Leuze LES 36 Series, LES 36HI Series Original Operating Instructions

LES - Line Edge Sensor

Light section sensors

en 05-2018/03 50116497

We reserve the right

to make technical changes

Original operating instructions

© 2018

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.com

Leuze electronic LES 36

Table of contents

Figures and tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Laser safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Generation of 2D profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Limits of light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.1 Occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.2 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Overview of light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.1 Mechanical design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.2 General performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.3 Line Edge Sensor - LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Operating the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.1 Connection to PC / process control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.2 Activation - laser on/off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.3 Triggering - Free Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.4 Cascading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Measurement functions: LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3.1 Inspection Task. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Possible measure against laser occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Possible measures against receiver occlusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specific performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Typical areas of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Measurement operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PROFIBUS trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Trigger settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cascading settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Functional principle of object and edge detection with the LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TNT 35/7-24V

Leuze electronic LES 36 1

Table of contents

4.3.2 Edge Analysis Window (EAW). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.3 Definition of EAWs and their analysis results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Characteristics of EAWs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Edge detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Relative window positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Object detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.4 Application examples for EAWs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Application example: web-edge measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Application example: height and width measurement of a cubic object . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4 Analysis Window (AW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5 Installation and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1 Storage, transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Mounting the LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1 BT 56 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.2 BT 59 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3 Device arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.1 Selecting a mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.2 Aligning the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4 Attach laser warning sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.5 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1 Safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2 Shielding and line lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Shielding: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

General shielding information: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Connect the ground potential to the light section sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Connecting the cable shielding in the switch cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Connecting the cable shielding to the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.3 Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.3.1 Connection X1 - logic and power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.3.2 Connection X2 - Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3.3 Connection X3 - switching inputs/outputs (LES 36…/VC6) . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.4 Connection X4 - PROFIBUS DP (LES 36…/PB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3.5 Connection X4 - voltage/current output (LES 36…/VC6) . . . . . . . . . . . . . . . . . . . . . . . . . 50

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Activation input InAct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Trigger input InTrig. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cascading output OutCas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Output "ready" OutReady . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Ethernet cable assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Switching outputs of connection X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Switching inputs of connection X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Characteristic curve of analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

TNT 35/7-24V

Leuze electronic LES 36 2

Table of contents

7 Display and control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.1 Indicators and operational controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.1.1 LED status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.1.2 Control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.1.3 Indicators in the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.2 Menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.2 Operation/navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.3 Reset to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8 Commissioning and configuration. . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1 Switching on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2 Establish connection to PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Alignment aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Status indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Command mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Menu navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Selecting values or selection parameters for editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Editing value parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Editing selection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Interrupting a reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Executing a reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting the default gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Setting an alternative IP address on the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9 LESsoft configuration software. . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.2.1 Possible error message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.2.2 Device list update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.3 Starting LESsoft/Communication tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

PROFIBUS settings (only LES 36/PB and LES 36HI/PB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.4 Parameter settings/Parameters tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.4.1 Standard tab - Task Parameters panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Leuze electronic LES 36 3

Inspection Task Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Trigger Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Light Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Field of View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Apply Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

TNT 35/7-24V

Table of contents

9.4.2 Standard tab - Analysis Functions panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Edit Analysis Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Using the mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Keyboard input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Position type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Relative to Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Offset X / Offset Z . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Edge Detection Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Analysis Window Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Edit Logical Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Edge State (result of edge and object detection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Object Point/EAW State (result of edge detection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Show Edge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

X, Width (X), Z, Height (Z) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Profibus Inputs 1 , Profibus Inputs 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Application example 1: web edge measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Application example 2: height and width monitoring of cubic objects . . . . . . . . . . . . . . . . . . . . . . . . . 84

Additional object detection with LES sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

EAW1 … EAW4, AW05 … AW08. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

AW Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Analysis Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

AW Logic Analysis Depth (result of object detection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Application example 3: width monitoring of cubic objects with object detection (narrow objects

are not to be detected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.4.3 Standard tab - Single Shot Mode panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.4.4 Standard tab - Global Parameters panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.4.5 Analog Output tab - configuring the analog output (only LES 36…/VC) . . . . . . . . . . . . . 90

Edge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

mm For Min. Val. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

mm For Max. Val. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.5 Menu commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.5.1 Saving parameter settings/File menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.5.2 Transmitting parameter settings/Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.5.3 Zoom and Pan/toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.6 Definition of inspection tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Typical procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

TNT 35/7-24V

10 Integrating the LES in the process control (Ethernet) . . . . . . . . . . 95

10.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.2 Protocol structure: Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Protocol structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.2.1 Command number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.2.2 Packet number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.2.3 Transaction number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.2.4 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.2.5 Encoder High / Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.2.6 Scan number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Leuze electronic LES 36 4

Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table of contents

10.2.7 Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.2.8 Number of user data words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.2.9 Evaluation telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.3 Ethernet commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.3.1 Elementary commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.3.2 Commands in command mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.3.3 Explanation of user data in command mode (command parameters) . . . . . . . . . . . . . . 103

10.3.4 Commands in measure mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.3.5 Explanation of user data in measure mode (command parameters) . . . . . . . . . . . . . . . 112

10.4 Working with the protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.5 Operation with LxS_Lib.dll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.6 Operation with native C++ DLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.7 Additional support when integrating sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Set Laser Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Set Actual Inspection Task. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Get Actual Inspection Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Set Scan Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Set Single User parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Get Single User parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Set Single Inspection Task Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Get Single Inspection Task Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Ethernet Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Command without user data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Command with user data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11 Integration of the LES 36…/PB in the PROFIBUS . . . . . . . . . . . . 115

11.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Characteristics of LES 36…/PB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.2 PROFIBUS address assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Automatic address assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Address assignment with LESsoft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Address assignment with membrane keyboard and display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

11.3 General information about the GSD file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.4 Overview of the GSD modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Output data (from viewing position of control). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Input data (from viewing position of control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11.5 Description of the output data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

PROFIBUS trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Activation - Sensor activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Inspection Tasks - Selection of inspection tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.6 Description of the input data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Leuze electronic LES 36 5

TNT 35/7-24V

Table of contents

11.6.1 Module M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Scan number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Sensor info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Sensor state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Object detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Measurement value 1 in Edge Analysis Window EAW1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

11.6.2 Module M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Measurement value 2 in Edge Analysis Window EAW1 (wEdgeAW1Data2) . . . . . . . . . . . . . . . . . . . . 123

Measurement value 1 in Edge Analysis Window EAW2 (wEdgeAW2Data1) . . . . . . . . . . . . . . . . . . . . 123

Measurement value 2 in Edge Analysis Window EAW2 (wEdgeAW2Data2) . . . . . . . . . . . . . . . . . . . . 123

Measurement value 1 in Edge Analysis Window EAW3 (wEdgeAW3Data1) . . . . . . . . . . . . . . . . . . . . 123

11.6.3 Module M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Measurement value 2 in Edge Analysis Window EAW3 (wEdgeAW3Data2) . . . . . . . . . . . . . . . . . . . . 124

Measurement value 1 in Edge Analysis Window EAW4 (wEdgeAW4Data1) . . . . . . . . . . . . . . . . . . . . 124

Measurement value 2 in Edge Analysis Window EAW4 (wEdgeAW4Data2) . . . . . . . . . . . . . . . . . . . . 124

12 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 125

12.1 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

12.2 Interface error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

12.3 Error messages in display (starting from firmware V01.40) . . . . . . . . . . . . . . . . . . . . . 127

13 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

13.1 General maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

13.2 Repairs, servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

13.3 Disassembling, packing, disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

14 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

14.1 General technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

14.2 Typical measurement range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

14.3 Dimensioned drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

15 Type overview and accessories . . . . . . . . . . . . . . . . . . . . . . . . . 134

15.1 Type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

15.1.1 LPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

15.1.2 LRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

15.1.3 LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

15.2.1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

15.2.2 Accessories – Ready-made cables for voltage supply X1 . . . . . . . . . . . . . . . . . . . . . . . 136

Leuze electronic LES 36 6

Mounting devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Contact assignment for connection cable X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Order codes of the cables for voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

TNT 35/7-24V

Table of contents

15.2.3 Accessories for Ethernet interface X2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Ready-made cables with M 12 connector/open cable end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Ready-made cables with M 12 connector/RJ-45 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Ready-made cables with M 12 connector/M12 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

15.2.4 ccessories - Ready-made cables for X3 (only LES 36…/VC6). . . . . . . . . . . . . . . . . . . . 139

Contact assignment for X3 connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Order code of X3 connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

15.2.5 Connection accessories / ready-made cables for X4 (only LES 36…/PB) . . . . . . . . . . . 140

Contact assignment for X4 connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Order codes for X4 connection accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Order code of PROFIBUS connection cables for X4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

15.2.6 Connection accessories / ready-made cables for X4 (only LES 36…/VC6) . . . . . . . . . . 142

Contact assignment for X4 connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Order code of X4 connection cables (only LES 36…/VC6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

15.2.7 Configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

15.2.8 Configuration memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

16 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

16.1 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

16.2 Revision History / Feature list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

16.2.1 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

16.2.2 Configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Leuze electronic LES 36 7

TNT 35/7-24V

Figures and tables

Figures and tables

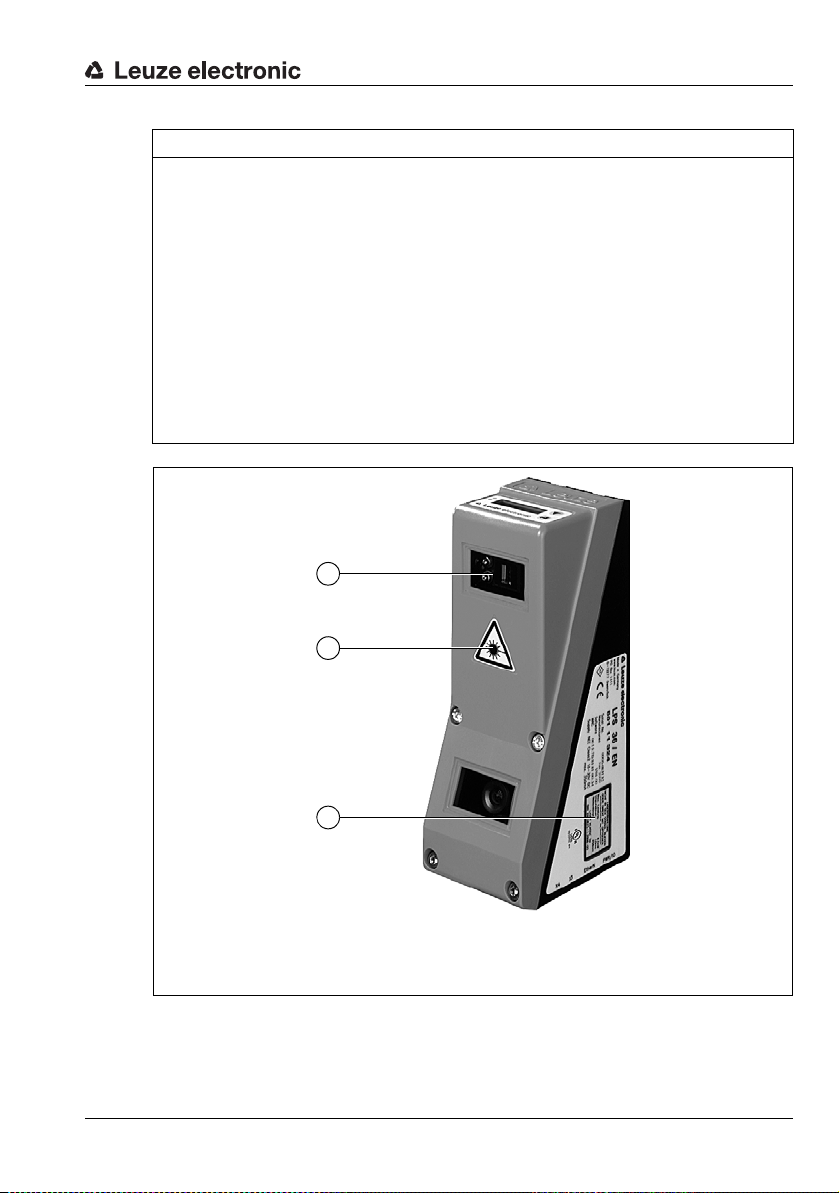

Figure 2.1: Laser apertures, laser warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2.2: Laser warning and information signs – supplied stick-on labels . . . . . . . . . . . . . . . 15

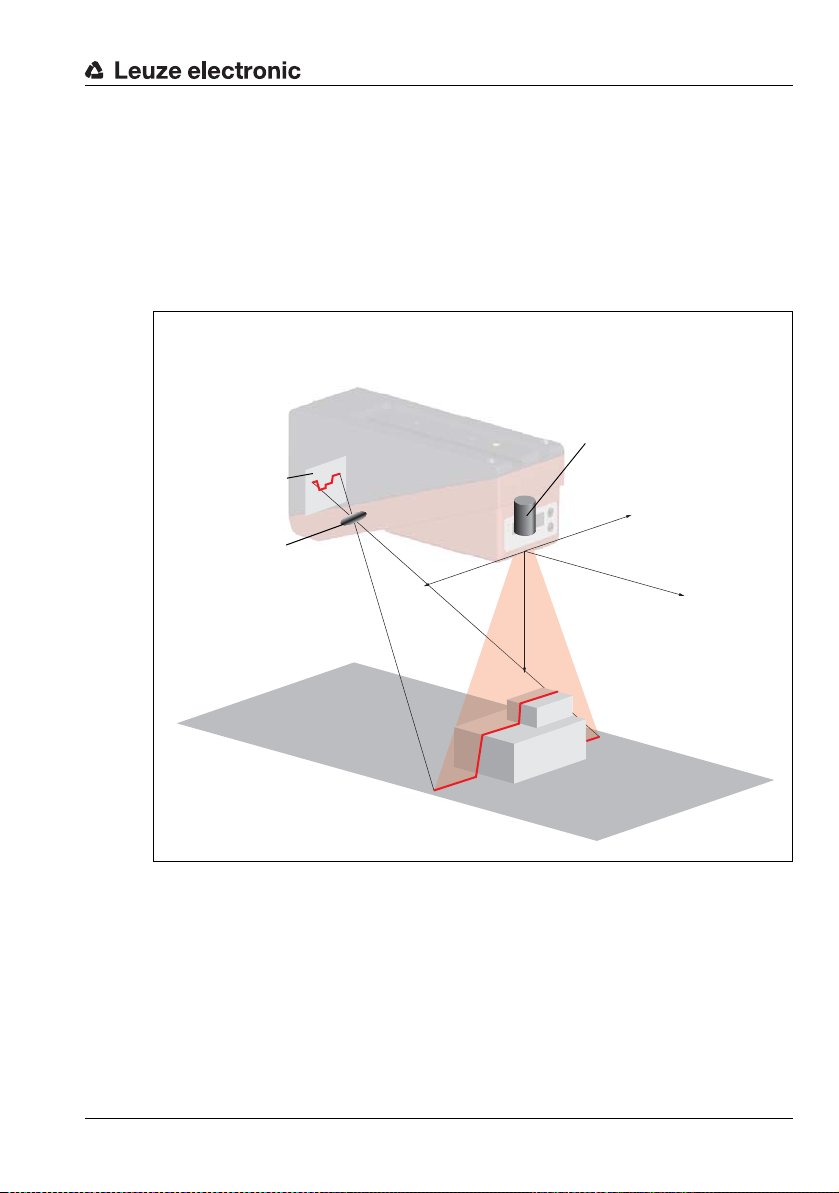

Figure 3.1: Light section sensor design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

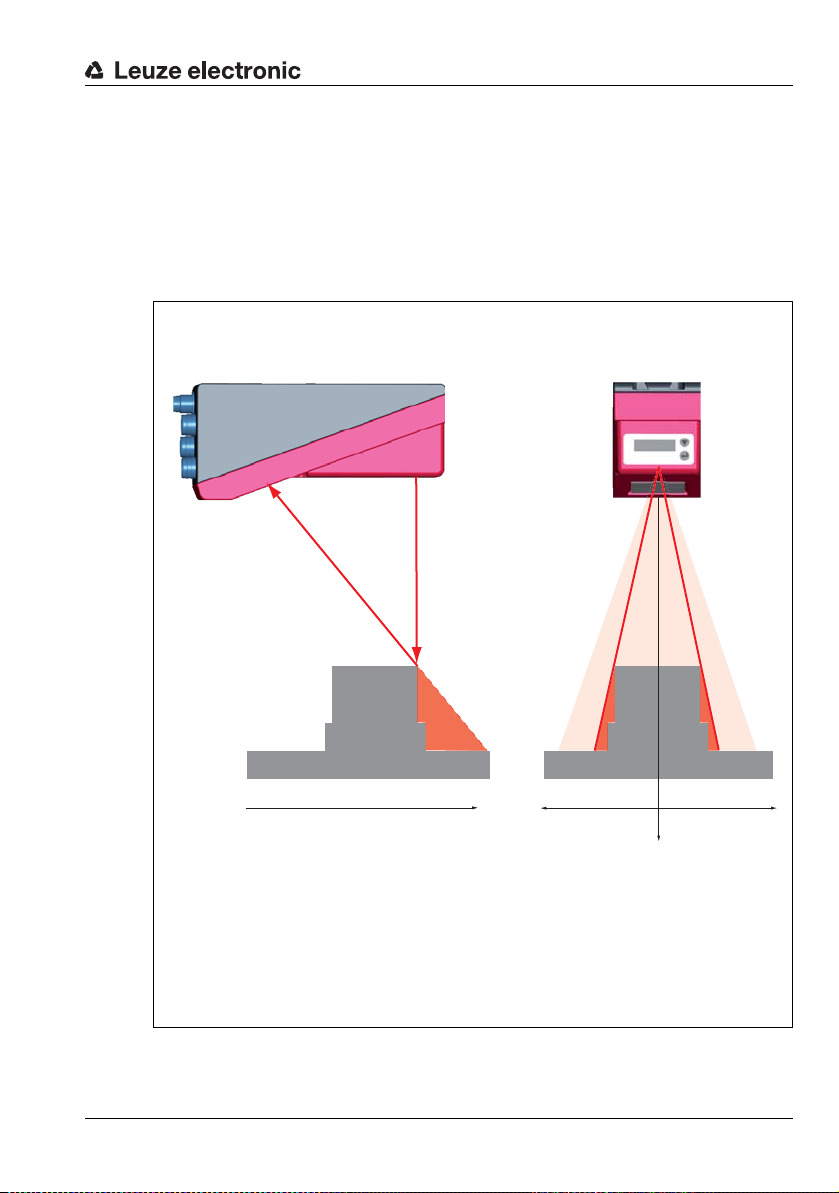

Figure 3.2: Occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3.3: Typical resolution LES 36… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3.4: Typical minimum object size LES 36HI… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 4.1: Mechanical design of Leuze light section sensors. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 4.2: Activation input signal sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 4.3: Trigger input signal sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 4.4: Signal sequence for cascading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 4.5: Cascading application example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 4.6: Edge detection with EAWs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 4.7: Meaning of Sequent Hits for edge detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 4.8: Edge detection with EAWs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 4.9: Edge detection with varying object position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 4.10: Application example: web-edge measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 4.11: Application example: height and width measurement of a cubic object . . . . . . . . . 33

Figure 5.1: Device name plate LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 5.2: Fastening options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 5.3: Mounting example LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 5.4: BT 56 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 5.5: BT 59 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 5.6: Alignment to the measuring plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 6.1: Location of the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 6.2: Connections of the LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 6.1: Interface version of X3 and X4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 6.2: Cable lengths and shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 6.3: Connecting the ground potential to the light section sensor . . . . . . . . . . . . . . . . . . 44

Figure 6.4: Connecting the cable shielding in the switch cabinet . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 6.5: Connecting the cable shielding to the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 6.3: Pin assignment X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 6.6: Internal wiring at X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 6.4: Pin assignment X2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 6.7: HOST / BUS IN cable assignments on RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 6.5: Pin assignment X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 6.6: Pin assignment X4 for LES 36…/PB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 6.7: Pin assignment X4 for LES 36…/VC6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 6.8: Response of analog output LES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 7.1: Indicator and operating elements of the LES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 7.1: LED function indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 7.2: Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 8.1: Address allocation in the Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 9.1: Initial screen LESsoft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 9.2: PROFIBUS settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 9.3: Parameter settings LESsoft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 9.4: Edit Analysis Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 9.5: ’Edge Analysis Window Combination Tables’ window . . . . . . . . . . . . . . . . . . . . . . 80

TNT 35/7-24V

Leuze electronic LES 36 8

Figures and tables

Figure 9.6: Display of the edge positions (green and blue) in the 2D display . . . . . . . . . . . . . . 81

Figure 9.7: Application example 1: web edge measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 9.8: Application example 2: height and width monitoring of cubic objects . . . . . . . . . . 84

Figure 9.9: Application example 3.1: width monitoring of cubic objects with object

Figure 9.10: Application example 3.2: width monitoring of cubic objects with object

Figure 9.11: Parameter settings in LRSsoft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 9.12: Zoom function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 10.1: Connection commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 10.2: Command mode control commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 10.3: Sensor control commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Table 10.4: Commands in measure mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 11.1: PROFIBUS address assignment with LESsoft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 11.1: PROFIBUS - Overview of output data (from viewing position of control) . . . . . . . 118

Table 11.2: Input data byte

Table 11.3: Input data byte

Table 11.4: Input data byte

Table 11.5: Input data byte

Table 11.6: Input data bytes

Table 12.1: General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Table 12.2: Interface error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 12.3: Error messages in display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 14.1: Typical measurement range LES 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 14.2: Typical measurement range LES 36HI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 14.3: LES dimensioned drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Table 15.1: LPS type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Table 15.2: LRS type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Table 15.3: LES type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Table 15.4: Mounting devices for the LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 15.5: Cable assignment KD S-M12-8A-P1-… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 15.6: X1 cables for the LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 15.7: Cable assignment KS ET-M12-4A-P7-…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Table 15.8: Ethernet connection cables featuring M12 plug/open cable end . . . . . . . . . . . . . 137

Table 15.9: Cable assignment KSS ET-M12-4A-RJ45-A-P7-…. . . . . . . . . . . . . . . . . . . . . . . . 137

Table 15.10: Ethernet connection cables M 12 connector/RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . 137

Table 15.11: Cable assignment KSS ET-M12-4A-M12-4A-P7-… . . . . . . . . . . . . . . . . . . . . . . . 138

Table 15.12: Ethernet connection cables featuring M 12 plug/M 12 plug . . . . . . . . . . . . . . . . . . 138

Table 15.13: Connectors for the LES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Table 15.14: Cable assignment KS S-M12-8A-P1-…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Table 15.15: X3 cables for the LES 36…/VC6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Table 15.16: Pin assignment X4 (PROFIBUS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 15.1: Cable structure for PROFIBUS connection cable . . . . . . . . . . . . . . . . . . . . . . . . . 140

Table 15.17: PROFIBUS connection accessories for the LES 36…/PB . . . . . . . . . . . . . . . . . . . 140

Table 15.18: PROFIBUS cables for LES 36…/PB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Table 15.19: Pin assignment X4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Table 15.20: Connection cables for LES 36/VC6, LES 36HI/VC6. . . . . . . . . . . . . . . . . . . . . . . . 142

Table 15.21: Configuration memory for LxS 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Table 16.1: Revision History - Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

uSensorInfo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

uSensorState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

uResultEdge/Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

uResultAWs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

wEdgeAW1Data1

(high and low byte) . . . . . . . . . . . . . . . . . . . . 123

TNT 35/7-24V

Leuze electronic LES 36 9

Figures and tables

Table 16.2: Revision History - Configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Leuze electronic LES 36 10

TNT 35/7-24V

1 General information

U

L

US

C

LISTED

1.1 Explanation of symbols

The symbols used in this technical description are explained below.

Attention!

This symbol precedes text messages which must strictly be observed. Failure to observe

the provided instructions could lead to personal injury or damage to equipment.

Attention Laser!

This symbol warns of possible danger through hazardous laser radiation.

The light section sensors of the LES series use a class 2M laser: Viewing the laser output

with certain optical instruments, e.g. magnifying glasses, microscopes or binoculars, may

result in eye damage.

Note!

This symbol indicates text passages containing important information.

General information

1.2 Declaration of Conformity

The laser light section sensors of the 36 and 36HI series have been developed and manufactured in accordance with the applicable European standards and directives. They comply

with the safety standards UL508 and CSA C22.2 No. 14 (Industrial Control Equipment).

Note!

The CE Declaration of Conformity for these devices can be requested from the manufacturer.

The manufacturer of the product, Leuze electronic GmbH & Co. KG in D-73277 Owen,

possesses a certified quality assurance system in accordance with ISO 9001.

Leuze electronic LES 36 10

TNT 35/7-24V

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The Light section sensors of the LES series are laser distance sensors for presence detection of dimensions of objects using their edges.

Areas of application

The LES series Light section sensors are especially designed for the following areas of

application:

• Edge and height measurement of web material products and paper rolls

• Width and height measurement of cartons

• Edge and height measurement of stackable materials (e.g. chipboards)

• Complex object detection with window tracking

CAUTION

Observe intended use!

The protection of personnel and the device cannot be guaranteed if the device is operated

in a manner not complying with its intended use.

Only operate the device in accordance with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read these operating instructions before commissioning the device. Knowledge of

this document is required in order to use the equipment for its intended purpose.

Safety

NOTE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

OPERATION NOTICE IN ACCORDANCE WITH UL CERTIFICATION:

CAUTION – Use of controls or adjustments or performance of procedures other than

specified herein may result in hazardous light exposure.

Leuze electronic LES 36 11

TNT 35/7-24V

CAUTION

UL applications!

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC

(National Electric Code).

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is

considered improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• as stand-alone safety component in accordance with the machinery directive

• for medical purposes

NOTE

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

1)

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried

out by competent persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at

work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation

of the device.

1) Use as safety-related component within the safety function is possible, if the component combination is designed

correspondingly by the machine manufacturer.

Leuze electronic LES 36 12

TNT 35/7-24V

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with

relevant standards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser safety notices

ATTENTION, LASER RADIATION – LASER CLASS 2M

Never look directly into the beam or point the beam in the direction of telescope

users!

The device fulfills the IEC 60825-1:2007 (EN 60825-1:2007) safety regulations for a

product in laser class 2M as well as the U.S. 21 CFR 1040.10 regulations with deviations

corresponding to "Laser Notice No. 50" from June 24th, 2007.

Never look directly into the laser beam or in the direction of reflected laser beams!

If you look into the beam path over a longer time period, there is a risk of injury to the

retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser

beam is accidentally directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflec-

tive surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here

or carrying out of differing procedures may lead to dangerous exposure to radiation.

The use of optical instruments or devices (e.g., magnifying glasses, binoculars) with

the product will increase eye danger.

Observe the applicable statutory and local laser protection regulations.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

TNT 35/7-24V

Leuze electronic LES 36 13

Safety

A Laser aperture

B Laser warning sign

C Laser information sign with laser parameters

B

C

A

NOTE

Affix laser information and warning signs!

Laser warning and laser information signs are affixed to the device (see Figure 2.1):

In addition, self-adhesive laser warning and information signs (stick-on labels) are supplied

in several languages (see Figure 2.2).

Affix the laser information sheet to the device in the language appropriate for the place

of use.

When using the device in the U.S.A., use the stick-on label with the "Complies with

21 CFR 1040.10" notice.

Affix the laser information and warning signs near the device if no signs are attached

to the device (e.g., because the device is too small) or if the attached laser information

and warning signs are concealed due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing

the reader to the laser radiation of the device or other optical radiation.

Figure 2.1: Laser apertures, laser warning signs

Leuze electronic LES 36 14

TNT 35/7-24V

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

ODER DIREKT MIT OPTISCHEN

INSTRUMENTEN BETRACHTEN

LASER KLASSE 2M

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelenght:

RADIAZIONE LASER

NON FISSARE IL FASCIO AD OCCHIO

NUDO NÉ GUARDARE DIRETTAMENTE

CON STRUMENTI OTTICI

APARRECCHIO LASER DI CLASSE 2M

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

NI À L`ŒIL NU NI Á L`AIDE D`UN

INSTRUMENT D`OPTIQUE

APPAREIL À LASER DE CLASSE 2M

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

NI MIRAR DIRECTAMENTE CON

INSTRUMENTOS ÓPTICOS

PRODUCTO LÁSER DE CLASE 2M

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

NEM OLHAR DIRECTAMENTE

COM INSTRUMENTOS ÓPTICOS

EQUIPAMENTO LASER CLASSE 2M

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

0伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

䉏⏘戟⺓

▎䦃展㒥抩扖⏘ⷵ

ⅹ⣷䦃㘴屑䦚⏘㧮

8,7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

50111877-02

Safety

Figure 2.2: Laser warning and information signs – supplied stick-on labels

TNT 35/7-24V

Leuze electronic LES 36 15

3 Operating principle

CMOS area

detector

Receiving optics

Laser with expansion optics

The zero point of the coordinate system is the intersection

of optical axis and front edge of

the housing.

3.1 Generation of 2D profiles

Light section sensors work according to the triangulation principle. Using transmission

optics a laser beam is expanded to a line and aimed at an object. The light remitted by the

object is received by a camera, which consists of receiver optics and the CMOS area

detector.

Operating principle

-X

+X

-Y

Z

Figure 3.1: Light section sensor design

Depending on the distance of the object the laser line is projected to a different position on

the CMOS planar detector as shown in Figure 3.1. By means of this position the distance

of the object can be calculated.

Leuze electronic LES 36 16

TNT 35/7-24V

3.2 Limits of light section sensors

Laser occlusionReceiver occlusion

In the red areas the laser does not

strike the object. Thus it is not possible to determine any data here.

The receiver does not "see" any object contours in the

red area because they are obscured by the upper right

edge of the object.

When the object is shifted to the left the object contour will still be detected by the laser but the laser line

does not lie within the receiver's field of view at that

point, and therefore no measurement values can be

detected.

3.2.1 Occlusion

The detection of high and wide objects from just one point poses the particular problem

that depending on the object contour, parts of the object may be obscured by others. This

effect is called occlusion.

The Figure 3.2 illustrates the problem:

Operating principle

Leuze electronic LES 36 17

Figure 3.2: Occlusion

-Y

+X

TNT 35/7-24V

Z

-X

Operating principle

Y

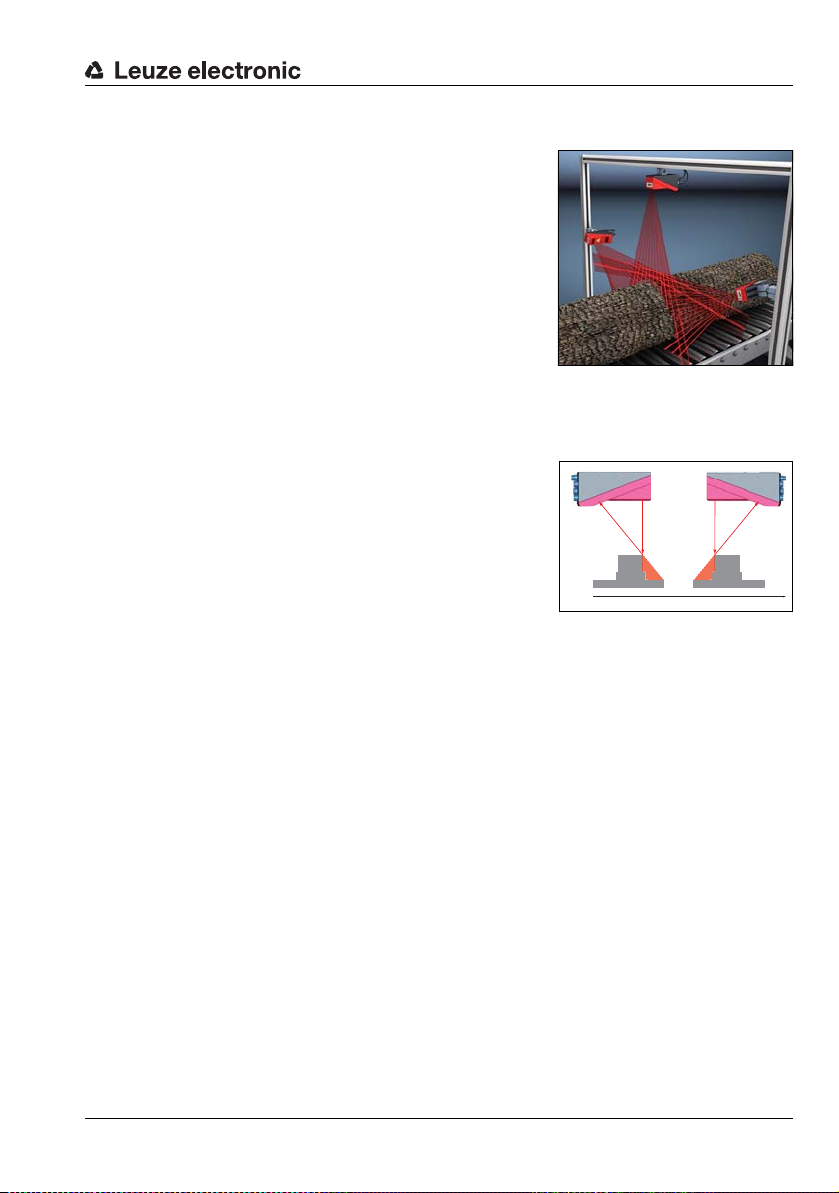

Possible measure against laser occlusion

• Using multiple Light section sensors with rotated

viewing direction. In the application example on

the right you can clearly see that the fields of vision

of the three sensors complement each other and

merge. The first of the sensors is operated as a

master, the two others are cascaded (see "Cascading" on page 24). This reliably prevents mutual

interference of the sensors.

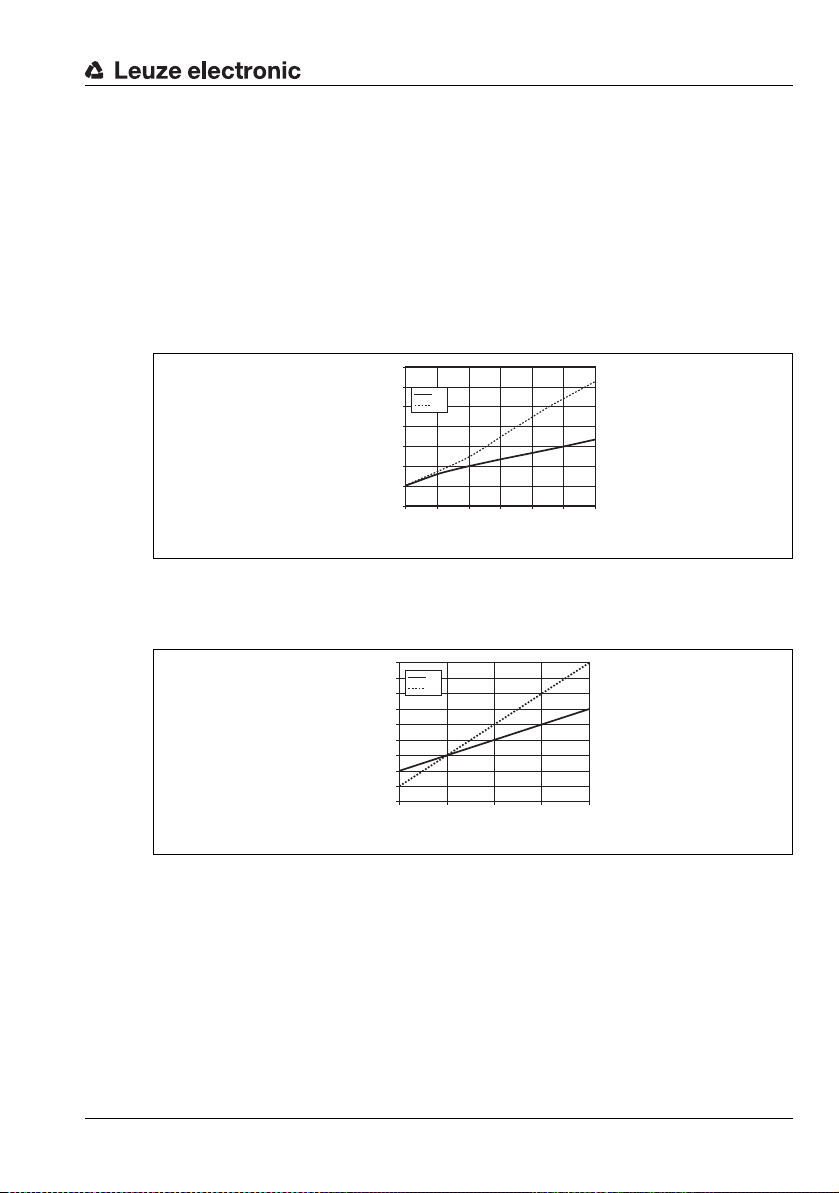

Possible measures against receiver occlusion

• Alignment of the measurement objects so that all profile data to be measured can be

seen by the receiver.

Or:

• Installing a second sensor featuring a viewing

direction rotated by 180° about the z-axis so that

the objects can be viewed from 2 sides.

In the example to the right, the left sensor detects

the profile data on the left side of the product, and

the right sensor the profile data on the right side.

In this situation the second sensor is then cascaded. "Cascading" on page 24.

Leuze electronic LES 36 18

TNT 35/7-24V

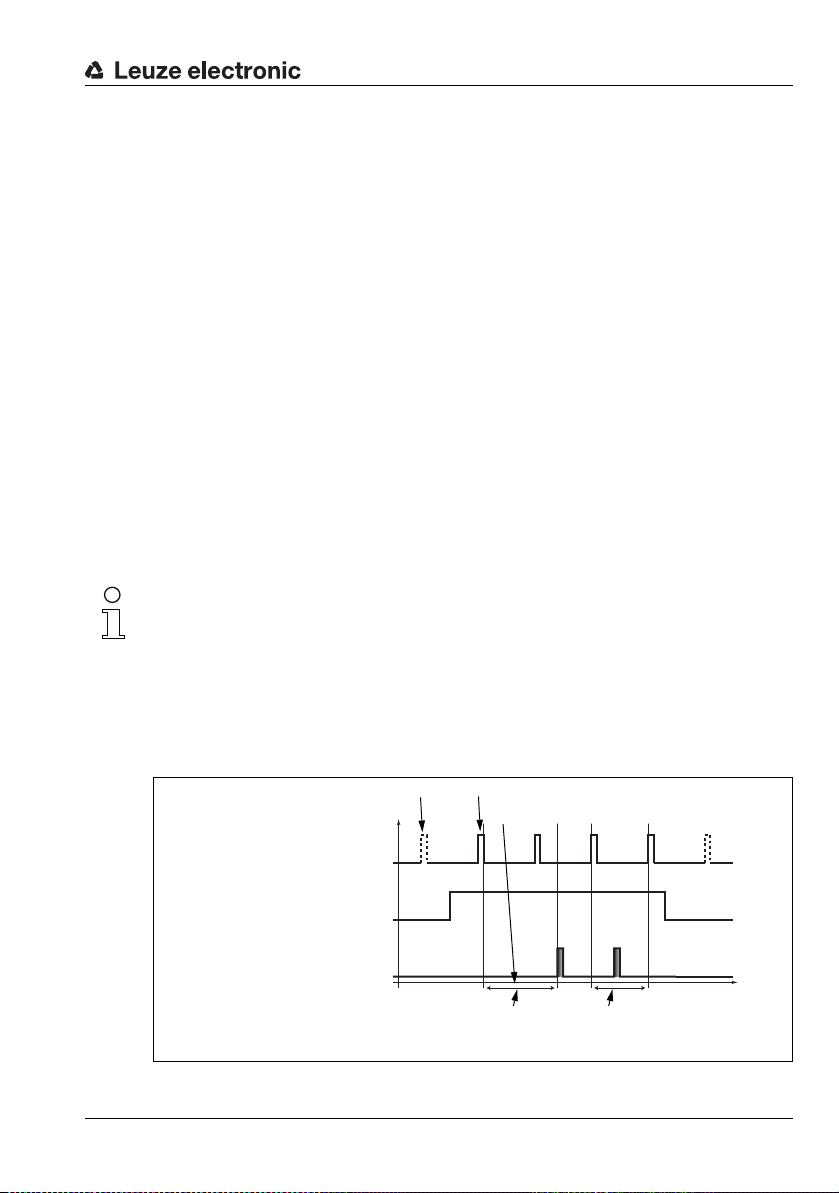

3.2.2 Resolution

0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

200 300 400 500 600 700 800

X

Z

Object distance in Z-direction in mm

Typical resolution in mm

0

0,1

0,2

0,3

0,4

0,5

0,8

0,9

0,6

0,7

200 300 400 500 600

X

Z

Object distance in Z direction [mm]

Typical minimum

object size [mm]

In this context resolution means the smallest possible change in distance of the measurement object, which causes a unique change of the output signal. Resolution is higher in the

short range than in the distant range. Small objects can be recognized better in the short

range.

The length of the laser line in the X-direction is dependent on the distance Z of the measurement object from the sensor . Always the same number of measurement points is measured.

From this it follows that the resolution in X-direction decreases with increasing distance in

Z-direction.

The following illustration shows this relation:

Figure 3.3: Typical resolution LES 36…

The output resolution of the measurement values on the process interface is 1/10mm with

Standard-Connect, 1/100mm with HI-Connect (only with LES 36HI/VC6).

Operating principle

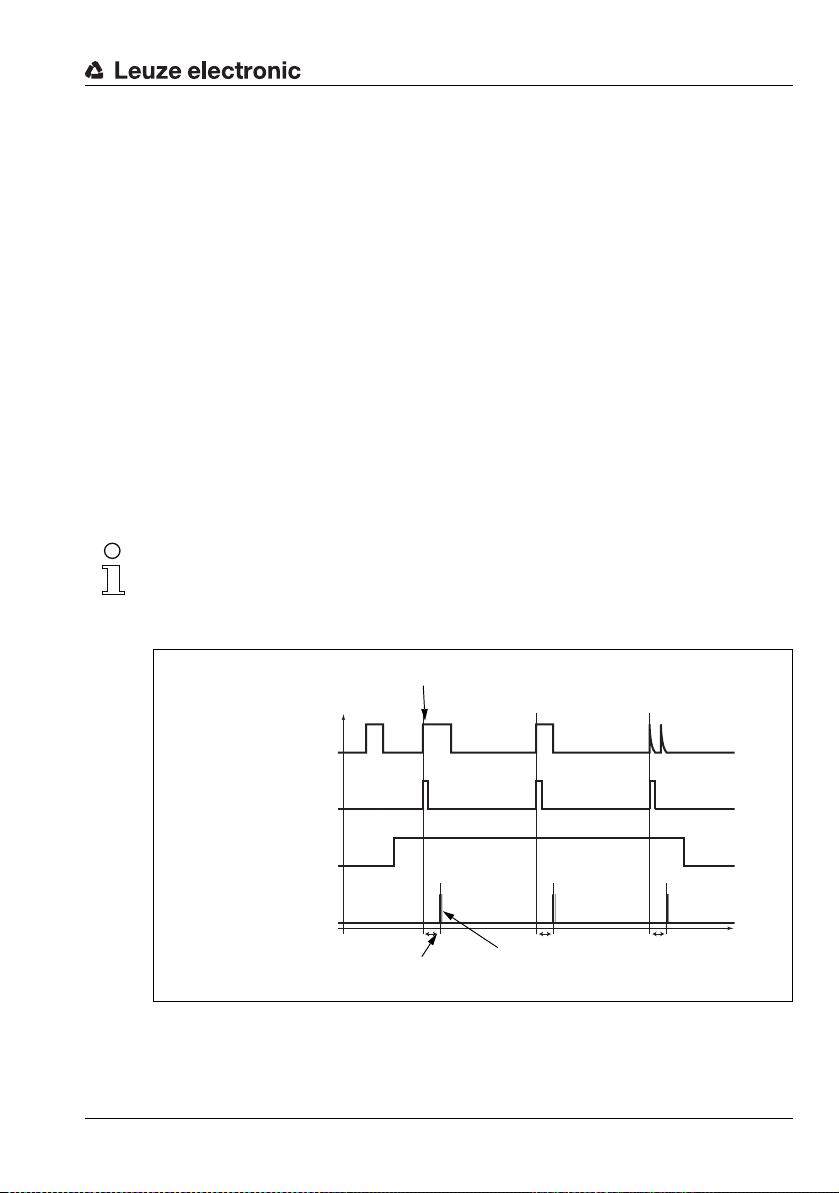

Figure 3.4: Typical minimum object size LES 36HI…

Leuze electronic LES 36 19

TNT 35/7-24V

4 Device description

Laser transmitter

Receiver

(CMOS camera)

Display with membrane

keyboard

Electrical connection and

grounding terminal

Groove for dovetail mounting and fastening holes

Note:

The following shows a light section sensor as an example.

An overview of the available types may be found in Chapter 15.1

4.1 Overview of light section sensors

4.1.1 Mechanical design

Figure 4.1: Mechanical design of Leuze light section sensors

Device description

4.1.2 General performance characteristics

• Light section sensor for width, height and position detection

• Measurement time/response time: 10ms

• Measurement range/detection area: 200 … 800mm

• Measurement range/detection area: LES 36…: 200 to 800mm, LES 36HI…: up to

600mm

• Length of laser line: max. 600 mm

• Length of the laser line: LES 36…: max. 600 mm, LES 36HI…: max. 140 mm

• Configuration and transmission of process data via Fast Ethernet

• OLED display with membrane keyboard

• Measurement value display in mm on OLED display as an alignment aid

• Up to 16 inspection tasks

• Compact construction

• Robust design and easy operation

• Activation input, trigger input, cascading output

Leuze electronic LES 36 20

TNT 35/7-24V

4.1.3 Line Edge Sensor - LES

Width and height measurement of cartons

Determining width and diameter of roll goods

Line edge sensors determine the positions and

dimensions of objects via their edges. The

sensor determines the edge positions in mm

and, from those, calculates the object width and

height. These data are transferred to the

process control. One sensor can be used to

simultaneously detect up to four value pairs of

edges.

Specific performance characteristics

• Configuration software LESsoft

• Data calculation and processing directly

inside the sensor

• Integrated PROFIBUS interface or analog

output

• Up to 4 edge analysis windows with 2

edge-value pairs each

• Up to 8 analysis windows with logic operation option

• Detailed information on measurement

function, analysis windows, detection

functions and sensor state via Ethernet

and PROFIBUS

Device description

Typical areas of application

• Edge and height measurement of web

material products and paper rolls

• Width and height measurement of

cartons

• Edge and height measurement of

stackable materials (e.g. chipboards)

Leuze electronic LES 36 21

TNT 35/7-24V

4.2 Operating the sensor

p

t

Laser off

Laser off

Exposing and measuring

Processing and transmitting

Laser

Activation input

Pin 2 at X1

Output

10ms between 2 consecutive

laser pulses in "Free Running"

mode

Axes: p = level, t = time

Approx. 14ms

between laser pulse and

associated data output

4.2.1 Connection to PC / process control

Configuration

For commissioning the Light section sensors are connected to a PC via the Ethernet interface (see "Connection X2 - Ethernet" on page 47) and are then set using the configuration

software supplied LESsoft.

Measurement operation

In measurement operation, the LES 36…/VC6 is connected to the process control via its

analog output, the LES 36…/PB is connected to the process control via PROFIBUS. Alternatively, the LES can be operated via the Ethernet interface on X2, see chapter 10 "Integrating the LES in the process control (Ethernet)". Additional sensor information is then

available.

4.2.2 Activation - laser on/off

The laser and the data transmission can selectively be switched on and off via the activation

input InAct (pin 2 at X1) or via the 'Ethernet Trigger' command. Thus possible glares due

to laser radiation can be prevented during time periods when no measurements are

performed.

Note!

The sensor is delivered ex works with the Activation Input Disregard setting. The

possible activation sources (activation input and Ethernet activation) are ignored - the measurement function of the sensor is enabled.

The activation function can be switched on via the configuration software. To do this, the

Activation Input parameter must be set to Regard. The sensor then only measures if

one of the activation sources is activated. If the sensor is waiting for activation, it displays

!Act

in the display.

Device description

Leuze electronic LES 36 22

Figure 4.2: Activation input signal sequence

TNT 35/7-24V

The Figure 4.2 shows the effect of the activation on laser and measurement value output in

A second trigger

pulse before 10ms

have elapsed has

no effect

Trigger time (rising edge)

Laser

Activation input

Pin 2 at X1

Output

(Ethernet)

Data packets, approx. 1ms

t

fix

Approx. 14ms

Trigger input

Pin 5 at X1

Axes: p = level, t = time

"Free Running" mode.

4.2.3 Triggering - Free Running

The Light section sensors can measure in two modes:

• In "Free Running" operation the Light section sensor determines measurement results

with a frequency of 100Hz and outputs these continuously via the interface X2.

• Alternatively, single measurements can also be carried out. For this purpose, the Light

section sensor requires a trigger signal at the trigger input (pin 5 on X1), a PROFIBUS

trigger or the Ethernet Trigger command in measure mode (see

Chapter 10.3.4"Commands in measure mode" on page 111).

When triggering via pin 5 at X1, note:

- Triggering occurs on the rising edge.

-The trigger pulse must be at least 100μs long.

- Before the next trigger, the trigger cable must be on low-level for at least 1 ms.

- Activation must occur at least 100μs before the trigger edge.

- The shortest possible time interval between two successive trigger edges is 10ms.

Note!

Ex works, the LES is set to Free Running (shown on display:

respond to signals on the trigger input, the operating mode must be set via the LESsoft configuration software to Input Triggered (shown on display:

Device description

fRun

). In order for it to

Trig

).

Leuze electronic LES 36 23

p

Figure 4.3: Trigger input signal sequence

TNT 35/7-24V

t

PROFIBUS trigger

Laser

Measurement value output

Trigger input, pin 5 at X1

/ not required

Cascading output,

pin 6 at X1

Sensor 1 / Master

Laser

Measurement value output

Trigger input, pin 5 at X1

Cascading output,

pin 6 at X1

Sensor 2 / 1st slave

Laser

Measurement value output

Trigger input, pin 5 at X1

Cascading output,

pin 6 at X1

Sensor 3 / 2nd slave

Figure 4.4: Signal sequence for cascading

So that a measurement can be triggered on each PROFIBUS cycle, the PROFIBUS trigger

of the LES responds to a change of master output byte uTrigger. The control only needs

to increment the trigger value in order to initiate a new measurement.

The maximum trigger frequency is 100Hz. If triggering occurs during a measurement, the

trigger signal is ignored, as is the case in the Free Running operating mode.

4.2.4 Cascading

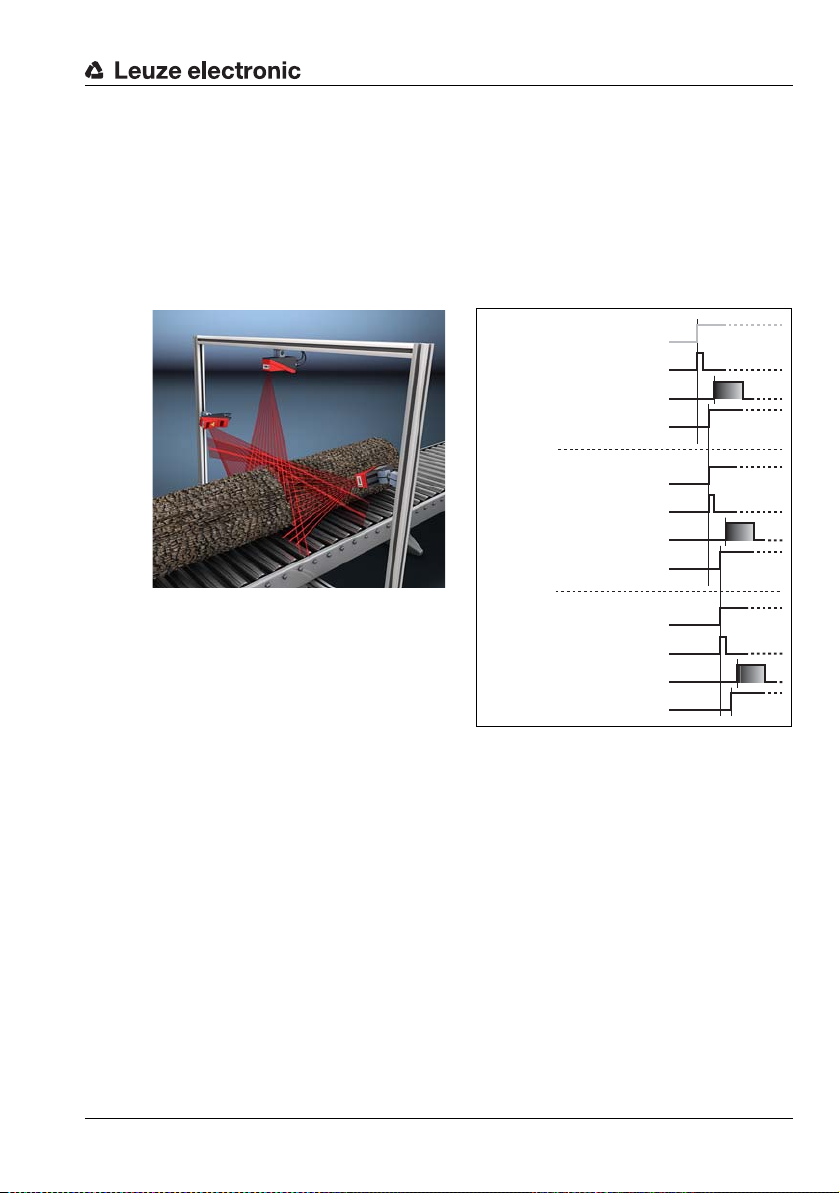

Figure 4.5: Cascading application example

If several Light section sensors are operated, there is the risk of mutual interference

if the reflected laser beam of one sensor can

be received by the receiver of another

Leuze electronic LES 36 24

sensor at the time of reading.

This can easily be seen in Figure 4.5. Here

three Light section sensors are used to

determine the log thickness reliably from all

sides.

To prevent mutual interference the Light

section sensors can be operated cascaded: the exposure by the second sensor will be initiated following completion of the exposure by the first sensor. To achieve this, the cascading

output of the first sensor must be connected to the trigger input of the second sensor. Up

to 6 sensors can thus be operated cascaded.

Trigger settings

Se nso r 1, or the m ast er, can be ope rat ed i n th is c ase bot h tr igg ere d as wel l as con tin uou sly.

All other sensors must be operated triggered.

Cascading settings

For all sensors except the last slave, the cascading output must be enabled via configuration

software: Cascading Output: Enable.

Device description

TNT 35/7-24V

Note!

In PROFIBUS operation, cascading only functions as described above via the InTrig and

OutCas inputs/outputs at X1. In this case, the maximum detection rate of 100Hz is achieved.

Make certain, however, that the input data of the PROFIBUS light section sensors are still

transmitted in the same bus cycle; monitor the scan numbers if necessary.

Alternatively, light section sensors with PROFIBUS can be selectively triggered in sequence.

Master output 'uTrigger' of the sensor to be triggered is incremented on each PLC cycle;

the master outputs of the other sensors do not change. The maximum detection rate of

100Hz is not achieved with this process.

If multiple sensors are triggered in a PROFIBUS cycle, mutual interference may occur

between the sensors if they are in the same visual field and the time between updating byte

'uTrigger' is shorter than the maximum exposure time (Exposure Time) of 1.3 ms.

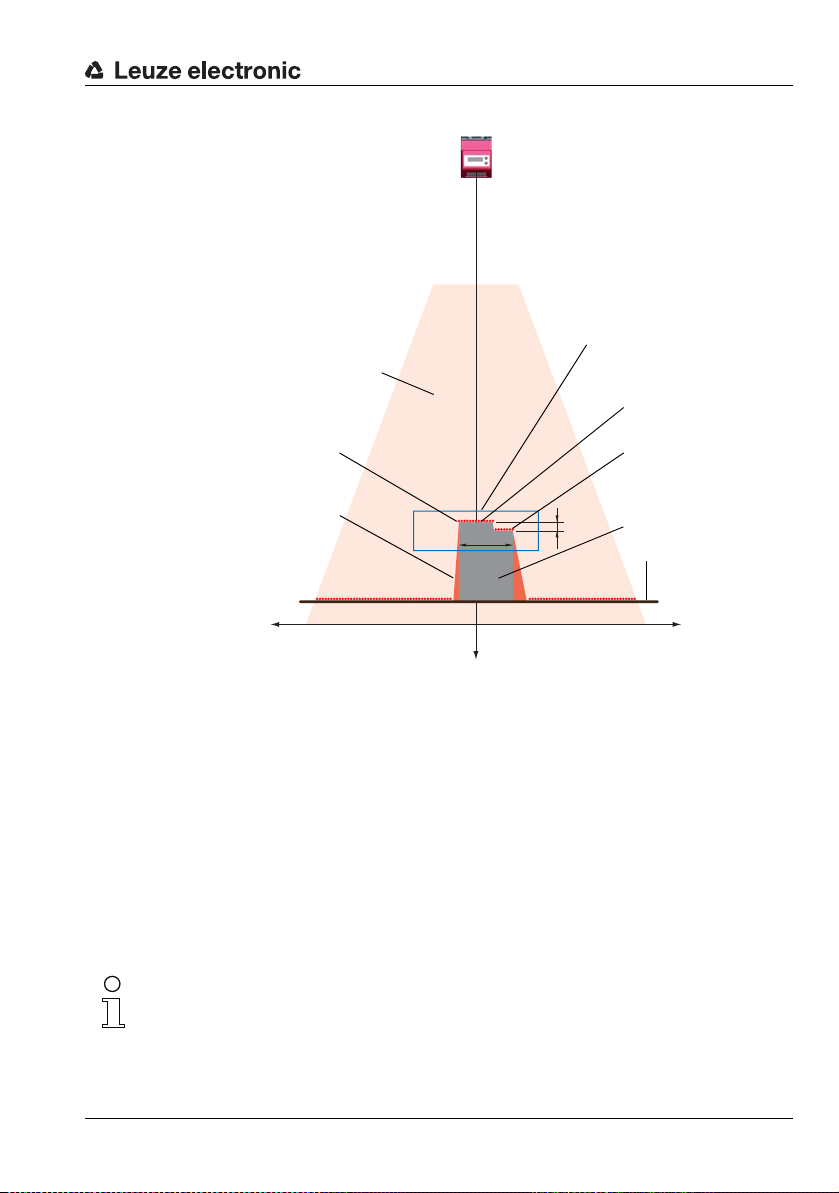

4.3 Measurement functions: LES

With the LES, you can reliably detect objects and measure their edge position, height and

width. Adaptation of the LES to an application is performed using the LESsoft configuration

software. All settings for the application are made there and stored in up to 16 inspection

tasks.

Functional principle of object and edge detection with the LES

The distance profile of the application is determined along the laser line in 376 measurement

points. Rectangular analysis windows, used for object and edge detection, can be defined

in the measurement range.

Object detection:

The number of measurement points is counted in the analysis window (Analysis Window

= AW or Edge Analysis Window = EAW) and compared with two adjustable limits. From this,

the logical state ok or not ok of the analysis window is determined. For unique object detection, it may be necessary to combine multiple analysis windows. For this purpose, the LES

offers the AND combination and inversion of multiple analysis windows. The logic combinations ensure the detection of problematic objects.

Edge detection:

Windows for edge detection are called Edge Analysis Windows (EAW). In an EAW, object

detection can be performed as described above. Also determined in an EAW are the X and

Z coordinates of the first ("left-most") and the last ("right-most") measurement point. By

appropriately selecting the size and position of the EAWs, it is possible to determine coordinates of edge positions. From these, the width and height of an object are calculated. For

robust edge detection, the "Sequent Hits" parameter was introduced. The minimum number

of measurement points set there must occur in succession in the EAW to detect a valid edge.

Outliers or missing measurement points reset the counter.

Device description

TNT 35/7-24V

Leuze electronic LES 36 25

4.3.1 Inspection Task

The LES supports up to 16 individual inspection tasks. Grouped together in an inspection

task are all parameter settings relevant for an application:

• Operation Mode (Free Running, Input Triggered)

• Activation Input (switch laser on and off)

• Cascading Output

• Light Exposure (exposure duration of the laser)

• Field of View (sensor detection range)