Page 1

LPS - Line Profile Sensor

Light section sensors

en08-2018/03 50113402E

We reserve the right

to make technical changes

Original operating instructions

Page 2

© 2018

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.com

Leuze electronic LPS 36

Page 3

Table of contents

Figures and tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Laser safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Generation of 2D profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Limits of light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 Occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.2 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Overview of light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Mechanical design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 General performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3 Line Profile Sensor - LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Operating the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 Connection to PC / process control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.2 Activation - laser on/off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.3 Triggering - Free Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.4 Cascading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 Inspection Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

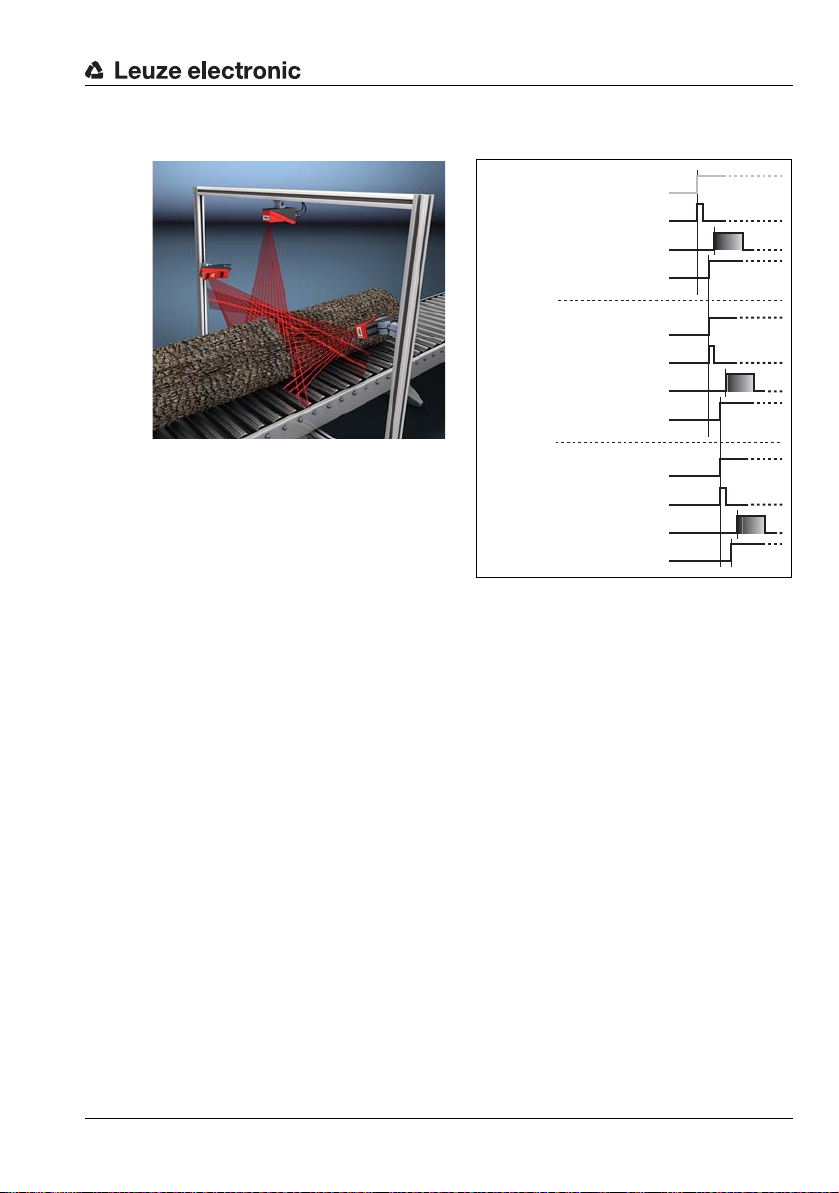

Possible measure against laser occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Possible measures against receiver occlusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Specific performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Typical areas of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Measurement operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Trigger settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cascading settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

TNT 35/7-24V

5 Installation and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Storage, transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Leuze electronic LPS 36 1

Page 4

Table of contents

5.2 Mounting the LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2.1 BT 56 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.2 BT 59 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Device arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.1 Selecting a mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.2 Aligning the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4 Attach laser warning sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Shielding and line lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Shielding: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

General shielding information: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connect the ground potential to the light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting the cable shielding in the switch cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting the cable shielding to the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3 Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.1 Connection X1 - logic and power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.2 Connection X2 - Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.3 Connection X3 - incremental encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Activation input InAct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Trigger input InTrig. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cascading output OutCas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Output "ready" OutReady . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Ethernet cable assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Two-channel incremental encoder with open collector outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Two-channel incremental encoder, single-ended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Two-channel incremental encoder, differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Single-channel incremental encoder (beginning with firmware V01.20) . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Display and control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Indicators and operational controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.1 LED status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.2 Control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.3 Indicators in the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 Menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.2 Operation/navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Leuze electronic LPS 36 2

Alignment aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Status indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Command mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Menu navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Selecting values or selection parameters for editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Editing value parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Editing selection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

TNT 35/7-24V

Page 5

Table of contents

7.3 Reset to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Interrupting a reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Executing a reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Commissioning and configuration. . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Switching on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.2 Establish connection to PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting the default gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting an alternative IP address on the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 LPSsoft configuration software. . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2.1 Possible error message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.2.2 Device list update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.3 Starting LPSsoft/Communication tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.4 Parameter settings/Parameters tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.4.1 Standard tab - Task Parameters panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.4.2 Encoder tab - Encoder Parameters area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.5 Measurement function/Visualization tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.5.1 Evaluating saved measurement data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.6 Menu commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6.1 Saving parameter settings/File menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6.2 Transmitting parameter settings/Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6.3 Saving measurement data/Measure Records menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6.4 Zoom and Pan/toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.7 Definition of inspection tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Inspection Task Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Trigger Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Light Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Field of View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Apply Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Encoder Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Evaluation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Counter Value Overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Typical procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

TNT 35/7-24V

10 Integrating the LPS in the process control (Ethernet) . . . . . . . . . . 71

10.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Leuze electronic LPS 36 3

Page 6

Table of contents

10.2 Protocol structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Protocol structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.2.1 Command number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.2.2 Packet number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.2.3 Transaction number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.2.4 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.2.5 Encoder High / Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.2.6 Scan number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.2.7 Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.2.8 Number of user data words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.2.9 User data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.3 Ethernet commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.3.1 Elementary commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.2 Commands in command mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.3.3 Explanation of user data in command mode (command parameters) . . . . . . . . . . . . . . . 81

10.3.4 Commands in measure mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.3.5 Explanation of user data in measure mode (command parameters) . . . . . . . . . . . . . . . . 93

10.4 Working with the protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.5 Operation with LxS_Lib.dll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.6 Operation with native C++ DLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.7 Operating with HALCON® image processing software . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.8 Additional support when integrating sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

User data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Set Laser Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Set Encoder Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Set Actual Inspection Task. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Get Actual Inspection Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Set Scan Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Set Single User parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Get Single User parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Set Single Inspection Task Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Get Single Inspection Task Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Ethernet Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Command without user data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Command with user data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

TNT 35/7-24V

11 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.1 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.2 Interface error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11.3 Error messages in display (starting from firmware V01.40) . . . . . . . . . . . . . . . . . . . . . . 99

12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Leuze electronic LPS 36 4

Page 7

Table of contents

12.1 General maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.2 Repairs, servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.3 Disassembling, packing, disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.1 General technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.2 Typical measurement range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.3 Dimensioned drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14 Type overview and accessories . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1 Type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1.1 LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1.2 LRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1.3 LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

14.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

14.2.1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

14.2.2 Accessories – Ready-made cables for voltage supply X1 . . . . . . . . . . . . . . . . . . . . . . . 108

14.2.3 Accessories for Ethernet interface X2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.2.4 Accessories - Ready-made cables for X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

14.2.5 Configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

14.2.6 Configuration memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Mounting devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Contact assignment for connection cable X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Order codes of the cables for voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Ready-made cables with M 12 connector/open cable end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Ready-made cables with M 12 connector/RJ-45 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Ready-made cables with M 12 connector/M12 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Contact assignment for X3 connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Order code of X3 connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

TNT 35/7-24V

15 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.1 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.2 Revision History / Feature list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.2.1 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.2.2 Configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Leuze electronic LPS 36 5

Page 8

Figures and tables

Figures and tables

Figure 2.1: Laser apertures, laser warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2.2: Laser warning and information signs – supplied stick-on labels. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 3.1: Light section sensor design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 3.2: Occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

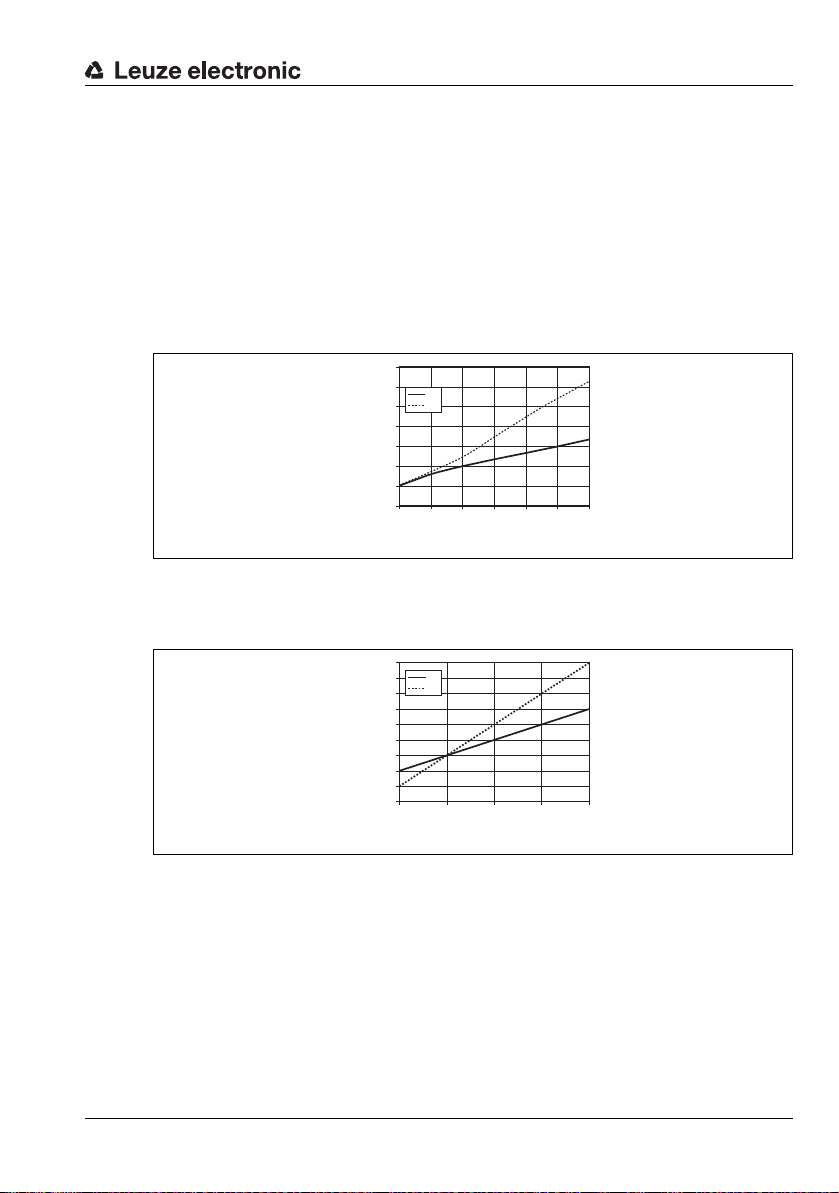

Figure 3.3: Typical resolution LPS 36… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3.4: Typical resolution LPS 36HI… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

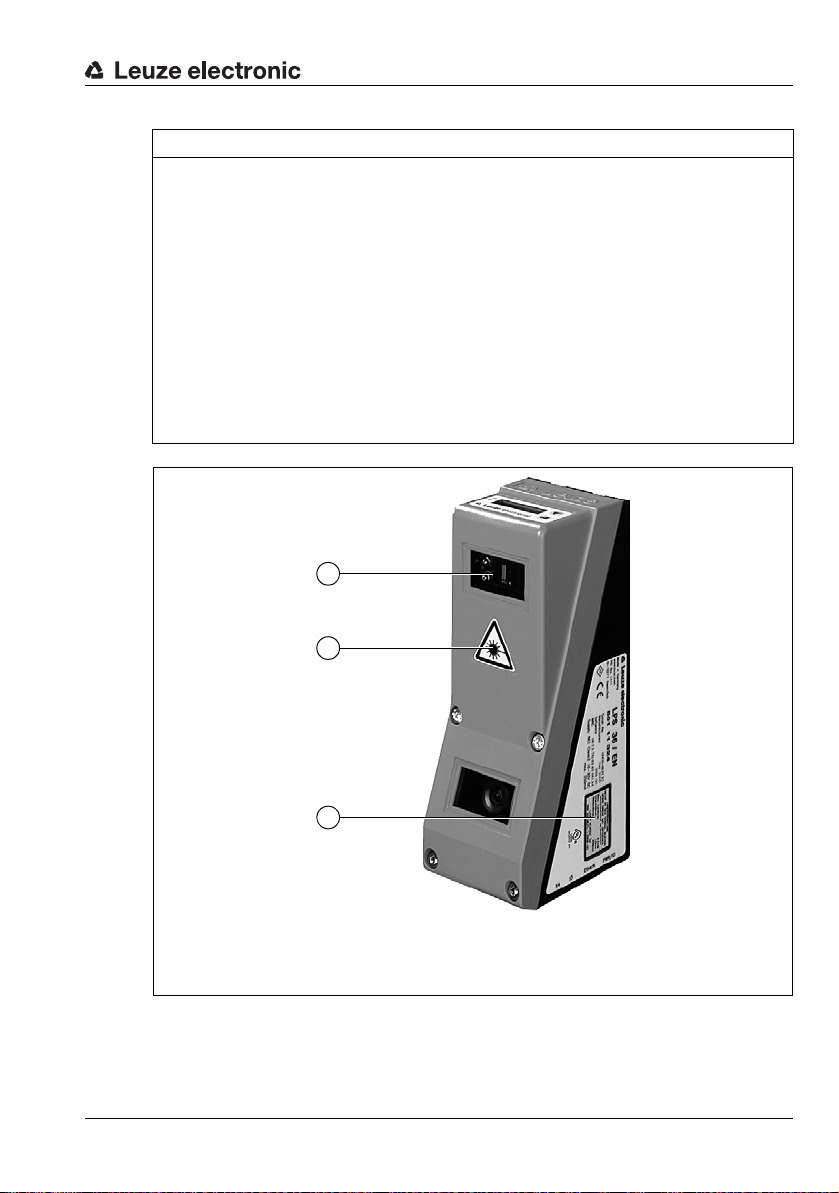

Figure 4.1: Mechanical design of Leuze light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 4.2: Activation input signal sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 4.3: Trigger input signal sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

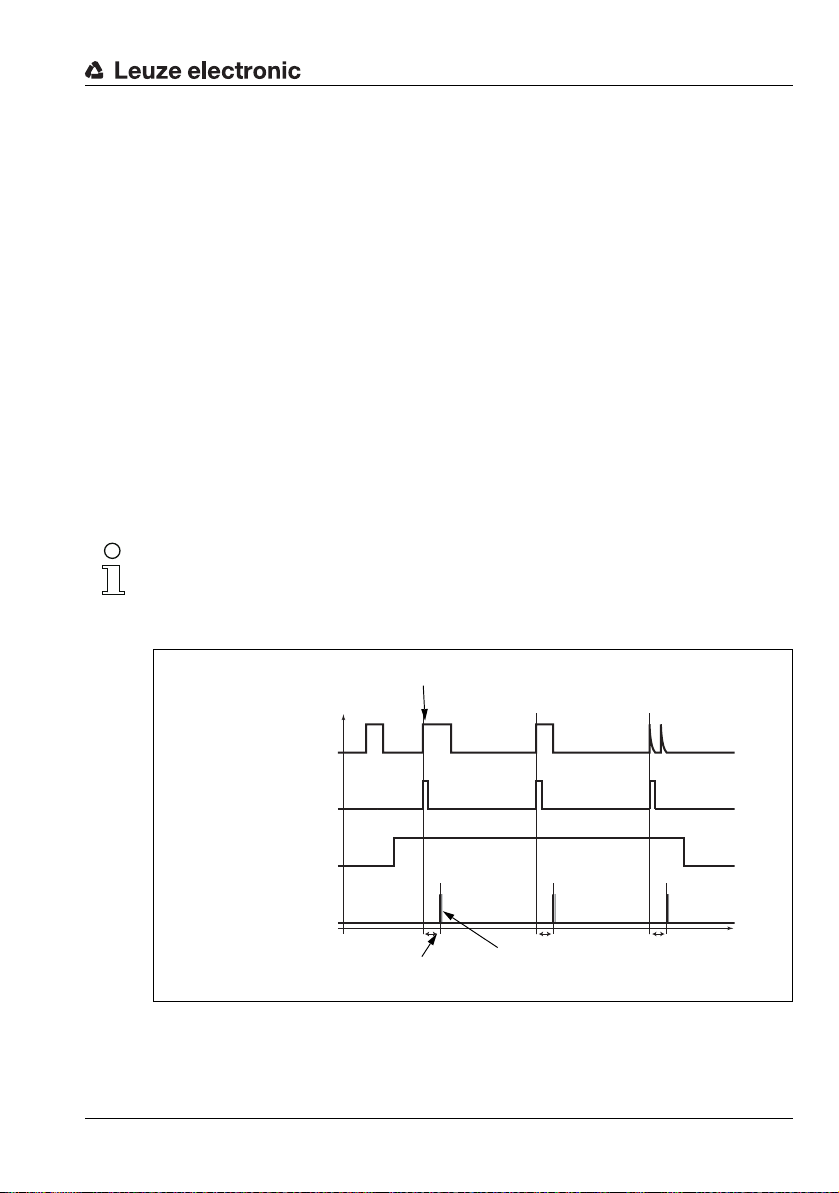

Figure 4.4: Signal sequence for cascading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 4.5: Cascading application example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

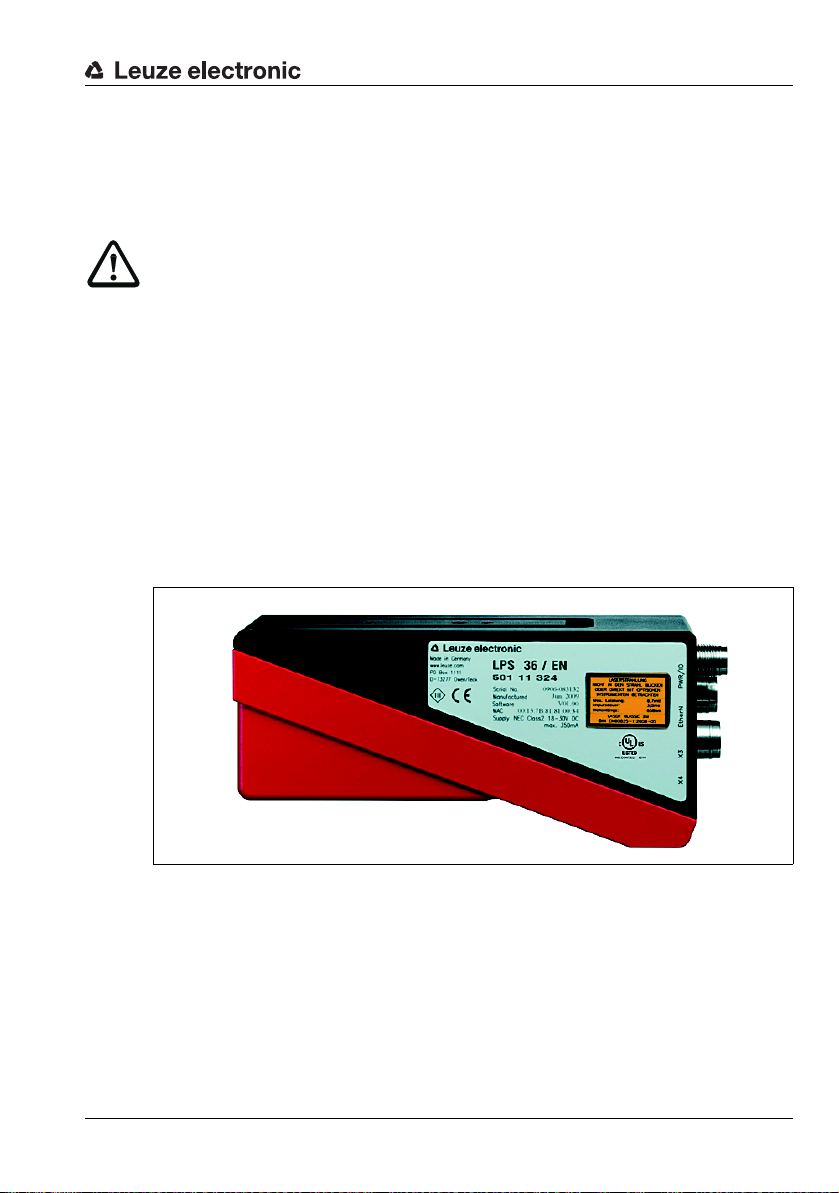

Figure 5.1: Device name plate LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 5.2: Fastening options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 5.3: Mounting example LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 5.4: BT 56 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 5.5: BT 59 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 5.6: Alignment to the measuring plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 6.1: Location of the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 6.2: Connections of the LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 6.1: Interface version of X3 and X4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 6.2: Cable lengths and shielding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 6.3: Connecting the ground potential to the light section sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 6.4: Connecting the cable shielding in the switch cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 6.5: Connecting the cable shielding to the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 6.3: Pin assignment X1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 6.6: Internal wiring at X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 6.4: Pin assignment X2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 6.7: HOST / BUS IN cable assignments on RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 6.5: Pin assignment X3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 6.8: Two-channel incremental encoder connection: example with NPN/PNP open collector . . . . . . . . 39

Figure 6.9: Two-channel incremental encoder connection: single-ended example. . . . . . . . . . . . . . . . . . . . . 39

Figure 6.10: Two-channel incremental encoder connection: differential - RS 422 example . . . . . . . . . . . . . . . 40

Figure 6.11: Single-channel incremental encoder connection: single-ended example (schematic illustration) . 41

Figure 7.1: Indicator and operating elements of the LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 7.1: LED function indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 7.2: Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 8.1: Address allocation in the Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 9.1: Initial screen LPSsoft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 9.2: Parameter settings in LPSsoft when LPS 36Hi is connected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 9.3: Encoder settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 9.4: 3D Visualization with LPSsoft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 9.5: Evaluating saved 3D data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 9.6: Zoom function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 10.1: Connection commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 10.2: Connection commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 10.3: Command mode control commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

TNT 35/7-24V

Leuze electronic LPS 36 6

Page 9

Figures and tables

Table 10.4: Sensor control commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 10.5: Commands in measure mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 11.1: General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 11.2: Interface error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 11.3: Error messages in display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 13.1: Typical measurement range LPS 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 13.2: Typical measurement range LPS 36HI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 13.3: LPS dimensioned drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 14.1: LPS type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 14.2: LRS type overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 14.3: LES type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 14.4: Mounting devices for the LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 14.5: Cable assignment KD S-M12-8A-P1-… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 14.6: X1 cables for the LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 14.7: Cable assignment KS ET-M12-4A-P7-…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 14.8: Ethernet connection cables featuring M12 plug/open cable end . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 14.9: Cable assignment KSS ET-M12-4A-RJ45-A-P7-… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 14.10: Ethernet connection cables M 12 connector/RJ-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 14.11: Cable assignment KSS ET-M12-4A-M12-4A-P7-…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 14.12: Ethernet connection cables featuring M12 plug/M12 plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 14.13: Connectors for the LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 14.14: Cable assignment KS S-M12-8A-P1-…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 14.15: X3 cables for the LPS 36/6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 14.16: Configuration memory for LxS 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 15.1: Revision History - Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 15.2: Revision History - Configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Leuze electronic LPS 36 7

TNT 35/7-24V

Page 10

1 General information

U

L

US

C

LISTED

1.1 Explanation of symbols

The symbols used in this technical description are explained below.

Attention!

This symbol precedes text messages which must strictly be observed. Failure to observe

the provided instructions could lead to personal injury or damage to equipment.

Attention Laser!

This symbol warns of possible danger through hazardous laser radiation.

The light section sensors of the LPS series use a class 2M laser: Viewing the laser output

with certain optical instruments, e.g. magnifying glasses, microscopes or binoculars, may

result in eye damage.

Note!

This symbol indicates text passages containing important information.

General information

1.2 Declaration of Conformity

The laser light section sensors of the 36 and 36HI series have been developed and manufactured in accordance with the applicable European standards and directives. They comply

with the safety standards UL508 and CSA C22.2 No. 14 (Industrial Control Equipment).

Note!

The CE Declaration of Conformity for these devices can be requested from the manufacturer.

The manufacturer of the product, Leuze electronic GmbH & Co. KG in D-73277 Owen,

possesses a certified quality assurance system in accordance with ISO 9001.

Leuze electronic LPS 36 8

TNT 35/7-24V

Page 11

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The Light section sensors of the LPS series are laser distance sensors to determine 2D

profiles.

Areas of application

The LPS series Light section sensors are especially designed for the following areas of

application:

• 3D Measurement of moving objects

• Manipulator control

• Measurement of free formed surfaces

• Case picking

CAUTION

Observe intended use!

The protection of personnel and the device cannot be guaranteed if the device is operated

in a manner not complying with its intended use.

Only operate the device in accordance with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read these operating instructions before commissioning the device. Knowledge of

this document is required in order to use the equipment for its intended purpose.

Safety

NOTE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

OPERATION NOTICE IN ACCORDANCE WITH UL CERTIFICATION:

CAUTION – Use of controls or adjustments or performance of procedures other than

specified herein may result in hazardous light exposure.

Leuze electronic LPS 36 9

TNT 35/7-24V

Page 12

CAUTION

UL applications!

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC

(National Electric Code).

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is

considered improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• as stand-alone safety component in accordance with the machinery directive

• for medical purposes

NOTE

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

1)

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried

out by competent persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at

work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation

of the device.

1) Use as safety-related component within the safety function is possible, if the component combination is designed correspondingly by the machine manufacturer.

Leuze electronic LPS 36 10

TNT 35/7-24V

Page 13

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with

relevant standards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser safety notices

ATTENTION, LASER RADIATION – LASER CLASS 2M

Never look directly into the beam or point the beam in the direction of telescope

users!

The device fulfills the IEC 60825-1:2007 (EN 60825-1:2007) safety regulations for a

product in laser class 2M as well as the U.S. 21 CFR 1040.10 regulations with deviations

corresponding to "Laser Notice No. 50" from June 24th, 2007.

Never look directly into the laser beam or in the direction of reflected laser beams!

If you look into the beam path over a longer time period, there is a risk of injury to the

retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser

beam is accidentally directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflec-

tive surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here

or carrying out of differing procedures may lead to dangerous exposure to radiation.

The use of optical instruments or devices (e.g., magnifying glasses, binoculars) with

the product will increase eye danger.

Observe the applicable statutory and local laser protection regulations.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

TNT 35/7-24V

Leuze electronic LPS 36 11

Page 14

Safety

A Laser aperture

B Laser warning sign

C Laser information sign with laser parameters

B

C

A

NOTE

Affix laser information and warning signs!

Laser warning and laser information signs are affixed to the device (see Figure 2.1):

In addition, self-adhesive laser warning and information signs (stick-on labels) are supplied

in several languages (see Figure 2.2).

Affix the laser information sheet to the device in the language appropriate for the place

of use.

When using the device in the U.S.A., use the stick-on label with the "Complies with

21 CFR 1040.10" notice.

Affix the laser information and warning signs near the device if no signs are attached

to the device (e.g., because the device is too small) or if the attached laser information

and warning signs are concealed due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing

the reader to the laser radiation of the device or other optical radiation.

Figure 2.1: Laser apertures, laser warning signs

Leuze electronic LPS 36 12

TNT 35/7-24V

Page 15

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

ODER DIREKT MIT OPTISCHEN

INSTRUMENTEN BETRACHTEN

LASER KLASSE 2M

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelenght:

RADIAZIONE LASER

NON FISSARE IL FASCIO AD OCCHIO

NUDO NÉ GUARDARE DIRETTAMENTE

CON STRUMENTI OTTICI

APARRECCHIO LASER DI CLASSE 2M

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

NI À L`ŒIL NU NI Á L`AIDE D`UN

INSTRUMENT D`OPTIQUE

APPAREIL À LASER DE CLASSE 2M

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

NI MIRAR DIRECTAMENTE CON

INSTRUMENTOS ÓPTICOS

PRODUCTO LÁSER DE CLASE 2M

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

NEM OLHAR DIRECTAMENTE

COM INSTRUMENTOS ÓPTICOS

EQUIPAMENTO LASER CLASSE 2M

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

0伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

䉏⏘戟⺓

▎䦃展㒥抩扖⏘ⷵ

ⅹ⣷䦃㘴屑䦚⏘㧮

8,7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

50111877-02

Safety

Figure 2.2: Laser warning and information signs – supplied stick-on labels

TNT 35/7-24V

Leuze electronic LPS 36 13

Page 16

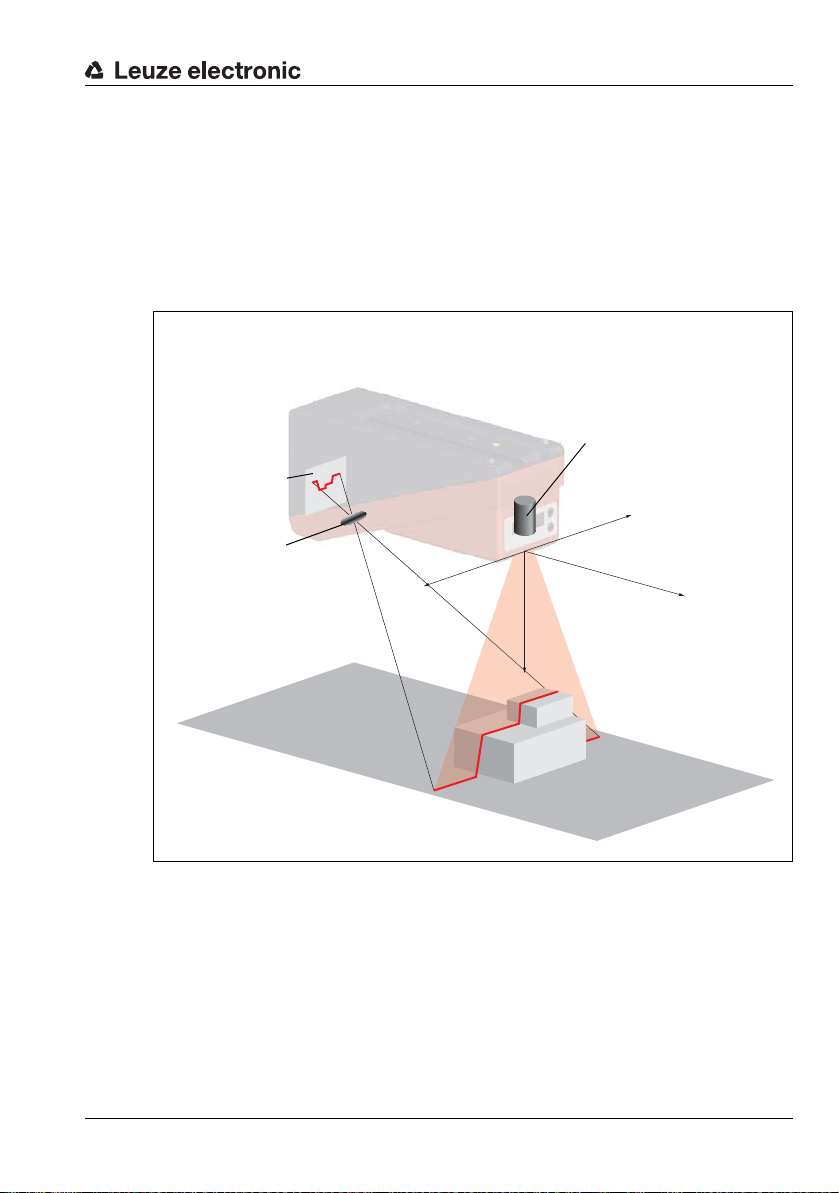

3 Operating principle

CMOS area

detector

Receiving optics

Laser with expansion optics

The zero point of the coordinate system is the intersection

of optical axis and front edge of

the housing.

3.1 Generation of 2D profiles

Light section sensors work according to the triangulation principle. Using transmission

optics a laser beam is expanded to a line and aimed at an object. The light remitted by the

object is received by a camera, which consists of receiver optics and the CMOS area

detector.

Operating principle

-X

+X

-Y

Z

Figure 3.1: Light section sensor design

Depending on the distance of the object the laser line is projected to a different position on

the CMOS planar detector as shown in Figure 3.1. By means of this position the distance

of the object can be calculated.

Leuze electronic LPS 36 14

TNT 35/7-24V

Page 17

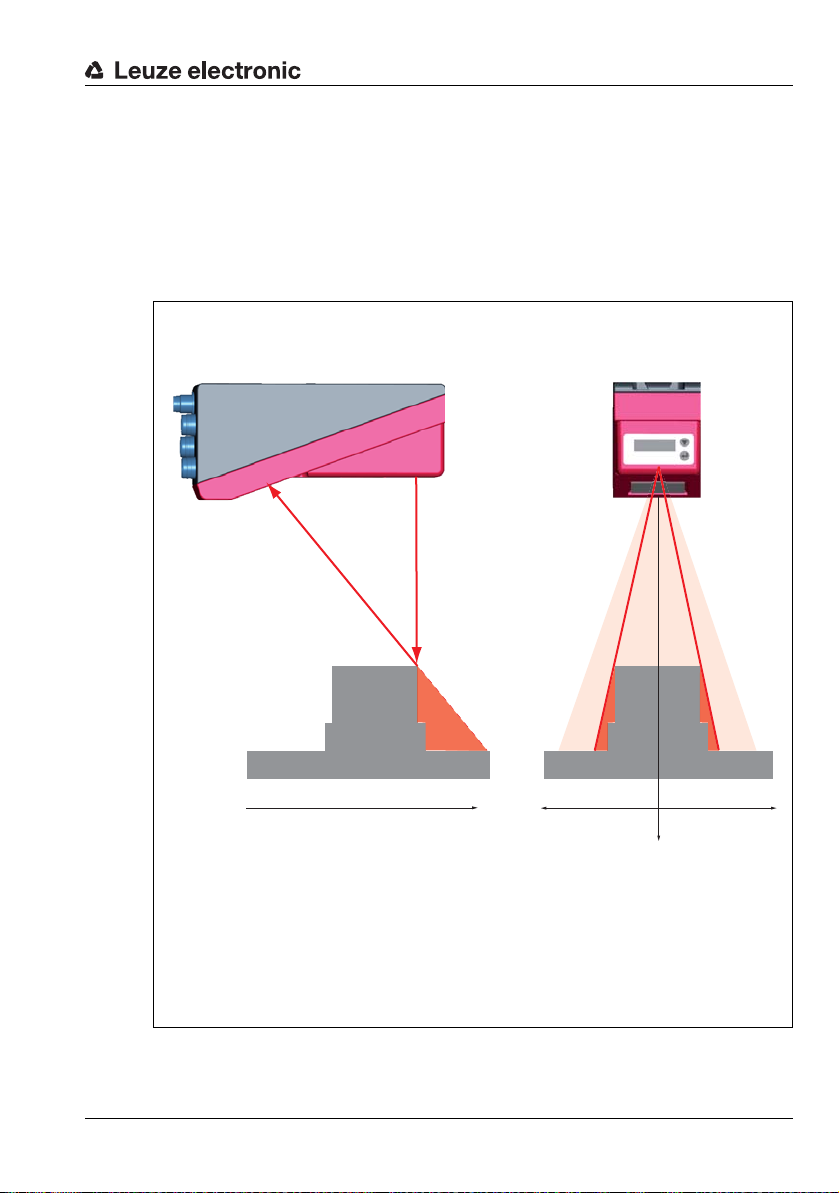

3.2 Limits of light section sensors

Laser occlusionReceiver occlusion

In the red areas the laser does not

strike the object. Thus it is not possible to determine any data here.

The receiver does not "see" any object contours in the

red area because they are obscured by the upper right

edge of the object.

When the object is shifted to the left the object contour will still be detected by the laser but the laser line

does not lie within the receiver's field of view at that

point, and therefore no measurement values can be

detected.

3.2.1 Occlusion

The detection of high and wide objects from just one point poses the particular problem

that depending on the object contour, parts of the object may be obscured by others. This

effect is called occlusion.

The Figure 3.2 illustrates the problem:

Operating principle

Leuze electronic LPS 36 15

Figure 3.2: Occlusion

-Y

+X

TNT 35/7-24V

Z

-X

Page 18

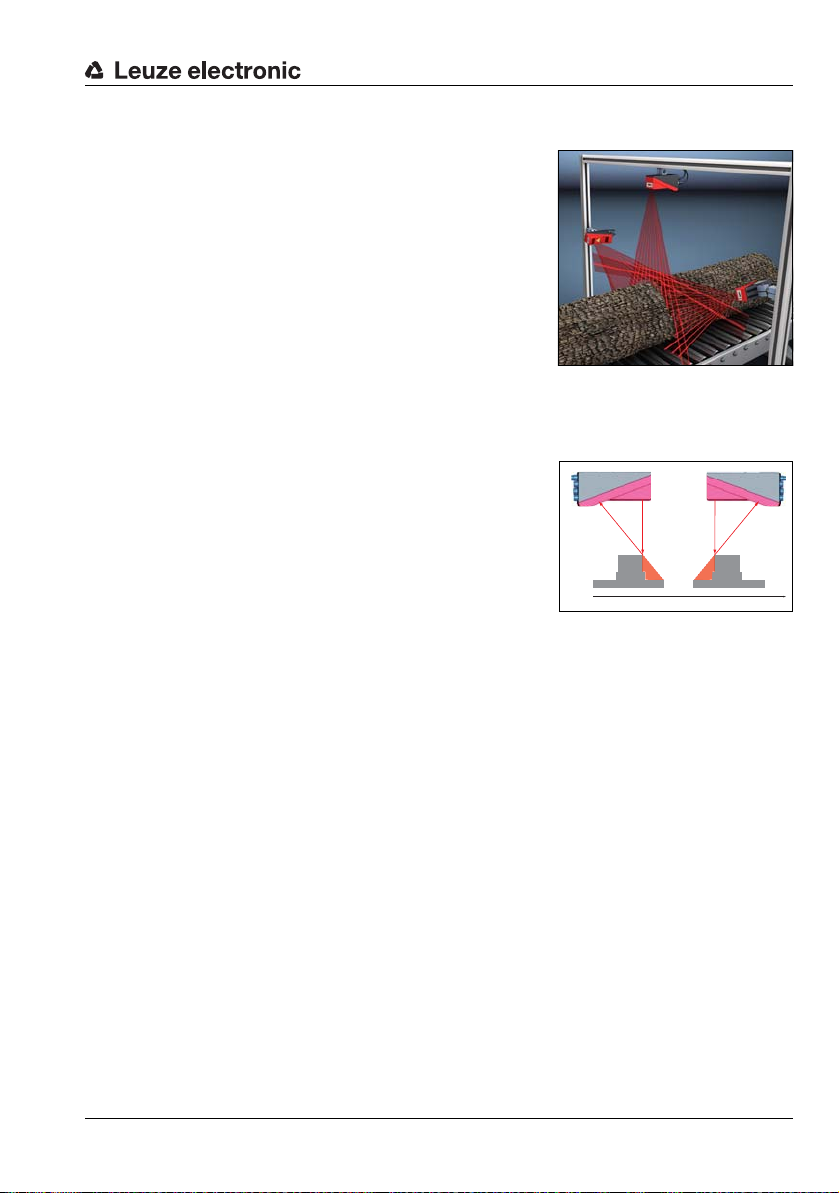

Operating principle

Y

Possible measure against laser occlusion

• Using multiple Light section sensors with rotated

viewing direction. In the application example on

the right you can clearly see that the fields of vision

of the three sensors complement each other and

merge. The first of the sensors is operated as a

master, the two others are cascaded (see "Cascading" on page 22). This reliably prevents mutual

interference of the sensors.

Possible measures against receiver occlusion

• Alignment of the measurement objects so that all profile data to be measured can be

seen by the receiver.

Or:

• Installing a second sensor featuring a viewing

direction rotated by 180° about the z-axis so that

the objects can be viewed from 2 sides.

In the example to the right, the left sensor detects

the profile data on the left side of the product, and

the right sensor the profile data on the right side.

In this situation the second sensor is then cascaded. See "Cascading" on page 22.

Leuze electronic LPS 36 16

TNT 35/7-24V

Page 19

3.2.2 Resolution

0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

200 300 400 500 600 700 800

X

Z

Object distance in Z-direction in mm

Typical resolution in mm

0

0,1

0,2

0,3

0,4

0,5

0,8

0,9

0,6

0,7

200 300 400 500 600

X

Z

Object distance in Z-direction in mm

Typical resolution in mm

In this context resolution means the smallest possible change in distance of the measurement object, which causes a unique change of the output signal. Resolution is higher in the

short range than in the distant range. Small objects can be recognized better in the short

range.

The length of the laser line in the X-direction is dependent on the distance Z of the measurement object from the sensor . Always the same number of measurement points is measured.

From this it follows that the resolution in X-direction decreases with increasing distance in

Z-direction.

The following illustration shows this relation:

Figure 3.3: Typical resolution LPS 36…

The output resolution of the measurement values on the process interface is 1/10mm with

Standard-Connect, 1/100mm with HI-Connect (only with LPS 36HI/EN).

Operating principle

Figure 3.4: Typical resolution LPS 36HI…

Leuze electronic LPS 36 17

TNT 35/7-24V

Page 20

4 Device description

Laser transmitter

Receiver

(CMOS camera)

Display with membrane

keyboard

Electrical connection and

grounding terminal

Groove for dovetail mounting and fastening holes

Note:

The following shows a light section sensor as an example.

An overview of the available types may be found in Chapter 14.1

4.1 Overview of light section sensors

4.1.1 Mechanical design

Figure 4.1: Mechanical design of Leuze light section sensors

Device description

4.1.2 General performance characteristics

• Light section sensor for object/contour measurement

• Measurement time/response time: 10ms

• Measurement range/detection area: 200 … 800mm

• Measurement range/detection area: LPS 36…: 200 to 800 mm, LPS 36HI…: 200 to

600mm

• Length of laser line: max. 600 mm

• Length of the laser line: LPS 36…: max. 600 mm, LPS 36HI…: max. 140 mm

• Configuration and transmission of process data via Fast Ethernet

• OLED display with membrane keyboard

• Measurement value display in mm on OLED display as an alignment aid

• Up to 16 inspection tasks

• Compact construction

• Robust design and easy operation

• Activation input, trigger input, cascading output

Leuze electronic LPS 36 18

TNT 35/7-24V

Page 21

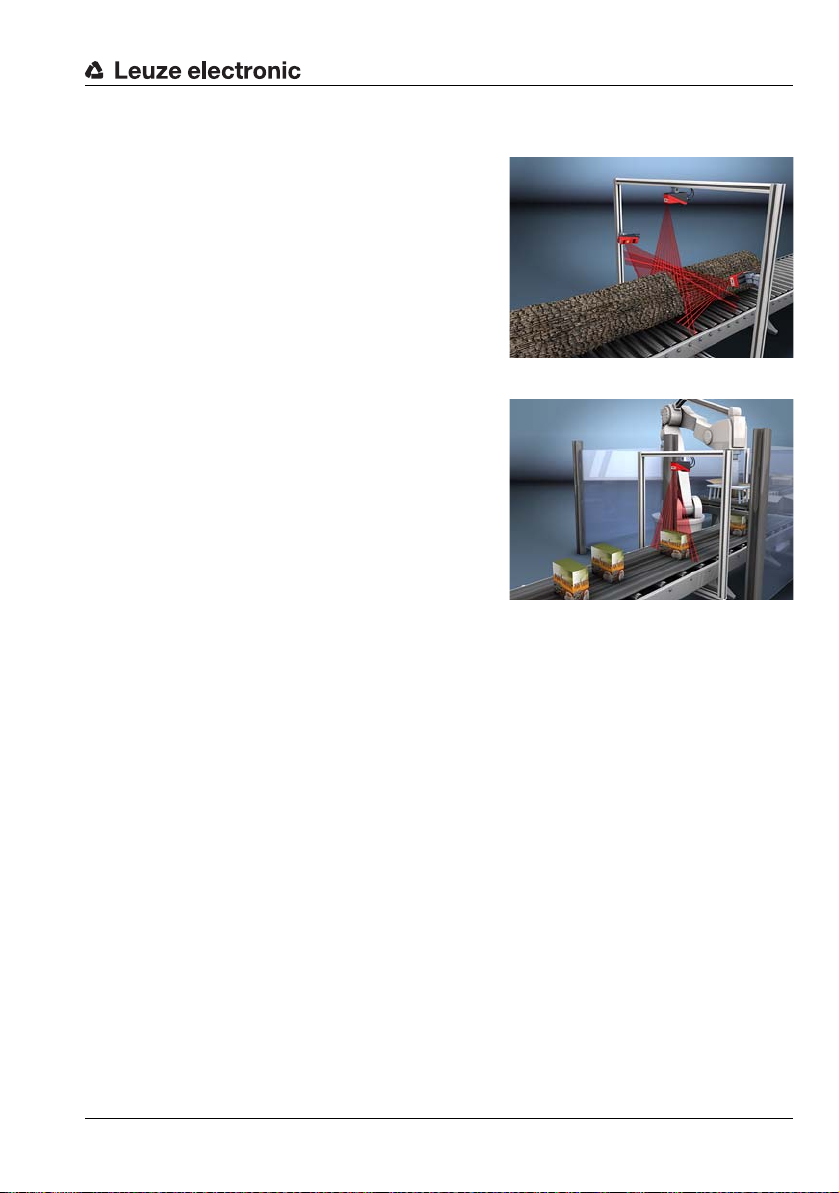

4.1.3 Line Profile Sensor - LPS

Manipulator control

Measurement of free formed surfaces

Wherever stationary or moving objects of

various sizes and positions are to be measured

or detected, the LPS sensor is used. 3D data are

provided reliably due to precise 2D profile

measurements in connection with mobile scanning. Thus numerous application possibilities

are available to determine positions, surfaces

and contents.

Specific performance characteristics

• Measurement data transfer via Ethernet

• LPSsoft configuration software

• Optional: Interface for incremental

encoder

Typical areas of application

• Case picking

• Manipulator control

• Measurement of free formed surfaces

• 3D Measurement of moving objects

Device description

Leuze electronic LPS 36 19

TNT 35/7-24V

Page 22

4.2 Operating the sensor

p

t

Laser off

Laser off

Exposing and measuring

Processing and transmitting

Laser

Activation input

Pin 2 at X1

Output

10ms between 2 consecutive

laser pulses in "Free Running"

mode

Axes: p = level, t = time

Approx. 14ms

between laser pulse and as-

sociated data output

4.2.1 Connection to PC / process control

Configuration

For commissioning the Light section sensors are connected to a PC via the Ethernet interface (see "Connection X2 - Ethernet" on page 36) and are then set using the configuration

software supplied LPSsoft.

Measurement operation

In measurement operation the Light section sensors are connected to a process control via

the same X2 interface, and communicate with it via Ethernet (UDP), see chapter 10 "Integrating the LPS in the process control (Ethernet)".

4.2.2 Activation - laser on/off

The laser and the data transmission can selectively be switched on and off via the activation

input InAct (pin 2 at X1) or via the 'Ethernet Trigger' command. Thus possible glares due

to laser radiation can be prevented during time periods when no measurements are

performed.

Note!

The sensor is delivered ex works with the Activation Input Disregard setting. The

possible activation sources (activation input and Ethernet activation) are ignored - the measurement function of the sensor is enabled.

The activation function can be switched on via the configuration software. To do this, the

Activation Input parameter must be set to Regard. The sensor then only measures if

one of the activation sources is activated. If the sensor is waiting for activation, it displays

!Act

in the display.

Device description

Leuze electronic LPS 36 20

Figure 4.2: Activation input signal sequence

TNT 35/7-24V

Page 23

The Figure 4.2 shows the effect of the activation on laser and measurement value output in

A second trigger

pulse before 10ms

have elapsed has

no effect

Trigger time (rising edge)

Laser

Activation input

Pin 2 at X1

Output

(Ethernet)

Data packets, approx. 1ms

t

fix

Approx. 14ms

Trigger input

Pin 5 at X1

Axes: p = level, t = time

"Free Running" mode.

4.2.3 Triggering - Free Running

The Light section sensors can measure in two modes:

• In "Free Running" operation the Light section sensor determines measurement results

with a frequency of 100Hz and outputs these continuously via the interface X2.

• Alternatively, single measurements can also be carried out. For this purpose, the Light

section sensor requires either a trigger signal at the trigger input (pin 5 on X1) or the

Ethernet Trigger command in measure mode (see Chapter 10.3.4"Commands in

measure mode" on page 91).

When triggering via pin 5 at X1, note:

- Triggering occurs on the rising edge.

-The trigger pulse must be at least 100μs long.

- Before the next trigger, the trigger cable must be on low-level for at least 1 ms.

- Activation must occur at least 100μs before the trigger edge.

- The shortest possible time interval between two successive trigger edges is 10ms.

Note!

Ex works, the LPS is set to Free Running (shown on display:

respond to signals on the trigger input, the operating mode must be set via the LPSsoft configuration software to Input Triggered (shown on display:

Device description

fRun

). In order for it to

Trig

).

Leuze electronic LPS 36 21

p

Figure 4.3: Trigger input signal sequence

TNT 35/7-24V

t

Page 24

4.2.4 Cascading

Laser

Measurement value output

Trigger input, pin 5 at X1

/ not required

Cascading output,

pin 6 at X1

Sensor 1 / Master

Laser

Measurement value output

Trigger input, pin 5 at X1

Cascading output,

pin 6 at X1

Sensor 2 / 1st slave

Laser

Measurement value output

Trigger input, pin 5 at X1

Cascading output,

pin 6 at X1

Sensor 3 / 2nd slave

Figure 4.4: Signal sequence for cascading

Figure 4.5: Cascading application example

If several Light section sensors are operated, there is the risk of mutual interference

if the reflected laser beam of one sensor can

be received by the receiver of another

sensor at the time of reading.

This can easily be seen in Figure 4.5. Here

three Light section sensors are used to

determine the log thickness reliably from all

sides.

To prevent mutual interference the Light

section sensors can be operated cascaded: the exposure by the second sensor will be initi-

Leuze electronic LPS 36 22

ated following completion of the exposure by the first sensor. To achieve this, the cascading

output of the first sensor must be connected to the trigger input of the second sensor. Up

to 6 sensors can thus be operated cascaded.

Trigger settings

Se nso r 1, or the m ast er, can be ope rat ed i n th is c ase bot h tr igg ere d as wel l as con tin uou sly.

All other sensors must be operated triggered.

Cascading settings

For all sensors except the last slave, the cascading output must be enabled via configuration

software: Cascading Output: Enable.

Device description

TNT 35/7-24V

Page 25

4.3 Inspection Task

The LPS supports up to 16 individual inspection tasks. Grouped together in an inspection

task are all parameter settings relevant for an application:

• Operation Mode (Free Running, Input Triggered)

• Activation Input (switch laser on and off)

• Cascading Output

• Light Exposure (exposure duration of the laser)

• Field of View (sensor detection range)

The selection of the inspection tasks is carried out:

• via LPSsoft (on a PC connected via X2)

• via Ethernet (on a process control connected via X2)

• via the control panel of the sensor beginning with firmware V01.40.

Device description

Leuze electronic LPS 36 23

TNT 35/7-24V

Page 26

5 Installation and mounting

Note:

The following shows a light section sensor as an example. An

overview of the available types may be found in Chapter 14.1

5.1 Storage, transportation

Attention!

When transporting or storing, package the Light section sensor so that it is protected against

collision and humidity. Optimum protection is achieved when using the original packaging.

Ensure compliance with the approved environmental conditions listed in the specifications.

Unpacking

Check the packaging content for any damage. If damage is found, notify the post office

or shipping agent as well as the supplier.

Check the delivery contents using your order and the delivery papers:

• Delivered quantity

• Device variant and model as indicated on the nameplate

• Laser warning signs

• Brief manual

The name plate provides information as to what Light section sensor type your device is.

For specific information, please refer to Chapter 14.

Installation and mounting

Figure 5.1: Device name plate LPS

Save the original packaging for later storage or shipping.

If you have any questions concerning your shipment, please contact your supplier or your

local Leuze electronic sales office.

Observe the applicable local regulations when disposing of the packaging materials.

Leuze electronic LPS 36 24

TNT 35/7-24V

Page 27

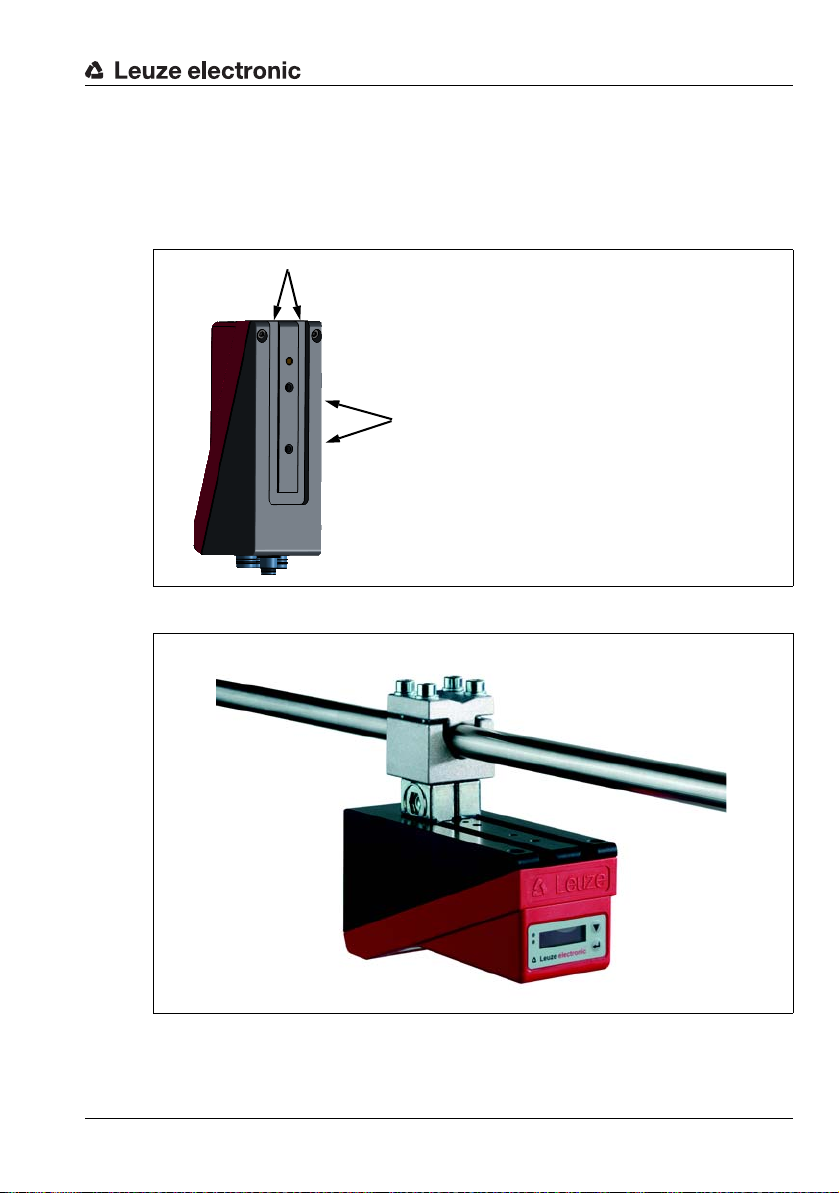

5.2 Mounting the LPS

Dovetail fastening grooves

M4 threaded holes

The Light section sensors can be mounted in different ways:

• By means of two M4x6 screws on the back of the device

• Using a BT 56 mounting device on the two fastening grooves.

• Using a BT 59 mounting device on the two fastening grooves.

Figure 5.2: Fastening options

Installation and mounting

Figure 5.3: Mounting example LPS

Leuze electronic LPS 36 25

TNT 35/7-24V

Page 28

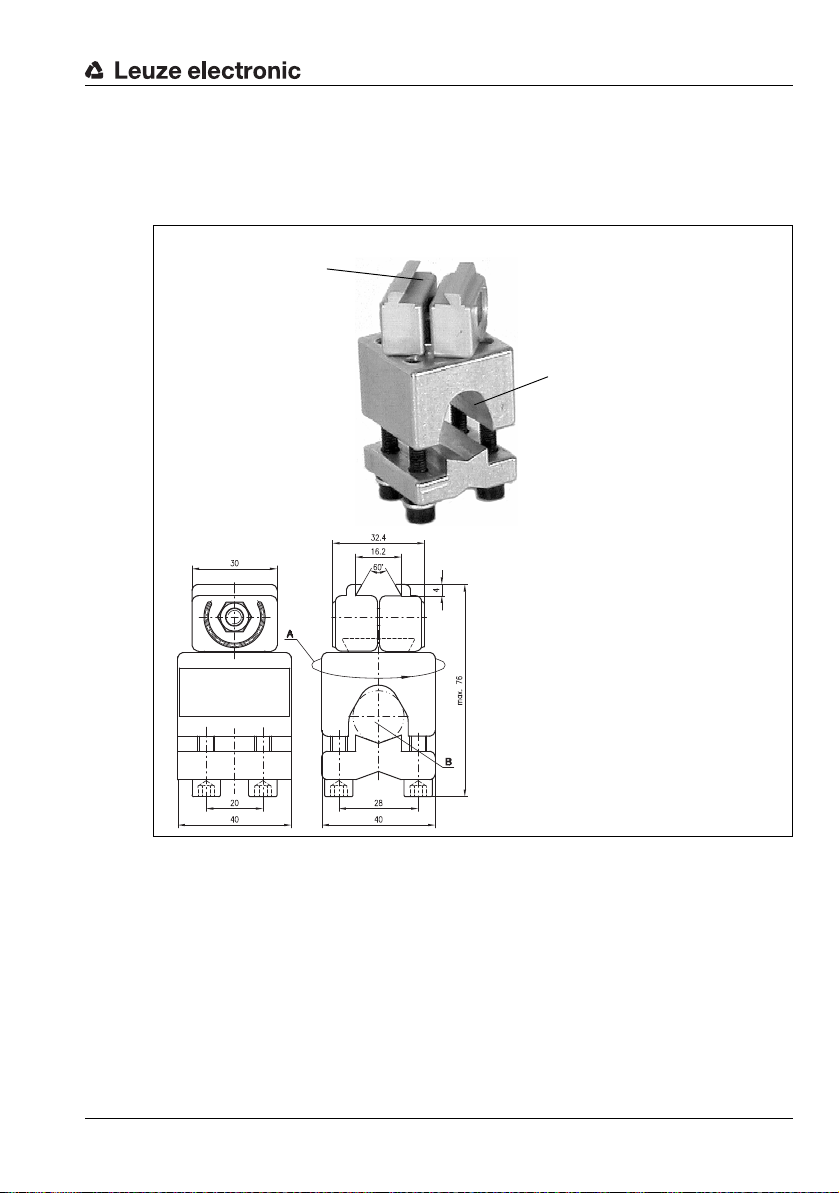

5.2.1 BT 56 mounting device

Clamping jaws for

mounting on the LPS

Clamp profile for

mounting to round or

oval pipes

Ø16…20mm

A Rod holder, turnable 360°

B Rods Ø 16 … 20mm

all dimensions in mm

The BT 56 mounting device is available for mounting the LPS using the fastening grooves.

It is designed for rod mounting (Ø 16 mm to 20mm). For order guide, please refer to chapter

"Type overview and accessories" on page 106.

Installation and mounting

Figure 5.4: BT 56 mounting device

Leuze electronic LPS 36 26

TNT 35/7-24V

Page 29

5.2.2 BT 59 mounting device

Clamping jaws for

mounting on the LPS

A Holder, turnable 360°

B ITEM joint, angle adjustable ±90°

C M8x16 screw cylinder, M8 serrated washer,

M8 sliding block, connectors for ITEM profile (2x)

all dimensions in mm

The BT 59 mounting device is available for mounting the LPS on ITEM profiles using the

fastening grooves. For order guide, please refer to chapter "Type overview and accessories"

on page 106.

Installation and mounting

Figure 5.5: BT 59 mounting device

Leuze electronic LPS 36 27

TNT 35/7-24V

Page 30

5.3 Device arrangement

5.3.1 Selecting a mounting location

In order to select the right mounting location, several factors must be considered:

• The required resolution. This is a result of the distance and the resulting line length.

• The permissible cable lengths between the LPS and the host system depending on

which interface is used.

• The display and control panel should be very visible and accessible.

When selecting a mounting location, pay further attention to:

• Maintaining the required environmental conditions (temperature, humidity).

• Possible soiling of the optics covers on transmitter and receiver by discharged liquids,

abrasion from cartons or packaging residues.

• Lowest possible chance of damage to the LPS by mechanical collision or jammed

parts.

• Possible extraneous light (no direct sunlight or sunlight reflected by the measurement

object).

• The optimal perspective for detecting the relevant contours of objects, see

chapter 3.2.1 "Occlusion".

Attention, laser radiation!

When mounting and aligning the LPS, avoid reflections of the laser beam off reflective surfaces!

Note!

The prevention of ambient light due to shielding of the sensor for example, ensures stable

and precise measurement values. Secondary reflections of the laser line on reflective objects

must be avoided as these can result in faulty measurements.

The best measurement results are obtained when:

Installation and mounting

- You adapt the operating mode (light/dark) to the application

- You do not measure high-gloss objects.

- There is no direct sunlight.

5.3.2 Aligning the sensor

The zero point of the sensor coordinate system is the intersection of optical axis and front

edge of the housing. The general principle is that the Light section sensor should be aligned

so that the back of the sensor is aligned parallel to the conveying belt or measuring plane.

A rotation about the y-axis is undesirable as this then necessitates a coordinate transformation of the measurement values.

The Figure 5.6 illustrates the problem:

Leuze electronic LPS 36 28

TNT 35/7-24V

Page 31

Installation and mounting

+X

-X

Z

-Y

-X

+X

Z

-Y

Figure 5.6: Alignment to the measuring plane

A rotation of the sensor about the y-axis distorts the entire coordinate system, which the

measurement values relate to. The sensor measures along the solid line in the right picture,

however the measuring plane is located on the dotted line, and a measurement towards the

conveying belt shown in gray would result in a tilted plane.

A conversion into correct X/Z-coordinates is possible but to achieve this the user has to

carry out a coordinate transformation in the process control. The Light section sensor does

not offer a conversion option internally.

When setting up an application it is therefore very important to ensure correct alignment

and that the integrated alignment aid on the display is used.

5.4 Attach laser warning sign

Attention Laser!

Observe the safety notices in Chapter 2.

It is essential that you attach the stick-on label (laser warning signs and laser beam exit

symbol) supplied with the Light section sensor to the Light section sensor! If the signs

would be concealed as a result of the mounting situation of the LPS, attach the signs in

the vicinity of the LPS such that reading the signs cannot lead to looking into the laser

beam!

When installing the LPS in North America, also attach the stick-on label saying "Complies

with 21 CFR 1040.10"

5.5 Cleaning

Clean the optics cover of the LPS with a soft cloth after mounting. Remove all packaging

remains, e.g. carton fibers or styrofoam balls. In doing so, avoid leaving fingerprints on

the optics cover of the LPS.

Attention!

Do not use aggressive cleaning agents such as thinner or acetone for cleaning the device.

Leuze electronic LPS 36 29

TNT 35/7-24V

Page 32

6 Electrical connection

Note:

The following shows a light section sensor as an example.

An overview of the available types may

be found in Chapter 14.1

Tx+

1

2

3

4

Rx+

Rx-

Tx-

X2

X3

X4

7

8

X1

VIN

Act

Trig

Ready

OutCas

GND

7

8

Note:

The following shows a light section sensor as an example.

An overview of the available types may

be found in Chapter 14.1

The Light section sensors are connected using variously coded M12 connectors. This

ensures unique connection assignments.

For the locations of the individual device connections, please refer to the device detail shown

below.

Note!

The corresponding mating connectors and ready-made cables are available as accessories

for all connections. For additional information, refer to Chapter 14.

Figure 6.1: Location of the electrical connections

All the Light section sensors are equipped with three M 12 plugs / sockets which are A- and

D-coded.

Electrical connection

TNT 35/7-24V

Leuze electronic LPS 36 30

Figure 6.2: Connections of the LPS

The pin assignment of X1 and X2 is identical for all Light section sensors; X3 and X4 differ

depending on device type.

Page 33

Using the name plate check the exact type designation. The version of X3/X4 is contained

in the following table:

Type designation X3 X4 Relevant chapter

LPS 36/EN Encoder Not assigned Chapter 6.3.3

LPS 36HI/EN Encoder Not assigned Chapter 6.3.3

LPS 36 Not assigned Not assigned -

Table 6.1: Interface version of X3 and X4

6.1 Safety notices

Attention!

Do not open the Light section sensor yourself under any circumstances! There is otherwise

a risk of uncontrolled emission of laser radiation from the Light section sensor. The housing

of the LPS contains no parts that need to be adjusted or maintained by the user.

Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

Connection of the device and cleaning must only be carried out by a qualified electrician.

If faults cannot be cleared, the LPS should be switched off from operation and protected

against accidental use.

The LPS Light section sensors are designed in accordance with protection class III for supply

by PELV (protective extra-low voltage with reliable disconnection).

Electrical connection

Note!

Degree of protection IP 67 is achieved only if the connectors and caps are screwed into

place! The connectors used must be equipped with O-ring seals. Therefore, preferably,

please use the ready-made cables by Leuze electronic.

Leuze electronic LPS 36 31

TNT 35/7-24V

Page 34

6.2 Shielding and line lengths

The Light section sensors of the 36/36HI series are equipped with modern electronics developed for industrial applications. In industrial environments, a number of sources of interference may affect the sensors. In the following, information is provided on EMC-compliant

wiring of the sensors and of the other components in the switch cabinet and on the machine.

Observe the following maximum line lengths:

Connection to sensor Interface Max. cable length Shielding

Power supply unit X1 50m required

Activation / cascading / trigger X1 50m required

PC/Host X2 50m required

Encoder X3 50m required

Table 6.2: Cable lengths and shielding

Shielding:

1. Ground the LPS housing:

Connect the housing of the LPS via the functional earth (FE) screw provided for this

purpose (see Figure 6.3, devices produced after April 2011) with the protective conductor on the machine star point. The cable should have an impedance as low as possible for high-frequency signals, i.e., be as short as possible and have a large crosssectional area (grounding strip, …).

If the LPS does not yet have an FE screw of its own, please use one of the M4 holes

on the dovetail.

Important: Place a lock washer underneath and check the penetration of the anodized

coating of the LPS housing by measuring the electrical connection from FE star point

to the connector sleeves without connected sensor cables so that other FE interruptions can be detected on the machine base and profile rails as well.

2. Shield all connection cables to the LPS:

Apply the shield to FE on both sides. On the LPS end, this is ensured if the LPS housing

is connected to FE (PE) as described under 1. (shield fitted over the connector sleeves

to the housing).

In the switch cabinet, clamp the shield flat to FE. To do this, use special shielding

clamps (e.g., Wago, Weidmüller, …).

Keep the length of the shieldless end of the cable as short as possible.

The shield should not be connected at a terminal in a twisted fashion (no "RF braid").

3. Disconnect power and control cables:

Lay the cables for the power components (motor cables, lifting magnets, frequency

inverters, …) as far from the sensor cables as possible (distance > 30 cm). Avoid laying

power and sensor cables parallel to one another.

Cable crossings should be laid as perpendicular as possible.

4. Lay cables close to grounded metal surfaces:

This measure reduces interference coupling in the cables.

5. Avoid leakage currents in the cable shield:

Leakage currents arise from incorrectly implemented equipotential bonding. Therefore, carefully ground all parts of the machine.

Note: You can measure leakage currents with a clip-on ammeter.

Electrical connection

TNT 35/7-24V

Leuze electronic LPS 36 32

Page 35

Electrical connection

Devices produced after April 2011 are

equipped with an additional grounding terminal.

All devices can also be connected

to ground potential at the M4

threaded hole on the dovetail.

Attention!

Place lock washer underneath and check

the penetration of the

anodized coating!

6. Star-shaped cable connections:

To avoid interference between various consumers, ensure that the devices are connected in a star shape. This will prevent cable loops.

General shielding information:

Avoid spurious emissions when using power components (frequency inverters, …). The

technical descriptions of the power components provide the necessary specifications

according to which the respective power component satisfies its CE conformity.

In practical work, the following measures have proven effective:

• Screw the mains filter, frequency inverter flat on the galvanized mounting plate.

• Mounting plate in the switch cabinet made of galvanized sheet steel, thickness 3mm

• Keep cable between mains filter and inverter as short as possible and twist cables.

• Shield both ends of the motor cable.

• Properly ground the total system.

Carefully ground all parts of the machine and of the switch cabinet using copper strips,

ground rails or grounding cables with large cross section.

Below, the EMC-compliant connection of the Light section sensors LPS is described in practical use with images.

Connect the ground potential to the light section sensors

Figure 6.3: Connecting the ground potential to the light section sensor

Leuze electronic LPS 36 33

TNT 35/7-24V

Page 36

Connecting the cable shielding in the switch cabinet

• Shield connected flat to PE

• Connect PE star point with short cables

• Galvanized mounting sheet steel

Comment:

Depicted shield components from Wago,

series 790 ...:

- 790-108 Shield clamping bracket 11 mm

- 790-300 Busbar holder for TS35