Page 1

EDKVF93−02

.MUw

Ä.MUwä

Global Drive

Information for the operator of the machine

9300 vector 15 ... 30 kW

EVS9327−xV ... EVS9329−xV

Frequency inverter

Page 2

9300vec155

Page 3

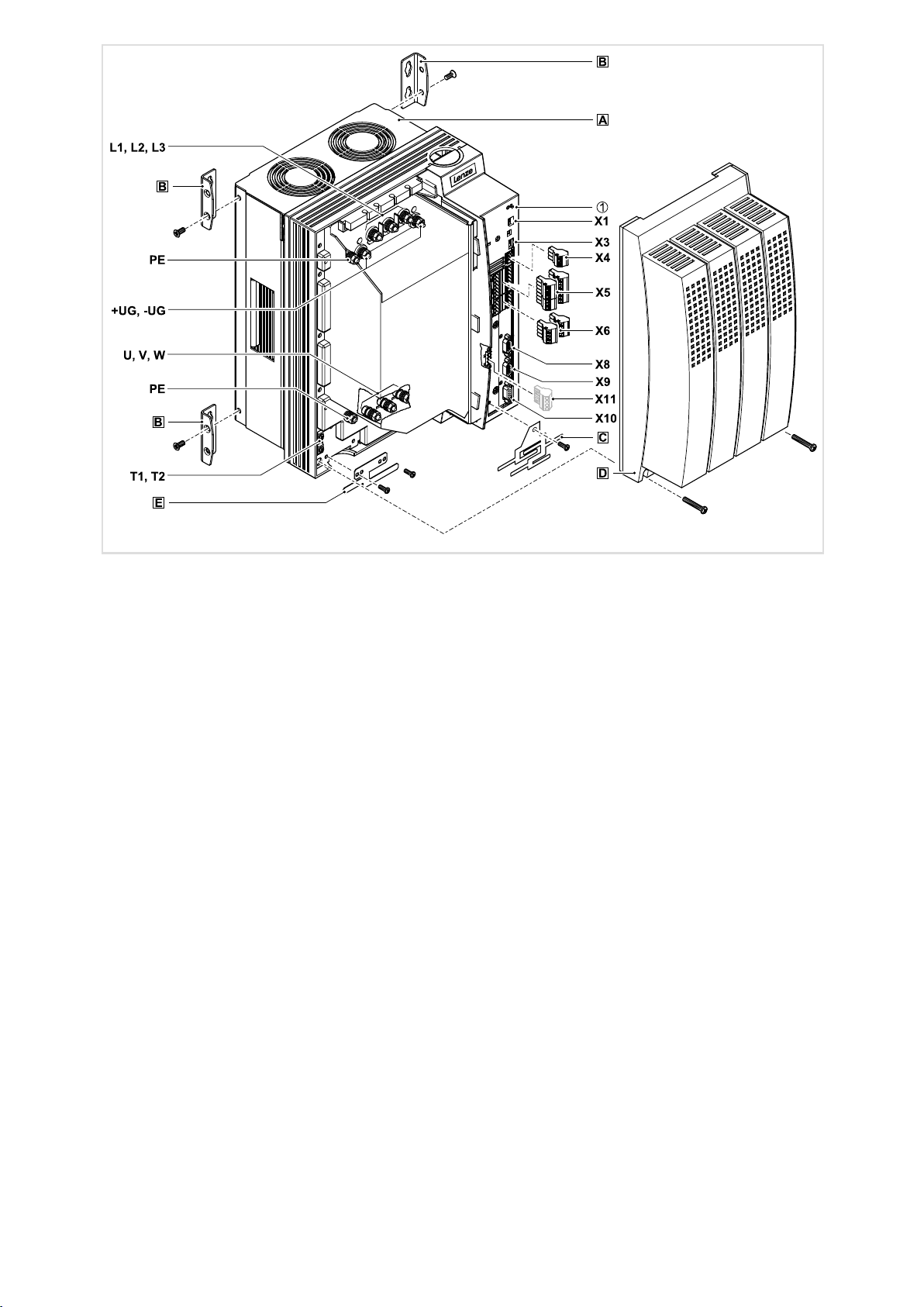

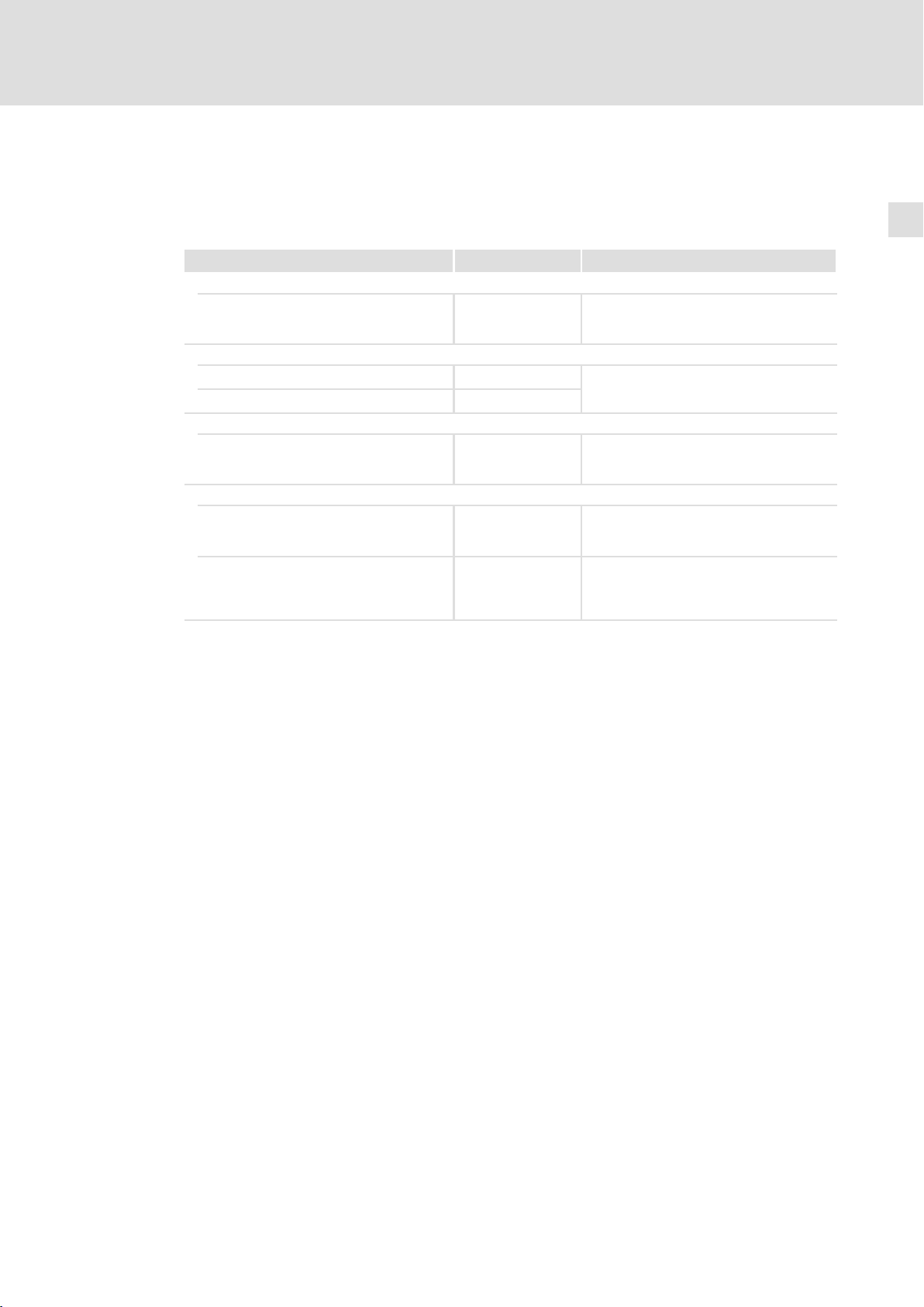

Key for overview

Position Description

Controller

Fixing bracket for standard mounting

EMC shield sheet with fixing screws for shielded control cables

Cover with fixing screws

EMC shield sheet for the motor cable and the feed cable for the motor temperature monitoring with PTC ther-

mistor or thermal contact (NC contact)

Interfaces and displays

Position Description

L1, L2, L3, PE Mains connection

+UG, −UG DC supply

U, V, W, PE Motor connection

T1, T2 Connection of PTC thermistor or thermal contact (NC contact) of the motor

X1 AIF interface (automation interface)

Slot for communication module (e. g. XT EMZ9371BC keypad)

X3 Jumper for setting analog input signal at X6/1, X6/2

X4 System bus (CAN) connection

X5 Connection of digital inputs and outputs

X6 Connection of analog inputs and outputs

X8 Connection of incremental encoder with TTL level or SinCos encoder and KTY temperature sensor of the motor

X9 Connection of digital frequency input signal

X10 Connection of digital frequency output signal

X11 Connection of KSR relay output for "safe standstill" (for variants V004 and V024 only)

Status displays

Position LED red LED green Operating status

Off On Controller is enabled

On On Mains is switched on and automatic start is inhibited

Off Blinking slowly Controller is inhibited

Off On Motor data identification is active

Blinking quickly Off Undervoltage or overvoltage

Blinking slowly Off Active fault

0Fig. 0Tab. 0

Page 4

Contentsi

1 About this documentation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Validity information 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Conventions used 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Notes used 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety and application notes for Lenze controllers 9. . . . . . . . . . . . . . . . . .

2.2 Thermal motor monitoring 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Forced ventilated or naturally ventilated motors 13. . . . . . . . . . . . . . . . . . .

2.2.2 Self−ventilated motors 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Safety instructions for the installation according to UL 18. . . . . . . . . . . . . . . . . . . . .

3 Parameter setting 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Parameter setting with the XT EMZ9371BC keypad 20. . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 General data and operating conditions 20. . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Installation and commissioning 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Display elements and function keys 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Troubleshooting and fault elimination 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Changing and saving parameters 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5 Loading a parameter set 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6 Transferring parameters to other standard devices 26. . . . . . . . . . . . . . . . .

3.1.7 Activating password protection 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.8 Diagnostics 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.9 Menu structure 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Display of operating data, diagnostics 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Display of operating data 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Diagnostics 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Troubleshooting 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Status display via controller LEDs 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Fault analysis with the history buffer 35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Drive behaviour in the event of faults 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Fault elimination 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Drive errors 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Controller in clamp operation 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Behaviour in case of overvoltage in the DC bus (OU message) 39. . . . . . . .

4.5 System error messages 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 General error messages 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Resetting system error messages 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

EDKVF93−02 EN 3.0

Page 5

1 About this documentation

Note!

This documentation contains all the information required by the machine

operator to run the drive controllers of the 9300 vector series installed in your

machine/system.

You may make further use of the information contained in this documentation

without asking Lenze for permission if you do not change the contents.

1.1 Document history

What is new / what has changed?

Material number Version Description

.MUw 3.0 11/2013 TD06 Error corrections

13217737 2.1 03/2010 TD23 Change of the company’s address

13217737 2.0 03/2010 TD14 New edition due to reorganisation of the company

13217737 1.0 07/2007 TD23 First edition

About this documentation

Document history

UL−warnings updated

Revision for software version 8x

1

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

1.2 Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

EDKVF93−02 EN 3.0

5

Page 6

1

About this documentation

Validity information

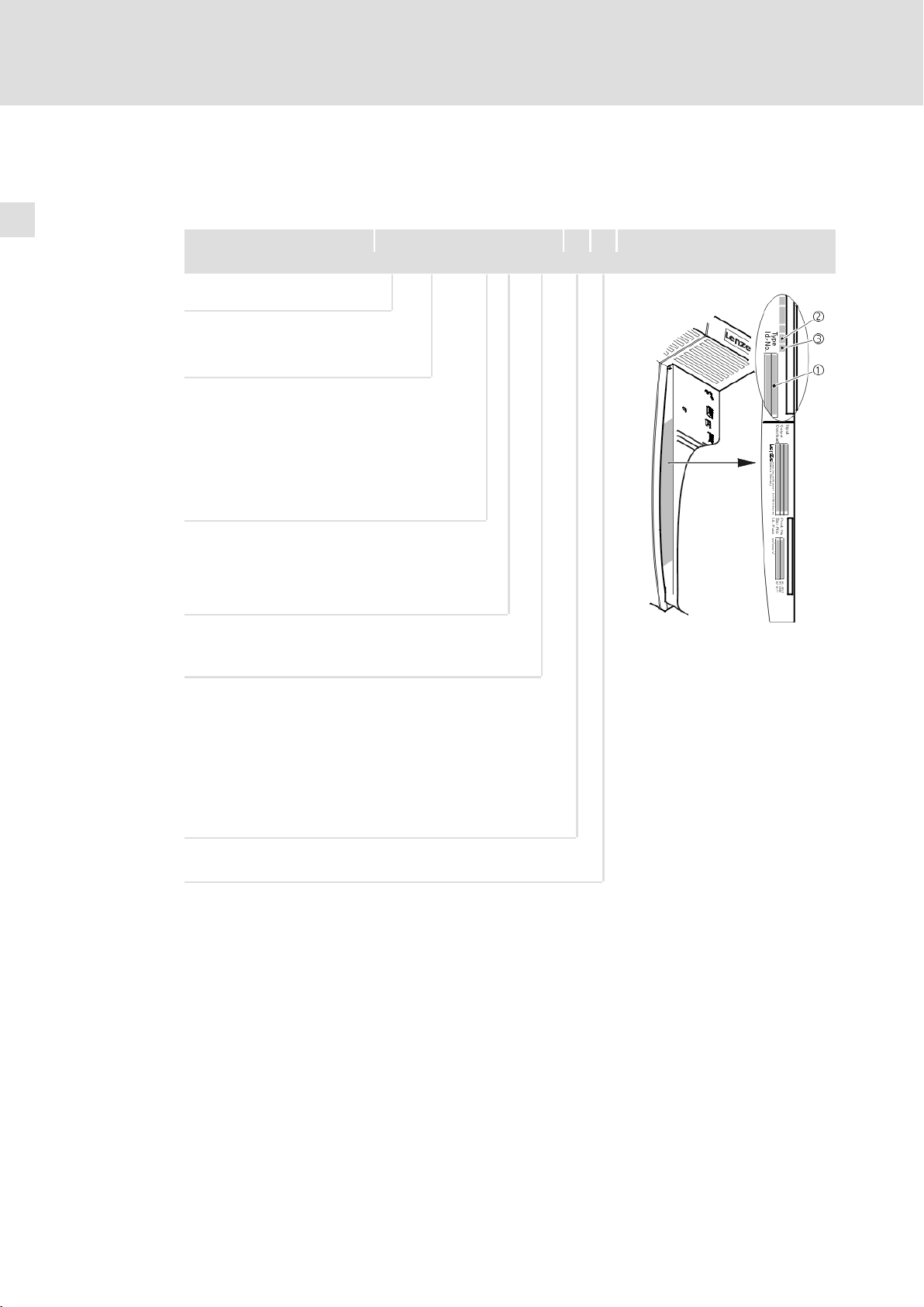

1.3 Validity information

... 9300 vector frequency inverters as of nameplate data:

Product series

EVF = Frequency inverter

Type no. / rated power

400V 480 V

9327 = 15 kW 18.5 kW

9328 = 22 kW 30 kW

9329 = 30 kW 37 kW

Type

E = Built−in unit

C = Built−in unit in "cold plate" technique

Nameplate

EVF 93xx ˘ x V Vxxx 1x 8x

Design

V = Vector−controlled frequency inverter

Variant

˘ Standard

V003 = In "cold plate" technique

V004 = With "safe standstill" function

V024 = With "safe standstill" function and for IT mains

V100 = For IT systems

Hardware version

Software version

9300vec112

6

EDKVF93−02 EN 3.0

Page 7

About this documentation

Conventions used

1

1.4 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator language−dependentIn each case, the signs typical for the target

Warnings

UL warnings

UR warnings

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

Documentation reference Reference to another documentation with

language are used as decimal separators.

For example: 1234.56 or 1234,56

Given in English and French

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

additional information

For example: EDKxxx = see

documentation EDKxxx

EDKVF93−02 EN 3.0

7

Page 8

1

About this documentation

Notes used

1.5 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Special safety instructions and application notes

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety note or application note for the operation according to

UL or CSA requirements.

The measures are required to meet the requirements according

to UL or CSA.

8

EDKVF93−02 EN 3.0

Page 9

Safety instructions

General safety and application notes for Lenze controllers

2 Safety instructions

2.1 General safety and application notes for Lenze controllers

(in accordance with Low−Voltage Directive 2006/95/EC)

For your personal safety

Disregarding the following safety measures can lead to severe injury to persons and

damage to material assets:

ƒ Only use the product as directed.

ƒ Never commission the product in the event of visible damage.

ƒ Never commission the product before assembly has been completed.

ƒ Do not carry out any technical changes on the product.

ƒ Only use the accessories approved for the product.

2

ƒ Only use original spare parts from Lenze.

ƒ Observe all regulations for the prevention of accidents, directives and laws

applicable on site.

ƒ Transport, installation, commissioning and maintenance work must only be carried

out by qualified personnel.

– Observe IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or

DIN VDE 0110 and all national regulations for the prevention of accidents.

– According to this basic safety information, qualified, skilled personnel are persons

who are familiar with the assembly, installation, commissioning, and operation of

the product and who have the qualifications necessary for their occupation.

ƒ Observe all specifications in this documentation.

– This is the condition for safe and trouble−free operation and the achievement of

the specified product features.

– The procedural notes and circuit details described in this documentation are only

proposals. It is up to the user to check whether they can be transferred to the

particular applications. Lenze Automation GmbH does not accept any liability for

the suitability of the procedures and circuit proposals described.

ƒ Depending on their degree of protection, some parts of the Lenze controllers

(frequency inverters, servo inverters, DC speed controllers) and their accessory

components can be live, moving and rotating during operation. Surfaces can be hot.

– Non−authorised removal of the required cover, inappropriate use, incorrect

installation or operation, creates the risk of severe injury to persons or damage to

material assets.

– For more information, please see the documentation.

EDKVF93−02 EN 3.0

ƒ High amounts of energy are produced in the controller. Therefore it is required to

wear personal protective equipment (body protection, headgear, eye protection, ear

protection, hand guard).

9

Page 10

2

Safety instructions

General safety and application notes for Lenze controllers

Application as directed

Controllers are components which are designed for installation in electrical systems or

machines. They are not to be used as domestic appliances, but only for industrial purposes

according to EN 61000−3−2.

When controllers are installed into machines, commissioning (i.e. starting of the operation

as directed) is prohibited until it is proven that the machine complies with the regulations

of the EC Directive 2006/42/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of the operation as directed) is only allowed when there is

compliance with the EMC Directive (2004/108/EC).

The controllers meet the requirements of the Low−Voltage Directive 2006/95/EC. The

harmonised standard EN 61800−5−1 applies to the controllers.

The technical data and supply conditions can be obtained from the nameplate and the

documentation. They must be strictly observed.

Warning: Controllers are products which can be installed in drive systems of category C2

according to EN 61800−3. These products can cause radio interferences in residential areas.

In this case, special measures can be necessary.

Transport, storage

Please observe the notes on transport, storage, and appropriate handling.

Observe the climatic conditions according to the technical data.

Installation

The controllers must be installed and cooled according to the instructions given in the

corresponding documentation.

The ambient air must not exceed degree of pollution 2 according to EN 61800−5−1.

Ensure proper handling and avoid excessive mechanical stress. Do not bend any

components and do not change any insulation distances during transport or handling. Do

not touch any electronic components and contacts.

Controllers contain electrostatic sensitive devices which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this

might endanger your health!

10

EDKVF93−02 EN 3.0

Page 11

Safety instructions

General safety and application notes for Lenze controllers

Electrical connection

When working on live controllers, observe the applicable national regulations for the

prevention of accidents (e.g. VBG 4).

The electrical installation must be carried out according to the appropriate regulations

(e.g. cable cross−sections, fuses, PE connection). Additional information can be obtained

from the documentation.

This documentation contains information on installation in compliance with EMC

(shielding, earthing, filter, and cables). These notes must also be observed for CE−marked

controllers. The manufacturer of the system is responsible for compliance with the limit

values demanded by EMC legislation. The controllers must be installed in housings (e.g.

control cabinets) to meet the limit values for radio interferences valid at the site of

installation. The housings must enable an EMC−compliant installation. Observe in

particular that e.g. the control cabinet doors have a circumferential metal connection to

the housing. Reduce housing openings and cutouts to a minimum.

Lenze controllers may cause a DC current in the PE conductor. If a residual current device

(RCD) is used for protection against direct or indirect contact for a controller with

three−phase supply, only a residual current device (RCD) of type B is permissible on the

supply side of the controller. If the controller has a single−phase supply, a residual current

device (RCD) of type A is also permissible. Apart from using a residual current device (RCD),

other protective measures can be taken as well, e.g. electrical isolation by double or

reinforced insulation or isolation from the supply system by means of a transformer.

2

Operation

If necessary, systems including controllers must be equipped with additional monitoring

and protection devices according to the valid safety regulations (e.g. law on technical

equipment, regulations for the prevention of accidents). The controllers can be adapted to

your application. Please observe the corresponding information given in the

documentation.

After the controller has been disconnected from the supply voltage, all live components

and power terminals must not be touched immediately because capacitors can still be

charged. Please observe the corresponding stickers on the controller.

All protection covers and doors must be shut during operation.

Safety functions

Certain controller versions support safety functions (e.g. "Safe torque off", formerly "Safe

standstill") according to the requirements of the EC Directive 2006/42/EC (Machinery

Directive). The notes on the integrated safety system provided in this documentation must

be observed.

Maintenance and servicing

The controllers do not require any maintenance if the prescribed operating conditions are

observed.

EDKVF93−02 EN 3.0

Disposal

Recycle metal and plastic materials. Ensure professional disposal of assembled PCBs.

The product−specific safety and application notes given in these instructions must be

observed!

11

Page 12

2

Safety instructions

Thermal motor monitoring

2.2 Thermal motor monitoring

Note!

From software version 8.1 onwards, the 9300 vector controllers are provided

with an I2xt function for sensorless thermal monitoring of the connected

motor.

2

ƒ I

xt monitoring is based on a mathematical model which calculates a

thermal motor utilisation from the detected motor currents.

ƒ The calculated motor utilisation is saved when the mains is switched off.

ƒ The function is UL−certified, i.e. additional protective measures for the motor

are not required in UL−approved systems.

ƒ Nevertheless, I

because other influences on the motor utilisation such as changes in the

cooling conditions (e.g. cooling air flow interrupted or too warm) cannot be

detected.

2

xt monitoring does not provide full motor protection

2

x t load of the motor is displayed in C0066.

Die I

The thermal loading capacity of the motor is expressed by the thermal motor time

constant (t, C0128). Find the value in the rated motor data or contact the manufacturer of

the motor.

2

x t monitoring has been designed such that it will be activated after 179 s in the

The I

event of a motor with a thermal motor time constant of 5 minutes (Lenze setting C0128),

a motor current of 1.5 x I

and a trigger threshold of 100 %.

N

Two adjustable trigger thresholds provide for different responses.

ƒ Adjustable response OC8 (TRIP, warning, off).

– The trigger threshold is set in C0127.

– The response is set in C0606.

– The response OC8, for instance, can be used for an advance warning.

ƒ Fixed response OC6−TRIP.

– The trigger threshold is set in C0120.

Behaviour of the I2 x t monitoring Condition

The I2 x t monitoring is deactivated.

C0066 is set = 0 % and

MCTRL−LOAD−I2XT is set = 0.00 %.

I2 x t monitoring is stopped.

The current value in C0066 and at the

MCTRL−LOAD−I2XT output is frozen.

I2 x t monitoring is deactivated.

The motor load is displayed in C0066.

When C0120 = 0 % and C0127 = 0 %, set controller

inhibit.

When C0120 = 0 % and C0127 = 0 %, set controller

enable.

Set C0606 = 3 (off) and C0127 > 0 %.

12

Note!

An error message OC6 or OC8 can only be reset if the I2 x t load falls below the

set trigger threshold by 5 %.

EDKVF93−02 EN 3.0

Page 13

Forced ventilated or naturally ventilated motors

2.2.1 Forced ventilated or naturally ventilated motors

Parameter setting

2

The following codes can be set for I

Code Meaning Value range Lenze setting

C0066 Display of the I2 x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

x t monitoring:

Calculate release time and I2xt load

Formula for release time Information

t +*(t) ln

ȡ

ȧ

ȧ

Ȣ

1 *

I

ȣ

z ) 1

I

Mot

ǒ

Ǔ

I

N

2

100

ȧ

ȧ

Ȥ

Mot

I

r

t Thermal motor time constant (C0128)

z Threshold value in C0120 (OC6) or C0127 (OC8)

Actual motor current (C0054)

Rated motor current (C0088)

Safety instructions

Thermal motor monitoring

2

Formulae for I2 x t load Information

L(t) Chronological sequence of the I2 x t load of the motor

2

I

Mot

ǒ

L(t) +

If the controller is inhibited, the I2 x t load is reduced:

Ǔ

100% ǒ1 * e

I

N

L(t) + L

Start

Ǹ

e

*t

t

t

*

t

I

Ǔ

Mot

Ir Rated motor current (C0088)

t Thermal motor time constant (C0128)

L

Start

(Display: C0066)

Actual motor current (C0054)

I2 x t load before controller inhibit

If an error is triggered, the value corresponds to the

threshold value set in C0120 (OC6) or

C0127 (OC8).

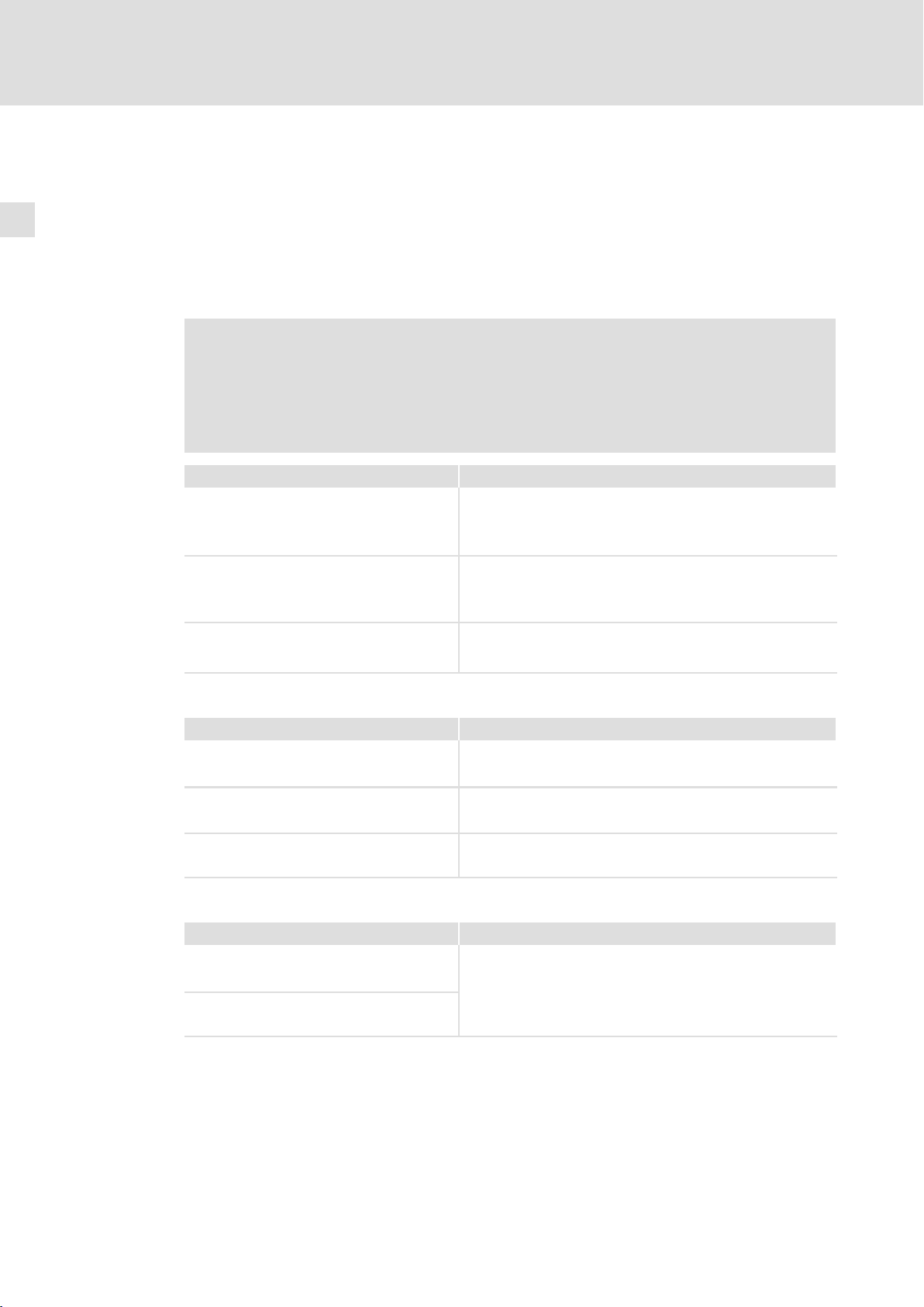

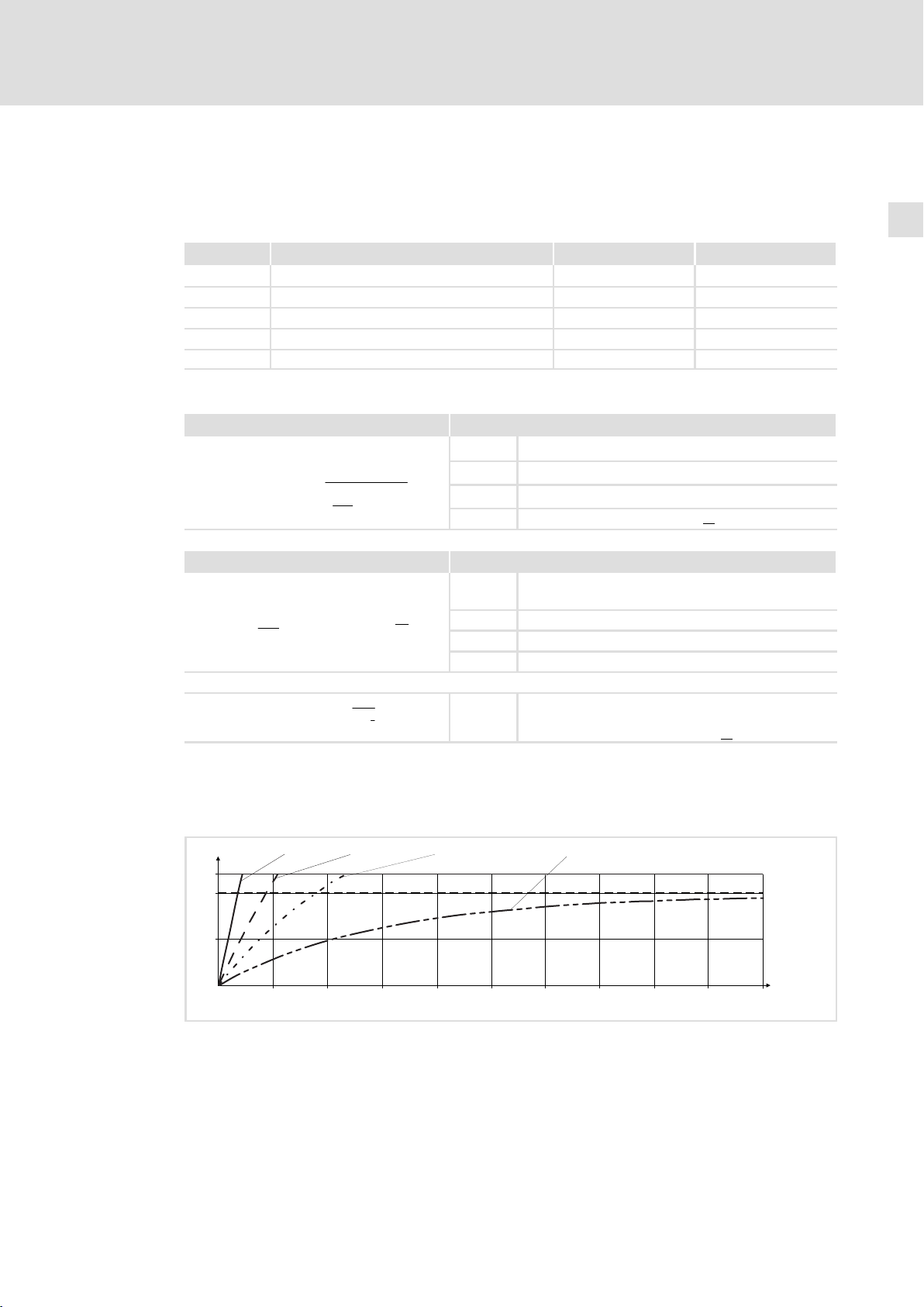

Read release time in the diagram

Diagram for detecting the release times for a motor with a thermal motor time constant

of 5 minutes (Lenze setting C0128):

L [%]

120

100

50

0

Fig. 2−1 I2 × t−monitoring: Release times for different motor currents and trigger thresholds

I = 3 × I

Mot N

0 100 200 300 400 500 600 700 800 900

I

Mot

I

r

LI

T Time

I = 2 × I

Mot N

Actual motor current (C0054)

Rated motor current (C0088)

2

x t load of the motor (display: C0066)

I = 1.5 × I

Mot N

I = 1 × I

Mot N

t [s]

1000

9300STD105

EDKVF93−02 EN 3.0

13

Page 14

2

Safety instructions

Thermal motor monitoring

Self−ventilated motors

2.2.2 Self−ventilated motors

Due to the construction, self−ventilated standard motors are exposed to an increased heat

generation in the lower speed range compared to forced ventilated motors.

Warnings!

For complying with the UL 508C standard, you have to set the

speed−dependent evaluation of the permissible torque via code C0129/x.

Parameter setting

The following codes can be set for I

Code Meaning Value range Lenze setting

C0066 Display of the I2 x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

C0129/1 S1 torque characteristic I1/I

C0129/2 S1 torque characteristics n2/n

2

x t monitoring:

rated

rated

10 ... 200 % 100 %

10 ... 200 % 40 %

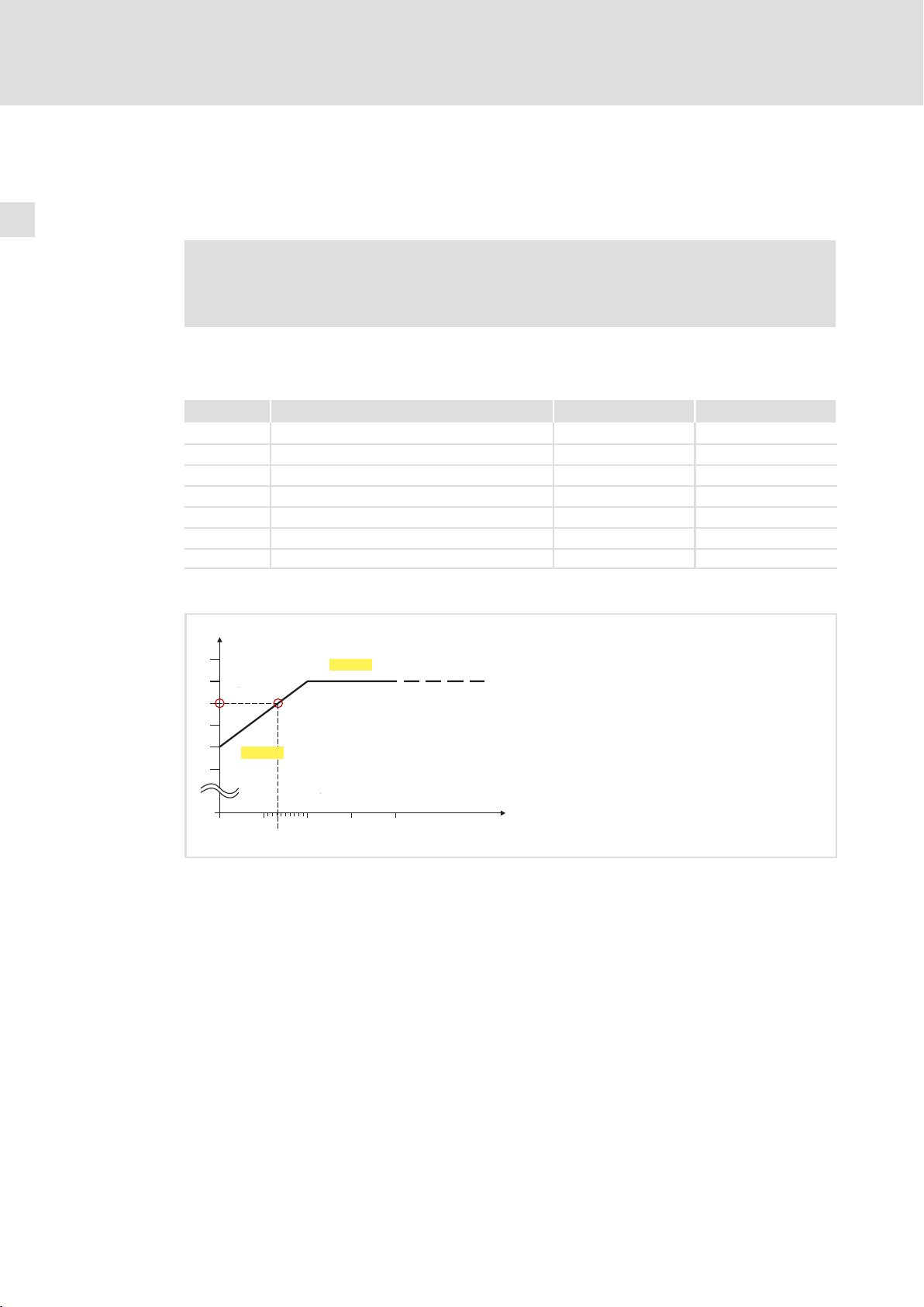

Effect of code C0129/x

I / I

N

1.1

1.0

3

0.9

0.8

0.7

0

0.6

0

0 0.1

Fig. 2−2 Working point in the range of characteristic lowering

2

C0129/1

0.132

C0129/2

1

0.2 0.3 0.4

n / n

N

9300STD350

The lowered speed / torque characteristic (Fig. 2−2) reduces the permissible thermal load

of self−ventilated standard motors. The characteristic is a line the definition of which

requires two points:

ƒ Point : Definition with C0129/1

This value also enables an increase of the maximally permissible load.

ƒ Point : Definition with C0129/2

With increasing speeds, the maximally permissible load remains unchanged

(I

Mot

= I

rated

).

In Fig. 2−2, the motor speed and the corresponding permissible motor torque () can be

read for each working point (on the characteristic () ... ). can also be calculated

using the values in C0129/1and C0129/2 (evaluation coefficient "y", 15).

14

EDKVF93−02 EN 3.0

Page 15

Thermal motor monitoring

Calculate release time and I2xt load

Calculate the release time and the I

2

x t load of the motor considering the values in

C0129/1 and C0129/2(evaluation coefficient "y").

Formulae for release time Information

T Release time of the I2 x t monitoring

ȡ

I

Mot

ǒ

y I

Ǹ

e

z ) 1

Ǔ

N

n

) C0129ń1

n

N

*

T +*(t) ln

ȧ

ȧ

1 *

Ȣ

100% * C0129ń1

y +

Formulae for I2 x t load Information

If the controller is inhibited, the I2 x t load is reduced:

L(t) +

C0129ń2

I

Mot

ǒ

y I

L(t) + L

2

Ǔ

100% ǒ1 * e

N

Start

2

100

t

t

ȣ

t Thermal motor time constant (C0128)

In Function: Natural logarithm

ȧ

ȧ

I

Mot

Ȥ

I

r

z Threshold value in C0120 (OC6) or C0127 (OC8)

y Evaluation coefficient

n

rated

L(t) Chronological sequence of the I2 x t load of the motor

y Evaluation coefficient

*t

Ǔ

t

I

Mot

Ir Rated motor current (C0088)

t Thermal motor time constant (C0128)

L

Start

Actual motor current (C0054)

Rated motor current (C0088)

Rated speed (C0087)

(Display: C0066)

Actual motor current (C0054)

I2 x t load before controller inhibit

If an error is triggered, the value corresponds to the

threshold value set in C0120 (OC6) or

Safety instructions

Self−ventilated motors

C0127 (OC8).

2

EDKVF93−02 EN 3.0

15

Page 16

2

2.3 Residual hazards

Safety instructions

Residual hazards

Protection of persons

ƒ Before working on the controller, check that no voltage is applied to the power

terminals:

– Because the power terminals V, W, +U

after disconnecting from mains.

– Because the power terminals L1, L2, L3; U, V, W, +U

motor is stopped.

ƒ The leakage current to earth (PE) is >3.5 mA. According to EN 61800−5−1

– a fixed installation is required,

– a double PE connection is required, or, if there is only a single PE connection, the PE

conductor must have a cross−section of at least 10 mm

ƒ The heat sink of the controller has an operating temperature of > 80 °C:

– Contact with the heatsink results in burns.

and −UG remain live for at least 3 minutes

G

and −UG remain live when the

G

2

.

ƒ If you use the "flying−restart circuit" function (C0142 = 2, 3) for machines with a low

moment of inertia and minimum friction:

– After controller enable in standstill, the motor may start or change its direction of

rotation for a short time, because the flying restart process also is carried out at a

speed of 0.

ƒ During parameter set transfer, the control terminals of the controller can have

undefined states!

– Therefore the plugs X5 and X6 must be unplugged, before the transfer is executed.

This ensures that the controller is inhibited and all control terminals have the

defined "LOW" state.

Device protection

ƒ Frequent mains switching (e.g. inching mode via mains contactor) can overload and

destroy the input current limitation of the drive controller:

– At least 3 minutes must pass between switching off and restarting the devices

EVS9321−xS and EVS9322−xS.

– At least 3 minutes must pass between two starting procedures of the devices

EVS9323−xS ... EVS9332−xS.

– Use the "safe torque off" safety function (STO) if safety−related mains

disconnections occur frequently. The drive variants Vxx4 are equipped with this

function.

16

Motor protection

ƒ Certain drive controller settings can overheat the connected motor:

– E. g. long−time operation of the DC injection brake.

– Long−time operation of self−ventilated motors at low speeds.

EDKVF93−02 EN 3.0

Page 17

Safety instructions

Residual hazards

Protection of the machine/system

ƒ Drives can reach dangerous overspeeds (e. g. setting of high output frequencies in

connection with motors and machines not suitable for this purpose):

– The drive controllers do not provide protection against such operating conditions.

For this purpose, use additional components.

2

EDKVF93−02 EN 3.0

17

Page 18

2

Safety instructions

Safety instructions for the installation according to UL

2.4 Safety instructions for the installation according to UL

Original − English

Warnings!

ƒ Motor Overload Protection

– For information on the protection level of the internal overload protection

for a motor load, see the corresponding manuals or software helps.

– If the integral solid state motor overload protection is not used, external or

remote overload protection must be provided.

ƒ Branch Circuit Protection

– The integral solid state protection does not provide branch circuit

protection.

– Branch circuit protection has to be provided externally in accordance with

corresponding instructions, the National Electrical Code and any

additional codes.

ƒ Please observe the specifications for fuses and screw−tightening torques in

these instructions.

ƒ EVS9327 EVS9329:

– Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 480 V maximum, when protected by fuses.

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 480 V maximum, when protected by J, T or R class

fuses.

– Maximum surrounding air temperature: 0 ... +50 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

18

EDKVF93−02 EN 3.0

Page 19

Original − French

Warnings!

ƒ Protection du moteur contre les surcharges

– Pour obtenir des informations sur le niveau de protection offert par la

protection intégrée contre les surcharges du moteur, se reporter aux

manuels correspondants ou aux systèmes d’aide logiciels.

– Si la protection statique intégrée contre les surcharges du moteur n’est

pas utilisée, prévoir impérativement un dispositif de protection externe ou

séparé contre les surcharges.

ƒ Protection par disjoncteur

– La protection statique intégrée n’offre pas la même protection qu’un

disjoncteur.

– Une protection par disjoncteur externe doit être fournie, conformément

aux indications fournies, au National Electrical Code et aux autres

dispositions applicables.

ƒ Se conformer aux spécifications relatives aux fusibles et aux couples de

serrage contenues dans le présent document.

ƒ EVS9327 EVS9329 :

– Convient aux circuits non susceptibles de délivrer plus de 5000 ampères

symétriques eff., maximum 480 V, avec protection par fusibles.

– Convient aux circuits non susceptibles de délivrer plus de 50000 ampères

symétriques eff., maximum 480 V, avec protection par des fusibles de

calibre J, T ou R.

– Température ambiante maximale : 0 ... +50 °C

– > +40 °C: ramener le courant assigné de sortie à 2,5 %/°C

– Utiliser exclusivement des conducteurs en cuivre 60/75 °C ou 75 °C.

Safety instructions

Safety instructions for the installation according to UL

2

EDKVF93−02 EN 3.0

19

Page 20

3

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

General data and operating conditions

3 Parameter setting

3.1 Parameter setting with the XT EMZ9371BC keypad

Description

The keypad is available as an accessory. A full description of the keypad can be obtained

from the Instructions included in the keypad delivery.

Plugging in the keypad

It is possible to plug the keypad into the AIF interface or remove it during operation.

As soon as the keypad is supplied with voltage, it carries out a self−test. The keypad is ready

for operation if it is in display mode.

3.1.1 General data and operating conditions

dABbc

Menu

p

SHPRG

Code

Para

0

b

MCTRL-NOUT

z

YZ

0050

50.00_Hz

T

V

00

y

S

U

ca

Feature Values

Dimensions

Width a 60 mm

Height b 73.5 mm

Depth c 15 mm

Environmental conditions

Climate

Storage IEC/EN 60721−3−1 1K3 (−25 ... +60 °C)

Transport IEC/EN 60721−3−2 2K3 (−25 ... +70 °C)

Operation IEC/EN 60721−3−3 3K3 (−10 ... +60 °C)

9371BC011

Enclosure IP 20

20

EDKVF93−02 EN 3.0

Page 21

Parameter setting with the XT EMZ9371BC keypad

dABbc

0

1

2

3

3.1.2 Installation and commissioning

E82ZWLxxx

00

ABbc

50

00

enu

M

e

od

0_

C

ra

a

p

P

d

G

R

0.0

P

H

5

S

MCTRL-NOUT

T

z

S

YZ

y

EMZ9371BC

00

Hz

V

U

dABbc

Menu

p

SHPRG

Code

0050

Para

GLOBAL DRIVE

Init

z

T

V

YZ

y

S

U

dABbc

Menu

p

SHPRG

Code

Para

50.00_Hz

MCTRL-NOUT

z

YZ

y

E82ZBBXC

Parameter setting

3

Installation and commissioning

00

0050

T

V

S

U

d

z

YZ

y

d

z

YZ

y

0050

50.00 Hz

T

S

0050

50.00 Hz

T

S

00

20 %

V

U

00

20 %

V

U

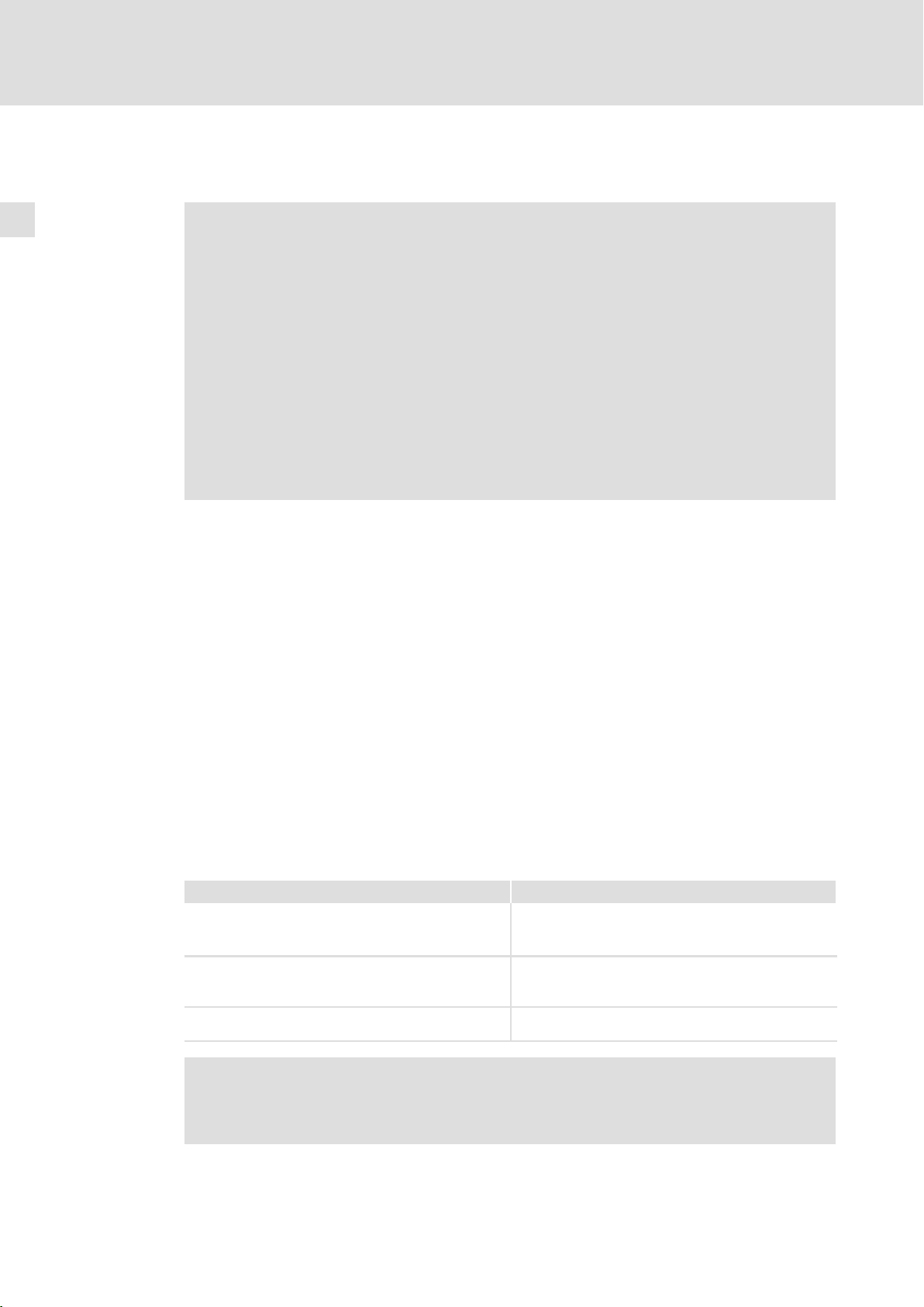

Fig. 3−1 Installation and commissioning of XT EMZ9371BC keypad or E82ZBBXC diagnosis terminal

Connect keypad to the AIF interface on the front of the standard device.

The keypad can be connected/disconnected during operation.

As soon as the keypad is supplied with voltage, it carries out a short self−test.

The operation level indicates when the keypad is ready for operation:

Current state of the standard device

Memory location 1 of the user menu (C0517):

Code number, subcode number, and current value

Active fault message or additional status message

Actual value in % of the status display defined in C0004

must be pressed to leave the operation level

3.1.3 Display elements and function keys

9371BC018

EDKVF93−02 EN 3.0

0

1

2

3

dABbc

Menu

p

SHPRG

Code

0050

Para

50.00_Hz

MCTRL-NOUT

z

YZ

T

00

V

4

5

6

7

8

y

S

U

9371BC002

Fig. 3−2 Display elements and function keys of the XT EMZ9371BC keypad

21

Page 22

3

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Display elements and function keys

Displays

Status displays of standard device

Display Meaning Explanation

Acceptance of the parameters

Display Meaning Explanation

Parameter is accepted immediately Standard device operates immediately with

SHPRG Parameter must be acknowledged with Standard device operates with the new

SHPRG Parameter must be acknowledged in case of

None Display parameter Change is not possible

Active level

Display Meaning Explanation

Menu Menu level is active Select main menu and submenus

Code Code level is active Select codes and subcodes

Para Parameter level is active Change parameters in the codes or

None Operating level is active Display operating parameters

Short text

Display Meaning Explanation

alphanumericalContents of the menus, meaning of the codes

Number

Active level Meaning Explanation

Menu level Menu number Display is only active for operation with

Code level Four−digit code number

Number

Active level Meaning Explanation

Menu level Submenu number Display is only active for operation with

Code level Two−digit subcode number

Parameter value

Cursor

Function keys

Ready for operation

Pulse inhibit is active Power outputs are inhibited

The set current limit is exceeded in motor or

generator mode

Speed controller 1 in the limitation Drive is torque−controlled

(Only active for operation with standard

devices of the 9300 series)

Active fault

the new parameter value

parameter value after being acknowledged

controller inhibit

and parameters

In the operating level display of C0004 in % and

the active fault

Parameter value with unit

In the parameter level, the digit above the cursor can be directly changed

For description see the following table

Standard device operates with the new

parameter value after the controller is

enabled again

subcodes

standard devices of the 8200 vector or 8200

motec series

standard devices of the 8200 vector or 8200

motec series

22

EDKVF93−02 EN 3.0

Page 23

Function keys

Note!

Shortcuts with :

Press and hold , then press the second key in addition.

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Changing and saving parameters

3

Key

Menu level Code level Parameter level Operating level

Go to the "Short setup"

!

!

"

#

$

%

1)

menu and load

predefined

configurations

Change between menu

items

Quick change between

menu items

Change between main menu, submenu and code

level

Deactivate the function of the key %, the LED in the key goes off

Inhibit the controller, the LED in the key is lit.

Reset fault (TRIP−Reset): 1. Remove the cause of malfunction

Only active for operation with standard devices of the 8200 vector or 8200 motec series

1)

Change to the

parameter level

Change of code number

Quick change of code

number

2. Press %

3. Press $

3.1.4 Changing and saving parameters

Function

Change to the operating

level

Accept parameters

when SHPRG or

SHPRG is displayed

Change of digit via

cursor

Quick change of digit

via cursor

Cursor to the right

Cursor to the left

Change to the code

level

Note!

Your settings have an effect on the current parameters in the main memory.

You must save your settings in a parameter set so that they are not lost when

the mains are connected.

If you only need one parameter set, save your settings as parameter set 1,

since parameter set 1 is loaded automatically after mains connection.

Step Key

1. Select the menu ! " # Use the arrow keys to select the desired menu

2. Change to the code level " Display of the first code in the menu

3. Select code or subcode ! Display of the current parameter value

4. Change to the parameter level

5. When SHPRG is displayed, inhibit the

controller

6. Change parameter

sequence

1)

%

A " # Move cursor below the digit to be changed

B ! Change of digit

!

Action

The drive coasts

Quick change of digit

EDKVF93−02 EN 3.0

23

Page 24

3

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Changing and saving parameters

Step

7. Accept the changed parameter

Display of SHPRG or SHPRG Confirm change to accept the parameter

Display − The parameter has been accepted immediately

8. Enable the controller, if required $

9. Change to the code level

10. Change further parameters Restart the "loop" with step 1. or 3.

11. Save changed parameters

Select the parameter set in which

the parameters are to be saved

permanently

12.

Change to the code level

13. Set parameters for another parameter

set

1)

The function of the % key can be programmed:

C0469 = 1: Controller inhibit

C0469 = 2: Quick stop (Lenze setting)

sequence

1)

A Display of the operating level

B Display of the code with changed parameter

A ! " # Select the code C0003 "PAR SAVE" in the menu

B Change to the parameter level

C Save as parameter set 1:

D When "OK" is displayed, the settings are permanently

A Display of the operating level

B Display of C0003 "PAR SAVE"

ActionKey

Display "OK"

The drive runs again

"Load/Store"

Display "0" and "READY"

ð Set "1" "Save PS1"

Save as parameter set 2:

ð Set "2" "Save PS2"

Save as parameter set 3:

ð Set "3" "Save PS3"

Save as parameter set 4:

ð Set "4" "Save PS4"

saved in the selected parameter set.

Restart the "loop" with step 1. or 3.

24

EDKVF93−02 EN 3.0

Page 25

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Loading a parameter set

3

3.1.5 Loading a parameter set

The keypad serves to load a saved parameter set into the main memory when the controller

is inhibited. After the controller is enabled, it operates with the new parameters.

Danger!

ƒ When a new parameter set is loaded, the controller is reinitialised and acts

as if it had been connected to the mains:

– System configurations and terminal assignments can be changed. Make

sure that your wiring and drive configuration comply with the settings of

the parameter set.

ƒ Only use terminal X5/28 as source for the controller inhibit! Otherwise the

drive may start in an uncontrolled way when switching over to another

parameter set.

Note!

ƒ After switching on the supply voltage, the controller always loads parameter

set 1 into the main memory.

ƒ It is also possible to load other parameter sets into the main memory via the

digital inputs or bus commands.

Step Key

1. Inhibit controller Terminal X5/28 = LOW

2. Load the saved parameter set into the

main memory

Select the parameter set to be

loaded

3.

Change to the code level

4. Enable controller Terminal X5/28 = HIGH

sequence

A ! " # Select the code C0002 "PAR LOAD" in the menu

B Change to the parameter level

C Load parameter set 1:

D "RDY" goes off. The parameter set is loaded completely

A Display of the operating level

B Display of C0002 "PAR LOAD"

Action

"Load/Store"

The active parameter set is displayed, e. g. display "0"

and "Load Default"

If you want to restore the delivery status, proceed with

D

ð Set "1" "Load PS1"

Load parameter set 2:

ð Set "2" "Load PS2"

Load parameter set 3:

ð Set "3" "Load PS3"

Load parameter set 4:

ð Set "4" "Load PS4"

into the main memory if "RDY" is displayed again.

The drive is running with the settings of the loaded

parameter set

EDKVF93−02 EN 3.0

25

Page 26

3

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Transferring parameters to other standard devices

3.1.6 Transferring parameters to other standard devices

Parameter settings can be easily copied from one standard device to another by using the

keypad.

For this purpose use the "Load/Store" menu

Danger!

During the parameter transfer from the keypad to the standard device the

control terminals can adopt undefined states!

Therefore the plugs X5 and X6 must be disconnected from the standard device

before the transfer takes place. This ensures that the controller is inhibited and

all control terminals have the defined state "LOW".

Copying parameter sets from the standard device into the keypad

Note!

After copying the parameter sets into the XT keypad (C0003 = 11), always the

parameter set that was loaded last via C0002 is activated.

Like this the current parameters also remain active after copying:

ƒ Save the current parameters in the parameter set before copying and load

this parameter set in the controller via C0002.

Step Key

1. Connect the keypad to standard

device 1

2. Inhibit controller Terminal X5/28 = LOW

3. Select C0003 in the "Load/Store"

menu

4. Change to the parameter level

5. Copy all parameter set into the

keypad

6. Start copying

7.

Change to the code level

8. Enable controller Terminal X5/28 = HIGH

9. Remove keypad from standard device

1

A

B

sequence

!"#

Action

The drive coasts.

Select code C0003 "PAR SAVE" in the "Load/Store"

menu using the arrow keys.

Display "0" and "READY"

The settings saved in the keypad are overwritten.

Set "11" "Save extern"

The "RDY" status display goes off. As parameter value

"BUSY" is displayed.

If "BUSY" goes off after approx. one minute, all

parameter sets were copied into the keypad. The

"RDY" status display is lit.

Display of the operating level

Display C0003 and "PAR SAVE"

26

EDKVF93−02 EN 3.0

Page 27

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Transferring parameters to other standard devices

Copying parameter sets fom keypad into the standard device

3

Step Key

1. Connect the keypad to standard

device 2

2. Inhibit controller Terminal X5/28 = LOW

3. Pull the plugs X5 and X6 All control terminals have the defined "LOW" status.

4. Select C0002 in the "Load/Store"

menu

5. Change to the parameter level

6. Select the correct copy function The settings saved in the standard device are

l Copy all parameter sets available into the

EEPROM of the standard device and save them

permanently.

l Copy individual parameter sets into the main

memory of the standard device.

7. Start copying

8.

Change to the code level

9. l If the function "Copy all parameter

sets into the EEPROM"

(C0002 = 20) is selected, they

might have to be loaded in the

main memory manually.

l If the function "Copy individual

parameter sets into the main

memory" (C0002 = 1x) is selected,

they might have to be saved

permanently in the EEPROM

manually.

10. Plug in plugs X5 and X6

11. Enable controller Terminal X5/28 = HIGH

A

B

sequence

!"#

!"#

Action

The "IMP" status display is it.

The drive coasts

Select code C0002 "PAR LOAD" in the "Load/Store"

menu using the arrow keys.

The active parameter set is shown, e. g. display "0" and

"Load Default"

overwritten.

l The parameter set that was active before copying is

overwritten.

l The parameters are not yet active after copying.

Select parameter set and load it in the main

memory. 25

Set "20" "ext −> EEPROM"

Copy parameter set 1 into the main memory:

Set ð "11" "Load ext PS1"

Copy parameter set 2 into the main memory:

Set ð "12" "Load ext PS2"

Copy parameter set 3 into the main memory:

Set ð "13" "Load ext PS3"

Copy parameter set 4 into the main memory:

Set ð "14" "Load ext PS4"

The "RDY" status display goes off. As parameter value

"BUSY" is displayed.

If "BUSY" goes off, the parameter sets selected were

copied into the standard device. The "RDY" status

display is lit.

Display of the operating level

Display C0002 and "PAR LOAD"

Select code C0003 "PAR SAVE" in the "Load/Store"

menu using the arrow keys and store the contents of

the main memory permanently.

The drive is running with the new settings.

EDKVF93−02 EN 3.0

27

Page 28

3

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Activating password protection

3.1.7 Activating password protection

Note!

ƒ If the password protection is activated (C0094 = 1 ... 9999), you only have

free access to the user menu.

ƒ To access the other menus, you must enter the password. By this, the

password protection is annulled until you enter a new password.

ƒ Please observe that the password−protected parameters can be overwritten

as well when transferring the parameter sets to other standard devices. The

password is not transferred.

ƒ Do not forget your password! If you have forgotten your password, it can

only be reset via a PC or a bus system!

Activate password protection

Step Key

sequence

1. Select the "USER menu" ! " # Change to the user menu using the arrow keys

2. Change to the code level " Display of code C0051 "MCTRL−NACT"

3. Select C0094 Display of code C0094 "Password"

4. Change to the parameter level Display "0" = no password protection

5. Set password

A Select password (1 ... 9999)

B Confirm password

6. Change to the code level

A Display of the operating level

B Display of C0094 and "Password"

7. Change to the "USER menu" # # !

The password protection is active now.

You can only quit the user menu if you re−enter the password and confirm it with

Action

.

Remove password protection

Step Key

1. Change to the code level in the user

menu

2. Select C0094 Display of code C0094 "Password"

3. Change to the parameter level Display "9999" = password protection is active

4. Enter password

5. Change to the code level

The password protection is deactivated now. All menus can be freely accessed again.

sequence

"

A ! Set valid password

B Confirm

A Display of the operating level

B Display of C0094 and "Password"

Action

The password protection is deactivated by entering the

password once again.

28

EDKVF93−02 EN 3.0

Page 29

3.1.8 Diagnostics

In the "Diagnostic" menu the two submenus "Actual info" and "History" contain all codes

for

ƒ monitoring the drive

ƒ fault/error diagnosis

In the operating level, more status messages are displayed. If several status messages are

active, the message with the highest priority is displayed.

Priority Display Meaning

1 GLOBAL DRIVE INIT Initialisation or communication error between

2 XXX − TRIP Active TRIP (contents of C0168/1)

3 XXX − MESSAGE Active message (contents of C0168/1)

4

Special device states:

5

Source for controller inhibit (the value of C0004 is displayed simultaneously):

STP1

STP3 Operating module or LECOM A/B/LI

STP4 INTERBUS or PROFIBUS−DP

STP5

STP6 C0040

6

Source for quick stop (QSP):

QSP−term−Ext The MCTRL−QSP input of the MCTRL function block is on HIGH signal.

QSP−C0135 Operating module or LECOM A/B/LI

QSP−AIF INTERBUS or PROFIBUS−DP

QSP−CAN

7 XXX − WARNING Active warning (contents of C0168/1)

8 xxxx Value below C0004

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Diagnostics

keypad and controller

Switch−on inhibit

9300 servo: Terminal X5/28

ECSxS/P/M/A: Terminal X6/SI1

9300 servo, ECSxA/E: System bus (CAN)

ECSxS/P/M: MotionBus (CAN)

9300 servo, ECSxA: System bus (CAN)

ECSxS/P/M: MotionBus (CAN)

3

EDKVF93−02 EN 3.0

29

Page 30

3

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Menu structure

3.1.9 Menu structure

For simple, user−friendly operation, the codes are clearly arranged in function−related

menus:

Main menu Submenus Description

Display Display

User−Menu Codes defined in C0517

Code list All available codes

ALL All available codes listed in ascending order (C0001 ... C7999)

PS 1 Codes in parameter set 1 (C0001 ... C1999)

PS 2 Codes in parameter set 2 (C2001 ... C3999)

PS 3 Codes in parameter set 3 (C4001 ... C5999)

PS 4 Codes in parameter set 4 (C6001 ... C7999)

Load/Store Parameter set management

Diagnostic Diagnostic

Actual info Display codes to monitor the drive

History Fault analysis with history buffer

Short setup Quick configuration of predefined applications

Parameter set transfer, restore delivery status

Configuration of the user menu

The predefined applications depend on the type of the standard device (frequency

inverter, servo inverter, position controller, ...)

Main FB Configuration of the main function blocks

NSET Setpoint processing

NSET−JOG Fixed setpoints

NSET−RAMP1 Ramp function generator

MCTRL Motor control

DFSET Digital frequency processing

DCTRL Internal control

Terminal I/O Connection of inputs and outputs with internal signals

AIN1 X6.1/2 Analog input 1

AIN2 X6.3/4 Analog input 2

AOUT1 X6.62 Analog output 1

AOUT2 X6.63 Analog output 2

DIGIN Digital inputs

DIGOUT Digital outputs

DFIN Digital frequency input

DFOUT Digital frequency output

State bus State bus (not with 9300 frequency inverter)

Controller Configuration of internal control parameters

Speed Speed controller

Current Current controller or torque controller

Phase Phase controller (not with 9300 frequency inverter)

Motor/Feedb. Input of motor data, configuration of speed feedback

Motor adj Motor data

Feedback Configuration of feedback systems

Monitoring Configuration of monitoring functions

30

EDKVF93−02 EN 3.0

Page 31

Parameter setting

Parameter setting with the XT EMZ9371BC keypad

Menu structure

DescriptionSubmenusMain menu Description

DisplayDisplay

LECOM/AIF Configuration of operation with communication modules

LECOM A/B Serial interface

AIF interface Process data

Status word Display of status words

System bus Configuration of system bus (CAN)

Management CAN communication parameters

CAN−IN1

CAN−OUT1

CAN−IN2

CAN−OUT2

CAN−IN3

CAN−OUT3

Status word Display of status words

FDO Free digital outputs

Diagnostic CAN diagnostic

FB config Configuration of function blocks

CAN object 1

CAN object 2

CAN object 3

3

Func blocks Parameterisation of function blocks

The submenus contain all available function blocks

FCODE Configuration of free codes

Identify Identification

Drive Software version of standard device

Op Keypad Software version of keypad

EDKVF93−02 EN 3.0

31

Page 32

4

Troubleshooting and fault elimination

Display of operating data, diagnostics

Display of operating data

4 Troubleshooting and fault elimination

4.1 Display of operating data, diagnostics

4.1.1 Display of operating data

Description

Important operating parameters are measured by the controller. They can be displayed

with the keypad or PC.

Some operating data can be calibrated to be displayed or selected directly with the unit of

the process quantity (e.g. pressure, temperature, speed).

Note!

The calibration always affects all specified codes simultaneously.

Codes for parameter setting

Code Possible settings IMPORTANT

No. Name Lenze Selection

C0051 MCTRL−NACT −36000 {1 rpm} 36000 Actual speed value, function block

C0052 MCTRL−Umot 0 {1 V} 800 Motor voltage, function block MCTRL

C0053 UG−VOLTAGE 0 {1 V} 900 DC−bus voltage, function block MCTRL

C0054 IMot 0.0 {0.1 A} 500.0 Current motor current, function block

C0061 Heatsink temp 0 {1 °C} 100 Heatsink temperature

C0063 Mot temp 0 {1 °C} 200 Motor temperature

MCTRL

l Read only

l Read only

l MCTRL−VACT = 100 % = C0090

l Read only

l MCTRL−DCVOLT = 100 % = 1000 V

MCTRL

l Read only

l MCTRL−IACT = 100 % = C0022

l Read only

l If the temperature of the heatsink

> 85 °C, the controller sets TRIP OH

l Early warning is possible via OH4,

temperature is set in C0122

l Read only

l Monitoring of the motor

temperature must be activated.

l KTY at X8/5, X8/8:

– At 150 °C, TRIP OH3 is set

– Early warning is possible via OH7,

temperature is set in C0121

l PTC, thermal contact at T1, T2:

– Release sets TRIP or warning OH8

32

EDKVF93−02 EN 3.0

Page 33

Troubleshooting and fault elimination

Display of operating data, diagnostics

Diagnostics

IMPORTANTPossible settingsCode

SelectionLenzeNameNo.

C0064 Utilization 0 {1 %} 150 Device utilisation I×t

l Read only

l Device utilisation during the last

180 s of operating time

l C0064 > 100 % releases warning

OC5

l C0064 > 140 % limits the output

current of the controller to 67 % of

the maximum current in C0022

C0150 Status word

Bit00 — Bit08 Status code

Bit01 IMP Bit09 Status code

Bit02

Bit03

Bit04

Bit05

Bit06

Bit07 CINH Bit15 —

— Bit10 Status code

— Bit11 Status code

— Bit12 Warning

— Bit13 Message

n = 0 Bit14 —

Read only

Decimal status word for networking

via automation interface (AIF)

l Binary interpretation indicates the

bit states

4

4.1.2 Diagnostics

Description

Display codes for diagnostics

Codes for parameter setting

Code Possible settings IMPORTANT

No. Name Lenze Selection

C0093 DRIVE IDENT

C0099 S/W version

0 invalid Damaged power section

1 none No power section

9321

...

9333

x.y

x

y

9321VC

...

9333VC

Main version

Subversion

Controller identification

l Read only

Display of the controller used

Software version

l Read only

EDKVF93−02 EN 3.0

33

Page 34

4

Troubleshooting and fault elimination

Troubleshooting

Status display via controller LEDs

4.2 Troubleshooting

Detecting breakdowns

A breakdown can be detected quickly via the LEDs at the controller or via the status

information at the keypad.

Analysing errors

Analyse the error using the history buffer. The list of fault messages gives you advice how

to remove the fault. ( 40)

4.2.1 Status display via controller LEDs

During operation the operating status of the controller is shown by 2 LEDs.

LED Operating status

Red Green

Off On Controller is enabled

On On Mains is switched on and automatic start is

Off Blinking slowly Controller is inhibited

Off On Motor data identification is being performed

Blinking quickly Off Undervoltage

Blinking slowly Off Active fault

inhibited

34

EDKVF93−02 EN 3.0

Page 35

Troubleshooting and fault elimination

Troubleshooting

Fault analysis with the history buffer

4

4.2.2 Fault analysis with the history buffer

Retracing faults

Faults can be retraced via the history buffer. Fault messages are stored in the 8 memory

locations in the order of their appearance.

The memory locations can be retrieved via codes.

Structure of the history buffer

Code Memory location Entry Note

C0168/1 C0169/1 C0170/1 Memory location 1 Active fault

C0168/2 C0169/2 C0170/2 Memory location 2 Last fault

C0168/3 C0169/3 C0170/3 Memory location 3 Last but one fault

C0168/4 C0169/4 C0170/4 Memory location 4 Last but two fault

C0168/5 C0169/5 C0170/5 Memory location 5 Last but three fault

C0168/6 C0169/6 C0170/6 Memory location 6 Last but four fault

C0168/7 C0169/7 C0170/7 Memory location 7 Last but five fault

C0168/8 C0169/8 C0170/8 Memory location 8 Last but six fault

Explanations regarding the codes

C0168 Fault indication and response

l The entry is effected as a LECOM error number

l If several faults with different responses occur at the same time:

– Only the fault with the highest priority response is entered (1. TRIP, 2. message,

3. warning).

l If several faults with the same response (e.g. 2 messages) occur at the same time:

– Only the fault which occurred first is entered.

C0169 Time of fault occurence

l The reference time is provided by the power−on time meter (C0179).

l If the same fault occurs several times in succession, only the time of the last occurrence

is stored.

C0170 Fault frequency

l Only the time of the last occurrence is stored.

If the fault is no longer pending or has been

acknowledged:

l The contents of the memory locations

l The content of memory location 8 is

l Memory location 1 is deleted (= no active

1 ... 7 are shifted "up" to the next memory

location.

deleted from the history buffer and cannot

be retrieved anymore.

fault).

EDKVF93−02 EN 3.0

Clear history buffer

Set C0167=1 to clear the history buffer.

35

Page 36

4

Troubleshooting and fault elimination

Drive behaviour in the event of faults

Fault analysis with the history buffer

4.3 Drive behaviour in the event of faults

The controller responds differently to the three possible fault types TRIP, message, or

warning:

TRIP

TRIP (display in keypad XT: )

ƒ Switches the power outputs U, V, W to a high−resistance state until TRIP reset is

executed.

ƒ The fault indication is entered into the history buffer as "current fault" in C0168/1.

ƒ The drive coasts without any control!

ƒ After TRIP reset ( 45):

– The drive travels along the ramps to its setpoint.

– The fault indication is moved to C0168/2 as "last fault".

Messages

Message (display in keypad XT: )

ƒ Switches the power outputs U, V, W to a high−resistance state.

ƒ The fault indication is entered into the history buffer as "current fault" in C0168/1.

ƒ In case of a fault £5 s:

– The drive coasts without any control as long as the message is active!

– If the message is not active anymore, the drive travels to its setpoint with

maximum torque.

ƒ In case of a fault > 5 s:

– The drive coasts without any control as long as the message is active!

– If the message is not active anymore, the drive travels to its setpoint along the

adjusted ramps.

ƒ If the message is not active anymore, the fault indication is moved to C0168/2 as

"last fault".

Warnings

"Heatsink overtemperature" (keypad XT:OH )

ƒ The drive continues to travel in a controlled way!

ƒ The warning signal goes off when the fault is not active anymore.

"Error in motor phase" (keypad XT:LP1)

"PTC monitoring" (keypad XT:OH51)

36

ƒ The drive continues to travel in a controlled way!

ƒ The fault indication is entered into the history buffer as "current fault" in C0168/1.

ƒ After TRIP reset, the fault indication is moved to C0168/2 as "last fault".

EDKVF93−02 EN 3.0

Page 37

Troubleshooting and fault elimination

Fault elimination

4.4 Fault elimination

4.4.1 Drive errors

Malfunction Cause Remedy

An asynchronous motor

with feedback rotates in an

uncontrolled manner and

with low speed

Motor does not rotate

although the controller is

enabled ( is off) and a

speed setpoint has been

specified.

The monitoring of the

motor phases (LP1) does

not respond if a motor

phase is interrupted,

although C0597 = 0 or 2

If during high speeds

DC−injection braking (GSB)

is activated, the fault OC1

(TRIP) or OU (TRIP) occurs

The motor phases are reversed so that the rotating field

of the motor is not identical with the rotating field of

the feedback system. The drive shows the following

behaviour:

l V/f characteristic control (C0006 = 5)

– The motor rotates faster than the speed setpoint by

the value set in C0074 (influence of the speed

controller, Lenze setting 10 % of n

controller is enabled, it does not stop at zero speed

setpoint or quick stop (QSP).

– The final motor current depends, among other

things, on the set value of the V

and can rise to I

fault message OC5.

l Vector control (C0006 = 1)

– The motor rotates slowly with maximum slip speed

(depending on motor data and maximum current)

and does not react to a speed setpoint. The

direction of rotation, however, is determined by

the sign of the speed setpoint.

– The motor current rises up to I

may activate the fault message OC5 with a time

delay.

The two terminal strips X5 are reversed. Since X5/A1 and

X5/28 face each other, the controller can be enabled if

the control terminals are internally supplied. All other

connections, however, are assigned incorrectly so that

the motor cannot start.

The function block MLP1 is not entered into the

processing table.

During DC−injection braking the controller sets pulse

inhibit for a short time (DCTRL−IMP) to reduce the

magnetisation in the motor before a DC voltage is

injected into the motor. At high speeds (e. g. in case of

mid−frequency motors) the residual voltage which

develops from the residual magnetism and high speed

can generate such a high motor current that OC1 or OU

are activated.

(C0022). This may activate the

max

). After the

max

boost (C0016)

min

(C0022). This

max

l Check motor cable for correct phase

relation.

l If possible, operate the motor with

deactivated feedback (C0025 = 1) and

check the direction of rotation of the

motor.

Check the position of the terminal strips:

l If you look at the connection unit in

reading direction, the left terminal

strip X5 must be connected with the

input signals and the right terminal

strip X5 must be connected with the

output signals.

Enter the function block MLP1 into the

processing table. The function block MLP1

requires 30 ms of calculating time.

Prolong the duration of the pulse inhibit:

l Connect the output signal DCTRL−IMP

to the function block TRANSx and

adjust the desired switch−off time

there (usually 500 ms). If

DCTRL−CINH1 is set to HIGH, the

duration of the pulse inhibit is

prolonged by the time adjusted.

4

Drive errors

EDKVF93−02 EN 3.0

37

Page 38

4

4.4.2 Controller in clamp operation

Troubleshooting and fault elimination

Fault elimination

Controller in clamp operation

The clamp operation is a permissible operating mode. But since, however, pulse inhibit is

set again and again, the controller cannot provide the optimum power.

If the output power is optimal, the output current mainly is right below the clamp

threshold.

9300vec110

Fig. 4−1 Output current when starting a motor with high load (shown with the oscilloscope in GDC)

Clamp threshold

Output current

Function

1. When the output current reaches 2.25 × I

2. The controller sets pulse inhibit for a short time. The motor current decreases as a

function of the inductance in the motor circuit.

– An internal counter is increased by the value one.

3. After max. 250 ms the pulse inhibit is deactivated.

4. If a software clamp reoccurs within 2 s, the internal counter is again increased by the

value one. Otherwise the counter is set to zero.

– If the counter reaches the value 4300, OC3 (TRIP) is activated.

, a software clamp is activated.

r

38

EDKVF93−02 EN 3.0

Page 39

Troubleshooting and fault elimination

Fault elimination

Behaviour in case of overvoltage in the DC bus (OU message)

4

4.4.3 Behaviour in case of overvoltage in the DC bus (OU message)

Description

If the DC−bus voltage (U

) exceeds the switch−off threshold OU, the pulse inhibit is set. At

DC

the same time, an internal timing element starts for a delay time (C0912).

The pulse inhibit is deactivated if the voltage falls below the switch−on threshold OU and

the delay time has elapsed.

Switching thresholds in case of overvoltage in the DC bus (OU):

Mains voltage range C0173 Switch−off threshold OU Switch−on threshold OU

< 400 V Operation with / without

400 V Operation with / without

460 V Operation with / without

480 V Operation without brake

480 V Operation with brake

*

Lenze setting

brake chopper

brake chopper

brake chopper

chopper

chopper

0 770 V 755 V

*

1

2 770 V 755 V

3 770 V 755 V

4 800 V 785 V

770 V 755 V

Codes for parameter setting

Code Possible settings IMPORTANT

No. Name Lenze Selection

C0912 OV delay time à − {1 ms} − Delay time of the pulse enable after

an OU message

à Depending on C0082, C0086,

C0087, C0088, C0089, C0090,

C0091, C0092

A change of one of the codes

resets C0912 to the time of the

selected motor

l The time is derived from the

double rotor time constant

EDKVF93−02 EN 3.0

39

Page 40

4

Troubleshooting and fault elimination

System error messages

General error messages

Adjustment

U

DC

IMP

Fig. 4−2 Influence of the delay time (C0912)

01

t < C0912

t C0912³

Switch−off threshold OU

Switch−on threshold OU

The period of time between exceeding the switch−off threshold OU and undershooting the

switch−on threshold OU equals or is higher than the delay time set in C0912.

After undershooting the switch−on threshold OU, the pulse inhibit is deactivated.

The period of time between exceeding the switch−off threshold OU and undershooting the

switch−on threshold OU is lower than the delay time set in C0912.

The pulse inhibit is deactivated after the delay time in C0912 has elapsed.

t = C0912

9300vec142

ƒ The delay time in [ms] is set under C0912. The Lenze setting can be changed by the

factor 0.5 ... 2.

4.5 System error messages

4.5.1 General error messages

Note!

In the case of a query via system bus (CAN), the fault messages are

represented as numbers (see first column of the table).

40

EDKVF93−02 EN 3.0

Page 41

Troubleshooting and fault elimination

System error messages

General error messages

4

Fault message

Description Cause Remedy

No. Display

−−− −−− No fault − −

0011 OC1 Overcurrent in motor cable

> 2.25 x IN; Hardware

(I

a

monitoring)

In the event of a short circuit l Search for the cause of the

Capacitive charging current of the

motor cable is too high

Too short acceleration or

deceleration times in proportion

to the load (C0012, C0013, C0105)

The drive is connected to the

coasting machine. The coasting is

caused by a short−time pulse

inhibit, e.g. at

l OU (overvoltage in the DC bus)

l external or internal controller

inhibit

l Encoder error

l Tracks during encoder

feedback of the motor speed

are interchanged

DC−injection braking at high

speeds

Missing mains phase l Check the connections and the

0012 OC2 Motor cable earth fault One of the motor phases has

earth contact.

0013 OC3 Overload during acceleration. Too short acceleration or

deceleration times in proportion

to the load (C0012, C0013,

C0105).

0015 OC5 I x t overload l Frequent and too long

acceleration with overcurrent

l Continuous overload with

I

motor

> 1.05 x I

rx.

0016 OC6 I2xt overload l Frequent and too long

acceleration processes with

motor overcurrent.

l Permanent motor overload

with I

motor>Irmotor

x018 OC8 I2xt overload advance warning l Frequent and too long

acceleration processes with

motor overcurrent.

l Permanent motor overload

with I

motor>Irmotor

2020 OU Overvoltage in the DC bus Braking energy is too high.

(DC−bus voltage is higher than set

in C0173.)

1030 LU Undervoltage in the DC bus DC bus voltage is lower than

specified in C0173.

short circuit.

l Check the motor cable.

Use motor cable which is shorter

or of lower capacitance

l Increase the gain (P

component) of the Imax

controller (C0075).

l Reduce integral−action time

(integral action component) of

the Imax controller (C0076)

l Activate flying restart circuit

Check wiring of the encoder

l See 37

supply cable of the device

l Check mains voltage

l Search for cause of short

circuit.

l Check motor cable.

l Increase the gain (P

component) of the current

controller (C0075).

l Reduce the reset time (integral

action component) of the I

controller (C0076).

l Increase ramp times.

l 38, "controller in clamp

max

operation (fault OC3)"

Check drive dimensioning.

Check drive dimensioning.

Check drive dimensioning.

l Use a braking unit or

regenerative module.

l Check dimensioning of the

brake resistor.

l Check mains voltage

l Check supply cable

EDKVF93−02 EN 3.0

41

Page 42

4

Troubleshooting and fault elimination

System error messages

General error messages

DisplayNo.

x032 LP1 Motor phase failure