Page 1

MC3000 Series Drives

Metasys N2 Communications Guide

Page 2

About These Instructions

This documentation applies to the use of an MC3000 Series Variable Frequency Drive with Metasys N2 protocol and

should be used in conjunction with the MC3000 Series Installation and Operation Manual (Document M301) that

shipped with the drive. These documents should be read in their entirety as they contain important technical data

and describe the installation and operation of the drive.

Metasys® is a registered trademark of Johnson Controls, Inc., http://www.johnsoncontrols.com

© 2003 Lenze AC Tech Corporation

No part of this documentation may be copied or made available to third parties without the explicit written approval

of Lenze AC Tech Corporation. All information given in this documentation has been carefully selected and tested

for compliance with the hardware and software described. Nevertheless, discrepancies cannot be ruled out. Lenze

AC Tech does not accept any responsibility nor liability for damages that may occur. Any necessary corrections will

be implemented in subsequent editions.

Page 3

Contents

1 Safety Information .............................................................................................................1

1.1 Warnings, Cautions and Notes ..............................................................................1

1.1.1 General ....................................................................................................1

1.1.2 Application ...............................................................................................1

1.1.3 Installation ...............................................................................................1

1.1.4 Electrical Connection ................................................................................2

1.1.5 Operation .................................................................................................2

2 Introduction .......................................................................................................................3

2.1 Metasys N2 Communications ................................................................................3

2.2 Serial Communications Wiring ..............................................................................3

3 Drive Setup and Programming ...........................................................................................4

3.1 Serial Communication Setup .................................................................................4

3.2 Communication Overrides .....................................................................................5

4 MC3000 N2 Points ............................................................................................................6

4.1 Metasys N2 Point Map ..........................................................................................7

4.2 Analog Input (AI) Point Descriptions .......................................................................8

4.3 Binary Input (BI) Point Descriptions .......................................................................11

4.4 Analog Output (AO) Point Descriptions ...................................................................11

4.5 Binary Output (BO) Point Descriptions ...................................................................13

4.6 Reference and Links .............................................................................................13

i RG-MCMET

Page 4

1 Safety Information

1.1 Warnings, Cautions and Notes

1.1.1 General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live, moving

and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation

creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be

carried out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report

664 or DIN VDE0110 and national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with

the installation, assembly, commissioning, and operation of the product and who have the qualifications

necessary for their occupation.

1.1.2 Application

Safety Information

Drive controllers are components designed for installation in electrical systems or machinery. They are

not to be used as appliances. They are intended exclusively for professional and commercial purposes

according to EN 61000-3-2. The documentation includes information on compliance with EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as directed)

is prohibited until it is proven that the machine complies with the regulations of the EC Directive 98/37/EC

(Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting drive as directed) is only allowed when there is compliance to the EMC Directive

(89/336/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 73/23/EEC. The harmonised

standards of the series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause

radio interference in residential areas. In the case of radio interference, special measures may be

necessary for drive controllers.

1.1.3 Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not

change any insulation distances during transport or handling. Do not touch any electronic components

and contacts. Controllers contain electrostatically sensitive components, which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this might endanger

your health! When installing the drive ensure optimal airflow by observing all clearance distances in the

drive's user manual. Do not expose the drive to excessive: vibration, temperature, humidity, sunlight, dust,

pollutants, corrosive chemicals or other hazardous environments.

1 RG-MCMET

Page 5

Safety Information

1.1.4 Electrical Connection

When working on live drive controllers, applicable national regulations for the prevention of accidents (e.g.

VBG 4) must be observed.

The electrical installation must be carried out in accordance with the appropriate regulations (e.g.

cable cross-sections, fuses, PE connection). Additional information can be obtained from the regulatory

documentation.

The regulatory documentation contains information about installation in compliance with EMC (shielding,

grounding, filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values

demanded by EMC legislation.

1.1.5 Operation

Systems including controllers must be equipped with additional monitoring and protection devices according

to the corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.).

You are allowed to adapt the controller to your application as described in the documentation.

DANGER!

• After the controller has been disconnected from the supply voltage, do not touch the live

components and power connection until the capacitors have discharged. Please observe the

corresponding notes on the controller.

• Do not continuously cycle input power to the controller more than once every three minutes.

• Close all protective covers and doors during operation.

WARNING!

Network control permits automatic starting and stopping of the inverter drive. The system design

must incorporate adequate protection to prevent personnel from accessing moving equipment

while power is applied to the drive system.

Table 1: Pictographs used in these instructions

Pictograph Signal word Meaning Consequences if ignored

DANGER!

WARNING!

STOP!

NOTE

Warning of Hazardous Electrical

Voltage.

Impending or possible danger

for persons

Possible damage to equipment Damage to drive system or its surroundings

Useful tip: If observed, it will

make using the drive easier

Reference to an imminent danger that may

result in death or serious personal injury if the

corresponding measures are not taken.

Death or injury

RG-MCMET 2

Page 6

2 Introduction

This document will explain how to operate a Lenze-AC Tech MC3000 Variable Frequency Drive using

Metasys N2 protocol. It is intended as a serial communications supplement only and will not discuss

normal drive operations. For more information regarding normal drive setup and functionality, refer to the

MC3000 Installation and Operation Manual (M301).

2.1 Metasys N2 Communications

MC3000 drives running N2 protocol act as N2 devices on a Metasys® Network and function as slaves only.

Thus the device communicating with an MC3000 drive must be an N2 master. The communication rate is

9600 bps with 8 data bits, no parity, 1 start bit and 1 stop bit. The bit sequence is as follows:

START 1 2 3 4 5 6 7 8 STOP

2.2 Serial Communications Wiring

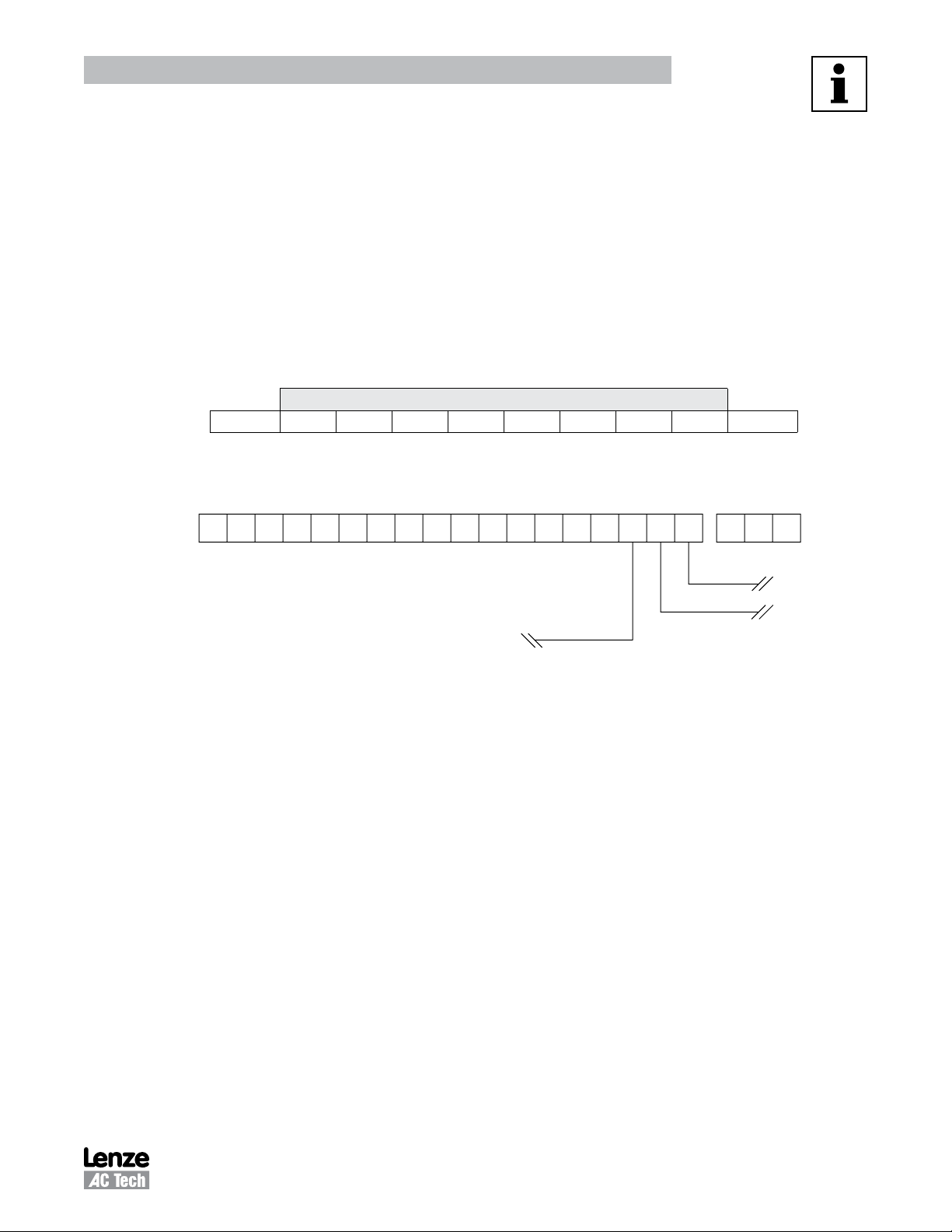

Figure 1 illustrates the MC3000 Series Terminal Strip and connections for the N2 Metasys network.

21 5A 5B 6 10A 10B 2 13A12A 13B 13C 13D 14 15 2 TXBRXA 16 17 18

Introduction

DATA

N2

Reference

Figure 1: MC3000 Terminal Strip

The N2+ terminal is connected to MC3000 drive terminal RXA.

The N2- terminal is connected to MC3000 drive terminal TXB.

The N2 Reference is connected to MC3000 drive terminal 2.

N2+

N2-

3 RG-MCMET

Page 7

Drive Setup & Programming

3 Drive Setup and Programming

Most drive parameters (including those required for serial communications) are not accessible through the

N2 Network. They can only be accessed by entering the Programming Mode of the drive itself. Refer to the

MC3000 Installation and Operation Manual (M301) for more information.

When in Programming Mode, the drive will not accept any write, memorize or characterize commands from

the N2 Network. This is necessary to prevent conflicts between the two modes of parameter modification.

3.1 Serial Communication Setup

The factory default values for all drive parameters are setup to allow immediate serial communications

(without serial start and serial speed/setpoint commands). For serial speed/setpoint and/or serial start

control, modify the setting of Drive Parameter #30 (Control). The drive parameters that are required for

serial communications, including Drive Parameter #30, are described below.

30 CONTROL should be set to accommodate the specific application intent. The action of a

Watchdog timeout depends on the setting of the CONTROL parameter. If the

CONTROL parameter is set for:

− LOCAL : the drive will stop when a serial timeout occurs.

− KEYPAD 2 (LOCAL contol without the need for TB-1 to run): the drive will stop

when a serial timeout occurs.

− REMOTE: serial timeout will not work since the drive cannot be unlocked in

REMOTE mode.

MC3000 drives STOP when a serial timeout occurs. There is no fault for this. Any

time CONTROL is changed from LOCAL to REMOTE the drive STOPS immediately.

The Control Parameter on MC drives (Programming Parameter #30 / AC Tech Register #81) determines

how much control a user has over a drive via the serial link. The Control Parameter must be appropriately

programmed for a particular application. Refer to the MC Series Installation and Operation Manual (M301)

for a detailed explanation on programming the drive parameters.

Table 2: Control (Parameter #30)

MC3000

Setting Description

00 LOCAL (default)

01 REMOTE

02 SERIAL

03 KEYPAD

04 TB STRIP

05 KEYPAD 2

All control options are subject to the Parameter and Control Locking/Unlocking procedures.

RG-MCMET 4

Page 8

Drive Setup & Programming

57 SERIAL Must be set to WITH TIMER (default) or W/O TIMER for the drive to communicate

with the N2 Network. Serial communications will not work if this parameter is set

to DISABLED. The timeout period is fixed at a value of 30 seconds.

58 SERIAL ADDRESS This point contains the address of the N2 Network device. It is adjustable from

1−255. The default address (30) is intended for configuration purposes only.

3.2 Communication Overrides

Overrides are also released under the following circumstances:

• Drive Parameter #57 (Serial) is set to DISABLED.

• Drive Parameter #58 (Serial Address) is changed.

• Drive Parameter #30 (Control) is changed.

• Drive Parameter #65 (Program) is changed to RESET 60 or REST 50 (i.e., a factory reset is

performed) and Drive Parameter #58 (Serial Address) was not previously set to 30. In this case,

serial communications will be terminated immediately.

• Drive Parameter #65 (Program) is changed to RESET 60 or REST 50 (i.e., a factory reset is

performed) and Drive Parameter #30 (Control) was not previously set to NORMAL.

NOTE - Drive Stop unrelated to Serial Communication

The drive will also be brought to a stop if changed from LOCAL to REMOTE or from REMOTE to LOCAL.

5 RG-MCMET

Page 9

N2 Points

4 MC3000 N2 Points

The entries in Table 3 are based upon MC3000 Drive Software Version 213-043 Revision 05 (Parameter

Version 143). If a later revision of software changed parameter definitions or added parameters it could

seriously affect the drive’s operation. This will be identified for a given drive by examining Analog Input

Point 1 (Parameter Version). If it is not 143, writing to any register on the drive MUST NOT BE ATTEMPTED

unless your Controller has been setup to support the new configuration.

NOTE

The Change of State (COS) feature as a means of alarm/warning notification on MC3000

Series Drives has not been implemeted. Upon being polled, the Analog Input points

that can change value will report that a change of state (COS) has occurred. However,

since the alarm limits that have been specified are ignored, the alarm and warning flags

will never be set. As this feature is not implemented, normal Metasys Alarm/Warning

Notification will be defeated. This is generally NOT an issue since none of the Analog

Input Points require alarm limits in standard operation.

If, for some reason, notification for alarms and warnings is required, it will be necessary for the operator

to perform the following:

• Map the specific object requiring COS to a CS object.

• Define an AD or BD object with the CS object of the required COS point as the “Associated In”.

• Assign Alarm Limits to the AD object.

• The AD or BD point will only be scanned at a minimum of 30 seconds

• The normal state of the BO must be updated (written to) by GPL.

Analog/Binary Input points that are mapped in directly that do not support COS will never report a change

of state condition. They will report the current value when read but no alarm notification will occur. A read

will only occur if a focus window is open or a feature requires the current value.

The MC3000 N2 Points are divided into four types: analog input, binary input, analog output and binary

output. Sections 4.2 through 4.5 describe each of these point types and the individual point numbers within

each.

RG-MCMET 6

Page 10

4.1 Metasys N2 Point Map

Table 3: Metasys N2 Point Map for MC3000 Series Drives

Point

Point

1

Type

#

1 1 Parameter Version R -- 0 -- -- 143

1 2 Software Version R -- 0 -- -- 043

1 3 Software Revision R -- 0 -- -- 05

1 4 Drive Config/Size R -- 0 0 57 --

1 5 Drive Class R -- 0 -- -- 65

1 6 Total Runtime (RUNTIME HRS) R hrs 0 0 --

1 7 Total Runtime (RUNTIME MIN) R min 0 0 --

1 8 Operational Status (RUN STATUS) R -- 0 0 10 --

1 9 Load Percent (LOAD PERCENT) R % 0 150 180 180

1 10 Motor Voltage (MOTOR VOLTS) R VAC 0

1 11 Present Fault (FAULT) R -- 0 0 23 0

1 12 Recorded Fault 1 R -- 0 0 23 0

1 13 Recorded Fault 2 R -- 0 0 23 0

1 14 Recorded Fault 3 R -- 0 0 23 0

1 15 Recorded Fault 4 R -- 0 0 23 0

1 16 Recorded Fault 5 R -- 0 0 23 0

1 17 Recorded Fault 6 R -- 0 0 23 0

1 18 Recorded Fault 7 R -- 0 0 23 0

1 19 Recorded Fault 8 R -- 0 0 23 0

1 20 PID Feedback (PID FEEDBACK) R PID 0 Note 3 Note 3 Note 3

1 21 PID Setpoint Command (PID SETPOINT) R PID 0 Note 3 Note 3 Note 3

1 22 Actual Speed (ACTUAL FREQ) R Hz 2 0 12000 --

2 01 Fault Condition (OK.FAULT) R -- 0 OK FLT OK

3 01 Command Speed (COMMAND SPD) R/O Hz 2 0 120.00 20.00

3 02 Keypad Command Speed (CMD KEY SPD) R/O Hz 2 0 120.00 20.00

3 03 Normal Acceleration (ACCEL) R/O sec 1 * 3600.0 30.0

3 04 Normal Deceleration (DECEL) R/O sec 1 * 3600.0 30.0

3 05 Local PID Command R/O PID 0 Note 3 Note 3 Note 3

3 06 Control Mode R/O -- 0

4 01 History R/O -- 0 0 (maintain) 1 (clear) 0

4 02 Start/Stop Drive (CMD RUN.STOP) R/O -- 0 0 (stop) 1 (start) 0

4 03 Speed Control Auto/Manual R/O -- 0 0 (auto) 1 (manual) 0

4 04 Clear Present Fault (CLEAR FAULT) R/O -- 0 0 1 (clear)

Description (Point Name) Read (R)/

Override (R/O)

N2 Points

Point

Units

Decimal

Places

MIN

Value

MAX

Value

Default

Value

2

2

2

NOTES:

1. Point Types: 1 = Analog Input; 2 = Binary Input; 3 = Analog Output; 4 = Binary Output

2. Current Value of the parameter version, software version and software revision.

3. Units, MIN/MAX Values: for this point are defined via Drive Parameters #31, 75 and 76 respectively.

Refer to notes in sections 4.2 and 4.4.

* Refer to MC3000 Installation & Operation Manual (M301)

7 RG-MCMET

Page 11

N2 Points

4.2 Analog Input (AI) Point Descriptions

Point Description

1-01: Parameter Version

The entries in Table 1 are based upon Parameter Version = 143. If a later revision of

software changed parameter definitions or added parameters it could seriously affect the

drive’s operation. This will be identified for a given drive by examining Analog Input Point

1 (1-01) Parameter Version. If it is not 143, writing to any register on the drive MUST NOT

BE ATTEMPTED unless your Controller has been setup to support the new configuration.

1-02: Software Version

This point represents the Software Version for MC3000 Metasys Software in the numerical

format "xxx-xxx". The current software version number is 213-043.

1-03: Software Revision

This point represents the drive’s software revision level in the numerical format "xx". The

current revision status is 05.

1-04: Drive Configuration

This point represents the drive size (Configuration) as listed in the following table:

Drive Config Horsepower Drive Voltage Drive Config Horsepower Drive Voltage

0 0.25 120 V 29 2.00 590/480 VAC

1 0.25 240/200 VAC 30 3.00 590/480 VAC

2 0.50 240/200 VAC 31 5.00 590/480 VAC

3 1.00 240/200 VAC 32 7.50 590/480 VAC

4 1.50 240/200 VAC 33 10.0 590/480 VAC

5 2.00 240/200 VAC 34 15.0 590/480 VAC

6 3.00 240/200 VAC 35 20.0 590/480 VAC

7 5.00 240/200 VAC 36 25.0 590/480 VAC

8 7.50 240/200 VAC 37 30.0 590/480 VAC

9 10.0 240/200 VAC 38 40.0 590/480 VAC

10 15.0 240/200 VAC 39 50.0 590/480 VAC

11 20.0 240/200 VAC 40 60.0 590/480 VAC

12 25.0 240/200 VAC 41 75.0 590/480 VAC

13 50.0 480/400 VAC 42 100.0 590/480 VAC

14 60.0 480/400 VAC 43 125.0 590/480 VAC

15 1.00 480/400 VAC 44 150.0 590/480 VAC

16 1.50 480/400 VAC 45 200.0 590/480 VAC

17 2.00 480/400 VAC 46 75.0 480/400 VAC

18 3.00 480/400 VAC 47 100.0 480/400 VAC

19 5.00 480/400 VAC 48 125.0 480/400 VAC

20 7.50 480/400 VAC 49 150.0 480/400 VAC

21 10.0 480/400 VAC 50 200.0 480/400 VAC

22 15.0 480/400 VAC 51 30.0 240/200 VAC

23 20.0 480/400 VAC 52 40.0 240/200 VAC

24 25.0 480/400 VAC 53 50.0 240/200 VAC

25 30.0 480/400 VAC 54 60.0 240/200 VAC

26 40.0 480/400 VAC 55 75.0 240/200 VAC

27 1.00 590/480 VAC 56 100.0 240/200 VAC

28 1.50 590/480 VAC 57 Unknown Unknown

RG-MCMET 8

Page 12

N2 Points

Point Description

1-05: Drive Class

This point represents the MC series drive class = 65 (41h).

1-06: Total Runtime Hours

This point represents the total accumulated time the drive has run in hours. This value can

be reset to 0 by entering the password 4425 and restoring factory defaults via parameter

65 (PROGRAM).

1-07: Total Runtime Minutes

This point represents the total accumulated time the drive has run in minutes. This

value can be reset to 0 by entering the password 4425 and restoring factory defaults via

parameter 65 (PROGRAM).

1-08: Operational Status

This point is for monitoring the actual operating condition of the drive. The value returned

is a number between 0 and 10 which corresponds to one of the following operating states:

Value Operational State Value Operational State

0 FAULT LOCKOUT 6 RUN

1 FAULT 7 ACCEL

2 START PENDING 8 DECEL

3 STOP 9 CURRENT LIMIT

4 DC BRAKE 10 DECEL OVERRIDE

5 RUN AT 0Hz

1-09: Load %

This point represents the drive load as a percentage of full load. The high limit for this point

is dictated by Parameter 1 (Current Limit). Depending on the setting of Parameter 0 (Line

Volts), the drive is capable of delivering 150% or 180% of its rated output current. This

value can be viewed on the local display by pressing the Enter key once.

1-10: Motor Voltage

This point represents the AC voltage that is currently being sent to the motor. This number

can be viewed on the local display by pressing the Enter key twice.

9 RG-MCMET

Page 13

N2 Points

Point Description

1-11: Present Fault

This point indicates the type of fault on which the drive is currently tripped. This point returns

a value between 0 and 23 which corresponds to one of the following fault conditions:

Value Fault Value Fault

0 NO FAULT 12 POWER SAG

1 OUTPUT FAULT 13 CONTROL FAULT

2 RESERVED 14 LANGUAGE

3 HIGH DC BUS VOLTS 15 EXTERNAL FAULT

4 HIGH DRIVE TEMPERATURE 16 INTERNAL16

5 THERMAL OVERLOAD 17 POWER TRANSIENT

6 RESERVED 18 S/W ERROR #1

7 LOW DC BUS VOLTS 19 S/W ERROR #2

8 RESERVED 20 S/W ERROR #3

9 DC BRAKE ERROR 21 S/W ERROR #4

10 FOLLOWER LOSS 22 S/W ERROR #5

11 DB ERROR 23 GENERAL S/W ERROR

1-12: Recorded Fault 1

This point represents the most recent fault condition that has occurred according to the

same code scheme as for the present fault object. To clear the fault history, refer to Point

4-01 (Clear Fault History)

1-13: Recorded Fault 2

This point represents the 2nd most recent fault condition that has occurred.

1-14: Recorded Fault 3

This point represents the 3rd most recent fault condition that has occurred.

1-15: Recorded Fault 4

This point represents the 4th most recent fault condition that has occurred.

1-16: Recorded Fault 5

This point represents the 5th most recent fault condition that has occurred.

1-17: Recorded Fault 6

This point represents the 6th most recent fault condition that has occurred.

1-18: Recorded Fault 7

This point represents the 7th most recent fault condition that has occurred.

1-19: Recorded Fault 8

This point represents the 8th most recent fault condition that has occurred.

RG-MCMET 10

Page 14

Point Description

1-20: PID Feedback

This point monitors the current state of the PID Feedback. If the drive is running in Local or

Serial Control Mode, the PID Setpoint will be as dictated by Local PID Cmd. If the drive is

running in Remote Control Mode, the Setpoint will come from either analog source TB-5A

or TB-5B. Refer to the MC3000 Installation and Operation Manual (M301) for more details

on PID functionality.

1-21: Command PID Setpoint

This point monitors the current state of the PID Setpoint. If the drive is running in Local or

Serial Control Mode, the PID Setpoint will be as dictated by Local PID Cmd. If the drive is

running in Remote Control Mode, the Setpoint will come from either analog source TB-5A

or TB-5B. Refer to the MC3000 Installation and Operation Manual (M301) for more details

on PID functionality.

1-22: Actual Speed

This point indicates the speed (in Hz) at which the drive is currently running.

4.3 Binary Input (BI) Point Descriptions

N2 Points

Point Description

2-01: Fault Condition

This point indicates whether or not the drive is currently tripped on a fault. This point

returns 0 (OK) if the drive is not in a fault condition or 1 (FAULT) if the drive is currently

faulted.

4.4 Analog Output (AO) Point Descriptions

Point Description

3-01: Command Speed

This point represents the speed at which the drive is being commanded to run. It is

acquired from the currently selected speed source (preset speeds, speed pot, etc. if set to

auto speed control; keypad if set for manual speed control). Overriding this parameter will

force the drive to operate at the override speed until released. Until the point is released,

the drive will ignore any changes in speed induced by the currently selected speed source.

The value of this point is limited by drive Parameters 10 (minimum frequency) and 11

(maximum frequency). Parameter 10 can be set down to 0.00 Hz. Parameter 11 can be set

up to 120.00 Hz.

3-02: Keypad Command Speed

This point represents the command speed as dictated by the keypad. This speed is only

used if the drive is set for MANUAL speed control. Therefore, overriding this parameter will

only have an effect if MANUAL speed control is selected. The value of this point is also

limited by Parameters 10 and 11.

11 RG-MCMET

Page 15

N2 Points

Point Description

3-03: Normal Acceleration

This point sets the time that it will take for the drive to ramp up the motor from 0.0Hz to the

value set in Parameter 18 (Base Frequency). The maximum value for this point is 3600.0

seconds. The minimum value is either 0.1 sec or 0.3 sec depending on the horsepower of

the drive. For the actual minimum boundary, refer to the MC3000 Installation and Operation

Manual (M301).

When this object is overridden, the override value is stored in a temporary variable and

not in the drive’s memory. If this parameter is viewed on the drive itself via program

mode while it is being overridden, the value that is displayed will not reflect the override

value but rather the value that was last stored into the drive’s memory via programming

mode. Example: if the initial value of Parameter 8 (ACCEL), is 30.0 seconds and this object

is overridden to be 15.0 seconds, the serial link will report the 15.0 second value and

the drive response will be based on the 15.0 second value but in programming mode,

Parameter 8 will still display the original value of 30.0 seconds.

3-04: Normal Deceleration

This point sets the time that it will take for the drive to ramp down the motor from the

value set in Parameter 18 (Base Frequency) to 0.0Hz. The maximum value for this point

is 3600.0 seconds. The minimum value is between 0.1 sec and 2.0 sec depending on the

voltage rating and horsepower of the drive as well as the presence of a dynamic brake.

For the actual minimum boundary, refer to the MC3000 Installation and Operation Manual

(M301).

The Normal Deceleration time is only used when Parameter 26 (Stop) is set to RAMP.

When this object is overridden, the override value is stored in a temporary variable and

not into the drive’s memory. If this parameter is viewed on the drive itself via program

mode while it is being overridden, the value that is displayed will not reflect the override

value but rather the value that was last stored into the drive’s memory via programming

mode. Example: if the initial value of Parameter 9 (DECEL) is 30.0 seconds and this object

is overridden to be 15.0 seconds, the serial link will report the 15.0 second value and

the drive response will be based on the 15.0 second value but in programming mode,

Parameter 9 will still display the original value of 30.0 seconds.

3-05: Local PID Command

This point indicates the PID Setpoint that is used when the drive is running in LOCAL or

SERIAL modes. The PID Setpoint is the number that the drive is attempting to match with

the PID Feedback value. Refer to the MC3000 Installation and Operation Manual (M301)

for more details on PID functionality.

RG-MCMET 12

Page 16

Point Description

3-06: Control Mode

This point allows the user to manipulate the control mode in which the drive is running. The

drive powers up and will remain in LOCAL Control Mode until the first override or release

command is sent to it. The drive will then switch to SERIAL Control Mode. This point can be

used to change the control mode back to LOCAL (0) for front panel manipulation. It can also

be used to change the control mode to REMOTE to control the drive from the terminal strip.

If this point is overridden with REMOTE (1), no overrides or releases will be recognized

except for the CONTROL MODE point until the drive is returned to SERIAL control mode. The

release of this parameter will return it to the value specified by Parameter 30 (CONTROL).

4.5 Binary Output (BO) Point Descriptions

Point Description

4-01: Clear Fault History

This history stores the last eight (8) faults that tripped the drive. These are viewable via

Analog Input Points 1-12 through 1-19. This history can be cleared by overriding Binary

Output Point 1 with a one (1). This will reset each of the eight fault blocks to a no fault

status. Once the fault history is cleared, this object will not reset itself to a zero state until

another fault is recorded in the history or until serial control is shut down.

N2 Points

4-02: Start/Stop Drive

Allows the drive to be started and stopped through the serial link. The value of this object

should follow the current run status of the motor. It will reset itself to a zero state if the

drive is stopped, decelerating to a stop or in a fault condition. It will set itself to a set state

if the drive is started locally while serial control is disabled.

4-03: Auto/Manual Select

This object controls the speed source from which the drive receives its command speed.

AUTO If this point is set to Auto (0), then the drive will get its command speed from

the currently selected speed source on the terminal strip (i.e. speed pot, preset

speeds 1 - 4, etc. ...) or from the PID Setpoint if PID Mode is enabled.

MANUAL If this point is set to Manual (1), then the drive’s command speed will come

directly from the keypad. This selection is restricted by Parameter 28 (Keypad

Programming) which has four settings: AUTO, MANUAL, A/M LOC and A/M SPD.

AUTO If parameter 28 is set to AUTO, then the drive can only get its

command speed from the source selected on the terminal strip or

from the PID setpoint.

MANUAL If parameter 28 is set to MANUAL, then the drive can only get its

operating speed from the keypad.

13 RG-MCMET

Page 17

N2 Points

Point Description

4-03: Auto/Manual Select - Contimued

A/M LOC If parameter 28 is set to A/M LOC, then the drive can be set to get its

speed from either an automatic speed source or from the keypad.

When in either Local or Serial Control Mode, this setting allows the

user to change from Auto to Manual or vice versa via the keypad

(when in Local) or the serial link (when in Serial).

A/M SPD If parameter 28 is set to A/M SPD, the drive is forced into AUTO

mode during a transition from LOCAL to REMOTE or from SERIAL

to REMOTE. It forces the drive into MANUAL during the transition

from REMOTE to LOCAL control mode. A/M SPD leaves the Auto/

Man key active at all times enabling the user to toggle their Auto/

Man selection while in REMOTE control mode.

4-04: Clear Present Fault

If the drive is currently in fault, the fault can be cleared by pressing the STOP key on the

keypad. Overriding 4-04 to (1) simulates the pressing of the STOP key via the serial link.

4-04 will reset to (0) whenever the drive enters a fault condition or serial control is shut

down.

4.6 Reference and Links

MC3000 Series Variable Frequency Drives visit:

http://www.lenze-actech.com

Metasys N2 and Johnson Controls, Inc. visit:

http://www.johnsoncontrols.com/publish/us/en/products/building_efficiency/building_

management/metasys.html

RG-MCMET 14

Page 18

Lenze AC Tech Corporation

630 Douglas Street • Uxbridge MA 01569 • USA

Sales: 800-217-9100 •Service: 508-278-9100

www.lenze-actech.com

RG-MCMET-e6

Loading...

Loading...