Page 1

,

EPA CERTIFIED

WOOD BURNING

STOVE

INSTALLATION AND OPERATION

MANUAL

Model CI2000HT Shown

RETAIN THESE

INSTRUCTIONS

Spectra Series Wood Stoves

FOR FUTURE

REFERENCE

THIS APPLIANCE MUST BE INSTALLED BY A QUALIFIED INSTALLER. READ

MODELS CI1000HT and CI2000HT

ENTIRE MANUAL THOROUGHLY BEFORE INSTALLATION.

P/N 775

080M; Rev. F, 3/2005

Page 2

IMPORTANT WARNINGS

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW ROOM HEATER. FOR

YOUR SAFETY, FOLLOW THE INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS EXACTLY,

WITHOUT DEVIATION. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE,

BODILY INJURY, OR EVEN DEATH. IF THIS APPLIANCE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY

RESULT. CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA.

1. If utilizing an older chimney, it must be inspected

for adequate serviceability. Refer to the heading

Chimney Inspection on page 11 of this manual.

2. The minimum clearances must be maintained for all

combustible surfaces. The following materials

should be kept a minimum of 36 inches (914 mm)

from the heater; furniture, carpet, drapes, clothing,

wood, papers, etc. Do not store firewood within this

clearance space. Failure to maintain clearances to

all combustibles may result in a house fire.

3. This appliance requires floor protection as outlined in this manual (see Floor Protection on

pages 5, 6 and 7).

4. WARNING: improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. This appliance must be

properly installed or the listing will be void. Installations other than those specifically covered

herein have not been confirmed by test and are

not covered by the listing.

5. Minimum ceiling height must be 5 feet (measured

from base of appliance to ceiling).

6. DO NOT CONNECT THIS UNIT TO A CHIMNEY

FLUE CONNECTED TO ANOTHER APPLIANCE.

7. Do not connect this appliance to air ducts or any

air distribution system.

8. PREVENT CREOSOTE FIRE: Inspect and clean

chimney connector and chimney daily for creosote build-up until experience shows how often

you need to clean to be safe. Under certain conditions of use, creosote buildup may occur rapidly.

Be aware that the hotter the fire the less creosote

is deposited, and weekly cleaning may be necessary in mild weather even though monthly cleaning may be enough in the coldest months. Using

green or inadequately seasoned wood can greatly

increase creosote buildup. Use dry wood to minimize creosote buildup.

9. USE SOLID WOOD FUEL ONLY: This appliance is approved for burning dry seasoned natural wood only.

CAUTION: BURN UNTREATED WOOD ONLY. DO

NOT BURN GARBAGE OR FLAMMABLE FLUIDS

SUCH AS GASOLINE, NAPHTHA OR ENGINE OIL.

10. Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids

to start or "freshen up" a fire in this heater. Keep

all such liquids well away from the heater while it

is in use.

11. DO NOT OVERFIRE: If heater or chimney connector glows, you are overfiring. Overfiring this appliance could cause a house fire. Overfiring is a

condition where the appliance is operated at temperatures above its design capabilities. Overfiring

can be caused by improper installation, improper

PAGE 2

operation, lack of maintenance or improper fuel

usage. Do not operate the stove with the doors

open or ajar, as this will produce extreme temperatures within the stove.

overfiring is NOT covered under the manufacturers limited warranty (see Care and Operation,

pages 15 to 20).

12. NEVER LEAVE AN UNATTENDED STOVE BURNING ON HIGH. Operation of the stove with the

primary air draft control at its highest burn rate

setting for extended periods can cause dangerous overfiring conditions. The primary air draft

control should only be positioned at the highest

setting during start-up procedures (see How to

Start and Maintain a Fire on page 16) and for short

durations. When leaving the stove unattended ensure that the primary air draft control is set to the

low or medium low range.

13. It is imperative that the control compartments and

circulating air passageways of the appliance be

kept clean.

14. Use a metal container with a tight fitting lid to dispose of ashes.

15. IN THE EVENT OF A COMPONENT FAILURE, USE

ONLY COMPONENTS PROVIDED BY THE MANUFACTURER AS REPLACEMENT PARTS.

16. Burning any kind of fuel uses oxygen from the

dwelling. Be sure that you allow an adequate

source of fresh air into the room where the stove

is operating (see Ventilation Requirements on

page 12).

17. CAUTION: HOT WHILE IN OPERATION. An appliance hot enough to warm your home can severely

burn anyone touching it. Keep children, clothing

and furniture away. Contact may cause skin

burns. Do not let children touch the appliance.

Train them to stay a safe distance from the unit.

The use of a fireguard is recommended.

18. Do not operate this appliance without the firebox

baffle brick properly installed.

19. Always build wood fires directly on the firebox

grate. Do not use andirons or any other method

to elevate the fire.

20. Do not install these appliances into a Manufactured (Mobile) Home.

21. See the listing label located on the back of stove

(or see Safety/Listing Labels on pages 35 & 36).

22. These appliances are designed as supplemental

heaters. Therefore, it is advisable to have an alternate heat source when installed in a dwelling.

23. SAVE THESE INSTRUCTIONS. Ensure that this

manual remains with the appliance and passed to

the user after installation.

Damage caused from

Page 3

TABLE OF CONTENTS

Important Warnings ................................................ 2

Testing/Listing, EPA, Using this Manual.................. 3

Planning Your Installation ..................................... 4-9

Installation ........................................................ 10-14

Care and Operation .......................................... 15-20

Recommended Fuel / Wood Storage ............... 19-20

Maintenance ..................................................... 21-23

Troubleshooting ................................................ 23-24

Specifications.................................................... 25-26

Replacement Parts List..................................... 27-33

Optional Accessories ..............................................34

Safety/Listing Labels......................................... 35-36

EPA Labels .............................................................37

Service and Maintenance Log ................................38

TESTING/LISTING

Models CI1000HT and CI2000HT have been Listed to

UL Standard #1482 and ULC-S627 by OMNI-Test Laboratories, Inc.; Beaverton, OR; Report numbers;

CI1000HT #132-S-03-2 and CI2000HT #132-S-05-2.

EPA CERTIFICATION

This heater meets EPA particulate matter (smoke) control requirements for noncatalytic wood heaters built on

or after July 1, 1990.

CONGRATULATIONS ON THE PURCHASE OF YOUR

NEW WOODSTOVE MANUFACTURED BY LENNOX

HEARTH PRODUCTS.

When you purchased your new woodstove, you

joined the ranks of thousands of concerned individuals whose answer to their home heating needs

reflects their concern for aesthetics, efficiency and

our environment. We extend our continued support

to help you achieve the maximum benefit and enjoyment available from your new wood stove.

It is our goal at Lennox Hearth Products to provide

you, our valued customer, with an appliance that will

ensure you years of trouble free warmth and pleasure.

Thank you for selecting a Lennox Hearth Products

stove as the answer to your home heating needs.

Sincerely,

All of us at Lennox Hearth Products

USING THIS MANUAL

Please carefully read and follow all instructions in this

manual before starting the installation. Please pay special attention to the safety instructions provided in this

manual. The Homeowner’s Care and Operation Instructions included here will assure you have many years of

dependable and enjoyable service from your appliance.

PACKAGING LIST

This appliance is packaged with an accessory package,

which contains the following:

One - Installation and Operation Manual

One - Warranty Certificate

One - Wood and Brass, Removable Door Handle (for

opening the ashpan door, firebox door and side

door)

One - Air Control / Ash Pan Removal Tool

One - Fire Poker

Four - Leg Cushions

One - Spray Can of Charcoal Paint

PAGE 3

Page 4

PLANNING YOUR INSTALLATION

QUESTIONS TO ASK LOCAL BUILDING OFFICIAL

A correct installation is critical and imperative for reducing fire hazards and perilous conditions that can arise

when wood burning appliances are improperly installed.

The installer must follow all of the manufacturers’ instructions. These models are designed as radiant room

heaters and should be used for no other purpose.

The installation of a wood burning appliance must conform to local codes and applicable state and federal

requirements and a building permit must be obtained

before installing. Familiarity with these requirements

before installation is essential. Important considerations

to discuss with local building officials include:

1. Applicable codes (i.e. Uniform Mechanical Code,

State or Regional Codes.)?

2. Local amendments?

3. Is a permit required - cost?

(You may wish to contact your insurance company

to ask if they require this?).

4. Rooms where the installation is not allowed?

SMOKE DETECTORS

Since there are always several potential sources of fire

in any home, we recommend installing smoke detectors. If possible, install the smoke detector in a hallway

adjacent to the room (to reduce the possibility of occasional false activation from the heat produced by the

stove). If your local code requires a smoke detector be

installed within the same room, you must follow the requirements of your local code. Check with your local

building department for requirements in your area.

NOTE – This appliance is NOT

tion into a Manufactured (Mobile) Home.

SELECTING A LOCATION

The design of your home and where you place your

stove will determine its value as a source of heat. A

wood stove depends primarily on air circulation (convection) to disperse its heat, and therefore, a central

location is often best. There are other practical considerations, which must be considered before a final selection of locations is made.

approved for installa-

♦ Existing Chimneys

♦ Wood Storage

♦ Aesthetic Considerations

♦ Roof Design (Rafter Locations & Roof Pitch)

♦ Room Traffic

♦ Proximity to Combustibles

♦ Electrical Wiring

The installation of this stove will require some research.

Once your options are determined, consult with your

local building department who will be able to give you

the necessary installation requirements for your area (Is

a building permit required?, Rooms where installation

may not be allowed?, etc.).

WARNING: CHECK ALL LOCAL BUILDING AND

SAFETY CODES BEFORE INSTALLATION. THE INSTALLATION INSTRUCTIONS AND APPROPRIATE

CODE REQUIREMENTS MUST BE FOLLOWED EXACTLY AND WITHOUT COMPROMISE. ALTERATIONS TO THE STOVE ARE NOT ALLOWED. DO

NOT CONNECT THE STOVE TO A CHIMNEY SYSTEM SERVING ANOTHER STOVE, APPLIANCE, OR

ANY AIR DISTRIBUTION DUCT. FAILURE TO FOLLOW THESE INSTRUCTIONS WILL VOID THE

MANUFACTURERS WARRANTY.

If you plan to vent your stove into an existing masonry

chimney, have it inspected by a local fire marshal or

qualified installer. Remember that a stove's performance is heavily influenced by the chimney and its location on the roof. An oversized flue may not provide effective draw, and a flue liner may be required (see Draft

Requirements on page 12). Consult your dealer or

qualified installer before final selection is made.

This stove requires pre-installation work to be completed before installation can take place. This may include modification for flue and chimney.

The appliance should be inspected before use and the

chimney cleaned at least annually. More frequent cleaning may be required due to poor operation, installation,

or low quality fuel.

CAUTION: THE STOVE BODY IS VERY HEAVY. THE

USE OF A HEAVY DUTY ESCALARA (STAIR STEP

HAND TRUCK) IS RECOMMENDED FOR LIFTING

THE STOVE BODY.

PAGE 4

Page 5

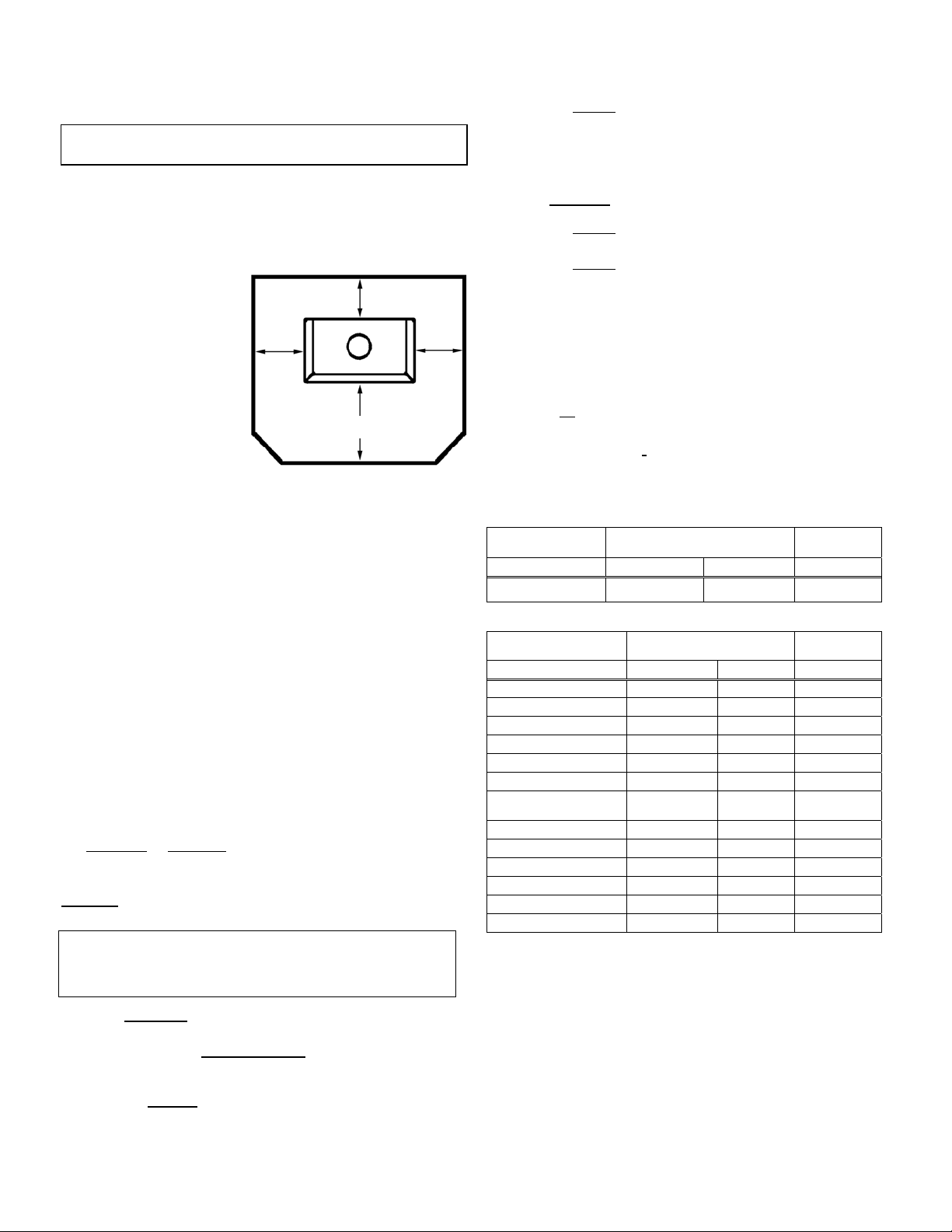

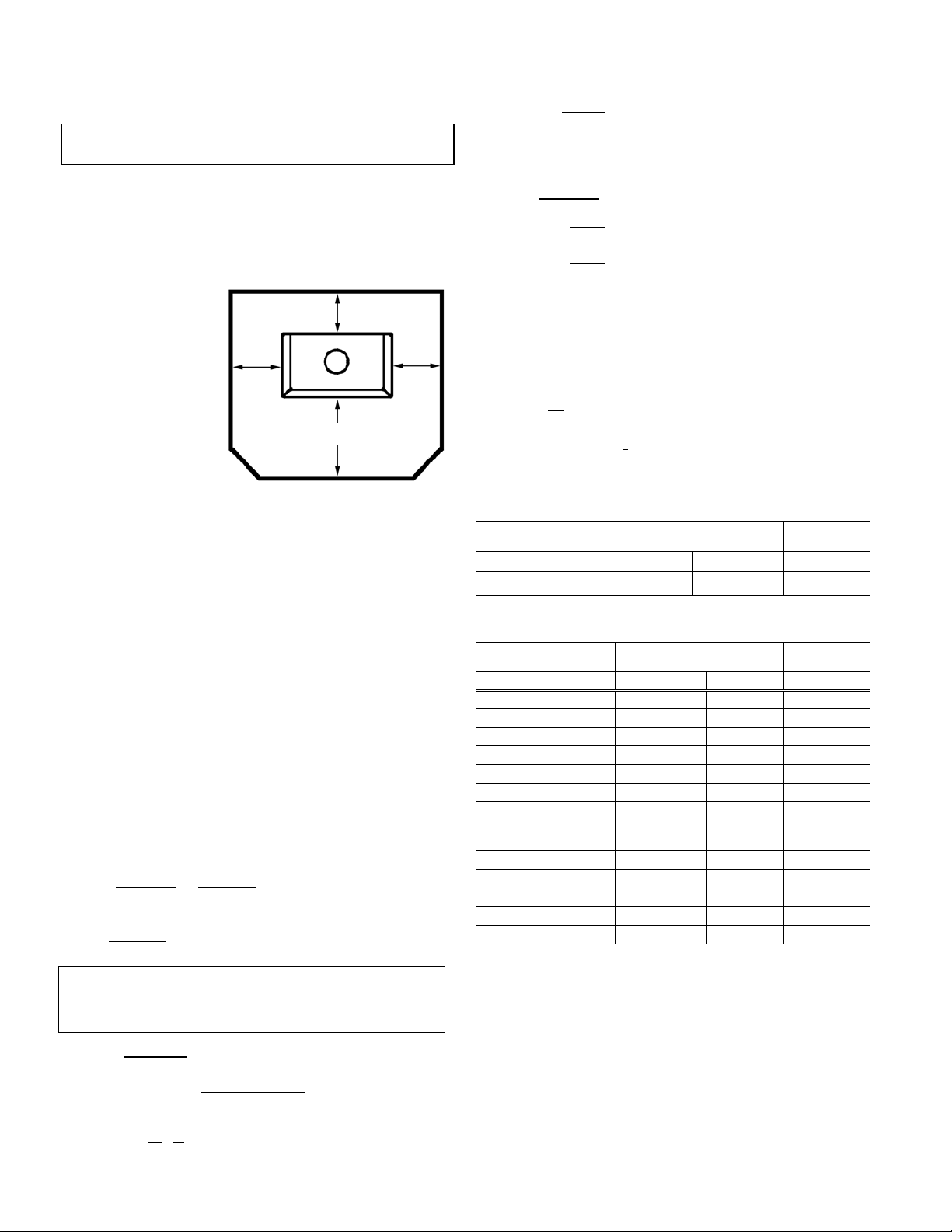

PLANNING YOUR INSTALLATION – Model CI1000HT

T

aterials

↓

FLOOR PROTECTION

FOR INSTALLATIONS IN THE USA

MODEL CI1000H

The floor protector must meet or exceed the minimum thermal requirements as defined on this page (see Floor Protec-

tion Using Alternate Material As Floor Protector). If the floor

protection is to be stone, tile, brick, etc., it must be mortared

or grouted to form a continuous noncombustible surface. If a

chimney connector extends

horizontally over the floor,

protection must also cover

the floor under the

Top View

0 "

(0 mm)

connector and at least 2"

(51 mm) to either side.

The floor protector must

fully cover the area

beneath the appliance

5.2"

(132 mm)

5.2"

(132 mm)

and extend 18” to the

front, 5.2” to the sides,

and 0” from the back as

18" (457 mm)

shown in the illustration

to the right.

FLOOR PROTECTION

USING ALTERNATE MATERIAL AS FLOOR PROTECTOR

The hearth pad or alternate material used as a floor protector must be constructed of a durable noncombustible material having an equal or better thermal conductivity value

(lower k value) of k = .84 BTU / IN FT

2

HR °F or a thermal

resistance that equals or exceeds r = 1.19 HR °F FT

IN/BTU with a minimum thickness of 1/2”. With these values, determine the minimum thickness of the alternate material required using the formula(s) and the table shown

here (see chart – Approved Alternative Materials for Floor

Protection).

Note: Any noncombustible material having a thickness of

1/2” (13 mm) whose k value is less than .84 or whose r

value is more than 1.19 is acceptable. If the alternate material used has a higher k value or lower r value will require a

greater thickness of the material used. In some cases, if the

k value is less or the r value higher, a thinner material may

be used.

Methods of determining floor protection equivalents:

To determine the thickness required for the alternate material when either the k value or r value is known, use either

the k formula

or r formula:

Example: Durock Cement Board is to be used for the floor

protection. How thick must this material be? The following

formulas

required.

T

M

give the means of determining minimum thickness

= minimum thickness required for alternate material

kM = k value per inch of alternate material

TL = minimum thickness of listed material

rM = r value per inch of alternate material

Using the k formula

Desired Thickness k value of desire Minimu

of the alternate = material (per inch)

material k value of listed of listed

material (per inch) material

(inches) = kM x TL

T

M

.84

:

x thickness

TM (inches) = 1.92 x 1/2”

.84

Answer using k: 2.286 x 0.50” = 1.143 = ~ 1 9/64”

1 9/64” thickness Durock Cement Board will be required.

Using the r formula:

TM (inches) = 1.19 x TL

r

T

.52

Answer using r: 2.288 x 0.50” = 1.143 = ~ 1 9/64”

1 9/64” thickness Durock Cement Board will be required.

At times it is important to know what combination of materials are

acceptable for use as floor protection. The “R values” are used to

determine acceptable combinations of materials because “R values” are additive where r and k values are not.

“R value” = 1

k

Example: “R value” = 1/k

that the required “R value” for a suitable floor protector used must be

equal to or greater than:“R” = r x T

2

Note: To convert inches to millimeters divide by .03937.

(*) After minimum thickness is calculated, the thickness can

be no less than 1/2” (13mm).

(**) If the floor protector to be used is a noncombustible material and is NOT listed on this chart on this page, the manufacturer of the material must provide either the listed k-value

per inch or r-value per inch and the minimum thickness will

need to be calculated per instructions on this page.

M

(inches) = 1.19 x .5”

M

= r x thickness of material used

= r x thickness of material used. Given

= 1.19 x .5” = .60.

L

Listed Material

Listed Material Thermal Values Listed Min.

Listed Material → .84 1.19 1/2”

k (per inch) r (per inch) T

Thickness

L

Approved Alternate Materials for Floor Protection (**)

Alternative

M

k (per inch) r ( per i nch) TM

Kaowool M Board .47 2.13 * 1/2”

Micore 160 .35 2.86 * 1/2”

Micore 300 .46 2.18 * 1/2”

Durock Cement Board 1.92 .52 1 3/16”

Hardibacker 1.95 .51 1 3/16”

Hardibacker 500 2.30 .44 1 3/8”

Cultered Stone

Hearthstone

Wonderboard 3.23 0.31 1 15/16”

Face brick 9.00 0.11 5 3/8”

Common brick 5.00 0.20 3”

Cement mortar 5.00 0.20 3”

Ceramic tile 12.5 .08 7 ½”

Marble ~20.0 ~.05 11 15/16”

Thermal Values * Minimum

Thickness

2.82 .35 1 11/16”

PAGE 5

Page 6

PLANNING YOUR INSTALLATION – Model CI1000HT

T

aterials

↓

FLOOR PROTECTION

FOR INSTALLATIONS IN CANADA

MODEL CI1000H

The floor protector must meet or exceed the minimum thermal requirements as defined on this page (see Floor Pro-

tection Using Alternate Material As Floor Protector). If the

floor protection is to be stone, tile, brick, etc., it must be

mortared or grouted to form a continuous noncombustible

surface. If a chimney connector extends horizontally over

the floor, protection

must also cover the

floor under connector

and at least 2" (51

mm) to either side.

Top View

8" (203 mm)

The floor protector must

fully cover the area

beneath the appliance

8"

(203 mm)

8"

(203 mm)

and extend 18” to the

front, 8” to the sides,

and 8” from the back as

18" (457 mm)

shown in the illustration

to the right.

FLOOR PROTECTION USING ALTERNATE MATERIAL

AS FLOOR PROTECTOR

The hearth pad or alternate material used as a floor protector must be constructed of a durable noncombustible

material having an equal or better thermal conductivity

value (lower k value) of k = .84 BTU / IN FT

thermal resistance that equals or exceeds r = 1.19 HR °F

2

IN/BTU with a minimum thickness of 1.45”. With these

FT

2

HR °F or a

values, determine the minimum thickness of the alternate

material required using the formula(s) and the table

shown here (see chart – Approved Alternative Materials

for Floor Protection).

Note: Any noncombustible material having a thickness of

1.45" (37 mm) whose k value is less than .84 or whose r

value is more than 1.19 is acceptable. If the alternate material used has a higher k value or lower r value will require a greater thickness of the material used. In some

cases, if the k value is less or the r value higher, a thinner

material may be used.

Methods of determining floor protection equivalents:

To determine the thickness required for the alternate material when either the k value or r value is known, use either the k formula

or r formula:

Example: Durock Cement Board is to be used for the

floor protection. How thick must this material be? The following formulas

thickness required.

= minimum thickness required for alternate material

T

M

give the means of determining minimum

kM = k value per inch of alternate material

TL = minimum thickness of listed material

rM = r value per inch of alternate material

Using the k formula

Desired thickness k value of desire Minimum

of the alternate = material (per inch)

material k value of listed of listed

material (per inch) material

TM (inches) = k

.84

:

x TL

M

x thickness

TM (inches) = 1.92 x .1.45”

.84

Answer using k: ~2.287 x ~1.45” = ~ 3.316” = ~ 3 5/16”

~ 3 5/16” thickness Durock Cement Board will be required.

Using the r formula:

TM (inches) = 1.19 x TL

r

T

M

.52

Answer using r: ~2.287 x 1.45” = ~3.316 =~ 3 5/16”

~ 3 5/16” thickness Durock Cement Board will be required.

At times it is important to know what combination of materials are

acceptable for use as floor protection. The “R values” are used to

determine acceptable combinations of materials because “R values” are additive where r and k values are not.

“R value” = 1

k

Example: “R value” = 1/k = r x thickness of material used. Given that

the required “R value” for a suitable floor protector used must be equal to

or greater than:“R” = r x T

Listed Material Thermal Values Listed Min.

Listed Material → .84 1.19 1.45”

Alternative

M

k (per inch) r ( per i nch) TM

Kaowool M Board .47 2.13 * 1.45”

Micore 160 .35 2.86 * 1.45”

Micore 300 .46 2.18 * 1.45”

Durock Cement Board 1.92 .52 3.5/16”

Hardibacker 1.95 .51 3 3/8”

Hardibacker 500 2.30 .44 4”

Cultered Stone

Hearthstone

Wonderboard 3.23 0.31 5 9/16”

Face brick 9.00 0.11 15 9/16”

Common brick 5.00 0.20 8 5/8”

Cement mortar 5.00 0.20 8 5/8”

Ceramic tile 12.5 .08 21 9/16”

Marble ~20.0 ~.05 34 9/16”

Note: To convert inches to millimeters divide by .03937.

(*) After minimum thickness is calculated, the thickness can be

no less than 1.45” (36.8mm).

(**) If the floor protector to be used is a noncombustible material and is NOT listed on this chart on this chart, the manufacturer of the material must provide either the listed k-value per

inch or r-value per inch and the minimum thickness will need to

be calculated per instructions on this page.

PAGE 6

M

(inches) = 1.19 x .1.45”

= r x thickness of material used

= 1.19 x 1.45” = ~ 1.73.

L

Listed Material

k (per inch) r (per inch) T

Approved Alternate Materials for

Floor/Hearth Protection (**)

Thickness

L

Thermal Values * Minimum

2.82 .35 4 7/8”

Thickness

Page 7

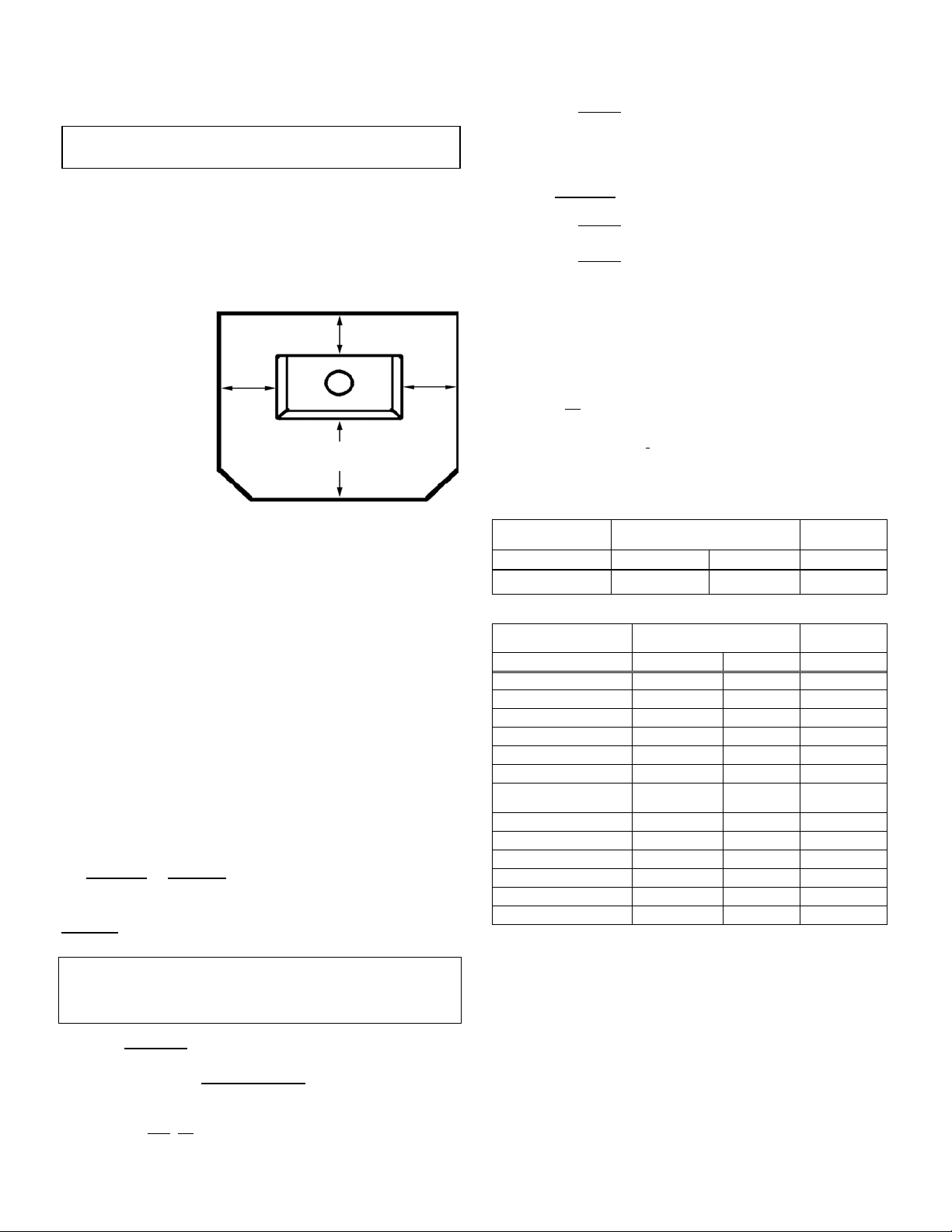

PLANNING YOUR INSTALLATION– Model CI2000HT

aterials

↓

a

a

FLOOR PROTECTION

FOR INSTALLATIONS IN THE USA & CANADA

The floor protector must meet or exceed the minimum thermal requirements as defined on this page (see Floor Protec-

tion Using Alternate Material As Floor Protector). If the floor

protection is to be stone, tile, brick, etc., it must be mortared

or grouted to form a continuous noncombustible surface. If a

chimney connector extends horizontally over the floor, protection must also cover the floor under the connector and at

least 2" (51 mm) to

either side.

The floor protector

must fully cover the

area beneath the

appliance and extend

18” to the front, 5”USA and 8”-Canada

to the sides, and 0”USA and 8”-Canada

from the back as

shown in the illustration to the right.

FLOOR PROTECTION USING ALTERNATE MATERIAL AS

FLOOR PROTECTOR

The hearth pad or alternate material used as a floor protector must be constructed of a durable noncombustible material having an equal or better thermal conductivity value

(lower k value) of k = .84 BTU / IN FT

resistance that equals or exceeds r = 1.19 HR °F FT

with a minimum thickness of 1/2”. With these values, determine the minimum thickness of the alternate material required using the formula(s) and the table shown here (see

chart – Approved Alternative Materials for Floor Protection).

Note: Any noncombustible material having a thickness of

1/2” (13 mm) whose k value is less than .84 or whose r value

is more than 1.19 is acceptable. If the alternate material

used has a higher k value or lower r value will require a

greater thickness of the material used. In some cases, if the

k value is less or the r value higher, a thinner material may

be used.

Methods of determining floor protection equivalents:

To determine the thickness required for the alternate material when either the k value or r value is known, use either

the k formula

or r formula:

Example: Durock Cement Board is to be used for the floor

protection. How thick must this material be? The following

formulas

required.

T

M

give the means of determining minimum thickness

= minimum thickness required for alternate material

kM = k value per inch of alternate material

TL = minimum thickness of listed material

rM = r value per inch of alternate material

Using the k formula

Desired thickness k value of desire Minimum

of the alternate = material (per inch)

material k value of listed of listed

material (per inch) material

(inches) = k

T

M

.84

MODEL CI2000HT

Canad

8"/203mm

USA

5" / 127 mm

:

x TL

M

Top View

USA & Canada

18" (457 mm)

2

HR °F or a thermal

x thickness

0" / 0 mm USA

8" / 203mm Canada

Canad

8"/203mm

USA

5" / 127 mm

2

IN/BTU

PAGE 7

T

(inches) = 1.92 x 1/2”

M

.84

Answer using k: 2.286 x 0.50” = 1.143 = ~ 1 9/64”

~1 9/64” thickness Durock Cement Board will be required.

Using the r formula:

(inches) = 1.19 x TL

T

M

r

(inches) = 1.19 x .5”

T

M

.52

M

Answer using r: 2.288 x 0.50” = 1.143 = ~ 1 9/64”

~1 9/64” thickness Durock Cement Board will be required.

At times it is important to know what combination of materials

are acceptable for use as floor protection. The “R values” are

used to determine acceptable combinations of materials because “R values” are additive where r and k values are not.

“R value” = 1

k

= r x thickness of material used

Example: “R value” = 1/k = r x thickness of material used. Given

that the required “R value” for a suitable floor protector used must be

equal to or greater than:“R” = r x T

= 1.19 x .5” = .60.

L

Listed Material

Listed Material Thermal Values Listed Min.

Listed Material → .84 1.19 1/2”

k (per inch) r (per inch) T

Thickness

L

Approved Alternate Materials for Floor Protection (**)

Alternative

M

k (per inch) r ( per i nch) TM

Kaowool M Board .47 2.13 * 1/2”

Micore 160 .35 2.86 * 1/2”

Micore 300 .46 2.18 * 1/2”

Durock Cement Board 1.92 .52 1 3/16”

Hardibacker 1.95 .51 1 3/16”

Hardibacker 500 2.30 .44 1 3/8”

Cultered Stone

Hearthstone

Wonderboard 3.23 0.31 1 15/16”

Face brick 9.00 0.11 5 3/8”

Common brick 5.00 0.20 3”

Cement mortar 5.00 0.20 3”

Ceramic tile 12.5 .08 7 ½”

Marble ~20.0 ~.05 11 15/16”

Thermal Values * Minimum

Thickness

2.82 .35 1 11/16”

Note: To convert inches to millimeters divide by .03937.

(*) After minimum thickness is calculated, the thickness can

be no less than 1/2” (13mm).

(**) If the floor protector to be used is a noncombustible material and is NOT listed on this chart on this chart, the manufacturer of the material must provide either the listed k-value

per inch or r-value per inch and the minimum thickness will

need to be calculated per instructions on this page.

Page 8

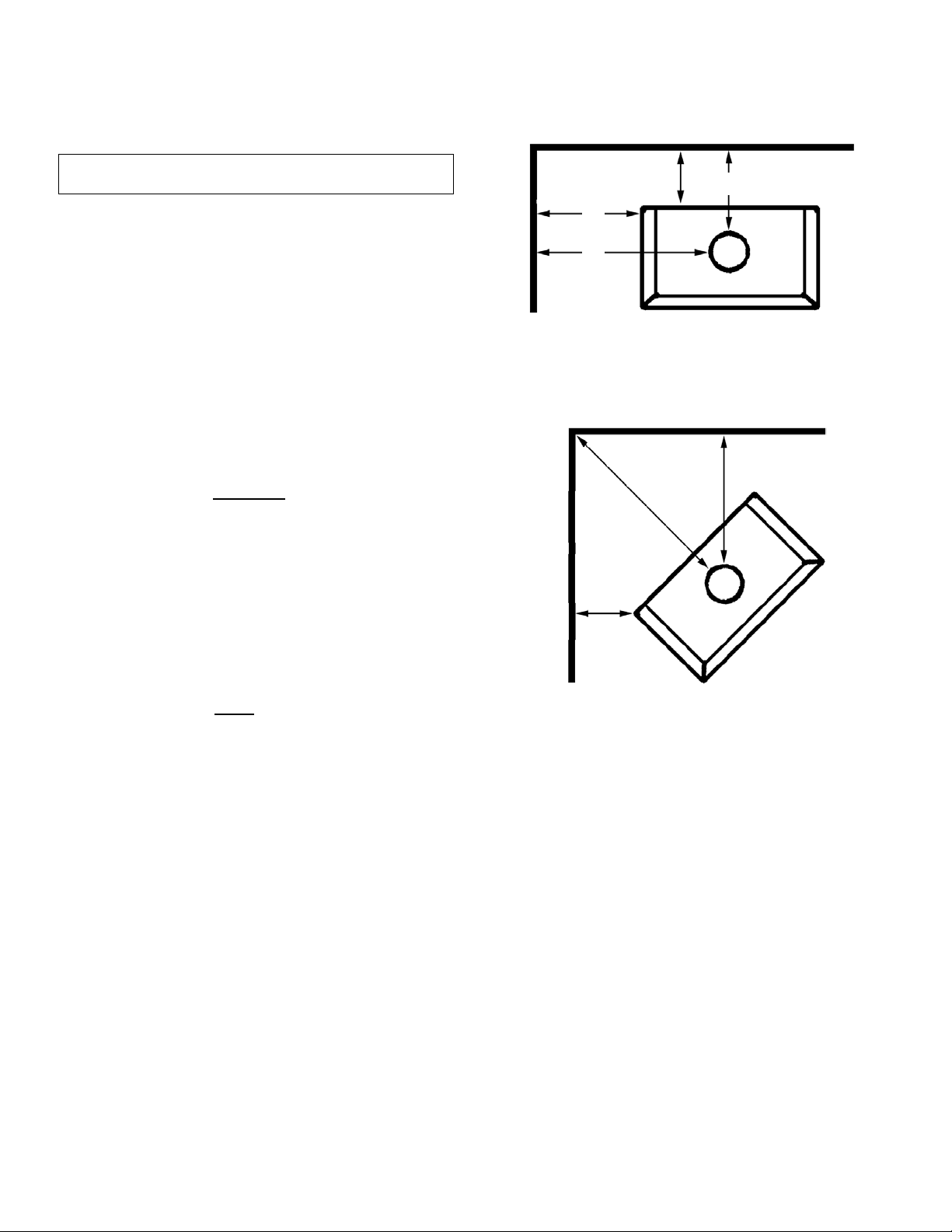

PLANNING YOUR INSTALLATION– Model CI1000HT

E

MODEL CI1000HT

COMBUSTIBLE WALL CLEARANCE – USA & Canada

WARNING: It is very important that you observe the

minimum clearances.

There are listed clearances for your stove which were

determined in a Laboratory test using various "classes"

of stove pipe or chimney. Minimums are first established for the stove itself and increased based on how

much heat is transferred by each class of pipe.

Position the unit no closer than the minimum clearances

to combustible materials. Check that no overhead

cross members in the ceiling or roof will be cut. Reposition unit if necessary being careful not to move closer

than the minimum clearances.

Minimum Ceiling Height – 7 feet / 2133mm from floor

to ceiling.

SINGLE WALL PIPE WITHOUT

Using single wall 24 MSG black or 25 MSG blued steel

connector pipe with factory-built chimney listed to either

UL 103HT or ULC S629.

Minimum Clearances (inches)

A. 27 1/2" / 699mm D. 24" / 610mm

B. 27" / 686mm E. 18" / 457mm

C. 27" / 686mm F. 19" / 483mm

G. 35 3/16” / 894 mm (this is a reference dimension only)

SINGLE WALL PIPE WITH

CLEARANCE

Using single wall 24 MSG black or 25 MSG blued steel

connector pipe with factory-built chimney listed to either

UL 103HT or ULC S629. The use of a pipe shield for 6"

connector with 1" clearance to the pipe is mandatory.

Minimum Clearances (Inches)

A. 21 1/2" / 546mm D. 18" / 457 mm

B. 27" / 686mm E. 18" / 457mm

C. 19" / 483mm F. 11" / 279mm

G. 23 7/8” / 606 mm (this is a reference dimension only)

PROTECTED WALL CLEARANCE

Some local codes will allow reduced clearances when the

stove is installed adjacent to a protected wall system. The

variance must be approved by your local building official.

Normally, the protected wall system is defined as a noncombustible material with a minimum of 1" air space behind. Check your local building codes or with a qualified

installer (Ref. NFPA 211).

PIPE SHIELD

PIPE SHIELD / REDUCED

Parallel Installation

D

B

Corner Installation

G

F

• MODEL CI1000HT IS NOT APPROVED FOR USE

WITH DOUBLE WALL PIPE.

• DO NOT INSTALL THE CI1000HT INTO AN AL-

COVE OR A CONFINED SPACE. This unit has

not been tested or approved for installation into

a confined space such as an alcove (see the national standard below).

NFPA 211-96, 9-2.2: (Applies to Solid Fuel Burn-

ing Appliances, which are not alcove tested) Solid fuel-burning appliances shall not be installed in confined spaces. The space or room

shall be of ample size to allow adequate circulation of heated air. Appliances shall be so located as not to interfere with the proper circulation of air within the heated space.

A

C

PAGE 8

Page 9

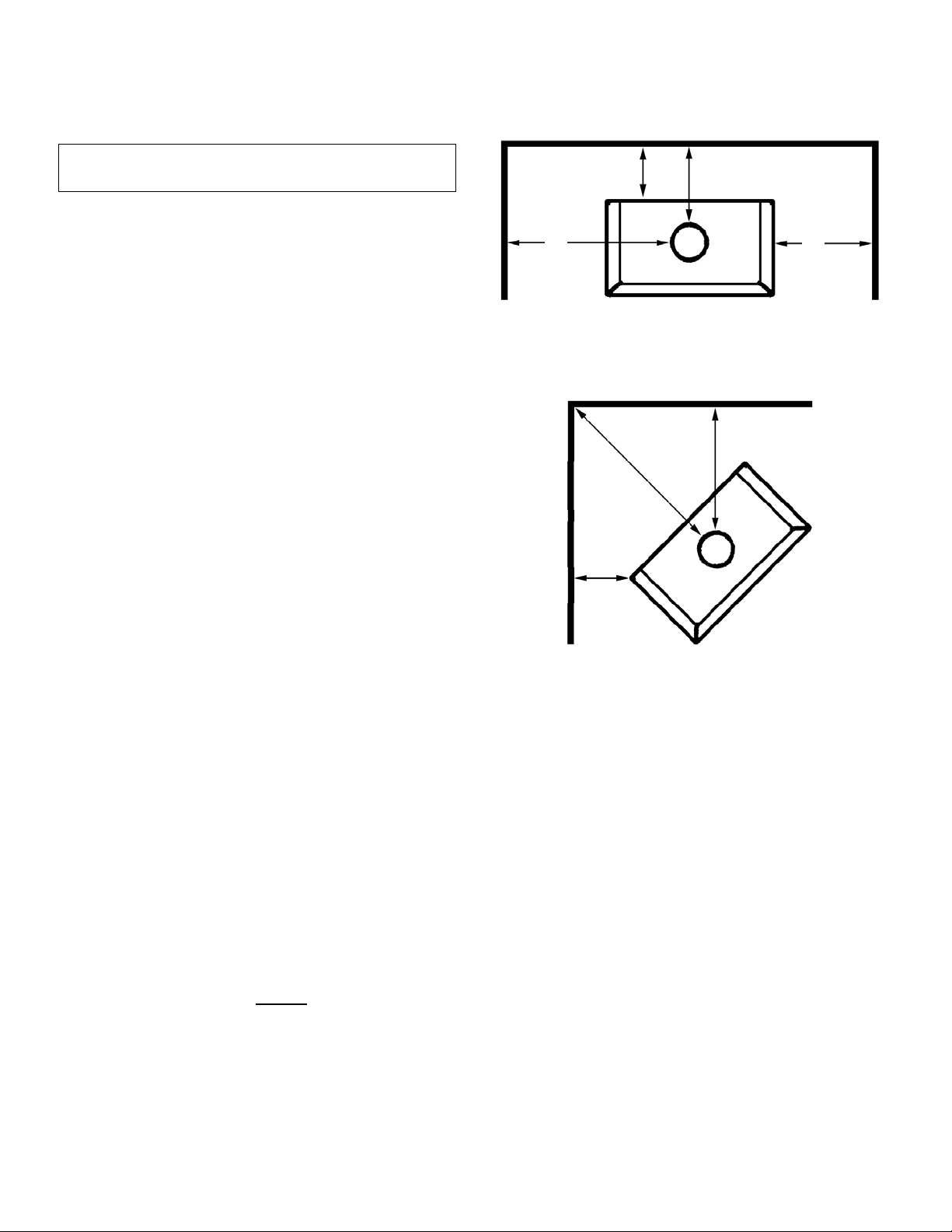

PLANNING YOUR INSTALLATION– Model CI2000HT

MODEL CI2000HT

COMBUSTIBLE WALL CLEARANCE – USA & Canada

WARNING: It is very important that you observe the

minimum clearances.

There are listed clearances for your stove which were

determined in a Laboratory test using various "classes"

of stove pipe or chimney. Minimums are first established

for the stove itself and increased based on how much

heat is transferred by each class of pipe.

Position the unit no closer than the minimum clearances

to combustible materials. Check that no overhead cross

members in the ceiling or roof will be cut. Reposition

unit if necessary being careful not to move closer than

the minimum clearances.

SINGLE WALL PIPE (Not approved for alcove installations) Using single wall 24 MSG black or 25 MSG

blued steel connector pipe with factory-built chimney

listed to either UL 103HT or ULC S629.

Minimum Clearances (inches)

A. 18" / 457mm D. 13" / 330mm

B. 32" / 813mm E. 20" / 508mm

C. 27" / 686mm F. 16" / 406mm

G. 35 3/16” / 894 mm (this is a reference dimension only)

DOUBLE WALL PIPE (For alcove installations,

clearances "C" and "F" are not applicable) Use listed

double wall chimney connector or Type L vent pipe to

the top of the stove.

Minimum Clearances (Inches)

A. 14 1/2" / 368mm D. 10" / 254mm

B. 28 1/2" / 724mm E. 17" / 432mm

C. 18" / 457mm F. 7" / 178mm

Minimum Ceiling Height for Single wall pipe and

double wall pipe installations and Alcove Installations – 60" / 1524mm from floor to ceiling and 29" /

737mm from stove top to ceiling.

ALCOVE INSTALLATION CLEARANCES

Alcove Installations Require Double Wall Pipe Only

Use listed double wall chimney connector or Type L

vent pipe to the top of the stove.

Minimum Clearances (Inches)

A. 14 1/2" (368 mm) D. 10" (254 mm)

B. 28 1/2" (724 mm) E. 17" (432 mm)

C. N/A F. N/A

Note: Alcove clearances cannot

wall protection. Maximum alcove depth must be no

more than 48" (1220 mm).

be reduced using

Parallel & Alcove Installations

D

B E

A

Corner Installation

C

G

F

PROTECTED WALL CLEARANCE

Some local codes will allow reduced clearances when the

stove is installed adjacent to a protected wall system. The

variance must be approved by your local building official.

Normally, the protected wall system is defined as a non- combustible material with a minimum of 1" air space behind.

Check your local building codes or with a qualified installer

(Ref. NFPA 211).

PAGE 9

Page 10

INSTALLATION

INSTALLING LEG PADS

The four leg pads (included in accessory package), are

provided for placement under the four legs.

TYPES OF CHIMNEYS

The unit must be connected to either a code-approved

masonry chimney with a flue liner, or a 6 inch diameter

factory-built chimney complying with the requirements for

Type HT chimneys in the standard UL 103.

The chimney is a vital part of your stove installation. A

properly built masonry chimney or a properly installed

factory-built chimney will assure a consistent draft under

a variety of weather conditions (a smoking stove is usually caused by a chimney problem). The stove flue size is

6 inches diameter, which is approximately 28 square

inches minimum. The maximum flue size should be no

more than (3)-three times the cross sectional area of the

size of the stove flue collar. In this case, that would be no

larger than an 10-inch diameter stack, or approximately

85 square inches maximum.

All chimneys must be installed as specified by local

building codes and according to the chimney manufacturer instructions (in the case of a factory-built chimney).

See the chimney manufacturer instructions for exact

specifications. Factory-built chimneys must comply with

UL 103HT or ULC S629. A chimney connector shall not

pass through an attic or roof space, closet or similar concealed space, or a floor, or ceiling. Where passage

through a wall, or partition of combustible construction is

desired, the installation shall conform to CAN/CSA-B365,

Installation Code for Solid-Fuel-Burning Appliances and

Equipment.

Factory

Built

Chimney

Tile-lined

Masonry

ACCEPTABLE CONNECTOR PIPE FOR INSTALLATIONS

When Using Single Wall Pipe:

ameter, single wall, 24 MSG black steel or 26 MSG

blued steel connector pipe on the flue collar of the unit.

When installing pipe, the crimped ends of the pipe

should all point down. Position all seams toward the

back for aesthetics. Three (3) pre-drilled holes are provided in the flue collar for fastening the pipe securely to

the stove. Use sheet metal screws to do this. Additional

sections of single wall pipe should be fastened together

with at least three (3) sheet metal screws each section.

All pipe connections must be sealed (ie. high temperature silicone). When connecting to the factory-built ceiling

support package, use the manufacturer's transition

piece, usually called a dripless connector, to join single

wall pipe to their factory-built chimney section.

Chimney

Install a six (6) inch di-

When Using Approved Double Wall Pipe (Approved

for Model CI2000HT Only): Type L and listed double

wall connector pipe is acceptable. Install any factory-built

brand of pipe according to the manufacturer's instructions. All pipe connections must be sealed (ie. high temperature silicone).

Minimum / Maximim Flue Diameter

Minimum 6", Maximum 10"

Chimney Connector Adapter

tor adapter to connect the chimney connector up to the

chimney. The small ends of the chimney connector

should all point down for a drip free installation. Position

all seams toward the back for aesthetics. The chimney

connector must be 6-inch diameter.

Secure adjoining sections of chimney connector to each

other using three equally spaced sheet metal screws.

Secure the connector pipe to flue collar using three

equally spaced sheet metal screws. DO NOT secure

chimney connector to chimney with screws.

Connection To A Factory-built Chimney

heater is to be connected to a factory-built chimney conforming to CAN / ULC – S629, Standard for 650°C Factory-Built Chimneys. All pipe connections must be sealed

(ie. high temperature silicone).

For Reduced Residential Clearances Using Double

Wall Pipe (Approved for Model CI2000HT Only): Type

L and listed double wall connector pipe is acceptable.

Install any factory-built brand of pipe according to the

manufacturer's instructions.

Vapor Barrier at Chimney Penetration

Install all venting components per the Vent Manufacturers installation instructions. Ensure that there is an effective vapor barrier at the location where the chimney

penetrates to the exterior of the structure. This can be

accomplished by applying a non-hardening waterproof

sealant to the following components:

• Around the chimney at the point where the storm

collar will meet the chimney just above the Flashing.

• Along the vertical seam of the chimney pipe, where it

is exposed to the weather.

• On each nail head on the flashing.

• Around the chimney at the point where the storm

collar will meet the chimney just above the flashing.

Notes:

• On a flat or tarred and graveled roofs, nail and seal

the flat roof flashing to the roof on all sides with roofing compound.

• Do not put screws through the flashing into the chim-

ney pipe.

:

- Use a chimney connec-

- This space

PAGE 10

Page 11

INSTALLATION

CHIMNEY INSPECTION

Existing chimneys must be inspected before installing

your stove. Consult your local building department for

chimney code requirements. A masonry chimney must

have a code approved liner. This liner must not have

broken or missing pieces. Some non-code masonry

chimneys may be brought up to code by being relined.

(Consult your dealer or qualified chimney sweep).

Factory-built chimneys should also be inspected, first

for creosote deposits (which should be removed), and

then for integrity of the stainless steel liner. Look for

obvious bulges in the lining, which may indicate the

need to replace that section (use a bright flashlight).

Also, inspect the attic to see that the chimney has

proper clearance to combustible framing members. For

interior masonry chimneys and most factory-built chimneys, this must be a (2) two inch air space clearance,

which must not be filled with insulation or any other

material. An exterior masonry chimney must have a (1)

one-inch air space clearance.

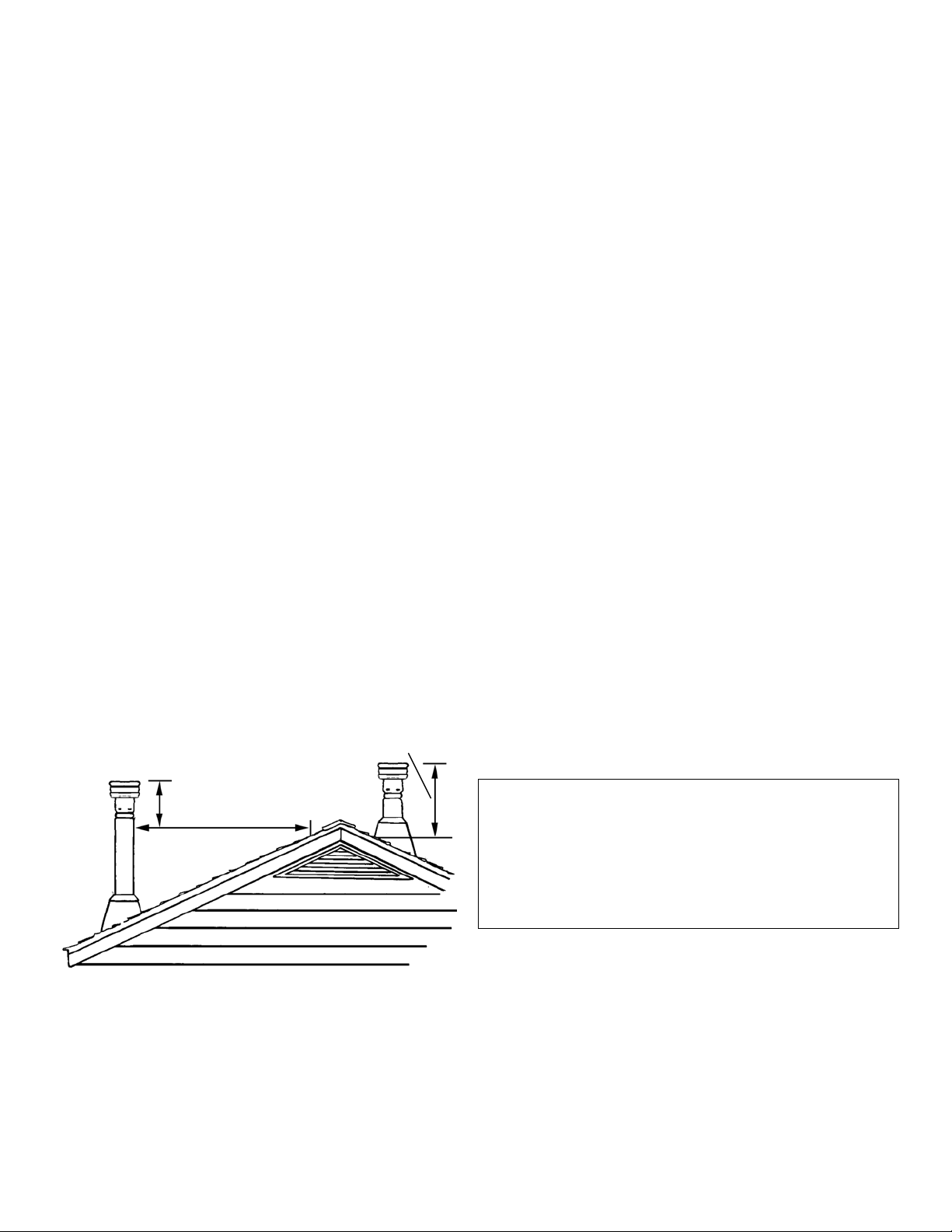

CHIMNEY HEIGHT REQUIREMENTS

The chimney must extend 3 feet above the level of roof

penetration and a minimum of 2 feet higher than any

roof surface within 10 feet (see below). Check with

your local building officials for any additional requirements for your area.

Due to prevailing winds, local terrain, adjacent tall

trees, a hill, or ravine near the home, or adjacent structures, additional chimney height or a special chimney

cap may be required to ensure optimum performance.

The 10’ by 2’ Rule for Vent Termination

Requires A Listed

Termination Cap

2’ (610mm)

10’ (305 cm)

The top of the flue must be 2’ (610 mm) higher than

any part of the roof within 10’ (305 cm) horizontal and a

minimum of 3’ (915 mm) higher than the highest point of roof

penetration.

3’ (915mm)

SPECIAL NOTE:

The installation of a barometric damper is recommended

for all freestanding stoves in areas that may have high

winds, which can effect the draft. The installation must be

only in units with a newly constructed chimney, free of

creosote deposits. The barometric damper is an automatic

device designed to regulate the draft in a heating appliance, which in turn, stabilizes the chimney temperatures,

lessening the potential of over-firing. Do not place the

barometric damper greater than 24 inches (610 mm) above

the unit. Excessive draft will lead to poor control of the

burning rate and possible over-firing of the stove and damage to the cast iron firebox. Most barometric dampers are

calibrated in inches of water column and can be set to draft

requirements of -.03 to -.08 inches (-7.5 to -20 Pa). It is

recommended that the barometric dampers to be set between -.05 and -.06 inches.

THE RECOMMENDED DRAFT REQUIREMENTS FOR

THESE APPLIANCES IS NO LESS THAN -.05 AND NO

GREATER THAN -.06. OPERATION OF YOUR STOVE

WITH A DRAFT GREATER THAN -.06 CAN POSSIBLY

CAUSE DAMAGE TO THE STOVE AND VOID THE

WARRANTY.

Fire intensity is a function of several factors. One of these

factors is DRAFT. Normally, increasing draft increases fire

intensity. Conversely, increasing the fire intensity will increase draft. Draft can also be affected by external factors

such as wind strength and direction, outside temperature,

airflow in or out of the structure, and so forth. If one of

these factors changes, the draft of a low-burning appliance

may increase. This increased draft may cause dangerously high temperature to develop, possibly causing failure

of the unit or flue, or ignition of nearby combustibles. Closing down the combustion airflow ("Primary Air Draft Control") may not guarantee that this will not happen.

CAUTION: MANY STRUCTURE FIRES HAVE RESULTED WHEN A SLOW BURNING FIRE HAS BEEN

LEFT UNATTENDED FOR ANY EXTENDED PERIOD OF

TIME. THESE FIRES NORMALLY OCCUR BECAUSE

COMBUSTIBLE MATERIALS CLOSE TO AN APPLIANCE BECOME HEATED TO THE IGNITION POINT BY

AN OVERFIRED APPLIANCE WHICH THE OPERATOR

THOUGHT WAS SAFETY "THROTTLED DOWN."

PAGE 11

Page 12

INSTALLATION

DRAFT REQUIREMENTS

The appliance is merely one component of a larger

system. The other equally important component is the

venting system which is necessary for achieving the

required flow of combustion air to the fire chamber and

for safely removing unwanted combustion byproducts

from the appliance. If the venting system's design does

not promote these ends, the system may not function

properly. Poorly functioning venting systems may create performance problems (i.e. smoking stove, poor

heat output, fire goes out, window blackens, increased

creosote buildup, etc.) as well as be a safety hazard.

Some factors that may lead to performance problems

are as follows:

• Oversized or undersized chimney.

• Excessive offsets in venting.

• Insufficient vertical height of chimney.

• Insufficient chimney termination height in relation-

ship to roof.

• Insufficient ventilation.

• Lack of maintenance.

• Improper operation.

• Burning improper fuel (unit is approved for use with

natural dry well-seasoned wood only).

• Down drafts in the chimney (may need a special wind

cap).

To ensure that the venting system is functioning properly a draft test should be performed (see Draft Test

Procedure on this page).

American National Standards Institute ANSI/NFPA

211-96: A chimney or vent shall be so designed and

constructed to develop a flow sufficient to completely

remove all flue and vent gases to the outside atmosphere. The venting system shall satisfy the draft requirements of the connected appliance in accordance

with the manufacturer instructions.

DRAFT TEST PROCEDURE

After this appliance is installed a draft test should be

performed to ensure proper draft. A qualified technician should perform the draft test procedure as follows:

1) Close all windows and doors in the dwelling.

2) Turn on or operate all appliances which remove air

from the home (such as a furnace, heat pump, air

conditioner, clothes dryer, exhaust fans, fireplaces,

and other fuel burning appliances).

3) Drill a hole in the vent pipe per the draft gauge manufacturers instructions (to create a draft test port). Note:

Hole location should be a minimum of 1 foot above flue

outlet collar.

4) Start a fire (See How To Start And Maintain A Fire on

page 16).

5) After the fire is well established (20-25 minutes) and

burning at a low setting, perform the draft test per the

gauge manufacturer instructions. The draft gauge

should read between .05 and .06” W.C. (inches water column). Excessive draft (above .06 W.C.I.) can result in too

much combustion air to be pulled into the firebox, this will

produce hotter burns and could result in overfiring. Too little draft (below .05” W.C.) will not allow enough combustion air delivery to maintain a fire well or cause performance problems such as smoking (this may result in improper operation of appliance, i.e. will not maintain fire well

unless ash drawer or fuel door is left open).

6) Install a screw to seal the draft test port in the vent pipe. If

the draft test reading was not within the required range,

correct the installation and repeat this procedure.

VENTILATION REQUIREMENTS / PROVIDE ADEQUATE

AIR FOR COMBUSTION

THE FRESH AIR REQUIREMENTS OF THIS APPLIANCE MUST BE MET WITHIN THE SPACE WHERE IT

WILL BE INSTALLED. VENTILATION IS ESSENTIAL

WHEN USING A SOLID FUEL BURNING HEATER.

In well insulated and weather tight homes, it may be difficult to establish a good draft up the chimney (caused by a

shortage of air in the home). The lack of air is caused by

many common household appliances which exhaust air

from the home (such as a furnace, heat pump, air conditioner, clothes dryer, exhaust fans, fireplaces, and other

fuel burning appliances). Also, the combustion process of

this heater uses oxygen from inside the dwelling. If the

available fresh air delivery in the dwelling is insufficient to

support the demands of these appliances, problems can

result (i.e. excessive negative pressure can develop in the

dwelling which will affect the rate at which this appliance

can draft thus resulting in performance problems; See

Draft Requirements on this page). To correct this problem

it may help to open a window (preferably on the windward

side of the house) or install a vent to provide make-up air

into the dwelling.

PAGE 12

Page 13

INSTALLATION

a

e

See Pipe Manufacturers Instructions For Installation Requirements Of Venting Components And Vent Clearances.

SINGLE WALL PIPE

Using 6” Diameter Single Wall Connector Pipe

Storm

Collar

Roof

Flashing

Chimney

Termination

Cap

(Approved for Model CI2000HT Only)

Using 6” Diameter Type L-Vent Connector Pipe

DOUBLE WALL PIPE

3 Feet

Minimum

Termination

Cap with

Spark Arrestor

Storm Collar

Flashing

Ceiling Support

Assembly

Slip

Adapter

6" x 24" 24-gage

black steel or 26 gag

blued steel single wall

pipe

Chimney

Connector

Minimum of 12-15' of

Flue to achieve

stable draft

.

7 Feet

Minimum

Support

Box

DVL Close

Clearance

Connector

Pipe

Floor

Protector

IMPORTANT NOTES:

• Minimize the use of elbows (30°, 45° or 90°) - Offsets in the

venting system are very restrictive and will inhibit the draft

(i.e. You will lose approximately 5 feet of effective draft for

every 90 degrees of direction change). This appliance requires 12 to 15 feet of effective draft for optimum performance (see Draft Requirements on page 12).

• First section of pipe must be vertical - Use as much straight

vertical pipe directly above the appliance as possible before using an elbow (a 2’ to 3’ initial vertical rise is suggested).

PAGE 13

Page 14

INSTALLATION – Combustible Wall Chimney Connector Pass-Throughs

y

d

pp

pp

y

y

A

Min. 12 in. (304.8mm)

to Combustibles

Min. Chimney Clearance from Masonry to Sheet Steel

B

Supports & Combustibles – 2 in. (51mm)

Factory Built

Chimney Length

Air Space – 9 in.

(228.6mm) Min.

C

Min. Chimney Clearance from Masonry to Sheet Steel

Supports & Combustibles – 2 in. (51mm)

2 Ventilated Air

Channels, Each

1 in. (25.4 mm)

Construction of

Sheet Steel

D

Sheet Steel

Supports

Chimney

Section

Air Space – 2 in.

(51mm) Min.

NOTES:

1. Connectors to a masonry chimney, excepting method B, shall extend in one continuous section through the wall

pass-through system and the chimney wall, to but not past the inner flue liner face.

2. A chimney connector shall not pass through an attic

ceiling.

3. Where passage through a wall, or partition of combustible construction is desired, the installation shall conform to

CAN/CSA-B365.

Min. Chimney Clearance to Brick &

Combustibles – 2 in. (51mm)

Min. Clearance 12 in.

(304.8mm) of Brick

Chimney Flue

Fire Clay

Liner

Nonsoluble

Refractory

Cement

Chimney Length

Flush with Inside of Flue

Chimney

Flue

Masonr

Chimney

Sheet Steel Su

Chimney Flue

Sheet Steel Su

Masonr

Chimney

Min. Chimney Clearance from

Masonry to Sheet Steel Supports

& Combustibles – 2 in. (51mm)

Chimney

Connector

Masonr

Chimney

orts

2 Air Channels, Each 1

in. (25.4 mm)

Min. 6 in.

(152.4mm) glass

Fiber Insulation

Min. Clearance

2 in. (51 mm)

Chimney

Length

Sheet

Steel

Supports

Chimney

Connector

Min. Clearance

9 in. (228.6mm)

Chimney

Connector

Use Chimney

Mfrs. Parts to

Attach Connector Securely

-Insulated

Soli

Listed FactoryBuilt Chimney

Length

Chimney

Connector

orts

1 in. (25.4 mm)

Air Space to

Chimney

Length

Chimney

Connector

Method A. 12” (305 mm) Clearance to Combustible Wall Member: Using a minimum thickness 3.5” (89 mm) brick and a 5/8” (16

mm) minimum wall thickness clay liner, construct a wall passthrough. The clay liner must conform to ASTM C315 (Standard

Specification for Clay Fire Linings) or its equivalent. Keep a minimum of 12” (305 mm) of brick masonry between the clay liner and

wall combustibles. The clay liner shall run from the brick masonry

outer surface to the inner surface of the chimney flue liner but not

past the inner surface. Firmly grout or cement the clay liner in

place to the chimney flue liner.

Method B. 9” (229 mm) Clearance to Combustible Wall Member:

Using a 6” (153 mm) inside diameter, listed, factory-built Solid-Pak

chimney section with insulation of 1” (26 mm) or more, build a wall

pass-through with a minimum 9” (229 mm) air space between the

outer wall of the chimney length and wall combustibles. Use sheet

metal supports fastened securely to wall surfaces on all sides, to

maintain the 9” (229 mm) air space. When fastening supports to

chimney length, do not penetrate the chimney liner (the inside wall

of the Solid-Pak chimney). The inner end of the Solid-Pak chimney section shall be flush with the inside of the masonry chimney

flue, and sealed with a non-water soluble refractory cement. Use

this cement to also seal to the brick masonry penetration.

Method C. 6” (153 mm) Clearance to Combustible Wall Member: Starting with a minimum 24 gage (.024” [.61 mm]) 6” (153

mm) metal chimney connector, and a minimum 24 gage ventilated

wall thimble which has two air channels of 1” (26 mm) each, construct a wall pass-through. There shall be a minimum 6” (153 mm)

separation area containing fiberglass insulation, from the outer

surface of the wall thimble to wall combustibles. Support the wall

thimble, and cover its opening with a 24-gage minimum sheet

metal support. Maintain the 6” (153 mm) space. There should

also be a support sized to fit and hold the metal chimney connector. See that the supports are fastened securely to wall surfaces

on all sides. Make sure fasteners used to secure the metal chimney connector do not penetrate chimney flue liner.

Method D. 2” (51 mm) Clearance to Combustible Wall Member: Start with a solid-pak listed factory built chimney section at

least 12” (304 mm) long, with insulation of 1” (26 mm) or more,

and an inside diameter of 8” (2 inches [51 mm] larger than the 6”

[153 mm] chimney connector). Use this as a pass-through for a

minimum 24-gage single wall steel chimney connector. Keep

solid-pak section concentric with and spaced 1” (26 mm) off the

chimney connector by way of sheet metal support plates at both

ends of chimney section. Cover opening with and support chimney section on both sides with 24 gage minimum sheet metal supports. See that the supports are fastened securely to wall surfaces

on all sides. Make sure fasteners used to secure chimney section

do not penetrate chimney flue liner.

or roof space, closet or similar concealed space, or a floor, or

PAGE 14

Page 15

CARE AND OPERATION

PRIMARY AIR DRAFT CONTROL

Use the air control adjustment tool (provided) to adjust

the air controls per the following instructions.

Air Control / Ash Pan Removal Tool

The primary combustion air delivery is controlled by the

Primary Air Draft Control Assembly (located above the

front door). The heat output can be controlled by sliding

the control to a higher or lower heat output setting using

the Air Control Tool Provided (See Primary Air Draft Con-

trol below).

The fuel, the amount of heat and burn times desired, the

type of installation are all variables that will affect the

control setting. The same control settings in a variety of

installations will produce different results. You will need

to try different settings so you can learn how much heat

to expect and how long the fire will burn.

With the air control tool (provided in accessory package)

the control can be adjusted to the heat output desired

(see following illustration).

Primary Air Draft Control

Using the air control tool (provided) slide the control

above door to adjust burn rate.

Lower Burn / Slide Left

Higher Burn / Slide Right

Adjusting Burn Rate:

The primary air draft control located above the front door

can be adjusted to the right for higher temperatures and

to the left for lower temperatures.

Generally, you will want to set the draft control somewhere in the low or medium range

Tips - Adjust the primary air control to a medium to

low setting for a slow and more efficient burn. When

burning on a higher setting, it is more efficient to

burn with a bright but not roaring fire.

START UP AIR CONTROL (IGNITION BOOSTER)

To facilitate lighting, your stove is equipped with an ignition booster, which brings start-up air to the fire for a

short period of time. This can be especially helpful when

your chimney is cold. The ignition booster can also be

used to allow the fire to recover quickly following refuelling.

Start-Up Air Control

PROVIDES SUPPLEMENTAL PRIMARY AIR. DO NOT

LEAVE THE START-UP AIR CONTROL OPEN FOR MORE

THAN FIVE MINUTES.

Slide

to

Open

Before Initial Lighting

1. Using the air control tool open the start-up air control

by pulling the lever outwards (see illustration above).

2. Load fuel into the firebox and light the fire as usual

(see How To Start And Maintain A Fire on page 16)

DO NOT LEAVE THE START-UP AIR CONTOL IN THE

OPEN POSITION FOR MORE THAN FIVE MINUTES

(THIS COULD RESULT IN DANGEROUS OVERFIRING

WHICH IS NOT COVERED UNDER THE WARRANTY).

CLOSE BY PUSHING THE LEVER INWARDS.

See How to Start And Maintain A Fire on page 16

Stove

Back

Start-Up Air

Control Module.

PAGE 15

Page 16

CARE AND OPERATION

HOW TO START AND MAINTAIN A FIRE

1. Using the Air Control Tool (provided), open the

Start-Up Air Control (see Start-Up Air Control, on

page 15).

2. Adjust the primary air draft control to the full open

position (see Primary Air Draft Control on page 15).

3. Open the side fuel loading door and build your fire

directly on the grate in the firebox.

a. Place five or six loosely crumpled sheets of

newspaper in the stove.

b. Add a small amount of dry kindling randomly on

the top of the newspaper.

c. Place a few more loosely crumpled newspapers

on top of the kindling and light the bottom paper

first, then light the top paper. Once the fire is

well underway, close the door. The upper fire

should preheat the chimney and create an effective draft while the lower fire ignites the kindling.

4. After the kindling is burning well, add increasingly

larger pieces of wood until the fire is actively burning (see notes below). Leave the fuel door open

(slightly ajar for 5 minutes). Then close the stove

door. Never leave the stove unattended when the

door is open.

When loading fuel, be careful not to smother

the fire.

Load logs evenly across the base being cau-

tious not to place wood in front of the rear edge

of the log guard.

5. Once a bed of coals has been established, adjust

the primary air control to a lower setting AND

CLOSE THE START-UP AIR CONTROL.

AIR DELIVERY SYSTEMS

Tip – Using the air control tool, adjust the primary air

draft control to a medium to low setting for a slow and

more efficient burn. On higher settings, it is more efficient to burn with a bright but not roaring fire.

When Refueling

1. Follow the normal procedure for refuelling described on page 18. However, instead of cracking the

door open ½ ″, open the start-up air control by pul-

ling the lever outwards. This will supply enough

primary combustion air to allow the fire to recover.

DO NOT LEAVE THE START-UP AIR CONTROL

OPEN FOR MORE THAN FIVE MINUTES. CLOSE BY

PUSHING THE LEVER INWARDS.

Primary Air

Control

Secondary Air

Tubes (2)

Permanent Primary Air Intake.

Supplimental Primary Air is Delivered

through this Small

Opening (to improve

efficiency). There is

no adjustment controls for this intake.

Primary Air

Control

Secondary Air

Tubes (3)

CI1000HT

Side Cut-A-Way View

CI2000HT

Side Cut-A-Way View

Permanent

Secondary

Combustion

Air Intake.

Secondary Air is

Delivered through

this Opening to

ignite secondary

gases. There is no

adjustment control for this intake.

Start-up

Air Control.

See Start-Up Air

Control Illustration on page 15.

Supplemental

Secondary

Air Delivery

Secondary Air is

delivered through

this opening to

ignite secondary

gases. There is no

adjustment control for this intake.

PAGE 16

Page 17

CARE AND OPERATION

FRONT ASH REMOVAL DOOR AND SIDE FUEL LOADING DOOR

CAUTION: When opening the doors, do not extend

them beyond their normal travel. Overextending the

doors to a further open position can put excessive

stress on the hinge area of the doors which may result

in breakage.

Latch Assemblies

(For front ash removal door, side fuel loading door and

ash drawer door).

The door latch assemblies are designed to securely latch

the front door, side door and ash drawer door. To open the

latches, insert the door handle (provided) into hole in the

latch assembly and rotate counterclockwise until door releases. To close and latch, reverse the process

GLASS

The glass is a 5mm super heat resistant ceramic that withstands continuous temperatures up to 1256° F. This temperature is well beyond the temperatures in which you operate your stove.

These models are designed to provide a flow of air over the

inside of the glass, where along with high heat helps keep it

clean. When operating the stove on low for extended periods of time, the glass may get dirty. A short, hot fire (15 20 minutes) will help clean off much of the normal buildup

(see Dirty Glass, page 23). A commercial glass cleaner

designed for stoves is recommended for cleaning.

The glass should be cleaned thoroughly with glass

cleaner and a soft cloth BEFORE the stove is burned.

USE CONTROL SETTINGS THAT WORK FOR YOU

CAUTION: NEVER LEAVE STOVE UNATTENDED ON

HIGH SETTINGS.

The fuel, the amount of heat you want, the type of installation you have and how long you wish the fire to burn

are all variables that will affect the control setting. The

same control settings in a variety of installations will produce different results.

Familiarize yourself with your stove by trying different

settings so you can learn how much heat to expect and

how long the fire will burn. It may take a week or two to

learn but your patience will be rewarded by the warmth

and pleasant satisfaction that only a wood fire can provide.

REPLENISH HUMIDITY LEVEL OF DWELLING

Heating the air in a closed building decreases the relative

humidity of the air, which will dry wood and other combustible materials. This drying lowers the ignition temperature of these materials, thus increasing the fire hazard. To reduce the risk of fire, some provision should be

made for replenishing moisture to the air whenever a

structure is being heated for extended periods.

• BREAK-IN PERIOD

Your stove finish is a high temperature paint that re-

quires time and temperature to completely cure. We

recommend that you ventilate the house during the

initial burns. The paint emits non-toxic odors during

this process.

KEEP YOUR HOUSE WELL VENTILATED DURING

THE CURING PROCESS TO PREVENT ACTIVATION OF YOUR HOME SMOKE DETECTOR.

It will take approximately three burn cycles to cure the

paint. The first two burns should be low heat, approximately 250°F., for 20 minutes each, using paper

and light kindling.

After each 20-minute burn, allow the appliance to cool

completely. The third burn should be at least medium

high or about 450°F. for 45 - 60 minutes. The paint

will become soft and emit non-toxic haze during these

burns. Keep the area well ventilated.

As the paint cures it will become slightly lighter in color.

Eventually the entire surface will become an even color.

Once the paint has been softened and cooled two or

three times, it will harden. Do not place anything on the

stove surface until the paint is completely cured. Do not

attempt to repaint the stove until the paint is completely

cured. If the surface later becomes stained or marred, it

may be lightly sanded and touched up with spray paint

from the same paint (See Small Area Paint Touch-up,

page 21). Paint is available at your local authorized Lennox Hearth Products dealer. Never attempt to paint a

hot stove.

PAGE 17

Page 18

CARE AND OPERATION

FIRST FIRE

NOTE: There is often an unpleasant odor and nontoxic fumes during the first initial burns (this is a

natural result of the paint curing). We recommend

that a window should be left open near the appliance

during this curing process. See Break-In Period on

page 17.

When your installation has been completed and inspected you are ready to build your first fire.

1. Using the air control tool, open the primary air draft

control to the full open position (see Primary Air Draft

Control, page 15).

2. Open fuel loading door and build a small fire in the

stove using tightly rolled paper and dry kindling. Wait

a few minutes for a good updraft to establish the fire.

3. Now place two or three thoroughly dried logs on the

burning kindling and secure door.

5. After about 25-30 minutes of burning (when fire is well

established), slide the primary air draft control to a

medium setting. This will keep the fire burning at a

moderate level so heat is transferred through the

stove rather than up the chimney.

6. Once a bed of coals has been established, adjust the

primary air draft control to a low setting.

7. During the first few fires, keep the combustion rate at

a low to moderate level. Avoid burning fires with the

primary air control wide open for long periods of time.

This results in an updraft fire with most of the heat escaping up the chimney.

WARNING! READ AND USE THE INFORMATION

PROVIDED IN THIS SECTION. TO DISREGARD THIS

MAY CAUSE SERIOUS PERMANENT DAMAGE TO

THE STOVE AND VOID YOUR WARRANTY. IT IS

BEST TO WARM YOUR STOVE UP SLOWLY AND

KEEP IT AT A MODERATE LEVEL.

REFUELING

CAUTION: ALWAYS CHECK FOR HIGH FLAMES

WHEN OPENING A DOOR BY PARTIALLY OPENING

DOOR FOR A FEW SECONDS BEFORE OPENING

FULLY.

To prevent smoke blowing into the room follow these

recommendations:

1. Using the air control tool adjust the primary air draft

control and start-up air control to the full open position and let the fire "liven up" for about one minute

before opening the fuel loading door. Open door

about 1/2" and hold in this position about 30 seconds

or until stove is drafting well, then fully open the door.

2. Rake the embers towards the front of the stove and

spread evenly. If there are logs only partially burned

rake these to the front of stove.

• Feed the logs to the embers. When loading wood,

add one or two logs at a time, depending on size.

Try and use the side fuel loading door as it will allow for cleaner operation. Load logs evenly

across the base being cautious not to place wood

in front of the rear edge of the log guard.

• Close the fuel loading door.

• With the primary air draft control in the full open

position. Crack the door open about ½" and let it

burn for approximately 5 minutes. Then close the

door and adjust the primary air draft control to the

desired setting and CLOSE THE START-UP AIR

CONTROL.

• In order to maintain an attractively burning fire,

logs should be up to 18" (457 mm) long and well

seasoned. Loading the appliance full of damp

wood on a low fire is certain to cause low combustion efficiency resulting in tar and dirty glass.

• High combustion temperatures are the secret to

clean glass operation.

OVERNIGHT BURNING

To inhibit excessive build-up on the glass during a slow

overnight burn, it is recommended that the primary air

draft control be adjusted to at least a slightly open position (the optimum setting will depend on how well your

chimney draws). To achieve a slow burn (the maximum

burn time is 8 hours under optimum conditions - dry,

high BTU wood such as oak and proper draft from the

chimney).

Note: With a good drafting chimney, the primary air

control will need to be closed further than with a poor

drafting chimney.

PAGE 18

Page 19

CARE AND OPERATION

BURN RECOMMENDED FUEL

This appliance is designed for use with natural wellseasoned wood. Do not burn particleboard scraps or

pressed logs because they can produce conditions which

will deteriorate metal. Green or uncured wood does not

work well as fuel, and can cause increased creosote

buildups. The value of green wood as a source of heat is

limited. Do not overload or use kindling wood or mill ends

as primary fuel as this may cause overfiring. Overfiring is

a condition where excessive temperatures are reached,

beyond the design capabilities of the stove. The damage

that occurs from overfiring is not covered under the stove

warranty.

What is the best wood for the fire?

Some woods are easier to light than others (i.e. hornbeam, beech, & oak do not light easily whereas aspen,

birch and lime light easily but they do not last as long).

Then come the softwoods and conifers. Regardless if

you are burning a softer or harder wood, what is most

important is that it is well-seasoned dry wood. Damp

wood has far less heating power, this lowers the combustion temperature of the fire therefore, the output.

Green wood is difficult to light, it burns badly and gives

off smoke and causes the formation of deposits (tarring

and soot staining) in the chimney flue and on the door

glass.

What is tarring and soot staining in the chimney?

When the smoke arrives in the chimney at low temperature, part of the water vapor which they convey condenses. The heaviest constituents are deposited on the

inside of the flue (this is TARRING). The mixture oxidizes

in the air and forms brownish patches (this is SOOT

STAINING). Four essential points for avoiding these

drawbacks, use dry wood, use a stove designed for

wood, connect it to a chimney with thick walls and of suitable cross-section (size and height), and ensure the connecting pipes are as short as possible (horizontal pipes

should be no more than 6" / 150mm).

Flue Gas Temperature

It is recommended to thoroughly heat the flue system

during start-up, before adjusting the burn rate to a medium or low setting (see How To Start And Maintain A

Fire, Page 16). To ensure that the flue system is thoroughly heated, adjust the primary air to a medium/high

position for approximately 20-25 minutes after the startup air is closed before adjusting to a lower setting. This

helps to establish the draft and it reduces creosote deposits on the internal surfaces of the stove, glass and

chimney.

Hints:

Creosote condenses in a cold chimney, not a warm

one. Avoid a smoldering fire for more than a twelvehour period and your chimney will never get cold.

Burn a hot fire for a short period once or twice a day

(and after reloading), and then adjust the primary air

draft module to a medium or low position.

When loading wood, add one or two logs at a time,

depending on size. Loading the appliance full of

damp wood on a low fire is certain to cause poor

combustion efficiency resulting in creosote and dirty

glass.

If the wood is not quite as dry as it should be, to as-

sist for a short period, smokeless coal can be added

with the wood to raise the combustion temperature.

Have the chimney cleaned and inspected by a professional chimney sweep once a year.

WARNING: BURNING IMPROPER FUEL (I.E. CHARCOAL) CAN RESULT IN CARBON MONOXIDE POISONING WHICH MAY LEAD TO DEATH!

CARBON MONOXIDE POISONING – EARLY SIGNS

OF CARBON MONOXIDE POISONING RESEMBLE

THE FLU WITH HEADACHES, DIZZINESS, OR NAUSEA. IF YOU HAVE THESE SIGNS, GET FRESH AIR

AT ONCE! HAVE THE HEATER INSPECTED BY A

QUALIFIED SERVICE TECHNICIAN. SOME PEOPLE

ARE MORE AFFECTED BY CARBON MONOXIDE

THAN OTHERS. THESE INCLUDE PREGNANT

WOMEN, PEOPLE WITH HEART OR LUNG DISEASE

OR ANEMIA, THOSE UNDER THE INFLUENCE OF

ALCOHOL, AND THOSE AT HIGH ALTITUDES.

WHY SEASON WOOD?

The key to the success of a good fire that produces heat

from a woodstove is the wood. It needs to be wellseasoned natural wood.

What does “Well-Seasoned” mean?

When a tree is cut down, the wood is green, full of sap and

moisture. This moisture content can exceed 80%, which

must be reduced to less than 20%. Wood properly seasoned is then capable of generating the heat the stove was

designed to provide.

Green wood does not burn easily. Attempting to burn

green wood often results in a lot of smoke and very little

fire. Time is the most important factor in seasoning wood.

Ideally the moisture content should be reduced to 11-20%,

although very few of us will be able to check that figure.

There are several steps that should be taken to ensure that

you come close to these figures.

PAGE 19

Page 20

CARE AND OPERATION

SEASONING GUIDE

Softwoods – 18 months

Hardwoods – 18 months to 24 months

This period can be shortened (12 to 15 months) if the

wood is cut to the right length and immediately stored

under a ventilated shelter.

Logs that are 5” diameter across or larger should be split in

half, three pieces if over 8 inches, and four pieces when

over a foot across (split wood dries quicker than round

logs). Round logs left in the open for more than a year

end up rotten. If the tree was fell 2 to 4 years ago, it still

needs to be cut, split, and seasoned for 18 to 24 months

depending on the wood.

Wood which is too small to split must be drained, by removing some of the bark.

WOOD STORAGE

Wood to be seasoned should be stacked in an area open

enough to ensure good air circulation on both sides –

leaving adequate space between woodpiles to walk comfortable. Do not stack wood against a wall or building. It

helps to elevate the woodpiles off the ground (two 2 x 4’s

running lengthwise beneath the woodpile works well).

This allows air to flow under the bottom logs.

Store wood in a cool, dry place, well away from any

source of flame or heat. Keep paper, wood, rags and

other easily ignited materials away from the wood. If

wood should become wet, separate it and allow it to dry

naturally; do not mix wet and dry wood or pile wet wood

on top of dry wood. If Wood is kept outdoors, either covered with a tarp, or not covered at all, it will not burn well

until it has been in an enclose space for one to two months.

If stored outside, keep the wood covered to protect from

rain or snow.

Wood supplied in ready-cut lengths stored immediately

under a ventilated shelter dries quicker than wood

stocked in high piles.

PAGE 20

Page 21

MAINTENANCE

DO NOT CLEAN STOVE WHILE HOT

INSPECT THE ENTIRE STOVE FREQUENTLY FOR

PROPER OPERATION, FIT AND SOUNDNESS OF

PARTS. IF ANY MALFUNCTIONING, CRACKED, BROKEN, OR LOOSE PARTS OR OTHER PROBLEMS ARE

NOTED, CONTACT YOUR DEALER OR QUALIFIED

SERVICEMAN TO INSPECT AND REPAIR THE UNIT.

DO NOT OPERATE THE UNIT IF INSTALLED OR

FUNCTIONING IMPROPERLY.

SUMMER SHUT DOWN

Remove ashes and cinders from the stove and dispose of