Page 1

EDSVS9332K

.M)+

Ä.M)+ä

Global Drive

System Manual

9300 0.37 ... 75 kW

EVS9321xK ... EVS9332xK

Servo cam profiler

Page 2

Page 3

Contents i

1 Preface 1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 How to use this System Manual 1.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Information provided by the System Manual 1.1−1. . . . . . . . . . . . .

1.1.2 Products to which the System Manual applies 1.1−3. . . . . . . . . . . .

1.1.3 Document history 1.1−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Legal regulations 1.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Conventions used 1.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 1.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 2.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Thermal motor monitoring 2.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Forced ventilated or naturally ventilated motors 2.2−2. . . . . . . . . .

2.2.2 Self−ventilated motors 2.2−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 2.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Safety instructions for the installation according to UL 2.4−3. . . . . . . . . . . .

3 Technical data 3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 General data and operating conditions 3.1−1. . . . . . . . . . . . . . . . . . . . . . . .

3.2 Open and closed loop control 3.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Rated data 3.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Operation at 400 V 3.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Operation at 480 V 3.3−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Overcurrent operation 3.3−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Current characteristics 3.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSVS9332K EN 8.0−07/2013

i

Page 4

Contentsi

4 Installation of the standard device 4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Standard devices in the power range 0.37 ... 11 kW 4.1−1. . . . . . . . . . . . . . .

4.1.1 Important notes 4.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Mounting with fixing rails (standard) 4.1−2. . . . . . . . . . . . . . . . . . .

4.1.3 Thermally separated mounting (push−through technique) 4.1−3.

4.1.4 Mounting in "cold plate" technique 4.1−4. . . . . . . . . . . . . . . . . . . .

4.2 Standard devices in the power range 15 ... 30 kW 4.2−1. . . . . . . . . . . . . . . . .

4.2.1 Important notes 4.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Mounting with fixing brackets (standard) 4.2−2. . . . . . . . . . . . . . .

4.2.3 Thermally separated mounting (push−through technique) 4.2−3.

4.2.4 Mounting in "cold plate" technique 4.2−4. . . . . . . . . . . . . . . . . . . .

4.3 Standard devices with a power of 45 kW 4.3−1. . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Important notes 4.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Mounting with fixing brackets (standard) 4.3−2. . . . . . . . . . . . . . .

4.3.3 Thermally separated mounting (push−through technique) 4.3−3.

4.3.4 Modification of the fan module for push−through technique 4.3−4

4.4 Standard devices in the power range 55 ... 75 kW 4.4−1. . . . . . . . . . . . . . . . .

4.4.1 Important notes 4.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Mounting with fixing brackets (standard) 4.4−2. . . . . . . . . . . . . . .

4.4.3 Thermally separated mounting (push−through technique) 4.4−3.

ii

EDSVS9332K EN 8.0−07/2013

Page 5

Contents i

5 Wiring of the standard device 5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 5.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Protection of persons 5.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Device protection 5.1−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Motor protection 5.1−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Notes on project planning 5.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Supply forms / electrical supply conditions 5.2−1. . . . . . . . . . . . . .

5.2.2 Operation on public supply systems (EN 61000−3−2) 5.2−1. . . . . . .

5.2.3 Controllers in the IT system 5.2−2. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Operation at earth−leakage circuit breaker (e.l.c.b.) 5.2−3. . . . . . . .

5.2.5 Interaction with compensation equipment 5.2−3. . . . . . . . . . . . . .

5.2.6 Discharge current for mobile systems 5.2−4. . . . . . . . . . . . . . . . . . .

5.2.7 Optimisation of the controller and mains load 5.2−5. . . . . . . . . . .

5.2.8 Reduction of noise emissions 5.2−6. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9 Mains choke/mains filter assignment 5.2−7. . . . . . . . . . . . . . . . . . .

5.2.10 Motor cable 5.2−8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Basics for wiring according to EMC 5.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Shielding 5.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Mains connection, DC supply 5.3−1. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Motor cable 5.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Control cables 5.3−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Installation in the control cabinet 5.3−4. . . . . . . . . . . . . . . . . . . . . .

5.3.6 Wiring outside of the control cabinet 5.3−5. . . . . . . . . . . . . . . . . . .

5.3.7 Detecting and eliminating EMC interferences 5.3−6. . . . . . . . . . . .

5.4 Standard devices in the power range 0.37 ... 11 kW 5.4−1. . . . . . . . . . . . . . .

5.4.1 Wiring according to EMC (CE−typical drive system) 5.4−1. . . . . . . .

5.4.2 Important notes 5.4−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Mains connection, DC supply 5.4−4. . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.4 Mains connection: Fuses and cable cross−sections 5.4−6. . . . . . . .

5.4.5 Mains choke/mains filter assignment 5.4−7. . . . . . . . . . . . . . . . . . .

5.4.6 Motor connection 5.4−8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Standard devices in the power range 15 ... 30 kW 5.5−1. . . . . . . . . . . . . . . . .

5.5.1 Wiring according to EMC (CE−typical drive system) 5.5−1. . . . . . . .

5.5.2 Important notes 5.5−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Mains connection, DC supply 5.5−4. . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.4 Mains connection: Fuses and cable cross−sections 5.5−5. . . . . . . .

5.5.5 Mains choke/mains filter assignment 5.5−6. . . . . . . . . . . . . . . . . . .

5.5.6 Motor connection 5.5−7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSVS9332K EN 8.0−07/2013

iii

Page 6

Contentsi

5.6 Standard devices with a power of 45 kW 5.6−1. . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Wiring according to EMC (CE−typical drive system) 5.6−1. . . . . . . .

5.6.2 Important notes 5.6−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Mains connection, DC supply 5.6−4. . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.4 Mains connection: Fuses and cable cross−sections 5.6−5. . . . . . . .

5.6.5 Mains choke/mains filter assignment 5.6−6. . . . . . . . . . . . . . . . . . .

5.6.6 Motor connection 5.6−7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Standard devices in the power range 55 ... 75 kW 5.7−1. . . . . . . . . . . . . . . . .

5.7.1 Wiring according to EMC (CE−typical drive system) 5.7−1. . . . . . . .

5.7.2 Important notes 5.7−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.3 Mains connection, DC supply 5.7−4. . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.4 Mains connection: Fuses and cable cross−sections 5.7−5. . . . . . . .

5.7.5 Mains choke/mains filter assignment 5.7−6. . . . . . . . . . . . . . . . . . .

5.7.6 Motor connection 5.7−7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Control terminals 5.8−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.1 Important notes 5.8−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.2 Connection terminal of the control card 5.8−3. . . . . . . . . . . . . . . . .

5.8.3 Device variant without "Safe torque off" function 5.8−4. . . . . . . .

5.8.4 Device variant with "Safe torque off" function 5.8−5. . . . . . . . . . .

5.8.5 State bus 5.8−8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.6 Terminal assignment 5.8−9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.7 Technical data 5.8−10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Wiring of the system bus (CAN) 5.9−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Wiring of the feedback system 5.10−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.1 Important notes 5.10−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.2 Resolver at X7 5.10−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.3 Incremental encoder with TTL level at X8 5.10−3. . . . . . . . . . . . . . . .

5.10.4 SinCos encoder at X8 5.10−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 Wiring of digital frequency input / digital frequency output 5.11−1. . . . . . .

5.12 Communication modules 5.12−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

EDSVS9332K EN 8.0−07/2013

Page 7

Contents i

6 Commissioning 6−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 6.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Before switching on 6.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Switch−on sequence 6.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Controller inhibit 6.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Basic settings 6.5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Changing the basic configuration 6.5−1. . . . . . . . . . . . . . . . . . . . . .

6.5.2 Adapting the controller to the mains 6.5−2. . . . . . . . . . . . . . . . . . .

6.5.3 Entry of gearbox factors and feed constants 6.5−3. . . . . . . . . . . . .

6.5.4 Entry of motor data 6.5−5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.5 Motor selection list 6.5−9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.6 Motor temperature monitoring with PTC or thermal contact 6.5−17

6.5.7 Motor temperature monitoring with KTY 6.5−18. . . . . . . . . . . . . . . .

6.6 Setting the speed feedback 6.6−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Resolver at X7 6.6−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Incremental encoder with TTL level at X8 6.6−1. . . . . . . . . . . . . . . .

6.6.3 SinCos encoder at X8 6.6−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Current controller adjustment 6.7−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Adjusting the rotor position 6.8−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Changing the assignment of the control terminals X5 and X6 6.9−1. . . . . .

6.9.1 Free configuration of digital input signals 6.9−1. . . . . . . . . . . . . . .

6.9.2 Free configuration of digital outputs 6.9−2. . . . . . . . . . . . . . . . . . .

6.9.3 Free configuration of analog input signals 6.9−3. . . . . . . . . . . . . . .

6.9.4 Free configuration of analog outputs 6.9−4. . . . . . . . . . . . . . . . . . .

6.10 Generation of motion profiles 6.10−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.1 Important notes 6.10−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.2 Definition of data model 6.10−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.3 Entry of basic motion profile data 6.10−3. . . . . . . . . . . . . . . . . . . . . .

6.10.4 Profile data import 6.10−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.5 Mathematical specification of profiles 6.10−5. . . . . . . . . . . . . . . . . .

6.10.6 Saving of motion profiles 6.10−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.7 Application example − generation of feed profiles 6.10−7. . . . . . . . .

6.11 Transfer of motion profiles 6.11−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.1 Transfer methods 6.11−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.2 Background data field and active data field 6.11−2. . . . . . . . . . . . . .

6.11.3 Transfer of profile data from GDC to the controller 6.11−3. . . . . . . .

6.11.4 Transfer of profile data from the PLC/IPC to the controller 6.11−4. .

6.11.5 Transfer of profile data from the controller to the PLC/IPC 6.11−9. .

6.12 Acceptance of reloaded profile data 6.12−1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSVS9332K EN 8.0−07/2013

v

Page 8

Contentsi

6.13 Activation/deactivation of password protection 6.13−1. . . . . . . . . . . . . . . . . .

6.13.1 Master PIN 6.13−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.13.2 User PIN 6.13−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14 Commissioning examples 6.14−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14.1 Replacement of a mechanical cam 6.14−1. . . . . . . . . . . . . . . . . . . . .

6.14.2 Multi−axis application 6.14−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.15 Handwheel function 6.15−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

EDSVS9332K EN 8.0−07/2013

Page 9

Contents i

7 Parameter setting 7−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Important notes 7.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Parameter setting with the XT EMZ9371BC keypad 7.2−1. . . . . . . . . . . . . . .

7.2.1 General data and operating conditions 7.2−1. . . . . . . . . . . . . . . . .

7.2.2 Installation and commissioning 7.2−2. . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Display elements and function keys 7.2−2. . . . . . . . . . . . . . . . . . . .

7.2.4 Changing and saving parameters 7.2−4. . . . . . . . . . . . . . . . . . . . . .

7.2.5 Loading a parameter set 7.2−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.6 Transferring parameters to other standard devices 7.2−7. . . . . . .

7.2.7 Activating password protection 7.2−9. . . . . . . . . . . . . . . . . . . . . . . .

7.2.8 Diagnostics 7.2−10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.9 Menu structure 7.2−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Configuration 8−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Important notes 8.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Monitoring 8.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Fault responses 8.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Setting of responses 8.2−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Monitoring times for process data input objects 8.2−3. . . . . . . . . .

8.2.4 Maximum speed 8.2−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 Motor 8.2−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.6 Controller current load (I x t monitoring) 8.2−5. . . . . . . . . . . . . . . .

8.2.7 Motor temperature 8.2−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.8 Current load of motor (I2 x t monitoring: OC6, OC8) 8.2−7. . . . . . .

8.2.9 Heatsink temperature 8.2−10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.10 DC−bus voltage 8.2−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.11 External error (EEr) 8.2−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Monitoring functions 8.31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Code table 8.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Selection lists 8.5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Selection list 1: Analog output signals 8.5−1. . . . . . . . . . . . . . . . . .

8.5.2 Selection list 2: Digital output signals 8.5−3. . . . . . . . . . . . . . . . . . .

8.5.3 Selection list 3: Angle signals 8.5−8. . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.4 Selection list 4: Speed signals 8.5−10. . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.5 Selection list 5: Function blocks 8.5−11. . . . . . . . . . . . . . . . . . . . . . . .

8.5.6 Selection list 10: Error messages 8.5−13. . . . . . . . . . . . . . . . . . . . . . .

8.6 Table of attributes 8.6−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSVS9332K EN 8.0−07/2013

vii

Page 10

Contentsi

9 Troubleshooting and fault elimination 9−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Display of operating data, diagnostics 9.1−1. . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Troubleshooting 9.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Status display via controller LEDs 9.2−1. . . . . . . . . . . . . . . . . . . . . .

9.2.2 Fault analysis with the history buffer 9.2−2. . . . . . . . . . . . . . . . . . .

9.2.3 Fault analysis via LECOM status words (C0150/C0155) 9.2−3. . . .

9.3 System error messages 9.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 General error messages 9.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Resetting system error messages 9.3−6. . . . . . . . . . . . . . . . . . . . . . .

9.4 Error messages during profile download 9.4−1. . . . . . . . . . . . . . . . . . . . . . . .

10 DC−bus operation 10−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Function 10.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Conditions for trouble−free DC−bus operation 10.2−1. . . . . . . . . . . . . . . . . . .

10.3 Fuses and cable cross−sections 10.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Distributed supply (several supply points) 10.4−1. . . . . . . . . . . . . . . . . . . . . . .

10.5 Central supply (one supply point) 10.5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Safety engineering 11−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Important notes 11.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Operating mode 11.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Accessories (overview) 12−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Appendix 13−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Safety relay KSR 11.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Wiring 11.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 Functional test 11.5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.1 Important notes 11.5−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.2 Manual safety function check 11.5−2. . . . . . . . . . . . . . . . . . . . . . . . .

11.5.3 Monitoring the safety function with a PLC 11.5−3. . . . . . . . . . . . . . .

12.1 General accessories 12.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Type−specific accessories 12.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Code−oriented transfer mode 13.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Glossary 13.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.1 Terminology and abbreviations used 13.2−1. . . . . . . . . . . . . . . . . . .

13.3 Index 13.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

EDSVS9332K EN 8.0−07/2013

Page 11

1 Preface

Contents

1.1 How to use this System Manual 1.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Information provided by the System Manual 1.1−1. . . . . . . . . . . .

1.1.2 Products to which the System Manual applies 1.1−3. . . . . . . . . . .

1.1.3 Document history 1.1−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Legal regulations 1.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Conventions used 1.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 1.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface and general information

Contents

1

EDSVS9332K EN 8.0−07/2013

1−1

Page 12

Page 13

Preface and general information

Information provided by the System Manual

1.1 How to use this System Manual

1.1.1 Information provided by the System Manual

How to use this System Manual

1

1.1

1.1.1

Target group

Contents

This System Manual is directed at all persons who design, install,

commission and adjust the 9300 servo cam profilers.

Together with the System Manual (Extension), document number

EDSVS9332K−EXT, and the catalogue it forms the project planning basis for

the manufacturer of plants and machinery.

The System Manual is the basis of the 9300 servo cam profiler’s description.

Together with the System Manual (Extension), document number

EDSVS9332K−EXT, it provides a complete System Manual:

ƒ The features and functions are described in detail.

ƒ The parameter setting for typical applications is explained with the

help of examples.

ƒ In case of doubt, the Mounting Instructions supplied with the 9300

servo cam profiler are valid.

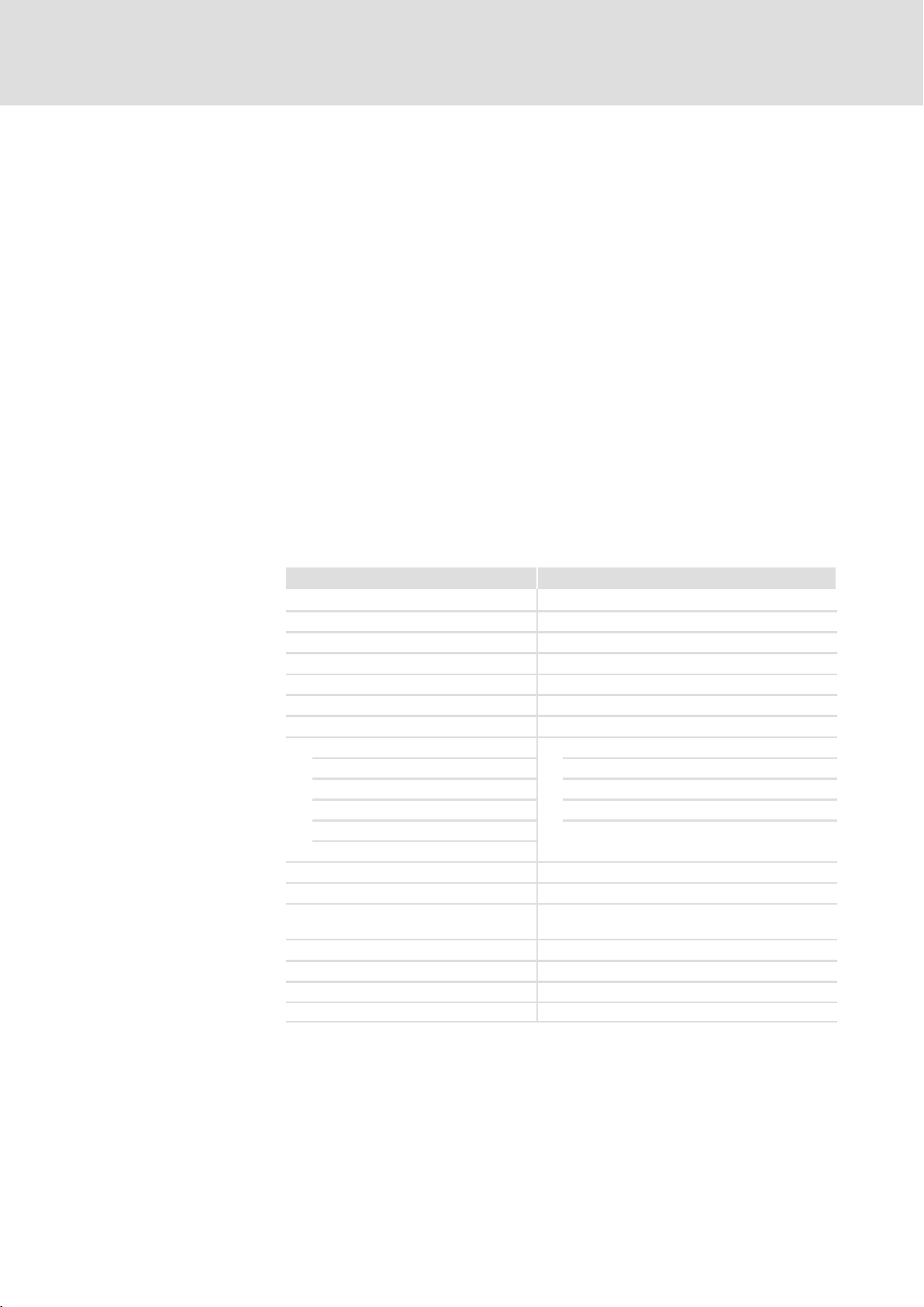

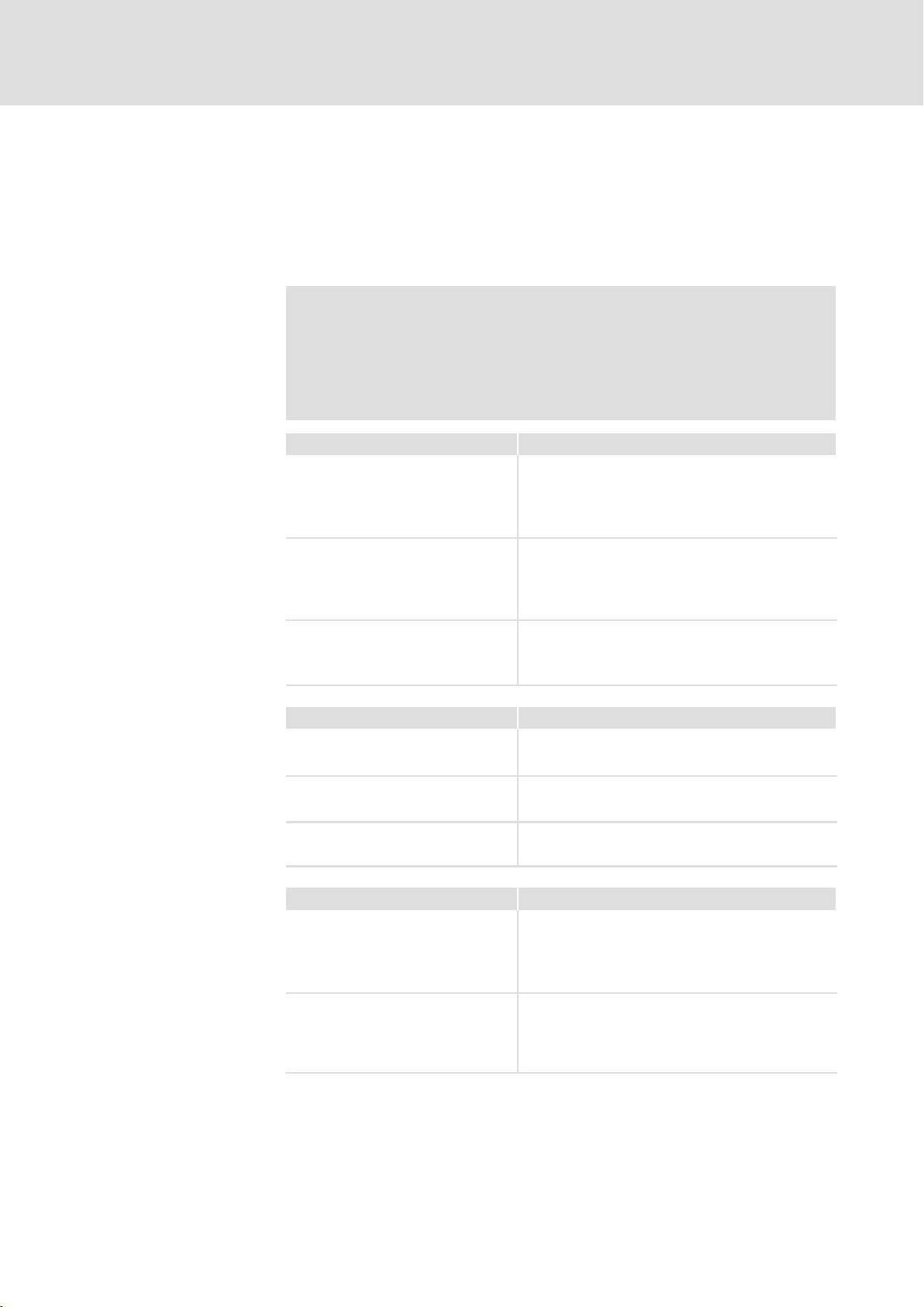

Contents of System Manual Contents of System Manual (Extension)

1 Preface 1 Preface

Safety instructions −

2

3 Technical data −

4 Installation of the standard device −

5 Wiring of the standard device −

6 Commissioning −

7 Parameter setting −

8

Configuration

8.1 Monitoring

8.2 Monitoring functions 2.2 Basic configurations

8.3 Code table 2.3 Operating modes

8.4 Selection lists

8.5 Table of attributes

− 3 Function library

− 4 Application examples

9 Troubleshooting and fault

elimination

10 DC−bus operation −

11 Safe standstill −

12 Accessories −

13 Appendix 5 Appendix

2

Configuration

2.1 Configuring with Global Drive Control

−

EDSVS9332K EN 8.0−07/2013

1.1−1

Page 14

1

1.1

1.1.1

Preface and general information

How to use this System Manual

Information provided by the System Manual

How to find information

Use the System Manual as the basis. It contains references to the

corresponding chapters in the System Manual Supplement:

ƒ Each chapter is a complete unit and comprehensively informs about a

subject.

ƒ The Table of Contents and Index help you to find all information about

a certain topic.

ƒ Descriptions and data of other Lenze products (Drive PLC, Lenze geared

motors, Lenze motors, ...) can be found in the corresponding catalogs,

Operating Instructions and manuals. The required documentation can

be ordered at your Lenze sales partner or downloaded as PDF file from

the Internet.

Tip!

Information and auxiliary devices related to the Lenze products

can be found in the download area at

http://www.Lenze.com

1.1−2

EDSVS9332K EN 8.0−07/2013

Page 15

Preface and general information

How to use this System Manual

Products to which the System Manual applies

1

1.1

1.1.2

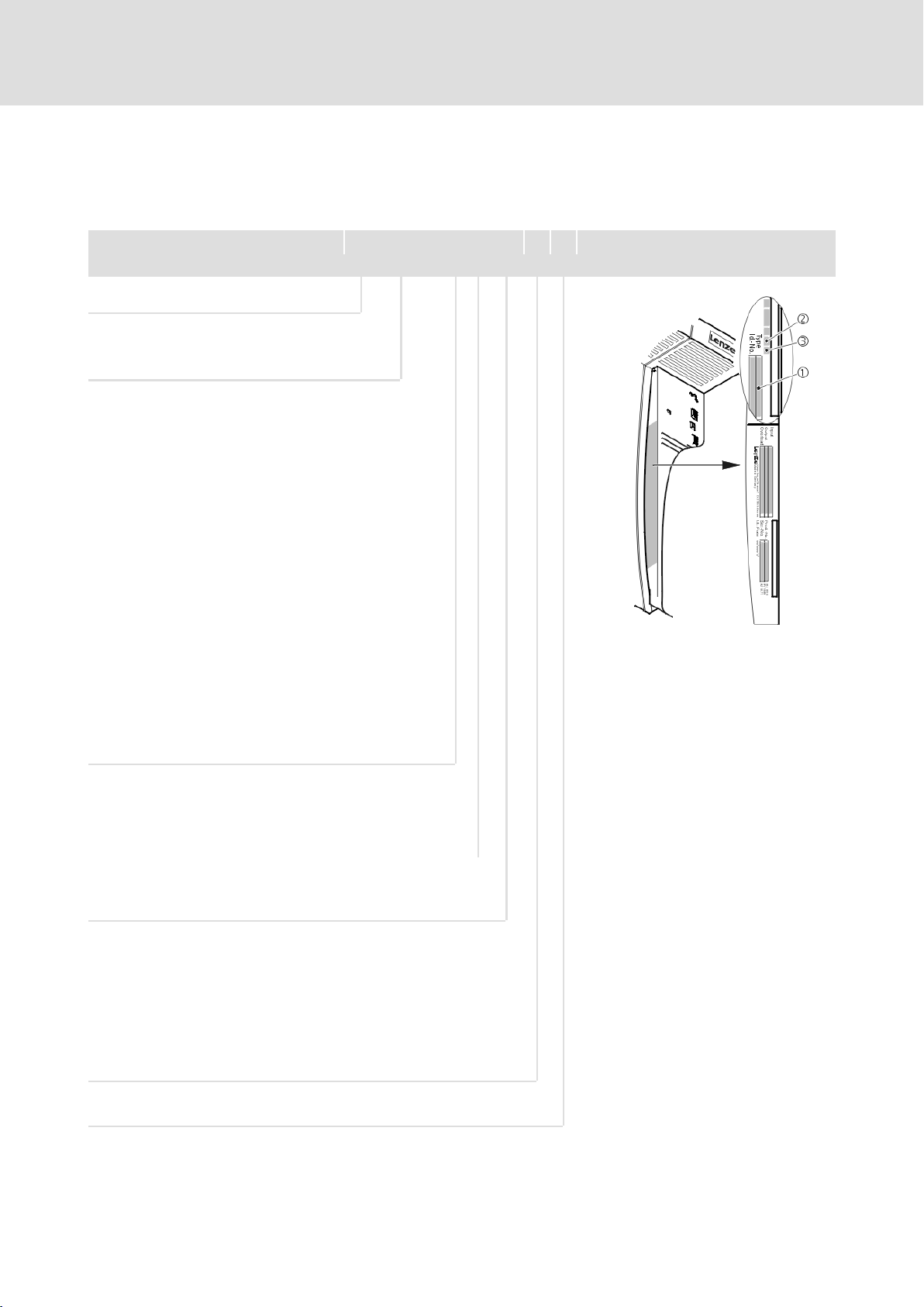

1.1.2 Products to which the System Manual applies

This documentation is valid for 9300 servo cam profilers as of nameplate

data:

Nameplate

EVS 93xx ˘ x x Vxx 1x 8x

Product series

EVS = Servo controller

Type no. / rated power

400 V 480 V

9321 = 0.37 kW 0.37 kW

9322 = 0.75 kW 0.75 kW

9323 = 1.5 kW 1.5 kW

9324 = 3.0 kW 3.0 kW

9325 = 5.5 kW 5.5 kW

9326 = 11 kW 11 kW

9327 = 15 kW 18.5 kW

3928 = 22 kW 30 kW

9329 = 30 kW 37 kW

9330 = 45 kW 45 kW

9331 = 55 kW 55 kW

9332 = 75 kW 90 kW

Type

E = Panel−mounted unit

C = Built−in unit in "cold plate" technique

Design

K = Servo cam profiler

Variant

˘ Standard

V003 = In "cold plate" technique

V004 = With "safe standstill" function

V100 = For IT systems

V104 = With "safe standstill" function and for IT systems

9300vec112

Hardware version

Software version

EDSVS9332K EN 8.0−07/2013

1.1−3

Page 16

1

1.1

1.1.3

Preface and general information

How to use this System Manual

Document history

1.1.3 Document history

What is new / what has

changed?

Material number Version Description

.M)+ 8.0 07/2013 TD06 Error corrections

13375725 7.2 06/2011 TD23 Error corrections

13375725 7.1 06/2011 TD23 Chapter "DC−bus operation" updated due to

13344178 6.1 09/2010 TD23 Error correction

13344178 6.0 07/2010 TD23 Added description about the fan module

13167298 5.0 10/2006 TD23 Revision for software version 4.0

00481341 4.0 02/2004 TD23 Revision for software version 3.4

00453265 3.0 02/2003 TD23 Revision for software version 3.3

00412939 2.0 02/2000 − Revision for software version 2.0

00403216 1.0 09/1998 − First edition

changes of DC fuses

being modified for push−through technique

on the 45 kW device

Information about motor cable

cross−section was updated

Complete editorial revision and fault

correction

Division of the System Manual into 2 parts

(EDSVS9332K and EDSVS9332K−EXT)

Technical data supplemented by

circuit−breaker specifications for EVS9321

and EVS9322

Error correction

Editorial revision and fault correction

Editorial revision

1.1−4

EDSVS9332K EN 8.0−07/2013

Page 17

1.2 Legal regulations

Preface and general information

Legal regulations

1

1.2

Identification

Manufacturer

CE conformity

Application as directed

Lenze controllers are unambiguously identified by the contents of the

nameplate.

Lenze Automation GmbH, Hans−Lenze−Str. 1, D−31855 Aerzen, Germany

In conformity with EC "Low Voltage" Directive

9300 servo controllers and accessories

ƒ may only be operated under the conditions specified in this System

Manual.

ƒ are components

– for open and closed loop control of variable speed drives with PM

synchronous motors, asynchronous standard motors or asynchronous

servo motors.

– for installation in a machine.

– for assembly with other components to form a machine.

ƒ comply with the protection requirements of the EC "Low Voltage"

Directive.

ƒ are not machines for the purpose of the EC "Machinery" Directive.

ƒ are not to be used as domestic appliances, but only for industrial

purposes.

Drive systems with 9300 servo controllers

ƒ comply with the EC "Electromagnetic Compatibility" Directive if they

are installed according to the guidelines of CE−typical drive systems.

ƒ can be used

– for operation on public and non−public mains supplies.

– for operation in industrial premises and residential and commercial

areas.

ƒ The user is responsible for the compliance of the machine application

with the EC Directives.

Any other use shall be deemed inappropriate!

EDSVS9332K EN 8.0−07/2013

1.2−1

Page 18

1

1.2

Preface and general information

Legal regulations

Liability

Warranty

The information, data and notes given in this System Manual met the state

of the art at the time of printing. Claims on modifications referring to

controllers and components which have already been supplied cannot be

derived from the information, illustrations and descriptions contained in

this manual.

The procedural notes and circuit details given in this System Manual are

suggestions and their transferability to the respective application has to be

checked. Lenze does not take any responsibility for the suitability of the

given procedures and circuit suggestions.

The specifications given in this System Manual describe the product features

without guaranteeing them.

Lenze does not accept any liability for damage and malfunctioning caused

by:

ƒ Disregarding the System Manual

ƒ Unauthorised modifications to the controller

ƒ Operating faults

ƒ Improper working on and with the controller

See terms of sales and delivery of Lenze Automation GmbH.

Warranty claims must be made to Lenze immediately after detecting the

deficiency or fault.

The warranty is void in all cases where liability claims cannot be made.

1.2−2

EDSVS9332K EN 8.0−07/2013

Page 19

1.3 Conventions used

This documentation uses the following conventions to distinguish between

different types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator language−depen

Warnings

UL warnings

UR warnings

Text

Program name » « PC software

Icons

Page reference

Documentation reference

Preface and general information

Conventions used

dent

In each case, the signs typical for

the target language are used as

decimal separators.

For example: 1234.56 or 1234,56

Are only given in English.

For example: »Engineer«, »Global

Drive Control« (GDC)

Reference to another page with

additional information

For instance:

Reference to another

documentation with additional

information

For example:

documentation EDKxxx

16 = see page 16

EDKxxx = see

1

1.3

EDSVS9332K EN 8.0−07/2013

1.3−1

Page 20

Page 21

1.4 Notes used

Preface and general information

Notes used

The following pictographs and signal words are used in this documentation

to indicate dangers and important information:

1.4

1

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to

prevent dangerous situations)

Pictograph and signal word Meaning

Danger of personal injury through dangerous

electrical voltage.

Danger!

Danger!

Stop!

Reference to an imminent danger that may result in

death or serious personal injury if the corresponding

measures are not taken.

Danger of personal injury through a general source of

danger.

Reference to an imminent danger that may result in

death or serious personal injury if the corresponding

measures are not taken.

Danger of property damage.

Reference to a possible danger that may result in

property damage if the corresponding measures are

not taken.

Application notes

Special safety instructions

and application notes for UL

and UR

Pictograph and signal word Meaning

Note!

Tip!

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety or application note for the operation of a

UL−approved device in UL−approved systems.

Possibly the drive system is not operated in

compliance with UL if the corresponding measures are

not taken.

Safety or application note for the operation of a

UR−approved device in UL−approved systems.

Possibly the drive system is not operated in

compliance with UL if the corresponding measures are

not taken.

EDSVS9332K EN 8.0−07/2013

1.4−1

Page 22

Page 23

2 Safety instructions

Contents

2.1 General safety information 2.1−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Thermal motor monitoring 2.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Forced ventilated or naturally ventilated motors 2.2−2. . . . . . . . .

2.2.2 Self−ventilated motors 2.2−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 2.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Safety instructions for the installation according to UL 2.4−3. . . . . . . . . . . .

Safety instructions

Contents

2

EDSVS9332K EN 8.0−07/2013

2−1

Page 24

Page 25

2.1 General safety information

Safety instructions

General safety information

2

2.1

Scope

For your own safety

The following general safety instructions apply to all Lenze drive and

automation components.

The product−specific safety and application notes given in this

documentation must be observed!

Note for UL−approved systems: UL warnings are notes which only apply to

UL systems. The documentation contains specific notes with regard to UL.

Danger!

Disregarding the following basic safety measures may lead to

severe personal injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or

rotating parts during or after operation. Surfaces can be hot.

Transport, storage

ƒ All specifications of the corresponding enclosed documentation must

be observed.

This is vital for a safe and trouble−free operation and for achieving the

specified product features.

The procedural notes and circuit details provided in this document are

proposals which the user must check for suitability for his application.

The manufacturer does not accept any liability for the suitability of the

specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze

drive and automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and

operation of the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent

regulations, directives and laws applicable at the place of use.

ƒ Transport and storage in a dry, low−vibration environment without

aggressive atmosphere; preferably in the packaging provided by the

manufacturer.

– Protect against dust and shocks.

– Comply with climatic conditions according to the technical data.

EDSVS9332K EN 8.0−07/2013

2.1−1

Page 26

2

2.1

Safety instructions

General safety information

Mechanical installation

Electrical installation

ƒ Install the product according to the regulations of the corresponding

documentation. In particular observe the section "Operating

conditions" in the chapter "Technical data".

ƒ Provide for a careful handling and avoid mechanical overload. During

handling neither bend components, nor change the insulation

distances.

ƒ The product contains electrostatic sensitive devices which can easily be

damaged by short circuit or static discharge (ESD). Thus, electronic

components and contacts must not be touched unless ESD measures

are taken beforehand.

ƒ Carry out the electrical installation according to the relevant

regulations (e. g. cable cross−sections, fusing, connection to the PE

conductor). Additional notes are included in the documentation.

ƒ When working on live products, observe the applicable national

regulations for the prevention of accidents (e.g. BGV 3).

ƒ The documentation contains information about EMC−compliant

installation (shielding, earthing, arrangement of filters and laying

cables). The system or machine manufacturer is responsible for

compliance with the limit values required by EMC legislation.

Warning: The controllers are products which can be used in category C2

drive systems as per EN 61800−3. These products may cause radio

interference in residential areas. If this happens, the operator may need

to take appropriate action.

ƒ For compliance with the limit values for radio interference emission at

the site of installation, the components − if specified in the technical

data − have to be mounted in housings (e. g. control cabinets). The

housings have to enable an EMC−compliant installation. In particular

observe that for example control cabinet doors preferably have a

circumferential metallic connection to the housing. Reduce openings or

cutouts through the housing to a minimum.

ƒ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

Operation

Safety functions

2.1−2

ƒ If required, you have to equip the system with additional monitoring

and protective devices in accordance with the respective valid safety

regulations (e. g. law on technical equipment, regulations for the

prevention of accidents).

ƒ Before commissioning remove transport locking devices and keep them

for later transports.

ƒ Keep all protective covers and doors closed during operation.

ƒ Without a higher−level safety system, the described product must

neither be used for the protection of machines nor persons.

ƒ Certain controller versions support safety functions (e.g. "Safe torque

off", formerly "Safe standstill").

The notes on the safety functions provided in the documentation of the

versions must be observed.

EDSVS9332K EN 8.0−07/2013

Page 27

Safety instructions

General safety information

2

2.1

Maintenance and servicing

Disposal

ƒ The components are maintenance−free if the required operating

conditions are observed.

ƒ If the cooling air is polluted, the cooling surfaces may be contaminated

or the air vents may be blocked. Under these operating conditions, the

cooling surfaces and air vents must be cleaned at regular intervals.

Never use sharp objects for this purpose!

ƒ Only replace defective fuses in the deenergised state to the type

specified.

ƒ After the system has been disconnected from the supply voltage, live

components and power connections must not be touched immediately

because capacitors may be charged. Please observe the corresponding

notes on the device.

ƒ Recycle metals and plastic materials. Ensure professional disposal of

assembled PCBs.

EDSVS9332K EN 8.0−07/2013

2.1−3

Page 28

Page 29

2.2 Thermal motor monitoring

From software version 8.0 onwards, the 9300 controllers are provided with

2

an I

xt function for sensorless thermal monitoring of the connected motor.

Note!

2

ƒ I

calculates a thermal motor load from the detected motor

currents.

ƒ The calculated motor load is saved when the mains is

switched.

ƒ The function is UL−certified, i.e. no additional protective

measures are required for the motor in UL−approved systems.

ƒ However, I

influences on the motor load could not be detected as for

instance changed cooling conditions (e.g. interrupted or too

warm cooling air flow).

Safety instructions

Thermal motor monitoring

x t monitoring is based on a mathematical model which

2

x t monitoring is no full motor protection as other

2

2.2

2

x t load of the motor is displayed in C0066.

Die I

The thermal loading capacity of the motor is expressed by the thermal motor

time constant (t, C0128). Find the value in the rated motor data or contact

the manufacturer of the motor.

2

The I

x t monitoring has been designed such that it will be activated after

179 s in the event of a motor with a thermal motor time constant of

5 minutes (Lenze setting C0128), a motor current of 1.5 x I

and a trigger

N

threshold of 100 %.

Two adjustable trigger thresholds provide for different responses.

ƒ Adjustable response OC8 (TRIP, warning, off).

– The trigger threshold is set in C0127.

– The response is set in C0606.

– The response OC8, for instance, can be used for an advance warning.

ƒ Fixed response OC6−TRIP.

– The trigger threshold is set in C0120.

Behaviour of the I2 x t monitoring Condition

The I2 x t monitoring is deactivated.

C0066 is set = 0 % and

MCTRL−LOAD−I2XT is set = 0.00 %.

I2 x t monitoring is stopped.

The current value in C0066 and at the

MCTRL−LOAD−I2XT output is frozen.

I2 x t monitoring is deactivated.

The motor load is displayed in C0066.

When C0120 = 0 % and C0127 = 0 %, set

controller inhibit.

When C0120 = 0 % and C0127 = 0 %, set

controller enable.

Set C0606 = 3 (off) and C0127 > 0 %.

EDSVS9332K EN 8.0−07/2013

Note!

An error message OC6 or OC8 can only be reset if the I2 x t load

falls below the set trigger threshold by 5 %.

2.2−1

Page 30

2

2.2

2.2.1

Safety instructions

Thermal motor monitoring

Forced ventilated or naturally ventilated motors

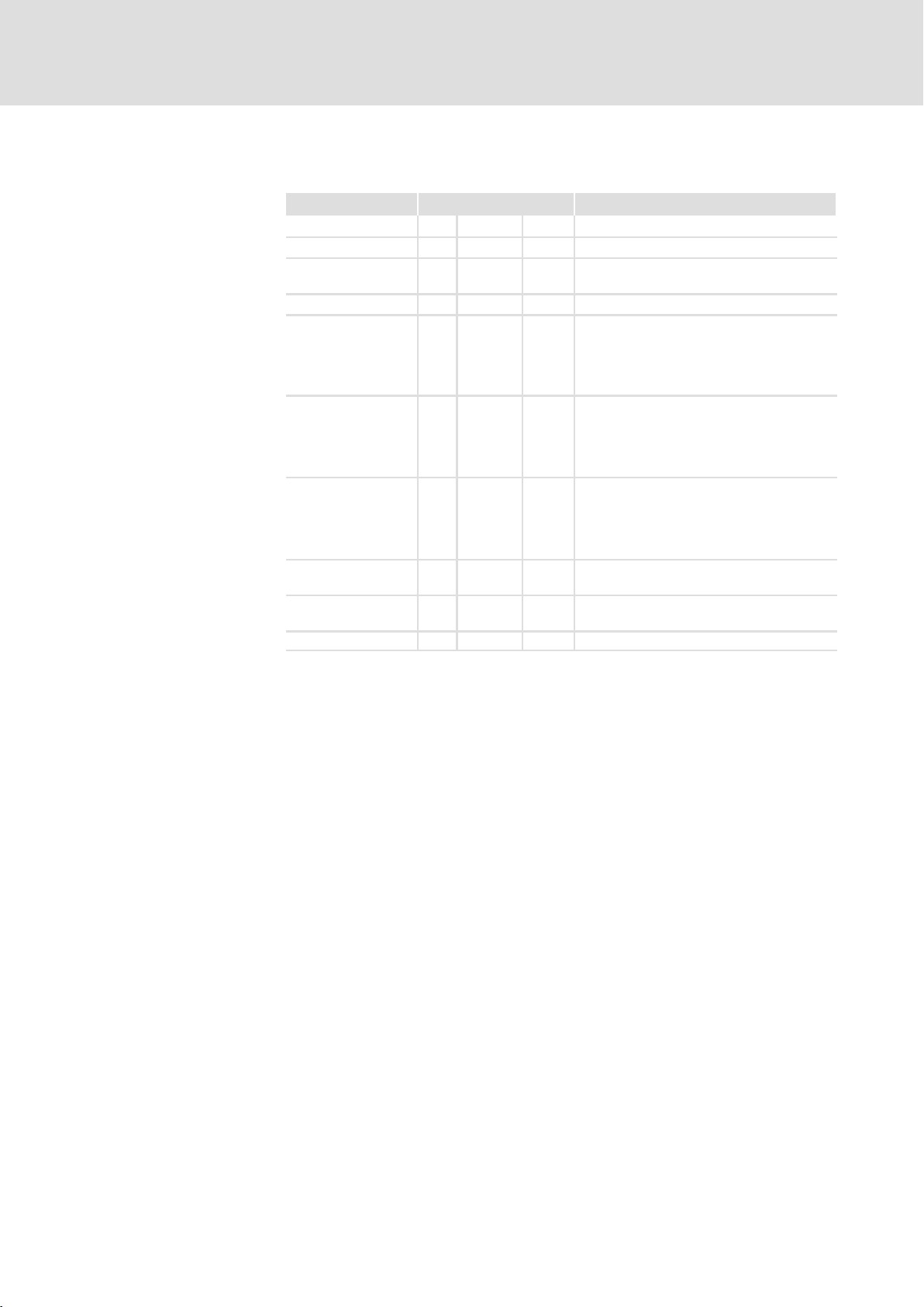

2.2.1 Forced ventilated or naturally ventilated motors

Parameter setting

Calculate release time and

2

xt load

I

The following codes can be set for I

Code Meaning Value range Lenze setting

C0066 Display of the I2 x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

Formula for release time Information

ȡ

t +*(t) ln

ȧ

ȧ

1 *

Ȣ

Formulae for I2 x t load Information

2

I

Mot

ǒ

L(t) +

If the controller is inhibited, the I2 x t load is reduced:

Ǔ

100% ǒ1 * e

I

N

L(t) + L

Start

I

Mot

ǒ

I

N

Ǹ

e

z ) 1

2

Ǔ

100

*

*t

t

t

2

x t monitoring:

I

ȣ

ȧ

ȧ

Ȥ

Ǔ

t

Mot

I

r

t Thermal motor time constant (C0128)

z Threshold value in C0120 (OC6) or

L(t) Chronological sequence of the I2 x t

I

Mot

Ir Rated motor current (C0088)

t Thermal motor time constant (C0128)

L

Actual motor current (C0054)

Rated motor current (C0088)

C0127 (OC8)

load of the motor

(Display: C0066)

Actual motor current (C0054)

I2 x t load before controller inhibit

Start

If an error is triggered, the value

corresponds to the threshold value set

in C0120 (OC6) or

C0127 (OC8).

Read release time in the

diagram

Diagram for detecting the release times for a motor with a thermal motor

time constant of 5 minutes (Lenze setting C0128):

I = 3 × I

L [%]

Mot N

120

100

50

0

0 100 200 300 400 500 600 700 800 900

Fig. 2.2−1 I2 × t−monitoring: Release times for different motor currents and trigger

I = 2 × I

Mot N

thresholds

I

Actual motor current (C0054)

Mot

I

Rated motor current (C0088)

r

2

LI

T Time

x t load of the motor (display: C0066)

I = 1.5 × I

Mot N

I = 1 × I

Mot N

t [s]

1000

9300STD105

2.2−2

EDSVS9332K EN 8.0−07/2013

Page 31

2.2.2 Self−ventilated motors

Due to the construction, self−ventilated standard motors are exposed to an

increased heat generation in the lower speed range compared to forced

ventilated motors.

Warnings!

Safety instructions

Thermal motor monitoring

Self−ventilated motors

For complying with the UL 508C standard, you have to set the

speed−dependent evaluation of the permissible torque via code

C0129/x.

2.2.2

2

2.2

Parameter setting

Effect of code C0129/x

The following codes can be set for I2 x t monitoring:

Code Meaning Value range Lenze setting

C0066 Display of the I2 x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

C0129/1 S1 torque characteristic I1/I

C0129/2 S1 torque characteristics n2/n

I / I

N

1.1

1.0

3

0.9

0.8

0.7

0.6

Fig. 2.2−2 Working point in the range of characteristic lowering

0

0

0 0.1

C0129/1

0.132

C0129/2

1

2

0.2 0.3 0.4

rated

rated

10 ... 200 % 100 %

10 ... 200 % 40 %

n / n

N

9300STD350

EDSVS9332K EN 8.0−07/2013

The lowered speed / torque characteristic (Fig. 2.2−2) reduces the

permissible thermal load of self−ventilated standard motors. The

characteristic is a line the definition of which requires two points:

ƒ Point : Definition with C0129/1

This value also enables an increase of the maximally permissible load.

ƒ Point : Definition with C0129/2

With increasing speeds, the maximally permissible load remains

unchanged (I

Mot

= I

rated

).

In Fig. 2.2−2, the motor speed and the corresponding permissible motor

torque () can be read for each working point (on the

characteristic () ... ). can also be calculated using the values in

C0129/1and C0129/2 (evaluation coefficient "y", 2.2−4).

2.2−3

Page 32

2

2.2

2.2.2

Safety instructions

Thermal motor monitoring

Self−ventilated motors

Calculate release time and

2

I

xt load

Calculate the release time and the I2 x t load of the motor considering the

values in C0129/1 and C0129/2(evaluation coefficient "y").

Formulae for release time Information

T Release time of the I2 x t monitoring

ȡ

I

Mot

ǒ

y I

n

Ǹ

e

z ) 1

2

Ǔ

100

N

n

) C0129ń1

N

t

*

t

T +*(t) ln

ȧ

ȧ

1 *

Ȣ

100% * C0129ń1

y +

Formulae for I2 x t load Information

If the controller is inhibited, the I2 x t load is reduced:

L(t) +

C0129ń2

I

Mot

ǒ

y I

L(t) + L

2

Ǔ

100% ǒ1 * e

N

Start

t Thermal motor time constant (C0128)

ȣ

In Function: Natural logarithm

ȧ

ȧ

I

Mot

Ȥ

I

r

z Threshold value in C0120 (OC6) or

y Evaluation coefficient

n

L(t) Chronological sequence of the I2 x t

y Evaluation coefficient

*t

Ǔ

t

I

Mot

Ir Rated motor current (C0088)

t Thermal motor time constant (C0128)

L

Actual motor current (C0054)

Rated motor current (C0088)

C0127 (OC8)

Rated speed (C0087)

rated

load of the motor

(Display: C0066)

Actual motor current (C0054)

I2 x t load before controller inhibit

Start

If an error is triggered, the value

corresponds to the threshold value set

in C0120 (OC6) or

C0127 (OC8).

2.2−4

EDSVS9332K EN 8.0−07/2013

Page 33

2.3 Residual hazards

Safety instructions

Residual hazards

2

2.3

Protection of persons

ƒ According to their enclosure, Lenze controllers (frequency inverters,

servo inverters, DC speed controllers) and their components can carry a

voltage, or parts of the controllers can move or rotate during operation.

Surfaces can be hot.

– If the required cover is removed, the controllers are used

inappropriately or installed or operated incorrectly, severe damage to

persons or material assets can occur.

– For more detailed information please see the documentation.

ƒ There is a high amount of energy within the controller. Therefore

always wear personal protective equipment (body protection,

headgear, eye protection, ear protection, hand guard) when working on

the controller when it is live.

ƒ Before working on the controller, check if no voltage is applied to the

power terminals.

– the power terminals U, V, W, +UG and −UG still carry dangerous

voltage for at least 3 minutes after power−off.

– the power terminals L1, L2, L3; U, V, W, +UG and −UG carry dangerous

voltage when the motor is stopped.

ƒ Before power−off during DC−bus operation, all controllers must be

inhibited and disconnected from the mains.

ƒ The discharge current to PE potential is > 3.5 mA. In accordance with

EN 61800−5−1

– a fixed installation is required.

– the design of the PE conductor has to be double or, in the case of a

single design, must have a cable cross−section of at least 10 mm

ƒ The controller can only be safely disconnected from the mains via a

contactor on the input side.

ƒ During parameter set transfer the control terminals of the controller

can have undefined states.

– Therefore the connectors X5 and X6 must be disconnected from the

controller before the transfer takes place. This ensures that the

controller is inhibited and all control terminals have the defined state

"LOW".

2

.

EDSVS9332K EN 8.0−07/2013

2.3−1

Page 34

2

2.3

Safety instructions

Residual hazards

ƒ Controllers can cause a DC current in the PE conductor. If a residual

current device (RCD) or a fault current monitoring unit (RCM) is used

for protection in the case of direct or indirect contact, only one

RCD/RCM of the following type can be used on the current supply side:

– Type B for the connection to a three−phase system

– Type A or type B for the connection to a single phase system

Alternatively another protective measure can be used, like for instance

isolation from the environment by means of double or reinforced

insulation, or isolation from the supply system by using a transformer.

Device protection

Motor protection

ƒ Frequent mains switching (e.g. inching mode via mains contactor) can

overload and destroy the input current limitation of the drive

controller:

– At least 3 minutes must pass between switching off and restarting

the devices EVS9321−xK and EVS9322−xK.

– At least 3 minutes must pass between two starting procedures of the

devices EVS9323−xK ... EVS9332−xK.

– Use the "safe torque off" safety function (STO) if safety−related mains

disconnections occur frequently. The drive variants Vxx4 are

equipped with this function.

ƒ For some controller settings, the connected motor may overheat (e.g.

when operating the DC injection brake or a self−ventilated motor at

low speed for longer periods).

– Using an overcurrent relay or a temperature monitoring device

provides a large degree of protection against overload.

– We recommend to use PTC thermistors or thermal contacts for motor

temperature monitoring. (Lenze three−phase AC motors are equipped

with thermal contacts (NC contacts) as standard)

– PTC thermistors or thermal contacts can be connected to the

controller.

2.3−2

ƒ Drives can attain dangerous overspeeds (e.g. setting of high output

frequencies with motors and machines not qualified for this purpose).

EDSVS9332K EN 8.0−07/2013

Page 35

Safety instructions

Safety instructions for the installation according to UL

2

2.4

2.4 Safety instructions for the installation according to UL

Warnings!

ƒ Motor Overload Protection

– For information on the protection level of the internal

overload protection for a motor load, see the corresponding

manuals or software helps.

– If the integral solid state motor overload protection is not

used, external or remote overload protection must be

provided.

ƒ Branch Circuit Protection

– The integral solid state protection does not provide branch

circuit protection.

– Branch circuit protection has to be provided externally in

accordance with corresponding instructions, the National

Electrical Code and any additional codes.

ƒ Please observe the specifications for fuses and

screw−tightening torques in these instructions.

ƒ EVS9321 EVS9326:

– Suitable for use on a circuit capable of delivering not more

than 5000 rms symmetrical amperes, 480 V maximum,

when protected by fuses.

– Suitable for use on a circuit capable of delivering not more

than 50000 rms symmetrical amperes, 480 V maximum,

when protected by CC, J, T or R class fuses.

– Maximum surrounding air temperature: 0 ... +55 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 75 °C copper wire only.

ƒ EVS9327 EVS9329:

– Suitable for use on a circuit capable of delivering not more

than 5000 rms symmetrical amperes, 480 V maximum,

when protected by fuses.

– Suitable for use on a circuit capable of delivering not more

than 50000 rms symmetrical amperes, 480 V maximum,

when protected by J, T or R class fuses.

– Maximum surrounding air temperature: 0 ... +50 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

EDSVS9332K EN 8.0−07/2013

2.4−3

Page 36

2

2.4

Safety instructions

Safety instructions for the installation according to UL

ƒ EVS9330 EVS9332:

– Suitable for use on a circuit capable of delivering not more

than 10000 rms symmetrical amperes, 480 V maximum,

when protected by fuses.

– Suitable for use on a circuit capable of delivering not more

than 50000 rms symmetrical amperes, 480 V maximum,

when protected by J, T or R class fuses.

– Maximum surrounding air temperature: 0 ... +50 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

2.4−4

EDSVS9332K EN 8.0−07/2013

Page 37

3 Technical data

Contents

3.1 General data and operating conditions 3.1−1. . . . . . . . . . . . . . . . . . . . . . . .

3.2 Open and closed loop control 3.2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Rated data 3.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Operation at 400 V 3.3−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Operation at 480 V 3.3−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Overcurrent operation 3.3−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Current characteristics 3.4−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical data

Contents

3

EDSVS9332K EN 8.0−07/2013

3−1

Page 38

Page 39

General data and operating conditions

3.1 General data and operating conditions

Technical data

3

3.1

General data

Conformity and approval

Conformity

CE

Approval

UL cULus Power Conversion Equipment (File No. E132659)

Protection of persons and equipment

Type of protection EN 60529

Earth leakage current IEC/EN 61800−5−1 > 3.5 mA Observe regulations and

Insulation of control

circuits

Insulation resistance IEC/EN 61800−5−1

Protective measures Against short circuit, earth fault (earth−fault

2006/95/EC Low−Voltage Directive

2004/108/EG EMC Directive

IP20

IP41 in case of thermally separated installation

(push−through technique) between the control

cabinet (inside) and the environment.

NEMA 250 Protection against accidental contact in accordance

with type 1

safety instructions!

EN 61800−5−1 Safe mains isolation by double (reinforced)

insulation for terminals X1 and X5.

Basic insulation (single isolating distance) for

terminals X3, X4, X6, X7, X8, X9, X10 and X11.

< 2000 m site altitude: overvoltage category III

> 2000 m site altitude: overvoltage category II

protected during mains connection, limited

earth−fault protection during operation),

overvoltage, motor overtemperature (input for PTC

or thermal contact)

Operating conditions

EMC

Noise emission IEC/EN 61800−3

Interference

immunity

Ambient conditions

Climatic

Storage

Transport IEC/EN 60721−3−2 2K3 (−25 ... +70 °C)

Operation

EVS9321 ...

EVS9326

EVS9327 ...

EVS9332

Pollution EN 61800−5−1 Degree of pollution 2

IEC/EN 61800−3 Category C3

IEC/EN 60721−3−1

IEC/EN 60721−3−3

Cable−guided, up to 10 m motor cable length with

mains filter A: category C2.

Radiation, with mains filter A and installation in

control cabinet: category C2

1K3 (−25 ... +55 °C) < 6 months

1K3 (−25 ... +40 °C) > 6 months

3K3 (0 ... +55 °C)

> +40 °C: reduce the rated output current by

2.5 %/°C.

3K3 (0 ... +50 °C)

> +40 °C: reduce the rated output current by

2.5 %/°C.

> 2 years: anodise DC bus

capacitors

EDSVS9332K EN 8.0−07/2013

3.1−1

Page 40

3

3.1

Technical data

General data and operating conditions

Ambient conditions

Site altitude < 4000 m amsl

Mechanical

Vibration resistance EN 50178

EN 61800−5−1

Germanischer

Lloyd, general

conditions

Electrical

AC−mains

connection

Max. mains

voltage range

Mains frequency 45 Hz − 0 % ... 65 Hz + 0 %

Power system TT,

TN

Power system IT Operation only permitted with the device variants

Operation on

public supply

systems

DC−mains

connection

Max. mains

voltage range

Operating

conditions

Motor connection

Length of the

motor cable

EN 61000−3−2

> 1000 m amsl: reduce the rated output current by

5 %/ 1000 m

Tested according to "General Vibration Stress

Characteristic 1"

320 V − 0 % ... 528 V + 0 %

Operation permitted without restrictions with

earthed neutral.

V024 or V100.

Operation permitted without restrictions with

insulated neutral.

Observe instructions on specific measures!

Limitation of harmonic currents

Total output at the

mains

< 1 kW With mains choke.

> 1 kW Without additional

1)

The additional measures mentioned have the effect that solely

the controllers meet the requirements of EN 61000−3−2. The

machine/system manufacturer is responsible for the compliance

with the requirements for the machine/system!

450 V − 0 % ... 740 V + 0 %

DC voltage must be symmetrical to PE.

The controller will be destroyed when +U

are earthed.

< 50 m

No additional output filters are required at a rated

mains voltage and a switching frequency of 8 kHz.

If EMC requirements have to be met, the

permissible cable length may be affected.

Compliance with the

requirements

measures.

1)

or −U

G

G

3.1−2

Mounting conditions

Mounting place

Mounting position Vertical

Free spaces

Dimensions

Weights

In the control cabinet

4−1

EDSVS9332K EN 8.0−07/2013

Page 41

3.2 Open and closed loop control

Open and closed loopcontrol

Switching frequency 8 kHz or 16 kHz

Digital setpoint

selection

Accuracy ± 0.005 Hz (= ± 100 ppm)

Analog setpoint

selection

Linearity ± 0.15 % Signal level: 5 V or 10 V

Temperature

sensitivity

Offset ± 0.1 %

Analog inputs

Analog outputs

Digital inputs

Digital outputs

Cycle times

Digital inputs 1 ms

Digital outputs 1 ms

Analog inputs 1 ms

Analog outputs 1 ms (smoothing time: t= 2 ms)

± 0.1 % 0 ... 50 °C

l 2 inputs (bipolar)

l 2 outputs (bipolar)

l 5 inputs (freely assignable)

l 1 input for controller inhibit

l 4 outputs (freely assignable)

l 1 resolver input; design: 9−pole Sub−D socket

l 1 incremental encoder input (500 kHz, TTL level); design: 9−pole Sub−D socket (pin)

l 1 digital frequency input (500 kHz, TTL level); design: 9−pole Sub−D socket (pin); can be optionally

used as incremental encoder input (500 kHz, TTL level)

l 1 digital frequency output (500 kHz, TTL level); design: 9−pole Sub−D socket

Technical data

Open and closed loop control

3

3.2

EDSVS9332K EN 8.0−07/2013

3.2−1

Page 42

Page 43

3.3 Rated data

Note!

The controllers EVS9324, EVS9326 and EVS9328 EVS9333 may

only be operated with the prescribed mains chokes and mains

filters.

3.3.1 Operation at 400 V

Basis of the data

Voltage Frequency

AC mains connection [V

DC−mains connection

(alternatively)

Output voltage

With mains choke 3 ~ 0 approx. 94 % V

Without mains choke 3 ~ 0 ... U

rate

]

d

[UDC] DC 450 V − 0 % ... 620 V + 0 % ˘

3/PE AC 320 V − 0 % ... 440 V + 0 %

Technical data

Rated data

Operation at 400 V

45 Hz − 0 % ... 65 Hz + 0 %

rated

N

˘

˘

3

3.3

3.3.1

9300 Mains current

With

mains choke

Type Ir [A] Ir [A] Pr [kW] Pr [hp] S r8 [kVA] PDC [kW] P

EVS9321−xK 1.5 2.1 0.37 0.5 1.0 2.0 100

EVS9322−xK 2.5 3.5 0.75 1.0 1.7 0.75 110

EVS9323−xK 3.9 5.5 1.5 2.0 2.7 2.2 140

EVS9324−xK 7.0 ˘ 3.0 4.0 4.8 0.75 200

EVS9325−xK 12.0 16.8 5.5 7.5 9.0 0 260

EVS9326−xK 20.5 ˘ 11.0 15.0 16.3 0 390

EVS9327−xK 27.0 43.5 15.0 20.0 22.2 10 430

EVS9328−xK 44.0 ˘ 22.0 30.0 32.6 4 640

EVS9329−xK 53.0 ˘ 30.0 40.0 40.9 0 810

EVS9330−xK 78.0 ˘ 45.0 60.0 61.6 5 1100

EVS9331−xK 100 ˘ 55.0 75.0 76.2 0 1470

EVS9332−xK 135 ˘ 75.0 100 100.5 0 1960

1)

Without

mains choke

Bold print = Lenze setting

1)

Mains currents at 8 kHz switching frequency

2)

Switching frequency of the inverter

3)

Power which can additionally be drawn from the DC bus at operation with power−adapted motor

Typical motor power Output power Power loss

ASM

(4−pole)

2)

8 kHz

U, V, W +UG, −UG

3)

V

[W]

EDSVS9332K EN 8.0−07/2013

3.3−1

Page 44

3

3.3

3.3.2

9300 Output currents

Type Ir8 [A] I

EVS9321−xK 1.5 2.25 2.3 1.1 1.65 1.7

EVS9322−xK 2.5 3.75 3.8 1.8 2.7 2.7

EVS9323−xK 3.9 5.85 5.9 2.9 4.35 4.4

EVS9324−xK 7.0 10.5 10.5 5.2 7.8 7.8

EVS9325−xK 13.0 19.5 19.5 9.7 14.6 14.6

EVS9326−xK 23.5 35.3 23.5 15.3 23.0 15.3

EVS9327−xK 32.0 48.0 32.0 20.8 31.2 20.8

EVS9328−xK 47.0 70.5 47.0 30.6 45.9 30.6

EVS9329−xK 59.0 88.5 52.0 38.0 57.0 33.0

EVS9330−xK 89.0 133.5 80.0 58.0 87.0 45.0

EVS9331−xK 110 165 110 70.0 105 70.0

EVS9332−xK 145 21.5 126 90.0 135 72.0

Technical data

Rated data

Operation at 480 V

8 kHz

Rated current Maximum

current

[A] I08 [A] I

M8

Bold print = Lenze setting

1)

Switching frequency of the inverter

2)

The currents apply to a periodic load change cycle with max. 1 minute overcurrent duration and 2

minutes base load duration at max. 75 % I

1)

Standstill current Rated current Maximum

2)

[A] I

r16

r

1)

16 kHz

2)

current

[A] I

M16

Standstill current

016

[A]

3.3.2 Operation at 480 V

Basis of the data

Supply

3/PE 480 V AC [Ur] 320 V − 0 % ... 528 V + 0 % 45 Hz − 0 % ... 65 Hz + 0 %

DC 678 V (alternatively) [UDC] 460 V − 0 % ... 740 V + 0 % ˘

Output voltage

With mains choke 3 ~ 0 ... approx. 94 % U

Without mains choke 3 ~ 0 ... U

Voltage Frequency

r

r

˘

˘

3.3−2

EDSVS9332K EN 8.0−07/2013

Page 45

Technical data

Rated data

Operation at 480 V

3

3.3

3.3.2

9300 Mains current

With

mains choke

Type Ir [A] Ir [A] Pr [kW] Pr [hp] S r8 [kVA] PDC [kW] P

EVS9321−xK 1.5 2.1 0.37 0.5 1.2 2.0 100

EVS9322−xK 2.5 3.5 0.75 1.0 2.1 0.75 110

EVS9323−xK 3.9 5.5 1.5 2.0 3.2 2.2 140

EVS9324−xK 7.0 ˘ 3.0 4.0 5.8 0.75 200

EVS9325−xK 12.0 16.8 5.5 7.5 10.8 0 260

EVS9326−xK 20.5 ˘ 11.0 15.0 18.5 0 390

EVS9327−xK 27.0 43.5 18.5 25.0 25.0 12 430

EVS9328−xK 44.0 ˘ 30.0 40.0 37.0 4.8 640

EVS9329−xK 53.0 ˘ 37.0 50.0 46.6 0 810

EVS9330−xK 78.0 ˘ 45.0 60.0 69.8 6 1100

EVS9331−xK 100 ˘ 55.0 75.0 87.3 0 1470

EVS9332−xK 135 ˘ 90.0 125 104 6 1960

9300 Output currents

Rated current Maximum

Type Ir8 [A] I

EVS9321−xK 1.5 2.25 2.3 1.1 1.65 1.7

EVS9322−xK 2.5 3.75 3.8 1.8 2.7 2.7

EVS9323−xK 3.9 5.85 5.9 2.9 4.35 4.4

EVS9324−xK 7.0 10.5 10.5 5.2 7.8 7.8

EVS9325−xK 13.0 19.5 19.5 9.7 14.6 14.6

EVS9326−xK 22.3 33.5 22.3 14.5 21.8 14.5

EVS9327−xK 30.4 45.6 30.4 19.2 28.8 19.2

EVS9328−xK 44.7 67.1 44.7 28.2 42.3 28.2

EVS9329−xK 56.0 84.0 49.0 35.0 52.5 25.0

EVS9330−xK 84.0 126 72.0 55.0 82.5 36.0

EVS9331−xK 105 157.5 105 65.0 97.5 58.0

EVS9332−xK 125 187.5 111 80.0 120 58.0

1)

Without

mains choke

Bold print = Lenze setting

1)

Mains currents at 8 kHz switching frequency

2)

Switching frequency of the inverter

3)

Power which can additionally be drawn from the DC bus at operation with power−adapted motor

8 kHz

current

M8

Bold print = Lenze setting

1)

Switching frequency of the inverter

2)

The currents apply to a periodic load change cycle with max. 1 minute overcurrent duration and 2

minutes base load duration at max. 75 % I

Typical motor power Output power Power loss

ASM

(4−pole)

1)

Standstill current Rated current Maximum

2)

[A] I08 [A] I

r16

r

2)

8 kHz

U, V, W +UG, −UG

16 kHz

current

[A] I

[A] I

M16

3)

1)

2)

Standstill current

V

016

[W]

[A]

EDSVS9332K EN 8.0−07/2013

3.3−3

Page 46

3

3.3

3.3.3

Technical data

Rated data

Overcurrent operation

3.3.3 Overcurrent operation

Under the operating conditions described here, the

EVS9321−xK ... EVS9324−xK controllers can supply a rated output current

which is up to twice as high.

Note!

If you enter values > 1.5 × rated output current under C0022, the

controller switches to overcurrent operation.

ƒ Switching between overcurrent operation and standard

operation is only possible if the controller is inhibited

(X5/28 = LOW).

ƒ The continuous current is automatically reduced to 70 % of

the rated output current.

3.3.3.1 Operation at 400 V

Basis of the data

Voltage Frequency

AC mains connection [V

DC−mains connection

(alternatively)

Output voltage

With mains choke 3 ~ 0 approx. 94 % V

Without mains choke 3 ~ 0 ... U

rate

]

d

[UDC] DC 450 V − 0 % ... 620 V + 0 % ˘

9300 Mains current

With

mains choke

Type Ir [A] Ir [A] Pr [kW] Pr [hp] S r8 [kVA] PDC [kW] P

EVS9321−xK 1.5 2.1 0.37 0.5 1.0 2.0 100

EVS9322−xK 2.5 3.5 0.75 1.0 1.7 0.75 110

EVS9323−xK 3.9 5.5 1.5 2.0 2.7 2.2 140

EVS9324−xK 7.0 ˘ 3.0 4.0 4.8 0.75 200

1)

Without

mains choke

Bold print = Lenze setting

1)

2)

3)

3/PE AC 320 V − 0 % ... 440 V + 0 %

rated

N

Typical motor power Output power Power loss

ASM

(4−pole)

Mains currents at 8 kHz switching frequency

Switching frequency of the inverter

Power which can additionally be drawn from the DC bus at operation with power−adapted motor

8 kHz

U, V, W +UG, −UG

45 Hz − 0 % ... 65 Hz + 0 %

˘

˘

2)

3)

V

[W]

3.3−4

EDSVS9332K EN 8.0−07/2013

Page 47

Technical data

Rated data

Overcurrent operation

9300 Output currents

1)

8 kHz

Rated current Continuous

thermal

current

Type Ir8 [A] Ir8 [A] I

3)

Maximum

current

M8

Standstill

2)

current

[A] I08 [A] I

Rated current Continuous

thermal

current

[A] I

r16

[A] I

r16

EVS9321−xK 1.5 1.05 3.0 3.0 1.1 0.77 2.2 2.2

EVS9322−xK 2.5 1.75 5.0 5.0 1.8 1.26 3.6 3.6

EVS9323−xK 3.9 2.73 7.8 7.8 2.9 2.03 5.8 5.8

EVS9324−xK 7.0 4.9 14.0 14.0 5.2 3.64 10.4 10.4

1)

Switching frequency of the inverter

2)

The currents apply to a periodic load change cycle with max. 10 seconds overcurrent duration and

50 seconds base load duration at max. 44 % of the rated current

3)

70 % of the rated current

3.3.3.2 Operation at 480 V

Basis of the data

Voltage Frequency

Supply

3/PE 480 V AC [Ur] 320 V − 0 % ... 528 V + 0 % 45 Hz − 0 % ... 65 Hz + 0 %

DC 678 V (alternatively) [UDC] 460 V − 0 % ... 740 V + 0 % ˘

Output voltage

With mains choke 3 ~ 0 ... approx. 94 % U

Without mains choke 3 ~ 0 ... U

r

r

16 kHz

3)

1)

Maximum

current

M16

˘

˘

2)

[A] I

Standstill

current

016

3

3.3

3.3.3

[A]

9300 Mains current

With

mains choke

Type Ir [A] Ir [A] Pr [kW] Pr [hp] S r8 [kVA] PDC [kW] P

1)

Without

mains choke

Typical motor power Output power Power loss

ASM

(4−pole)

2)

8 kHz

U, V, W +UG, −UG

3)

[W]

V

EVS9321−xK 1.5 2.1 0.37 0.5 1.2 2.0 100

EVS9322−xK 2.5 3.5 0.75 1.0 2.1 0.75 110

EVS9323−xK 3.9 5.5 1.5 2.0 3.2 2.2 140

EVS9324−xK 7.0 ˘ 3.0 4.0 5.8 0.75 200

Bold print = Lenze setting

1)

Mains currents at 8 kHz switching frequency

2)

Switching frequency of the inverter

3)

Power which can additionally be drawn from the DC bus at operation with power−adapted motor

9300 Output currents

1)

8 kHz

Rated current Continuous

thermal

current

Maximum

3)

Type Ir8 [A] Ir8 [A] I

current

[A] I08 [A] I

M8

current

Standstill

2)

Rated current Continuous

thermal

current

[A] I

r16

[A] I

r16

16 kHz

3)

1)

Maximum

current

M16

2)

[A] I

Standstill

current

016

EVS9321−xK 1.5 1.05 3.0 3.0 1.1 0.77 2.2 2.2

EVS9322−xK 2.5 1.75 5.0 5.0 1.8 1.26 3.6 3.6

EVS9323−xK 3.9 2.73 7.8 7.8 2.9 2.03 5.8 5.8

EVS9324−xK 7.0 4.9 14.0 14.0 5.2 3.64 10.4 10.4

1)

Switching frequency of the inverter

2)

The currents apply to a periodic load change cycle with max. 10 seconds overcurrent duration and

50 seconds base load duration at max. 44 % of the rated current

3)

70 % of the rated current

[A]

EDSVS9332K EN 8.0−07/2013

3.3−5

Page 48

Page 49

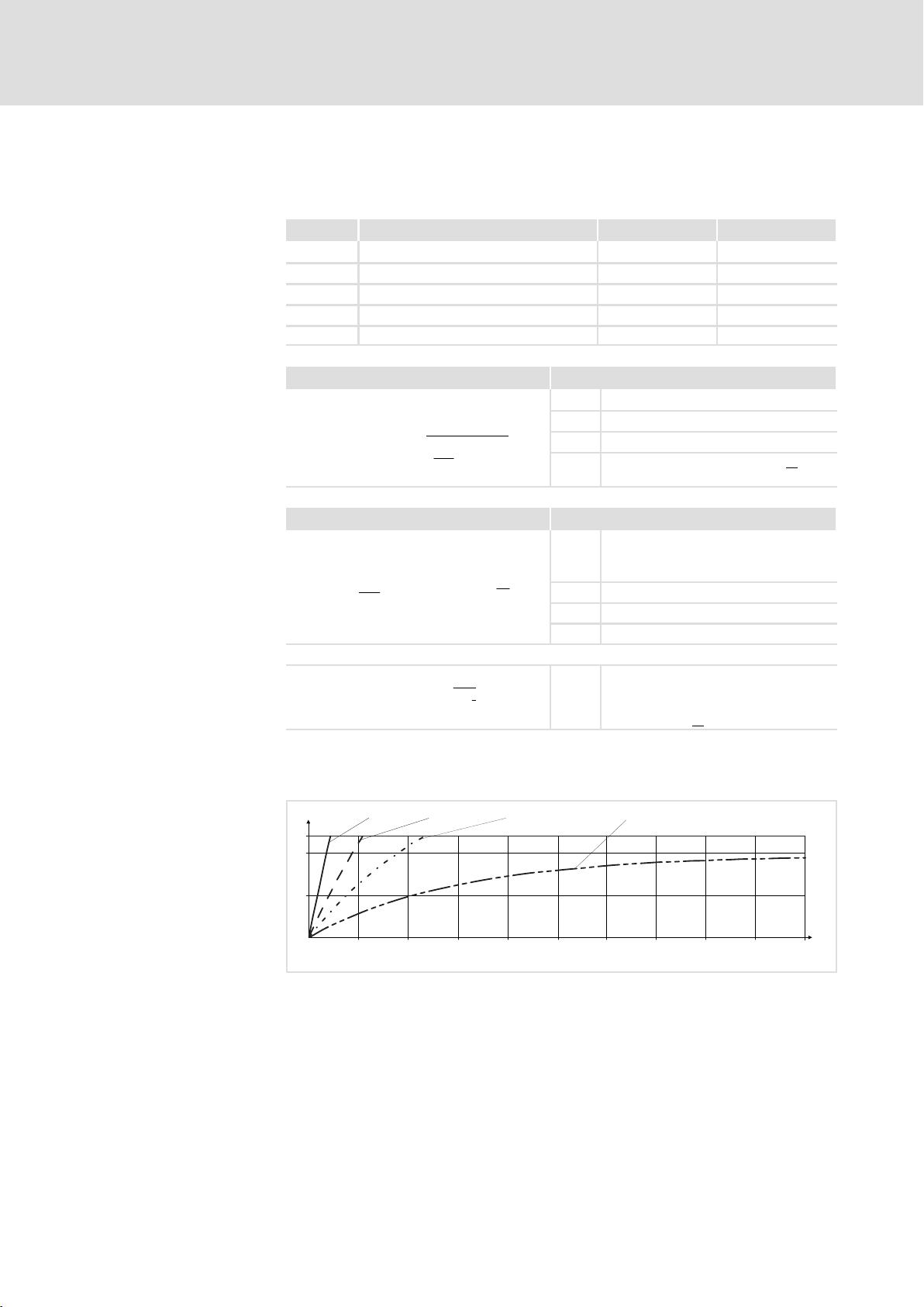

3.4 Current characteristics

The maximum output current of the EVS9326 ... EVS9332 devices is limited

under certain operating conditions:

Technical data

Current characteristics

3

3.4

ƒ At output frequencies f

> 40° C.

J

K

< |5 Hz| and heatsink temperatures

out

ƒ The current limitation depends on the switching frequency.

01

I

OUT

I

max

I

0max

00

0055

<40°C

K

=80°C

K

fout [Hz] fout [Hz]

Fig. 3.4−1 Current derating characteristics