Page 1

BCL 600i/BCL 601i

Bar code readers

EN 2016/10 - 50134518

We reserve the right to

make technical changes

Original operating instructions

Page 2

© 2016

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.de

Leuze electronic BCL 600i/BCL 601i 2

Page 3

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Laser safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.1 Laser safety notices– laser class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Device overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Device construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5.1 Structure of the control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5.2 Status display and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.3 LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Operational controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7 External parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 autoReflAct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Reference codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 autoConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Stand-alone connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Networking - Leuze multiNet plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Leuze multiScan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.7 Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Reading techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Line scanner (single line). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Line scanner with oscillating mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Omnidirectional reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Device arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.1 Selecting a mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.2 Avoiding total reflection – Line scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.3 Avoiding total reflection – oscillating-mirror scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.4 Possible read angles between device and bar code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Installing the external parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 PWR – Voltage supply and switching inputs/outputs 3 and 4 . . . . . . . . . . . . . . . . . . . . . . 29

7.3 SERVICE – USB interface (type A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.4 SW IN/OUT – Switching input/switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.5 HOST / BUS IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Leuze electronic BCL 600i/BCL 601i 3

Page 4

7.6 BUS OUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.7 Cable lengths and shielding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.8 Leuze multiNet plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.8.1 Wiring the multiNet plus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.8.2 The BCL 600i as network master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.8.3 The BCL 600i as network slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.8.4 The BCL 601i as network slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 Menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1 The main menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 Parameter menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Language selection menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.4 Service menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.5 Actions menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9 Commissioning – Leuze electronic webConfig tool . . . . . . . . . . . . . . . . . . . . . . 49

9.1 Connecting the service USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2.2 Installing the USB driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 Starting the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

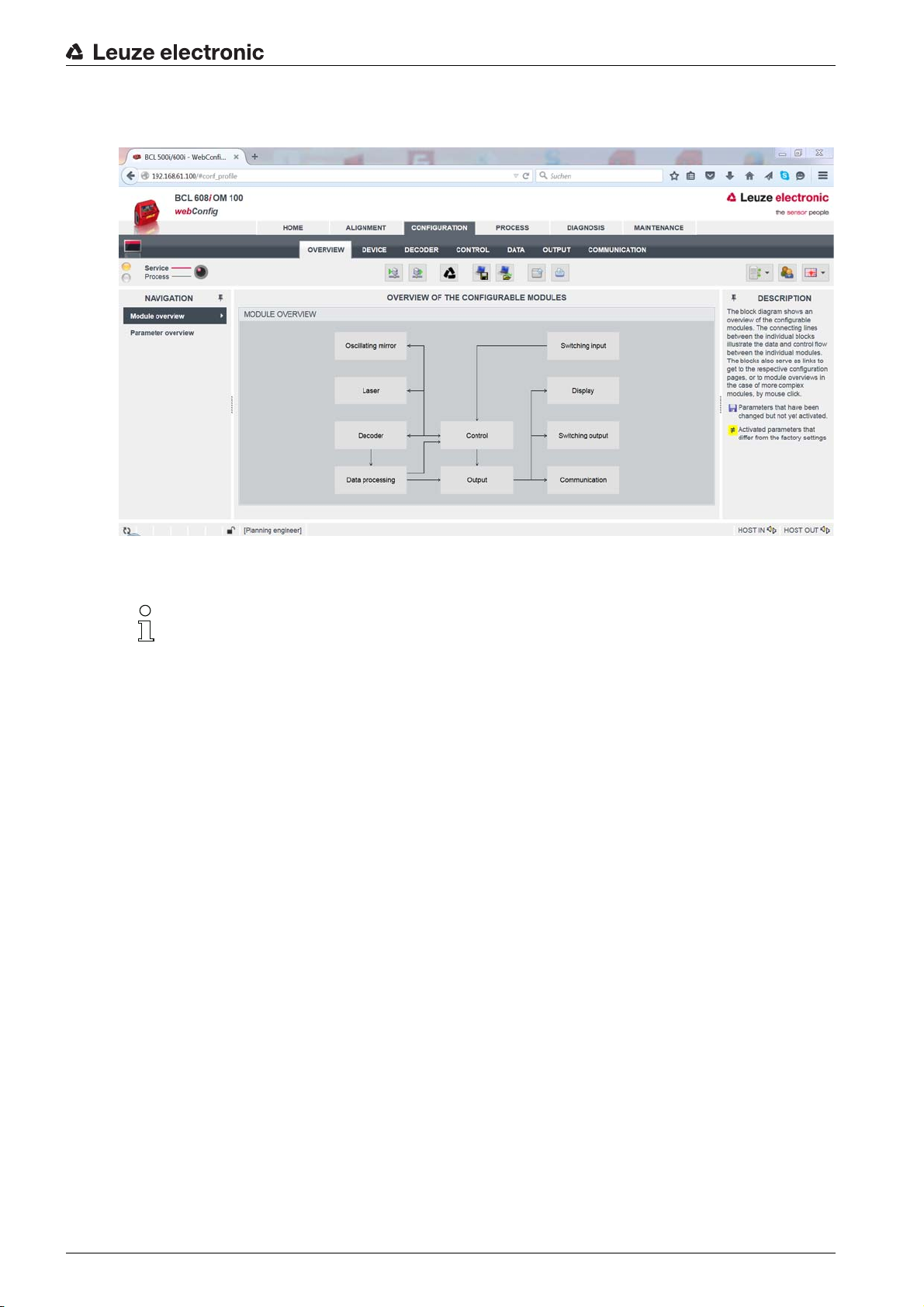

9.4 Short description of the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.5 Module overview in the Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10 Starting up the device - Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.1 Measures to be performed prior to the initial commissioning . . . . . . . . . . . . . . . . . . . . . . 52

10.2 Starting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.3 BCL 600i operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.3.1Operation as stand-alone device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.3.2Selecting the operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.3.3Operation as multiNet plus master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.4 BCL 601i operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.5 Further settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.5.1Decoding and processing the read data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.5.2Control of the decoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.5.3Control of the switching outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.6 Transmitting configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.6.1Via the webConfig tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.6.2With the external parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11 Online commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

11.1 General online commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

11.2 Online commands for system control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.3 Online commands for the parameter set operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

12 Care, maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12.3 Disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

13 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.1 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Leuze electronic BCL 600i/BCL 601i 4

Page 5

13.2 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

14 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

14.1 What to do should servicing be required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

15 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

15.1 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

15.1.1 Line scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

15.1.2Oscillating-mirror scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

15.2 Heating models of the bar code readers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

15.2.1Line scanner with heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

15.2.2Oscillating-mirror scanner with heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

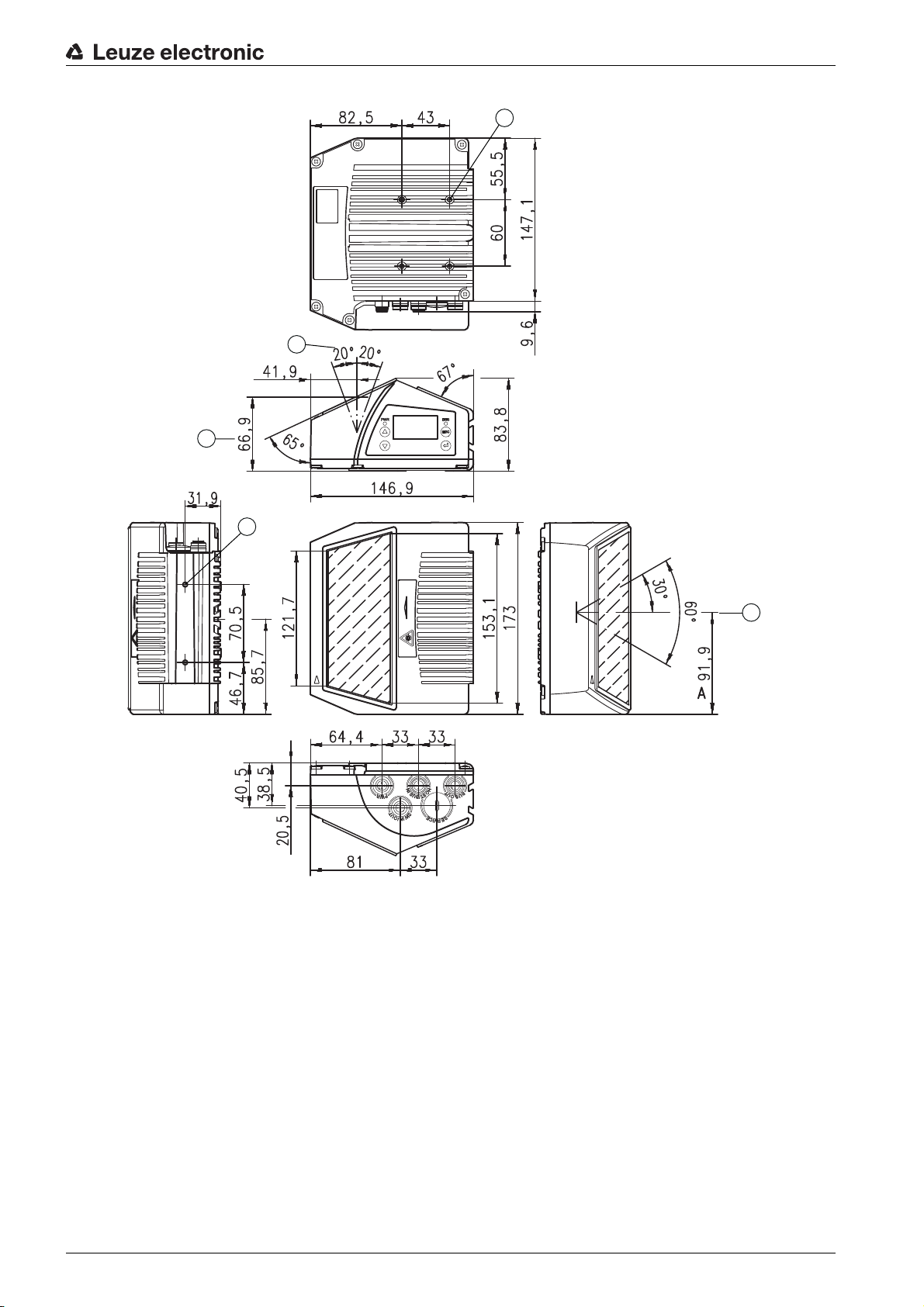

15.3 Dimensioned drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

15.4 Dimensioned drawings: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

15.5 Reading field curves / optical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

15.6 Reading field curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

15.6.1Medium Density (M) - optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

15.6.2Low Density (F) - optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

15.7 Reading field curves for heating devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

15.7.1Medium Density (M) - optics: (with heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

15.7.2Medium Density (M) - optics: (with heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

15.7.3Low Density (F) - optics: (with heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

15.7.4Low Density (F) - optics: (with heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

16.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

16.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

16.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

17 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

18 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

18.1 ASCII character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

18.2 Bar code samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

18.2.1Module 0.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

18.2.2Module 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Leuze electronic BCL 600i/BCL 601i 5

Page 6

1 About this document

1.1 Used symbols and signal words

Table 1.1: Warning symbols and signal words

Symbol indicating dangers to persons

NOTE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger avoidance are not followed.

Table 1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

About this document

Table 1.3: Terms and abbreviations

BCL Bar code reader

CRT Code reconstruction technology

Symbol for action steps

Text passages with this symbol instruct you to perform actions.

Leuze electronic BCL 600i/BCL 601i 6

Page 7

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The device is designed as a stationary high-speed scanner with integrated decoder for all common bar

codes for automatic object detection.

Areas of application

The device is specially designed for the following areas of application:

• Object identification on fast-moving conveyor lines

• Omnidirectional reading

CAUTION

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability insurance asso-

ciation.

Safety

2.2 Foreseeable misuse

Any use other than that defined under “Intended use” or which goes beyond that use is considered

improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• in circuits which are relevant to safety

• for medical purposes

CAUTION

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant stan-

dards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

Leuze electronic BCL 600i/BCL 601i 7

Page 8

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser safety notices

2.5.1 Laser safety notices– laser class 2

ATTENTION, LASER RADIATION – LASERCLASS2

Never look directly into the beam!

The device satisfies the requirements of IEC 60825-1:2007 (EN 60825-1:2007) safety regulations for a

product of laser class 2 as well as the U.S. 21 CFR 1040.10 regulations with deviations corresponding

to “Laser Notice No. 50” from June 24, 2007.

Never look directly into the laser beam or in the direction of reflected laser beams!

If you look into the beam path over a longer time period, there is a risk of injury to the retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser beam is accidentally

directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflective surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here or carrying out

of differing procedures may lead to dangerous exposure to radiation.

Observe the applicable statutory and local laser protection regulations.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

CAUTION

Affix laser information and warning signs!

Laser information and warning signs attached to the device(see figure 2.1). Also included with the device

are self-adhesive laser warning and laser information signs (stick-on labels) in multiple languages (see

figure 2.3).

Affix the laser information sheet to the device in the language appropriate for the place of use.

When using the device in the U.S.A., use the stick-on label with the “Complies with 21 CFR 1040.10”

notice.

Affix the laser information and warning signs near the device if no signs are attached to the device (e.g.

because the device is too small) or if the attached laser information and warning signs are concealed

due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing the reader to the

laser radiation of the device or other optical radiation.

Leuze electronic BCL 600i/BCL 601i 8

Page 9

1 Laser aperture

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

2 mW

<150 µs

405 nm

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

2 3

1

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

2 mW

<150 μs

405 nm

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

2 3

1

2 Laser warning sign

3 Laser information sign with laser parameters

Figure 2.1: Laser aperture, laser warning and information signs - line scanner

Safety

1 Laser aperture

2 Laser warning sign

3 Laser information sign with laser parameters

Figure 2.2: Laser aperture, laser warning and information signs - oscillating-mirror scanner

Leuze electronic BCL 600i/BCL 601i 9

Page 10

Safety

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER

NON FISSARE IL FASCIO

APARRECCHIO LASER DI CLASSE 2

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

PRODUCTO LÁSER DE CLASE 2

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

EQUIPAMENTO LASER CLASSE 2

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

䉏⏘戟⺓

▎䦃展⏘㧮

伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150

µ

s

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

50127630

Figure 2.3: Laser warning and information signs – supplied stick-on labels

Leuze electronic BCL 600i/BCL 601i 10

Page 11

3 Device description

2

1

3.1 Device overview

Bar code readers of the BCL 600i series are high-speed scanners with integrated decoder for all

commonly used bar codes, e.g. 2/5 Interleaved, Code 39, Code 128, EAN 8/13 etc., as well as codes from

the GS1 DataBar family.

Bar code readers of the BCL 600i series are available in various optics models as well as line scanners

and oscillating mirrors and also optionally as heated models.

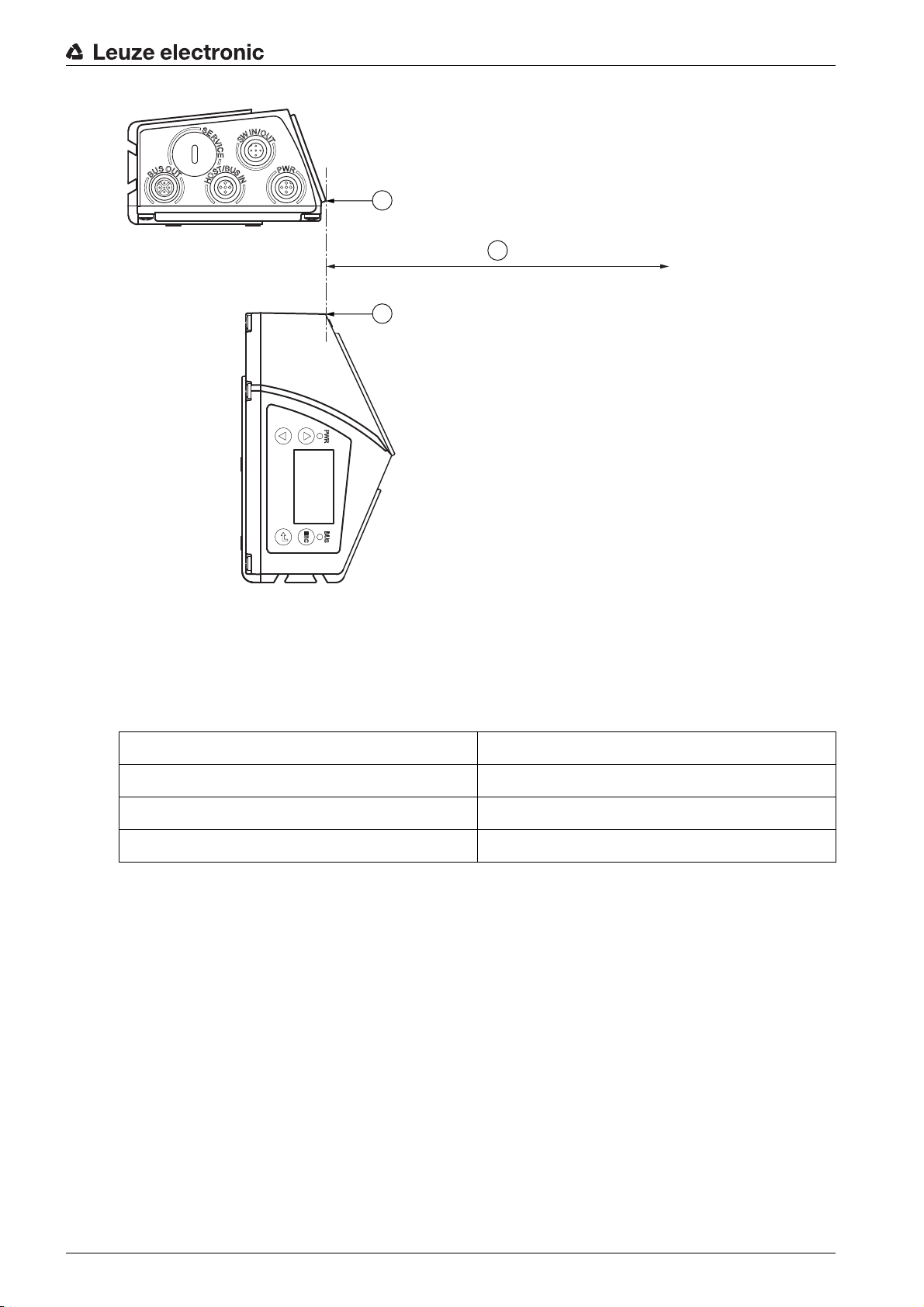

Device description

1 Line scanner

2 Oscillating-mirror scanner

Figure 3.1: Line scanner and oscillating-mirror scanner

The extensive options for device configuration via display or software enable adaptation to a multitude of

reading tasks. Due to the large reading distance combined with the great depth of field and a very compact

construction, the device is ideally suited for package and pallet transportation systems. In general, the bar

code readers of the BCL 600i series are designed for the conveyor and storage technology market.

The interfaces (RS 232, RS 485 and RS 422) integrated in the various device models and the fieldbus

systems (Profibus DP , PROFINET -IO, Ethernet TCP/IP / UDP and E thernet/IP) of the BCL 600i series bar

code readers offer optimum connection to the superior host system.

3.2 Performance characteristics

• Integrated fieldbus connectivity = i -> Plug-and-Play fieldbus coupling and easy networking

• Numerous interface variants facilitate connection to the superior systems

• RS 232, RS 422 as well as with integrated multiNet plus master

• RS 485 and multiNet plus slave

• Alternatively, various fieldbus systems, such as

PROFIBUS DP

PROFINET-IO

Ethernet TCP/IP and UDP

Ethernet/IP

Leuze electronic BCL 600i/BCL 601i 11

Page 12

Device description

• Integrated code reconstruction technology (CRT) enables the identification of soiled or damaged bar

codes

• Maximum depth of field and reading distances from 400 mm to 1450 mm

• Large optical opening angle and, thus, large reading field width

• High scanning rate of 800 / 1000 scans/s for fast reading tasks

• Intuitive, backlit, multi-language display with user-friendly menu navigation

• Integrated USB 1.1 service interface

• Adjustment of all device parameters with a web browser

• Connection options for an external parameter memory

• Easy alignment- and diagnostics functions

• M 12 connections with Ultra-Lock ™ technology

• Four freely programmable switching inputs/outputs for the activation or signaling of states

• Automatic monitoring of the read quality with autoControl

• Automatic recognition and setting of the bar code type using autoConfig

• Reference code comparison

• Optional heating models to -35 °C

• Heavy-duty housing of degree of protection IP 65

Leuze electronic BCL 600i/BCL 601i 12

Page 13

3.3 Device construction

1

1

2

3

5

6

4

66

Device description

1 Reading window

2 Control panel with display, LEDs and buttons

3 M 12 connection technology

4 USB interface

5 Dovetail mounting

6 M4 mounting thread

Figure 3.2: Device construction

3.4 Connection technology

The bar code readers are connected using variously coded M 12 connectors. This ensures unique connection assignments.

Leuze electronic BCL 600i/BCL 601i 13

Page 14

Device description

3 4 5

2

1

3

2

1

4

5

6

The additional USB interface is used for configuring the device.

The two product series BCL 600i and BCL 601i differ in their interfaces and in their function as multiNet

plus master or slave.

Table 3.1: BCL 600i/BCL 601i interfaces

HOST / BUS IN BUS OUT

BCL 600i

(Stand alone or multiNet plus Master)

BCL 601i

(multiNet plus slave)

RS 232 / RS 422 RS 485

RS 485 RS 485

For the locations of the individual device connections, please refer to the device detail shown below.

1 Service, USB socket, type A

2 SW IN/OUT, M 12 socket (A-coded)

3 Bus OUT, M 12 socket (D-coded)

4 HOST/BUS IN, M 12 socket (D-coded)

5 PWR, M 12 connector (A-coded)

Figure 3.3: Location of the electrical connections

3.5 Display elements

3.5.1 Structure of the control panel

1PWR LED

2 NET LED

3 Navigation buttons

4 Escape button

5 Enter button

6 Display

Figure 3.4: Structure of the control panel

Leuze electronic BCL 600i/BCL 601i 14

Page 15

3.5.2 Status display and operation

Indicators in the display

Table 3.2: Status displays of the switching inputs/outputs

IO1 Switching input or switching output 1 active (function dependent on set configuration).

Default: Switching input with the “Reading gate activation”

IO2 Switching input or switching output 2 active (function dependent on set configuration).

Default: Input with the “Teach-in”

IO3 Switching input or switching output 3 active (function dependent on set configuration).

Default: Switching input with the “Reading gate activation”

IO4 Switching input or switching output 4 active (function dependent on set configuration).

Default: Switching output with the “No read”

ATT Warning (Attention)

ERR Internal device error (Error) -> The device must be sent in for inspection

Table 3.3: Status display of the USB interface

Device description

USB The device is connected to a PC via the USB interface.

MS An external parameter memory is properly connected to the USB interface of the device.

Read result

The read bar code information is displayed.

3.5.3 LED indicators

PWR LED

Off Device OFF

Flashes green Device ok, initialization phase

Green,

continuous light

Orange,

continuous light

• No supply voltage

• No bar code reading possible

• Voltage connected

• Self test running

• Initialization running

Device ok

• Bar code reading possible

• Self test successfully finished

• Device monitoring active

Service mode

• Bar code reading possible

• Configuration via the USB service interface

• Configuration via the display

• No data on the host interface

Flashes red Device ok, warning set

• Bar code reading possible

• Temporary operating fault

Red,

continuous light

Leuze electronic BCL 600i/BCL 601i 15

Device error / parameter enable

• No bar code reading possible

Page 16

NET LED

Off No supply voltage

• No communication possible

Flashes green Initialization

• Of the device, establishing communication

Device description

Green,

Operation ok

continuous light

Flashes red Communication error

Red,

continuous light

Network error

No communication (protocol) to IO controller established (no data exchange)

3.6 Operational controls

Navigating within the menus

Use the navigation buttons to move through the menu. Activate the desired selection with the enter

button .

Press the escape button to move up one menu level.

When one of the buttons is actuated, the display illumination is activated for 10 min.

Setting values

Set the desired value with the navigation buttons and the enter button .

An accidental incorrect entry can be corrected by selecting the left arrow button and then pressing the

enter button.

Then use the navigation buttons to select save and save the set value by pressing the enter button.

• Network mode ok

• Parameterization or configuration failed (parameter failure)

•IO error

• No data exchange

ESC

Selecting options

Set the desired option with the navigation buttons and the enter button .

3.7 External parameter memory

The optionally available external parameter memory – based on a USB memory stick (compatible with

version 1.1) – is housed in an external hood with integrated connectors which cover the USB service interface when installed (IP 65).

The external parameter memory makes it easy and reduces the time needed to replace a device on site

by providing a copy of the current parameter set of the device. This eliminates the need to configure the

exchanged device manually.

The delivery contents of the external parameter memory include the hood with integrated connectors with

unscrewable cover and the USB memory stick.

For transferring the configuration with the aid of the external parameter memory see chapter 6.2.

Leuze electronic BCL 600i/BCL 601i 16

Page 17

4 Functions

General information

The integrated fieldbus connectivity = i contained in the bar code readers of the BCL 600i series facilitates

the use of identification systems which function without connection unit or gateways. The integrated

fieldbus interface considerably simplifies handling. The Plug-and-Play concept enables easy networking

and very simple commissioning: Directly connect the respective fieldbus and all configuration is performed

with no additional software.

For decoding bar codes, the bar code readers of the BCL 600i series make available the proven CRT

decoder with code reconstruction technology:

The proven code reconstruction technology (CRT) enables bar code readers of the BCL 600i series to read

bar codes with a small bar height, as well as bar codes with a damaged or soiled print image.

With the aid of the CRT decoder, bar codes can also be read without problem in other demanding situations, such as with a large tilt angle (azimuth angle or even twist angle).

Functions

Figure 4.1: Possible bar code orientation

The BCL 600i / BCL 601i can be operated and configured using the integrated webConfig tool via the USB

service interface; alternatively, the bar code readers can be adjusted using configuration commands via

the host/service interface.

The device needs a suitable activation to start a read process as soon as an object is in the reading field.

This opens a time window (reading gate) in the device for the read process during which the bar code

reader has time to detect and decode a bar code.

In the basic setting, triggering takes place through an external reading cycle signal. Alternative activation

options include online commands via the host interface and the autoReflAct function. Through the read

operation, the device collects additional useful pieces of data for diagnosis which can also be transmitted

to the host. The quality of the read operation can be inspected using the alignment mode which is integrated in the webConfig tool.

A multi-language display with buttons is used to operate the device as well as for visualization purposes.

Two LEDs provide additional optical information on the current operating state of the device.

The four freely configurable switching inputs/outputs SWIO 1 … SWIO 4 can be assigned various functions and control e.g. activation of the device or external devices, such as a PLC.

Leuze electronic BCL 600i/BCL 601i 17

Page 18

System, warning and error messages provide assistance in setup/troubleshooting during commissioning

and read operation.

4.1 autoReflAct

autoReflAct st a nds for automatic Reflector Activation and permits an activation without additional sensors.

This is achieved by directing the scanner with reduced scanning beam towards a reflector mounted behind

the conveyor path. As long as the scanner is targeted at the reflector, the reading gate remains closed. If,

however, the reflector is blocked by an object such as a container with a bar code label, the scanner activates the read procedure, and the label on the container is read. When the path from the scanner to the

reflector has cleared, the read procedure has completed and the scanning beam is reduced and again

directed onto the reflector. The reading gate is closed.

You will find a matching reflector in Accessories, and more are available on request.

Functions

Figure 4.2: Reflector arrangement for autoReflAct

The autoReflAct function uses the scanning beam to simulate a photoelectric sensor and thus permits an

activation without additional sensors.

4.2 Reference codes

The device offers the possibility of storing one or two reference codes.

It is possible to store the reference codes by means of teach-in (display command), via the webConfig tool

or via online commands.

The device can compare read bar codes with one and/or both reference codes and execute user-config-

urable functions depending on the comparison result.

4.3 autoConfig

With the autoConfig function, the device offers an extremely simple and convenient configuration option

to users who only want to read one code type (symbology) with one number of digits at a time.

Leuze electronic BCL 600i/BCL 601i 18

Page 19

After starting the autoConfig function via the display, switching input or from a superior control, it is sufficient to position a bar code label with the desired code type and number of digits in the reading field of the

device.

Afterward, bar codes with the same code type and number of digits are recognized and decoded.

4.4 Stand-alone connection

The bar code readers of the BCL 600i series can be operated as single “stand-alone” devices. The device

features multiple M 12 connectors / sockets for the electrical connection of the supply voltage, the interface

and the switching inputs and outputs.

1 Switching inputs/outputs

2 Supply voltage

3 PC / PLC host interface

Figure 4.3: Stand-alone connection

Functions

1

2

3

4.5 Networking - Leuze multiNet plus

In the Leuze multiNet plus network, up to 32 bar code readers can be networked together. The respective

network devices transmit the read data when requested to by the BCL 600i (or MA 31) network master.

For this purpose, each device is assigned its own station address, which is set using the display of the

corresponding device.

The master then transmits the data of all network devices via its host interface to a superior PLC control

system or a computer, i.e. it “collects” the scanner data in the network and transmits it to an interface on

the host computer. This reduces interface costs (CPs) and time spent programming the software.

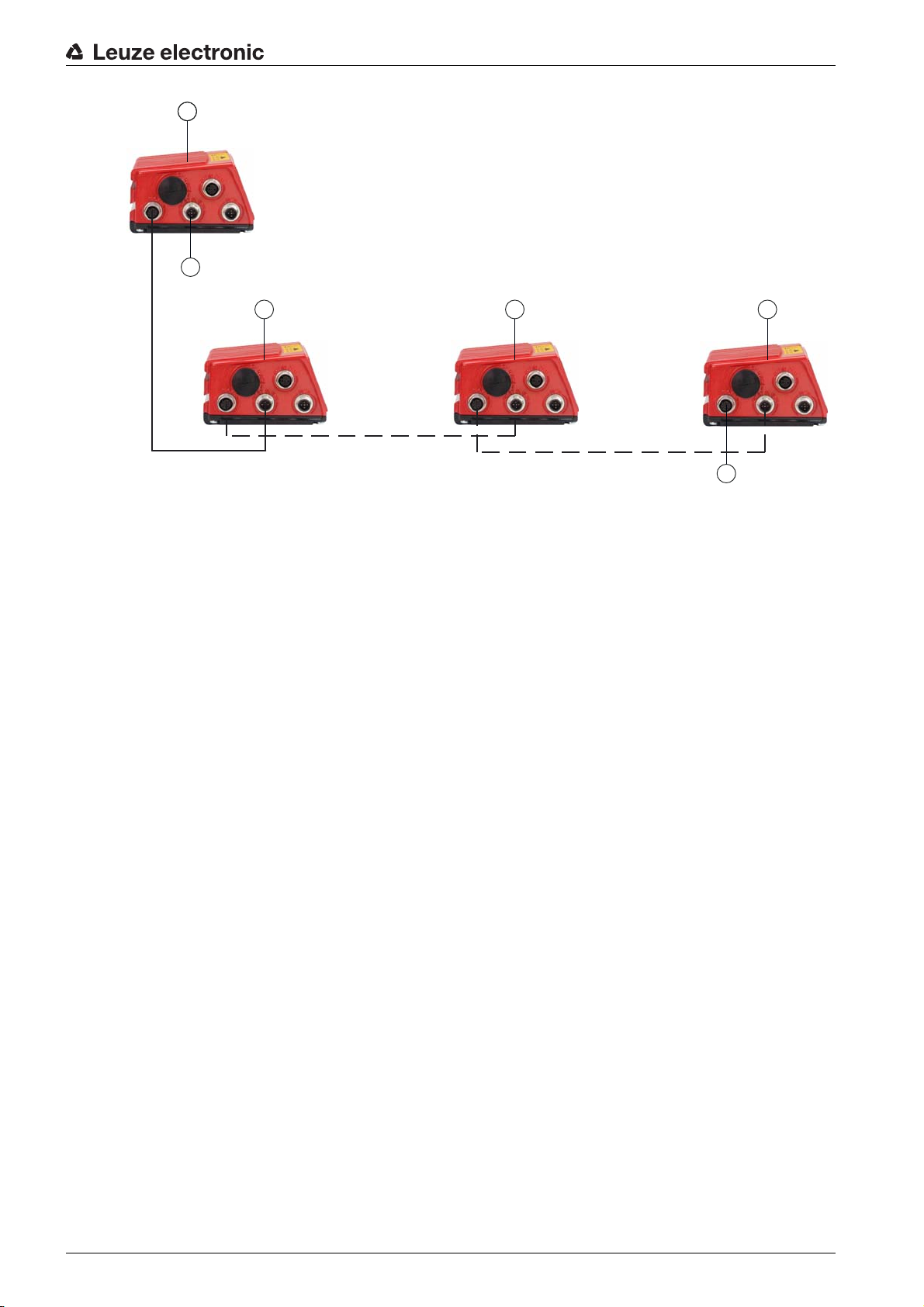

1

1

2

3 4 5

6

1 BCL 600i master

2 To PC/PLC

3 BCL 601i slave 1

4 BCL 601i slave 2

5 BCL 601i slave n

6 Terminating resistor on the last slave

Figure 4.4: Networking possibilities using the multiNet plus

Leuze electronic BCL 600i/BCL 601i 19

Page 20

Two-wire RS 485

The Leuze multiNet plus is optimized for fast transmission of scanner data to a primary host computer. The

multiNet plus consists physically of a two-wire RS 485 interface through which the Leuze multiNet plus

software protocol is controlled. This makes wiring the network easy and inexpensive as slaves are looped

through to one another in parallel.

In principle, networking occurs via a parallel connection of the individual RS 485 interfaces of the respective bar code scanners. Shielded, twisted pair conductors should be used for the Leuze multiNet plus. This

allows a total network length of up to 1200m.

4.6 Leuze multiScan

The multiScan operating mode is based on Leuze multiNet plus and links individual bar code readings from

multiple bar code scanners into a single decoding result. This is used, for example, on a packet conveyor

system on which the label can be affixed on either the right or left side, thereby requiring two read stations.

To prevent the host from having to always process two readings for a single packet, i.e. a decoding result

and a No Read, a multiScan arrangement is used which transmits only one reading from the two read

stations to the host; this single reading is transmitted by the multiScan master.

Thus, from the perspective of the host, the scanner network appears to be just a single bar code

reader!

Functions

For this purpose one multiScan master and one or more multiScan slaves are connected together via the

RS 485 interface.

Figure 4.5: Scanner arrangement with the multiScan function

The multiScan function on the RS 485 interface is possible for minimum of 2 and a maximum of

32 devices!

The protocol set on the RS 485 interface is the multiNet protocol. As a result, during multiScan operation

on the RS 485 interface, the multiNet master also functions as the multiScan master and the

multiNet slaves function as multiScan slaves (thus, all multiNet slave are included in multiScan operation).

4.7 Heater

For low-temperature applications to min. -35°C (e.g. in cold storage), the bar code readers of the BCL 600i

series can optionally be permanently fitted with a built-in heating and these bar code readers purchased

as separate device models.

Leuze electronic BCL 600i/BCL 601i 20

Page 21

5 Reading techniques

5.1 Line scanner (single line)

A line (scan line) scans the label. Due to the opt. opening angle, the reading field width is dependent on

the read distance. Through the movement of the object, the entire bar code is automatically transported

through the scan line.

The integrated code reconstruction technology permits twisting of the bar code (tilt angle) within certain

limits. These are dependent on the transport speed, the scanning rate of the scanner and the bar code

properties.

Areas of application of the line scanner

The line scanner is used:

• when the bars of the bar code are printed in the conveying direction ('ladder arrangement').

• with bar codes having very short bar lengths.

• when the ladder code is turned out of the vertical position (tilt angle).

• when the reading distance is large.

Reading techniques

Figure 5.1: Deflection principle for the line scanner

5.2 Line scanner with oscillating mirror

The oscillating mirror deflects the scan line additionally to both sides across the scan direction at a

randomly adjustable oscillation frequency. In this way, the device can also scan larger areas or spaces for

bar codes. The reading field height (and the scan line length useful for evaluation) depends on the reading

distance due to the optical opening angle of the oscillating mirror.

Leuze electronic BCL 600i/BCL 601i 21

Page 22

Reading techniques

Areas of application of the line scanner with oscillating mirror

For line scanners with oscillating mirror, oscillation frequency, start/stop position etc. are adjustable. It is

used:

• when the position of the label is not fixed, e.g. on pallets – various labels can, thus, be detected at

various positions.

• when the bars of the bar code are printed perpendicular to the conveying direction (“picket fence

arrangement”).

• when reading stationary objects.

• when the bar code is turned out of the horizontal position.

• when the reading distance is large.

• when a large reading field (reading window) has to be covered.

Figure 5.2: Deflection principle for the line scanner with oscillating mirror add-on

5.3 Omnidirectional reading

In order to read arbitrarily oriented bar codes on an object, at least 2 bar code readers are necessary. If

the bar code is not printed over-square, i.e. bar length > code length, bar code readers with integrated code

reconstruction technology are necessary.

Leuze electronic BCL 600i/BCL 601i 22

Page 23

Figure 5.3: Principle arrangement for omnidirectional reading

Reading techniques

Leuze electronic BCL 600i/BCL 601i 23

Page 24

6 Mounting

The bar code readers can be mounted in different ways:

• Using two M4x6 screws on the rear of the device or using four M4x6 screws on the bottom of the

device (see figure 3.2).

• Using a BT 56 mounting device on the two fastening grooves (see figure 15.3).

• Using a BT 59 mounting device on the two fastening grooves (see figure 15.4).

6.1 Device arrangement

6.1.1 Selecting a mounting location

In order to select the right mounting location, several factors must be considered:

• Size, orientation, and position tolerance of the bar codes on the objects to be scanned.

• The reading field of the device in relation to the bar code module width.

• The resulting minimum and maximum reading distance from the respective reading field (see

chapter 15.5 "Reading field curves / optical data").

• The permissible cable lengths between the device and the host system depending on which interface

is used.

• The correct time for data output. The device should be positioned in such a way that, taking into consideration the time required for data processing and the conveyor belt speed, there is sufficient time

to e.g. initiate sorting operations on the basis of the read data.

• The display and control panel should be very visible and accessible.

• For configuring and commissioning with the webConfig tool, the USB interface should be easily

accessible.

• Maintaining the required environmental conditions (temperature, humidity).

• Possible soiling of the reading window due to liquids, abrasion by boxes, or packaging material residues.

• Lowest possible chance of damage to the device by mechanical collision or jammed parts.

• Possible extraneous light (no direct sunlight or sunlight reflected by the bar code).

Mounting

With the line scanner, the beam exits the device parallel to the housing base; with the oscillating

mirror, the beam exits perpendicular to the housing base. The housing base is the black surface.

The best read results are obtained when:

• The device is mounted in such a way that the scanning beam is incident on the bar code at an angle

of inclination greater than ±10° … 15° to vertical.

• The reading distance lies in the middle area of the reading field.

• The bar code labels are of good print quality and have good contrast ratios.

• You do not use high-gloss labels.

• There is no direct sunlight.

6.1.2 Avoiding total reflection – Line scanner

The bar code label must be positioned at an angle of inclination greater than ±10° … 15° from vertical in

order to avoid total reflection of the laser beam (see figure 6.1)!

Total reflection occurs whenever the laser light of the bar code reader is directly incident on the surface of

the bar code at an angle of 90°. The light directly reflected by the bar code may overload the bar code

reader and thereby cause non-readings!

Leuze electronic BCL 600i/BCL 601i 24

Page 25

1 Zero position

x

1

2

x

1

2

2Bar code

x Distance acc. to reading field curves

±10 … 15°

Figure 6.1: Total reflection – line scanner

6.1.3 Avoiding total reflection – oscillating-mirror scanner

For the device with oscillating mirror, the laser beam exits at an angle of 90° to vertical.

In addition, the swivel range of ±20° is to be taken into account.

This means that in order to be on the safe side and to avoid total reflection, the device with oscillating mirror

must be inclined upward or downward 20° … 30°!

Mounting

1 Zero position

2Bar code

x Distance acc. to reading field curves

±25°

Figure 6.2: Total reflection – oscillating-mirror scanner

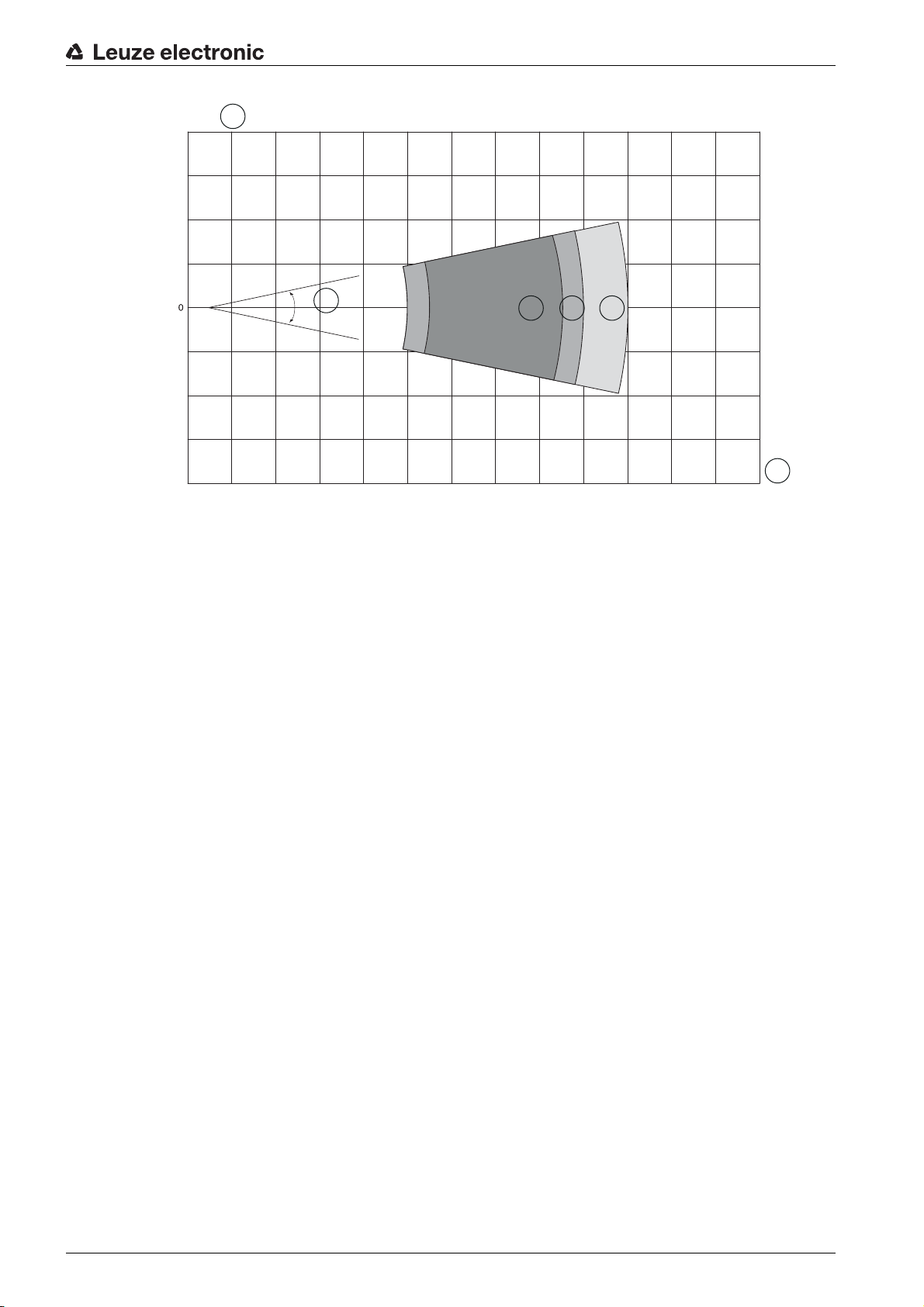

6.1.4 Possible read angles between device and bar code

The optimum alignment of the device is accomplished when the scan line scans the bar code bars almost

at a right angle (90°). All reading angles that are possible between the scan line and bar code must be

taken account (see figure 6.3).

Leuze electronic BCL 600i/BCL 601i 25

Page 26

Mounting

Azimuth angle (tilt)

Inclination angle (pitch)

Angle of rotation (skew)

In order to avoid total reflection, the skew should be greater than 10 °

Figure 6.3: Reading angle for the line scanner

6.2 Installing the external parameter memory

Remove the cover of the USB connection on the device.

Insert the USB memory stick into the USB connection and then cover it with the connector hood to

ensure degree of protection IP 65.

The USB memory stick can be inserted regardless of whether or not the device is connected to supply

voltage.

• After the USB memory stick has been inserted and supply voltage applied, the following message

appears on the display.

Memory stick connected: Export internal configuration?

Use the navigation buttons to select OK and activate with the enter button .

The configuration is now transferred to the external parameter memory and is from now on updated imme-

diately when the configuration is changed via display or online commands.

• The display of MS under the device address indicates that the USB memory stick is correctly connected and functional.

Replacing a defective device

Uninstall the defective device.

Remove the external parameter memory from the defective device by unscrewing the protection hood.

Mount the external parameter memory on the new device.

Install and start up the new device.

The following message appears on the display again:

• Memory stick connected: Export internal configuration?

Leuze electronic BCL 600i/BCL 601i 26

Page 27

Mounting

Use the navigation buttons to select Cancel and activate with the enter button .

Make sure you select Cancel. Otherwise, the configuration in the external parameter memory is

lost!

The configuration is now imported from the external parameter memory and the device is immediately

operational without any further configuration.

Leuze electronic BCL 600i/BCL 601i 27

Page 28

7 Electrical connection

3 4 5

2

1

CAUTION

Do not open the device yourself under any circumstances! There is otherwise a risk of uncontrolled

emission of laser radiation from the device. The housing of the device contains no parts that need to

be adjusted or maintained by the user.

Before connecting the device, be sure that the supply voltage agrees with the value printed on the

name plate.

Connection of the device and cleaning must only be carried out by a qualified electrician.

Ensure that the functional earth (FE) is connected correctly. Unimpaired operation is only guaranteed

when the functional earth is connected properly.

If faults cannot be cleared, the device should be switched off and protected against accidental use.

CAUTION

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National

Electric Code). The bar code readers are designed in accordance with protection class III for supply by

PELV (protective extra-low voltage with reliable disconnection).

Electrical connection

CAUTION

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into place!

7.1 Overview

As a “stand-alone” device, or multiNet plus “master” participant or network slave participant, the device is

equipped with four M 12 plugs/sockets which are A- and B-coded.

The voltage supply (PWR) as well as the four freely configurable switching inputs/outputs (SW IN/OUT and

PWR) are connected there.

An RS 232 or optionally RS 422 interface is available as “HOST / BUS IN” interface for connecting to the

host system. An RS 485 is available as a second physical “BUS OUT” interface for setting up the

Leuze multiNet plus scanner network. The device is suitable for use in the Leuze multiNet plus as network

master/multiScan master.

An USB connection is used as a SERVICE interface.

1 Service, USB socket, type A

2 SW In/Out, M 12 socket (A-coded)

3 Bus Out RS 485, M 12 socket (B-coded)

4 HOST/BUS in, M 12 connector (B-coded)

5 PWR, M 12 connector (A-coded)

Figure 7.1: Connections of the device

Described in detail in the following are the individual connections and pin assignments.

Leuze electronic BCL 600i/BCL 601i 28

Page 29

7.2 PWR – Voltage supply and switching inputs/outputs 3 and 4

2

3

1

4

5

FE

Figure 7.2: PWR, M 12 connector (A-coded)

Table 7.1: Pin assignments - PWR

Pin Name Comment

1 VIN Positive supply voltage +10 ... +30 V DC

2 SWIO_3 Configurable switching input / output 3

3 GND Negative supply voltage 0 V DC

4 SWIO_4 Configurable switching input / output 4

5 FE Functional earth

Electrical connection

Thread FE Functional earth (housing)

Supply voltage

CAUTION

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National

Electric Code).

CAUTION

The bar code readers of the BCL 600i series are designed in accordance with protection class III for

supply by PELV (protective extra-low voltage with reliable disconnection).

Connecting functional earth FE

Ensure that the functional earth (FE) is connected correctly. Unimpaired operation is only guaranteed

when the functional earth is connected properly. All electrical disturbances (EMC couplings) are discharged via the functional earth connection.

Switching input/output

The device is equipped with four freely programmable, opto-decoupled switching inputs and outputs

SWIO_1 … SWIO_4.

The switching inputs can be used to activate various internal functions of the device (decoding, autoConfig,

…). The switching outputs can be used to signal the state of the device and to implement external functions

independent of the superior control.

The two switching inputs/outputs SWIO_1 and SWIO_2 are located on the SW IN/OUT M 12 socket (see

chapter 7.4). The other two (SWIO_3 and SWIO_4) of the four freely configurable switching inputs/outputs

are located on the PWR M 12 connector.

The respective function as input or output can be set via the display or with the aid of the

“webConfig” configuration tool!

The external wiring as switching input and switching output is described in the following. For the respective

function assignment to the switching inputs/outputs see chapter 10.

Leuze electronic BCL 600i/BCL 601i 29

Page 30

Function as switching input

1

2

3

Electrical connection

1

2

3

1 Switching input

2 Switching output from controller (deactivated)

3 Switching input to controller

Figure 7.3: Switching input connection diagram SWIO_3 and SWIO_4

If you use a sensor with a standard M 12 connector, please note the following:

Pins 2 and 4 must not be operated as switching outputs if sensors which function as inputs are also

connected to these pins.

If, for example, the inverted sensor output is connected to pin 2, and pin 2 of the bar code reader is, at

the same time, configured as an output (and not as an input), the switching output malfunctions.

CAUTION

The maximum input current must not exceed 8 mA!

Function as switching output

1 Switching output

2 Switching input from controller

3 Switching output to controller (deactivated)

Figure 7.4: Switching output connection diagram SWIO_3 / SWIO_4

NOTICE

Each configured switching output is short-circuit proof! Do not load the respective switching output of the

device with more than 60 mA at +10 … +30 V DC in normal operation!

By default, the two switching inputs/outputs SWIO_3 and SWIO_4 are configured so that switch-

ing input SWIO_3 activates the reading gate and switching output SWIO_4 switches on

“No Read”.

Leuze electronic BCL 600i/BCL 601i 30

Page 31

7.3 SERVICE – USB interface (type A)

4

3

1

2

1

3

2

4

5

FE

Figure 7.5: Service, USB, type A

Table 7.2: Pin assignments of SERVICE – USB interface

Pin Name Comment

1 VB Positive supply voltage +5 V DC

2 D- Data -

3 D+ Data +

4 GND Ground

NOTICE

Maximum load of the +5 V DC supply voltage of the USB interface is 200 mA!

Ensure adequate shielding.

The entire interconnection cable must absolutely be shielded acc. to the USB specifications. Cable

length must not exceed 3 m.

Use the Leuze-specific USB service cable (see chapter 16 "Ordering information and accessories") for

the connection and use a service PC to configure.

Electrical connection

NOTICE

IP 65 is achieved only if the connectors and caps are screwed into place. Alternatively, a parameter

memory in the form of a USB memory stick certified by Leuze electronic GmbH + Co. can be connected

to the provided USB service interface. With this Leuze memory stick, degree of protection IP 65 is also

ensured.

7.4 SW IN/OUT – Switching input/switching output

Figure 7.6: SW IN/OUT, M 12 socket (A-coded)

Table 7.3: Pin assignment SW IN/OUT

Pin Name Comment

1 VOUT Voltage supply for sensor system (VOUT identical to VIN at PWR IN)

2SWIO_

1

Configurable switching input / output 1

3 GND GND for the sensor system

Leuze electronic BCL 600i/BCL 601i 31

Page 32

Pin Name Comment

1

2

3

4

Electrical connection

4SWIO_

Configurable switching input / output 2

2

5 FE Functional earth

Thread FE Functional earth (housing)

The device is equipped with four freely programmable, opto-decoupled switching inputs and outputs

SWIO_1 … SWIO_4.

The two switching inputs/outputs SWIO_1 and SWIO_2 are located on the SW IN/OUT M 12 socket. The

other two (SWIO_3 and SWIO_4) of the four freely configurable switching inputs/outputs are located on

the PWRsee chapter 7.4 M 12 connector.

The external wiring as switching input and switching output is described in the following. For the respective

function assignment to the switching inputs/outputs see chapter 10.

Function as switching input

1 Output

2 Switching output from controller (deactivated)

3 Switching input to controller

4 Diffuse reflection sensor

Figure 7.7: Switching input connection diagram SWIO_1 and SWIO_2

NOTICE

If you use a sensor with a standard M 12 connector, please note the following: Pins 2 and 4 must not be

operated as switching outputs if sensors which function as inputs are also connected to these pins. If, for

example, the inverted sensor output is connected to pin 2, and pin 2 of the bar code reader is, at the same

time, configured as an output (and not as an input), the switching output malfunctions.

NOTICE

The maximum input current must not exceed 8 mA!

Leuze electronic BCL 600i/BCL 601i 32

Page 33

Function as switching output

3

1

2

4

FE

5

Electrical connection

1

2

3

1 Switching output

2 Switching output from controller

3 Switching input to controller (deactivated)

Figure 7.8: Switching output connection diagram SWIO_1 / SWIO_2

NOTICE

Each configured switching output is short-circuit proof! Do not load the respective switching output of the

device with more than 60 mA at +10 … +30 V DC in normal operation!

By default, the two switching inputs/outputs SWIO_1 and SWIO_2 are configured so that they

function as switching inputs. Switching input SWIO_1 activates the start reading gate function

and switching input SWIO_2 activates the reference code teach-in function.

The functions of the individual switching inputs/outputs are programmed via the display or via configuration

in the webConfig tool under the Switching input or Switching output heading (see chapter 10 "Starting up

the device - Configuration").

7.5 HOST / BUS IN

HOST / BUS IN for BCL 600i

The BCL 600i makes either the RS 232 or RS 422 interface available as host interface. This is selected

via the display or the “webConfig” configuration software. The pin assignments change depending on the

selected interface type (see table 7.4, see figure 7.10 and see figure 7.11).

Figure 7.9: HOST/BUS IN, M 12 connector (B-coded)

Table 7.4: Pin assignment HOST / BUS IN for BCL 600i

Pin Name Comment

1 CTS /

RX+

CTS signal (RS 232) / RX+ (RS 422)

2TxD /

TXD signal (RS 232) / TX- (RS 422)

Tx-

3 GND_H Reference potential 0V for RS 232 / RS 422

Leuze electronic BCL 600i/BCL 601i 33

Page 34

Pin Name Comment

3

1

2

4

FE

5

Electrical connection

4RTS/

RTS signal (RS 232) / TX+ (RS 422)

Tx+

5 RxD /

RxD signal (RS 232) / Rx- (RS 422)

Rx-

Thread FE Functional earth (housing)

RS 232 interface

2

1

RXD

TXD

GND

CTS

RTS

GND_H

3

1Host

2Shield

3 Max. 10 m

Figure 7.10: Pin assignments - HOST / BUS IN as RS 232

RXD/RX-

TXD/TX-

3

5

RTS/TX+

2

CTS/RX+

1

4

NOTICE

Ensure adequate shielding. The entire interconnection cable must be shielded and earthed. The cables

for RTS and CTS must only be connected if RTS/CTS hardware handshake is used.

RS 422 interface

1

RX-

TX-

GND

RX+

TX+

2

TXD/TX-

2

GND_H

RXD/RX-

3

RTS/TX+

CTS/RX+

1

5

4

2

1Host

2 Twisted pair

Figure 7.11: Pin assignments - HOST / BUS IN as RS 422

NOTICE

Ensure adequate shielding. The entire interconnection cable must be shielded and earthed. The signal

lines must be stranded in pairs.

HOST / BUS IN for BCL 601i

The BCL 601i makes available an RS 485 as HOST / BUS IN interface for the connection to the host

system. This interface is physically looped through to the BUS OUT RS 485 socket.

With its RS 485 interface, the BCL 601i is suitable for use in the Leuze multiNet plus scanner network.

Leuze electronic BCL 600i/BCL 601i 34

Figure 7.12: HOST/BUS IN, M 12 connector (B-coded)

Page 35

Table 7.5: Pin assignment HOST / BUS IN for BCL 601i

1

3

2

4

5

Pin Name Comment

1 N.C. Reserved

2 RS 485 BRS 485 B - signal line

Electrical connection

3GND

4 RS 485 ARS 485 A - signal line

5 FE Functional earth / shield

Thread FE Functional earth (housing)

7.6 BUS OUT

To set up the Leuze multiNet plus network with additional participants, the device makes available another

interface in the form of an RS 485.

Figure 7.13: M 12 socket (B-coded)

Table 7.6: Pin assignment BUS OUT

Pin Name Comment

Reference ground RS 485 - potential equalization

485

1 VCC485+5VDC for bus termination

2 RS 485 BRS 485 B - signal line

3GND

Reference ground RS 485 - potential equalization

485

4 RS 485 ARS 485 A - signal line

5 FE Functional earth / shield

Thread FE Functional earth (housing)

NOTICE

Ensure adequate shielding. The entire interconnection cable must be shielded and earthed. The signal

lines must be stranded in pairs.

Termination of the RS 485 interface on the master (BCL 600i)

The RS 485 interface must always be terminated externally on the master via a T-connector and a termi-

nating resistor (see chapter 16 "Ordering information and accessories").

Termination of the RS 485 interface on the slave (BCL 600i)

On the last network participant, the Leuze multiNet plus network (RS 485 interface) should be terminated

with a terminating resistor on the BUS OUT socket (see chapter 16 "Ordering information and accessories").

Leuze electronic BCL 600i/BCL 601i 35

Page 36

The BCL 600i can only participate as a slave in the Leuze multiNet plus on the BUS OUT socket

and via an external M 12 T-connector (see chapter 7.8.3 and see figure ).

Termination of the RS 485 interface (BCL 601i)

The device operates as slave in the Leuze multiNet plus network. On the last physical participant, the

Leuze multiNet plus network (RS 485 interface) must be terminated with a terminating resistor (see

chapter 16 "Ordering information and accessories"). This prevents reflections on the Leuze multiNet plus

and improves the immunity to interference.

7.7 Cable lengths and shielding

Observe the following maximum cable lengths and shielding types:

Table 7.7: Cable lengths and shielding

Connection Interface Max. cable length Shielding

BCL – service USB 3 m Shielding absolutely

Electrical connection

necessary acc. to USB

specifications

BCL – host RS 232

Network from the first

BCL to the last BCL

BCL – power supply

unit

Switching input 10 m Not necessary

Switching output 10 m Not necessary

7.8 Leuze multiNet plus

The Leuze multiNet plus is optimized for fast transmission of scanner data to a primary host computer. The

multiNet plus consists physically of a two-wire RS 485 interface through which the multiNet plus software

protocol is controlled.

This makes wiring the network easy and inexpensive as slaves are looped through to one another in

parallel.

10 m

RS 422

RS 485

RS 485 1200 m shielding absolutely

1200 m

1200 m

30 m Not necessary

shielding absolutely

required

RS 422/485 conductors, stranded in pairs

required

RS 485 conductors,

stranded in pairs

Leuze electronic BCL 600i/BCL 601i 36

Page 37

1

1

2

3 4 5

1 BCL 600i master

2 To PC/PLC

3 BCL 601i slave 1

4 BCL 601i slave 2

5 BCL 601i slave n

6 Terminating resistor on the last slave

Figure 7.14: Leuze multiNet plus system topology

Electrical connection

6

With the aid of a BCL 600i network master, up to 31 bar code readers can be networked. For this purpose,

each participating device is assigned the respective station address via the display and the control panel.

The devices are networked by connecting the individual RS 485 interfaces in parallel.

In the Leuze multiNet plus network, the individual network devices sequentially transfer their data to the

BCL 600i network master when requested.

The BCL 600i master then transmits the data of all network devices via its host interface (either an RS 232

or RS 422) to a superior PLC control or to a computer, i.e. it “collects” the scanner data in the network and

transmits it to an interface on the host computer. This reduces interface costs (CPs) and time spent

programming the software.

7.8.1 Wiring the multiNet plus

Leuze multiNet plus connection hints

Shielded, twisted pair conductors should be used for the Leuze multiNet plus. This allows a total network

length of up to 1200 m.

Recommended network cable (e.g. LiYCY 2x0.2 mm

• Twisted pairs, shielded

• Cross section: min. 0.2 mm

• Copper resistance <100 W/km

When wiring the network, note the following points:

The RS 485A, RS 485B and GND cables are looped through in the network and must not in any case

be misconnected; the Leuze multiNet plus network is otherwise not functional. It is recommended to wire

through the GND of the RS 485 interface of the participants.

Connect the shielding to the slaves on one side with FE.

The maximum cable length in the network is 1200m.

The (physically) last slave in the network should be equipped with a terminating resistor of 220

between RS 485A and RS 485B. This prevents reflections on the multiNet plus and improves the immunity to interference.

²

):

²

W

Leuze electronic BCL 600i/BCL 601i 37

Page 38

Use the recommended connectors / sockets or the ready-made cables and terminating resistors

(see chapter 16 "Ordering information and accessories").

7.8.2 The BCL 600i as network master

Master operation

The BCL 600i bar code readers are specially designed for master operation in a network. They manage

the data of the slaves in multiNet plus and establish the connection to the superior host computer. Only a

few parameters need to be set for master operation. Network commissioning can thus be performed in

very little time (see chapter 10 "Starting up the device - Configuration").

Last slave address

Unlike the slaves, the display of the BCL 600i is not used to set the network address (the master always

has the address 00), but the last slave address, i.e. the number of the most significant slave. This “informs”

the BCL 600i master of the number of slaves operating on the network, without requiring you to call up the

webConfig tool. If the network is expanded at a later time, you only need to change the number of slaves

(last slave address) accordingly via the display.

Start-up / timeout messages

During the initialization phase, i.e. after switching on the operating voltage, the master searches for the set

number of slaves. If a slave is found, the master generates a start-up message “S” for the respective

address found, e.g. “04S” -> Slave with the address 04 has responded correctly.

If a slave is not found or does not respond, the master generates a “timeout” (response timeout) at this

address.

The slave address and a “T” are output on the host interface. For example, “08T” means that no slave

responded at the network address 08. The network is still operational with one or several reported

“timeouts”, however, a slave, for which a timeout was generated, can no longer be addressed.

Electrical connection

BCL 600i master mounting location

Ensure that the BCL 600i is mounted in an easily accessible and visible place in your system. Once the

network has been put into operation, you can set (configure) every scanner in the network centrally via the

USB service or host interface of the BCL 600i, without having to connect a PC/terminal to the individual

read stations.

7.8.3 The BCL 600i as network slave

Alternatively, the bar code readers of the BCL 600i series can also operate as slave participants in the

network mode. They now transmit data to the multiNet master (e.g. BCL 600i) only after the master

prompts them to do so, and, using an external M 12 T-connector, they establish the continuing connection

via the BUS OUT socket to the slaves which follow (order information see chapter 16.3 "Accessories").

The last network participant must be terminated with a terminating resistor.

Leuze electronic BCL 600i/BCL 601i 38

Page 39

1

1

2

3 4 5

1 BCL 600i master

2 To PC/PLC

3 BCL 600i slave 1

4 BCL 600i slave 2

5 BCL 600i slave n

6 Terminating resistor on the last slave

Figure 7.15: Leuze multiNet plus system topology with BCL 600i as slave

Electrical connection

6

Only a few parameters need to be set for slave operation. Network commissioning can thus be performed

in very little time (see chapter 10 "Starting up the device - Configuration").

Slave address

The BCL 600i display has an important function for setting the network address. The network address, i.e.

the corresponding station number of the slave, is set via the display. The address which is set must be > 0

since the master always has address 0 (Adr.00).

Each network device with an address > 0 is thereby automatically informed that it is a slave in the

Leuze multiNet plus with this address and that it is initialized and queried by the network master. No other

settings are necessary for commissioning in the Leuze multiNet plus.

Other settings

The parameters necessary for the reading task, such as the code ty p e s to be read and the number of di g i t s

of the code, must be set. This can be done via the display, as well as with the help of the webConfig tool.

7.8.4 The BCL 601i as network slave

The BCL 601i bar code readers are specially designed for slave operation in a network. They transmit data

to the multiNet master only after the master prompts it to do so and establish the continuing connection

via the BUS OUT socket to the slaves which follow. Only a few parameters need to be set for slave operation. Network commissioning can thus be performed in very little time (see chapter 10 "Starting up the

device - Configuration").

The connection is performed as described above (see figure 7.14).

Slave address

With the BCL 601i, the network address, i.e. the corresponding station number of the slave, is set via the

display. The address which is set must be > 0 since the master always has address 0 (Adr.00).

Each network device with an address > 0 is thereby automatically informed that it is a slave in the

Leuze multiNet plus with this address and that it is initialized and queried by the network master. No other

settings are necessary for commissioning in the Leuze multiNet plus.

Other settings

The parameters necessary for the reading task, such as the code ty p e s to be read and the number of di g i t s

of the code, must be set. This can be done via the display, as well as with the help of the webConfig tool.

Leuze electronic BCL 600i/BCL 601i 39

Page 40

8 Menu description

After voltage is applied to the bar code reader, a startup screen is displayed for several seconds. The

display then shows the bar code reading window with all status information.

8.1 The main menus

Use the navigation buttons to move through the menu. Activate the desired selection with the enter

button .

Device information This menu item contains detailed information on

Menu description

• Device type

• Software version

• Hardware version

• Serial number

Network settings

Bar code reading

window

Parameter

Language selection

Service

Actions

The display offers only limited configuration options. The configurable parameters are described

in this chapter. Only the webConfig tool provides complete configuration options and is largely

self-explanatory. For the use of webConfig tool see chapter 9. Notes on commissioning via the

webConfig tool see chapter 10.

8.2 Parameter menu

Parameter handling

The Parameter handling submenu is used to lock and release the parameter input via the display and for

resetting to default values.

• Display of the network settings

• Visualization of the read bar code information

• Status overview of the switching inputs/outputs

• Bar graphs for read quality of the current bar code.

Further information see chapter "Indicators in the display".

• Configuration of the bar code reader