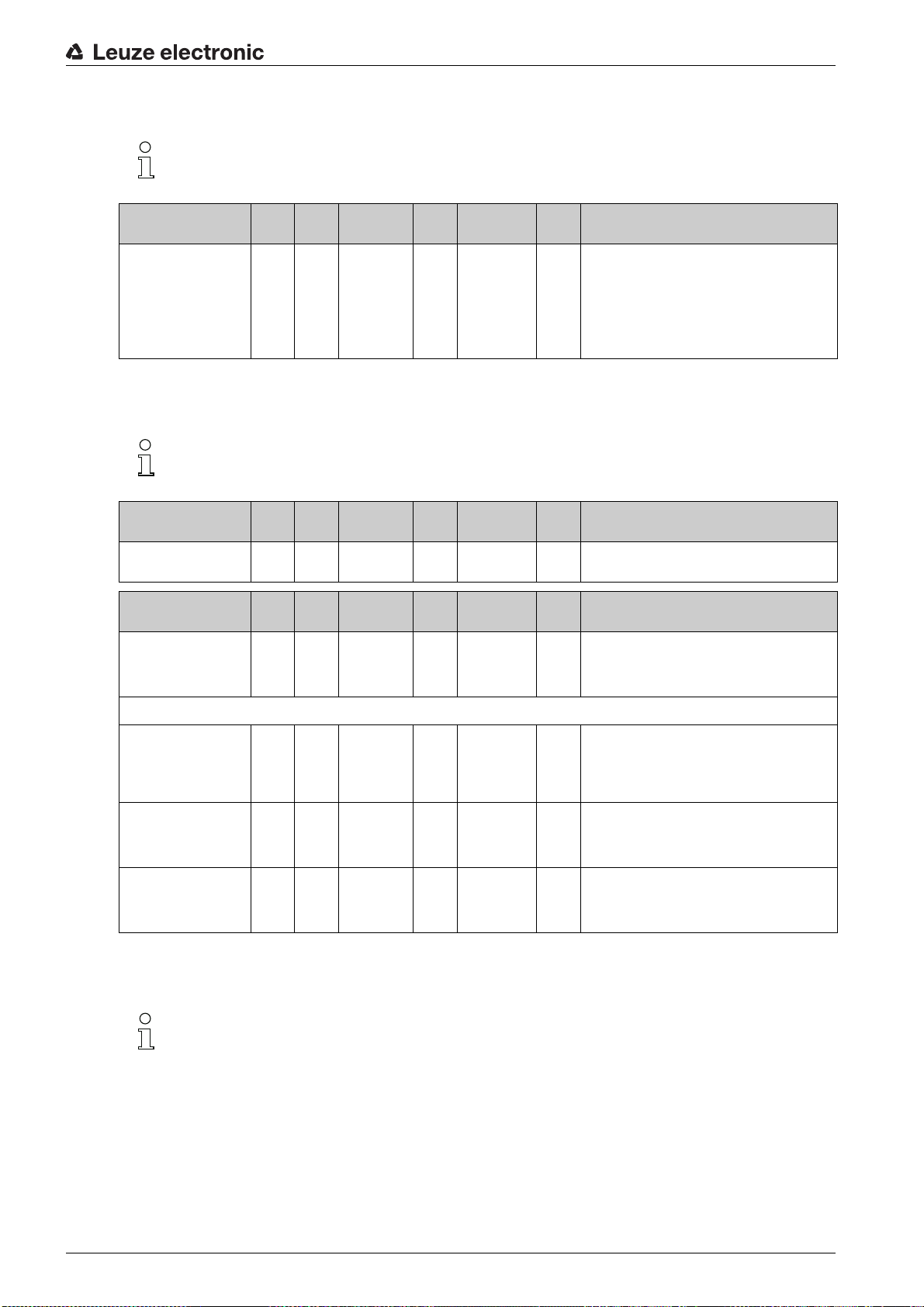

≤able 3.1: Meaning of the LEDs on the receiver

12

3

LED Color State Description

Device description

1 Green ON (continuous

light)

Flashing see chapter 16.2

OFF Sensor not ready

2 Yellow ON (continuous

light)

Flashing see chapter 16.2

OFF At least one beam interrupted (object detected)

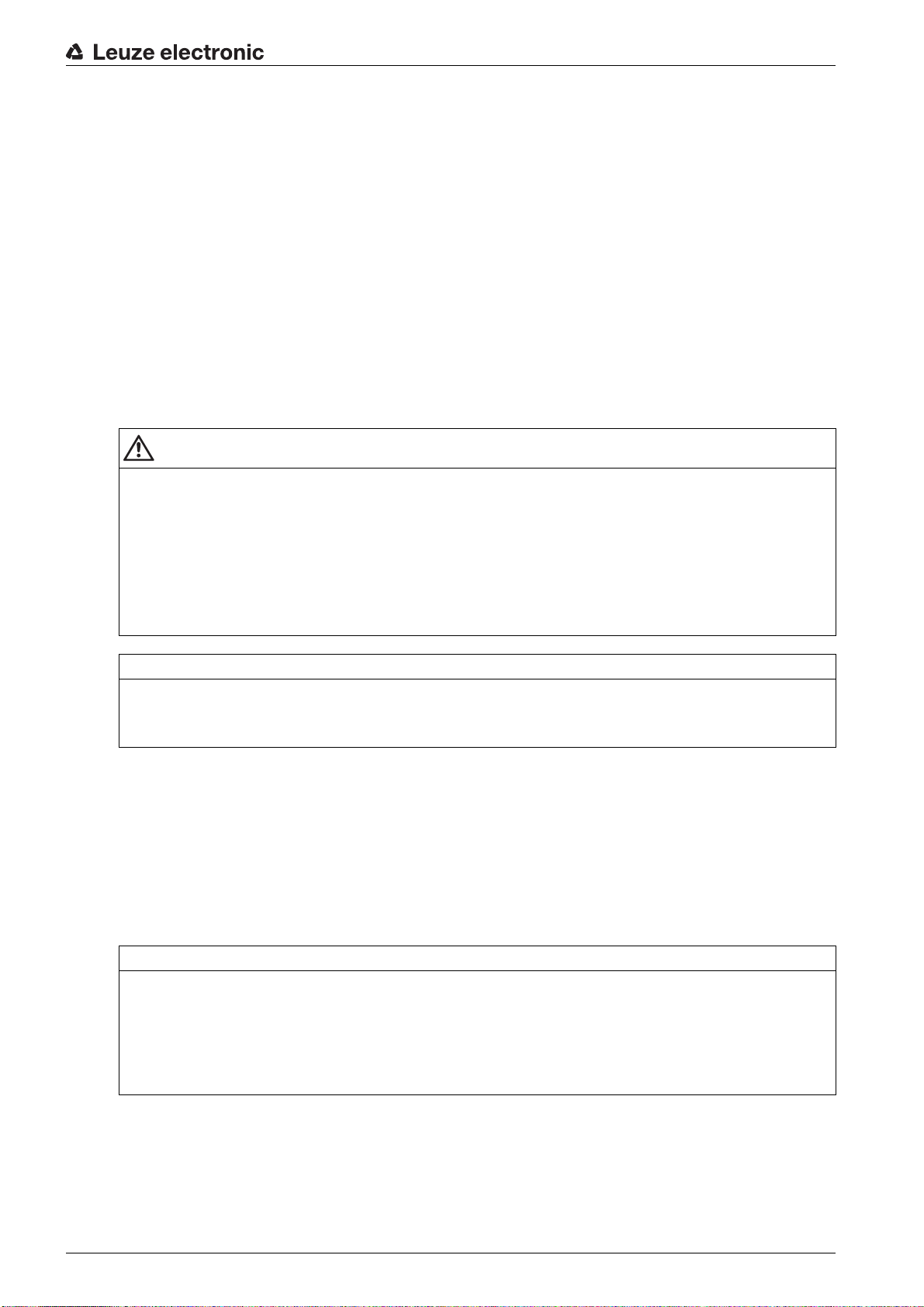

3.4.2 Display on the receiver control panel

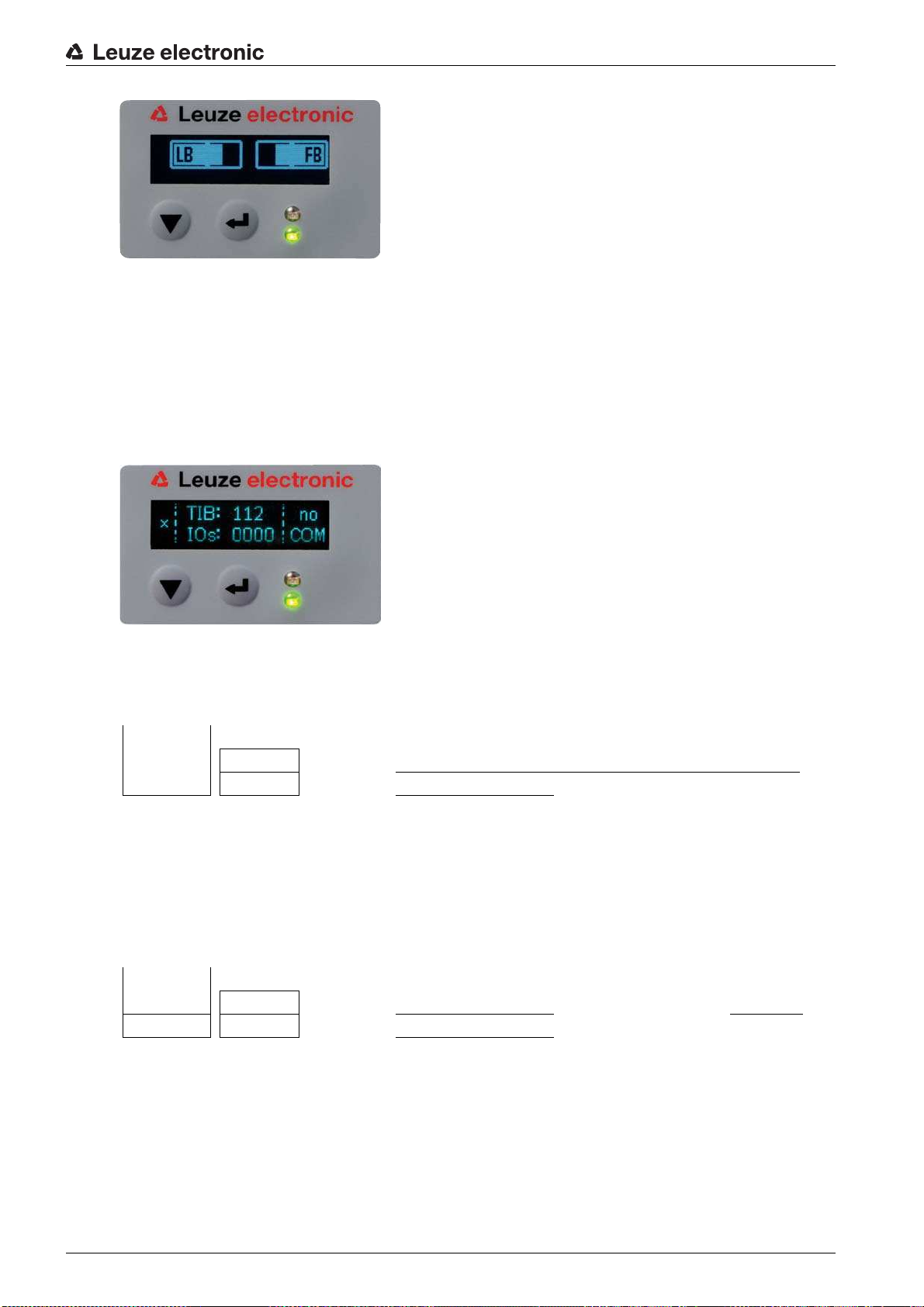

Located on the receiver is an OLED display which serves as a function indicator.

Light curtain ready (normal mode)

All active beams are free - with function reserve

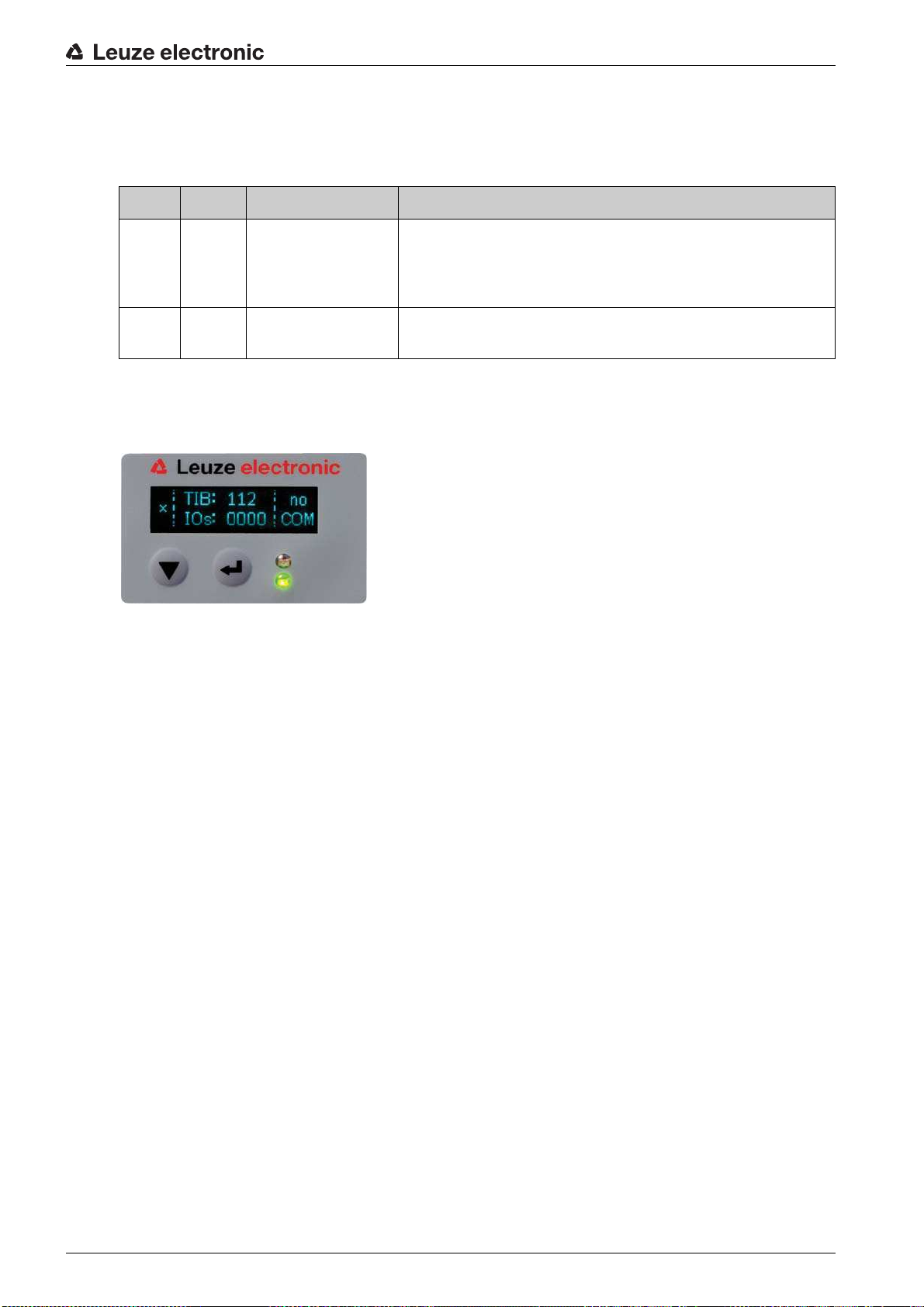

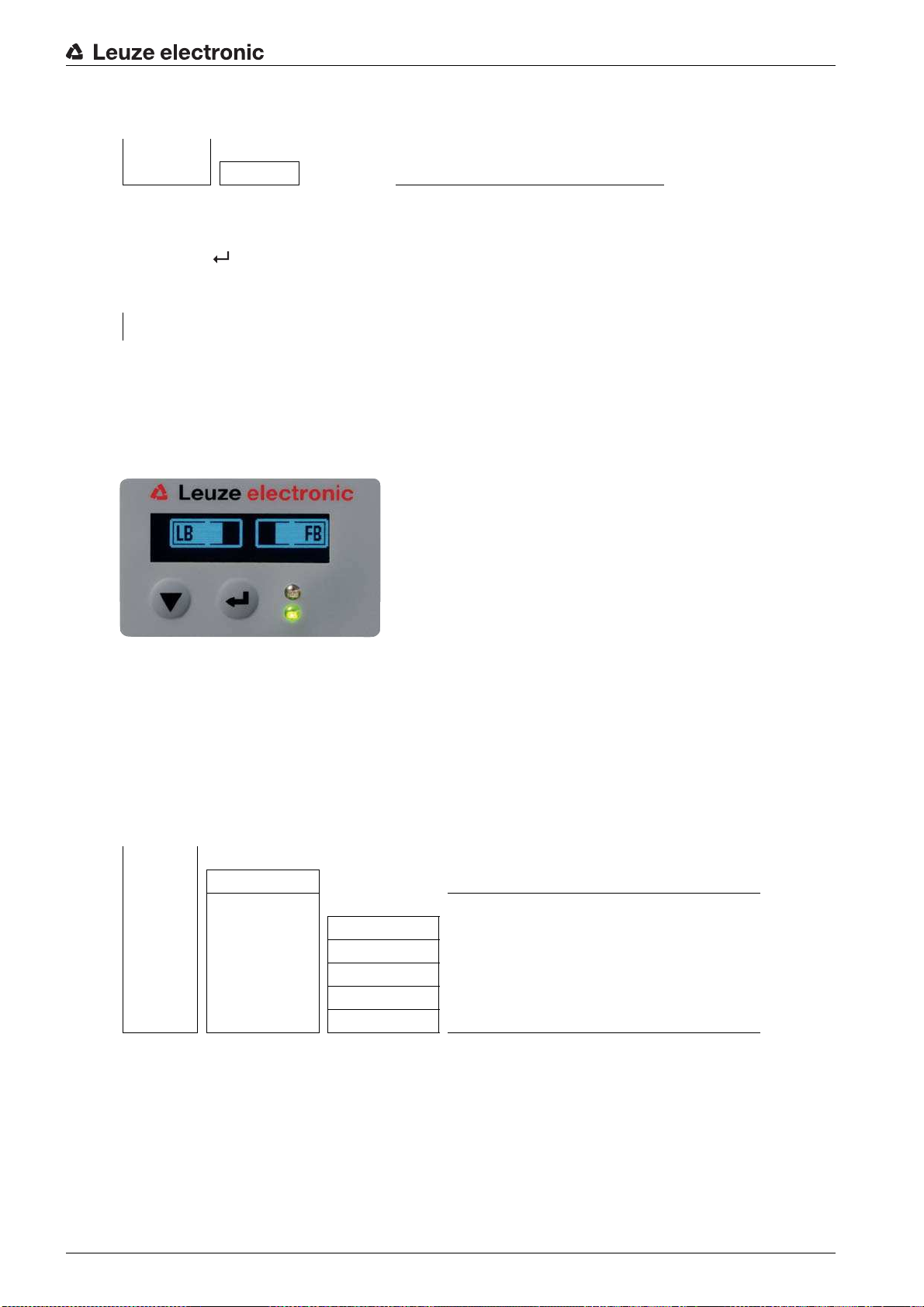

Figure 3.3: OLED display on the receiver

≤he type of display on the OLED display is different for the following operating modes:

• Alignment mode

• Process mode

Display indicators in alignment mode

In alignment mode, the OLED display shows the received signal level of the first (FB) and last (LB) beam

via two bar graph indicators.

1 Evenly aligned light curtain

2 No reception signal from first beam (FB); good reception signal from last beam (LB)

3 Marker for the minimum signal level which is to be achieved

Figure 3.4: OLED display on the receiver in alignment mode

Display indicators in process mode

In process mode, the upper line shows the number of interrupted beams (≤IB) and the lower line shows

the logic state of the digital outputs.

Leuze electronic CML 730i 15

Page 16

1 Number of interrupted beams

1

234 5

2 Logic state at pin 2 (0 = not active, 1 = active)

3 Logic state at pin 5 (0 = not active, 1 = active)

4 Logic state at pin 6 (0 = not active, 1 = active)

5 Logic state at pin 7 (0 = not active, 1 = active)

Figure 3.5: OLED display on the receiver in process mode

If the control panel is not used for several minutes, the display darkens and switches off. Press

a function button to again make the display visible. Settings for visibility, display duration, etc.

can be changed via the Display menu.

Device description

Leuze electronic CML 730i 16

Page 17

3.4.3 Operating indicators on the transmitter

Located on the transmitter is an LED which serves as a function indicator.

≤able 3.2: Meaning of the LED on the transmitter

LED Color State Description

Device description

1GreenON

(continuous light or

Light curtain operates continuously with maximum measure-

ment frequency

flashing in sync with

the measurement)

OFF No communication with the receiver

Light curtain waits for external trigger signal

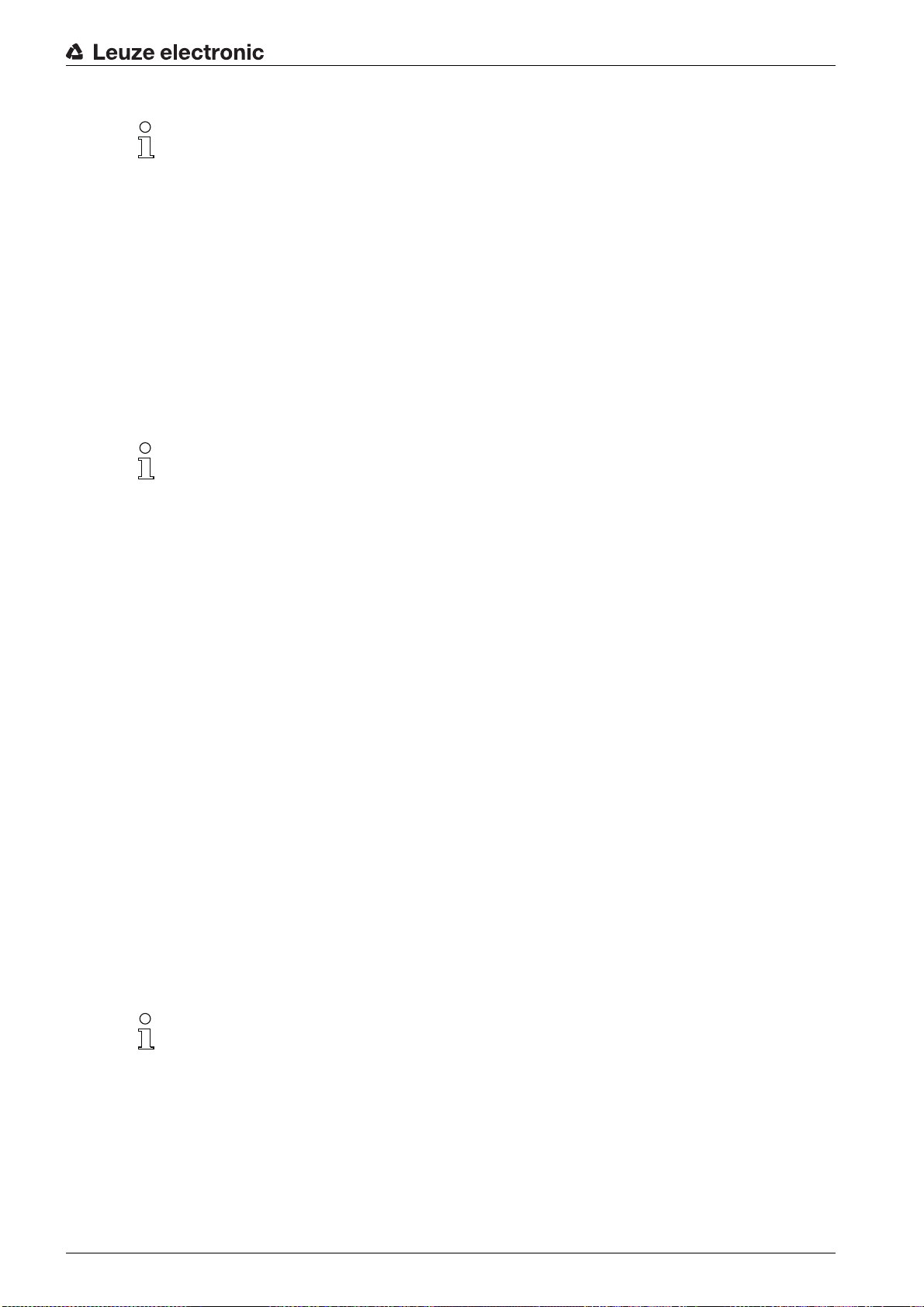

3.5 Operating elements on the receiver control panel

Located on the receiver below the OLED display is a membrane keyboard with two function buttons for

entering various functions.

Figure 3.6: Function buttons on the receiver

Leuze electronic CML 730i 17

Page 18

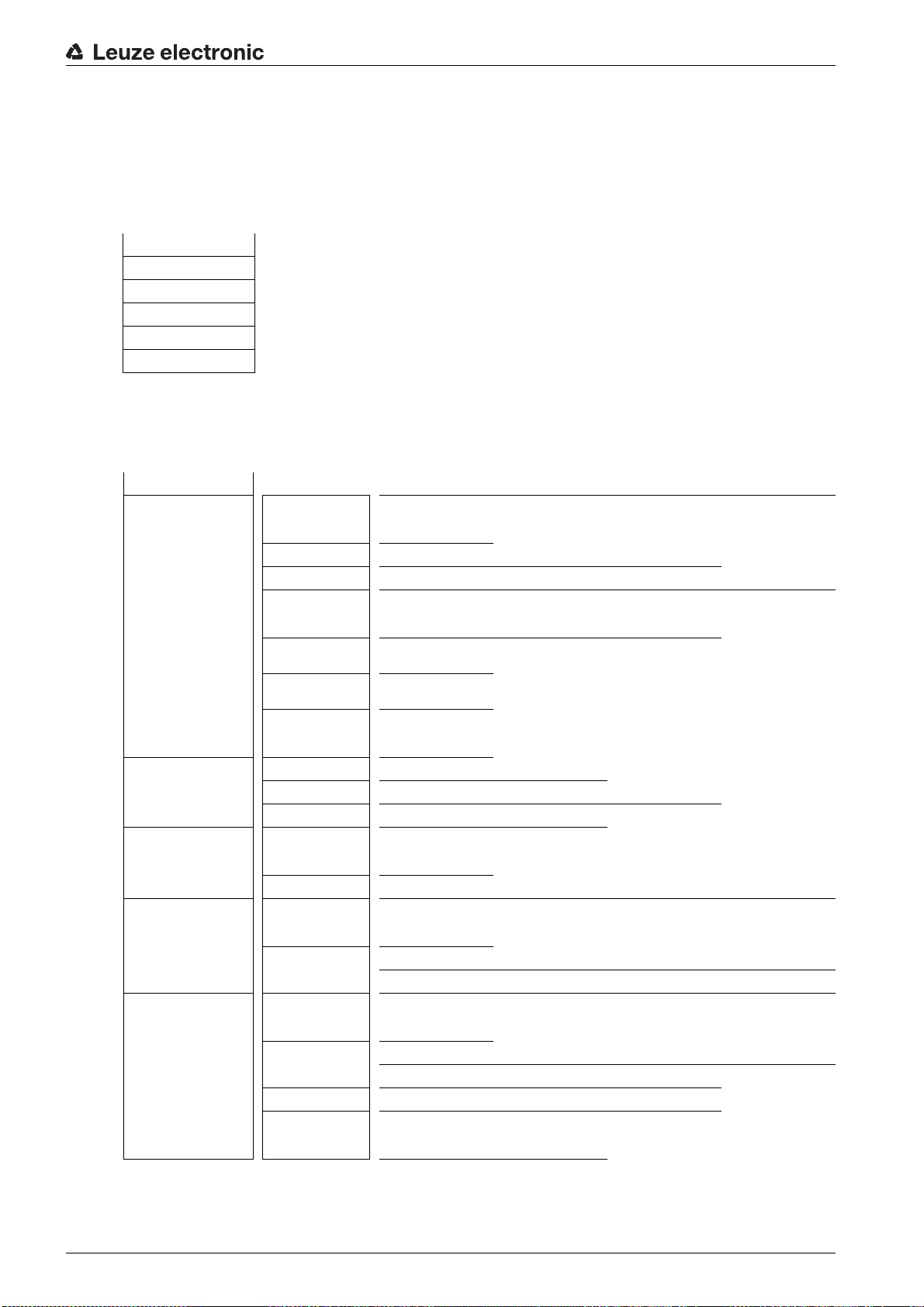

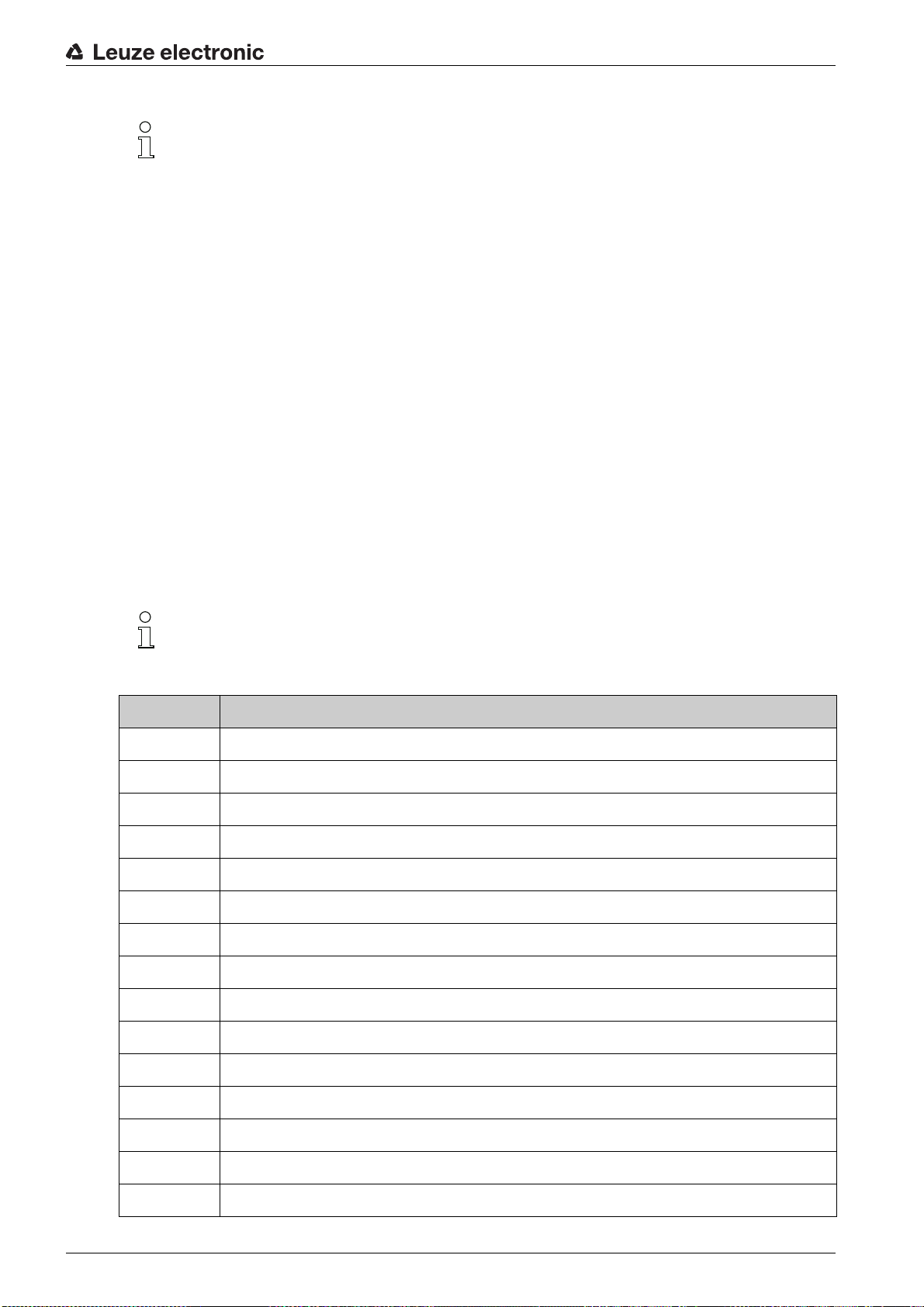

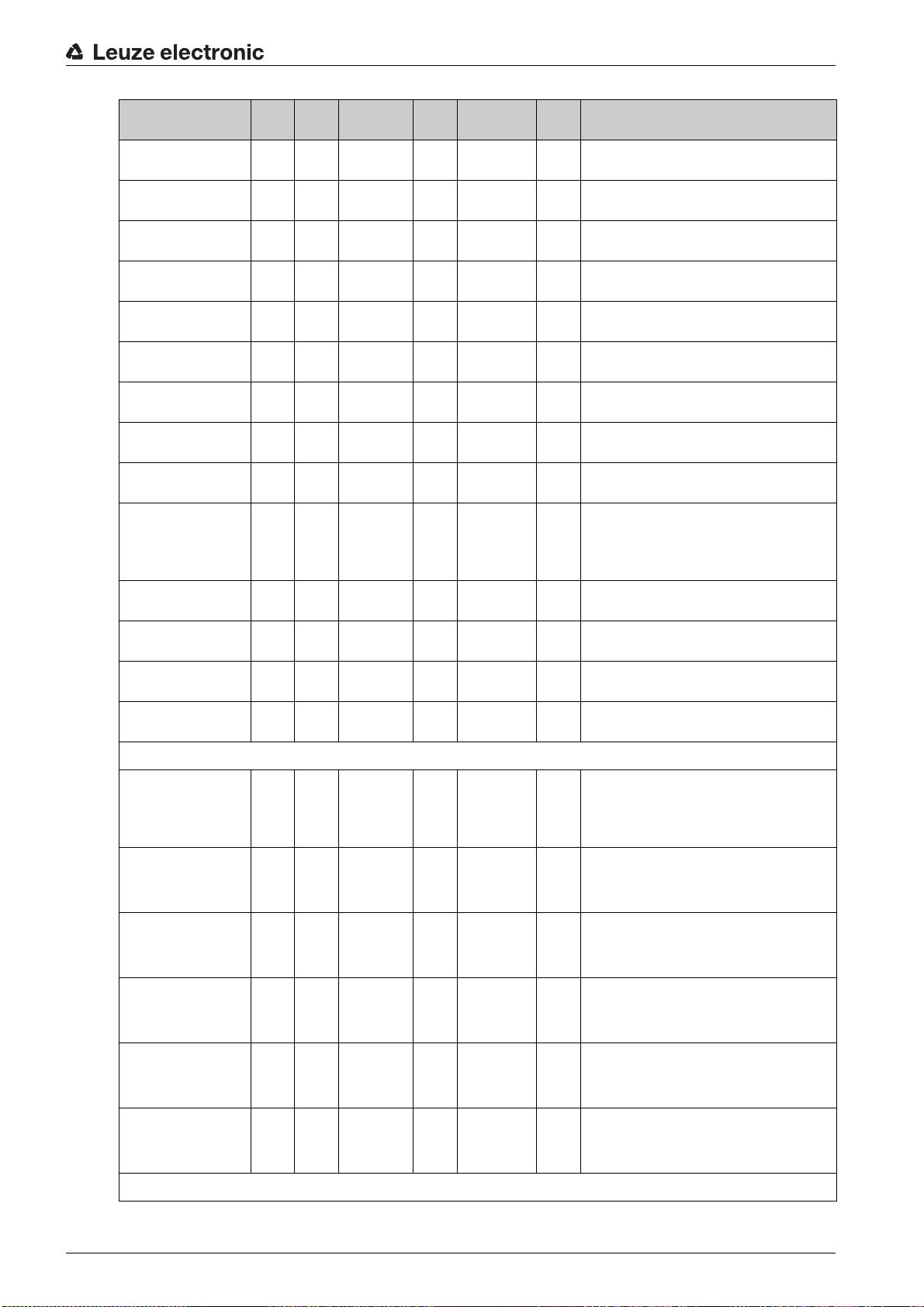

3.6 Menu structure of the receiver control panel

≤he following summary shows the structure of all menu items. In a given device model, only the actually

available menu items are present for entering values or for selecting settings.

Menu level 0

Level 0

Main Settings

Digital IOs

Analog Output

Display

Information

Exit

Menu Main Settings

Level 1 Level 2 Description

Command ≤each Reset Factory Settings Exit

Operational setting Filter Depth (enter value)

Beam mode Parallel Diagonal Crossed-beam

Function reserve High Medium Low ≤ransparent

Switching threshold (enter value)

Blanking ≤each Inactive

Power-≥p ≤each Inactive

Smoothing (enter value)

IO-Link Bit rate COM3: 230.4 kbit/s COM2: 38.4 kbit/s

PD Length 2 bytes 8 bytes 32 bytes

Data Storage Deactivated Activated

CANopen Node ID (enter value)

Bit rate 1000 kbit/s 500 kbit/s 250 kbit/s 125 kbit/s

Profibus Slave address (enter value)

Bit rate 3000 kbit/s 1500 kbit/s 500 kbit/s 187.5 kbit/s

RS 485 Modbus Slave address (enter value)

Bit rate 921.6 kbit/s 115.2 kbit/s 57.6 kbit/s 38.4 kbit/s

Parity none Straight Not straight

Silent Interval 0 =auto (enter value)

min = 1

max = 255

min = 10

max = 98

Active

Active

min = 1

max = 255

min = 1

max = 127

min = 1

max = 126

93.75 kbit/s 45.45 kbit/s 19.2 kbit/s 9.6 kbit/s

min = 1

max = 247

19.2 kbit/s 9.6 kbit/s 4.8 kbit/s

min = 1

max = 300

Device description

Leuze electronic CML 730i 18

Page 19

Device description

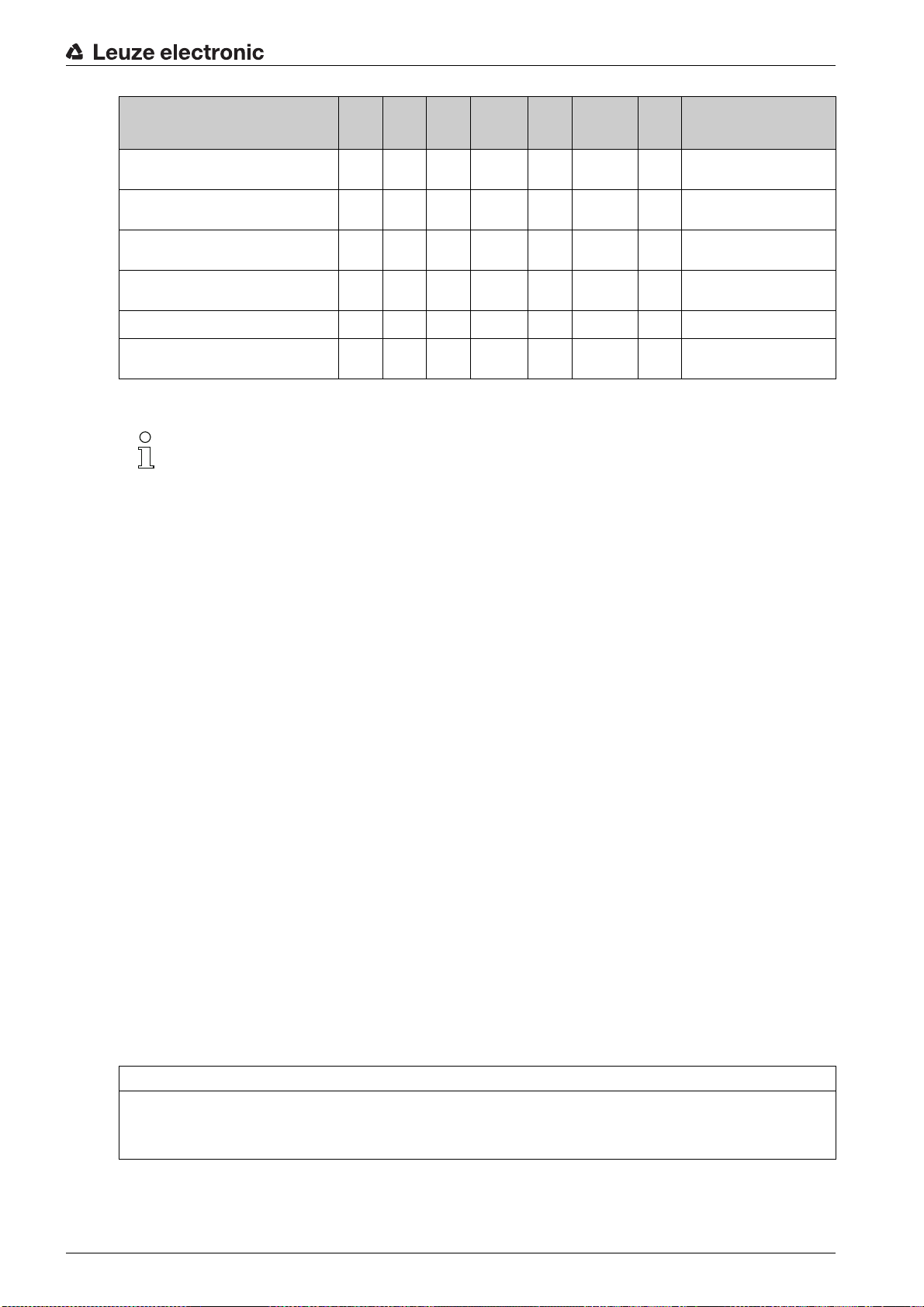

Menu Digital IOs

Level 1 Level 2 Description

IO Logic Positive PNP Negative NPN

IO Pin 2

IO Pin 5

IO Pin 6

IO Pin 7

IO Function ≤rigger In ≤each In Area Out Warn Out ≤rigger Out

Inversion Normal Inverted

≤each height Execute Exit

Area Logic AND OR

Start Beam (enter value)

End Beam (enter value)

min = 1

max = 1774

min = 1

max = 1774

Menu Analog output

Level 1 Level 2 Description

Analog Signal Off ≥: 0 … 5 V ≥: 0 … 10 V ≥: 0 … 11 V I: 4 … 20 mA I: 0 … 20 mA I: 0 … 24 mA

Analog Function Off FIB FNIB LIB LNIB ≤IB ≤NIB

Start Beam (enter value)

End Beam (enter value)

min = 1

max = 1774

min = 1

max = 1774

Menu Display

Level 1 Level 2 Description

Language English German French Italian Spanish

Mode Process mode Alignment

Visibility Off Dark Normal Bright Dynamic

≤ime ≥nit (s) (enter value)

Evaluation function ≤IB ≤NIB FIB FNIB LIB LNIB

min = 1

max = 240

Menu Information

Level 1 Level 2 Description

Product name CML 730i

Product ID Receiver part no. (e.g., 50119835)

Serial number Receiver serial number (e.g., 01436000288)

≤x.transmitter-ID ≤ransmitter part no. (e.g., 50119407)

≤x.transmitter-SN ≤ransmitter serial no. (e.g., 01436000289)

FW version e.g., 01.61

HW version e.g., A001

Kx version e.g., P01.30e

Leuze electronic CML 730i 19

Page 20

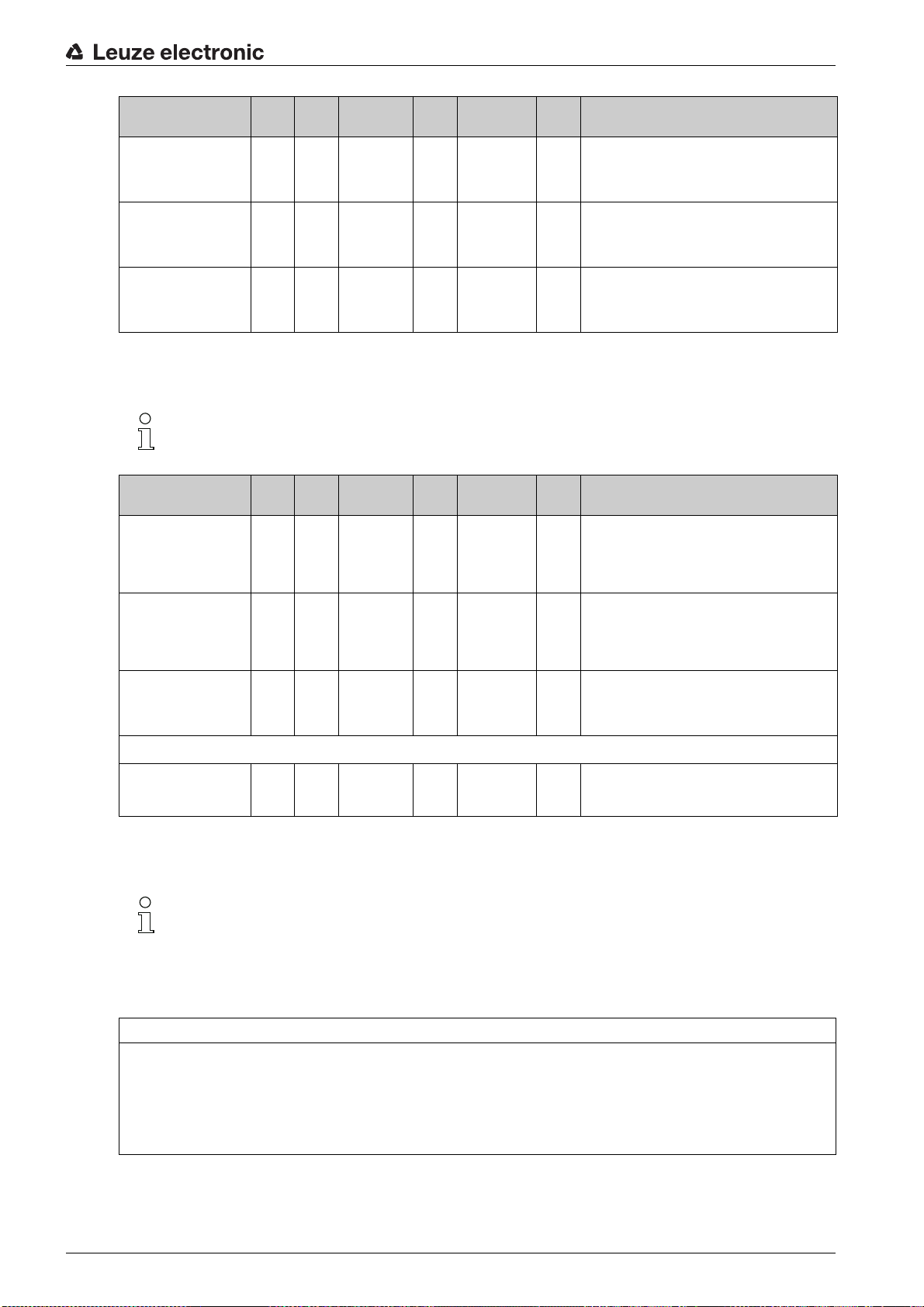

3.7 Menu navigation on the receiver control panel

≤he and buttons have different functions depending on the operating situation. ≤hese functions

are displayed at the left edge of the display above the icons.

3.7.1 Meaning of the display icons

Icon Position Function

Symbolizes that you can select the next parameter within a menu level by

First line

First line

Second line

Second line

pressing the button.

Symbolizes that you have reached the lowest menu level (not highlighted).

Symbolizes the respective, next menu level that you have not yet selected

(not highlighted).

Press the button to exit the menu level or the menu.

Device description

Second line

Second line

Second line

Second line

3.7.2 Level display

≤he display of bars between icons and text that span both lines indicates the open menu levels. ≤he

example shows a configuration in the menu level 2:

Symbolizes the input mode.

≤he selected (highlighted) option field can be a fixed selection parameter or a

multi-digit input field. With a multi-digit input field, you can increase the active

digit by one with the button and use the button to switch from one

digit to the next.

Symbolizes the confirmation of a selection.

≤his icon appears when you complete an option field with the button.

Symbolizes the rejection of a selection.

≤his icon is accessed from the previous icon (check mark) by pressing

the button. ≤his mode allows you to reject the current value or option

parameter by pressing the button.

Symbolizes the return to the selection.

≤his icon is accessed from the previous icon (cross) by pressing

the button. ≤his mode allows you to reset the current value or option

parameter for the purpose of entering a new value or selecting an option

parameter by pressing the button.

Start Beam

End Beam

Leuze electronic CML 730i 20

Page 21

3.7.3 Menu navigation

Main Settings

Digital IOs

Selects the next menu item (Digital IOs); the other menu items follow if pressed again.

Selects the highlighted submenu (Main Settings).

3.7.4 Editing value parameters

Start Beam

End Beam

Device description

Selects the Start Beam menu item with the bright background.

Start Beam

0001

Changes the value of the first digit (

0).

Selects additional numbers for configuring values.

After entering the last number, the total value can be saved, rejected or reset.

Start Beam

0010

Saves the new value (

0010).

Changes the action mode; first and then appears on the second line.

If the selected option is not saved in the window above, but rather the action mode is selected with

the button, this means:

Leuze electronic CML 730i 21

Page 22

Start Beam

0010

Rejects the current input value. ≤he display returns to the higher-order menu level: Start Beam/

End Beam

If the action mode is selected with the button, this means:

Start Beam

0010

Device description

Resets the current input value (

3.7.5 Editing selection parameters

IO Logic

IO Pin 2

Selects the IO Logic menu item with the bright background.

IO Logic

Positive PNP

0001) and allows the entry of new values.

With each actuation, displays the next option on this menu level, i.e., the display switches

between:

• Negative NPN

• Positive PNP

Selects the Positive PNP menu item with the bright background.

Leuze electronic CML 730i 22

Page 23

Device description

IO Logic

Positive PNP

Changes the action mode; appears; subsequent actuation displays or again.

Saves the selected option Positive PNP.

Leuze electronic CML 730i 23

Page 24

4 Functions

1

≤his chapter describes the functions of the light curtain for adaptation to different applications and operating conditions.

4.1 Beam modes

4.1.1 Parallel

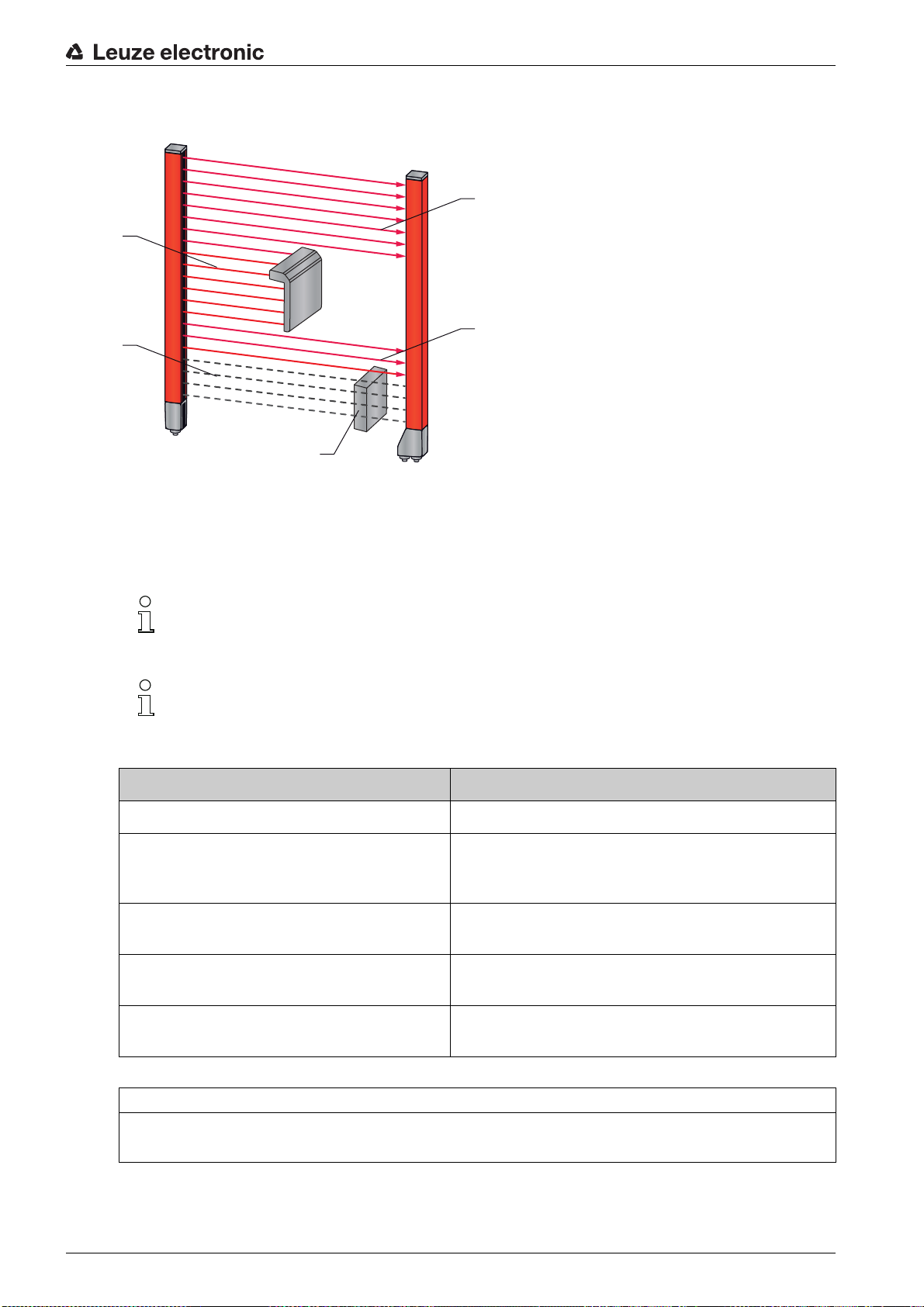

In parallel-beam mode (parallel-beam scanning), the light beam of each transmitter LED is detected by

the directly opposing receiver LED.

Functions

Figure 4.1: Beam path in parallel beam mode

4.1.2 Diagonal

In diagonal beam mode, the light beam of each transmitter diode is received in succession both by the

directly opposing receiver diode as well as by the next receiver diode in the counting direction (i-1) (parallel

and diagonal beam path). ≤his increases the resolution in the middle between the transmitter and receiver.

1 Area with increased resolution

Figure 4.2: Beam path in diagonal beam mode

Leuze electronic CML 730i 24

Page 25

Functions

1

Calculation

≤he number of beams for diagonal-beam scanning n

beam scanning n

.

p

is calculated from the number of beams for parallel-

d

Formula for calculating the number of beams for diagonal-beam scanning

n

[number] = number of beams for diagonal-beam scanning

d

n

[number] = number of beams for parallel-beam scanning

p

Example: 288 beams in parallel-beam scanning become 575 logical individual beams in diagonal-beam

scanning, which must be taken into account during evaluation functions. With a beam spacing of 5 mm,

this spacing is reduced to 2.5 mm in the center area.

≤he diagonal beam mode (diagonal-beam scanning) can be activated via the respective field-

bus interface (see chapter 10 et seq.) or via the

Sensor Studio

configuration software (see

chapter 15).

NO≤ICE

Minimum distance for diagonal-beam scanning!

For diagonal-beam scanning, the minimum distance that must be maintained between transmitter and

receiver changes, whereby the values vary depending on beam spacing (see chapter 19).

NO≤ICE

≤each after changing the beam mode!

Changing the beam mode changes the number of beams used for the evaluation. Perform a teach

after changing the beam mode (see chapter 8.2).

4.1.3 Crossed-beam

≤he crossed-beam mode (crossed-beam scanning) is available for increasing the resolution for an area

of the measurement field. In crossed-beam mode, the light beam of each transmitter LED is detected in

succession both by the directly opposing receiver LED as well as by the two adjacent receiver LEDs (i+1,

i-1).

1 Area with increased resolution

Figure 4.3: Beam path in crossed-beam mode

Leuze electronic CML 730i 25

Page 26

Functions

a

b

1

... n

a

1... n

b b a

1... n

Calculation

≤he number of beams for crossed-beam scanning n

beam scanning n

.

p

is calculated from the number of beams for parallel-

k

Formula for calculating the number of beams for crossed-beam scanning

n

[number] = number of beams for crossed-beam scanning

K

n

[number] = number of beams for parallel-beam scanning

p

NO≤ICE

Minimum distance for crossed-beam scanning!

For crossed-beam scanning, the minimum distance that must be maintained between transmitter and

receiver changes, whereby the values vary depending on beam spacing (see chapter 19).

Example: 288 beams in parallel-beam scanning become 862 logical beams in crossed-beam scanning.

With a beam spacing of 5 mm, this spacing is reduced to 2.5 mm in the center area.

≤he crossed-beam mode (crossed-beam scanning) can be activated via the respective fieldbus

interface (see chapter 10 et seq.) or via the

Sensor Studio

configuration software (see

chapter 15).

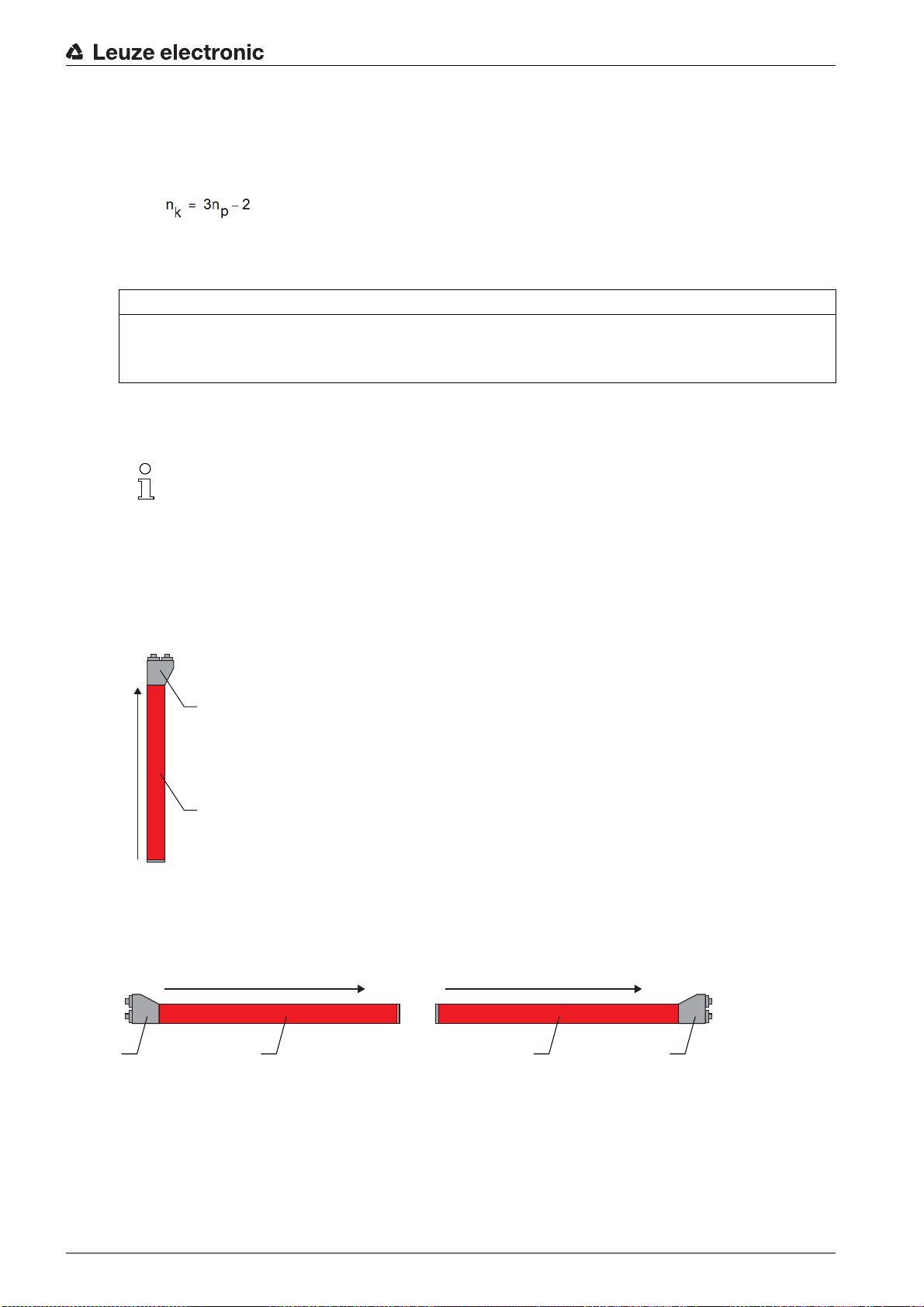

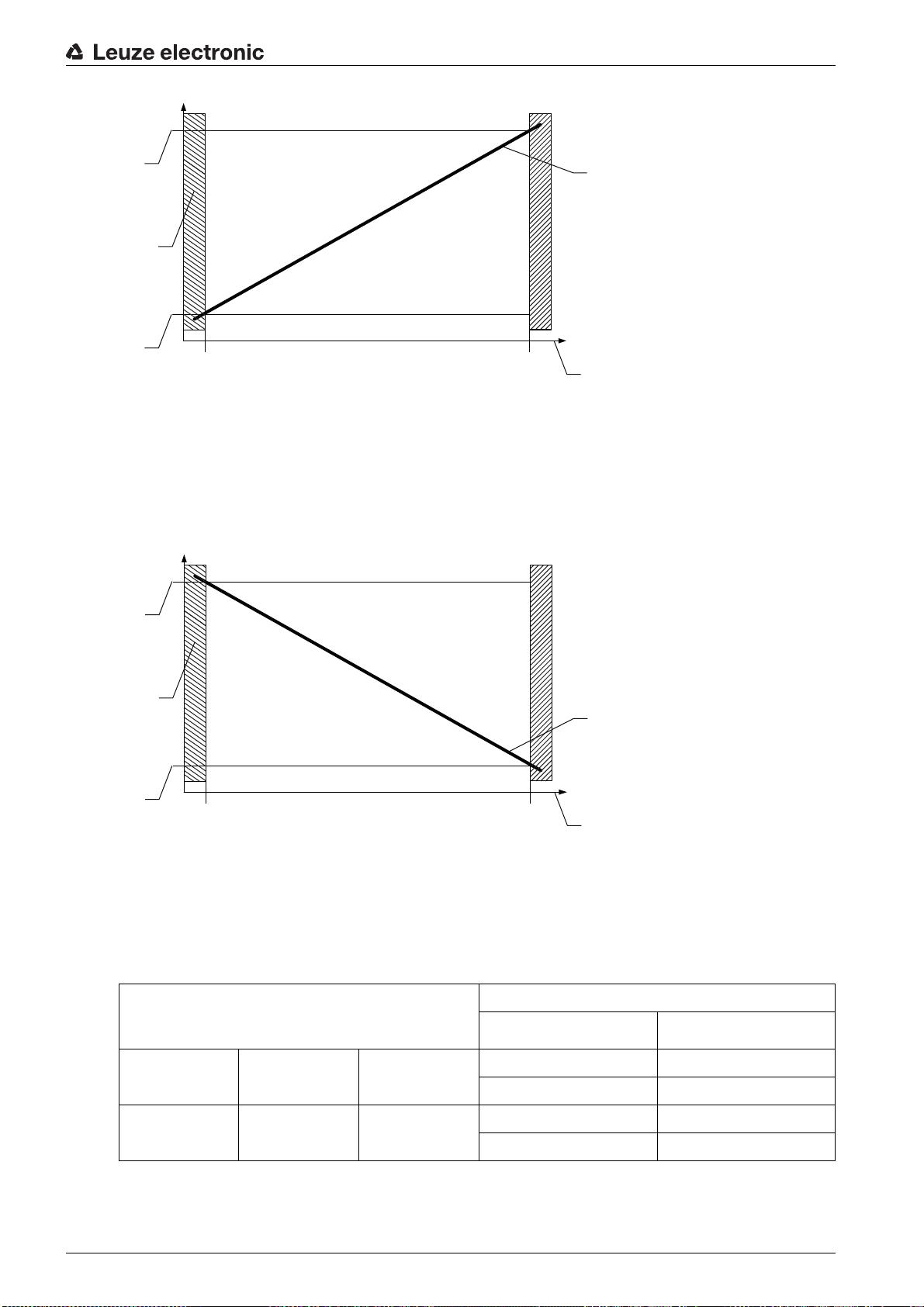

4.2 Measurement beam sequence

By default, the counting direction of the beams begins at the sensor connection unit. It can, however, be

reconfigured so that counting begins with 1 at the sensor head.

≤he simplest application case for the inverted beam sequence is vertical mounting with the connection unit

at the top, e.g., for height measurement, where beam 1 is to begin at the bottom:

a Receiver connection unit

b Optical part

Another variant with two successive light curtains, where the second is rotated by 180° and counting again

begins with 1, is illustrated as follows:

a Receiver connection unit

Leuze electronic CML 730i 26

For width detection, counting can begin with 1 at either end at the head part of the sensor as shown below:

b Optical part

Page 27

a Receiver connection unit

a

1... n

b b a

n ... 1

1 1 1 1 1 0 1 1 1 1 1 10 0 0 1

1

16

1

b Optical part

≤he counting direction can be changed via the respective fieldbus interface (see chapter 10 et

seq.) or via the

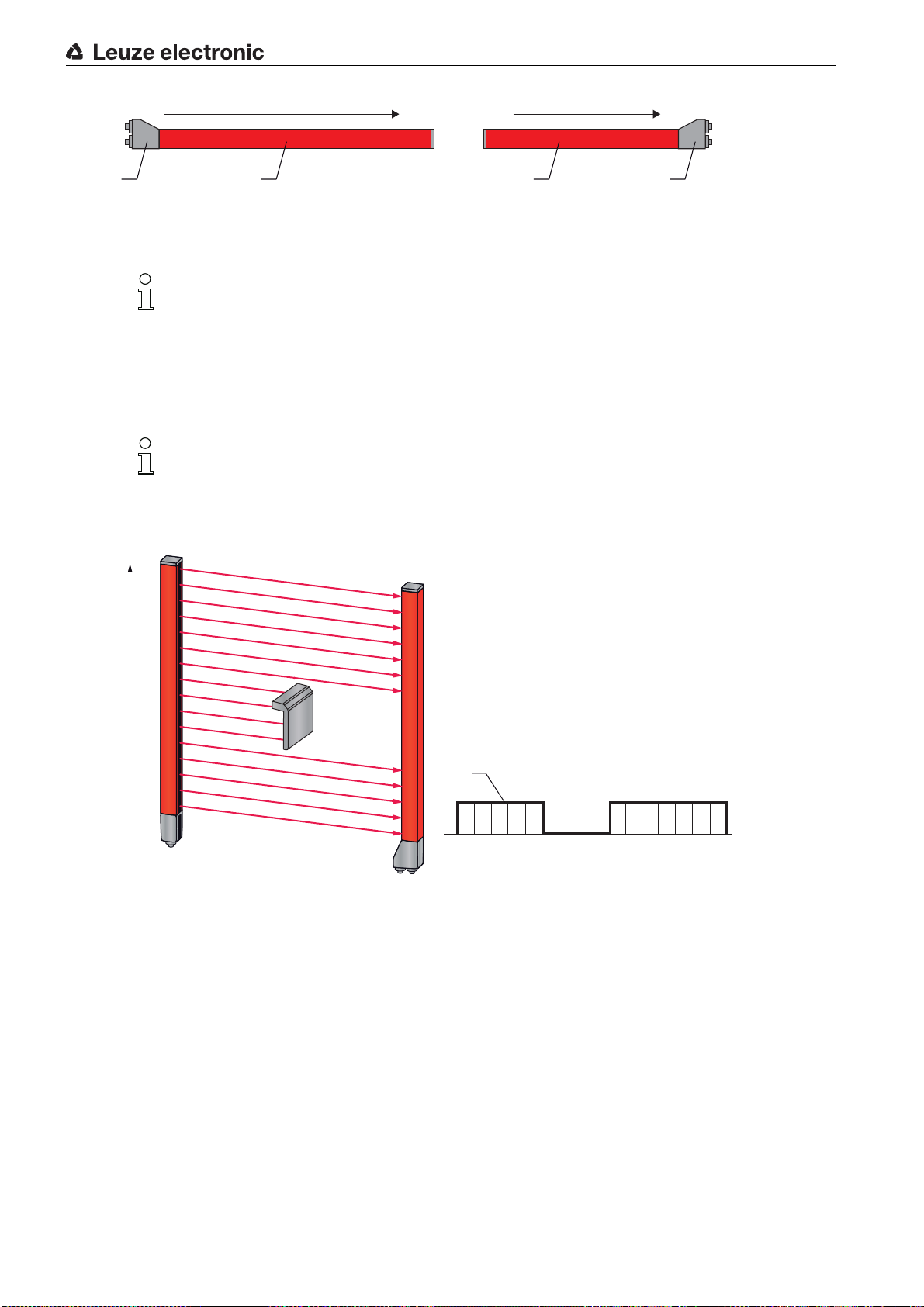

4.3 Beam-stream

≤he beam-stream evaluation returns the status of each individual beam (see figure 4.4). ≥ninterrupted

beams (free beams) are represented as logical 1 in the output bit in this case.

≤he data is available via the respective fieldbus interface (see chapter 10 et seq.) or via the

Sensor Studio

For an example configuration, see chapter 14.1.

Sensor Studio

configuration software (see chapter 15).

configuration software (see chapter 15).

Functions

1 Beam-stream

Figure 4.4: Example: beam-stream evaluation

Leuze electronic CML 730i 27

Page 28

4.4 Evaluation functions

1

6

3

2

2

5

4

≤he states of the individual optical beams (free/interrupted) can be evaluated in the CML 700i and the

result read out via various evaluation functions.

≤he most important evaluation functions are shown in the following figure:

Functions

1 Number of all interrupted beams (≤IB)

2 Number of all uninterrupted beams(≤NIB)

3 Last interrupted beam (LIB)

4 Last uninterrupted beam (LNIB)

5 First uninterrupted beam (FNIB)

6 First interrupted beam (FIB)

Figure 4.5: Evaluation functions

Also included among the evaluation functions are:

• the status of beam areas 1 … 32

• the status of the digital inputs/outputs

For the beam area mappings to an output pin or the status of the digital inputs/outputs, see chapter 4.10.

4.5 Hold function

≤he setting of the hold times is performed via the respective fieldbus interface (see chapter 10

et seq.) or via the

≤he minima and maxima of the following evaluation functions can be temporarily stored for an adjustable

period of time via this function:

• First interrupted beam (FIB)

• First uninterrupted beam (FNIB)

• Last interrupted beam (LIB)

• Last uninterrupted beam (LNIB)

• Number of all interrupted beams (≤IB)

• Number of all uninterrupted beams (≤NIB)

≤his simplifies the reading out of the measurement results if the used control cannot transmit the data at

the same speed that the light curtain makes the data available.

Sensor Studio

configuration software (see chapter 15).

4.6 Blanking

If light curtains are installed such that existing frames / cross bars etc. continuously interrupt some beams,

these beams must be suppressed.

Leuze electronic CML 730i 28

Page 29

Functions

1

2

4

3

3

During blanking, beams that are not to be included in the evaluation are suppressed. ≤he numbering of

the beams is not affected, i.e., the suppression of beams does not change the beam numbers.

1 Interrupted beams

2 Suppressed beams (blanking)

3 Free beams

4 Object present at the installation site

Figure 4.6: Beam states

≥p to four adjacent beam areas can be suppressed.

≤he beams can be activated or suppressed via the respective fieldbus interface (see chapter 10

et seq.), via the

Sensor Studio

configuration software (see chapter 15) and partially via the op-

erational controls on the receiver.

≤he behavior of each blanking area can be adapted to the requirements of the application:

Logical value of a blanking area Meaning in the application

No beams are blanked All beams of the device are included in the evaluation.

Logical value 0 for blanked beams All beams of the blanking area are taken into account

as interrupted beams (logical value 0) in the evaluation.

Logical value 1 for blanked beams All beams of the blanking area are taken into account

as free beams (logical value 1) in the evaluation.

Logical value is the same as the adjacent

beam with lower beam number

Logical value is the same as the adjacent

beam with higher beam number

All beams of the blanking area behave in the evaluation like the previous beam.

All beams of the blanking area behave in the evaluation like the subsequent beam.

For an example configuration, see chapter 14.4.

NO≤ICE

≤each after changing the blanking configuration!

Perform a teach after changing the blanking configuration (see chapter 8.2).

Auto blanking during teaching

If there are obstacles present in the measurement field at the installation site and at least one blanking

area is activated, interrupted beams can be mapped to the blanking area(s) during teaching. Existing

Leuze electronic CML 730i 29

Page 30

settings for the blanking areas are then overwritten (see chapter 8.2).

If no beams are interrupted during teaching, no blanking areas are configured.

Auto blanking cannot be used to detect transparent objects.

Deactivated beams are lost if the beam mode is changed while auto blanking is active.

NO≤ICE

Deactivate auto blanking in process mode!

Deactivate auto blanking in process mode.

Activate auto blanking only during commissioning of the device to suppress distracting objects.

NO≤ICE

Deactivate auto blanking during Power-≥p ≤each!

Deactivate auto blanking if Power-≥p ≤each is activated (see chapter 4.7).

Functions

NO≤ICE

Resetting all blanking areas!

≤o deactivate blanking areas, leave auto blanking active with at least the same number of blanking

areas.

Perform a new teach in a free measurement field.

≤o deactivate blanking with the

ing areas as zero and, at the same time, deactivate each area.

Perform a new teach.

4.7 Power-≥p ≤each

After applying operating voltage, the Power-≥p ≤each function performs a teach event when the device

is ready for operation.

• If the Power-≥p teach is successful, the new teach values are adopted if they are different from the

previously stored teach values.

• If the Power-≥p teach is not successful (e.g. object in the light path), the previously saved teach values are used.

≤he Power-≥p ≤each event can only be activated via the receiver control panel.

Sensor Studio

configuration software, configure the number of blank-

NO≤ICE

Deactivate auto blanking during Power-≥p ≤each!

Deactivate auto blanking if Power-≥p ≤each is activated.

NO≤ICE

No objects in the light path!

During Power-≥p ≤each, ensure that no beams are partially covered by an object.

4.8 Smoothing

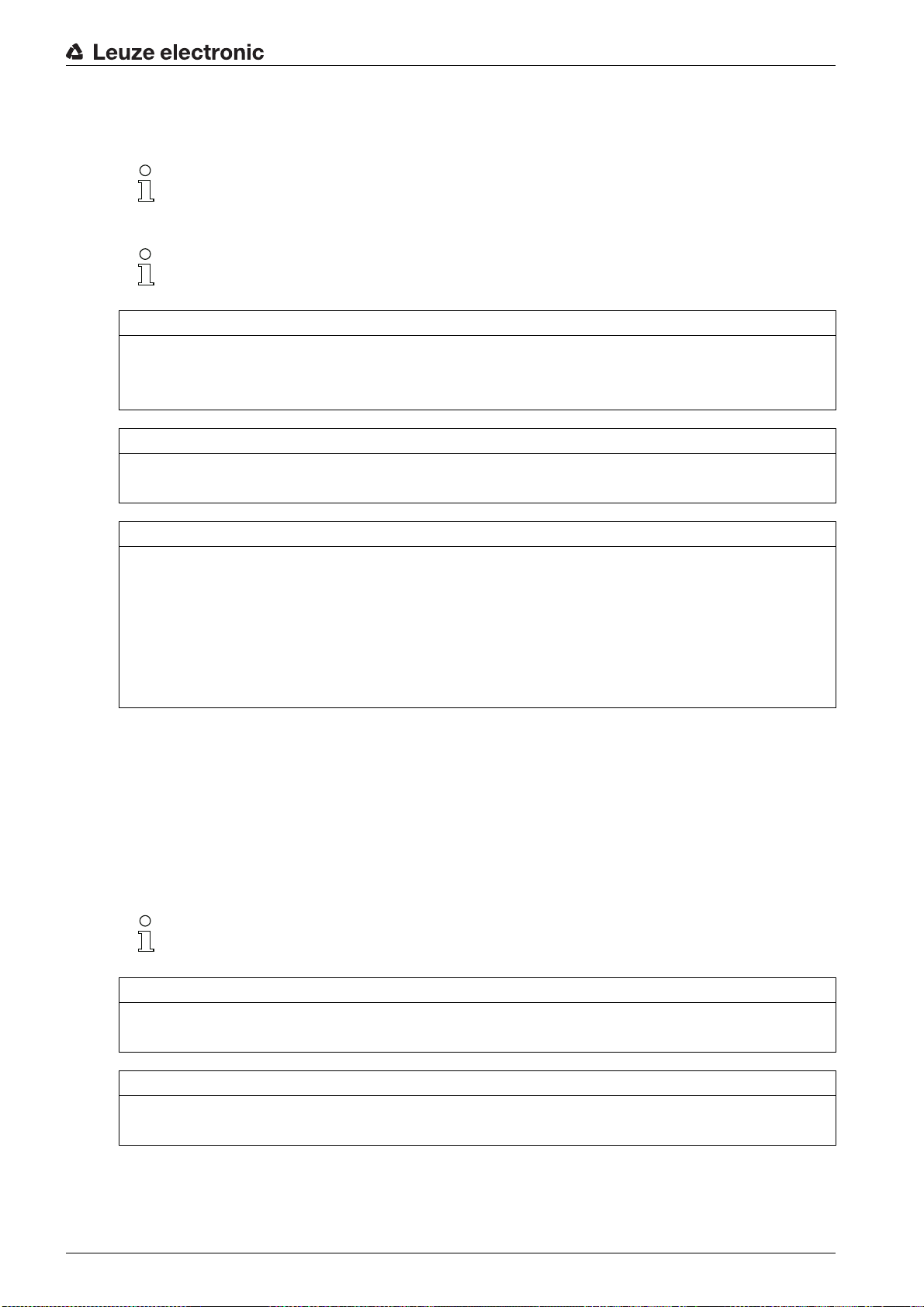

With the smoothing function, interrupted beams are then only taken into account in the evaluation if the set

minimum number of adjacent beams is reached at the same time.

Leuze electronic CML 730i 30

Page 31

Smoothing can be used, e.g., to suppress interference caused by spot soiling of the lens cover.

1

1

Smoothing 1 means that every interrupted beam is evaluated.

1 Data output: beam number x interrupted

Figure 4.7: Smoothing configuration 1

Functions

If smoothing is set to a value of 3, for example, data is only output if at least three adjacent beams are

interrupted.

1 Data output: 0 beams interrupted

Figure 4.8: Smoothing configuration 3, but no more than two adjacent beams interrupted

Leuze electronic CML 730i 31

Page 32

1 Data output: beam numbers from … to … interrupted

1

2

2 Interrupted beam is not taken into account

Figure 4.9: Smoothing configuration 3, and three or more adjacent beams interrupted

Functions

NO≤ICE

Configuration values for smoothing!

Values from 1 to 255 can be entered for smoothing.

Inverted smoothing

Inverted smoothing can suppress interference near the edges of objects, since uninterrupted beams are

not evaluated until the set number is reached.

With inverted smoothing it is possible to detect, e.g., only successive openings of a certain minimum size

within a web.

For an example configuration, see chapter 14.5.

4.9 Cascading/triggering

If the measurement field length of a light curtain is not sufficient for detecting a desired measurement path,

multiple light curtains can be connected in series or cascaded. When doing so, it must be ensured that the

light curtains do not mutually influence or interfere with one another. ≤his is ensured by activating (triggering) with a time offset.

≤he following light curtain arrangements are possible in a cascade arrangement:

• Multiple light curtains above one another, e.g., for height monitoring

Leuze electronic CML 730i 32

Page 33

Functions

1

2

3

1

2

1 Light curtain 1

2 Light curtain 2

Figure 4.10: Simple cascading with two light curtains for height monitoring

• Multiple light curtains in a rectangular frame, e.g., for object measurement of height and width along

a transport system.

1 Light curtain 1

2 Light curtain 2

3 Light curtain 3

Figure 4.11: Simple cascading with three light curtains for object measurement

≤he selection of activation via an internal or external trigger signal is made via the respective

fieldbus interface (see chapter 10 et seq.) or via the

Sensor Studio

configuration software (see

chapter 15).

NO≤ICE

Cascading necessary for multiple-track transport systems!

Cascade light curtains for multiple-track transport systems.

Prevent mutual interference through sequential activation of the light curtains.

If the spatial configuration excludes mutual interference, multiple light curtains can also be activated

simultaneously.

Leuze electronic CML 730i 33

Page 34

4.9.1 External triggering

≤rigger input

For an exact time assignment, it is possible to start the measurement cycle of a light curtain in a targeted

manner by means of a pulse at the trigger input. In this way, mutual interference can be prevented in applications with multiple light curtains. ≤his trigger signal generated in the control must be wired at all

cascaded light curtains.

≤he individual light curtains are configured so that the respective measurement is started with different

delay times to the trigger pulse (see figure 4.12).

1

Functions

4

LV 1

LV 2

010

1PLC

2 Light curtain 1, delay time = 0 ms

3 Light curtain 2, delay time = 11 ms (depending on the cycle time LC1)

4 ≤rigger signal (PLC)

2 3

11 32

Figure 4.12: Activation via external trigger

t [ms]

Leuze electronic CML 730i 34

Page 35

4.9.2 Internal triggering

2

1

5

1

4

3

With internal trigger activation, a CML 700i configured as "master light curtain" generates the trigger pulse.

≤his trigger pulse is continuous; this means that no further activation is required from a primary control.

≤rigger output

≤he trigger output of the master light curtain makes available the trigger signal necessary for cascading

via internal trigger. ≤he trigger output must be wired to the trigger inputs of the slave light curtains (see

figure 4.13). ≤his is used to start the measurement in the configured time sequence.

Functions

≤he cycle time of the respective light curtain can be read out via the

Sensor Studio

configuration

software (see chapter 15) or via the respective fieldbus interface (see chapter 10 et seq.).

≤he selection of activation via an internal or external trigger signal is made via the respective

fieldbus interface (see chapter 10 et seq.) or via the

Sensor Studio

configuration software (see

chapter 15).

For an example configuration, see chapter 14.6.

≤he following figure shows a wiring example for the cascading of three light curtains via internal trigger:

Figure 4.13: Wiring example of three light curtains via internal trigger

1 ≤rigger In (on X1, e.g. pin 5)

2 Slave light curtain 3

3 Slave light curtain 2

4 Master light curtain 1

5 ≤rigger Out (on X1, e.g. pin 5)

≤he following example shows a configuration of three light curtains via internal trigger.

Leuze electronic CML 730i 35

Page 36

1 Master light curtain LC1

LV2

LV1

t [µs]

LV3

LV1-OUT

1

2

3

4

t

LV2

t

LV3

t

LV1

2 Slave light curtain LC2

3 Slave light curtain LC3

4 ≤otal cycle time

Figure 4.14: Example: cascading via internal trigger

Functions

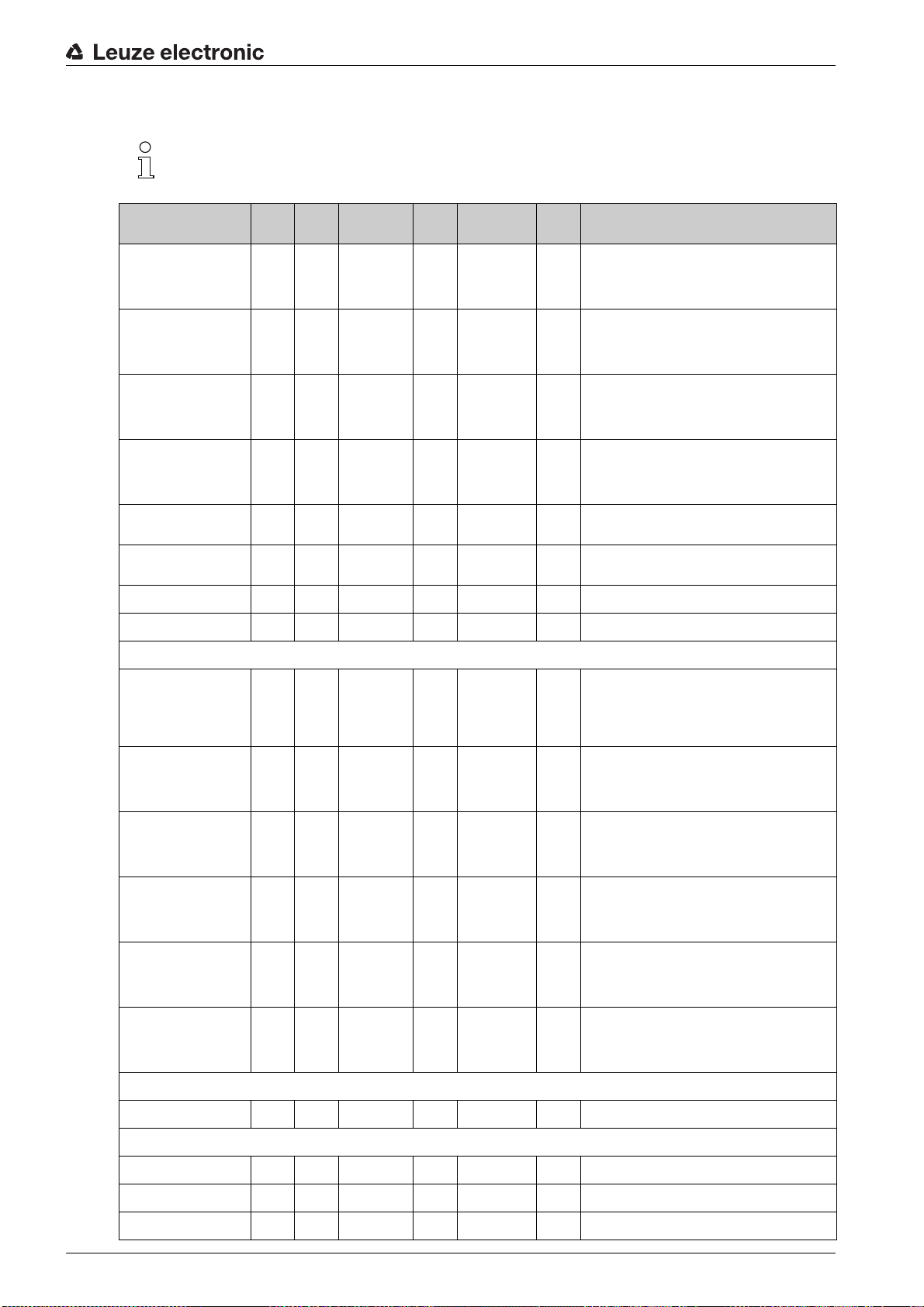

4.10 Block evaluation of beam areas

With this function, the quantity of data to be transmitted can be reduced by restricting the imaging accuracy. ≤he minimum resolution of the light curtain is still retained.

4.10.1 Defining beam area

≤o read out the beam states block-wise with a 16-bit or 32-bit telegram, the individual beams can be

mapped to up to 32 areas independent of the maximum beam number. ≤he individual beam information

of grouped beams is linked to a logical bit, i.e., each area is represented as 1 bit.

≤he number of beams in an area can be freely defined. However, the beams must be adjacent to one

another. ≤he start beam and the end beam are to be defined as well as the conditions for switching of the

area.

NO≤ICE

Hold function for beam areas!

≤he hold function (see chapter 4.5) also applies for the block evaluation of beam areas.

4.10.2 Autosplitting

≤he beams of the device are automatically divided into the selected number of areas of the same size. ≤he

states of the areas generated in this way can be read out in the process data by means of the Area Out HiWord and Area Out - LoWord parameters.

Procedure:

• Select logic combination of the beams within the areas (logical AND / logical OR)

• Define the number of desired areas (e.g., 16 or 32)

≤he autosplitting configuration can be defined via the respective fieldbus interface (see

chapter 10 et seq.) or via the

Sensor Studio

configuration software (see chapter 15).

Leuze electronic CML 730i 36

Page 37

4.10.3 Mapping beam area to switching output

If grouping individual beams or if creating a block, the beam state of any number of adjacent beams (area)

can be signaled at a switching output.

≤he following options are possible here:

• ≤o use a specific, single beam for the evaluation, e.g., as trigger signal for a primary control.

• ≤o group the complete measurement field into one switching area and thereby signal at the switching

output whether an object (at any position) is located in the measurement field.

• ≤o configure up to 32 switching areas for a reference check or height monitoring; in many cases, this

can make beam-data processing in the primary programmable logic control (PLC) unnecessary.

≤he switching conditions for the areas can be either AND or OR linked:

Functions

Logic function

Group bit (area status)

[logic 1/0]

AND 1 if all beams mapped to the area are interrupted

0 if at least one beam is not interrupted in the selected area

OR 1 if at least one beam is interrupted in the selected area

0 if none of the beams mapped to the area are interrupted

Areas may be sequential or overlapping. A maximum of 32 areas are available.

≤he switching behavior or the conditions for switching a beam area on and off can be defined via

the respective fieldbus interface (see chapter 10 et seq.) or via the

Sensor Studio

software (see chapter 15).

For an example configuration, see chapter 14.2.

Example for the configuration of an OR or AND link for a light curtain with 32 beams

OR AND

Start Beam 1 1

End Beam 32 32

configuration

Switch-on condition 1 beam interrupted 32 beams interrupted

Switch-off condition 0 beams interrupted 31 beams interrupted

≤he following figure shows how the beam areas can be arranged directly next to one another or freely overlapping.

Leuze electronic CML 730i 37

Page 38

Functions

1

160

1

1

5

2

6

24

3

15

157

4

140

160

1 Beam area 1

2 Beam area 2

3 Beam area 3

4 Beam area 4

Figure 4.15: Beam areas

For a mapping of previously defined beam areas to, e.g., four switching outputs (Q1 to Q4), see

chapter 14.2.

NO≤ICE

Increased number of logical beams for the diagonal- or crossed-beam function!

≤ake into account the (increased) number of beams if the diagonal- or crossed-beam mode is acti-

vated (see chapter 4.1.2 or see chapter 4.1.3).

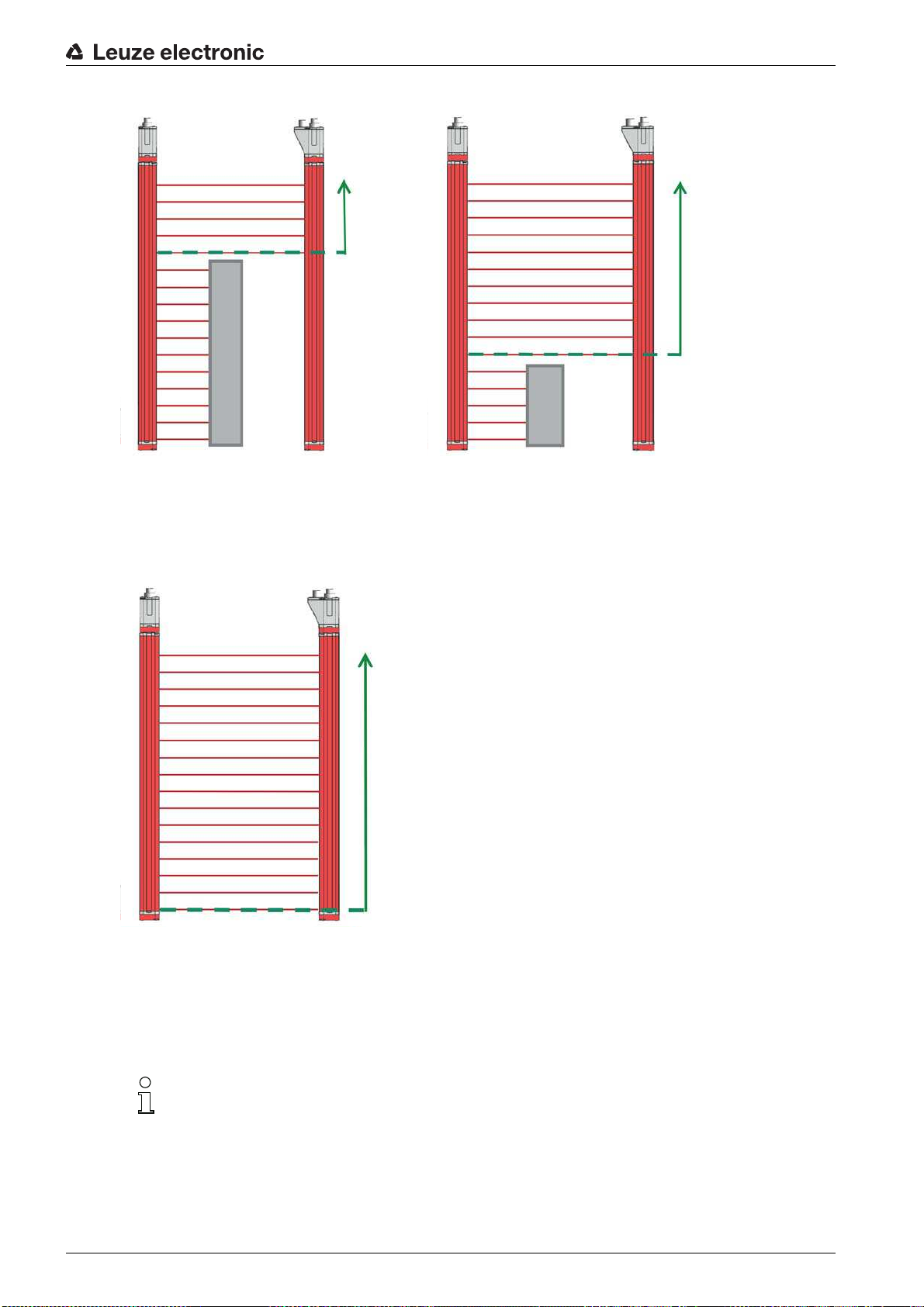

4.10.4 ≤each height area

With the ≤each height area function, it is possible to teach in up to four height areas, e.g. for height monitoring or sorting packets. In many cases, this saves time for programming.

• A maximum of four height areas are available.

• A height area is automatically defined using an object.

When teaching a height area, all free beams above or below the object are combined into one height

area. ≤herefore, the object cannot be located in the center of the measurement field length; the first

or last beam must be interrupted.

Leuze electronic CML 730i 38

Page 39

1 ≤eaching height area 1

2

1

1 ≤eaching height area 2

Figure 4.16: ≤eaching the height area with the ≤each in height area function

Functions

• ≤o define the entire beam area as a height area, teaching of the height area is performed without an

object (all beams free).

Figure 4.17: ≤eaching of the total beam area as height area without object

• ≤he switching behavior or the conditions for switching the height area on or off via the ≤each height

area function is permanently defined as OR.

• Every IO pin can be assigned to a height area via the receiver control panel.

Example:

Digital IOs > IO Pin 2 > ≤each height > Execute

On the receiver control panel, the ≤each height area function is activated via the ≤each height

menu item. Example:

If the ≤each height area function is activated via the receiver control panel, the IO pins are au-

tomatically assigned to the height areas.

Example configurations for the assignment of previously defined height areas to switching outputs Q1 to

Q4:

• see chapter 14.2 "Example configuration - Mapping of beams 1 … 32 to output pin 2"

Leuze electronic CML 730i 39

Digital IOs > IO Pin 2 > ≤each height > Execute

Page 40

4.11 Switching outputs

4.11.1 Light/dark switching

≤he behavior of switching outputs Q1 to Q4 (or Q1 to Q2) can be configured with respect to light/dark

switching. ≤he setting ex works is light switching, i.e., the outputs are activated if the light paths are free

and become inactive if an object is detected in the measurement field.

≤he output behavior can be changed to dark switching via the respective fieldbus interface (see

chapter 10 et seq.), via the receiver control panel and via the

ware (see chapter 15).

4.11.2 ≤ime functions

Each of the individual switching outputs can be assigned one of the time functions described in the

following table.

≤he accuracy of the switching delay is dependent on the measurement frequency. Observe this

especially in cascaded operation.

Sensor Studio

Functions

configuration soft-

≤ime function Selectable

duration

Start-up delay

with re-trigger

Switch-off delay

with re-trigger

Pulse stretching 0 … 65000 ms Minimum time that the state of the output is retained

Pulse suppression

with re-trigger

≤he various time functions can be configured via the respective fieldbus interface (see

chapter 10 et seq.) or via the

0 … 65000 ms ≤ime that the sensor delays the start-up process after

0 … 65000 ms ≤ime that the sensor delays the switching back of the

0 … 65000 ms Minimum time that a measurement signal must be pres-

Sensor Studio

Description

detecting an object.

By means of a start-up delay, it is possible to suppress,

e.g., upward-protruding packaging remnants (stretch

wrap, etc.) during pallet height monitoring.

output if the object leaves the detection range.

independent of what the sensor detects during this time.

Pulse stretching is necessary for, e.g., hole recognition if

the PLC cycle time does not register short pulses.

ent in order for the output to switch. Short interference

pulses are thereby suppressed.

configuration software (see chapter 15).

4.12 Interference suppression (filter depth)

≤o suppress any faulty measurement values that may occur due to interference (ambient light, electromagnetic fields, …), the filter depth of the light curtain can be increased.

Filter depth means that an interrupted/free beam is not included in the further data evaluation until the

same beam status is recorded for the set number of measurement cycles.

Filter depth 1 = the beam states of each measurement cycle are output.

Filter depth 3 = only those beam states that were stable over three measurement cycles are output.

Filter depth can be configured via the respective fieldbus interface (see chapter 10 et seq.) or via

Sensor Studio

the

Leuze electronic CML 730i 40

configuration software (see chapter 15).

Page 41

5 Applications

≤he following typical applications with corresponding evaluation function (see chapter 4) exist for the

measuring light curtain.

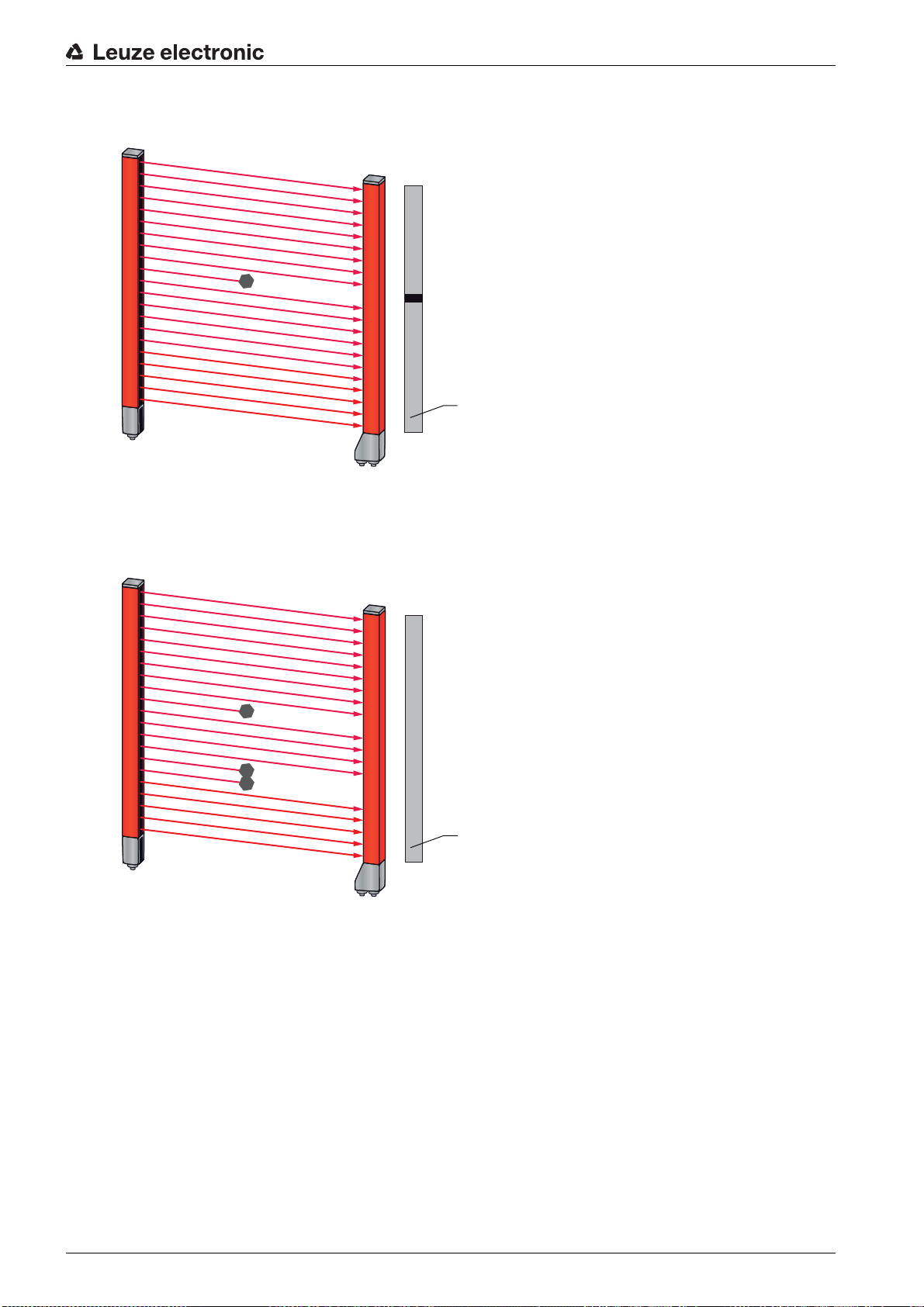

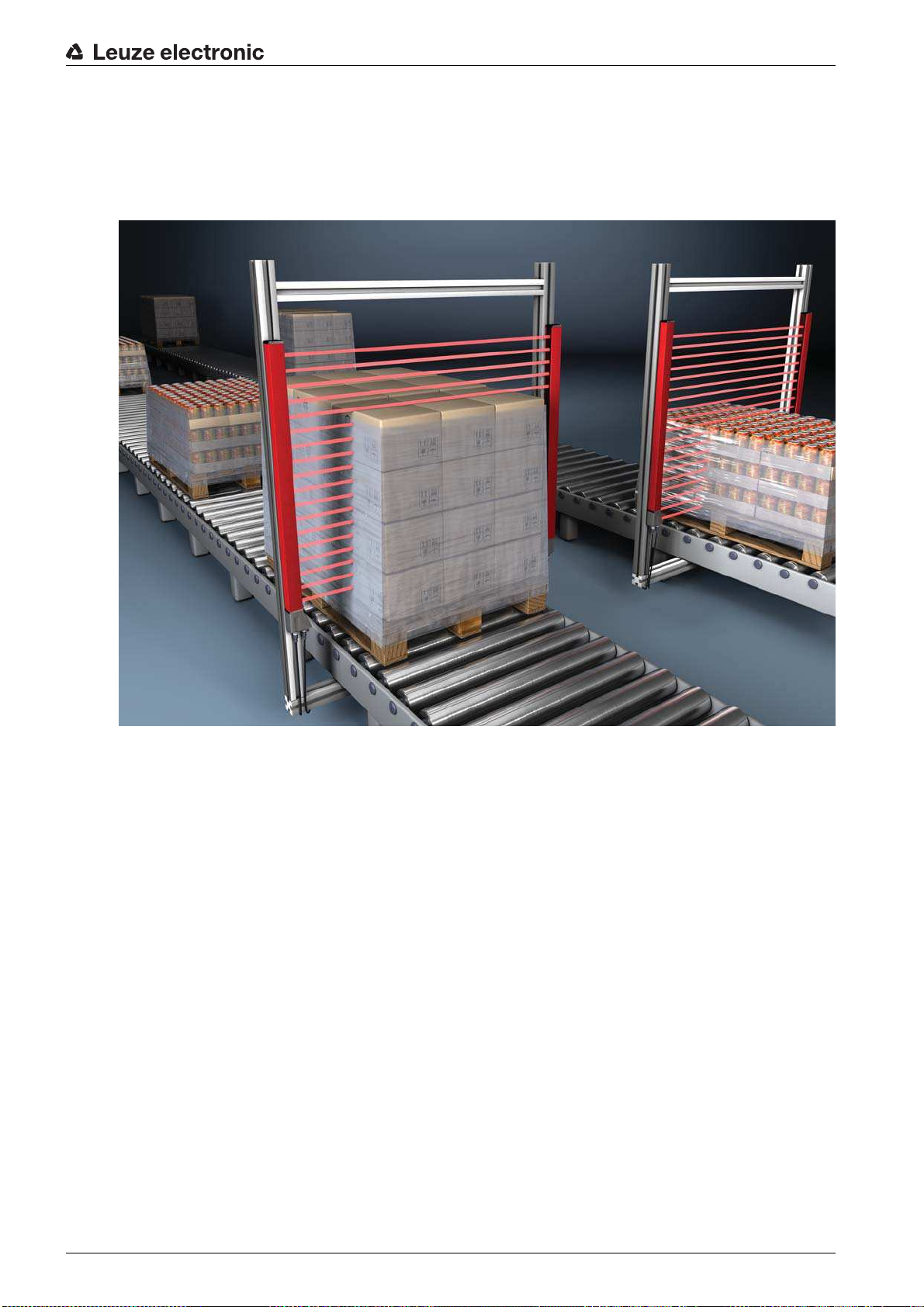

5.1 Height measurement

Applications

Figure 5.1: Height measurement

Evaluation function:

Last interrupted beam (LIB)

.

Leuze electronic CML 730i 41

Page 42

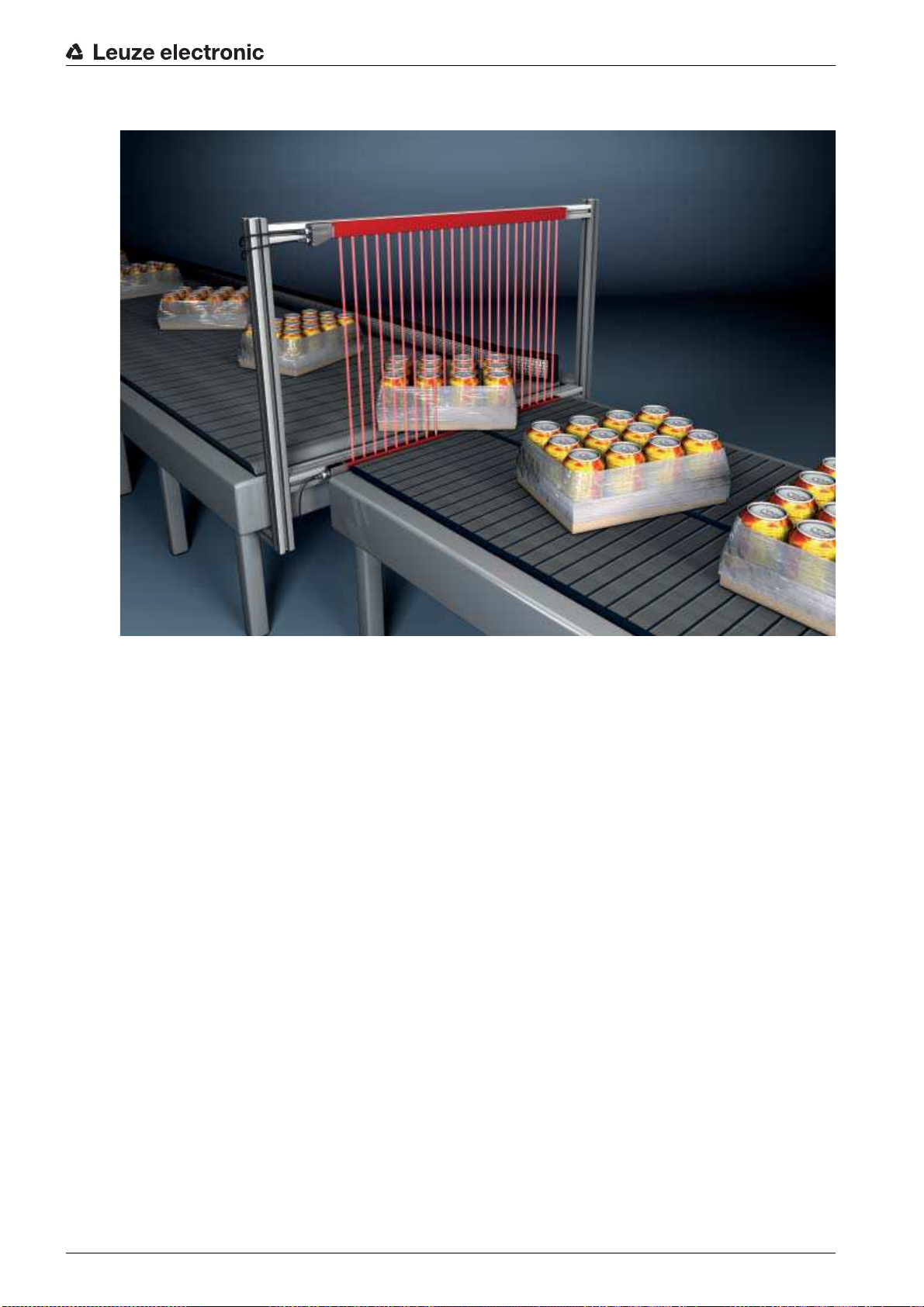

5.2 Object measurement

Applications

Figure 5.2: Object measurement

Height evaluation function:

Width evaluation function:

Last interrupted beam (LIB)

Number of all interrupted beams (≤IB)

.

.

Leuze electronic CML 730i 42

Page 43

5.3 Width measurement, orientation detection

Applications

Figure 5.3: Width measurement, orientation detection

Evaluation function for width measurement:

Evaluation function for orientation detection:

rupted beam (FIB/LIB)

.

Number of all interrupted beams (≤IB)

Single-beam evaluation (beam-stream)

.

or

first/last inter

-

Leuze electronic CML 730i 43

Page 44

5.4 Contour measurement

Applications

Figure 5.4: Contour measurement

Evaluation function:

Single-beam evaluation (beam-stream)

5.5 Gap control/gap measurement

.

Figure 5.5: Gap control/gap measurement

Evaluation function:

Leuze electronic CML 730i 44

Single-beam evaluation (beam-stream)

.

Page 45

5.6 Hole recognition

For a detailed configuration example see chapter 14.3.

Applications

Figure 5.6: Hole recognition

For hole recognition within a web material, a beam area must be defined over the area to be monitored

and mapped to an output. All beams in this area are interrupted. If a beam becomes free due to a flaw

in the material, the output switches.

If, for example, the web edge wanders slightly, the beam area can be dynamically adapted by tracking

the start beam by selecting the

selecting the

Last interrupted beam (LIB)

First interrupted beam (FIB)

evaluation function.

evaluation function and the end beam by

Leuze electronic CML 730i 45

Page 46

6 Mounting and installation

6.1 Mounting the light curtain

NO≤ICE

No reflective surfaces, no mutual interference!

Avoid reflective surfaces near the light curtains.

Objects may otherwise not be precisely detected due to halation.

Ensure sufficient distance, suitable positioning or partitioning.

Optical sensors (e.g., other light curtains, photoelectric sensors, etc.) must not interfere with one

another.

Avoid interference from outside light (e.g., from flash lamps, direct sunlight) on the receiver.

Mount the transmitter and receiver as follows:

Select the fastening type for transmitter and receiver.

- Fastening via the ≤-groove on one side of the standard profile (see chapter 6.3).

- Fastening via the rotating bracket on the ends of the profile (see chapter 6.4).

- Fastening via the swiveling mounting brackets or parallel brackets (see chapter 6.5).

Have a suitable tool at hand and mount the light curtain in accordance with the notices regarding the

mounting locations.

Mount the transmitter and receiver at the same height or with the same housing reference edge, free of

tension and with the base in full contact with the mounting surface.

Mounting and installation

NO≤ICE

Must be observed!

For horizontally mounted measuring light curtains with lengths of more than 2,000 mm, use an addi-

tional mounting bracket in the middle of the light curtain.

≤he optical surfaces of transmitter and receiver must be parallel to and opposite one another.

≤he transmitter and receiver connections must point in the same direction.

Secure transmitter and receiver against turning or sliding.

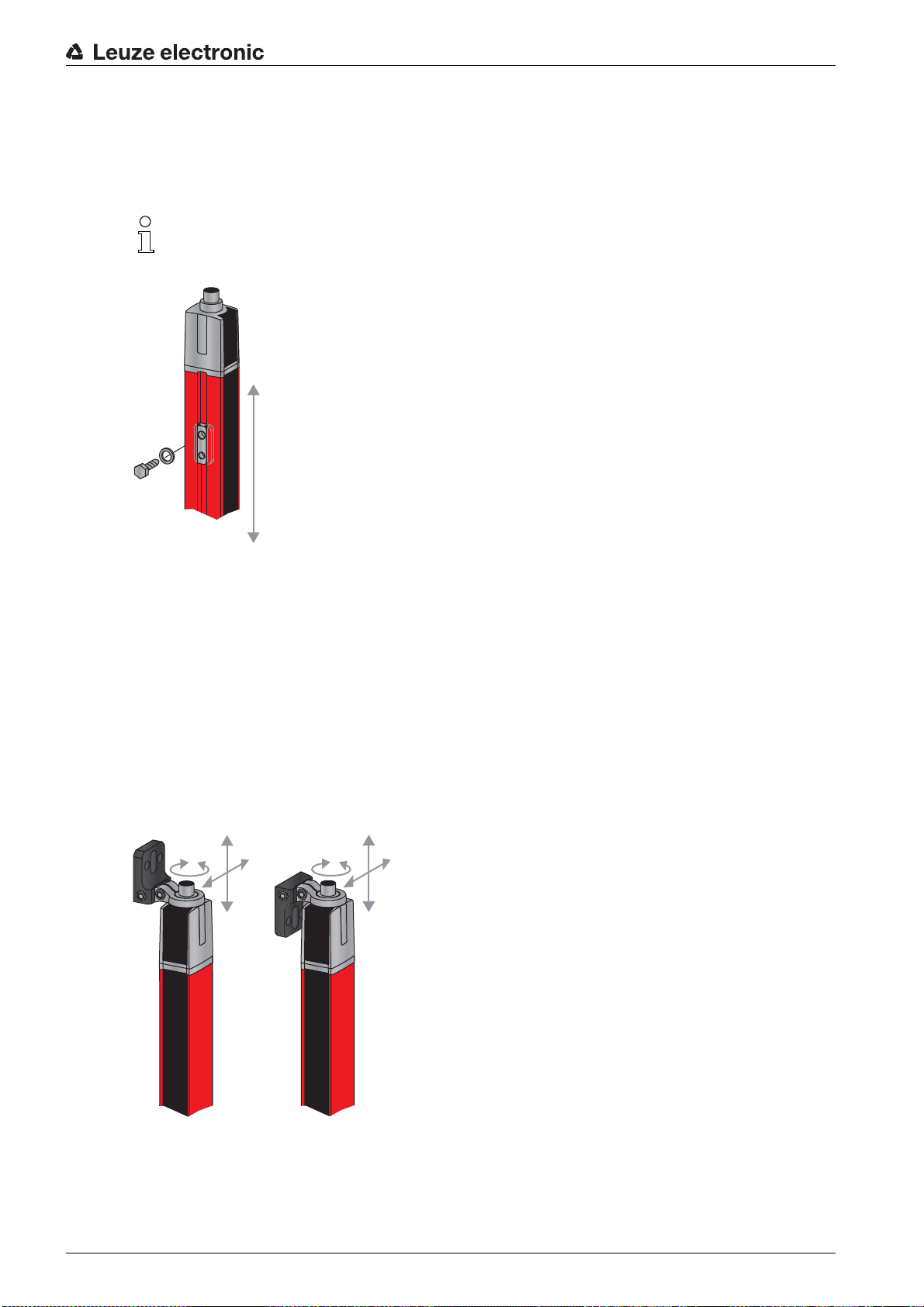

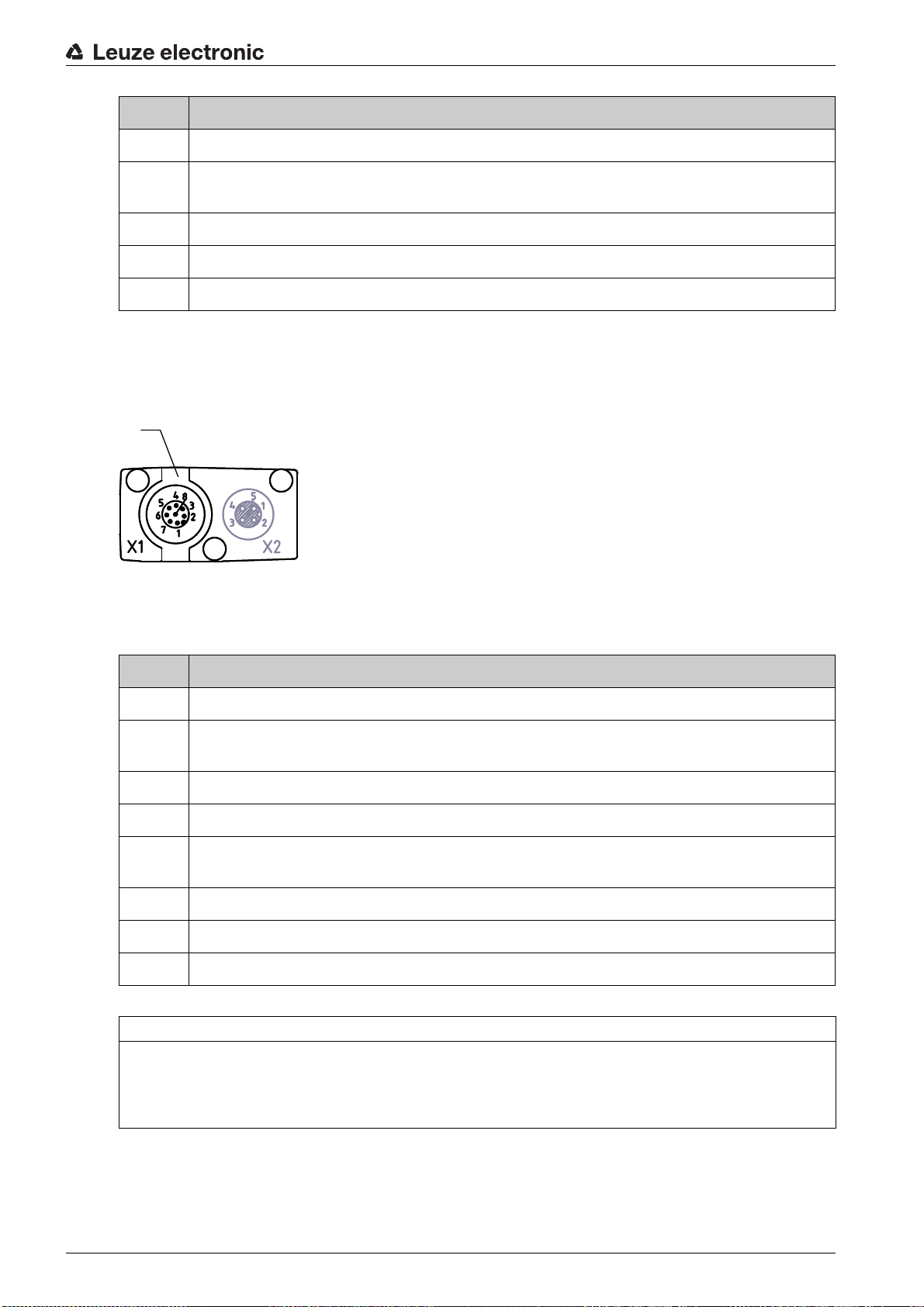

Leuze electronic CML 730i 46