Lenox ML180UH110AP36C, ML180UH135AP60D, ML180UH110AP60C, ML180UH070AP36A, ML180UH090AP48B Unit Information

Page 1

Corp. 1218-L4

Service Literature

ML180UHA series units are mid-efficiency gas furnaces

used for upflow or horizontal applications only, manufac

tured with Lennox Duralok Plust heat exchangers formed

of aluminized steel. ML180UHA units are available in heat

ing capacities of 69.6 to 139.3 MJ/h and cooling applica

tions 10 to 17 kW. Refer to Engineering Handbook for prop

er sizing.

Units are factory equipped for use with natural gas. Kits are

available for conversion to LP/Propane operation.

ML180UHA model units are equipped with a hot surface

ignition system. All units use a redundant gas valve to as

sure safety shut-off as required.

All specifications in this manual are subject to change. Pro

cedures outlined in this manual are presented as a recom

mendation only and do not supersede or replace local or

state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except

where noted) are recommended only and do not constitute

code.

Revised 05 /2017

WARNING

This product contains a chemical known to the State

of California to cause cancer, birth defects, or other

reproductive harm.

TABLE OF CONTENTS

Specifications Page 2.............................

Blower Data Page 3..............................

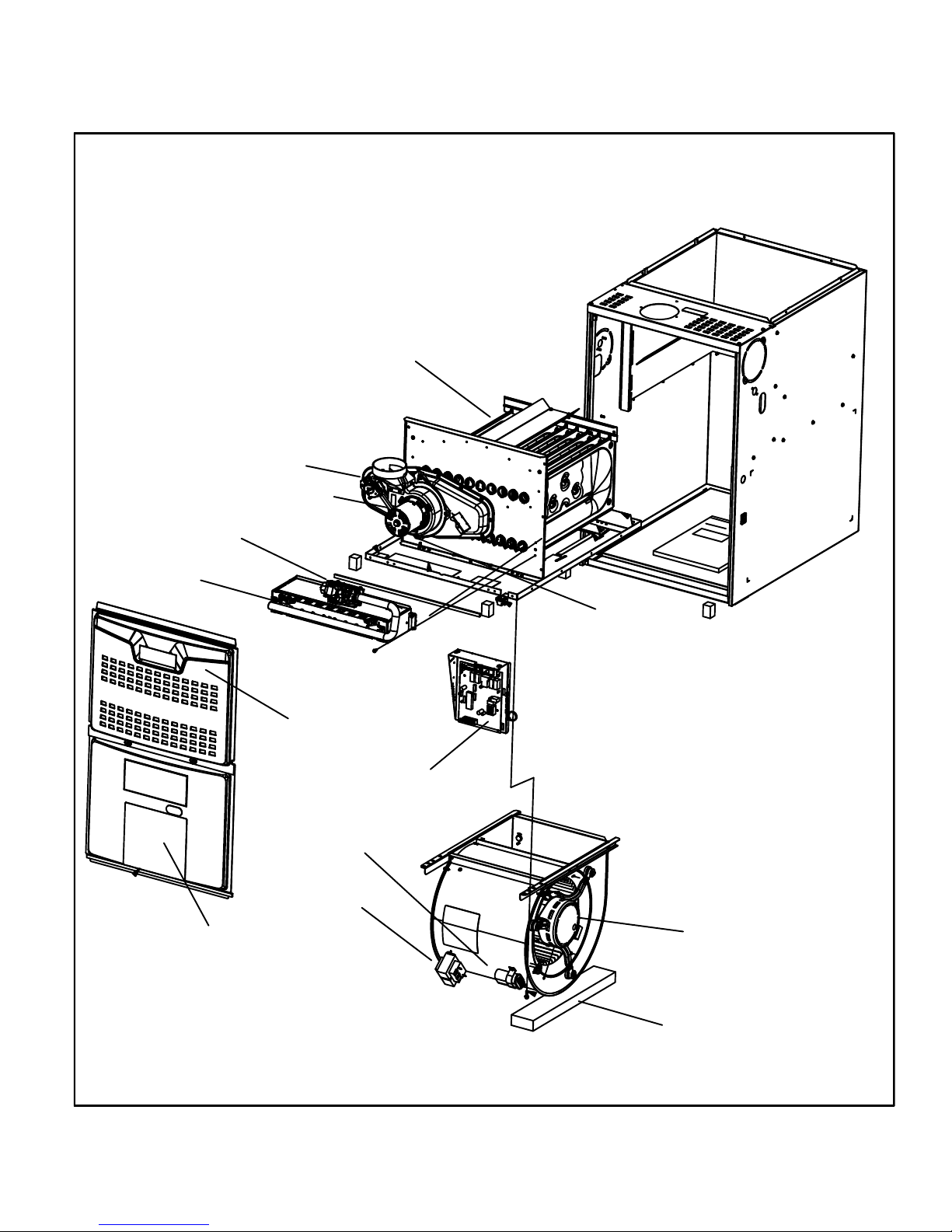

Parts Identification Page 5.........................

I Unit Components Page 6........................

ML180UHA

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person

al injury or loss of life. Installation and service must

be performed by a qualified installer, service agency

or the gas supplier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon

nect switch(es). Unit may have multiple

power supplies.

II Installation Page 14.............................

III Start Up Page 14..............................

IV Heating System Service Checks Page 15.........

V Typical Operating Characteristics Page 19.........

VI Maintenance Page 20..........................

VII Wiring and Sequence of Operation Page 22......

Page 1

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

WARNING

Do not modify this appliance.

© 2017 Lennox Industries Inc.

Page 2

Page 2

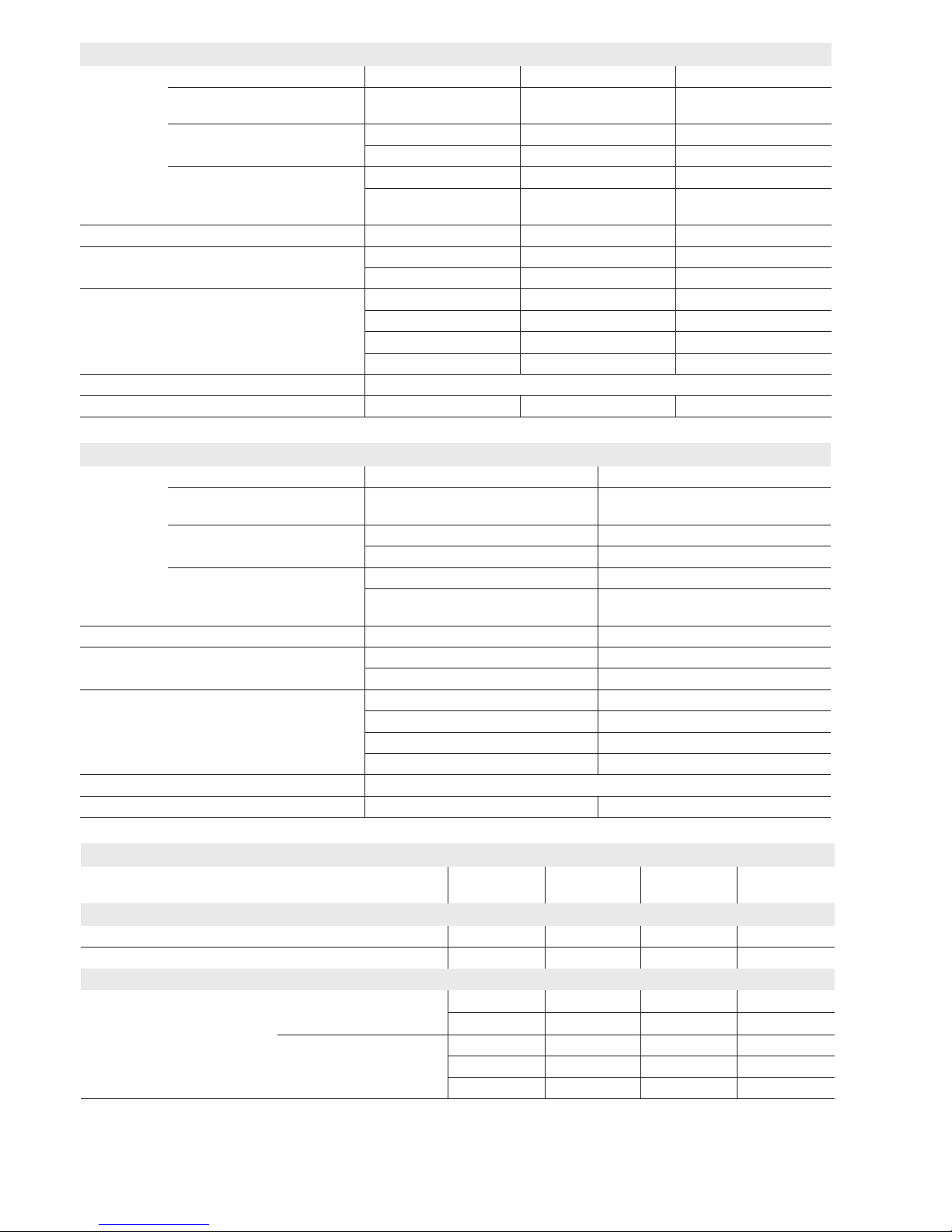

SPECIFICATIONS

Gas

Heating

Performance

Model Number ML180UH070AP36A ML180UH090AP48B ML180UH110AP36C

Australian Gas Association

Energy Rating - Stars

3.8 3.7 3.8

Input - Mj/h 69.6 92.8 116.1

Output - kW 15.5 20.6 25.8

Temperature rise range - °C 14 - 31 14 - 31 19 - 36

Gas Manifold Pressure (kPa)

Natural Gas / Propane

0.87 / 2.30 0.87 / 2.30 0.87 / 2.30

High Static - Pa 125 125 125

Connections Flue connection - mm round 102 102 102

Gas pipe size IPS 1/2 in. 1/2 in. 1/2 in.

Indoor

Blower

Wheel nom. diameter x width - mm 254 x 203 254 x 254 254 x 254

Motor output - W 248 373 373

Add-on cooling - kW 7-10.6 7-14.1 7-14.1

Air Volume Range - L/s 282 - 716 229 - 890 239 - 827

Electrical Data Voltage 220/240 volts - 50 hertz - 1 phase (less than 10 amps)

Shipping Data kg - 1 package 54 63 70

NOTE - Filters and provisions for mounting are not furnished and must be eld provided.

SPECIFICATIONS

Gas

Heating

Performance

Model Number ML180UH110AP60C ML180UH135AP60D

Australian Gas Association

Energy Rating - Stars

3.8 3.9

Input - Mj/h 116.1 139.3

Output - kW 25.8 31.0

Temperature rise range - °C 17 - 33 17 - 33

Gas Manifold Pressure (kPa)

Natural Gas / Propane

0.87 / 2.30 0.87 / 2.30

High Static - Pa 125 125

Connections Flue connection - mm round 102 102

Gas pipe size IPS 1/2 in. 1/2 in.

Indoor

Blower

Wheel nom. diameter x width - mm 292 x 254 279 x 279

Motor output - W 746 746

Add-on cooling - kW 14.1-17.6 14.1-17.6

Air Volume Range - L/s 633 - 1138 602 - 1159

Electrical Data Voltage 220/240 volts - 50 hertz - 1 phase (less than 10 amps)

Shipping Data kg - 1 package 71 79

NOTE - Filters and provisions for mounting are not furnished and must be eld provided.

OPTIONAL ACCESSORIES - ORDER SEPARATELY

“A” Width

Models

“B” Width

Models

“C” Width

Models

“D” Width

Models

CABINET ACCESSORIES

Horizontal Suspension Kit - Horizontal only 51W10 51W10 51W10 51W10

Return Air Base - Upow only 65W75 50W98 50W99 51W00

FILTERS

1

Air Filter and Rack Kit Horizontal (end) 87L95 87L96 87L97 87L98

Size of lter - mm 356 x 635 x 25 457 x 635 x 25 508 x 635 x 25 635 x 635 x 25

Side Return Single 44J22 44J22 44J22 44J22

Ten Pack 66K63 66K63 66K63 66K63

Size of lter - mm 406 x 635 x 25 406 x 635 x 25 406 x 635 x 25 406 x 635 x 25

1

Cleanable polyurethane, frame-type lter.

Page 3

Page 3

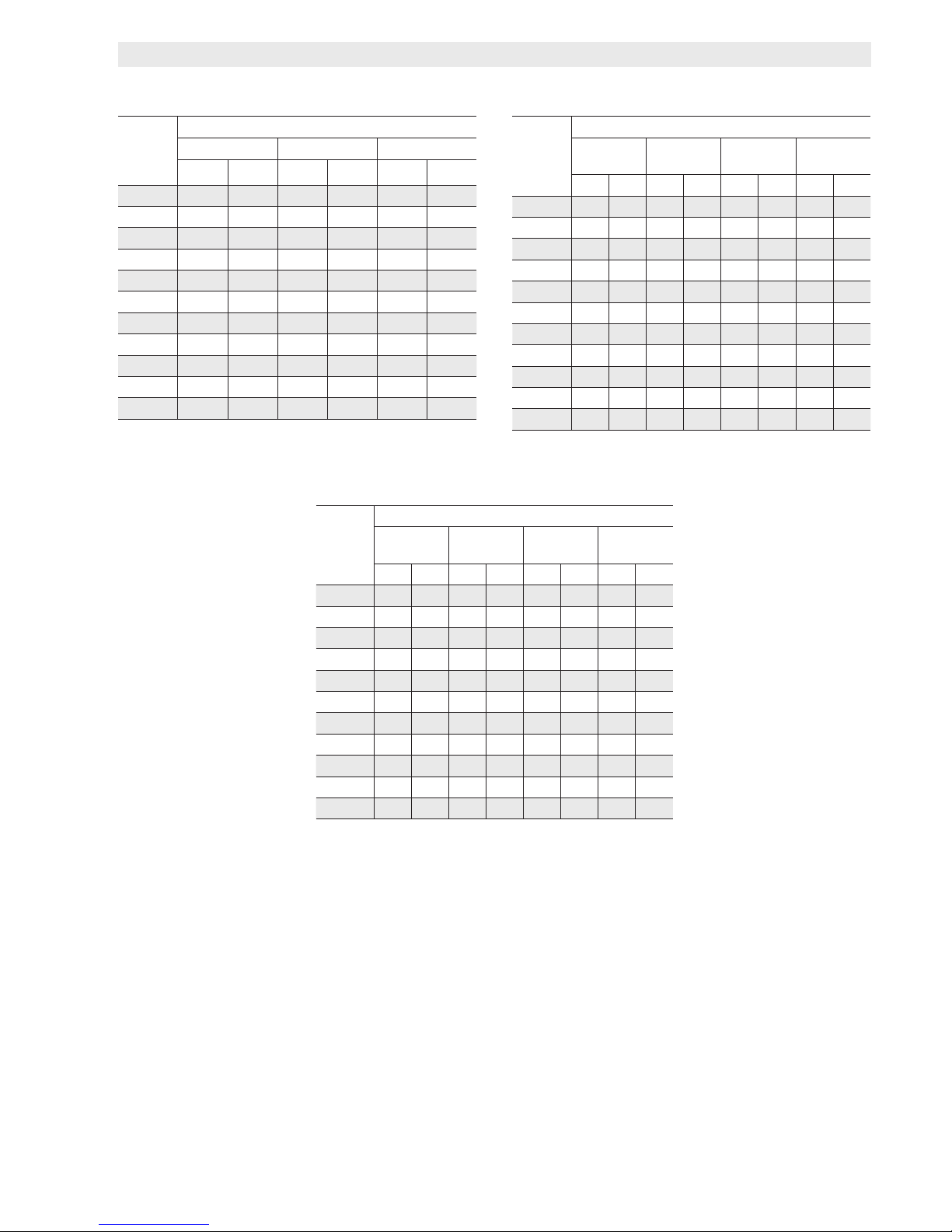

BLOWER DATA

ML180UH070AP36A PERFORMANCE (Less Filter)

External

Static

Pressure

Pa

Air Volume at Various Blower Speeds

High Medium Low

L/s Watts L/s Watts L/s Watts

0 716 771 589 615 469 468

25 687 752 564 597 435 448

50 675 724 554 583 430 441

75 662 708 547 569 421 430

100 649 691 530 554 408 417

125 633 672 517 541 393 405

150 616 650 503 524 372 387

175 595 624 488 514 359 375

200 573 608 472 494 324 363

225 551 590 447 477 307 346

250 523 561 424 454 282 331

ML180UH090AP48B PERFORMANCE (Less Filter)

External

Static

Pressure

Pa

Air Volume at Various Blower Speeds

High

Medium-

High

Medium-

Low

Low

L/s Watts L/s Watts L/s Watts L/s Watts

0 890 1085 715 892 497 598 423 493

25 849 1050 679 855 463 577 386 481

50 849 1016 679 831 460 565 384 464

75 831 967 676 807 456 546 369 447

100 827 937 667 773 452 526 364 434

125 816 906 660 747 439 509 349 421

150 799 872 647 718 426 494 331 408

175 784 845 629 691 411 477 308 394

200 754 808 601 642 394 460 290 383

225 722 765 577 622 359 435 256 363

250 674 713 555 593 332 421 229 348

ML180UH110AP36C PERFORMANCE (Less Filter)

External

Static

Pressure

Pa

Air Volume at Various Blower Speeds

High

Medium-

High

Medium-

Low

Low

L/s Watts L/s Watts L/s Watts L/s Watts

0 827 1106 660 884 460 574 404 478

25 800 1063 630 850 434 558 378 463

50 801 1043 631 819 432 541 369 451

75 779 984 631 807 434 527 359 438

100 773 962 624 777 422 512 352 422

125 773 938 620 758 408 490 335 4 11

150 761 907 609 725 382 472 331 396

175 741 854 593 695 383 460 319 386

200 722 832 580 659 366 441 299 372

225 699 777 554 638 351 432 263 354

250 677 741 527 600 331 4 11 239 340

Page 4

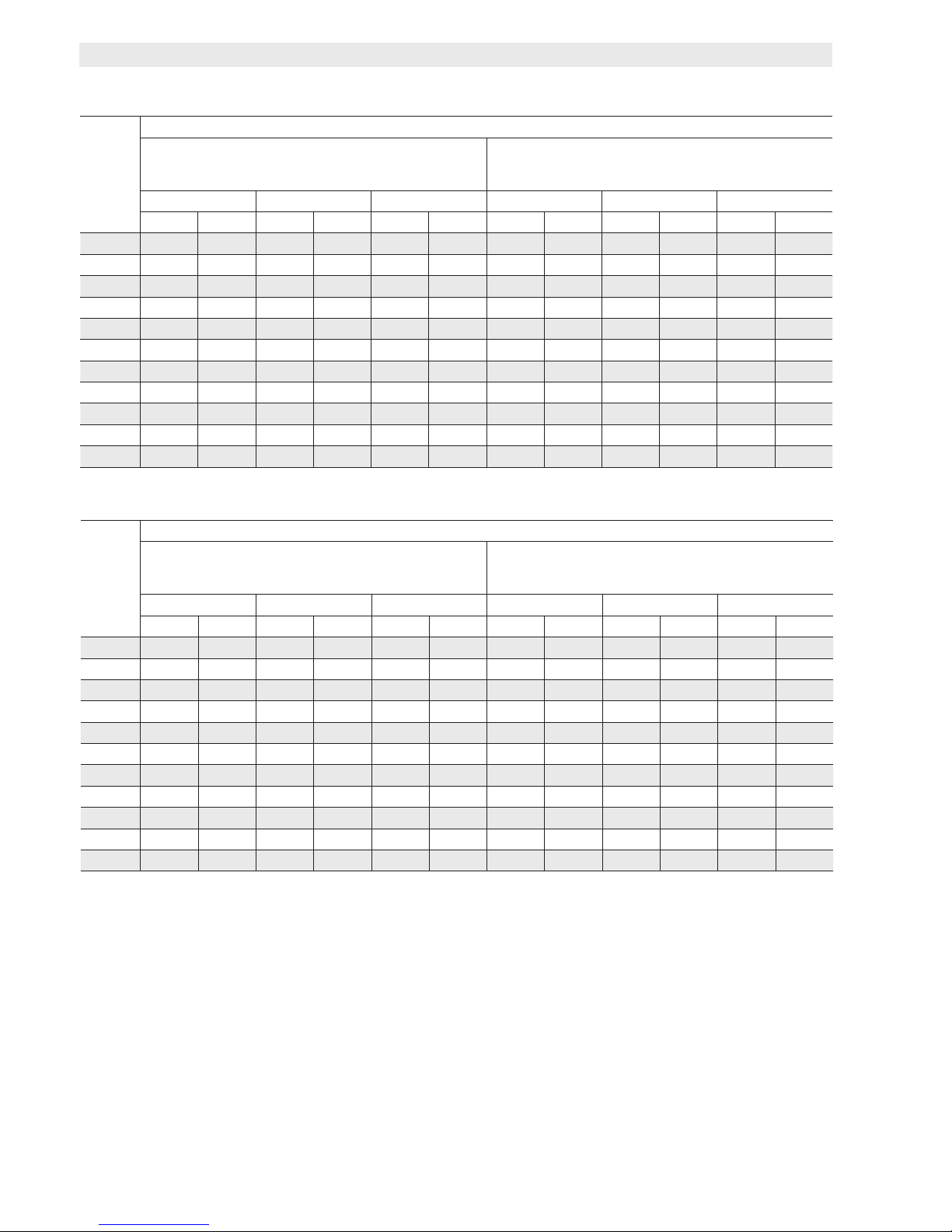

ML180UH110AP60C PERFORMANCE (Less Filter)

External

Static

Pressure

Pa

Air Volume at Different Blower Speeds

Bottom Return Air, Side Return Air with Optional

Return Air Base, Return Air from Both Sides or Return

Air from Bottom and One Side.

Single Side Return Air − Air volumes in bold require eld

fabricated transition to accommodate 508 x 635 x 25 mm

air lter in order to maintain proper air velocity.

High Medium Low High Medium Low

L/s Watts L/s Watts L/s Watts L/s Watts L/s Watts L/s Watts

0 1165 1447 964 1173 826 987 1126 1452 934 1172 794 984

25 1144 1408 938 1149 803 966 1104 1427 910 1150 772 964

50 1115 1389 932 1121 797 943 1085 1391 902 1126 768 943

75 1104 1358 922 1104 787 926 1071 1356 896 1110 756 925

100 1084 1333 908 1082 773 902 1059 1340 881 1079 750 907

125 1063 1303 905 1079 756 877 1037 1310 869 1064 741 890

150 1043 1274 888 1050 748 865 1020 1282 860 1041 731 872

175 1027 1249 871 1024 738 845

1005 1248 839 1022 717 852

200 1005 1224 849 994 723 815 987 1224 821 997 699 831

225 980 1179 835 974 696 800 956 1192 801 966 678 808

250 947 1140 807 943 677 775 939 1158 789 955 665 786

ML180UH135AP60D PERFORMANCE (Less Filter)

External

Static

Pressure

Pa

Air Volume at Different Blower Speeds

Bottom Return Air, Side Return Air with Optional

Return Air Base, Return Air from Both Sides or Return

Air from Bottom and One Side.

Single Side Return Air − Air volumes in bold require eld

fabricated transition to accommodate 508 x 635 x 25 mm

air lter in order to maintain proper air velocity.

High Medium Low High Medium Low

L/s Watts L/s Watts L/s Watts L/s Watts L/s Watts L/s Watts

0 1153 1460 958 1167 810 967 1114 1469 941 1219 786 992

25 1126 1425 931 1139 788 945 1091 1440 917 1196 759 967

50 1118 1411 923 1125 773 928 1079 1411 913 1173 751 950

75 1087 1374 915 1113 765 914 1064 1402 893 1149 743 933

100 1083 1344 891 1079 752 900 1048 1375 887 1130 734 920

125 1067 1325 890 1066 741 884 1032 1345 866 1101 720 899

150 1038 1284 862 1036 731 869 1012 1322 852 1072 708 881

175 1034 1269 844 1016 712 849

994 1291 834 1053 690 860

200 1005 1239 832 995 697 824 987 1271 820 1029 663 834

225 977 1204 804 975 677 813 956 1238 797 1010 650 815

250 952 1173 789 953 640 781 936 1220 783 988 627 795

BLOWER DATA

Page 5

Pressure Switch

Combustion Air Inducer

Gas Valve

Burner/Manifold Assembly

ML180UHA PARTS ARRANGEMENT

Heat Exchanger

Blower Access Panel

Upper Access Panel

Control Box

Capacitor

Transformer

Limit Switch

IEC Receptacle

(under combustion air inducer)

Blower Assembly

Shipping Pad

ML180UH090AP48B, & ML180UH110AP36C only.

(

Remove prior to operation

)

FIGURE 1

Page 5

Page 6

I-UNIT COMPONENTS

ML180UHA unit components are shown in figure 1.The

gas valve, combustion air inducer and burners can be ac

cessed by removing the upper access panel. Electrical

components are in the control box (figure 2) found in the

blower section.

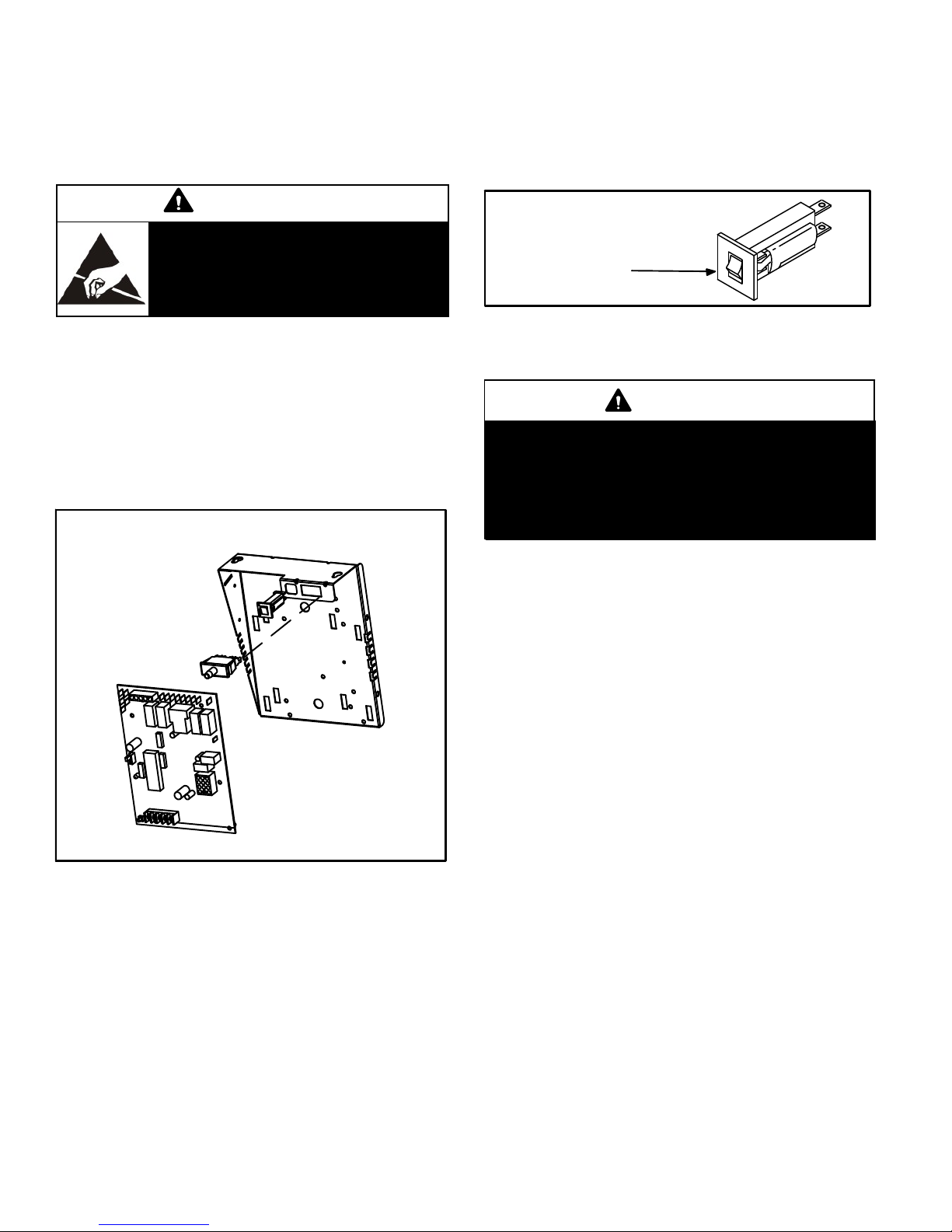

3. Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box.

The switch provides overcurrent protection to the trans

former (T1). The breaker is rated 3A at 32V. If the current

exceeds this limit the breaker will trip and all unit opera

tion will shutdown. The breaker can be manually reset

by pressing the button on the face. See figure 3.

CAUTION

Electrostatic discharge can affect elec

tronic components. Take precautions

to neutralize electrostatic charge by

touching your hand and tools to metal

prior to handling the control.

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. Transformers on all

models are rated 40VA with a 230V primary and a 24V sec

ondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 230VAC is wired in se

ries with line voltage. When the blower door is removed the

unit will shut down.

CONTROL BOX ML180UHA

Door Interlock Switch

Integrated Control

FIGURE 2

CIRCUIT BREAKER CB8

PRESS TO RESET

FIGURE 3

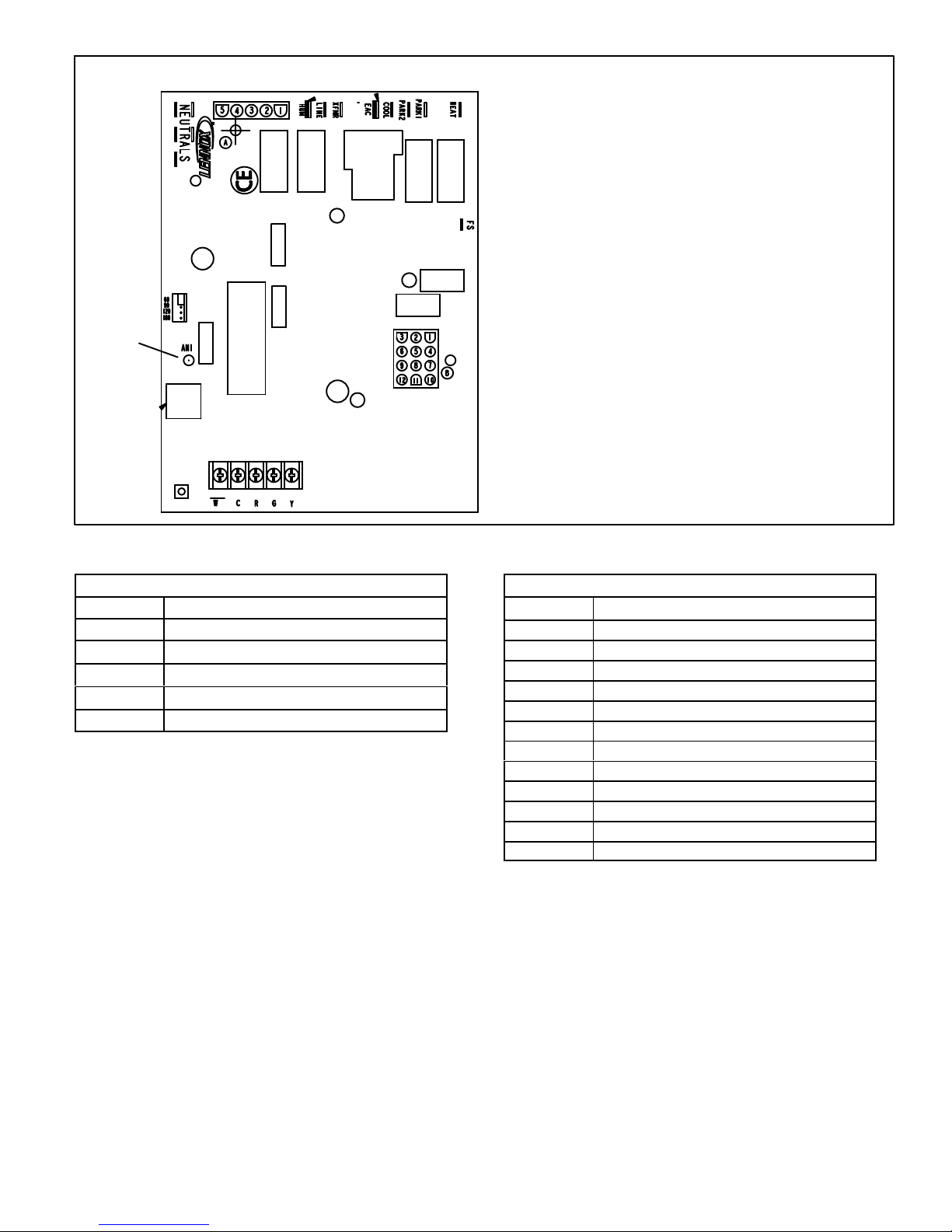

4. Integrated Control (A92)

WARNING

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply re

place entire control.

Can cause injury or death. Unsafe operation will re

sult if repair is attempted.

The hot surface ignition control system consisting of an in

tegrated control (figure 4 with control terminal designa

tions in tables 1 and 2.) sensor and ignitor (figure 6). The

integrated control and ignitor work in combination to en

sure furnace ignition and ignitor durability. The integrated

control, controls all major furnace operations. The inte

grated control also features one LED light (AN1 red) for

troubleshooting and two accessory terminals rated at (1)

one amp. The integrated control also features a (3) amp

fuse for overcurrent protection. See table 3 for trouble

shooting diagnostic codes. The nitride ignitor is made

from a non-porous, high strength proprietary ceramic ma

terial that provides long life and trouble free maintenance.

The integrated control continuously monitors line voltage

and maintains the ignitor power at a consistent level to

provide proper lighting and maximum ignitor life.

Page 6

Page 7

LED

(red)

INTEGRATED CONTROL

TERMINAL DESIGNATIONS

HUM - Humidifier 230VAC

LINE - Input 230VAC

XFMR - Transformer 230VAC

EAC - Electronic Air Cleaner 230VAC

COOL - Cool Speed 230VAC

PARK1, PARK2 - Dead terminals for alternate speed taps

NEUTRALS - Neutral terminals 230VAC

HEAT - Heating Speed 230VAC

FS - Flame Sense

TABLE 1

5-Pin Terminal Designation

PIN # FUNCTION

1 Ignitor Line

2

3

4

5

Not Used

Combustion Air Inducer Low

Combustion Air Inducer Neutral

Ignitor Neutral

FIGURE 4

TABLE 2

12-Pin Terminal Designations

PIN # FUNCTION

1 Not Used

2 Not Used

3 Rollout Switch Input

4 Ground

5 TH 24V Hot

6 High Limit Input

7 Gas Valve Line

8 Gas Valve Common

9 TR 24V Return

10 Ground

11 Rollout Switch Output

12 Pressure Switch

Page 7

Page 8

TABLE 3

FLASH CODE

(X + Y)

STATUS / ERROR DESCRIPTION

FLASH CODE DESCRIPTIONS

Pulse A 1/4 second flash followed by four seconds of off time.

Heartbeat Constant 1/2 second bright and 1/2 second dim cycles.

X + Y

Pulse Power on - Standby.

Heartbeat Normal operation - signaled when heating demand initiated at thermostat.

LED flashes X times at 2Hz, remains off for two seconds, flashes Y times at 2Hz, remains off for four

seconds, then repeats.

FLAME CODES

1 + 2 Low flame current -- check flame sensor.

1 + 3 Flame sensed out of sequence -- flame still present. Flame sensed without gas valve energized.

PRESSURE SWITCH CODES

2 + 3 Low pressure switch failed open. Check blocked inlet/exhaust .

2 + 4 Low pressure switch failed closed. Pressure switch closed prior to activation of combusiton air inducer.

LIMIT CODE

3 + 1 Limit switch open.

WATCHGUARD CODES

4 + 1 Watchguard -- Exceeded maximum number of retries. Burners failed to light.

4 + 2 Watchguard -- Exceeded maximum number of retries or last retry was due to pressure switch opening.

4 + 3 Watchguard -- Exceeded maximum number of retries or last retry was due to flame failure.

4 + 5 Watchguard -- Limit remained open longer than three minutes.

4 + 6 Watchguard -- Flame sensed out of sequence; flame signal gone.

4 + 8 Low line voltage.

HARD LOCKOUT CODES

5 + 1 Hard lockout -- Rollout circuit open or previously opened.

5 + 4

5 + 5 Gas valve fault ( sensed open when should be closed, or sensed closed when should be open).

5 + 6 Program memory fault (internal microprocessor memory fault)

5 + 7 Flame sense circuit fault. (flame sense circuit or bad flame probe fault).

5 + 8 No communication packet fault (loss of communications between redundant microprocessor fault).

5 + 9 Bad communication packet fault. (corrupted communications between redundant microprocessor fault).

5 + 10 Redundant variable fault. (internal microprocessor memory retention fault).

Reversed line voltage polarity (control will restart if the error recovers). And or no Earth groas valve

faulund

Page 8

Page 9

Electronic Ignition

On a call for heat the integrated control monitors the com

bustion air inducer pressure switch. The control board will

not begin the heating cycle if the pressure switch is closed

(by-passed). Once the pressure switch is determined to be

open, the combustion air inducer is energized. When the

differential in the pressure switch is great enough, the pres

sure switch closes and a 15-second pre-purge begins. If

the pressure switch is not proven within 2-1/2 minutes, the

integrated control goes into Watchguard-Pressure Switch

mode for a 5-minute re-set period.

After the 15-second pre-purge period, the ignitor warms up

for 20 seconds during which the gas valve opens at 19 sec

onds for a 4-second trial for ignition. The ignitor remains

energized for the first 3 seconds during the 4 second trial. If

ignition is not proved during the 4-second period, the inte

grated control will try four more times with an inter purge

and warm-up time between trials of 35 seconds. After a to

tal of five trials for ignition (including the initial trial), the inte

grated control goes into Watchguard-Flame Failure mode.

After a 60-minute reset period, the integrated control will

begin the ignition sequence again.

The integrated control has an added feature of ignitor pow

er regulation to maintain consistent lighting and longer igni

tor life under all line voltage conditions.

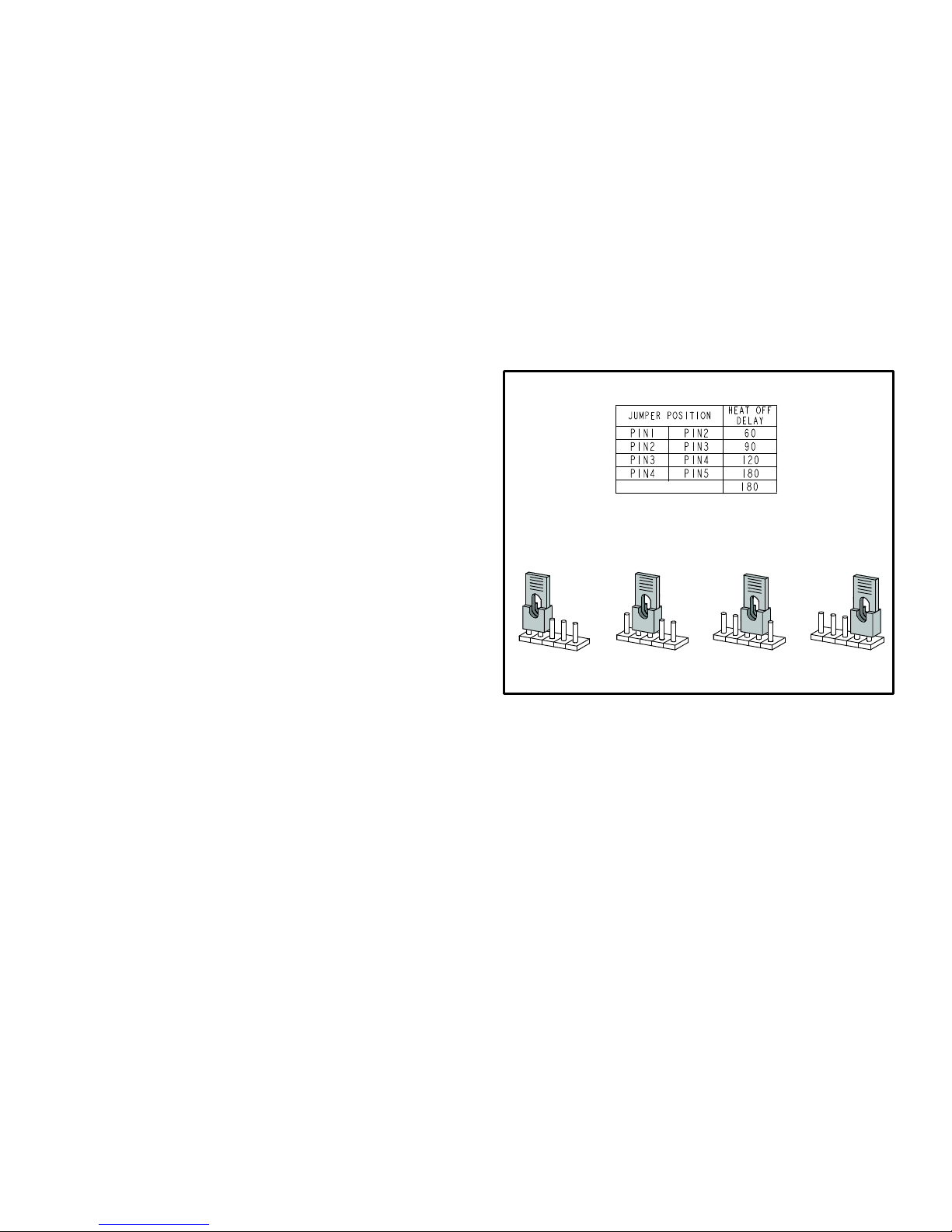

Fan Time Control

Heating Fan On Time

The fan on time of 30 seconds is not adjustable.

Heating Fan Off Time

Fan off time (time that the blower operates after the heat

demand has been satisfied) can be adjusted by moving the

jumper to a different setting. The unit is shipped with a fac

tory fan off setting of 60 seconds. For customized comfort,

monitor the supply air temperature once the heat demand

is satisfied. Note the supply air temperature at the instant

the blower is de-energized.

Adjust the fan-off delay to achieve a supply air temperature

between 32° C - 43° C (90° F - 110° F) at the instant the

blower is de-energized. (Longer delay times allow for lower

air temperature, shorter delay times allow for higher air

temperature). See figure 5.

Cooling Fan On Time

The fan on time is 2 seconds and is not adjustable.

Cooling Fan Off Time

The control has a 45 second fan off delay after cooling de

mand has been met. This delay is factory set and not ad

justable.

HEAT FAN‐OFF TIME IN SECONDS

NO JUMPER

To adjust fan-off timing, reposition jumper across pins to

60 Second

off Time

60

90

120

180

achieve desired setting.

90 Second

off Time

60

90

120

180

120 Second

off Time

60

90

120

180

180 Second

off Time

60

90

120

180

FIGURE 5

Page 9

Page 10

Rollout Switches

ML180UHA HEATING COMPONENTS

Flue Transition

Ignitor

Gasket

Pressure Switch

Sensor

Manifold And Gas Valve

FIGURE 6

5. Flame Sensor (Figure 6)

A flame sensor is located on the left side of the burner sup

port. The sensor is mounted on the flame rollout plate and

the tip protrudes into the flame envelope of the left-most

burner. The sensor can be removed for service without re

moving any part of the burners. During operation, flame is

sensed by current passed through the flame and sensing

electrode. The integrated control allows the gas valve to re

main open as long as flame signal is sensed.

6. Flame Rollout Switches (Figure 6) (S47)

Flame rollout switch is a high temperature limit. Each fur

nace is equipped with two identical switches. The limit is a

N.C. SPST manual‐reset limit connected in series with the

integrated control A92. When S47 senses rollout, the inte

grated control immediately stops ignition and closes the

gas valve. If unit is running and flame rollout is detected, the

gas valve will close and integrated control will be disabled.

Rollout can be caused by a blocked heat exchanger, flue or

lack of combustion air. The switch has a factory setpoint of

99°C (210°F) and cannot be adjusted. To manually reset a

tripped switch, push the reset button located on the control.

Orifice Plate

Combustion Air Inducer

Collector Box

7. Primary Limit Control (S10)

The primary limit on ML180UHA units is located in the heating

vestibule panel under the combustion air inducer. See figure 1.

When excess heat is sensed in the heat exchanger, the limit

will open. If the limit is open, the integrated control energizes

the supply air blower and closes the gas valve. The limit auto

matically resets when unit temperature returns to normal. The

switch must reset within three minutes or SureLight

will go into Watchguard for one hour. The switch is factory

set and cannot be adjusted. The switch may have a different

setpoint for each unit model number. If limit switch must be

replaced, refer to Lennox ProductZone repair parts list on

Lennox DaveNet®.

®

control

Page 10

Page 11

8. Ignitor (Figure 6)

The nitride ignitor used on ML180UHA units is made from a

proprietary ceramic material. Ignitor longevity is enhanced

by controlling the voltage to the ignitor. To check ignitor,

measure its resistance and voltage. A value of 300 to 1300

ohms indicates a good ignitor. Voltage to the ignitor should

be 150VAC.

See figure 7 for resistance, and voltage check.

Voltmeter

(set to ohms)

Test 2

Test 1

NOTE - The ML180UHA furnace contains electronic

components that are polarity sensitive. Make sure that

the furnace is wired correctly and is properly grounded.

Test 1 - Remove 5-pin plug

from control. Insert test pins

from meter into plug pin 1 and

5. If reading is correct test is

over. If reading is outside ac

ceptable range move to test 2.

Test 2 - Separate the 2-pin jackplug and again check resistance to

the ignitor. If reading is acceptable

then the problem is the wiring be

tween the jackplug and integrated

control. If reading is acceptable re

place the ignitor.

Voltmeter

(set to AC)

Test - Do not separate 5 pin

jack-plug. Use a true RMS me

ter and carefully insert test pins

in plug pins 1 and 5. Measure

voltage.

FIGURE 7

Page 11

Page 12

9. Gas Valve (Figure 6)

The ML180UHA uses internally redundant gas valve to as

sure safety shut-off. If the gas valve must be replaced, the

same type valve must be used.

24VAC terminals and valve switch are located on the valve. All

terminals on the gas valve are connected to wires from the in

tegrated control. 24V applied to the terminals energizes the

valve.

Inlet and outlet pressure taps are located on the valve. A regu

lator adjustment screw is located on the valve.

LPG changeover kits are available from Lennox. Kits include

burner orifices and a gas valve regulator spring.

10. Combustion Air Inducer (B6)

All ML180UHA units use a combustion air inducer to move

air through the burners and heat exchanger during heating

operation. The blower uses a 230VAC motor. The motor

operates during all heating operation and is controlled by

integrated control A92. The inducer also operates for 15

seconds before burner ignition (pre‐purge) and for 5 sec

onds after the gas valve closes (post‐purge).

A pressure switch connected to the combustion air inducer

orifice plate is used to prove inducer operation. The combus

tion air inducer orifice will be different for each model. See

table 4 for orifice sizes. The switch monitors air pressure in

the inducer housing. During normal operation, the pressure in

the housing is negative. If pressure becomes less negative

(signifying any obstruction in the flue) the pressure switch

opens. When the proving switch opens, the integrated con

trol (A92) immediately de-energizes the gas valve to prevent

burner operation.

TABLE 4

ML180UHA Unit

C.A.I. Orifice Size mm (in)

11. Combustion Air Inducer

Pressure Switch (S18)

ML180UHA series units are equipped with a combustion air

pressure switch located on the combustion air inducer ori

fice bracket. The switch is connected to the combustion air

inducer housing by means of a flexible silicone hose. It mon

itors negative air pressure in the combustion air inducer

housing.

The switch is a single‐pole single‐throw proving switch elec

trically connected to the furnace control. The purpose of the

switch is to prevent burner operation if the combustion air in

ducer is not operating or if the flue becomes obstructed.

On start‐up, the switch senses that the combustion air in

ducer is operating. It closes a circuit to the integrated con

trol when pressure inside the combustion air inducer de

creases to a certain set point. Set points vary depending on

unit size. See table 5. The pressure sensed by the switch is

negative relative to atmospheric pressure. If the flue be

comes obstructed during operation, the switch senses a

loss of negative pressure (pressure becomes more equal

with atmospheric pressure) and opens the circuit to the in

tegrated control and gas valve. A bleed port on the switch

allows relatively dry air in the vestibule to purge switch tub

ing, to prevent condensate build up.

TABLE 5

ML180UHA Set Point Pa (in)

070AP36A 150 (.60)

090AP48B 150 (.60)

110AP36C, 110AP60C 150 (.60)

135AP60D 150 (.60)

070AP36A 35.7 (1.406)

090AP48B 42.2 (1.660)

110A36C, 110AP60C 47.6 (1.875)

135AP60D 55.6 (2.188)

The switch is factory set and is not field adjustable. It is

a safety shut‐down control in the furnace and must not

be by-passed for any reason. If switch is closed or bypassed, the integrated control will not initiate ignition

at start up.

Page 12

Page 13

Multiple Venting

The ML180UHA furnace can vent in multiple positions. See

figure 8.

The make up box may be removed and the combustion air

inducer may be rotated clockwise or counterclockwise 90°

to allow for vertical or horizontal vent discharge in a vertical

or horizontal cabinet position. Remove the four mounting

Vent Pipe

Pressure

Switch

vent pipe

Collector Box

screws, rotate the assembly (assembly consists of orifice

plate, proving switch, gasket and combustion air inducer),

then reinstall the mounting screws. See unit Installation In

structions for more detail.

IMPORTANT

The combustion air pressure switch must be moved

for horizontal discharge air left position.

vent pipe

flue

vent pipe

transition

vent pipe

AIR

FLOW

Collector Box

FLOW

AIR

vent pipe

flue transition

AIR

FLOW

pressure switch

vent pipe

In all positions route the wires away from moving parts and the heat of the inducer

motor to prevent damage to the wires. The pressure switch must be installed above

the CAI to prevent moisture from collecting in the hoses or switch.

FIGURE 8

Page 13

Page 14

SUPPLY AIR BLOWER

AND SECONDARY LIMIT(S)

Left Side

ALIGN AND TIGHTEN SET SCREW WITH

FLAT SIDE OF MOTOR SHAFT

Right Side

SECONDARY

LIMIT (S)

MOTOR/BLOWER

ASSEMBLY

CAPACITOR

To Remove Blower From Unit: Disconnect Power, Remove

Control Box, Remove Bolts and Unplug Motor Wires From

Integrated Control. Then Slide Out Front of Unit.

FIGURE 9

12. Blower Motors and Capacitors

All ML180UHA units use direct drive blower motors. All mo

tors are 230V permanent split capacitor motors to ensure

maximum efficiency. Ratings for capacitors will be on motor

nameplate. If replacing the indoor blower motor or blower

wheel is necessary, placement is critical. The blower wheel

must be centered in the blower housing as shown in figure

10. When replacing the indoor blower motor the set screw

must be aligned and tightened with the motor shaft as

shown in figure 11.

Housing Hub

Set Screw

Motor

Shaft

NOTE - The 5 ton blower will have two flats

and two set screws 90° of each other .

FIGURE 11

13. Secondary Limit Controls

The secondary limit is located in the blower compartment in

the back side of the blower housing. See figure 9. When ex

cess heat is sensed in the blower compartment, the limit will

open. If the limit is open, the furnace control energizes the sup

ply air blower and closes the gas valve. The limit automatically

resets when unit temperature returns to normal. The secon

dary limit cannot be adjusted.

II- PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

III- START‐UP

A- Heating Start‐Up

BLOWER WHEEL REPLACEMENT

Center Blower Wheel

in Blower Housing

FIGURE 10

WARNING

Shock and burn hazard.

ML180UHA units are equipped with a hot surface

ignition system. Do not attempt to light manually.

Gas Valve Operation

MANIFOLD

PRESSURE

OUTLET

PORT

INLET

PRESSURE

PORT

White Rodgers 3600 Gas Valve

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

GAS VALVE SHOWN IN OFF POSITION

FIGURE 12

Page 14

Page 15

1 - STOP! Read the safety information at the beginning of

this section.

2 - Set the thermostat to the lowest setting.

3 - Turn off all electrical power to the unit.

4 - This furnace is equipped with an ignition device which

automatically lights the burners. Do not try to light the

burners by hand.

5 - Remove the upper access panel.

6 - Move gas valve lever to OFF position. Do not for c e .

See figure 12.

7 - Wait five minutes to clear out any gas. If you then smell

gas, STOP! Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's instruc

tions. If you do not smell gas go to next step.

8 - Move gas valve lever to ON position. Do not force.

See figure 12.

9 - Replace the upper access panel.

10- Turn on all electrical power to to the unit.

11- Set the thermostat to desired setting.

NOTE - When unit is initially started, steps 1 through 11

may need to be repeated to purge air from gas line.

12- If the appliance will not operate, follow the instructions

“Turning Off Gas to Unit” and call the gas supplier.

Turning Off Gas to Unit

1 - Set the thermostat to the lowest setting.

2 - Turn off all electrical power to the unit if service is to be

performed.

3 - Remove the upper access panel.

4 - Move gas valve lever to OFF position. Do not for c e .

See figure 12.

5 - Replace the upper access panel.

B- Safety or Emergency Shutdown

B- Gas Piping

Gas supply piping should not allow more than 125Pa (13

mm W.C.)drop in pressure between gas meter and unit.

Supply gas pipe must not be smaller than unit gas connec

tion.

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gases.

C- Testing Gas Piping

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outside

the furnace cabinet.

IMPORTANT

In case emergency shutdown is required, turn off

the main shut‐off valve and disconnect the main

power to unit. These controls should be properly

labeled by the installer.

WARNING

Do not exceed 68Nm (50 ft-lbs) torque when attach

ing the gas piping to the gas valve.

When pressure testing gas lines, the gas valve must be dis

connected and isolated. Gas valves can be damaged if

subjected to more than 3.48kPag (0.5psig) See figure 13. If

the pressure is equal to or less than 3.48kPag (0.5psig),

close the manual shut-off valve before pressure testing to

isolate furnace from gas supply.

GAS PIPING TEST PROCEDURE

MANUAL MAIN SHUT-OFF VALVE

WILL NOT HOLD TEST PRESSURE IN EXCESS

OF 3.48kPa (0.5 PSIG 355 mm W.C.)

Disconnect main power to unit. Close manual and main gas

valves.

C- Extended Period Shutdown

Turn off thermostat or set to “UNOCCUPIED” mode. Close

all gas valves (both internal and external to unit) to guaran

tee no gas leak into combustion chamber. Turn off power to

unit. All access panels and covers must be in place and se

cured.

IV-HEATING SYSTEM SERVICE CHECKS

A- Certification

All units are Australian Gas Installation Code (AS/

NZS5601) certified. Refer to the ML180UHA Installation In

struction.

CAP

GAS VALVE

FIELD PROVIDED

LINE PRESSURE TAP

FIGURE 13

When checking piping connections for gas leaks, use pre

ferred means. Kitchen detergents can cause harmful corro

sion on various metals used in gas piping. Use of a specialty

Gas Leak Detector is strongly recommended.

Do not use matches, candles, flame or any other source of

ignition to check for gas leaks.

Page 15

Page 16

D- Gas Pressure Adjustment

Gas Flow (Approximate)

TABLE 6

GAS METER CLOCKING CHART

Seconds for One Revolution

Unit

-045 80 160 200 400

-070 55 110 136 272

-090 41 82 102 204

-110 33 66 82 164

-135 27 54 68 136

Natural-1000 btu/cu ft LP-2500 btu/cu ft

Furnace should operate at least 5 minutes before check

ing gas flow. Determine time in seconds for two revolu

tions of gas through the meter. (Two revolutions assures a

more accurate time.) Divide by two and compare to time

in table 6 below. If manifold pressure matches table 8 and

rate is incorrect, check gas orifices for proper size and re

striction. Remove temporary gas meter if installed.

NOTE - To obtain accurate reading, shut off all other gas

appliances connected to meter.

Manifold Pressure Measurement

1 - Remove the threaded plug from the outlet side of the

gas valve and install a field-provided barbed fitting.

Connect to a test gauge to measure manifold pres

sure.

2 - Start unit and allow 5 minutes for unit to reach steady

state.

3 - While waiting for the unit to stabilize, observe the

flame. Flame should be stable and should not lift from

burner. Natural gas should burn blue.

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

4 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in table

8.

NOTE - Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to remove

barbed fitting and replace threaded plug. Re-fire unit and

check for gas leaks. Seal any leaks if found.

E- Proper Combustion

Furnace should operate a minimum 15 minutes with cor

rect manifold pressure and gas flow rate before checking

combustion. Take combustion sample beyond the flue out

let and compare to the tables below. The maximum carbon

monoxide reading should not exceed 100 ppm.

TABLE 7

ML180UHA

Unit

CO2%

For Nat

CO2%

For L.P.

-070

-090

-110

6.3 - 7.8 7.0 - 9.0

-135

F- High Altitude

The manifold pressure may require adjustment and com

bustion air pressure switch may need replacing to ensure

proper combustion at higher altitudes. Refer to table 8 for

manifold pressure and table 9 for pressure switch change

and gas conversion kits.

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

Manifold Pressure Settings at all Altitudes

Model

Input Size

All Models

Gas

Nat 0.87 0.72 0.67 0.62 0.87 1.13 3.23

LP/propane 2.30 2.30 2.19 2.12 2.30 2.75 3.23

0-610 m*

(0-2000 ft)

* See table 9 for proper high altitude gas conversion kit.

Pressure Switch and Gas Conversion Kits at all Altitudes

Model

Input Size

070

090 80W51 80W56

110 80W51 80W56

135 No Change 80W51

High Altitude Pressure Switch Kit

0-610 m

(0-2000 ft)

No Change

611-1219 m

(2001-4000 ft)

80W51 80W56

611-914 m*

(2001-3000 ft.)

1220-1981 m

(4001-6500 ft)

TABLE 8

915-1219 m*

(3001-4000 ft)

1220-1524 m*

(4001-5000 ft.)

1525-1981 m*

(5001-6500 ft)

TABLE 9

High Altitude

Natural Gas Burner

Orifice Kit

1525-1981 m

(5001-6500 ft)

73W37 11K15 97W04 96W95

Natural Gas to LP/Propane

Change Over Kit

0-1524 m

(0-5000 ft)

1525-1981 m

(5001-6500 ft)

Page 16

Line Pressure

kPa

Min Max

LP/Propane to

Natural Gas

Change Over Kit

1-1524 m

(1-5000 ft)

Page 17

G- Flame Signal

A microamp DC meter is needed to check the flame signal

on the integrated control.

Flame (microamp) signal is an electrical current which passes

from the integrated control to the sensor during unit operation.

Current passes from the sensor through the flame to ground to

complete a safety circuit.

To Measure Flame Signal - Integrated Control:

Use a digital readout meter capable of reading DC micro

amps. See figure 14 and table 10 for flame signal check.

1 - Set the meter to the DC amps scale.

2 - Turn off supply voltage to control.

Measuring Flame Signal

3 - Disconnect integrated control flame sensor wire from

the flame sensor.

4 - Connect (-) lead to flame sensor.

5 - Connect (+) lead to the ignition control sensor wire.

6 - Turn supply voltage on and close thermostat contacts to

cycle system.

7 - When main burners are in operation for two minutes, take

reading.

TABLE 10

Flame Signal in Microamps

Normal Low Drop Out

1.5 0.5 - 1.4 0.4

Flame

Sensor

Flame Sensor

Wire

Integrated

Control

(+)

Flame Sensor

Terminal

(+) To Control

Sensor

Terminal

Remove Sensor Wire from

Integrated Control and

Connect Alligator Clip (−)

to Frame Sensor Lead

DIGITAL METER

Set dial to measure dc microamps

Red Collar

Indicates

Positive Leads

(+)

(-) To

flame

sensor

Remove Sensor Wire from

Integrated Control and

Connect Alligator Clip (+)

to Terminal on Control

FIGURE 14

Page 17

Page 18

H- Proper Ground and Voltage

A poorly grounded furnace can contribute to premature ig

nitor failure. Use the following procedure to check for

ground and voltage to the integrated control.

1 - Measure the AC voltage between Line Neutral (spade

terminals) and “C” terminal (low voltage terminal

block) on the integrated control. See figure 15. A wide

variation in the voltage between Line Neutral and “C”

as a function of load indicates a poor or partial ground.

Compare the readings to the table below. If the read

ings exceed the maximum shown in table 11, make re

pairs before operating the furnace.

2 - In addition, measure the AC voltage from Line Hot to

Line Neutral (spade terminals) on the integrated con

trol. See figure 16. This voltage should be in the range

of 204 to 264VAC.

TABLE 11

Furnace Status

Power On Furnace Idle 0.3 2

CAI / Ignitor Energized 0.75 5

Indoor Blower Energized Less than 2 10

CHECK VOLTAGE BETWEEN LINE NEUTRAL

AND LOW VOLTAGE “C” TERMINAL

Measurement VAC

Expected Maximum

CHECK VOLTAGE BETWEEN LINE HOT

AND LINE NEUTRAL

AN2

AN1

GREEN

RED

AN1

RED

AN2

GREEN

FIGURE 16

FIGURE 15

Page 18

Page 19

V-TYPICAL OPERATING CHARACTERISTICS

A-Blower Operation and Adjustment

NOTE- The following is a generalized procedure and

does not apply to all thermostat controls.

1 - Blower operation is dependent on thermostat control

system.

2 - Generally, blower operation is set at thermostat sub

base fan switch. With fan switch in ON position, blower

operates continuously. With fan switch in AUTO position,

blower cycles with demand or runs continuously while

heating or cooling circuit cycles.

3 - Depending on the type of indoor thermostat, blower

and entire unit will be off when the system switch is in

OFF position.

B-Temperature Rise (Figure 17)

Temperature rise for ML180UHA units depends on unit in

put, blower speed, blower horsepower and static pressure

as marked on the unit rating plate. The blower speed must

be set for unit operation within the range of “TEMP. RISE

°C” listed on the unit rating plate.

C-External Static Pressure

1 - Tap locations shown in figure 18 .

2 - Punch a 6.3 mm (1/4”) diameter hole in supply and re

turn air plenums. Insert manometer hose flush with in

side edge of hole or insulation. Seal around the hose

with permagum. Connect the zero end of the manome

ter to the discharge (supply) side of the system. On

ducted systems, connect the other end of manometer

to the return duct as above.

3 - With only the blower motor running and the evaporator

coil dry, observe the manometer reading. Adjust blow

er motor speed to deliver the air desired according to

the job requirements. For heating speed external static

pressure drop must not be more than 125Pa (0.5”). For

cooling speed external static pressure drop must not

be more than 200Pa (0.8” W.C.)

4 - Seal the hole when the check is complete.

EXTERNAL STATIC PRESSURE

Supply Duct Static ________

Return Duct Static + _____

Total Duct Static =

________

(dry coil)

TEMPERATURE RISE

Supply Duct Temperature ________

Return Duct Temperature

Temperature Rise = ________

Supply Air

Return Air

FIGURE 17

_

_____

Supply Air

or

Return Air

FIGURE 18

-+

D-Blower Speed Taps

Blower speed tap changes are made on the integrated con

trol. See figure 4. The heating tap is connected to the

“HEAT” terminal and the cooling tap is connected to the

“COOL” terminal. On all units the continuous blower tap is

the same as the heating tap and unused taps must be se

cured on two dummy terminals labeled ”PARK. To change

out existing speed tap, turn off power and switch out speed

tap with tap connected to “PARK”. See blower speed tap

table on unit diagram for motor tap colors for each speed.

Page 19

Page 20

VI-MAINTENANCE

A-Preliminary and Seasonal Checks

1 - Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

2 - Check voltage at disconnect switch. Voltage must be

within range listed on the nameplate. If not, consult the

power company and have voltage condition corrected

before starting unit.

At the beginning of each heating season, the system

should be checked as follows:

B-Filters

Filters should be inspected monthly. Clean or replace the

filters when necessary to ensure that the furnace operates

properly. Replacement filters must be rated for high veloc

ity airflow. See table 12.

TABLE 12

Furnace

Cabinet

Width

A - 338

(14-1/2”)

B- 446

( 17-1/2”)

C - 533

( 21”)

D - 622

(24-1/2”)

Cleaning the Heat Exchanger and Burners

NOTE - Use papers or protective covering in front of the fur

nace during cleaning.

1 - Turn off both electrical and gas power supplies to fur

nace.

2 - Remove flue pipe and top cap (some applications top

cap can remain) from the unit.

3 - Label the wires from gas valve, rollout switches, prima

ry limit switch and make-up box then disconnect them.

4 - Remove the screws that secure the combustion air in

ducer/pressure switch assembly to the collector box.

Carefully remove the combustion air inducer to avoid

damaging blower gasket. If gasket is damaged, it must

be replaced to prevent leakage.

5 - Remove the collector box located behind the combus

tion air inducer. Be careful with the collector box gas

ket. If the gasket is damaged, it must be replaced to

prevent leakage.

Filter Size mm (in) and Quantity

Side Return Bottom Return

406 X 635 X 25 1

(16 X 25 X 1)

406 X 635 X 25 1

(16 X 25 X 1)

405 X 635 X 25 1

(16 X 25 X 1)

405 X 635 X 25 2

(16 X 25 X 1)

356 X 635 X 25 1

(14 X 25 X 1)

406 X 635 X 25 1

(16 X 25 X 1)

508 X 635 X 25 1

(20 X 25 X 1)

610 X 635 X 25 1

(24 X 25 X 1)

6 - Disconnect gas supply piping. Remove the screw se

curing the burner box cover and remove cover. Re

move the four screws securing the burner manifold as

sembly to the vestibule panel and remove the assem

bly from the unit.

7 - Remove screws securing burner box and remove

burner box.

9 - Remove screws from both sides, top and bottom of

vestibule panel.

10 -Remove heat exchanger. It may be necessary to

spread cabinet side to allow more room. If so, remove

five screws from the left side or right side of cabinet.

See figure 19.

11 - Backwash using steam. Begin from the burner opening

on each clam. Steam must not exceed 135°C (275°F).

12 -To clean burners, run a vacuum cleaner with a soft brush

attachment over the face of burners. Visually inspect in

side the burners and crossovers for any blockage

caused by foreign matter. Remove any blockage.

13 - To clean the combustion air inducer visually inspect and

using a wire brush clean where necessary. Use com

pressed air to clean off debris and any rust.

14 -Reinstall heat exchanger in vestibule. (Replace the

five screws in the cabinet from step 10 if removed).

15 - Reinstall collector box and combustion air assembly.

Reinstall all screws to the collector box and combustion

air inducer. Failure to replace all screws may cause

leaks. Inspect gaskets for any damage and replace if

necessary.

16 - Reinstall burner box, manifold assembly and burner box

cover.

17 -Reconnect all wires.

18 - Reconnect top cap and vent pipe to combustion air in

ducer outlet.

19 -Reconnect gas supply piping.

20 -Turn on power and gas supply to unit.

21 -Set thermostat and check for proper operation.

22 -Check all piping connections, factory and field, for gas

leaks. Use a leak detecting solution or other preferred

means.

Page 20

Page 21

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly af

ter leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

23 -If a leak is detected, shut gas and electricity off and

repair leak.

24 -Repeat steps 23 and 25 until no leaks are detected.

25 -Replace access panel.

Remove 5 screws if necessary

(either side of cabinet)

1

2

3

4

C-Supply Air Blower

1 - Check and clean blower wheel.

2 - Motors used on the Lennox ML180UHA series units

are permanently lubricated and need no further lu

brication.

D-Flue and Chimney

Flue must conform to local codes. Flue pipe deteriorates

from the inside out and must be disconnected in order to

check thoroughly. Check flue pipe, chimney and all con

nections for tightness and to make sure there is no block

age or leaks.

E-Electrical

1 - Check all wiring for loose connections.

2 - Check for the correct voltage at the furnace (furnace

operating). Correct voltage is 240VAC +

3 - Check amp-draw on the blower motor with inner blow

er access panel in place. See figure 20.

Motor Nameplate__________Actual__________

Check Motor AMP Draw

10%

FIGURE 19

5

OFF

P

−

EX

MR

W

3

2

1

kWh

kVAr

COMMV3V1

V2

AMP Meter

FIGURE 20

Page 21

Page 22

VII- Wiring and Sequence of Operation

1

8

2

5

3

4

1 - When there is a call for heat, W1 of the thermostat energizes W of the furnace control with 24VAC.

2 - Integrated control runs a self-check. S10 primary limit, S47 rollout switch and S21 secondary limit contacts are found to be closed. Call for

heat can continue.

3 - Integrated control (A92) energizes combustion air inducer B6. Combustion air inducer runs until combustion air pressure switch closes . Once

it closes, a 15-second pre-purge follows.

4 - Integrated control (A92) energizes ignitor. A 20-second warm-up period begins.

5 - Gas valve opens for a 4-second trial for ignition

6 - Flame is sensed, gas valve remains open for the heat call.

7 - After 45-second delay, integrated control (A92) energizes indoor blower B3.

8 - When heat demand is satisfied, W1 of the indoor thermostat de-energizes W of the ignition control which de-energizes the gas valve

Combustion air inducer B6 continues a 5-second post-purge period, and indoor blower B3 completes a selected OFF time delay.

6

7

3

Page 22

Page 23

Troubleshooting: Heating Sequence of Operation

HEATING SEQUENCE OF OPERATION

NORMAL AND ABNORMAL HEATING MODE

POWER ON

GAS VALVE OFF. COMBUSTION AIR INDUCER OFF.

CONTROL SELF-CHECK OKAY?

NO

INDOOR BLOWER OFF. (RESET CONTROL BY

TURNING MAIN POWER OFF.)

NO

POLARITY OKAY?

YES

IS THERE A

PROPER GROUND?

YES

A

NORMAL OPERATION:

STATUS LED -- PULSE

B

THERMOSTAT CALLS FOR HEAT:

STATUS LED -- HEARTBEAT

YES

PRIMARY AND SECONDARY LIMIT

SWITCHES CLOSED?

YES

ROLLOUT SWITCH CLOSED?

YES

PRESSURE SWITCH CONTACTS OPEN?

COMBUSTION AIR INDUCER ON

STATUS LED -- HEARTBEAT

NO

NO

NO

SIGNAL HOLDS UNTIL UNIT IS PROPERLY GROUNDED.

INDOOR BLOWER ON. HAS PRIMARY OR

SECONDARY LIMIT RESET WITHIN 3 MINUTES?

NO

NO

60-MINUTE LIMIT WATCHGUARD MODE.

GAS VALVE OFF, COMBUSTION AIR INDUCER

OFF, INDOOR BLOWER OFF WITH DELAY.

GAS VALVE OFF. COMBUSTION AIR INDUCER ON.

SEQUENCE HOLDS UNTIL ROLLOUT SWITCH IS

RESET AND MAIN POWER IS INTERRUPTED OR

T'STAT IS CYCLED OFF/ON FOR 3 SEC. MINIMUM.

GAS VALVE OFF. COMBUSTION AIR INDUCER OFF.

INDOOR BLOWER OFF. CONTROL REMAINS UNTIL

PRESSURE SWITCH IS DETECTED OPEN.

POLARITY REVERSED.

STATUS ERROR CODE 5 + 4.

STATUS ERROR CODE 5 + 4.

COMBUSTION AIR INDUCER OFF.

STATUS ERROR CODE 3 + 1.

NO

STATUS ERROR CODE 4 + 5.

INDOOR BLOWER ON.

STATUS ERROR CODE 5 + 1.

STATUS ERROR CODE 2 + 4

YES

YES

CONTINUED ON NEXT PAGE

Page 23

Page 24

Troubleshooting: Heating Sequence of Operation (Continued)

HEATING SEQUENCE OF OPERATION

CONTINUED

THERMOSTAT CALLS FOR HEAT

STATUS LED - HEARTBEAT

(Refer to box A on previous page)

PRESSURE SWITCH CLOSED WITHIN

2.5 MINUTES?

YES

15-SECOND COMBUSTION AIR INDUCER

PRE-PURGE INITIATED BY CLOSED FIRST-STAGE

PRESSURE SWITCH (or 15 SECOND

INTER-PURGE PERIOD.)

STATUS LED -- HEARTBEAT.

IGNITOR WARM-UP (20 SECONDS)

STATUS LED -- HEARTBEAT.

YES

IS IGNITOR INTACT AND CONNECTED?

YES

AT END OF IGNITOR 20 SECOND WARM UP

PERIOD, 4-SECOND TRIAL FOR IGNITION.

GAS VALVE OPENS, IGNITOR ENERGIZED DURING

4-SECOND TRIAL UNTIL FLAME SENSED.

YES

4-SECOND FLAME STABILIZATION PERIOD.

NO

NO

NO

GAS VALVE OFF. COMBUSTION AIR INDUCER

OFF. INDOOR BLOWER OFF. UNIT WILL RETRY

AFTER 5-MINUTE WAIT PERIOD.

STATUS ERROR CODE 2 + 3.

COMBUSTION AIR INDUCER STAYS ON, IGNITER

OFF, GAS VALVE OFF. RETRIES IGNITION 4

MORE TIMES, GOES INTO 1 HR. WATCHGUARD

MODE STATUS ERROR CODE 4 + 7.

IS VOLTAGE ABOVE 170 VOLTS?

NO

COMBUSTION AIR INDUCER OFF, IGNITER OFF.

SIGNAL HOLDS UNTIL VOLTAGE RISES ABOVE 170

VOLTS. STATUS ERROR CODE 4 + 8.

YES

FLAME RECTIFICATION CURRENT CHECK

CAN FLAME BE PROVEN WITHIN 4

SECONDS AFTER GAS VALVE OPENS?

(u0.20 microamps)

FLAME PRESENT?

YES

CONTINUED ON NEXT PAGE

NO

GAS VALVE OFF. COMBUSTION AIR

INDUCER ON. INDOOR BLOWER OFF.

STATUS LED -- HEARTBEAT.

HAS CONTROL FAILED TO SENSE

FLAME FOR FIVE CONSECUTIVE TRIES

DURING A SINGLE HEAT DEMAND?

YES

WATCHGUARD MODE. GAS VALVE OFF,

COMBUSTION AIR INDUCER OFF.

INDOOR BLOWER OFF.

STATUS ERROR CODE 4 + 1.

IS 60-MINUTE RESET PERIOD COMPLETE?

NO

HAS CONTROL RESET IGNITION SEQUENCE

FOUR (4) TIMES?

WATCHGUARD MODE.

STATUS ERROR CODE 4 + 3.

NO

YES

NO

Page 24

Page 25

Troubleshooting: Heating Sequence of Operation (Continued)

HEATING SEQUENCE OF OPERATION

CONTINUED

FLAME SIGNAL ABOVE

(u1.40 microamps)

NO

THERMOSTAT CALLS FOR HEAT.

STATUS LED -- HEARTBEAT.

SEE BOX A.

LOW FLAME SIGNAL

(Does not affect control operation)

STATUS ERROR CODE 1 + 2.

YES

ROLLOUT SWITCHES CLOSED?

YES

PRESSURE SWITCH CLOSED?

YES

HEAT DEMAND SATISFIED?

YES

GAS VALVE OFF, COMBUSTION AIR INDUCER

OFF FOLLOWING POST PURGE.

INDOOR BLOWER OFF WITH DELAY

STATUS LED -- PULSE

YES

DEMAND FOR HEAT SATISFIED.

POWER ON STAND BY.

STATUS LED -- PULSE.

NO

NO

YES

YES

30-SECOND INDOOR BLOWER ON DELAY BEGINS.

STATUS LED -- HEARTBEAT.

YES

PRIMARY & SECONDARY LIMIT SWITCHES

CLOSED?

GAS VALVE OFF. COMBUSTION AIR INDUCER ON.

INDOOR BLOWER ON.

STATUS ERROR CODE 5 + 1. SEQUENCE HOLDS

UNTIL ROLLOUT SWITCH IS RESET AND MAIN

POWER IS INTERRUPTED OR THERMOSTAT

IS CYCLED OFF/ON FOR 3 SECOND MINIMUM.

GAS VALVE OFF, COMBUSTION AIR INDUCER OFF,

INDOOR BLOWER ON.

STATUS ERROR CODE 3 + 1.

HAS PRIMARY OR SECONDARY LIMIT

SWITCH CLOSED WITHIN 3 MINUTES?

(Indoor blower on low speed during 3-minute period)

NO

LIMIT SWITCH WATCHGUARD MODE.

GAS VALVE OFF, COMBUSTION AIR INDUCER OFF,

INDOOR BLOWER OFF WITH DELAY.

STATUS ERROR CODE 4 + 5

IS 60-MINUTE RESET PERIOD COMPLETE?

NO

YES

YES

GAS VALVE OFF. COMBUSTION AIR INDUCER ON.

INDOOR BLOWER OFF AFTER DELAY.

STATUS ERROR CODE 2 + 3. CONTROL RESTARTS

IGNITION SEQUENCE IF PRESSURE SWITCH

CLOSES WITHIN 2-1/2 MINUTES.

YES

Page 25

Page 26

Troubleshooting: Cooling Sequence of Operation

COOLING SEQUENCE OF OPERATION

POWER ON

YES

IS POLARITY REVERSED?

NO

CONTROL WILL CONTINUE TO CALL FOR COOLING

SIGNAL POLARITY REVERSED.

IN THIS CONDITION.

STATUS ERROR CODE 5 + 4.

IS THERE

PROPER GROUND?

YES

THERMOSTAT CALLS FOR COOL.

COMPRESSOR AND CONDENSER FAN

ENERGIZED.

INDOOR BLOWER ENERGIZED ON COOL SPEED

AFTER 2 SECOND DELAY.

DEMAND FOR COOL SATISFIED?

YES

COMPRESSOR AND CONDENSER FAN DE-ENERGIZED.

INDOOR BLOWER DE-ENERGIZED AFTER 45-SECOND

DELAY.

NO

SIGNAL IMPROPER GROUND AT LED.

CONTROL WILL CONTINUE TO CALL FOR COOLING

IN THIS CONDITION.

STATUS ERROR CODE 5 + 4.

Page 26

Page 27

Troubleshooting: Continuous Fan Sequence of Operation

CONTINUOUS FAN SEQUENCE OF OPERATION

MANUAL FAN SELECTION MADE AT THERMOSTAT.

CONTROL (G) ENERGIZES SYSTEM FAN AT HEAT SPEED

THERMOSTAT CALLS FOR HEAT (W).

NO

THERMOSTAT CALLS FOR COOLING.

YES

SYSTEM FAN SWITCHED TO COOL SPEED.

EAC TERM. REMAINS ON.

THERMOSTAT OPENS.

MANUAL FAN SELECTION MADE AT THERMOSTAT.

CONTROL (G) ENERGIZES SYSTEM FAN AT HEAT

SPEED. EAC TERM. ENERGIZED.

NO

HUM TERM. ENERGIZES

YES

SYSTEM FAN REMAINS ON

THERMOSTAT OPENS.

HUM TERM. DE-ENERGIZES

WITH COMB. AIR INDUCER

SYSTEM FAN REMAINS ON HEATING SPEED.

WITH COMB. AIR INDUCER.

HEATING SPEED.

Page 27

Loading...

Loading...