Page 1

AMS 355i

Optical Laser Measurement System

DeviceNet

en 03-2014/12 50113345

We reserve the right to

make technical changes

TECHNICAL DESCRIPTION

Page 2

© 2014

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen - Teck / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic AMS 355i

Page 3

AMS 355i

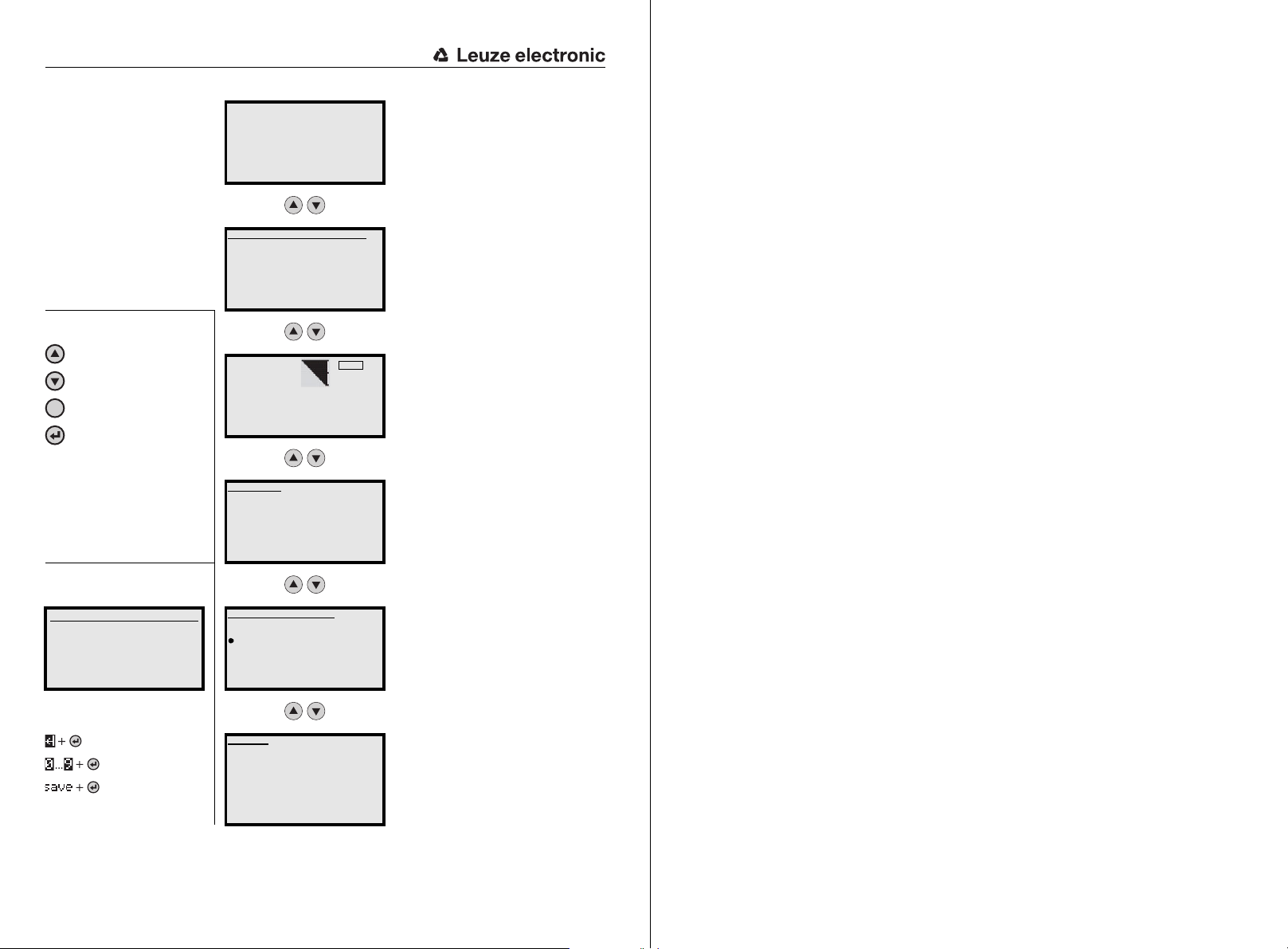

63

Navigate

upward/laterally

Navigate

downward/laterally

ESCAPE

leave

ENTER

confirm

Device buttons:

Delete character

Enter digit

Save input

The main menus

ESC

Input of values

AMS 355i 120

Leuze electronic

GmbH & Co. KG

SW: V 1.3.0 HW:1

SN: -----------------------

Network information

Address: -Baudrate: ---- kbit/s

Status: Not Powered,...

IO1 LSR PLB

IO2 TMP ATT DNET

ERR

+ 87.000m

Parameter

Parameter handling

DeviceNet

Position value

I/O

Other

Device information - main menu

This menu item contains detailed information on

• device type,

• manufacturer,

• software and hardware version,

• serial number.

No entries can be made via the display.

Network information - main menu

Explanations of address, baud rate, status.

No entries can be made via the display.

Status- and measurement data main menu

• Display of status-, warning-, and error messages.

• Status overview of the switching inputs/outputs.

• Bar graph for the reception level.

• Activated interface.

• Measurement value.

No entries can be made via the display.

See "Indicators in the display" on page 38.

Parameter - main menu

• Configuration of the AMS

See "Parameter menu" on page 44.

100

<-|0123456789 save

Standard ----- Unit

63 | |

Language selection

o Deutsch

English

o Español

o Français

o Italiano

Service

Status messages

Diagnostics

Expanded diagnostics

Language selection - main menu

• Selection of the display language.

See "Language selection menu" on page 47.

Service - main menu

• Display of status messages.

• Display of diagnostic data.

No entries can be made via the display.

See "Service menu" on page 47.

Page 4

Table of contents

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Description of functions AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Laser safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Fast commissioning / operating principle . . . . . . . . . . . . . . . . . . . 12

3.1 Mounting the AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Mounting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Mounting the reflector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Connecting the voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 AMS 355i on the DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Specifications of the laser measurement system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.1 General specifications AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

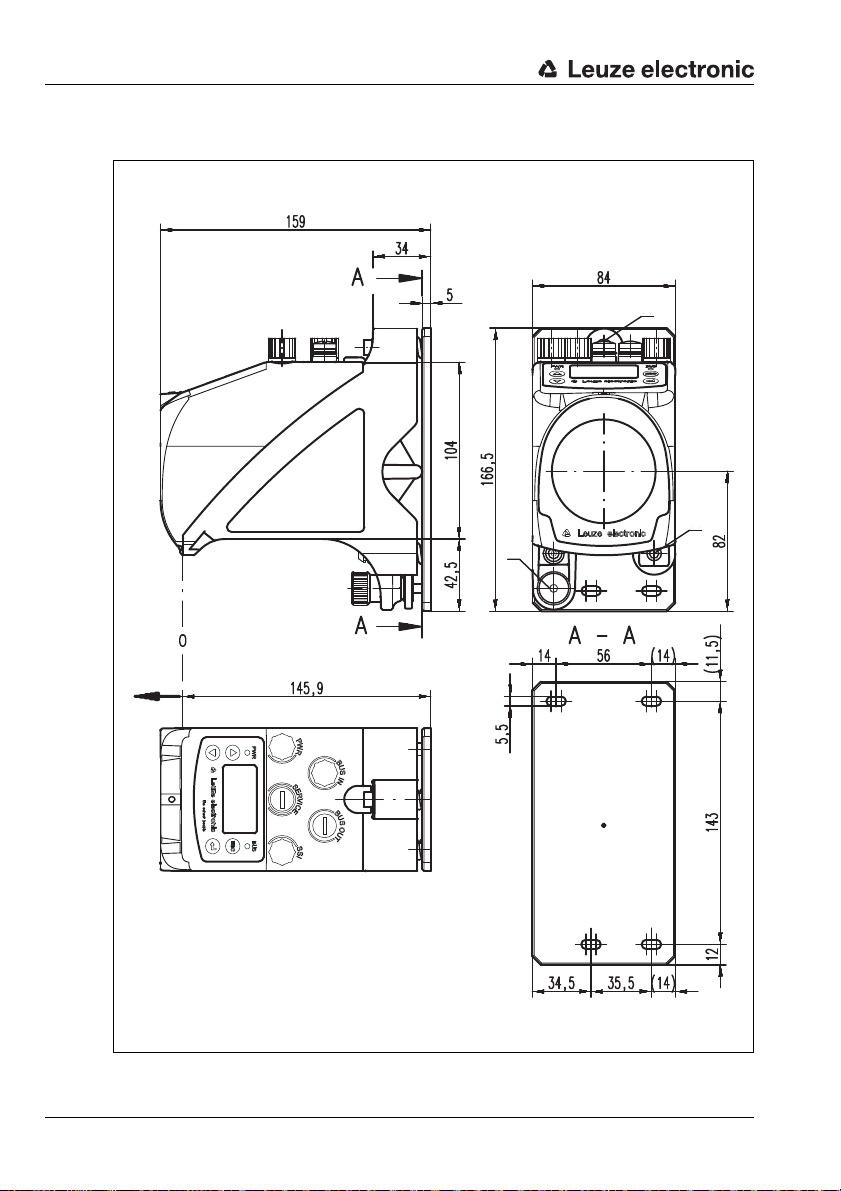

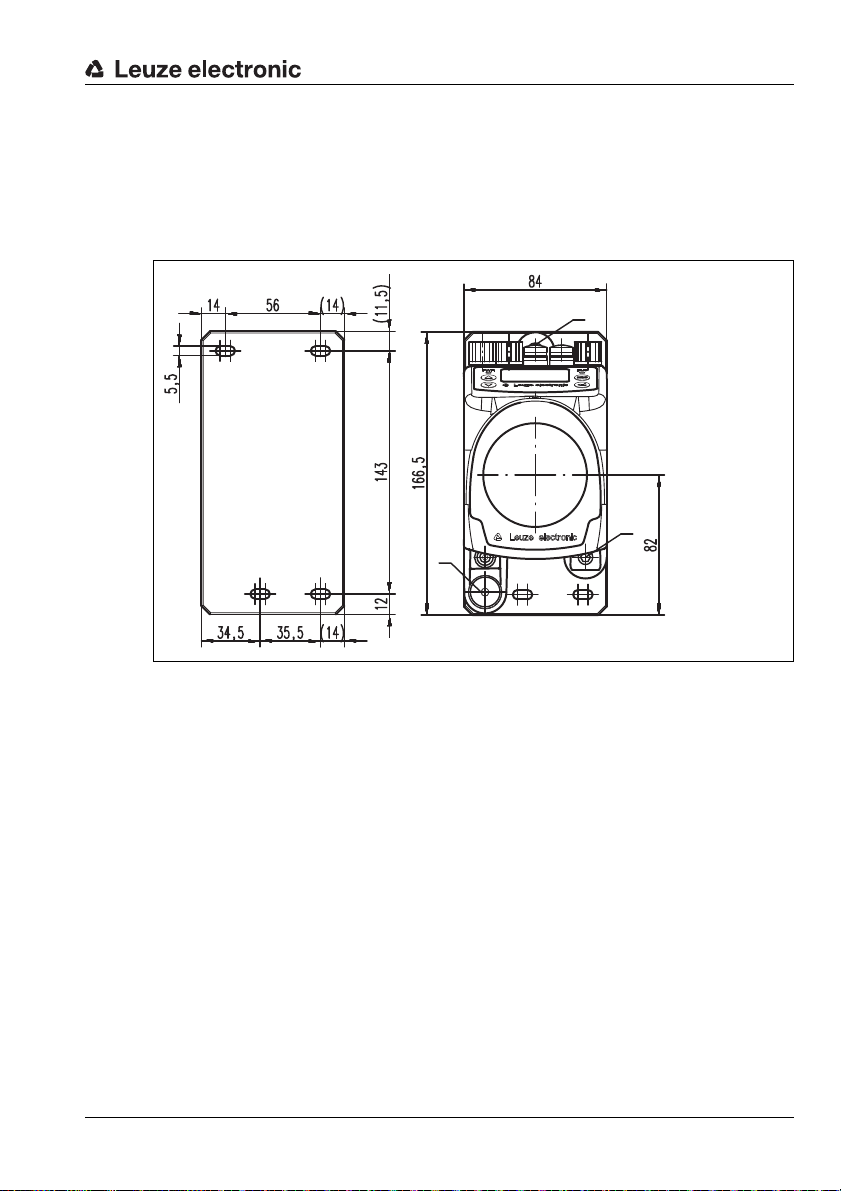

4.1.2 Dimensioned drawing AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.3 Type overview AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Installation and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Storage, transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Mounting the AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

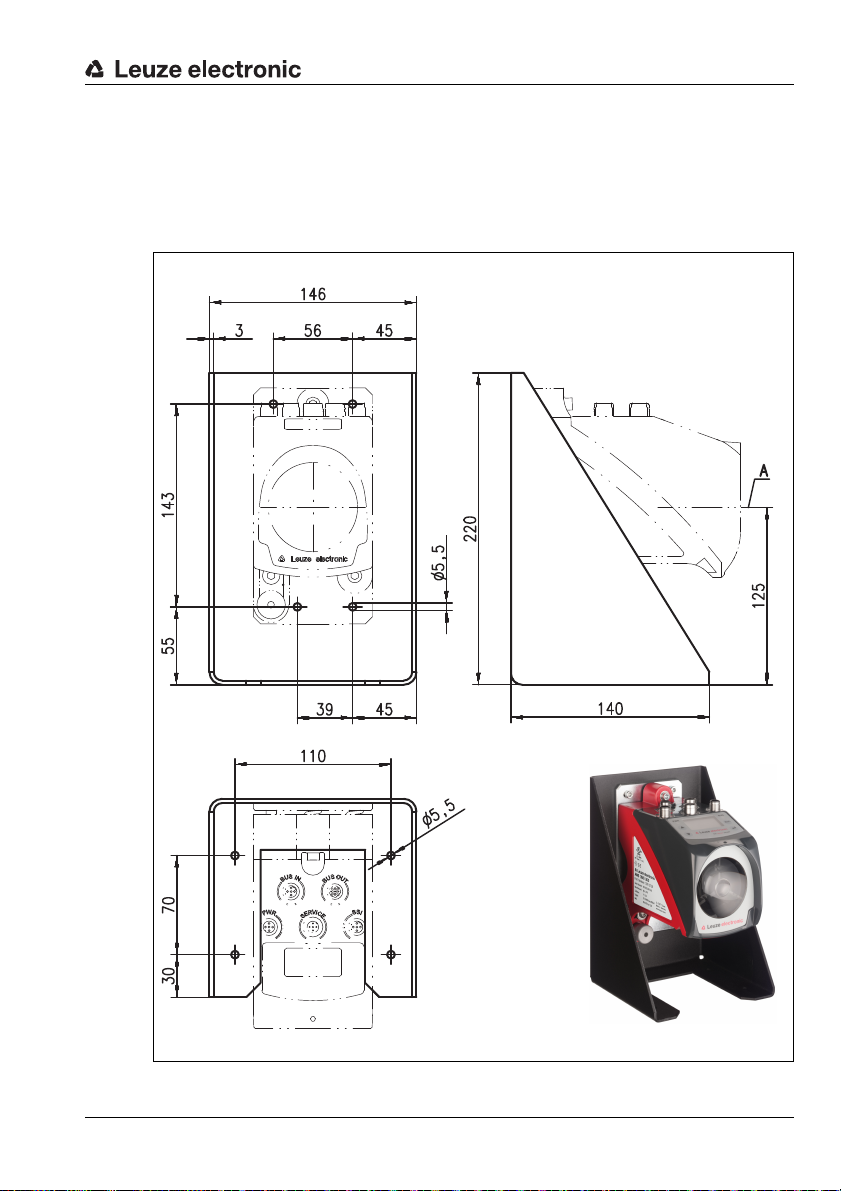

5.2.1 Optional mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.2 Parallel mounting of the AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.3 Parallel mounting of AMS 355i and DDLS optical data transmission. . . . . . . . . . . . . . . . 23

5.3 Mounting the AMS 355i with laser beam deflector unit . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Mounting the laser beam deflector unit With integrated mounting bracket . . . . . . . . . . . 24

5.3.2 Dimensioned drawing of US AMS 01 deflector unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.3 Mounting the US 1 OMS deflector unit without mounting bracket . . . . . . . . . . . . . . . . . 26

AMS 355i 1

Page 5

Table of contents

6 Reflectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.2 Description of the reflective tape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 Specifications of the self-adhesive foil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2.2 Specifications of the reflective tape on a metal plate . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.2.3 Dimensioned drawing of reflective tape on a metal plate . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.4 Specifications of heated reflectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.5 Dimensioned drawing of heated reflectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 Selecting reflector sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4 Mounting the reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.2 Mounting the reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4.3 Table of reflector pitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1 Safety notices for the electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 PWR – voltage supply / switching input/output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 DeviceNet BUS IN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.4 DeviceNet BUS OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8 Display and control panel AMS 355i . . . . . . . . . . . . . . . . . . . . . . . 40

8.1 Structure of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 Status display and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2.1 Indicators in the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2.2 LED status displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2.3 Control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.3 Menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

8.3.1 The main menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.3.2 Parameter menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.3.3 Language selection menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.3.4 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.4 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9 DeviceNet interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1 General information on DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1.1 Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2 AMS 355i

Page 6

Table of contents

9.1.2 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.2 DeviceNet electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.3 Electrical data for the supply voltage – Data V+ and Data V- . . . . . . . . . . . . . . . . . . . . 56

9.4 DeviceNet address entry - MAC ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.4.1 Entering the MAC ID (address) via the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.5 EDS file - general info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.6 EDS file - detailed description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.6.1 Class 4 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.6.2 Class 1 Identity object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.6.3 Class 35 Position sensor object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.6.4 Class 100 Display configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.6.5 Class 101 Selection assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.6.6 Class 103 Switching inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.6.7 Class 104 Behavior in the case of error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.6.8 Class 105 Velocity monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1 Service and diagnostics in the display of the AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1.1 Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.1.3 Expanded diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.2 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.2.1 Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.3 Interface errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.3.1 Net LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.4 Status display in the display of the AMS 355i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11 Type overview and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.1 Type key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.2 type overview AMS 355i (DeviceNet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.3 Overview of reflector types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.4.1 Accessory mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.4.2 Accessory deflector unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.4.3 Accessory M 12 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.4.4 Accessory terminating resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.4.5 Accessory ready-made cables for voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.4.6 Accessory ready-made cables for DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

AMS 355i 3

Page 7

Table of contents

12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.1 General maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.2 Repairs, servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.3 Disassembling, packing, disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4 AMS 355i

Page 8

1 General information

U

L

US

C

LISTED

1.1 Explanation of symbols

The symbols used in this operating manual are explained below.

Attention!

This symbol precedes text messages which must strictly be observed. Failure to comply with

this information results in injuries to personnel or damage to the equipment.

Attention Laser!

This symbol warns of possible danger caused by hazardous laser radiation.

Notice!

This symbol indicates text passages containing important information.

1.2 Declaration of conformity

The AMS 355i absolute measuring optical laser measurement system was designed and

manufactured in accordance with applicable European directives and standards.

The AMS series is "UL LISTED" according to American and Canadian safety standards and

fulfills the requirements of Underwriter Laboratories Inc. (UL).

General information

Notice!

The Declaration of Conformity for these devices can be requested from the manufacturer.

The manufacturer of the product, Leuze electronic GmbH + Co. KG in D-73277 Owen/Teck,

possesses a certified quality assurance system in accordance with ISO 9001.

Leuze electronic AMS 355i 5

TNT 35/7-24V

Page 9

General information

1.3 Description of functions AMS 355i

The AMS 355i optical laser measurement system calculates distances to fixed as well as

moving system parts. The distance to be measured is calculated according to the principle

of the propagation time of radiated light. Here, the light emitted by the laser diode is reflected

by a reflector onto the receiving element of the laser measurement system. The AMS 355i

uses the "propagation time" of the light to calculate the distance to the reflector. The high

absolute measurement accuracy of the laser measurement system and the fast integration

time are designed for position control applications.

With the AMS 3xxi product series, Leuze electronic makes available a range of internationally relevant interfaces. Note that each interface version listed below corresponds to a

different AMS 3xxi model.

AMS 304i

AMS 348i

AMS 355i

AMS 358i

AMS 335i

AMS 338i

AMS 308i

AMS 384i

AMS 301i

AMS 300i

6 AMS 355i Leuze electronic

Page 10

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The AMS is an absolute measuring optical laser measurement system which allows

distance measurement of up to 300m against a reflector.

Areas of application

The AMS is designed for the following areas of application:

• Positioning of automated, moving plant components

• Travel and lifting axes of high-bay storage devices

• Repositioning units

• Gantry crane bridges and their trolleys

•Lifts

• Electroplating plants

CAUTION

Observe intended use!

Only operate the device in accordance with its intended use. The protection of per-

sonnel and the device cannot be guaranteed if the device is operated in a manner not

complying with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read the technical description before commissioning the device. Knowledge of this

technical description is an element of proper use.

Safety

NOTICE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

Attention

For UL applications, use is permitted exclusively in Class 2 circuits according to NEC

(National Electric Code).

Leuze electronic AMS 355i 7

TNT 35/7-24V

Page 11

Safety

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is

considered improper use.

In particular, use of the device is not permitted in the following cases:

• Rooms with explosive atmospheres

• Circuits relevant to safety

• For medicinal purposes

NOTICE

Do not modify or otherwise interfere with the device.

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried

out by competent persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at

work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation

of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with

relevant standards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

8 AMS 355i Leuze electronic

Page 12

2.4 Disclaimer

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser safety notices

ATTENTION LASER RADIATION – LASER CLASS 2

Never look directly into the beam!

The device satisfies the requirements of IEC 60825-1:2007 (EN 60825-1:2007) safety

regulations for a product in laser class 2 as well as the U.S. 21 CFR 1040.10 regulations

with deviations corresponding to "Laser Notice No. 50" from June 24th, 2007.

Never look directly into the laser beam or in the direction of reflecting laser beams.

If you look into the beam path over a longer time period, there is a risk of injury to the

retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser

beam is accidentally directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflec-

tive surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here

or carrying out of differing procedures may lead to dangerous exposure to radiation.

Adhere to the applicable legal and local regulations regarding protection from laser

beams.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

TNT 35/7-24V

Leuze electronic AMS 355i 9

Page 13

Safety

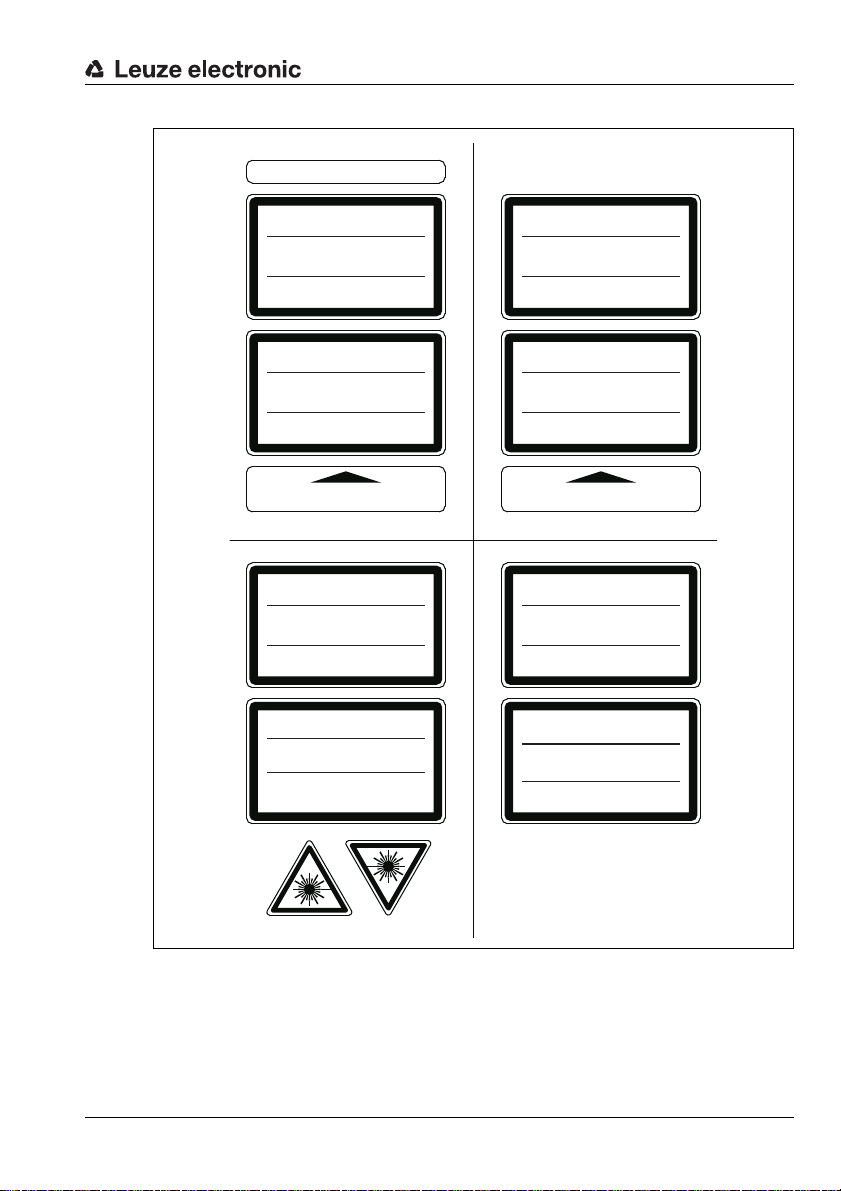

A Laser aperture

B Laser warning sign

C Laser information sign with laser parameters

A B

C

NOTICE

Affix laser information and warning signs!

Laser information and warning signs are attached to the device (see figure 2.1):

In addition, self-adhesive laser warning and information signs (stick-on labels) are supplied

in several languages (see figure 2.2).

Affix the laser information sheet to the device in the language appropriate for the place

of use.

When using the device in the US, use the stick-on label with the "Complies with

21 CFR 1040.10" notice.

Affix the laser information and warning signs near the device if no signs are attached

to the device (e.g., because the device is too small) or if the attached laser information

and warning signs are concealed due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing

the reader to the laser radiation of the device or other optical radiation.

Figure 2.1: Laser apertures, laser warning signs

10 AMS 355i Leuze electronic

Page 14

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER

NON FISSARE IL FASCIO

APARRECCHIO LASER DI CLASSE 2

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

PRODUCTO LÁSER DE CLASE 2

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

EQUIPAMENTO LASER CLASSE 2

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

䉏⏘戟⺓

▎䦃展⏘㧮

伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

4 mW

18 μs

655 nm

4 mW

18 μs

655 nm

4 mW

18 μs

655 nm

4 mW

18

μ

s

655 nm

4 mW

18 μs

655 nm

4 mW

18 μs

655 nm

4 mW

18 μs

655 nm

4 mW

18 μs

655 nm

50125612-01

Safety

Figure 2.2: Laser warning and information signs – supplied stick-on labels

TNT 35/7-24V

Leuze electronic AMS 355i 11

Page 15

Fast commissioning / operating principle

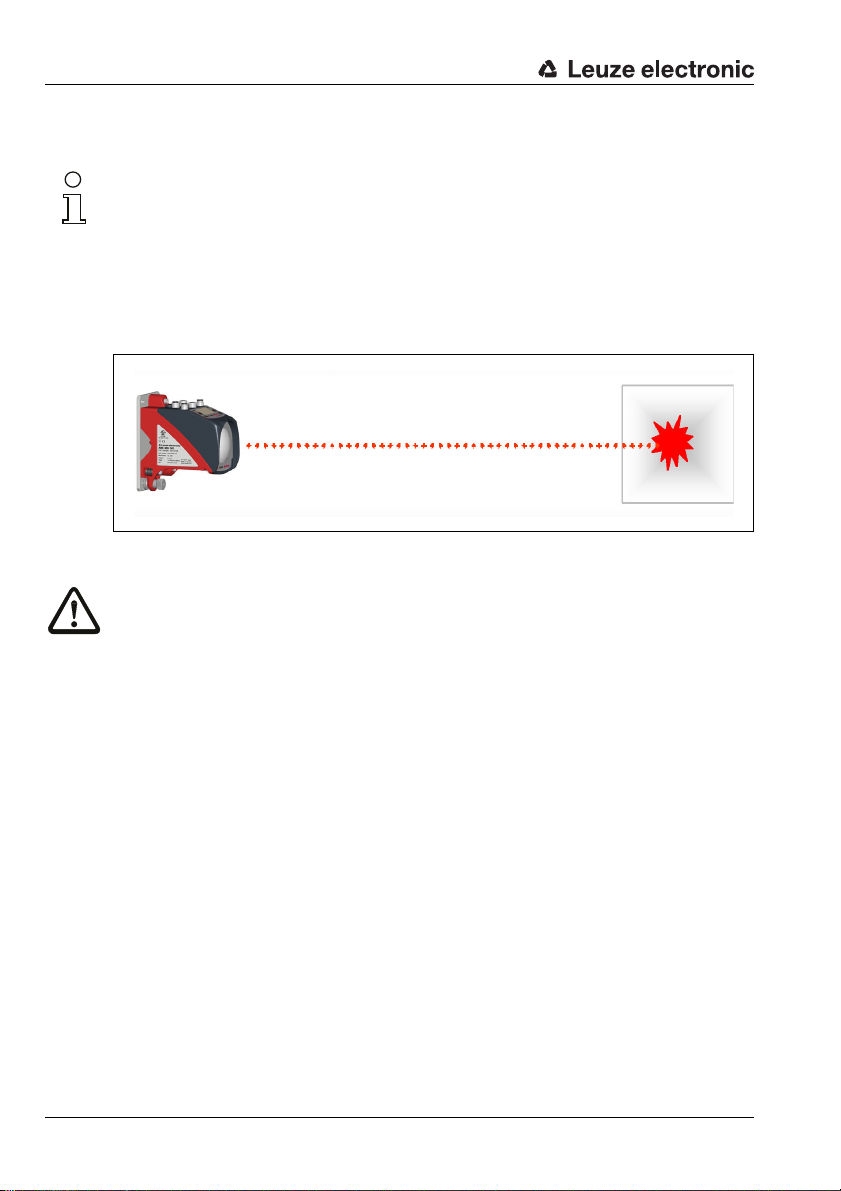

3 Fast commissioning / operating principle

Notice!

Below, you will find a short description for the initial commissioning of the AMS 355i.

Detailed explanations for the listed points can be found throughout the handbook.

3.1 Mounting the AMS 355i

The AMS 355i and the corresponding reflector are mounted on two mutually opposing,

plane-parallel, flat walls.

Figure 3.1: Schematic illustration of mounting

Attention!

For error-free position measurement, there must be an unobstructed line-of-sight between

the AMS 355i and the reflector.

3.1.1 Mounting the device

The laser is mounted on a vertical wall using 4 screws (M5).

Alignment is performed using 2 adjustment screws. Adjust so that the laser light spot is

positioned at the center of the reflector. The alignment is to be secured with the knurled nut

and locked with the M5 nut.

Further information can be found in chapter 5.2 and chapter 5.3.

3.1.2 Mounting the reflector

The reflector is mounted on a vertical wall with 4 screws (M5). The reflector is angled using

the included shims. Incline the reflector by approx. 1°.

Detailed information can be found in chapter 6.4.

12 AMS 355i Leuze electronic

Page 16

Fast commissioning / operating principle

3.2 Connecting the voltage supply

The laser measurement system is connected using M12 connectors. The voltage supply is

connected via the PWR M12 connection.

Detailed information can be found in chapter 7.

3.3 Display

Once the laser measurement system is supplied with voltage, the device status as well as

the measured position values can be read on the display. The display automatically switches

to the display of the measurement values.

Use the up/down buttons to the left of the display to read and change a wide range

of data and parameters.

Depending on connected interface, the network address must be configured via the display.

Detailed information can be found in chapter 8.

3.4 AMS 355i on the DeviceNet

Install the EDS file corresponding to the AMS 355i … in your planning tool/the control

(e.g., RS network).

Notice!

You can find the EDS file at

The AMS 355i is configured in the planning tool/control by means of the EDS file. If the

AMS 355i has been assigned an address in the planning tool, the address is to be set on

the AMS 355i via the control panel/display. Only if the addresses are the same between the

AMS 355i and the control can communication be established.

After all parameters have been set in the planning tool/control, the download to the

AMS 355i takes place. The set parameters are now stored on the AMS 355i.

Afterwards, all AMS 355i parameters should be stored via upload in the control. This aids

in retaining the parameters during device exchanges, as they a re now also stored centrally

in the control.

Each time a connection is established between the control and the AMS 355i, these

parameters are now transferred again to the AMS 355i. Note that this function must be

supported by the control.

The DeviceNet baud rate is defined for the entire network in the planning tool/control.

The baud rate is set on the AMS 355i via the control panel/display.

Only if the baud rates are the same is communication with the AMS 355i possible.

Detailed information can be found in chapter 9.

www.leuze.com.

TNT 35/7-24V

Leuze electronic AMS 355i 13

Page 17

Specifications

4 Specifications

4.1 Specifications of the laser measurement system

4.1.1 General specifications AMS 355i

Measurement data AMS 355i 40 (H) AMS 355i 120 (H) AMS 355i 200 (H) AMS 355i 300 (H)

Measurement range 0.2 … 40m 0.2 … 120m 0.2 … 200m 0.2 … 300m

Accuracy ± 2mm ± 2mm ± 3mm ± 5mm

Consistency

Light spot diameter ≤ 40mm ≤ 100mm ≤ 150 mm ≤ 225 mm

Measurement value output

Integration time 8ms

Resolution adjustable, see chapter of the individual interfaces

Temperature drift ≤ 0.1 mm/K

Ambient temperature sensitivity 1ppm/K

Air pressure sensitivity 0.3ppm/hPa

Tra ve rs e r at e ≤ 10 m/s

Electrical data

Supply voltage Vin

Supply voltage data V+ 11 … 25VDC

Supply voltage data V- reference potential

Current consumption AMS 355i

at Data V+

Current consumption without device heating: ≤ 250 mA / 24V DC

Optical data

Transmitter laser diode, red light, wavelength 650 … 690nm

Laser class 2 acc. to EN 60825-1, CDRH

Interfaces

DeviceNet 125kbit/s (default) / 250kbit/s / 500 kbit/s

Vendor ID 524

Device type 34

Position sensor type 8

Operating and display elements

Keyboard 4 buttons

Display monochromatic graphical display, 128 x 64 pixels

LED 2 LEDs, two-colored

1)

0.3mm 0.5mm 0.7mm 1.0mm

1.7ms

2)

18 … 30V DC

max. 80mA at 11VDC

(for supplying the bus transceiver, not for the complete device)

with device heating: ≤ 500 mA / 24VDC

/ 20C

Dec

/ 22H (encoder)

Dec

/ 8H (absolute encoder)

Dec

H

14 AMS 355i Leuze electronic

Page 18

Specifications

Inputs/outputs

Quantity

Input

Output

Mechanical data

Housing cast zinc and aluminum

Optics glass

Weight approx. 2.45kg

Protection class

Environmental conditions

Operating temperature

without device heating

with device heating

Storage temperature -30°C … +70°C

Air humidity max. 90% rel. humidity, non-condensing

Mechanical/electrical loading capacity

Vibrations acc. to EN 60068-2-6

Noise acc. to EN 60060-2-64

Shock acc. to EN 60068-2-27

EMC

1) Statistical error: 1 sigma; minimum switch-on time: 2min.

2) For UL applications: only for use in "Class 2" circuits acc. to NEC.

3) With screwed-on M12 plugs or mounted caps.

4) With devices with heating, the switch on/off area of the internal heating can be extended to prevent

condensation from forming. A 100% prevention of the formation of condensation cannot be guaranteed due to the limited heating capacity of the AMS 355i.

5) This is a Class A product. In a domestic environment this product may cause radio interference, in

which case the operator may be required to take adequate measures.

acc. to EN 61000-6-2 and EN 61000-6-4

2, programmable

protected against polarity reversal

max. 60mA, short-circuit proof

IP 65 acc. to EN 60529

3)

-5°C … +50°C

-30°C…+50°C

4)

5)

The AMS 355i is designed in accordance with safety class III for supply with

PELV (protective extra-low voltage).

Leuze electronic AMS 355i 15

TNT 35/7-24V

Page 19

Specifications

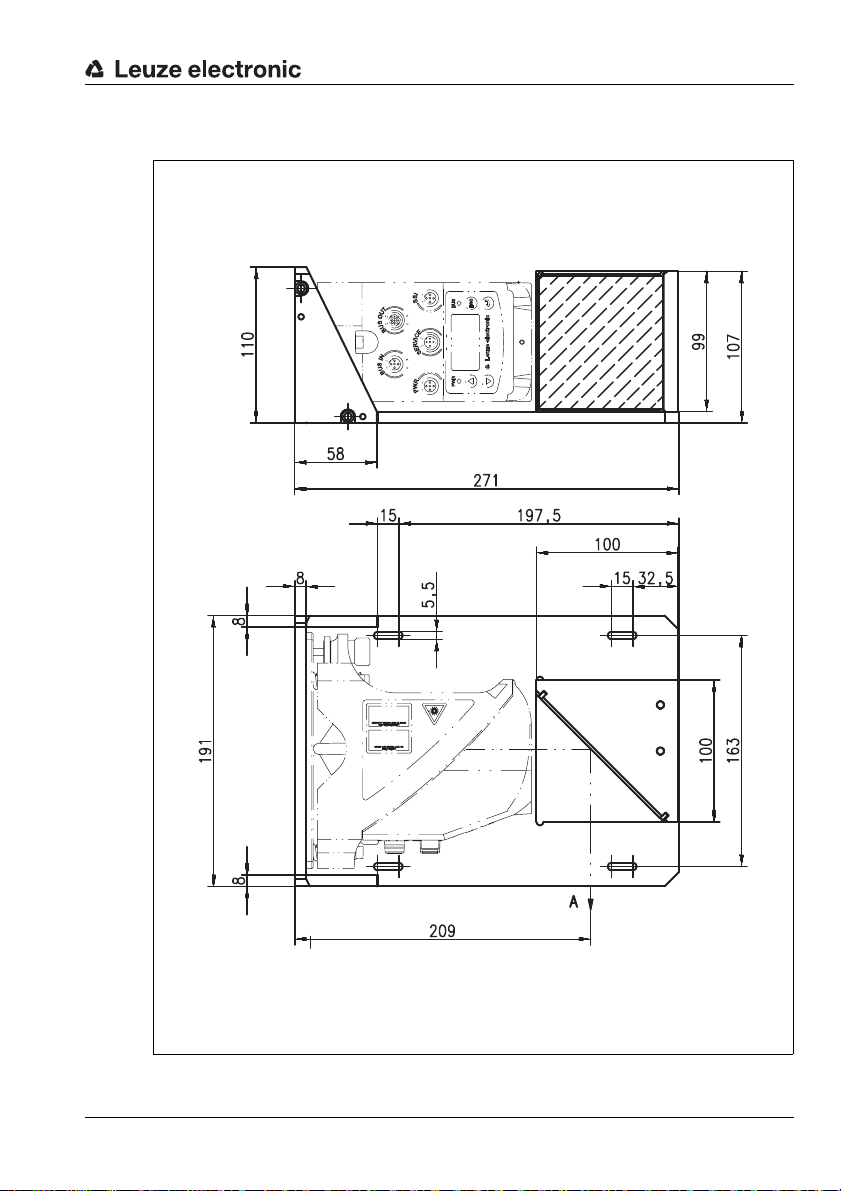

A M5 screw for alignment

B Knurled nut with WAF4

hexagon socket and M5 nut for securing

C Optical axis

D Zero point of the distance to be measured

A

B

D

A

C

4.1.2 Dimensioned drawing AMS 355i

16 AMS 355i Leuze electronic

Figure 4.1: Dimensioned drawing AMS 355i

Page 20

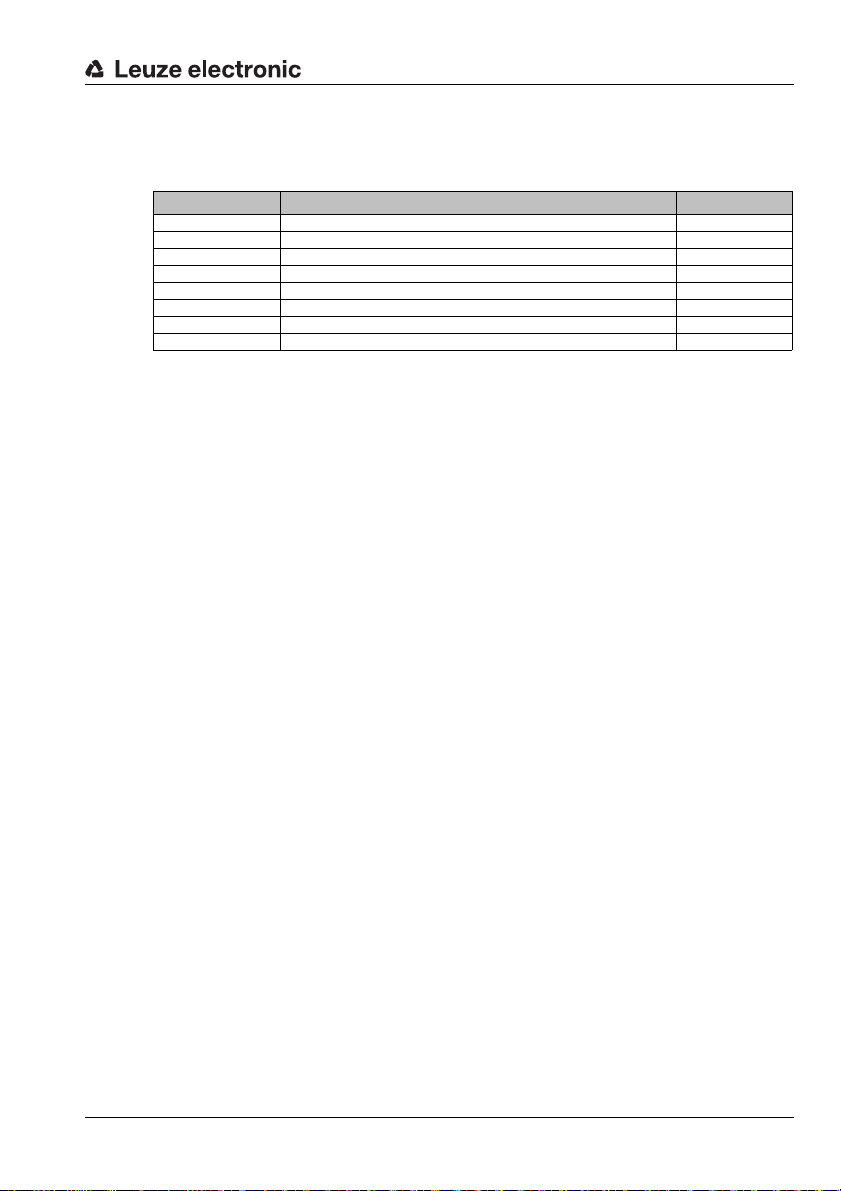

4.1.3 Type overview AMS 355i

AMS 355i (DeviceNet)

Type designation Description Part no.

AMS 355i 40 40m operating range, DeviceNet interface 50113717

AMS 355i 120 120m operating range, DeviceNet interface 50113718

AMS 355i 200 200m operating range, DeviceNet interface 50113719

AMS 355i 300 300m operating range, DeviceNet interface 50113720

AMS 355i 40 H 40m operating range, DeviceNet interface, integrated heating 50113721

AMS 355i 120 H 120m operating range, DeviceNet interface, integrated heating 50113722

AMS 355i 200 H 200m operating range, DeviceNet interface, integrated heating 50113723

AMS 355i 300 H 300m operating range, DeviceNet interface, integrated heating 50113724

Table 4.1: Type overview AMS 355i

Specifications

Leuze electronic AMS 355i 17

TNT 35/7-24V

Page 21

Installation and mounting

5 Installation and mounting

5.1 Storage, transportation

Attention!

When transporting or storing, package the device so that it i s prote cted against collision and

humidity. Optimum protection is achieved when using the original packaging. Heed the required environmental conditions specified in the technical data.

Unpacking

Check the packaging for any damage. If damage is found, notify the post office or shipping

agent as well as the supplier.

Check the delivery contents using your order and the delivery papers:

• Delivered quantity

• Device type and model as indicated on the nameplate

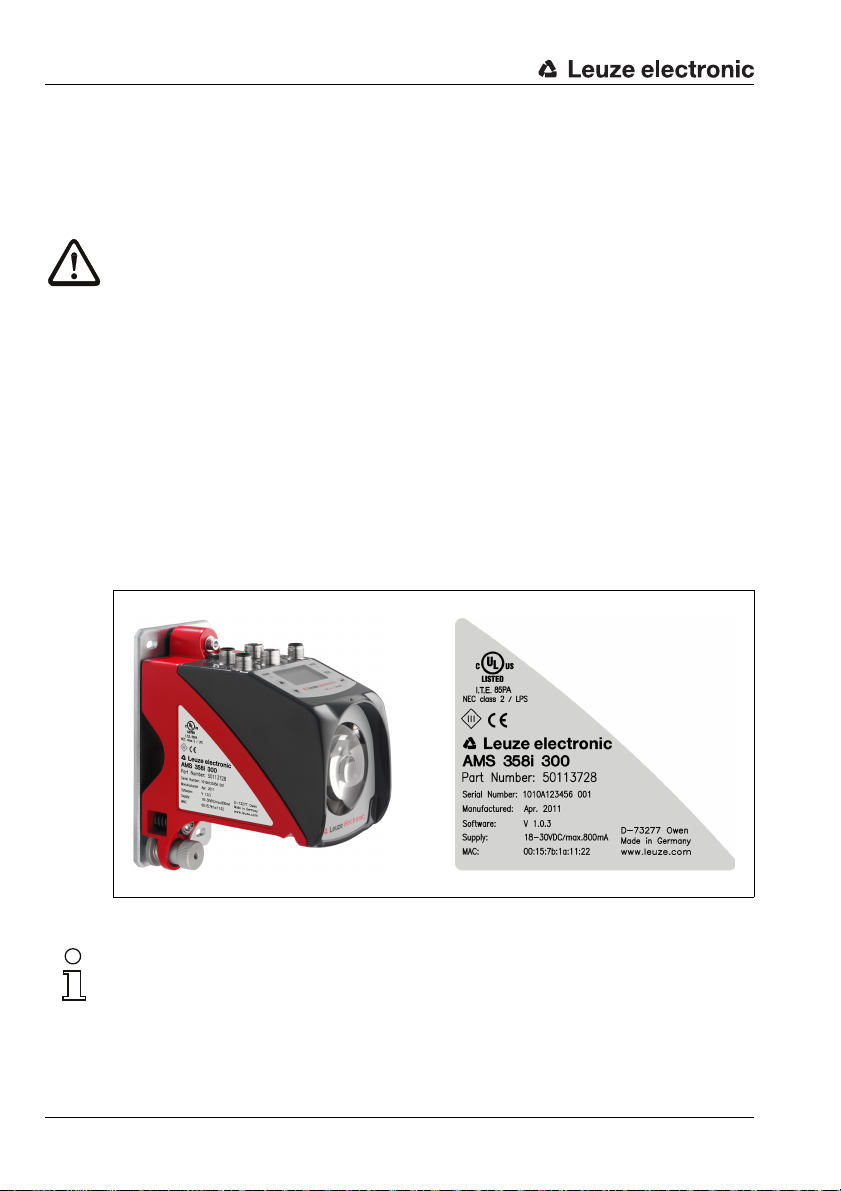

• Brief manual

The name plate provides information as to what AMS 355i type your device is. For specific

information, please refer to chapter 11.2.

Name plates

Figure 5.1: Device name plate using the AMS 300i as an example

Notice!

Please note that the shown name plate is for illustration purposes only; the contents do not

correspond to the original.

Save the original packaging for later storage or shipping.

18 AMS 355i Leuze electronic

Page 22

If you have any questions concerning your shipment, please contact your supplier or your

A M5 screw for align-

ment

B Knurled nut and nut

with WAF4 hexagon

socket for securing

C Optical axis

A

B

A

C

local Leuze electronic sales office.

Observe the applicable local regulations when disposing of the packaging materials.

5.2 Mounting the AMS 355i

Installation and mounting

Figure 5.2: Mounting the device

The AMS 355i and the corresponding reflector are mounted on two mutually opposing,

plane-parallel, flat walls or system parts. For error-free position measurement, there must

be an unobstructed line-of-sight connection between the AMS 355i and the reflector.

Use M5 screws to fasten the laser measurement system. Secure the screws with a toothed

lock washer to protect against loosening caused by vibrations.

Leuze electronic AMS 355i 19

TNT 35/7-24V

Page 23

Installation and mounting

Aligning the laser light spot in the center of the reflector

The laser light spot has to be aligned so that it always hits the center of the opposing

reflector, both at close range as well as at the maximum measurement distance. To align,

use the two M5 Allen screws ("A" in figure 5.2). When aligning please ensure that the

knurled nut and the lock nut ("B" in figure 5.2) are opened wide.

Attention!

To prevent the laser measurement system from moving out of alignment during continuous

operation, subsequently hand-tighten the knurled nut and counterlock with the nut with

WAF4 hexagon socket ("B" in figure 5.2). Knurled nut and nut must not be tightened until

alignment has been completed.

Attention!

The device must not be opened. Failure to comply will render the guarantee void. Warranted

features cannot be guaranteed after the device has been opened.

20 AMS 355i Leuze electronic

Page 24

5.2.1 Optional mounting bracket

A Laser beam

A mounting bracket for mounting the AMS 355i on a flat, horizontal surface is available as

an optional accessory.

Type designation: MW OMS/AMS 01

Part no.: 50107255

Installation and mounting

Leuze electronic AMS 355i 21

TNT 35/7-24V

Figure 5.3: Optional mounting bracket

Page 25

Installation and mounting

X

Reflector 1 Reflector 2

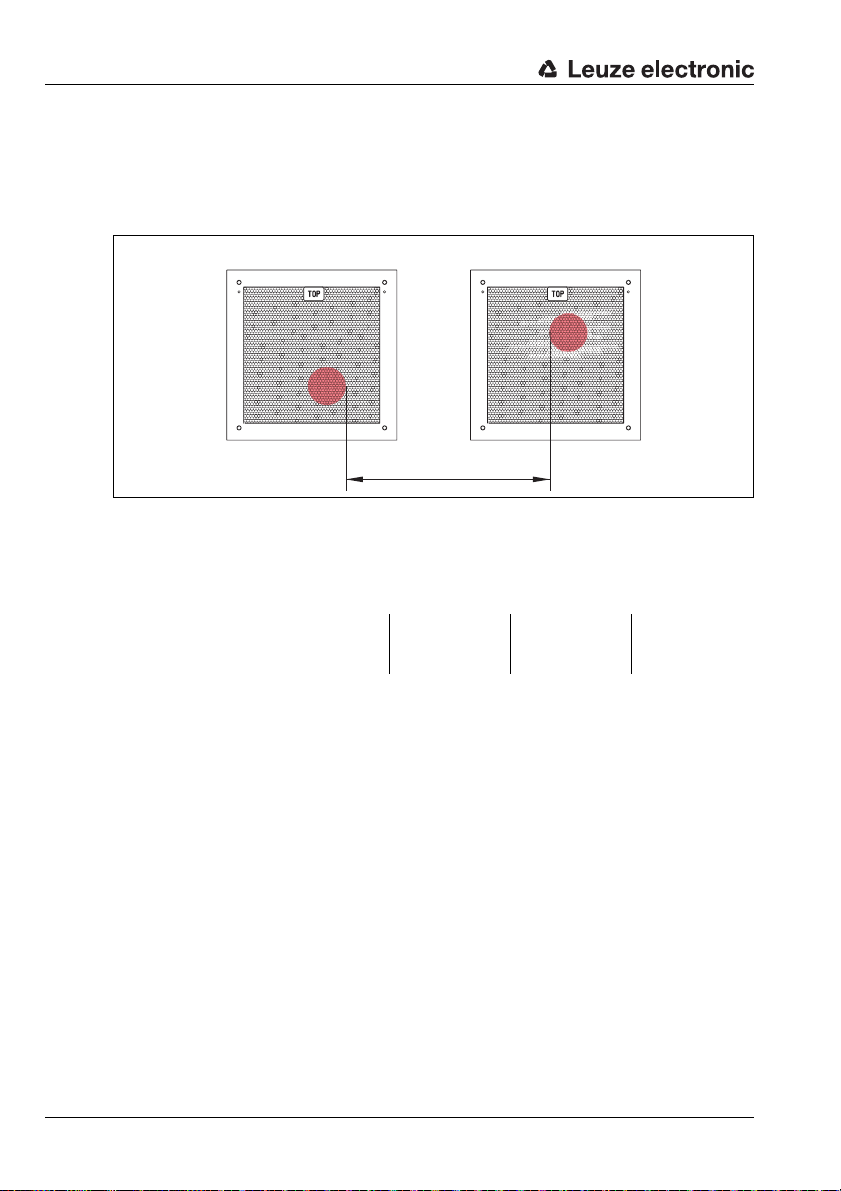

5.2.2 Parallel mounting of the AMS 355i

Definition of the term "parallel spacing"

As shown in figure 5.4, dimension X describes the "parallel spacing" of the inner edges of

the two laser light spots on the reflector.

Figure 5.4: Minimum parallel spacing X between adjacent AMS 355i

The diameter of the light spot increases with distance.

AMS 355i 40 (H) AMS 355i 120 (H) AMS 355i 200 (H) AMS 355i 300 (H)

Max. measurement distance

Light spot diameter ≤ 40mm ≤ 100mm ≤ 150mm ≤ 225 mm

Thus, the center-to-center spacing of the two AMS 355i devices with respect to one another

can be calculated as a function of the maximum measurement distance.

To define the minimum parallel spacing between two AMS 355i, it is necessary to distinguish

between three different arrangements of AMS 355i and reflectors.

40m 120m 200m 300m

The AMS 355i are mounted stationary and in parallel on one plane. Both reflectors move independently of one another at different distances to the AMS 355i.

Minimum parallel spacing X of the two laser light spots:

X = 100mm + (max. measurement distance in mm x 0.01)

The AMS 355i are mounted stationary and in parallel on one plane. Both reflectors move in parallel at the same distance to the AMS 355i.

Measurement distance up to 120m: minimum parallel spacing X ≥ 600mm

Measurement distance up to 200m: minimum parallel spacing X ≥ 750mm

Measurement distance up to 300m: minimum parallel spacing X ≥ 750mm

22 AMS 355i Leuze electronic

Page 26

Installation and mounting

The reflectors are mounted stationary and in parallel on one plane.

Both AMS 355i move independently of one another at different or the same distances to the reflectors.

Measurement distance up to 120 m: minimum parallel spacing X ≥ 600 mm

Measurement distance up to 200 m: minimum parallel spacing X ≥ 750 mm

Measurement distance up to 300 m: minimum parallel spacing X ≥ 750 mm

Notice!

Please note that when the AMS 355i are mounted in a mobile manner, travel tolerances could

cause the two laser light spots to move towards each other.

Take the travel tolerances of the vehicle into account when defining the parallel spacing of

adjacent AMS 355i.

5.2.3 Parallel mounting of AMS 355i and DDLS optical data transmission

The optical data transceivers of the DDLS series and the AMS 355i do not interfere with one

another. Depending on the size of the used reflector, the DDLS can be mounted with a

minimum parallel spacing of 100mm to the AMS 355i. The parallel spacing is independent

of the distance.

Leuze electronic AMS 355i 23

TNT 35/7-24V

Page 27

Installation and mounting

5.3 Mounting the AMS 355i with laser beam deflector unit

General information

The two available deflector units are used for the 90° deflection of the laser beam,

see "Accessory deflector unit" on page 88.

Attention!

The deflector units are designed for a maximum range of 40m.

Longer distances on request.

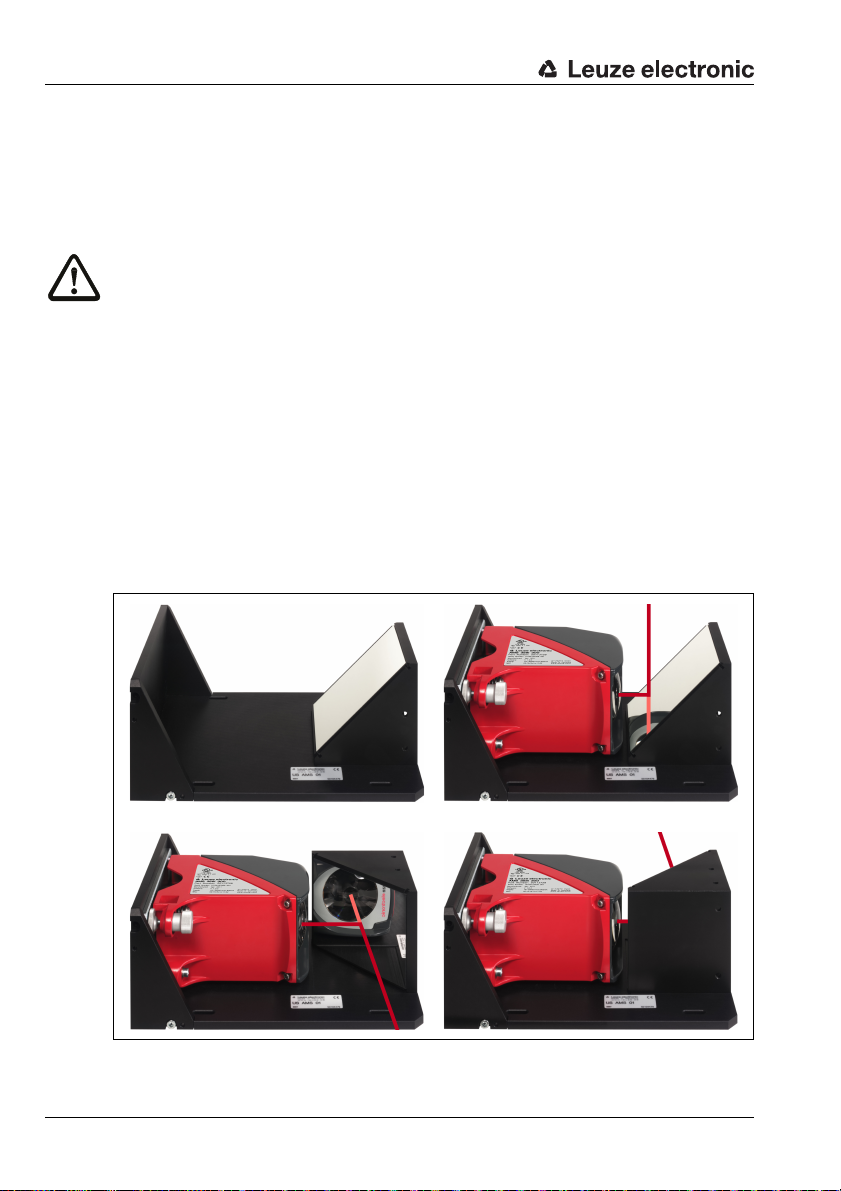

5.3.1 Mounting the laser beam deflector unit With integrated mounting bracket

The AMS 355i is screwed onto the mechanism of the US AMS 01 deflector unit. The mirror

can be mounted for three deflection directions:

1. Upward beam deflection

2. Beam deflection to the left

3. Beam deflection to the right

The deflector unit is mounted on plane-parallel, flat walls or plant components. For errorfree position measurement, there must be an interruption-free line-of-sight between the

AMS 355i… and the deflection mirror as well as between the mirror and the reflector.

Use the M5 screws to mount the deflector unit. Secure the screws with a toothed lock

washer to protect against loosening caused by vibrations.

Figure 5.5: Mounting variants of the US AMS 01 laser beam deflector unit

24 AMS 355i Leuze electronic

Page 28

Installation and mounting

A Laser beam

5.3.2 Dimensioned drawing of US AMS 01 deflector unit

Leuze electronic AMS 355i 25

TNT 35/7-24V

Figure 5.6: Dimensioned drawing of US AMS 01 deflector unit

Page 29

Installation and mounting

A Mirror

Height of the spring in

non-preloaded state

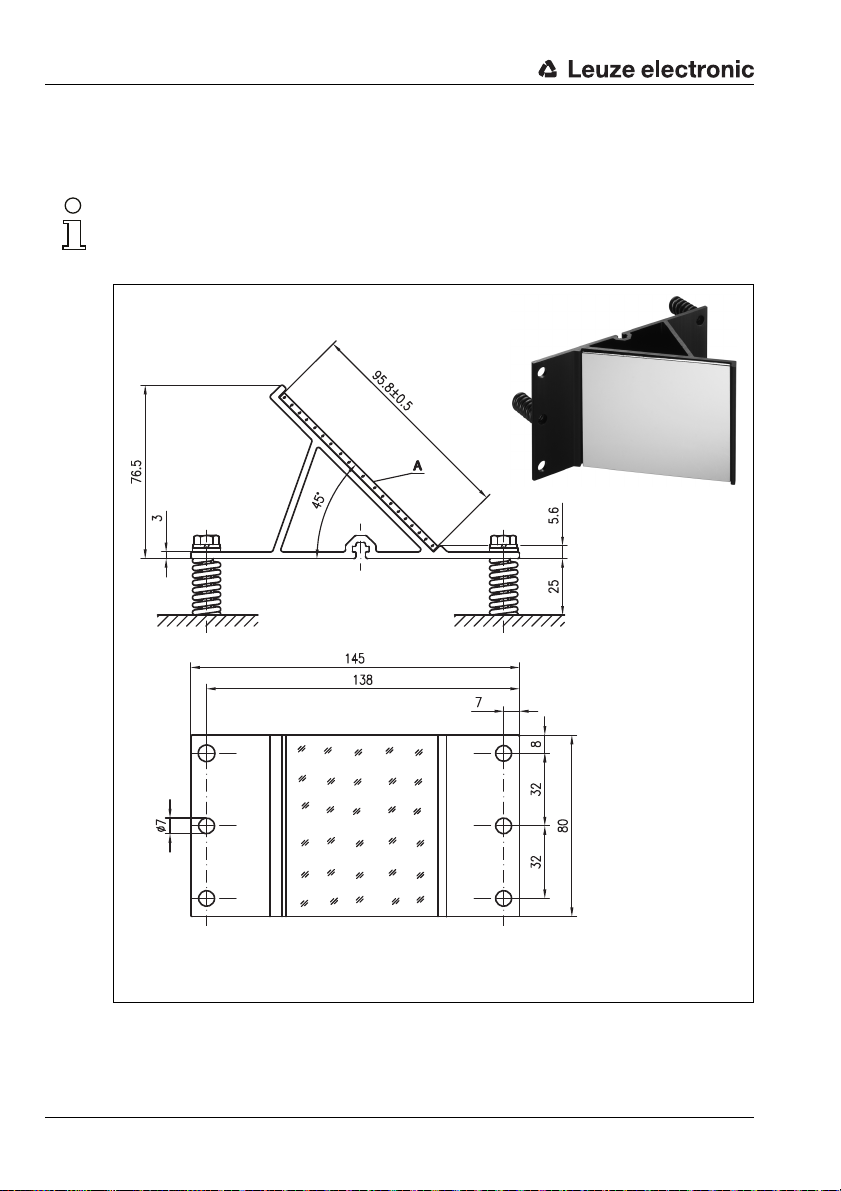

5.3.3 Mounting the US 1 OMS deflector unit without mounting bracket

The US 1 OMS deflector unit and the AMS 355i are mounted separately.

Notice!

When mounting, make certain that the laser light spot of the AMS 355i is aligned in the center

of the deflection mirror.

Figure 5.7: Photo and dimensioned drawing of the US 1 OMS deflector unit

Alignment of the laser light spot on the reflector is performed as described in chapter 5.2.

26 AMS 355i Leuze electronic

Page 30

6 Reflectors

6.1 General information

The AMS 355i measures distances against a reflective tape specified by Leuze electronic.

All provided specifications for the AMS 355i, such as the operating range or accuracy, can

only be achieved with the reflective tape specified by Leuze electronic.

The reflective tapes are available as adhesive tapes, affixed to a metal plate and with an

integrated heater especially for use at low temperatures. Reflective tapes with heating have

the designation "Reflective tape …x…-H", where "H" is an abbreviation for the heating

variant.

The reflective tapes/reflectors must be ordered separately. The choice of size is left to the

user. In chapter 6.3, recommendations on reflector size are provided as a function of the

distance that is to be measured. In any case, the user must check to determine whether the

recommendation is suitable for the respective application.

6.2 Description of the reflective tape

The reflective tape consists of a white, microprism-based reflective material. The microprisms are protected with a highly transparent, hard protective layer.

Under certain circumstances, the protective layer may lead to surface reflections. The

surface reflections can be directed past the AMS 355i by positioning the reflective tape at

a slight incline. The inclination of the reflective tape/reflectors is described in chapter 6.4.2.

The required pitch can be found in table 6.1 "Reflector pitch resulting from spacer sleeves"

on page 36.

The reflective tapes are provided with a protective fo il that ca n easily be p ulled off . This mus t

be removed from the reflector before the complete system is put into operation.

Reflectors

Leuze electronic AMS 355i 27

TNT 35/7-24V

Page 31

Reflectors

6.2.1 Specifications of the self-adhesive foil

Part

Type designation

Part no. 50104361 50104362 50108988

Foil size 200x 200mm 500 x500 mm 914 x914 mm

Recommended application temperature for adhesive tape

Temperature resistance,

affixed

Mounting surface The mounting surface must be clean, dry and free of grease.

Cutting the tape Cut with a sharp tool, always on the side of the prism structure.

Cleaning

Storing the foil Store in a cool and dry place.

Reflective tape

200x200-S

Do not use any agents that act with a grinding effect. A conventional household

detergent can be used as a cleaning agent. Rinse with clear water and dry the

6.2.2 Specifications of the reflective tape on a metal plate

The reflective tape is affixed to a metal plate. Included with the metal plate are spacers for

positioning at an incline - for avoiding surface reflections - (see chapter 6.4.2 "Mounting the

reflector").

Reflective tape

500x500-S

+5°C … +25 °C

-40°C…+80°C

surface.

Reflective tape

914x914-S

Part

Type designation

Part no. 50104364 50104365 50104366

Foil size 200x 200mm 500 x500 mm 914 x914 mm

Outer dimensions of the

metal plate

Weight 0.8kg 4kg 25kg

Cleaning

Storing the reflector Store in a cool and dry place.

28 AMS 355i Leuze electronic

Reflective tape

200x200-M

250x 250mm 550 x550 mm 964x964 mm

Do not use any agents that act with a grinding effect. A conventional household

detergent can be used as a cleaning agent. Rinse with clear water and dry the

Reflective tape

500x500-M

surface.

Reflective tape

914x914-M

Page 32

6.2.3 Dimensioned drawing of reflective tape on a metal plate

Always align the TOP marking

with the AMS connections!

(chapter 6.4.2)

Figure 6.1: Dimensioned drawing of reflectors

Part Reflective tape (mm) Reflector plate (mm)

xL yL XL YL L

Reflective tape 200x200-M 200 200 250 250 214

Reflective tape 500x500-M 500 500 550 550 514

Reflective tape 914x914-M 914 914 964 964 928

Reflectors

Leuze electronic AMS 355i 29

TNT 35/7-24V

Page 33

Reflectors

6.2.4 Specifications of heated reflectors

The reflective tape is affixed to a heated, thermally insulated base. The insulation results in

a very high energetic efficiency.

Only the reflective tape is kept at the specified temperature by the integrated heater.

Through the insulation on the back, the generated heat cannot be transferred via the steel

construction. Energy costs are greatly reduced in the case of continuous heating.

Type designation

Part no. 50115020 50115021 50115022

Voltage supply 230VAC

Power 100W 600W 1800 W

Current consumption ~ 0.5A ~ 3A ~ 8A

Length of the supply line 2 m

Size of the reflective tape 200 x200 mm 500 x500 mm 914x914mm

Outer dimensions of the base

material

Weight 0.5kg 2.5 kg 12 kg

Temperature control

Switch-on temperature ~ 5°C

Switch-off temperature ~ 20°C

Operating temperature -30°C … +70°C

Storage temperature -40°C … +80°C

Air humidity Max. 90%, non-condensing.

Cleaning

Storing the reflector Store in a cool and dry place.

Reflective tape

200x200-H

250x 250mm 550x 550mm 964x 964mm

Controlled heating with the following switch-on and switch-off tempera-

Do not use any agents that act with a grinding effect. A conventional household detergent can be used as a cleaning agent. Rinse with clear water and

Part

Reflective tape

500x500-H

tures, measured at the reflector surface.

dry the surface.

Reflective tape

914x914-H

30 AMS 355i Leuze electronic

Page 34

6.2.5 Dimensioned drawing of heated reflectors

18

6,5

2

L ± 0,5

XL ± 1

TOP

6

2000

115

90

XL ± 1

yL ± 1

L ± 0,5

YL ± 1

Always align the TOP marking

with the AMS connections!

(chapter 6.4.2)

Connection hood

Reflective tape

Si cable

3 x 0.75mm²

Reflectors

Figure 6.2: Dimensioned drawing of heated reflectors

Part Reflective tape (mm) Insulated base plate (mm)

Reflective tape 200x200-H 200 200 250 250 214

xL yL XL YL L

Reflective tape 500x500-H 500 500 550 550 514

Reflective tape 914x914-H 914 914 964 964 928

Leuze electronic AMS 355i 31

TNT 35/7-24V

Page 35

Reflectors

6.3 Selecting reflector sizes

Depending on system design, the reflector can be mounted so that it travels on the vehicle

or it can be mounted at a fixed location.

Attention!

The reflector sizes shown below are a recommendation from Leuze electronic for on-vehicle

mounting of the AMS 355i. For stationary mounting of the AMS 355i, a smaller reflector is

generally sufficient for all measurement distances.

On the basis of the system planning and design, always check whether mechanical travel

tolerances may require the use of a reflector larger than that which is recommended. This

applies, in particular, when the laser measurement system is mounted on a vehicle. During

travel, the laser beam must reach the reflector without interruption. For on-vehicle mounting

of the AMS 355i, the reflector size must accommodate any travel tolerances that may arise

and the associated "wandering" of the light spot on the reflector.

Overview of reflector types

AMS 355i selection

(Operating range in m)

AMS 355i 40 (max. 40m) 200x 200mm Reflective tape 200x200-S

AMS 355i 120 (max. 120m) 500x500mm Reflective tape 500x500-S

AMS 355i 200 (max. 200m) 749x 914mm

AMS 355i 300 (max. 300m) 749x 914mm

Recommended reflector sizes

Recommended

reflector size

(H x W)

914x 914mm

914x 914mm

Type designation

…-S = Self-adhesive

…-M = metal plate

…-H = heating

Reflective tape 200x200-M

Reflective tape 200x200-H

Reflective tape 500x500-M

Reflective tape 500x500-H

Reflective tape 749x914-S

Reflective tape 914x914-M

Reflective tape 914x914-S

Reflective tape 914x914-H

Reflective tape 749x914-S

Reflective tape 914x914-M

Reflective tape 914x914-S

Reflective tape 914x914-H

Part no.

50104361

50104364

50115020

50104362

50104365

50115021

50104363

50104366

50108988

50115022

50104363

50104366

50108988

50115022

32 AMS 355i Leuze electronic

Page 36

6.4 Mounting the reflector

6.4.1 General information

Self-adhesive reflective tapes

The reflective tapes of the "Reflective tape …x…-S" self-adhesive series must be affixed

to a flat, clean and grease-free surface. We recommend using a separate metal plate, which

is to be provided on-site.

As described in table 6.1, the reflective tape must be angled.

Reflective tapes on metal

The reflective tapes of the "Reflective tape …x…-M" series are provided with corresponding

mounting holes. Spacer sleeves are provided in the packet for achieving the necessary pitch

angle. For further information see table 6.1.

Heated reflectors

The reflective tapes of the "Reflective tape ...x...-H" series are provided with corresponding

mounting holes. Due to the voltage supply affixed on the rear, the reflector cannot be

mounted flat. Included in the package are four distance sleeves in two different lengths. Use

the distance sleeves to achieve a base separation to the wall as well as the necessary pitch

for avoiding surface reflection. For further information see table 6.1.

The reflector is provided with a 2m-long connection cable for supplying with 230V AC.

Connect the cable to the closest power outlet. Observe the current consumptions listed in

the specifications.

Reflectors

Attention!

Connection work must be carried out by a certified electrician.

6.4.2 Mounting the reflector

The combination of laser measurement system and reflective tape/reflector is mounted so

that the laser light spot hits the tape as centered as possible and without interruption.

For this purpose, use the alignment elements provided on the AMS 355i… (see chapter 5.2

"Mounting the AMS 355i"). If necessary, remove the protective foil from the reflector.

Attention!

The "TOP" label mounted on the reflectors should be aligned the same as the connections

of the AMS 355i.

Example:

If the AMS 355i is mounted so that the M12 connections are on the top, the "TOP" label of

the reflector is also on the top. If the AMS 355i is mounted so that the M12 connections are

on the side, the "TOP" label of the reflector is also on the side.

Leuze electronic AMS 355i 33

TNT 35/7-24V

Page 37

Reflectors

Pitch approx. 1°

Direct reflection from the

triad structure

Deflected surface reflection due to

the pitch of the reflective tape

Pitch approx. 1°

Spacer sleeves

Notice!

The reflector must be angled. To do this, use the spacer sleeves. Angle the reflectors so that

the surface reflections of the foil seal are deflected to the left, right or upwards, chapter

6.4.3 gives the correct pitch with respect to the reflector size and, thus, the length of the

spacers.

Reflective tapes …-S and …-M

Figure 6.3: Reflector mounting

Figure 6.4: Pitch of the reflector

34 AMS 355i Leuze electronic

Page 38

Reflective tapes …-H

Pitch approx. 1°

Deflected surface reflection due to

the pitch of the reflective tape

Direct reflection from the

triad structure

Pitch approx. 1°

Spacer sleeves

Figure 6.5: Mounting of heated reflectors

Reflectors

Figure 6.6: Pitch of the heated reflector

Leuze electronic AMS 355i 35

TNT 35/7-24V

Page 39

Reflectors

6.4.3 Table of reflector pitches

Reflector type Pitch resulting from spacer sleeves

Reflective tape 200x200-S

Reflective tape 200x200-M

Reflective tape 200x200-H 2x15mm 2x20mm

Reflective tape 500x500-S

Reflective tape 500x500-M

Reflective tape 500x500-H 2x15mm 2x25mm

Reflective tape 749x914-S 2x20mm

Reflective tape 914x914-S

Reflective tape 914x914-M

Reflective tape 914x914-H 2x15mm 2x35mm

1) Spacer sleeves are included in the delivery contents of reflective tape …-M and …-H

Table 6.1: Reflector pitch resulting from spacer sleeves

Notice!

Reliable function of the AMS 355i and, thus, max. operating range and accuracy can only

be achieved with the reflective tape specified by Leuze electronic. No function can be guaranteed if other reflectors are used!

2x5mm

2x10mm

2x20mm

1)

36 AMS 355i Leuze electronic

Page 40

7 Electrical connection

BUS IN

M12 connector

(A-coded)

PWR / IOs

M12 connector

(A-coded)

BUS OUT

M12 socket

(A-coded)

1)

Leuze SERVICE

M12 socket

(A-coded)

The AMS 355i laser measurement systems are connected using variously coded M 12

connectors. This ensures unique connection assignments.

Notice!

The corresponding mating connectors and ready-made cables are available as accessories

for all cables. For further information, see chapter 11 "Type overview and accessories".

Figure 7.1: Connections of the AMS 355i

1) After DeviceNet specification (Volume 3: DeviceNet Adaptation of CIP Chapter 8, Physical

Layer 8-3.3 Connectors), use of the BUS OUT connection is not allowed.

Electrical connection

7.1 Safety notices for the electrical connection

Attention!

Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

The device may only be connected by a qualified electrician.

Ensure that the functional earth (FE) is connected correctly. Unimpaired operation is only

guaranteed when the functional earth is connected properly.

If faults cannot be corrected, the device should be removed from operation and protected

against possible use.

Attention!

For UL applications, use is permitted exclusively in Class 2 circuits according to NEC (National Electric Code).

Leuze electronic AMS 355i 37

The laser measurement systems are designed in accordance with safety class III for supply

by PELV (protective extra-low voltage with reliable disconnection).

TNT 35/7-24V

Page 41

Electrical connection

PWR

I/O 2

I/O 1

3

2

1

4

5

GND VIN

FE

M12 plug

(A-coded)

BUS IN

V+

CAN_H

1

4

3

2

5

DRAIN

V-

CAN_L

M12 plug

(A-coded)

Notice!

Protection class IP65 is achieved only if the connectors and caps are screwed into place!

Described in detail in the following are the individual connections and pin assignments.

7.2 PWR – voltage supply / switching input/output

PWR (5-pin plug, A-coded)

Pin Name Remark

1 VIN Positive supply voltage +18 … +30V DC

2 I/O 1 Switching input/output 1

3 GND Negative supply voltage 0VDC

4 I/O 2 Switching input/output 2

5 FE Functional earth

Thread FE Functional earth (housing)

Table 7.1: Pin assignment PWR

Further information on configuring the input/output can be found in chapter 8 and chapter 9.

7.3 DeviceNet BUS IN

BUS IN (5-pin plug, A-coded)

Pin Name Remark

1 Drain Shield

2 V+ Supply voltage data V+

3 V- Supply voltage data V-

4 CAN_H Data signal CAN_H

5 CAN_L Data signal CAN_L

Thread FE Functional earth (housing)

Table 7.2: Pin assignments for DeviceNet BUS IN

38 AMS 355i Leuze electronic

Page 42

7.4 DeviceNet BUS OUT

1

2

3

4

5

BUS OUT

V+

CAN_H

DRAINV-

CAN_L

M12 socket

(A-coded)

SERVICE

1

2

3

4

NC

NC

RS232-RX

RS232-TX

GND

5

M12 socket

(A-coded)

Table 7.3: Pin assignments for DeviceNet BUS OUT

Attention!

After DeviceNet specification (Volume 3: DeviceNet Adaptation of CIP Chapter 8, Physical

Layer 8-3.3 Connectors), use of the BUS OUT connection is not allowed.

7.5 Service

Electrical connection

BUS OUT (5-pin socket, A-coded)

Pin Name Remark

1 Drain Shield

2 V+ Supply voltage data V+

3 V- Supply voltage data V-

4 CAN_H Data signal CAN_H

5 CAN_L Data signal CAN_L

Thread FE Functional earth (housing)

Service (5-pin socket, A-coded)

Pin Name Remark

1 NC Not used

2 RS232-TX Transmission line RS 232/service data

3 GND Voltage supply 0V DC

4 RS232-RX Receiving line RS 232/service data

5 NC Not used

Thread FE Functional earth (housing)

TNT 35/7-24V

Table 7.4: Service pin assignments

Notice!

The service interface is designed only for use by Leuze electronic!

Leuze electronic AMS 355i 39

Page 43

Display and control panel AMS 355i

Status display

Bar graph

LED

Bus/interface info

LED

Control buttons

Distance measurement value

8 Display and control panel AMS 355i

8.1 Structure of the control panel

Figure 8.1: Structure of the control panel using the AMS 304i PROFIBUS device variant as an example

8.2 Status display and operation

8.2.1 Indicators in the display

Status and warning messages in the display

IO1 Input 1 or output 1 active:

Function depending on configuration.

IO2 Input 2 or output 2 active:

Function depending on configuration.

LSR Warning - laser prefailure message:

TMP Warning - temperature monitoring:

40 AMS 355i Leuze electronic

Laser diode old, device still functional, exchange or have repaired.

Permissible internal device temperature exceeded / not met.

Page 44

Display and control panel AMS 355i

MAC ID (bus address)

DNET ID

Maximum position value

IO1 LSR PLB

IO2 TMP ATT DNET

ERR

+ 87.000m

63

PLB Plausibility error:

Implausible measurement value. Possible causes: light beam interruption, outside

of measurement range, permissible internal device temperature considerably

exceeded or traverse rate >10m/s.

Depending on the configuration, either zero or the last valid measurement value is

output at the interfaces.

ATT Warning received signal:

Laser outlet window or reflector soiled or fogged by rain, water vapor or fog. Clean

or dry surfaces.

ERR Internal hardware error:

The device must be sent in for inspection.

Bar graph

Indicates the strength of the received laser light.

The center bar represents the ATT warning threshold. The distance value remains

valid and is output at the interfaces.

If no bar graph is available, the PLB status information appears at the same time.

The measurement value has thus been assessed as being implausible. Depending

on the configuration, either zero or the last valid measurement value is output at the

interfaces.

Interface info

An activated DeviceNet interface is indicated by the presence of MAC ID (bus address) and

the "DNET" ID in the display. If the DeviceNet interface is deactivated, the MAC ID and DNET

ID are hidden from view.

Maximum position value

The measured position value is displayed in the configured unit of measurement.

+87.000m With the metric setting, the measurement value is always displayed in meters

+87.0in With the inch setting, the measurement value is always displayed in inches

Leuze electronic AMS 355i 41

with three decimal places.

with one decimal place.

TNT 35/7-24V

Page 45

Display and control panel AMS 355i

8.2.2 LED status displays

After power ON, a test of the Power LED and Net LED is performed in the following sequence:

1. LEDs off.

2. LEDs are switched to green for approx. 0.25s.

3. LEDs are switched to red for approx. 0.25s.

4. LEDs off.

This is followed by the status display for the power LED (see chapter 9.3) and the Net LED.

PWR LED

Off Device OFF

Flashing green Power LED flashes green

Green continuous light Power LED green

- No supply voltage

- LED function test for 0.25 s after power up

- No measurement value output

- Voltage connected

- Self test running

- Initialization running

- Parameter download running

- Boot process running

- AMS 355i ok

- Measurement value output

- Self test successfully finished

- Device monitoring active

Red flashing Power LED flashes red

- LED function test for 0.25 s after power up

- Device ok but warning message (ATT, TMP, LSR)

set in display

- Light beam interruption

- Plausibility error (PLB)

Red continuous light Power LED red

- No measurement value output; for details, see

Display

Orange continuous light Power LED orange

- Parameter enable active

42 AMS 355i Leuze electronic

Page 46

- No data on the host interface

Net

Net

Net

Net

Net

Net LED

Net

Off Net LED off

- The DUP MAC ID test is active

- No voltage supply

- The V+/V- voltage supply for the DeviceNet data

driver is missing

Flashing green Net LED flashes green

- LED function test for 0.25 s after power up

- DUP MAC ID test ok but no connection to other

addresses can be established

- AMS 355i is not assigned to any master

Green continuous light Net LED green

- AMS 355i bus communication ok

Red flashing Net LED flashes red

- LED function test for 0.25 s after power up

- Time-out in bus communication

Red continuous light Net LED red

- No communication can be established

Display and control panel AMS 355i

Green/red flashing Net LED flashes green/red

-The AMS355i has detected an identity communi-

cation error on the network. Protocol message too

long.

-

8.2.3 Control buttons

Up Navigate upward/laterally.

Down Navigate downward/laterally.

ESC

Leuze electronic AMS 355i 43

ESC Exit menu item.

ENTER Confirm/enter value, change menu levels.

TNT 35/7-24V

Page 47

Display and control panel AMS 355i

Delete character

Enter digit

Save

Navigating within the menus

The menus within a level are selected with the up/down buttons .

The selected menu item is activated with the enter button .

Press the ESC button to move up one menu level.

When one of the buttons is actuated, the display illumination is activated for 10min.

Setting values

If input of a value is possible, the display looks like this:

100

<-|0123456789 save

Default ----------------- unit

126 | |

Use the and buttons to set the desired value. An accidental, incorrect entry can

be corrected by selecting <-| and then pressing .

Then use the buttons to select Save and save the set value by pressing .

Selecting options

If options can be selected, the display looks like this:

o OFF

ON

Default ----------------- unit

OFF | |

ESC

Select the desired option with the buttons. Activate the option by pressing .

8.3 Menu description

8.3.1 The main menus

After voltage has been applied to the laser, device information is displayed for several

seconds. The display then shows the measurement window with all status information.

44 AMS 355i Leuze electronic

Page 48

Display and control panel AMS 355i

63

AMS 355i 120

Leuze electronic

GmbH & Co. KG

SW: V 1.3.0 HW:1

SN: ---------------

Network information

Address: -Baud rate: --- kbit/s

Status: Not powered, ...

IO1 LSR PLB

IO2 TMP ATT DNET

ERR

+ 87.000m

Parameter

Parameter handling

DeviceNet

Maximum position value

I/O

Other

Device information - main menu

This menu item contains detailed information on

• Device model,

• Manufacturer,

• Software and hardware version,

• Serial number.

No entries can be made via the display.

Network information - main menu

• Explanations of address, baud rate, status.

No entries can be made via the display.

Status and measurement data - main menu

• Display of status-, warning-, and error messages

• Status overview of the switching inputs/outputs.

• Bar graph for the reception level.

•Link.

• Measurement value.

No entries can be made via the display.

See "Indicators in the display" on page 40.

Parameter - main menu

• Configuration of the AMS.

See "Parameter menu" on page 46.

Language

selection

o Deutsch

o English

o Español

o Français

Service

Status messages

Diagnostics

Expanded diagnostics

Language selection - main menu

• Selection of the display language.

See "Language selection menu" on page 49.

Service - main menu

• Display of status messages.

• Display of diagnostic data.

No entries can be made via the display.

See "Service menu" on page 49.

TNT 35/7-24V

Notice!

The rear cover of this manual includes a fold-out page with the complete menu structure.

It describes the menu items in brief.

Leuze electronic AMS 355i 45

Page 49

Display and control panel AMS 355i

8.3.2 Parameter menu

Parameter handling submenu

The following functions can be called up in the Parameter handling submenu:

• Lock and enable parameter entry

• Set up a password

• Reset the AMS 355i to default settings.

Table 8.1: Parameter handling submenu

Level 3 Level 4 Level 5 Selection/configuration option

Parameter

enabling

Password Activate

Parameters to

default

password

Password

entry

Description

ON / OFF

The standard setting (OFF) prevents unintended parameter changes.

With parameter enabling activated (ON), the display is inverted. In this

state, it is possible to change parameters manually.

ON / OFF

To enter a password, parameter enabling must be activated.

If a password is assigned, changes to the AMS 355i can only be made

after the password is entered.

The master password 2301 bridges the individually set password.

Configuration option of a four-digit numerical password

By pressing the enter button after selecting

Parameters to default, all parameters are reset to their standard settings without any further security prompts.

In this case, English is selected as the display language.

Standard

OFF

OFF

Additional important information on parameter handling can be found at the end of the

chapter.

DeviceNet submenu

Table 8.2: DeviceNet submenu

Level 3 Level 4 Level 5 Selection/configuration option

Activation ON / OFF ON

Node ID Entry of the device address. 63

Baud rate 125kbit/s / 250kbit/s / 500kbit/s

Description

Selection of the baud rate for serial communication. The baud rate specifies the speed of data transmission. It must be the same at the transmission and reception sides to enable communication.

Standard

125 kbit/s

Position value submenu

Notice!

The parameters named under position value are to be set via the EDS file of the AMS 355i.

If parameters from the position value submenu are changed via the display, these are overwritten via the EDS file stored in the control with the values stored there.

46 AMS 355i Leuze electronic

Page 50

Table 8.3: Position value submenu

Display and control panel AMS 355i

Level 3 Level 4 Level 5 Selection/configuration option

Measurement

unit

Count direction Positive/Negative

Offset Output value=measurement value+offset.

Preset The preset value is accepted by means of teach pulse. The teach pulse

Free resolution

value

Error delay ON / OFF

Position value in

the case of error

Description

Metric/Inch

Specifies the units of the measured distances

Positive: The measurement value begins at 0 and increases with increasing distance.

Negative: The measurement value begins at 0 and decreases with

increasing distance. Negative distance values may need to be compensated with an offset or preset.

The resolution of the offset value is independent of the selected "Resolution position" and is entered in mm or inch/100. The offset value is

effective immediately following entry. If the preset value is activated, this

has priority over the offset. Preset and offset are not offset against each

other.

can be applied to a hardware input of the M12 PWR connector. The hardware input must be appropriately configured. See also configuration of

the I/Os.

The measurement value can be resolved in increments of 1/1000 within

the 5 … 50000 value range. If, e.g., a resolution of 0.875mm per digit

is required, the parameter is set to 875.

Although the parameter can be set via the display, it is overwritten in any

case by the values stored in the EDS file. I.e. it must be changed via the

EDS file.

Specifies whether, in the event of an error, the position value immediately

outputs the value of the "Position value in the case of error" parameter

or the last valid position value for the configured error delay time.

Last valid value / zero

Specifies which position value is output after the error delay time elapses.

I/O submenu

Standard

Metric

Positive

0mm

0mm

1000

ON/100 ms

Zero

Table 8.4: I/O submenu

Level 3 Level 4 Level 5 Selection/configuration option

I/O 1 Port config-

I/O 2 Port config-

uration

Switching

input

Switching

output

uration

Function No function/preset teach/laser ON/OFF No function

Activation Low active/High active Low active

Function Pos. limit value 1 / Pos. limit value 2 / Velocity / Intensity (ATT) /

Activation Low active/High active Low active

Description

Input/Output

Defines whether I/O 1 functions as an output or input.

Temp. (TMP) / Laser (LSR) / Plausibility (PLB) / Hardware (ERR)

The individual functions are "ORed" on the selected switching output.

Input/Output

Defines whether I/O 2 functions as an output or input.

Standard

Output

Plausibility (PLB),

hardware (ERR)

Output

Leuze electronic AMS 355i 47

TNT 35/7-24V

Page 51

Display and control panel AMS 355i

Table 8.4: I/O submenu

Level 3 Level 4 Level 5 Selection/configuration option

Switching

input

Switching

output

Limit values Upper pos.

limit 1

Lower pos.

limit 1

Upper pos.

limit 2

Lower pos.

limit 2

Function No function/preset teach/laser ON/OFF No function

Activation Low active/High active Low active

Function Pos. limit value 1 / Pos. limit value 2 / Velocity / Intensity (ATT) /

Activation Low active/High active Low active

Activation ON / OFF OFF

Limit value

input

Activation ON / OFF OFF

Limit value

input

Activation ON / OFF OFF

Limit value

input

Activation ON / OFF OFF

Limit value

input

Description

Temp. (TMP) / Laser (LSR) / Plausibility (PLB) / Hardware (ERR)

The individual functions are "ORed" on the selected switching output.

Value input in mm or inch/100 0

Value input in mm or inch/100 0

Value input in mm or inch/100 0

Value input in mm or inch/100 0

Other submenu

Table 8.5: Other submenu

Level 3 Level 4 Level 5 Selection/configuration option

Heating control Standard (10°C … 15°C)/Extended (30° C … 35°)

Display illumination

Display contrast Weak/Medium/Strong

Service RS232 Baud rate 57.6kbit/s / 115.2kbit/s

Format 8,e,1 / 8,n,1

Description

Defines a switch-on/switch-off range for the heating control.

The extended switch-on/switch-off range for heating may provide relief

in the event of condensation problems.

There is no guarantee that no condensation will occur on the optics in the

extended switch-on/switch-off range due to the limited heating capacity.

This parameter is available as standard, but functions only for devices

with integrated heating (AMS 355i… H).

10 minutes/ON

Display illumination is switched off after 10 minutes or, if the parameter

is set to "ON", illumination is always on.

The display contrast may change at extreme temperature values. The

contrast can subsequently be adapted using the three levels.

The service interface is only available to Leuze internally.

The service interface is only available to Leuze internally.

Standard

Intensity (ATT),

Tem p. ( TM P),

Laser (LSR)

Standard

Standard

10min.

Medium

115.2kbit/s

8,n,1

48 AMS 355i Leuze electronic

Page 52

8.3.3 Language selection menu

Language

selection

o Deutsch

English

o Español